Patents

Literature

56results about How to "Lower coercive field" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium niobic zincic acid bismuth sodium system leadless piezo-electric ceramic and preparation method thereof

InactiveCN101200369AImprove performanceHigh densityPiezoelectric/electrostrictive/magnetostrictive devicesElectricityPiezo electric

The invention discloses a triple system (Na,Bi)TiO3-NiO3-ZiO3-based lead-free piezoelectric ceramic material and preparation method, the B digital ion in the (Na0.5Bi0.5)TiO3 of the ABO3 type perovstike structure is replaced partially by composite ion (Zn(one-third)Nb(two-third))4+ and the A digital ion (Na0.5Bi0.5)2+ is replaced by Ba2+ to form lead-free piezoelectric ceramic that can be denoted with the formula ((Na0.5Bi0.5)Ti(1-x)(Zn(one-third)Nb(two-third))(x)O3)(+Z)M(a)O(b) and ((Na0.5Bi0.5)(1-y)Ba(y)Ti(1-x)(Zn(one-third)Nb(two-third))(x)O3)(+Z)M(a)O(b), wherein M(a)O(b) is one or more oxide. The piezoelectric ceramic adopts two-step synthetic method and is obtained by sintering. The lead-free piezoelectric ceramic has high ceramic density and excellent performance, piezoelectric constant d33 can reach above 150pC per N, Kt can reach above 0.50, and Kp can be below 0.20. The lead-free piezoelectric has strong anisotropy, simple and stable manufacture process and is suitable for industrialization production.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Calcium barium zirconate titanate base piezoceramics and preparation method thereof

InactiveCN101648807ALower coercive fieldLow equipment requirementsPiezoelectric/electrostrictive/magnetostrictive devicesBarium titanateZirconium dioxide

The invention discloses calcium barium zirconate titanate base piezoceramics and a preparation method thereof. The chemical formula of the calcium barium zirconate titanate base piezoceramics is (1-x-y)BaTiO3-xCaTiO3-yBaZrO3, wherein x is greater than 0 and smaller than 0.5, y is greater than 0 and smaller than 0.5, and both x and y are molar fractions. The preparation method comprises the following steps: mixing barium carbonate, calcium carbonate, titanium dioxide and zirconium dioxide according to the stoichiometric proportion (1-x-y)BaTiO3-xCaTiO3-yBaZrO3 (x is greater than 0 and smaller than 0.5, y is greater than 0 and smaller than 0.5, and both x and y are molar fractions), ball-milling, calcining, ball-milling for the second time, granulating, moulding, removing the binder, high-temperature sintering and the like so as to finally prepare the calcium barium zirconate titanate base piezoceramics with high piezoelectric performance. The method greatly enhances the piezoelectric performance of the lead-free piezoceramic system and the technical stability of the material, so that the lead-free piezoceramics in the barium titanate system achieve the practical level in the aspectsof components and technique.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Multi-component system nonleaded piezoelectric ceramic with good performance

InactiveCN1541976AExcellent piezoelectric ferroelectric propertiesImprove performanceCeramicsPiezoelectric/electrostrictive/magnetostrictive devicesRare earthPerovskite

The polycomponent lead-free piezoelectric ceramic composition with excellent performance is one perovskite type environment consistency piezoelectric ceramic composition. The composition has the general expression of (1-e-f-g)(Bi1-uLu)1-w(Na1-x-yKxLiy)wTiO3+eBaTiO3+fSrTiO3+gCaTiO3+aMalphaObeta, where x is 0-1, y 0-0.5, u 0-0.12, (x+y) 0-1, e 0-1, f 0-1, g 0-1, (e+f+g) 0-1, w 0.3-0.7, L is RE elements La, Ce, Pr, Nd, Sm, etc.; MalphaObeta is doping oxide(s) in the content an of 0-10 %; M is +1~+6 valent element capable of forming solid oxide, such as Na, K, Li, Zn, Cr, etc. with alpha and beta being atom number. The piezoelectric ceramic composition has d33 up to 200 pC / N, kp up to 36.0 % and stable technological process, may be produced via traditional piezoelectric ceramic preparation process and industrial material, and is practical.

Owner:SICHUAN UNIV

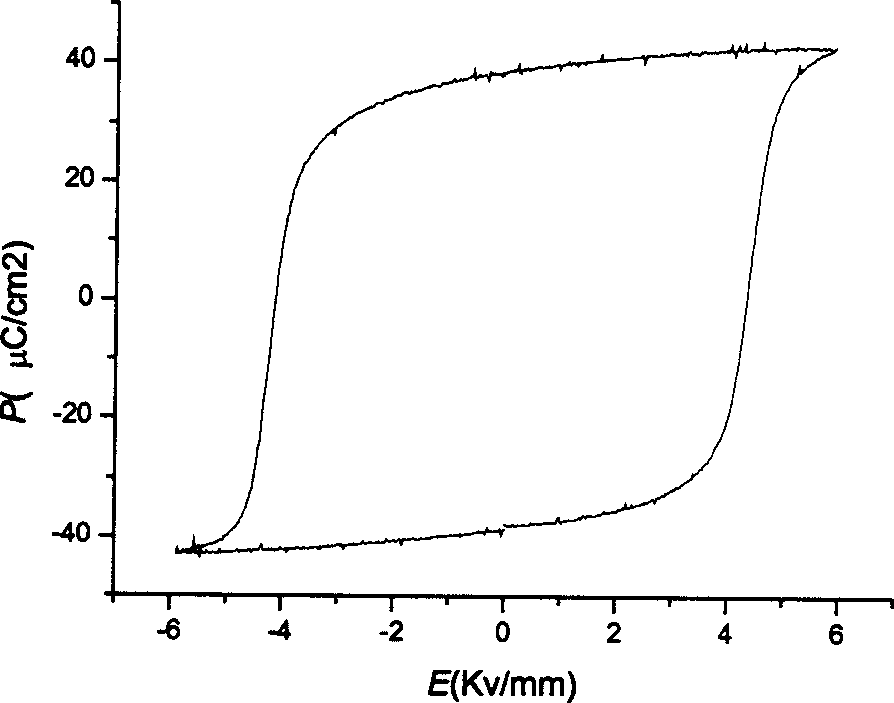

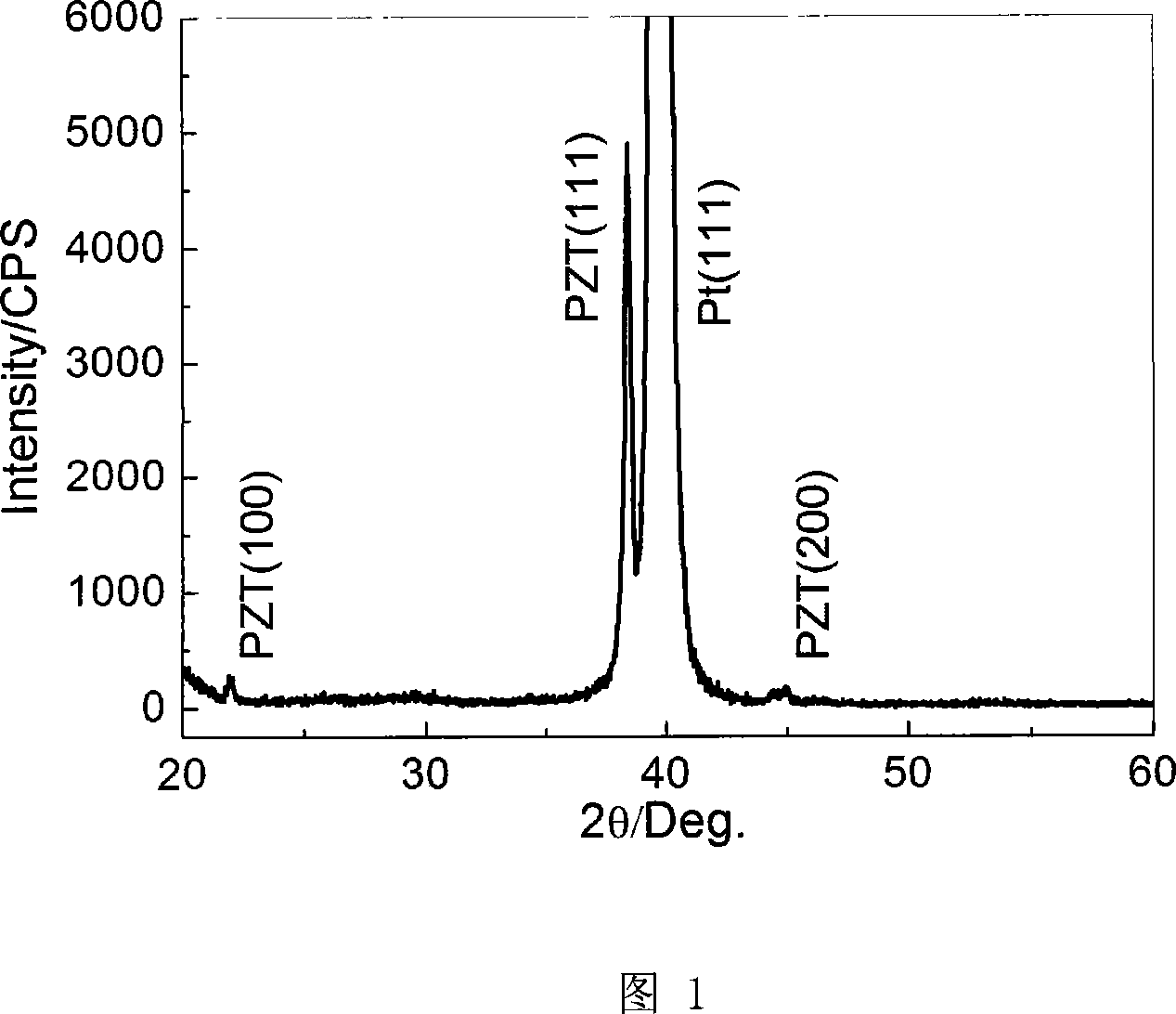

Method for fabricating film of aluminum zirconate titanate with high orientating (111)

InactiveCN101050119AFlat and dense surfaceUniform compositionCeramicsLead zirconate titanateZirconate

This invention discloses a method for preparing highly (111)-oriented PZT thin film. The method can solve the problems of complex process and low repeatability faced by sol-gel method. The method comprises: preparing PZT sol, depositing PZT thin film, pre-crystallizing PZT thin film, and crystallizing PZT thin film. The method is simple. The obtained PZT thin film has compact and smooth surface, uniform thickness, uniform grain sizes, high residual polarization value (43-60 muC / cm2), low coercive field (60-75 kV / cm), and high saturated polarization value.

Owner:HARBIN INST OF TECH

Bismuth sodium lithium titanate barium titanate strontium titanate calcium titanate based lead-free piezoelectric ceramics

InactiveCN1541978AExcellent piezoelectric ferroelectric propertiesImprove performanceCeramicsPiezoelectric/electrostrictive/magnetostrictive devicesStrontium titanateBarium strontium titanate

The lead-free bismuth sodium lithium barium strontium titanate piezoelectric ceramic is one polycomponent perovskite type environment consistency piezoelectric ceramic composition. The composition has the general expression of (1-y-z-u)Bi1-w(Na1-xLix)wTiO3+yBaTiO3+zSrTiO3+uCaTiO3+aMalphaObeta, where x is 0-0.5, y 0-1, z 0-1, u 0-1, (y+z+u) 0-1, w 0.3-0.7; MalphaObeta is doping oxide(s) in the content an of 0-10 %; M is +1~+6 valent element capable of forming solid oxide, such as Na, K, Li, Ni, Zn, etc. with alpha and beta being atom number. The piezoelectric ceramic composition has d33 up to 200 pC / N, kp up to 35.0 % and stable technological process, may be produced via traditional piezoelectric ceramic preparation process and industrial material, and is practical.

Owner:SICHUAN UNIV

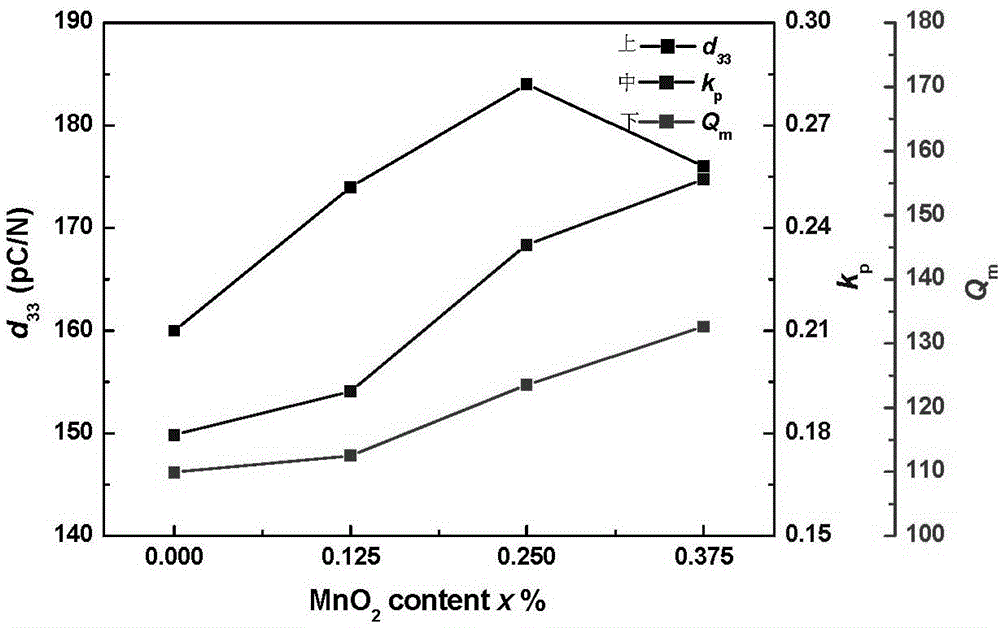

Lead-free piezoelectric ceramic and preparation method thereof

The invention relates to lead-free piezoelectric ceramic and a preparation method thereof. The problems that the production technology is complex, sintering is difficult, piezoelectric ceramic is poor in performance and requirements in actual application are not met are solved. The method includes the steps that BaCO3 powder, ZrO2 powder and TiO2 powder are contained in a ball milling tank, ethyl alcohol is added to be ground, dried, tabletted and pre-sintered to synthesize BaZr0.055Ti0.945O3; ethyl alcohol is added to Bi2O3, Na2CO3, TiO2, MnO2 and BaZr0.055Ti0.945O3 to be ball-milled and dried, an adhesive is added, compaction and plastic removal are conducted, the mixture is buried with powder to be sintered, silver paste coating and forging are conducted, and a silver electrode is formed on the surface; then the product is placed in silicon oil, the electric field is polarized, and the lead-free piezoelectric ceramic material is obtained. The Mn-codoped Bi0.5Na0.5TiO3-BaZr0.055Ti0.945O3 lead-free piezoelectric ceramic is designed and synthesized for the first time, the coercive field and leakage current of piezoelectric ceramic are effectively reduced, polarizability is improved, performance is good, the method is simple, and production and preparation are easy.

Owner:BEIJING ZHONGKE AOBEI ULTRASONIC TECH RES INST

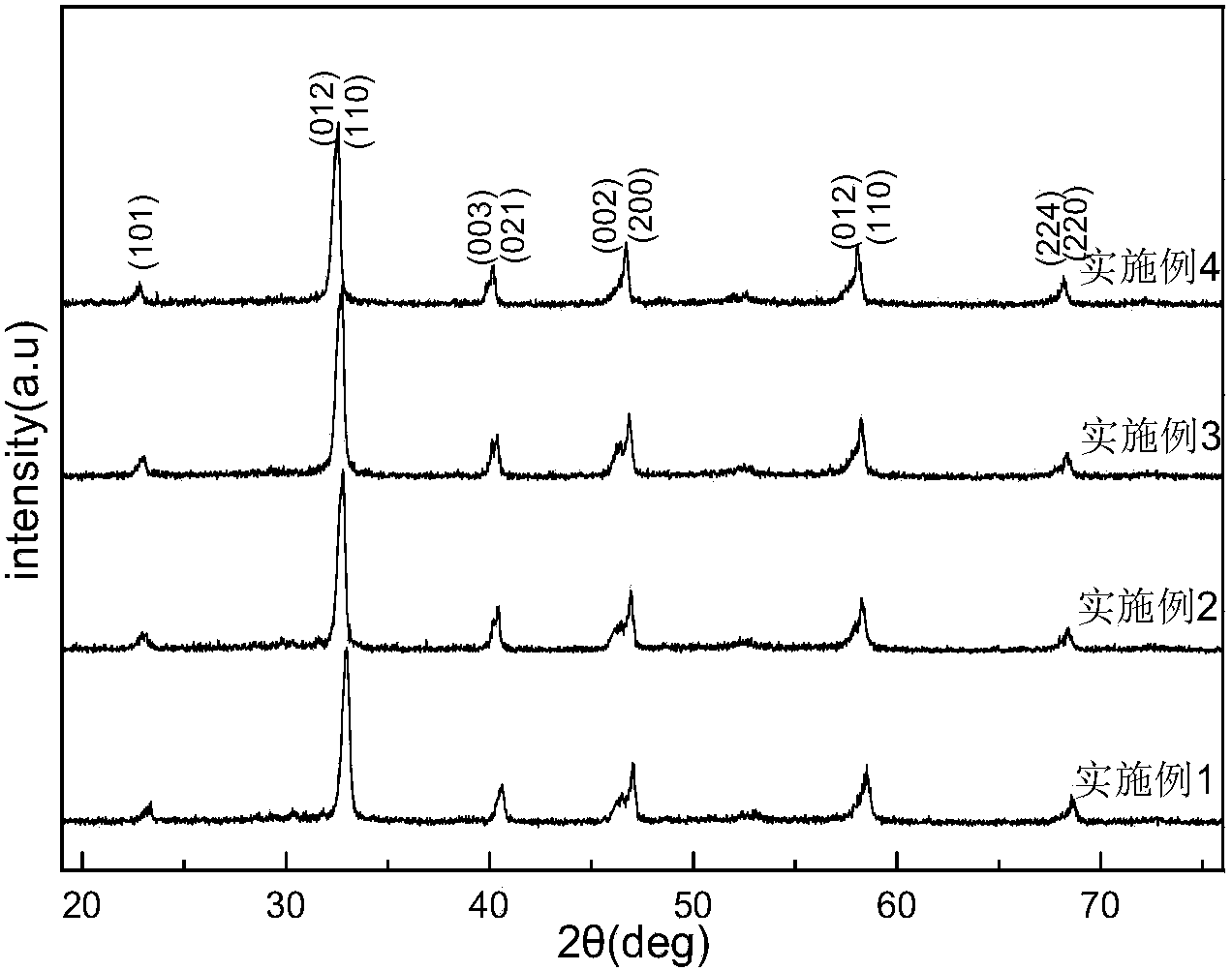

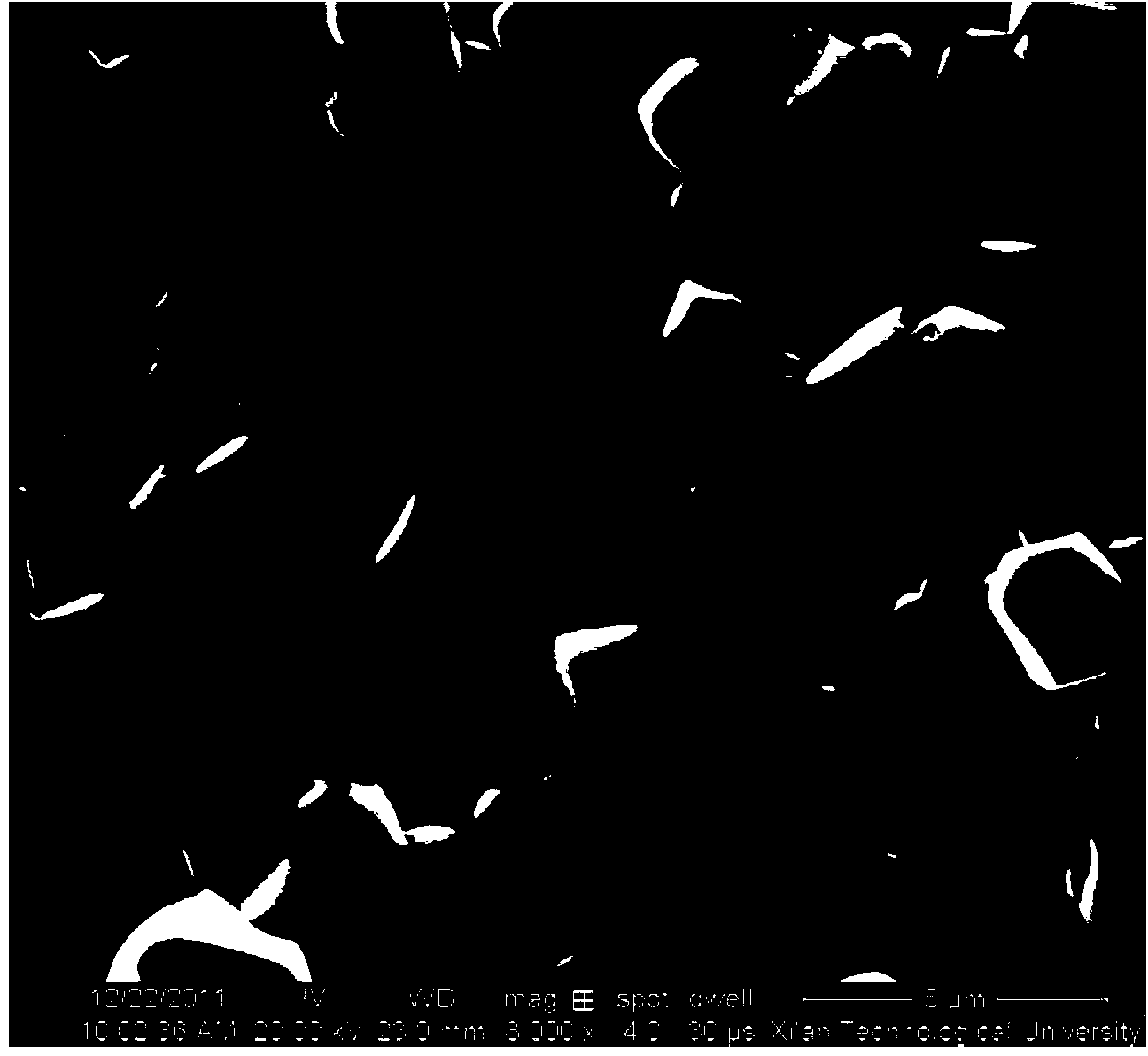

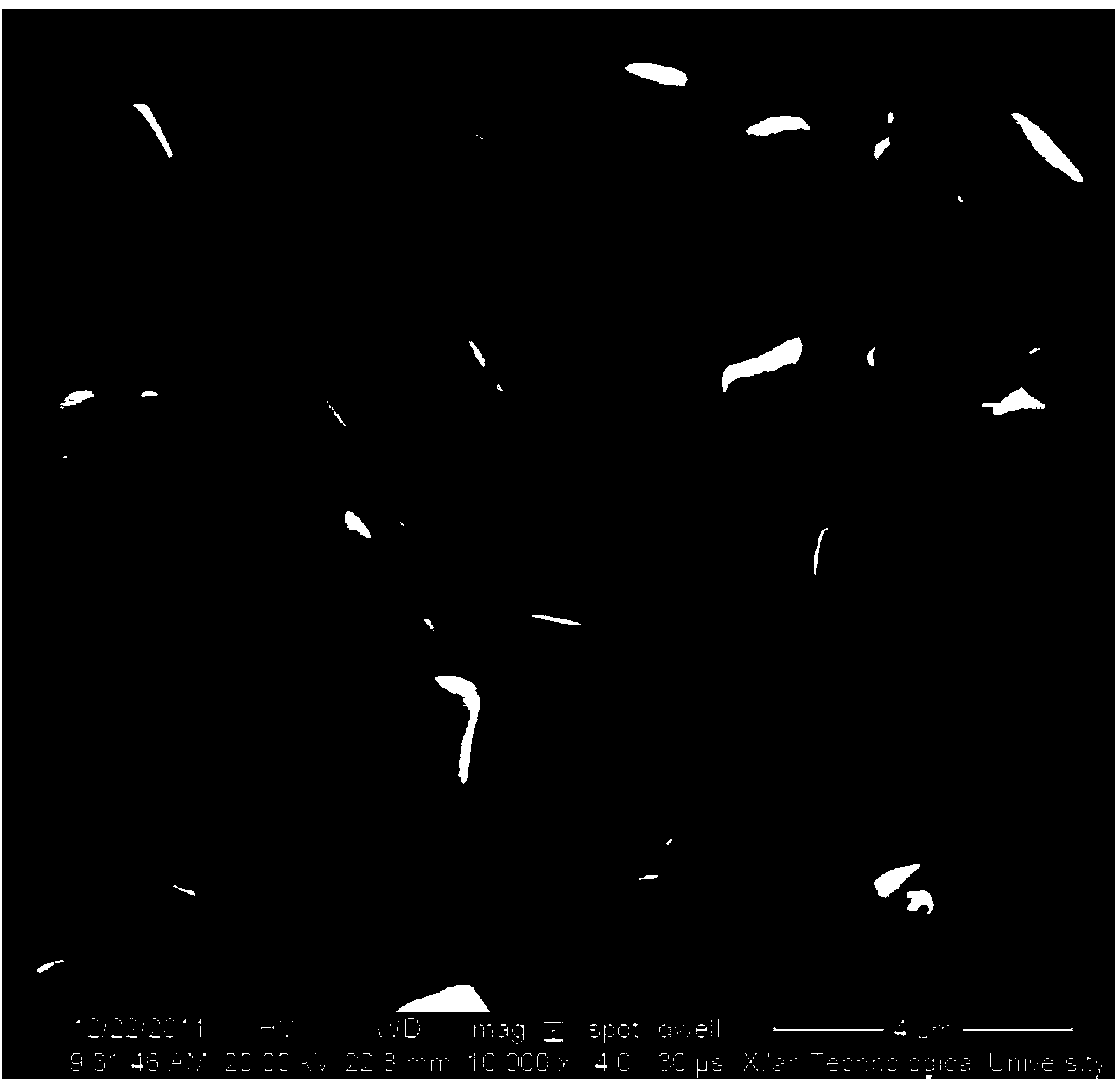

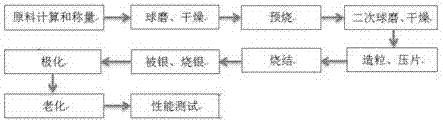

Solid solution-modified sodium bismuth titanate leadless piezoelectric ceramics and preparation method thereof

ActiveCN103833354AExcellent piezoelectric propertiesHigh electromechanical coupling coefficientElectromechanical coupling coefficientTwo step

The invention provides solid solution-modified sodium bismuth titanate leadless piezoelectric ceramics and a preparation method thereof. The piezoelectric ceramics are represented by chemical composition general formula of (1-x)(0.74Na0.5Bi0.5TiO3-0.26SrTiO3)-xBa(Zr0.05Ti0.95)O3 or (1-y)(0.9Na0.5Bi0.5TiO3-0.1CaTiO3)-yBa(Zr0.05Ti0.95)O3, wherein 0.04<=x<=0.1 and 0.04<=y<=0.1. Solid solution of Ba(Zr0.05Ti0.95)O3 is realized at the morphotropic phase boundary of a 0.74Na0.5Bi0.5TiO3-0.26SrTiO3 and 0.9Na0.5Bi0.5TiO3-0.1CaTiO3 system, and high-density microcrystalline structure ceramics with uniform crystal grain size distribution are obtained by a two-step forming method and a self-bearing pressure sintering process. The piezoelectric property of the material is optimized by the morphotropic phase boundary composition characteristics and the solid solution modification method, and the piezoelectric constant d33 reaches 110-138 PC / N; the electromechanical coupling coefficient of the material is also increased obviously; the preparation process of the material is simple and stable, and the material is an optimal material for manufacturing low-power ultrasonic devices and energy transducers used in fields of gas sensors, industrial nondestructive test, and the like.

