Patents

Literature

47results about How to "High piezoelectric constant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

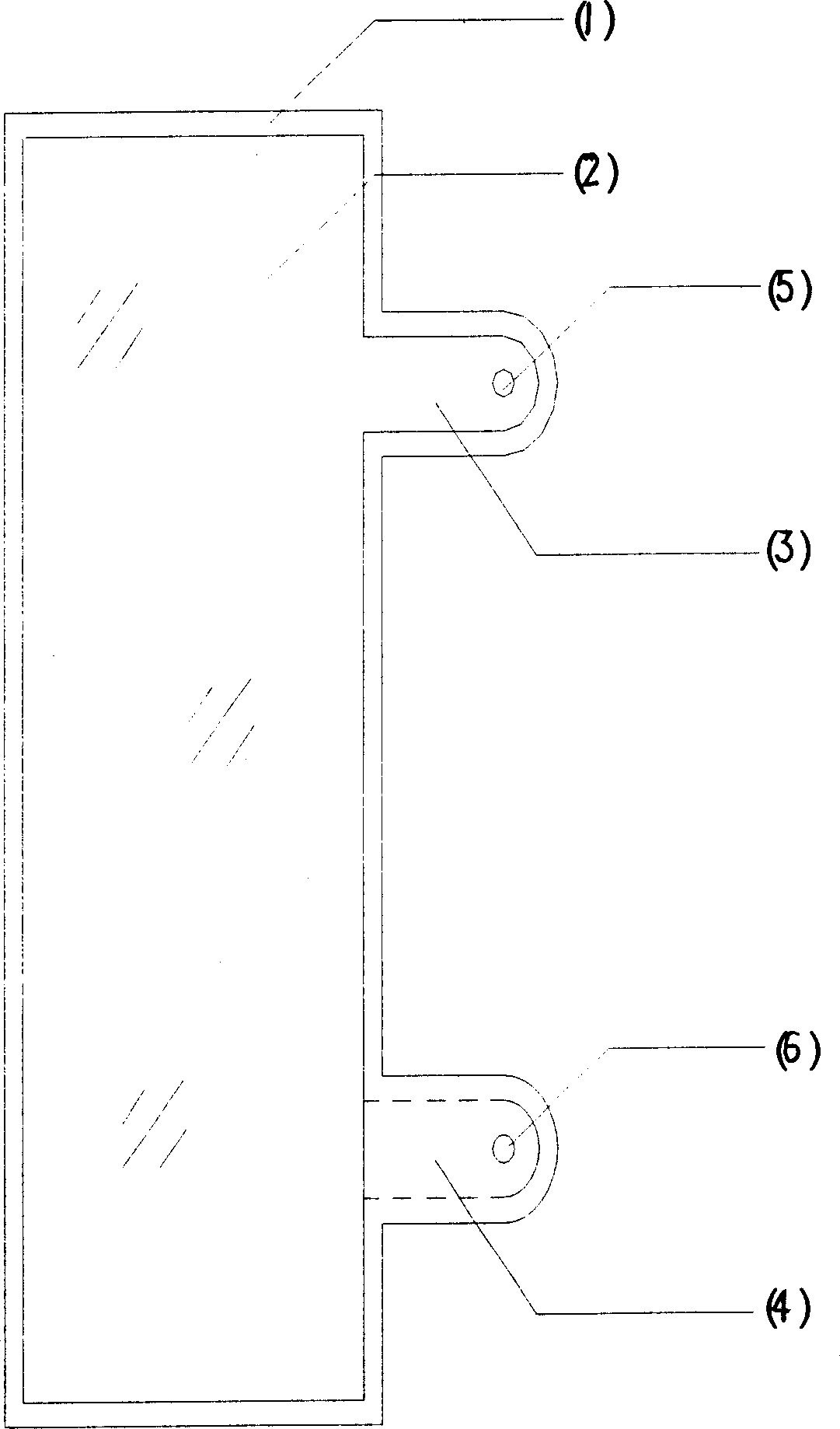

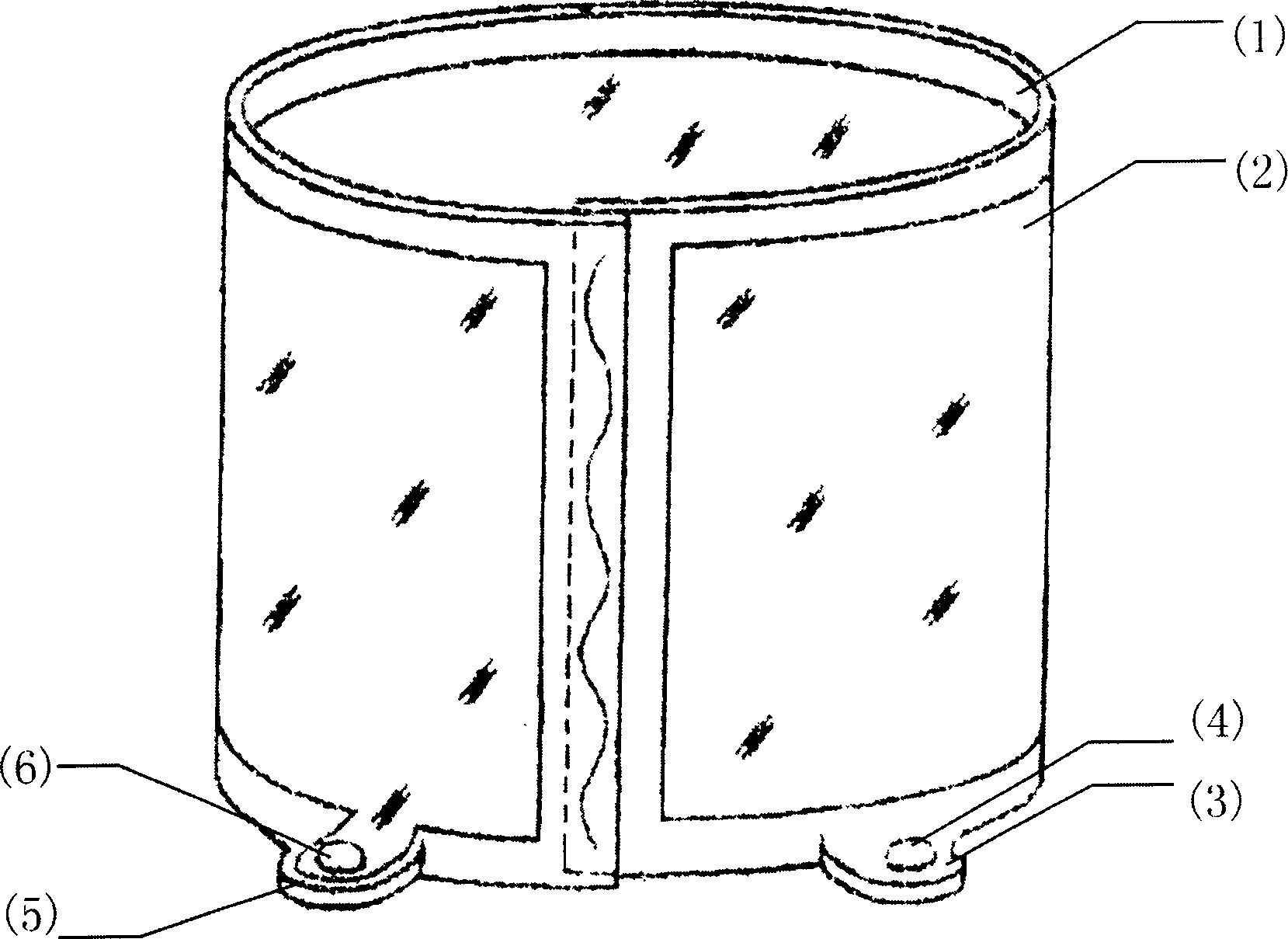

Piezoelectric electret film and preparation method thereof

InactiveCN103682083AImprove performanceEasy to operatePiezoelectric/electrostrictive device manufacture/assemblyPolymer scienceFerroelectret

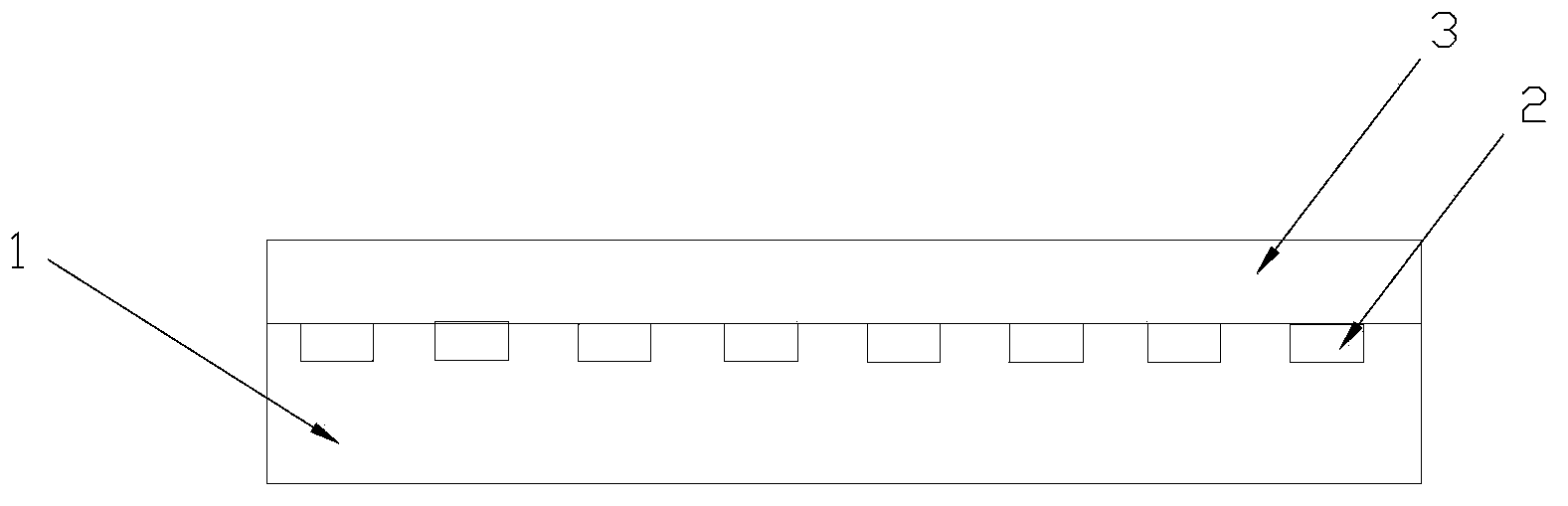

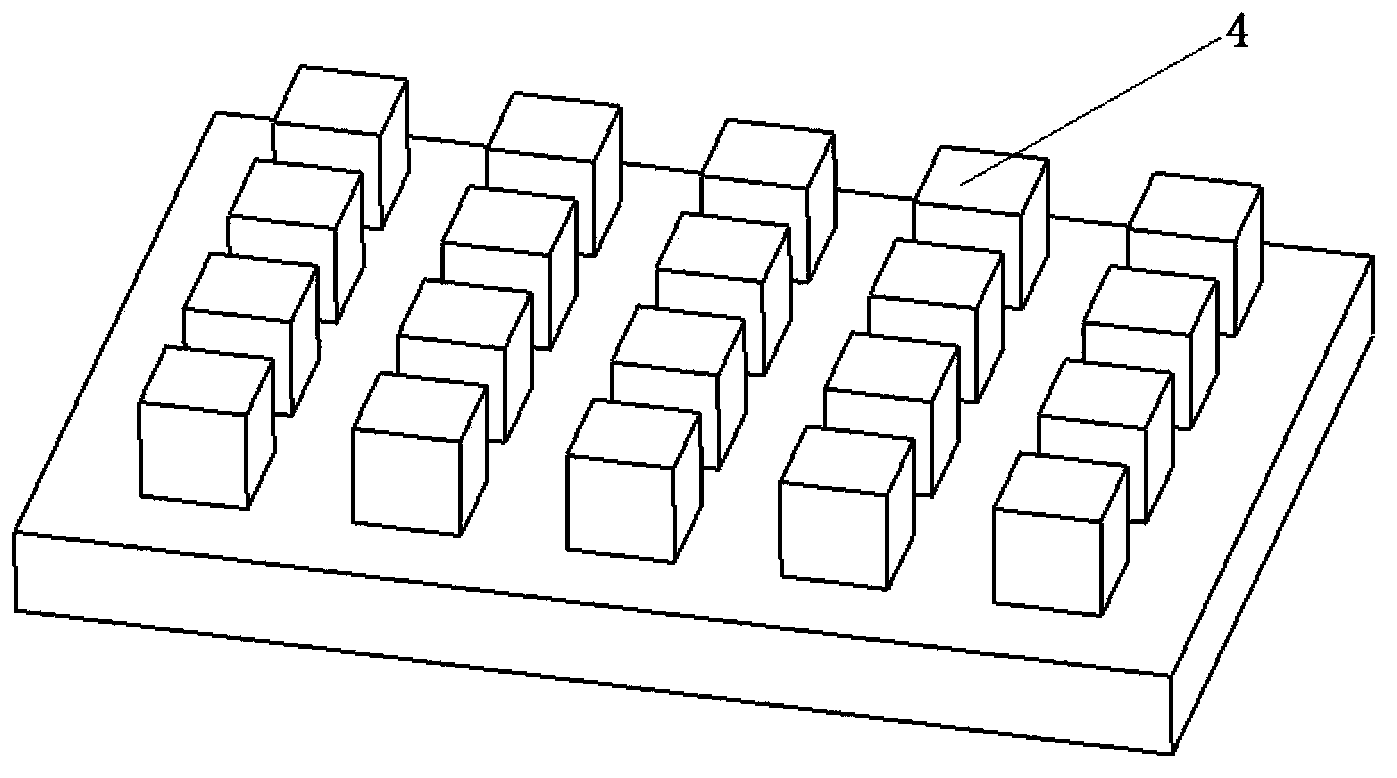

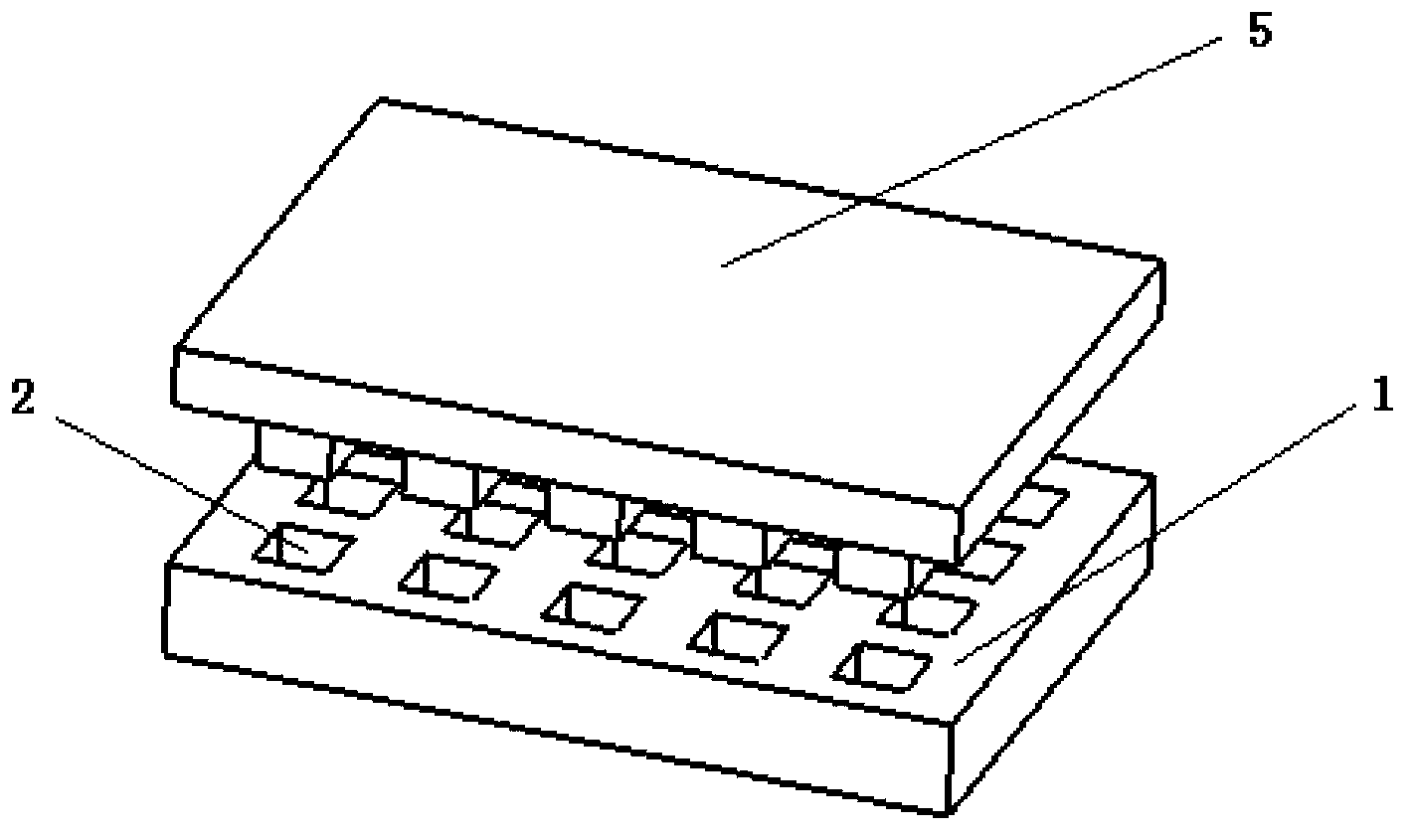

The invention relates to a preparation method for a piezoelectric electret film. The method comprises the following steps: (1) spraying a polymer solution on a template with bulges for drying, and after drying, removing the template to obtain a first polymer film with concave pits; (2) combining the dried first polymer film with a second polymer film to form a cavity; (3) distributing opposite charges on the opposite surfaces in the cavity through polarization to form the piezoelectric electret film. The invention provides the piezoelectric electret film prepared through the method. The piezoelectric electret film comprises the first polymer film (1) with the concave pits, the second polymer film (3), the cavity (2) and the opposite charges, wherein the second polymer film (3) is combined with the surface with the concave pits of the first polymer film (1), and the cavity (2) is formed between the first polymer film (1) and the second polymer film (3); the opposite charges are distributed on the surfaces of the cavity through polarization. The concave pits are formed by coating the template with the bulges with the polymer solution.

Owner:NEWNAGY TANGSHAN

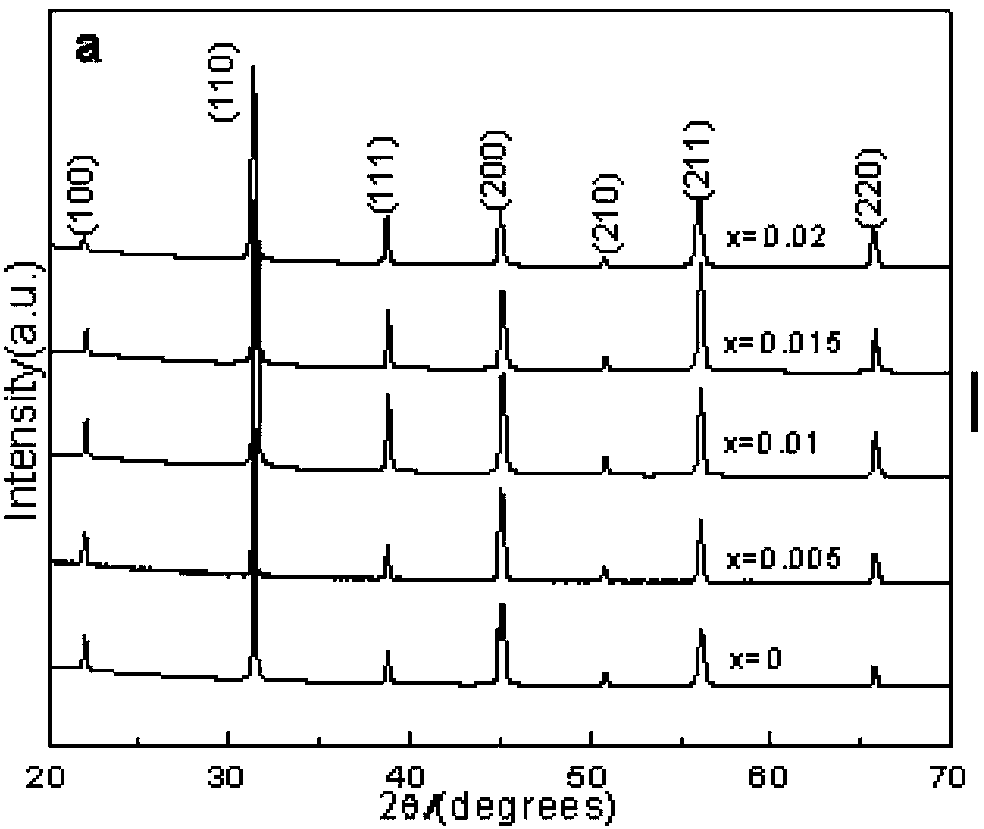

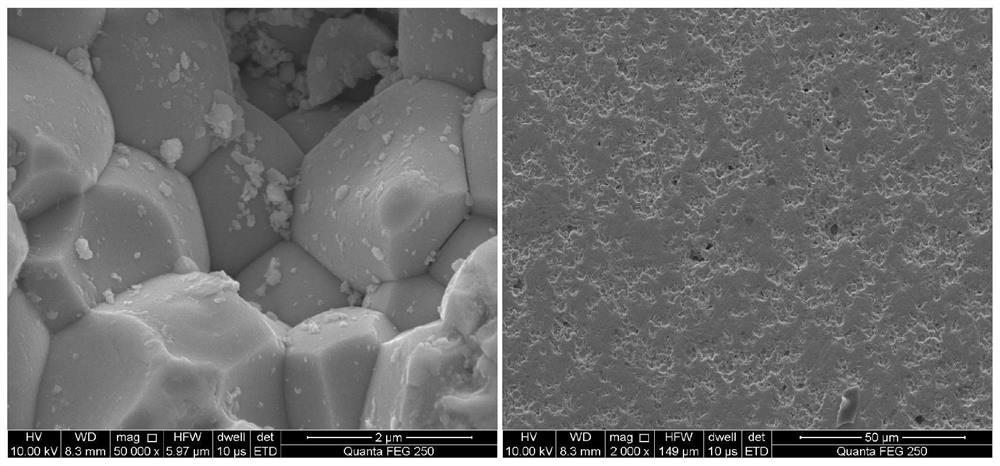

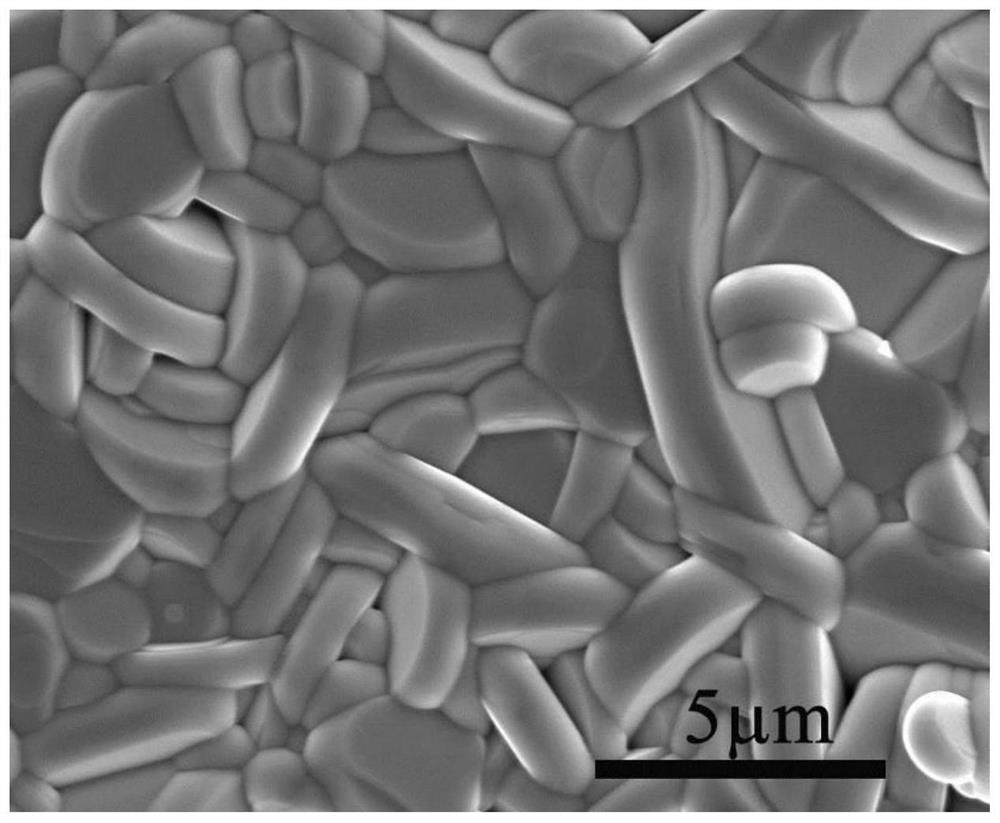

Solid solution-modified sodium bismuth titanate leadless piezoelectric ceramics and preparation method thereof

ActiveCN103833354AExcellent piezoelectric propertiesHigh electromechanical coupling coefficientElectromechanical coupling coefficientTwo step

The invention provides solid solution-modified sodium bismuth titanate leadless piezoelectric ceramics and a preparation method thereof. The piezoelectric ceramics are represented by chemical composition general formula of (1-x)(0.74Na0.5Bi0.5TiO3-0.26SrTiO3)-xBa(Zr0.05Ti0.95)O3 or (1-y)(0.9Na0.5Bi0.5TiO3-0.1CaTiO3)-yBa(Zr0.05Ti0.95)O3, wherein 0.04<=x<=0.1 and 0.04<=y<=0.1. Solid solution of Ba(Zr0.05Ti0.95)O3 is realized at the morphotropic phase boundary of a 0.74Na0.5Bi0.5TiO3-0.26SrTiO3 and 0.9Na0.5Bi0.5TiO3-0.1CaTiO3 system, and high-density microcrystalline structure ceramics with uniform crystal grain size distribution are obtained by a two-step forming method and a self-bearing pressure sintering process. The piezoelectric property of the material is optimized by the morphotropic phase boundary composition characteristics and the solid solution modification method, and the piezoelectric constant d33 reaches 110-138 PC / N; the electromechanical coupling coefficient of the material is also increased obviously; the preparation process of the material is simple and stable, and the material is an optimal material for manufacturing low-power ultrasonic devices and energy transducers used in fields of gas sensors, industrial nondestructive test, and the like.

