A method for growing lead zirconate titanate (pzt) nanorings using pulsed laser deposition

A technology of pulsed laser deposition and lead zirconate titanate, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of inability to prepare miniaturized and portable ferroelectric memory, PZT micro-nano The structure cannot realize precise control and does not conform to the development trend of the information society, etc., to achieve the effect of fast reading speed, low equipment requirements and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The whole technical solution is divided into the following five steps:

[0039] Step (1): Select the laser and target;

[0040] Step (2): preparing an AAO template;

[0041] Step (3): cleaning the substrate and transferring the AAO template;

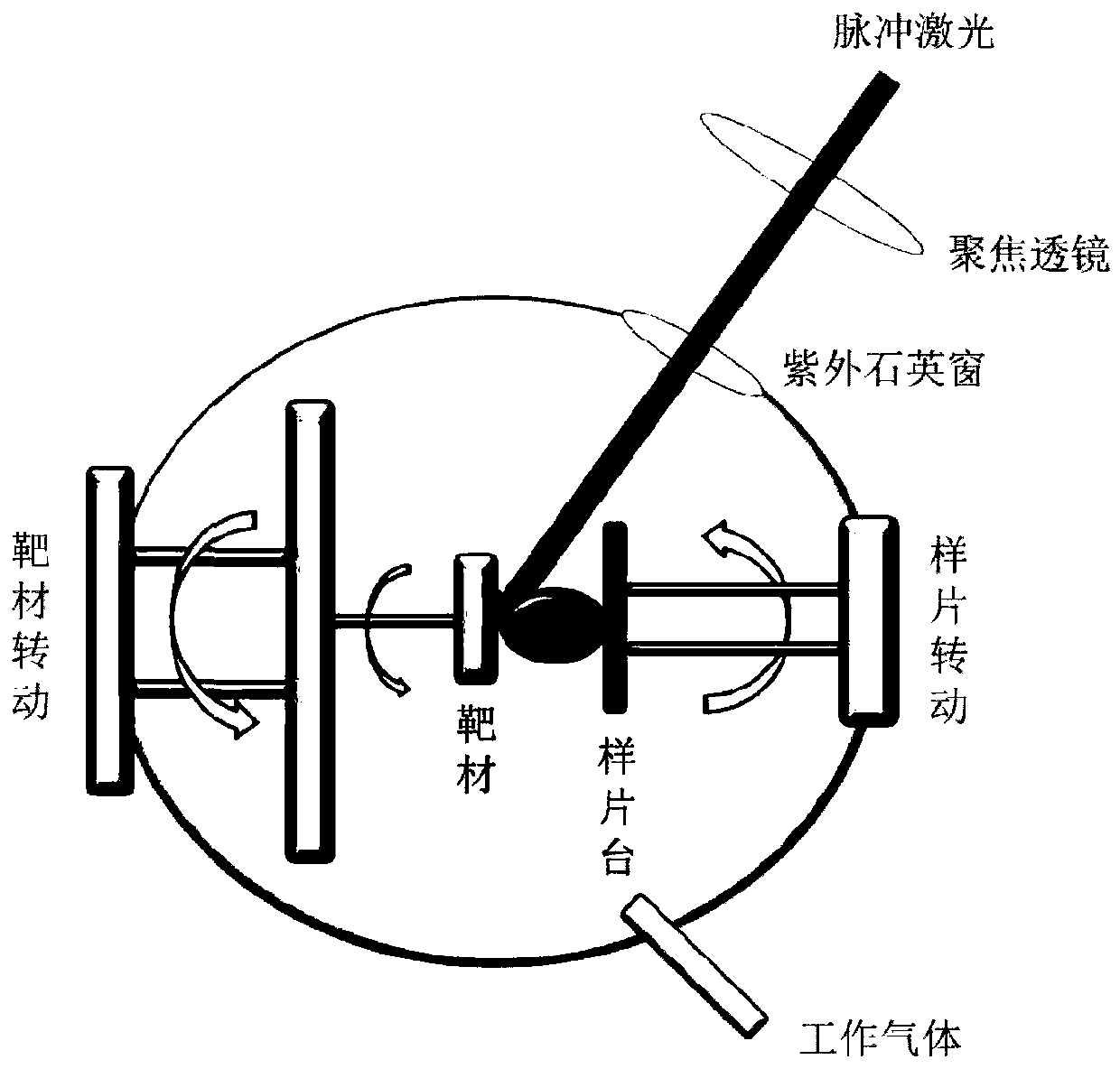

[0042] Step (4): Depositing PZT by PLD method;

[0043] Step (5): removing the AAO film.

[0044] Below are detailed instructions for each step.

[0045] In the step (1), the laser is a KrF excimer laser with a wavelength of 248nm, and the target is a PZT target with a purity of 99.9%.