Owner:XIAN UNIV OF SCI & TECH

Preparation method of potassium sodium niobate based piezoelectric ceramics

InactiveCN107512908AImprove electrical propertiesImprove solid solubilityPiezoelectric/electrostrictive/magnetostrictive devicesMicroscopic morphologyElectric properties

The invention relates to a preparation method of potassium sodium niobate based piezoelectric ceramics, and belongs to the field of novel lead-free based functional ceramics. The method is characterized in that the solid solubility between potassium niobate and sodium niobate in the potassium sodium niobate based piezoelectric ceramics is increased to improve the electric properties of the potassium sodium niobate based piezoelectric ceramics; and the potassium sodium niobate based piezoelectric ceramics comprise the following raw materials in mol percentage: 48-52% of K2CO3, 48-52% of Na2CO3, 96-100% of Nb2O5 and 0-4% of Sb2O3. The method provided by the invention can effectively regulate and control the phase structure and the microscopic morphology of the potassium sodium niobate based piezoelectric ceramics, thereby improving the electric properties of the potassium sodium niobate based piezoelectric ceramics.

Owner:KUNMING UNIV OF SCI & TECH

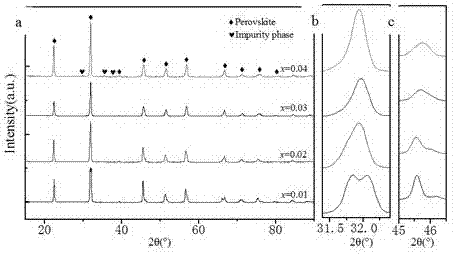

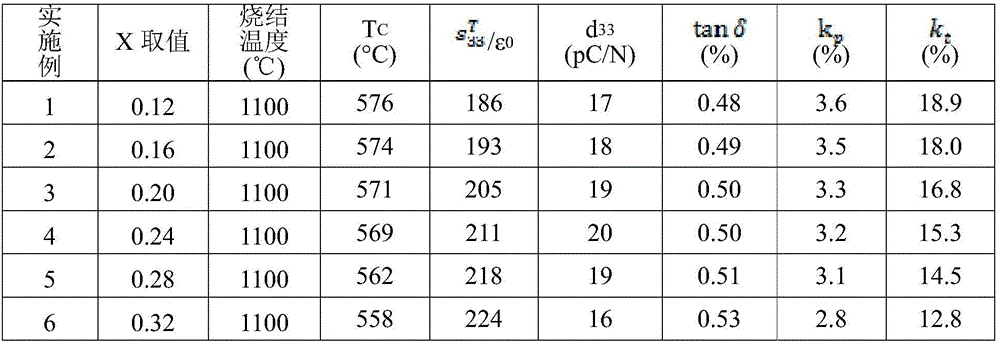

High Curie temperature lead-free SNKBT piezoelectric ceramic and preparation method thereof

ActiveCN106064942ALower coercive fieldVarious preparation techniquesPiezoelectric/electrostrictive device manufacture/assemblyPolyvinyl alcoholCurie temperature

The invention discloses a high Curie temperature lead-free SNKBT piezoelectric ceramic with a chemical formula of Sr0.9(Na0.5-xKxBi0.5)0.1Bi4Ti4O15, wherein x equals o 0.12-0.32wt.%. The method comprises the steps of: preparing ingredients of Na2CO3, K2CO3, SrCO3, material TiO2, and Bi2O3 according to their stoichiometric ratio, carrying out ball milling for 4h, drying, sieving, and synthesizing at 850 DEG C; then conducting secondary ball milling, drying, sieving, and adding 7wt.% of PVA water solution for granulation, and molding into a blank; discharging rubber, sintering the blank at 1100 DEG C for, then coating a layer of silver on the upper and lower surfaces of the piezoelectric ceramic, carrying out sintering permeation, and polarizing in silicone oil of 170 DEG C under the electric field strength of 10KV / mm for 5-10min so as to produce the high Curie temperature lead-free SNKBT piezoelectric ceramic. The invention overcomes the shortcomings of doping of other elements and large amount of replacement to obtain high voltage characteristic in the preparation process; and the system reduces the coercive field and low voltage characteristic of the electrical ceramic caused by inadequate polarization, improves the preparation process, and improves the piezoelectric properties.

Owner:TIANJIN UNIV

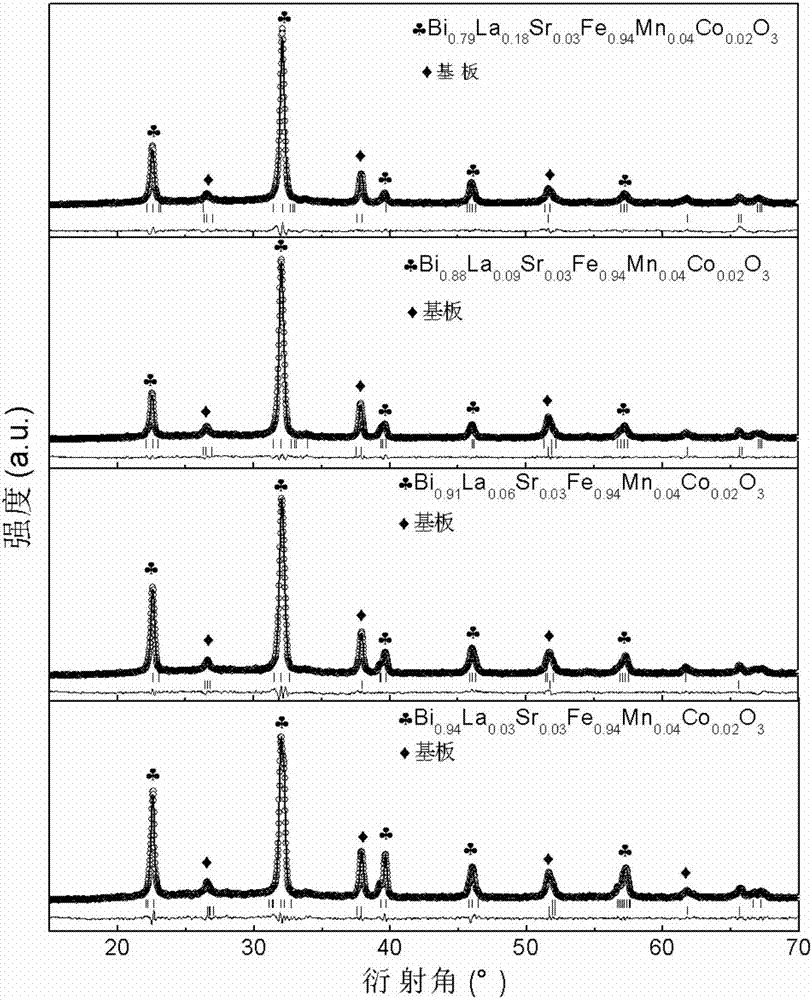

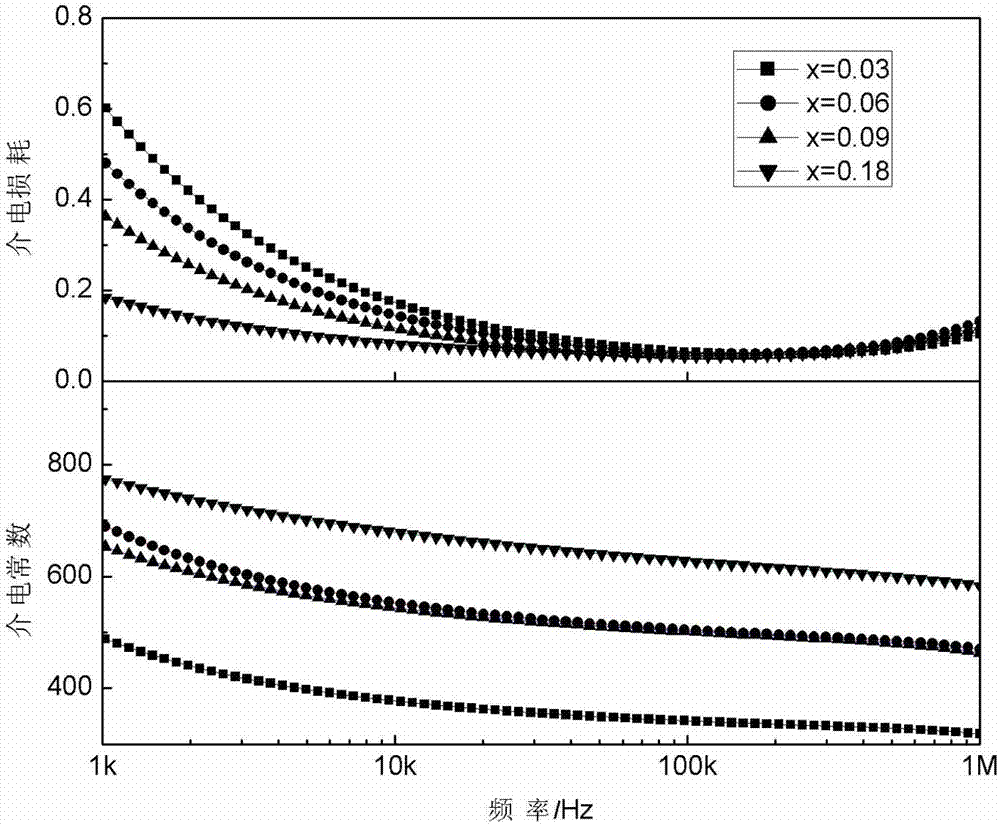

LaSrMnCo codoped bismuth ferrite multiferroic film and preparation method thereof

ActiveCN107117830AGood dielectricImprove ferroelectric propertiesCoatingsMANGANESE ACETATEAcetic anhydride

The invention provides a LaSrMnCo codoped bismuth ferrite multiferroic film and a preparation method thereof. A Bi(0.97-x)LaxSr0.03Fe0.94Mn0.04Co0.02O3 multiferroic film, namely the LaSrMnCo codoped bismuth ferrite multiferroic film, is prepared by taking bismuth nitrate, lanthanum nitrate, strontium nitrate, ferric nitrate, manganese acetate and cobalt nitrate as raw materials (bismuth nitrate of excessive 5 percent), taking ethylene glycol monomethyl ether and acetic anhydride as solvents and using a spin-coating method and a layer-by-layer annealing process. A sol-gel process is adopted, spin-coating and layer-by-layer annealing methods are adopted, equipment requirements are simple, experimental conditions are easy to realize, the film is suitably prepared on a large surface and an irregularly shaped surface, chemical components are accurately controllable, the multiferroic property of the BiFeO3 film can be improved, the prepared the LaSrMnCo codoped bismuth ferrite multiferroic film has high uniformity and is a multiferroic film with high residual polarization value and low coercive field, and the ferroelectric and dielectric properties of the film are effectively enhanced.

Owner:SHAANXI UNIV OF SCI & TECH

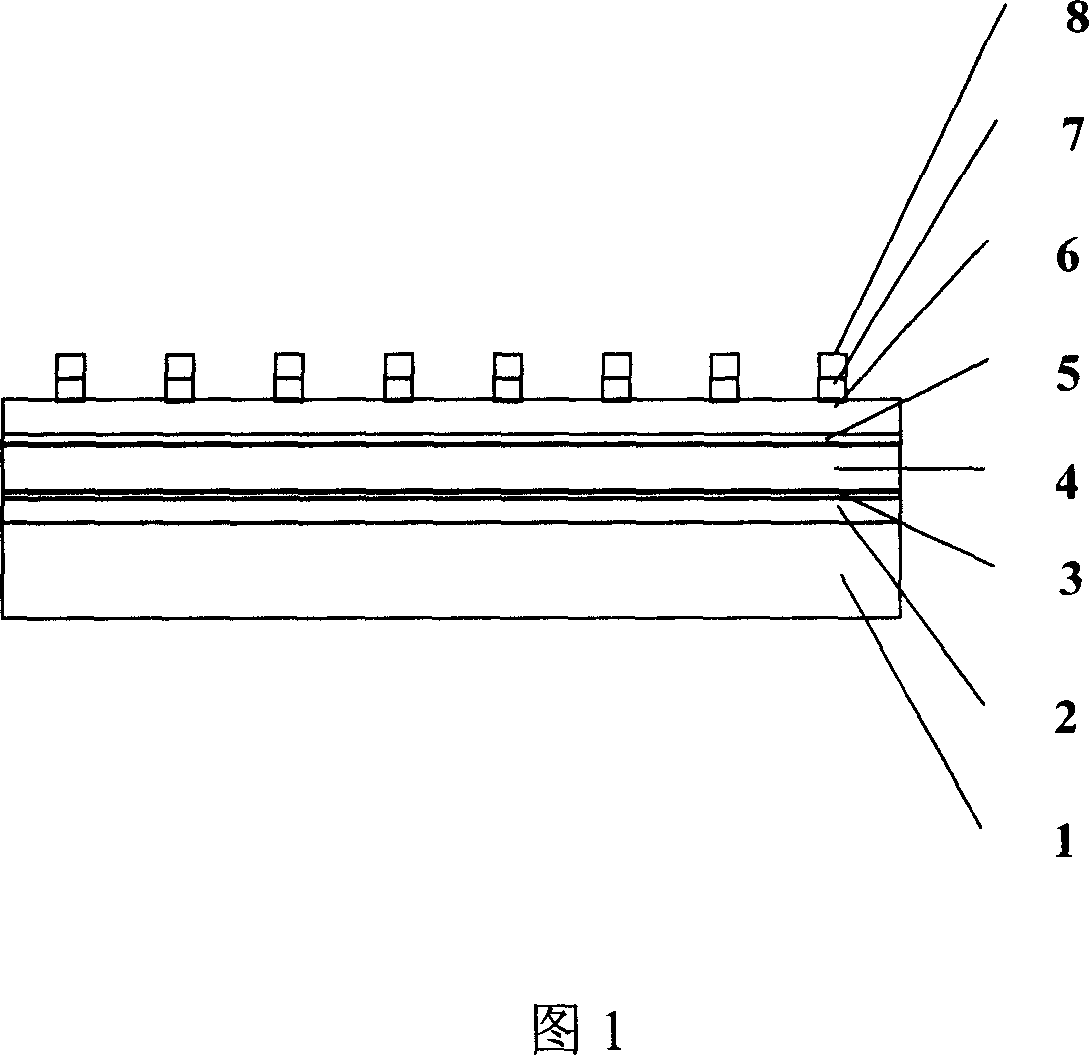

Ferroelectric film capacity used for ferroelectric memorizer and its manufacturing method

InactiveCN1967848AHigh crystallinityUniform and dense surfaceSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceSputtering

The invention relates to a ferro-electricity film capacitor of ferro-electricity and relative preparation, wherein said film capacitor is formed by silicon substrate, silica dioxide baffle layer, titania adhesive layer, low electrode metal layer, low buffer layer, ferro-electricity film layer, up buffer layer, and up electrode metal layer; the adhesive layer is 10-30nm thick; the low electrode metal layer is 100nm-300nm; the low buffer layer is 5-20nm thick; the ferro-electricity is 200-500nm thick; the up buffer layer is 100-200nm thick; the up electrode metal layer is 80-150nm thick. The inventive capacitor has low fatigue speed, low drain current. The invention uses magnetic control splash method to layer-to-layer splash production, while the product has better property, with single direction.

Owner:HUAZHONG UNIV OF SCI & TECH

Ternary material, preparation method and application thereof

ActiveCN105753467AGreat research valueImprove practicalityDevice material selectionDigital storageParamagnetismCapacitor

The invention discloses a ternary material. The ternary material is characterized in that it has a perovskite type structure and contains a three-element composite system of BiFeO3, PbTiO3 and NdFeO3. The ternary material has strong stability, also has piezoelectricity, ferroelectricity and paramagnetism, and can be applied to piezoelectric sensors, memory, and high performance capacitors and other related fields.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

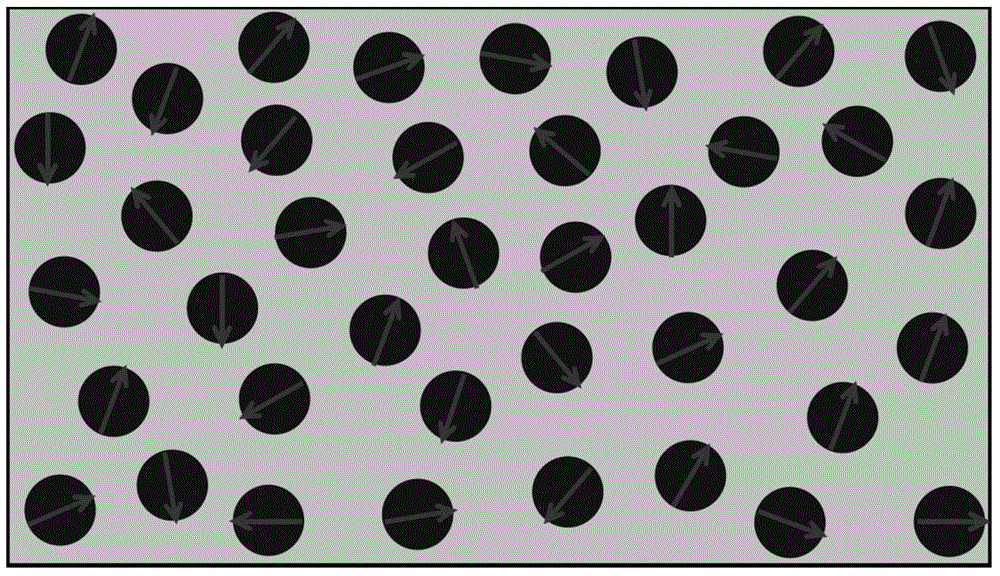

Multiferroic liquid and preparation method thereof

InactiveCN105016396AEasy to prepareExpand the scope of researchIron compoundsChemistryElectric field

The invention discloses a multiferroic liquid. The multiferroic liquid is a stable suspension liquid obtained by uniform dispersion of multiferroic nano-particles in a uniform mixed solution of a base liquid and a surfactant. The preparation method of the multiferroic liquid comprises pouring dry multiferroic nano-particles into a mixed solution of a base liquid and a surfactant in a container, sealing the container, putting the sealed container into a shaking table and carrying out shaking to obtain a stable multiferroic liquid. Compared with the solid multiferroic material, the multiferroic liquid has ferroelectricity, magnetism, fluidity, unique magneto-optic effect and optical direfringence effect, electric field (magnetic field) sensibility, and strong magnetoelectric effect. Through application of a small electric field (magnetic field), ferroelectricity and magnetism of the multiferroic liquid can be adjusted and controlled. Multiferroic nano-particles of the multiferroic liquid can easily rotate in the electric field (magnetic field) so that an electric domain direction is completely along an electric field direction. The multiferroic liquid provides a novel research direction of a multiferroic material and has a good application prospect.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

B-site Mn and Cu codoped high remanent polarization BiFeO3 film and preparation method

ActiveCN103613144AImprove multiferroic propertiesDistortionIron compoundsIonEthylene glycol monomethyl ether

The invention relates to a B-site Mn and Cu codoped high remanent polarization BiFeO3 film and a preparation method, the method comprises the following steps: dissolving bismuth nitrate, ferric nitrate, manganese acetate and cupric nitrate according to mol ratio of 1.05: [(0.92-0.98)-x]: (0.02-0.08):x in a mixed liquor of ethylene glycol monomethyl ether and acetic anhydride, then uniformly stirring to obtain a BiFeO3 precursor; wherein total metal ion concentration of the BiFeO3 precursor is 0.1-0.5mol / L, X is 0.01-0.03; performing spin coating of the BiFeO3 precursor on a FTO / glass substrate to prepare a wet membrane, baking the wet membrane to obtain a dry membrane, then annealing at 550 DEG C to obtain the crystalline state BiFeO3 film; cooling the crystalline state BiFeO3 film, and repeatedly making the crystalline state BiFeO3 film to reach a required thickness to obtain the B-site Mn and Cu codoped high remanent polarization BiFeO3 film. According to the invention, a sol gel technology is employed, the equipment requirement is simple, the film is prepared on large surface and surfaces with irregular shapes, the chemical component is accurate and controllable, and the regulation and control to its crystal structure can be carried out by codoping thereby the ferroelectric performance of the film is greatly increased.

