Piezoelectric ceramics and its preparation method, piezoelectric ceramic element and its preparation method

A piezoelectric ceramic element, piezoelectric ceramic technology, applied in the manufacture/assembly of electrical components, piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric/electrostrictive devices, etc., can solve the difficult to meet the working environment temperature, lowering the Curie temperature of the system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

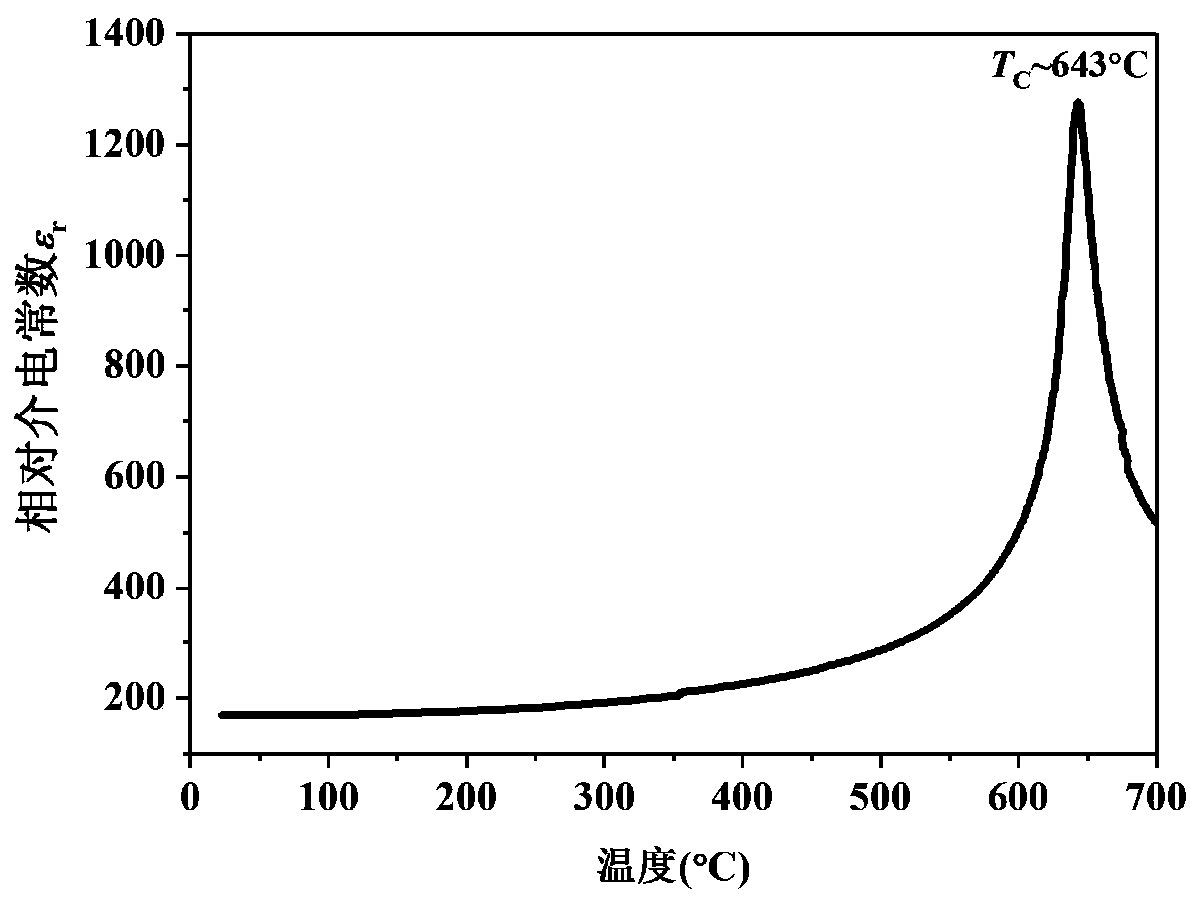

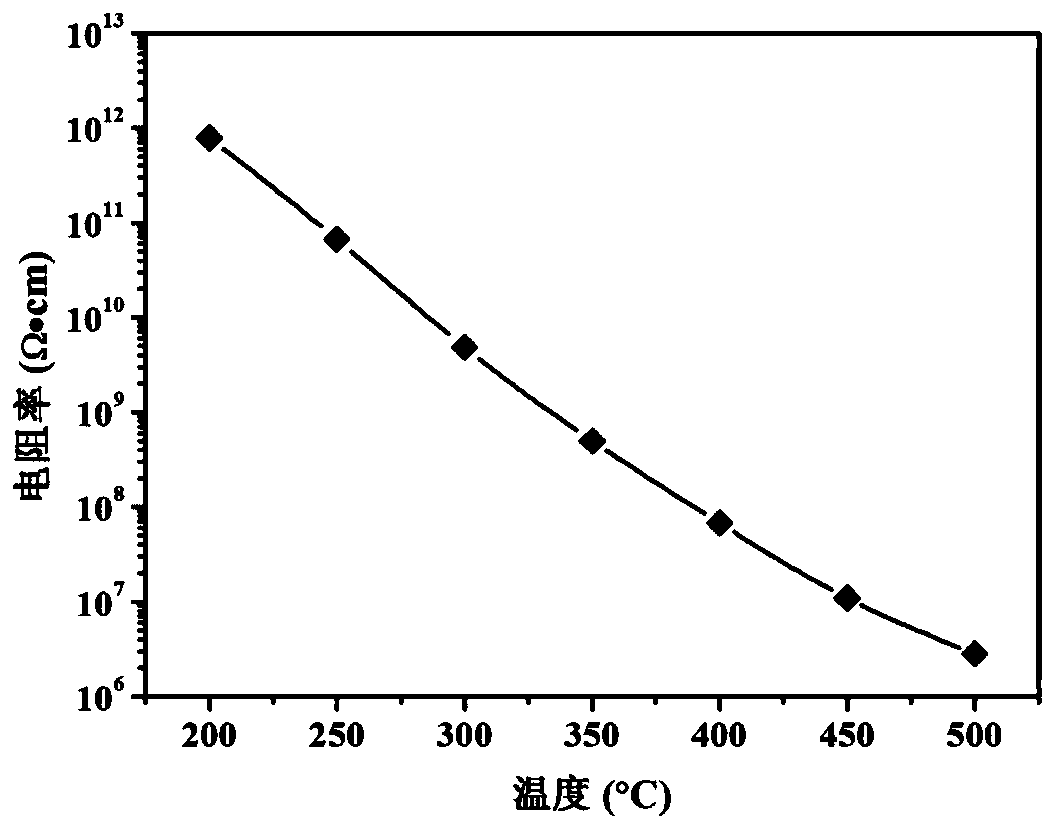

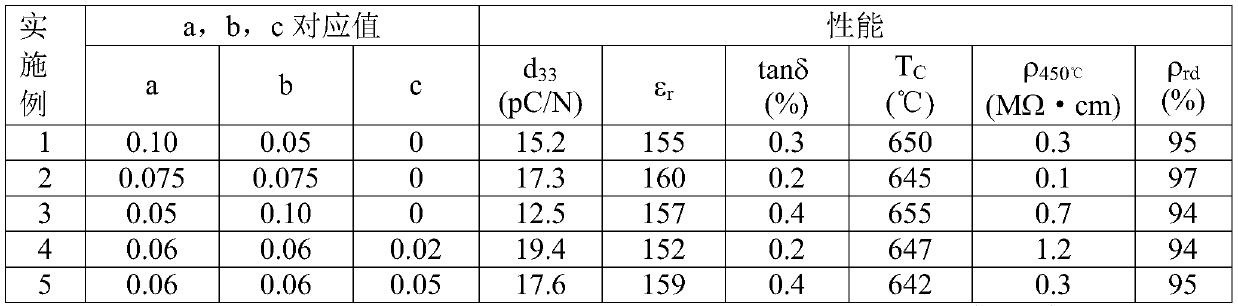

[0029] A kind of piezoelectric ceramic of the present invention, its general chemical formula is: (Na 0.5 Bi 0.5 ) 1-a-b+c (Li 0.35 K 0.15 Ho 0.5 ) a (Li 0.35 K 0.15 Er 0.5 ) b Bi 4 Ti 4 o 15 , where 0.05≤a≤0.20, 0.05≤b≤0.20, 0≤c≤0.05.

[0030] A preparation method of the above-mentioned piezoelectric ceramics of the present embodiment, comprising the following steps:

[0031] (1) According to the general chemical formula (Na 0.5 Bi 0.5 ) 1-a-b+c (Li 0.35 K 0.15 Ho 0.5 ) a (Li 0.35 K 0.15 Er 0.5 ) b Bi 4 Ti 4 o 15 The stoichiometric ratio of the metal elements in 2 CO 