Patents

Literature

725 results about "Evaporation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Evaporation rate is known as the rate at which a material vaporizes (or evaporates), meaning it will change from liquid to vapor when compared to the rate of vaporization of a specific known material. This quantity represents a ratio, which means it is unitless.

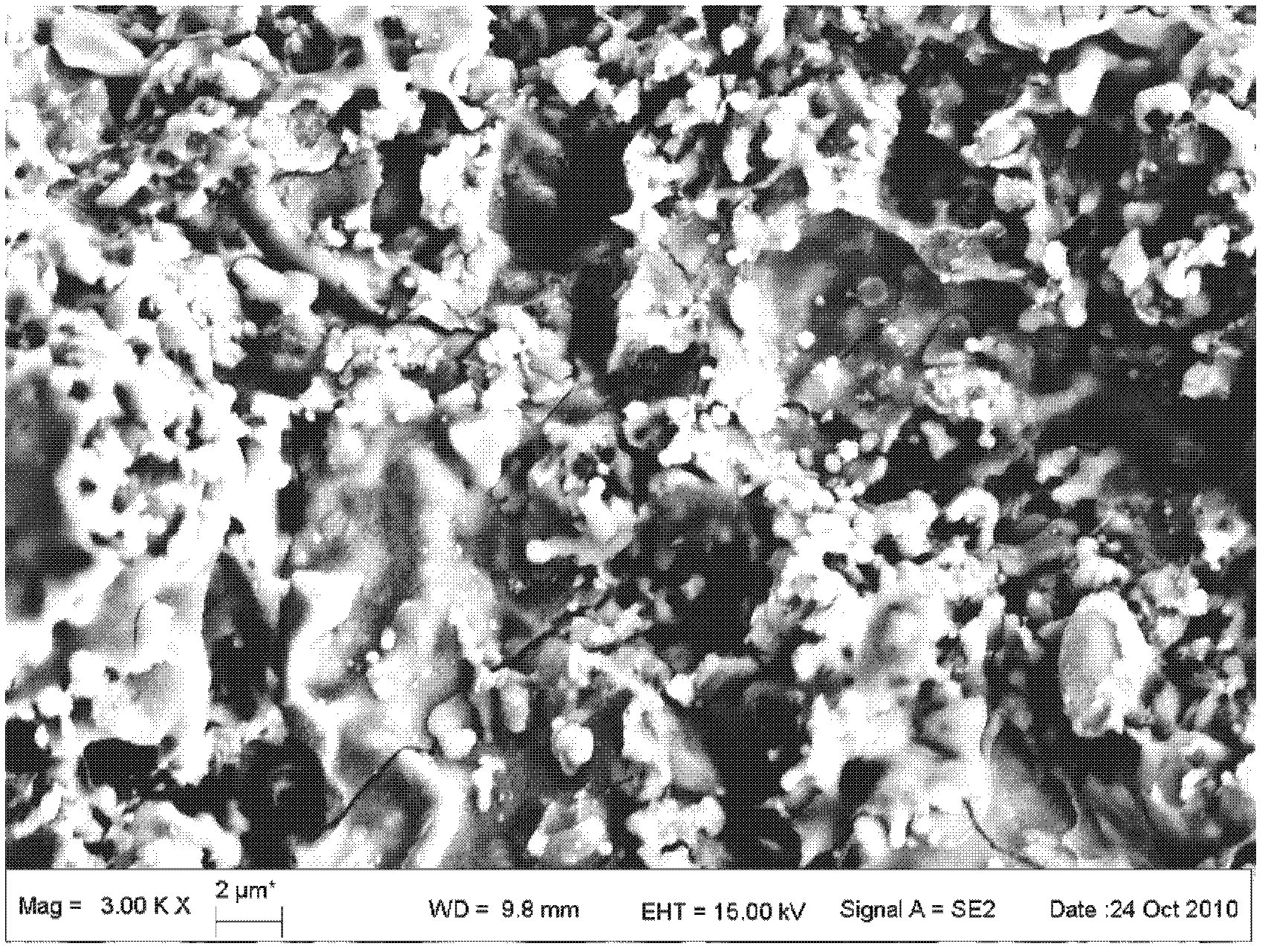

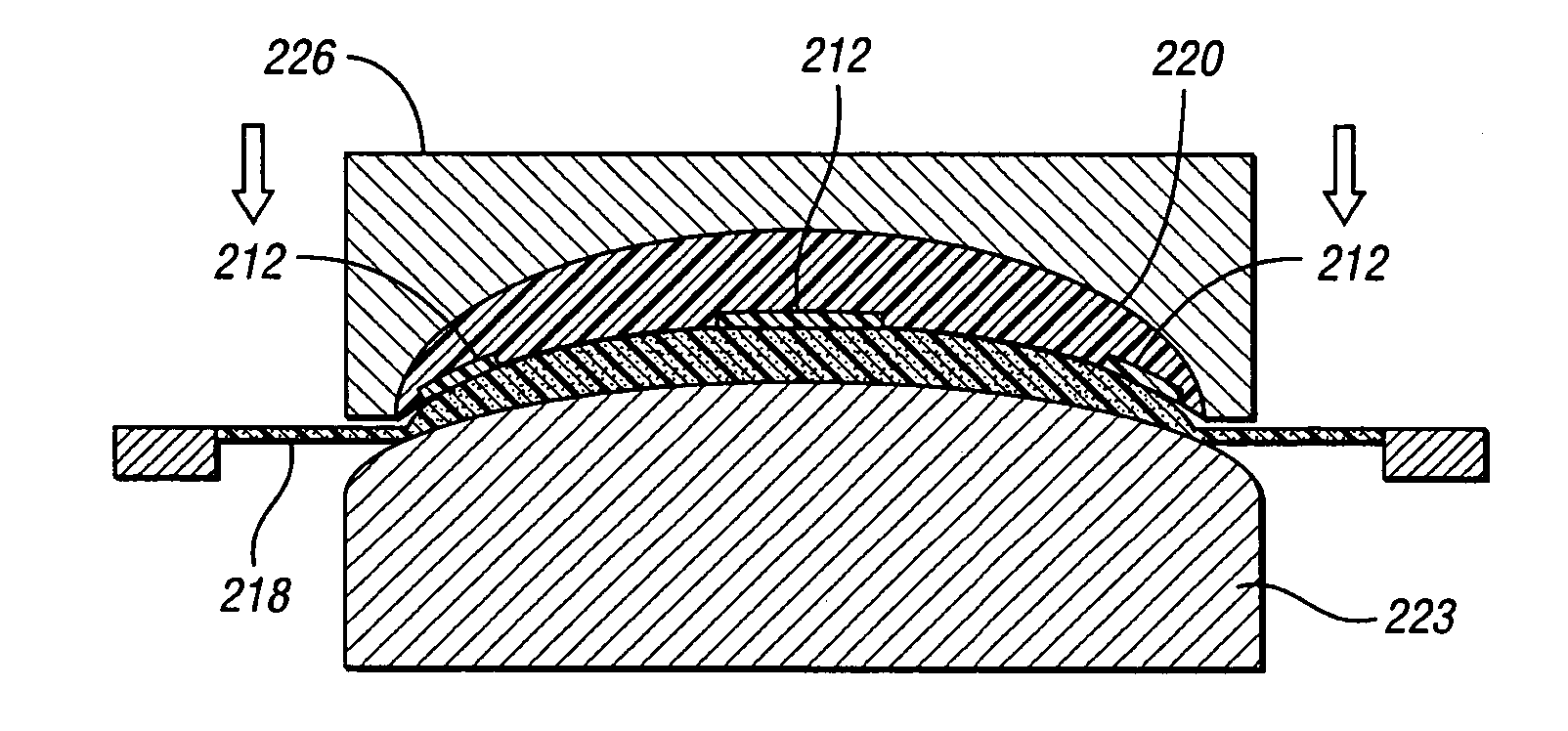

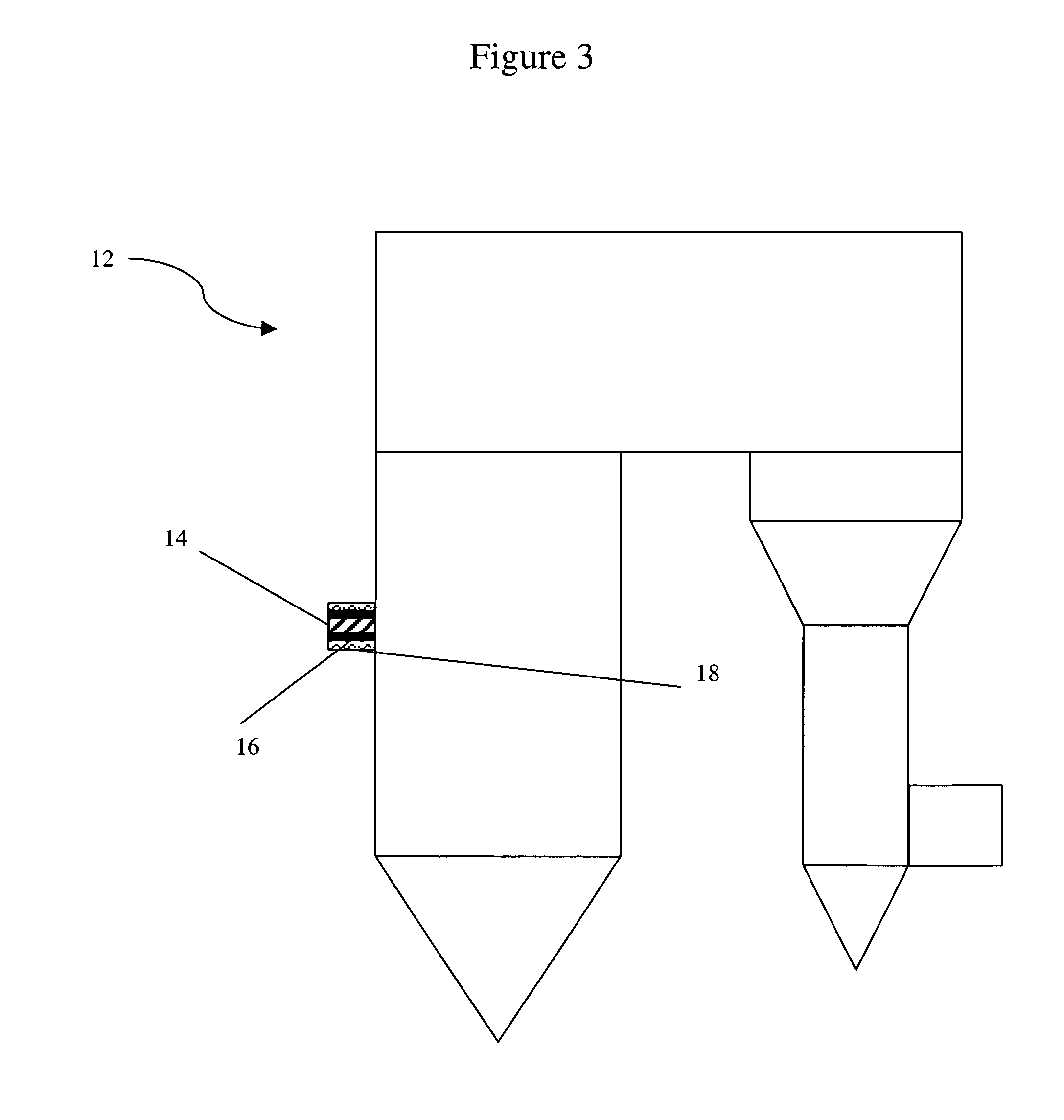

