Patents

Literature

155results about How to "Reduced risk of crystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

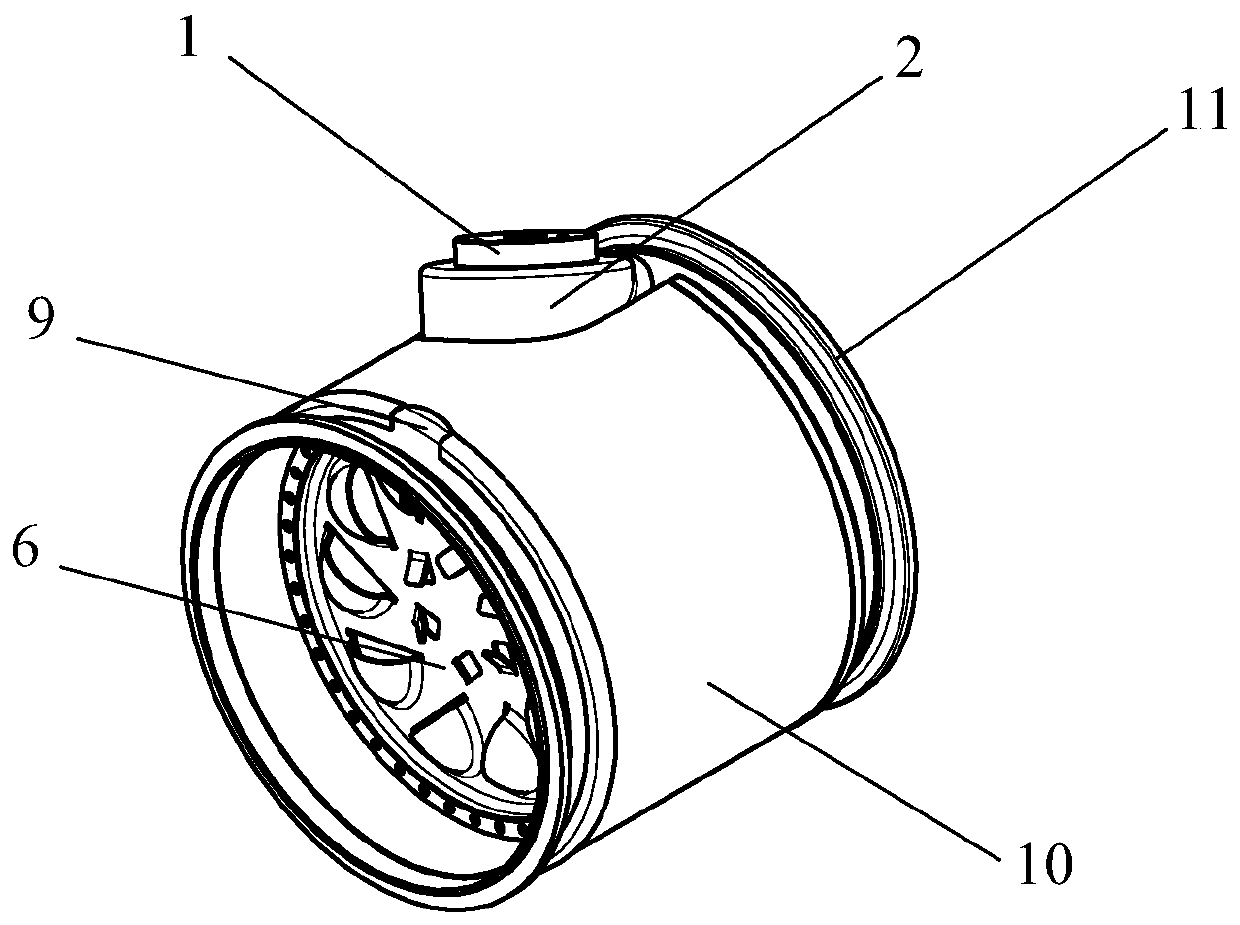

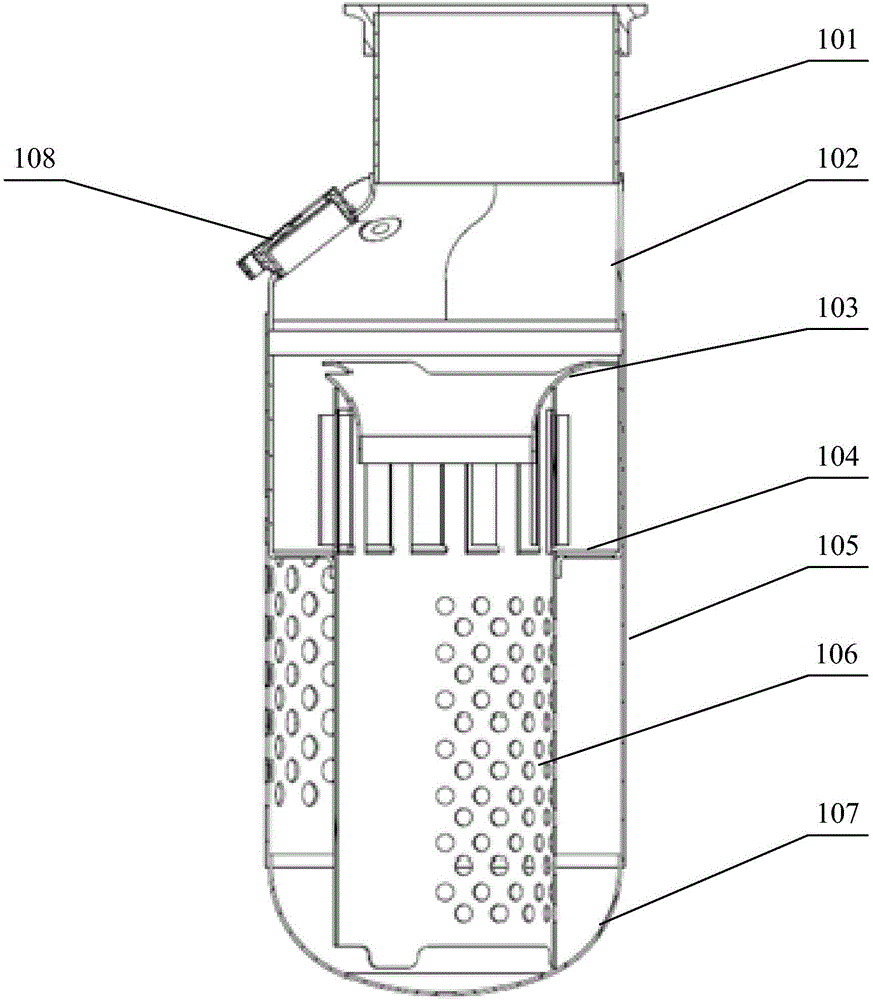

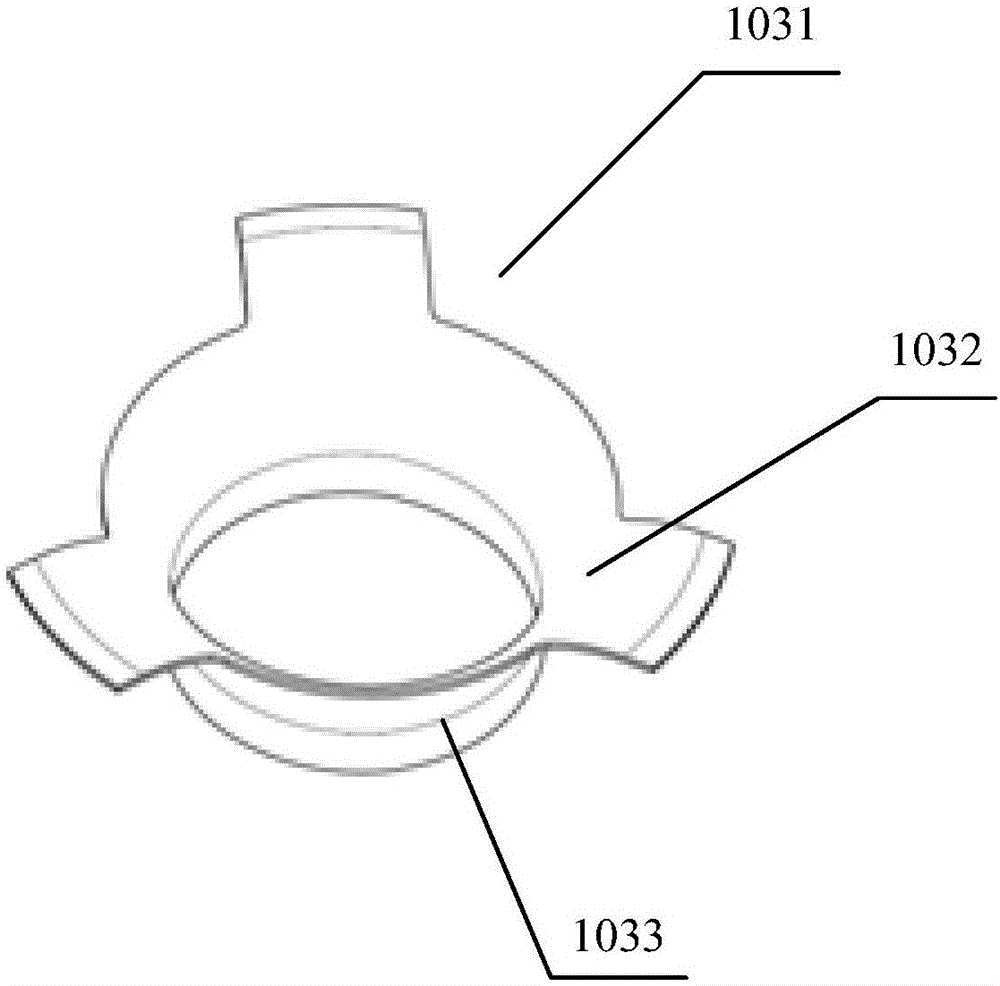

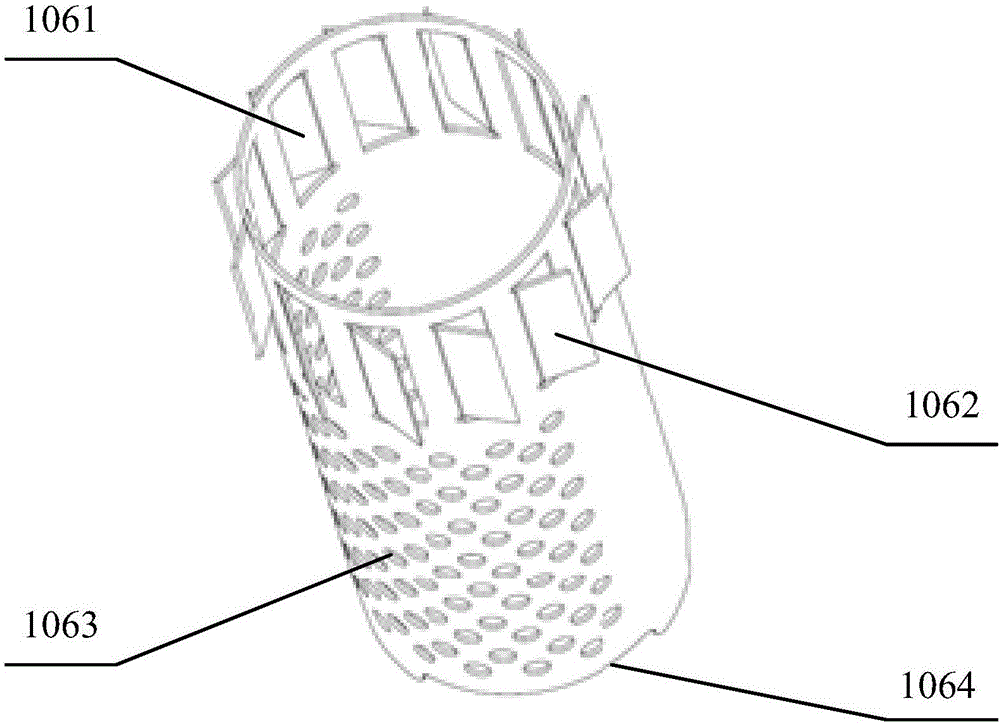

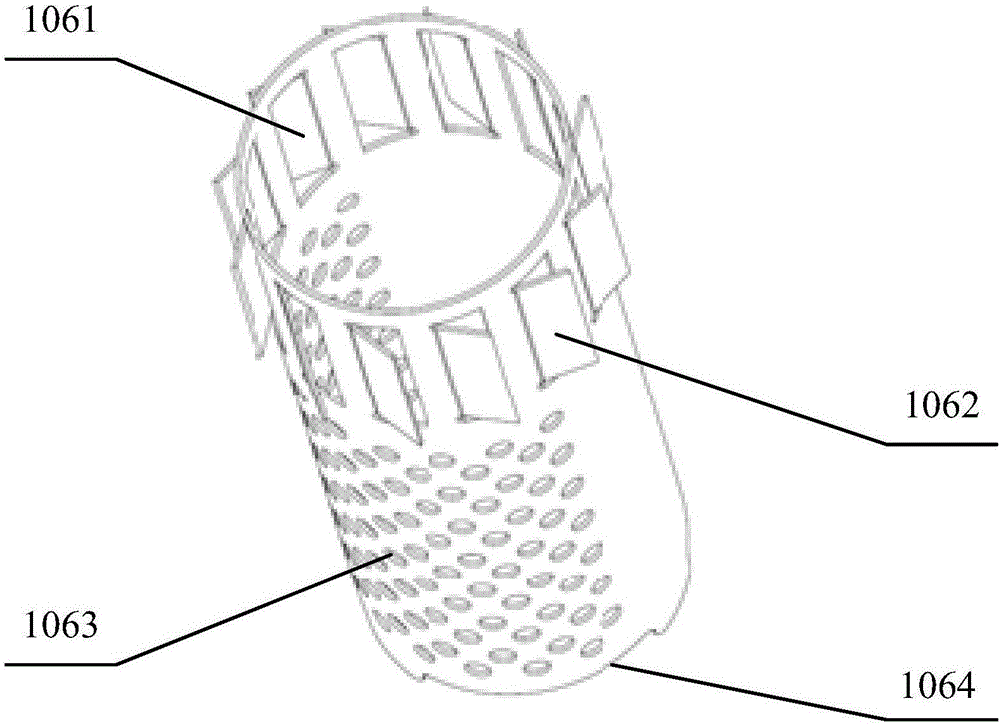

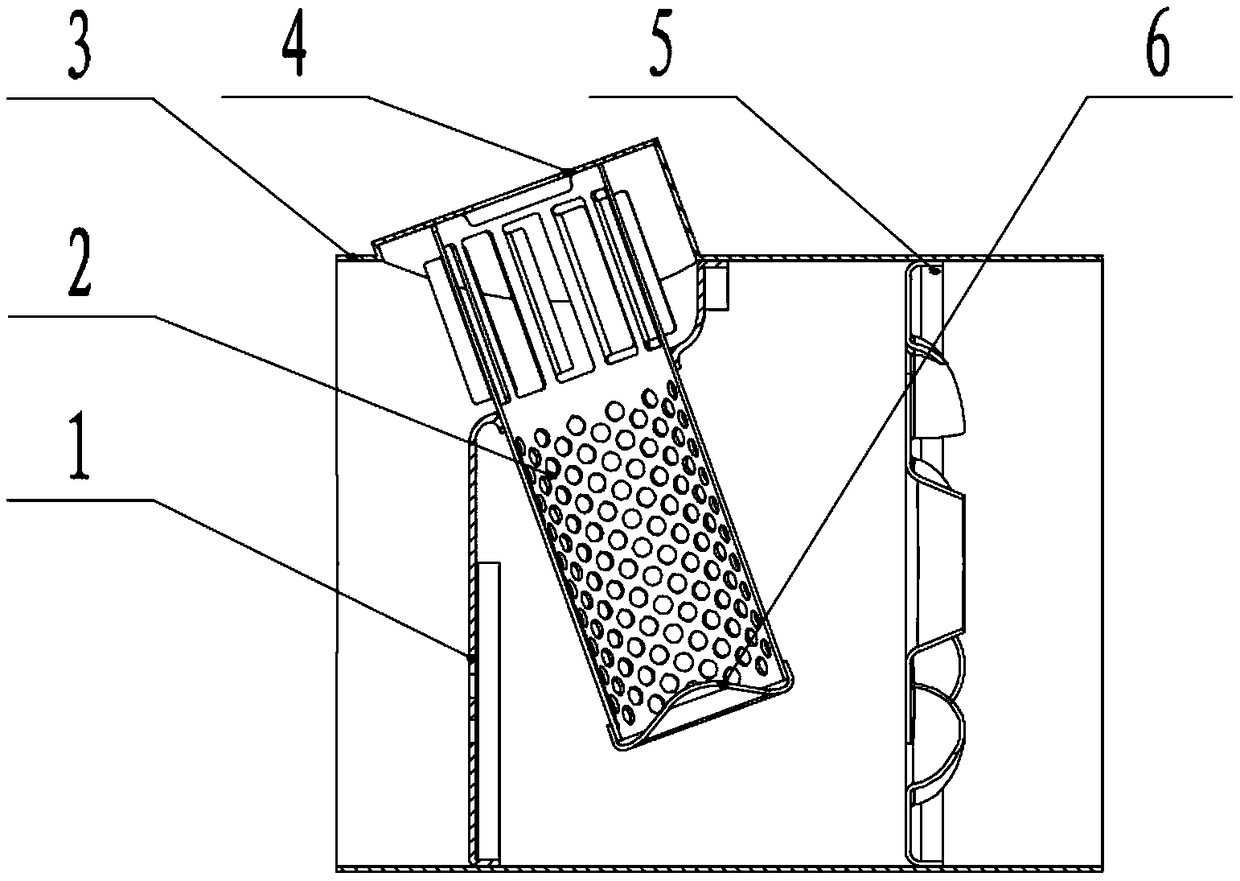

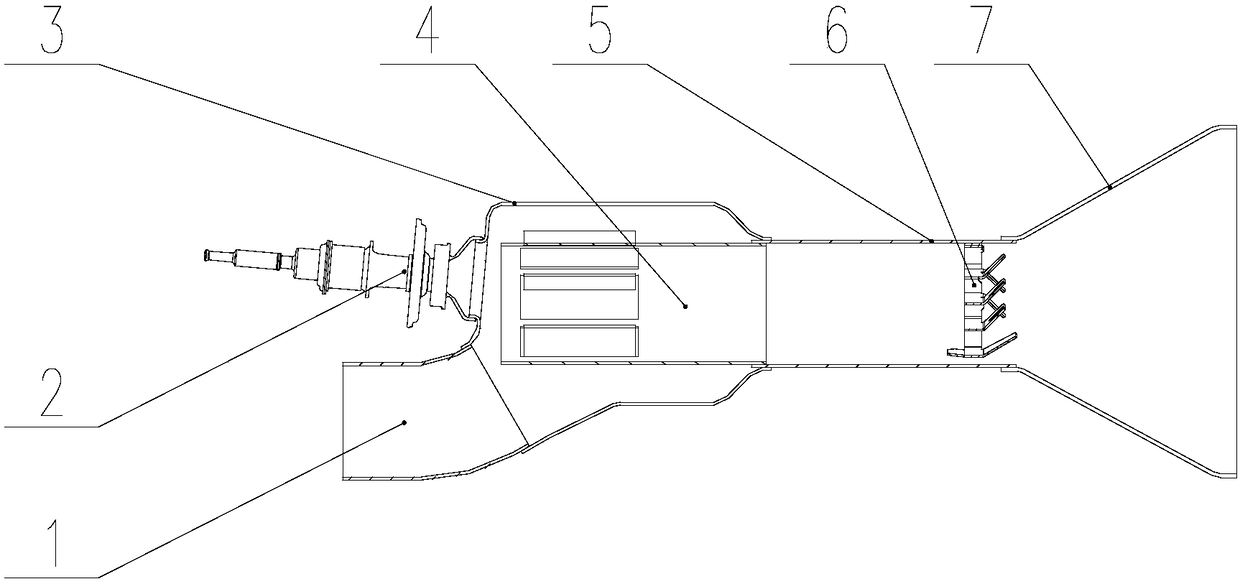

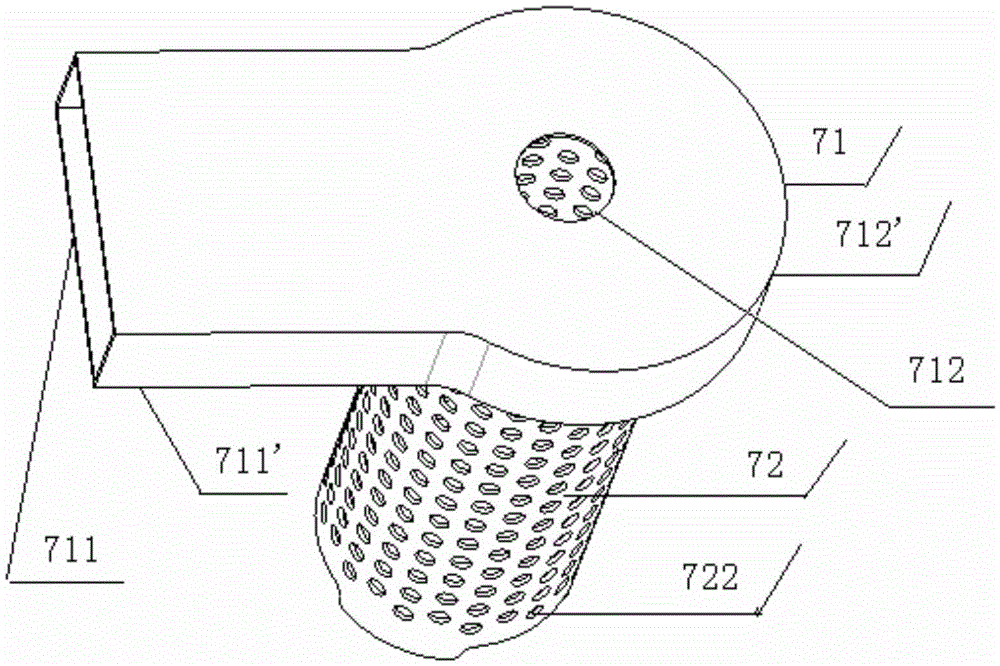

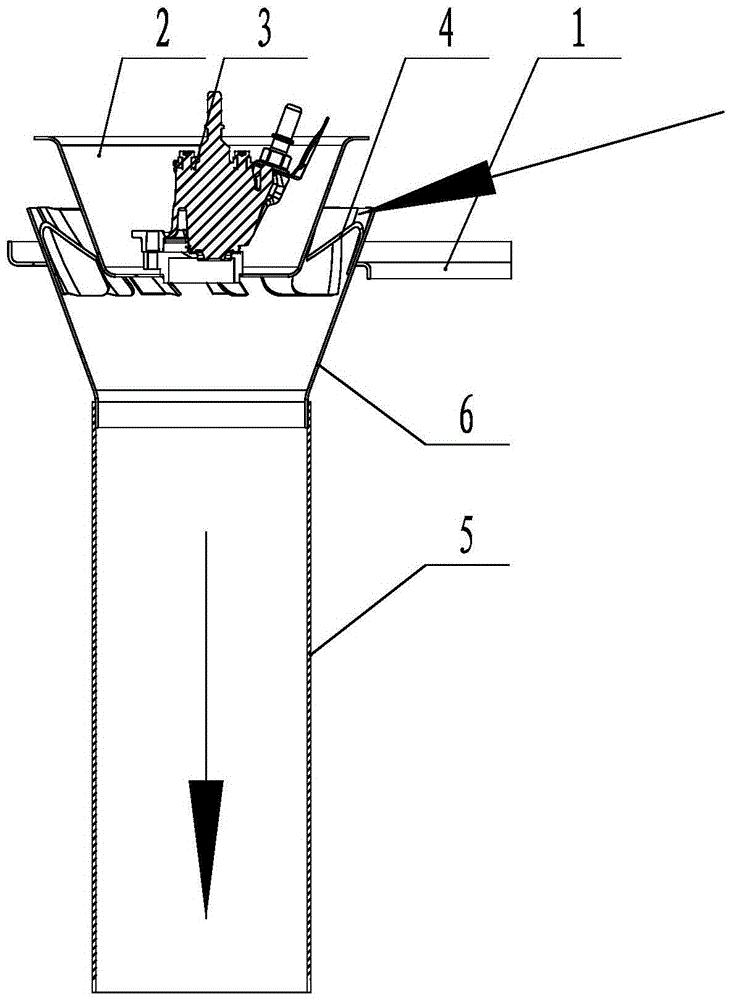

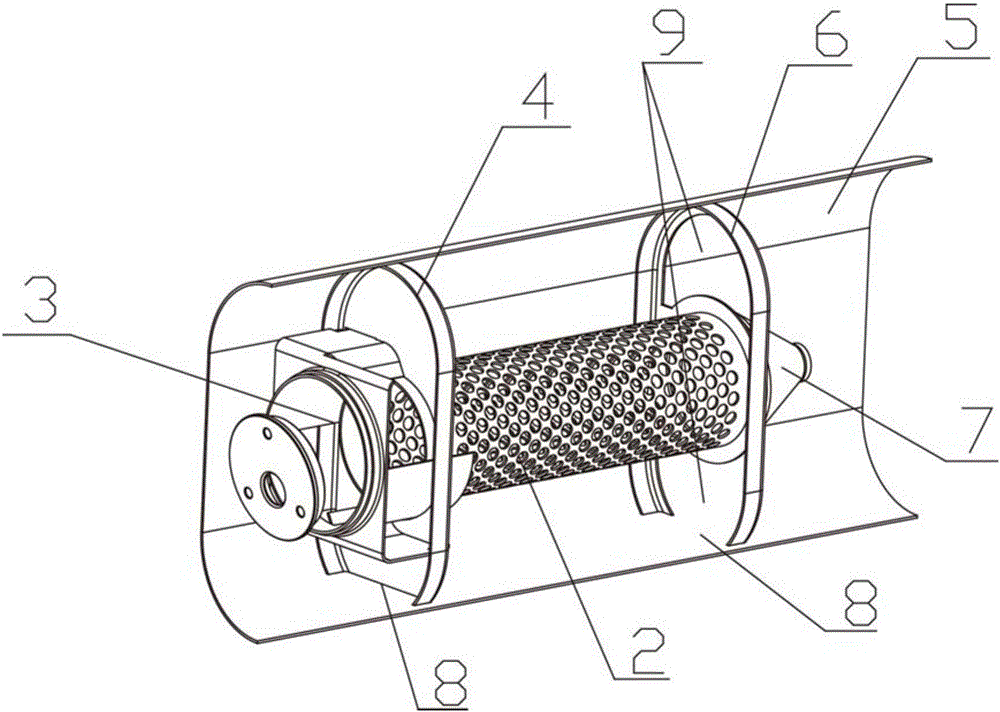

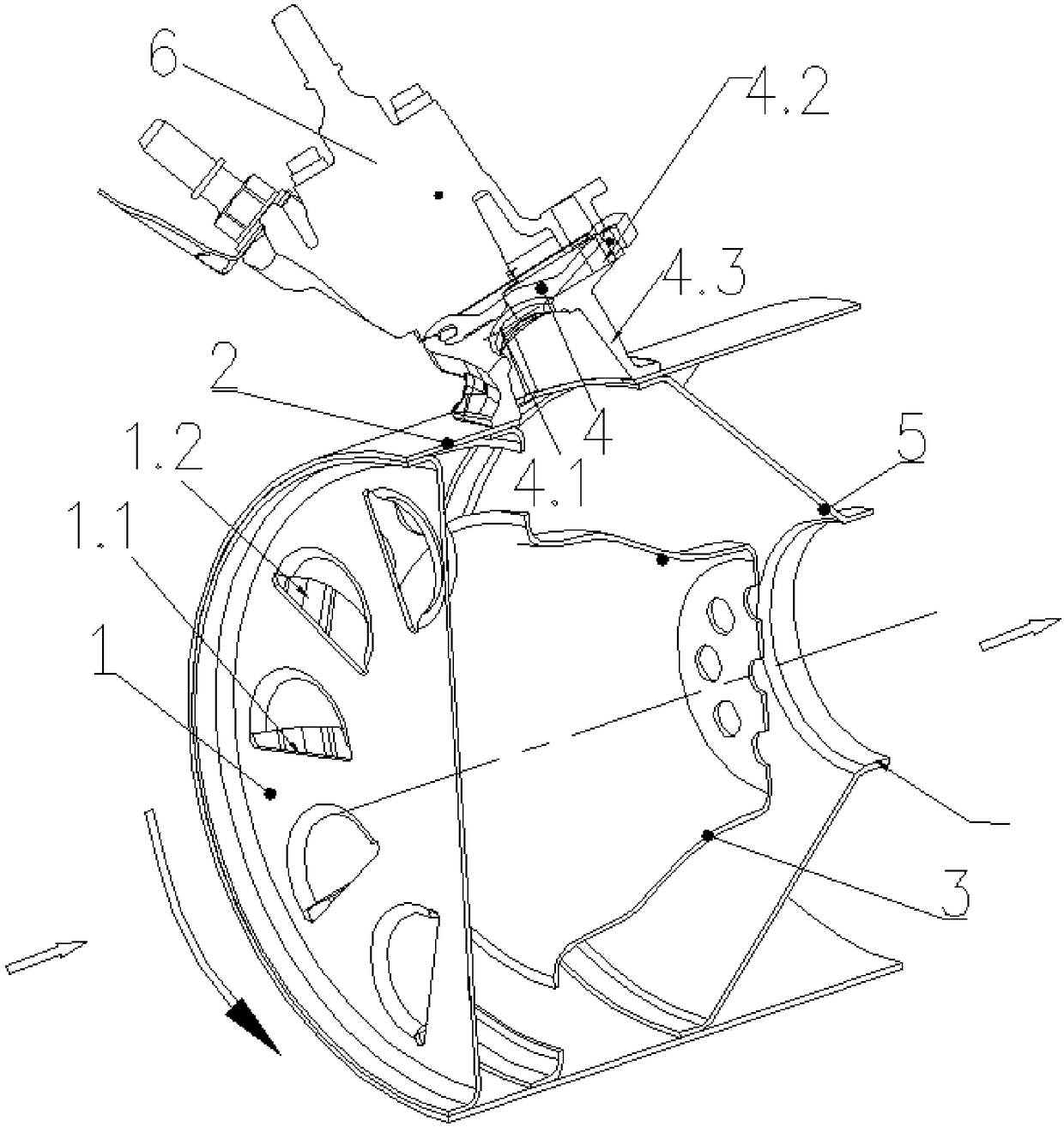

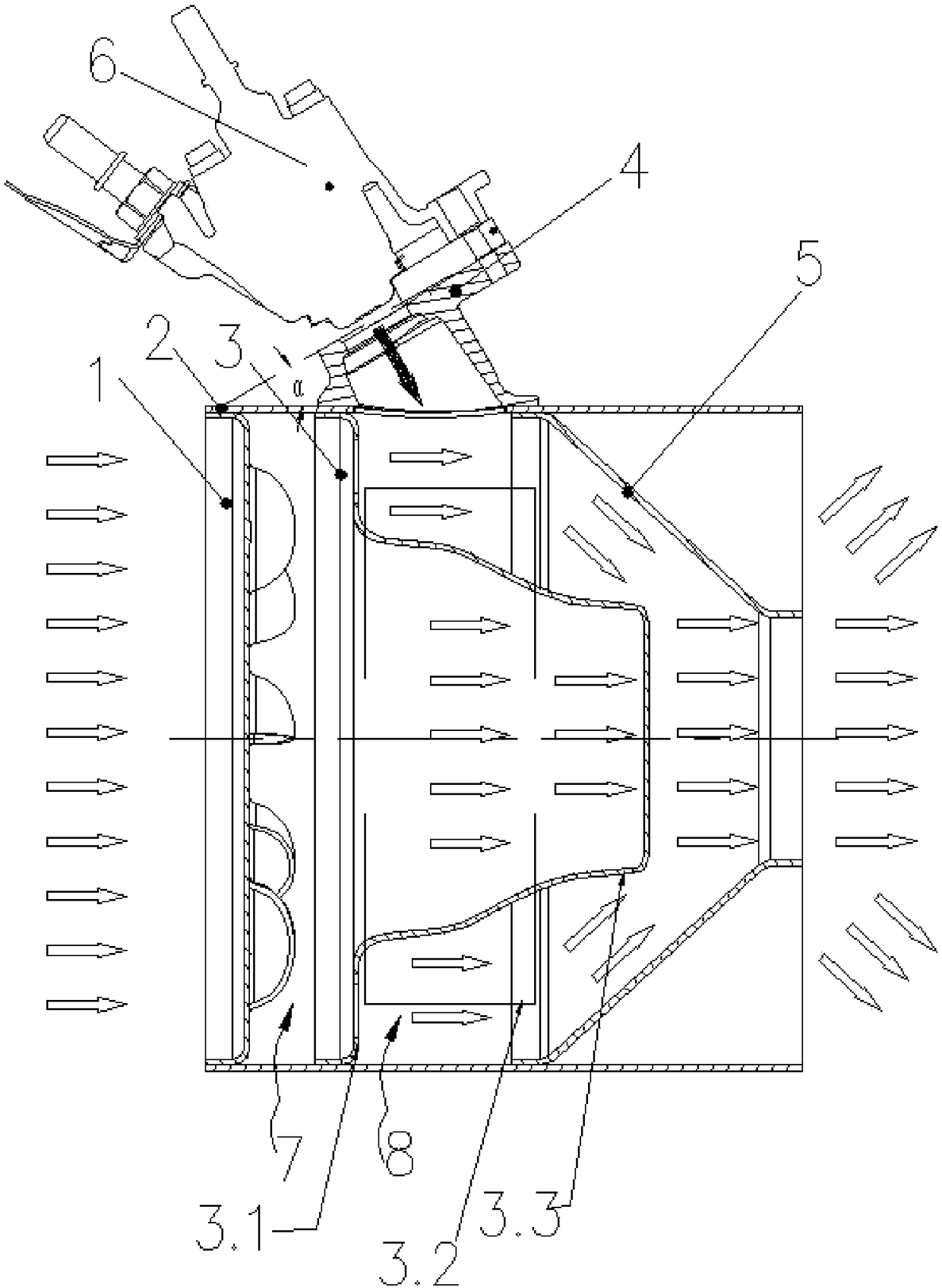

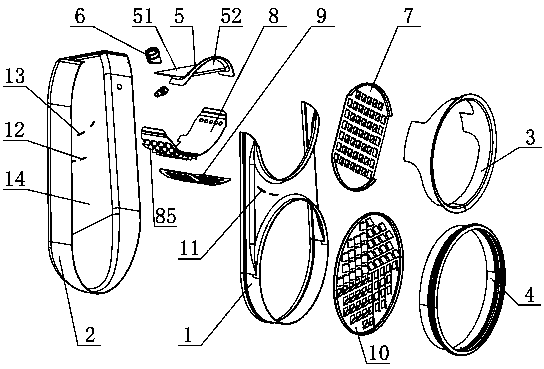

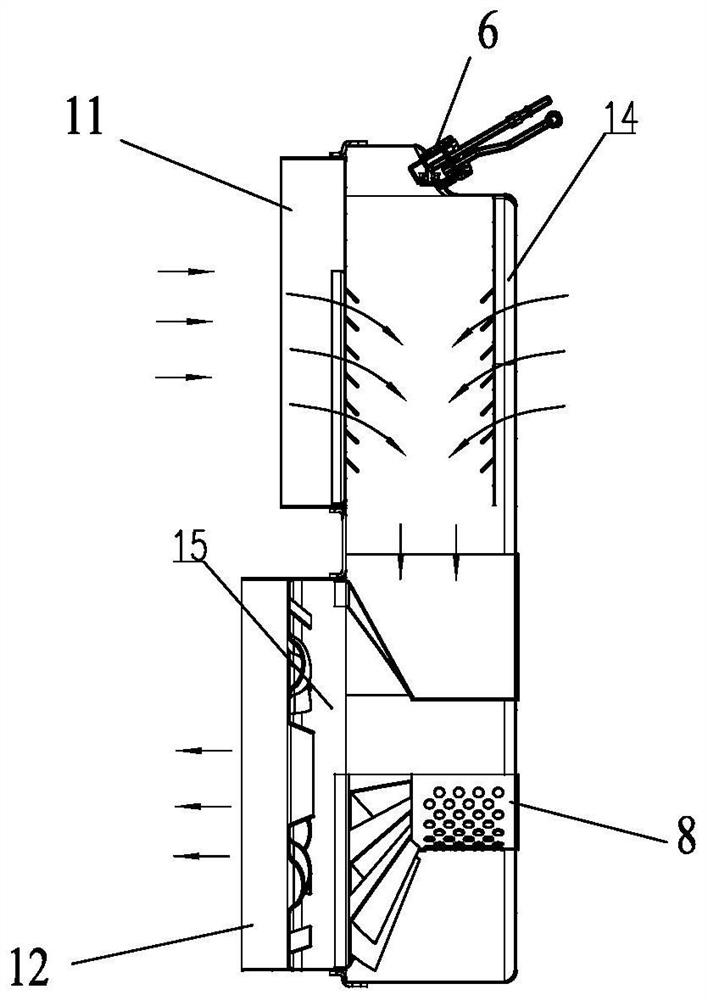

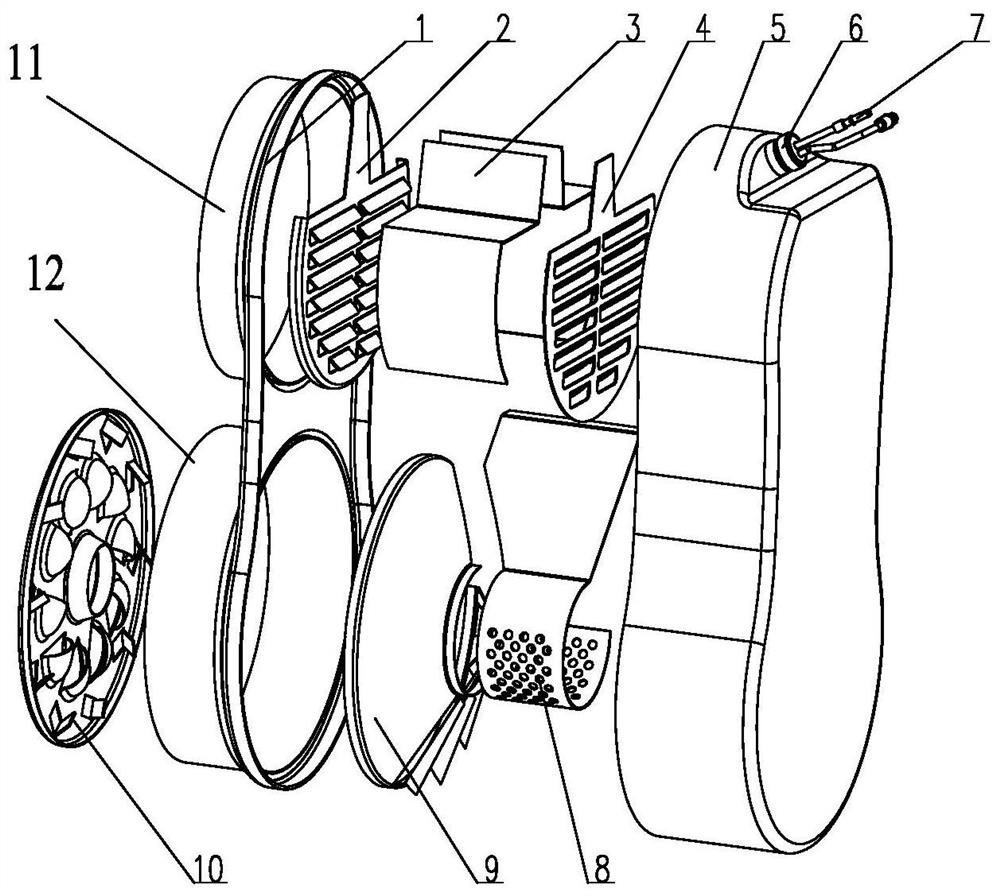

Two-way rotational flow cylinder type urea mixing device

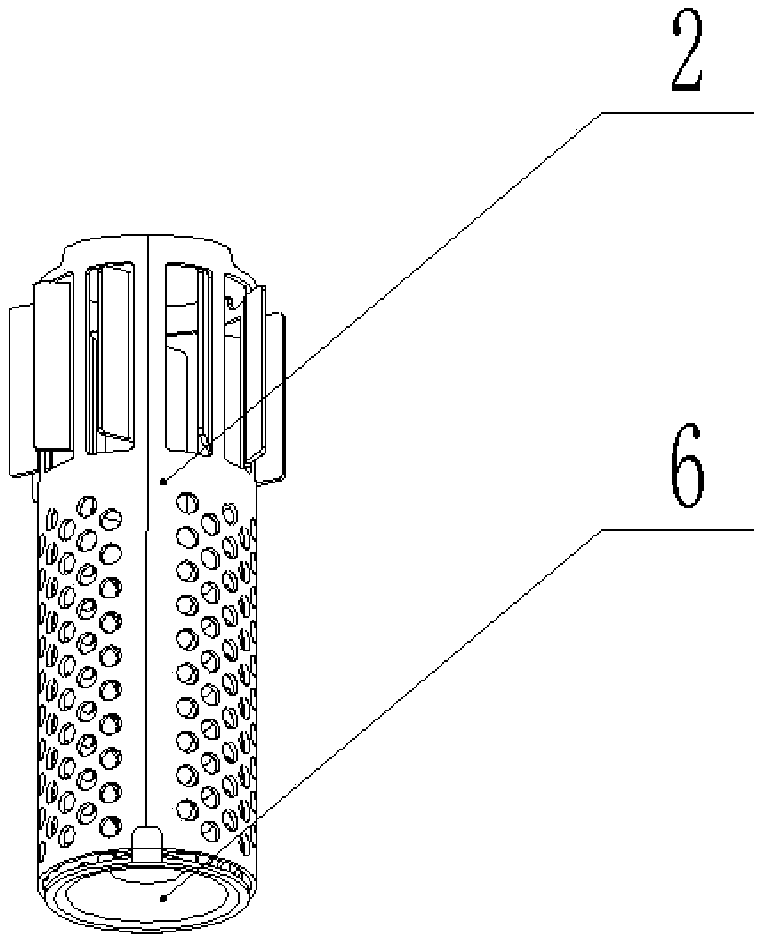

PendingCN110273734AGuaranteed mixing effectReduced risk of crystallizationExhaust apparatusSilencing apparatusRotational flowMetal mesh

The invention relates to a two-way rotational flow cylinder type urea mixing device which comprises a nozzle base, a base supporting cover, a rotational flow pipe, a metal mesh ring, a supporting plate, a back rotational flow plate, a front rotational flow plate and a cylinder; the supporting plate is arranged inside the cylinder, a hole is formed in the front part of the supporting plate, the front rotational flow plate is installed inside the hole, the back rotational flow plate is installed at the rear part of the supporting plate, and the front rotational flow plate, the supporting plate and the back rotational flow plate form a mixing cavity inside the cylinder; the nozzle base, the base supporting cover, the rotational flow pipe and the metal mesh ring are sequentially fixedly connected from top to bottom, the base supporting cover penetrates through the hole in the cylinder and is fixedly connected with the cylinder, and the rotational flow pipe runs into the hole in the middle of the supporting plate to be fixedly connected with the supporting plate; the metal mesh ring stretches into the mixing cavity; the nozzle base, the base supporting cover, the rotational flow pipe and the metal mesh ring are inclined. On the condition of ensuring urea mixing uniformity, the crystallization problem that the urea decomposition efficiency is not high in an SCR system is solved.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

