Potassium sodium niobate-based leadless piezoelectric ceramic and preparation method thereof

A technology based on lead-free piezoelectric and sodium potassium niobate, applied in the field of piezoelectric ceramic devices, can solve the problems of sintered ceramic components deviating from the design stoichiometric ratio, difficulty in obtaining high voltage, electromechanical properties, and difficulty in preparing KNN ceramics , to achieve the effect of removing damage to human health and social environment, decreasing porosity and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

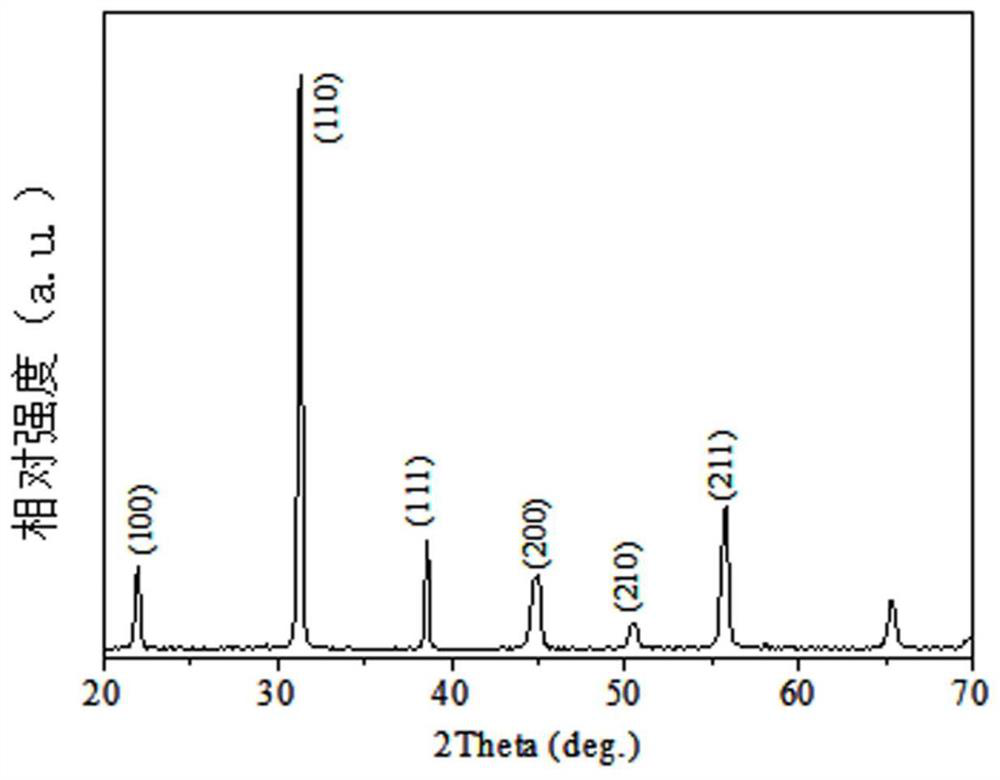

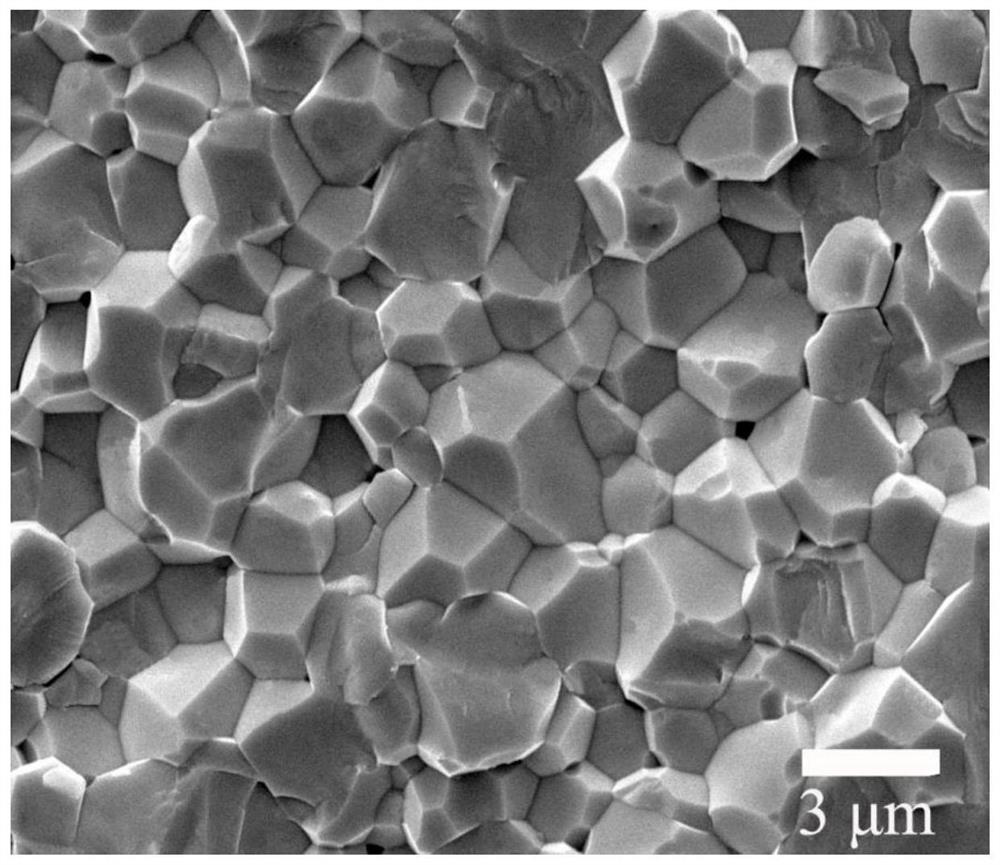

[0029] A kind of high-performance sodium potassium niobate base lead-free piezoelectric ceramics of the present invention, chemical formula is (1-x) (K 0.5 Na 0.5 )NbO 3 -xBi(Li 0.5 Sb 0.5 )O 3 , x represents the mole fraction, 0.01≤x≤0.20. Its preparation method comprises the following steps:

[0030] Step 1, pre-drying raw materials of analytically pure sodium carbonate, potassium carbonate, niobium pentoxide, bismuth oxide, lithium carbonate and antimony trioxide;

[0031] Step 2, according to (1-x)(K 0.5 Na 0.5 )NbO 3 -xBi(Li 0.5 Sb 0.5 )O 3 Stoichiometric ratio weighing of each drying raw material, mixing and ball milling and drying to obtain the mixed material A;

[0032] Step 3, pre-calcining the mixed material A to obtain the pre-calcined powder B;

[0033] Step 4, the powder synthesized after pre-calcination is ball-milled for the second time and dried to obtain the second ball-milled powder C;

[0034]Step 5, adding a binder to the secondary ball millin...

Embodiment 1

[0049] Step 1, pre-dry raw materials such as sodium carbonate, potassium carbonate, niobium pentoxide, bismuth oxide, lithium carbonate, antimony trioxide and the like in an oven at 120°C for 24 hours.

