Patents

Literature

420results about How to "Guaranteed mixing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

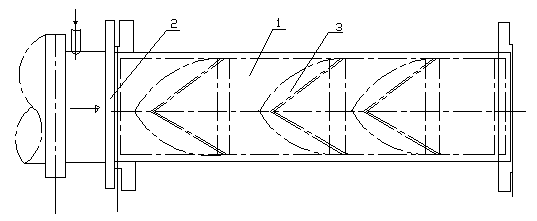

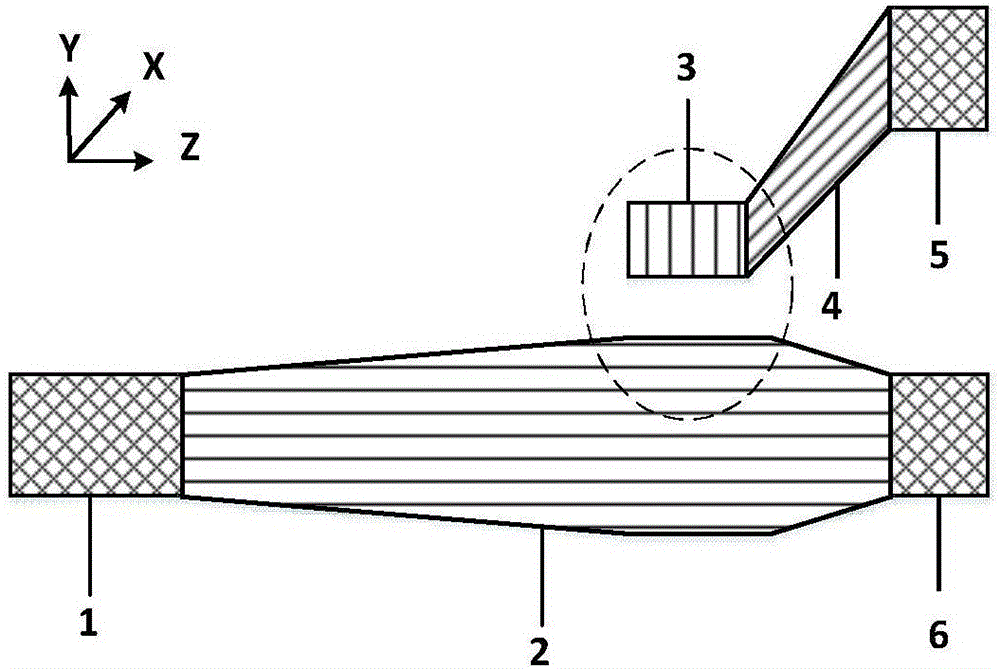

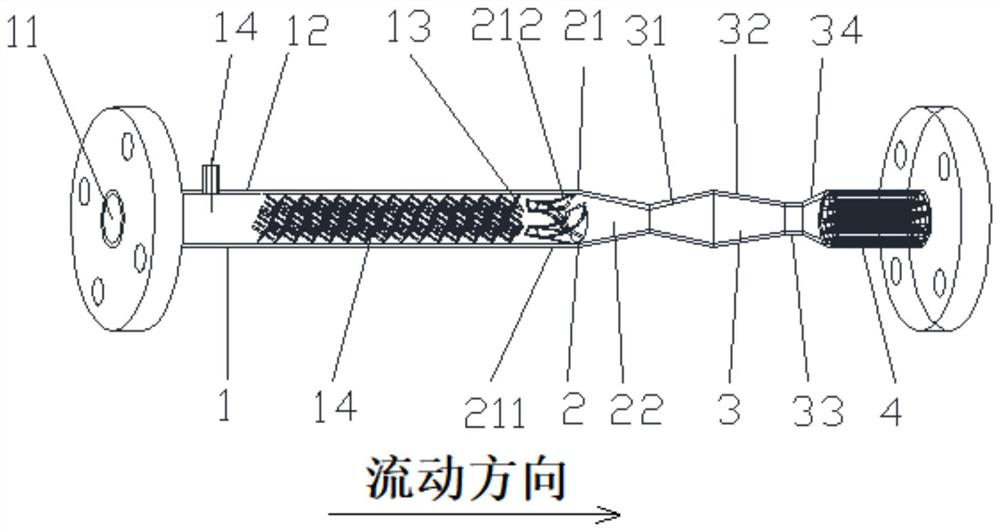

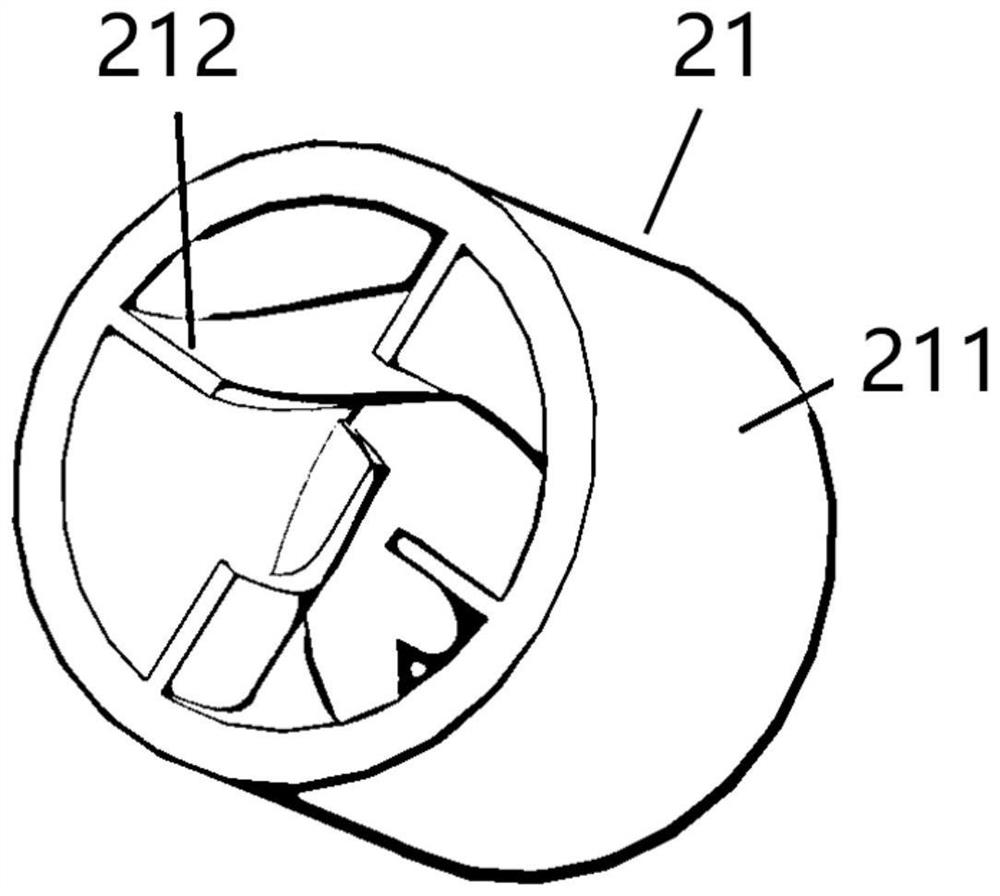

Spiral static mixer

The invention discloses a spiral static mixer which is applied to mixing of multiple materials and particularly mixing of high-viscosity materials. The spiral static mixer comprises a shell, mounting flanges, left rotating blades and right rotating blades and is characterized in that the mounting flanges are respectively arranged at the two ends of the shell, the left rotating blades and the right rotating blades are in multiple-spiral blade structures and sequentially and alternately arranged from an inlet of the shell to an outlet of the shell, the adjacent left rotating blades and right rotating blades are fixedly connected at the periphery in a staggering manner, and a washing lifting ring is connected at one end of a blade group formed by the left rotating blades and the right rotating blades. The spiral static mixer provided by the invention has the advantages of simple structure, high mixing efficiency, convenience and fastness in installation, low cost, convenience in washing and suitability for long-time working; a mixed blade unit can be replaced; and the spiral static mixer is more widely applied to mixing of the high-viscosity materials in the chemical engineering industry.

Owner:MECHANICS RES & DESIGN ACAD SICHUAN PROV

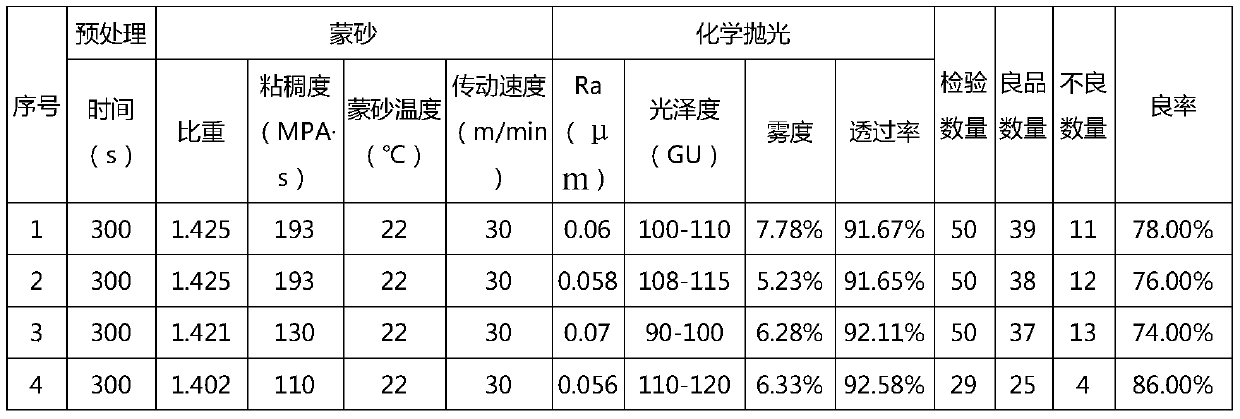

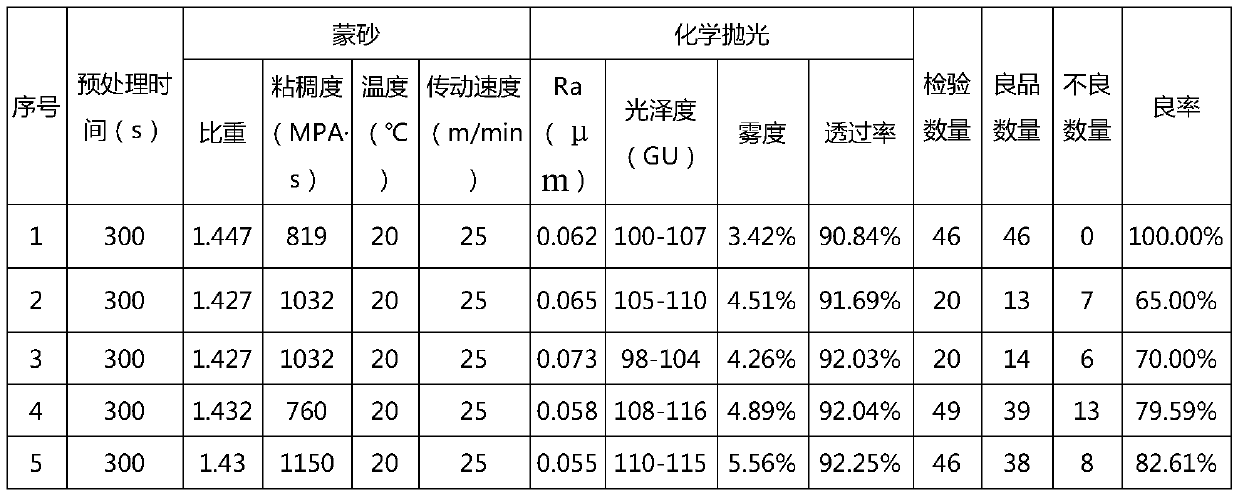

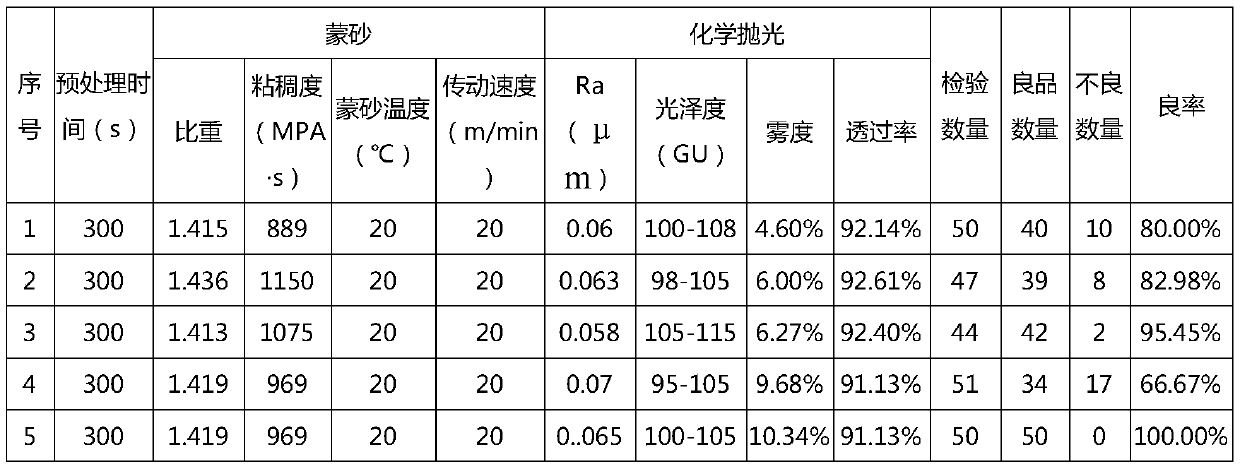

High-alumina glass frosting liquid and preparation method thereof

The invention discloses a high-alumina glass frosting liquid and a preparation method thereof. The high-alumina glass frosting liquid comprises the following components in parts by weight: 30-45 partsof ammonium bifluoride, 5-15 parts of citric acid, 2-5 parts of barium sulfate, 4-10 parts of starch, 2-6 parts of bentonite, 10-20 parts of ferric trichloride, 5-15 parts of potassium fluoride, 6-13parts of potassium nitrate, 2-6 parts of hydrofluoric acid and 10-30 parts of water. The frosting liquid is low in manufacturing cost and high in production yield; and anti-dazzle glass prepared fromthe frosting liquid has the characteristics of high glossiness, low flash point, low roughness and good anti-dazzle effect.

