Polyurethane foaming system

A foaming system and polyurethane technology, applied in the field of polyurethane foaming systems, can solve the problems of unstable foaming, blockage of discharge pipes, restrictions, etc., and achieve the effects of improving stirring efficiency, increasing force area, and improving foaming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

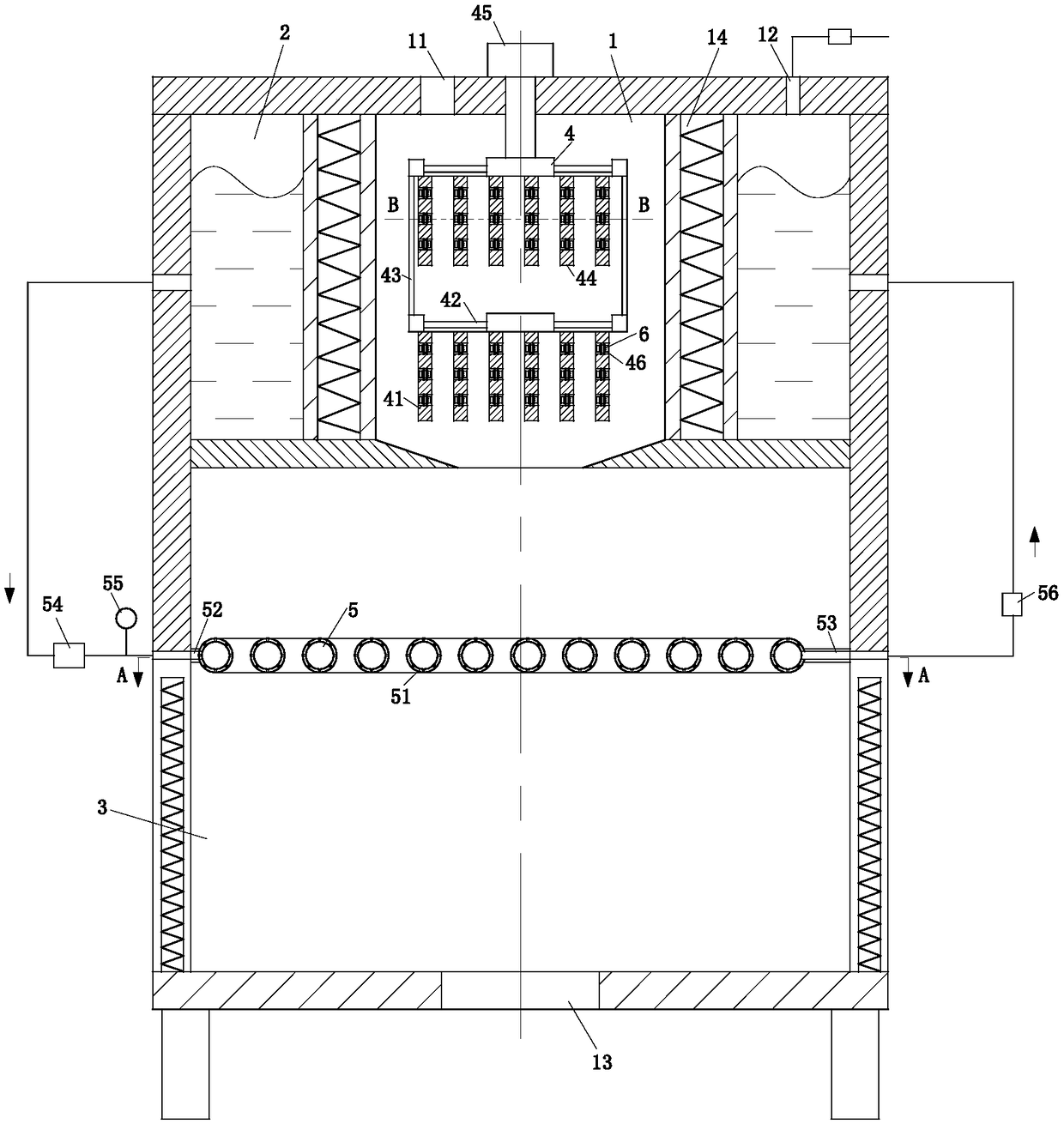

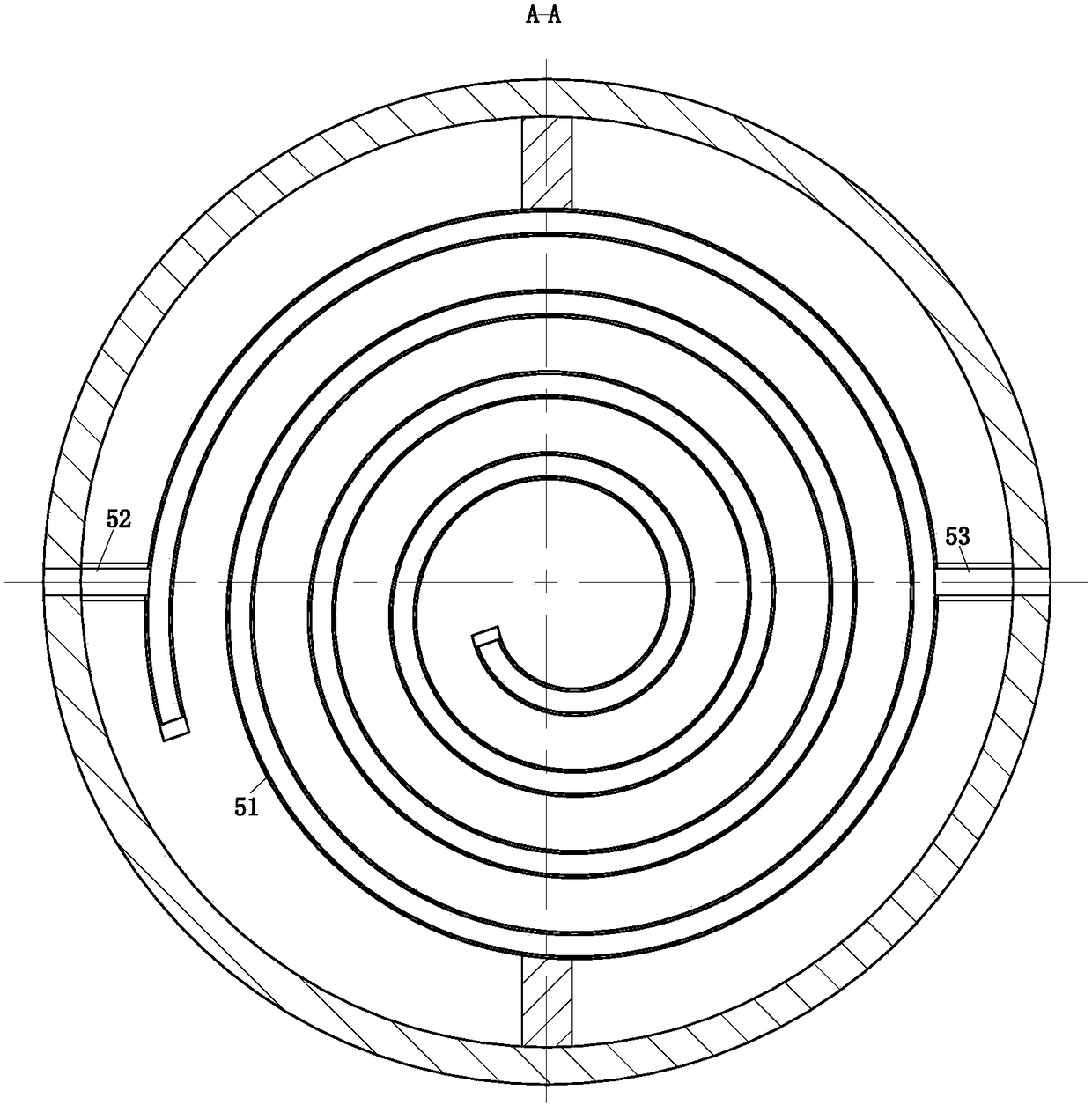

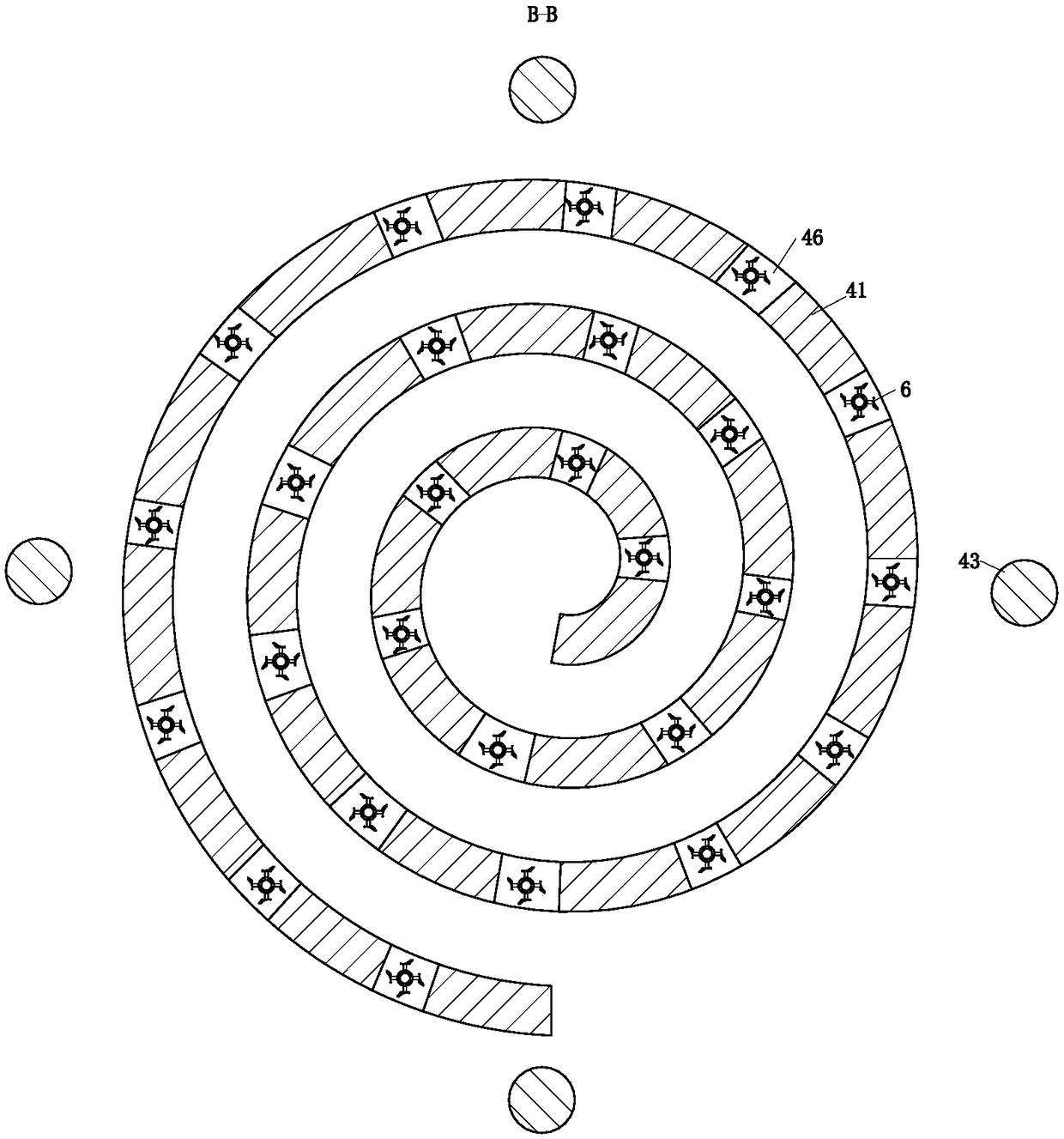

[0027] As an embodiment of the present invention, the water control unit 5 includes a spiral pipe 51, a No. 1 liquid inlet pipe 52, a No. 1 liquid outlet pipe 53, a No. 1 solenoid valve 54, a No. 1 hydraulic gauge 55 and a No. 2 solenoid valve. 56; the spiral tube 51 is fixedly installed on the inner wall of the No. 1 side plate through a bracket; the left end of the spiral tube 51 is connected to the water storage tank 2 through the No. 1 liquid inlet pipe 52, the No. 1 hydraulic gauge 55, and the No. 1 solenoid valve 54 Connected, the right side of the spiral tube 51 is connected with the water storage bin 2 through the No. 1 liquid outlet pipe 53 and the No. 2 solenoid valve 56; The spray holes evenly cover the surface of the spiral tube 51, and the apertures of the spray holes are relatively small. When the first solenoid valve 54 and the second solenoid valve 56 were all opened, the water in the spiral tube 51 could not be ejected from the spray holes. When No. 1 solenoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com