Vertical guide type vacuum melting inert gas shielding continuous feeding continuous casting machine

A vacuum smelting and inert gas technology, applied in the field of physical metallurgy, can solve the problems of broken wire rod mechanical properties, unstable electrical properties, inconsistent organizational structure, etc., to reduce the cost of raw materials, reduce the difficulty of vacuuming, and improve the effect of life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

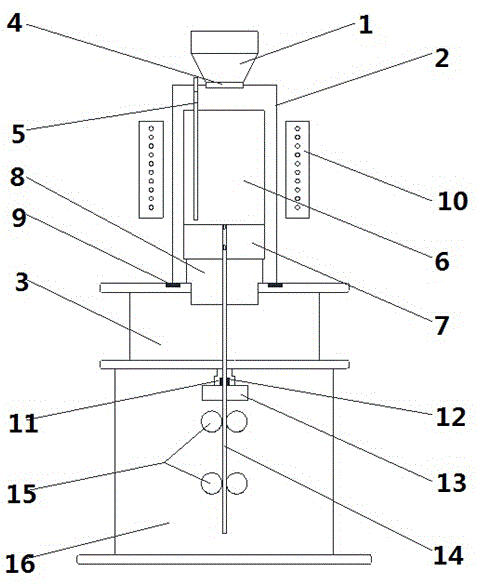

[0027] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the contents of the specific embodiments are not intended to limit the protection content of the present invention.

[0028] The vertical drawing type vacuum smelting inert gas protection continuous feeding continuous casting machine of the present invention enables metals and alloys to be continuously added to a high vacuum smelting device through a continuous feeding device, and the metal is placed in a vacuum degree higher than 5×10 -2 Melting and stirring are carried out under the condition of Pa, and continuous casting is realized at a set speed (0-1500mm / min) under the protection of inert gas, and a metal rod with columnar grain structure of infinite length is obtained.

[0029] figure 1 It shows the structural schematic diagram of the vertical-drawing type vacuum melting inert gas protection continuous feeding continuous casting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com