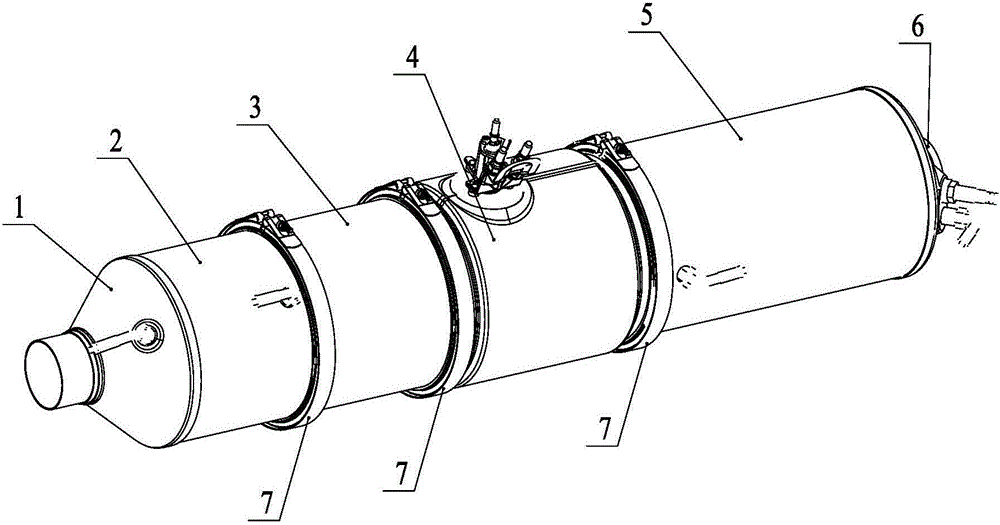

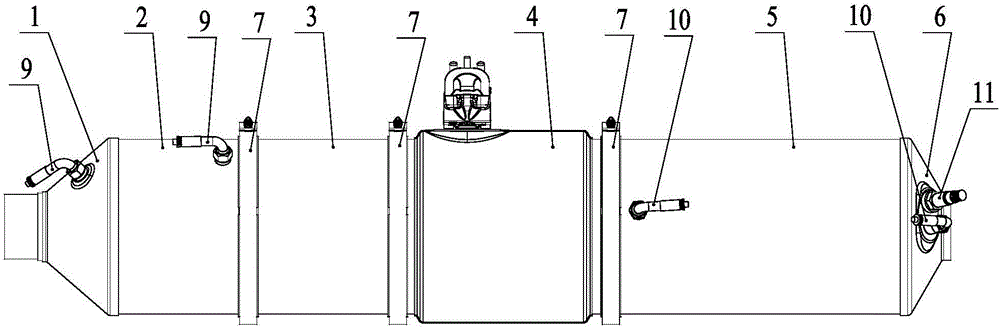

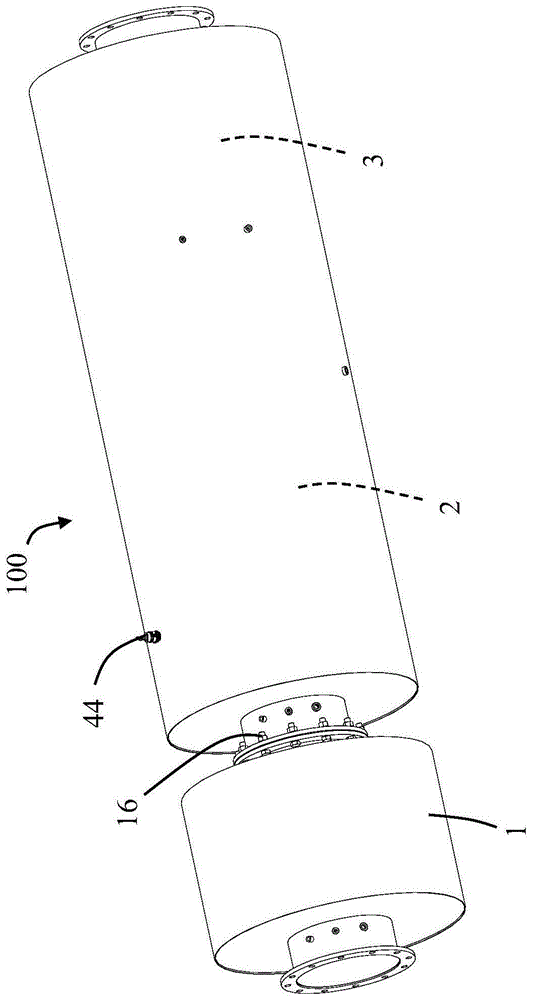

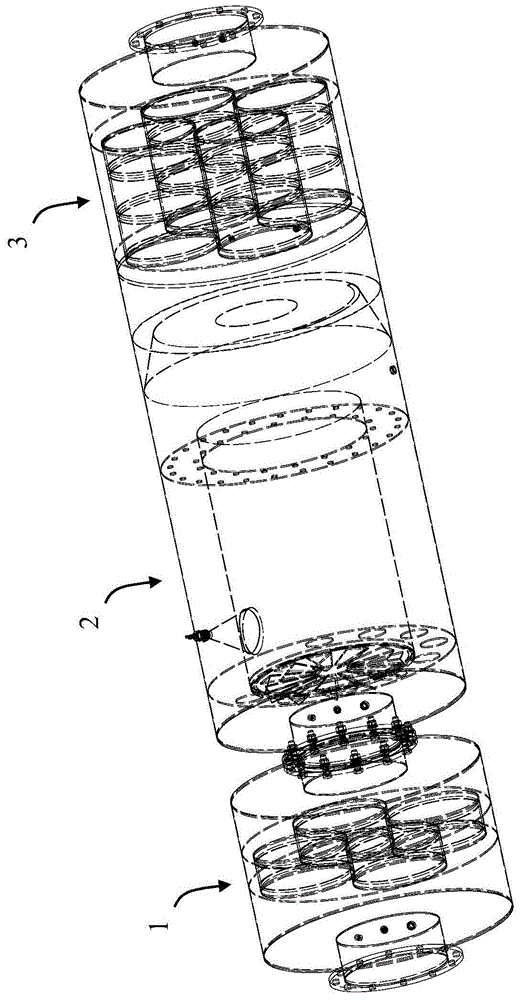

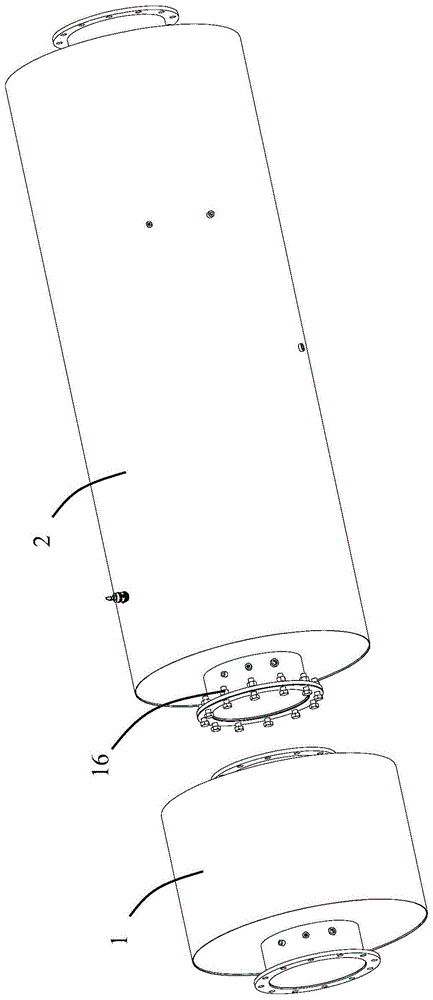

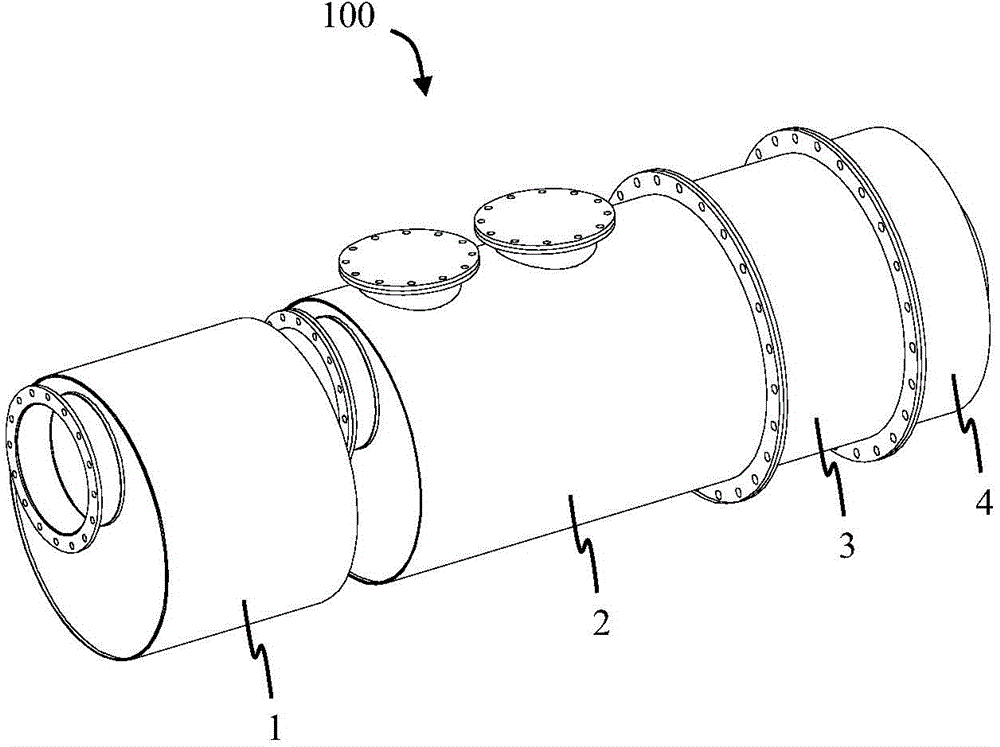

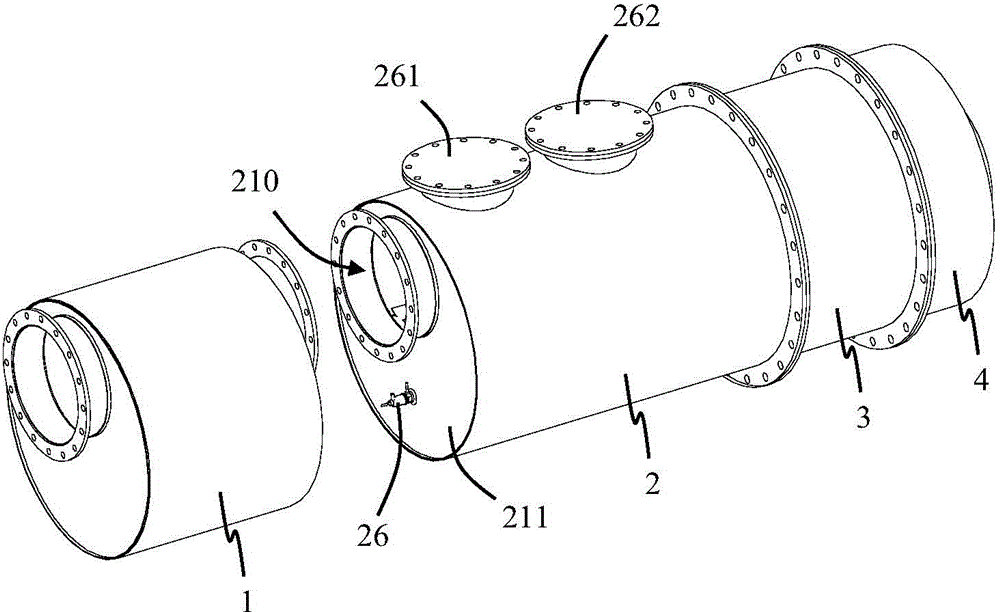

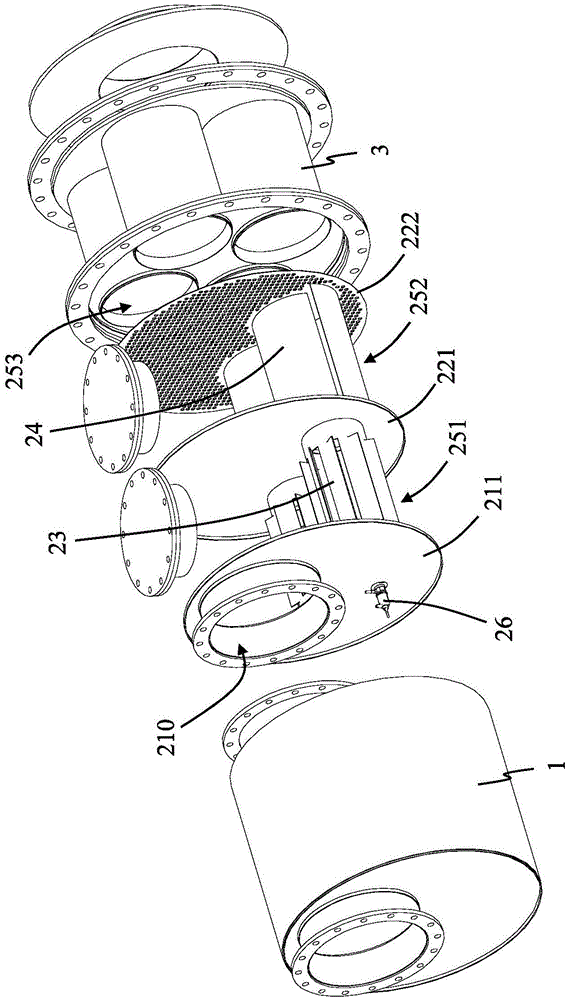

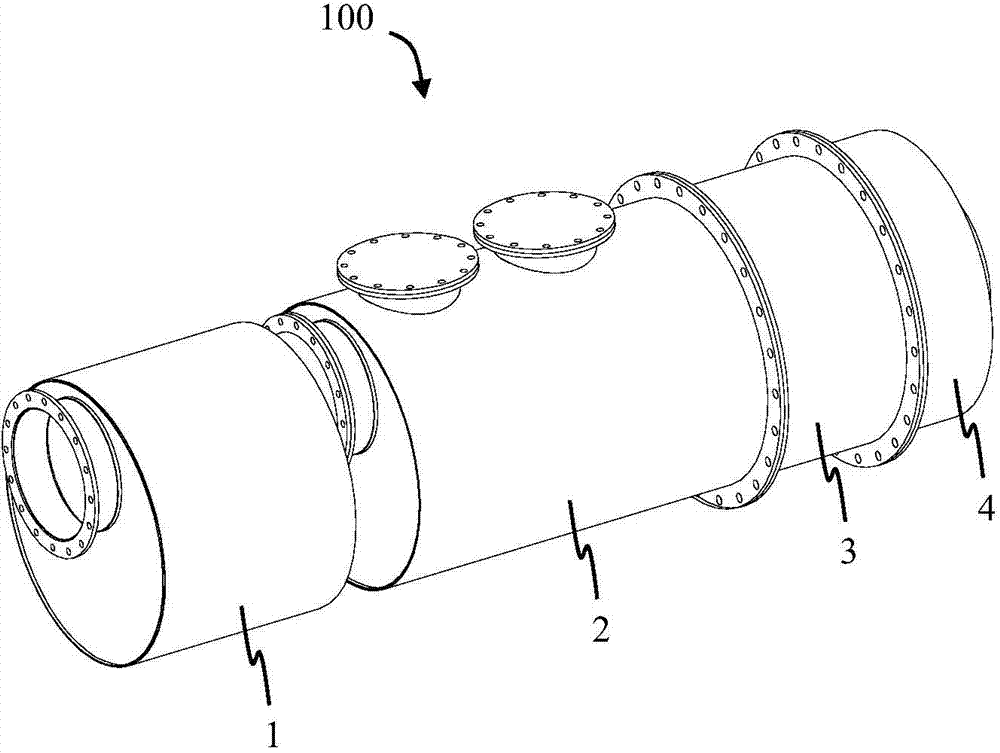

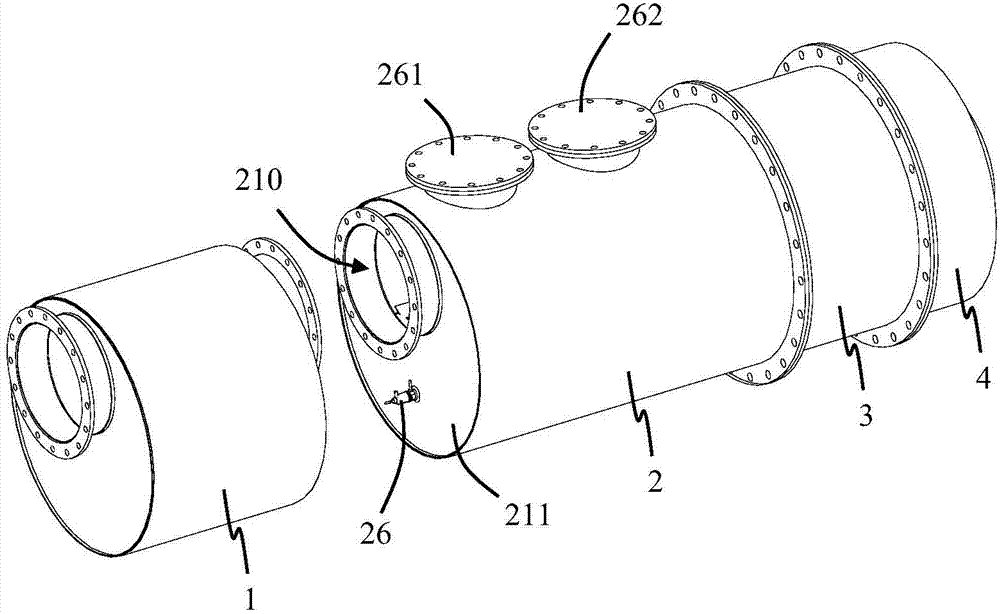

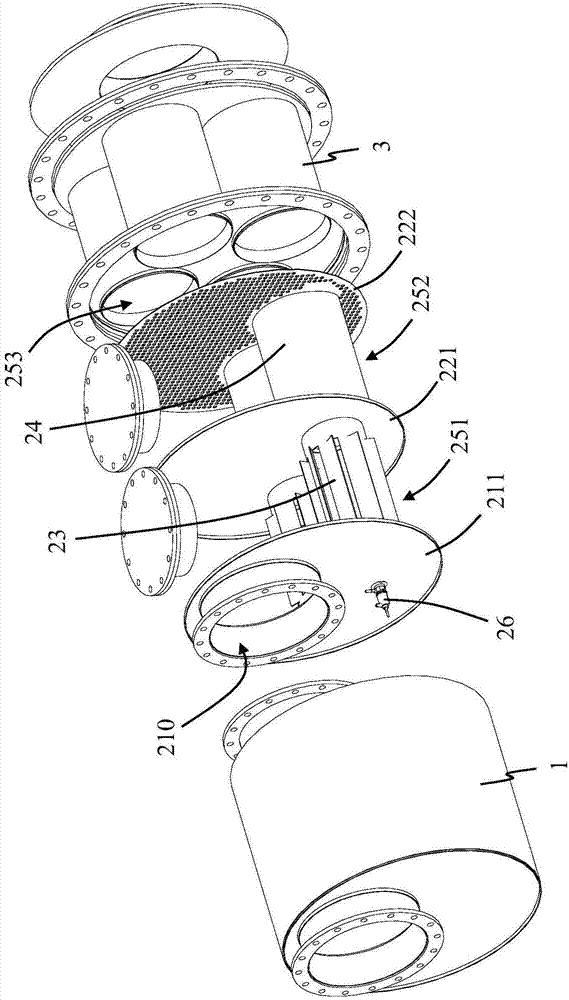

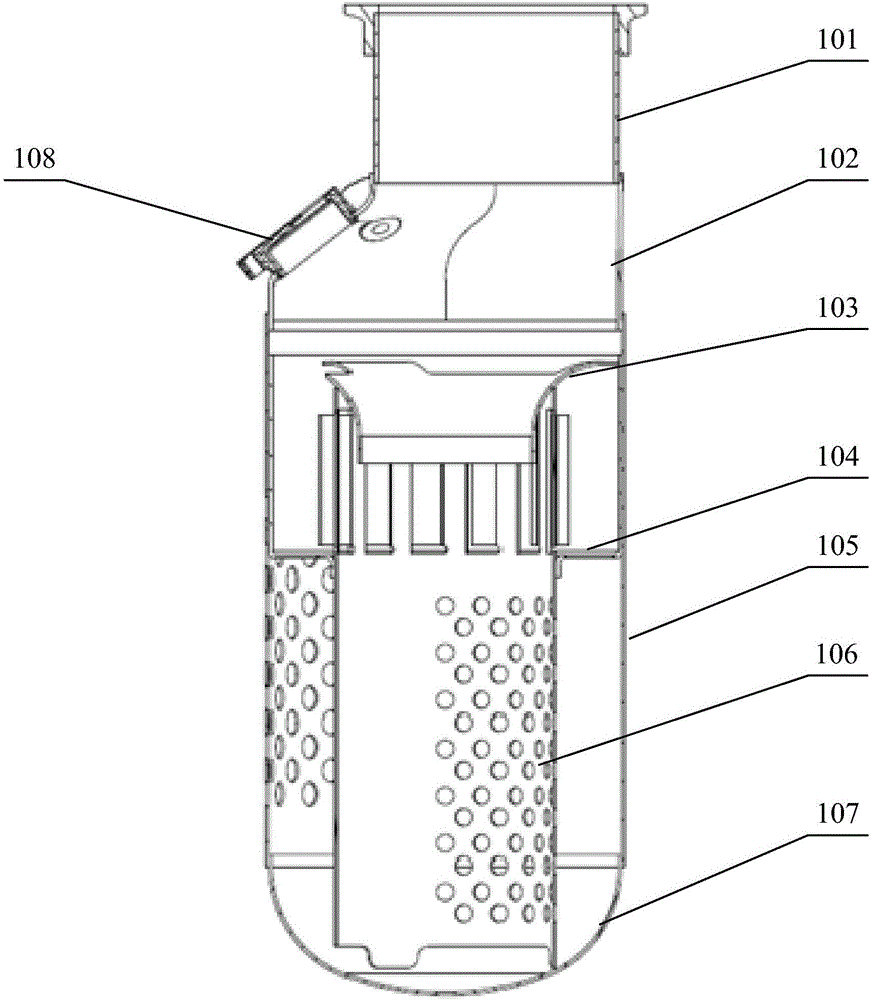

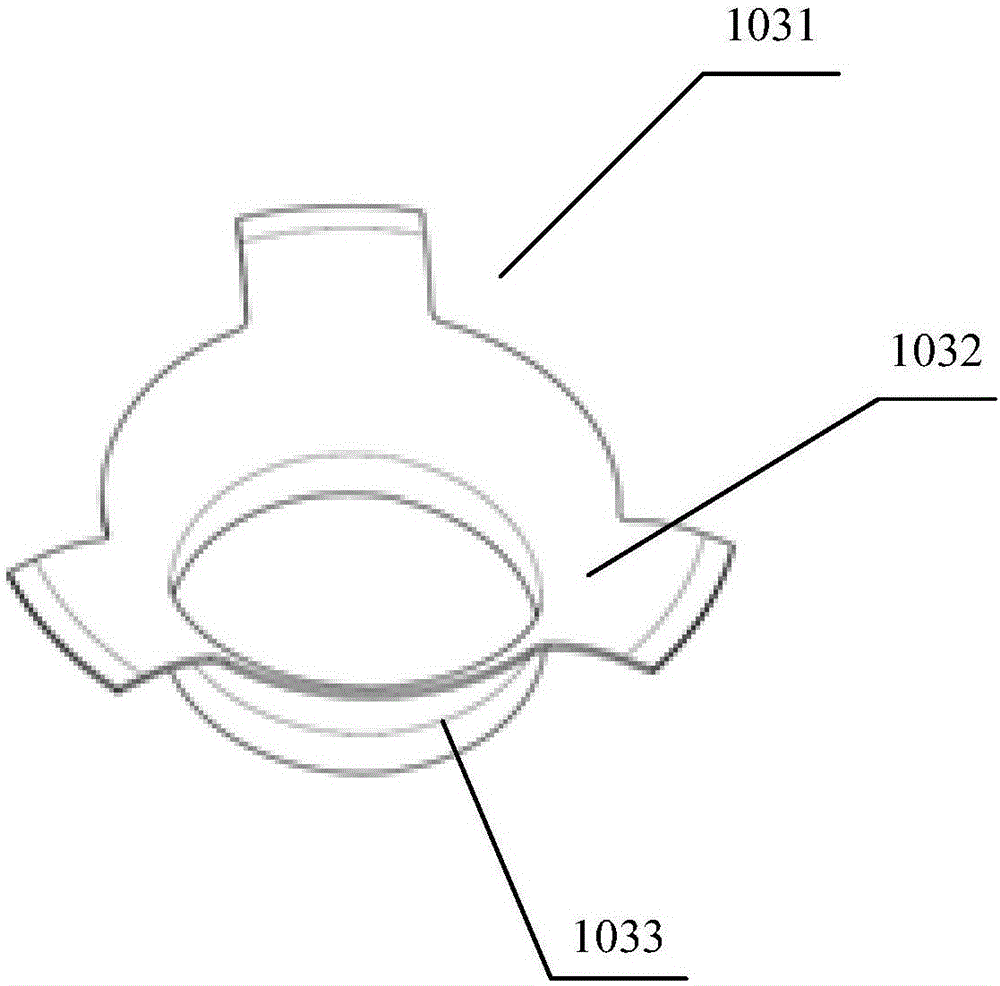

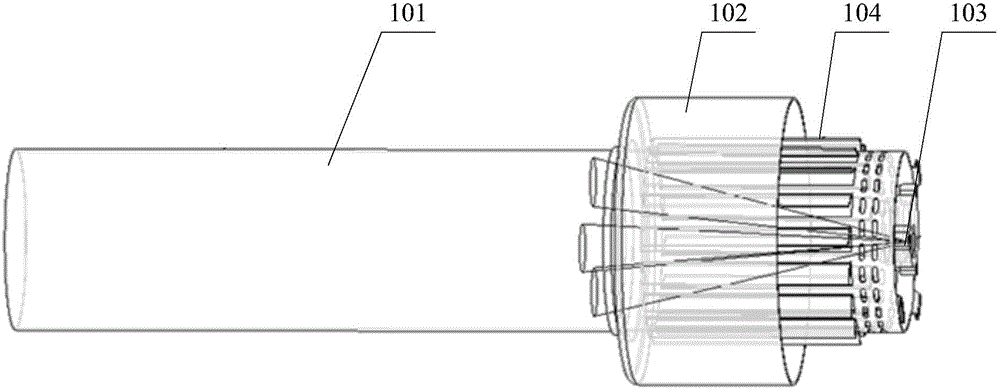

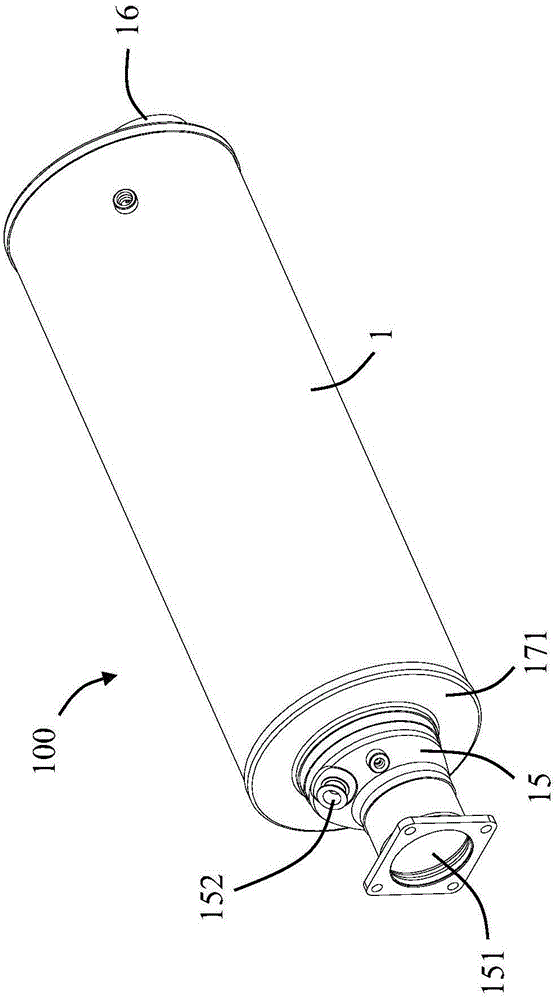

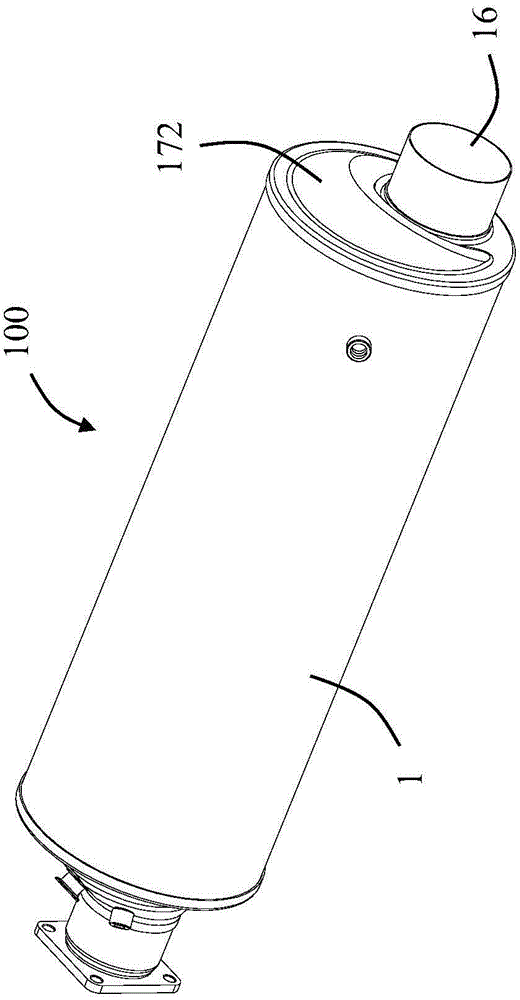

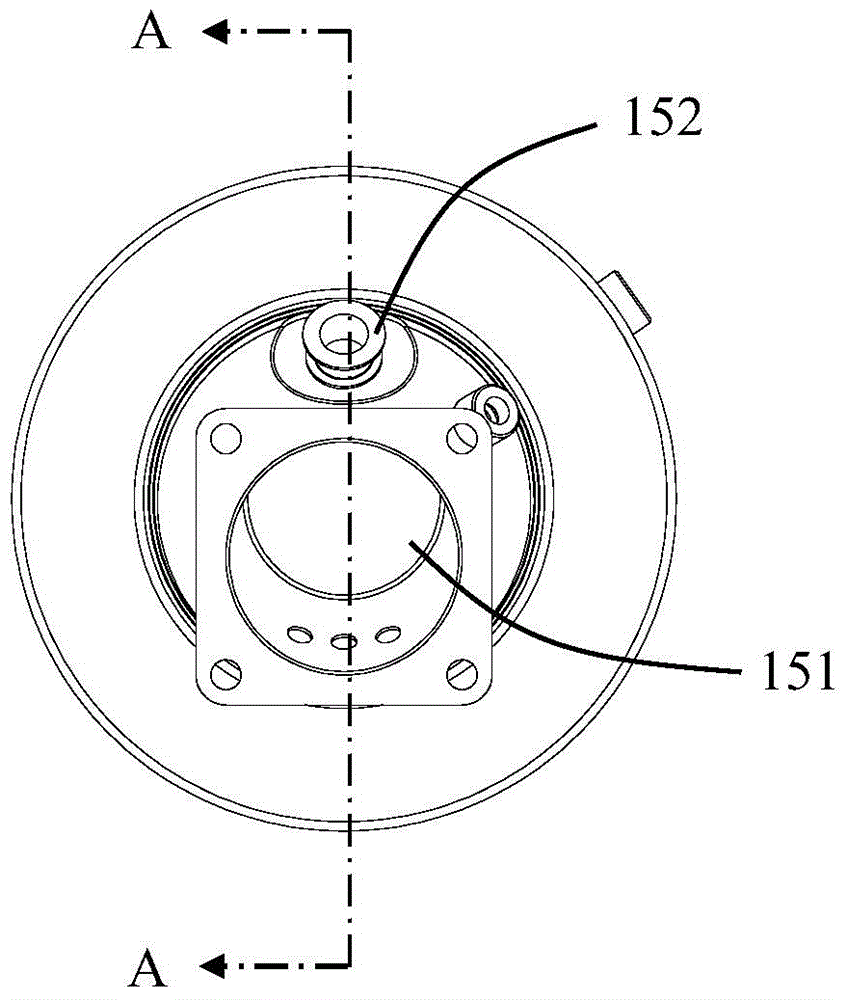

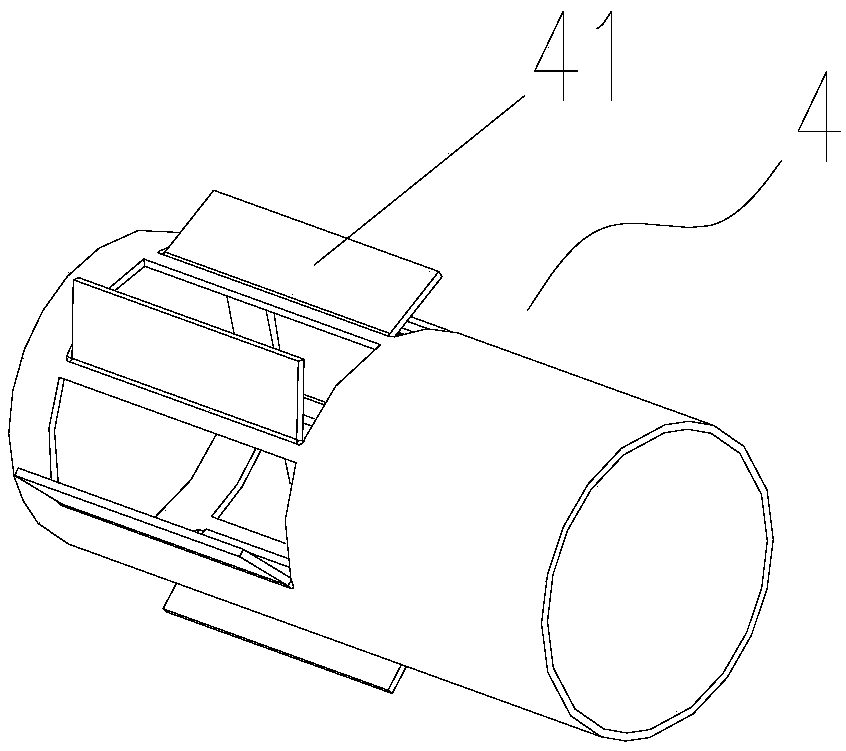

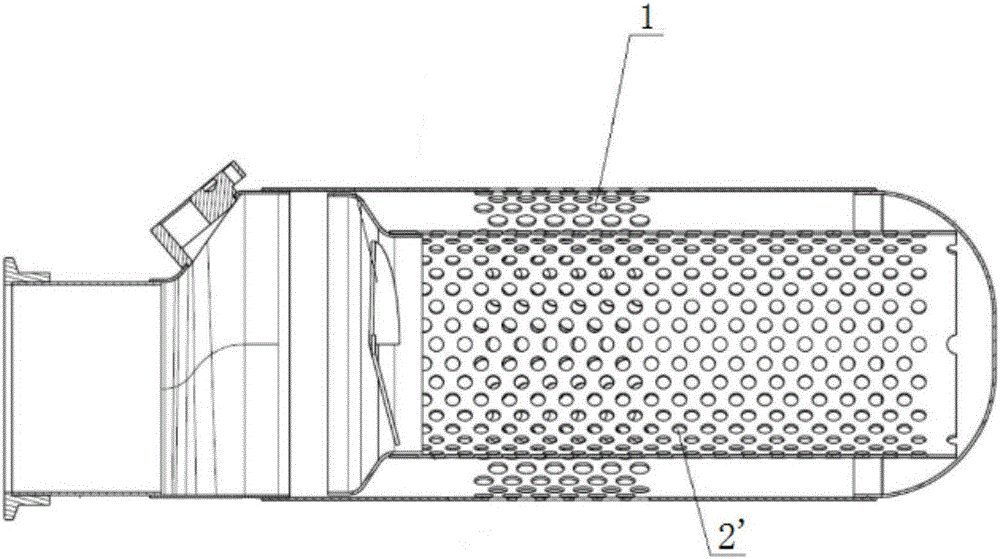

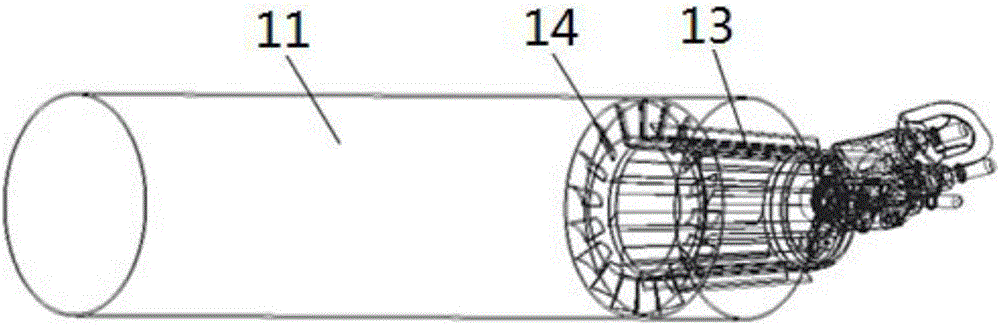

Shaft-inlet and shaft-outlet barrel type aftertreatment assembly

ActiveCN106437982ACompact and reliableGood versatility for loadingInternal combustion piston enginesExhaust apparatusParticulatesEngineering

The invention relates to a shaft-inlet and shaft-outlet barrel type aftertreatment assembly. The shaft-inlet and shaft-outlet barrel type aftertreatment assembly is characterized by comprising an oxidation catalysis converter, a particulate trap, a urea spraying and mixing unit and a selective catalytic reduction converter which are successively connected, wherein the front end of the oxidation catalysis converter is connected with a gas inlet end cap; and the tail end of the selective catalytic reduction converter is connected with a gas outlet end cap. The shaft-inlet and shaft-outlet barrel type aftertreatment assembly is compact in structure, DOC, DPF, SCR and the urea spraying and mixing unit can be integrated together effectively, stable and efficient operation of the DOC, the DPF and the SCR is ensured, urea is uniformly distributed on an end surface of the SCR, and urea crystallization is avoided.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER +1

