Dual-layer mixing pipe and exhaust treating device thereof

A technology of exhaust treatment device and mixing tube, which is applied in the direction of exhaust device, muffler device, engine components, etc. It can solve the problems of blocked exhaust pipe, decreased engine power performance, ammonia leakage, etc., to increase the evaporation distance, Effect of improving uniformity and increasing evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

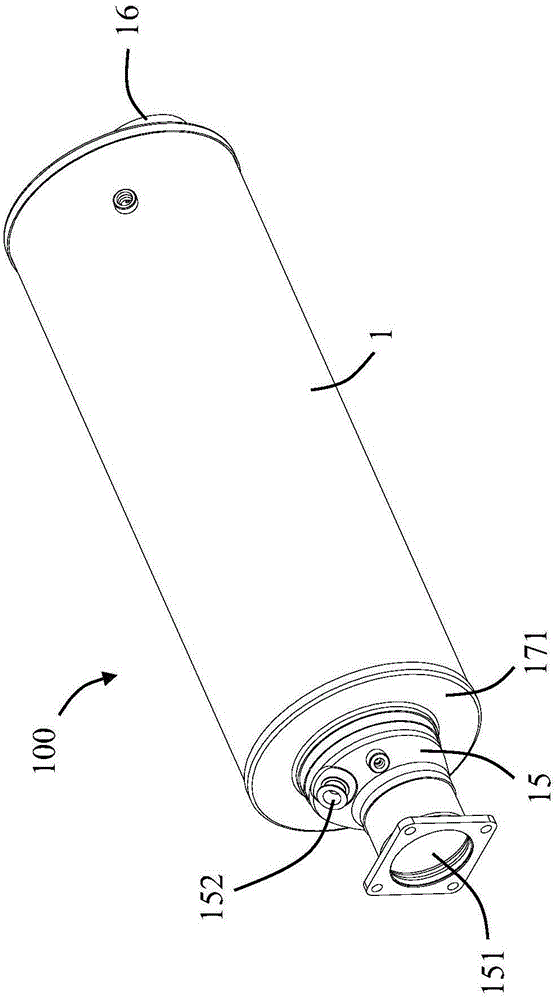

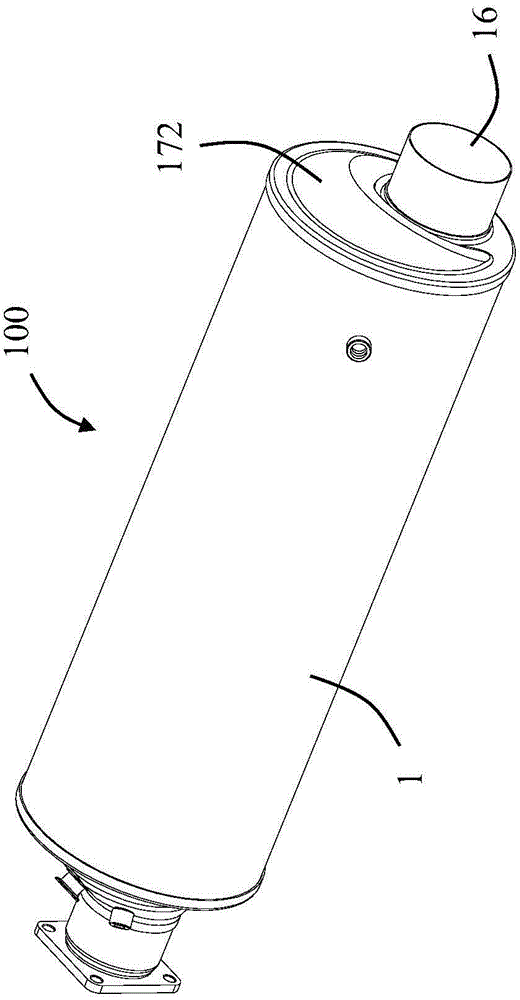

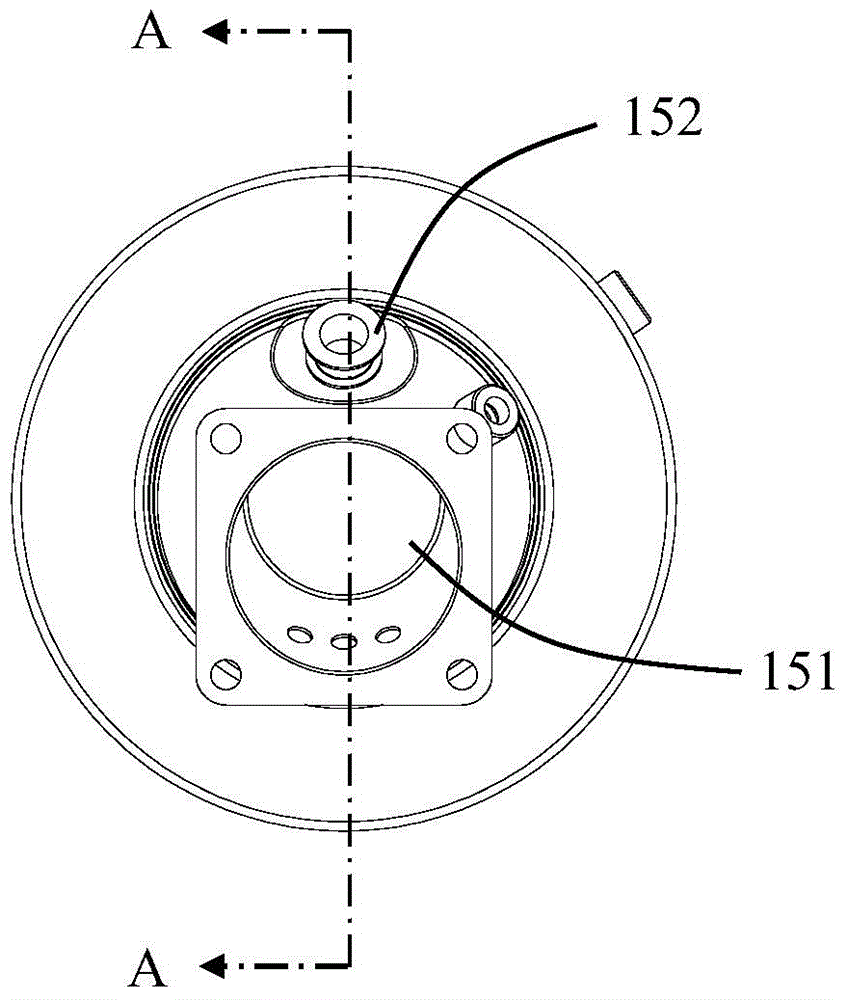

[0027] Please refer to Figure 1 to Figure 8 As shown, the present invention discloses an exhaust gas treatment device 100 for purifying the exhaust gas of an engine (for example, reducing the content of nitrogen oxides and / or reducing the content of particulate matter, etc.). The exhaust gas treatment device 100 includes a housing 1, an exhaust gas treatment module 2 (such as a selective oxidation catalyst module, SCR) installed in the housing 1, and an exhaust gas treatment module 2 installed in the housing 1 and located in the exhaust gas treatment Double layer mixing tube 3 upstream of module 2.

[0028] Please refer to Figure 6 to Figure 8 As shown, the housing 1 is roughly cylindrical, and it includes a first cavity 11 located upstream of the exhaust gas treatment module 2, a second cavity 12 located downstream of the exhaust gas treatment module 2, and a second cavity 12 located downstream of the exhaust gas treatment module 2. A first partition 13 inside a cavity 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com