3 (premium pure), Li 2 CO 3 (high purity), K 2 CO 3 (high purity), Bi 2 o 3 (high purity), TiO 2 (electronic grade), Ho 2 o 3 (high purity), Er 2 o 3 (high purity) put into a planetary ball mill jar made of nylon, use agate balls as a medium, deionized water or absolute ethanol as a dispersant, and ball mill for 18 hours. The ball-milled mixture is dried in a constant tempe...

Embodiment 1

[0037] A kind of piezoelectric ceramic of the present invention, its chemical formula is: (Na 0.5 Bi 0.5 ) 0.85 (Li 0.35 K 0.15 Ho 0.5 ) 0.1 (Li 0.35 K 0.15 Er 0.5 ) 0.05 Bi 4 Ti 4 o 15 .

[0038] A preparation method of the above-mentioned piezoelectric ceramics of the present embodiment, comprising the following steps:

[0039] (1) According to the chemical formula (Na 0.5 Bi 0.5 ) 0.85 (Li 0.35 K 0.15 Ho 0.5 ) 0.1 (Li 0.35 K 0.15 Er 0.5 ) 0.05 Bi 4 Ti 4 o 15 The stoichiometric ratio of the metal elements in 2 CO 3 (premium pure), Li 2 CO 3 (high purity), K 2 CO 3 (high purity), Bi 2 o 3 (high purity), TiO 2 (electronic grade), Ho 2 o 3 (high purity), Er 2 o 3 (high purity) put into a planetary ball mill jar made of nylon, use agate balls as a medium, deionized water or absolute ethanol as a dispersant, and ball mill for 18 hours. The ball-milled mixture is dried in a constant temperature oven at 80°C, the dried powder is put into an a...

Embodiment 2

[0045] A kind of piezoelectric ceramic of the present invention, its chemical formula is: (Na 0.5 Bi 0.5 ) 0.85 (Li 0.35 K 0.15 Ho 0.5 ) 0.075 (Li 0.35 K 0.15 Er 0.5 ) 0.075 Bi 4 Ti 4 o 15 .

[0046] A preparation method of the above-mentioned piezoelectric ceramic of this embodiment is basically the same as that of Example 2, the only difference being that in step (2), the amount of binder added is 8wt of the quality of the pre-sintered piezoelectric ceramic powder %, the molding pressure is 200MPa, the sintering temperature is 1150°C, and the sintering time is 2 hours.

[0047] A piezoelectric ceramic element of the present invention includes the piezoelectric ceramic of the present embodiment above, and metal electrodes formed on the piezoelectric ceramic.

[0048] The above-mentioned preparation method of the piezoelectric ceramic element of this embodiment is basically the same as that of Embodiment 2, the only difference being:

[0049] The polarization te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com