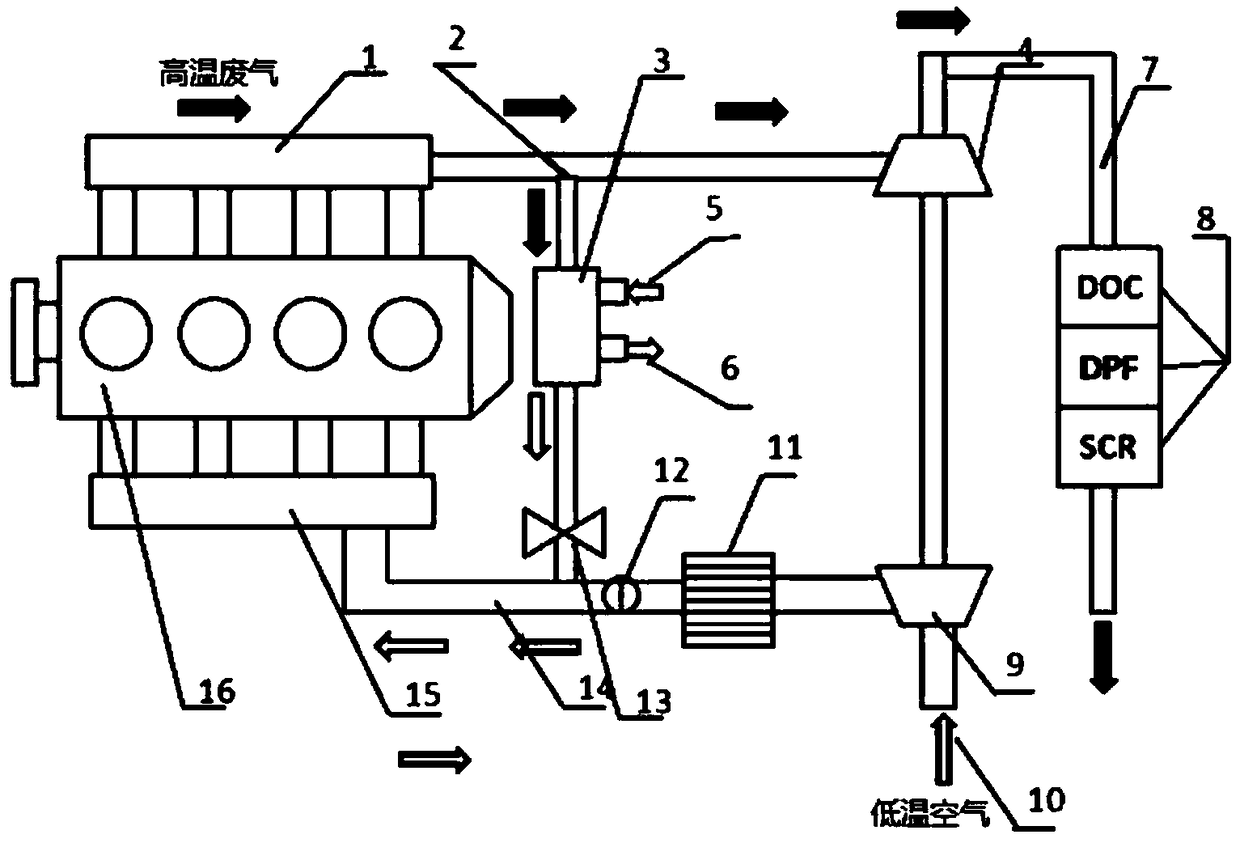

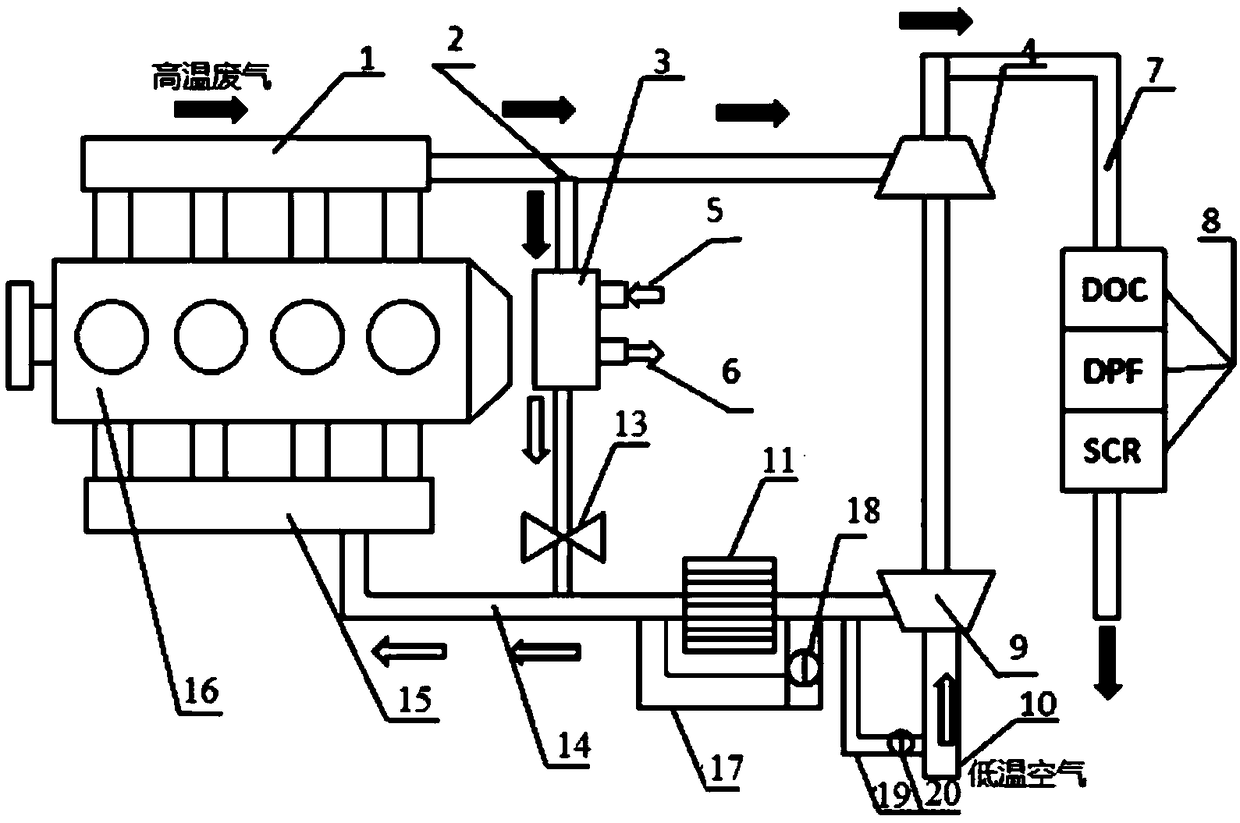

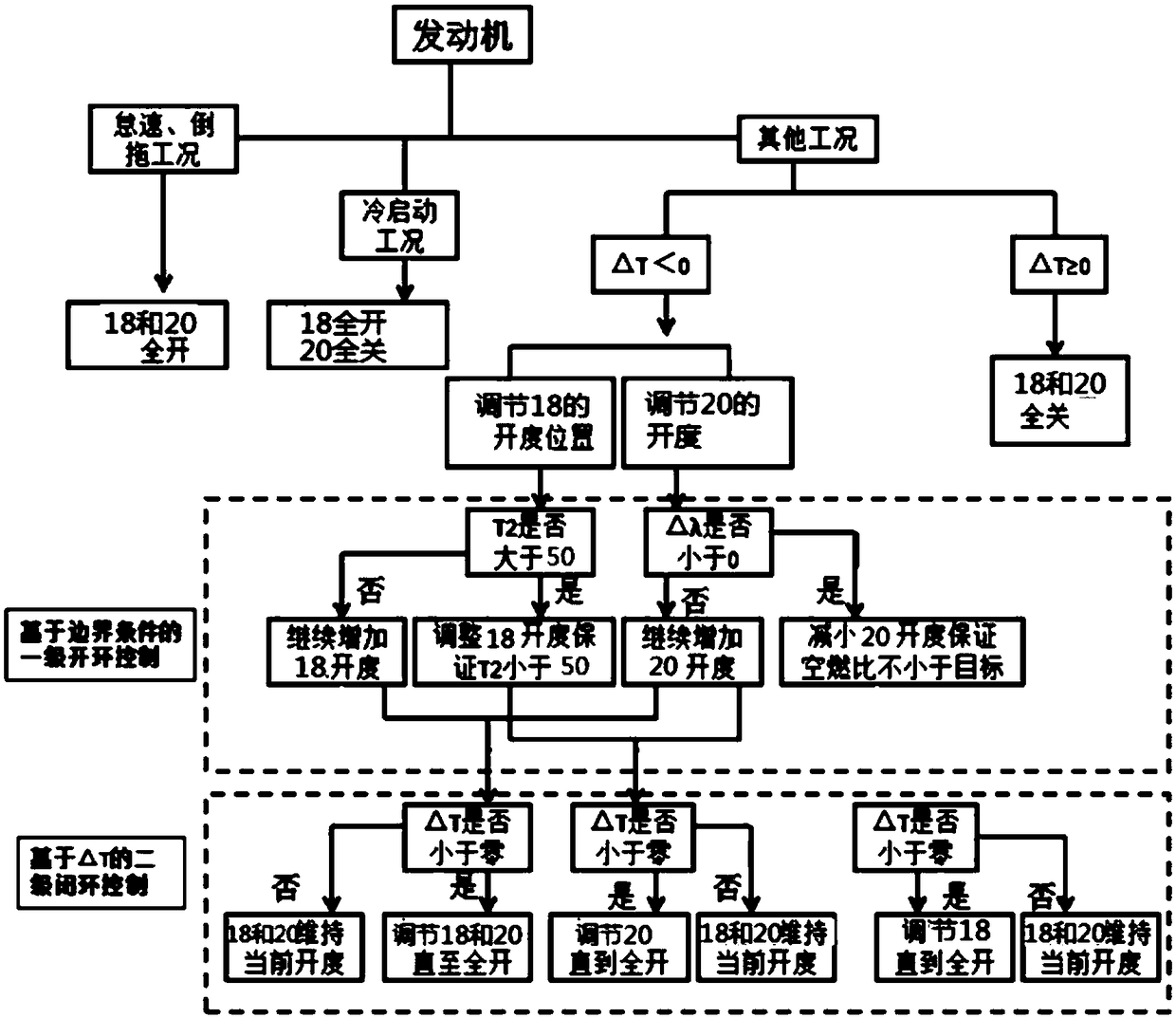

Engine thermal management system and control method thereof

ActiveCN108716433AIncrease intake air temperatureReduce fuel consumptionInternal combustion piston enginesExhaust apparatusThermal management systemIntercooler

The invention discloses an engine thermal management system. The system includes an engine air intake pipe, an engine air intake main pipe, an intercooler, and a supercharger compressor. The engine thermal management system also includes an intake air temperature control bypass pipeline, an intake air amount control bypass pipeline and a temperature sensor. The two ends of the intake air temperature control bypass pipeline are respectively connected to the inlet and outlet of the intercooler. The intake air temperature control bypass pipeline is connected in parallel with the intercooler. A first bypass proportional valve is arranged on the intake air temperature control bypass pipeline. The intake air flow bypass of different flow rates can be realized by adjusting the position ratio of the first bypass proportional valve. The two ends of the intake air amount control bypass pipeline are respectively connected to the inlet and outlet of the compressor. The intake air amount control bypass pipeline is connected in parallel with the supercharger compressor. A second bypass proportional valve is arranged on the intake air amount control bypass pipeline. The intake air flow demands ofdifferent working conditions can be met by adjusting the opening degree of the second bypass proportional valve. The temperature sensor is arranged on a pipeline of the engine air intake main pipe and is used for measuring the temperature of intake air entering the engine air intake main pipe. An EUC can collect measured values of the intake air temperature.

Owner:GUANGXI YUCHAI MASCH CO LTD

SCR (Selective Catalytic Reduction) urea solution mixer

InactiveCN106110980AComplicated air flowImprove mixing uniformityInternal combustion piston enginesExhaust apparatusUreaAirflow

The embodiment of the invention discloses an SCR (Selective Catalytic Reduction) urea solution mixer which comprises an outer-layer tube and an inner-layer tube, wherein the inner-layer tube is arranged inside the outer-layer tube; side wall air outlet holes through which air flows out are formed in the side wall of the inner-layer tube; outer-layer tube air outlet holes through which air flows out are formed in the side wall of the outer-layer tube; the side wall air outlet holes and the outer-layer tube air outlet holes are formed in a staggered manner. According to the SCR urea solution mixer which is disclosed by the invention, as the side wall air outlet holes in the inner-layer tube and the outer-layer tube air outlet holes in the outer-layer tube are formed in the staggered manner, and air needs to flow to another side of the inner-layer tube to flow into SCR through outer-layer tube air outlet holes in the outer-layer tube after flowing outside the side wall air outlet holes in the inner-layer tube, the air flowing situation between the inner-layer tube and the outer-layer tube is relatively complex, the mixing uniformity of a urea solution is further improved, sufficient utilization of the urea solution is promoted, and the purpose of preventing urea from excessive precipitation is finally achieved.

Owner:WEICHAI POWER CO LTD

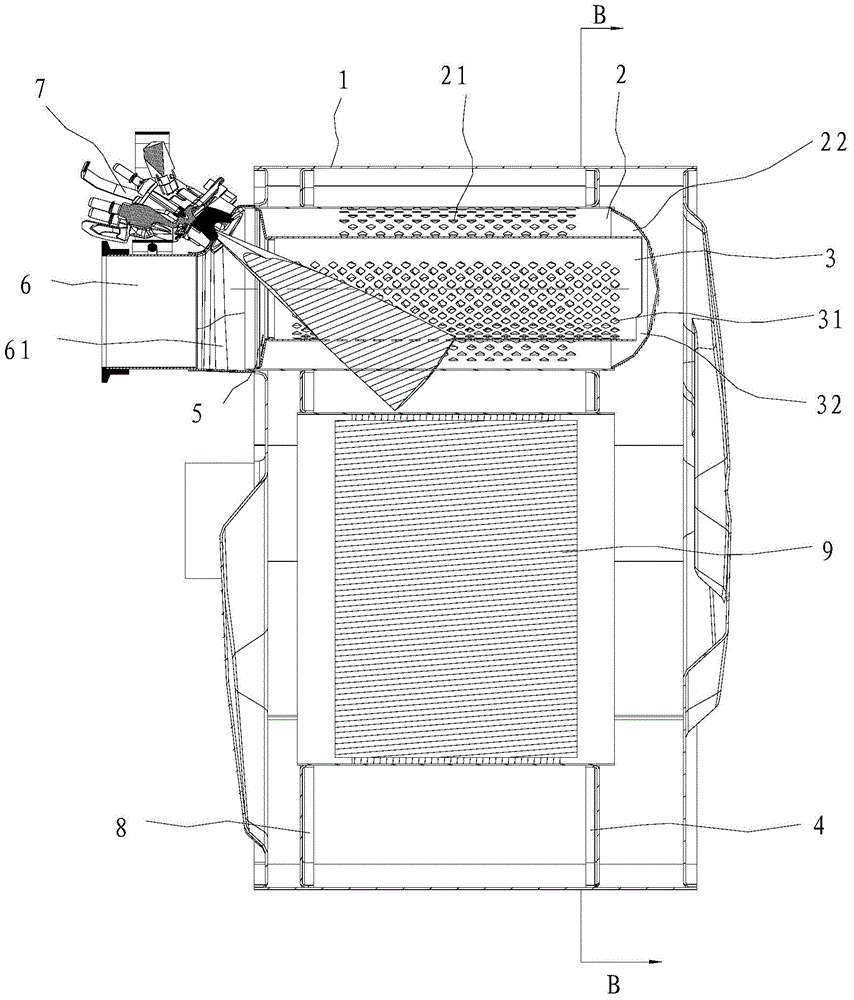

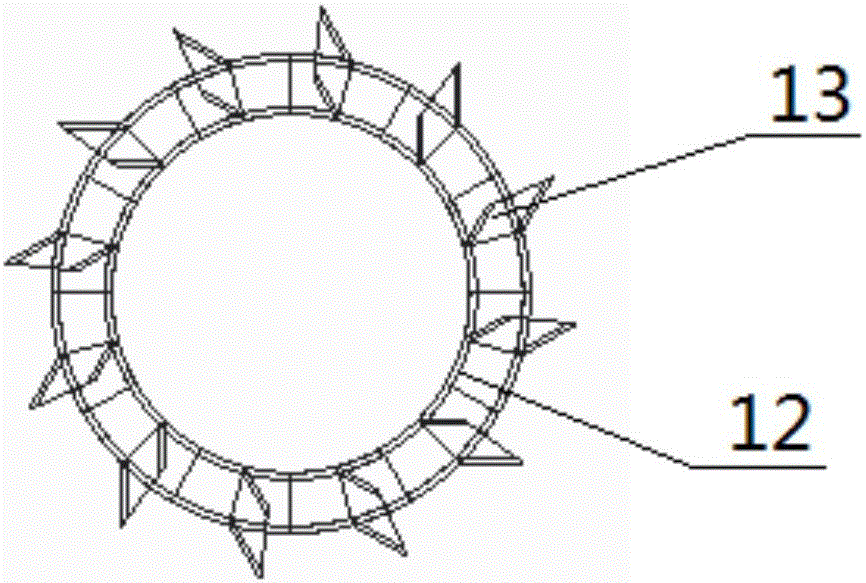

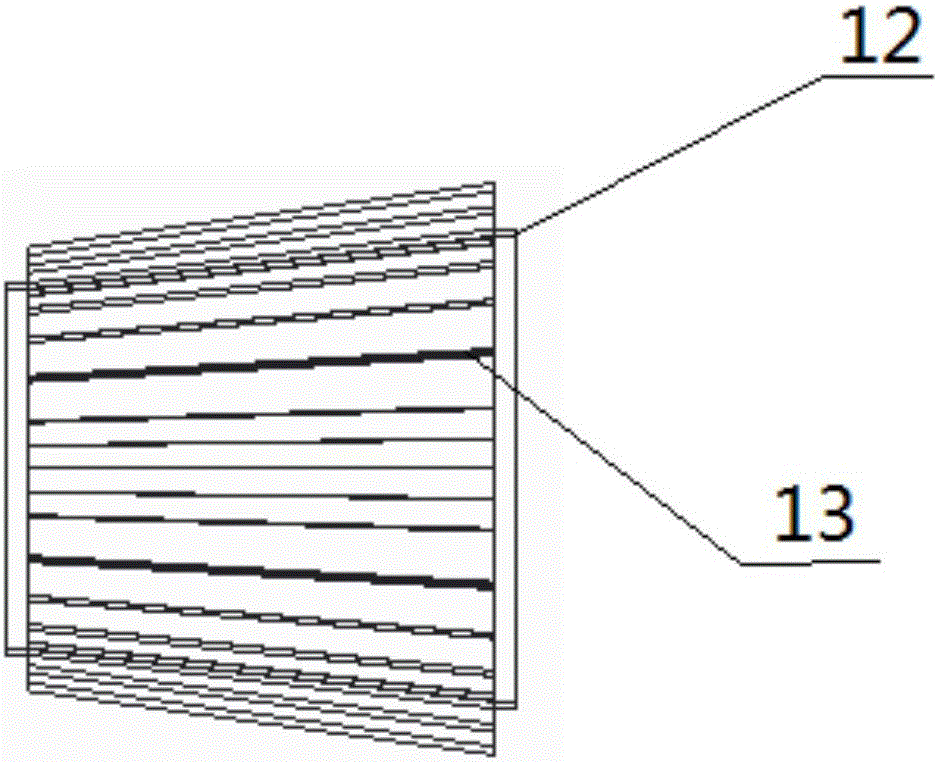

Exhaust gas disposal device

ActiveCN105134349AIncrease evaporation areaReduced risk of crystallizationExhaust apparatusSilencing apparatusProcess engineeringCentrifugal force

An exhaust gas disposal device comprises a shell, partition plates, a mixing cavity, a distributing cavity and a tail gas disposal module. The exhaust gas disposal device comprises a mixing device erected in the mixing cavity, and thus the mixing cavity is divided into a first cavity, a second cavity and a third cavity. The mixing device comprises a mixing pipe and a spinning disk installed on the mixing pipe, wherein the spinning disk comprises a plurality of fins which stretch into the first cavity in a protruding manner and are arranged in the circumferential direction. The exhaust gas disposal device further comprises a jet limiting cylinder fixed to the mixing pipe, and the jet limiting cylinder is used for enabling a urea nozzle to lead an atomized urea solution into the mixing pipe. Urea is evenly distributed on the pipe wall of the mixing pipe through centrifugal force generated by rotational flow, the urea evaporation area is increased, and the evaporation rate is increased. In addition, the distributing cavity is used for improving the distribution uniformity of urea liquid drips entering the distributing cavity from the mixing cavity, and thus the risk of urea crystallization is reduced.

Owner:TENNECO SUZHOU EMISSION SYST

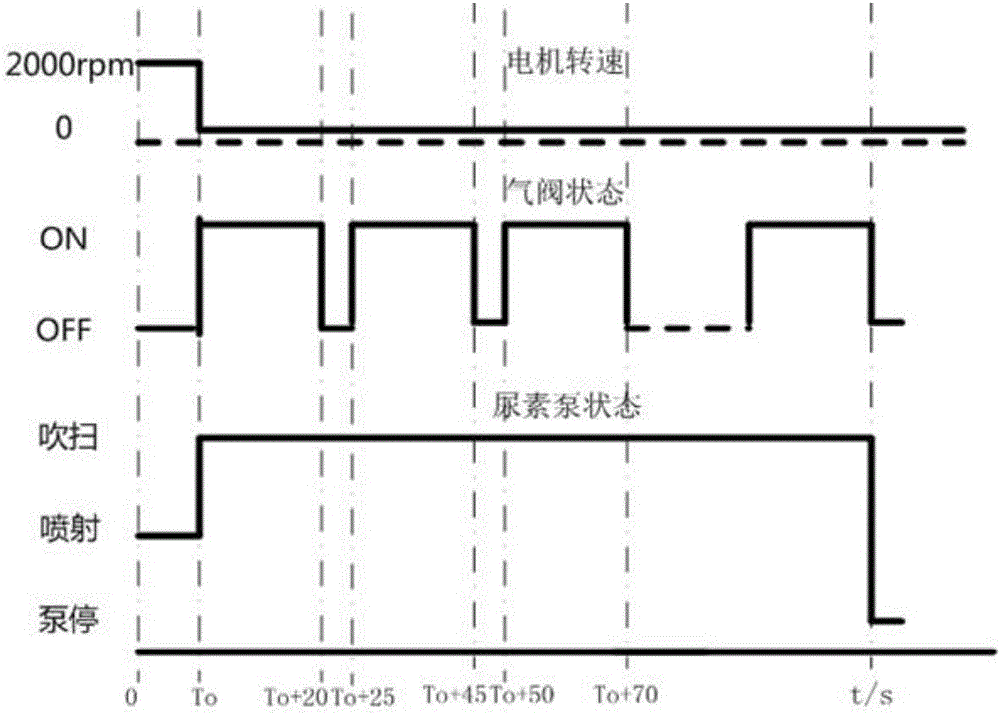

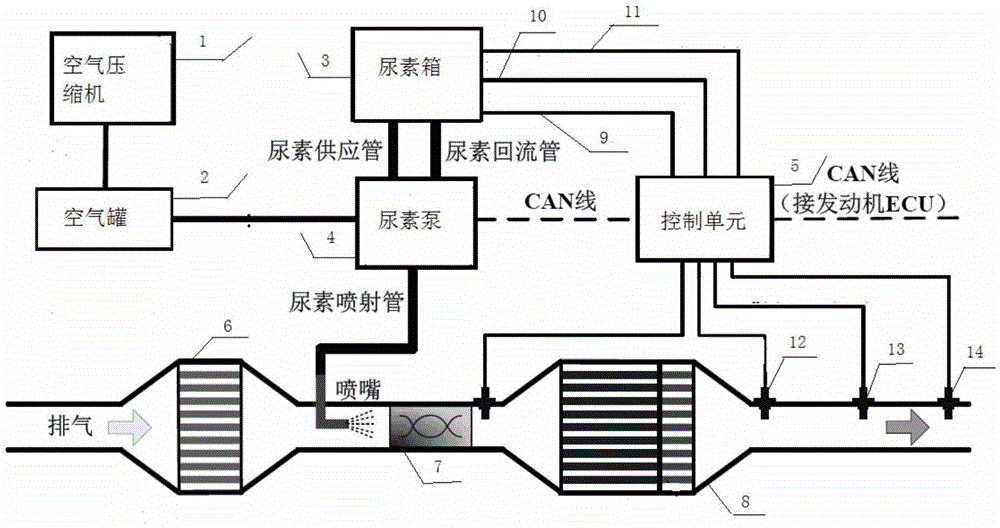

Control method for reducing crystallization risk of SCR urea injection system

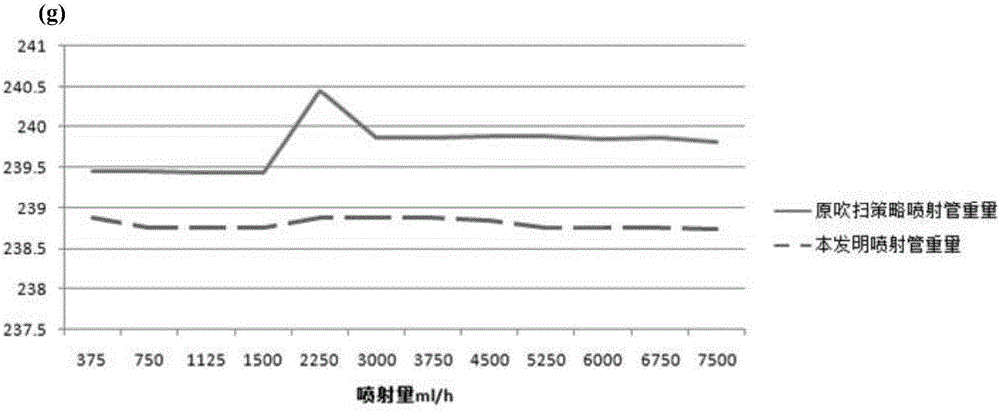

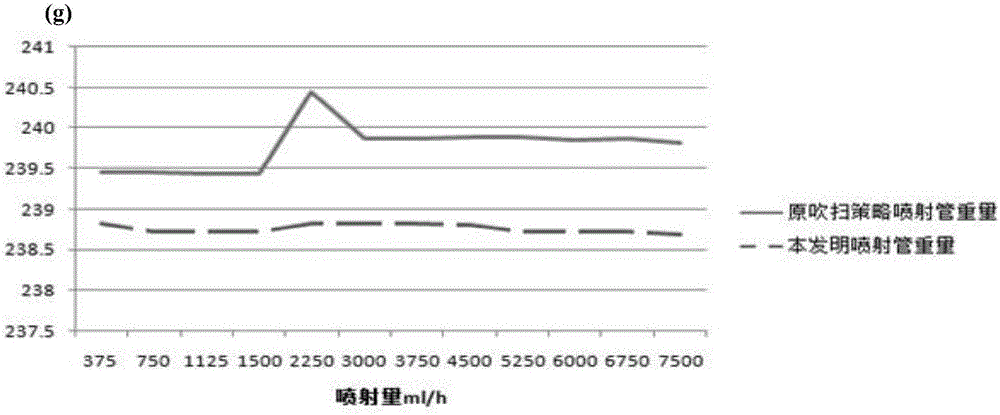

ActiveCN106567762AImprove reliabilityReduced risk of crystallizationInternal combustion piston enginesExhaust apparatusElectricityEngineering

The invention provides a control method for reducing the crystallization risk of an SCR urea injection system. According to the control method, after a urea pump is discharged and carries out continuous blowing or inverse suction for a certain period of time, the urea pump is stopped for a period of time, blowing or inverse suction continues to be carried out for a certain period of time after local liquid convergence, and intermittent blowing or inverse suction is carried out. Compared with the operation that blowing or inverse suction time is prolonged blindly, residual urea can be blown away or inversely sucked more thoroughly by means of the control strategy, and therefore the reliability of the SCR urea injection system is improved.