Owner:盐城梦心缘鞋服有限公司

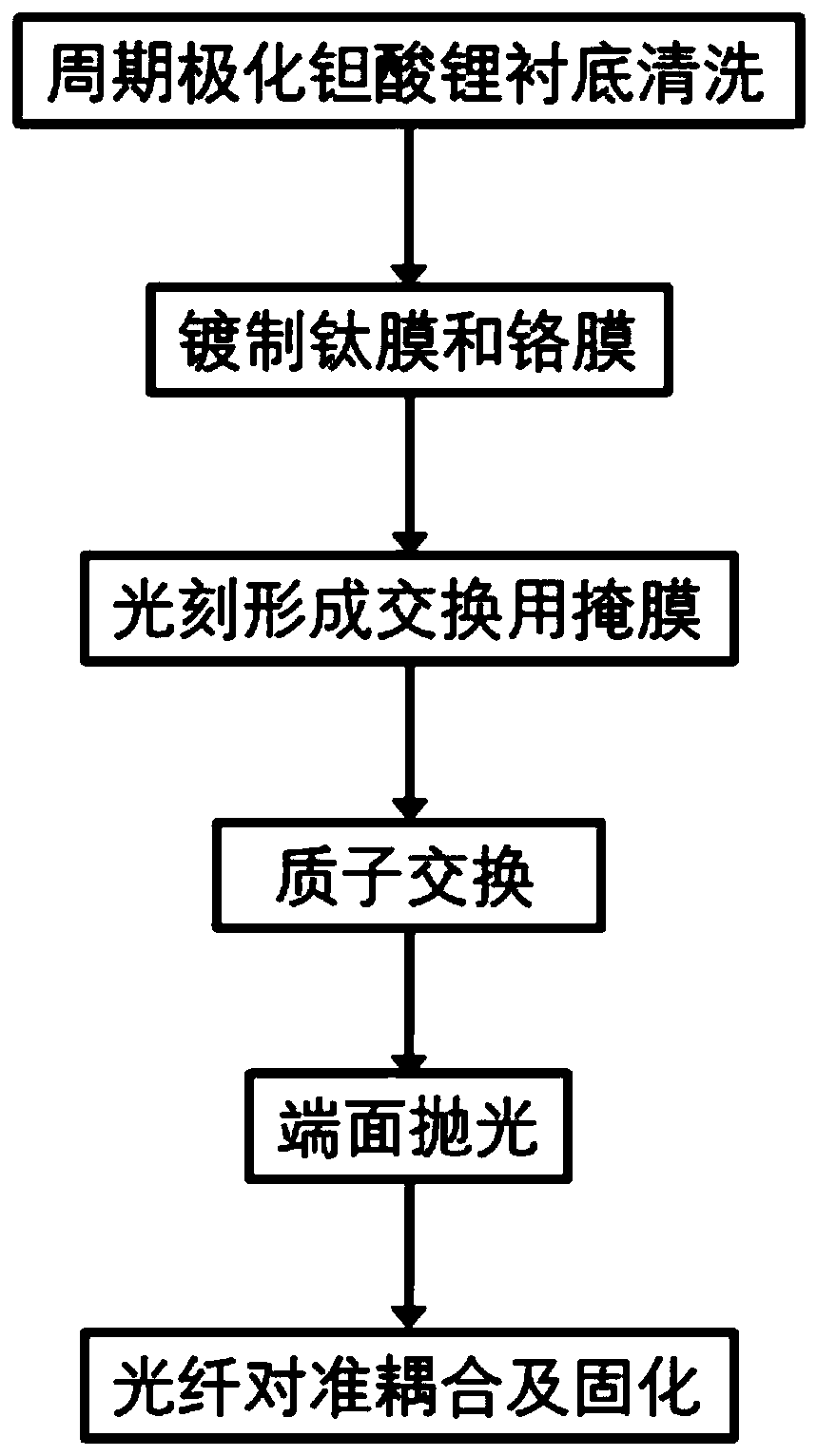

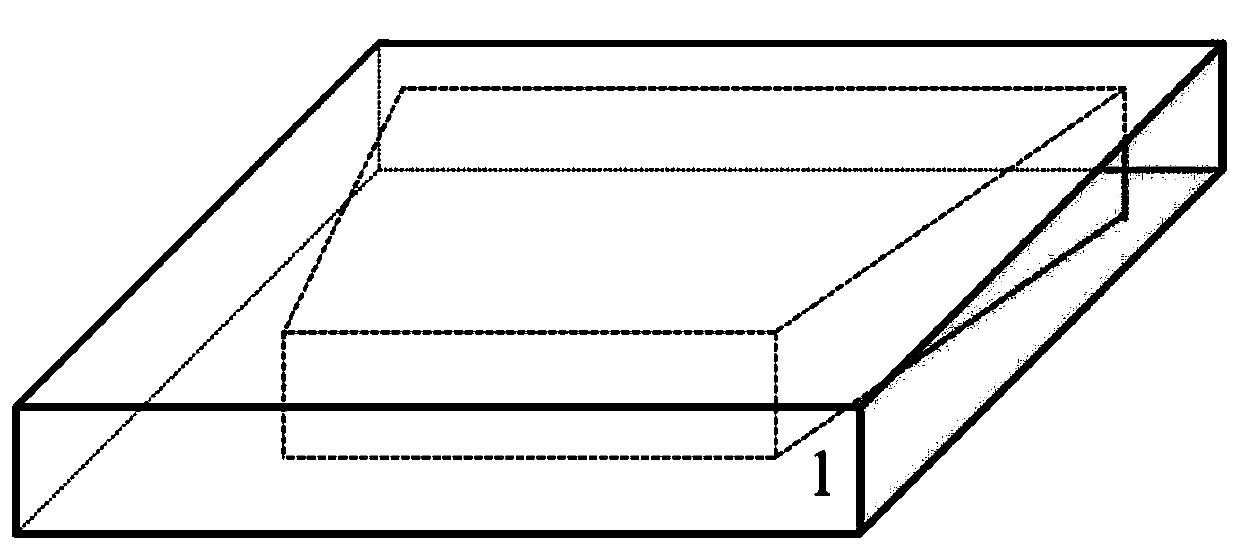

Method for forming optical waveguide quantum chip on gradual periodically polarized lithium tantalate by proton exchange method

ActiveCN110286439AImprove integration densityImprove adhesionOptical waveguide light guideMicron scaleUltraviolet lights

The invention relates to a method for forming an optical waveguide quantum chip on gradual periodically polarized lithium tantalate by a proton exchange method, and belongs to the field of optoelectronic device preparation methods. The method comprises the following steps: a gradual periodically polarized lithium tantalate is cleaned; a titanium film and a chromium film are sequentially plated on the surface of the substrate; a mask sample for proton exchange is form by performing ultraviolet light etching on the surface of the chromium film; the obtained sample is subjected to proton exchange at 200-300 DEG C so as to form a strip optical waveguide; the two end surfaces perpendicular to the optical waveguide are optically ground and polished; the optical waveguide performance of the waveguide is tested by a light passing experiment; and the two polished end surfaces are coupled by optical fiber end surfaces and cured by UV glue, and the two ends of the optical fiber jumper are used as input and output ends respectively so as to prepare the optical quantum chip. The optical waveguide chip with high performance, low transmission loss, micron scale and good crystal nonlinearity can be prepared and the crystal nonlinearity tuning range is wide.

Owner:SHANDONG UNIV

Liquid solar cell and preparation method thereof

The invention discloses a liquid solar cell with variable structure and adjustable photovoltaic effect and a preparation method of the liquid solar cell. The liquid solar cell comprises a container, wherein the container comprises a substrate and a surrounding wall; the surrounding wall is composed of a side wall and a top wall; the surrounding wall is fixed on the substrate to form the container; an upper electrode is arranged on the lower surface of the top wall; a lower electrode is arranged on the upper surface of the substrate; the container is filled with magnetoelectric liquid; the magnetoelectric liquid is prepared by mixing core-shell structure nanoparticles, a hydrophilic surfactant and oily base liquid; the cores of the core-shell structure nanoparticles are magnetic particles; and the claddings are ferroelectric particles. The preparation method of the liquid solar cell comprises the following steps: (1) preparing the upper electrode and the lower electrode; (2) preparing the container; and (3) adding the magnetoelectric liquid to the container to obtain the liquid solar cell.

Owner:嘉兴鼎尚信息科技有限公司

High-field, large-strain and lead-free ceramic with high energy storage density and preparation method of ceramic

InactiveCN104671778AImprove polarizationHigh dielectric strengthHigh energyEnergy storage efficiency

The invention discloses a lead-free ceramic dielectric material with high field-induced strain and high energy storage density. The composition is represented as a general formula: [(Bi0.95La0.05)0.5Na0.5](1-x-y)(Bi0.5K0.5)x(Ba0.85Sr0.10Mg0.05)yTi(1-u-v)Cu(A(1 / 2)B(1 / 2))vO3, wherein A represents a trivalent metal element and is selected from one or two of Al, Fe, Cr, Mn, Co, Y and Ga; B represents a pentavalent metal element and is selected from one or two of Nb, Sb, Ta and V; C represents a tetravalent metal element and is selected from one of Zr, Mn, Hf and Sn; x, y, u and v represent mole fraction, x is larger than or equal to 0.005 and smaller than or equal to 0.2, y is larger than or equal to 0.005 and smaller than or equal to 0.2, the sum of x and y is smaller than or equal to 0.3, u is larger than or equal to 0.005 and smaller than or equal to 0.3, v is larger than or equal to 0.005 and smaller than or equal to 0.3, and the sum of u and v is smaller than or equal to 0.4. Cold isostatic pressing is adopted, uniform and compact ceramic texture can be acquired, and a preparation process is simple, stable and suitable for industrial popularization and application; the ceramic with high field-induced strain and high energy storage density has excellent energy storage density, energy storage efficiency and high-field strain, the energy storage density can be 1.2 J / cm<3>, the energy storage efficiency can be 59%, the high-field strain can be 0.28%, and the ceramic is environment-friendly, low in energy consumption and good in practicability.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Inverse spinel zinc ferrite and preparation method thereof

InactiveCN102557146AHigh saturation susceptibilityHigh resistivityIron compoundsCompression moldingLithium chloride

The invention relates to a ferrite soft magnetic material and provides an inverse spinel zinc ferrite with high saturation magnetic susceptibility, resistivity, Curie temperature and resistance, a low coercive field and excellent properties and a preparation method thereof. The inverse spinel zinc ferrite has a chemical formula of ZnFe2O4 and a structural formula of (Zn0.5Fe0.5)[Zn0.5Fe1.5]O4. The preparation method comprises the following steps: mixing zinc sulfate hetahydrate with ferric sulfate and adding lithium chloride so as to obtain a mixture of zinc sulfate hetahydrate, ferric sulfate and lithium chloride; putting the mixture in a high temperature furnace for reaction; cooling and rinsing a resultant; dispersing the resultant in ethanol and separating magnetic products with a magnet so as to obtain zinc ferrite powder; and carrying out compression molding on the zinc ferrite powder with a binder after ball milling so as to obtain the inverse spinel zinc ferrite.