Owner:XIAN UNIV OF SCI & TECH

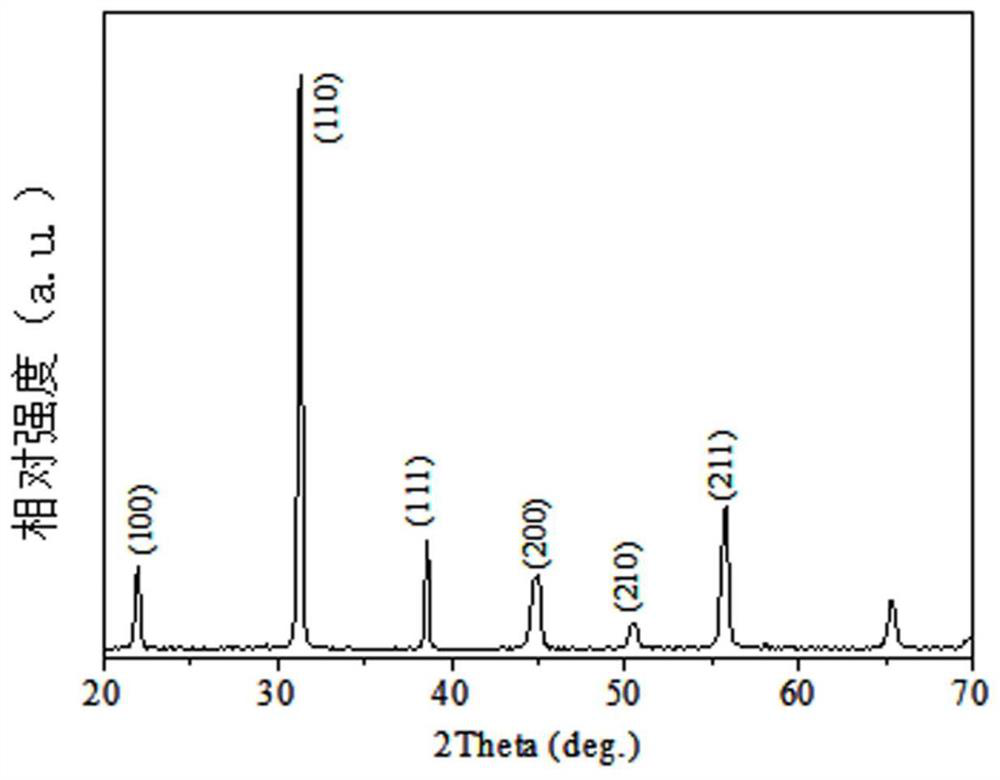

Niobium oxide doped barium calcium zirconate titanate leadless piezoelectric ceramic powder material

InactiveCN103373849AHigh piezoelectric constantIncrease the piezoelectric constant d <sub>33<</sub> ZirconateSlurry

The invention discloses a niobium oxide doped barium calcium zirconate titanate leadless piezoelectric ceramic powder material which is prepared through the following method comprising the steps of: weighting raw materials BaCO3, ZrO2, TiO2, CaCO3, MnO2 and Nb2O5 according to the stoichiometric ratio of elements in the chemical general formula: Ba0.85Ca0.15Ti0.895-xZr0.1Mn0.005NbxO3; carrying out ball milling on the raw materials for 10-16h by taking absolute ethyl alcohol as a medium, and drying the ball-milled slurry to obtain dry powder; and placing the dry powder into the air, and pre-sintering the dry powder at the temperature of 1100-1300 DEG C for 1-4h to obtain the niobium oxide doped barium calcium zirconate titanate leadless piezoelectric ceramic powder material. The Ba0.85Ca0.15Ti0.895-xZr0.1Mn0.005NbxO3 leadless piezoelectric ceramic with a perovskite type structure, which is obtained by using the traditional solid state sintering method and industrial raw materials, has more excellent performance. Shown by mass data statistics, the leadless piezoelectric ceramic prepared by using the niobium oxide doped barium calcium zirconate titanate leadless piezoelectric ceramic powder material disclosed by the invention has the piezoelectric constant d33 of 335pC / N, the electromechanical coupling factor kp of 39.5% and the dielectric loss of less than 2%. In addition, the niobium oxide doped barium calcium zirconate titanate leadless piezoelectric ceramic powder material is stable in preparation process and better in industrial prospect.

Owner:GUIZHOU UNIV

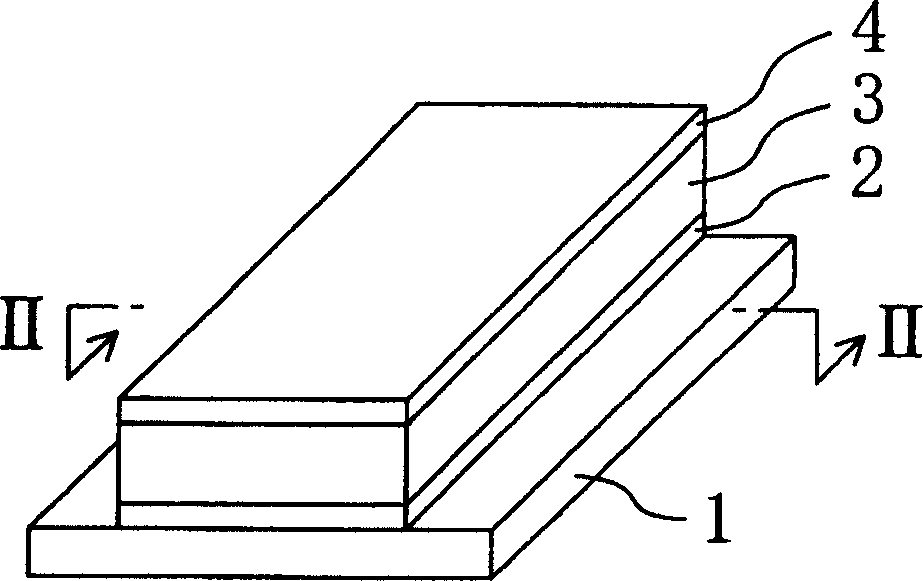

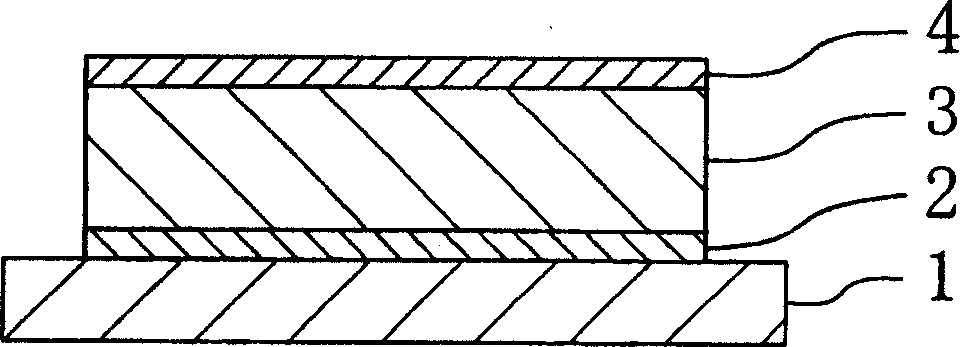

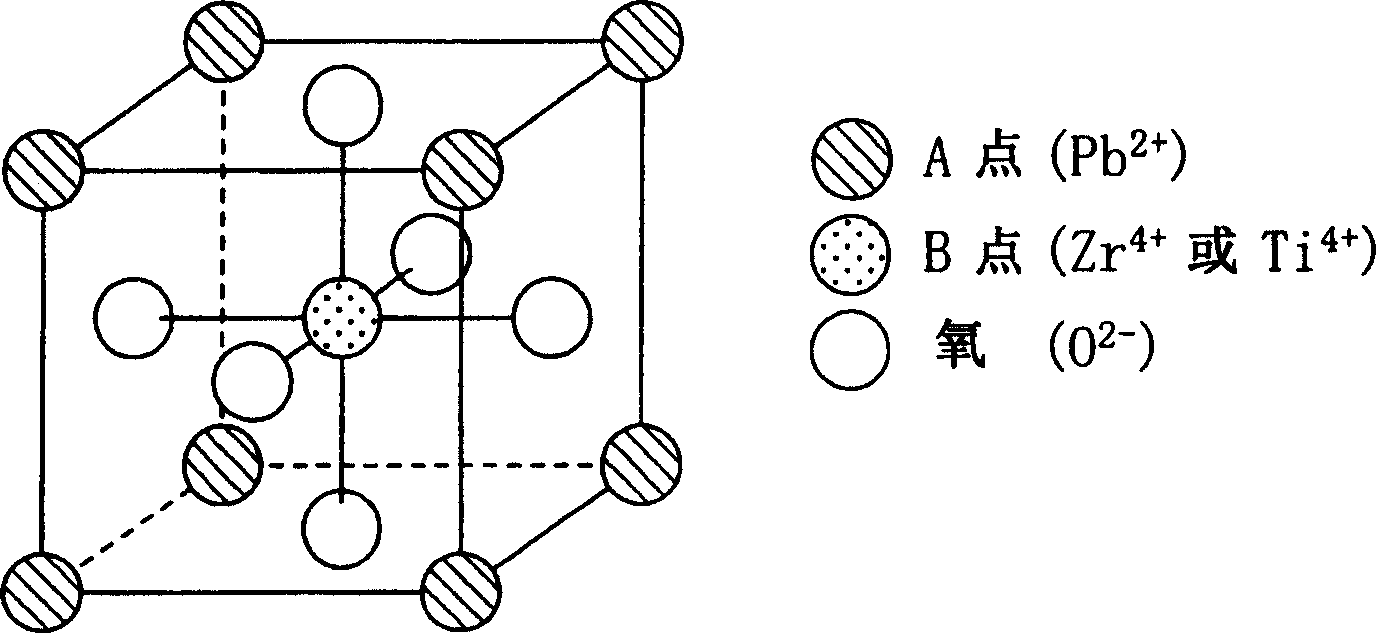

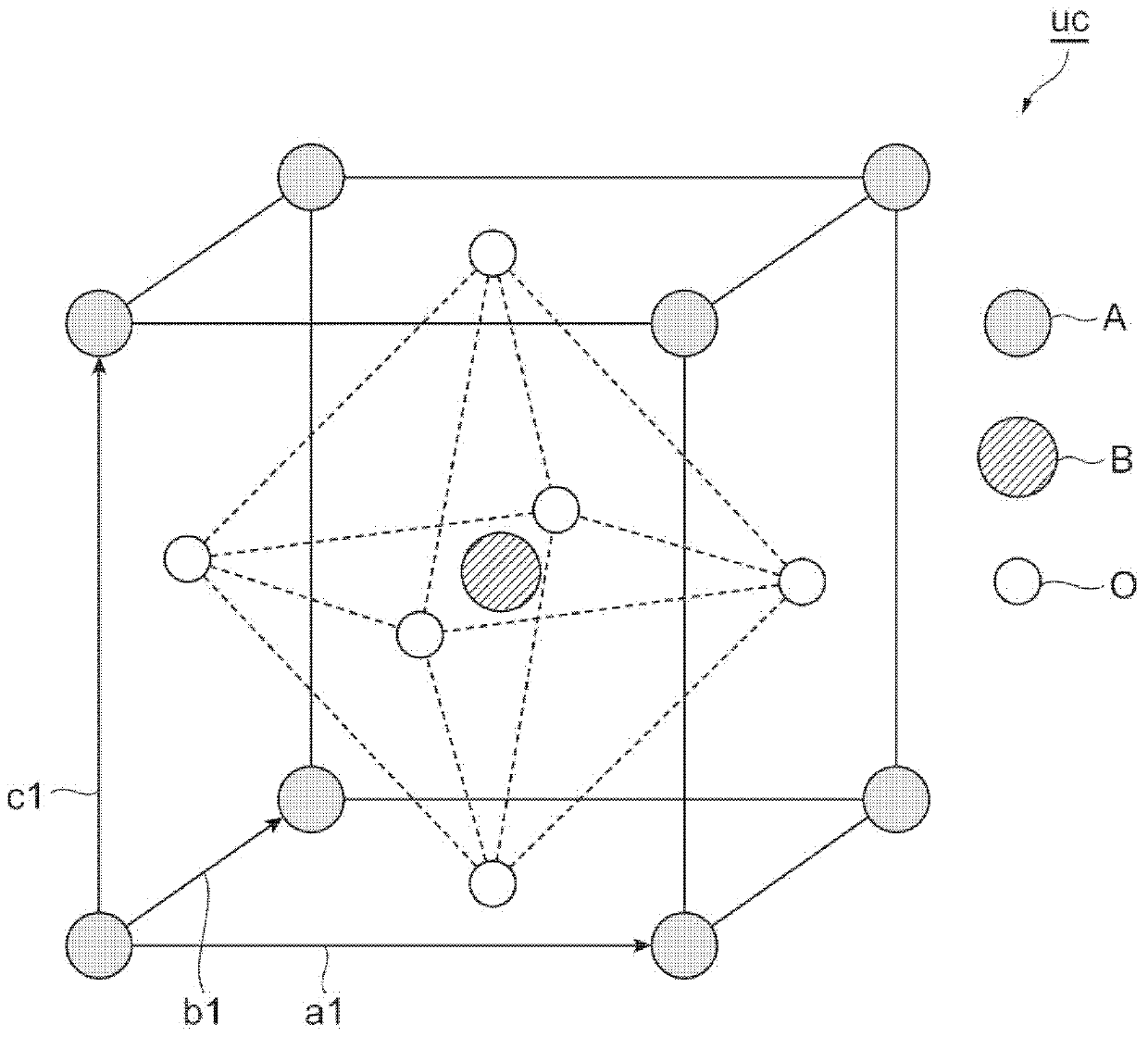

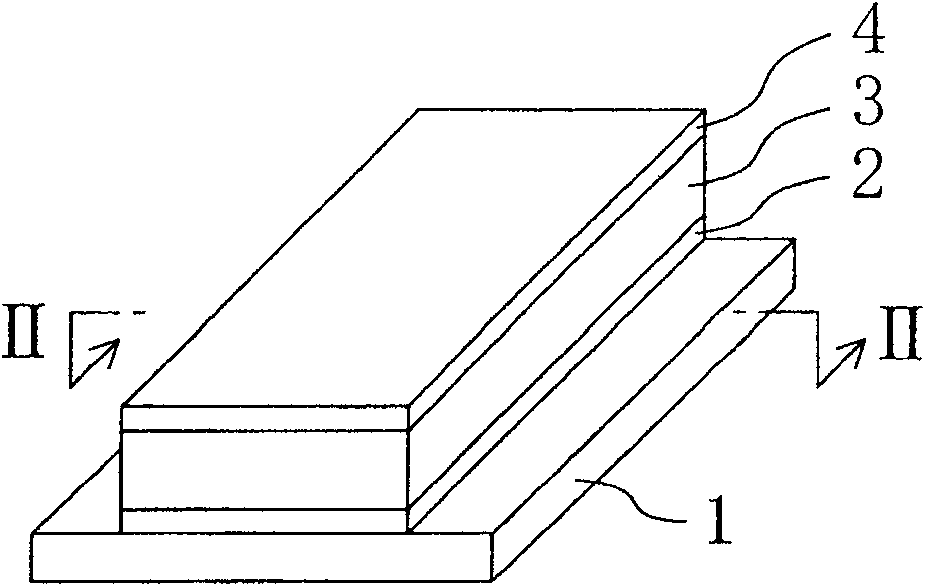

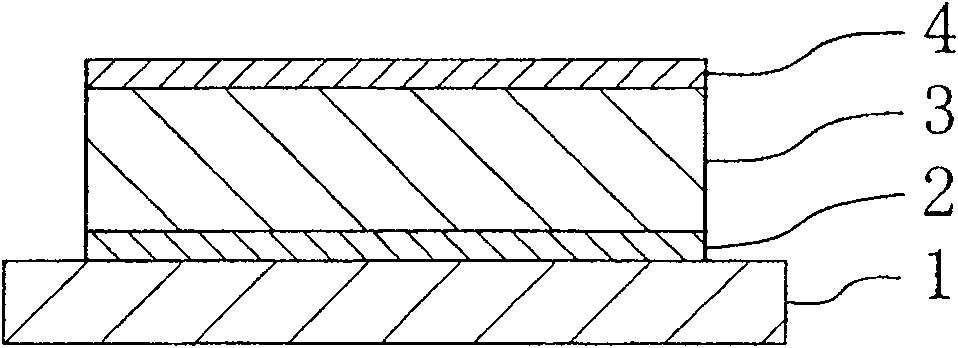

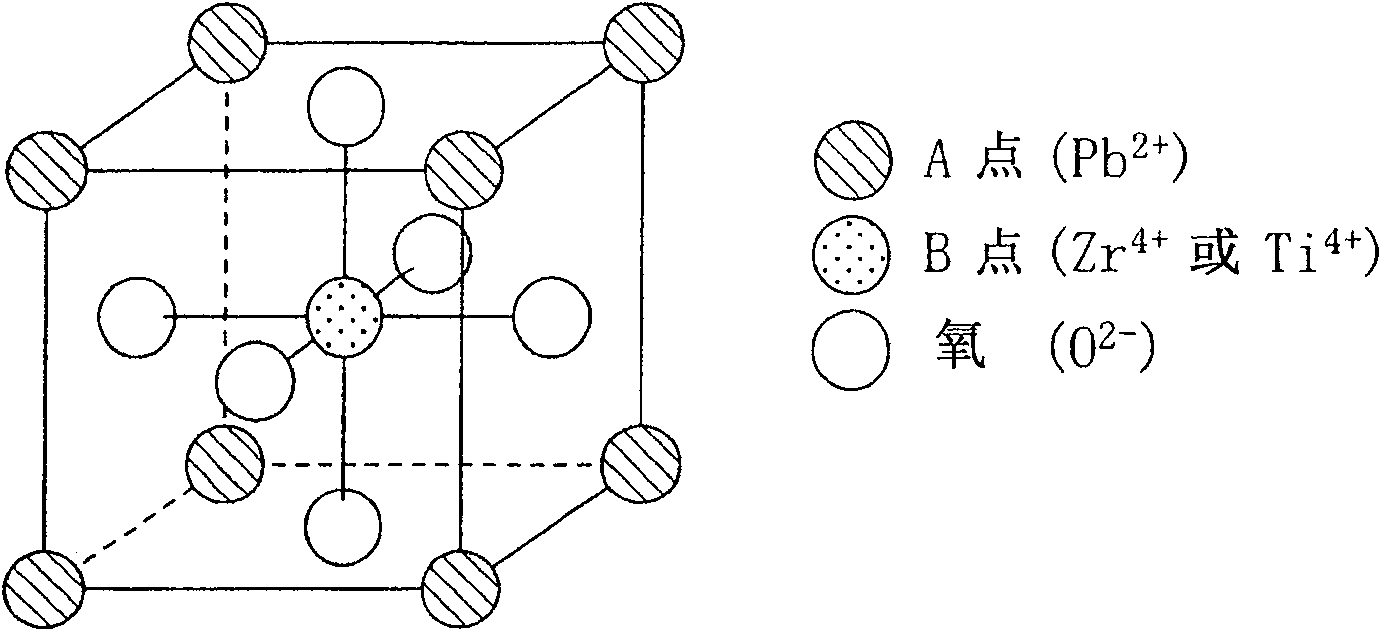

Piezoelectric body, mfg. method thereof, piezoelectric element having piezoelectric body, inkjet head and inkjet type recording device

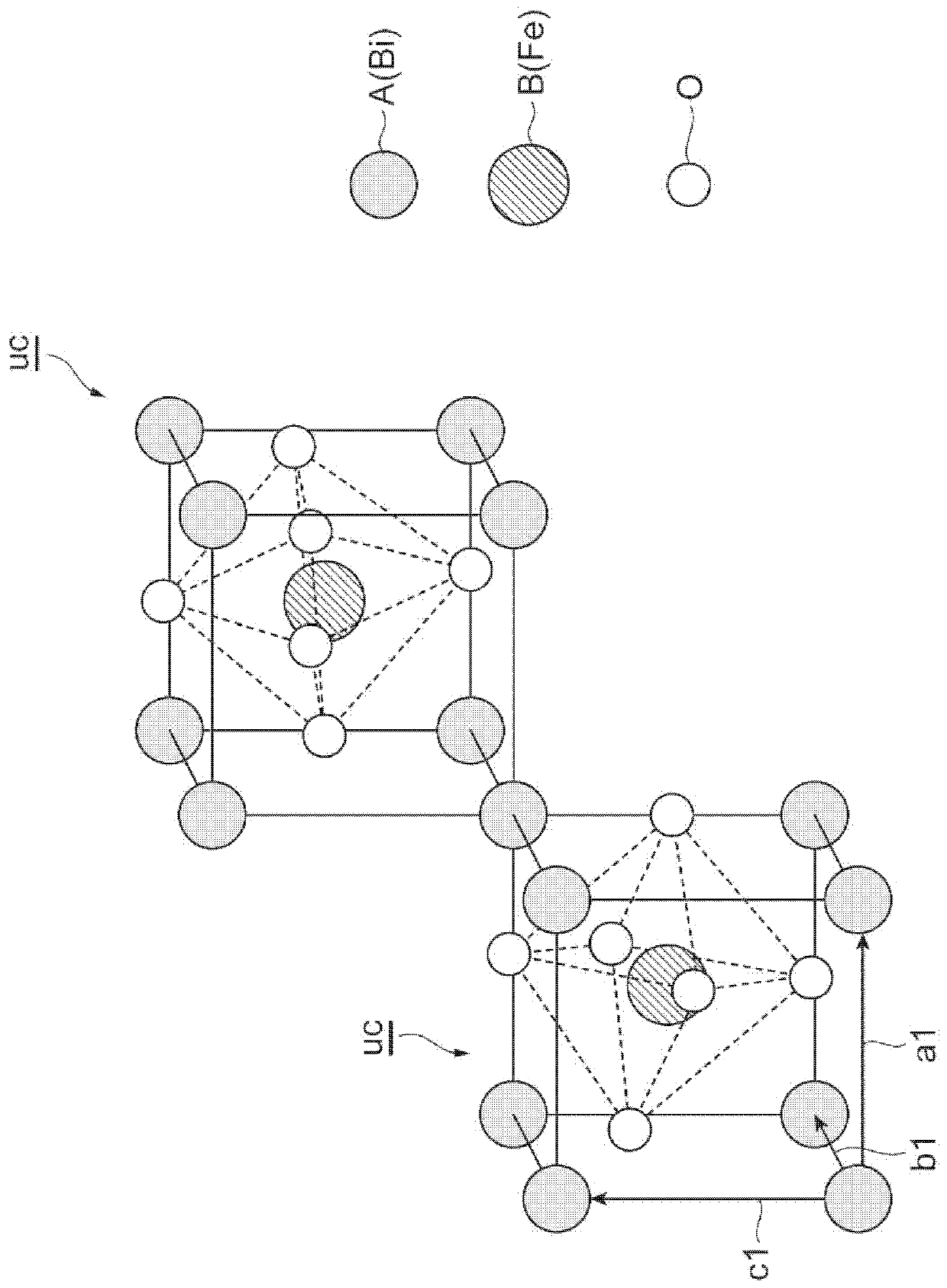

InactiveCN1514808AHigh piezoelectric constantImprove reliabilityPiezoelectric/electrostrictive device manufacture/assemblyZirconium compoundsCrystal structurePerovskite

In a piezoelectric element comprising a first electrode 2 provided on a substrate 1, a piezoelectric material 3 provided on the first electrode 2 and a second electrode 4 provided on the piezoelectric material 3, the piezoelectric material 3 is configured so as to have a perovskite type crystal structure which is represented by a formula ABO3 and in which the main component for the A site is Pb and the main components for the B site are Zr, Ti and Pb, and configured so that a ratio of Pb atoms to all atoms in the B site is more than 3% and not more than 30%. Namely, the piezoelectric material 3 is formed so as to contain Pb excessively and the excess Pb atoms are activated to be Pb<4+> during formation of the piezoelectric material 3 and then introduced into the B site.

Owner:PANASONIC CORP

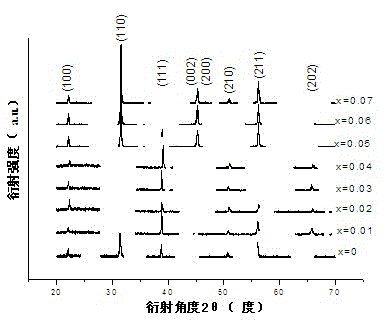

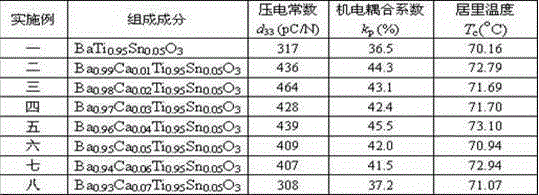

Tin barium titanate calcium leadless piezoelectric ceramic and preparation technology thereof

InactiveCN103145413AExcellent piezoelectric propertiesGood temperature stabilityBarium titanateElectromechanical coupling coefficient

The invention relates to tin barium titanate calcium leadless piezoelectric ceramic with excellent piezoelectric property and good temperature stability. The tin barium titanate calcium leadless piezoelectric ceramic is characterized by comprising a material (Ba[1-x]Cax)(Ti0.95Sn0.05)O3, wherein x is 0-0.07; in a component interval of 0.01-0.06, the the piezoelectric constant d33 of the ceramic of the system is more than 4000pC / N; the electromechanical coupling coefficient kp of the the piezoelectric constant d33 is more than 41%, so the performance of the traditional piezoelectric ceramic containing lead is achieved; in addition, the piezoelectric constant d33 of the ceramic and the electromechanical coupling coefficient kp have good temperature stability; the piezoelectric constant d33 and the electromechanical coupling coefficient kp can respectively achieve over 3000pC / N and 30% when x is 0.01-0.06; and the tin barium titanate calcium leadless piezoelectric ceramic displays that the material has good application prospect.