Owner:WEICHAI POWER CO LTD +1

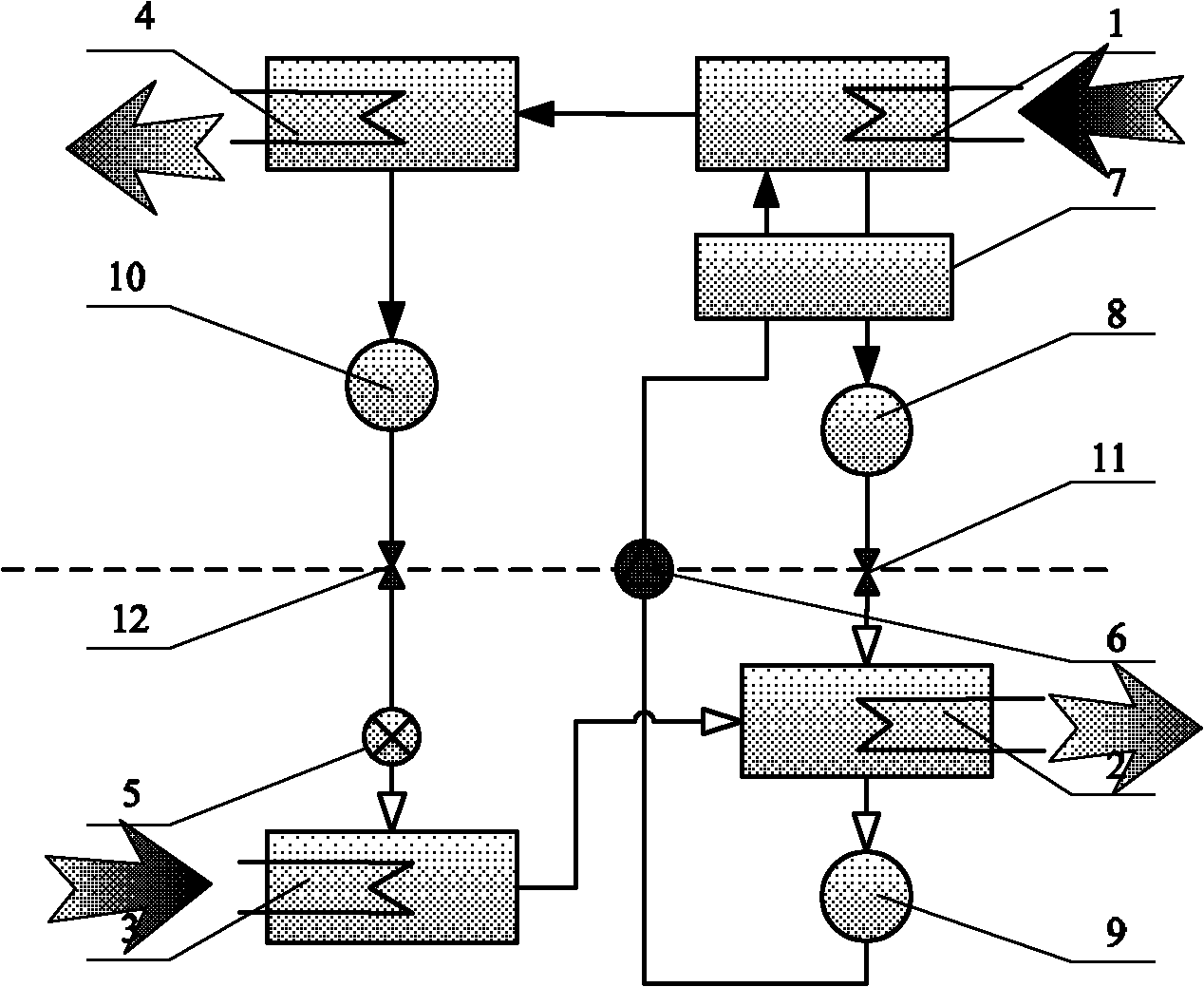

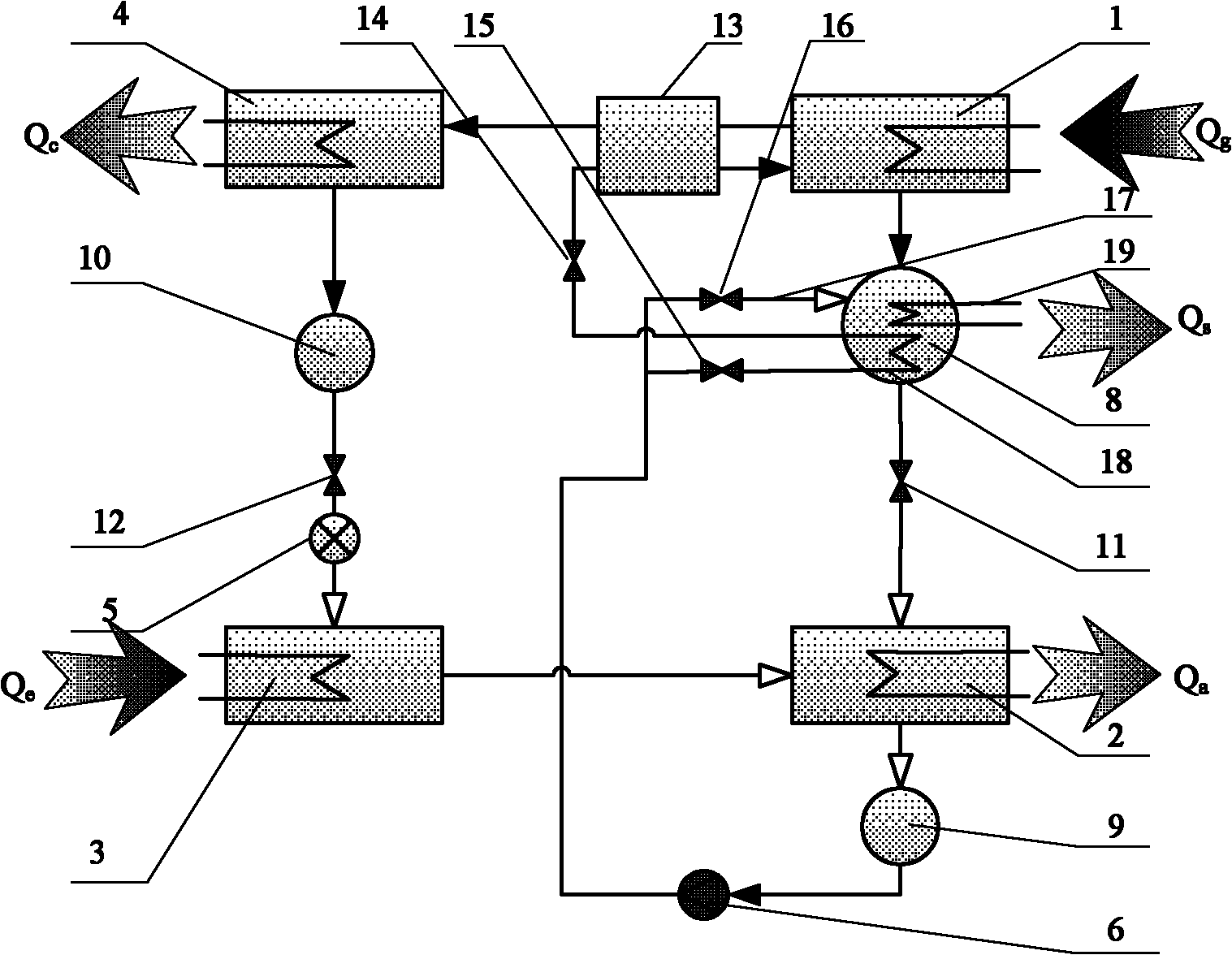

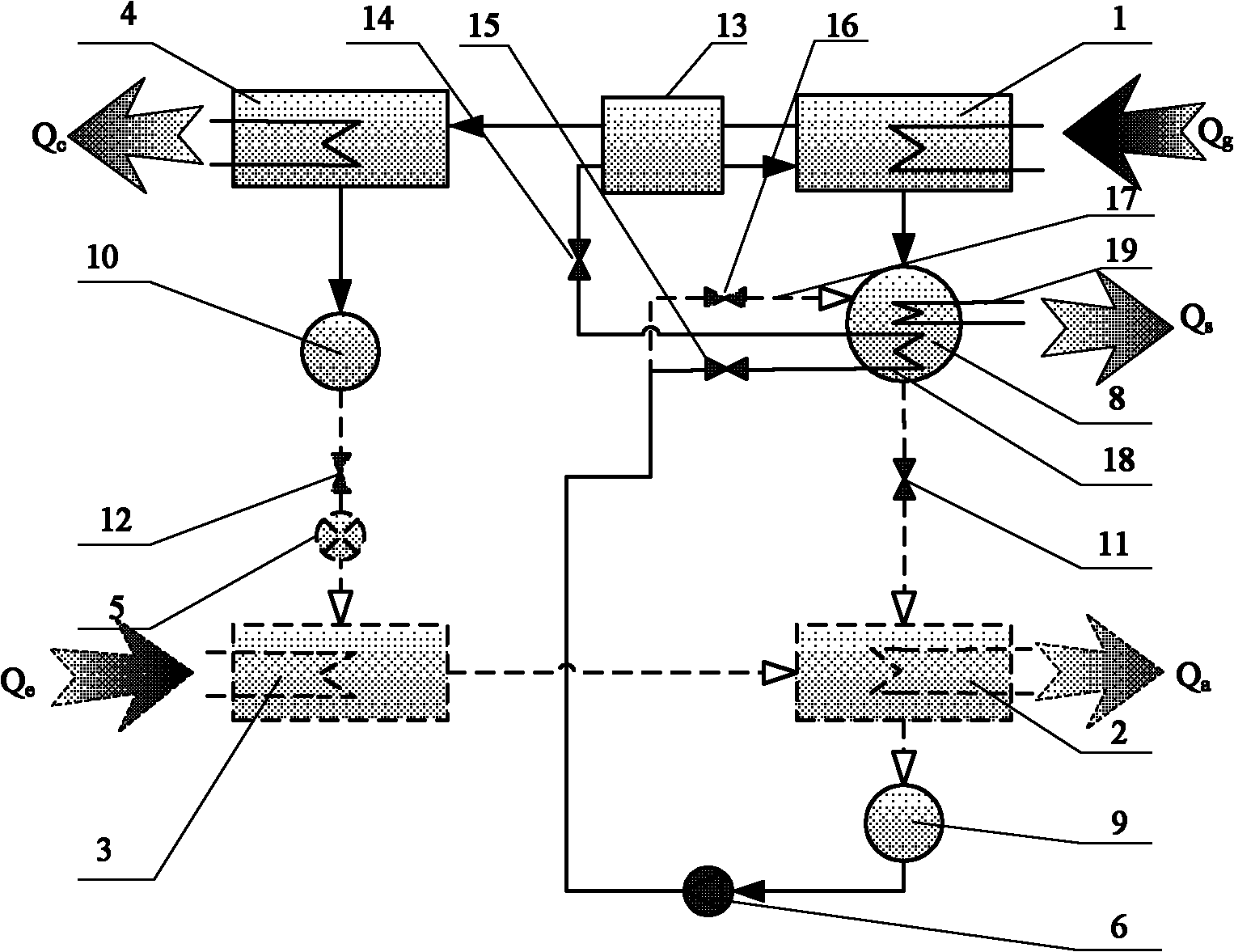

Absorption-type chemical energy storage device containing crystals

InactiveCN102305494AGuaranteed uptimeHigh densityEnergy efficient heating/coolingClimate change adaptationHeat energySupply energy

The invention discloses an absorption-type chemical energy storage device containing crystals. The device comprises a generator, an absorber, an evaporator, a condenser, a throttle valve, a solution pump, a concentrated solution storage tank, a dilute solution storage tank, a gas and liquid heat exchanger, a refrigerant storage tank and the like, wherein a solution heat exchange pipe and a cooling coil pipe are arranged in the concentrated solution storage tank; and an anti-crystallinic pipe is bypassed outside the solution heat exchange pipe for dissolving the crystals. The energy storage device disclosed by the invention can convert solar energy, industrial residual heat, sufficient electrical quantity and the like into chemical energy to be stored, and the mismatching of space, time and amount between a source side and an user side is solved; the energy storage technology can be used for changing defects into benefits, energy storage is carried out by utilizing an absorbent crystallization phenomenon, and the energy storage density is improved; anti-crystallinic measures are disclosed, and the normal operation of energy storage and release is ensured; the system circulation form is improved, the step heat energy utilization is realized, and the utilization efficiency of heat sources is improved; and functions of the device are expanded, so that four modes, namely energy storage, energy release, direct energy supply and simultaneous storage and release, are realized.

Owner:TSINGHUA UNIV

Hybrid tube and exhaust gas treatment device

ActiveCN104594990AIncrease the itineraryIncrease the evaporation distanceExhaust apparatusSilencing apparatusCycloneEngineering

The invention discloses a hybrid tube which is used in an exhaust gas treatment device of an engine and comprises a first semicircular tube and a second semicircular tube which are cooperated with each other, wherein the first semicircular tube and the second semicircular tube are staggered mutually in a radial direction to form a first outlet and a second outlet in the circumference; opening directions of the first outlet and the second outlet are opposite in order to form a cyclone. The hybrid tube provided by the invention is simple in structure, and the cyclone can rotate after entering a hybrid space, so that the stroke of airflow in a limited space is increased, the evaporation distance of urea droplets is increased, the evaporation rate is improved, and the hybrid uniformity is improved. The invention further relates to an exhaust gas treatment device with the hybrid tube.

Owner:TENNECO SUZHOU EMISSION SYST

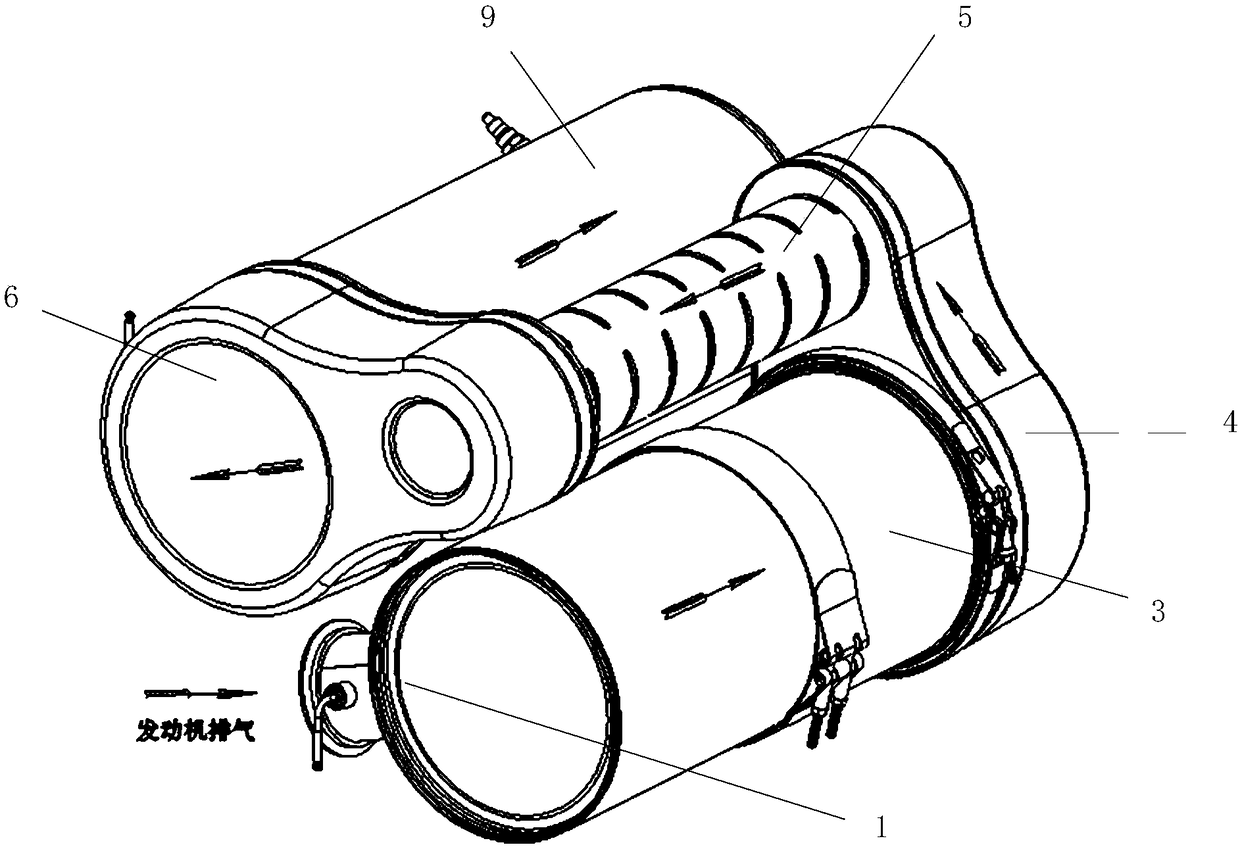

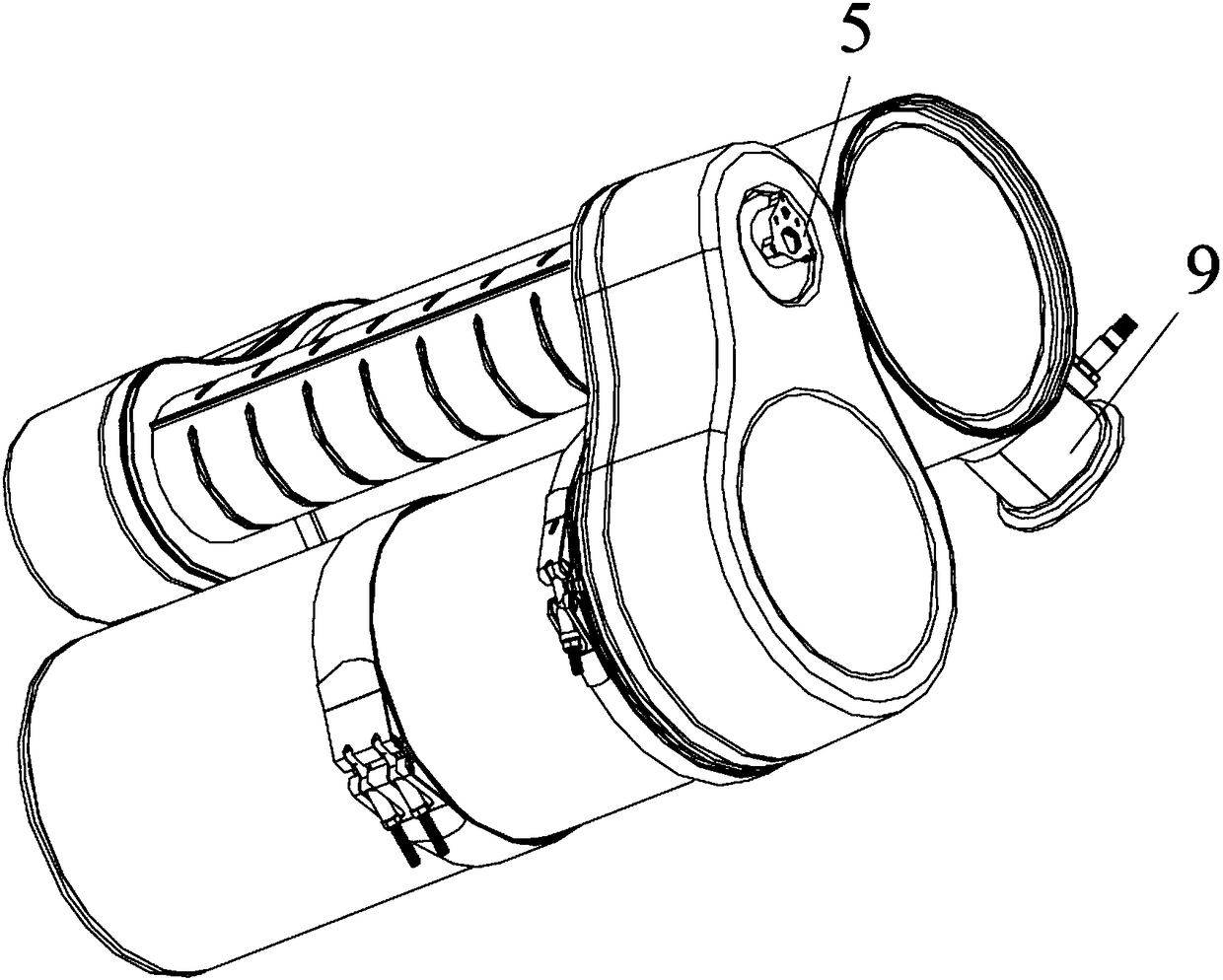

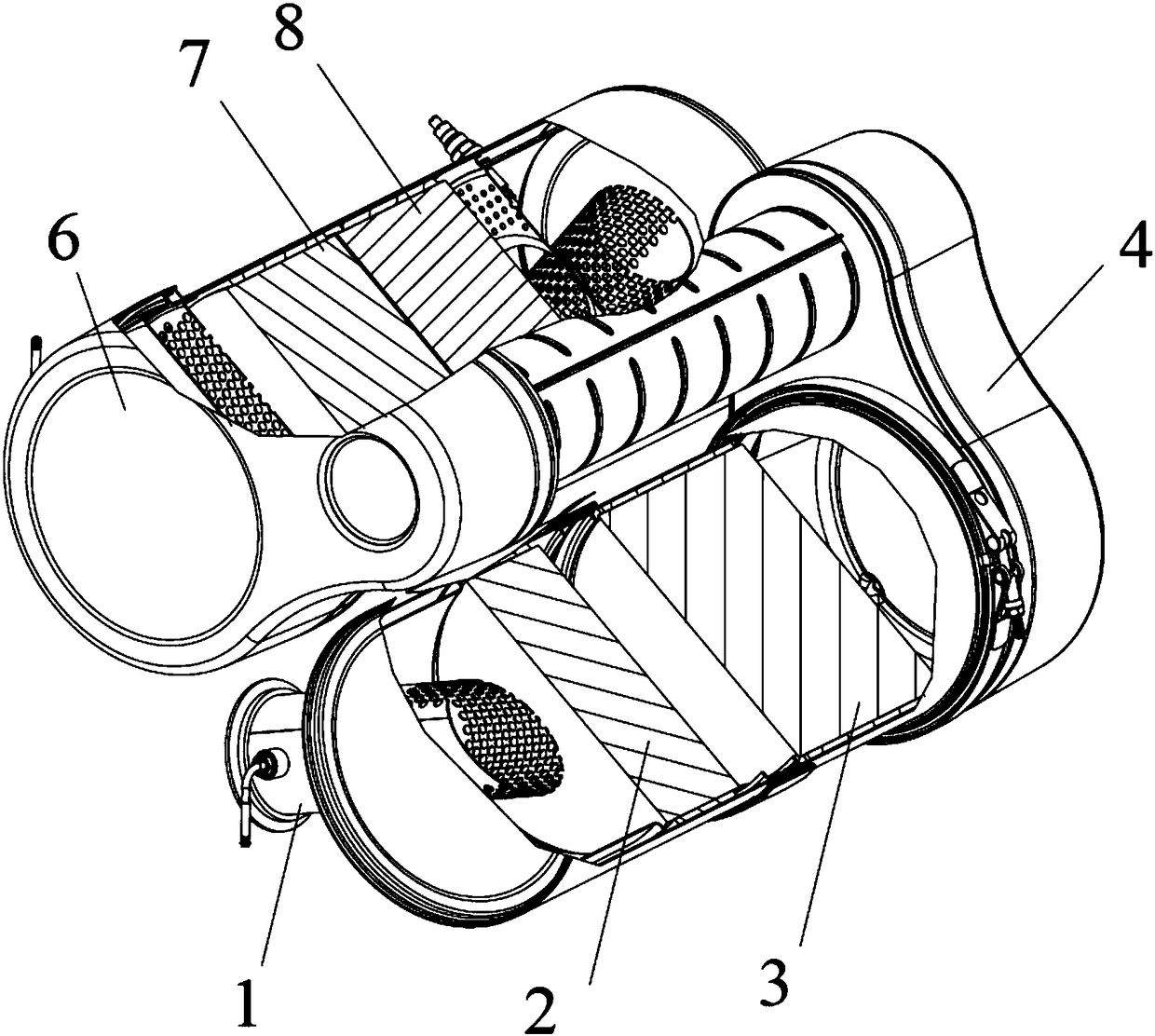

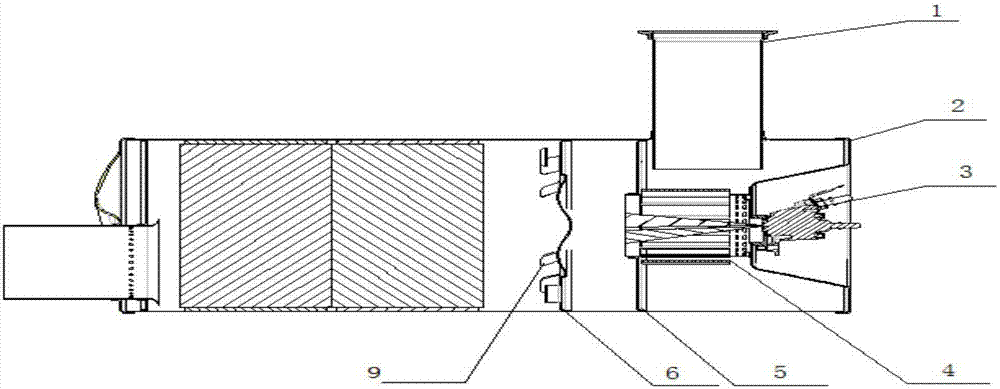

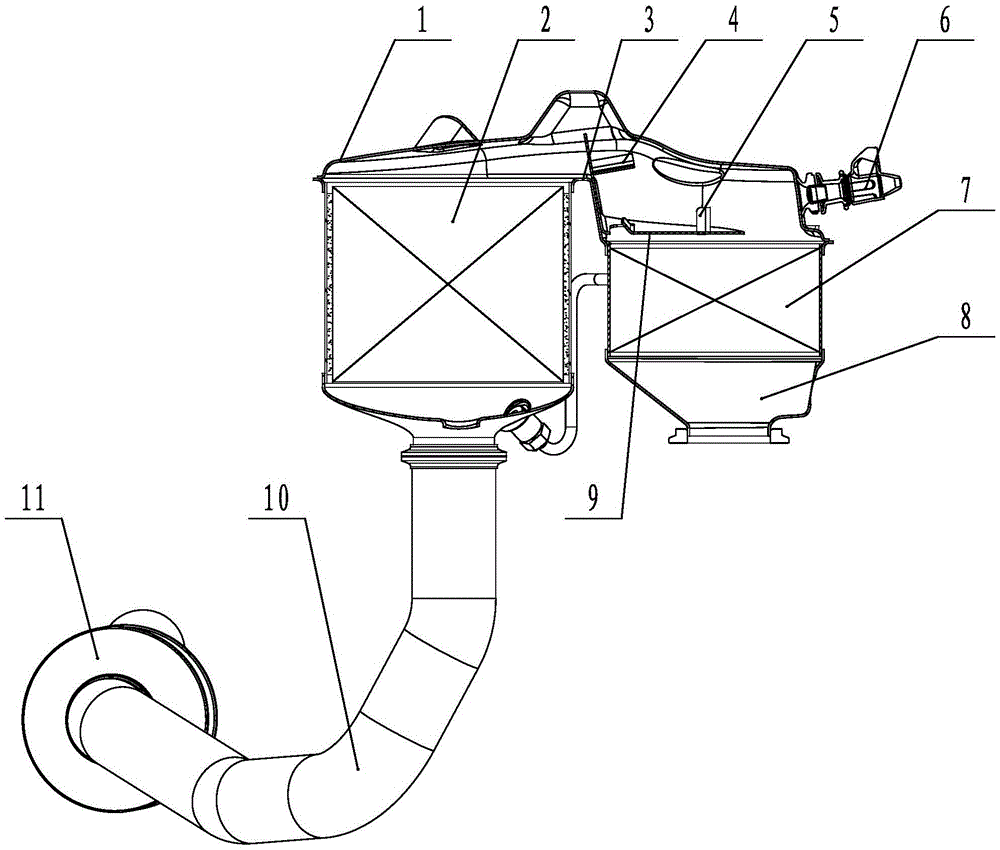

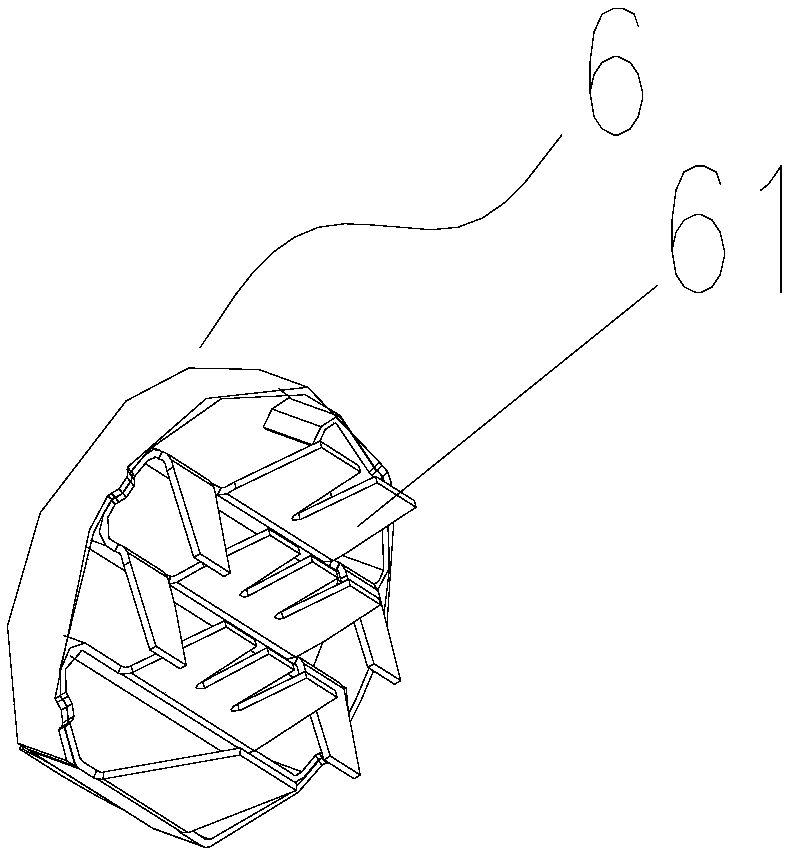

Parallel cylinder type aftertreatment structure assembly

InactiveCN108412593AImprove uniformitySafe Recycling GuaranteeInternal combustion piston enginesExhaust apparatusNitrogenNitrogen oxide

The invention relates to the field of diesel engine tail gas aftertreatment, in particular to a parallel cylinder type aftertreatment structure assembly. The parallel cylinder type aftertreatment structure assembly comprises a first cylinder, a second cylinder, and a connecting pipe for connecting the two cylinders; a first-grade SCR carrier and a second-grade SCR carrier are mounted in the firstcylinder in sequence; a small-head end of a right end cover is welded with the other end of the connecting pipe, and a large-head end is connected with one end of the second cylinder; an intake end cover is arranged at the other end of the second cylinder; the outer wall of the second cylinder is of a segmented structure, and all the sections are connected through hoops; and a DPF carrier and a DOC carrier are arranged between the right end cover and the intake end cover in the second cylinder in sequence. A cyclone mixing pipe is arranged in the connecting pipe. DOC, DPF and SCR are integrated as an aftertreatment circuit; and urea water solution is used as a reducing agent for spraying into an exhaust system to decompose as ammonia in waste gas currents for reaction with nitric oxides under the effect of a catalyst to finally convert to harmless nitrogen and water so as to achieve the effect of purifying vehicle tail gas.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

Mixing tube and exhaust-gas disposal device with same

InactiveCN104712401AIncrease the itineraryIncrease the evaporation distanceExhaust apparatusSilencing apparatusCycloneEngineering

A mixing tube is used for an engine exhaust-gas disposal device and is of a hollow structure. An airflow inlet is formed in one end of the mixing tube, and the other end of the mixing tube is blocked; the end face of the mixing tube is helical, an airflow outlet extending in the axial direction is formed in the outer wall of the mixing tube to form exhaust gas cyclone. In this way, the travel of air in a limited space is increased, the evaporation distance of urea liquid drops is increased, the evaporation rate is improved, mixing evenness is improved, and the risk of crystallization of urea is lowered. The invention further relates to an exhaust-gas disposal device with the mixing tube.