Owner:XIAMEN UNIV

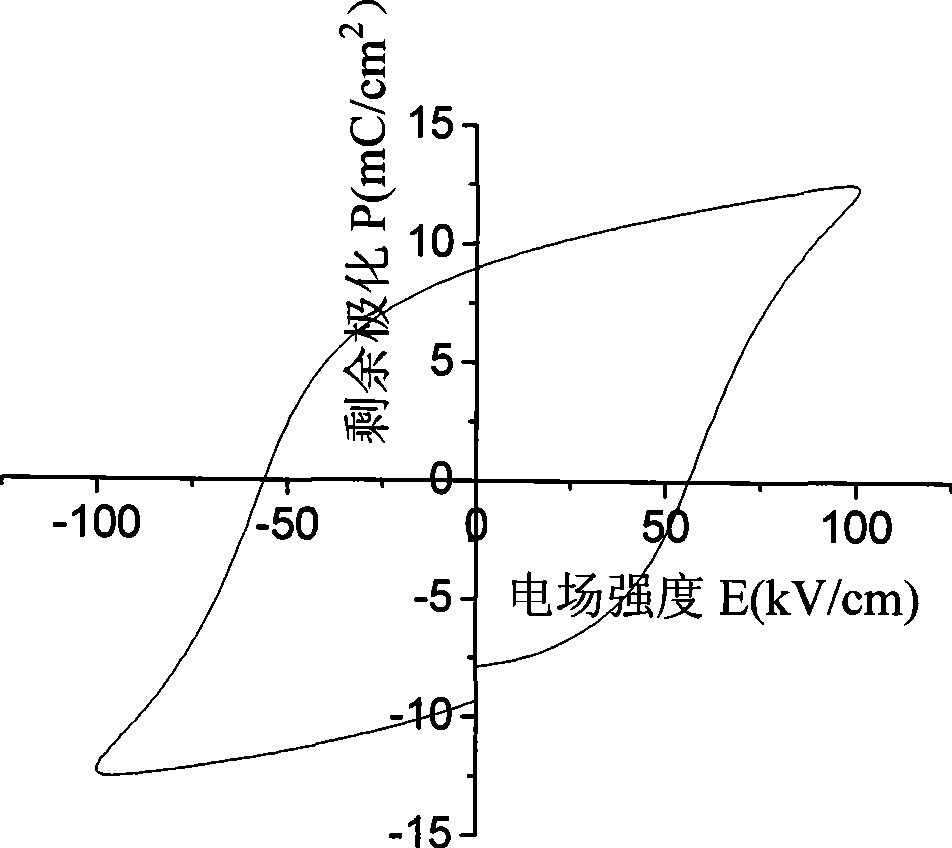

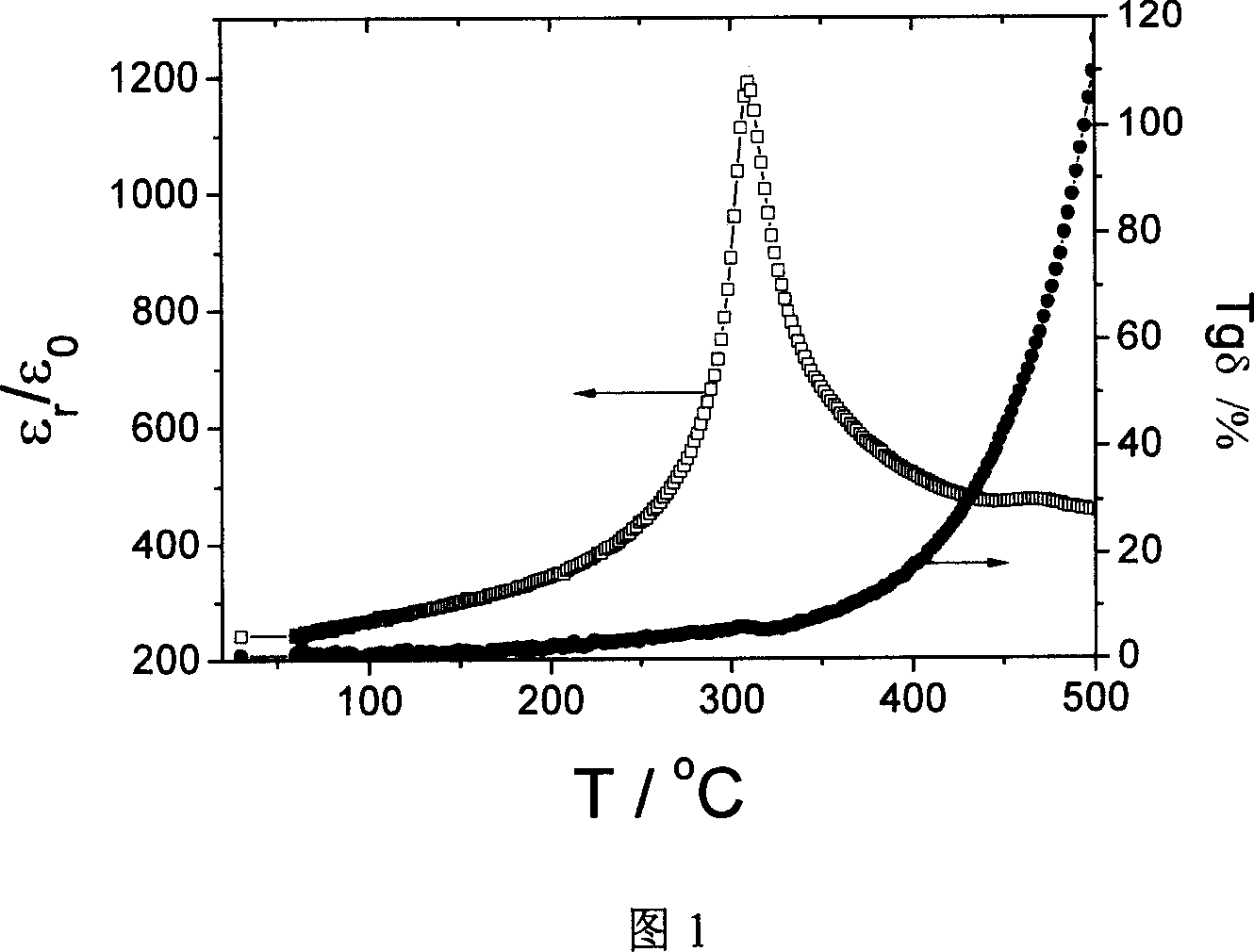

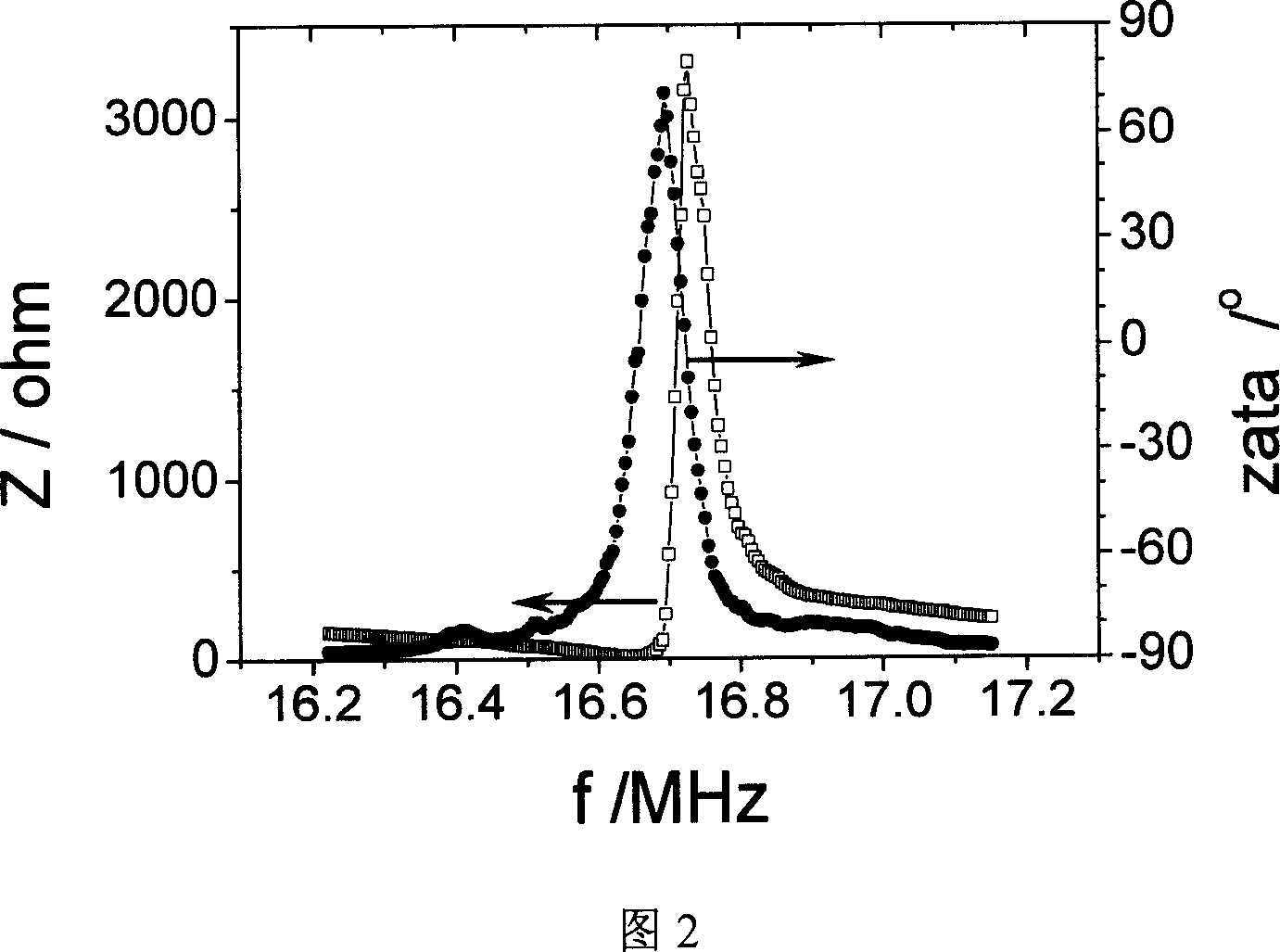

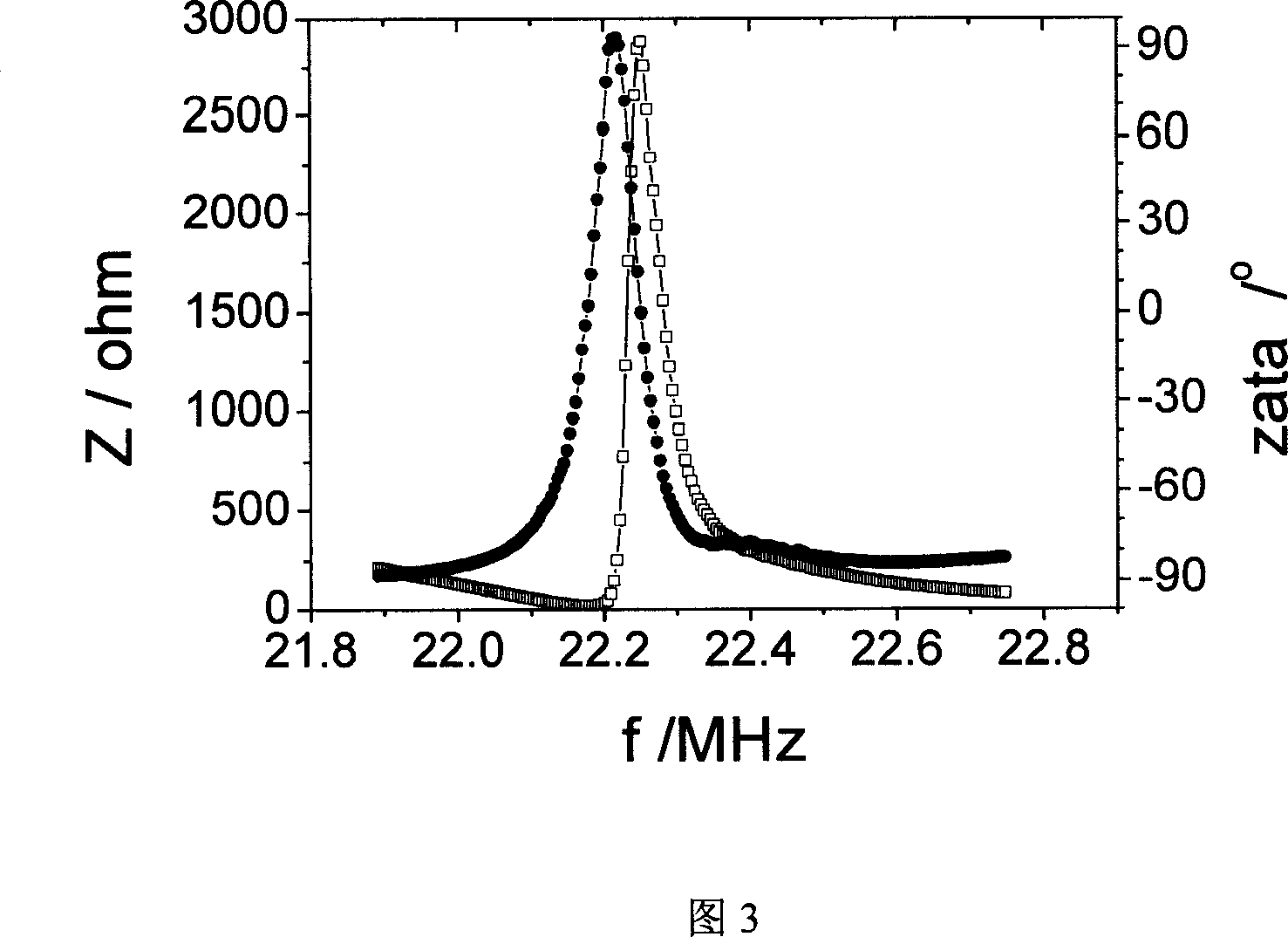

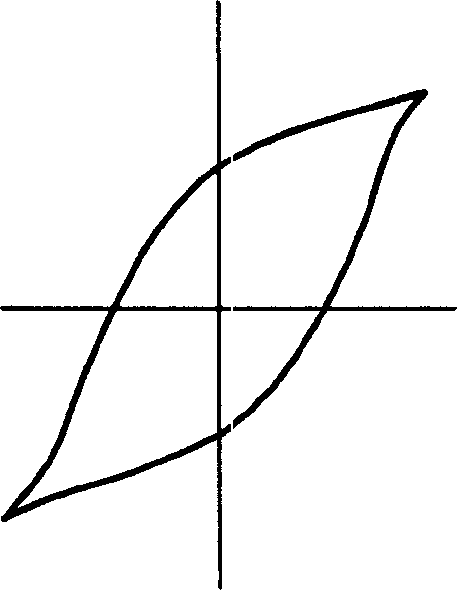

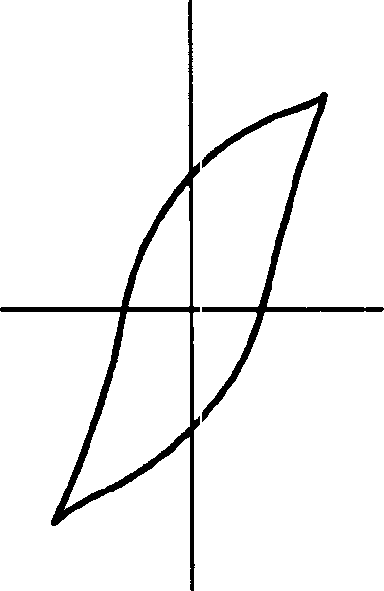

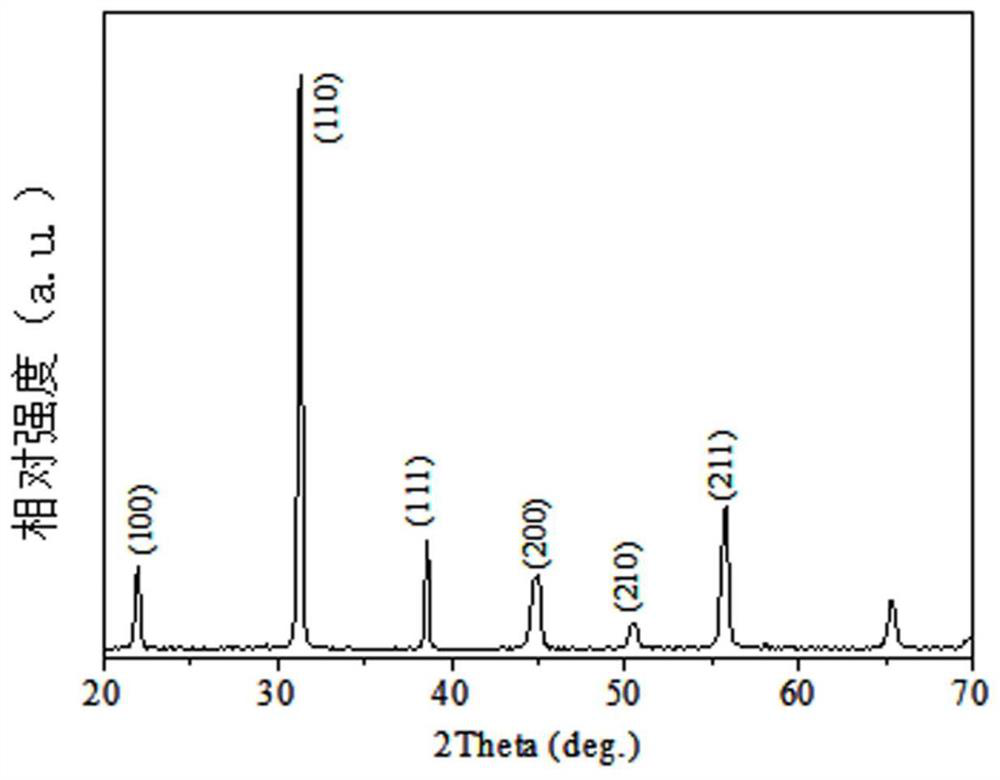

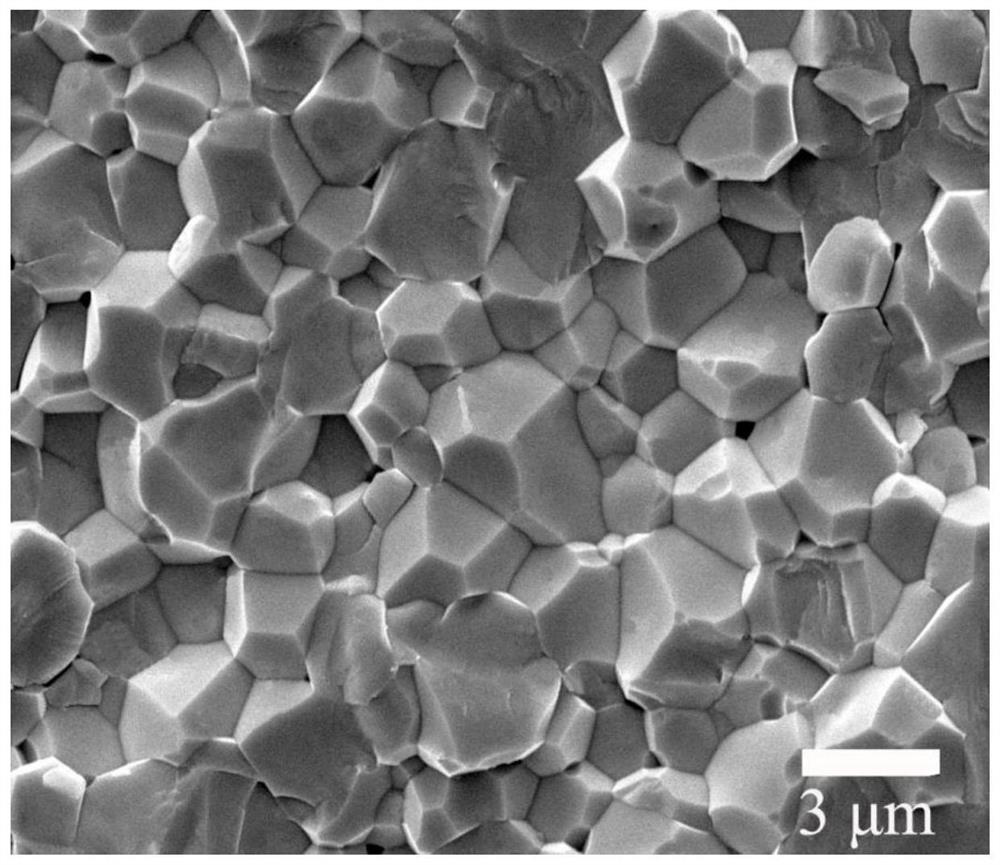

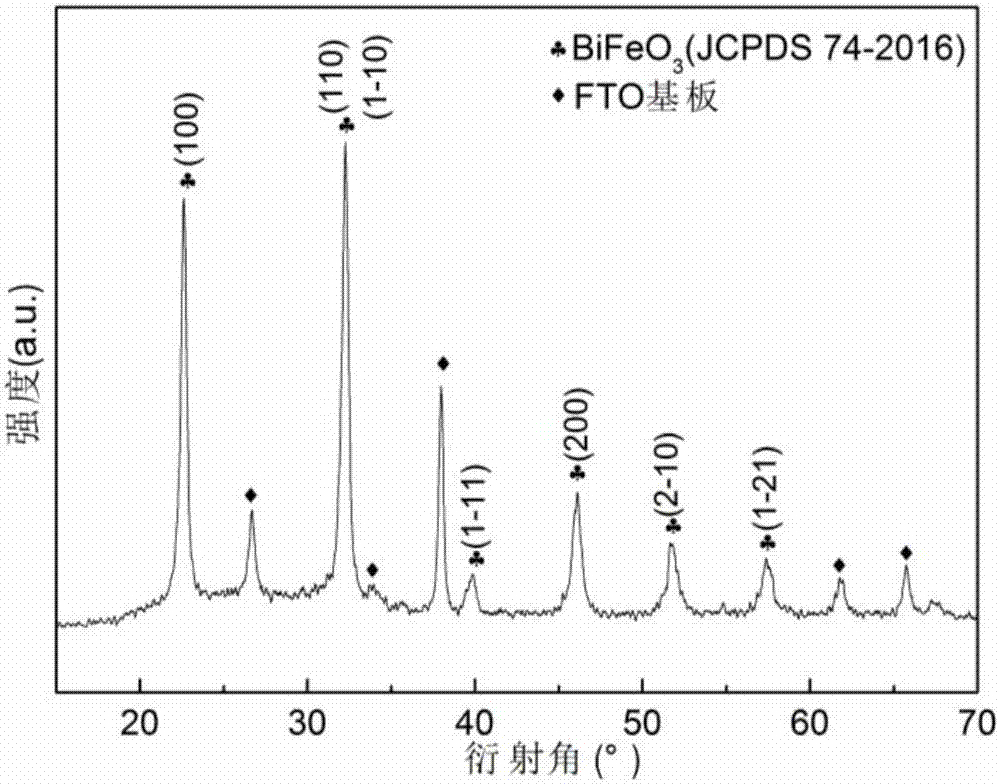

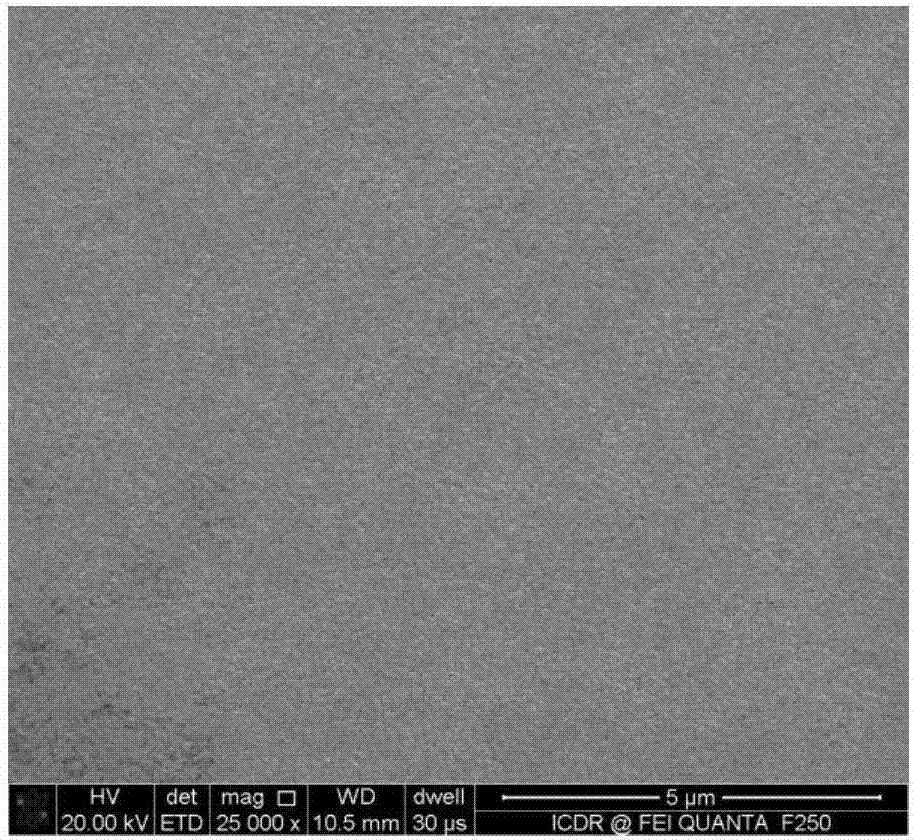

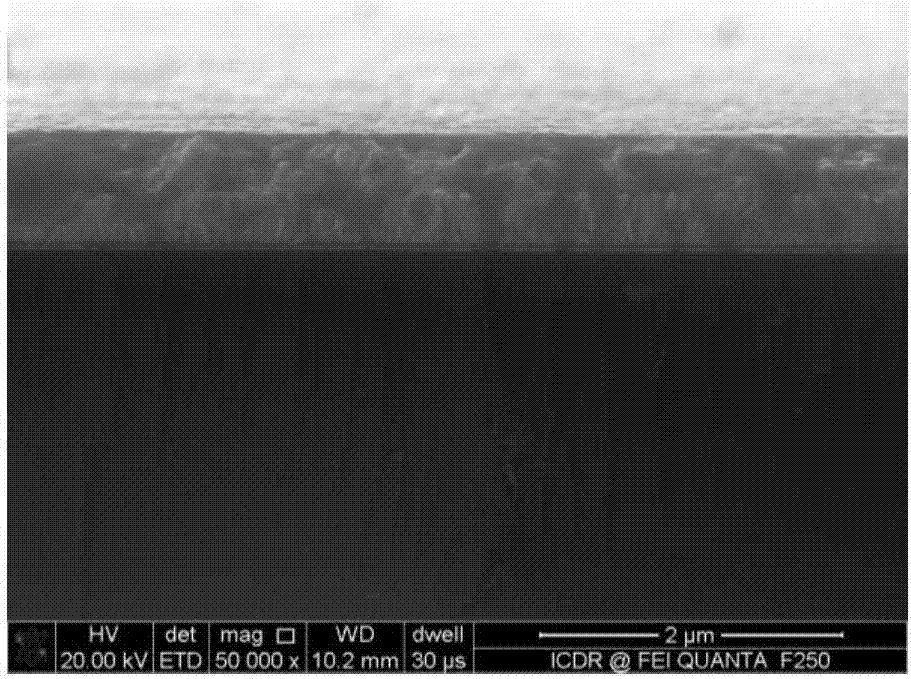

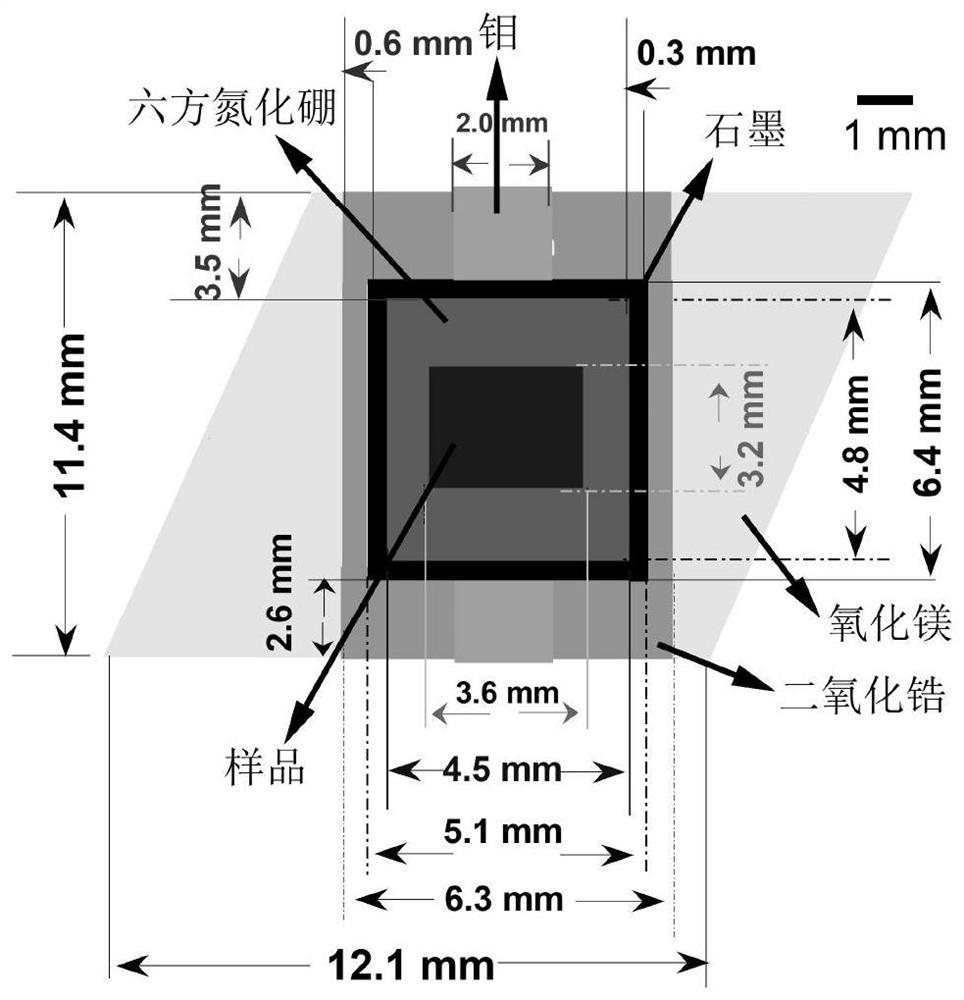

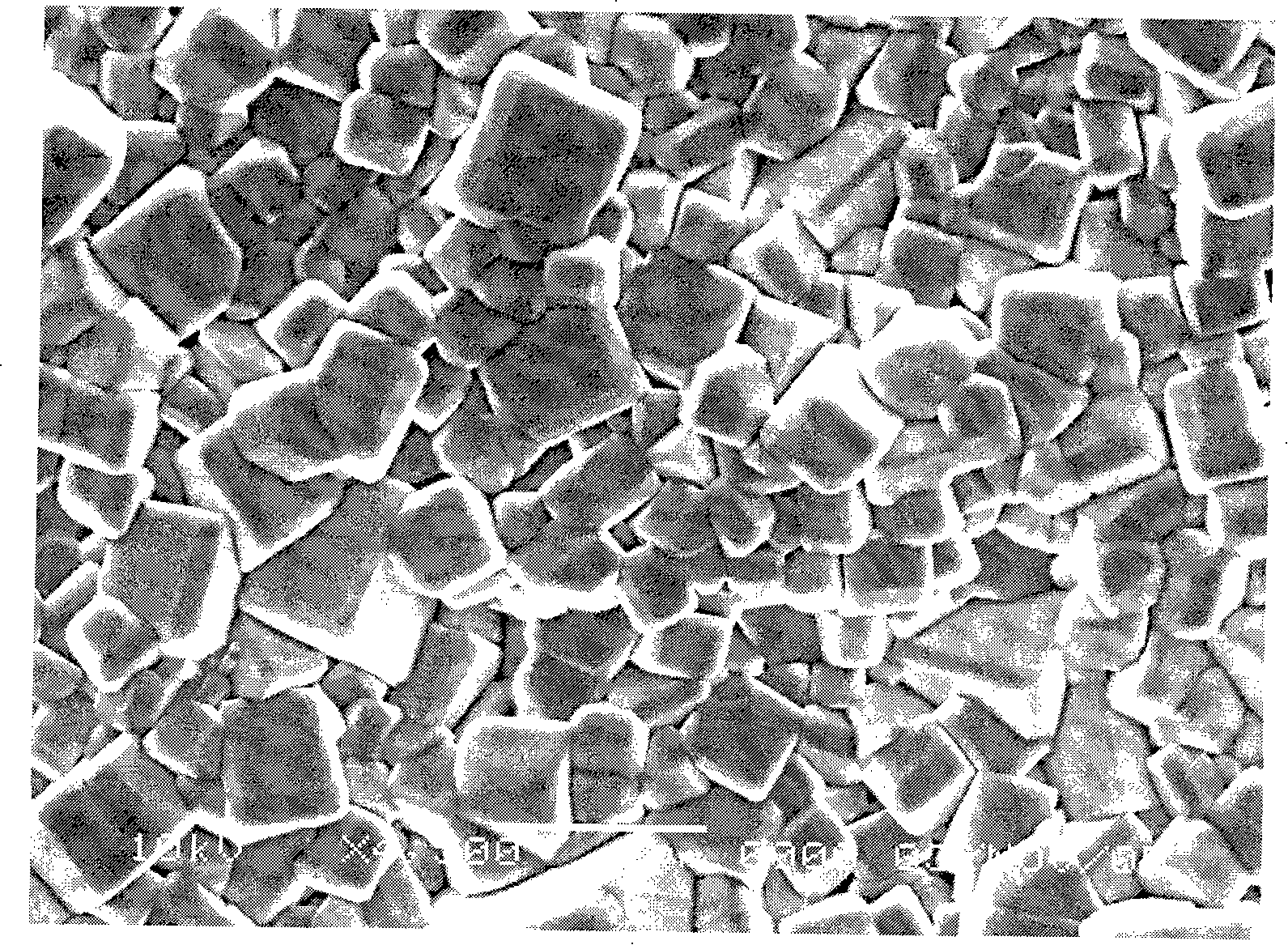

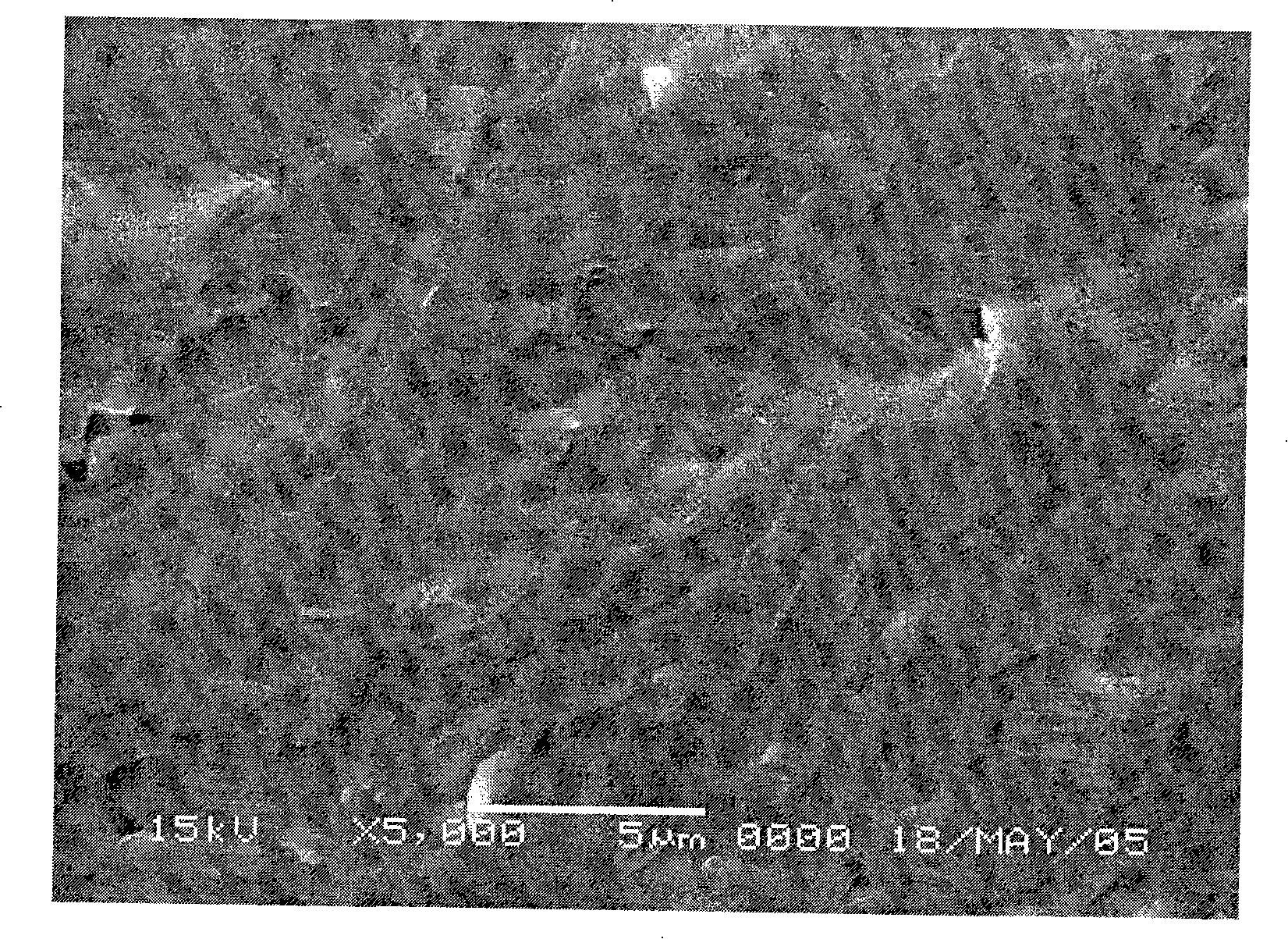

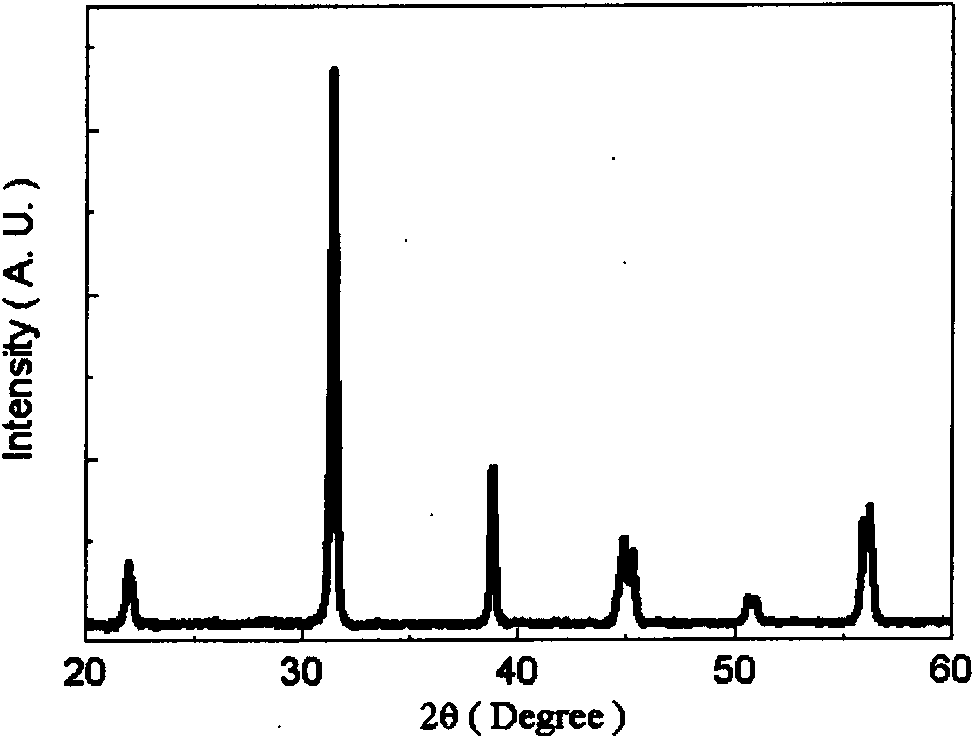

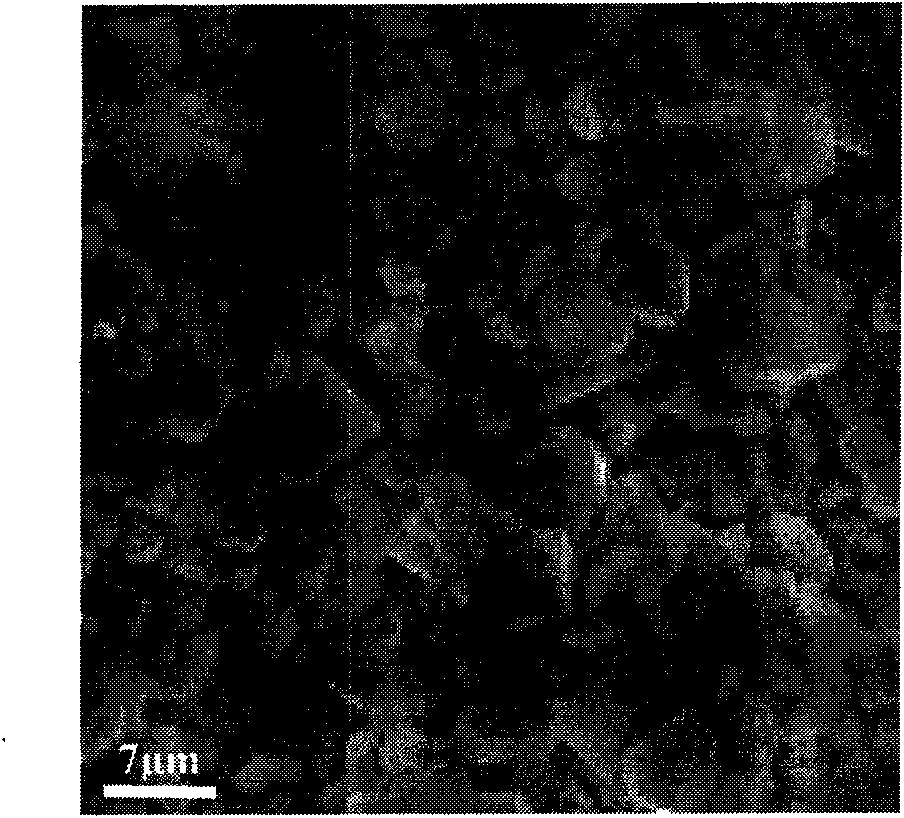

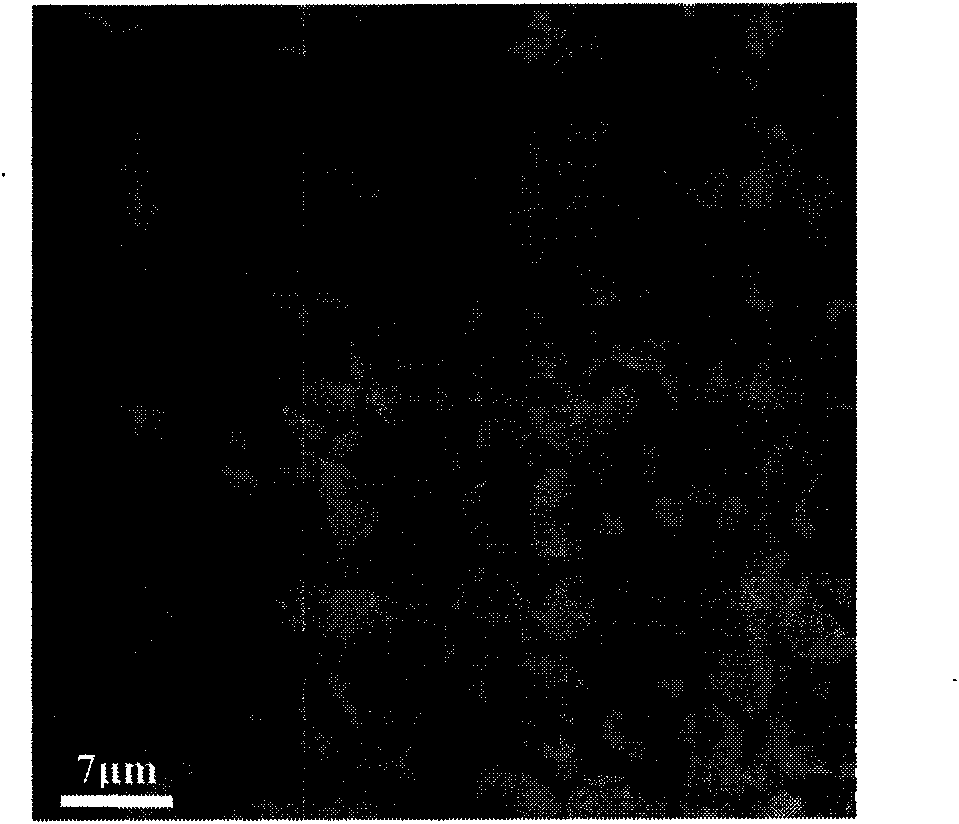

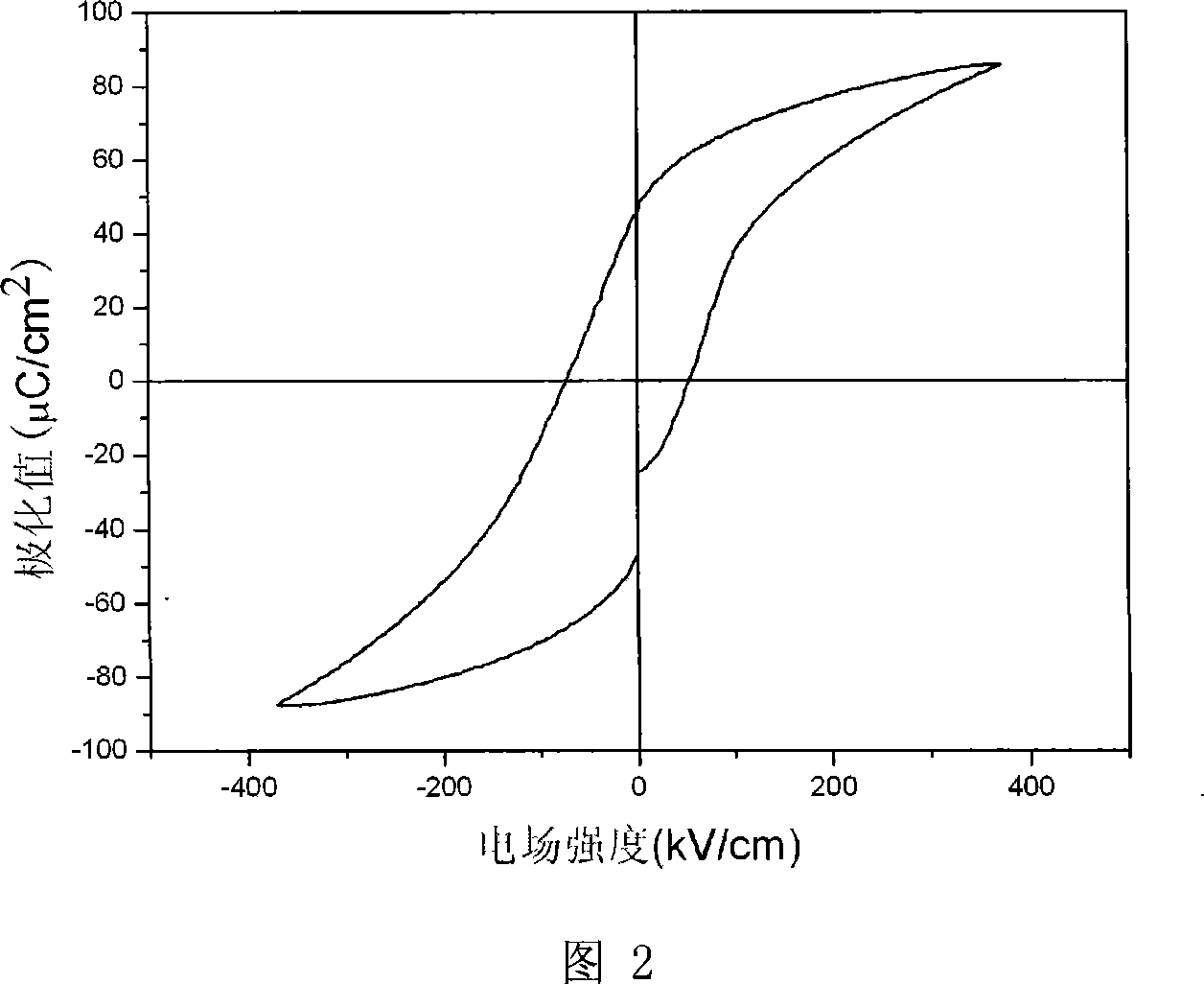

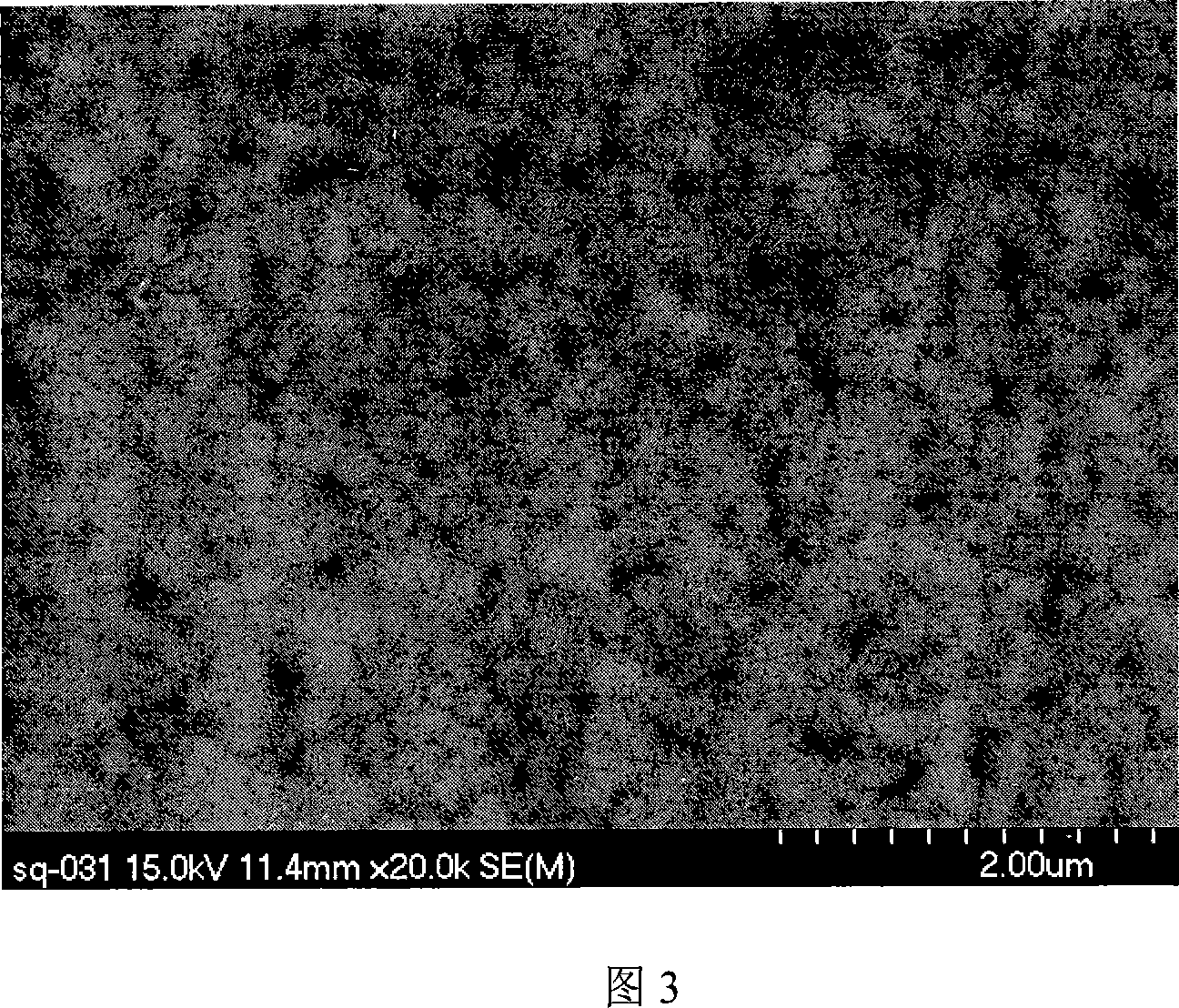

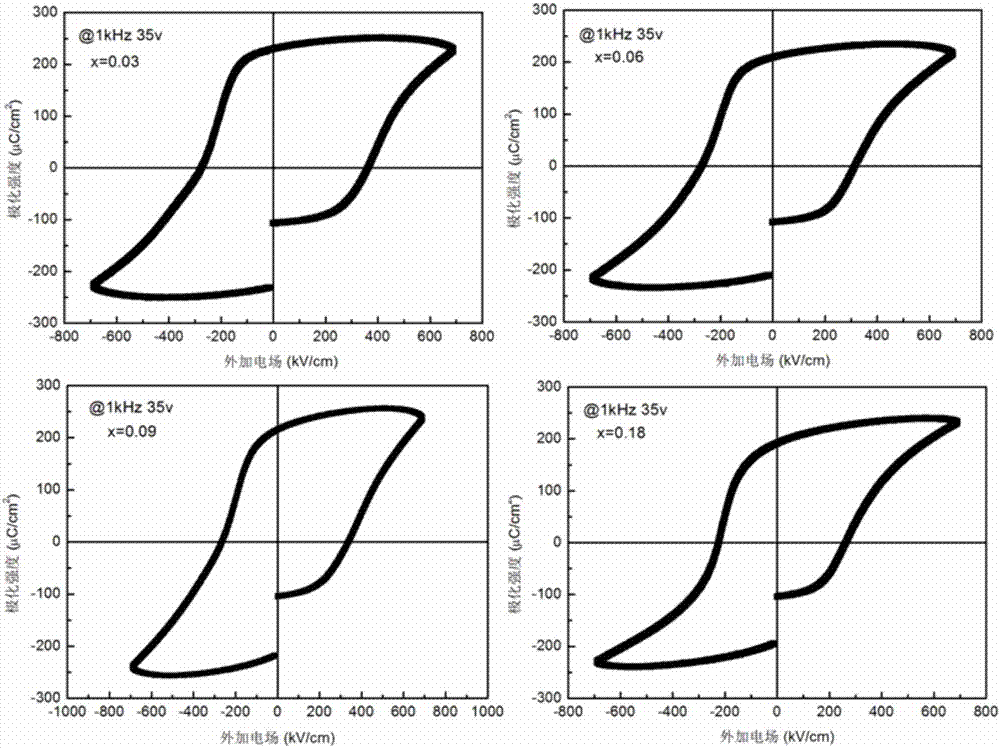

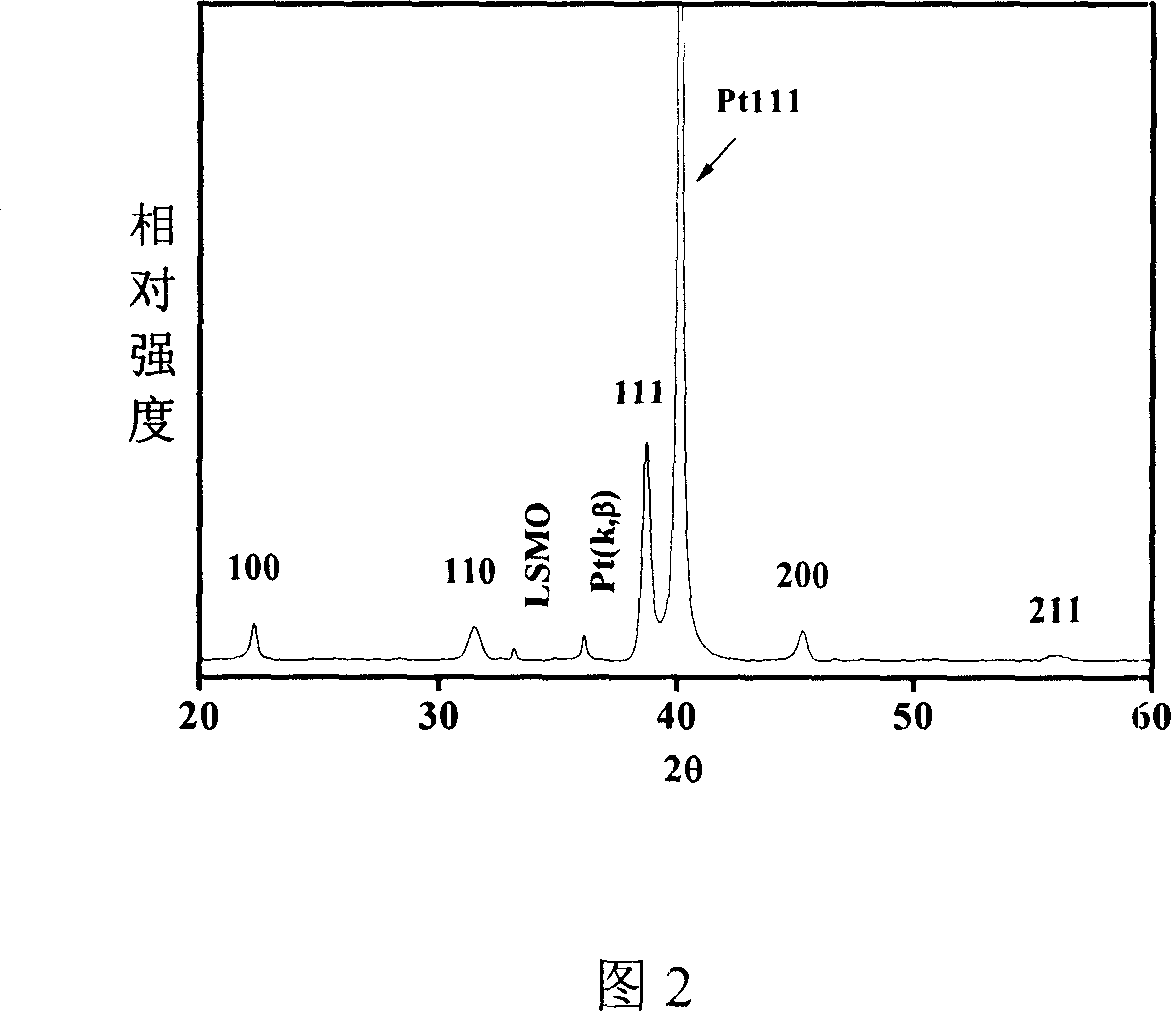

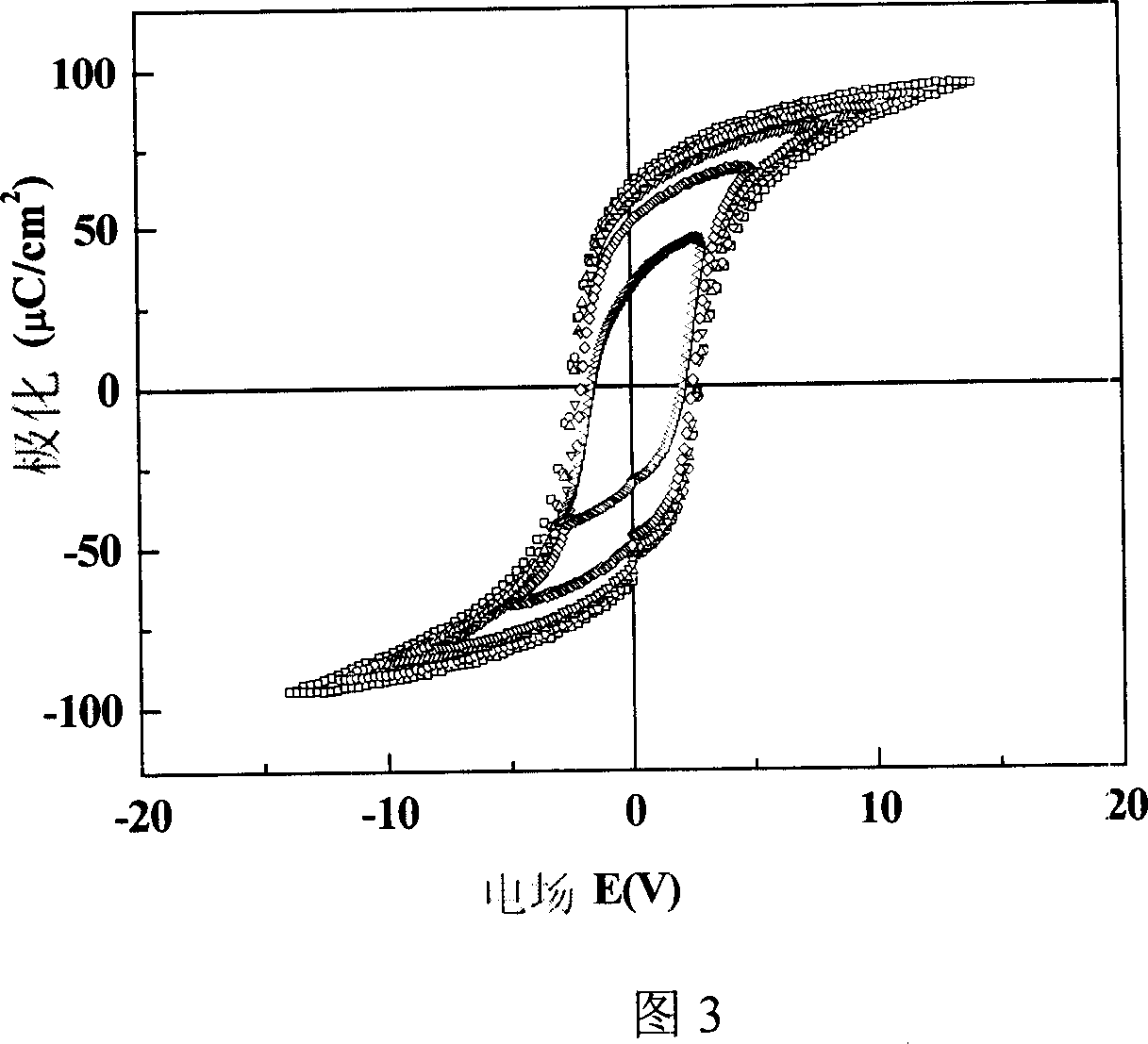

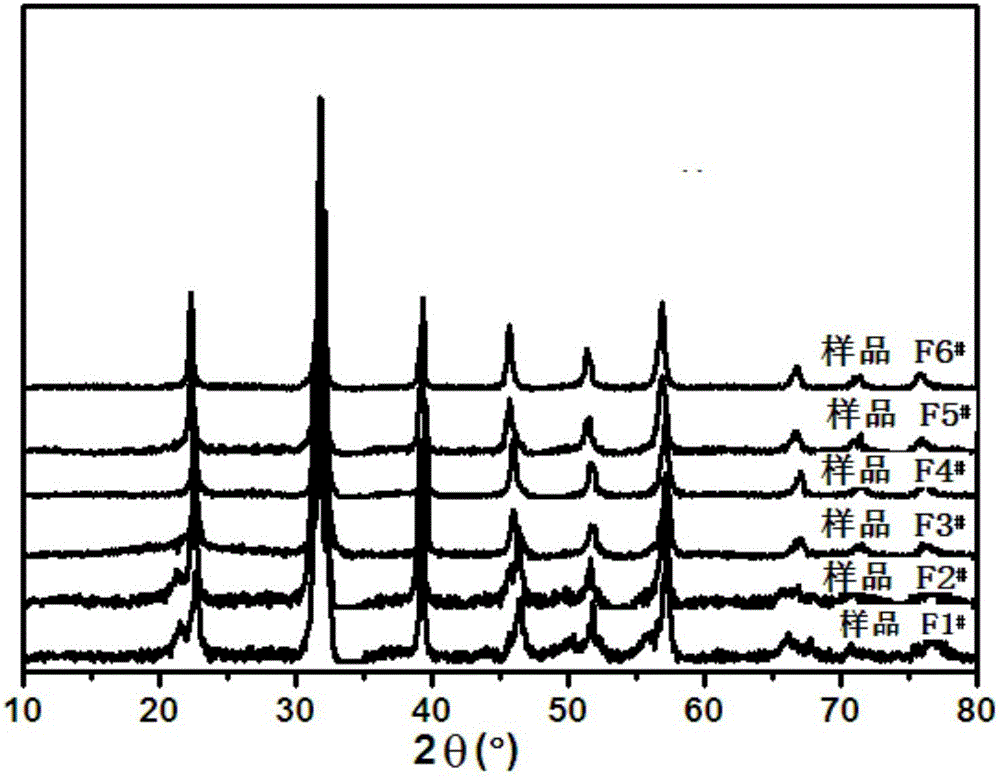

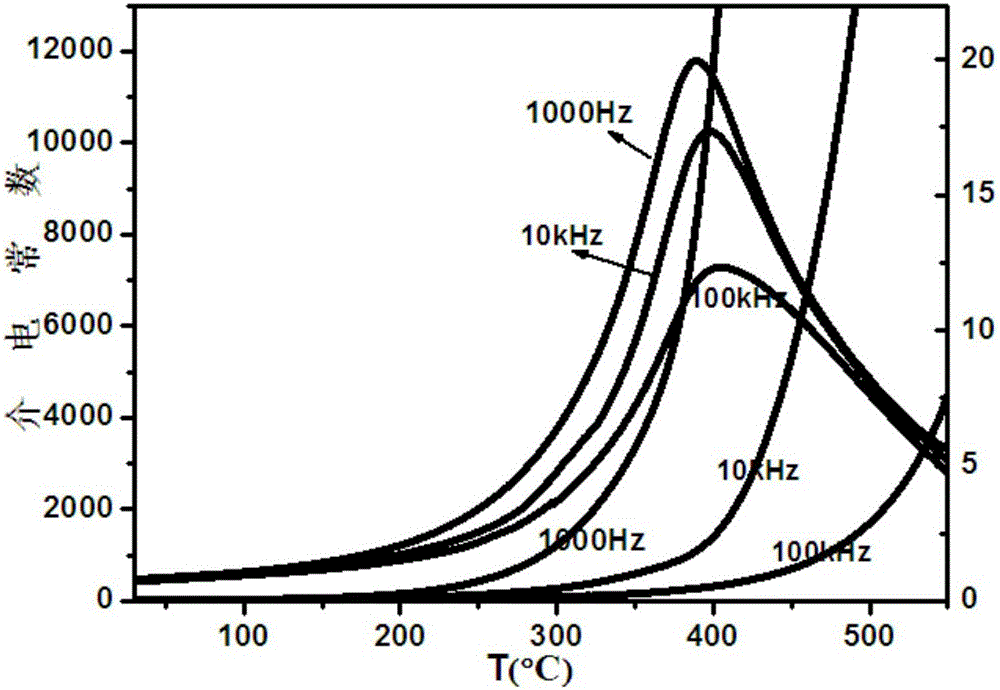

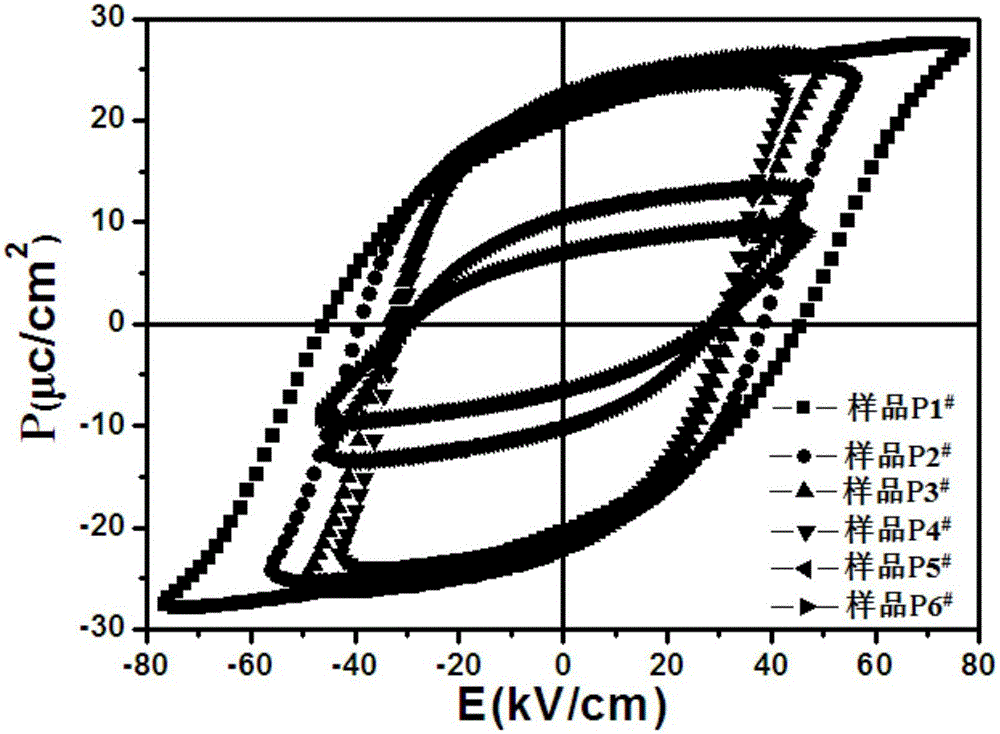

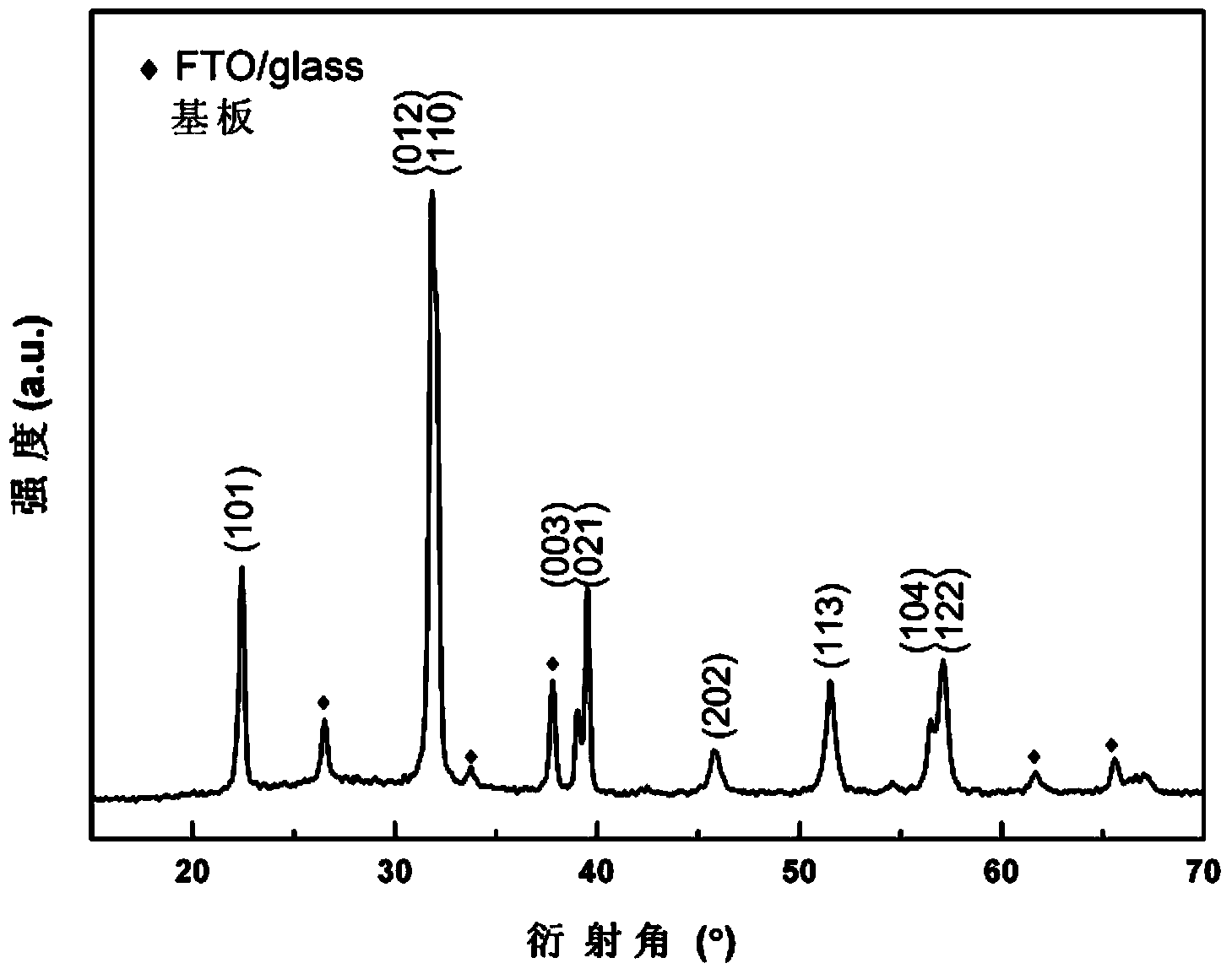

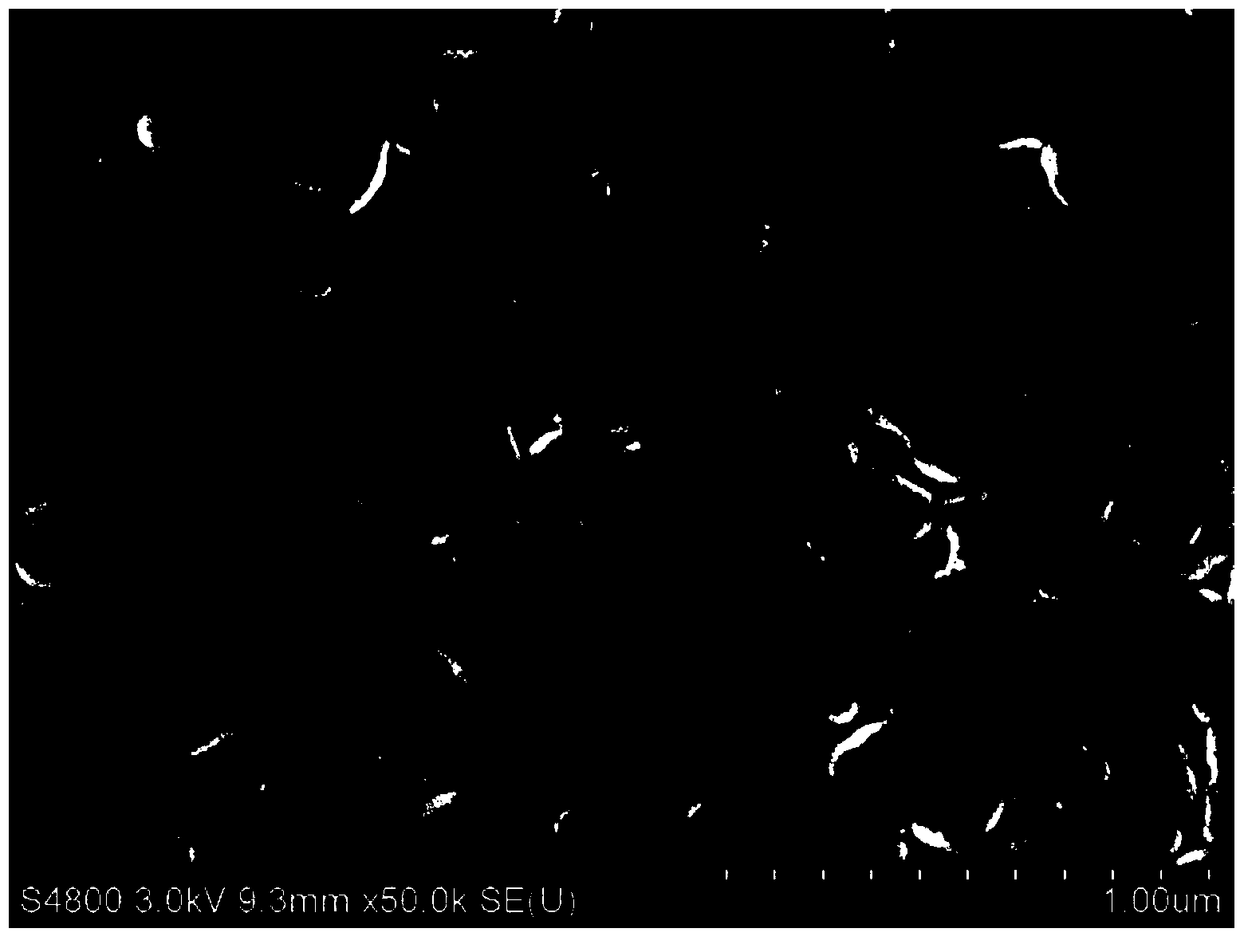

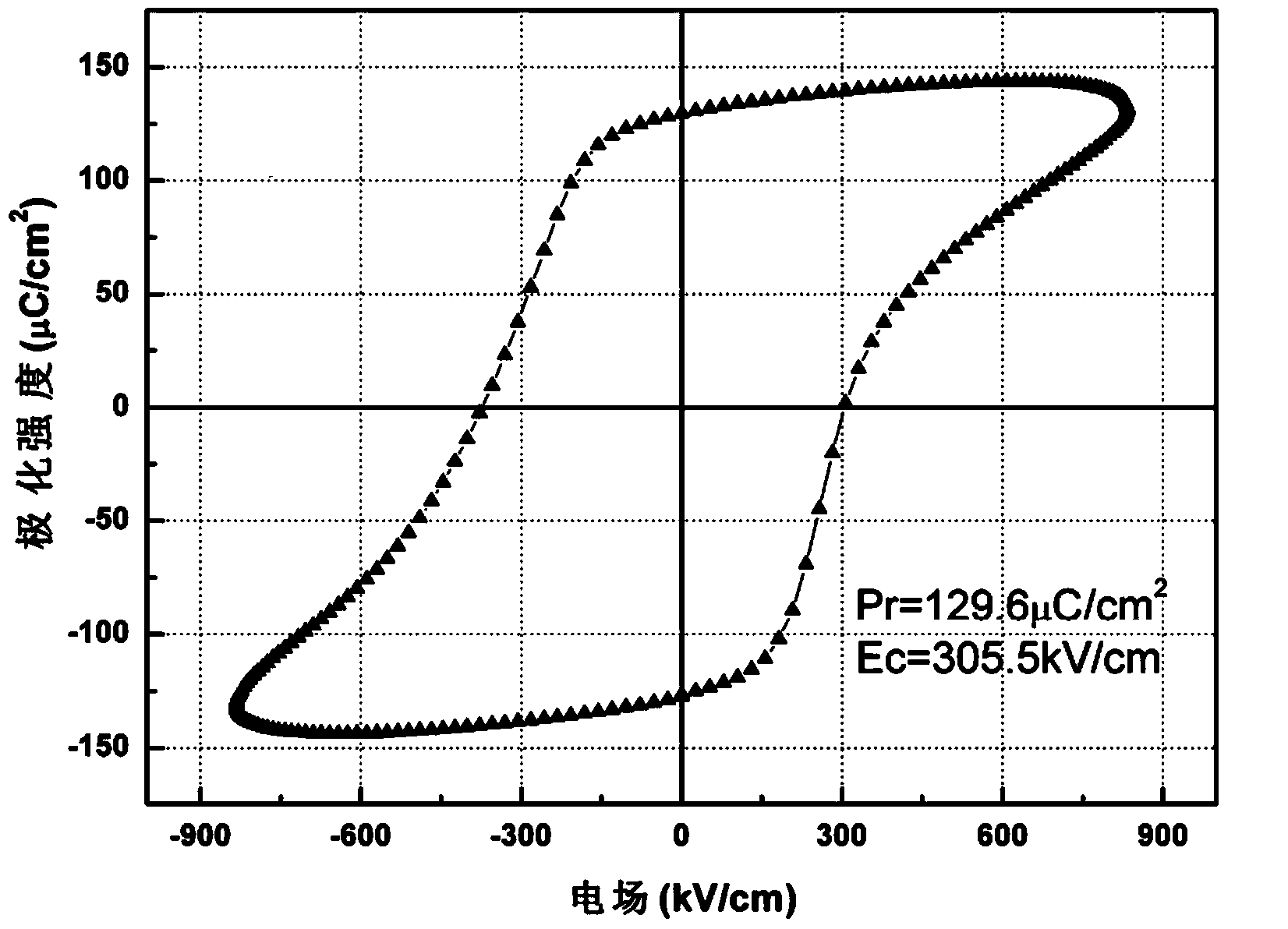

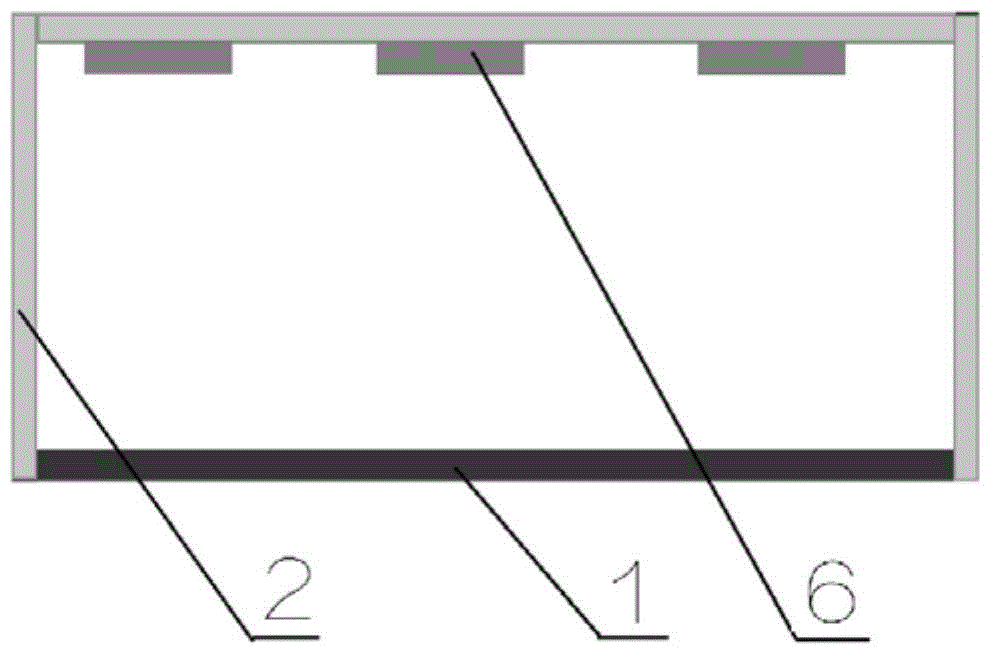

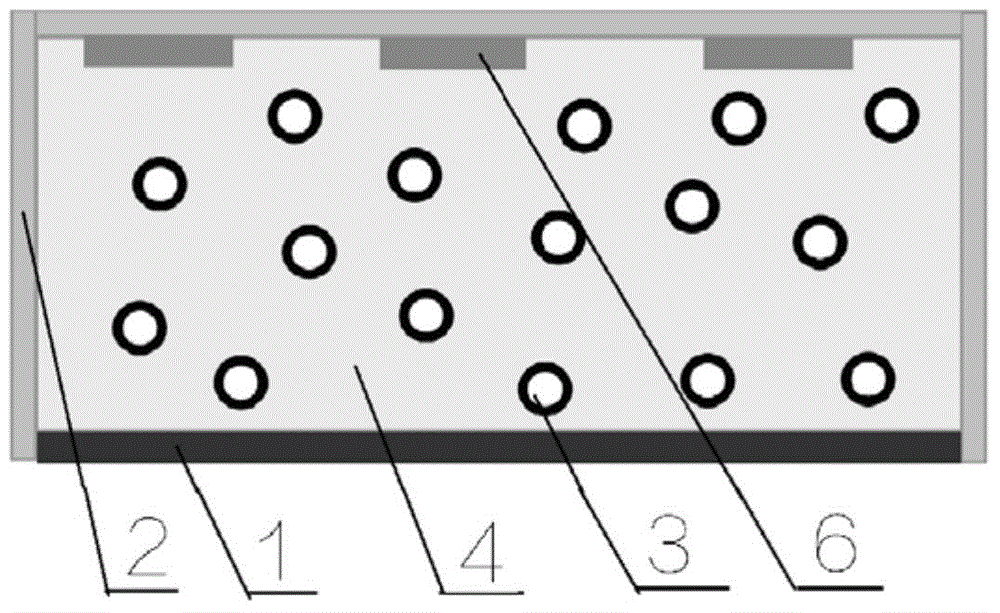

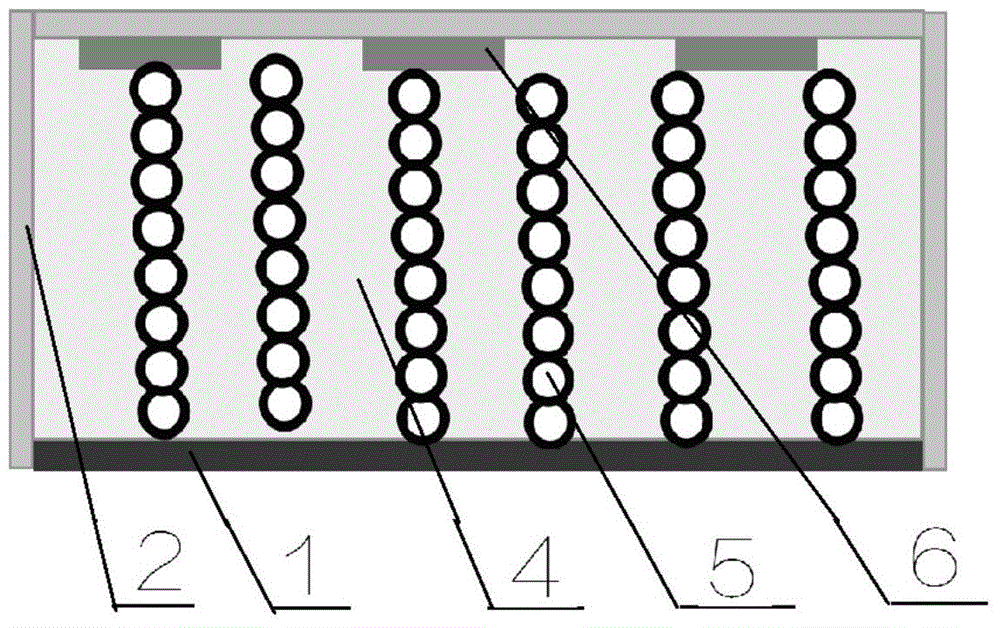

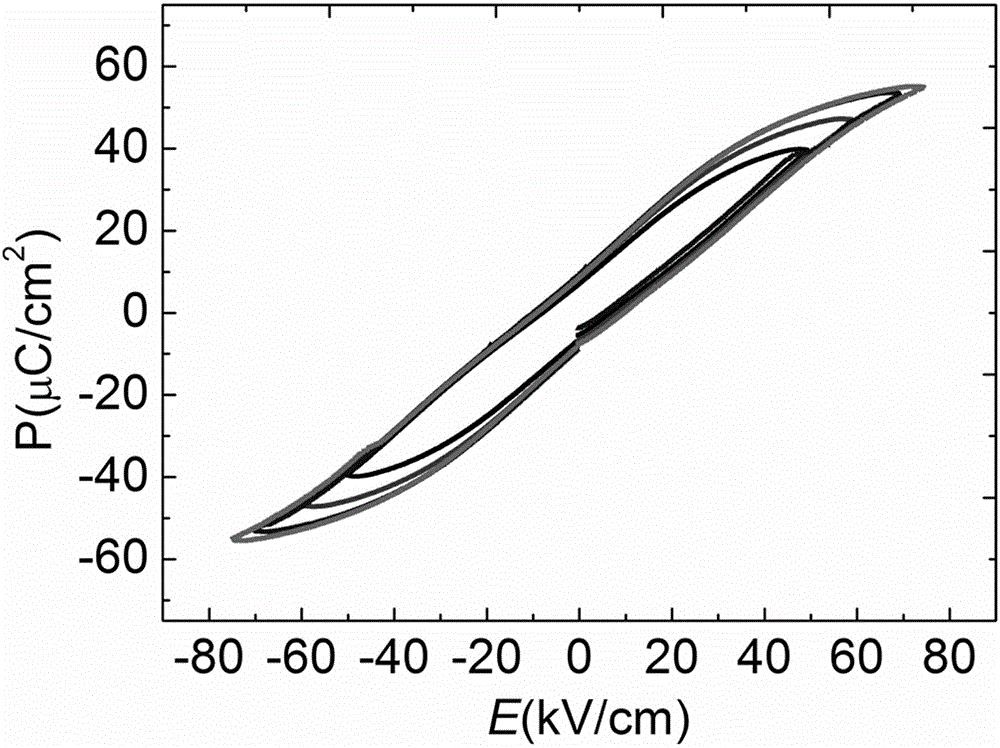

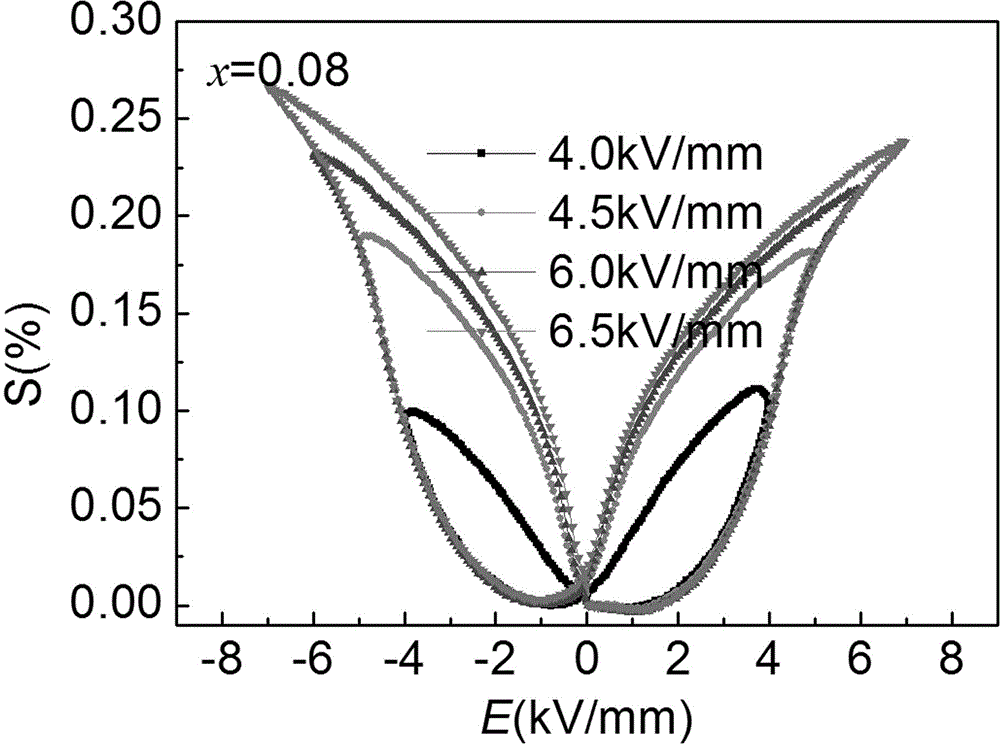

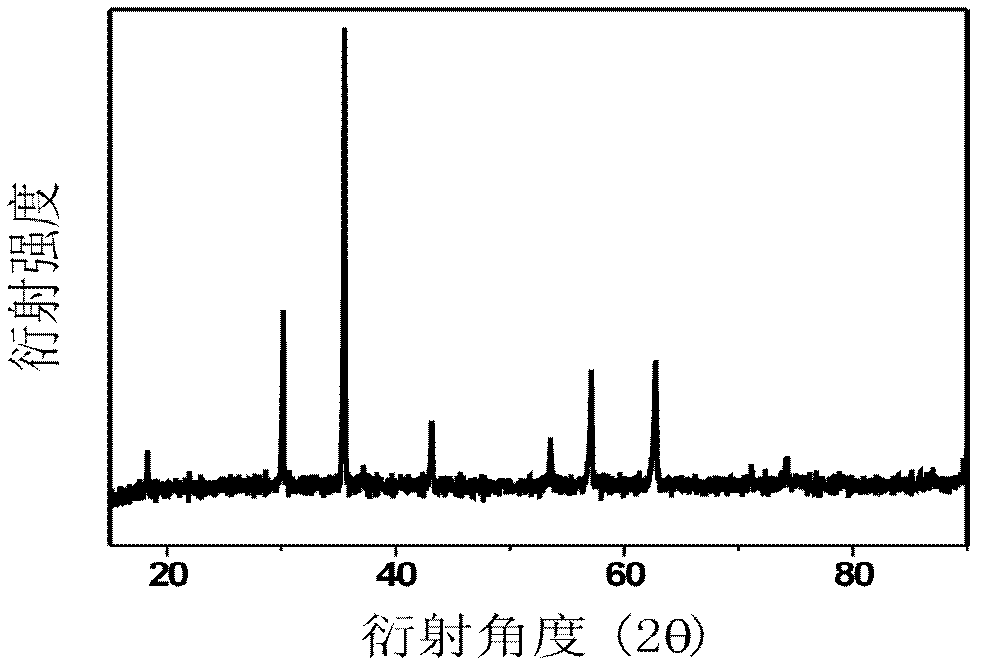

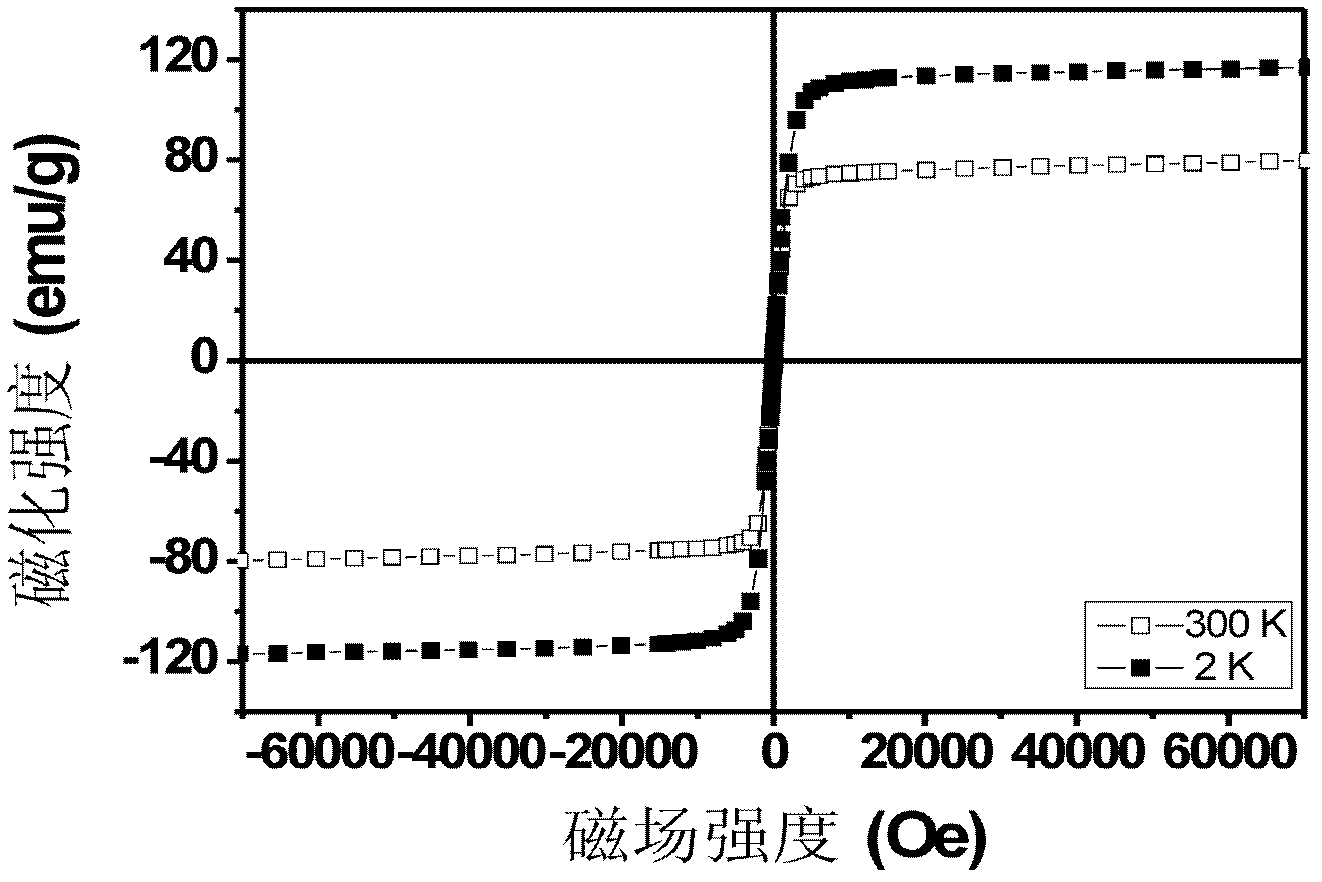

