Niobium oxide doped barium calcium zirconate titanate leadless piezoelectric ceramic powder material

A barium calcium zirconate titanate and lead-free piezoelectric technology is applied in the field of environmentally friendly lead-free piezoelectric ceramics, which can solve the problem that performance parameters cannot be achieved at the same time, the comprehensive electrical properties of lead-free piezoelectric ceramics are poor, and the electromechanical coupling coefficient is low. and other problems, to achieve the effect of promoting domain wall motion, excellent performance, and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

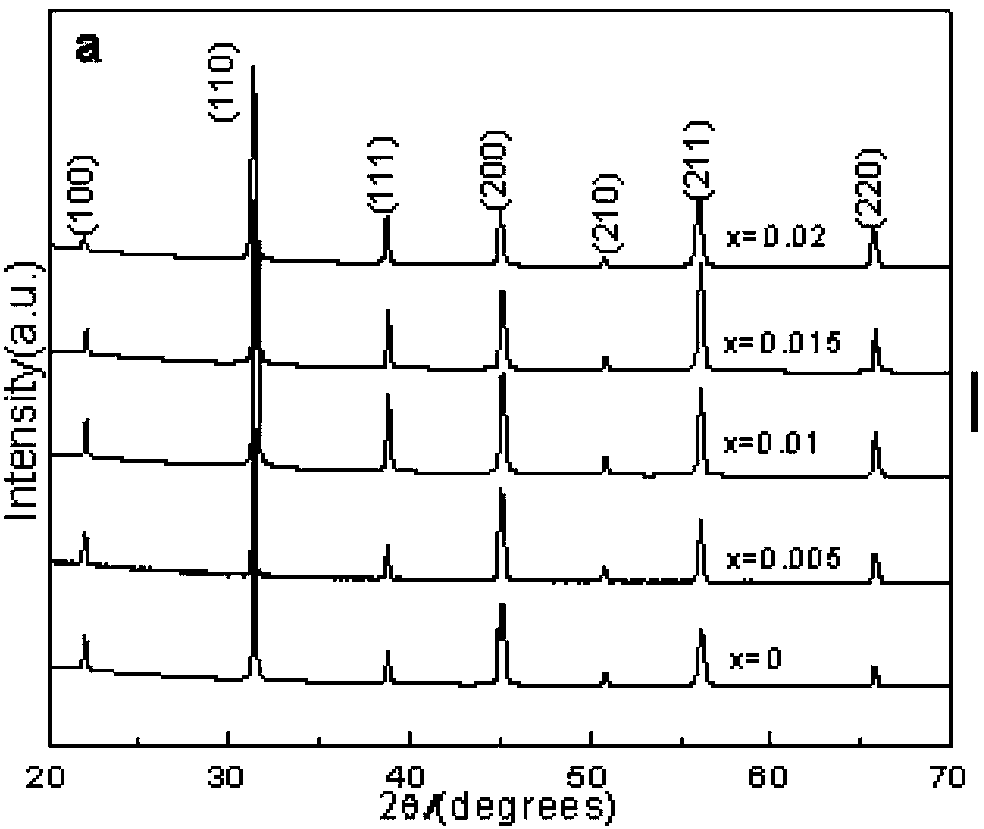

Image

Examples

Embodiment 1

[0022] Embodiment 1: A kind of barium zirconate calcium titanate lead-free piezoelectric ceramic powder material doped with niobium oxide, the chemical general formula of its component is Ba 0.85 Ca 0.15 Ti 0.895-x Zr 0.1 mn 0.005 Nb x o 3 , where x is the number of atoms in the ceramic system where Ti atoms are replaced by Nb atoms; it is prepared by the following method: according to the general chemical formula Ba 0.85 Ca 0.15 Ti 0.895-x Zr 0.1 mn 0.005 Nb x o 3 The stoichiometric ratio of the elements in the medium weighs the raw material BaCO 3 62.671g, ZrO 2 4.603g, TiO 2 26.778g, CaCO 3 5.614g, MnO 2 0.163g and Nb 2 o 5 0.0g; use absolute ethanol as the medium to ball mill the aforementioned raw materials for 12 hours, dry the ball-milled slurry to obtain dry powder; place the dry powder in the air and pre-calcine at 1200°C for 2 hours to obtain Ba 0.85 Ca 0.15 Ti 0.895-x Zr 0.1 mn 0.005 Nb x o 3 powder; wherein, x is 0.

[0023] A niobiu...

Embodiment 2

[0025] Embodiment 2: A kind of barium zirconate calcium titanate lead-free piezoelectric ceramic powder material doped with niobium oxide, the chemical general formula of its component is Ba 0.85 Ca 0.15 Ti 0.895-x Zr 0.1 mn 0.005 Nb x o 3 , where, x is the number of atoms in the ceramic system where Ti atoms are replaced by Nb atoms; it is prepared by the following method: Weigh the raw material BaCO 3 62.514g, ZrO 2 4.592g, TiO 2 26.558g, CaCO 3 5.600g, MnO 2 0.162g and Nb 2 o 5 0.251g; use absolute ethanol as the medium to wet grind the aforementioned raw materials for 11 hours, dry the ball-milled slurry to obtain dry powder; place the dry powder in the air and pre-calcine at 1100°C for 1 hour to obtain Ba 0.85 Ca 0.15 Ti 0.895-x Zr 0.1 mn 0.005 Nb x o 3 Powder, where x is 0.005.

[0026]A niobium oxide-doped barium calcium zirconate titanate lead-free piezoelectric ceramic, which is prepared by the following method: taking the above-mentioned niob...

Embodiment 3

[0028] Embodiment 3: A kind of niobium oxide doped barium zirconate calcium titanate lead-free piezoelectric ceramic powder material, the chemical general formula of its component is Ba 0.85 Ca 0.15 Ti 0.895-x Zr 0.1 mn 0.005 Nb x o 3 , where x is the number of atoms in the ceramic system where Ti atoms are replaced by Nb atoms. Prepared by the following method: Weigh the raw material BaCO 3 62.356g, ZrO 2 4.580g, TiO 2 26.338g, CaCO 3 5.586g, MnO 2 0.162g and Nb 2 o 5 0.502g; use absolute ethanol as the medium to wet grind the aforementioned raw materials for 15 hours, dry the ball-milled slurry to obtain dry powder; place the dry powder in the air and pre-calcine at 1300°C for 4 hours to obtain Ba 0.85 Ca 0.15 Ti 0.895-x Zr 0.1 mn 0.005 Nb x o 3 Powder, where x is 0.01.

[0029] A niobium oxide-doped barium calcium zirconate titanate lead-free piezoelectric ceramic, which is prepared by the following method: taking the above-mentioned niobium oxide-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com