Owner:TENNECO FAW FUSHENG CHANGCHUN AUTOMOTIVE COMPONENTS

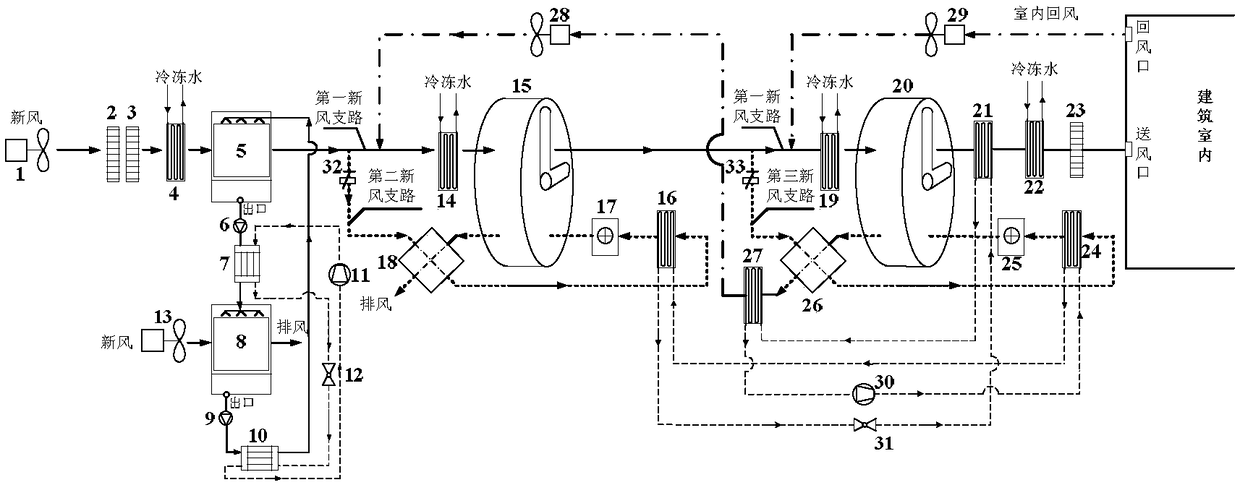

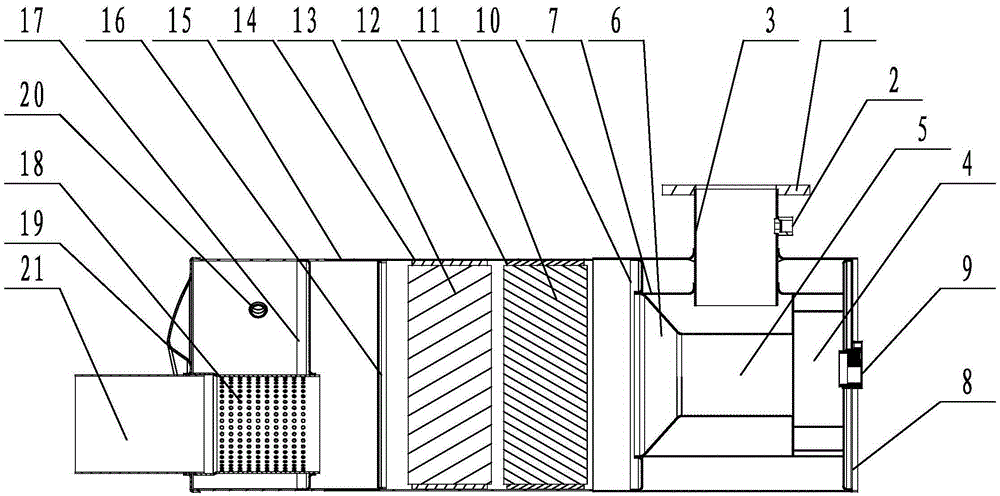

Multistage air deep dehumidification device for ultra-low dew point environments

ActiveCN108758807AReduce humidityLong-term stable operationAir treatment detailsLighting and heating apparatusElectricityFresh air

The invention discloses a multistage air deep dehumidification device for ultra-low dew point environments. The multistage air deep dehumidification device comprises a first fan, a primary efficiencyfilter, a medium efficiency filter and a first surface air cooler which are sequentially arranged in the outdoor fresh air direction and further comprises a solution dehumidification system, a first fresh air branch circuit, a second fresh air branch circuit, a third fresh air branch circuit, a first air returning branch circuit and a second air returning branch circuit which are arranged behind the first surface air cooler. A cold and heat source of a solution dehumidification cycle is provided by an independent vapor-compression-type refrigeration cycle, a regenerative heat source of two-stage rotary-wheel dehumidification uses condensation heat of another vapor-compression-type refrigeration cycle, and meanwhile shortage of the condensation heat is compensated in an electric heating mode. The evaporative cooling capacity of the vapor-compression-type refrigeration cycles is provided for an air-evaporator to cool air. After treating through the device, the humidity content of the fedair can be lowered to 0.01 g / kg.

Owner:SOUTHEAST UNIV

Spiral mixer for integrated injection of SCR catalyst

InactiveCN105402009AReduced insulation performanceNo insulationInternal combustion piston enginesExhaust apparatusEngineeringAmmonia

The invention belongs to the technical field of diesel engine tail gas aftertreatment, and relates to a spiral mixer for integrated injection of an SCR catalyst. The spiral mixer comprises a barrel. A front end cover and a rear end cover are arranged at the two ends of the barrel respectively. A first SCR carrier and a second SCR carrier are arranged in an inner cavity of the barrel. A gas inlet pipe is arranged at the position, between a first separation plate and the front end cover, of the barrel. A mixer device is arranged below the gas inlet pipe and comprises a taper pipe, a mixing pipe and a mixer body which are sequentially connected. The gas outlet end of the taper pipe is fixed to the first separation plate, and the gas inlet end of the mixer body is fixed to the front end cover. By means of the mixer, the aims of urea crushing, urea crystallization and even ammonia distribution can be effectively achieved.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

SCR urea solution mixer and inner tube assembly thereof

InactiveCN106237913AAvoid enteringNot easy to depositInternal combustion piston enginesExhaust apparatusEngineeringExhaust gas

The embodiment of the invention discloses an SCR urea solution mixer inner tube assembly which comprises an inner tube and a baffle cover. Airflow inlets of the inner tube comprise an end hole located at one end of the inner tube and side wall holes formed in the side wall of the inner tube, the side wall holes are close to the end hole, and a swirl plate used for producing swirling flow is arranged on one side of each side wall hole; the baffle cover is arranged on the outer side of the inner tube so as to block airflow, and the airflow can only enter the inner tube through the end hole and the side wall holes. According to the SCR urea solution mixer inner tube assembly, due to the fact that by means of the swirl effect of the swirl plates, the flow velocity of the airflow entering the inner tube is higher, tail gas and a urea solution are mixed to be more uniform, full utilization of the urea solution is promoted, and reduction of overdeposition of urea is finally achieved. The invention further discloses an SCR urea solution mixer.

Owner:WEICHAI POWER CO LTD

SCR urea solution mixer

ActiveCN106731932ANot easy to depositReduced risk of crystallizationInternal combustion piston enginesFlow mixersRotational flowCrystallization

The embodiment of the invention discloses an SCR urea solution mixer. The SCR urea solution mixer comprises a urea mixing pipe and a mixing assembly arranged in one end of the urea mixing pipe. The mixing assembly comprises an inner-layer pipe and an outer-layer pipe arranged on the outer side of the inner-layer pipe in a sleeving mode. A side wall hole is formed in the inner-layer pipe, and a spinning disk used for generating rotational flow is arranged on one side of the side wall hole. A spiral piece is arranged between the outer wall of the outer-layer pipe and the urea mixing pipe. Through the effect of the spiral piece, gas flow and rotation at the wall face position of the urea mixing pipe are accelerated, a urea liquid film thrown at the wall face position of the urea mixing pipe due to the strong rotational flow effect of the spinning disk is taken away in time, the urea crystallization risk is further reduced, and mixing of urea and airflow is improved. The SCR urea solution mixer can aim at engines with different displacements and different purposes, and the airflow volume can be reasonably distributed by adjusting the blade angles, lengths and numbers of the spinning disk and the spiral piece.

Owner:WEICHAI POWER CO LTD

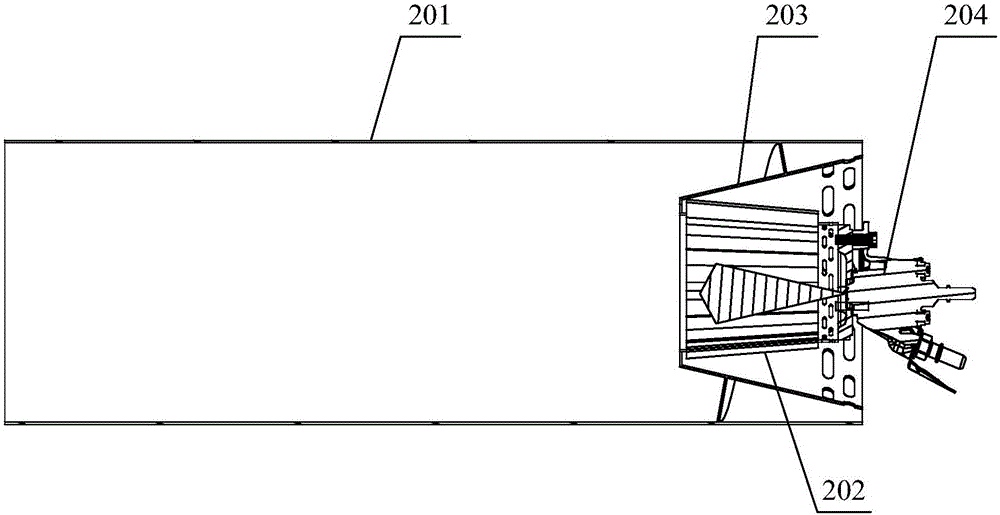

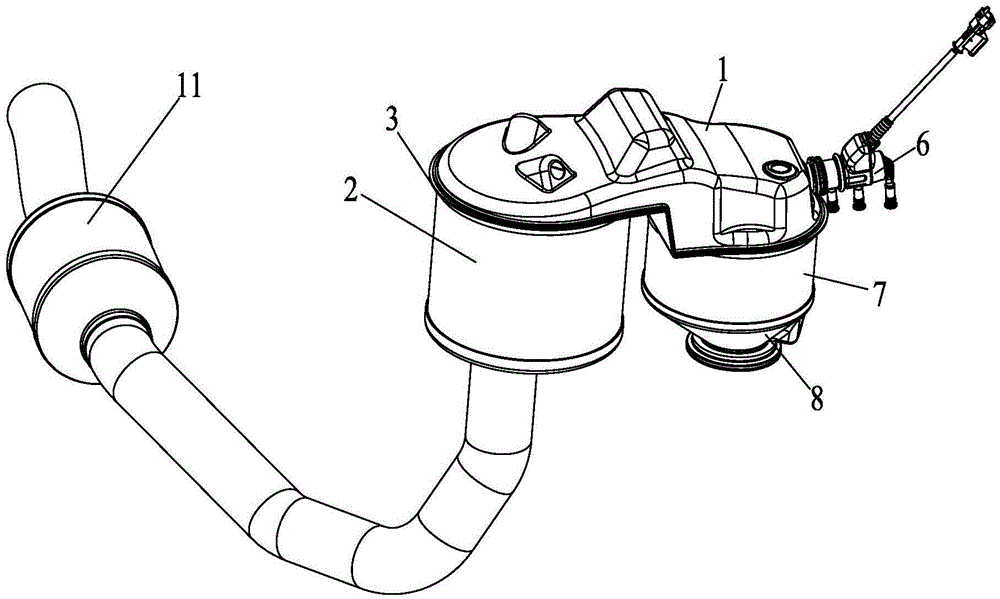

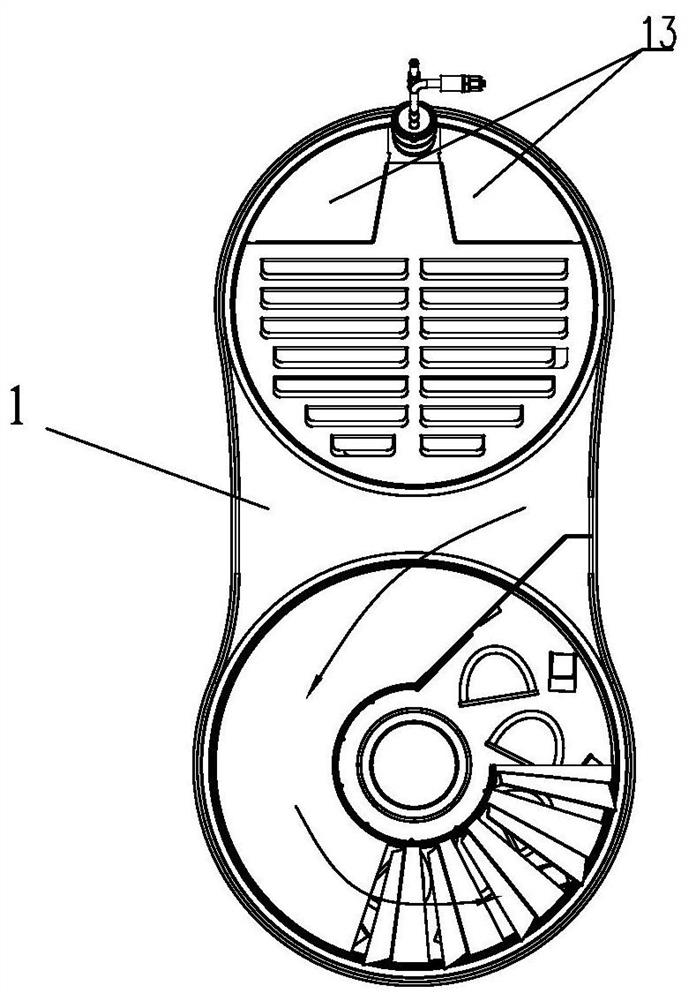

Integrated aftertreatment equipment

PendingCN108150250AReduced risk of crystallizationImprove conversion efficiencyInternal combustion piston enginesExhaust apparatusParticulatesNitrogen oxides

The invention provides integrated aftertreatment equipment comprising a first treatment device, a mixer and a second treatment device. The first treatment device and the second treatment device are arranged side by side and connected through the mixer. The first treatment device comprises a gas inlet device, a diesel oxidation catalysis aftertreatment device, a diesel particle filter and a first flow guiding cavity which are sequentially connected. The second treatment device comprises a second flow guiding cavity, a selective catalytic reduction aftertreatment device, an ammonia oxidation catalysis aftertreatment device and a noise reducing and exhausting device which are sequentially connected. One end of the mixer is connected with the first flow guiding cavity, and the other end of themixer is connected with the second flow guiding cavity. The DOC, the DPF, the SCR mixer integrated with a urea nozzle, an SCR, an ASC and a silencing structure are integrated, so that the purposes oflowering emission of particles and NOx (nitrogen oxides) and reducing engine noise are achieved at the same time.

Owner:CHINA FIRST AUTOMOBILE

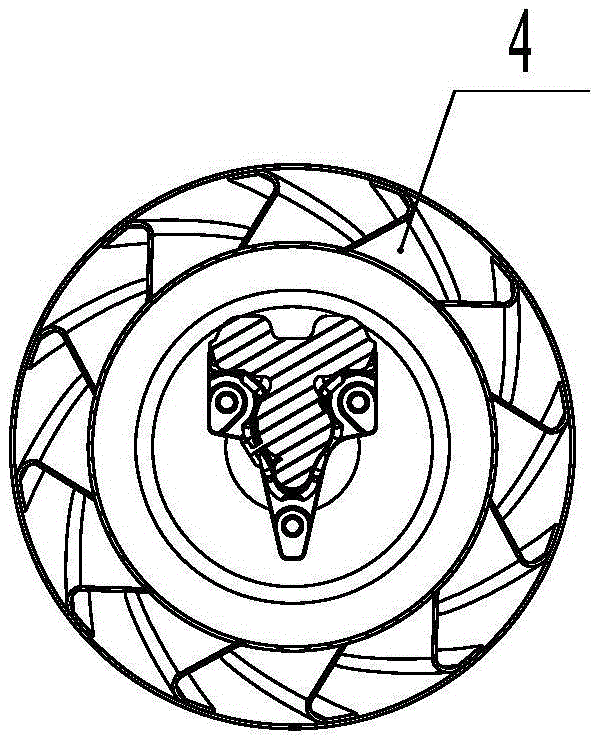

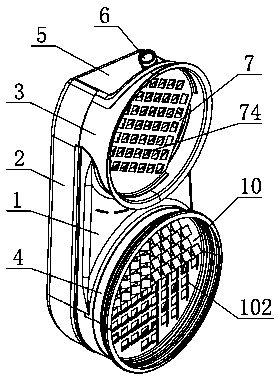

SCR catalytic silencer device

InactiveCN107060961AEffective protectionLow failure rateInternal combustion piston enginesExhaust apparatusCycloneEngineering

The invention provides a SCR catalytic silencer device. The device comprises an intake pipe and an urea nozzle, and further comprises a nozzle protection device and a first-grade cyclone; the nozzle protection device is a front end cover with an inward concave structure; multiple first blades are uniformly inclined on the outer wall of the first-grade cyclone at intervals, and are provided with gaps; the urea nozzle is vertically mounted on the upper surface of the inward concave structure of the front end cover; the first-grade cyclone is mounted on the lower surface of the inward concave structure of the front end cover; the intake pipe penetrates through the outer wall of a SCR box; and an outlet direction of the intake pipe is perpendicular to the axial direction of the first-grade cyclone, so that engine-exhausted gas fed from the intake pipe is fed in a pipe of the first-grade cyclone by the gaps of the multiple first blades.