Owner:YICHANG NANBO DISPLAY +1

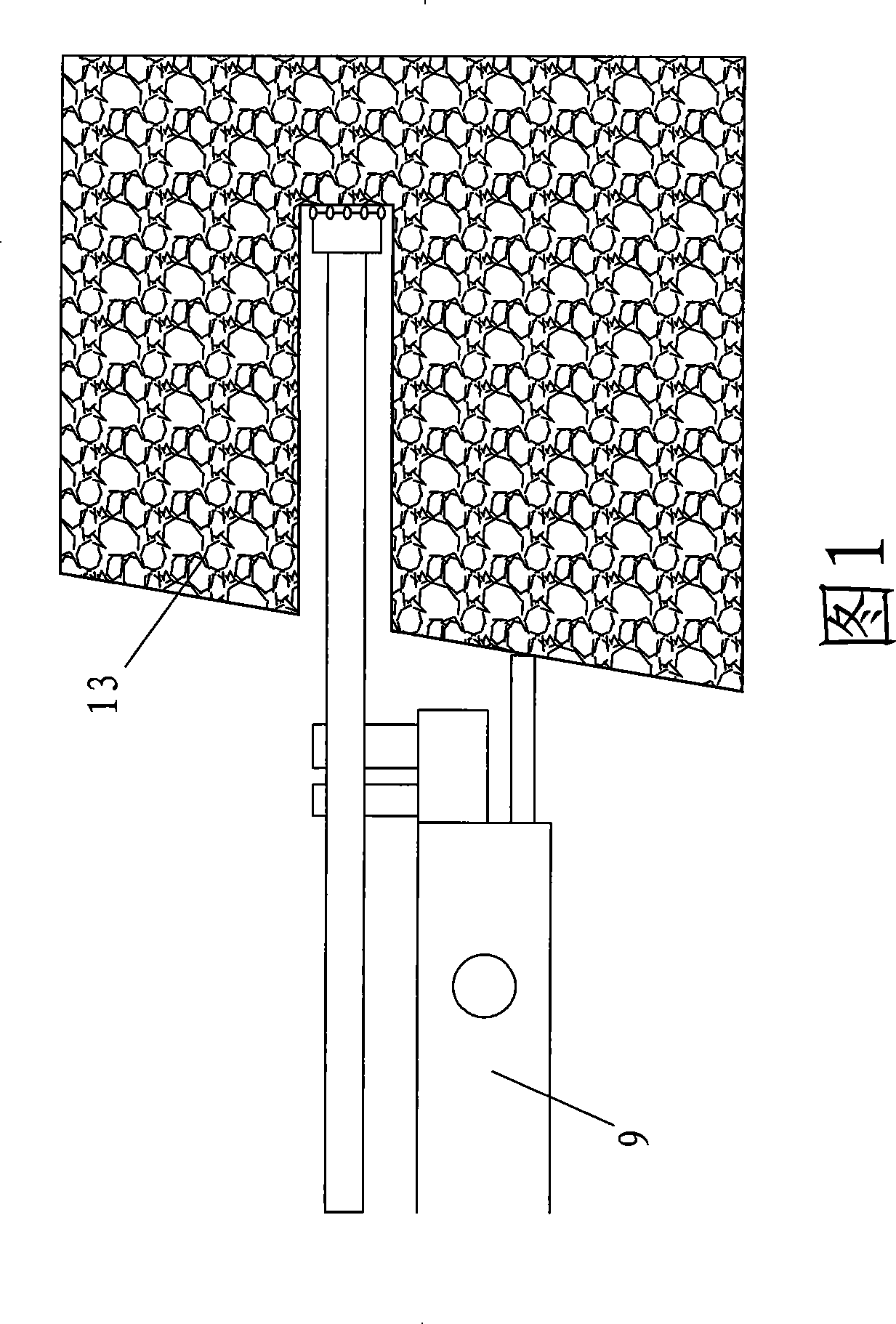

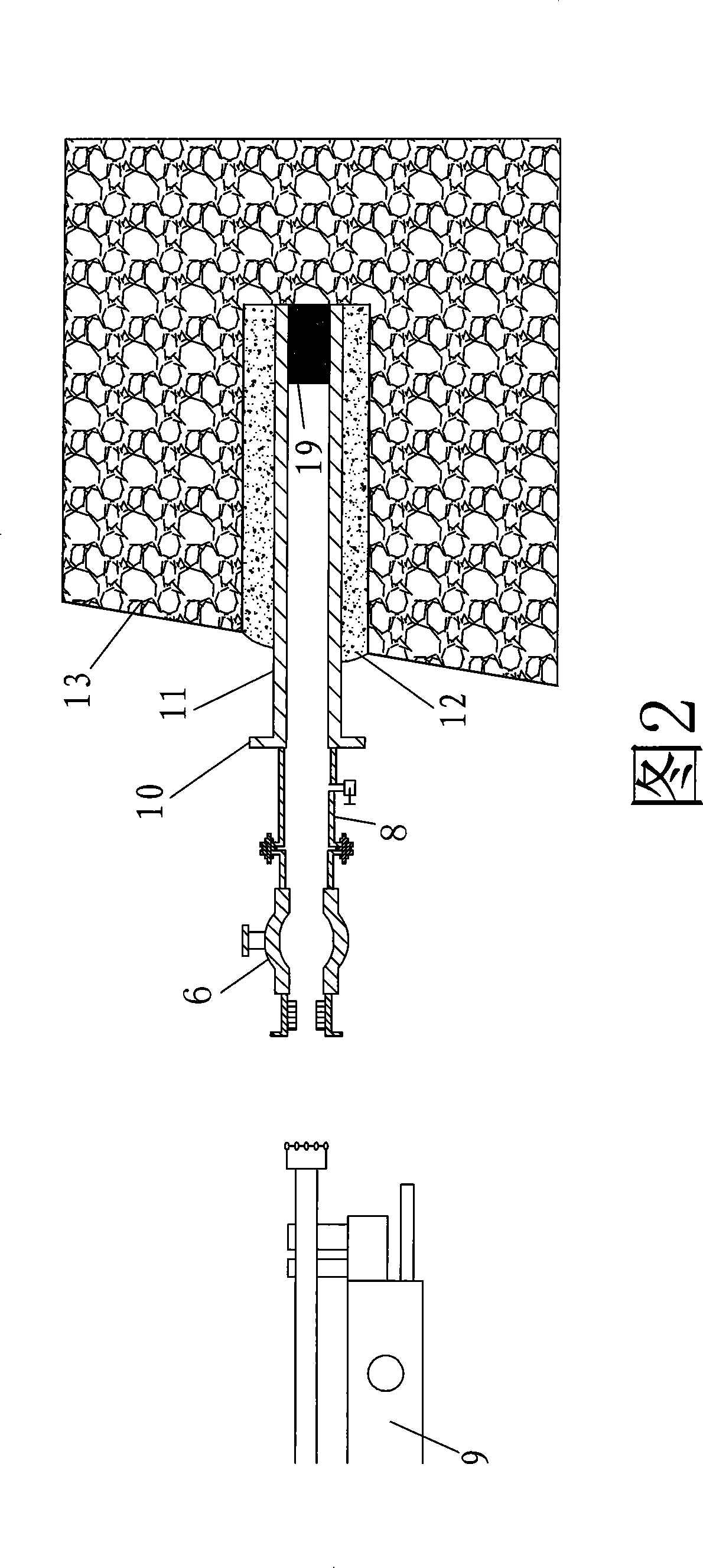

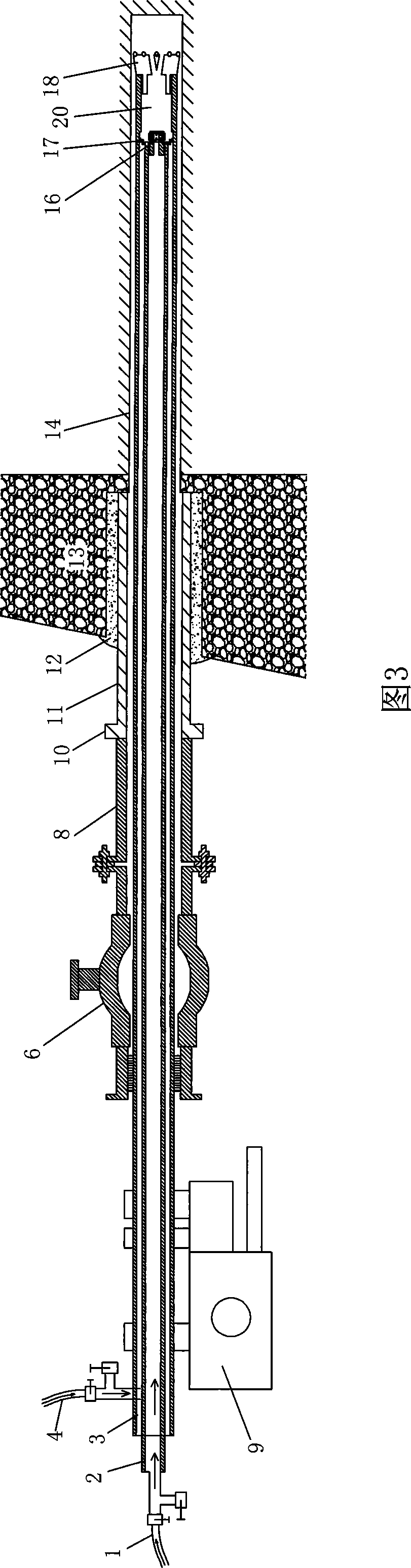

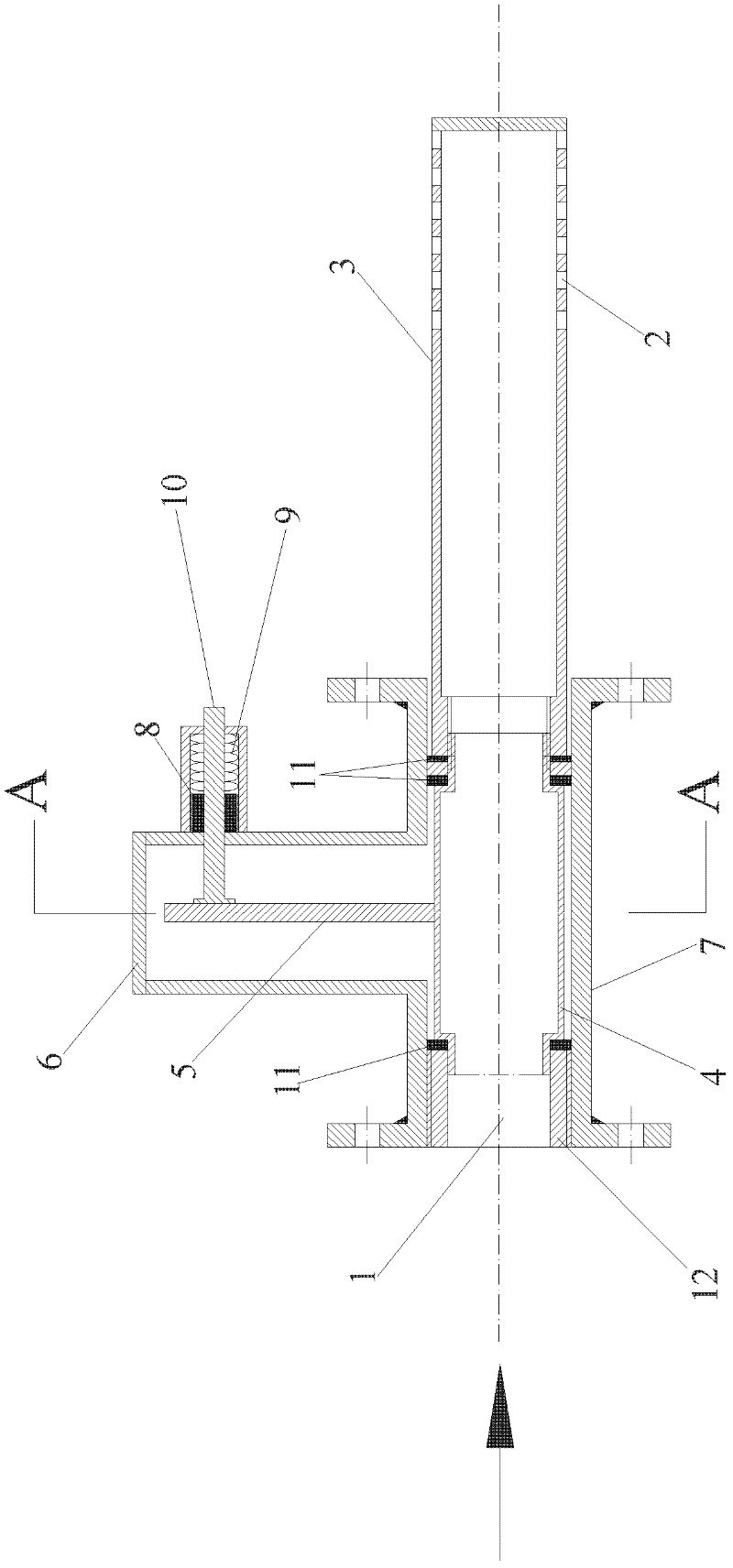

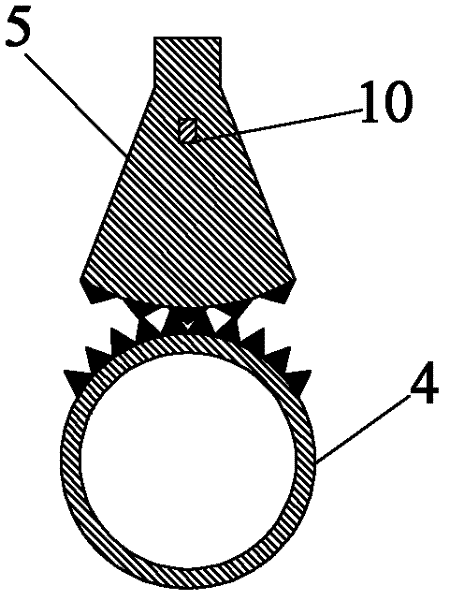

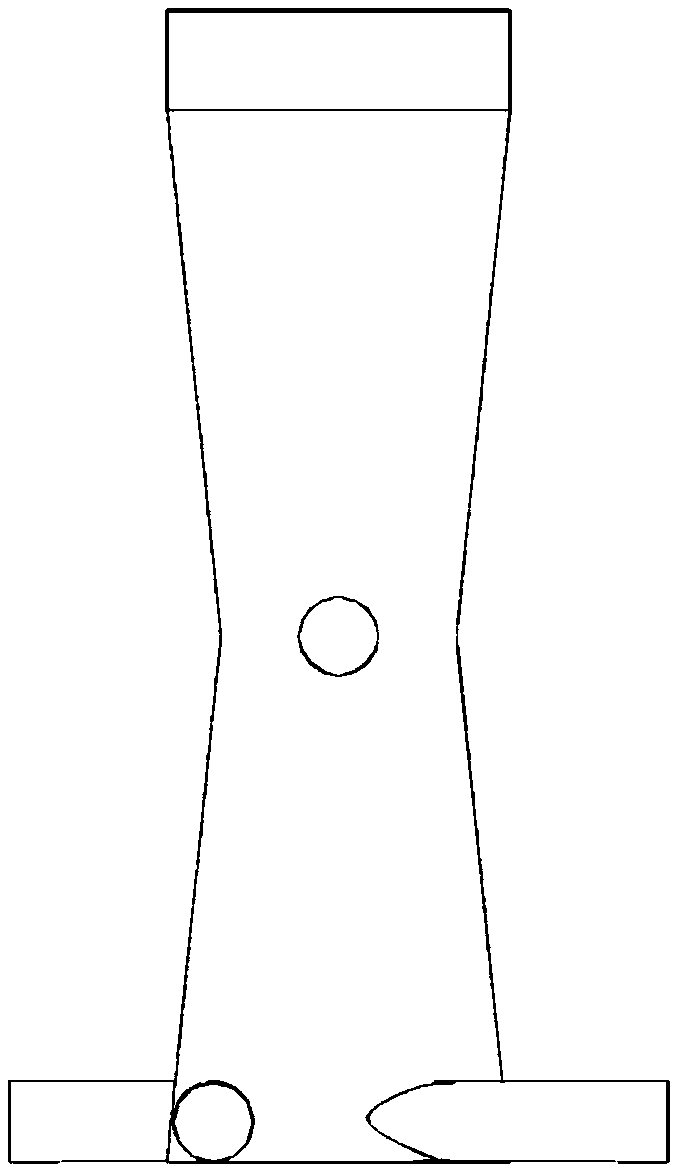

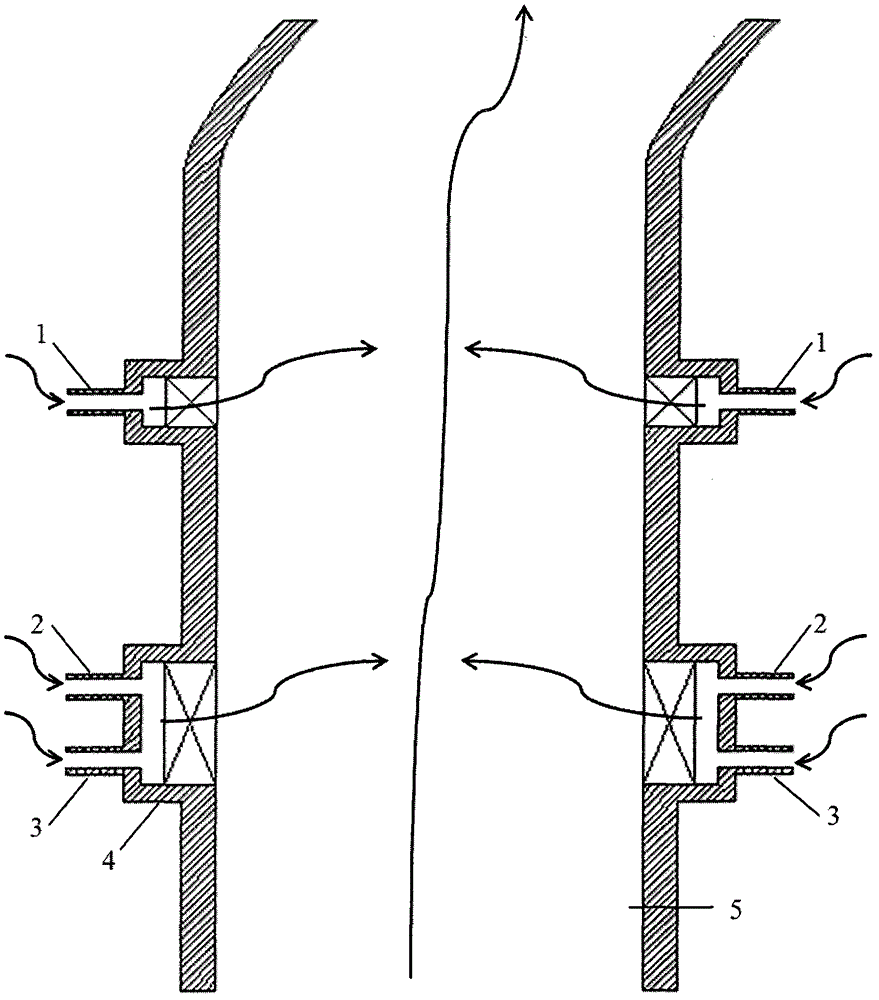

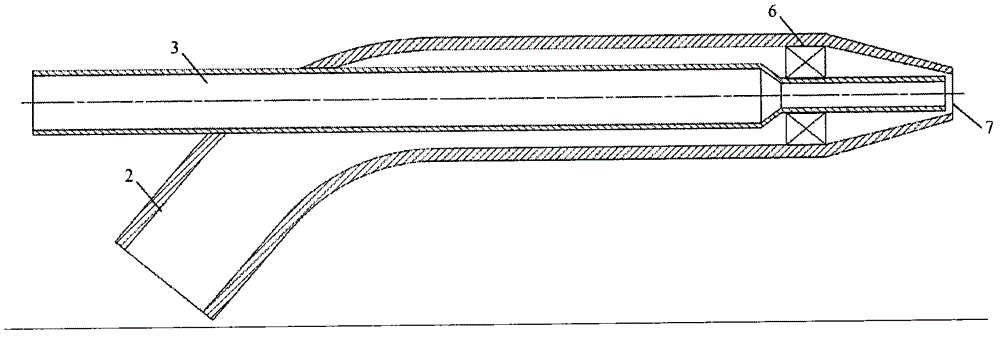

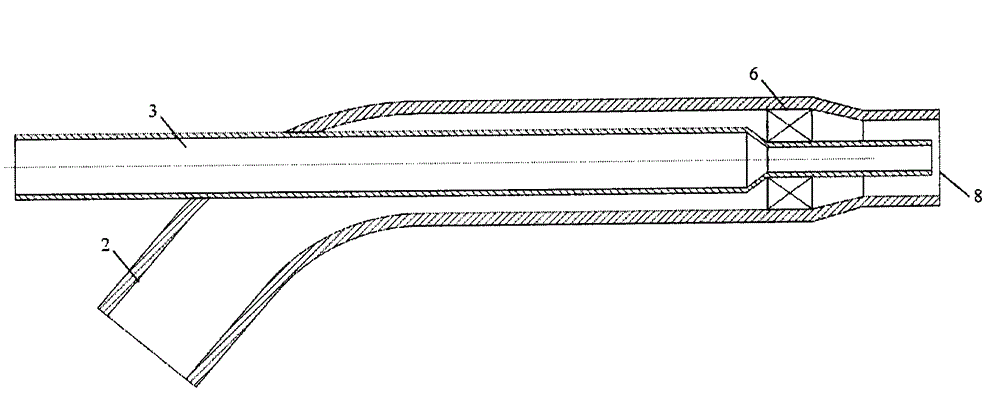

Subsection retrusive slip-casting method for porthole slurry-stop mixed double-pipe within tube

ActiveCN101251019AGuaranteed mixing effectGuaranteed pressureUnderground chambersTunnel liningDouble tubeEngineering

The invention provides a sectional retreating grouting method for a mixed duplex pipe inside an orifice stop-grouting pipe, comprising the following technological steps that: a shallow hole is drilled on a grouting wall (13) by utilization of a drilling machine at first; a drill rod is retreated; an orifice pipe (11) is arranged and then fixed on the orifice wall by utilization of anchor agents (12); the drill rod with a single drill bit and the structure of an inner sleeve and an outer sleeve is adopted for drilling; one end of the orifice pipe positioned on the outside of the drill hole is connected with a drainage (8) and a water inrush resistant device (6) during the drilling process; tail ends of both an inner pipe (2) and an outer pipe (3) of the drill rod are connected with water supply pipes; drilling is performed through the water inrush resistant device, the drainage and the orifice pipe until the designed drilling depth is reached; the water inrush resistant device is disassembled; a hollow pressure plate (5) and a stop-grouting plug (7) are sleeved on the drill rod; the water supply pipes on tail ends of the inner pipe and the outer pipe are respectively connected with a cement slurry supply pipe and a water glass slurry supply pipe; grouting is performed and cement slurry and water glass slurry are mixed in a hybrid chamber (20) and then ejected from the front of the drill bit; when the designed grouting quantity is reached, the drill rod is released by the stop-grouting plug; after the drill rod is retreated for a section of distance, the stop-grouting plug is sealed again, and a gap between the drainage and the outer pipe is grouted continuously; in such manner, a section is grouted and retreated and then another section is grouted until grouting of the hole is finished.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

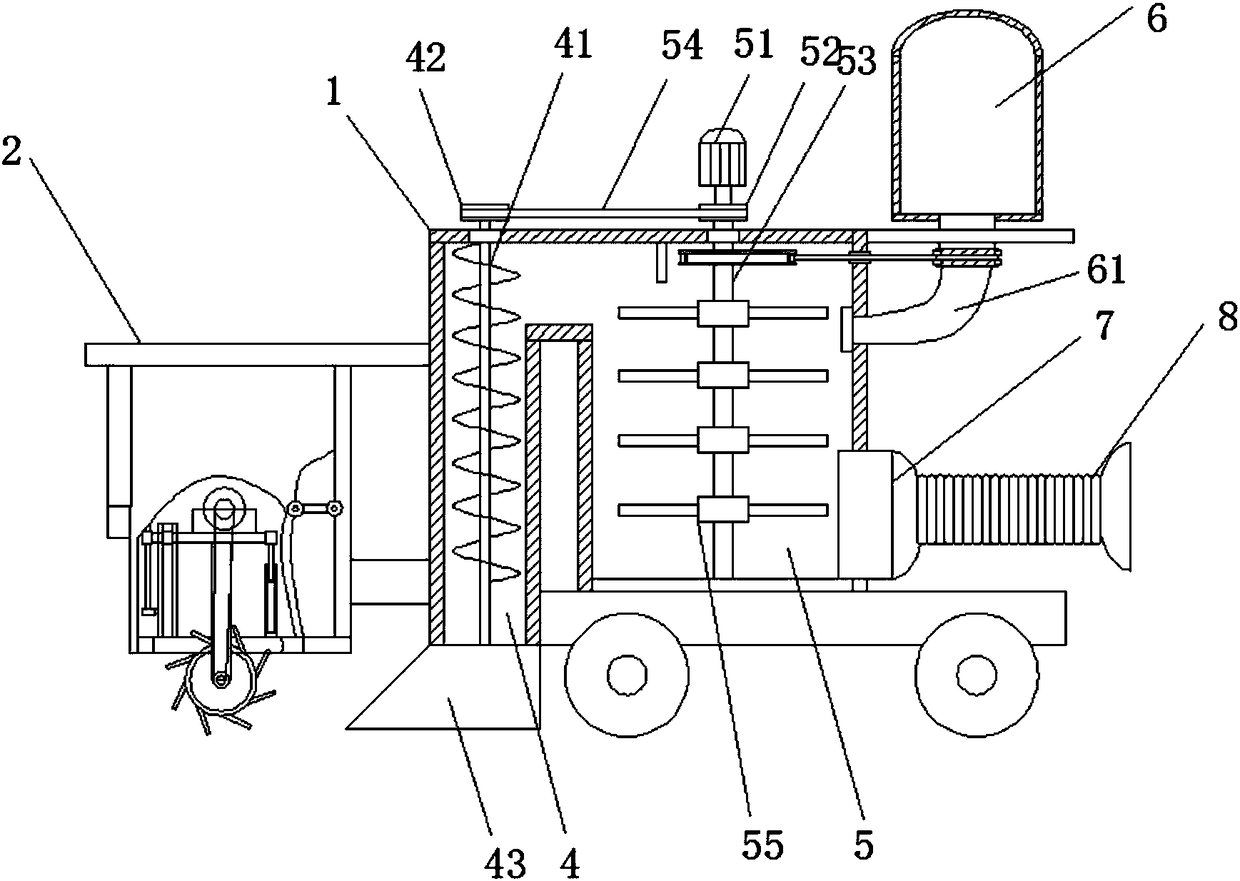

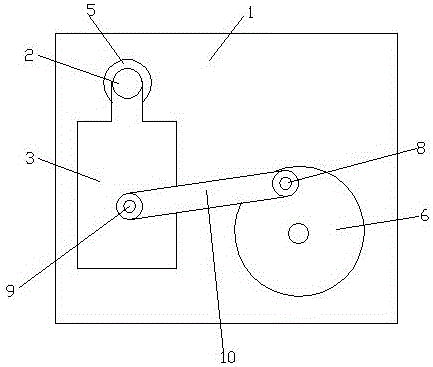

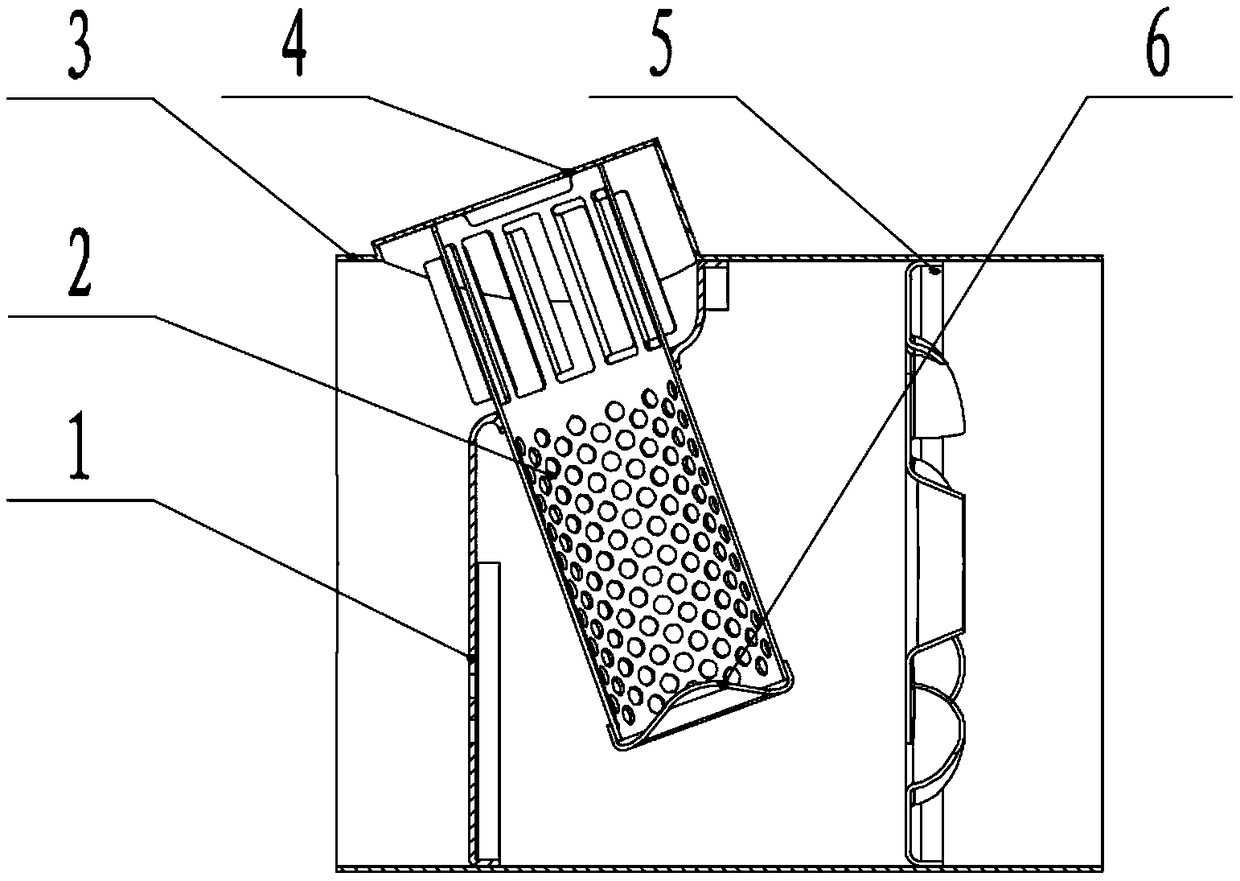

Fertilization mechanism for mixing soil with fertilizer

InactiveCN108419469AHeight adjustableEasy to digSpadesTransportation and packagingDrive wheelEngineering

The invention discloses a fertilization mechanism for mixing soil with a fertilizer. The fertilization mechanism comprises a tank and a soil turnover rack, wherein the tank comprises a conveying cavity and a mixing cavity; the conveying cavity is communicated with the top of the mixing cavity; a conveying rotating shaft is vertically mounted inside the conveying cavity; a spiral auger is mounted on the conveying rotating shaft; a stirring rotating shaft is vertically mounted inside the mixing cavity; a plurality of stirring rods are mounted in equal distances on the stirring rotating shaft; adriven wheel is mounted at the top of the conveying rotating shaft; a driving wheel is mounted at the top of the stirring rotating shaft; the driven wheel is connected with the driving wheel through atransmission belt; a fertilizer bucket is mounted at the top of the tank; a supply tube is connected with the conveying hole of the fertilizer bucket; the tail end of the supply tube extends into themixing cavity. By adopting the fertilization mechanism, a fertilizer is sufficiently mixed with soil, and then the mixture is paved on a field, so that the fertilization effect of a solid fertilizercan be greatly improved, and later absorption effects of crops can be improved.