Owner:LIAOCHENG UNIV

Piezoelectric thin-film sensor with vinylidene difluoride and production thereof

InactiveCN1819293AReduce thicknessSimple preparation processPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive devicesPolyvinylidene difluoridePolyvinylidene fluoride

The sensor shapes a rectangle slice with a thickness of 30-50mum. The polyvinylidene fluoride is extruded to form film. The synchronous draw polarization is made for the film, and then vacuum coating is made for it to get the sensor with piezoelectric effect for use in electronic whiteboard. The ration of drawing is 4.5:1. the polarization temperature is 65-90DEG C. The polarization electric fields 20-80MV / m. The coating material is silver and aluminum. The thickness of electrode is 50-100nm. The coating vacuum degree is 10x10-3-5 x10-7Pa. The distance between extraction electrodes is 21.6m m.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

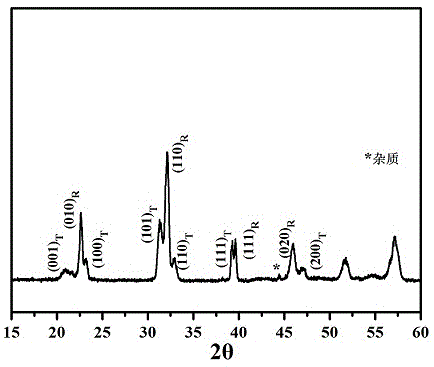

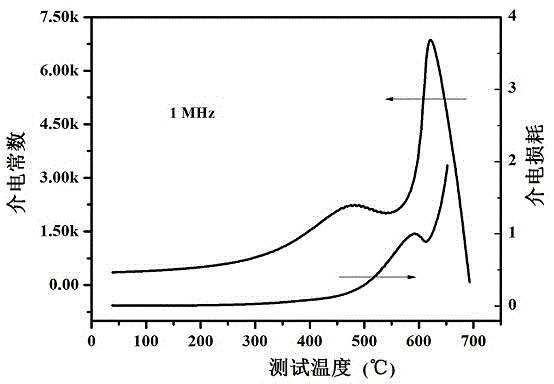

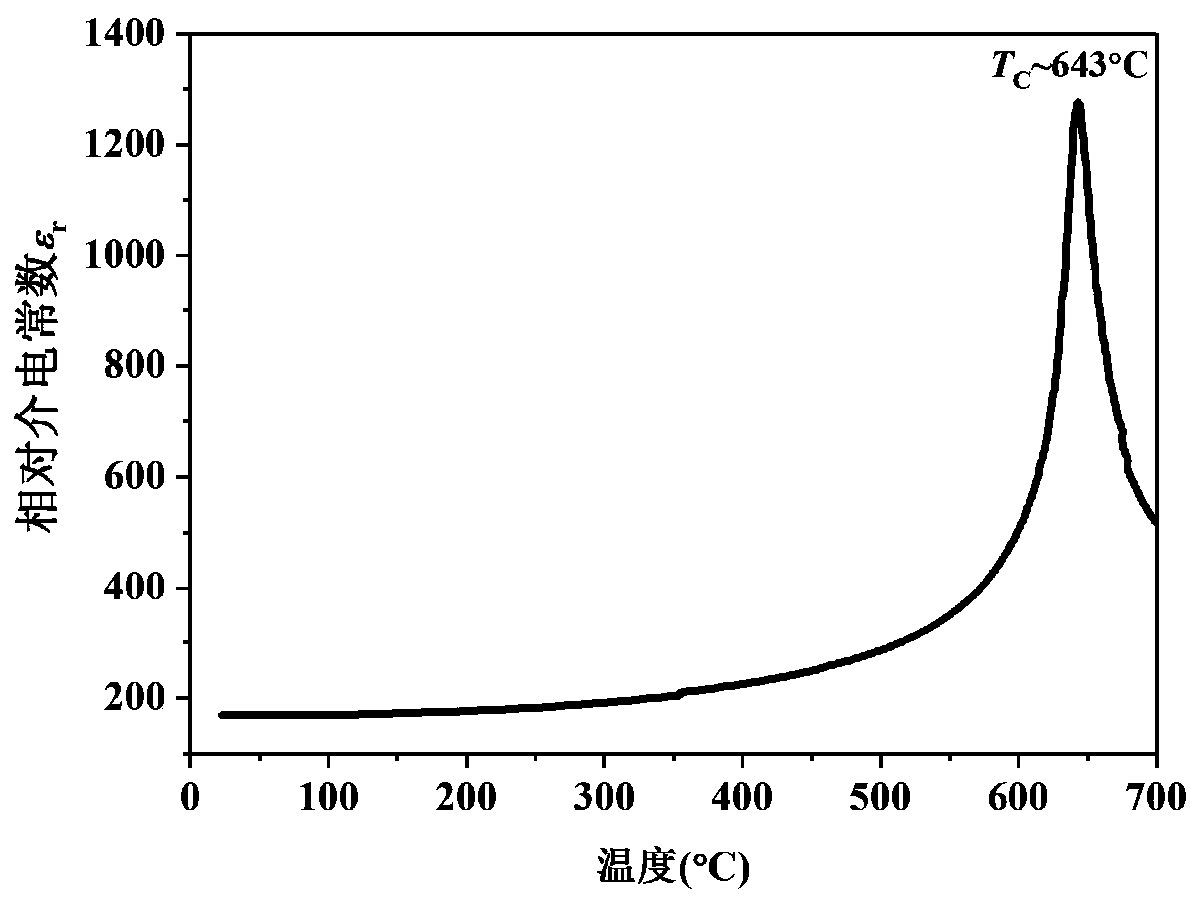

Ternary piezoceramic material with high Curie temperature and preparation method thereof

InactiveCN103951405AImproved high conductivity characteristicsImprove insulation performanceManganeseCurie temperature

The invention discloses a ternary piezoceramic material with high Curie temperature and a preparation method thereof. The piezoceramic material has a chemical formula of (1-y)((1-x)BF-xPT)-yPMN, wherein 0<y<0.1 and 0.2<x<0.4. A third component of plumbum manganese niobate (PMN) is introduced into a bismuth ferrite-plumbum titanate (BF-PT) system for the first time to form a ternary solid solution system. The characteristic of high Curie temperature of the BF-PT material itself is effectively used, and the introduction of the third component of PMN significantly improves the insulating property of the BF-PT material, which enables the BF-PT-PMN material of the invention to be easily polarized to obtain a high piezoelectric constant. The novel ternary piezoceramic material with high Curie temperature of the invention can prepare high temperature piezoelectric ceramics with a Curie temperature of up to 620 DEG C and a piezoelectric constant of up to 90 pC / N, and when compared with high temperature piezoelectric ceramics prepared in an US patent of Xiaoli Tan in 2013, the prepared high temperature piezoelectric ceramics have more excellent performance with not only a Curie temperature increased by nearly 50 DEG C, but also a piezoelectric constant increased by 26 pC / N. With the material and the method of the invention, application of BF-PT based materials in the high temperature piezoelectric field takes a big step forward.

Owner:SHANGHAI UNIV

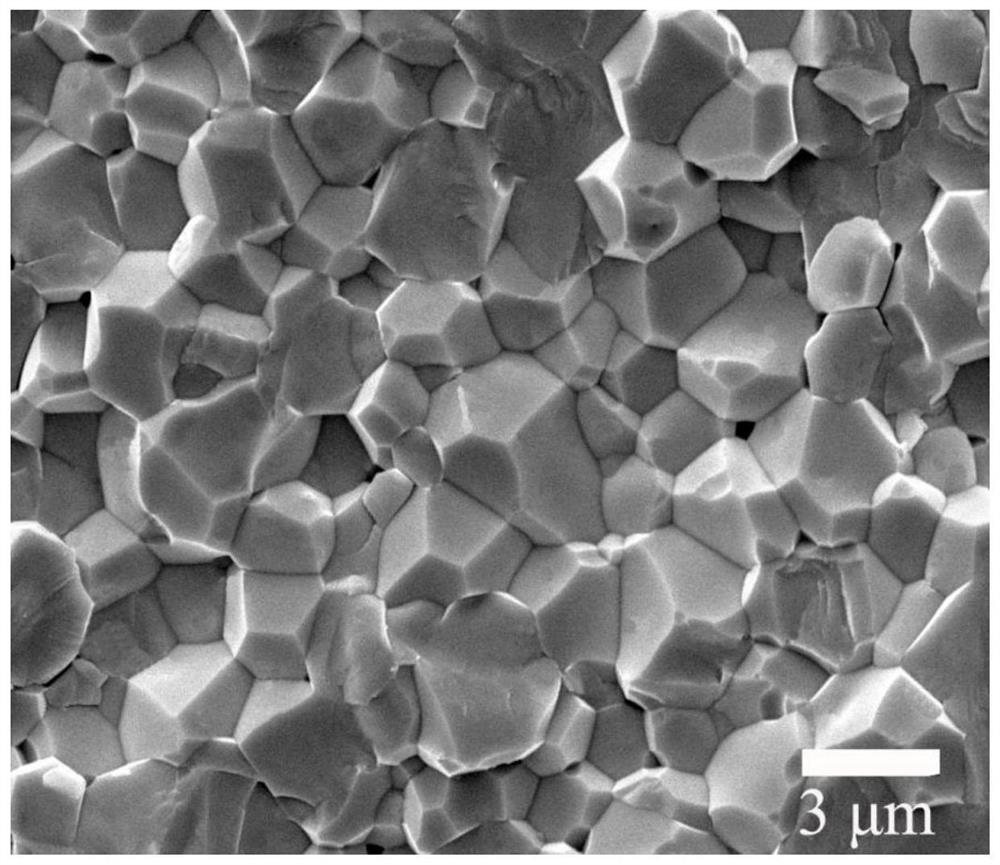

Abnormal piezoelectric anisotropy lead-free piezoelectric ceramic and texturing preparation method thereof

ActiveCN103708829AHigh piezoelectric constantShort preparation cycleHigh pressureSodium bismuth titanate

The invention discloses an abnormal piezoelectric anisotropy lead-free piezoelectric ceramic and a texturing preparation method thereof. The component of the abnormal piezoelectric anisotropy lead-free piezoelectric ceramic is (Bi1 / 2Na1 / 2)TiO3+x(Nb2O5+CeO2), wherein x is mole fraction, 0.005<x<0.1, and Nb2O5 and CeO2 content ratio (molar ratio) Nb2O5 / CeO2 is equal to 0.1-10. The texturing preparation method adopts a high-pressure cylinder forming method, can promote the texturing of the ceramic only by carrying out a conventional sintering process, and can significantly improve the piezoelectric property and anisotropy of sodium bismuth titanate based piezoelectric ceramic by cutting in the direction vertical to a pressure axis. The abnormal piezoelectric anisotropy sodium bismuth titanate based piezoelectric ceramic disclosed by the invention is simple and stable in preparation process and good in performance, and the piezoelectric constant d33 of the piezoelectric ceramic can reach 125pC / N; compared with a conventional non-texturing sample, the performance is increased by 65%, and the piezoelectric anisotropy kt / kp can reach 8.1; compared with the conventional non-texturing sample, the anisotropy is increased by 113%.