Defect-free semiconductor templates for epitaxial growth

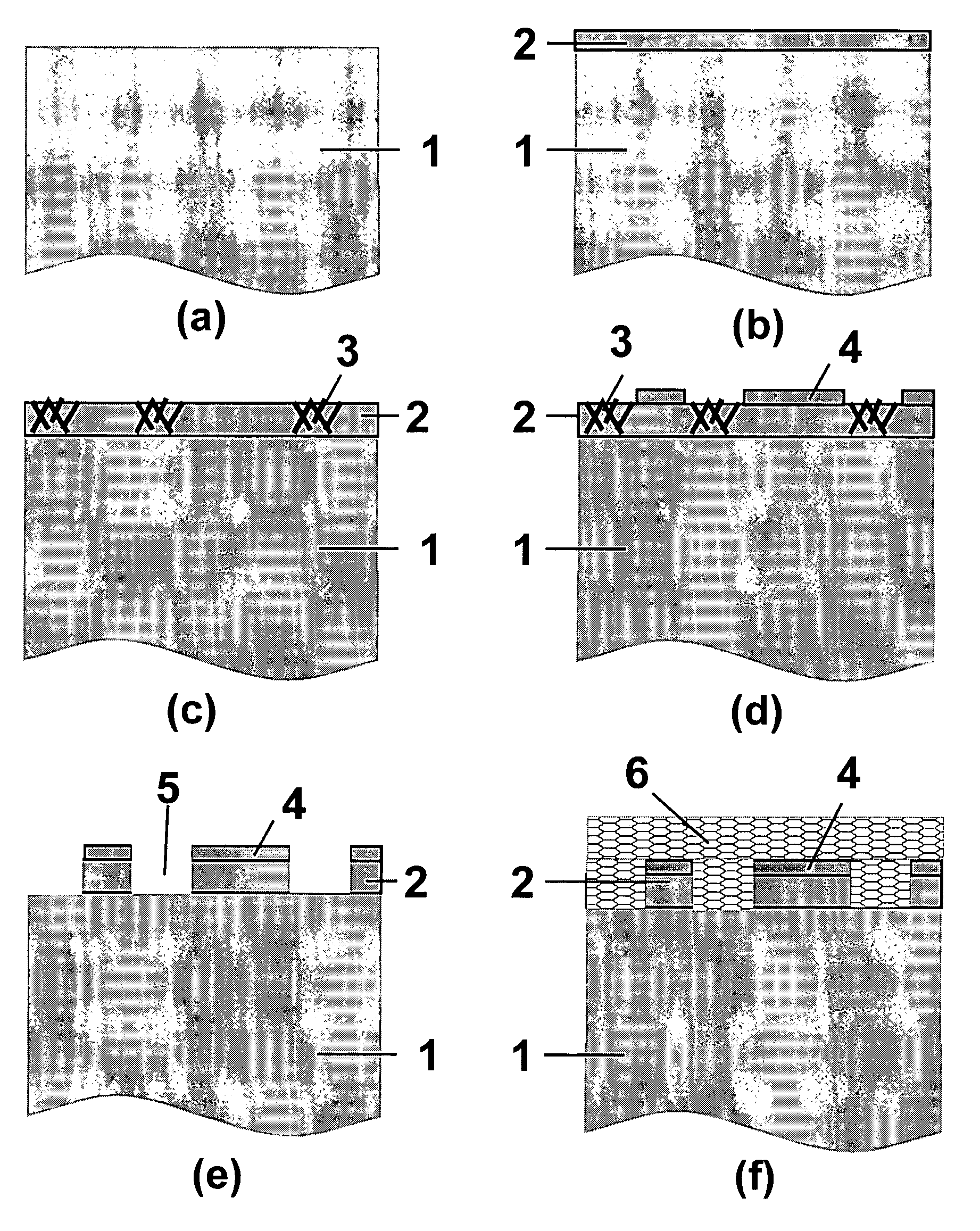

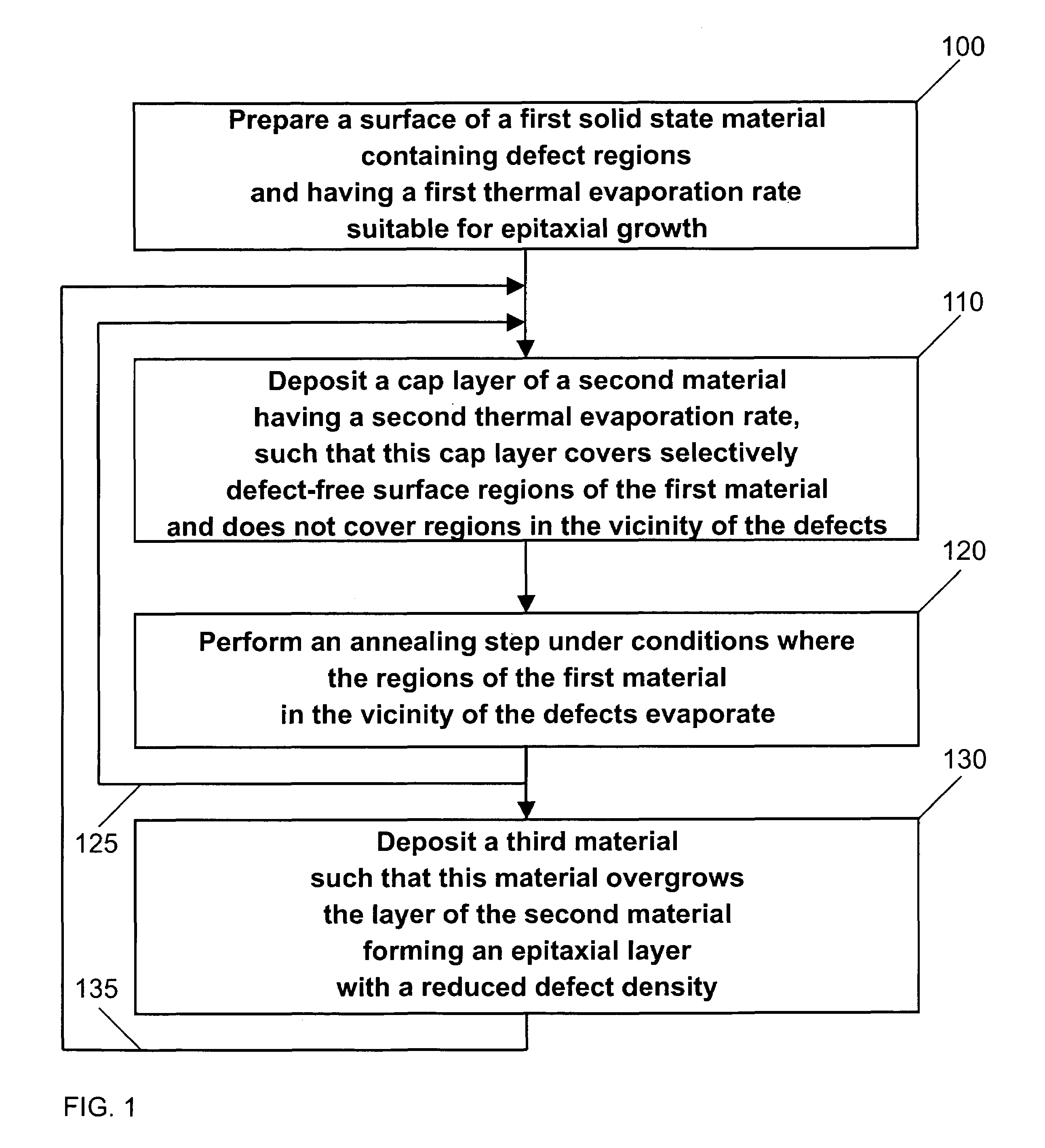

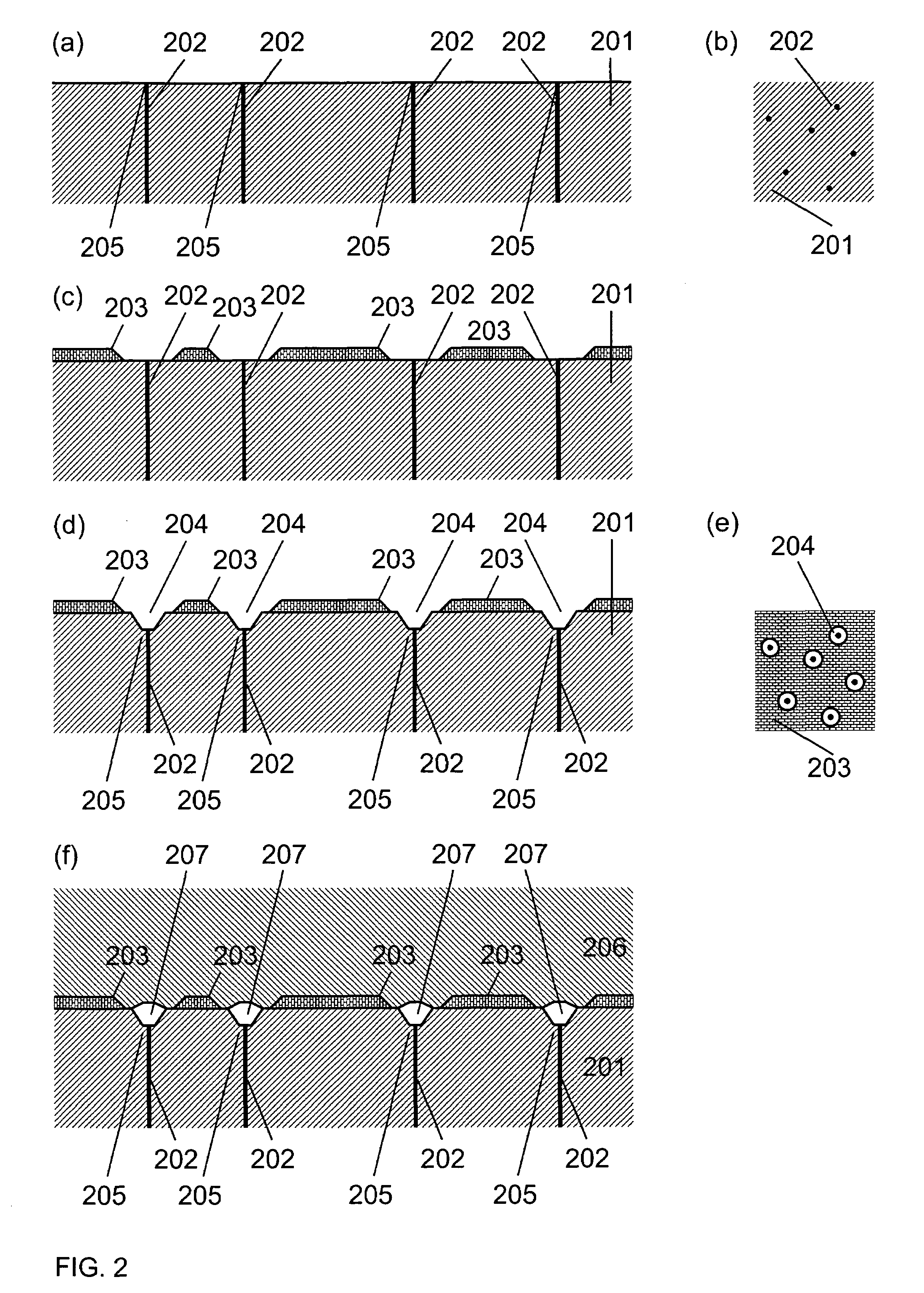

InactiveUS7101444B2Improve high temperature stabilityMaterial nanotechnologyLaser detailsSelective depositionSemiconductor

A semiconductor device includes at least one defect-free epitaxial layer. At least a part of the device is manufactured by a method of fabrication of defect-free epitaxial layers on top of a surface of a first solid state material having a first thermal evaporation rate and a plurality of defects, where the surface comprises at least one defect-free surface region, and at least one surface region in a vicinity of the defects, the method including the steps of selective deposition of a second material, having a high temperature stability, on defect-free regions of the first solid state material, followed by subsequent evaporation of the regions in the vicinity of the defects, and subsequent overgrowth by a third material forming a defect-free layer.