Owner:WEICHAI POWER CO LTD +1

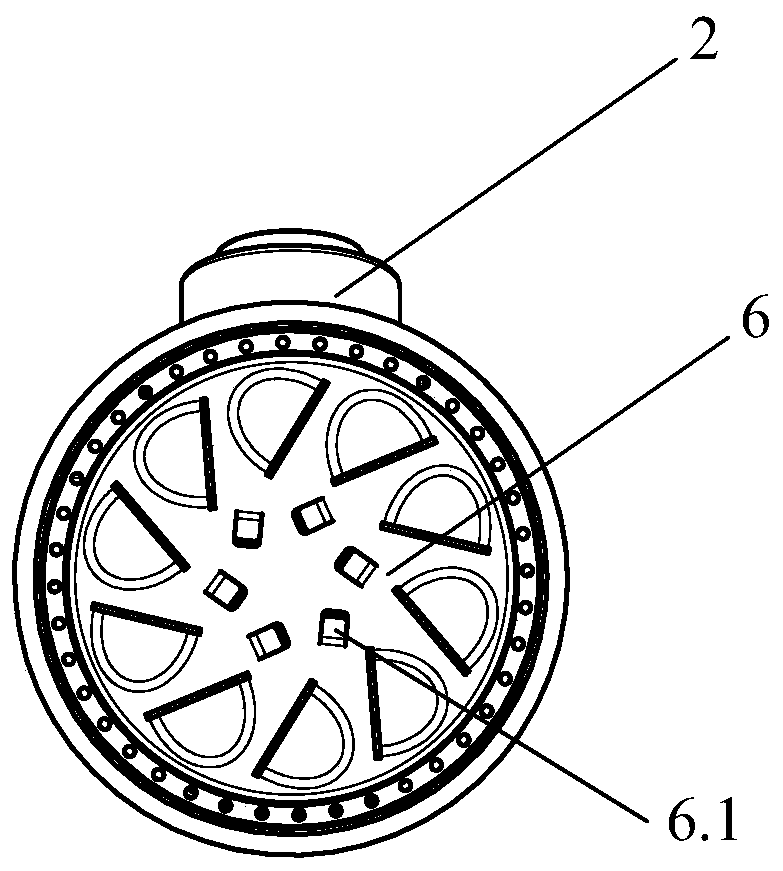

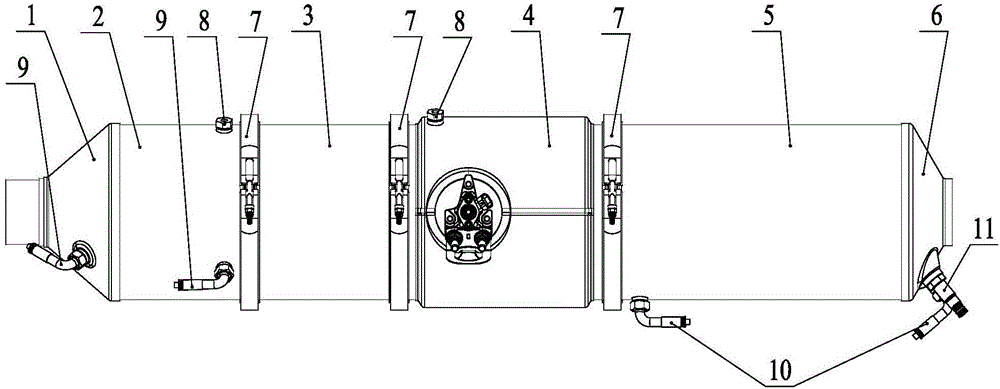

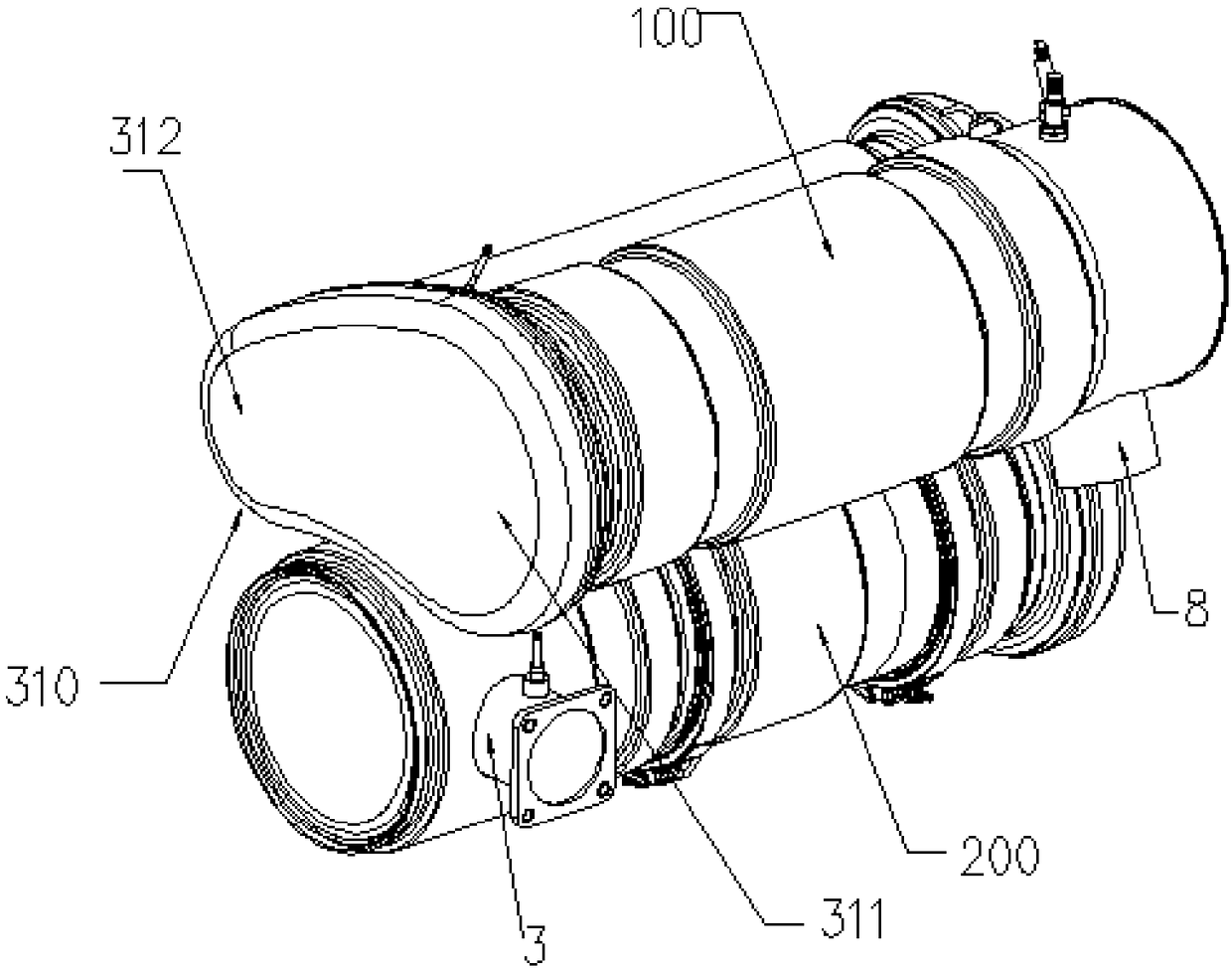

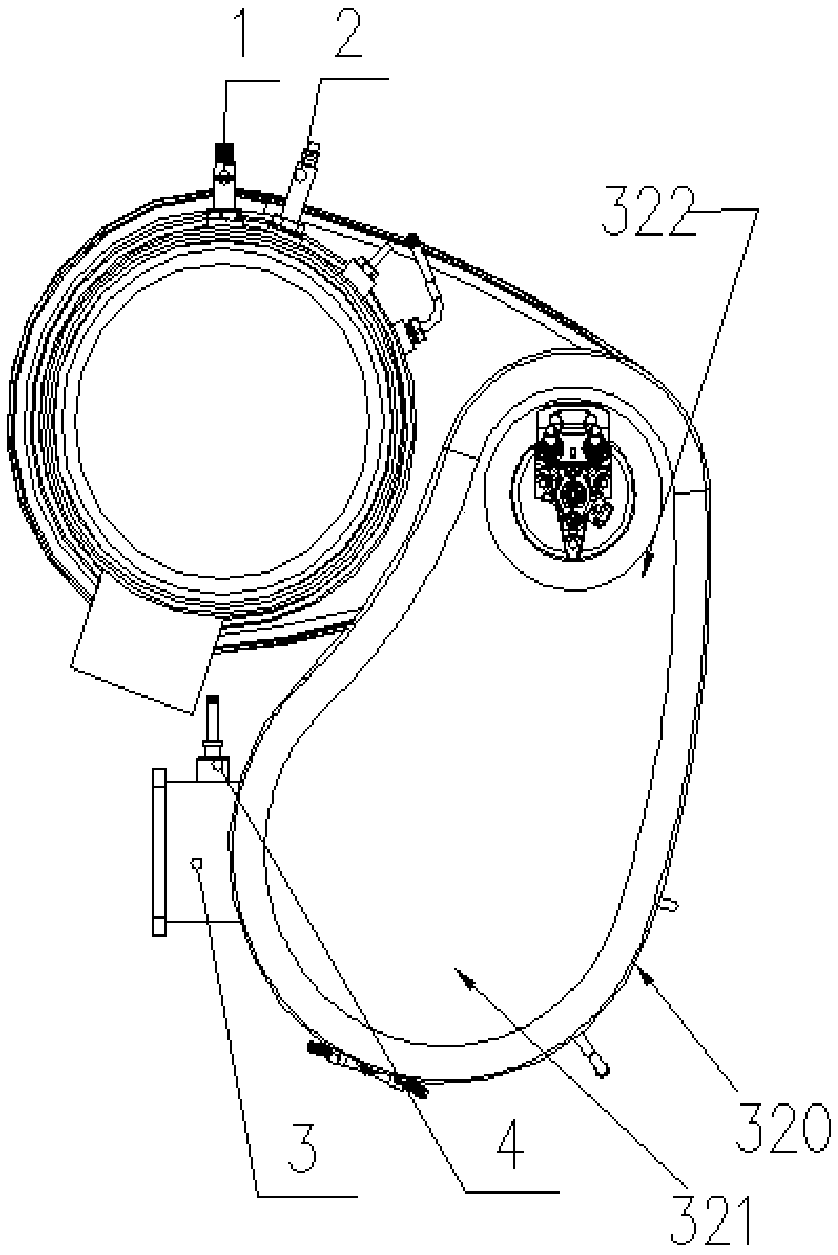

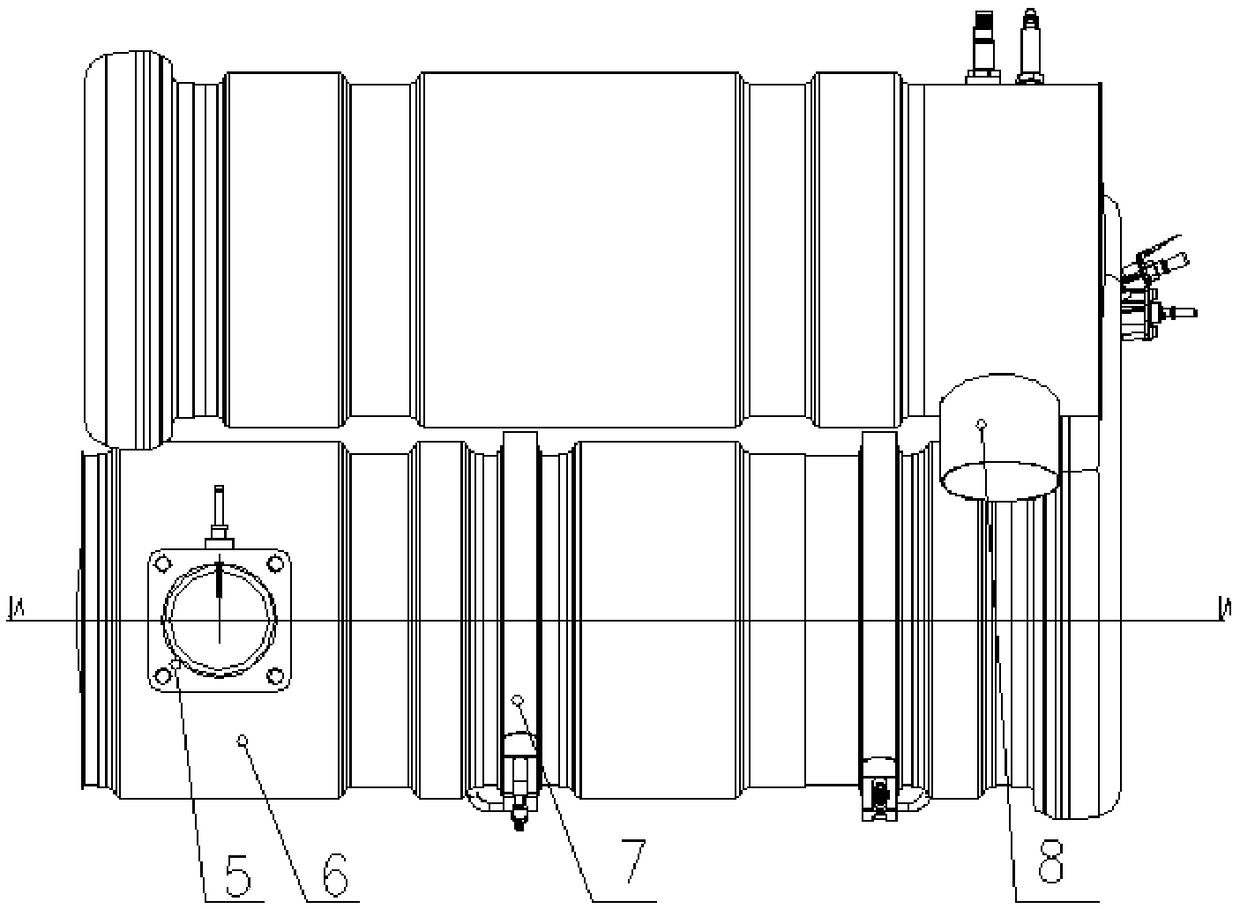

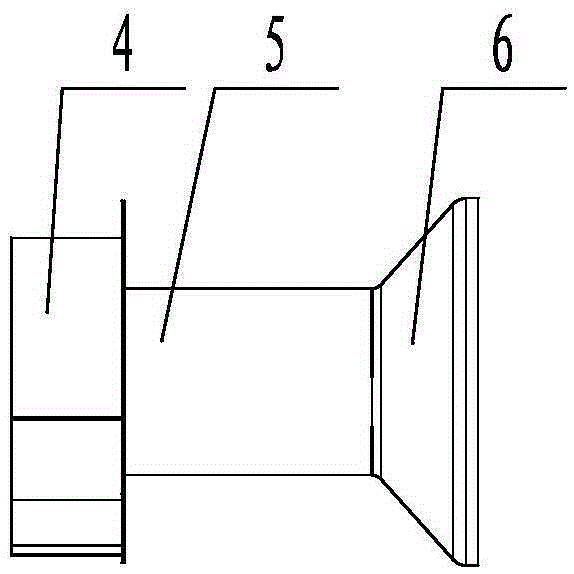

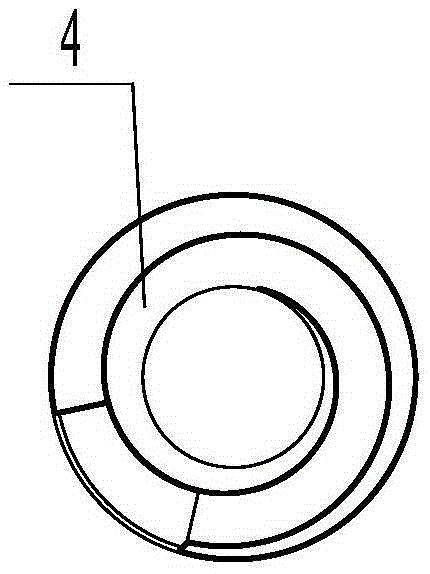

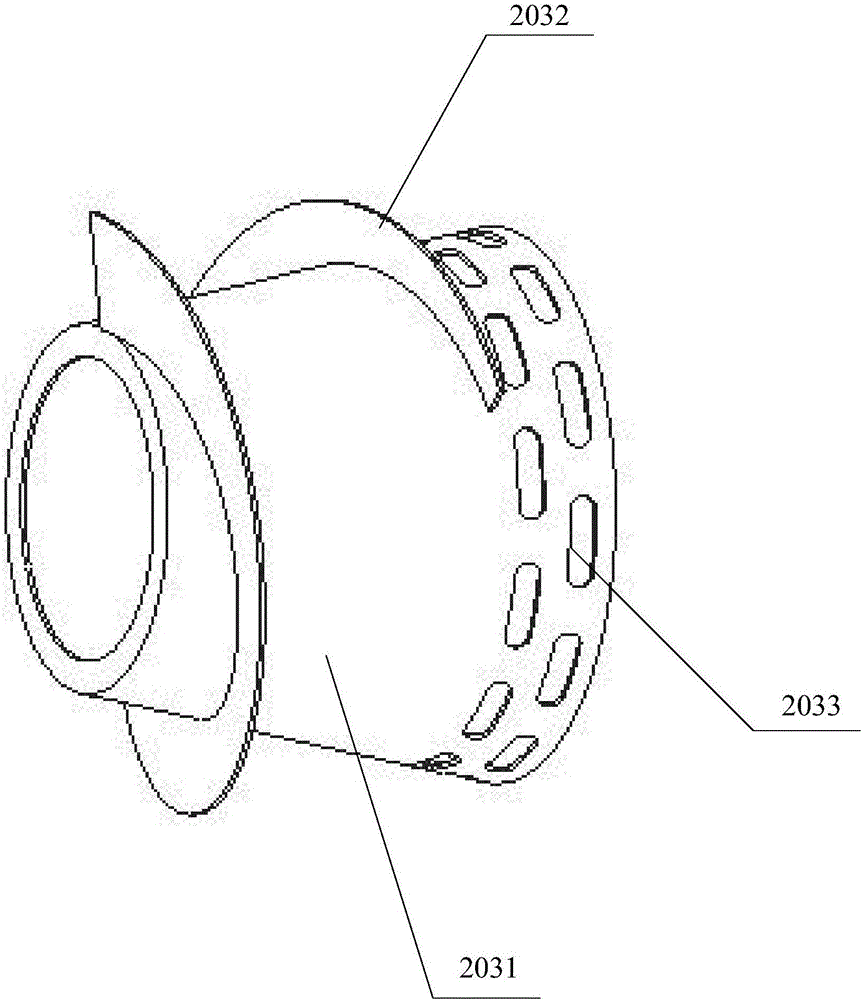

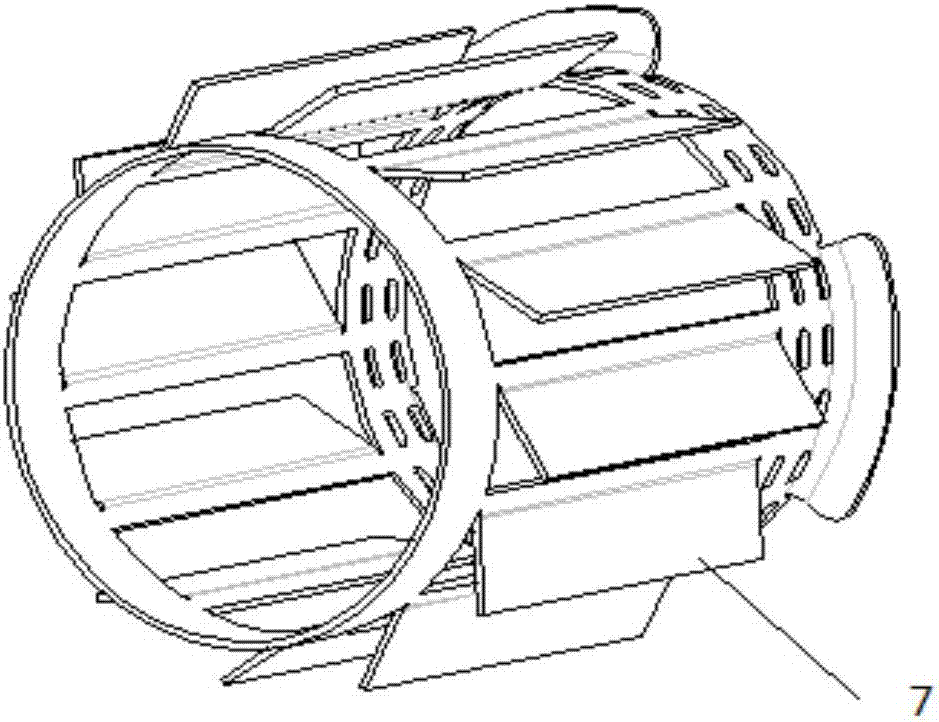

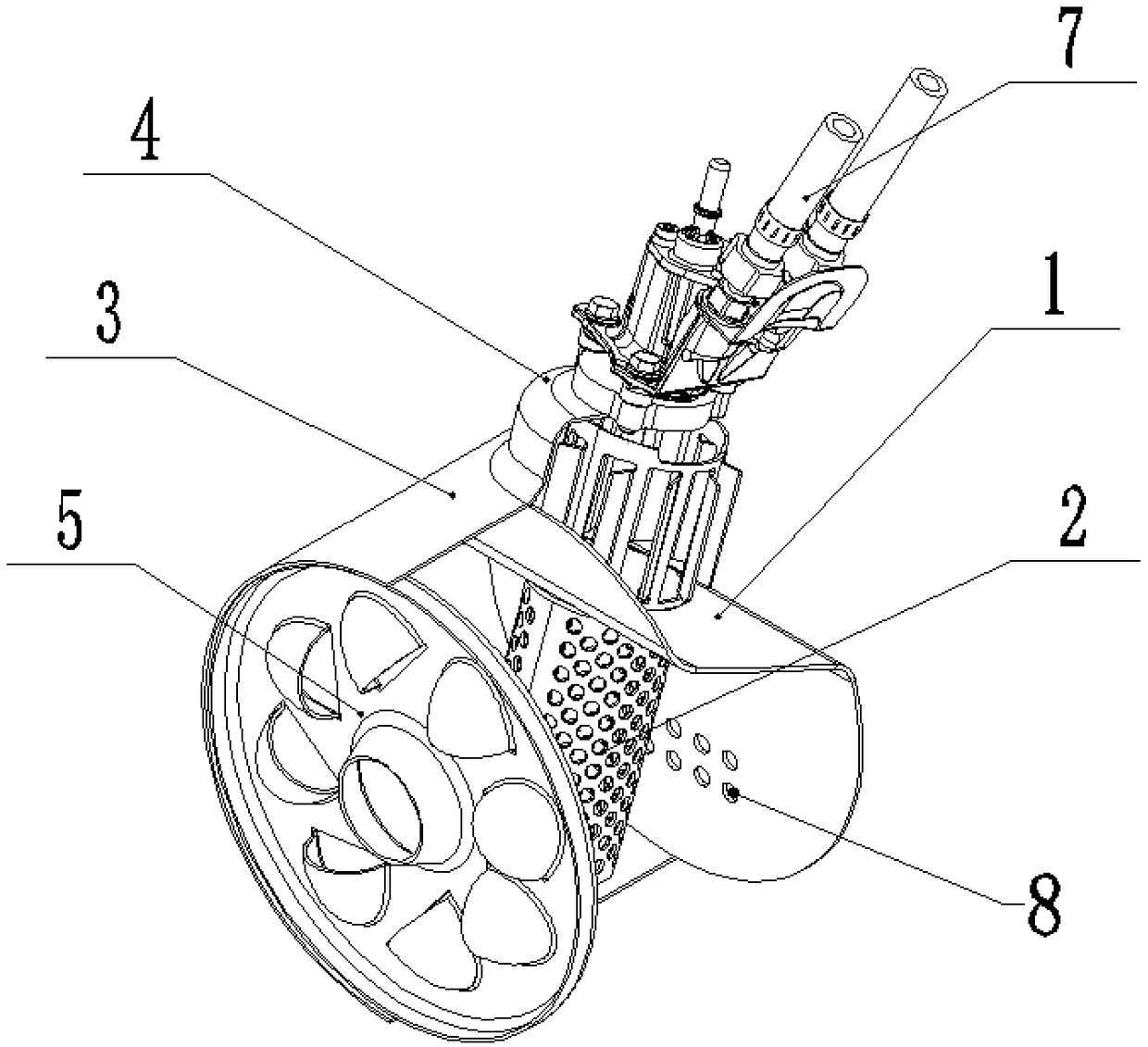

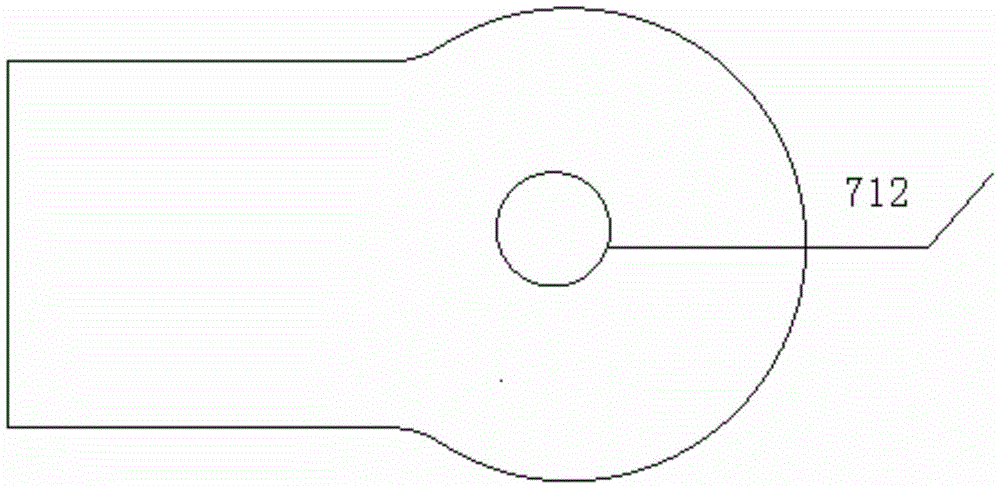

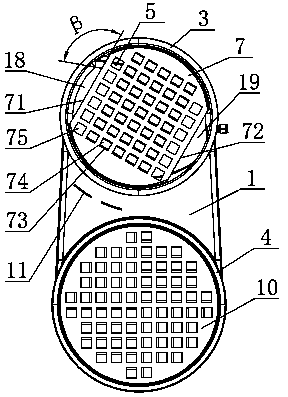

Dual-swirl inclined cylindrical type urea mixer and application in exhaust after-treatment device thereof

InactiveCN109505685APlay a secondary mixing effectReduced risk of crystallizationInternal combustion piston enginesExhaust apparatusAfter treatmentExhaust fumes

The invention relates to a dual-swirl inclined cylindrical type urea mixer and application in an exhaust after-treatment device thereof, and belongs to the technical field of tail gas after-treatmentof diesel engines. The double-swirl inclined cylindrical type urea mixer comprises a Z-shaped partition plate, a swirl tube, a cylinder body, a nozzle base, a swirl plate, a blocking cover and a ureanozzle, the urea nozzle is mounted on the nozzle base, both of the urea nozzle and the nozzle base are obliquely mounted on the cylinder body; and the blocking cover and the swirl tube are welded intoa whole and obliquely welded to the Z-shaped plate. According to the application of the dual-swirl inclined cylindrical type urea mixer in the exhaust after-treatment device, the exhaust after-treatment device is in a cylinder shape, and sequentially comprises an air inlet pipe assembly, a DOC assembly, a DPF assembly, the double-swirl inclined cylindrical type urea mixer, a SCR assembly and an air outlet pipe assembly in the air flow direction. According to the double-swirl inclined cylindrical type urea mixer, two swirl devices are adopted, the mixing effect of urea and waste gas is ensured, and the crystallization risk of the urea is effectively reduced.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

Dual-layer mixing pipe and exhaust treating device thereof

InactiveCN104832256AIncrease the itineraryIncrease the evaporation distanceExhaust apparatusSilencing apparatusEngineeringRotational flow

The invention discloses a dual-layer mixing pipe. The dual-layer mixing pipe comprises an inner pipe, an outer pipe, a transition pipe and an end cap, wherein the inner pipe is through along the axial direction and comprises a first end and a second end which are oppositely arranged in the axial direction; the transition pipe is connected with the first end; at least one opening groove is formed in the second end; a containing cavity containing at least one part of the second end is formed in the end cap; the outer pipe comprises a first half pipe and a second half pipe which are matched with each other; the first half pipe and the second half pipe are staggered in the radial direction, so that a first outlet and a second outlet are formed in the circumferential direction; the opening directions of the first outlet and the second outlet are opposite, so that exhaust rotational flow is formed. According to the dual-layer mixing pipe, the travel of air flow in a limited space is increased, the evaporating distance of urea droplets is increased, the evaporation rate is improved, the mixing uniformity is improved, and the risk of urea crystallization is reduced. The invention also discloses an exhaust treating device with the dual-layer mixing pipe.

Owner:TENNECO SUZHOU EMISSION SYST

Tightly-coupled selective catalytic reduction (SCR) aftertreatment packaging structure of light diesel vehicle

ActiveCN105587386AReduced risk of crystallizationReasonable mixed structureExhaust apparatusSilencing apparatusParticulatesPulp and paper industry

The invention belongs to the technical field of automobile exhaust aftertreatment and relates to a tightly-coupled selective catalytic reduction (SCR) aftertreatment packaging structure of a light diesel vehicle. The tightly-coupled SCR aftertreatment packaging structure comprises a particulate trap and a diesel oil oxidation catalyst. The particulate trap is connected with the diesel oil oxidation catalyst through a lower clamshell-shaped shell; the upper end of the lower clamshell-shaped shell is connected with an upper clamshell-shaped shell in a tightly coupled mode to form an enclosed cavity; a flow guide plate is fixedly connected to the vertical folded surface of the lower clamshell-shaped shell and comprises a horizontal plate and a vertical plate which are connected into a whole; the vertical plate extends towards the inside of the enclosed cavity; a flow guide groove is formed in the root position of the horizontal plate; a second flow guide block is disposed at the outer end of the horizontal plate; a first flow guide block is mounted on the vertical plate; a urea spray nozzle is installed on the upper clamshell-shaped shell; and the center line of the urea spray nozzle and the second flow guide block intersect. By means of the structural design, full mixing of urea liquid drops with air flow can be facilitated, and the urea pyrolysis and hydrolysis environment temperature is guaranteed.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

Compact-type mixing device capable of meeting Euro-VI emission standard

InactiveCN108119211ASave spaceHigh feasibilityExhaust apparatusSilencing apparatusEmission standardEngineering

The invention belongs to the technical field of the diesel engine tail gas posttreatment, and relates to a compact-type mixing device capable of meeting a Euro-VI emission standard. The compact-type mixing device comprises a gas inlet pipe, a urea nozzle, a housing, a transition pipe, and a cone, wherein the gas inlet pipe and the urea nozzle are welded at one side of the housing, and a certain included angle is formed between the gas inlet pipe and the urea nozzle, the other side of the housing is welded with the transition pipe, and the transition pipe is welded with the cone; the housing isinternally provided with a rotational flow pipe, and the tail end of the transition pipe is provided with an insert mixer. Through using the rotational flow pipe and the insert mixer, the effect of mixing and crushing is better, so the mixing uniformity is better, a risk of urea crystallization is greatly reduced, and the efficient and stable operation of an SCR can be guaranteed.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

Mixer used for exhaust facility and SCR system

ActiveCN105464764AEvenly distributedSpeed up evaporationExhaust apparatusSilencing apparatusCycloneSpray nozzle

The invention relates to a mixer used for an exhaust facility and an SCR system. The mixer used for the exhaust facility comprises a gas cyclone and a liquid disperser. The gas cyclone is shaped like a shell and comprises a gas inlet. A first hole and a second hole which are opposite are formed in the gas cyclone in the direction perpendicular to the gas inlet direction. One end of the liquid disperser penetrates the second hole to be perpendicularly connected with the gas cyclone. The first hole of the gas cyclone is used for leading in a reducing agent sprayed out of a spray nozzle. The liquid disperser is provided with at least one blade influencing the gas flow direction. The blades are located in the gas cyclone. A plurality of through holes are formed in the liquid disperser, located outside the gas cyclone and used for dispersing the reducing agent led in by the gas cyclone. By means of the mixer, distribution of the reducing agent can be uniform, crystallization is avoided, and the efficiency of the selective catalytic reduction reaction is improved.

