Dual-swirl inclined cylindrical type urea mixer and application in exhaust after-treatment device thereof

A double swirl and mixer technology, which is applied in the direction of exhaust treatment, exhaust device, noise reduction device, etc., can solve the problems of reducing the risk of urea crystallization, and achieve the effect of reducing the risk of crystallization, improving the uniformity and reducing the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

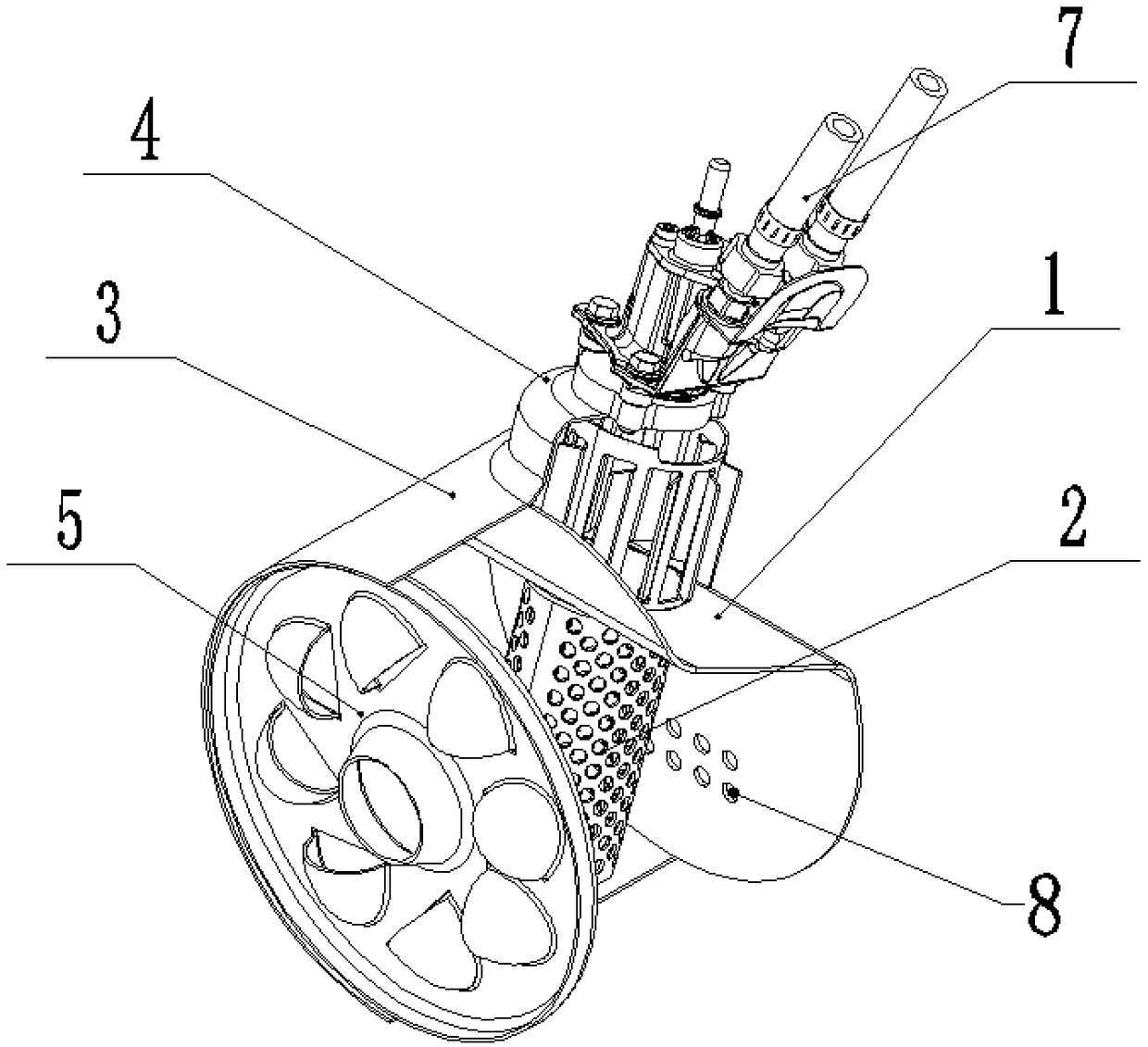

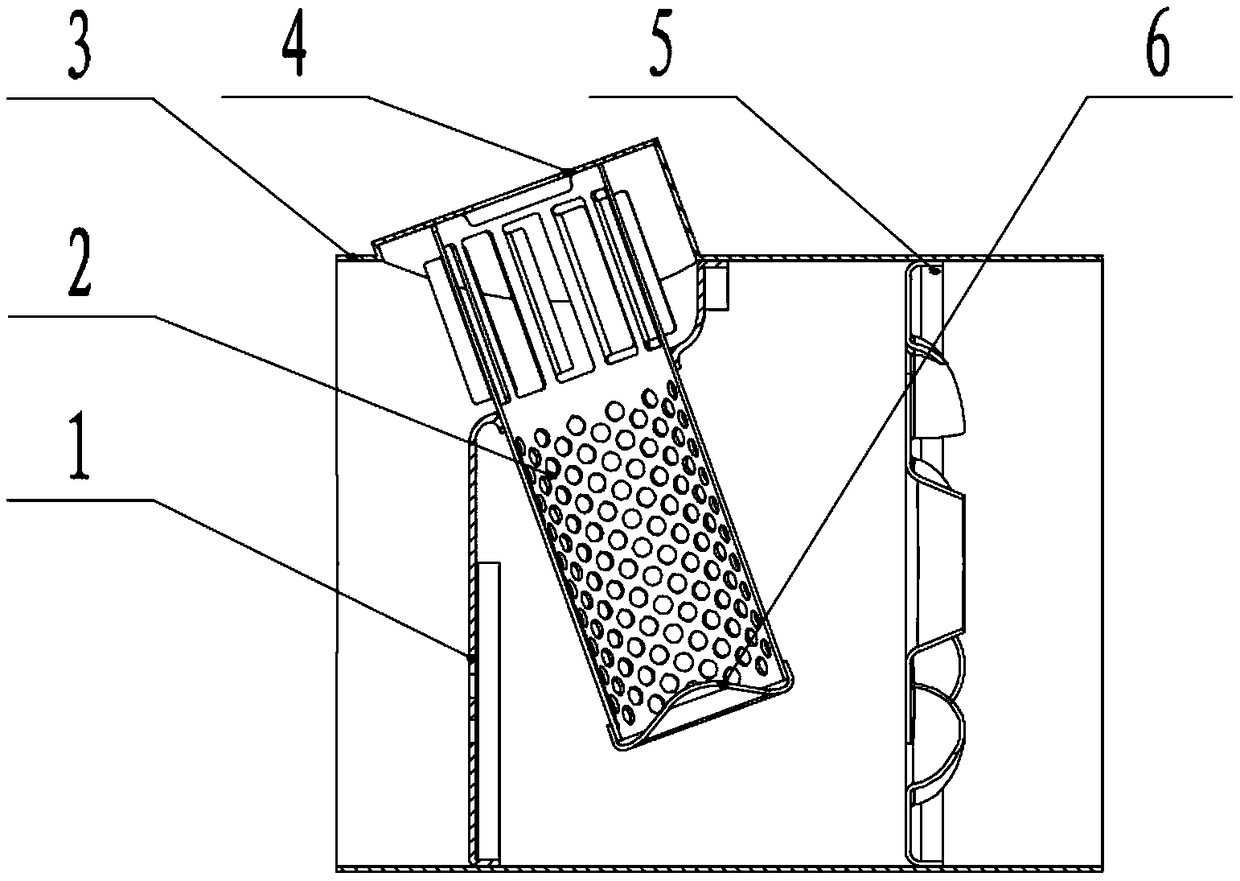

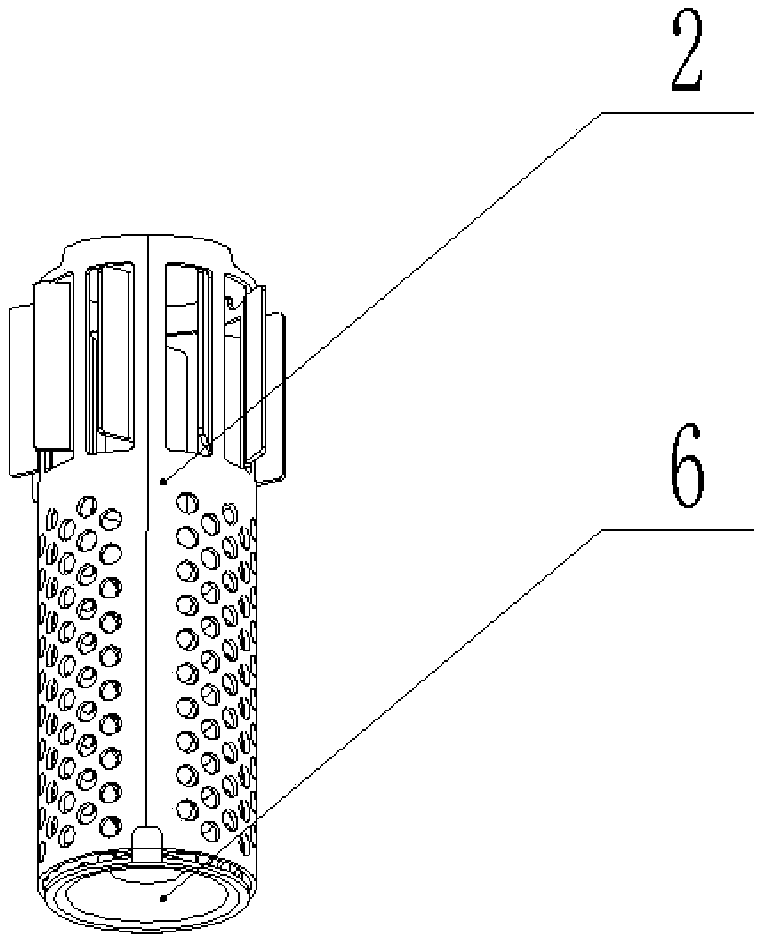

[0025] Double-swirl oblique cylindrical urea mixer, including Z-shaped partition 1, swirl pipe 2, cylinder body 3, nozzle base 4, swirl plate 5, blocking cover 6 and urea nozzle 7, the urea nozzle 7 is installed On the nozzle base 4, the two are obliquely installed on the cylinder body 3, and the blocking cover 6 is welded on the swirl tube 2, and the two are integrated and obliquely welded on the Z-shaped plate 1.

[0026] The swirl plate 5 is installed behind the swirl tube 2 and in front of the SCR catalyst carrier.

[0027] A gap of 2 mm is left between the outlet of the swirl tube 2 lower part and the plugging cover 6 to facilitate the rapid flow of urea particles through the swirl tube 2 .

[0028] The Z-shaped plate 1 and the swirl tube 2 have an included angle with the installation direction, which reduces the influence of the self-weight of urea particles on the position of the wall, and greatly reduces the risk of crystallization at the bottom of the swirl tube 2 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com