Multiferroic liquid and preparation method thereof

A multiferroic, liquid technology, used in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of weak effect, insignificant change, large coercive force, and inability to change, to broaden the scope of research and preparation methods. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

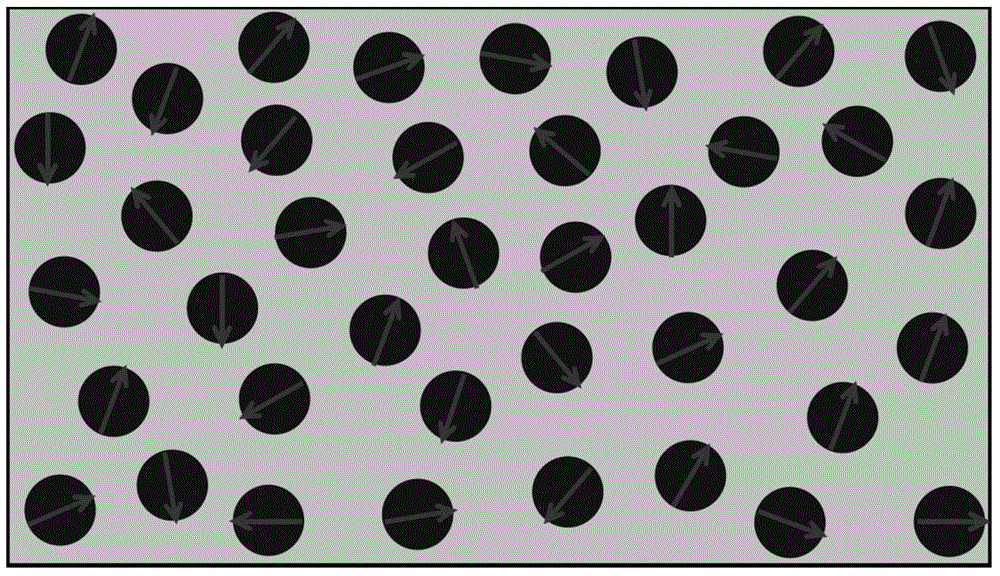

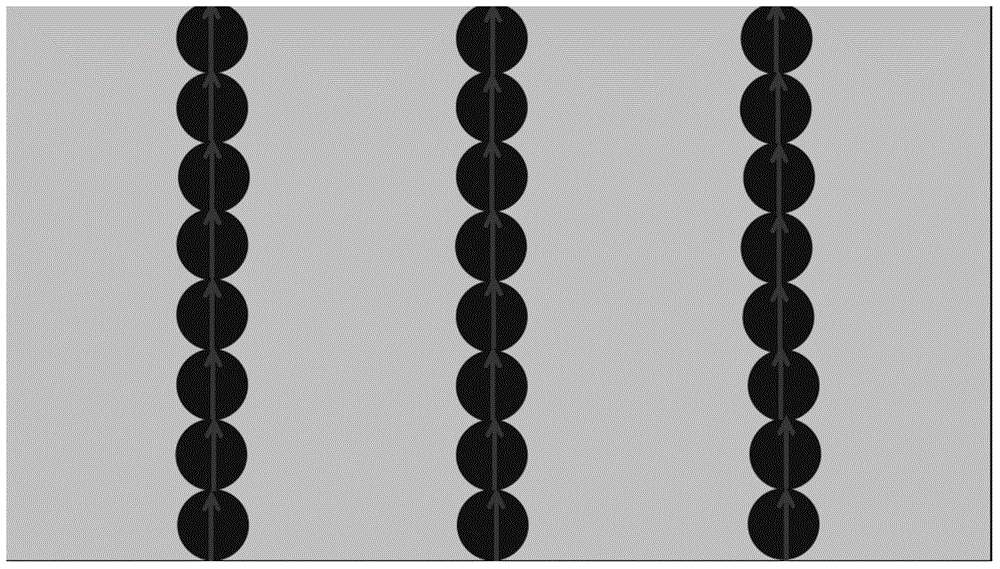

Image

Examples

example 1

[0031] Example 1: Bismuth ferrite (BiFeO 3 , referred to as BFO) the preparation of multiferroic liquid

[0032] Step 1: Preparation of multiferroic BFO nanoparticles by sol-gel method:

[0033]Measure ethylene glycol methyl ether and glacial acetic acid solution as a mixed solvent, the volume ratio of the two is 1:1, 25ml each. 15.36 g of bismuth nitrate and 12.3045 g of iron nitrate were dissolved in the mixed solvent. Stir magnetically until it is completely dissolved, then add 20ml acetic anhydride dropwise to remove crystal water, add 14g citric acid as a chelating agent after the solution is completely cooled, stir for 24 hours, then add 40 drops of ethanolamine to pH 1-1.2 of the solution, and stir for 1 hour Make up to volume with ethylene glycol methyl ether, and transfer the solution to a jar. Then the obtained solution was baked on a heating platform, and then put into a box furnace for sintering at a temperature of 600° C. for 2 hours. After the obtained produc...

example 2

[0038] Example 2: bismuth manganate (BiMnO 3 , referred to as BMO) preparation of multiferroic liquid

[0039] Step 1: Preparation of Ferroelectric BMO Nanoparticles by Solid State Reaction

[0040] Raw material Bi 2 o 3 , MnO 2 , Calculate the required mass of each raw material according to the ratio of atomic molar ratio Bi:Mn=1:1 and the purity of the raw materials, and grind them sufficiently to make them evenly mixed. Then put the above powder into a cleaned crucible and place it in a muffle furnace, and pre-fire it for the first time at 900°C for 10 hours to form a preliminary phase. The obtained product is fully ground and then calcined at 1100°C for 30 hours to completely react the raw materials. The third time of full grinding is carried out to obtain BMO nanoparticles.

[0041] Step 2: Prepare BMO Multiferroic Liquid:

[0042] A certain mass of BMO nanoparticles is evenly dispersed in a certain concentration of silicone oil. Silicone oil has the characteristi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com