Owner:GUILIN UNIV OF ELECTRONIC TECH

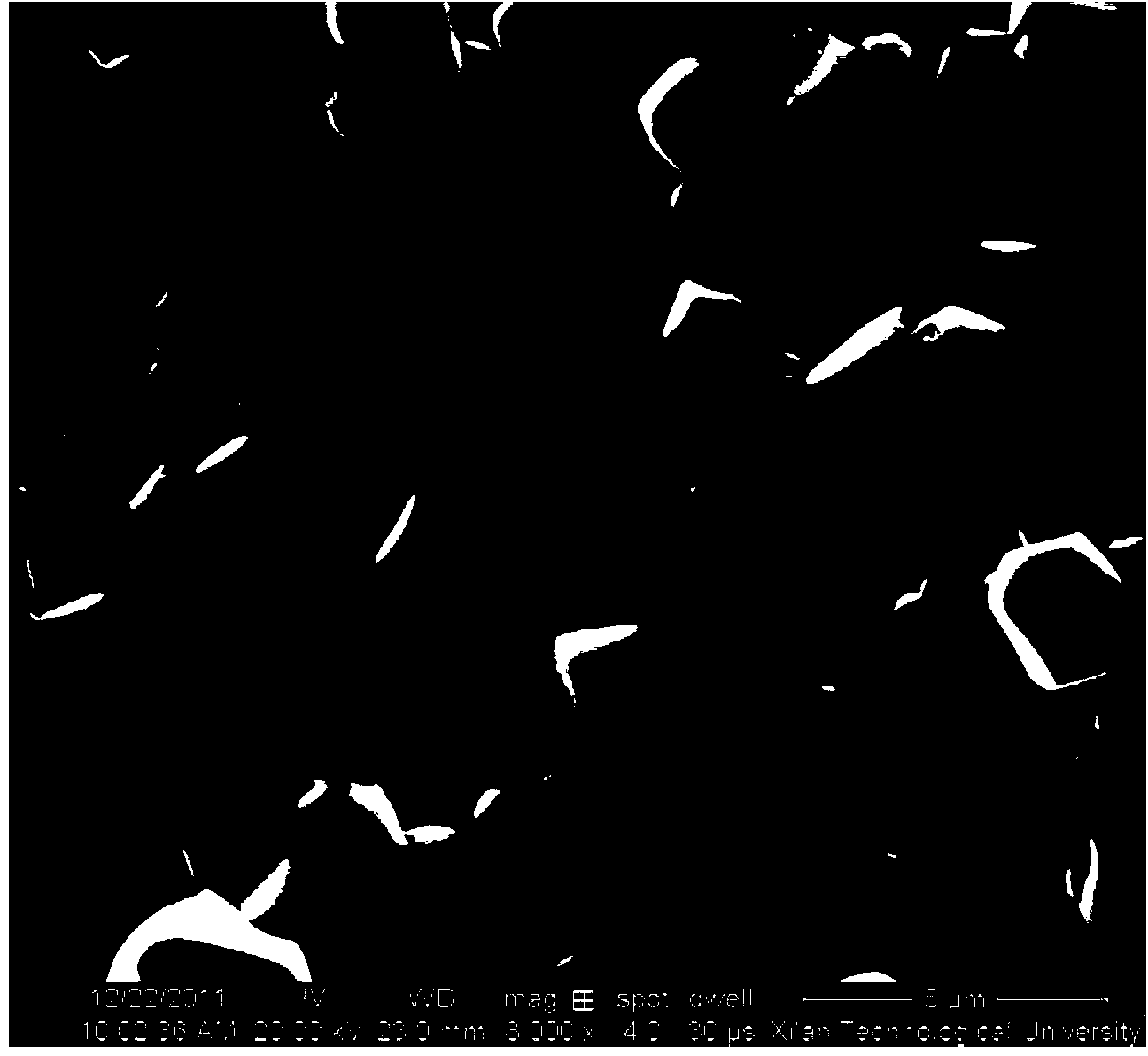

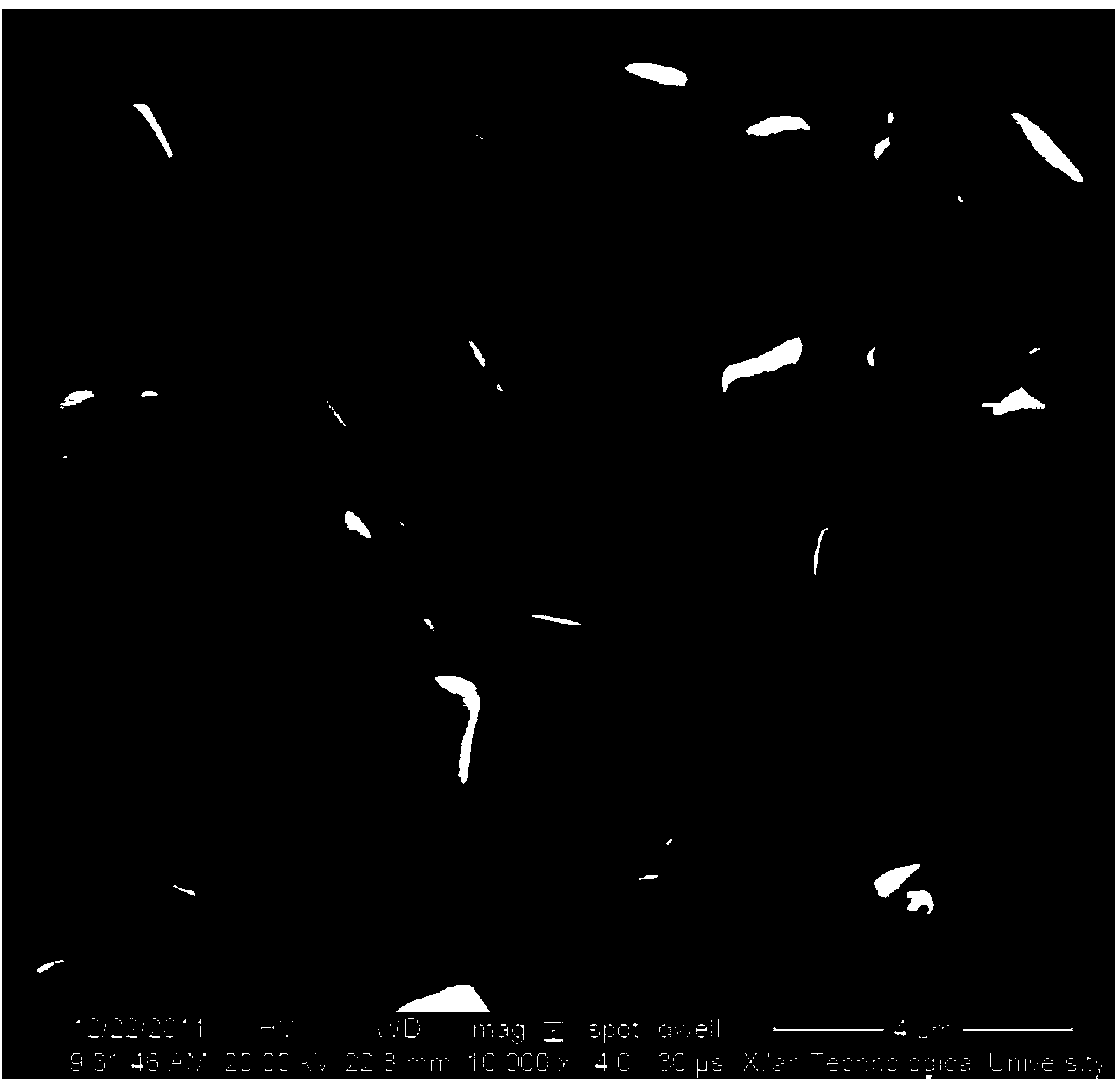

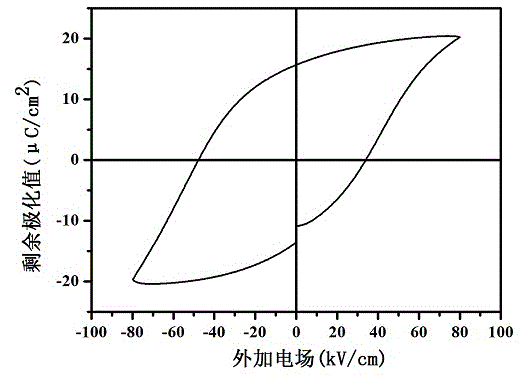

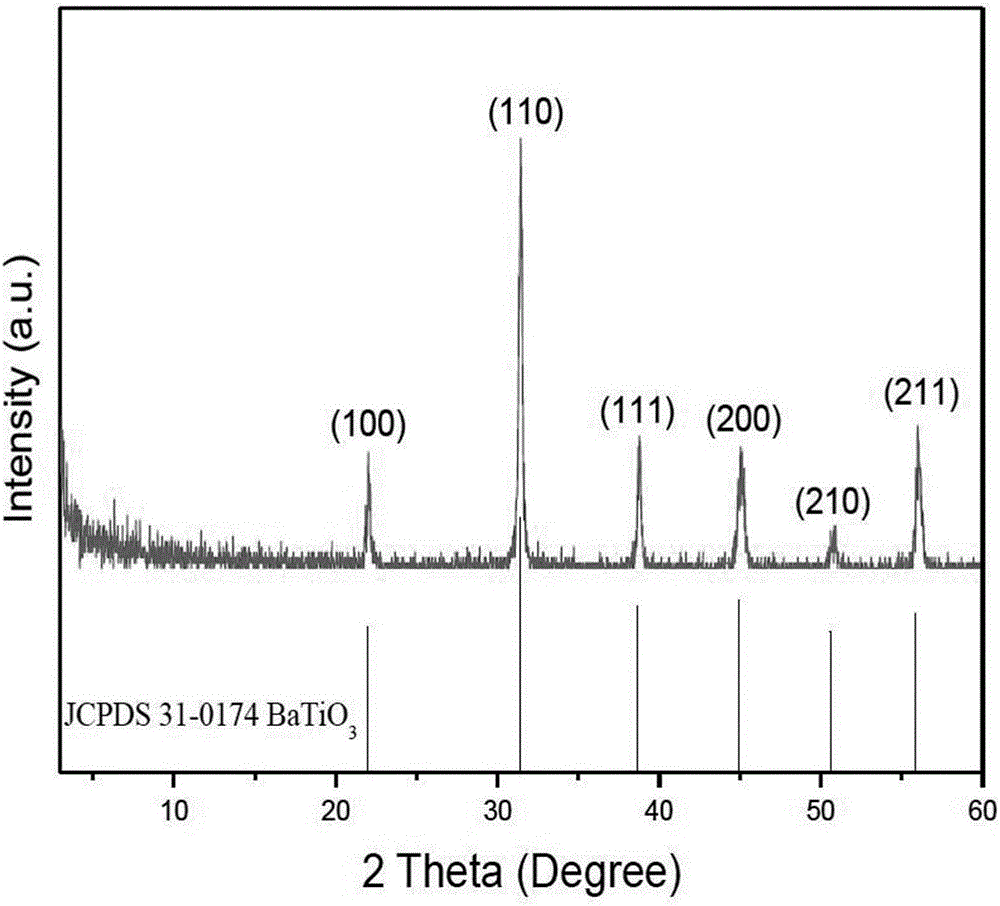

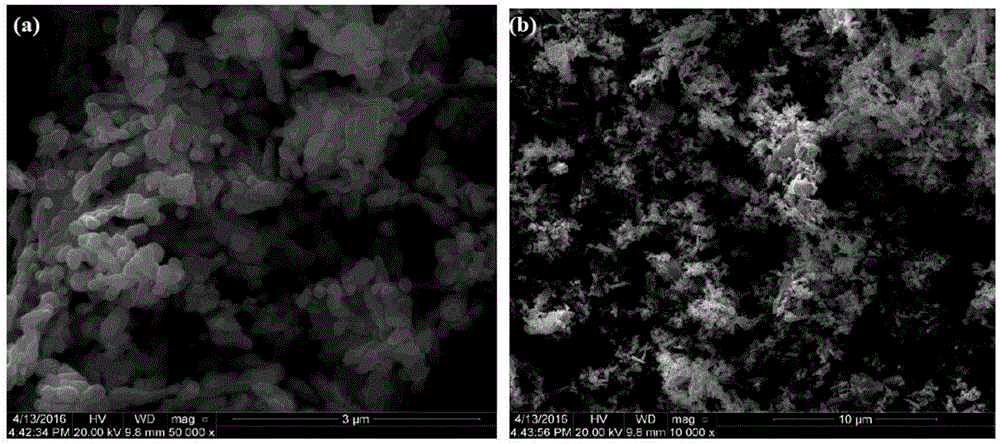

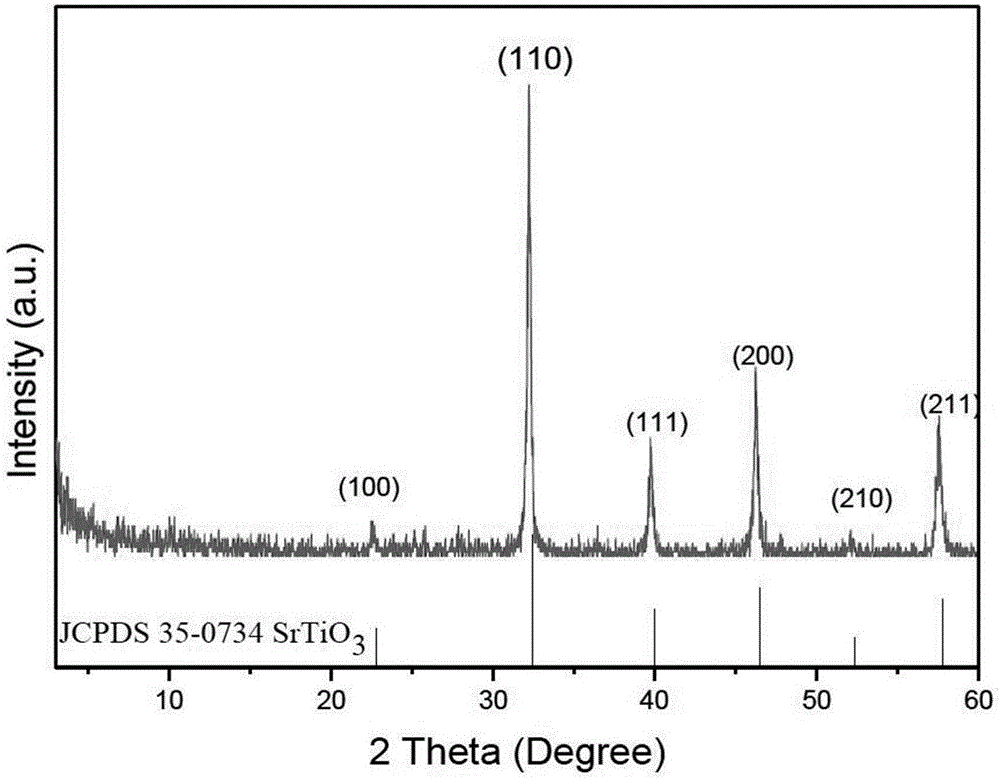

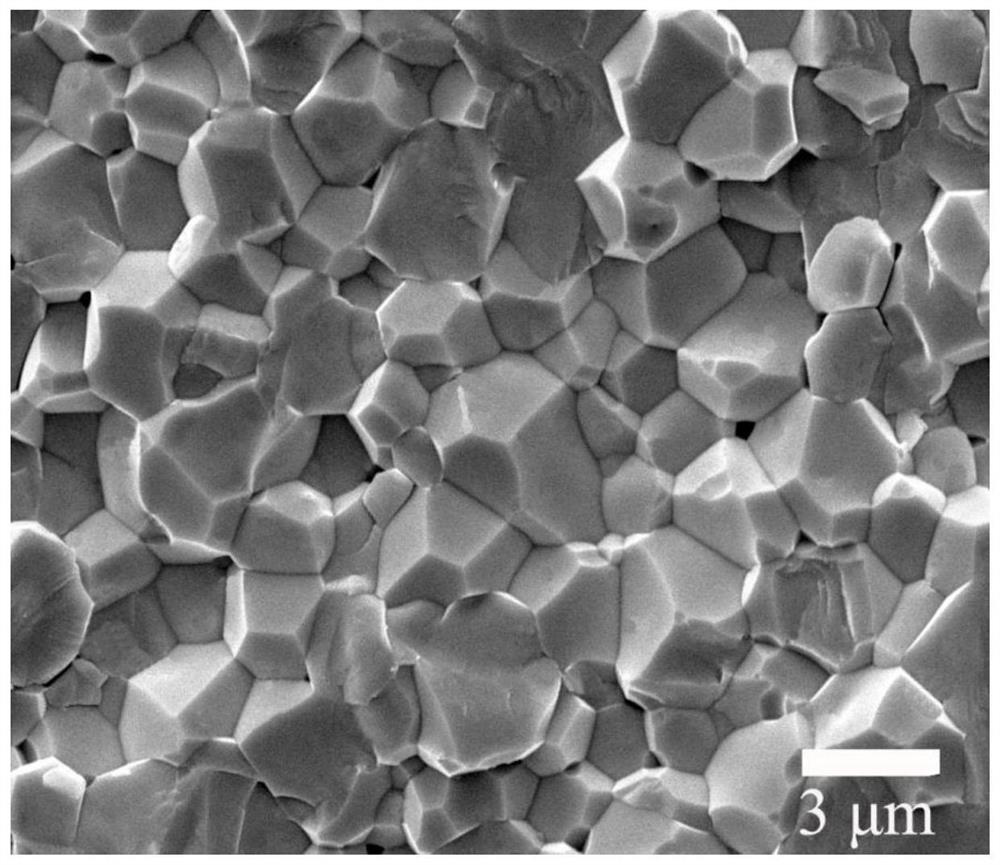

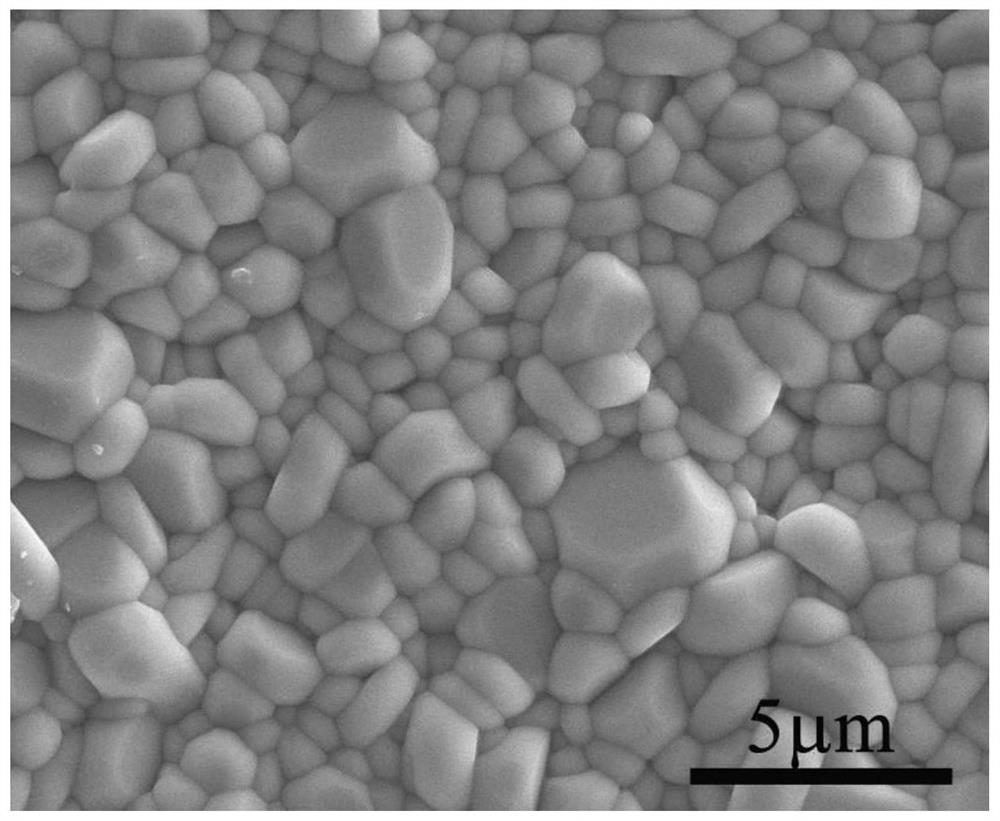

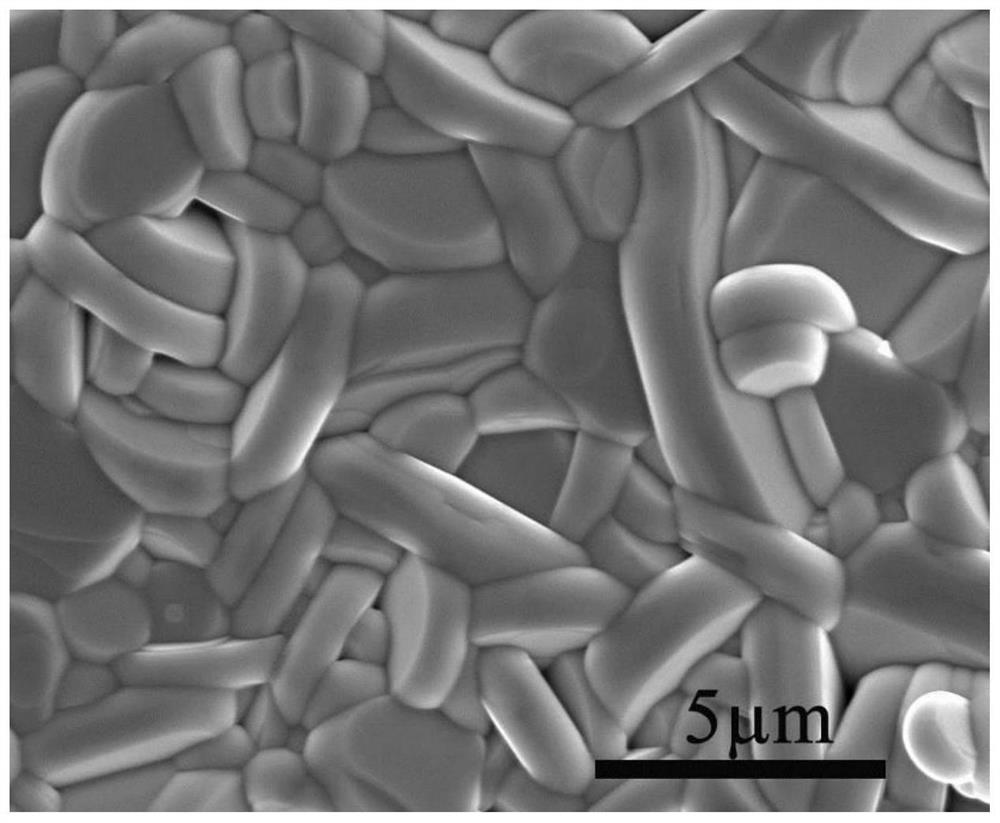

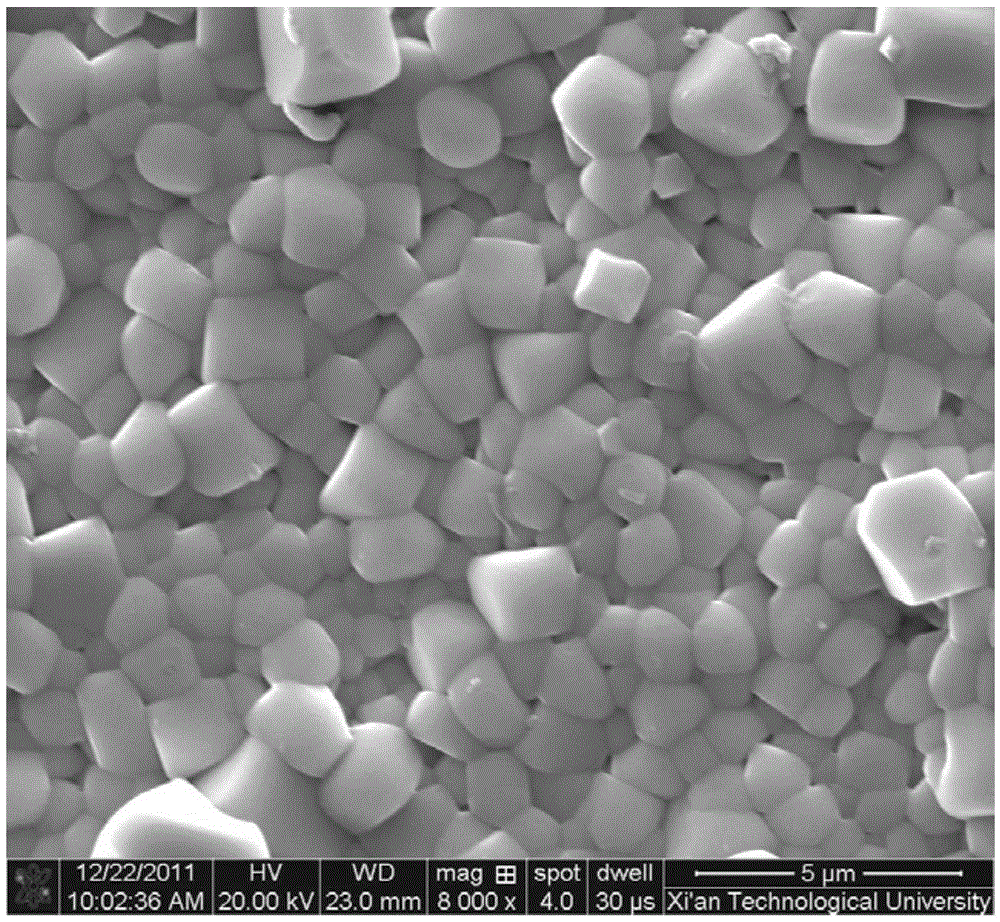

Preparation method of preferred orientation BaTiO3/SrTiO3 nano composite ceramic

ActiveCN106478089AHigh piezoelectric constantAlkaline earth titanatesComposite ceramicStrontium hydroxide octahydrate

The invention discloses a preparation method of preferred orientation BaTiO3 / SrTiO3 nano composite ceramic. The method includes that titanic acid, barium hydroxide and strontium hydroxide are taken as raw materials, a hydrothermal method is used to optimize technical parameters, and BT and ST ceramic powder is synthesized; through testing result analysis of a scanning electron microscope, all the prepared powder is nanoscale, a green structure is formed by tape-casting lamination according to a template grain growth method, and the composite ceramic is obtained by sintering according to a specific process. Calculation results show that the ceramic has a certain orientation; the piezoelectric constant (d33) of the polarized ceramic is big, and the preferred orientation BaTiO3 / SrTiO3 nano composite ceramic can be used as a leadless piezoelectric ceramic material.

Owner:BAOJI UNIV OF ARTS & SCI

Composite piezoelectric film and preparation method and application thereof

PendingCN111063794AUniform distribution of piezoelectric effectLarge output piezo voltagePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionFiberSpinning

The invention belongs to the technical field of piezoelectric materials, and particularly relates to a composite piezoelectric film and a preparation method and application thereof. The preparation method comprises the following steps: adding inorganic piezoelectric powder into a polymer solution to obtain a precursor solution; and carrying out electrostatic spinning on the precursor solution andperforming collection in a water medium to obtain the composite piezoelectric film. The composite piezoelectric film is a porous structure fiber film and is filled with inorganic piezoelectric powder,and a polymer piezoelectric material and a rigid piezoelectric material are well compounded. Moreover, the composite piezoelectric film is a beta-phase enhanced flexible composite film, can generatea relatively large output piezoelectric voltage, has a relatively high piezoelectric constant, is uniform in piezoelectric effect distribution, and can solve the problem that an existing polymer piezoelectric film cannot be effectively combined with an inorganic piezoelectric material to form a flexible device with high piezoelectric performance. In addition, the preparation method is simple in preparation process and beneficial to large-scale production.

Owner:GUANGDONG UNIV OF TECH

Preparation method of Fe2O3 doped with PHT-PNN piezoelectric ceramic

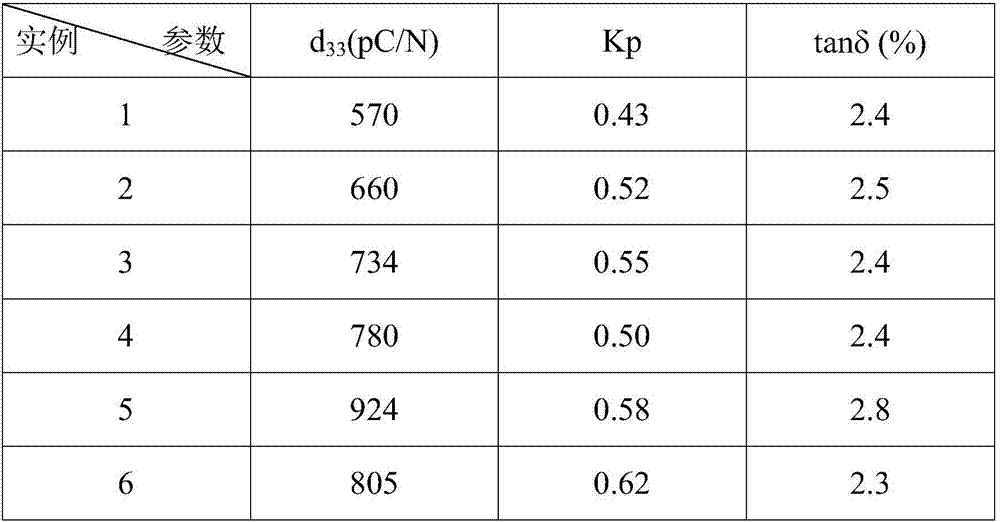

The invention discloses a preparation method of Fe2O3 doped with PHT-PNN piezoelectric ceramic. The preparation method comprises the following steps: (1) synthetizing prefabricated precursor nickel niobate powder; (2) proportioning according to 0.51Pb (Ti0.7Hf0.3) O3-0.49Pb (Ni1 / 3Nb1 / 3) O3 stoichiometry and doping with 0.4%-1.2% mol of Fe2O3; (3) preparing pre-synthetic powder; (4) granulating and forming embryo; (5) obtaining Fe2O3 doped with PHT-PNN piezoelectric ceramic primary products; (6) polishing, silvering and treating in a polarized mode to obtain the Fe2O3 doped with the PHT-PNN piezoelectric ceramic. The preparation method is simple and can obtain high performance piezoelectric ceramic materials with the piezoelectric coefficient greater than 900 pC / N.

Owner:XIDIAN UNIV

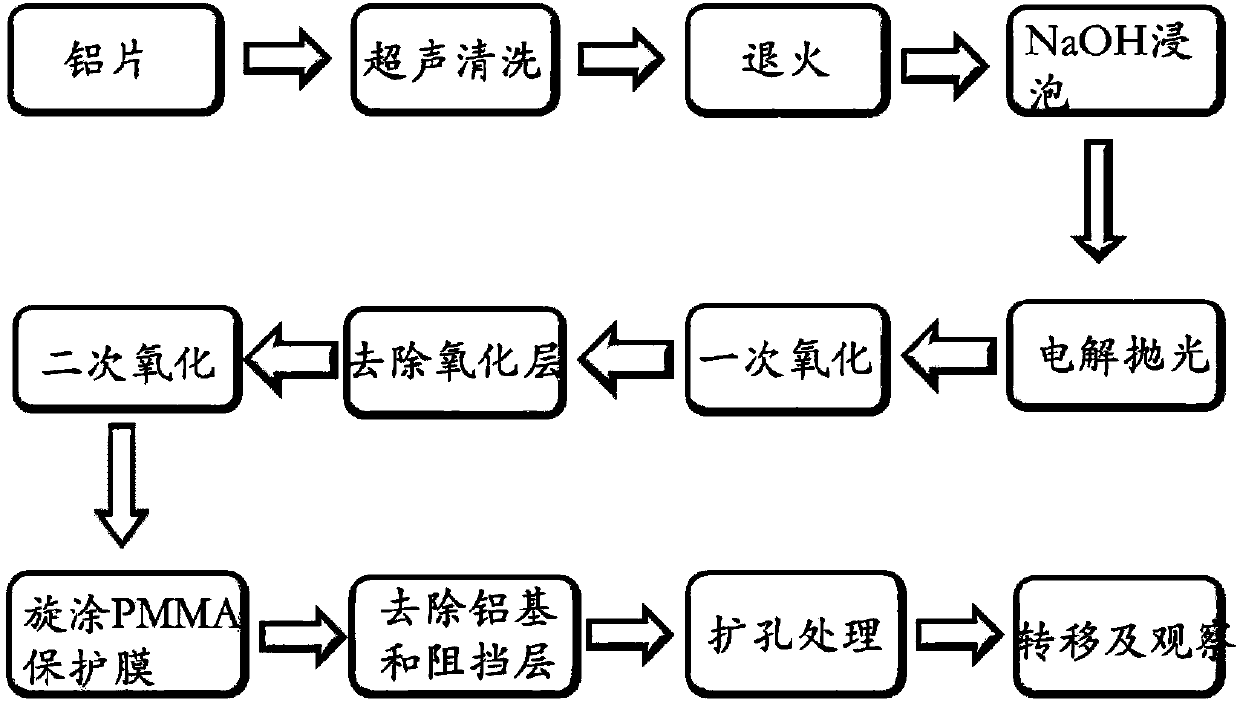

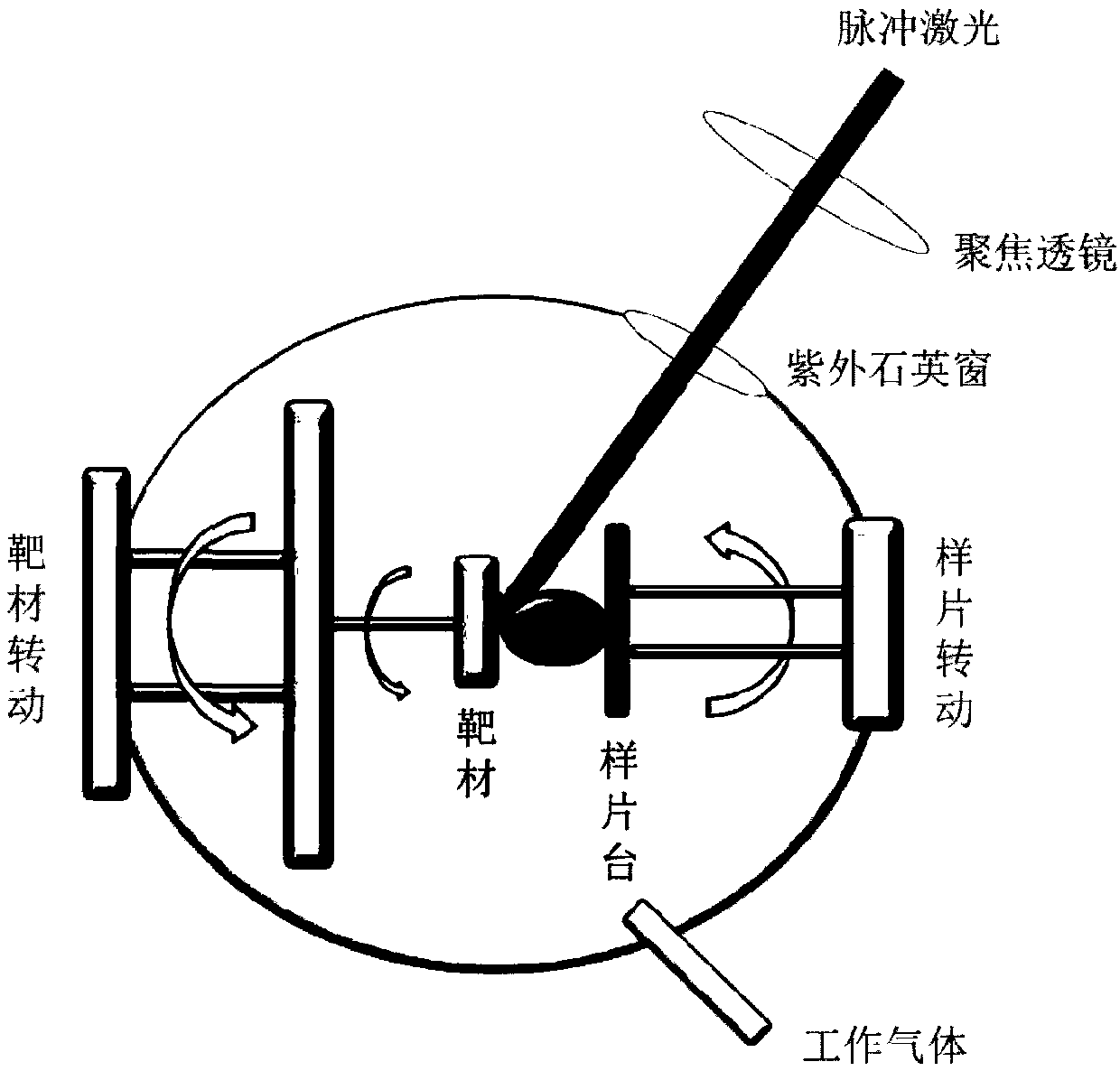

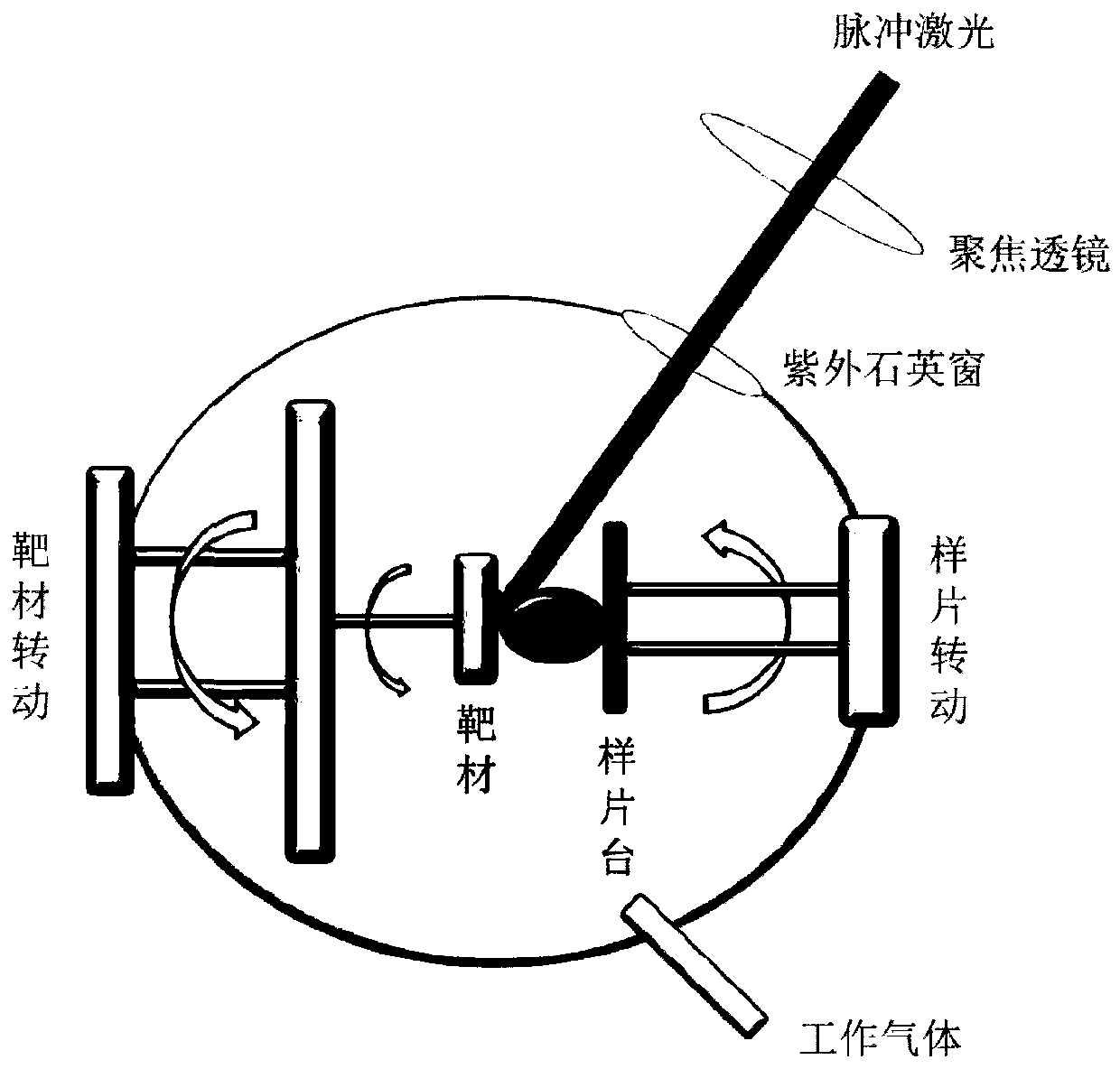

Method for growing lead zirconate titanate (PZT) nanorings by using pulsed laser deposition (PLD) technology

ActiveCN108018523ACause some damagesSimple processMaterial nanotechnologyVacuum evaporation coatingLead zirconate titanateDeposition temperature

The invention discloses a method for growing lead zirconate titanate (PZT) nanorings by using the pulsed laser deposition (PLD) technology. The PLD method is used, and preparation of the PZT nanoringsis realized by precisely controlling the deposition temperature, the annealing temperature, annealing time, the number of laser pulses, oxygen pressure and other parameters. The method can be used for preparing regularly arrayed PZT nanorings, parameter control is simple and convenient, repeatability is high, and no toxic and harmful exhaust gas is emitted. The method provides a possibility for the application of high-density ferroelectric memory devices in the future.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

A-position co-substituted piezoelectric ceramic material with high piezoelectric constant and preparation method

InactiveCN103724013AHigh piezoelectric constantImprove piezoelectric performanceElectromechanical coupling coefficientDielectric permittivity

The invention provides an A-position co-substituted piezoelectric ceramic material with a high piezoelectric constant. The material is characterized in that the composition is Pb1-e-f-BaeLaf(Ni1 / 3Nb2 / 3)x(Zn1 / 3Nb2 / 3)yZrmTinO3+awt%Al2O3+bwt%Sb2O3+cwt%Fe2O3+dwt%Bi2O3, wherein (e+f) is more than or equal to 0.04 and less than or equal to 0.2; (x+y) is more than or equal to 0.05 and less than or equal to 0.3; (x+y+m+n)=1; a=0-0.5; b=0-0.5; c=0-0.5; d=0-0.5. A preparation method of the piezoelectric ceramic material comprises burdening, mixing, pre-sintering for synthesizing, smashing, finely grinding, molding, discharging glue, sintering and loading onto an electrode for polarizing. By means of A-position co-substituting and proper doping, the piezoelectric constant can be increased greatly. The A-position co-substituted piezoelectric ceramic material has the characteristics of high relative dielectric constant epsilonT33 / epsilon0 and high piezoelectric constants d33 and d31, the electromechanical coupling coefficient Kp is 0.6-0.75, and the mechanical quality factor Qm is less than 50. The material can be applied to a plurality of piezoelectric sensors and actuators.

