Engine and double-whirl mixing device thereof

A mixing device and double swirl technology, applied in fluid mixers, engine components, combustion engines, etc., can solve the problems of poor atomization, insufficient decomposition, and uneven mixing of exhaust gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The purpose of this specific embodiment is to provide a double swirl flow mixing device, which can effectively avoid the problems of easy deposition of urea, poor atomization and uneven mixing with exhaust gas. The purpose of this specific embodiment is also to provide an engine comprising the above-mentioned double swirl mixing device.

[0023] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solution of the invention described in the claims.

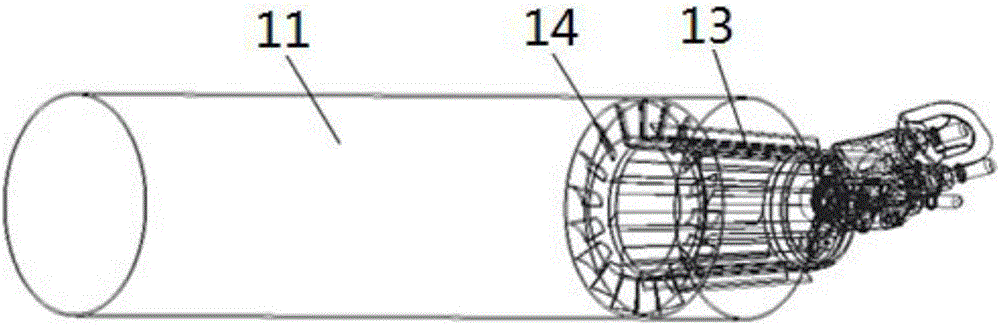

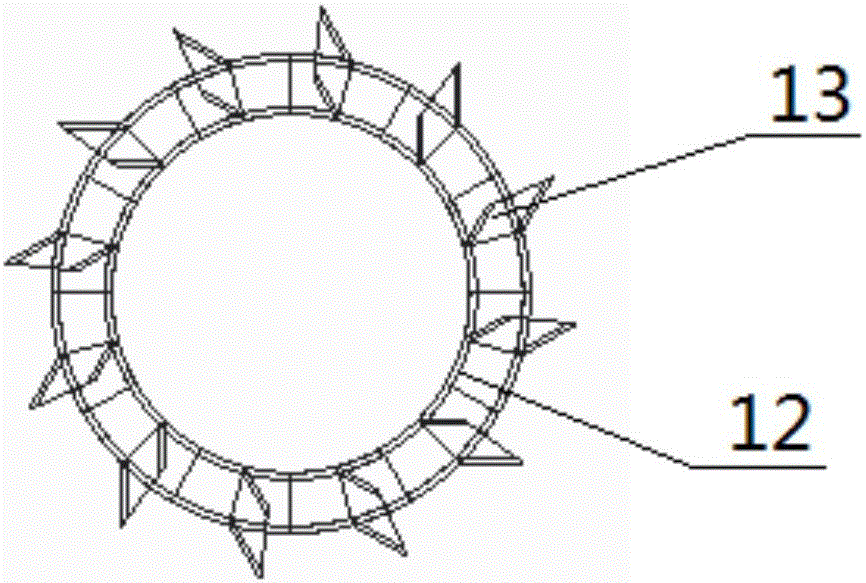

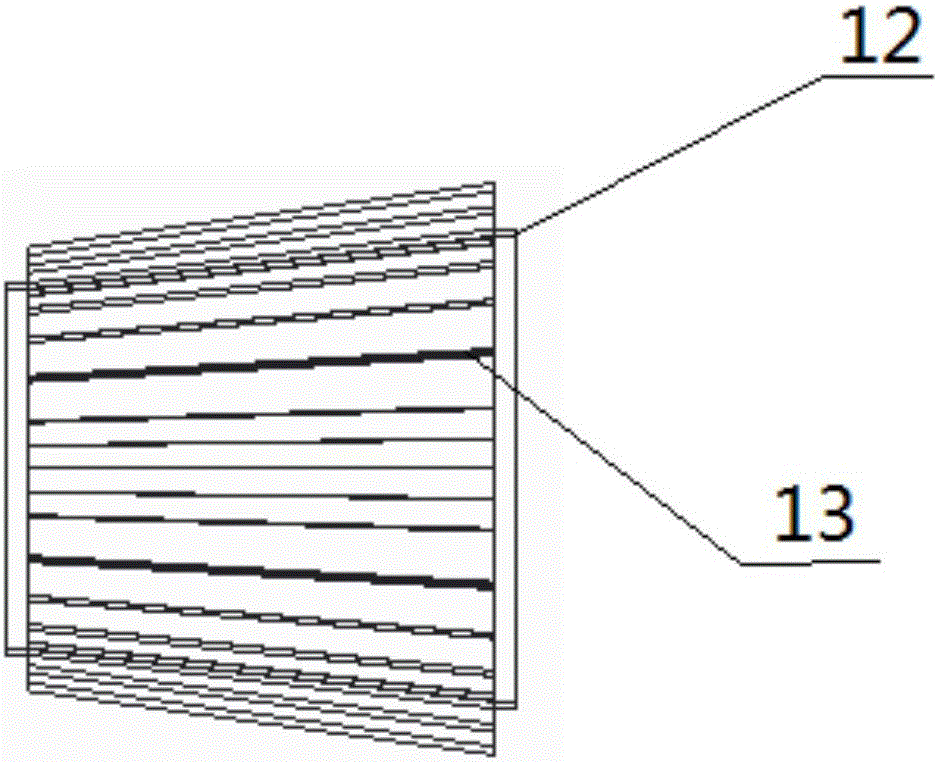

[0024] Please refer to Figure 1-Figure 5 , the double swirl mixing device provided in this embodiment includes a mixing tube 11 , a conical mixer and a fan blade 14 .

[0025] Wherein, the mixing pipe 11 is used for mixing the exhaust gas and urea together. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com