Owner:杨雪

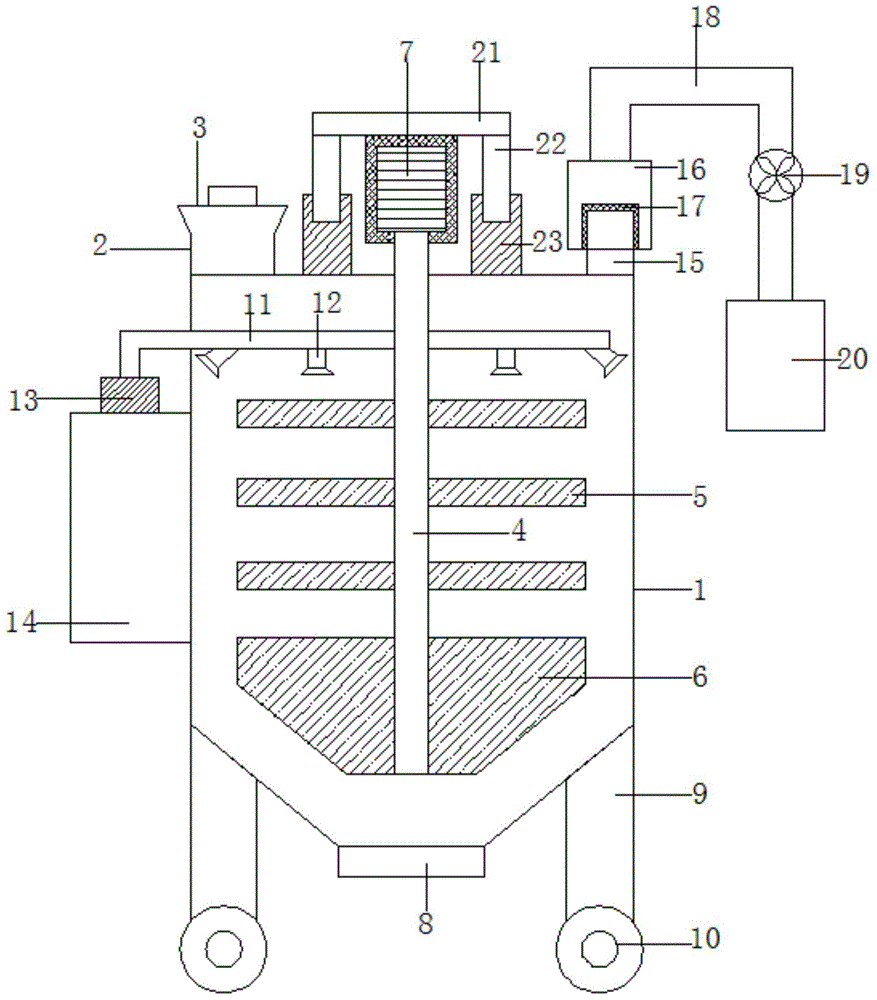

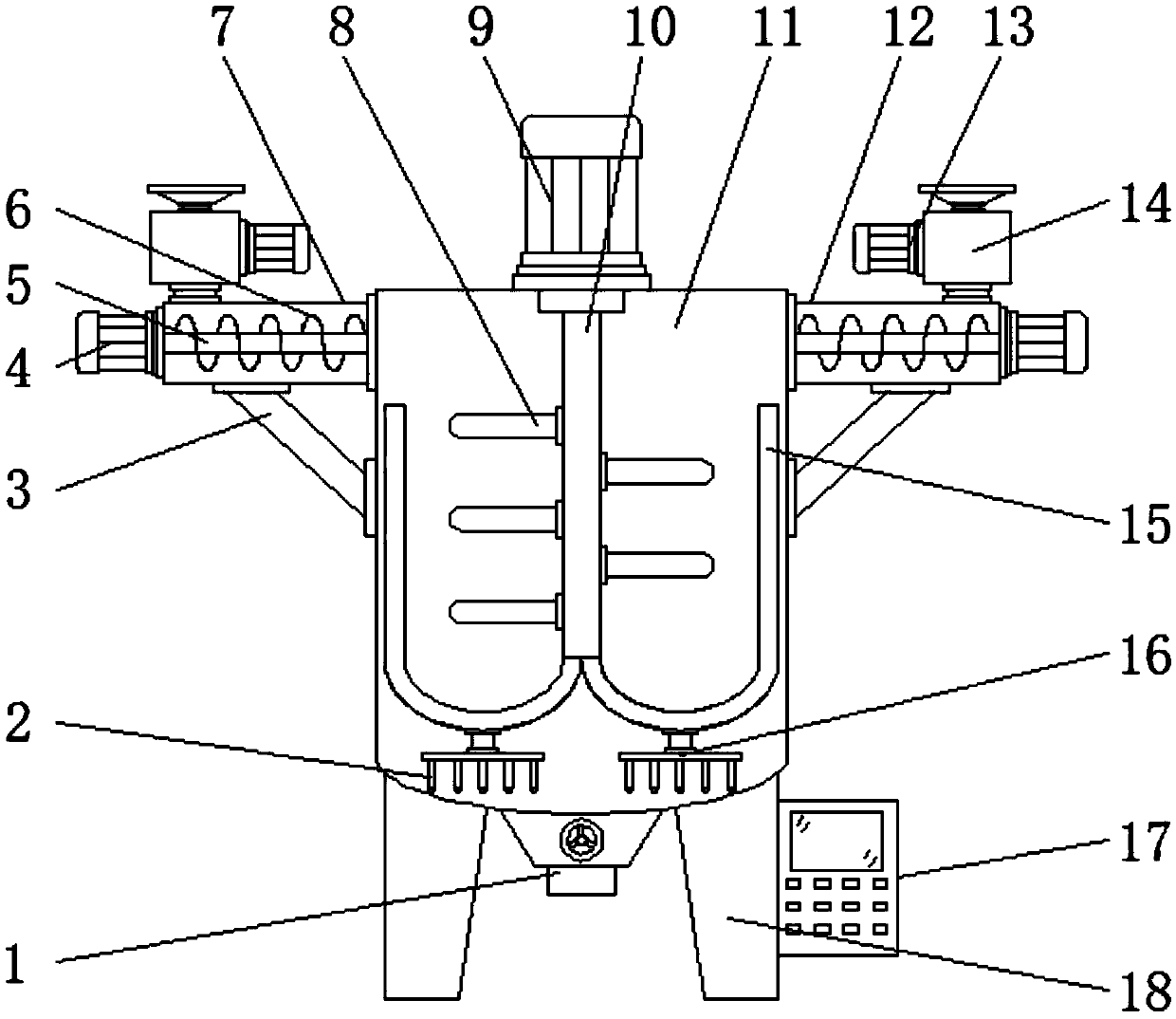

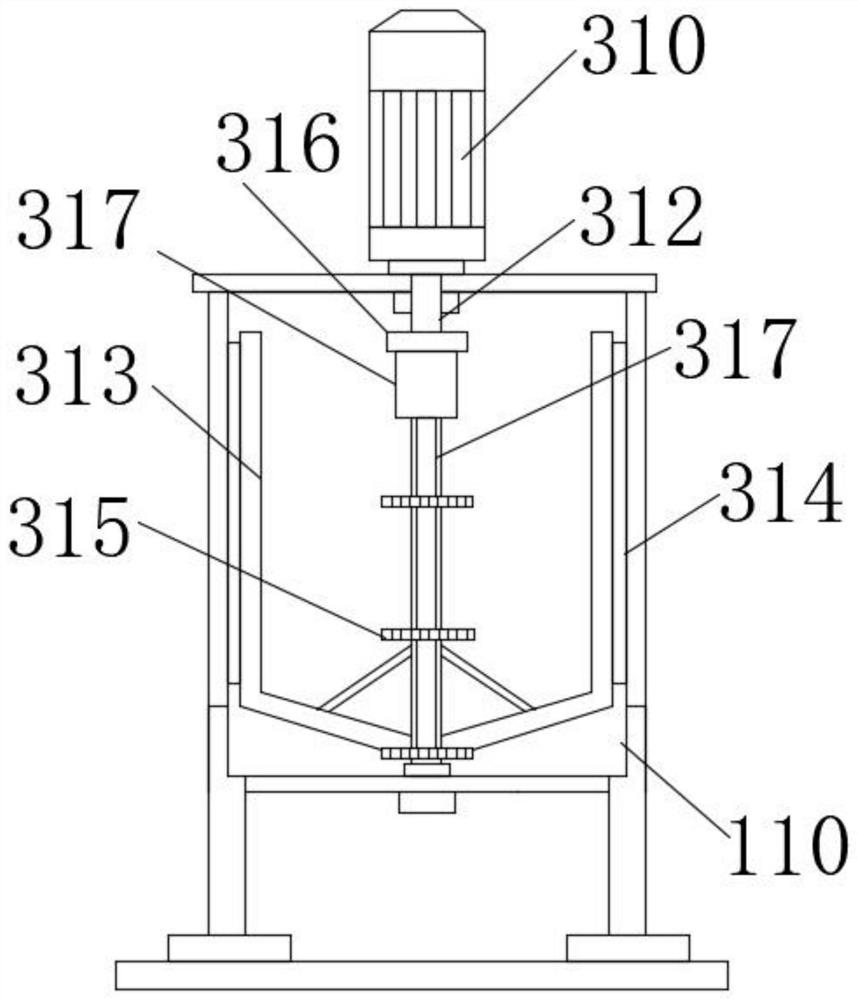

Vertical type efficient mixer for producing ceramics

InactiveCN104923101AStir wellNo stirring dead angleDispersed particle filtrationRotary stirring mixersHydraulic cylinderMixing effect

The invention discloses a vertical type efficient mixer for producing ceramics. The vertical type efficient mixer comprises a mixing cylinder, cleaning nozzles and a hydraulic cylinder, wherein a feeding funnel is disposed at the left end of the mixing cylinder, a cover plate is disposed at the top end of the feeding funnel, a rotary shaft is vertically disposed at the axis inside the mixing cylinder, mixing blades are disposed on the upper outer wall of the rotary shaft in a left-right symmetry manner, a mixing plate is fixed on the lower side of the rotary shaft, and the top end of the rotary shaft extends out of the mixing cylinder and is connected with a rotating motor. The vertical type efficient mixer has the advantages that the mixing blades and the mixing plate move up and down to jointly mix materials, mixing dead angle is avoided, mixing effect is guaranteed, mixing efficiency is increased, self-cleaning of the interior of the mixing cylinder can be achieved, manual cleaning is not needed, time and labor are saved, the mixing cylinder can be used conveniently next time, dust leakage during mixing can be avoided by the cover plate on the feeding funnel, dust produced during mixing can be recycled, dust pollution is avoided, and raw materials are saved.

Owner:顾马飞

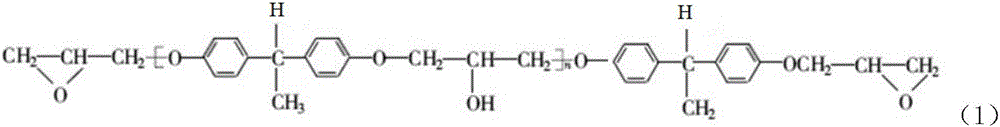

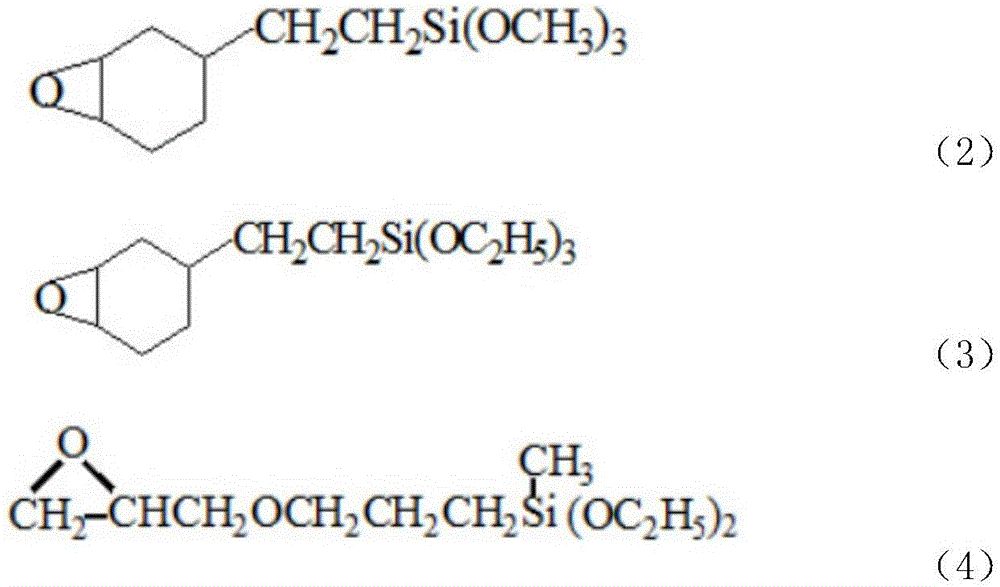

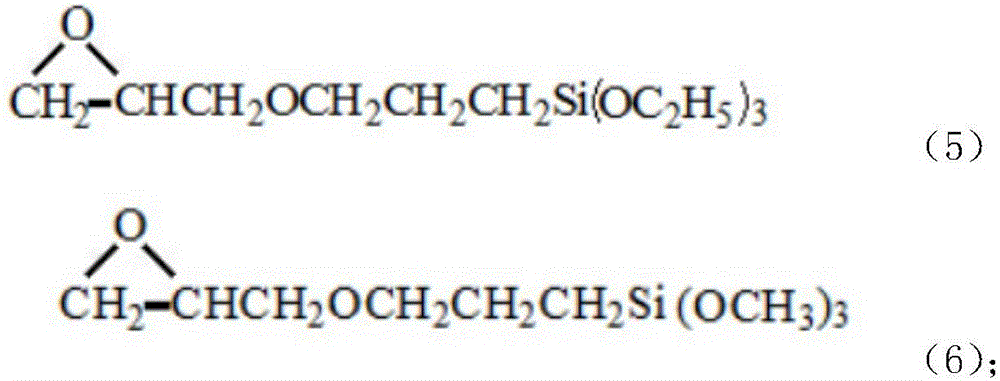

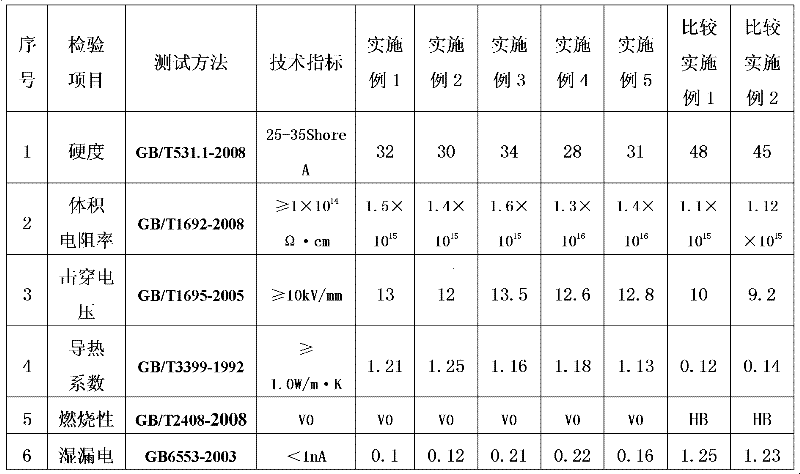

Low temperature curable bottom filling adhesive with heat transfer function and preparation method thereof

InactiveCN106753143AGuaranteed reliabilityGuaranteed storage stabilityNon-macromolecular adhesive additivesHeat-exchange elementsPolymer scienceLow temperature curing

The invention relates to low temperature curable bottom filling adhesive with heat transfer function, comprising component A and component B; the component A is made from 100 parts of epoxy resin, 10-35 parts of modified epoxy resin, 0.5-5 parts of epoxy modified silicone oil, 5-15 parts of active diluent, 250-600 parts of heat transfer filler, 0.5-2 parts of a dispersant, 0.5-2 parts of a defoaming agent, and 0.2-4 parts of a rheological agent; the component B is made from 100 parts of liquid epoxy curing agent, 8-20 parts of a toughening agent, 250-600 parts of heat transfer filler, 0.5-5 parts of epoxy modified silicone oil, 0.5-2 parts of an adhesion promoter, 0.5-2 parts of a dispersant, 1-4 parts of a rheological agent, and 0.5-2 parts of a defoaming agent. The defects of low heat transfer coefficient, low temperature storage, high temperature curing and the like in existing filling adhesive can be overcome, and a chip packaged and cured by 3D MCP has high adhesive strength, good resistance to mechanical impact and good radiating performance.

Owner:NANJING NUOBANG NEW MATERIAL CO LTD

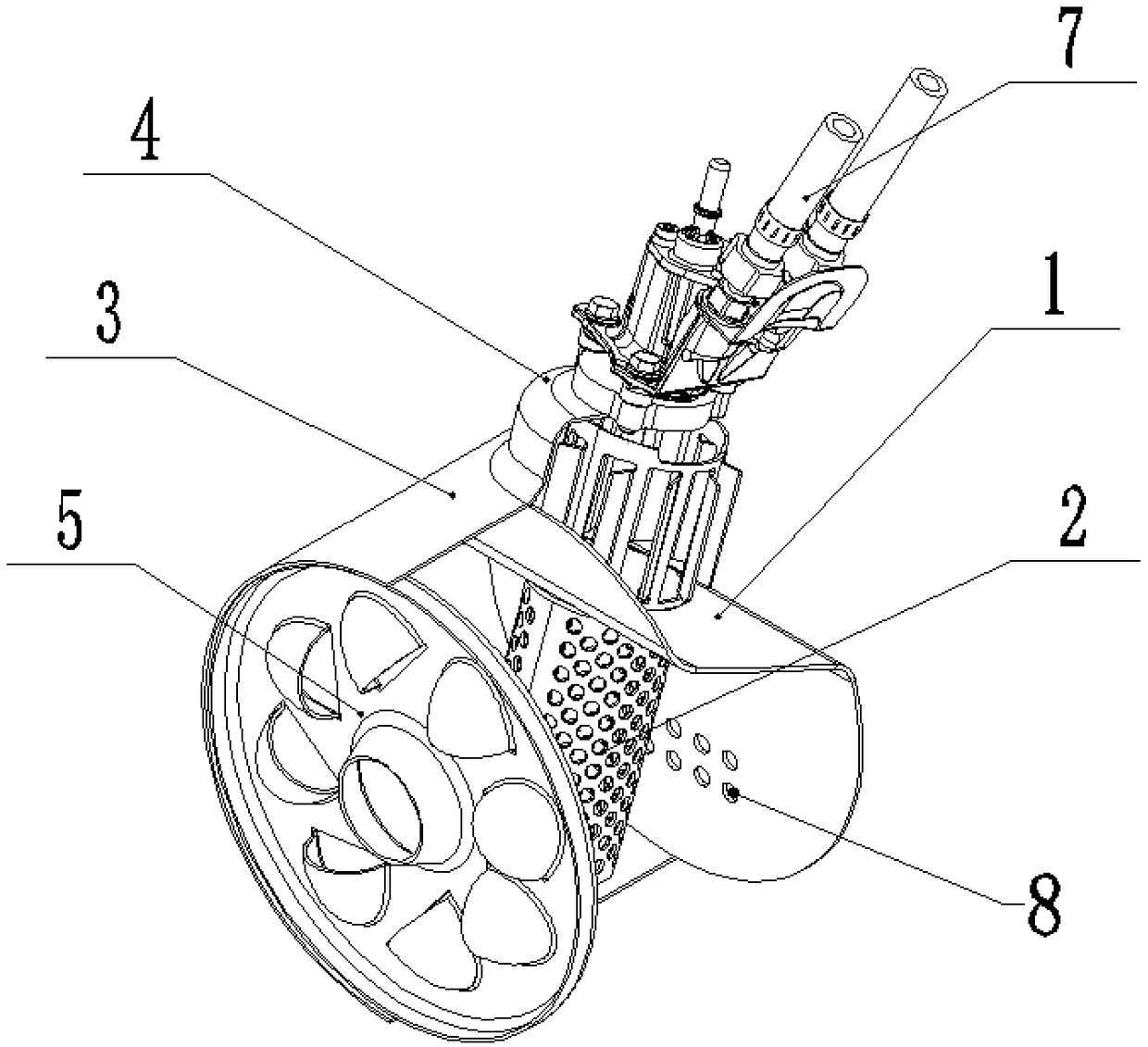

Two-way rotational flow cylinder type urea mixing device

PendingCN110273734AGuaranteed mixing effectReduced risk of crystallizationExhaust apparatusSilencing apparatusRotational flowMetal mesh

The invention relates to a two-way rotational flow cylinder type urea mixing device which comprises a nozzle base, a base supporting cover, a rotational flow pipe, a metal mesh ring, a supporting plate, a back rotational flow plate, a front rotational flow plate and a cylinder; the supporting plate is arranged inside the cylinder, a hole is formed in the front part of the supporting plate, the front rotational flow plate is installed inside the hole, the back rotational flow plate is installed at the rear part of the supporting plate, and the front rotational flow plate, the supporting plate and the back rotational flow plate form a mixing cavity inside the cylinder; the nozzle base, the base supporting cover, the rotational flow pipe and the metal mesh ring are sequentially fixedly connected from top to bottom, the base supporting cover penetrates through the hole in the cylinder and is fixedly connected with the cylinder, and the rotational flow pipe runs into the hole in the middle of the supporting plate to be fixedly connected with the supporting plate; the metal mesh ring stretches into the mixing cavity; the nozzle base, the base supporting cover, the rotational flow pipe and the metal mesh ring are inclined. On the condition of ensuring urea mixing uniformity, the crystallization problem that the urea decomposition efficiency is not high in an SCR system is solved.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

Pre-treatment method of asphalt and spherical graphite negative electrode material coated by using asphalt

ActiveCN103435820AGood dispersionGood for ultra-fine crushingCell electrodesBuilding insulationsPretreatment methodCarbonization

The invention discloses a pre-treatment method of asphalt and a spherical graphite negative electrode material coated by using the asphalt. The pre-treatment method of the asphalt comprises the following steps: crushing and sieving the asphalt, getting screen underflow and adding water and a surfactant for uniformly mixing to prepare suspension liquid; adding the suspension liquid into a sand mill or a colloid mill and grinding to obtain asphalt dispersion liquid; homogenizing the asphalt dispersion liquid in a strong homogenizing machine to complete a treatment process before coating spherical graphite with the asphalt; and carrying out semi-humid mixing by utilizing the asphalt dispersion liquid and the spherical graphite, drying the moisture after the mixing is completed, and dispersing and sieving after carrying out high-temperature treatment to obtain the negative electrode material. According to the pre-treatment method of the asphalt and spherical graphite negative electrode disclosed by the invention, the asphalt is dispersed in water to form the suspension liquid, grinding is carried out to obtain sheet-type and flocculent asphalt micro powder, homogenizing and efficient dispersing are carried out, then, semi-humid mixing with the spherical graphite and the drying are carried out, and high-temperature carbonization treatment is carried out to obtain the negative electrode material. The pre-treatment method disclosed by the invention is simple in treatment process, energy-saving and environment-friendly, and lower in cost. Moreover, the obtained negative electrode material is excellent in performances.

Owner:CHINA SCI HENGDA GRAPHITE

Silicone sealant used for electronic products, preparation method thereof, and application thereof

ActiveCN102516928AGuaranteed mixing effectTimely and effective exportNon-macromolecular adhesive additivesCross-linkSlurry

The invention relates to a silicone sealant used for electronic products. The invention belongs to the technical field of high-molecular materials. The sealant comprises a component A and a component B. The component A is composed of raw materials of, by weight: 100-110 parts of alpha-omega-dihydroxyl polydimethylsiloxane, 25-40 parts of silicone oil, 5-8 parts of a heat-conductive filling material, 35-65 parts of a fire-retarding filling material, and 20-35 parts of nano-grade calcium carbonate. The component B is composed of raw materials of, by weight: 90-110 parts of silicone oil, 12-15 parts of a cross-linking agent, 3-4 parts of a coupling agent, 1-1.5 parts of a catalyst, and 1.5-3 parts of a colored slurry. The silicone sealant is advantaged in excellent fire retardance, improved heat conductivity, ideal steam-penetration inhibiting capacity, excellent electrical property, excellent weathering resistance, and ideal corrosion resistance. A provided preparation method is advantaged in simple technology, and non-harsh requirements on technologies and equipments. With a provided application method, a mixing effect of the components A and B can be ensured.