[0050] Step 2, with the material obtained in step 1 according to the chemical formula 0.96 (K 0.5 Na 0.5 )NbO 3 -0.04Bi(Li 0.5 Sb 0.5 )O 3 Stoichiometric weighing, mixing and ball milling, and drying after ball milling to obtain the mixed material A. Among them, the mass ratio of raw materials to grinding balls is 1:1.5; the mass ratio of raw materials to absolute ethanol is 1:1.0, the ball milling time is 36 hours, and the drying temperature is 120°C.

[0051] In step 3, the dried mixed material A is put into a crucible, and pre-fired in a muffle furnace to obtain a pre-fired powder B. The pre-firing temperature is 800°C, and the holding time is 4h.

[0052] Step 4: The pre-burned material is ball milled for 48 hours a second time, and a binder PVA with a mass ratio of...

Embodiment 2

[0058] In step 1, raw materials such as sodium carbonate, potassium carbonate, niobium pentoxide, bismuth oxide, lithium carbonate, and antimony trioxide are pre-dried in an oven at 100° C. for 5 hours.

[0059] Step 2, with the material obtained in step 1 according to the chemical formula 0.99 (K 0.5 Na 0.5 )NbO 3 -0.01Bi(Li 0.5 Sb 0.5 )O 3 Stoichiometric weighing, mixing and ball milling, and drying after ball milling to obtain the mixed material A. Among them, the mass ratio of raw materials to grinding balls is 1:2.0; the mass ratio of raw materials to absolute ethanol is 1:0.5, the ball milling time is 24 hours, and the drying temperature is 100°C.

[0060] In step 3, the dried mixed material A is put into a crucible, and pre-fired in a muffle furnace to obtain a pre-fired powder B. The pre-firing temperature is 850°C, and the holding time is 3h.

[0061] Step 4: The pre-burned material is ball milled for 36 hours a second time, and a binder PVA with a mass ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com