Owner:INNOLUME

Recording ink, ink cartridge, ink media set, ink- jet recording method and ink-jet recording apparatus

InactiveUS20100196601A1Improve image qualityQuality improvementPigmenting treatmentMeasurement apparatus componentsWater dispersibleSolvent

An ink-jet recording ink including a colorant dispersible in water, a water-soluble organic solvent used as a wetting agent, a surfactant, a penetrant, a water-dispersible resin, and water, wherein when 2.5 g of the ink is weighed, placed in a glass Petri dish having a diameter of 33 mm and stored for 24 hr at a temperature of 50° C.±0.5° C. and a humidity of 12%±5%, the evaporation rate of a solvent (water+water-soluble organic solvent) in the ink is 50% by weight or more, and an ink residue has a viscosity of 20,000 mPa-S or greater, and wherein by storing the ink residue for 6 hr at a temperature of 23° C.±0.5° C. and a high humidity of 95%±3% to allow it to absorb moisture, the amount of moisture contained in the ink residue becomes 30% by weight to 40% by weight, in which case the ink residue has a viscosity of less than 500 mPa s.

Owner:RICOH KK

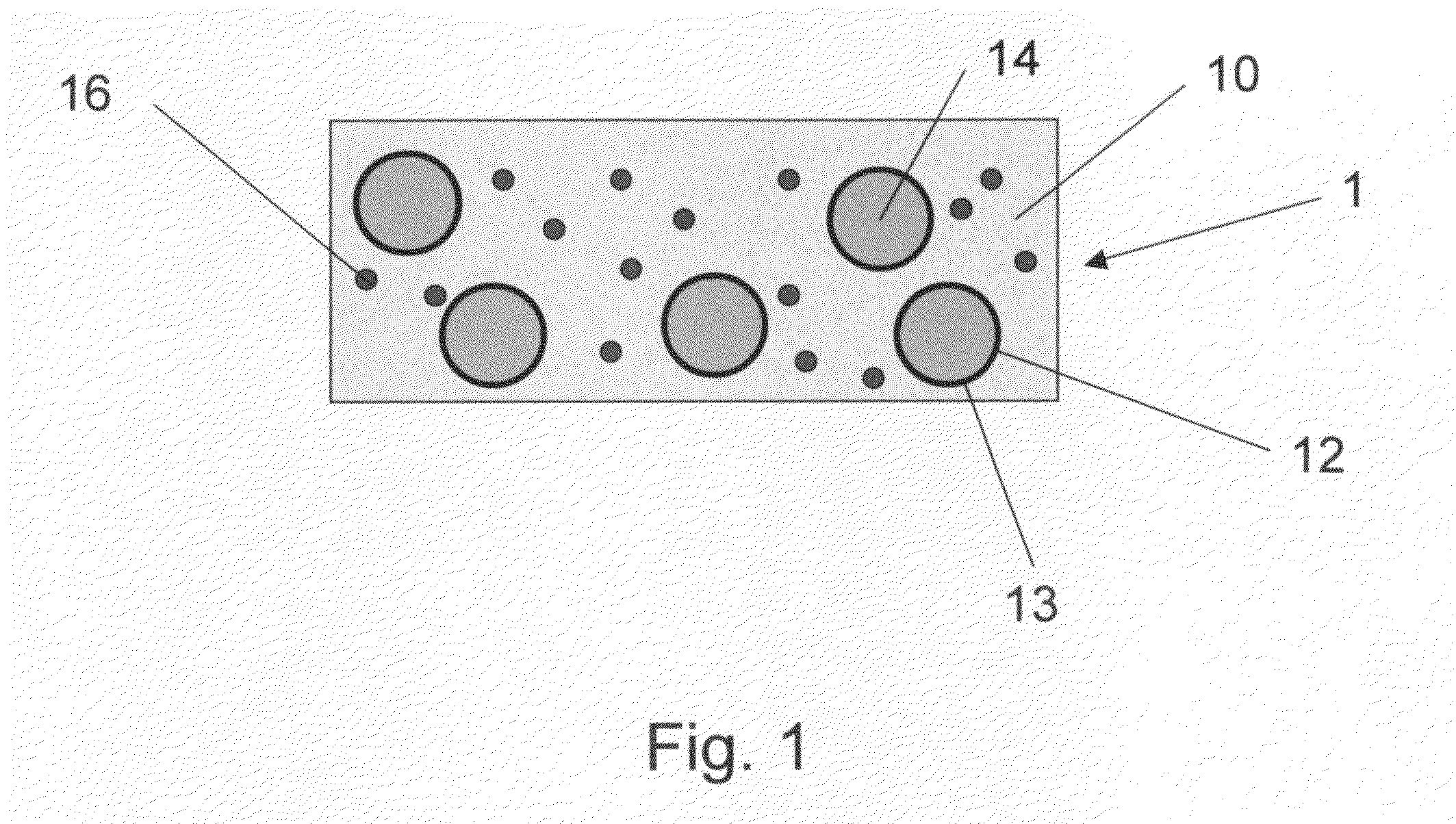

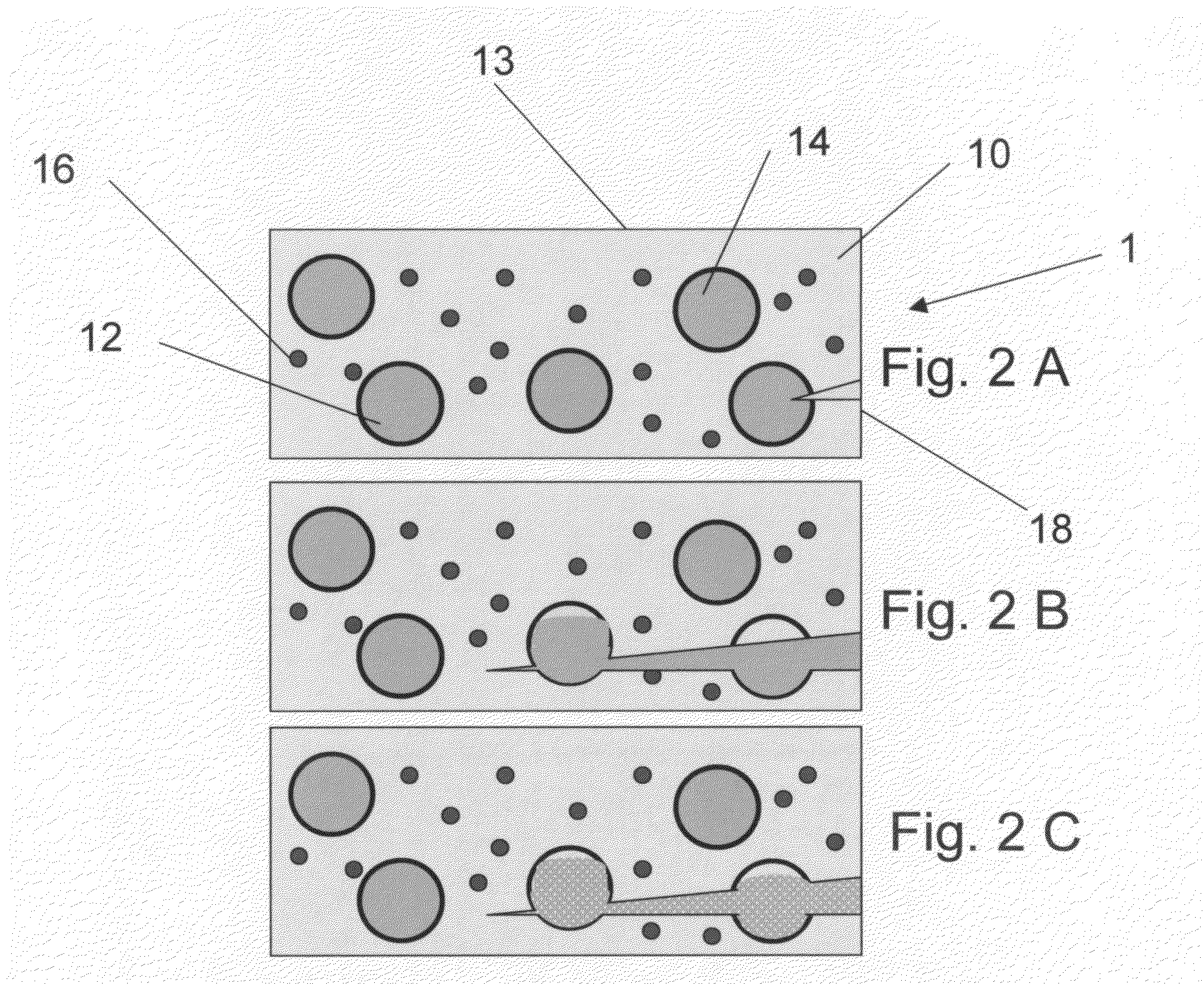

Self healing composite material and method of manufacturing same

InactiveUS20090036568A1Large operating rangeFaster rate of healingRadio transmissionThin material handlingEmulsionRestorative material

A self-healing material comprises a matrix embedded with micro-pockets of a healing-agent releasable by a crack in the matrix. The healing-agent is able to bond to the matrix to repair the crack. The healing-agent is contained in microcapsules. A corresponding catalyst for the healing-agent is embedded in the matrix and contained in a plurality of microcapsules as an emulsion. The emulsion comprises an oil, a perfluorated solvent, a hydrophobic ionic liquid, or mixtures thereof. A method of manufacturing the self-healing material comprises the steps of identifying an operational temperature range of the material, providing at least one substance as the healing-agent, which substance remaining substantially in a liquid state within the operational temperature range, identifying an operational evaporation rate of the healing-agent and providing the substance with a curing time according to the evaporation rate.