Owner:江苏明昊新材料科技股份有限公司

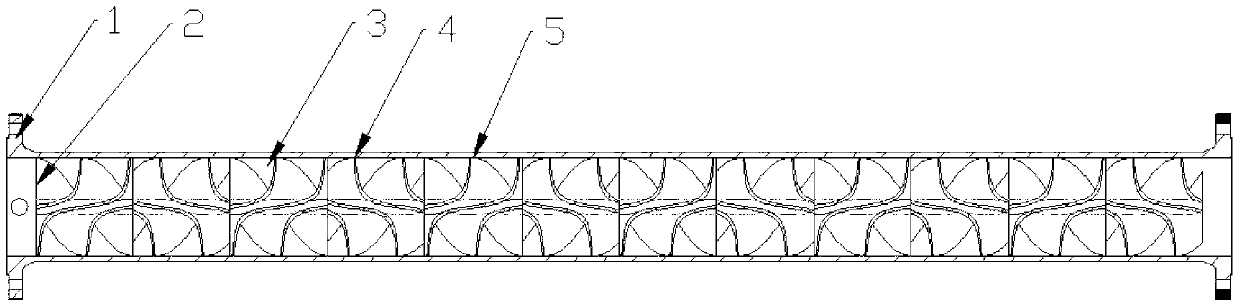

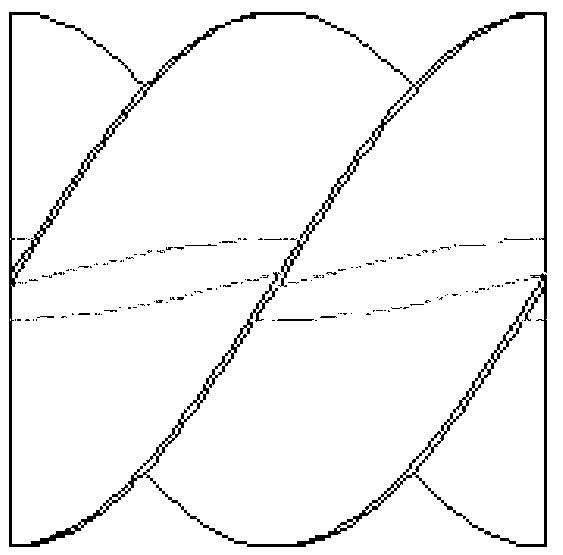

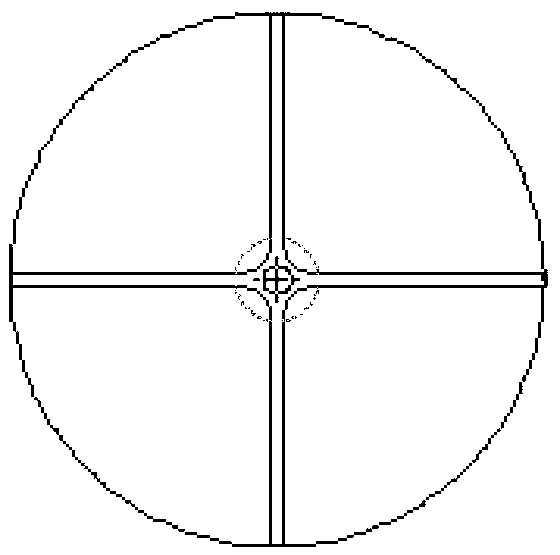

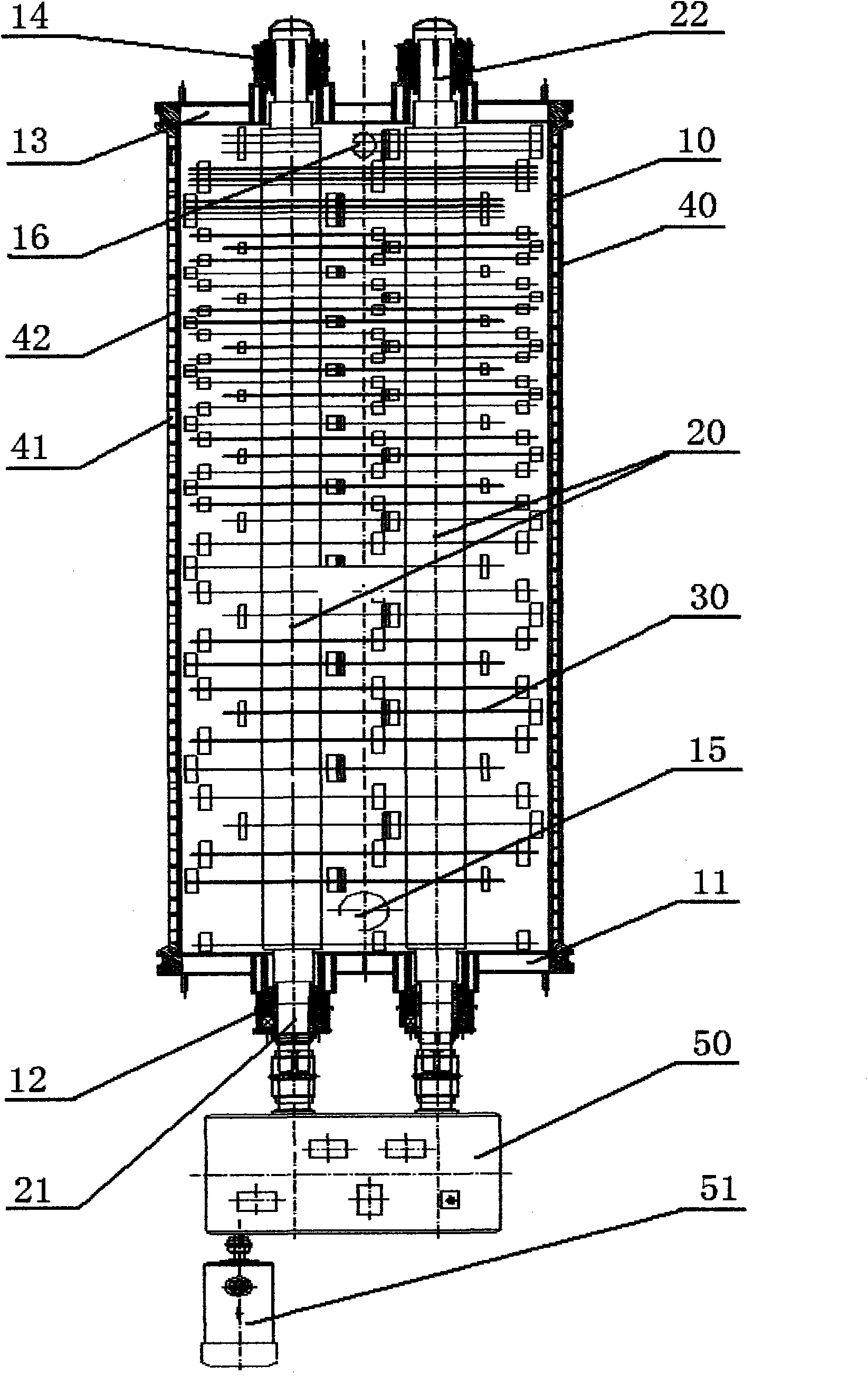

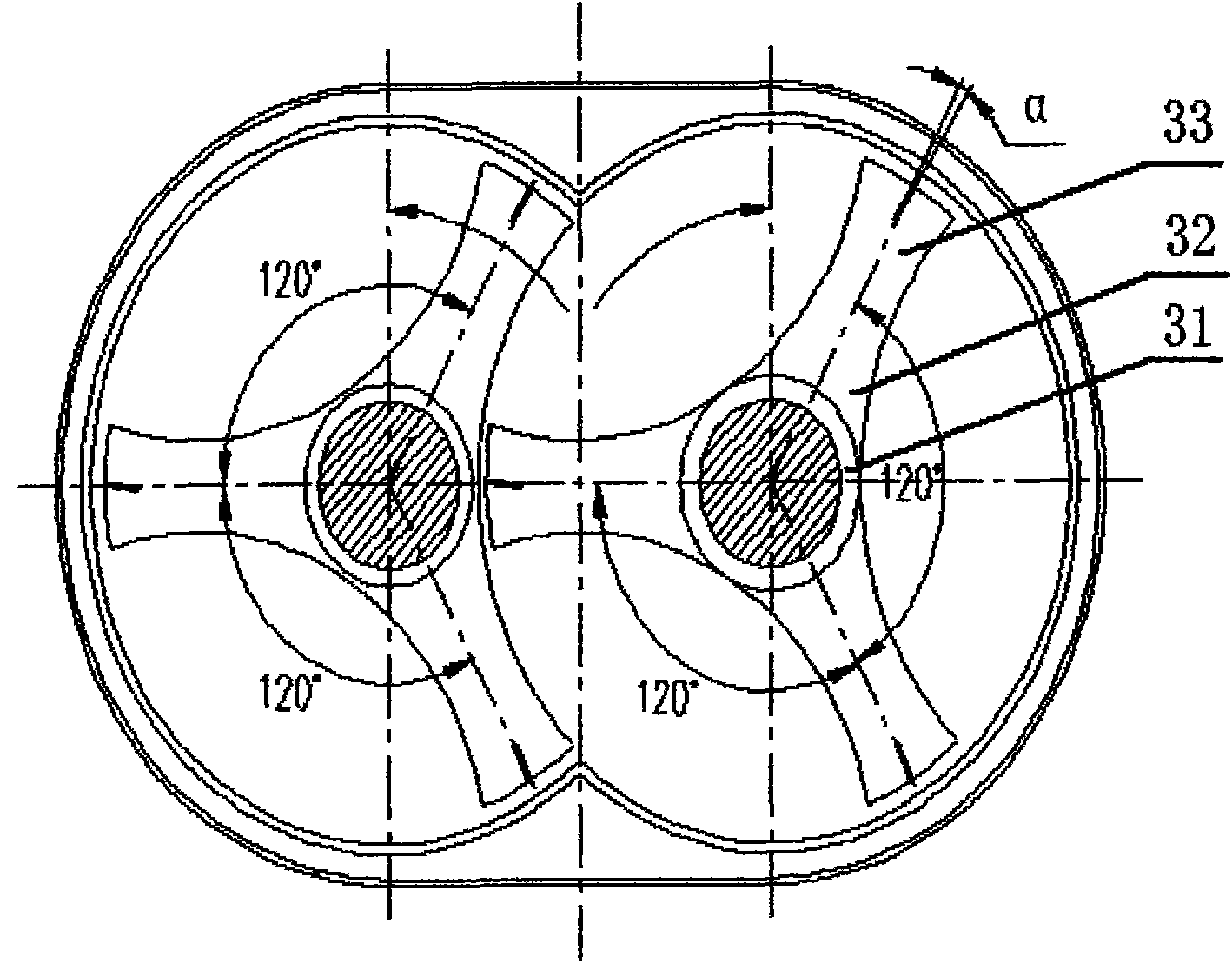

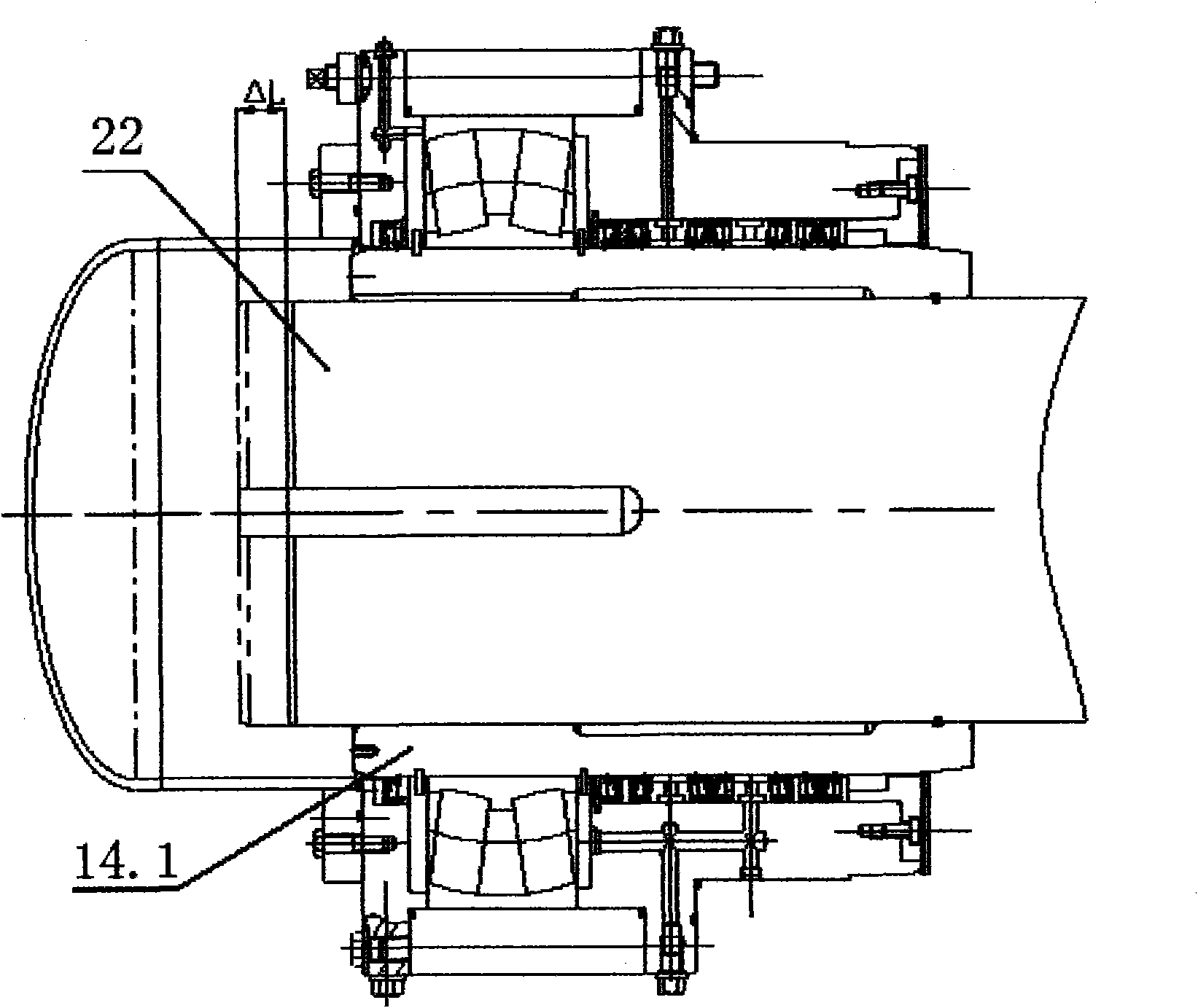

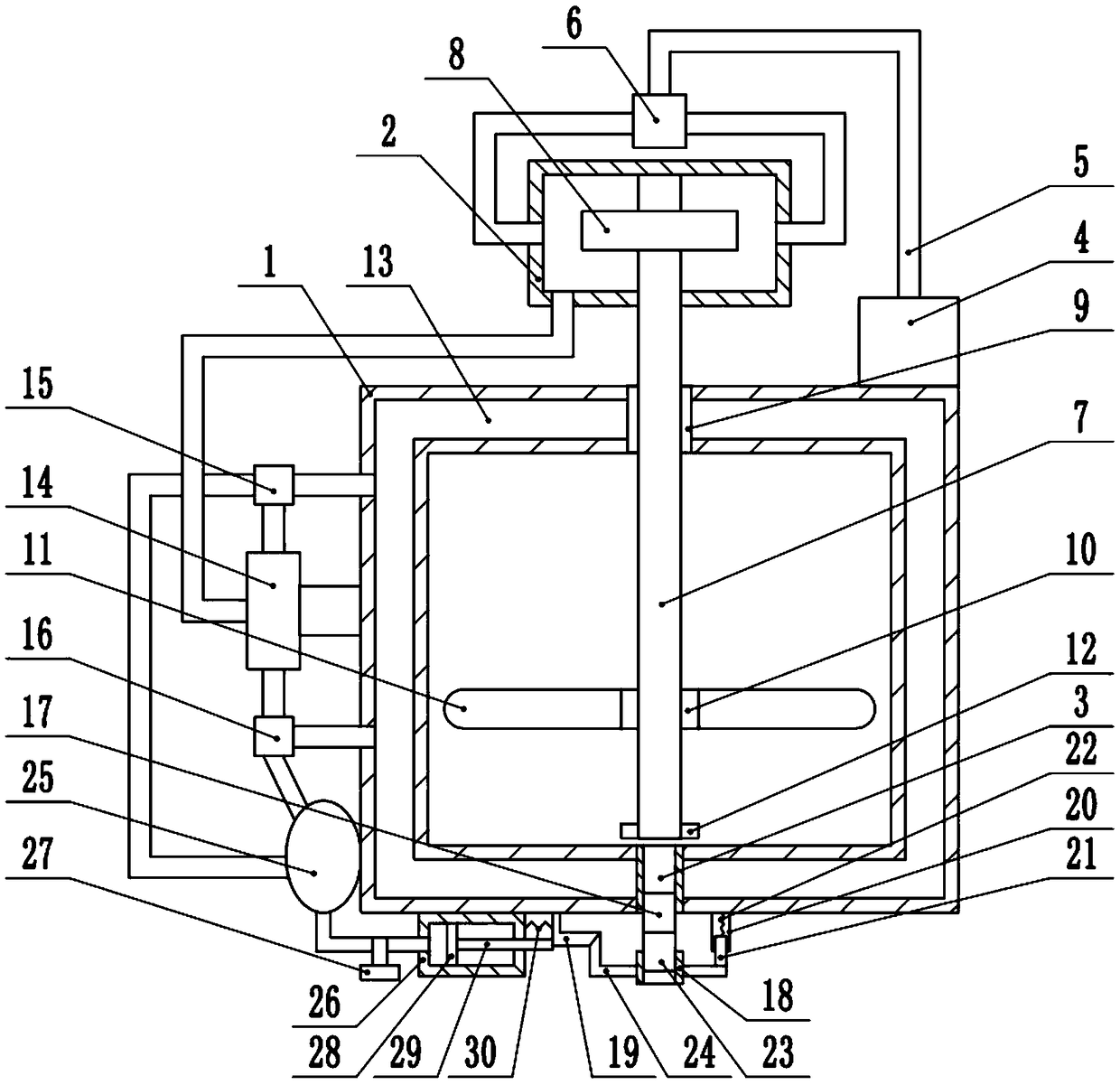

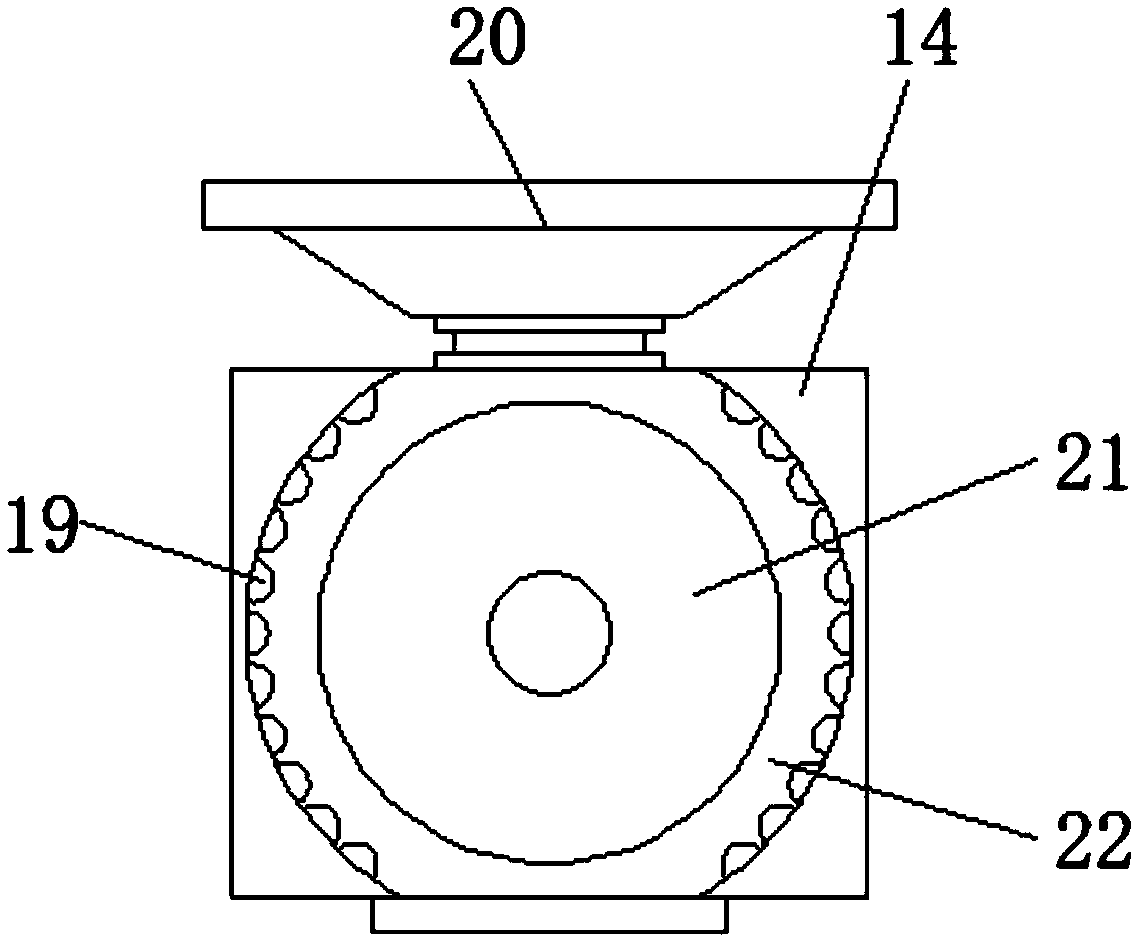

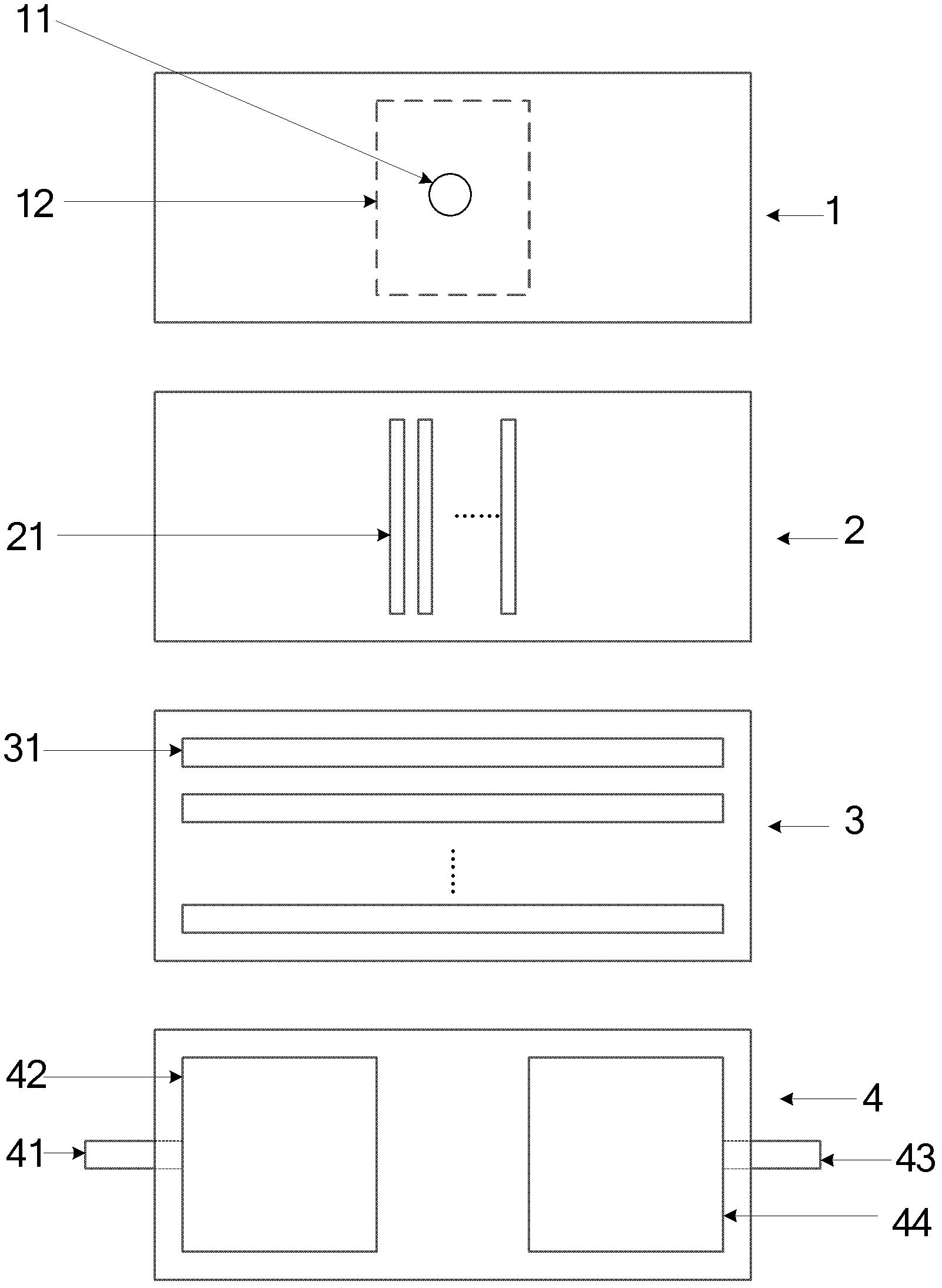

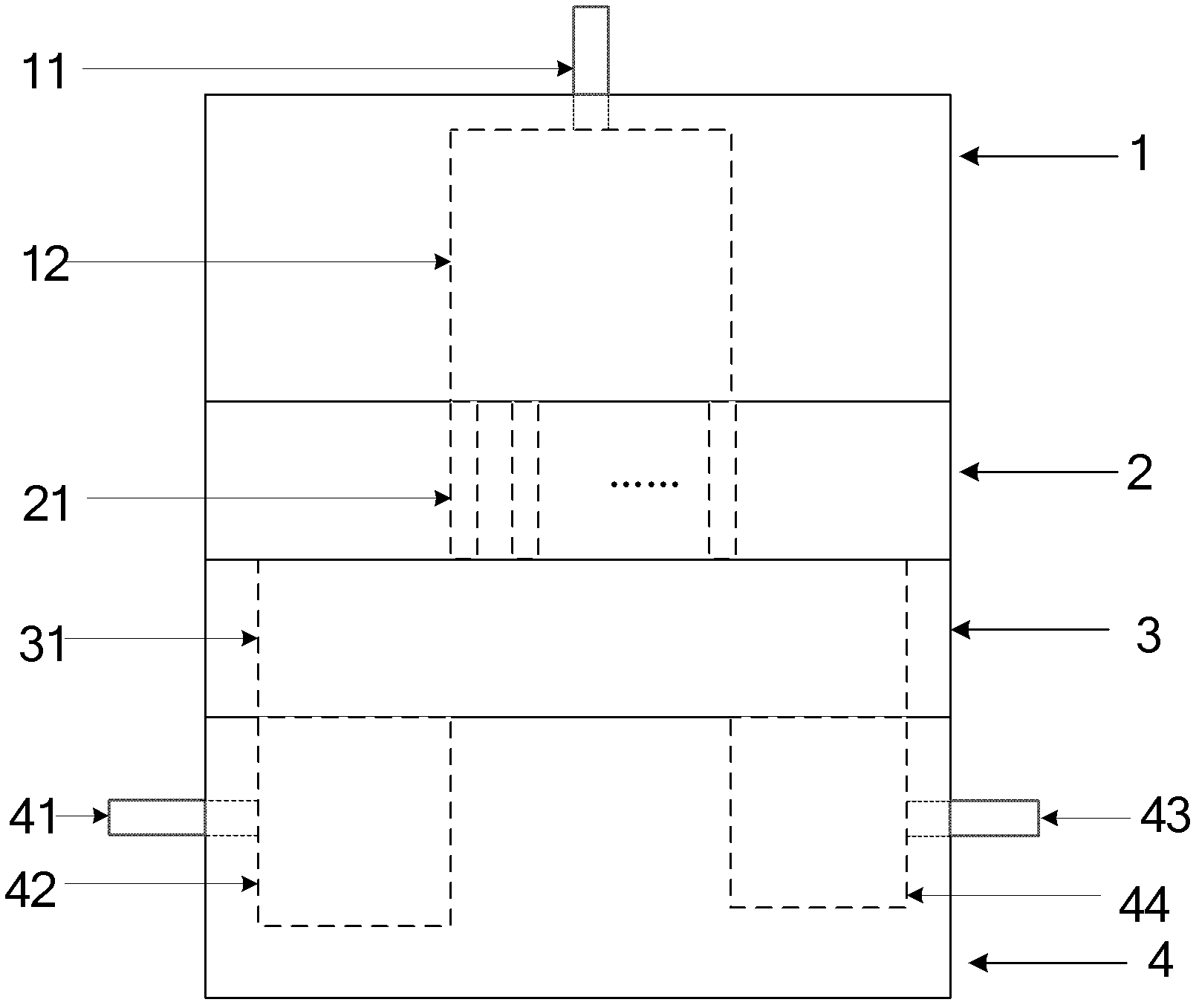

Self-cleaning polymerization reactor

ActiveCN101985096AAvoid product quality degradationGuaranteed mixing effectChemical/physical/physico-chemical stationary reactorsPolyesterEngineering

The invention relates to a self-cleaning polymerization reactor, which comprises a hermetic horizontal cylinder, wherein the cross section of the horizontal cylinder has a double circle shape; two main shafts are arranged in the cylinder, and are positioned in two centers of the double circles respectively; the main shafts are provided with a plurality of star rotors; each star rotor consists of a disc body and a hub in the center of the disc body; the disc body is provided with a plurality of spokes; the hub is sleeved on the main shaft; dynamic input ends of the two main shafts extend out of the horizontal cylinder, and are respectively connected with a drive device which is used for driving the two main shafts to rotate synchronously and reversely; the number of the spokes on the rotor is preferably 3; and the spokes are provided with a straight scraper or a scraper with a helical angle. When the reactor works, the spokes on the star rotors stir materials, and can continuously destroy and scrape remaining layers attached to the inner wall of the cylinder and the surfaces of the main shafts. The self-cleaning polymerization reactor is mainly used for the polymerization reaction of polylactic acid (PLA) and other polyesters.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

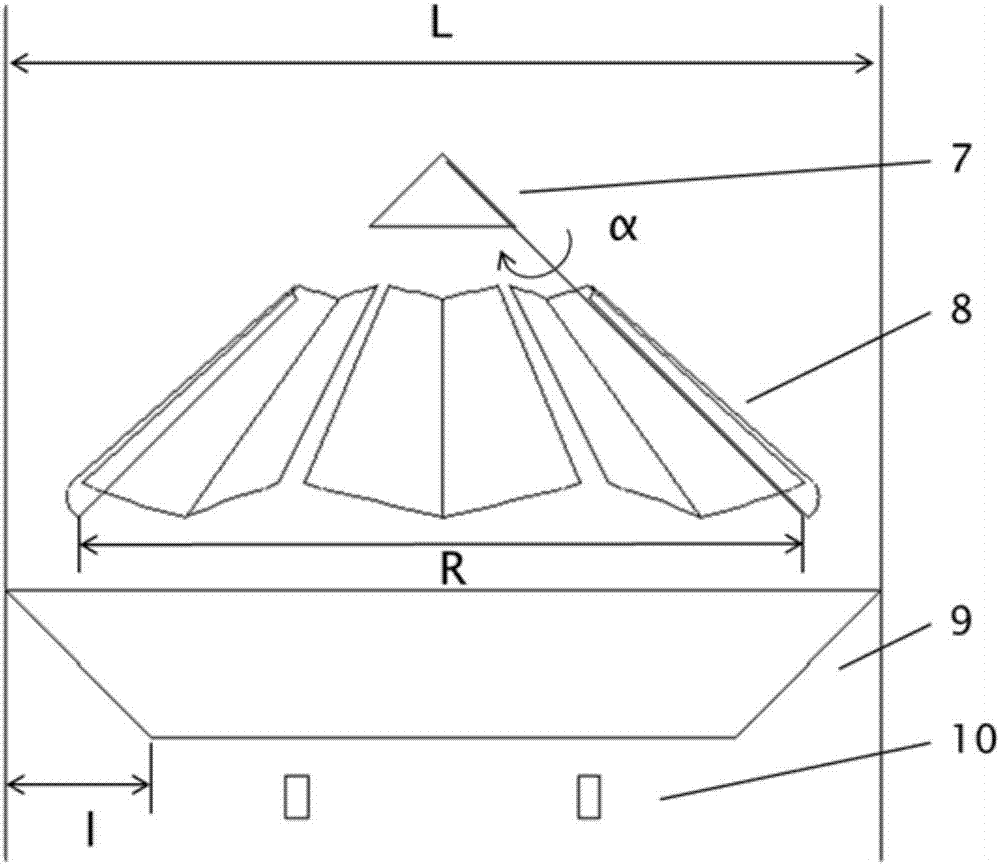

Vortex combined SCR static mixer

The invention discloses a vortex combined SCR static mixer, comprising a tip body, a plurality of arc flow deflectors with an axis where the tip body is located as a center axis, and a plurality of baffle plates uniformly distributed, with the axis as a center axis, on the lower ends of the flow deflectors, wherein the baffle plates allows flue gas to gather at an ammonia gas nozzle; the arc flow deflectors allow flue gas and ammonia gas to generate transverse speed and to spirally flow upward; and gas flow located at a central area and not directly influenced by the arc flow deflectors staggerly flows relative to peripheral gas flow after bumping onto the tip body, so flue gas and ammonia gas are mixed. The vortex combined SCR static mixer provided by the invention is beneficial for promoting diffusion of ammonia gas, greatly improves mixing effect, enhances the mol ratio uniformity of ammonia and nitrogen and exerts good effect on optimization and synergism of a SCR denitration system.

