Cable inner shielding material with copper damage prevention function, and preparation method thereof

A technology of inner shielding and shielding materials, which is applied in the field of inner shielding materials for cables and its preparation, can solve the problems of uneven mixing, water consumption, and affecting the uniformity of mixing, so as to reduce consumption, improve market competitiveness, and improve The effect of the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention relates to an inner shielding material for cables with the function of preventing copper damage and a preparation method thereof. The components of the shielding material are by weight:

[0057] EVA, 30-35 parts;

[0058] White oil, 5-8 parts;

[0059] Dispersant, 0.5-4 parts;

[0060] Cross-linking agent, 0.5-3 parts;

[0061] Plasticizer, 10-12 parts;

[0062] Ionic liquid surfactant, 0.6-0.8 part;

[0063] Conductive carbon black, 30-32 parts;

[0064] Antioxidant, 0.1 to 0.5 parts;

[0065] Anti-adhesive agent, 12-18 parts;

[0066] Plasticizers are various blends of stearic acid, paraffin, carbon toner and titanium dioxide

[0067] The dispersant is stearate, metal stearate, such as sodium stearate, zinc stearate, magnesium stearate;

[0068] The ionic liquid surfactant is a trisiloxane imidazole ionic liquid surfactant;

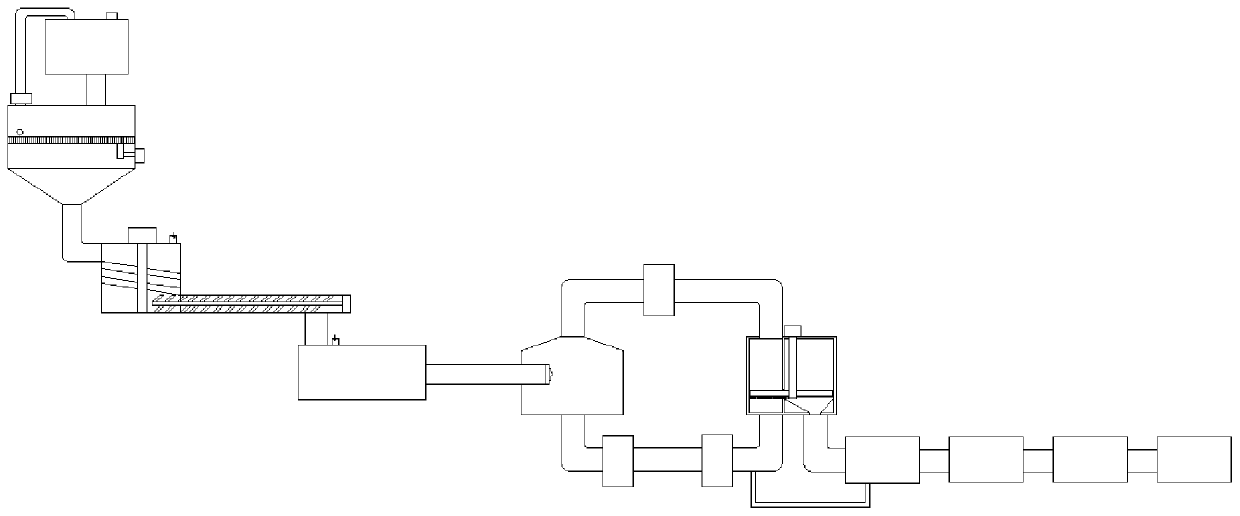

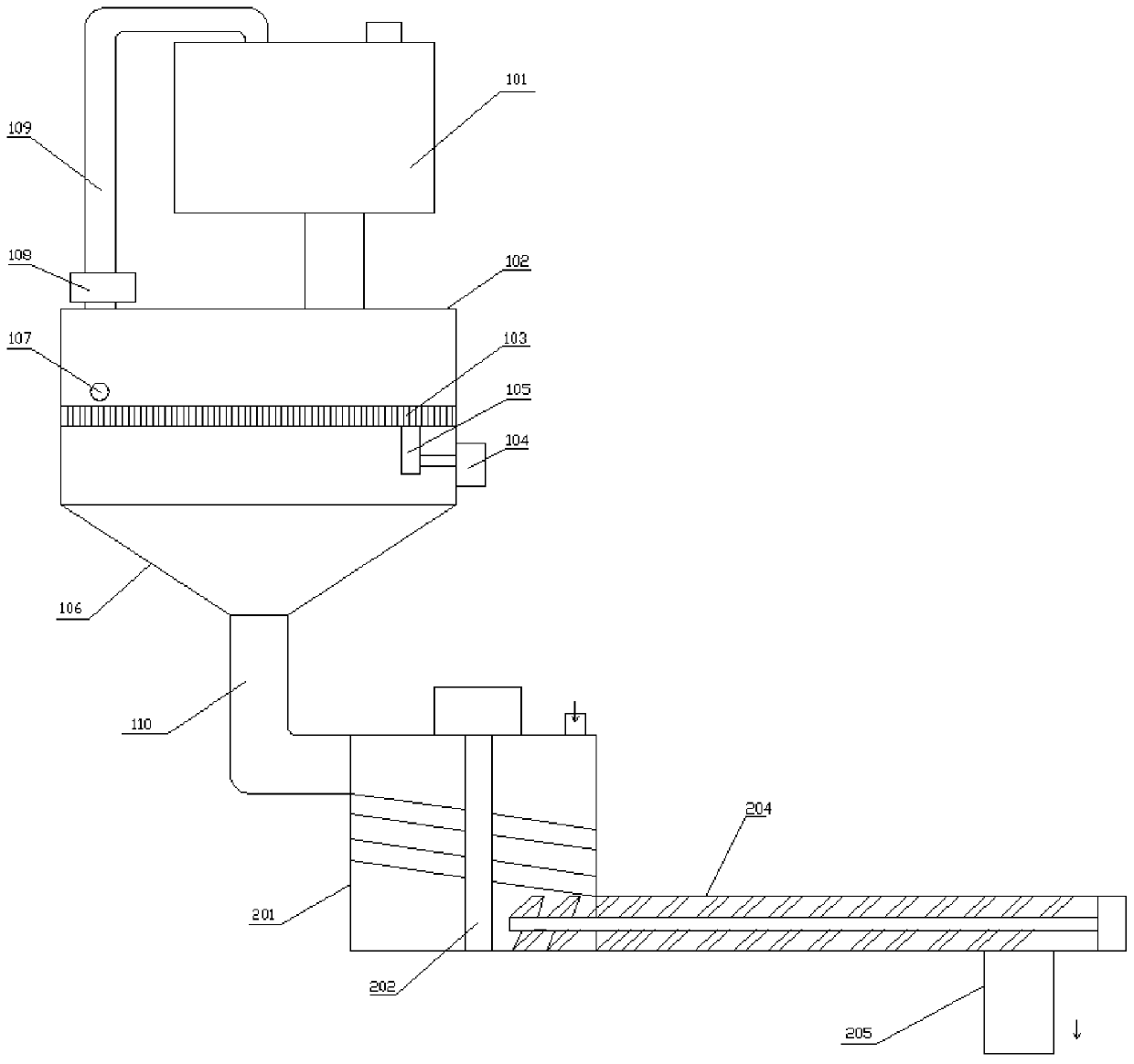

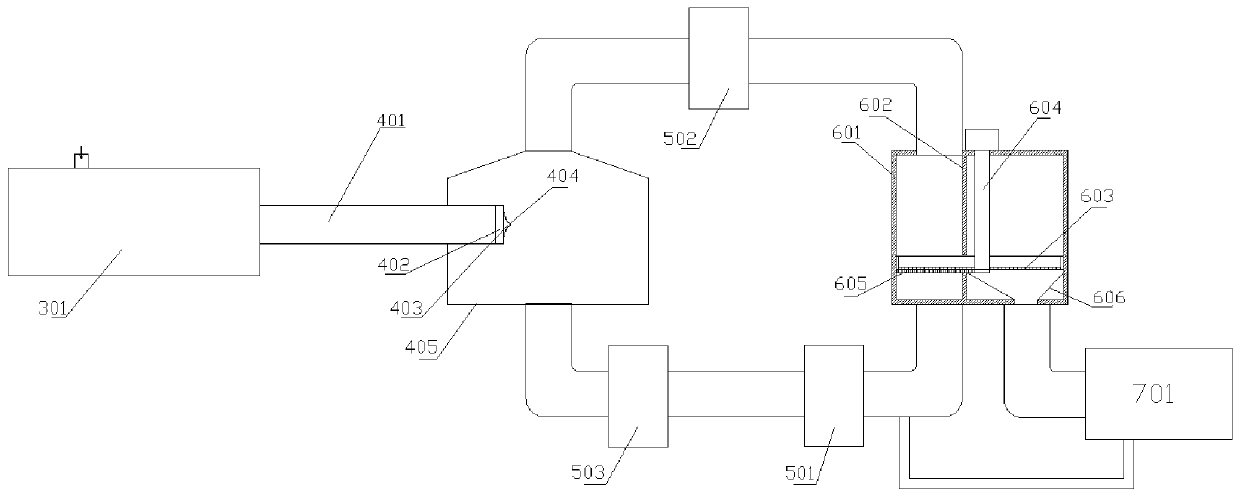

[0069] see Figure 1~6 , a preparation method of an inner shielding material for cables with anti-copper damage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com