Owner:重庆胜普昂凯科技有限公司

PZT-based piezoelectric ceramic and preparation method thereof

The invention discloses a PZT-based piezoelectric ceramic and a preparation method thereof. In component design, at least one of CaO, BaO, SrO and MgO is doped into PZT ceramic to improve the performance of a ceramic material; and in the preparation method, weighed chemical raw materials are subjected to primary grinding by a ball mill according to a design formula, and then, drying andsieving are carried out; then, the sieved powder is subjected to radiation synthesis in a microwave oven to form presintered powder; and secondary grinding is carried out according to the ball mill method, drying and sieving are carried out, a PVA solution is added for granulating, and then, dry-pressing molding is carried out to obtain a green body; and finally, sintering and densifying are carried out in a microwave oven to obtain the PZT-based piezoelectric ceramic product. Compared with the prior art, on the basis of a traditional powder metallurgy process, and by introducing the microwave radiation synthesis superfine powder and microwave sintering technology, the method has the advantages of being excellent in comprehensive performance, environmentally friendly, high in production efficiency, capable of easily achieving batch production and the like, can well meet commercial requirements and is very suitable for preparing PZT-based piezoelectric ceramic products.

Owner:HUNAN HANDLIKE MINIMALLY INVASIVE SURGERY CO LTD

Potassium sodium niobate-based leadless piezoelectric ceramic and preparation method thereof

The invention discloses potassium sodium niobate-based leadless piezoelectric ceramic and a preparation method thereof, the chemical formula of the potassium sodium niobate-based piezoelectric ceramic is (1-x) (K0. 5Na0. 5) NbO3-xBi (Li0. 5Sb0. 5) O3, and x is more than or equal to 0.01 and less than or equal to 0.20. The preparation method comprises the following steps: weighing dry raw materials according to a stoichiometric ratio of (1-x) (K0. 5Na0. 5) NbO3-xBi (Li0. 5Sb0. 5) O3, mixing, carrying out ball milling, and drying to obtain a mixed material; pre-sintering the mixed material obtained in the step 1 at a high temperature to obtain pre-sintered powder, and performing secondary ball-milling and drying to obtain secondary ball-milled powder; adding an adhesive into the secondary ball-milled powder, granulating, sieving, and carrying out compression molding, so as to obtain a ceramic blank; removing the organic adhesive, and sintering at high temperature to obtain sintered ceramic; coating the surfaces of the two sides of the sintered ceramic with silver and carrying out high-voltage polarization, and preparing the potassium sodium niobate-based leadless piezoelectric ceramic. Through component design and process optimization, the sintering characteristic of the potassium sodium niobate-based ceramic is effectively improved, volatilization of sodium and potassium elements is inhibited, the porosity is reduced, the density of the ceramic is improved, the dielectric constant is further improved, the loss is reduced, and the comprehensive performance of the KNN-based ceramic is improved.

Owner:XI AN JIAOTONG UNIV

Piezoelectric composition and piezoelectric device

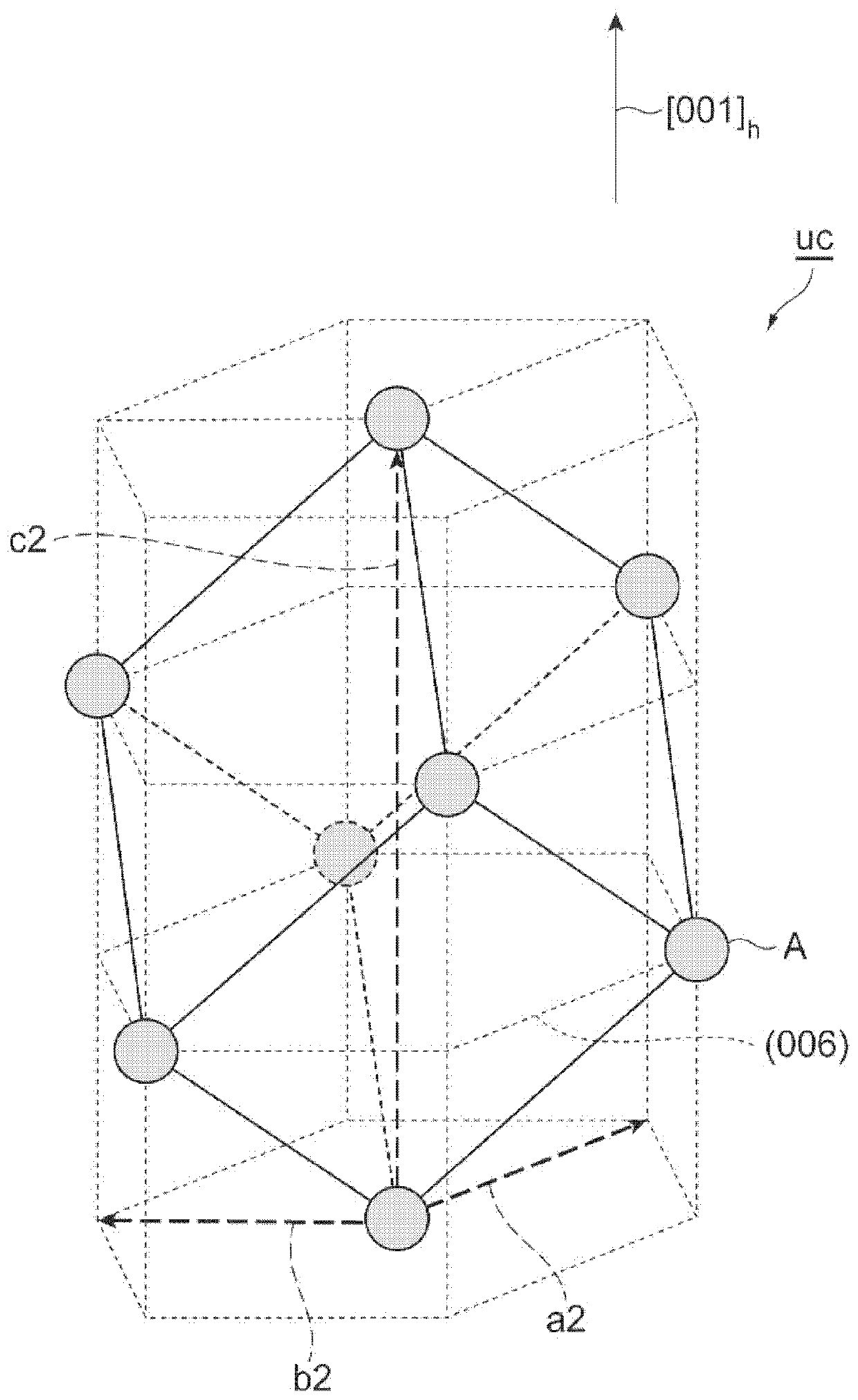

ActiveCN111454054AHigh piezoelectric constantPiezoelectric/electrostrictive device material selectionCrystallographyPerovskite (structure)

The invention discloses a piezoelectric composition, and the composition comprises an oxide having a perovskite structure, wherein the oxide contains bismuth, barium, iron and titanium; the X-ray diffraction pattern of the piezoelectric composition after a polarization treatment has a first peak and a second peak in the range of the diffraction angle 2theta of 38.6 degrees or more and 39.6 degreesor less; the diffraction angle 2theta of the first peak is smaller than the diffraction angle 2theta of the second peak; an intensity of the first peak is represented as IL; an intensity of the second peak is represented as IH; and IH / IL is 0.00 or more and 2.00 or less.

Owner:TDK CORPARATION

Rare-earth-doping-free high-Curie-temperature piezoelectric ceramic element and preparation method thereof

ActiveCN112125669AHigh piezoelectric constantLong-term useSubsonic/sonic/ultrasonic wave measurementUsing electrical meansComposite materialChemical formula

The invention discloses a rare-earth-doping-free high-Curie-temperature piezoelectric ceramic element, the general chemical formula of which is (1-x-y)CaBi2Ta2-aNbaO9+xNa0.5-bKbBi2.5Nb2O9+ySrBi2Nb2-cSbcO9+zwt%P, wherein x is greater than or equal to 0.05 and smaller than or equal to 0.85, and y is is greater than or equal to 0 and less than or equal to 0.1, and P is one of or a combination of twoof CoO and MnCO3. The invention also discloses a preparation method of the piezoelectric ceramic element. The piezoelectric ceramic element prepared by the method has the advantages of high Curie temperature and low aging rate.

Owner:NAT UNIV OF DEFENSE TECH

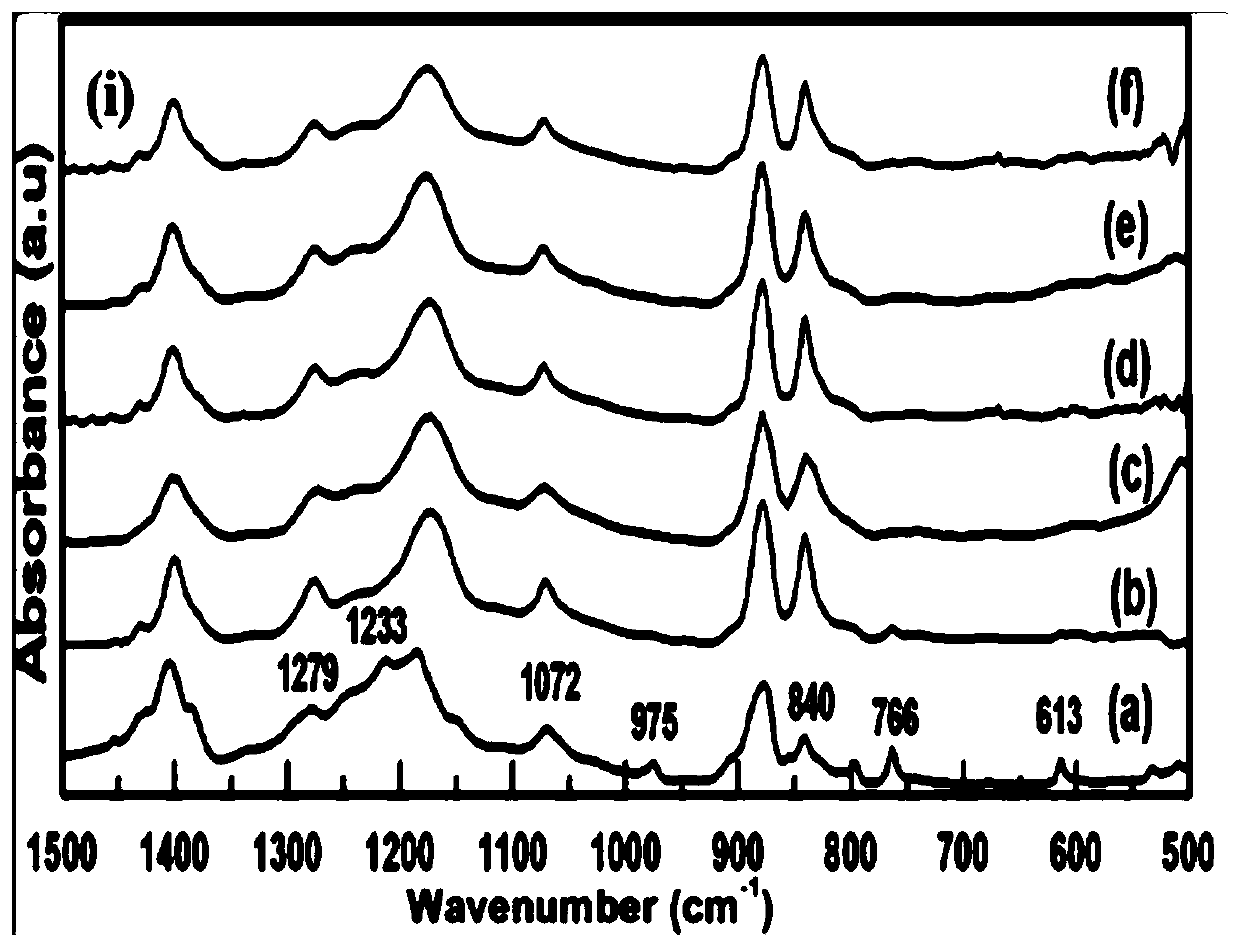

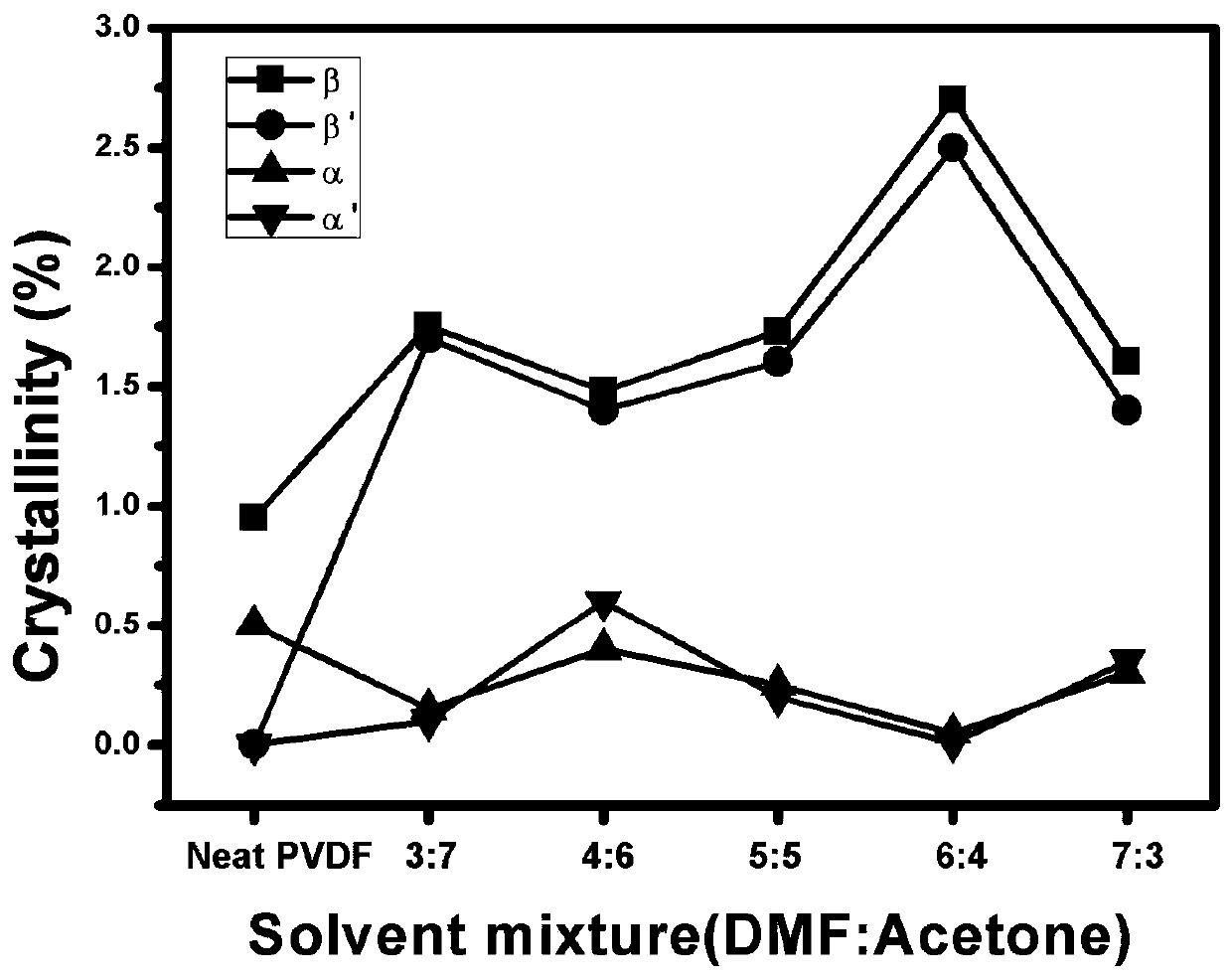

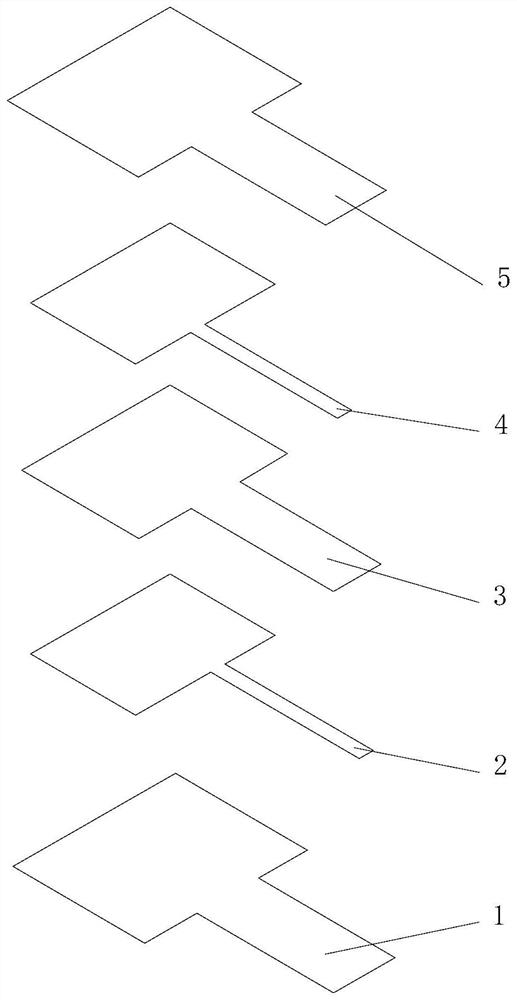

Flexible piezoelectric sensor and preparation method thereof

PendingCN114023873AAvoid deformationSolve processing difficultiesPiezoelectric/electrostrictive device manufacture/assemblyThin membraneBiocompatibility

The invention relates to a flexible piezoelectric sensor and a preparation method thereof. The flexible piezoelectric sensor is provided with a flexible substrate, a first electrode is arranged on the upper surface of the flexible substrate, a piezoelectric film layer is arranged on the upper surface of the first electrode, a second electrode is arranged on the upper surface of the piezoelectric film layer, and a protective layer is arranged on the upper surface of the second electrode; and the signal transmission sections of the first electrode and the second electrode are separately arranged in a staggered manner. According to the preparation method of the piezoelectric film layer, the mixed solvent with the high boiling point and the low boiling point is adopted for solution preparation, deformation caused by uneven tape casting of the edge part of the film in the forming process is avoided, and meanwhile machining difficulty caused by the fact that the solvent with the low boiling point is prone to volatilization is also avoided; and the piezoelectric sensor prepared by the invention has the advantages of simple structure, small volume, high sensitivity, good flexibility, high piezoelectric constant and good biocompatibility, is suitable for irregular object surfaces, and can be produced on a large scale.