Owner:SHANDONG UNIV

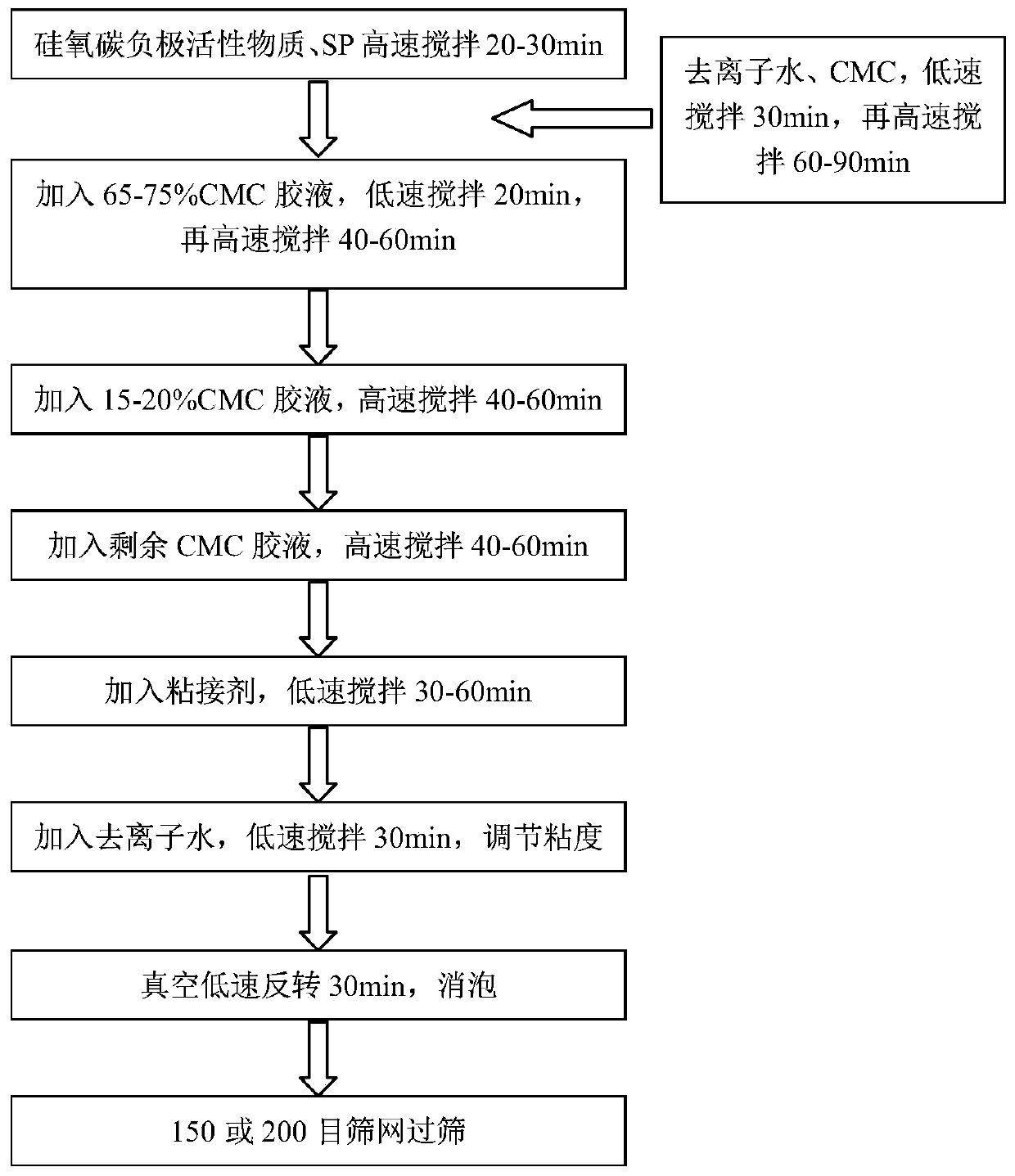

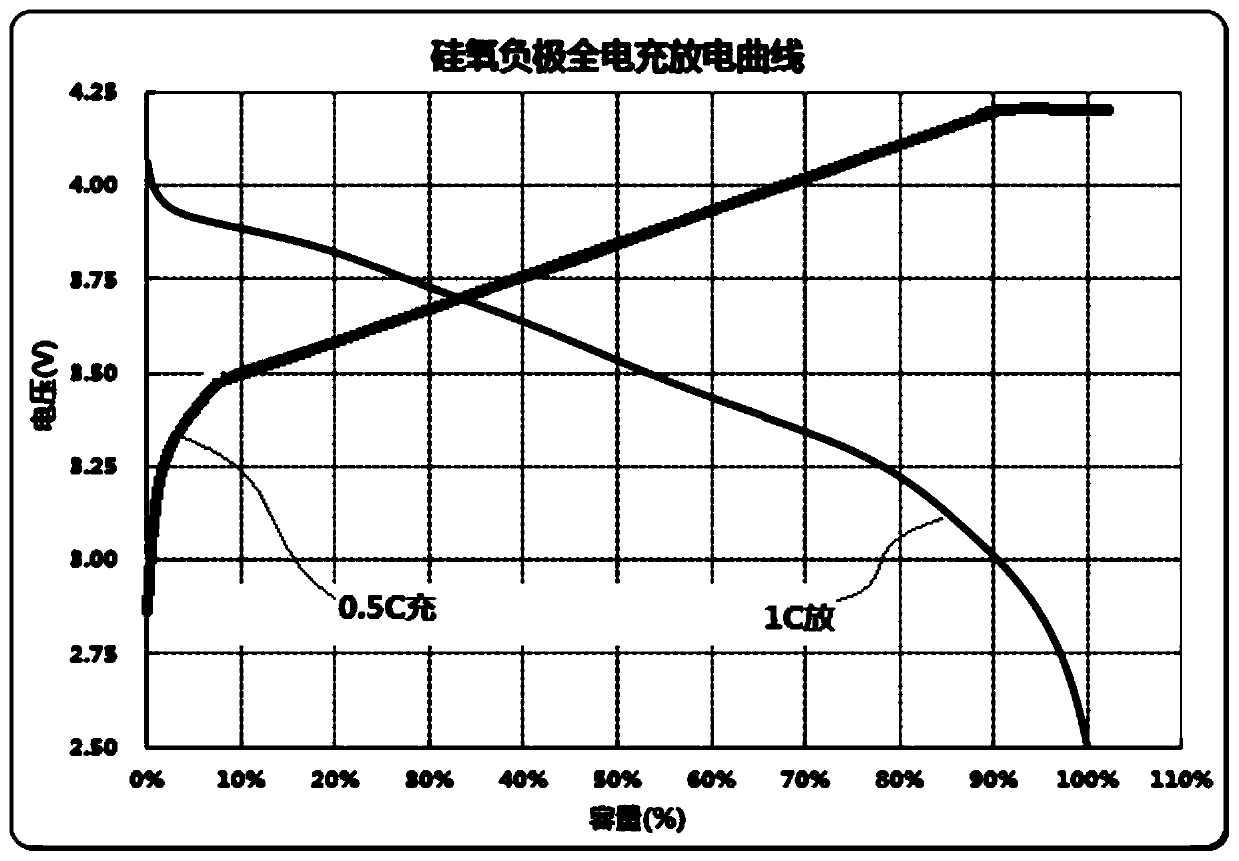

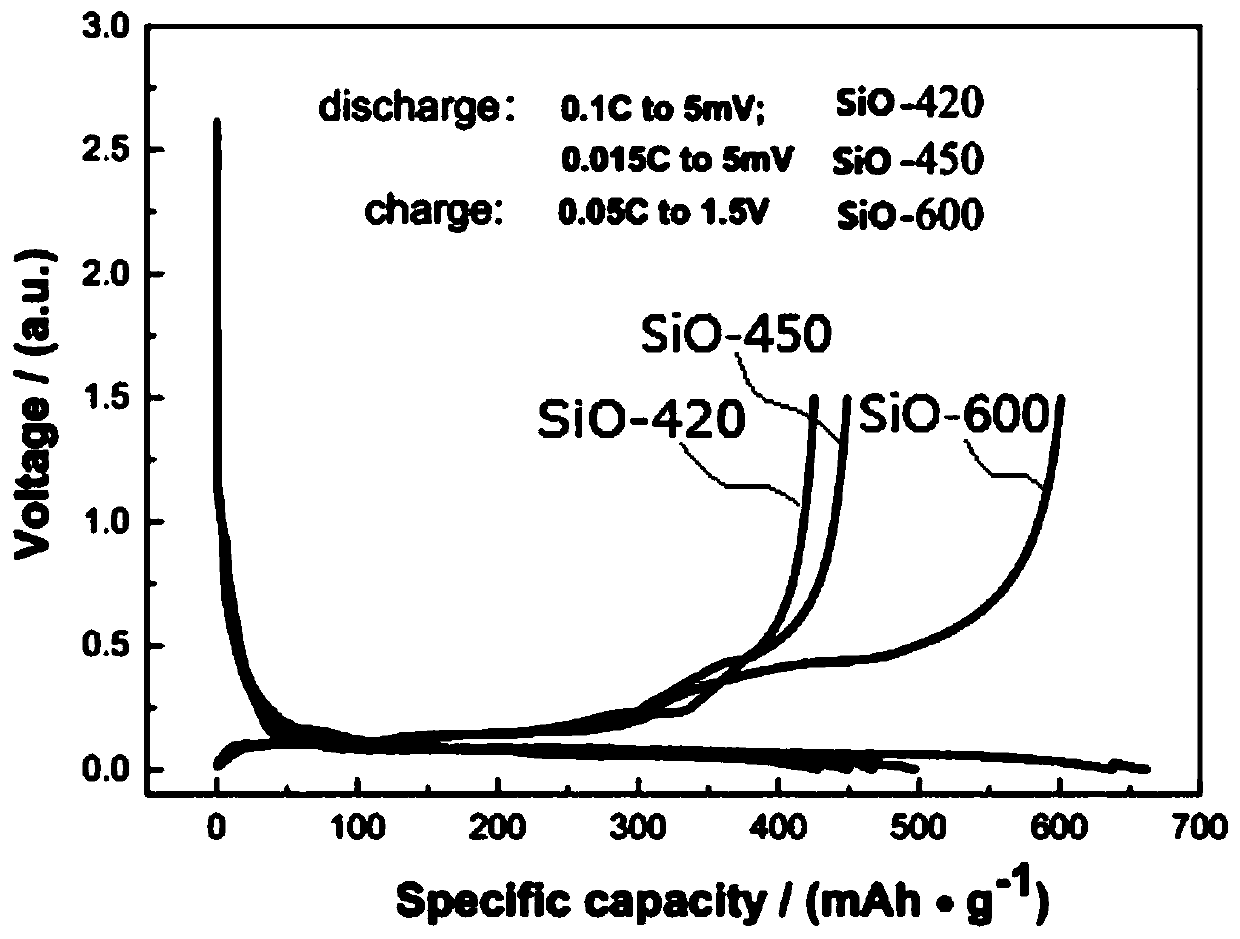

Lithium ion battery silicon oxygen anode paste, preparation method thereof, battery anode and lithium ion battery

PendingCN109950485AIncrease gram capacityImprove the first effectCell electrodesSecondary cellsGramSilicon oxygen

The invention discloses a lithium ion battery silicon oxygen anode paste, a preparation method thereof, a battery anode and a lithium ion battery, and belongs to the technical field of lithium ion battery manufacture. The lithium ion battery silicon oxygen anode paste comprises deionized water and a solid material. The solid materials comprises, with 100 total parts by weight, 93 to 97 parts of silicon-oxygen anode active material, 1 to 2 parts of CMC, binder of 1.2 to 2.0 times the CMC, and 1 to 2 parts of conductive agent SP. The solid material of the anode paste uses the 93 to 97 parts silicon-oxygen anode active material instead of the conventional graphite and the like. The prepared silicon-based anode has a much higher gram capacity than that of the graphite anode. The gram capacityof the anode active material can be greatly adjusted by adjusting the silicon content. The lithium ion battery silicon oxygen anode paste has stable later cycle stability, and high first effect.

Owner:SVOLT ENERGY TECH (MAANSHAN) CO LTD

Method of optimizing and returning to field of straw of cold region rice field

InactiveCN107484454ASolve floatingOvercoming the problem of easy hardeningSoil-working methodsEnvironment effectEcological safety

The invention discloses a method of optimizing and returning to field of straw of a cold region rice field, and relates to the field of returning to fields of straw of the rice fields. The method aims to solve the technical problems that according to a traditional method of returning to a field of straw, the effect of returning to the field is poor, during a process of returning to the field of the straw, the labor input of a farmer is increased, and the rice transplanting quality is affected. The method comprises the steps of (1) harvesting, wherein the straw is evenly dispersed in the field during harvesting; (2) land preparation and stubble burying, (3) irrigation for field steeping, stubble burying and land leveling and (4) rice transplanting and fertilizer application. Through the method, not only can returning to the field of the straw be achieved in the cold region rice field to achieve a purpose of land fertility betterment, but also negative environment effects caused by mass burning of the straw are alleviated, and fertilizer saving, the high yield, the high quality, the high efficiency and the ecological safety of the rice field are achieved; the method is used for returning to the field of the straw in a cold region.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

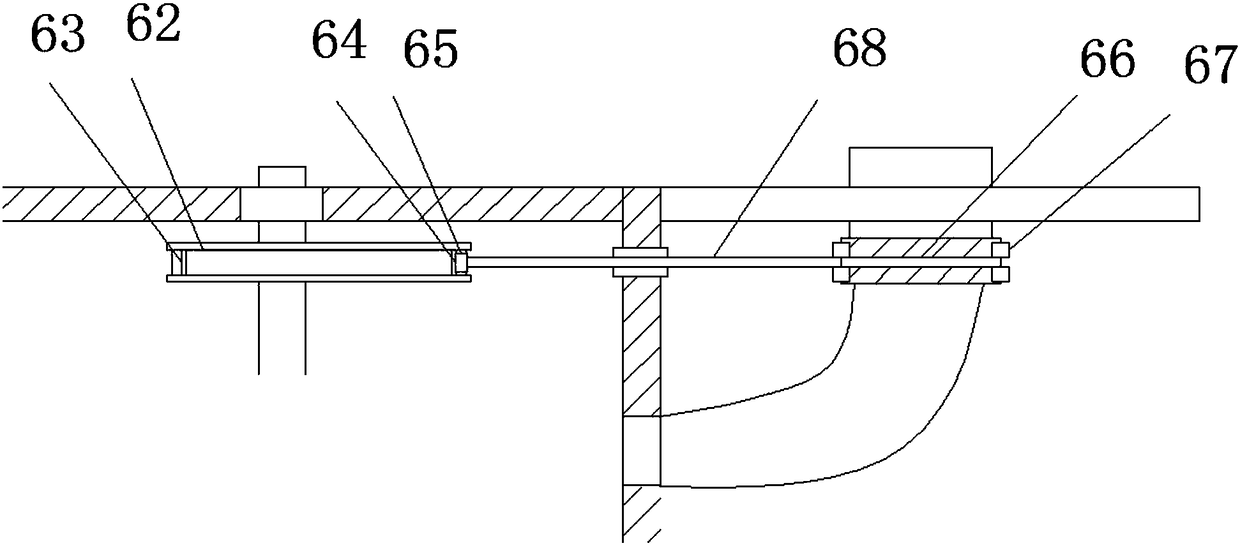

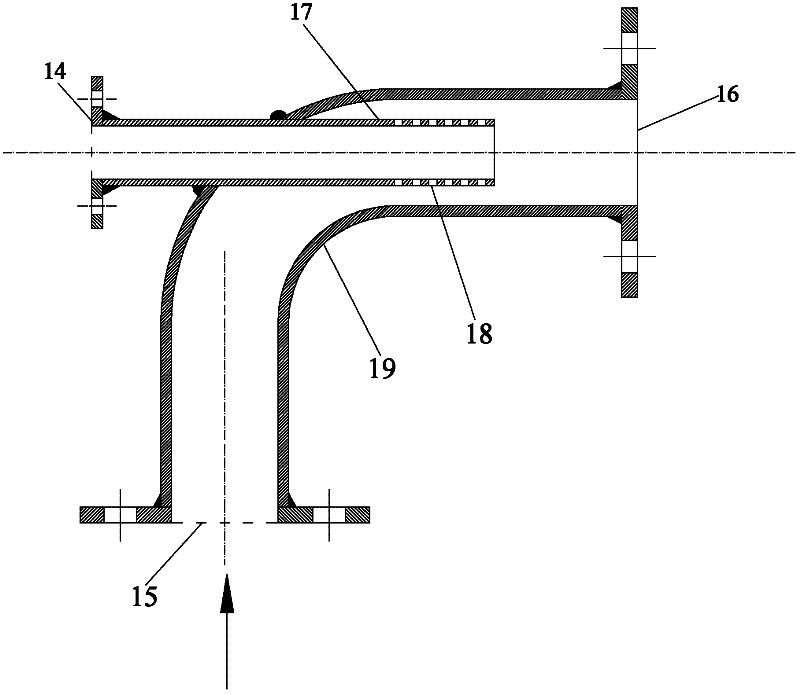

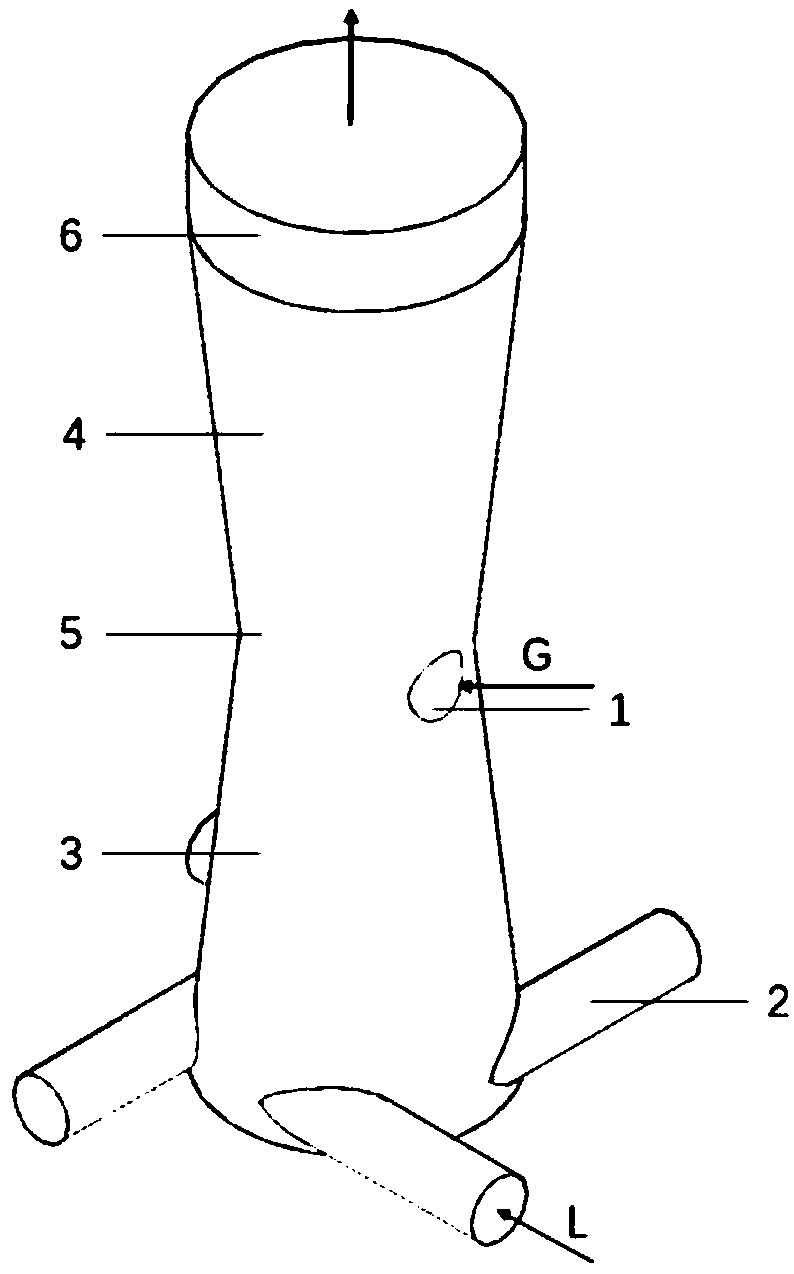

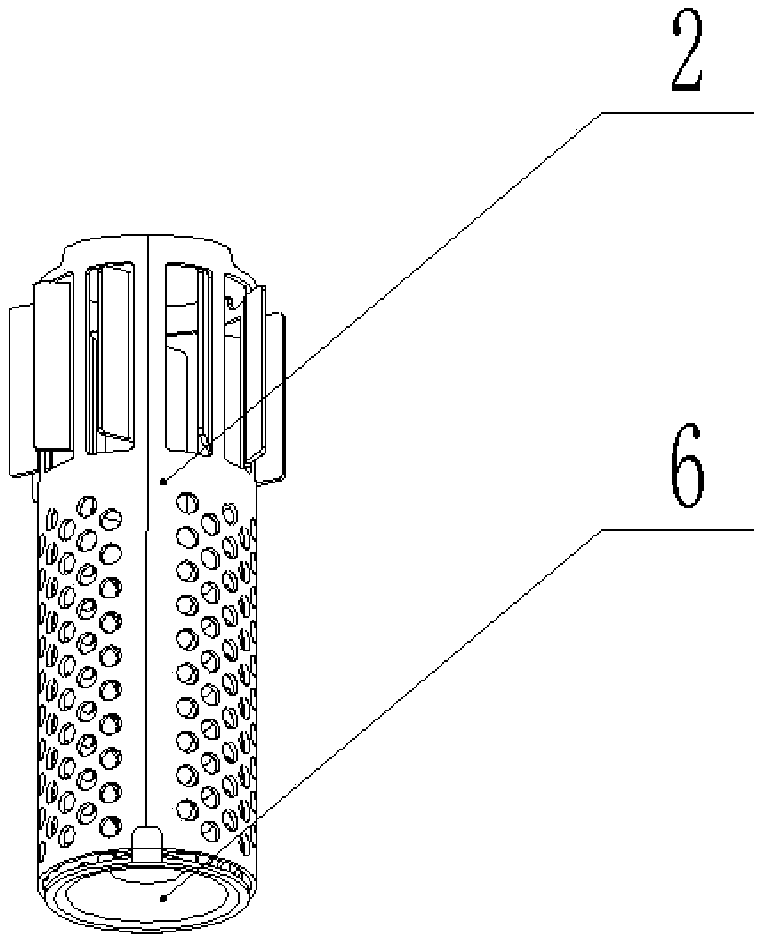

Gas liquid mixing apparatus and application method thereof

ActiveCN102309932AGuaranteed mixing effectWill not flow backFlow mixersMixing methodsEngineeringProcess engineering

The invention provides a gas liquid mixing apparatus and an application method thereof. The gas liquid mixing apparatus comprises a liquid inlet pipe (19) and a gas inlet pipe (17), and is characterized in that the gas liquid mixing apparatus also includes a gas distributor pipe (3) and a drive unit. One end of the gas inlet pipe (17) is equipped with a plurality of first gas spray orifices (18),which are inserted into liquid inlet pipe (19); the gas distributor pipe (3) is sleeved in the gas inlet pipe (17) and is equipped with a plurality of second gas spray orifices (2) on corresponding positions of the first gas spray orifices (18) at one end; the drive unit drives the gas distributor pipe (3) to move, so as to adjust relative positions of the first gas spray orifices (18) and the second gas spray orifices (2). The gas liquid mixing apparatus of the present invention can rapidly cut out gas feed when gas lateral pressure and flow are reduced, so as to guarantee no backflow.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