Owner:WEICHAI POWER CO LTD

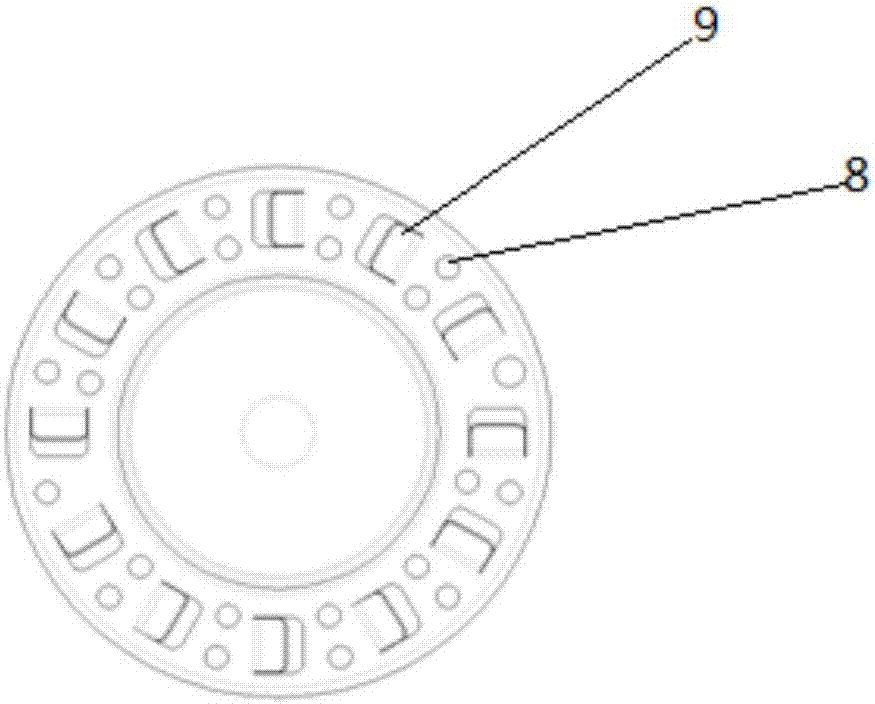

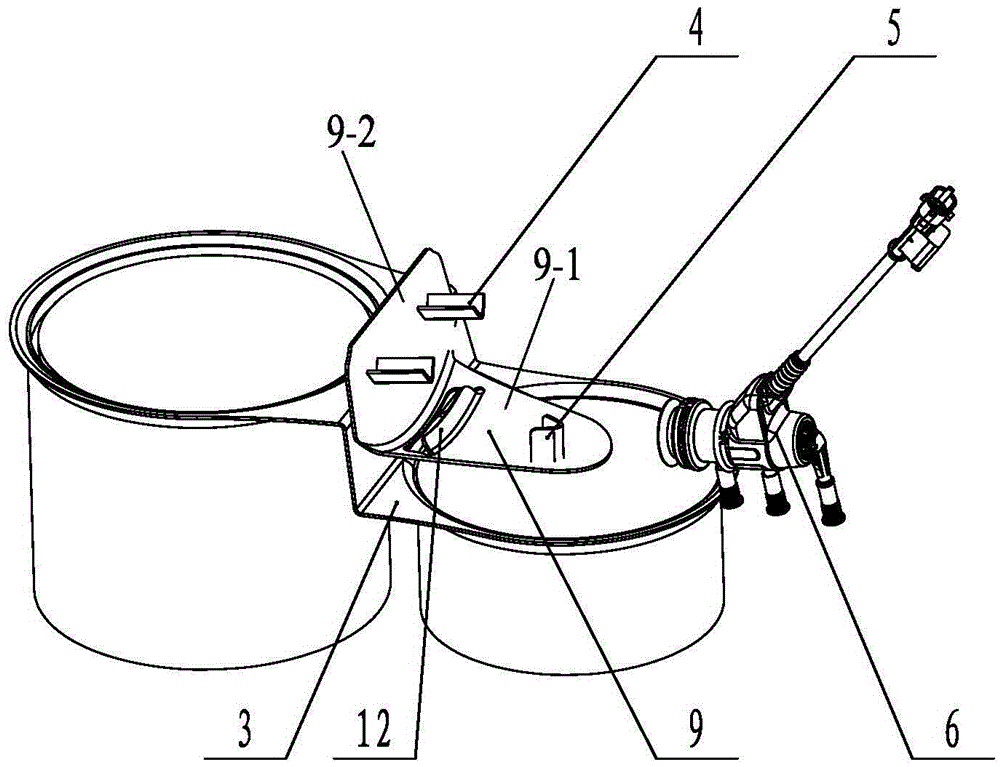

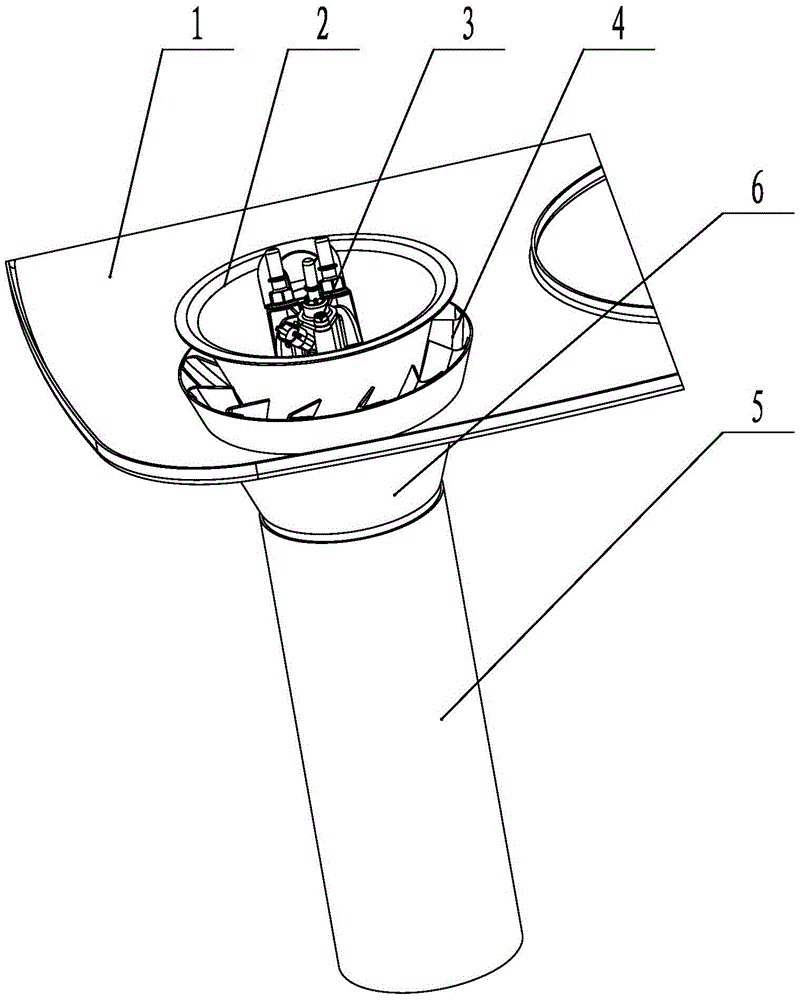

Mixer integrated type spraying unit

ActiveCN105597956ANo wallReduced risk of crystallizationInternal combustion piston enginesExhaust apparatusAfter treatmentPipe fitting

The invention belongs to the field of diesel engine tail gas after-treatment, and relates to a mixer integrated type spraying unit which comprises a conical piece. A hollow pipe fitting is fixedly connected with a pipe opening of the lower portion of the conical piece. A plurality of blades are circumferentially and evenly distributed on the surface of the inner wall of the conical piece. Sink bowl pieces are embedded in the inner sides of the blades. A urea nozzle is fixed to the bottom of each sink bowl piece through a urea spraying base and faces towards the pipe fitting. A partition plate is fixed to the surface of the conical piece. The spraying unit is compact and reasonable in structure, and the effects of being good in urea mixing effect and free of urea crystallization can be achieved during work.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

Urea mixing device

ActiveCN105888786AFully atomizedReduced risk of crystallizationInternal combustion piston enginesExhaust apparatusEngineeringUrea

The invention discloses a urea mixing device. The urea mixing device comprises a swirler, a porous tube, an opening necked tube and a mixing outer tube, wherein the swirler communicates with one end of the porous tube; the swirler and the porous tube are arranged inside the mixing outer tube; the periphery of the swirler fits the inner wall of the mixing outer tube; a cavity is formed between the porous tube and the inner wall of the mixing outer tube; a plurality of through holes are formed in the tube wall of the porous tube; the other end of the porous tube is connected with the opening necked tube; and the diameter of the opening necked tube is gradually smaller from the end connected with the porous tube to the exterior. According to the urea mixing device, the technical problems that urea is not fully decomposed and atomized, the mixing uniformity of urea and waste gas is poor, and the SCR conversion efficiency is low can be solved.

Owner:WEICHAI POWER CO LTD

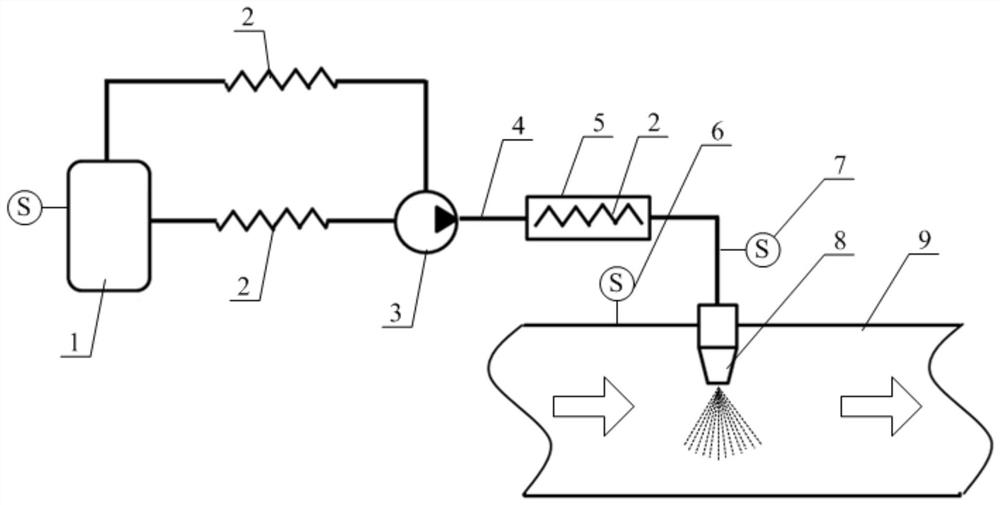

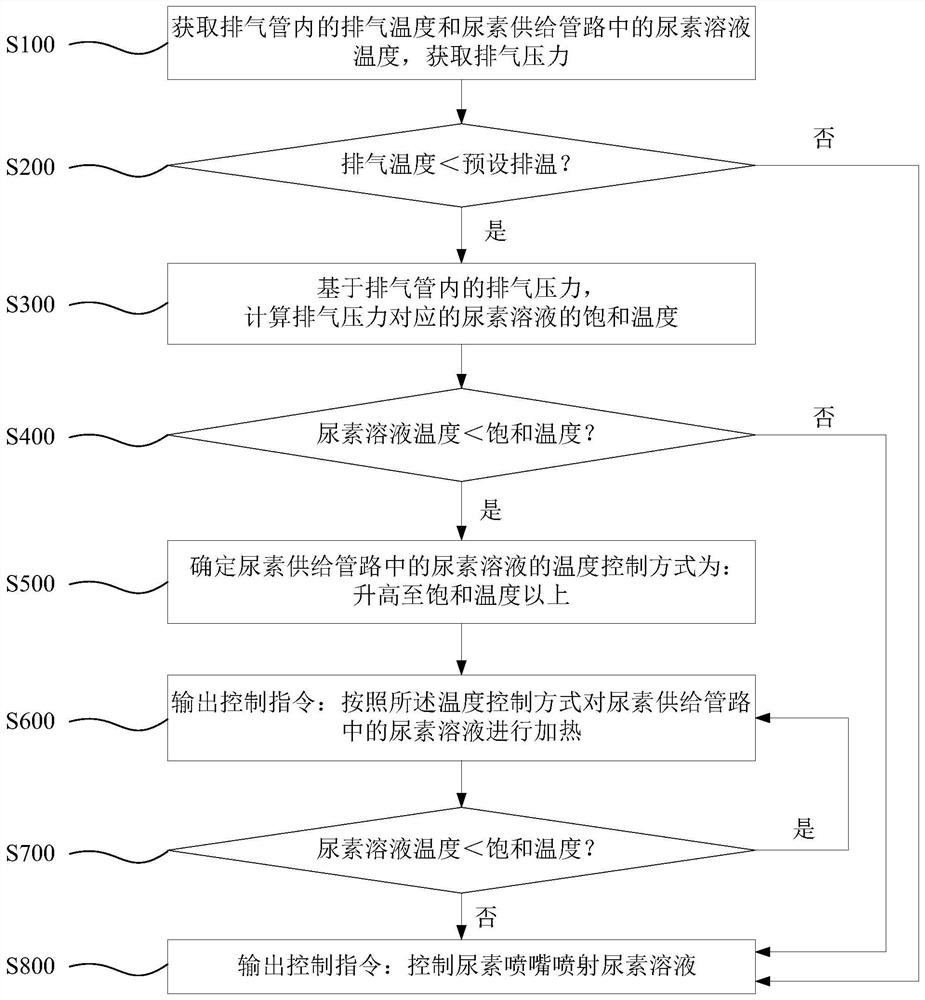

Urea injection system and control method thereof, controller and storage medium

InactiveCN112682133AImprove atomization effectReduced risk of crystallizationInternal combustion piston enginesExhaust apparatusTemperature control modeProcess engineering

The invention discloses a control method of a urea injection system. The control method comprises the following steps of acquiring the exhaust temperature in an exhaust pipe and the temperature of a urea solution in a urea supply pipeline; when the exhaust temperature is lower than a preset exhaust temperature, calculating the saturation temperature of the urea solution corresponding to the exhaust pressure based on the exhaust pressure in the exhaust pipe; and when the temperature of the urea solution is lower than the saturation temperature, determining that the temperature control mode of the urea solution in the urea supply pipeline is that the temperature of the urea solution is increased to be higher than the saturation temperature. According to the scheme, the temperature of the urea solution is increased to be higher than the saturation temperature of the urea solution corresponding to the exhaust pressure, and in the urea injection process, the urea solution can generate flash boiling, so that the urea atomization effect is improved, and the urea crystallization risk when the exhaust temperature is low is reduced. The invention further discloses the urea injection system, a controller and a storage medium.

Owner:WEICHAI POWER CO LTD

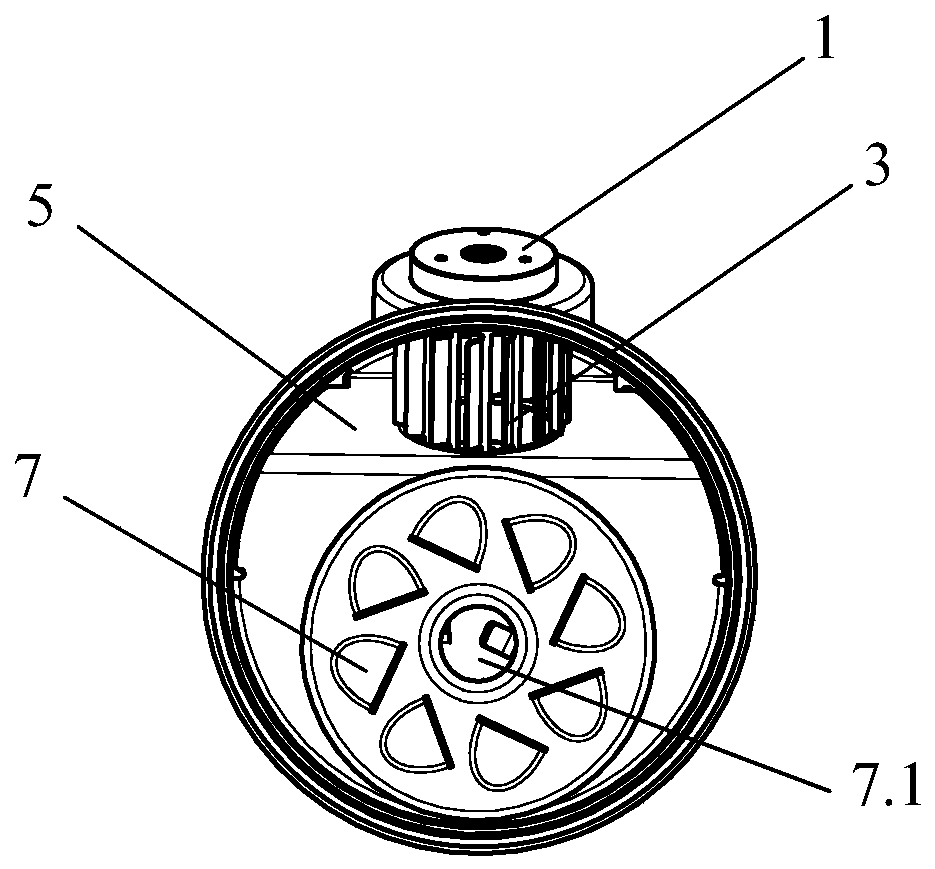

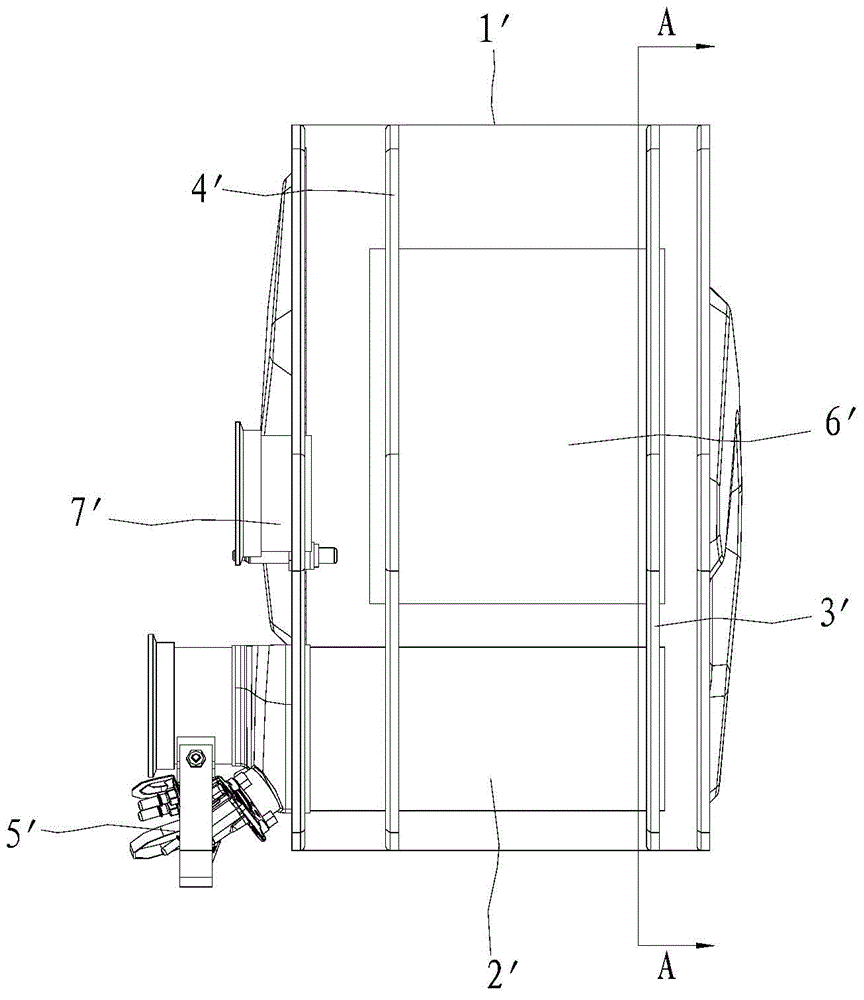

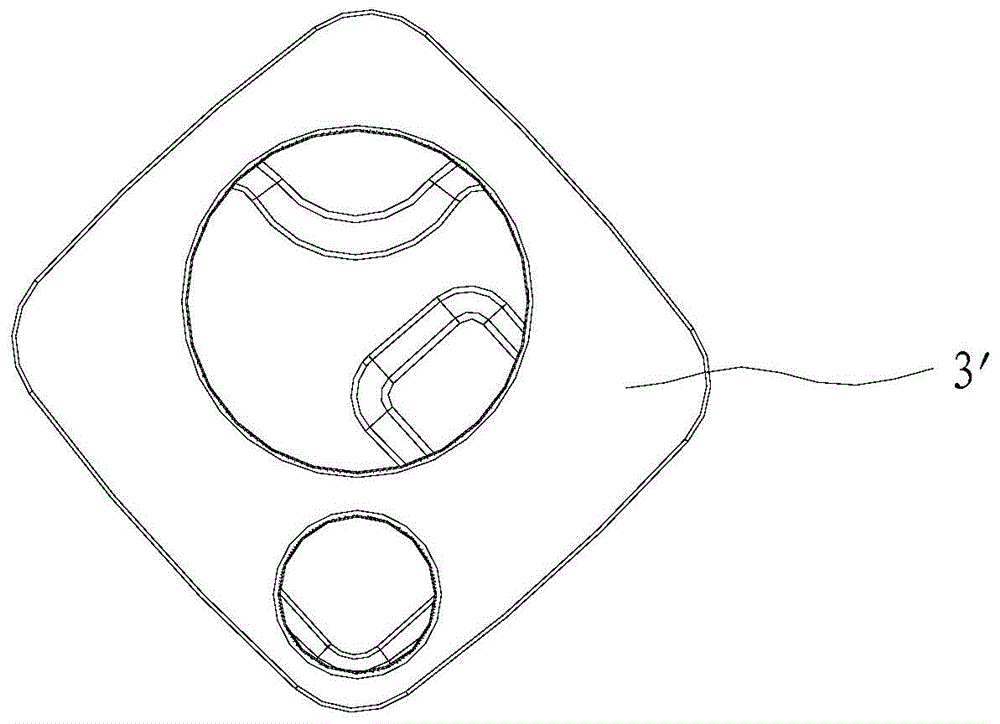

Radial injecting mixer for mixing exhaust gas and reducing agent fluid

ActiveCN108194178AAccelerated pyrolysis/hydrolysisWell mixedExhaust apparatusSilencing apparatusNitrogen oxidesPollutant emissions

The invention provides a radial injecting mixer for mixing exhaust gas and reducing agent fluid. The radial injecting mixer comprises a cylindrical barrel body, a reducing agent injecting base is arranged on the outer wall of the cylinder body; a first rotational flow partition plate is arranged at an air inlet end of the cylinder body; a plurality of semi-circular through holes are formed in thefirst rotational flow partition plate, the lower end of each through hole is provided with a hemispherical wall plate on the inner wall of the first rotational flow partition plate; a second rotational flow partition plate is arranged along the inner wall of the cylinder body at the rear end of the rotational flow partition plate; expanding partition plates are arranged along the inner wall of thecylinder body; and the reducing agent injecting base comprises a supporting plate and a supporting column, the supporting plate is of a generally triangular structure, and a nozzle is arranged on thesupporting plate, an injecting hole is formed in the center of the supporting plate, and the supporting column is arranged at the lower end of the supporting plate. According to the radial injectingmixer for the mixing exhaust gas and the reducing agent fluid, the radial injecting mixer is fully mixed with the radially injected reducing agent fluid, so that the uniformity of the reducing agent is improved, the sufficient reaction of the nitrogen oxide is realized, and the pollutant emission of the automobile is reduced.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

Aqueous urea solution decomposing mixing device

PendingCN110821615AReduce hindranceReduce lossesInternal combustion piston enginesExhaust apparatusVertical planeEngineering

The invention discloses an aqueous urea solution decomposing mixing device. A spoiler and a pore plate are arranged between a front shell and a rear shell. The spoiler and the pore plate divide an inner cavity into an upper spraying cavity, a middle flow guide cavity and a lower rotational flow cavity. A top cover is arranged at the top of the rear shell. An inclined plane is arranged in the spraying cavity, and an included angle is formed between the vertical plane and the inclined plane. A flow guide plate is provided with a flow guide vane. The spoiler is provided with a turbulent flow vane. A rotational flow plate is provided with a rotational flow vane outwards through a third vane hole. The inner cavity of the aqueous urea solution decomposing mixing device is divided into the spraying cavity, the flow guide cavity and the rotational flow cavity only through the spoiler and the pore plate. Little blocking occurs in an airflow channel, the airflow channel is smoother, mixed airflow passes through few turning points in the airflow channel, energy loss is small, and the airflow pressure drop is low. The top cover is provided with an inclined lower plane, and the spraying cavityforms a cavity which is asymmetric along the vertical plane. A nozzle seat is located in a low position of the lower plane, and thus the urea spraying line is toward the direction directly facing thedirection of the turbulent flow vane of the spoiler.

Owner:无锡亿利环保科技有限公司

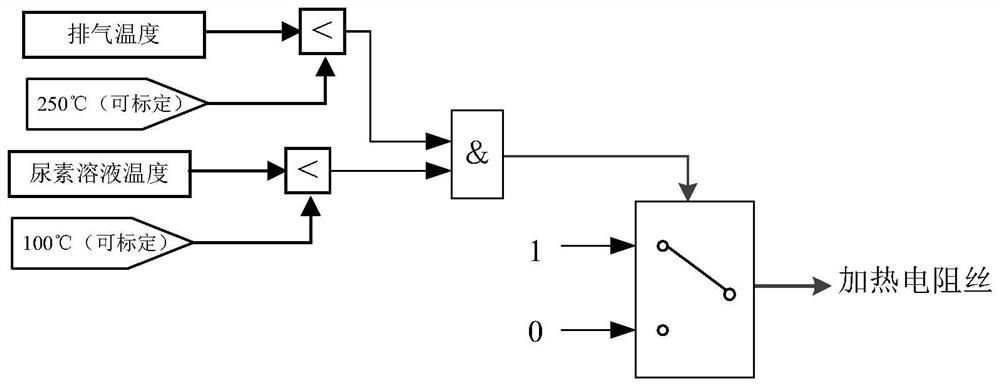

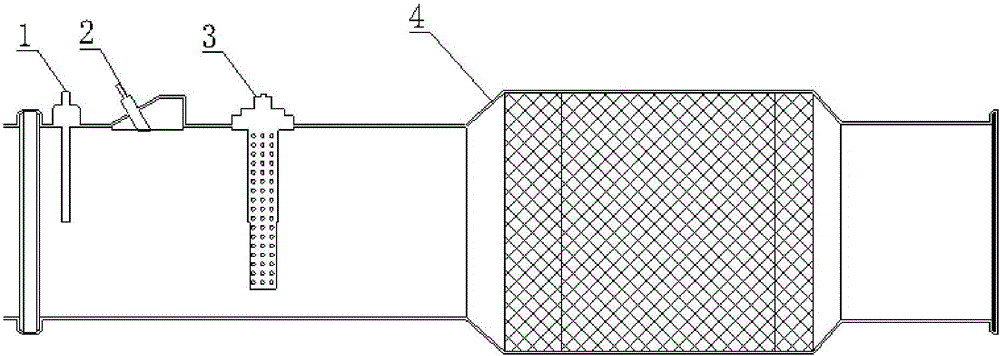

Urea heating device for efficient SCR, and use method thereof

InactiveCN105697106AFully pyrolyzedPrevent crystallizationInternal combustion piston enginesExhaust apparatusHeat managementProcess engineering

The invention relates to a urea heating device and a use method thereof, and particularly relates to a urea heating device for efficient SCR, and a use method thereof. The device comprises a temperature sensor, a urea nozzle, a metal carrier catalyst and an SCR device, wherein the temperature sensor, the urea nozzle and the metal carrier catalyst are arranged in front of the SCR device, and are sequentially arranged on an exhaust pipeline from the front to rear. According to the device disclosed by the invention, through the method of adding the metal carrier catalyst close to the urea nozzle, and carrying out ECU control heating, the crystallization risk of the efficient SCR is reduced, the energy consumed for engine heat management is reduced, and accurate control for the heating temperature and time is realized.

Owner:WEICHAI POWER CO LTD

Mixing device for spraying at upper end of U-shaped end cover

ActiveCN112012814AIncrease distanceImprove ammonia mixing uniformity indexInternal combustion piston enginesExhaust apparatusPhysicsEngineering

The invention relates to a mixing device for spraying at the upper end of a U-shaped end cover. The mixing device comprises a connecting end cover and an end cover which are fixedly connected, a baseis arranged at the top of the end cover, and a nozzle is arranged on the base; a first flow guide device is fixed to the position, corresponding to an air inlet, of the connecting end cover, and a second flow guide device is fixed to the position, corresponding to an air outlet, of the connecting end cover; the first flow guide device comprises a first flow guide plate, a second flow guide plate and a sealing plate; the second flow guide device comprises a third flow guide plate and a fourth flow guide plate which are fixedly connected, the third flow guide plate comprises a surface plate at the upper part and an arc-shaped panel at the lower part, and air guide holes are uniformly distributed in the arc-shaped panel; and the fifth flow guide plate is arranged in an air outlet cover, and athird mixing cavity is formed between the fifth flow guide plate and the fourth flow guide plate. According to the SCR mixing device capable of reducing urea crystallization as much as possible, an SCR carrier is prevented from being blocked, and therefore stable operation of SCR is guaranteed.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

SCR system and box type catalytic silencer thereof

ActiveCN104975920AReduced risk of crystallizationImprove conversion rateExhaust apparatusSilencing apparatusNitrogen oxidesAqueous solution

The invention discloses a box type catalytic silencer of an SCR system. The silencer comprises a box, and an outer layer pipe and a carrier coated with a catalyst, wherein the outer layer pipe and the carrier are arranged in an inner cavity of the box. The outer layer pipe is used for introducing tail gas and a urea aqueous solution, and is provided with an exhaust port. The inner wall of the box is connected with a rear baffle used for fixing the carrier. The rear baffle is provided with a plurality of first through holes so that the mixture of the tail gas and the urea aqueous solution can be exhausted from the exhaust port and then flows to the carrier through the first through holes. Mixing uniformity of the mixture is improved, so that the conversion rate of nitrogen oxide is increased, and the risk of urea crystallization is reduced. The invention further discloses the SCR system comprising the box type catalytic silencer.

Owner:WEICHAI POWER CO LTD

Engine and double-whirl mixing device thereof

ActiveCN106368773APrevent crystallizationReduced risk of crystallizationInternal combustion piston enginesFlow mixersConical tubeEngineering

The invention discloses an engine and a double-whirl mixing device thereof. The double-whirl mixing device comprises a mixing tube, a conical mixer and fan-type blades, wherein the mixing tube is used for mixing tail gas with urea; the conical mixer comprises a conical tube, an outlet end of which extends into the mixing tube, and a plurality of conical whirl plates which are arranged on the side wall of the conical tube and are distributed in the circumferential direction; the diameter of the inlet end of the conical tube is smaller than that of the outlet end of the conical tube; and the fan-type blades are arranged at the outlet end of the conical tube. In this way, the double-whirl mixing device provided by the invention can effectively avoid the problems that urea is easily deposited, is atomized poorly and is not mixed uniformly with the tail gas.

Owner:WEICHAI POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com