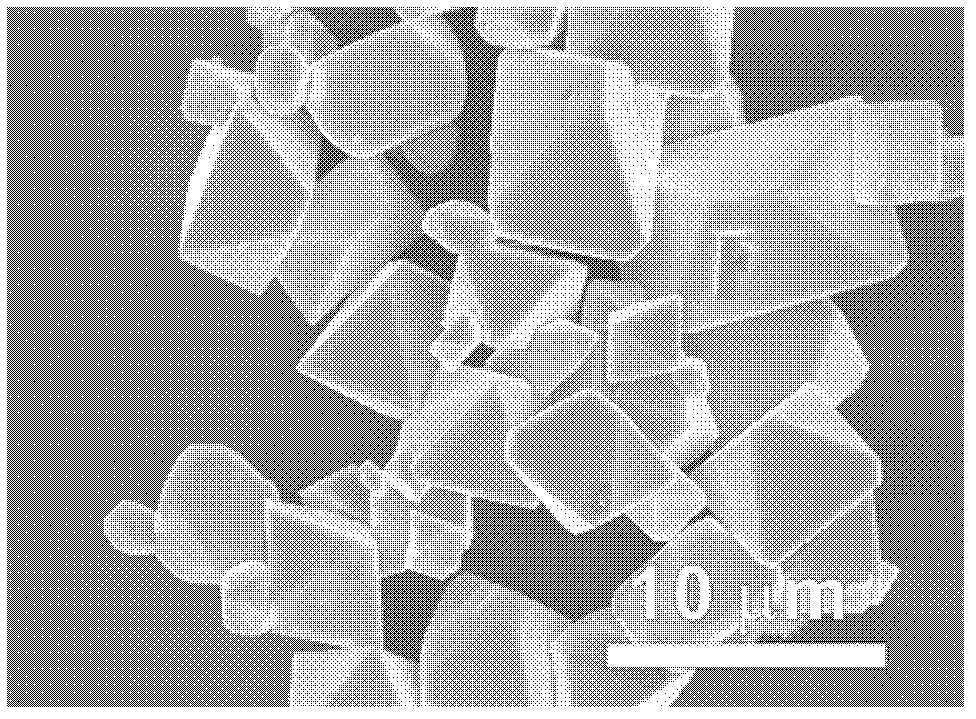

Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof

The invention provides a Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and a preparation method thereof. The method comprises the following steps: preparing a Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 precursor solution from bismuth nitrate, praseodymium nitrate, hydrogen nitrate AE, ferric nitrate and manganous nitrate, wherein AE is Sr, Ca or Ba, and x=0.02-0.05; spinning the precursor solution on a substrate; and then spinning, drying and annealing, so as to obtain the Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film. The Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film is simple in demands on equipment; the experiment condition is easy to achieve; the doping amount is easy to control; the ferroelectric property of the film can be greatly improved; and the prepared Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film is good in uniformity, low in leakage current, and low in coercive field, and has relatively high remanent polarization.

Owner:SHAANXI UNIV OF SCI & TECH

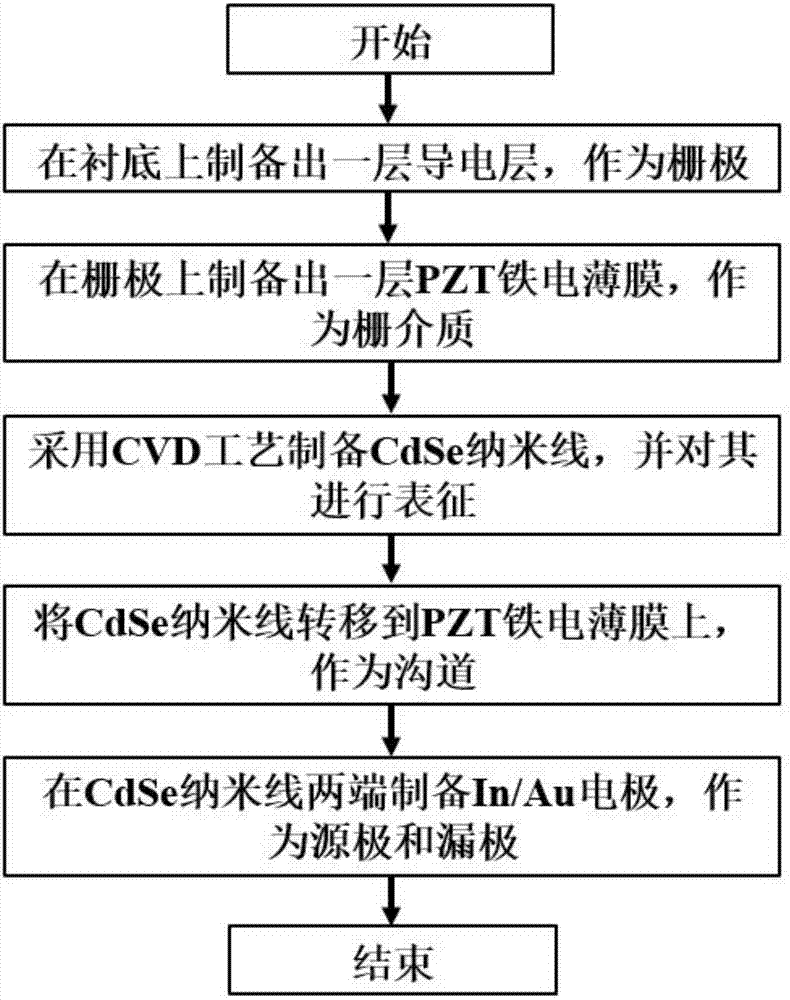

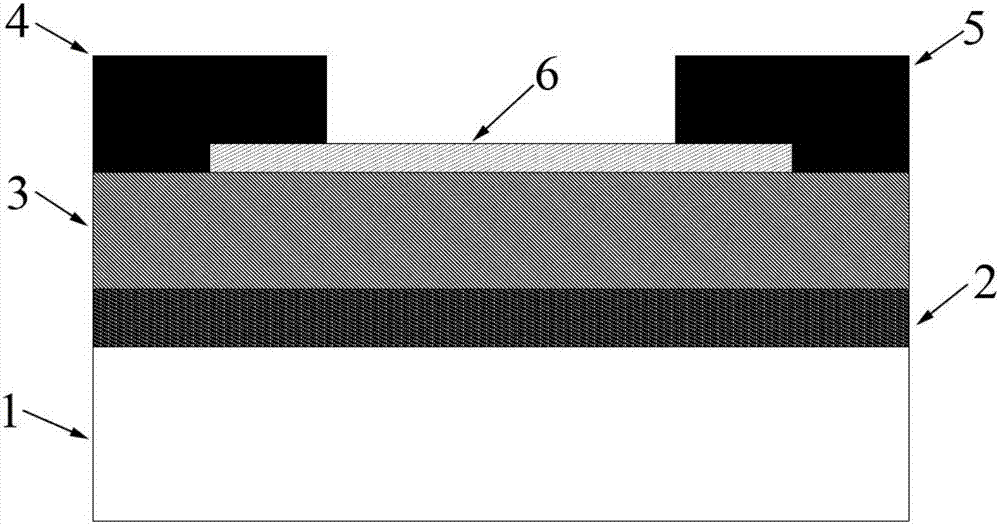

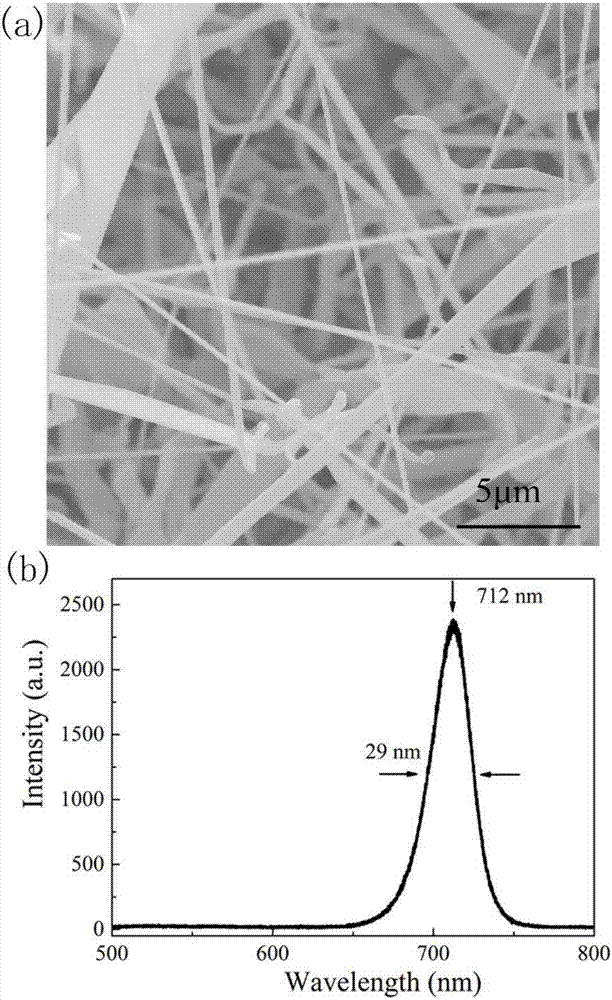

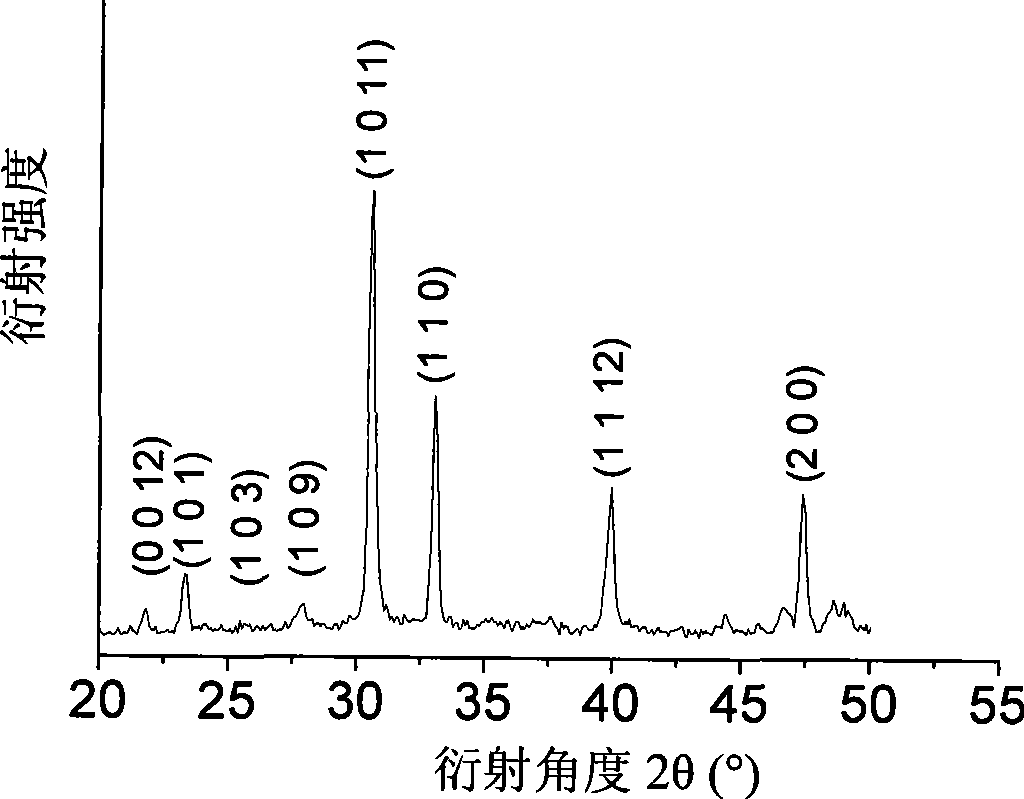

Ferroelectric gate dielectric CdSe nanowire photoelectric transistor and preparation method thereof