Owner:SUZHOU LEANSTAR ELECTRONICS TECH

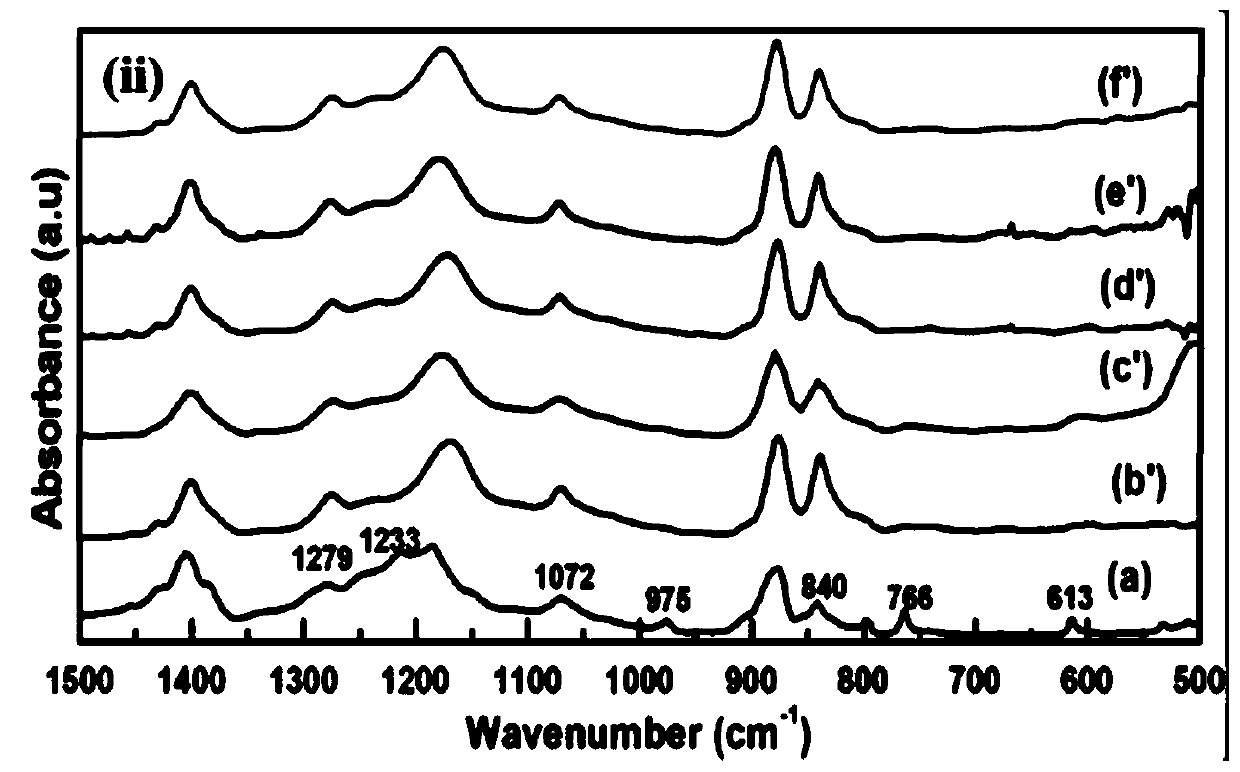

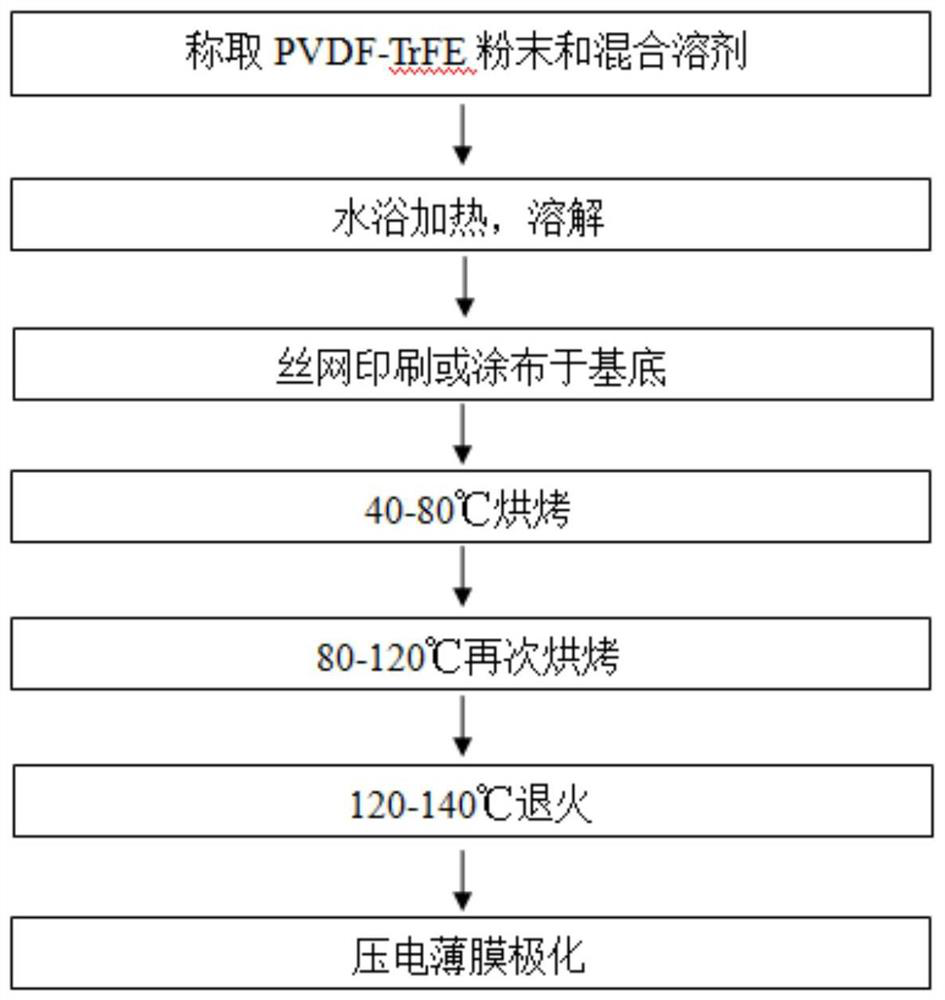

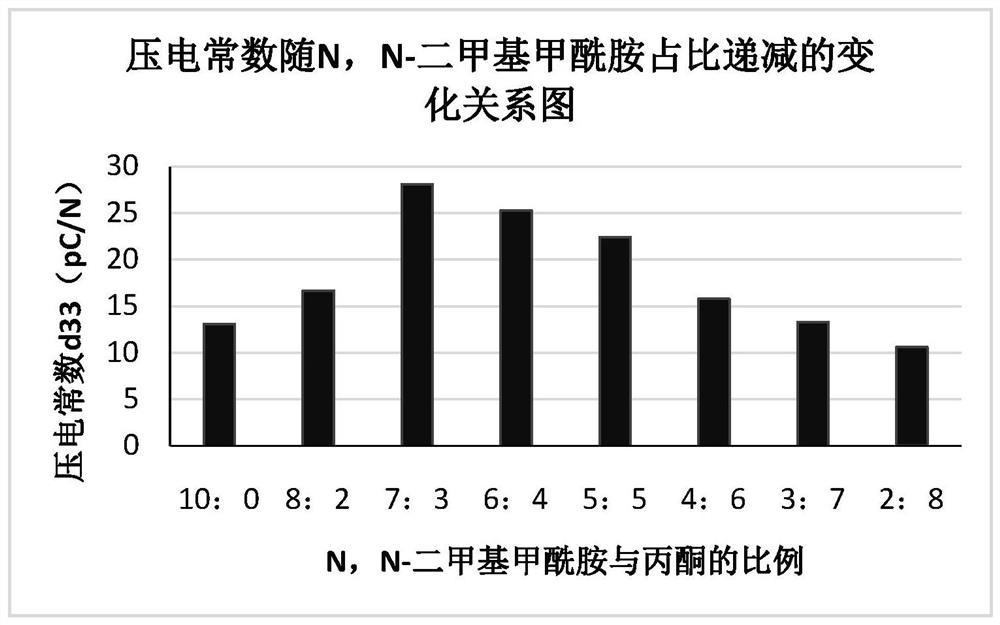

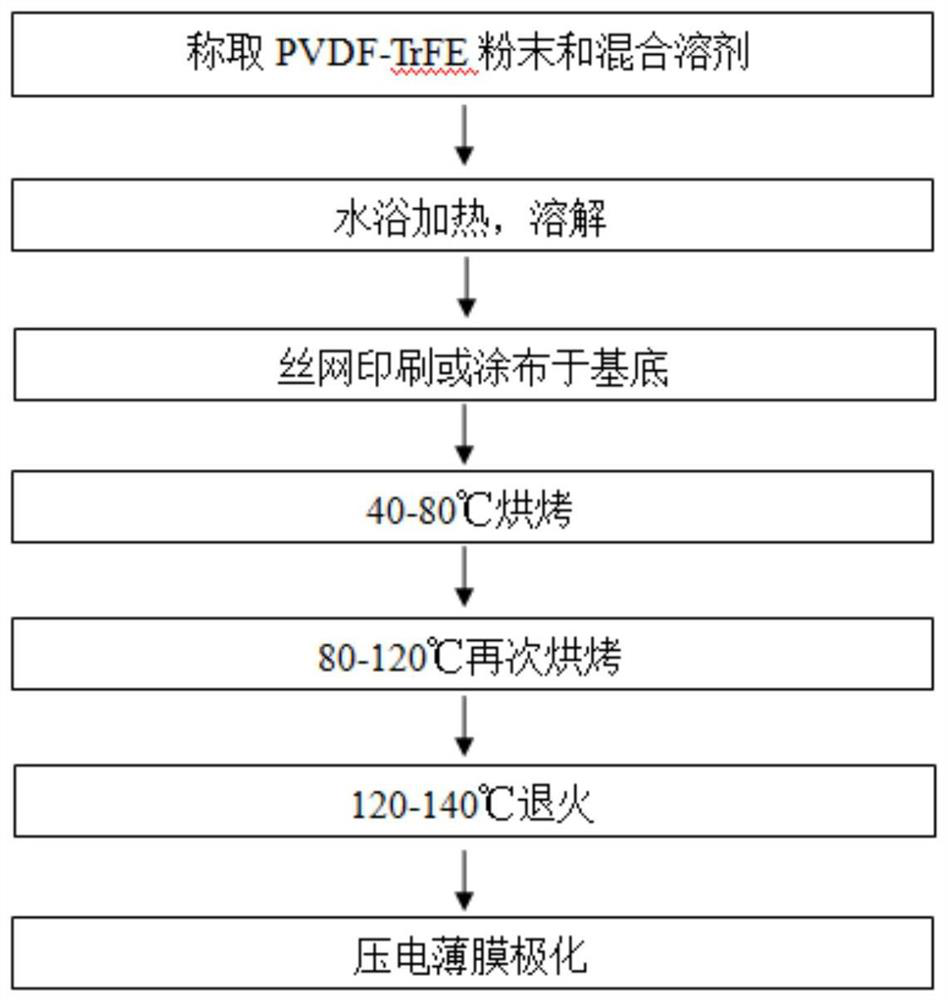

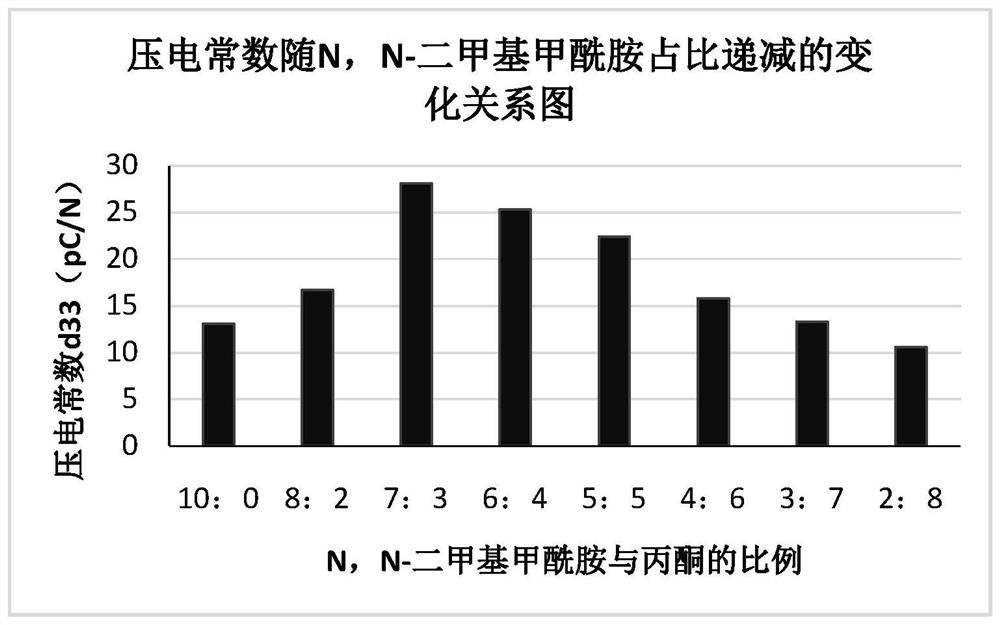

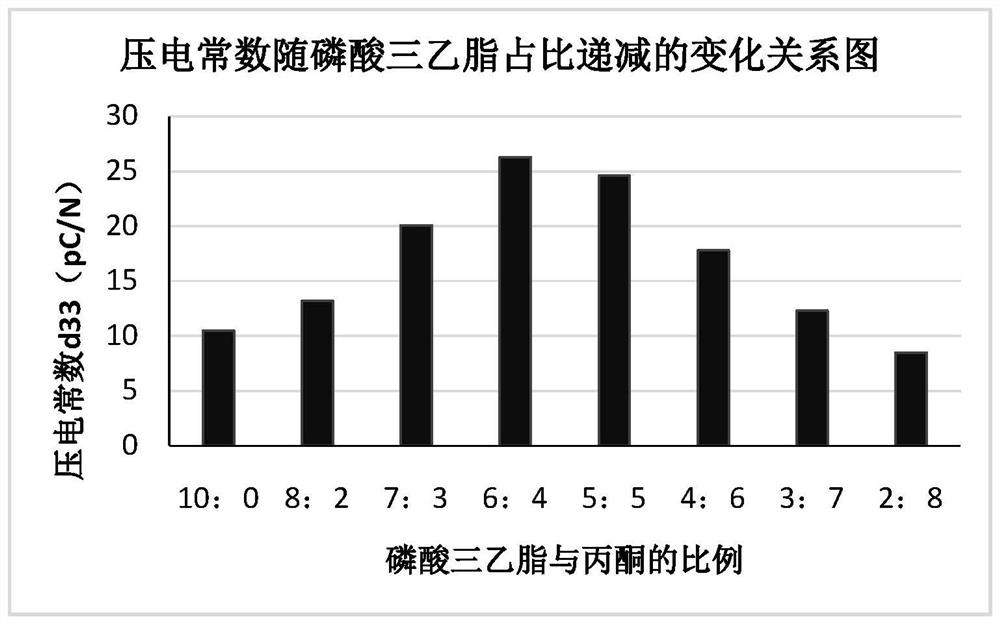

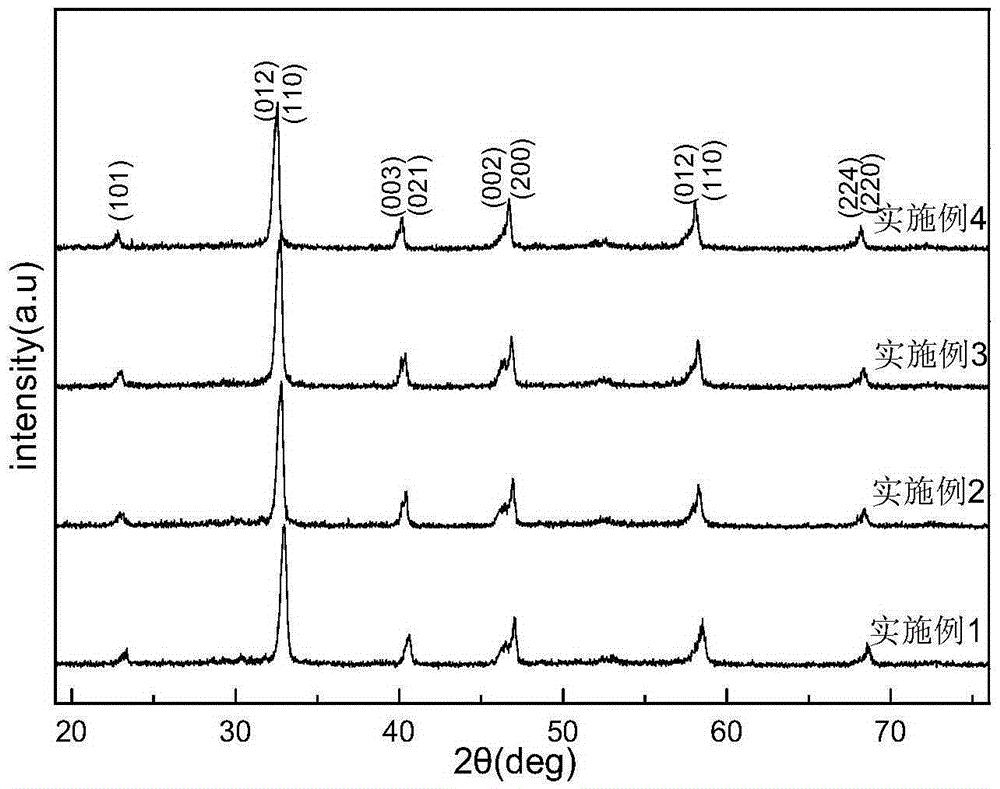

Preparation method of flexible piezoelectric film

PendingCN114122252AAvoid processing difficultiesImprove film qualityPiezoelectric/electrostrictive device manufacture/assemblyThin membranePiezoelectric thin films

The invention relates to a preparation method of a flexible piezoelectric film. The preparation method of the flexible piezoelectric film comprises the following steps: S1, weighing raw materials; s2, weighing a solvent; s3, heating in a water bath and dissolving; s4, patterning the mixed solution on a flexible substrate by adopting a silk-screen printing, spin-coating or coating process to form a film, firstly baking for 20-60 minutes at the temperature of 40-80 DEG C, then baking for 20-60 minutes at the temperature of 80-120 DEG C, and finally annealing for 0.5-8 hours at the temperature of 120-140 DEG C to obtain a flexible piezoelectric film semi-finished product; and S5, the annealed flexible piezoelectric film semi-finished product is polarized in the air at normal temperature, the polarization voltage is 10-35 MV / cm, the time is 1-60 min, and a flexible piezoelectric film finished product is obtained. The piezoelectric film with the high piezoelectric constant is prepared through the mixed solvent with the high boiling point and the low boiling point, and the requirement of a piezoelectric film sensor for the piezoelectric constant is met.

Owner:SUZHOU LEANSTAR ELECTRONICS TECH

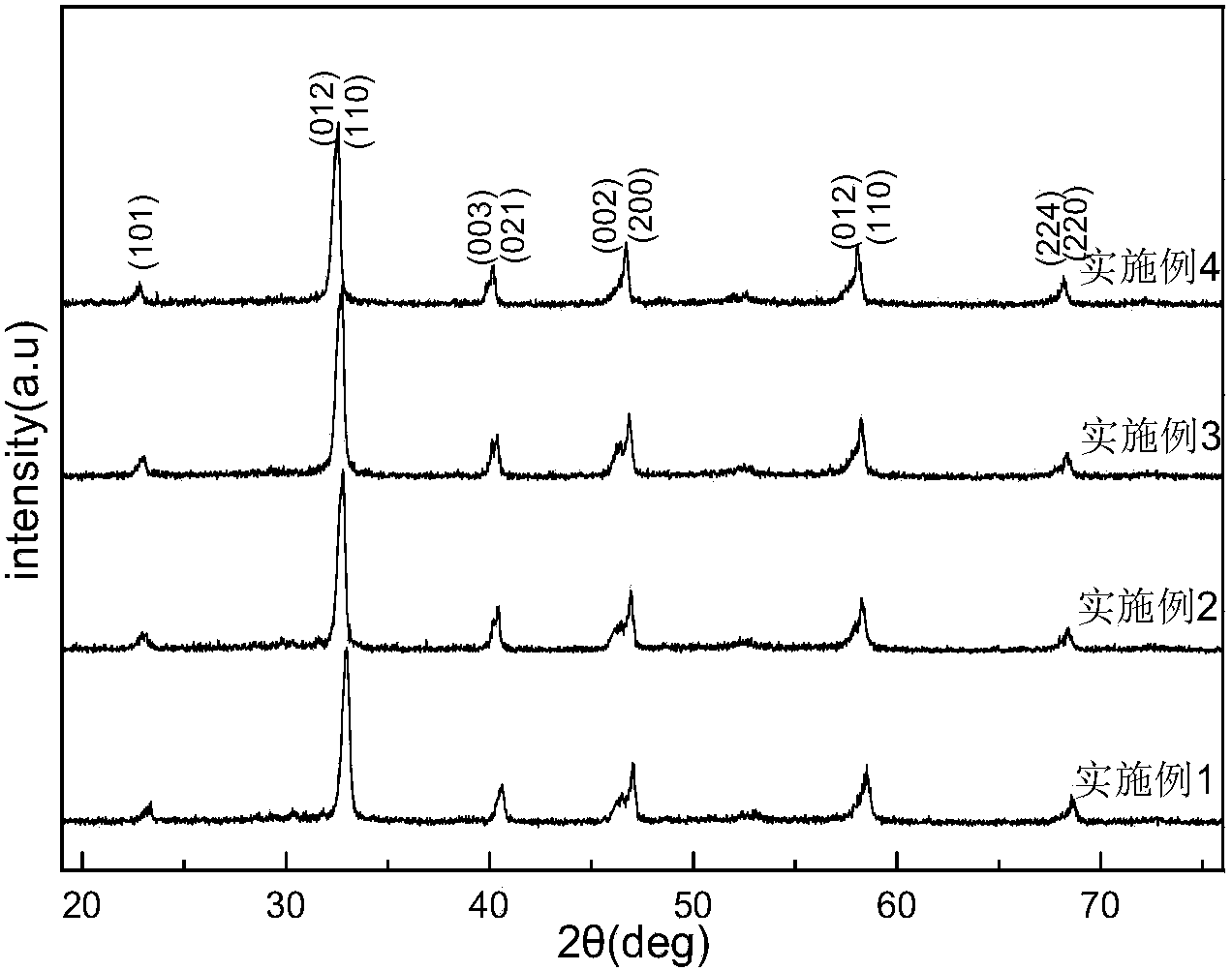

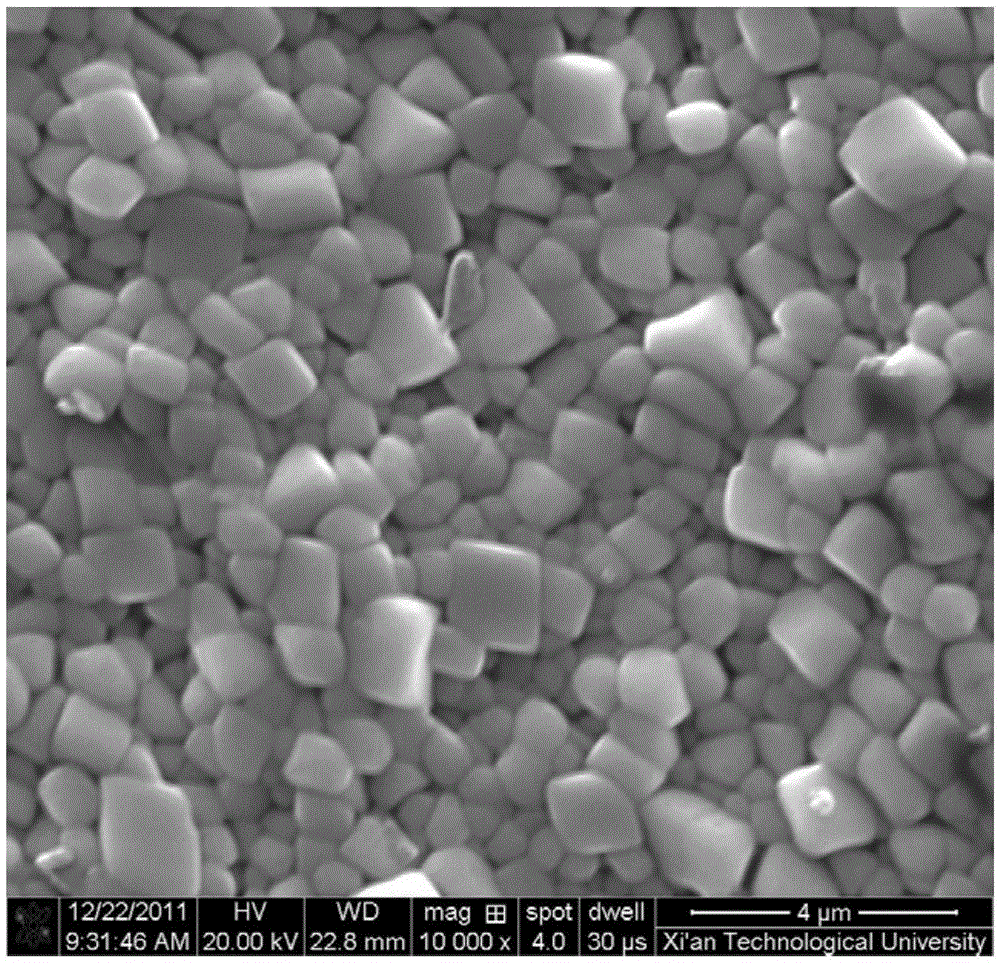

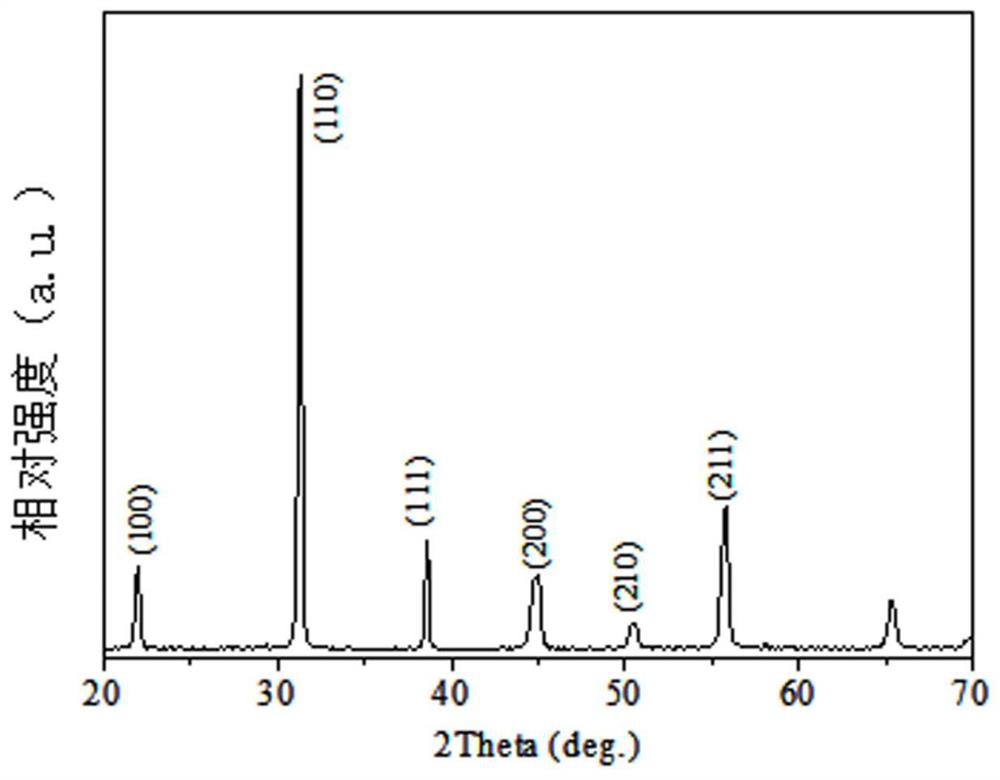

A kind of solid solution modified sodium bismuth titanate series lead-free piezoelectric ceramics and preparation method thereof

ActiveCN103833354BExcellent piezoelectric propertiesHigh electromechanical coupling coefficientElectromechanical coupling coefficientSodium bismuth titanate

The invention provides solid solution-modified sodium bismuth titanate leadless piezoelectric ceramics and a preparation method thereof. The piezoelectric ceramics are represented by chemical composition general formula of (1-x)(0.74Na0.5Bi0.5TiO3-0.26SrTiO3)-xBa(Zr0.05Ti0.95)O3 or (1-y)(0.9Na0.5Bi0.5TiO3-0.1CaTiO3)-yBa(Zr0.05Ti0.95)O3, wherein 0.04<=x<=0.1 and 0.04<=y<=0.1. Solid solution of Ba(Zr0.05Ti0.95)O3 is realized at the morphotropic phase boundary of a 0.74Na0.5Bi0.5TiO3-0.26SrTiO3 and 0.9Na0.5Bi0.5TiO3-0.1CaTiO3 system, and high-density microcrystalline structure ceramics with uniform crystal grain size distribution are obtained by a two-step forming method and a self-bearing pressure sintering process. The piezoelectric property of the material is optimized by the morphotropic phase boundary composition characteristics and the solid solution modification method, and the piezoelectric constant d33 reaches 110-138 PC / N; the electromechanical coupling coefficient of the material is also increased obviously; the preparation process of the material is simple and stable, and the material is an optimal material for manufacturing low-power ultrasonic devices and energy transducers used in fields of gas sensors, industrial nondestructive test, and the like.

Owner:XIAN UNIV OF SCI & TECH

A kind of sodium potassium niobate-based lead-free piezoelectric ceramic and preparation method thereof

The invention discloses a sodium-potassium niobate-based lead-free piezoelectric ceramic and a preparation method thereof. The chemical formula of the potassium-sodium niobate-based piezoelectric ceramic is (1-x)(K 0.5 Na 0.5 )NbO 3 ‑xBi(Li 0.5 Sb 0.5 )O 3 , where 0.01≤x≤0.20. According to the stoichiometric ratio (1‑x) (K 0.5 Na 0.5 )NbO 3 ‑xBi(Li 0.5 Sb 0.5 )O 3 The weighed and dried raw materials are mixed and then ball-milled and dried to obtain a mixed material; the obtained mixed material in step 1 is pre-burned at a high temperature to obtain a pre-burned powder, and then ball-milled and dried for a second time to obtain a secondary ball-milled powder; Add binder to the powder for granulation, and then sieve and then press and shape to obtain a ceramic blank; remove the organic binder and then sinter at high temperature to obtain a sintered ceramic; the two surfaces of the sintered ceramic are polarized by silver and high pressure , the sodium potassium niobate-based lead-free piezoelectric ceramics were obtained. Through component design and process optimization, the sintering characteristics of sodium potassium niobate-based ceramics are effectively improved, the volatilization of sodium and potassium elements is inhibited, the porosity is reduced, the density of ceramics is improved, and the dielectric constant is increased, the loss is reduced, and the Comprehensive properties of KNN-based ceramics.