Owner:MPB COMM +1

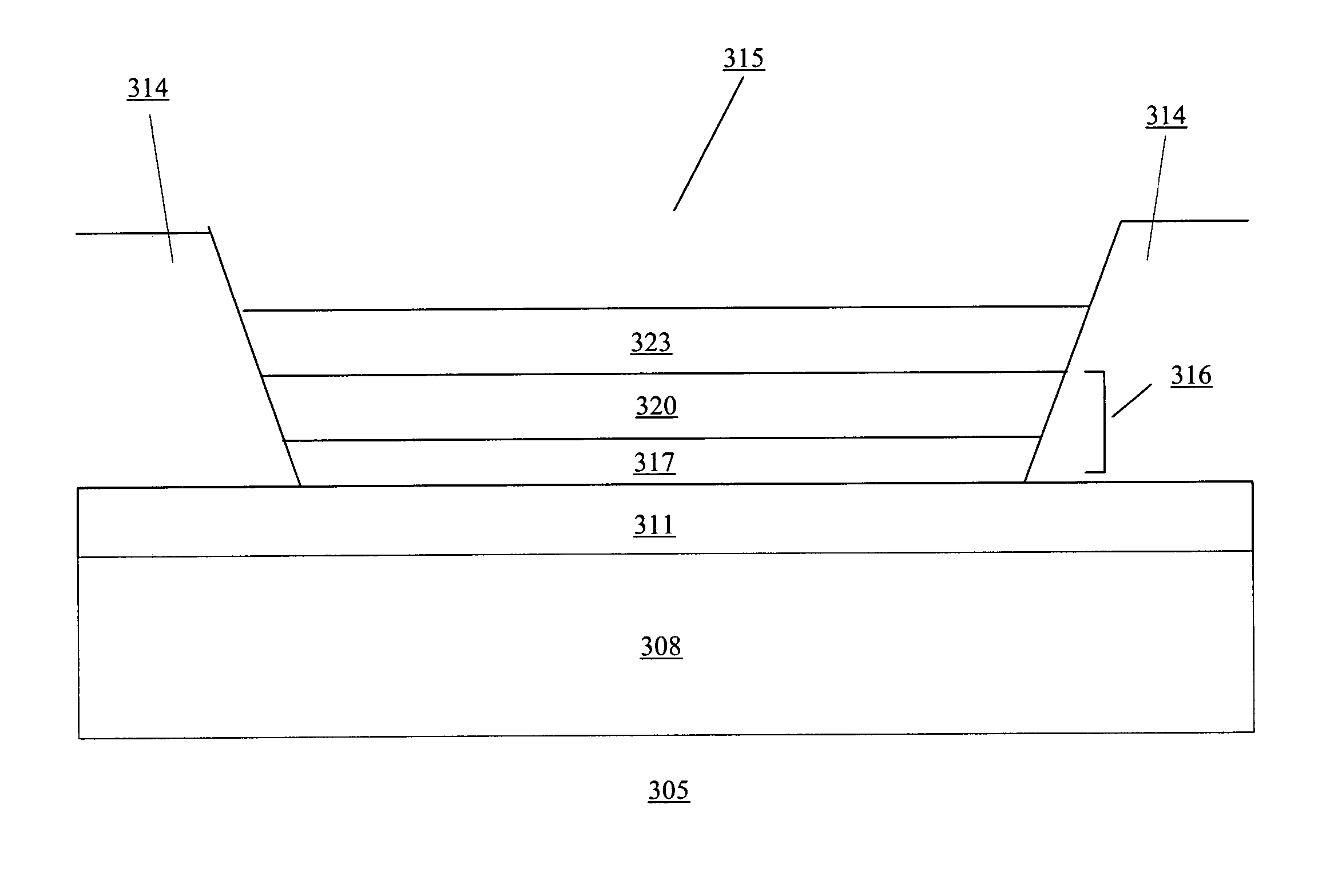

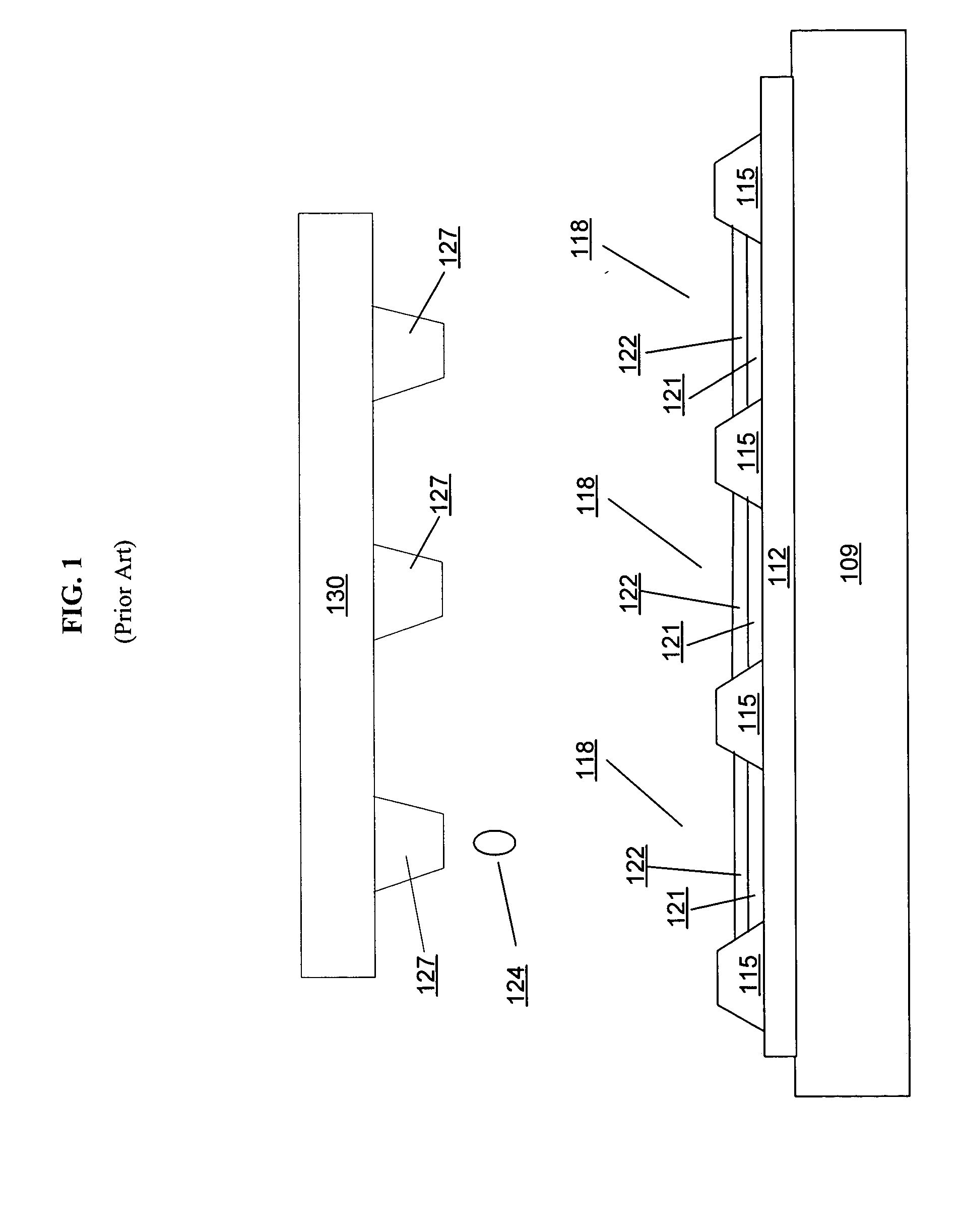

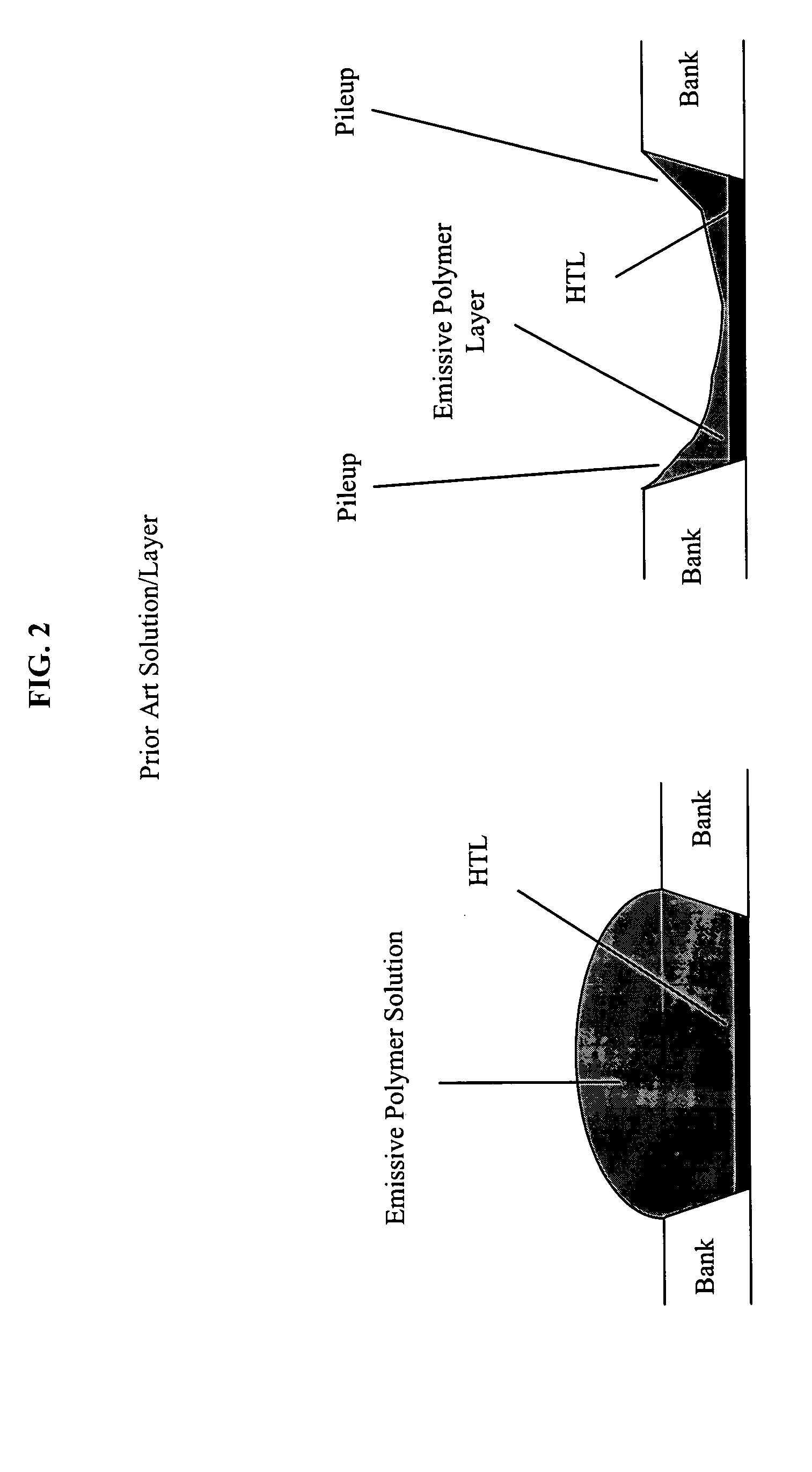

Solvent mixtures for an organic electronic device

InactiveUS20050067949A1Improve solubilityFast evaporationDischarge tube luminescnet screensElectroluminescent light sourcesSolubilitySolvent

An organic polymer solution is made of at least one organic polymer, a first solvent, and a second solvent. The first solvent has a high solubility (e.g., the first solvent dissolves at least about one weight percent of the organic polymers) and has a faster evaporation rate than the second solvent, and the second solvent has a very low solubility (e.g., the second solvent dissolves less than about one-fourth weight percent of the organic polymers). After the solution is deposited on an object, the solution is allowed to dry. As the solution dries, the first solvent due to its faster evaporation rate than the second solvent starts to evaporate from the solution, and soon after the first solvent starts to evaporate, the one or more organic polymers, due to its lower solubility in the second solvent, rapidly gels resulting in a substantially uniform organic polymer layer.