InactiveCN107293616AImprove control abilityReduce power consumptionFinal product manufactureSemiconductor devicesNanowireGate dielectric

The invention belongs to the micro-nano photoelectric detector field, to be specific, relates to a PZT ferroelectric gate dielectric CdSe nanowire photoelectric transistor and the preparation method thereof. A device comprises a back gate structure, mainly comprises a source electrode, a drain electrode, a channel, a gate, a gate dielectric, and a substrate. The channel material is an In-doped CdSe nanowire, the gate is metal or SrRuO3, the gate dielectric is a PZT ferroelectric thin film, and the substrate is a SiO2 / Si or SrTiO3 substrate. By comparing with the conventional CdSe nanowire photoelectric transistors, the ferroelectric gate dielectric CdSe nanowire photoelectric transistor is advantageous in that 1) the dielectric constant of the PZT ferroelectric thin film is higher than that of SiO2, HfO2, Al203, and other conventional gate dielectrics, and then the channel carrier regulation control capability of the gate is improved; 2) residual polarization field intensity is adopted by the PZT ferroelectric thin film to regulate and control the channel carrier, and then the power consumption of the device is reduced; 3) compared with the PZT ferroelectric thin film, an organic ferroelectric material P(VDF-TrFE) has advantages of high residual polarization, low coercive field intensity, stable property, and compatibility with microelectronic technology.

Owner:CHONGQING UNIV