Owner:XI AN JIAOTONG UNIV

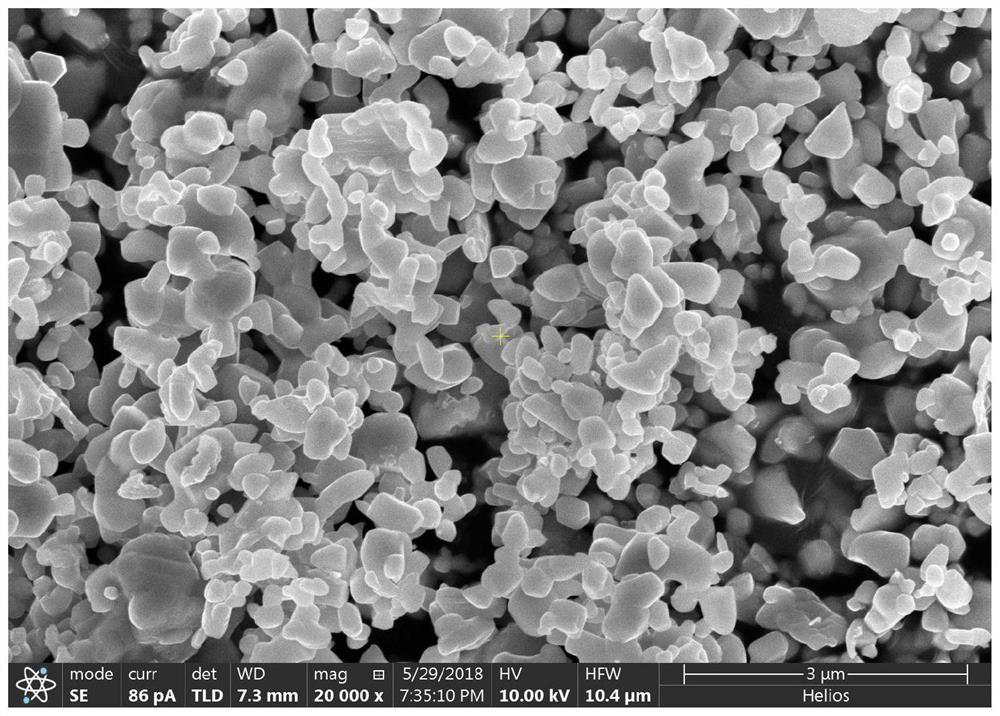

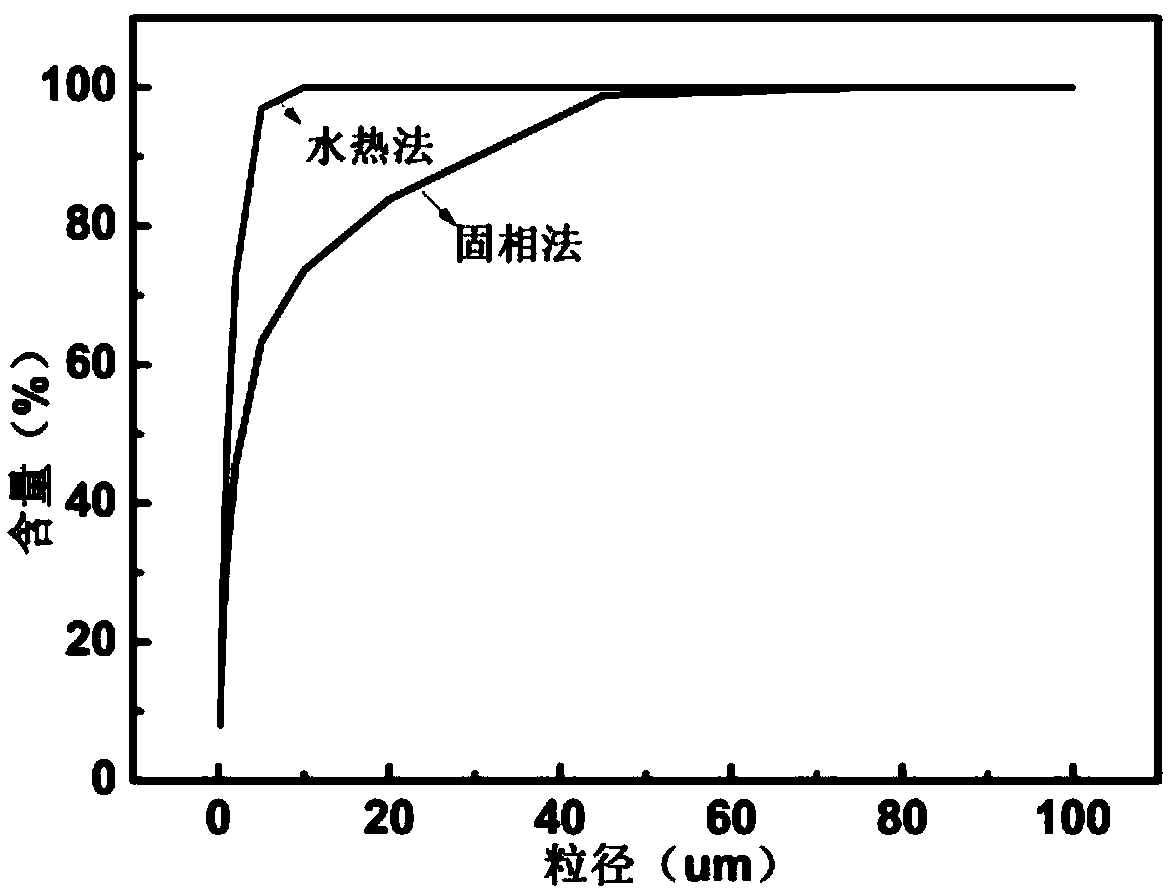

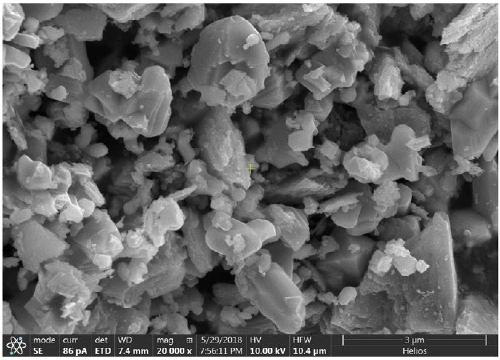

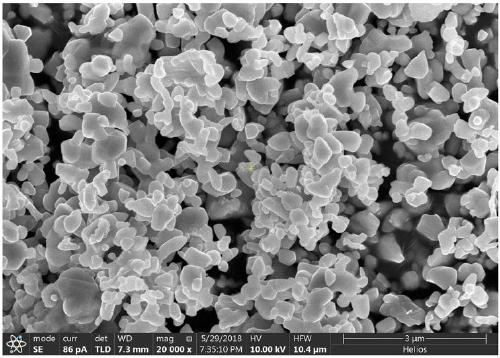

Preparation process of a high-performance piezoelectric ceramic

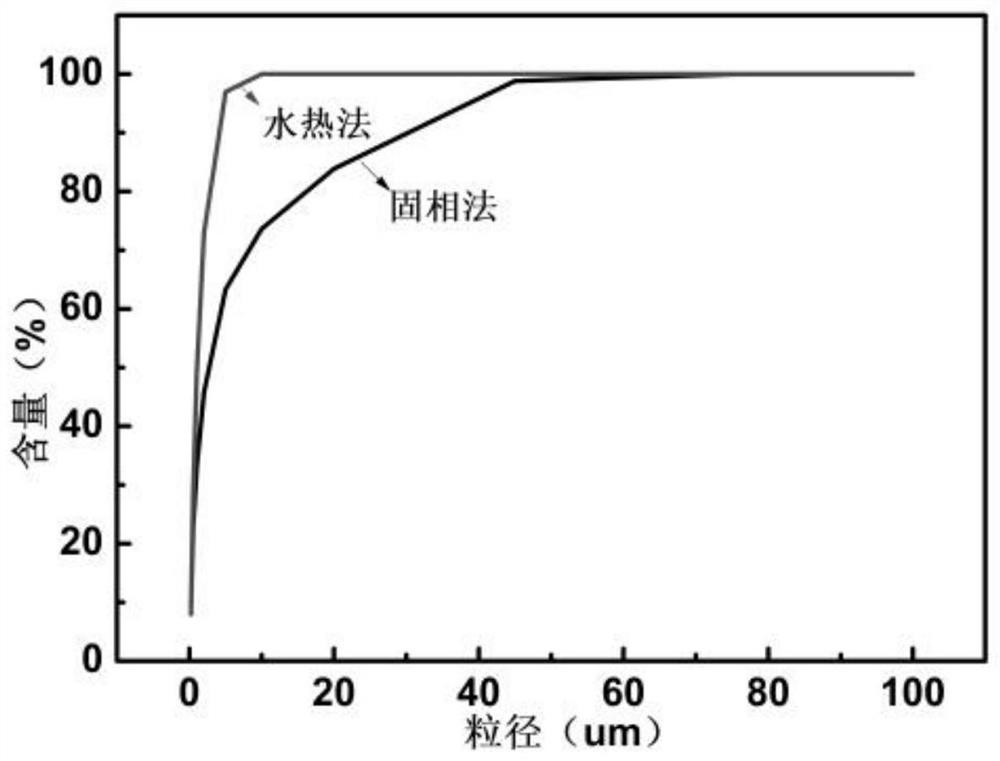

ActiveCN109020499BEvenly distributedSmall particle sizePiezoelectric/electrostrictive/magnetostrictive devicesOXALIC ACID DIHYDRATESlurry