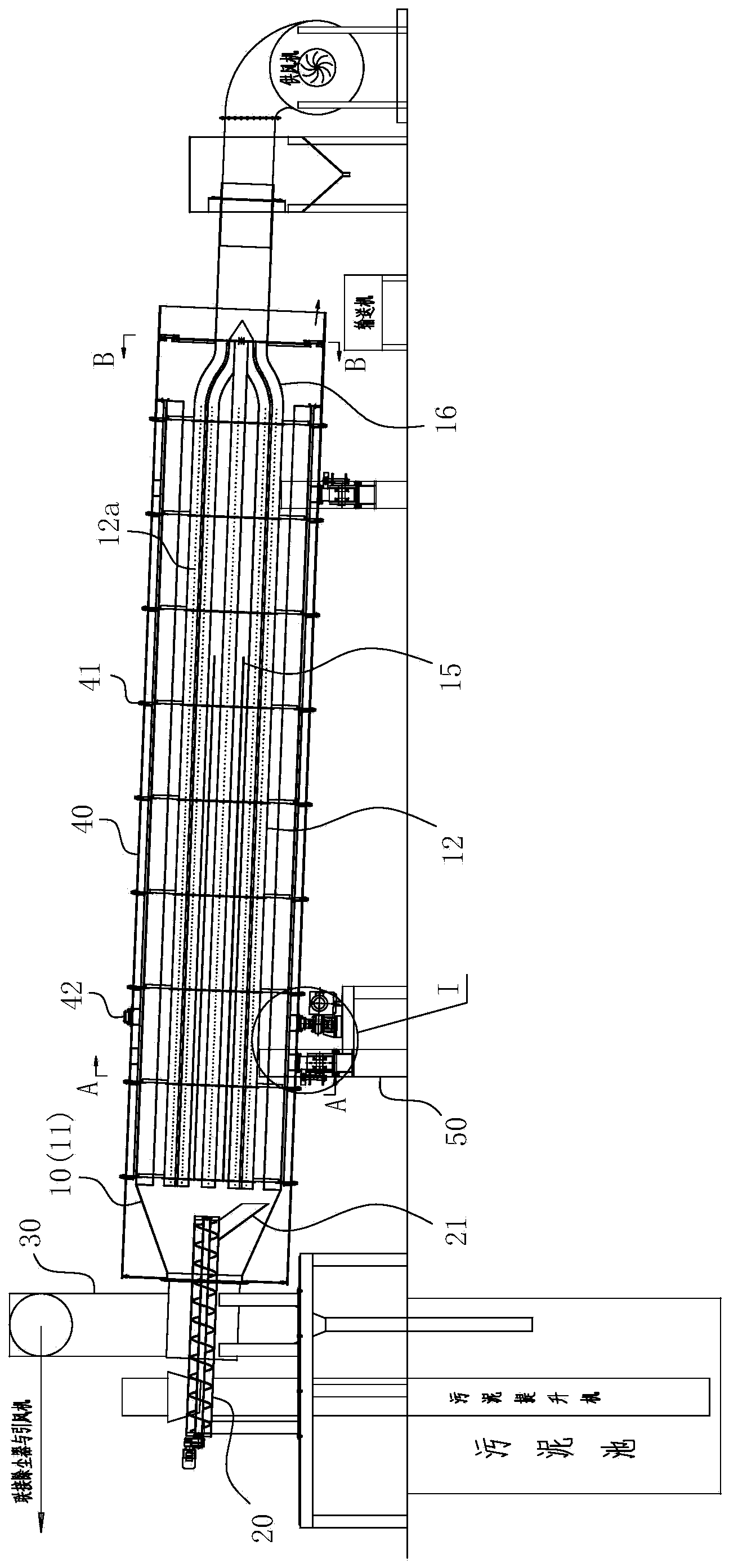

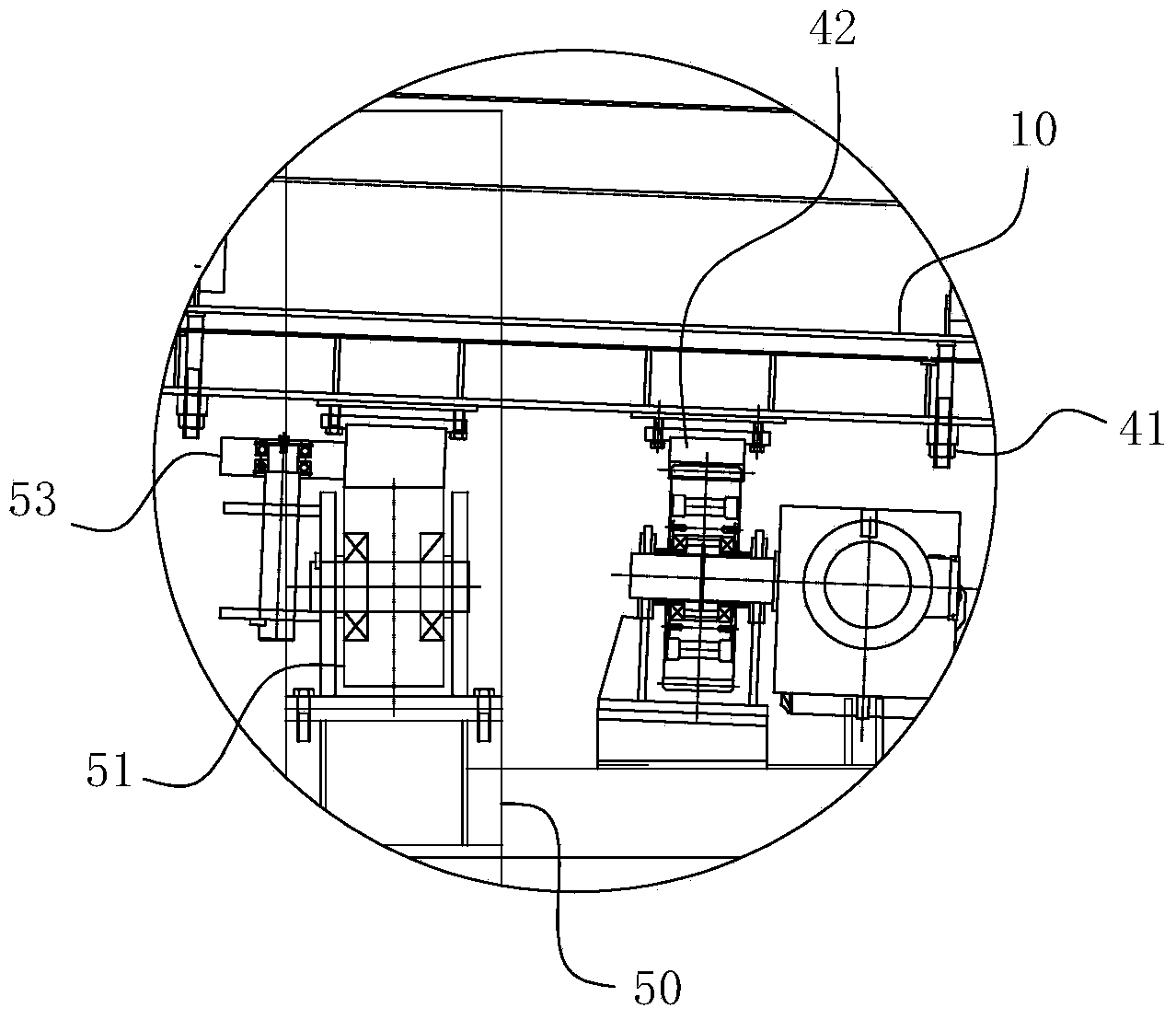

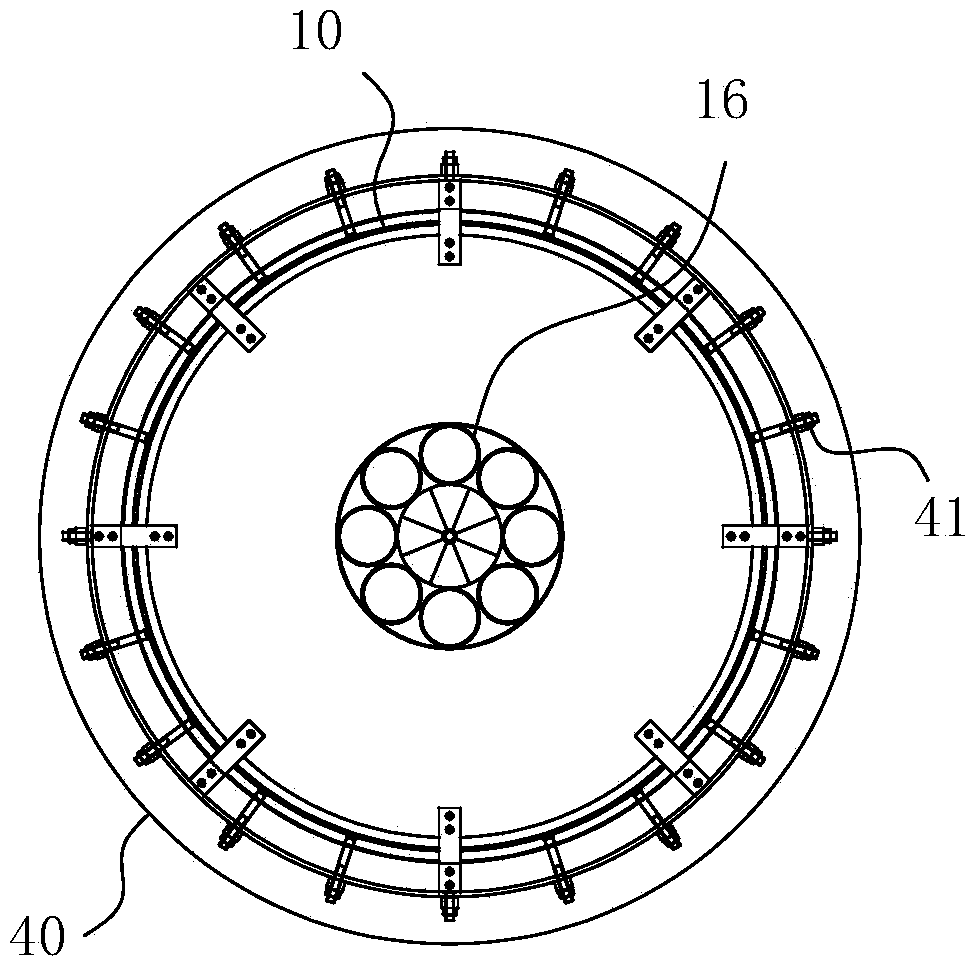

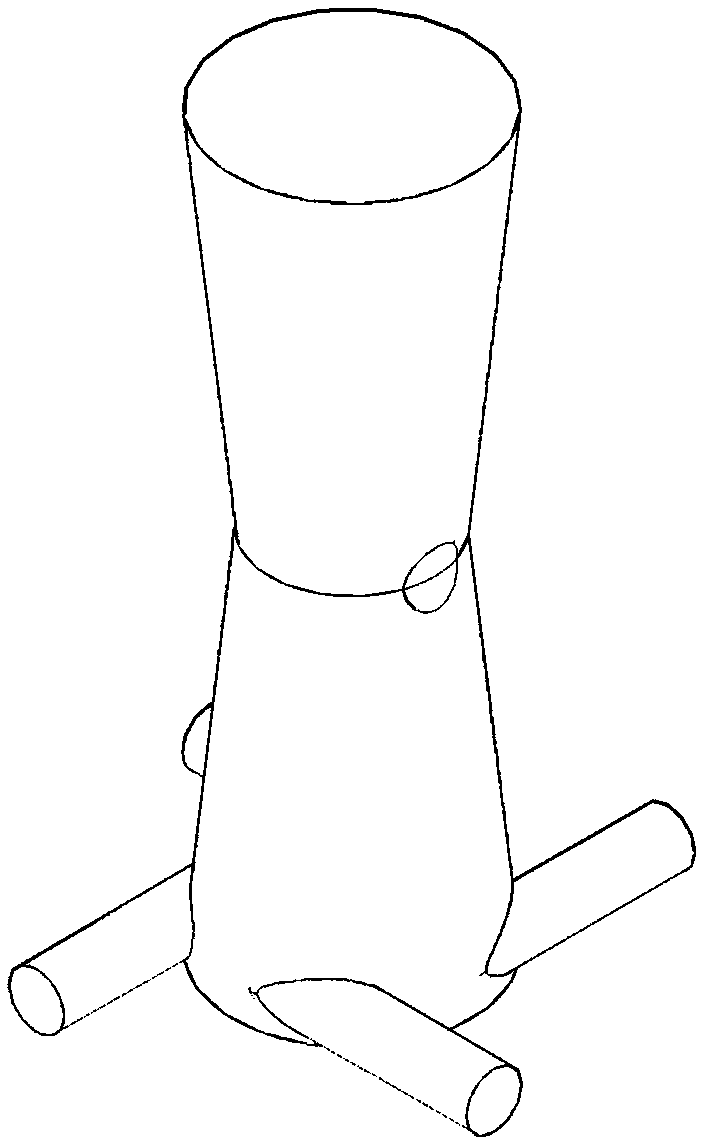

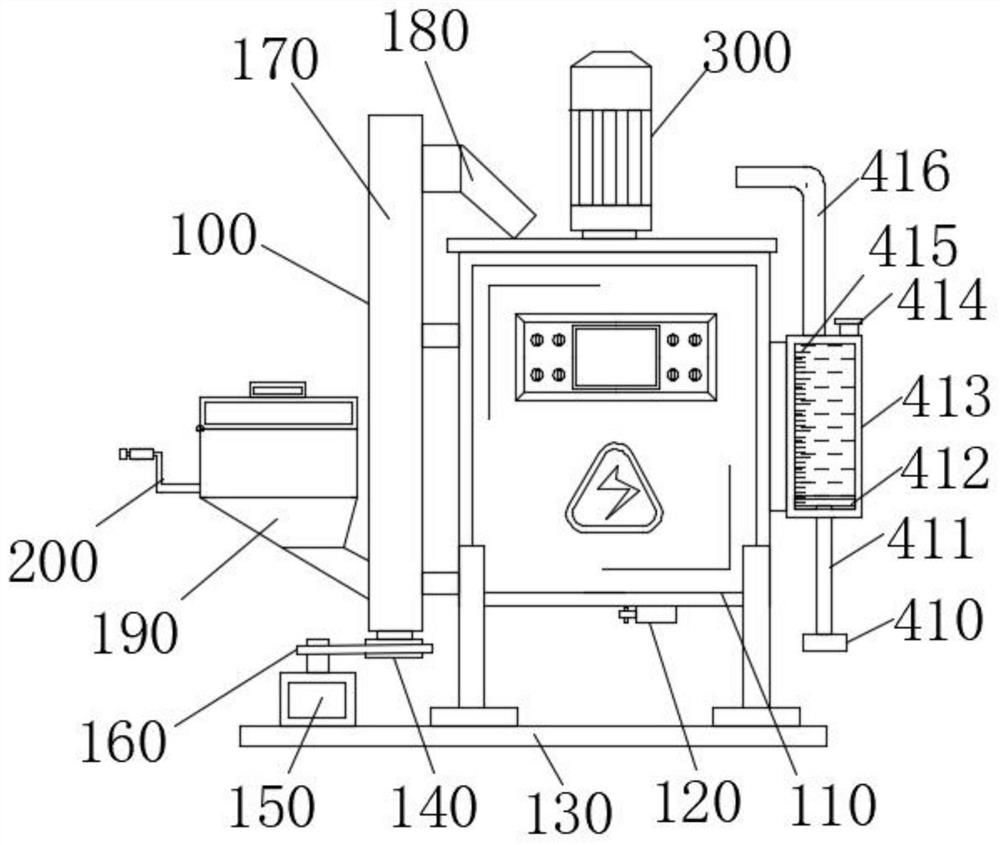

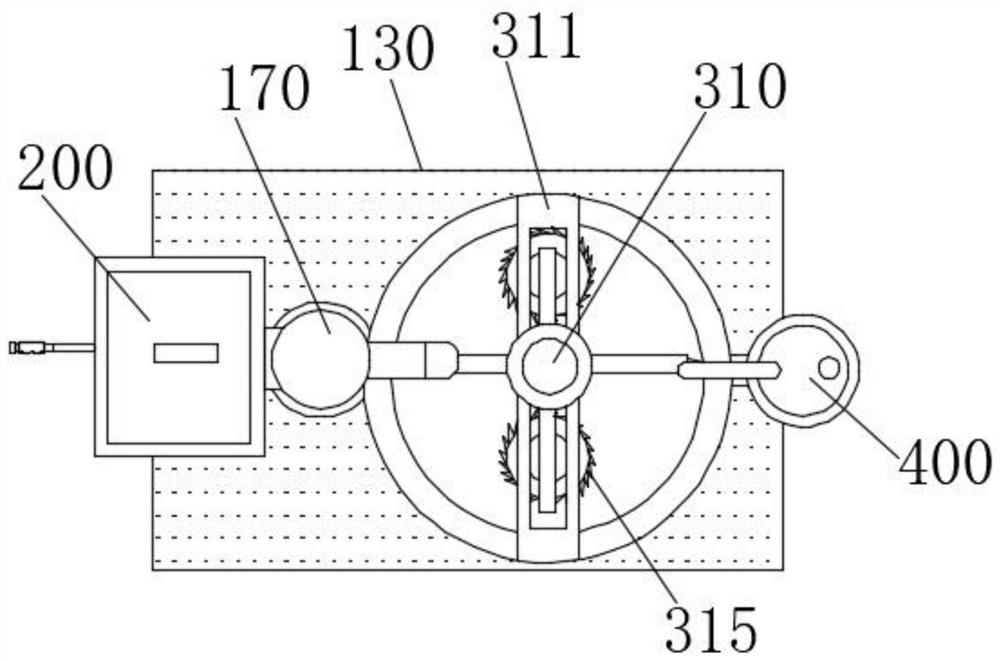

Sludge drying equipment

InactiveCN103588377ASolve the problem of fast bakingThe rapid baking problem reachesSludge treatment by de-watering/drying/thickeningSludgeWaste treatment

The invention belongs to the field of solid waste treatment, in particular relates to sludge drying equipment based on drying treatment of urban sludge. The sludge drying equipment comprises a drum with an inclined axis, and a driving assembly for driving the drum to rotate along the axis of the drum, wherein the drum is provided with an accommodating cavity for accommodating sludge; the accommodating cavity is arranged in the axial direction of the drum and in a penetrating manner; the feeding end of the accommodating cavity is arranged at the high end part of the drum, and the discharging end of the accommodating cavity is arranged at the lower end part of the drum; the sludge drying equipment further comprises heat supply pipes for supplying heat to the accommodating cavity; the heat supply pipes are arranged in the accommodating cavity; two or more heat supply pipes are arranged in the axial direction of the accommodating cavity; air vent holes communicated with the cavities of the heat supply pipes and the accommodating cavity are formed in the walls of the heat supply pipes. The heat supply pipes of the invention are used as stirring pipes of the whole accommodating cavity while performing the functions of supplying heat and drying. The sludge drying equipment has the advantages of simple structure, easy and reliable operation, effective achievement of purpose of drying existing wet sludge and extremely-high drying efficiency.

Owner:HEFEI HUANKUN SLUDGE DRYING EQUIP

Cyclone type micro-bubble generator and gas-liquid reactor

ActiveCN109550418AExtended stayImprove scoreFlow mixersTransportation and packagingCycloneEngineering

The invention discloses a micro-bubble generator and gas-liquid reactor comprising same. The micro-bubble generator is composed of a liquid inlet pipe, a gas inlet hole and a Venturi pipe. The Venturipipe at least includes, successively from bottom to top, a shrinking portion with sealed bottom, a throat tube portion and an expanding portion, wherein the liquid inlet pipe is located at the bottomof the shrinking portion of the Venturi pipe and the gas inlet hole is formed in the throat tube portion. The micro-bubble generator has compact structure, is low in energy consumption, is good in micro-bubble generation effect and is convenient to maintain. By using the micro-bubble generator, the gas-liquid reactor is greatly improved in gas-liquid mass transfer efficiency.

Owner:ZHEJIANG UNIV

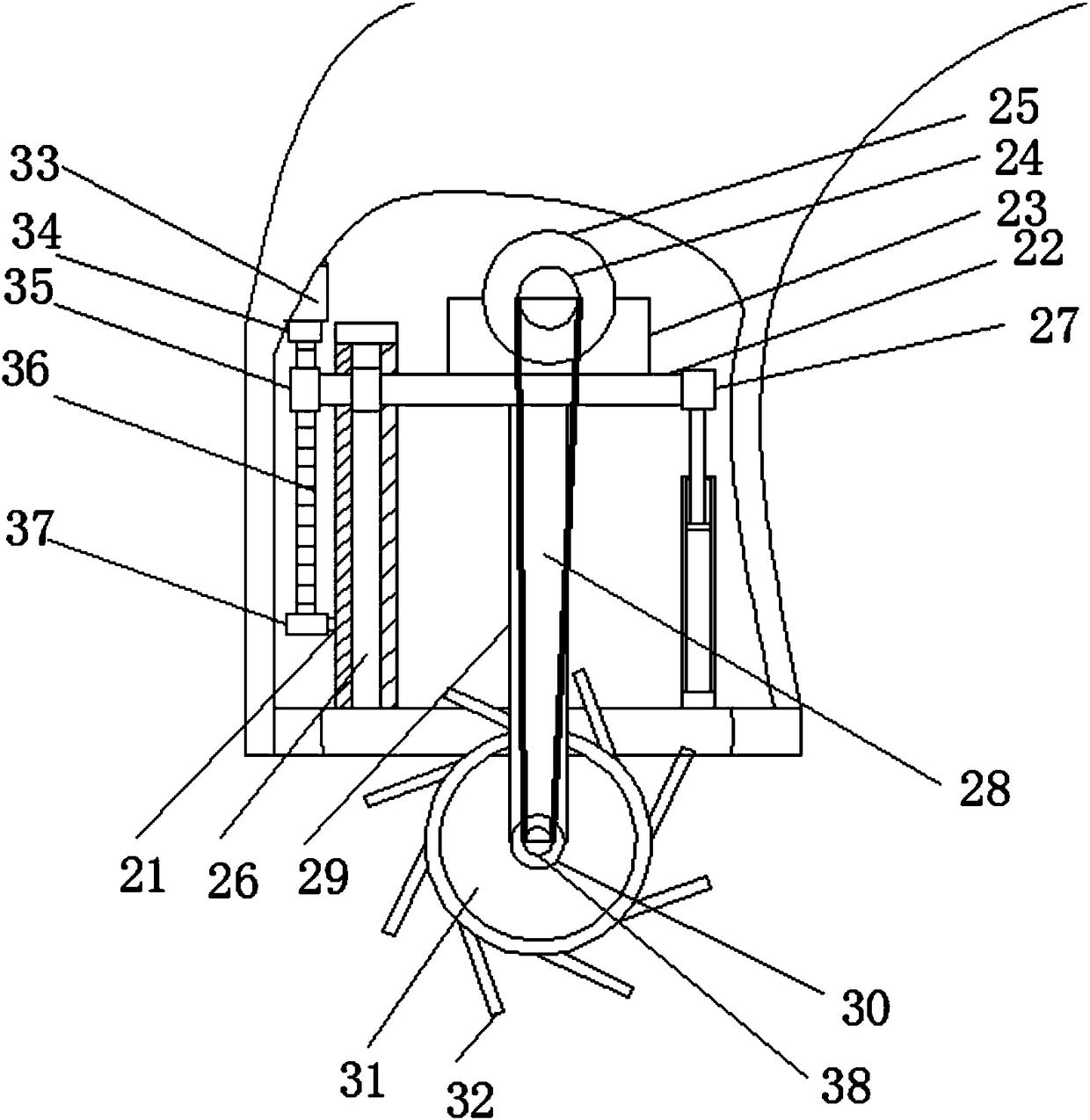

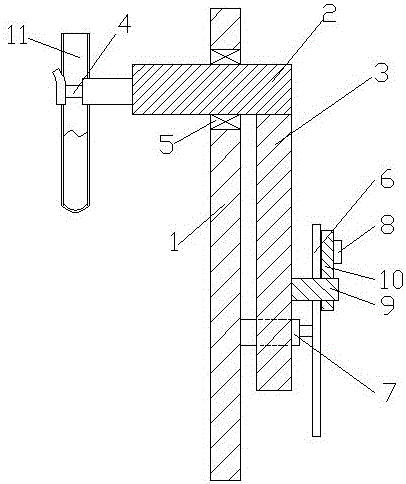

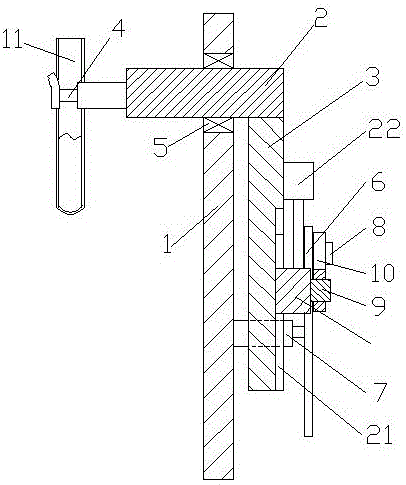

Blood shaker

InactiveCN106546475AStabilizing Oscillation EffectsGuaranteed mixing effectPreparing sample for investigationEngineeringMotor shaft

The invention belongs to the technical field of medical inspection equipment, and provides a blood shaker to avoid defects and insufficient in the prior art. The blood shaker comprises a fixing plate, a rotating shaft, a swing plate, a circular rotating disk arranged on one side of the swing plate, and a motor fixedly arranged on the fixing plate; one end of the rotating shaft is fixedly arranged on the swing plate; the fixing plate is penetrated by the other end of the rotating shaft, and the end is provided with a test tube clamp head; the rotating shaft and the fixing plate are connected and fixed using a bearing; a motor shaft is fixedly connected with the axis center of the circular rotating disk; an eccentric hinge shaft is arranged on the disk surface of an eccentric part of the circular rotating disk; one end of a connecting rod is connected with the eccentric hinge shaft via hinge joint, and the other end of the connecting rod is connected with the swing plate via hinge joint; and the swing plate can be driven by rotating of the circular rotating disk to perform pendular movement. The blood shaker is simple in structure, reasonable in design, and low in manufacturing cost.