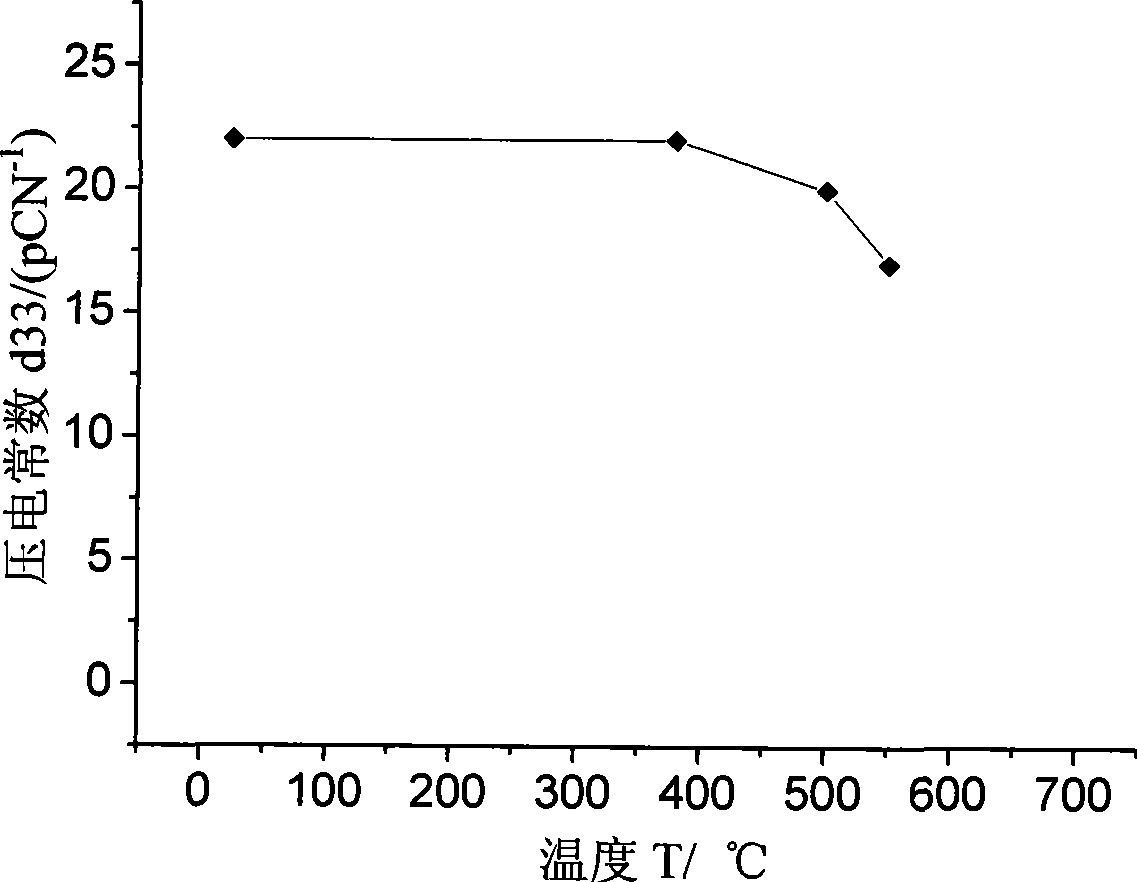

Piezoelectric ceramic complexes

InactiveCN101386532AImprove temperature stabilityDielectric constant - small temperature coefficientPiezoelectric/electrostrictive/magnetostrictive devicesDielectric lossTemperature coefficient

The invention relates to a ceramic composite with a bismuth layer structure with good comprehensive performance in high-temperature piezoelectricity, dielectric and so on. The chemical formula of the ceramic composite is (Sr2-xCax)1-yMyBi4Ti5O18, wherein M can be one or more of Mn, Ba, Ce, Pb and other elements; x is more than or equal to 0 and is less than or equal to 2, and y is more than or equal to 0 and is less than or equal to 1. The composite has good performance when x is equal to 1 and y is equal to 0, and the Curie temperature is more than or equal to 570 DEG C. At room temperature, piezoelectric constant d33 is more than or equal to 22pC.N<-1>; d33 is more than 17pC.N<-1> at a temperature of 550 DEG C, and 80 percent of the piezoelectric activity is still maintained. From room temperature to 550 DEG C, the dielectric loss of the composite in 100 kHz is less than or equal to 0.07, and the dielectric loss of the composite in 1MHz is less than or equal to 0.02, and the specific inductive capacity-temperature coefficient is small. The ceramic composite can fulfill the application in steel, chemical engineering, energy, aerospace engineering and other industrial fields.