Owner:GUIZHOU UNIV

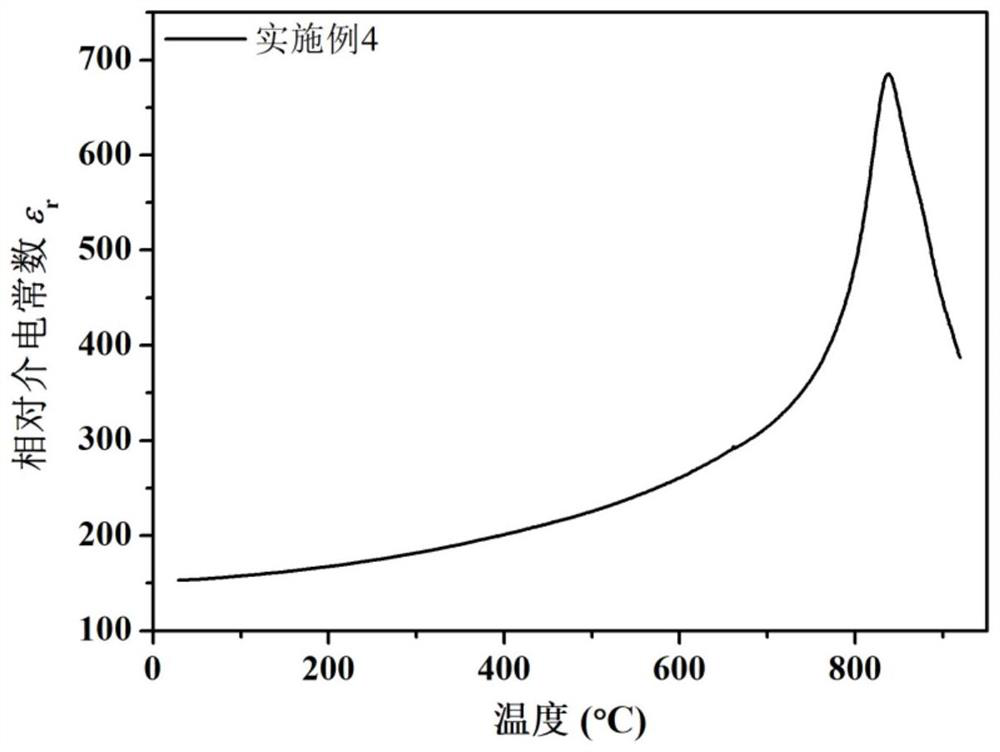

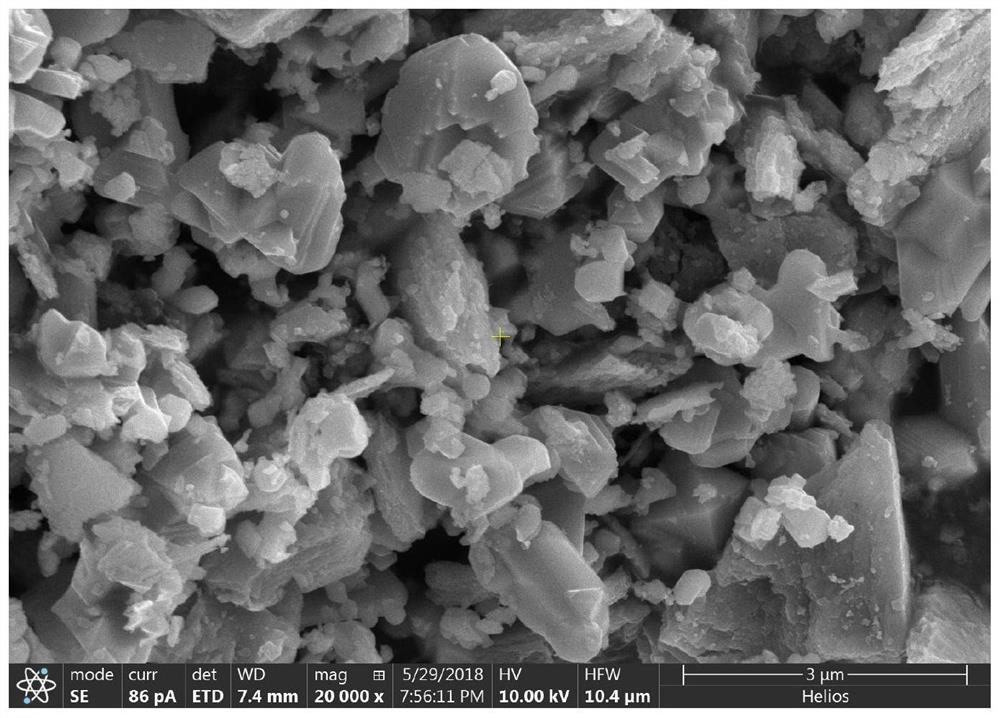

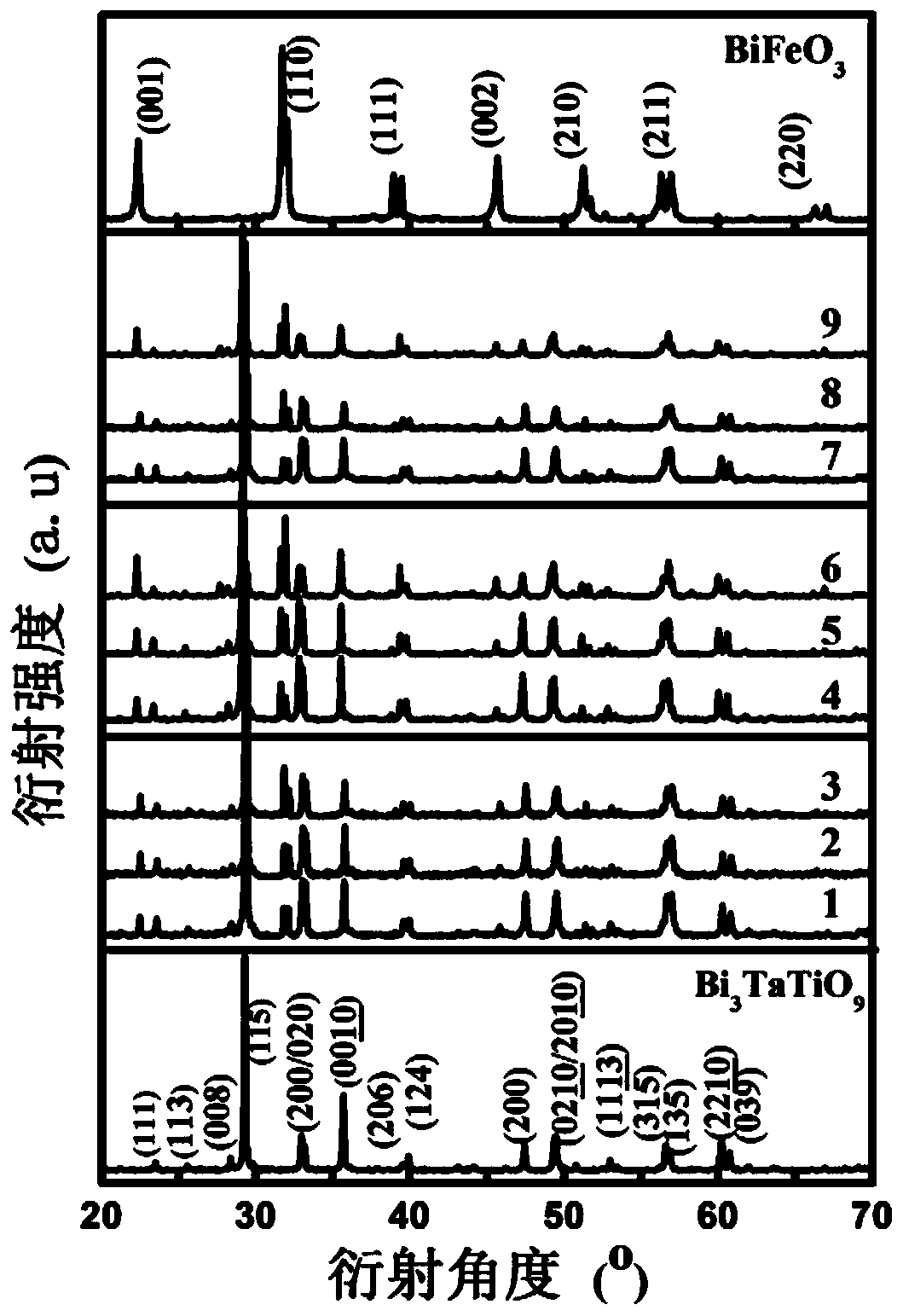

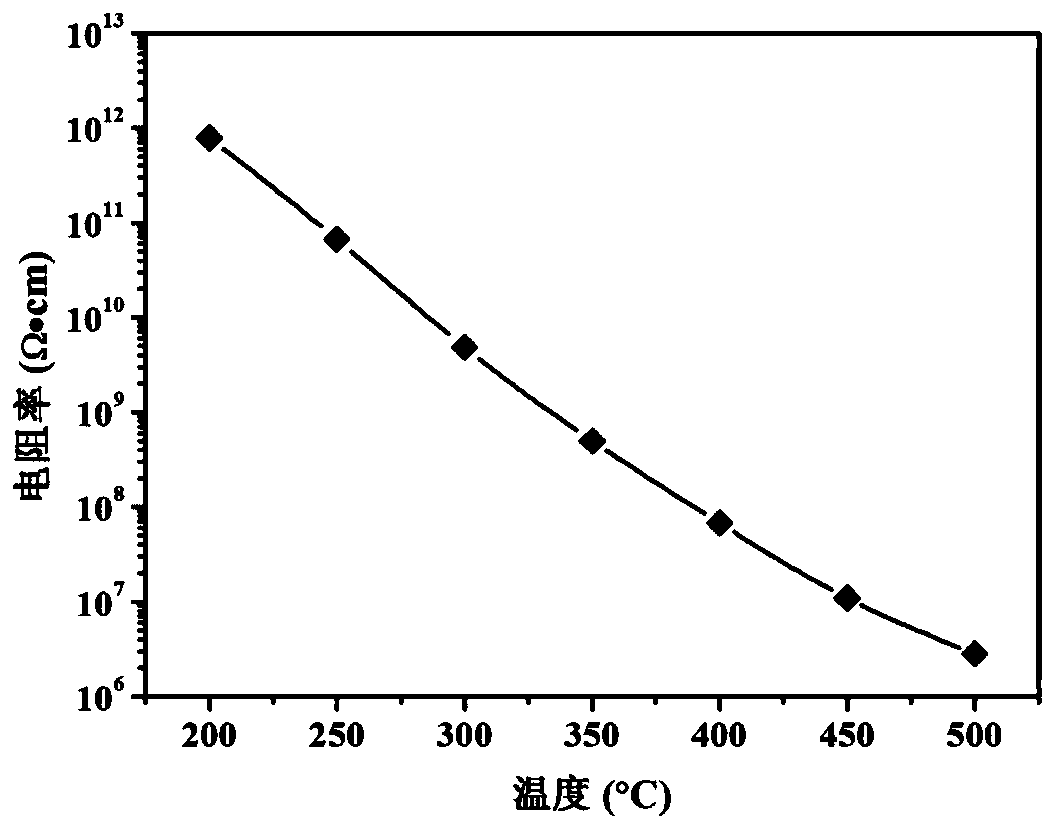

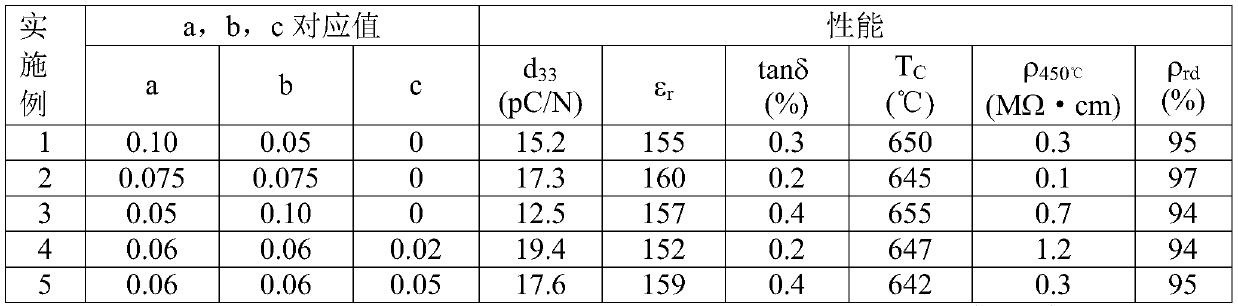

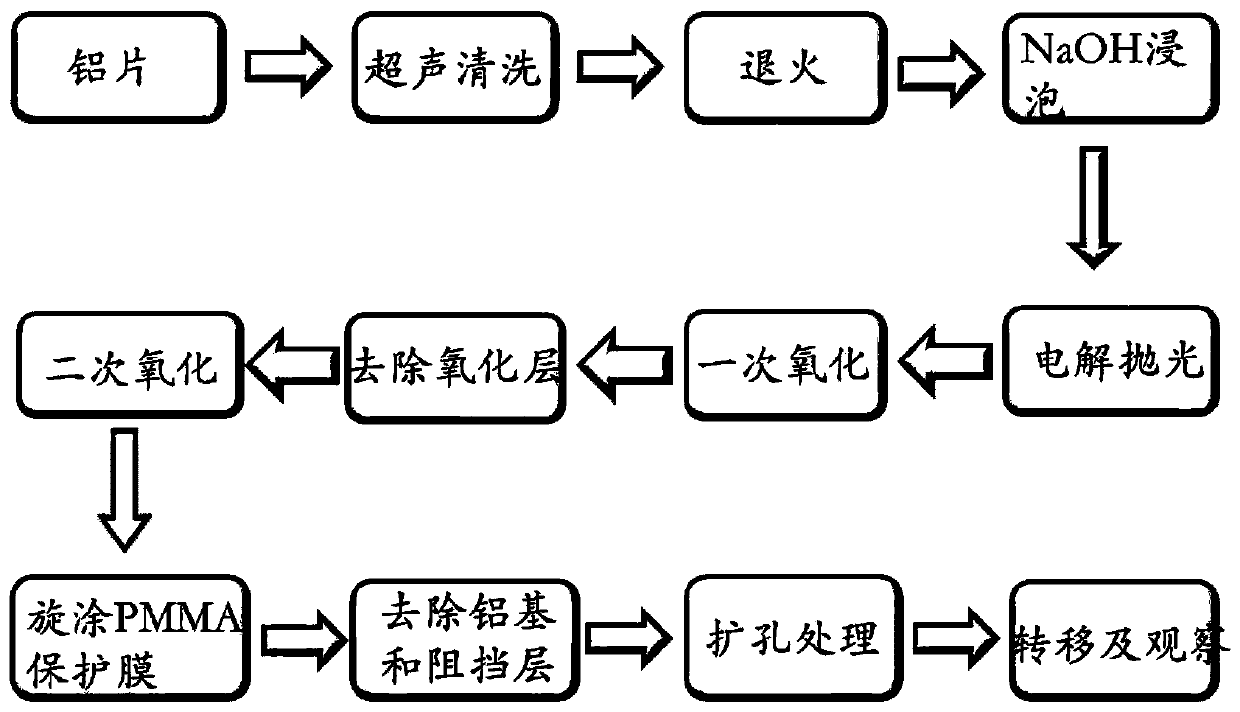

A composite high temperature piezoelectric ceramic material

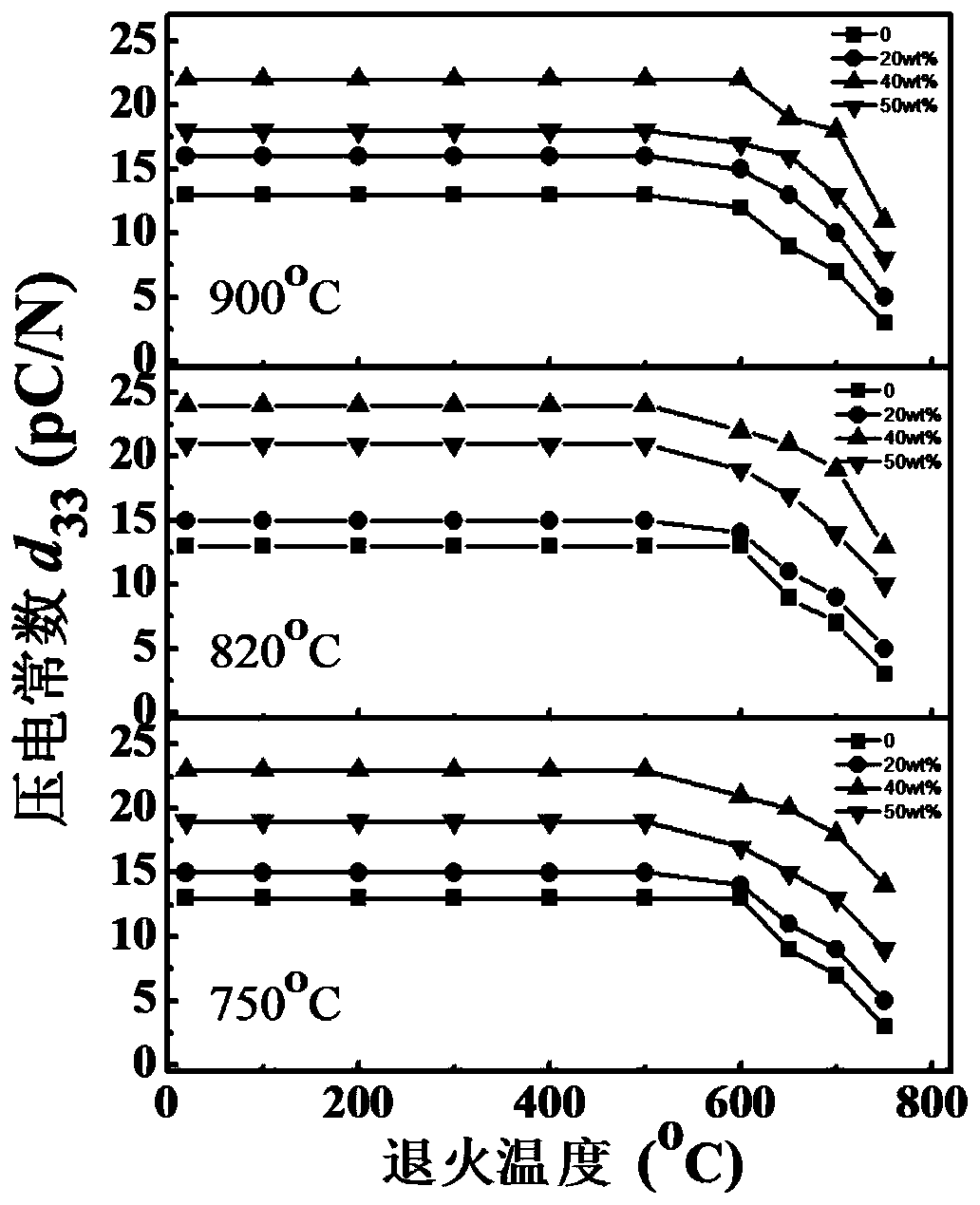

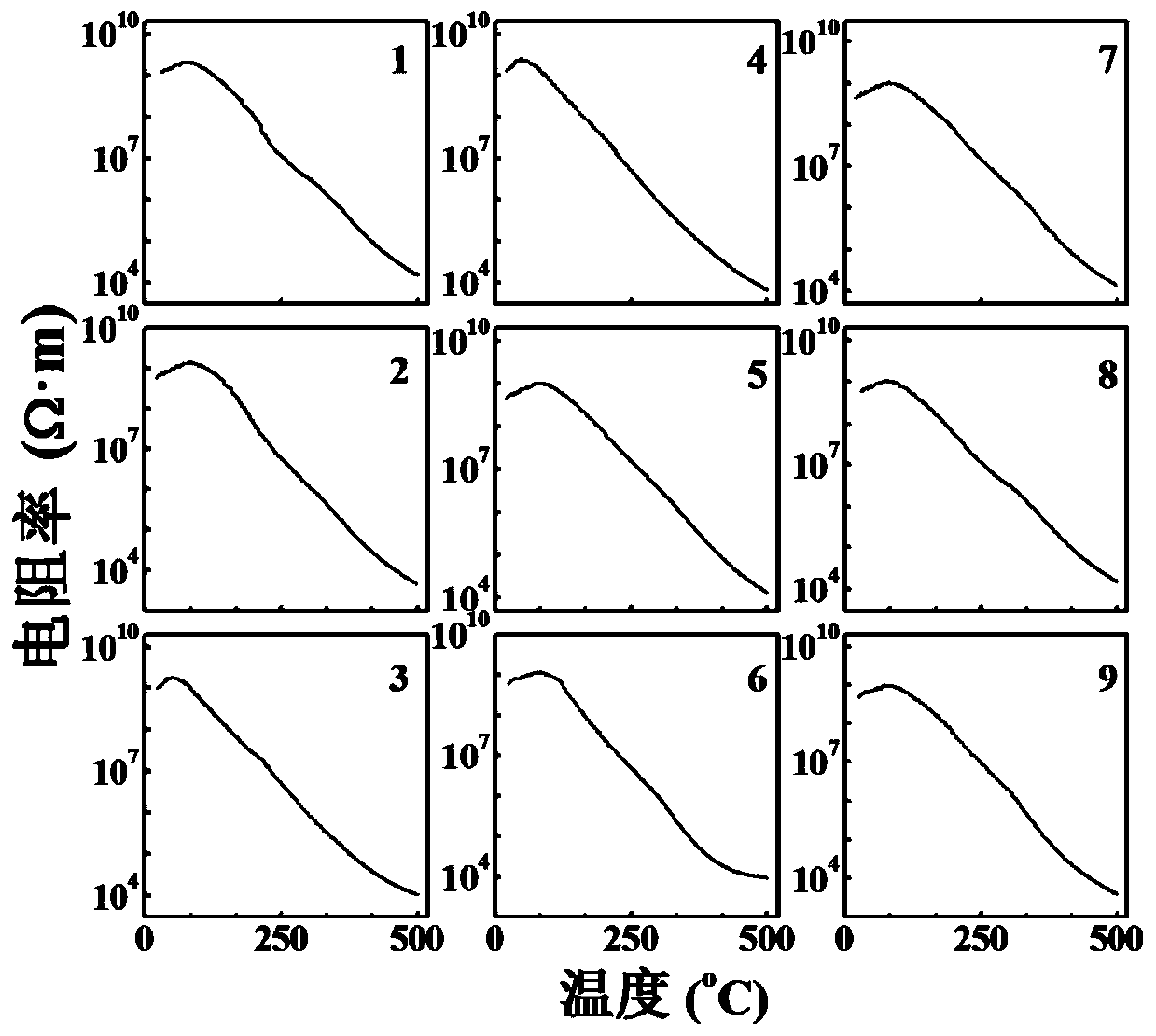

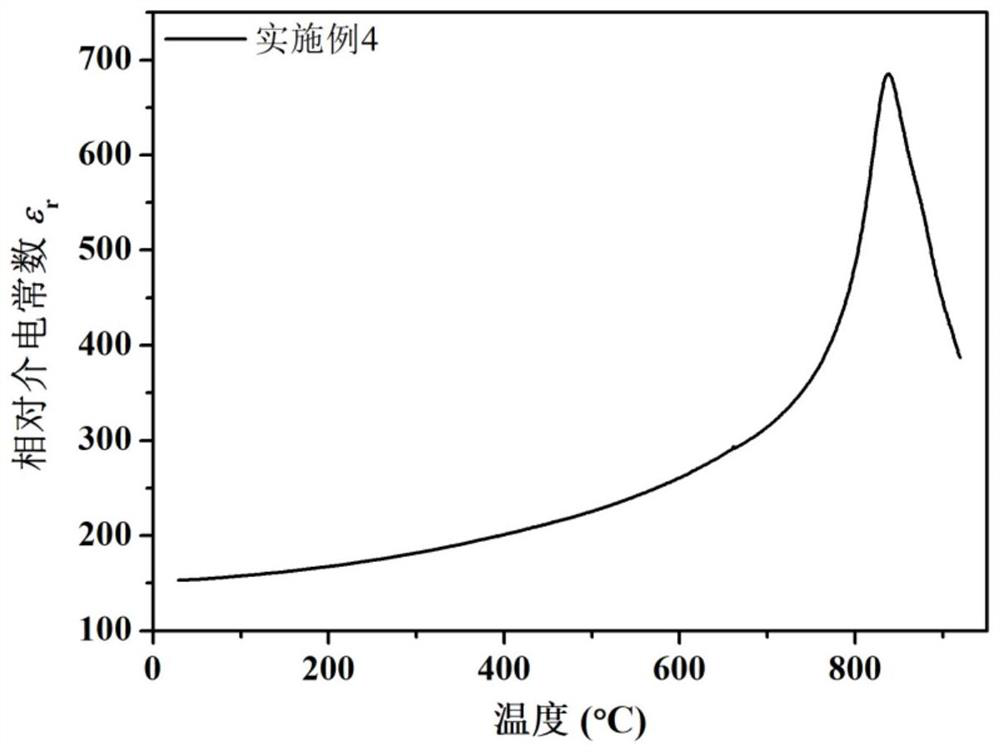

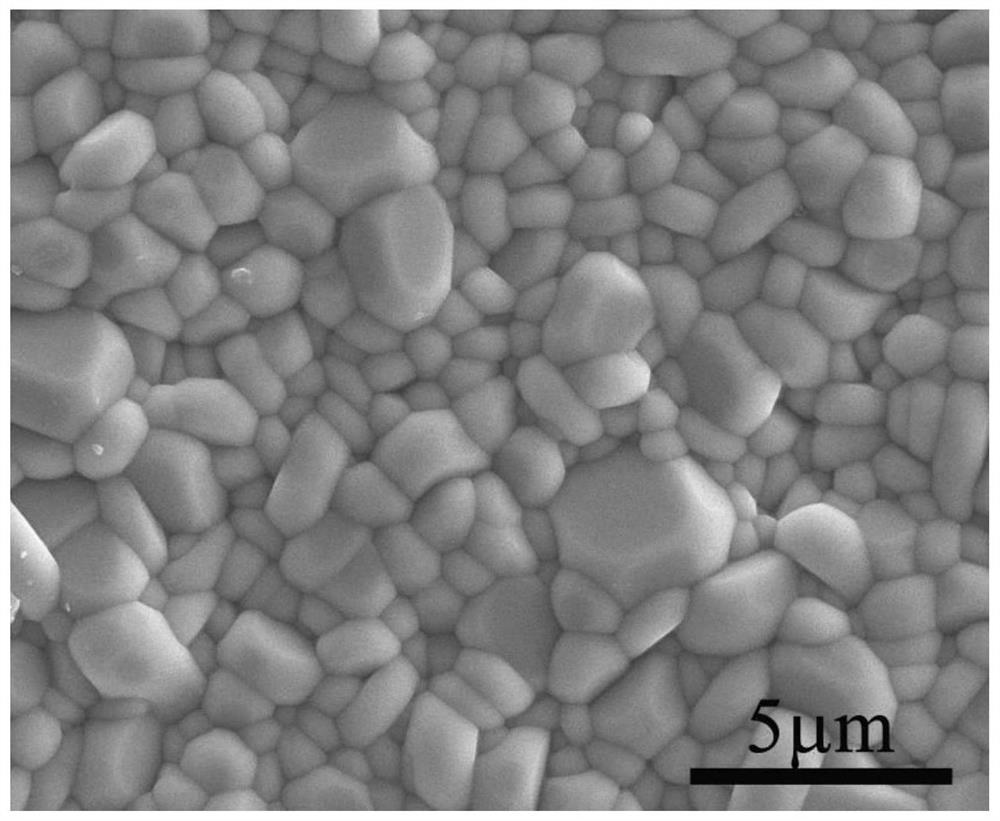

ActiveCN107244913BHigh piezoelectric constantHigh resistivityPiezoelectric/electrostrictive/magnetostrictive devicesComposite ceramicPiezoelectric actuators

The invention discloses a composite high-temperature piezoelectric ceramic material. The ceramic material composition is represented by the general formula Bi 3 tO 9 ‑xBiFeO 3 to represent, where x is BiFeO 3 with Bi 3 tO 9 weight percentage, and x=20wt%~50wt%. The preparation process of the materials is as follows: first, Bi is synthesized separately 3 tO 9 Powder and BiFeO 3 powder, and then Bi 3 tO 9 Ceramic powder and BiFeO 3 Ceramic powder is ball milled, mixed and sintered into porcelain. Piezoelectric constant d of the composite high-temperature piezoelectric ceramic material of the present invention 33 Reaching 24pC / N, it is single-phase Bi 3 tO 9 1.8 times that of ceramic materials. It has a large resistivity in a high temperature environment of 500℃, and ρ is about 10 4 Ω·m. The composite ceramic material of the present invention is suitable for preparing piezoelectric actuators and piezoelectric sensors used in high-temperature environments.

Owner:NANJING UNIV OF SCI & TECH

A rare earth-doped high Curie temperature piezoelectric ceramic element and its preparation method

ActiveCN112125669BHigh piezoelectric constantLong-term useSubsonic/sonic/ultrasonic wave measurementUsing electrical meansCurie temperatureComposite material

The invention discloses a rare-earth-doped high-Curie-temperature piezoelectric ceramic element. The general chemical formula of the rare-earth-doped high-Curie-temperature piezoelectric ceramic element is: (1‑x‑y)CaBi 2 Ta 2‑a Nb a o 9 +xNa 0.5‑b K b Bi 2.5 Nb 2 o 9 +ySrBi 2 Nb 2‑c Sb c o 9 +zwt%P, where, 0.05≤x≤0.85, 0≤y≤0.1, 0 <a≤0.2,0<b≤0.2,0<c≤0.1,0<z<5,p为coo和mnco3. A combination of one or two sintering aids. The invention also discloses a method for preparing the piezoelectric ceramic element. The piezoelectric ceramic element prepared by the invention has the advantages of high Curie temperature and low aging rate.< / a≤0.2,0<b≤0.2,0<c≤0.1,0<z<5,p为coo和mnco

Owner:NAT UNIV OF DEFENSE TECH

Piezoelectric body, manufacturing method thereof, piezoelectric element having piezoelectric body, inkjet head and inkjet type recording device

InactiveCN1514808BHigh piezoelectric constantImprove reliabilityPiezoelectric/electrostrictive device manufacture/assemblyZirconium compoundsCrystal structureEngineering

In a piezoelectric element comprising a first electrode (2) provided on a substrate (1), a piezoelectric material (3) provided on the first electrode (2) and a second electrode (4) provided on the piezoelectric material (3), the piezoelectric material (3) is configured so as to have a perovskite type crystal structure which is represented by a formula ABO3 and in which the main component for the A site is Pb and the main components for the B site are Zr, Ti and Pb, and configured so that a ratio of Pb atoms to all atoms in the B site is more than 3% and not more than 30%. Namely, the piezoelectric material (3) is formed so as to contain Pb excessively and the excess Pb atoms are activated to be Pb<4+> during formation of the piezoelectric material (3) and then introduced into the B site.

Owner:PANASONIC CORP

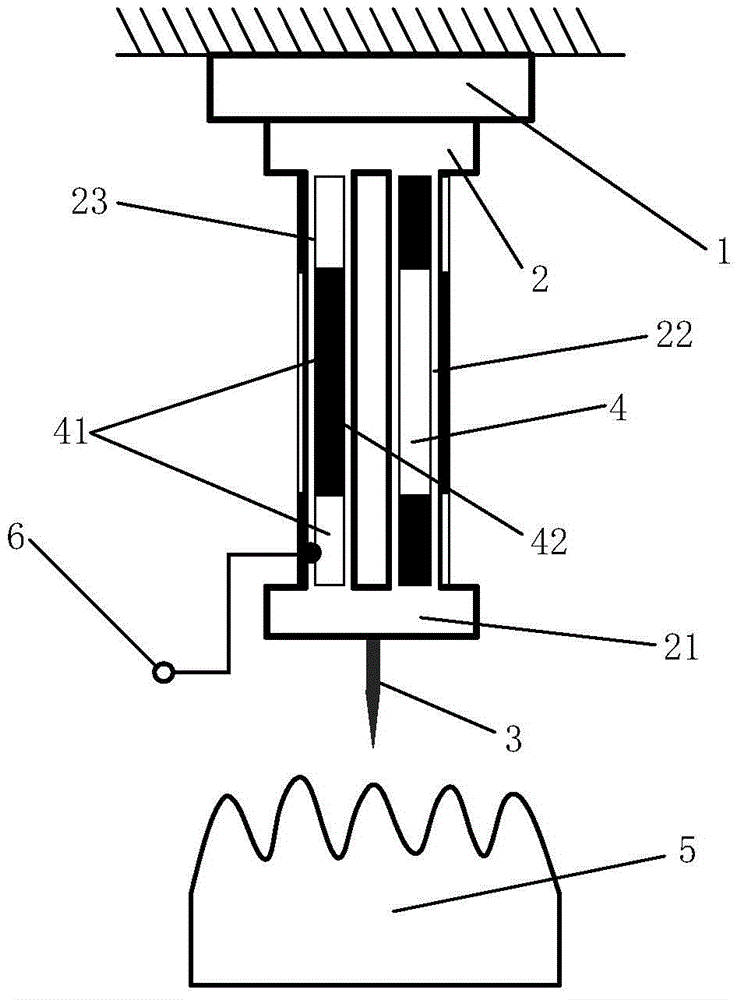

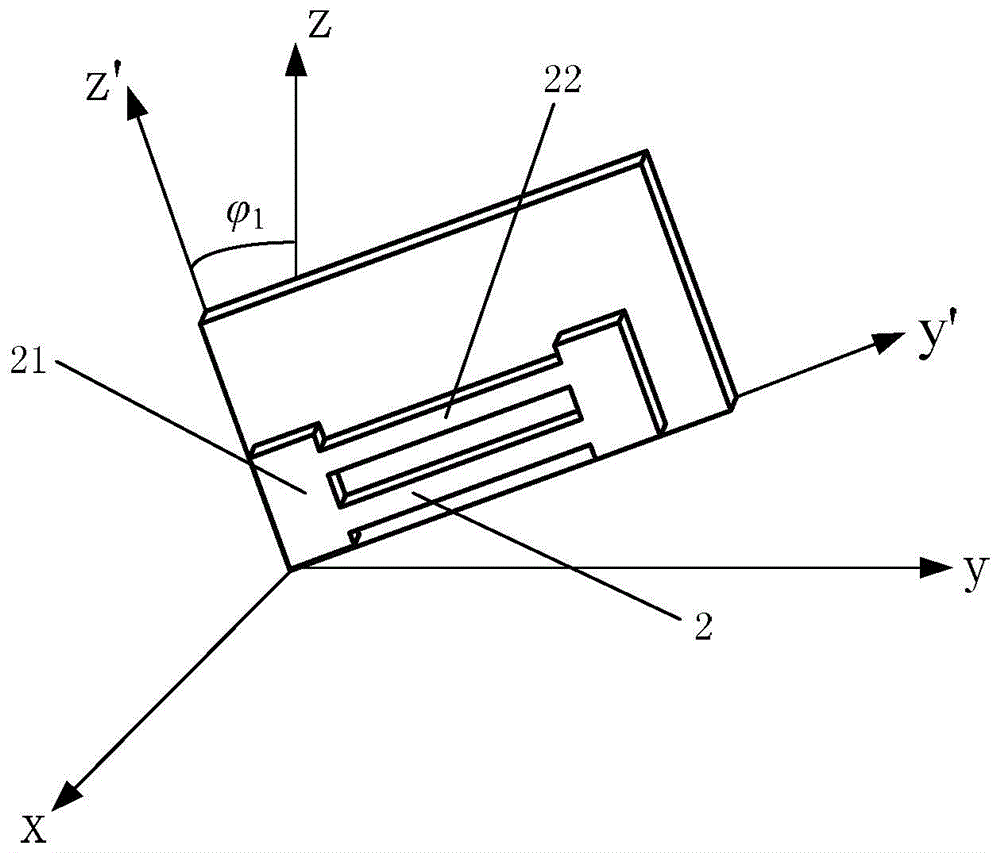

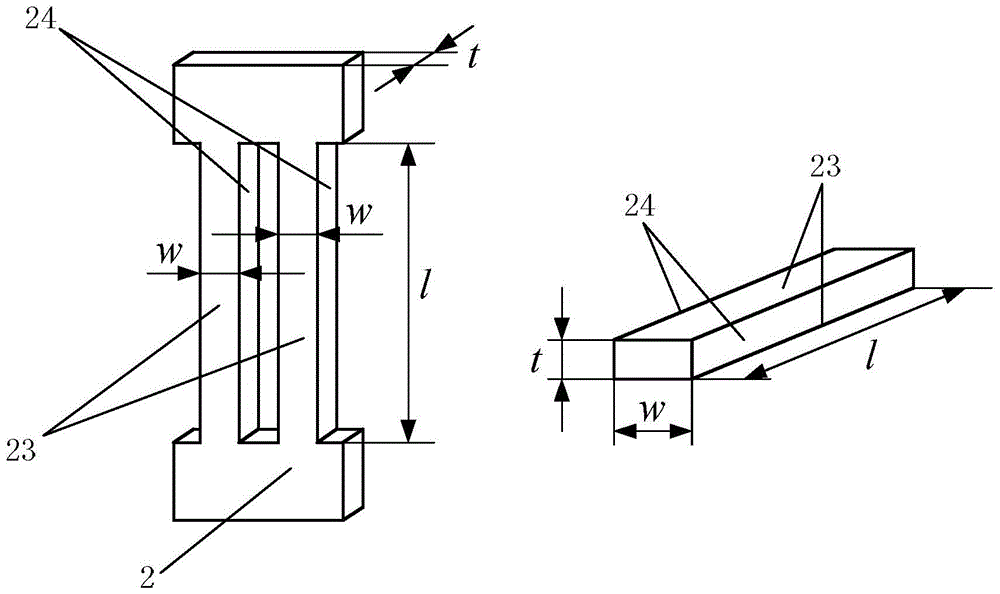

Double-ended tuning fork scanning probe probe system and its measurement method

ActiveCN104020317BRealize scanning measurementImprove sensitivityScanning probe microscopyNon destructiveTuning fork

The invention discloses a double-end tuning fork scanning probe measurement head system and a measurement method of the double-end tuning fork scanning probe measurement head system. The double-end tuning fork scanning probe measurement head system is composed of a rigidity support, a double-end tuning fork and a tungsten tipped probe. The rigidity support is a rigidity supporting piece of the whole scanning probe measurement head system and is used for fixing a whole measurement head mechanism and forming whole constraint on one fork end of the double-end tuning fork. One fork end of the double-end tuning fork is connected to the bottom face of the rigidity support, the other fork end of the double-end tuning fork serves as a free end, and the tungsten tipped probe with the large draw ratio is fixedly arranged in the middle of the bottom face below the free end. Electrodes are placed according to a periphery partition method and two fork arms of the double-end tuning fork are stimulated to be bent and vibrate in an opposite-phase mode in the thickness direction. The tungsten tipped probe is in contact with a sample in a touched mode in the vertical Z direction and changes of resonance signals of the fork arms are detected to express the touch degree of the tip end of the tungsten tipped probe and the surface of the sample. The double-end tuning fork scanning probe measurement head system can be used for high-resolution and non-destructive measurement on the surfaces of flexible materials and the like and surface appearance scanning on micro-devices such as micro-grooves and micro-steps with large depth-to-width ratios.

Owner:HEFEI UNIV OF TECH

Piezoelectric ceramics and its preparation method, piezoelectric ceramic element and its preparation method

ActiveCN107382310BImprove piezoelectric performancePiezoelectricity deteriorationPiezoelectric/electrostrictive device manufacture/assemblyBall millMetal salts

The invention discloses a piezoelectric ceramic and a preparation method thereof, a piezoelectric ceramic element and a preparation method thereof. The main chemical formula of the piezoelectric ceramic is: (Na 0.5 Bi 0.5 ) 1‑a‑b+c (Li 0.35 K 0.15 Ho 0.5 ) a (Li 0.35 K 0.15 Er 0.5 ) b Bi 4 Ti 4‑x‑ y V x Mo y o 15 , where 0.05≤a≤0.20, 0.05≤b≤0.20, 0≤c≤0.05, 0≤x≤0.05, 0≤y≤0.05. The preparation method includes: (1) according to the stoichiometric ratio of the metal elements in the general formula of the main components, respectively weigh the corresponding metal oxides or metal salts, mix them, pre-ball mill, dry, and pre-sinter to obtain pre-sintered Piezoelectric ceramic powder; (2) ball milling and drying the pre-sintered piezoelectric ceramic powder, then adding binder, molding, plastic discharge, and sintering to obtain piezoelectric ceramics. The piezoelectric ceramic element prepared by the piezoelectric ceramic has the advantages of high Curie temperature, high piezoelectric constant, excellent piezoelectric performance and high temperature stability, and the like.

Owner:NAT UNIV OF DEFENSE TECH

A method for growing lead zirconate titanate (pzt) nanorings using pulsed laser deposition

ActiveCN108018523BCause some damagesSimple processMaterial nanotechnologyVacuum evaporation coatingLead zirconate titanateDeposition temperature

The invention discloses a method for growing lead zirconate titanate (PZT) nanorings by using the pulsed laser deposition (PLD) technology. The PLD method is used, and preparation of the PZT nanoringsis realized by precisely controlling the deposition temperature, the annealing temperature, annealing time, the number of laser pulses, oxygen pressure and other parameters. The method can be used for preparing regularly arrayed PZT nanorings, parameter control is simple and convenient, repeatability is high, and no toxic and harmful exhaust gas is emitted. The method provides a possibility for the application of high-density ferroelectric memory devices in the future.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Potassium-sodium niobate-based leadless piezoelectric ceramic with high piezoelectric constant and preparation method of potassium-sodium niobate-based leadless piezoelectric ceramic

The invention discloses potassium-sodium niobate-based leadless piezoelectric ceramic with a high piezoelectric constant. The chemical composition of the potassium-sodium niobate-based leadless piezoelectric ceramic with the high piezoelectric constant is (1-x)(K<0.5>Na<0.5>)Nb<1-y>Sb<y>O<3>+xCuZr<0.5>Ti<0.5>O<3>, x and y are mole percentages, 0<=x<=0.4, and 0.01<=y<=0.2. According to the potassium-sodium niobate-based leadless piezoelectric ceramic with the high piezoelectric constant and the preparation method thereof, doping modification is carried out by adopting copper, antimony, zirconium and titanium elements, so that charge and vacancy compensation is realized, the piezoelectric constant is improved, and the piezoelectric sensitivity of the leadless piezoelectric ceramic is improved. The potassium-sodium niobate-based leadless piezoelectric ceramic adopted by the invention has a high piezoelectric constant, the application scene of the leadless piezoelectric ceramic is greatlybroadened, and meanwhile, the leadless piezoelectric ceramic is green and environment-friendly, so that the damage to human health and the environment can be effectively reduced.

Owner:YANGTZE DELTA REGION INST OF TSINGHUA UNIV ZHEJIANG +1

Preparation process of high-performance piezoelectric ceramic

The invention discloses a preparation process of a high-performance piezoelectric ceramic. The process comprises the following steps of (1) taking a piezoelectric ceramic raw material; (2) charging the piezoelectric ceramic raw material into a ball milling tank for sufficient mixing and ball milling; then, putting the slurry obtained after the ball milling into a drying box to be dried so as to obtain powder; (3) adding water into powder; then, adding any one or several kind of materials inof ammonium hydroxide, lemon acid or oxalic acid or a composition of several kinds of materials from ammonium hydroxide, lemon acid or oxalic acid; then, performing heating for hydrothermal treatment; drying the powder after the hydrothermal treatment; obtaining to obtain the piezoelectric ceramic raw material powder; (4) treating the piezoelectric ceramic raw material powder obtained in step (3) by a conventional piezoelectric ceramic treatment process to obtain the high-performance piezoelectric ceramic. The preparation process has the characteristics that the prepared piezoelectric ceramic has good performance; the raw material consumption is low; the cost is low; the pollution is low; the process is simple; the process stability is high.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com