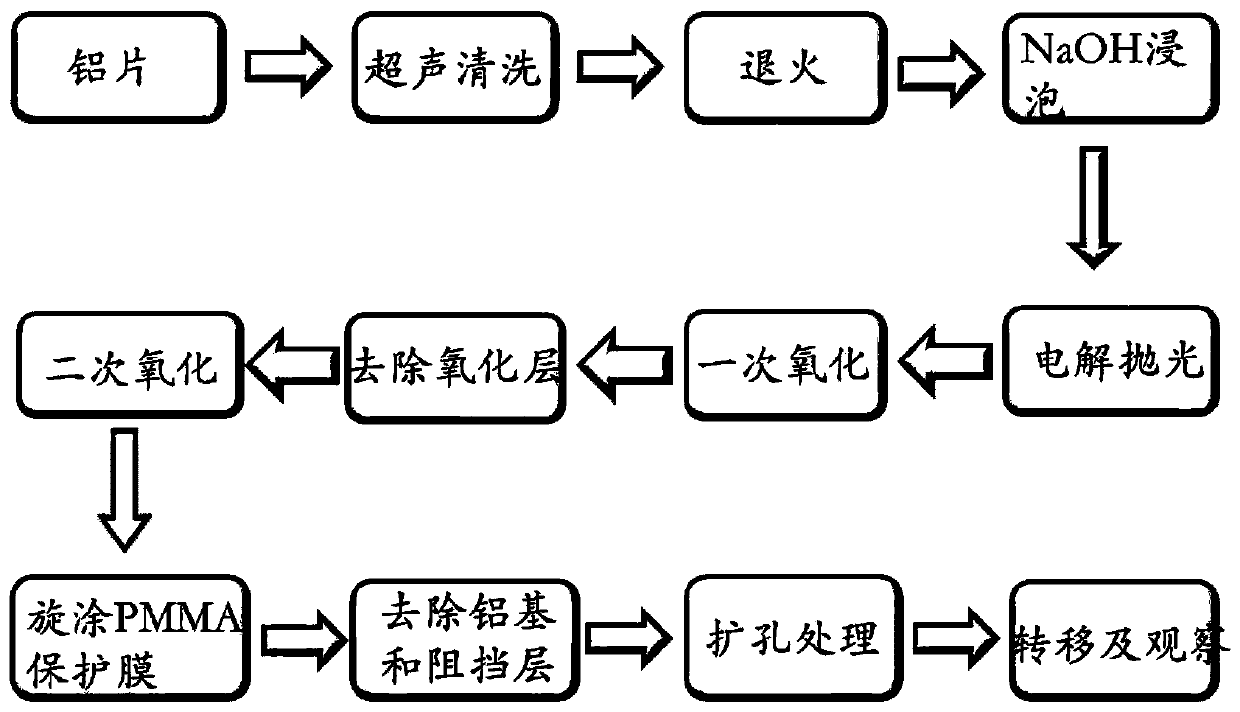

[0046] In the step (2), an ultra-thin AAO film is prepared using a two-step anodic oxidation method, figure 1 Shown is a schematic diagram of the preparation process, and the specific process is:

[0047] (a) Pretreatment: the purity is 99.99% aluminum foil, cut into 2cm*2cm. Ultrasonic treatment in acetone, isopropanol, ethanol, and deionized water for 15 minutes, then annealing at 500°C for 3 hours, and then placing in 1mol / L NaOH solution ...

Embodiment 2

[0058] This example provides a PZT nanoring prepared under another experimental parameter. The difference from Example 1 is:

[0059] In the step (4), the sample stage was raised to 550° C., and kept at an annealing temperature of 750° C. for 30 minutes, and the rest of the experimental conditions were kept the same. Image 6 The PZT nanorings prepared under this condition were found to be less regular than the PZT nanorings in Example 1. The diameter of the PZT nanorings was about 80nm, and the wall thickness was about 21nm.

Embodiment 3

[0061] This example provides the substrate as Si / SiO 2 Structured PZT nanorings prepared under silica wafers. The difference from Example 1 is:

[0062] In described step (3), select Si / SiO 2 Structured silicon dioxide wafers were ultrasonically cleaned with acetone, isopropanol, ethanol, and deionized water for 10 min, and then washed with N 2 Blow dry and perform ozone cleaning for 15 minutes.

[0063] In the step (4), the sample stage was raised to 550° C., and kept at an annealing temperature of 750° C. for 30 minutes, the oxygen pressure was adjusted to 25 Pa, and the rest of the experimental conditions were kept the same. Figure 7 It is the XRD pattern of the PZT nanoring prepared under this condition. It can be seen that the PZT diffraction peak is stronger near 31°, corresponding to the (110) crystal plane, which is a perovskite structure. Figure 8 It is the SEM image of the prepared PZT nano-rings, the PZT nano-rings are arranged regularly and have good order. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com