Owner:LIAOCHENG UNIV

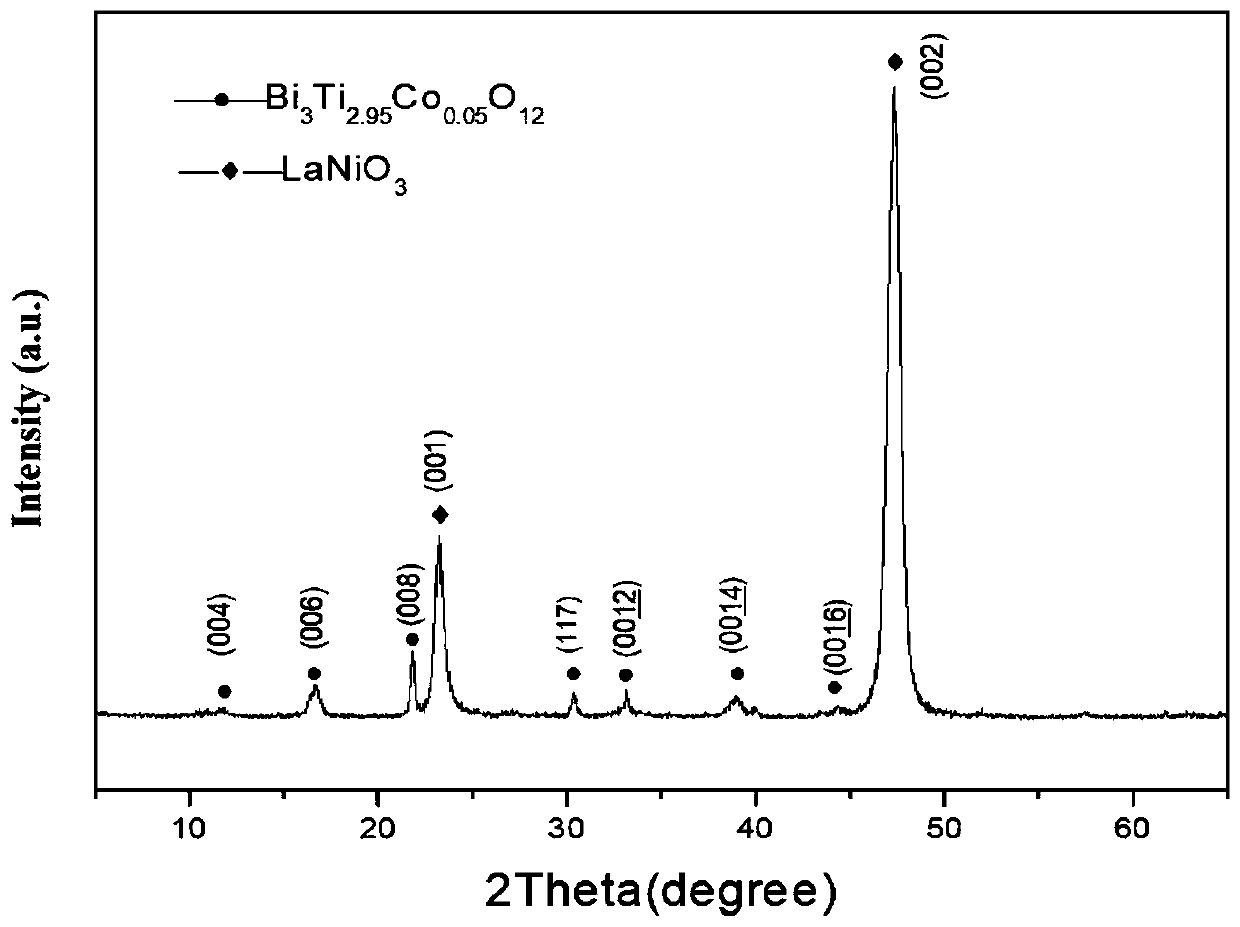

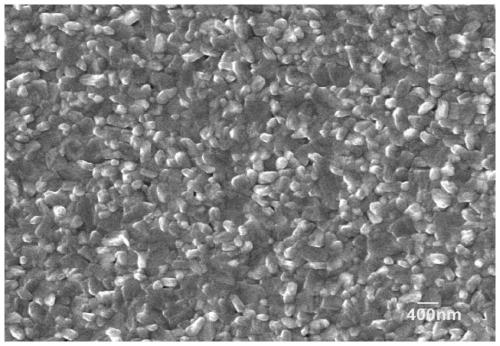

Bi4Ti2.95Co0.05O12 multiferroic film capable of realizing c-axis oriented growth on Si as substrate and preparation method of Bi4Ti2.95Co0.05O12 multiferroic film

A Bi4Ti2.95Co0.05O12 multiferroic film capable of realizing c-axis oriented growth on Si as a substrate is prepared from components as follows: Bi(NO3)2.5H2O, Co(NO3)2.6H2O, butyl titanate, ethylene glycol monomethyl ether and acetylacetone. The preparation method comprises the steps as follows: Bi4Ti2.95Co0.05O12 sol is used as a precursor, a Bi4Ti2.95Co0.05O12 gel film is prepared on the Si substrate taking c-axis oriented LaNiO3 as a buffer layer, then, drying and heat tretament are performed, and the Bi4Ti2.95Co0.05O12 multiferroic film with c-axis orientation is prepared. The Bi4Ti2.95Co0.05O12 multiferroic film has the characteristics that the film has excellent conductivity and can replace noble metals such as platinum and gold to be used as a bottom electrode for electric performance test of the Bi4Ti2.95Co0.05O12 film.

Owner:XIAN UNIV OF TECH

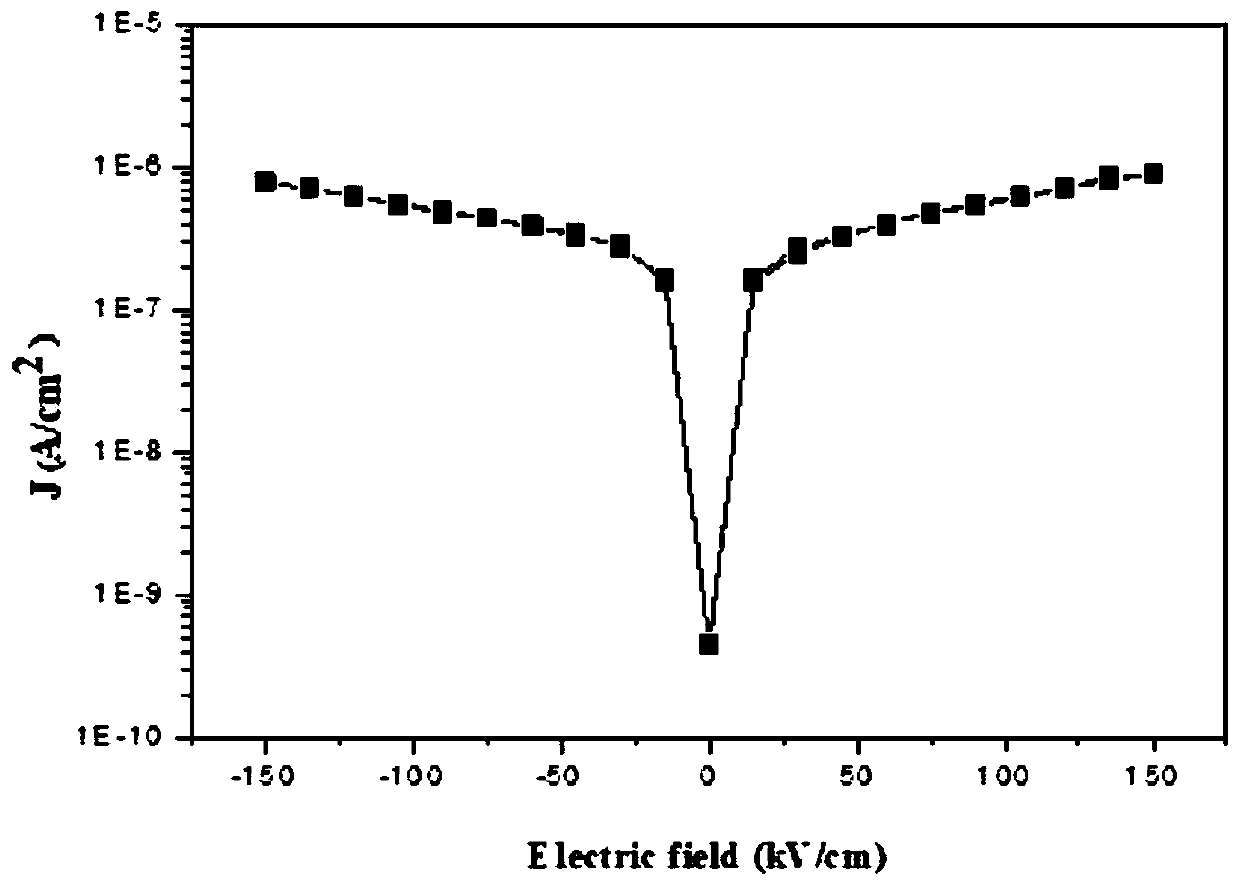

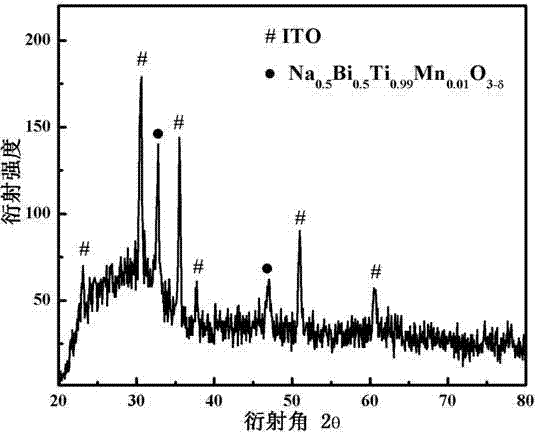

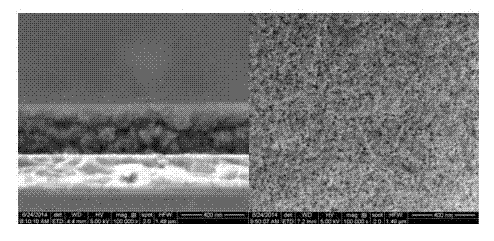

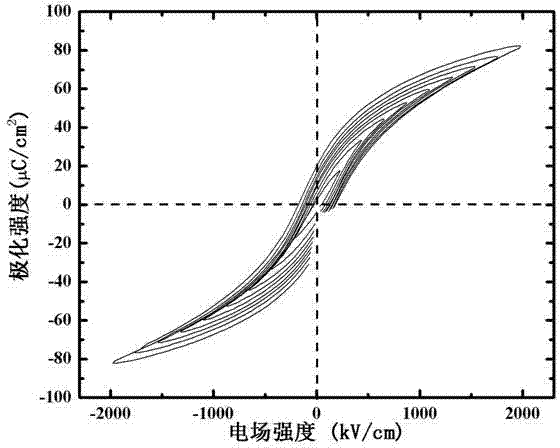

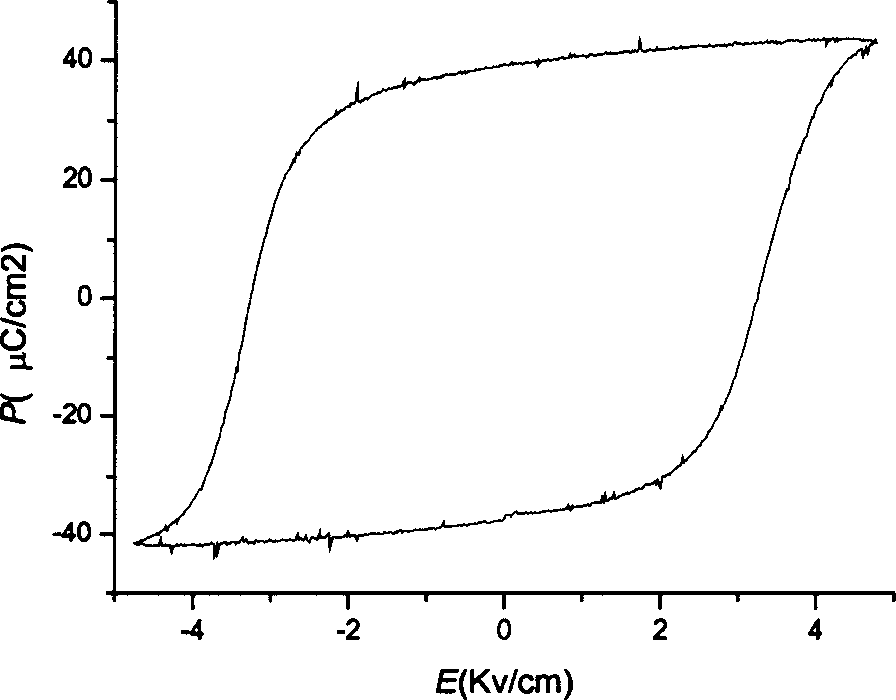

Method for realizing coercive field reduction and pressure resistance improvement of sodium bismuth titanate-based film

The invention belongs to the field of electronic functional materials, and concretely relates to a method for realizing coercive field reduction and pressure resistance improvement of a sodium bismuth titanate-based film. The general chemical formula of the film is Na0.5Bi0.5Ti1-xMnxO3-delta, wherein x is the mole content of manganese ions, x is greater than 0 and smaller than 0.05, and delta is the number of oxygen atoms which are lost to maintain the charge balance. An optimized chemical solution deposition preparation technology is adopted on the basis of the doping of the manganese ions to make the sodium bismuth titanate-based film with good ferroelectricity and dielectricity on an ITO / glass substrate. The sodium bismuth titanate-based film can be used to develop ferroelectric and dielectric functional materials and devices.

Owner:UNIV OF JINAN

High-dielectric constant lead-free piezoelectric ceramic composition and its use

InactiveCN101028977AReduce the starting voltageImpedance ratio is largePiezoelectric/electrostrictive/magnetostrictive devicesCeramic resonatorCeramic

A non-lead piezoelectric ceramic composition with high dielectric constant used for preparing the vibrating sheet of piezoelectric ceramic resonator, filter and vibrator is a 5-layer ceramics. Its chemical formula is Sr2-xM1xBi4Ti5-yM2y0.8+ delta MnO2, where x=0-1, y=0-1, M1 is chosen from Mg, Ca, Ba, La, Pr, Nd, Sm, Gd, Dy, Er, Yb, Sc and Y, M2 is chosen from Nb, Ta, W, Mo and V, and delta=0-1.5%.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

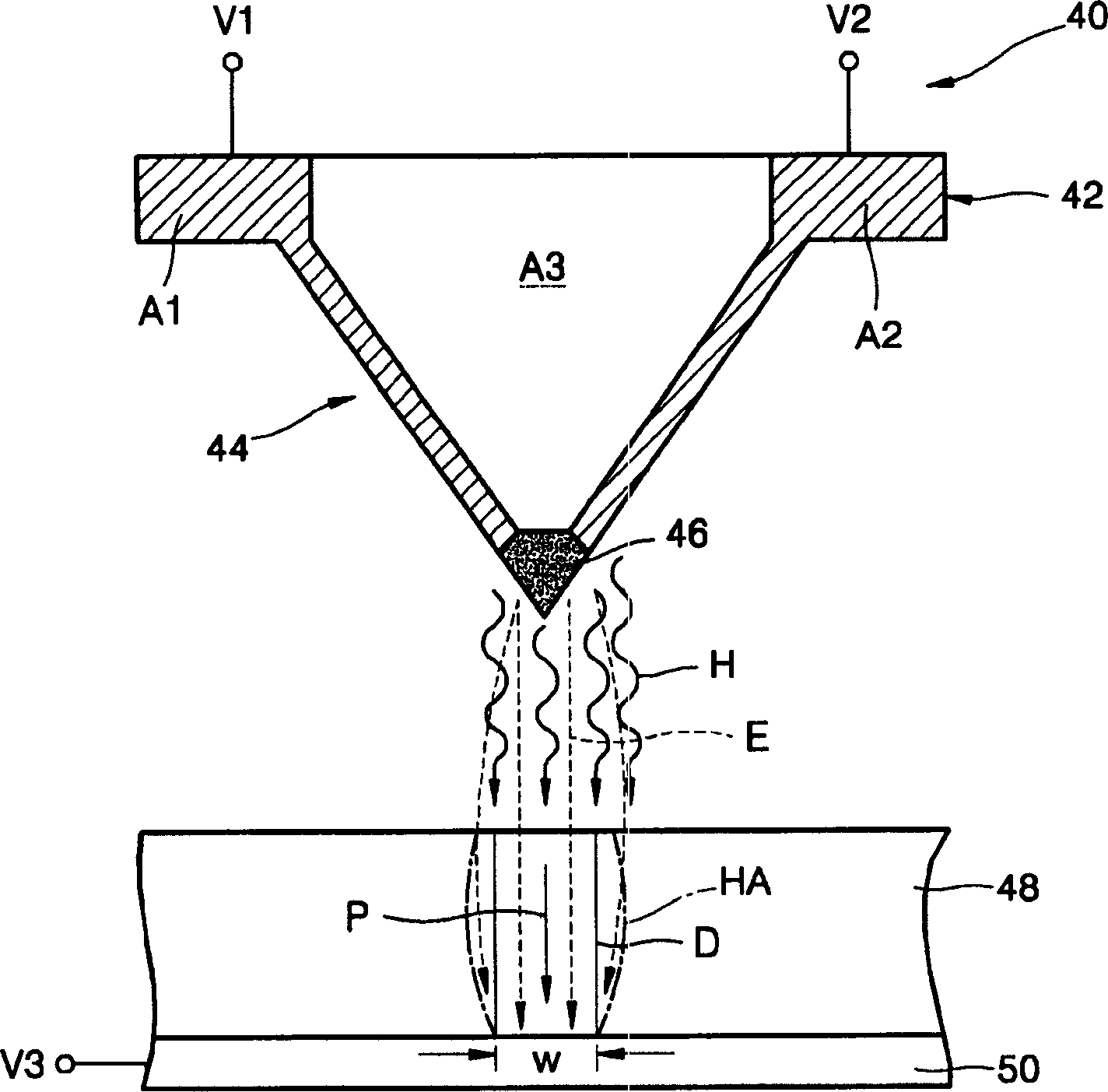

Method of writing data on a storage device using a probe technique

InactiveCN1604212ALower coercive fieldHigh speed write operationCombination recordingNanoinformaticsA domainComputer science

Provided is a method of writing data on a storage device using a probe technique. In the method of writing data on a memory device including a resistive probe used for reading and writing of data, a ferroelectric writing medium on which data is written by the resistive probe, and a lower electrode disposed on a bottom surface of the ferroelectric writing medium, a heat and electric field are applied at the same time to a domain of the ferroelectric writing medium, on which the data will be written, by applying a voltage to the resistive probe and the lower electrode.

Owner:SAMSUNG ELECTRONICS CO LTD

Potassium sodium niobate-based leadless piezoelectric ceramic and preparation method thereof

The invention discloses potassium sodium niobate-based leadless piezoelectric ceramic and a preparation method thereof, the chemical formula of the potassium sodium niobate-based piezoelectric ceramic is (1-x) (K0. 5Na0. 5) NbO3-xBi (Li0. 5Sb0. 5) O3, and x is more than or equal to 0.01 and less than or equal to 0.20. The preparation method comprises the following steps: weighing dry raw materials according to a stoichiometric ratio of (1-x) (K0. 5Na0. 5) NbO3-xBi (Li0. 5Sb0. 5) O3, mixing, carrying out ball milling, and drying to obtain a mixed material; pre-sintering the mixed material obtained in the step 1 at a high temperature to obtain pre-sintered powder, and performing secondary ball-milling and drying to obtain secondary ball-milled powder; adding an adhesive into the secondary ball-milled powder, granulating, sieving, and carrying out compression molding, so as to obtain a ceramic blank; removing the organic adhesive, and sintering at high temperature to obtain sintered ceramic; coating the surfaces of the two sides of the sintered ceramic with silver and carrying out high-voltage polarization, and preparing the potassium sodium niobate-based leadless piezoelectric ceramic. Through component design and process optimization, the sintering characteristic of the potassium sodium niobate-based ceramic is effectively improved, volatilization of sodium and potassium elements is inhibited, the porosity is reduced, the density of the ceramic is improved, the dielectric constant is further improved, the loss is reduced, and the comprehensive performance of the KNN-based ceramic is improved.

Owner:XI AN JIAOTONG UNIV

Ternary nano leadless piezoelectric ceramic material, and preparation method thereof

InactiveCN103896583AAvoid Polarization DifficultyExcellent piezoelectric dielectric propertiesPiezoelectric actuatorsEconomic benefits

The invention provides a ternary nano leadless piezoelectric ceramic material. General chemical formula of the ternary nano leadless piezoelectric ceramic material is (1-x)Na<0.5>Bi<0.5>TiO<3>-xNa<0.5>Bi<0.5>NbO<3>+yM, wherein M is used for representing a metallic element, x and y are used for representing mass contents, and 0<x<1, 0.0005<y<0.01. The invention also provides a method used for preparing the ternary nano leadless piezoelectric ceramic material via sol-gel method. Compared with existing technology, the ternary nano leadless piezoelectric ceramic material prepared via the method is small in particle size, narrow in particle size distribution range, uniform in composition, and high in piezoelectric activity; induction of impurities is difficult to happen in grinding processes; purity is high; sintering temperature is low; energy is saved; and compactness of ceramic powder after sintering is excellent. The preparation method is simple; processes are stable; industrialized degree is high; economic benefits are excellent; and application value is high.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

HoSrMnZn co-doped bismuth ferrite multiferroic film and preparation method thereof

ActiveCN107082579AHigh polarizationReduce Fe <sup>2+<</sup> CoatingsMANGANESE ACETATEAcetic anhydride

The invention provides a HoSrMnZn co-doped bismuth ferrite multiferroic film and a preparation method thereof. According to the invention, bismuth nitrate, holmium nitrate, strontium nitrate, ferric nitrate, manganese acetate and zinc nitrate are used as raw materials (wherein bismuth nitrate is 5% excess in amount), ethylene glycol monomethyl ether and acetic anhydride are used as solvents, and a spin-coating process and a layer-upon-layer annealing process are employed to prepare a Bi<0.89>Ho<0.08>Sr<0.03>Fe<0.97-x>Mn<0.03>Zn<x>O<3> multiferroic film, i.e., the HoSrMnZn co-doped bismuth ferrite multiferroic film. According to the invention, a sol-gel process is employed, and the spin-coating and layer-upon-layer annealing processes are utilized; requirements on equipment are simple; experimental conditions are easy to realize; the preparation method is suitable for preparation of films on large surfaces and surfaces with irregular shapes and allows chemical components to be accurate and controllable; and the prepared HoSrMnZn co-doped bismuth ferrite multiferroic film has good uniformity and improves the multiferroic performance of a BiFeO3 film.

Owner:SHAANXI UNIV OF SCI & TECH

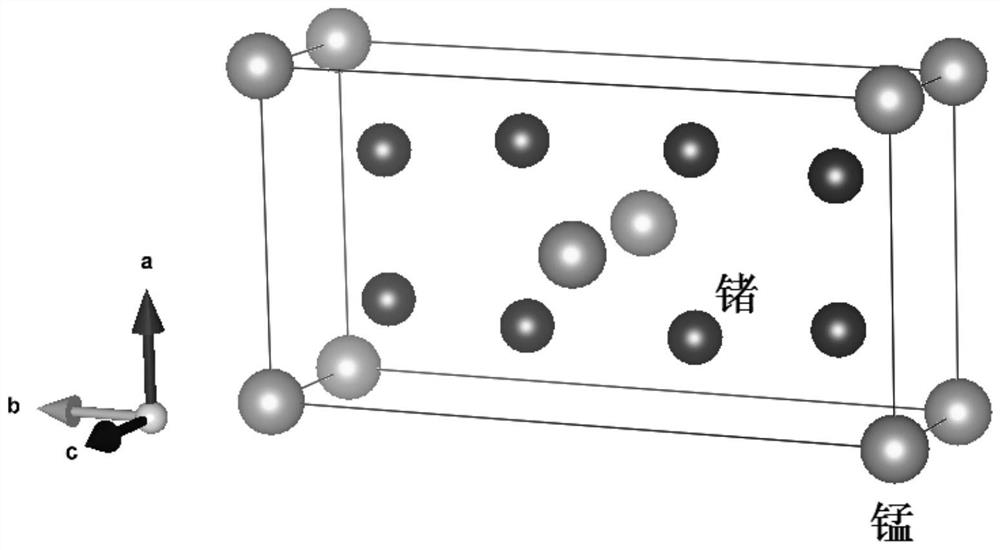

Orthogonal crystal system crystal material and preparation method thereof

ActiveCN114197052AThe synthesis method is simpleShort preparation cyclePolycrystalline material growthAfter-treatment detailsCurie temperatureSingle crystal

The invention discloses a MnxGey crystal with an orthogonal structure and a preparation method of the MnxGey crystal, and belongs to the field of preparation and application of magnetic materials, and the cell parameter of the crystal is that the space group of the crystal is Cmmm. According to the preparation method, elemental metal elements manganese and germanium are used as raw materials, the orthorhombic-phase MnxGey single crystal is finally prepared through the technological processes of raw material mixing, briquetting, assembling, high-temperature and high-pressure synthesis and cooling pressure relief, x is 1-2, y is 8-9, the preparation method is simple, the preparation period is short, and it is proved that the MnxGey crystal is single-phase and free of impurities and twin crystals. In addition, the single crystal material has a small coercive field, can be used as a soft magnetic material for increasing the magnetic flux density in a weak magnetic field, has the Curie temperature up to 322K and the magnetization intensity up to 10-30emu / g, has the advantages of high initial magnetic conductivity and maximum magnetic conductivity, has technical parameters applied to the soft magnetic material, and is suitable for being applied to low-frequency electromagnetic elements.

Owner:SHANGHAI TECH UNIV

Process for preparing chemical-specific Mg-doped lithium niobate crystal with periodic polarizing microstructure

InactiveCN1190530CStrong resistance to light damageImprove frequency conversion efficiencyPolycrystalline material growthAfter-treatment detailsNonlinear optical crystalHigh resistance

A Mg-doped lithium niobate crystal with periodically polarized microstructure is prepared frmo Mg-doped lithium niobate powder through growing crystal by Czochralsk method, gas-phase balanced diffusion and low-voltage polarizing at room temp. to make the crystal have periodic structure. It can be used to make optical device. Its advatages are high resistance to optical damage and high uniformity.

Owner:NANKAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof](https://images-eureka.patsnap.com/patent_img/d33c2ba5-ceec-44cc-a709-6bfddffa1e71/HDA0000631192430000011.PNG)

![Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof](https://images-eureka.patsnap.com/patent_img/d33c2ba5-ceec-44cc-a709-6bfddffa1e71/HDA0000631192430000012.PNG)

![Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof](https://images-eureka.patsnap.com/patent_img/d33c2ba5-ceec-44cc-a709-6bfddffa1e71/HDA0000631192430000021.PNG)