Tin barium titanate calcium leadless piezoelectric ceramic and preparation technology thereof

A technology based on lead-free piezoelectric and barium tin titanate is applied in the field of lead-free piezoelectric materials, which can solve the problems of poor temperature stability and poor piezoelectric performance of lead-free piezoelectric ceramics, and achieve good temperature stability performance, The effect of good temperature stability and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

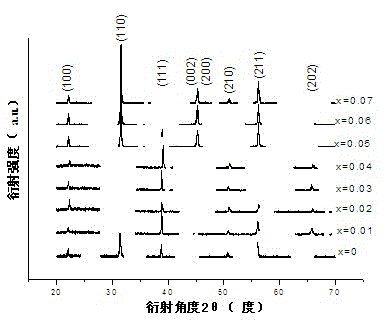

Image

Examples

Embodiment 1

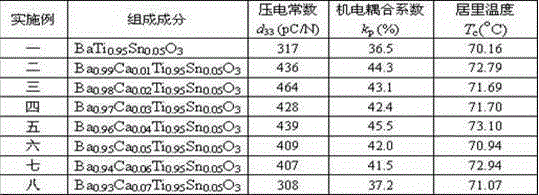

[0017] Embodiment one: The formula of this embodiment is Ba 1-x Ca x Ti 0.95 sn 0.05 o 3 ,in x =0.

[0018] Weigh raw materials according to the stoichiometric ratio of the formula: BaCO 3 , CaCO 3 , TiO 2 , SnO 2 . The so-called raw material powder is ball milled with deionized water as the medium for 10 hours, and the slurry obtained by ball milling is kept at 80°C for 8 hours. After drying the powder, it is pre-calcined at 1100°C for 4 hours to obtain BaTi 0.95 sn 0.05 o 3 Powder; add 5 wt% PVB to granulate, and press it into a disc with a diameter of 12mm and a thickness of 1mm under a pressure of 100MPa; after the ceramic body is fully degummed, it is sintered at 1400°C in air for 4 hours to prepare tin-titanium Barium calcium oxide based ceramics.

[0019] The obtained lead-free barium tin titanate-based piezoelectric ceramics were cleaned by silver electrodes after ultrasonic cleaning. At room temperature, it was polarized in silicone oil at 2kV / mm for 20m...

Embodiment 2

[0021] Embodiment two: The formula of this embodiment is Ba 1-x Ca x Ti 0.95 sn 0.05 o 3 ,in x =0.01.

[0022] Weigh raw materials according to the stoichiometric ratio of the formula: BaCO 3 , CaCO 3 , TiO 2 , SnO 2 . The so-called raw material powder is ball milled with deionized water as the medium for 10 hours, and the slurry obtained by ball milling is kept at 80°C for 8 hours. After drying the powder, it is pre-calcined at 1120°C for 4 hours to obtain Ba 0.99 Ca 0.01 Ti 0.95 sn 0.05 o 3 Powder; add 5 wt% PVB to granulate, and press it into a disc with a diameter of 12 mm and a thickness of 1 mm under a pressure of 100 MPa; after fully debinding the ceramic body, sinter it in air at 1430 ° C for 4 hours to prepare tin titanium Barium calcium oxide based ceramics.

[0023] The obtained lead-free barium tin titanate-based piezoelectric ceramics were cleaned by silver electrodes after ultrasonic cleaning. At room temperature, it was polarized in silicone oi...

Embodiment 3

[0025] Embodiment three: The formula of this embodiment is Ba 1-x Ca x Ti 0.95 sn 0.05 o 3 ,in x =0.02.

[0026] Weigh raw materials according to the stoichiometric ratio of the formula: BaCO 3 , CaCO 3 , TiO 2 , SnO 2 . The so-called raw material powder is ball milled with deionized water as the medium for 10 hours, and the slurry obtained by ball milling is kept at 80°C for 8 hours. After drying the powder, it is pre-calcined at 1130°C for 4 hours to obtain Ba 0.98 Ca 0.02 Ti 0.95 sn 0.05 o 3 Powder; add 5 wt% PVB to granulate, and press it into a disc with a diameter of 12 mm and a thickness of 1 mm under a pressure of 100 MPa; after fully debinding the ceramic body, sinter it in air at 1440 ° C for 4 hours to prepare tin titanium Barium calcium oxide based ceramics.

[0027] The obtained lead-free barium tin titanate-based piezoelectric ceramics were cleaned by silver electrodes after ultrasonic cleaning. At room temperature, it was polarized in silicone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com