Owner:蔡文玲

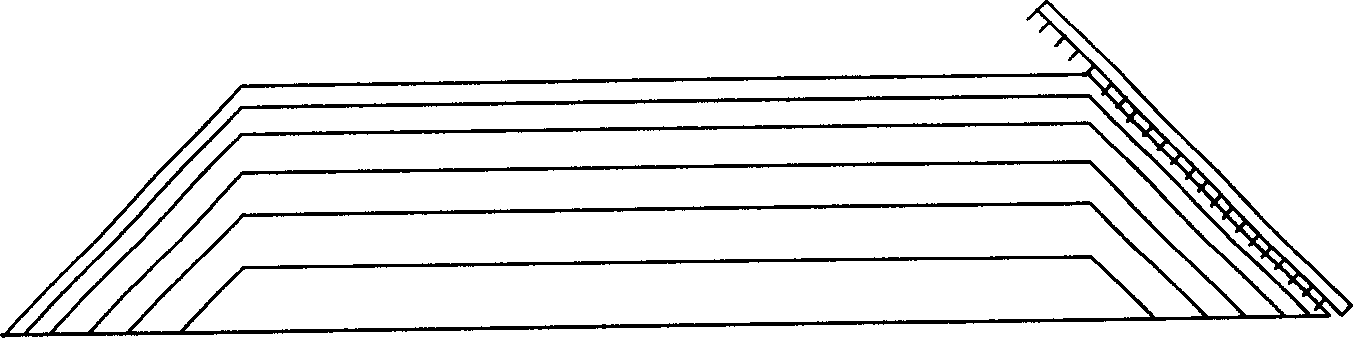

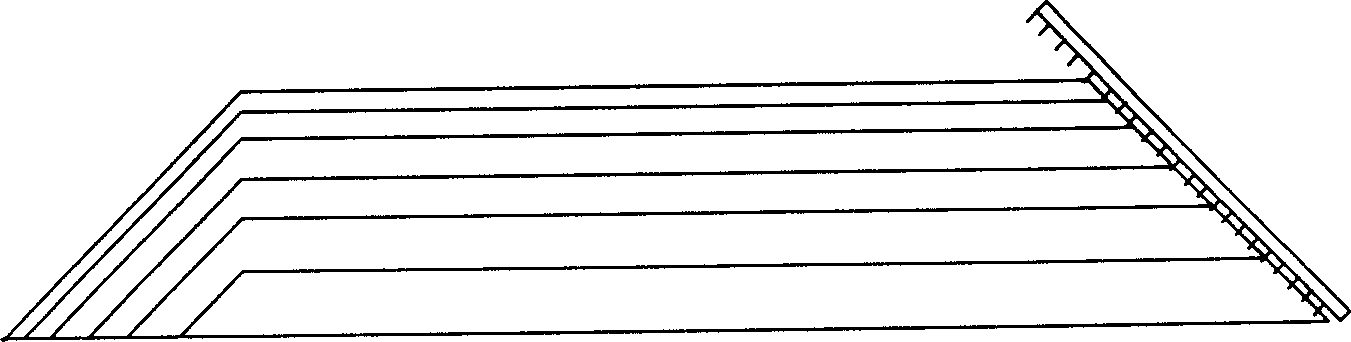

Materials piling method at end of rectangular pre-equalizing materials field

InactiveCN1817769AGuaranteed mixing effectEliminate the "end pile effect"Loading/unloadingProgramme control in sequence/logic controllersStack machineEngineering

A material stacking method for the stack end in rectangular pre-homogenized raw materials field of cement mill features that when the stacking machine moves the right end of a stack, its return point is shifted left by a certain distance as compared with previous return point, and it stays for a certain time for stacking. The higher the stack, the less the shift and the longer the stacking time.

Owner:沈阳矿山机械有限公司

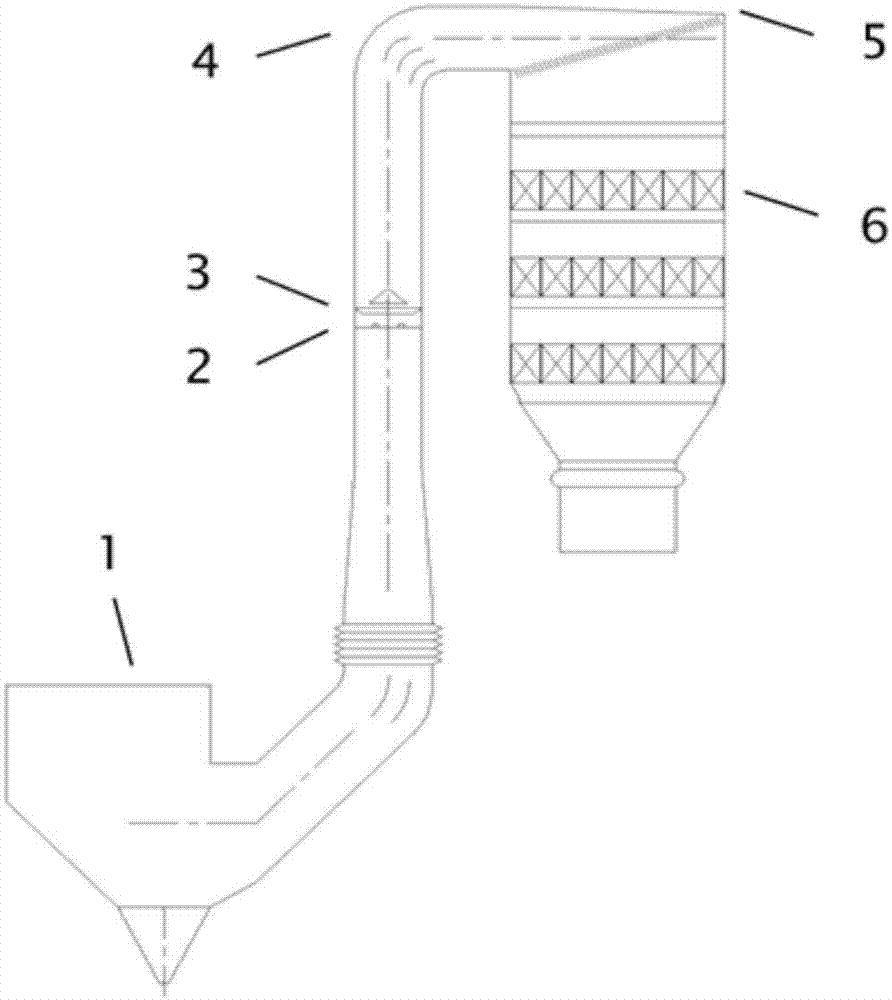

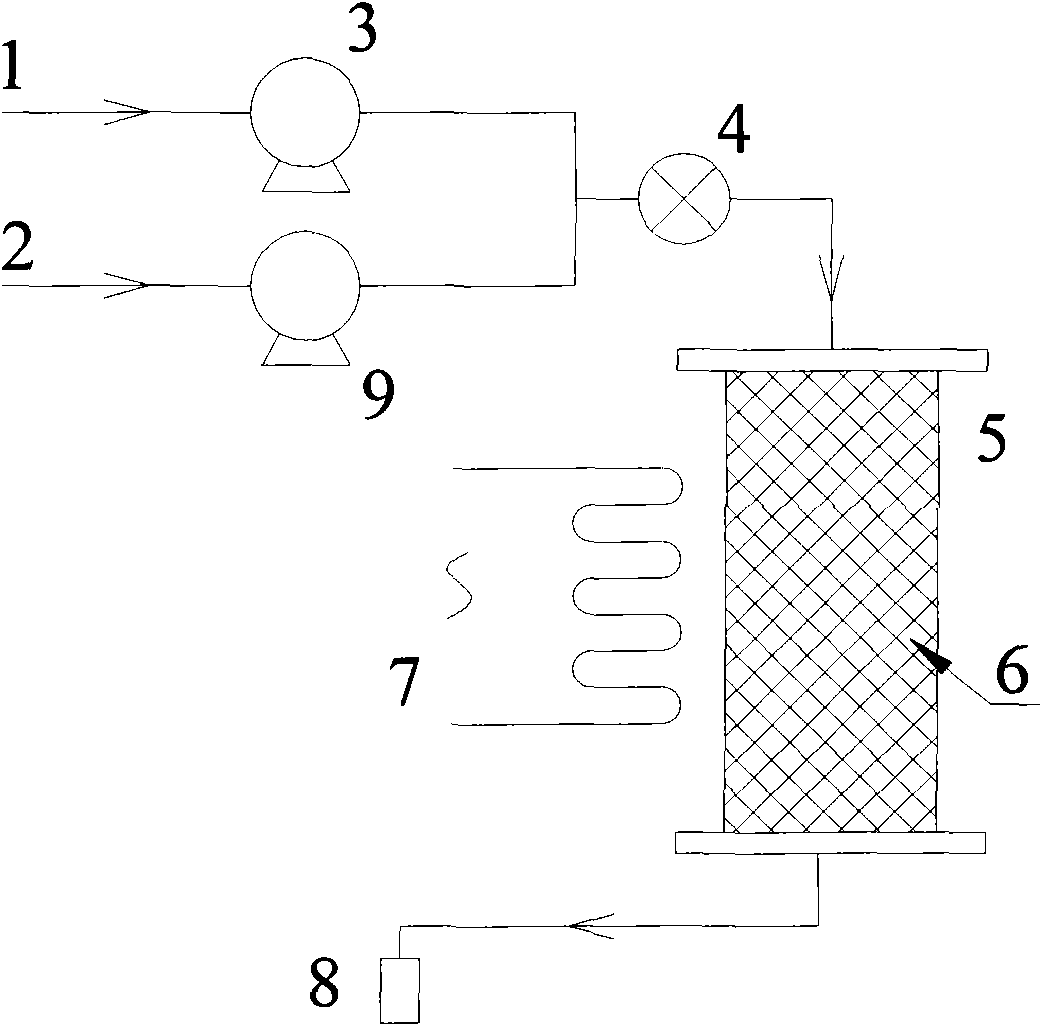

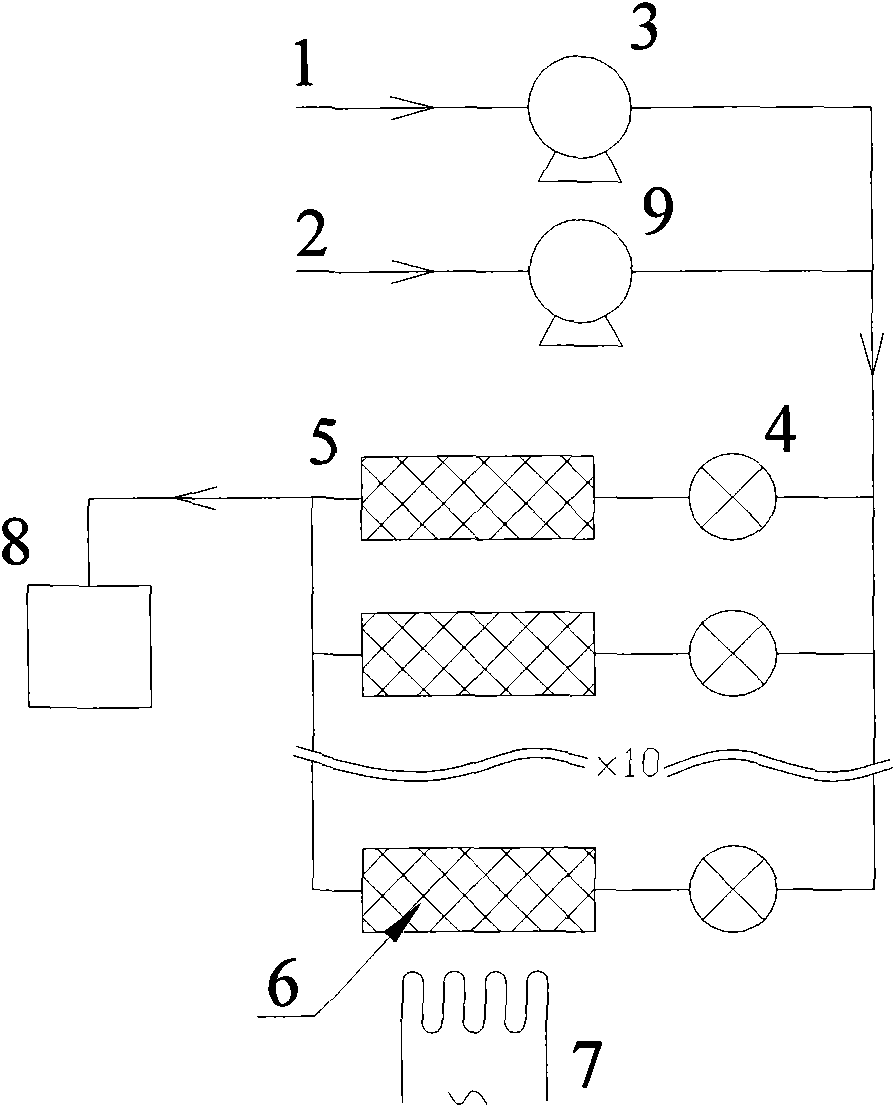

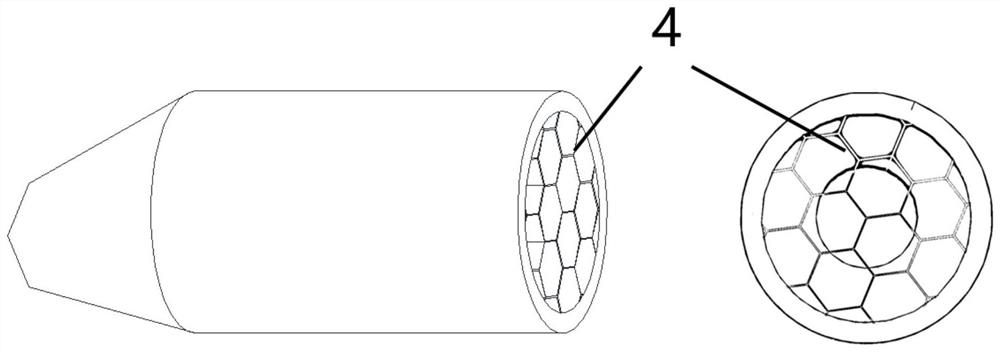

Device and method for continuously preparing biodiesel

InactiveCN101586041AImprove efficiencySimple processBiofuelsLiquid carbonaceous fuelsOil and greaseBiodiesel

The invention relates to a device and method for continuously preparing biodiesel with foamed metal filling reactor. The invention includes firstly injecting lipid and low carbon alcoholic solution with dissolved basic catalyst into a passive mixer 4 according to a setting ratio continuously and respectively, forming a chaotic stream intensified mixture inside, emulsifying and dispersing; and then continuously injecting the emulsified mixture into a reactor 5 for filling foamed metal 6, furthermore intensifying and mixing, and guaranteeing the reaction temperature through a heating mechanism 7 outside the reactor; at last, obtaining biodiesel through separation and purification from the reaction product. The apparatus and method for preparing biodiesel according to the invention have the advantages of simple technique, low energy consumption, high efficiency, continuous operation, mass production convenience or the like.

Owner:EAST CHINA UNIV OF SCI & TECH

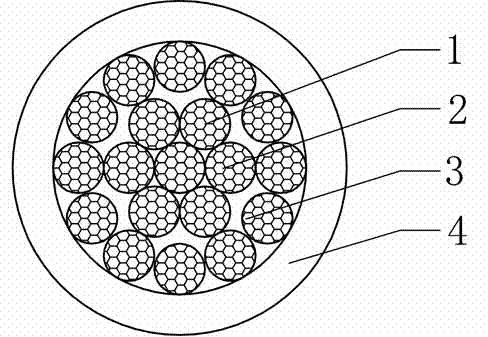

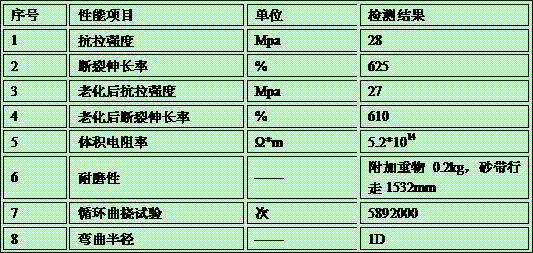

Preparation method of super-soft cable and external coating material of super-soft cable

ActiveCN104761909AWill not deformSmall bending radiusFlexible cablesCable/conductor manufactureYarnSesquioxide

The invention discloses a preparation method of a super-soft cable and an external coating material of the super-soft cable. The super-soft cable comprises a conductive core stranded by 7-61 groups of folded yarns and the external coating material of the conductive core, wherein each of the folded yarns is stranded by a plurality of tinned copper wires; the conductive core is coated with super-soft high-strength silicon rubber for insulation; the high-strength silicon rubber comprises the following components: methyl vinyl silicone rubber, precipitated white carbon, iron sesquioxide, chlorinated paraffin, magnesium hydrate, an anti-aging agent N-isopropyl benzene-N'-phenyl p-phenylenediamine, hydroxyl silicone oil, silicone oil containing hydrogen, dioctyl phthalate, a surfactant gamma-thiopropyl triethoxy silane, a silane coupling agent and a bis-2, 5 vulcanizing agent. The super-soft cable has the characteristics of bending resistance, corrosion resistance, wear resistance and the like, is relatively high in using temperature and relatively long in service life, and can be used for various types of equipment which is small in cable laying space and great in number of round trips.

Owner:西安飞机工业(集团)亨通航空电子有限公司

Ink box for copying machine

ActiveCN108790415ASpeed up the flowFast fullRotary stirring mixersTransportation and packagingCold airEngineering

The invention relates to the technical field of copying machine equipment and discloses an ink box for a copying machine. The ink box comprises an ink box body and an air guiding box. The ink box bodyis provided with an ink outlet. The air guiding box is provided with air inlets and an air outlet. The ink box body is provided with an air supply box. A guide pipe communicates with the air supply box and is provided with a first three-way valve. The first three-way valve communicates with the air inlets. A rotating shaft is connected into the air guiding box in a rotary manner. A turbine is connected to the rotating shaft in a sleeving manner. One end of the rotating shaft penetrates the air guiding box and extends into the ink box body. A sliding sleeve is connected to the rotating shaft in a sleeving and threaded manner. A stirring plate is fixedly connected to the sliding sleeve. A cavity is formed in the inner wall of the ink box body. A vortex tube is fixedly connected to the ink box body, wherein the vortex tube communicates with the air outlet. The hot air end and the cold air end of the vortex tube each communicate with the cavity. A second three-way valve is connected between the hot air end of the vortex tube and the cavity. A third three-way valve is connected between the cold air end of the vortex tube and the cavity. By means of the ink box, the problem that in theprior art, due to the fact that ink in an ink box is frozen, normal coping cannot be conducted is solved.

Owner:贵州省仁怀市西科电脑科技有限公司

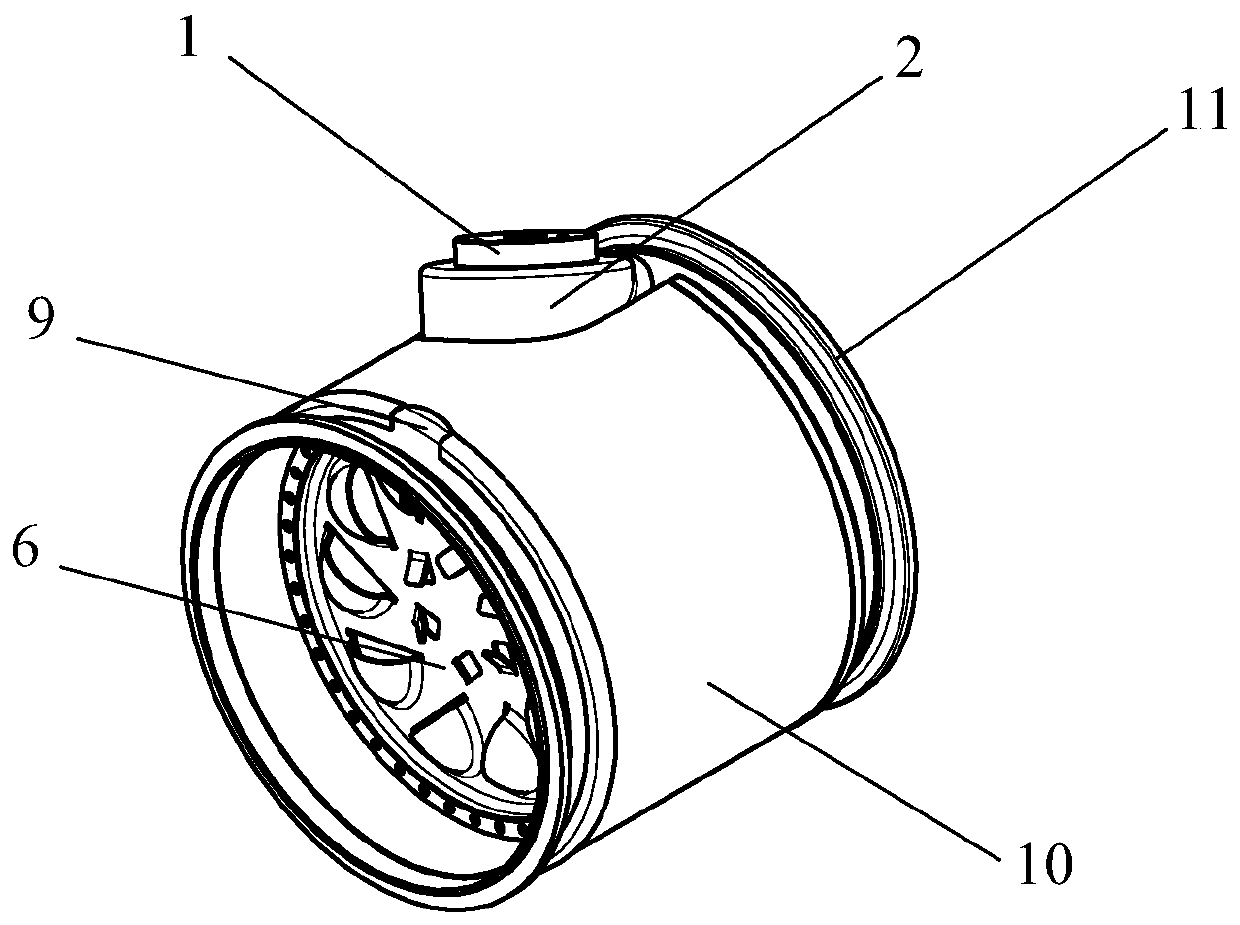

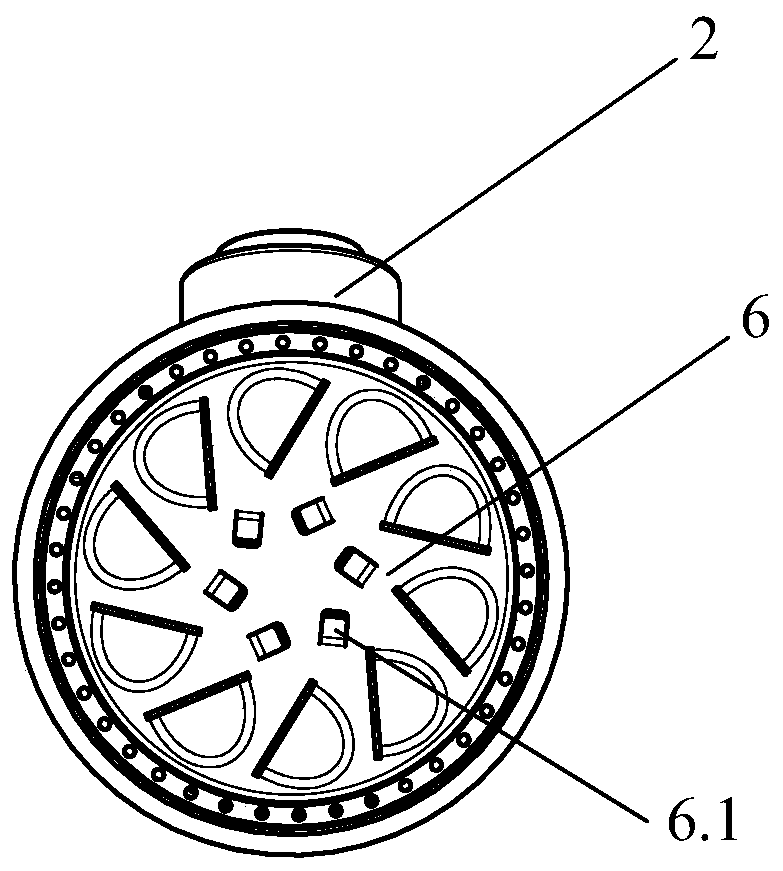

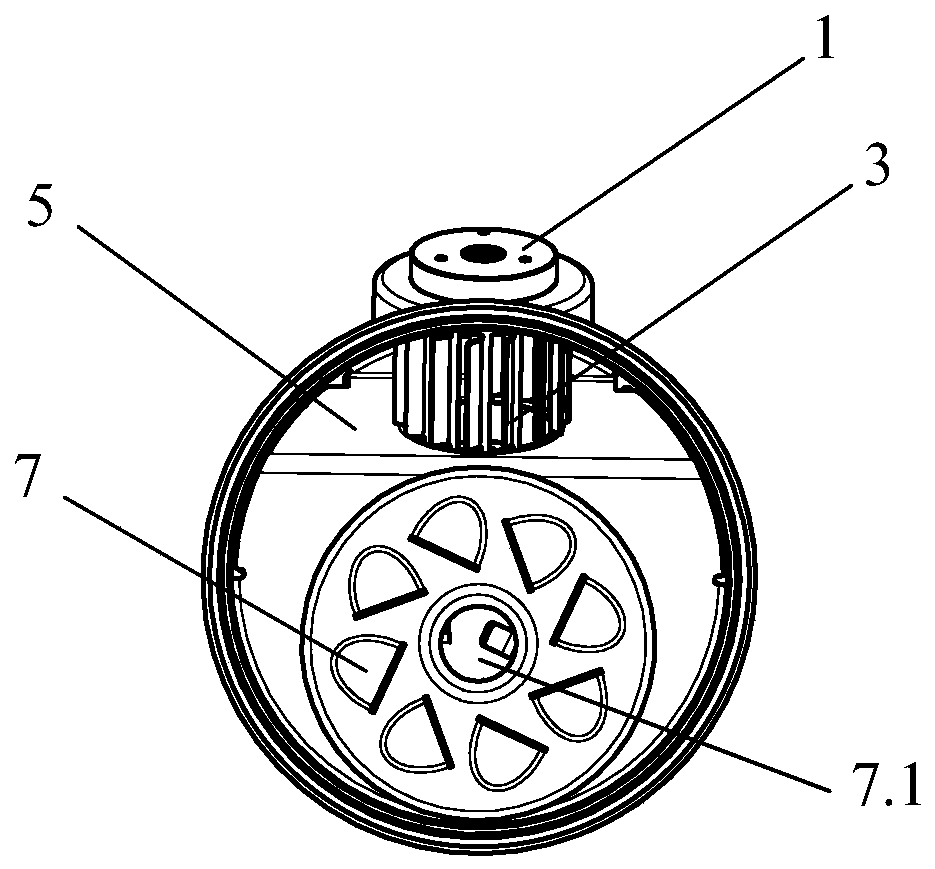

Dual-swirl inclined cylindrical type urea mixer and application in exhaust after-treatment device thereof

InactiveCN109505685APlay a secondary mixing effectReduced risk of crystallizationInternal combustion piston enginesExhaust apparatusAfter treatmentExhaust fumes

The invention relates to a dual-swirl inclined cylindrical type urea mixer and application in an exhaust after-treatment device thereof, and belongs to the technical field of tail gas after-treatmentof diesel engines. The double-swirl inclined cylindrical type urea mixer comprises a Z-shaped partition plate, a swirl tube, a cylinder body, a nozzle base, a swirl plate, a blocking cover and a ureanozzle, the urea nozzle is mounted on the nozzle base, both of the urea nozzle and the nozzle base are obliquely mounted on the cylinder body; and the blocking cover and the swirl tube are welded intoa whole and obliquely welded to the Z-shaped plate. According to the application of the dual-swirl inclined cylindrical type urea mixer in the exhaust after-treatment device, the exhaust after-treatment device is in a cylinder shape, and sequentially comprises an air inlet pipe assembly, a DOC assembly, a DPF assembly, the double-swirl inclined cylindrical type urea mixer, a SCR assembly and an air outlet pipe assembly in the air flow direction. According to the double-swirl inclined cylindrical type urea mixer, two swirl devices are adopted, the mixing effect of urea and waste gas is ensured, and the crystallization risk of the urea is effectively reduced.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

Static mixer

InactiveCN103285757AGuarantee unimpededEliminate radial differencesFlow mixersLiquid stateStatic mixer

The invention relates to a static mixer. A main body of the static mixer is a circular pipe; a plurality of mixer units are arranged sequentially in the circular pipe in the water inlet direction; a filtering barrier is arranged in a water inlet of the circular pipe. According to the static mixer, the cylindrical circular pipe is adopted as a pipeline and a flow guide element, so that the structure is simple, the manufacture is convenient, and the cost is low; in addition, the high flow flux is realized on the premise that the pipeline is small in size; the static mixer is provided with the plurality of mixer units, so that flowing dead corner is avoided, the radial difference of the liquid states is effectively removed, the turbulence motion of liquid flowing through the static mixer is improved, the uniformity of mixing is ensured, and a boundary layer is thinned, thus being beneficial for heat transfer and mass transfer; the barrier with the filtering performance is arranged in the water inlet, so that the mixing effect and the smoothness of the pipeline can be ensured.

Owner:扬州清溢环保科技有限公司 +1

Crushing and mixing device used for applying fertilizer to tea plant

InactiveCN107754713AAvoid cloggingEffective crushingRotary stirring mixersMixer accessoriesEngineeringMechanical engineering

The invention discloses a crushing and mixing device used for applying a fertilizer to a tea plant. The crushing and mixing device comprises a mixing barrel, a crushing tank and a controller, a mixingmotor is mounted on the central position of the top part of the mixing barrel through a bolt, an output end of the mixing motor extends to the inner part of the mixing barrel and is fixedly connectedwith a stirring main shaft, mutually staggered stirring blades are evenly fixed on a transmission main shaft, a first feed pipe and a second feed pipe are respectively mounted at the top parts of thetwo sides of the mixing barrel, a feed motor is mounted at one end, far from the mixing barrel, of each of the first feed pipe and the second feed pipe through a bolt, and a crushing tank is mountedat one end, far from the mixing barrel, of the top part of each of the first feed pipe and the second feed pipe. The fertilizer is effectively crushed when the raw material is conveyed in the mixing process, the crushing and mixing integrated structure is realized, the time and the labor are saved, and the production efficiency is improved while the crushing effect is guaranteed.

Owner:WUZHOU YAZHENG AGRI TECH CO LTD

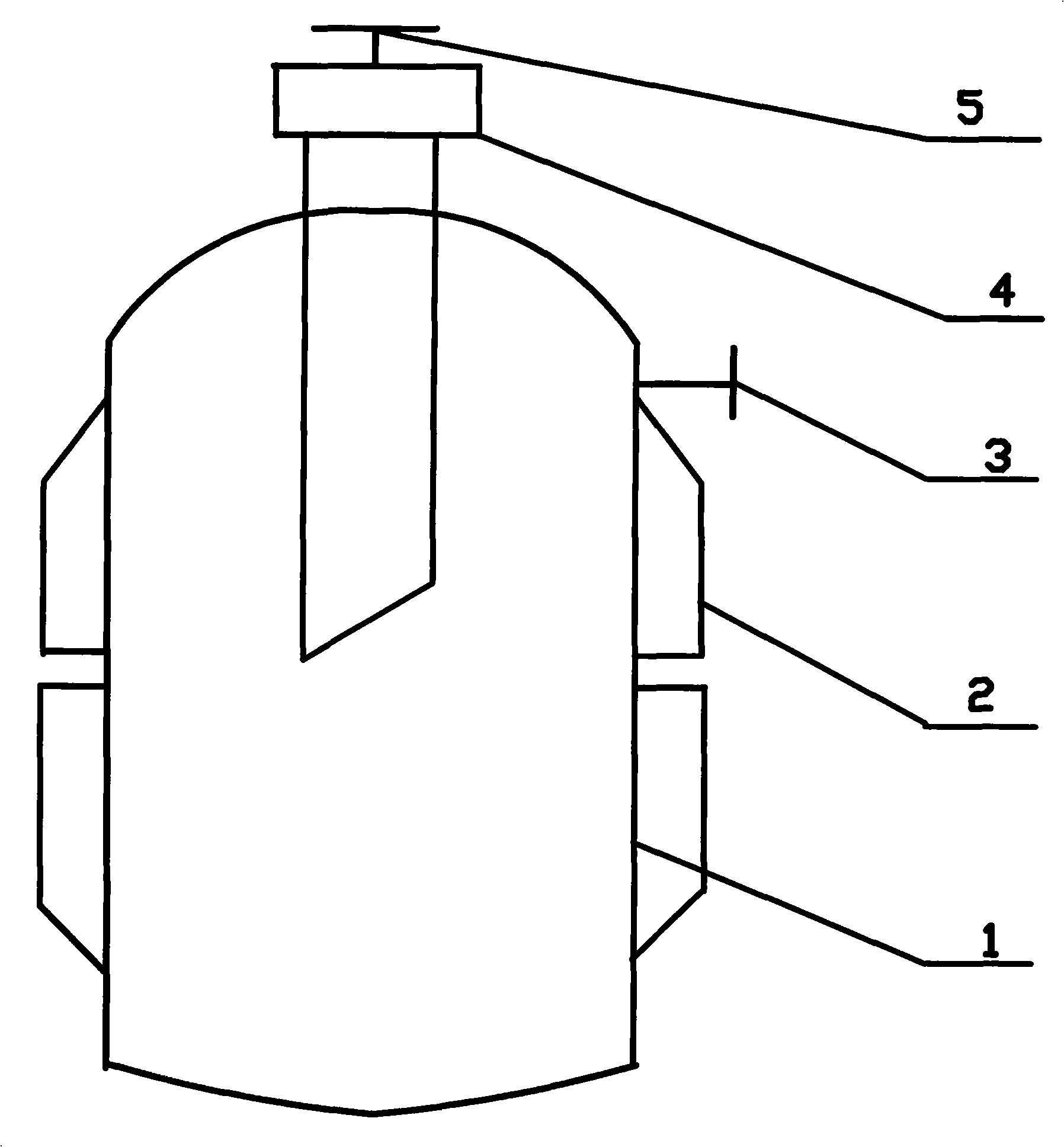

Reactor for producing tetrachloroethylene

ActiveCN101255092AGuaranteed mixing effectImprove conversion rateHalogenated hydrocarbon preparationTetrachloroethyleneNuclear engineering

The invention disclosesa reactor for generating tetrachloroethylene, wherein the reactor contains a reactor body fixed with a feed port and a feed port and a discharge port at the upper, connected with a mixer with a nozzle by flange at the upper and fixed with an electric heater at the outer wall which is secured at the support ring of the outer wall of the reactor by bolt. The reactor is specially used in the production of tetrachloroethylene by thermal chlorination process, and the reactor is convenient in installation and maintenance, has a high produce capacity and a simple operation, is security in use, and low in investment.

Owner:NINGBO JUHUA CHEM TECH CO LTD

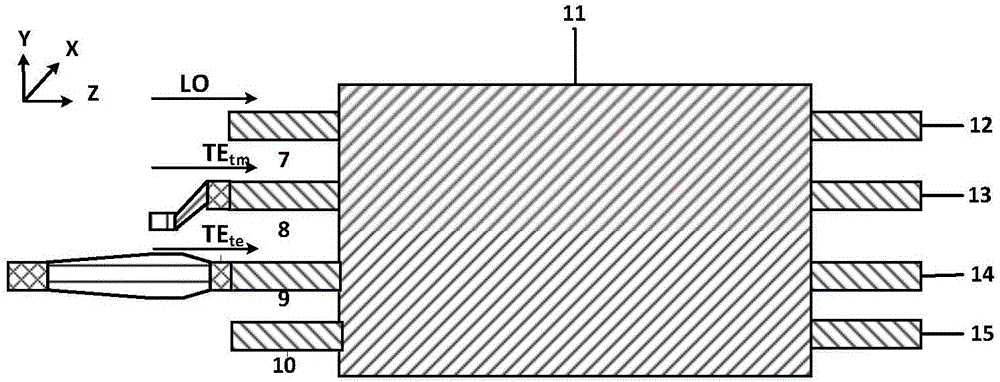

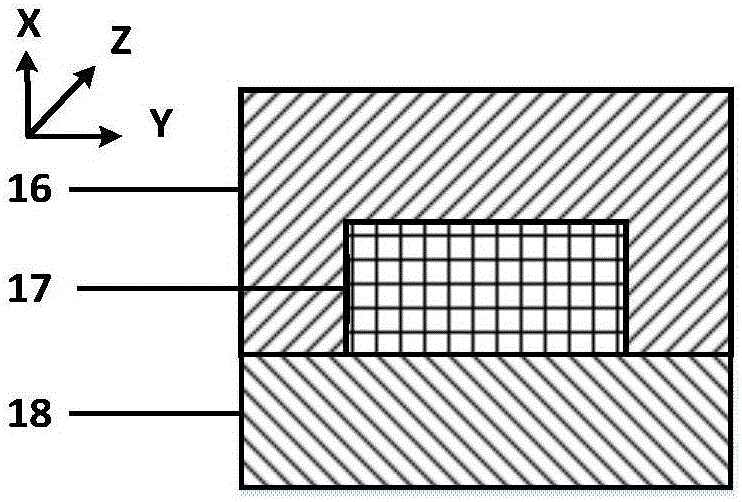

Optical mixer without polarization state diversity

ActiveCN106019483AEasy to integrateGuaranteed mixing effectCoupling light guidesPolarization diversityMultimode interference

The invention discloses a 90-degree optical mixer without a polarization state diversity. The 90-degree optical mixer is formed by a polarization beam splitter rotator and a multimode interference coupler (MMI) in a cascade connection. The polarization beam splitter rotator is formed by upper and low mode conversion modules in mutual coupling, inputted transverse electric mode (TE) and transverse magnetic mode (TM) are converted into transverse electric modes (TE), thus a mixer parameter can be accurately optimized regardless of an input mode, the multimode imaging positions in the MMI are maintained to be consistent in an integrated condition, and the optical mixing without polarization diversity is realized. Compared with a traditional mixer, the influence on the MMI by different mode imaging positions is made up, the inaccuracy brought by the compromise processing on the parameter in the integrated condition is avoided, and the loss and error of mixing are reduced. The optical mixer with the above structure has the characteristics of compact structure and good performance and is suitable for a coherent optical receiving system.

Owner:SOUTHEAST UNIV

Premixing and homogenizing coupling type bubble generator

ActiveCN113144929AGuaranteed mixing effectReduce stratified flowFlow mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a premixing and homogenizing coupling type bubble generator. The bubble generator comprises a gas-liquid premixing section, a gas-liquid intensified mixing section, a gas-liquid homogenizing section and a vortex breaking section which are connected in sequence; the gas-liquid pre-mixing section is configured to perform primary shearing dispersion on gas-liquid two phases by utilizing high-speed turbulent flow to form a gas-liquid mixing dispersion field; the gas-liquid reinforced mixing section comprises a swirling section and a contraction section which are sequentially distributed, and a multi-dimensional swirling flow field is formed in the swirling section and is configured to induce the gas-liquid mixed phase from the gas-liquid premixing section to generate swirling flow motion; a flow channel of which the diameter is gradually reduced along the flowing direction of the gas-liquid mixed phase is formed in the contraction section; at least two stages of venturi tube-shaped flow channels which are connected in series are formed in the gas-liquid homogenizing section; and a micro-channel is formed in the vortex breaking section.

Owner:CHINA NATIONAL OFFSHORE OIL (CHINA) CO LTD +1

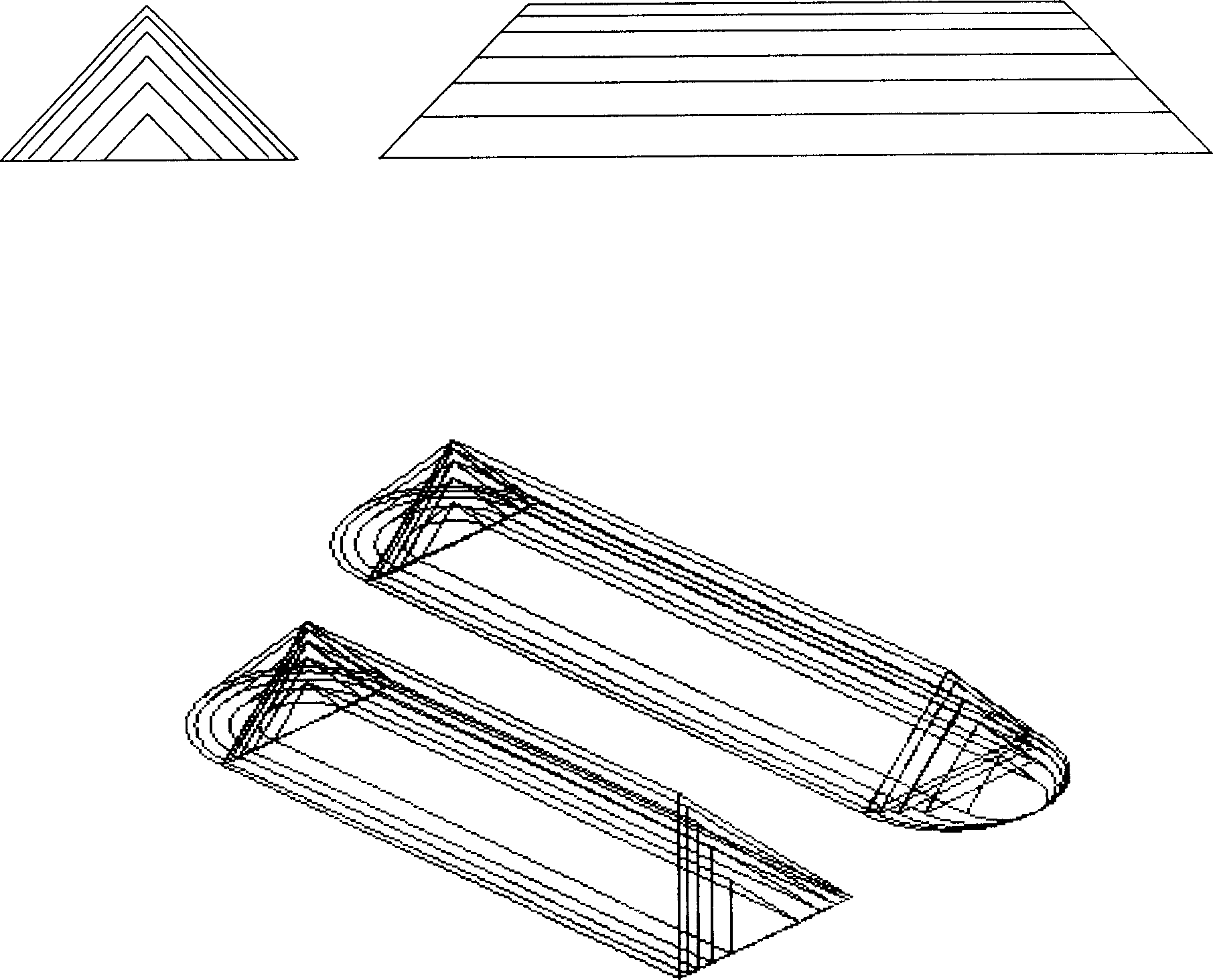

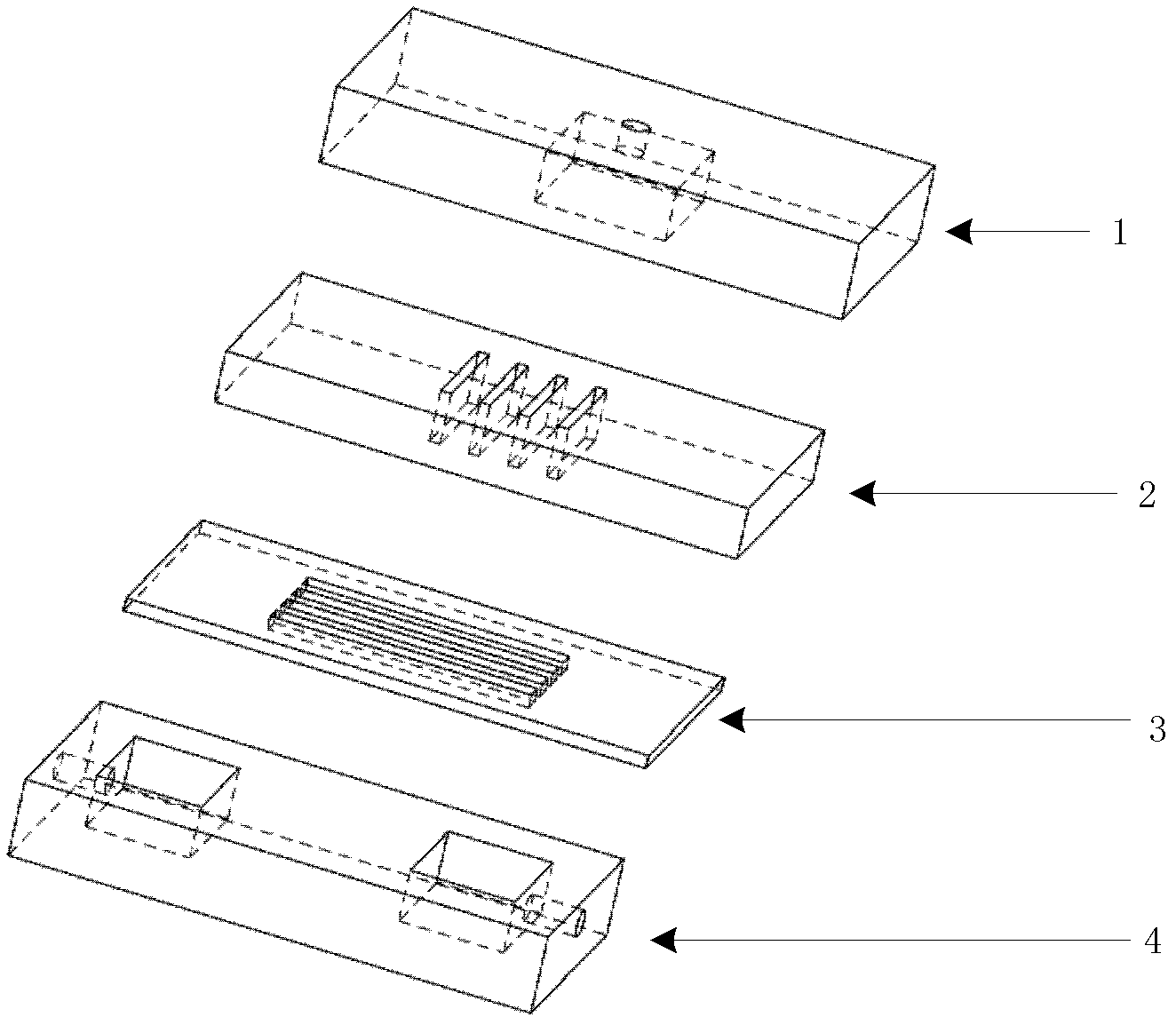

Micro-structured mixer

ActiveCN102847455AAvoid easy-to-block problemsGuaranteed mixing effectFlow mixersEngineeringPetrochemical

The invention discloses a micro-structured mixer, which belongs to the technical field of chemical and chemical engineering. The micro-structured mixer is formed by stacking a first interface board, a first fluid distributing plate, a fluid mixing plate and a second interface board in sequence, wherein the first interface board is provided thereon with a first fluid inlet pipe and a first fluid buffer chamber, the first fluid distributing plate is provided thereon with at least one through slot, the fluid mixing plate is provided thereon with at least one through slot, the second interface board is provided thereon with a second fluid inlet pipe, a second fluid buffer chamber, a mixed fluid buffer chamber and a mixed fluid outlet pipe, when the number of the through slots arranged on the first fluid distributing plate is larger than one, the arranged through slots are parallel through slots, when the number of the through slots arranged on the fluid mixing plate is larger than one, the arranged through slots are parallel through slots. The treatment capacity of unit volume of the micro-structured mixer is larger, the micro-structured mixer is easy to store and enlarge, has low requirement for material cleanliness, and can be used in chemical, chemical engineering, petrochemical, medicine and food industries.

Owner:TSINGHUA UNIV

Iron oxide pigment production equipment capable of being used for removing particle impurities

ActiveCN112473413ASimple structureEasy to operateTransportation and packagingMixer accessoriesBrown iron oxideReciprocating motion

The invention relates to the technical field of iron oxide pigment production equipment, in particular to iron oxide pigment production equipment capable of being used for removing particle impurities. The equipment comprises an iron oxide pigment production equipment main body, wherein the iron oxide pigment production equipment main body comprises a processing mixing box main body, a bottom plate, a conveying box, a second servo motor, a third servo motor, a first servo motor and a raw material feeding box main body, the processing mixing box main body is fixedly mounted at the top end of the bottom plate, and a discharging opening is fixedly formed in the bottom end of the processing mixing box main body; and a control valve is fixedly mounted in the discharge port. By arranging the screening mechanism, through the shape characteristics of the rotary arc cam and the arc cam, the threaded spring can be driven to do reciprocating motion up and down, raw materials can be rapidly filtered, the structure is simple, operation is convenient, meanwhile, impurity particles are easy to clean and convenient to put into production, and rectangular grooves in the two sides of the filtering screen plate body slide up and down on sliding blocks; the stability of the filter sieve plate main body in the vertical vibration process is ensured.

Owner:正太新材料科技有限责任公司

Combustion type heater device used in fume desulfurization and denitrification system

InactiveCN106287778AHeating evenlyGuaranteed stabilityLighting and heating apparatusFlueFlue-gas desulfurization

The invention relates to a combustion type heater device used in a fume desulfurization and denitrification system. According to the combustion type heater device, low-temperature fume is heated through fuel combustion, and the purpose of increasing the temperature of the fume to optimal catalysis temperature of a denitrification catalyst in a selective catalytic reduction (SCR) denitrification device can be achieved. By adoption of the combustion type heater device, a combustor and a mixer are additionally mounted on a flue, under the cooperation of the combustor and the mixer, the temperature of the fume inside the flue can be rapidly and uniformly increased to target temperature within a short distance, and the high-efficient operation and the service life of the SCR denitrification device can be ensured. In addition, the combustor and the mixer of the combustion type heater device are simple to mount and easy to replace.

Owner:张龙 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com