Owner:OSRAM OPTO SEMICONDUCTORS GMBH

Encapsulated essential oils

The invention provides a process for the preparation of essential oil microcapsules comprising dissolving a di- or polyisocyanate into an essential oil, emulsifying the resulting mixture in an aqueous solution containing a di- or polyamine, and / or a di or polyhydroxy compound to effect encapsulation of said essential oil through interfacial polymerization, whereby there is formed a polyurea and / or polyurethane film around the essential oil droplets which film enhances the stability of said essential oil, reduces its evaporation rate and controls its release rate when applied to a substrate.

Owner:内盖夫研发局属本古里昂大学

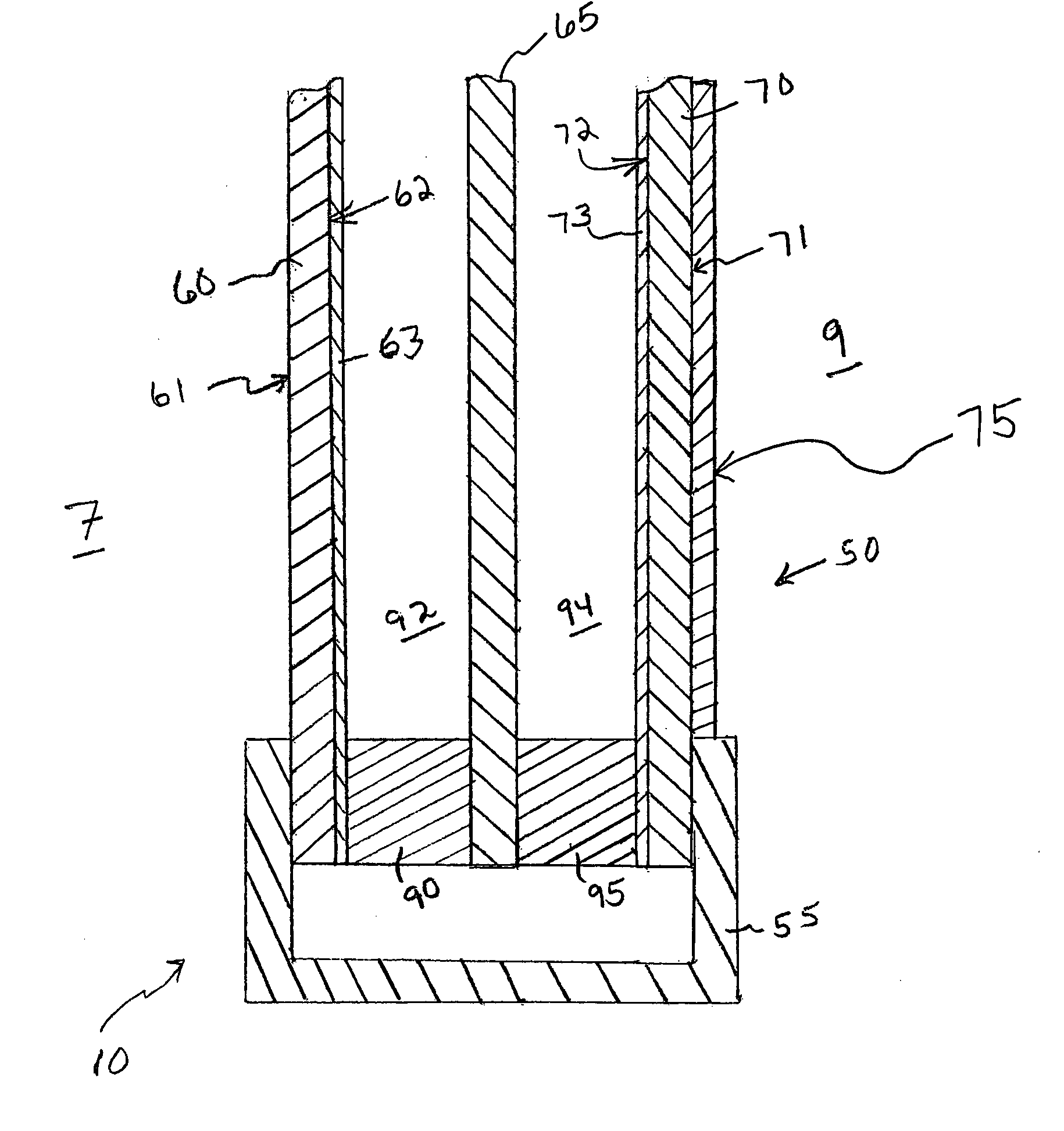

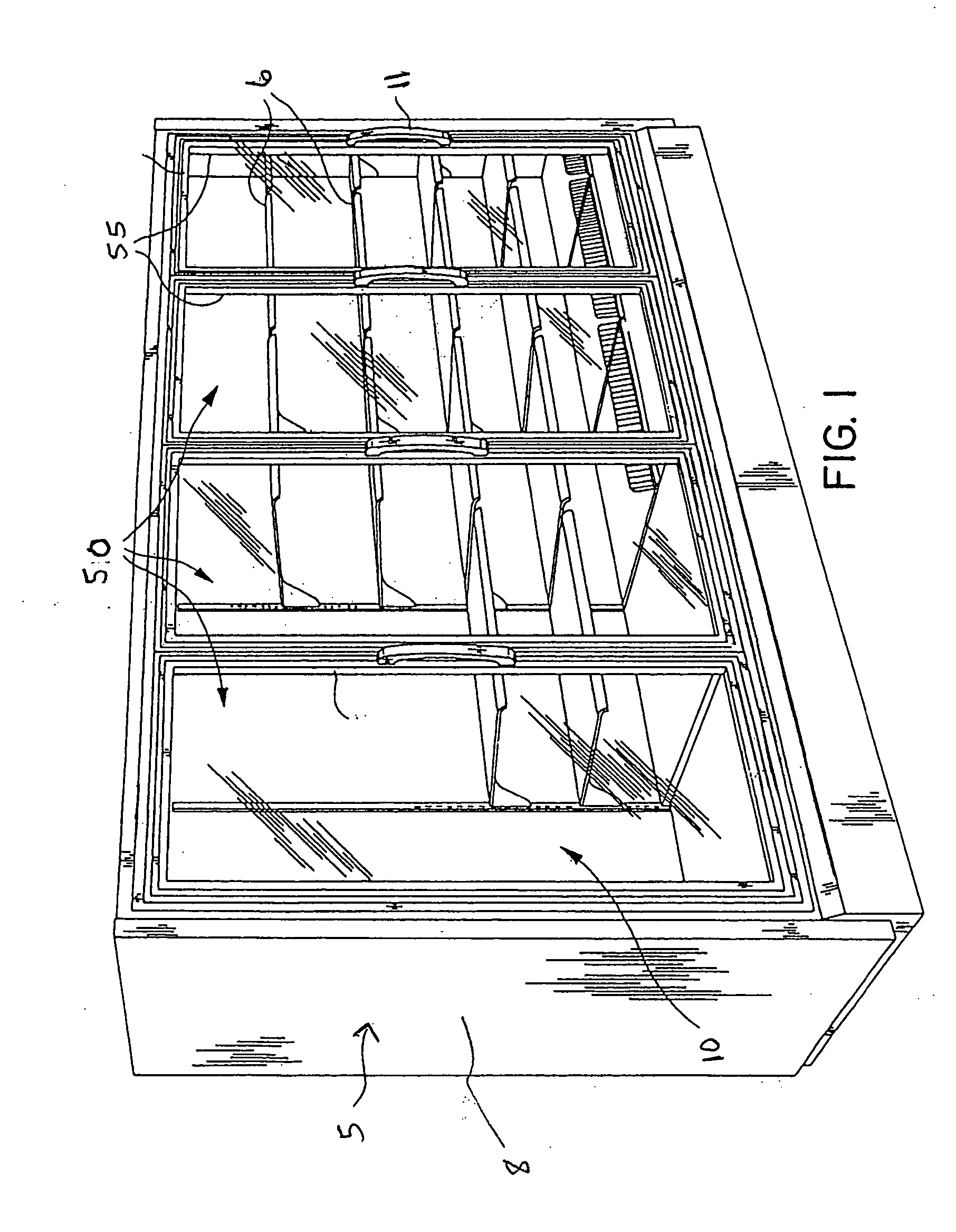

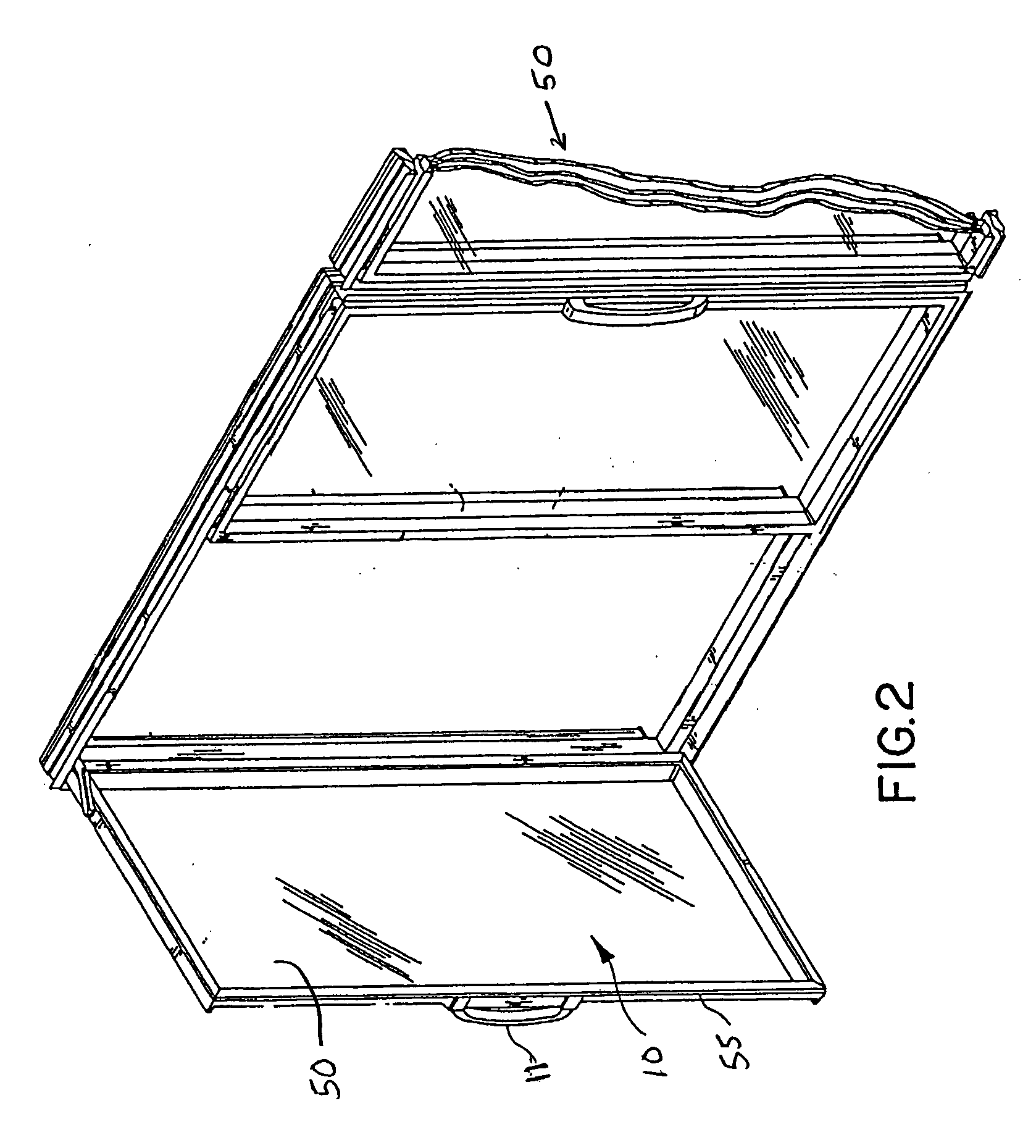

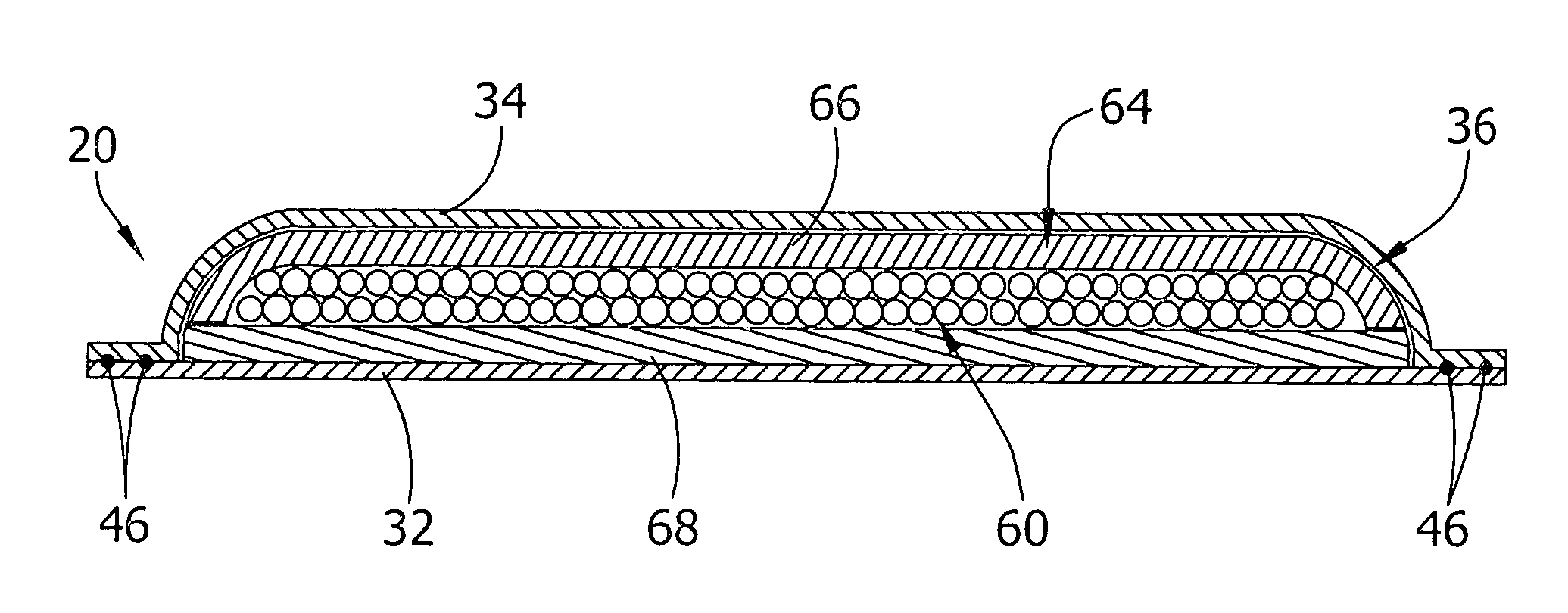

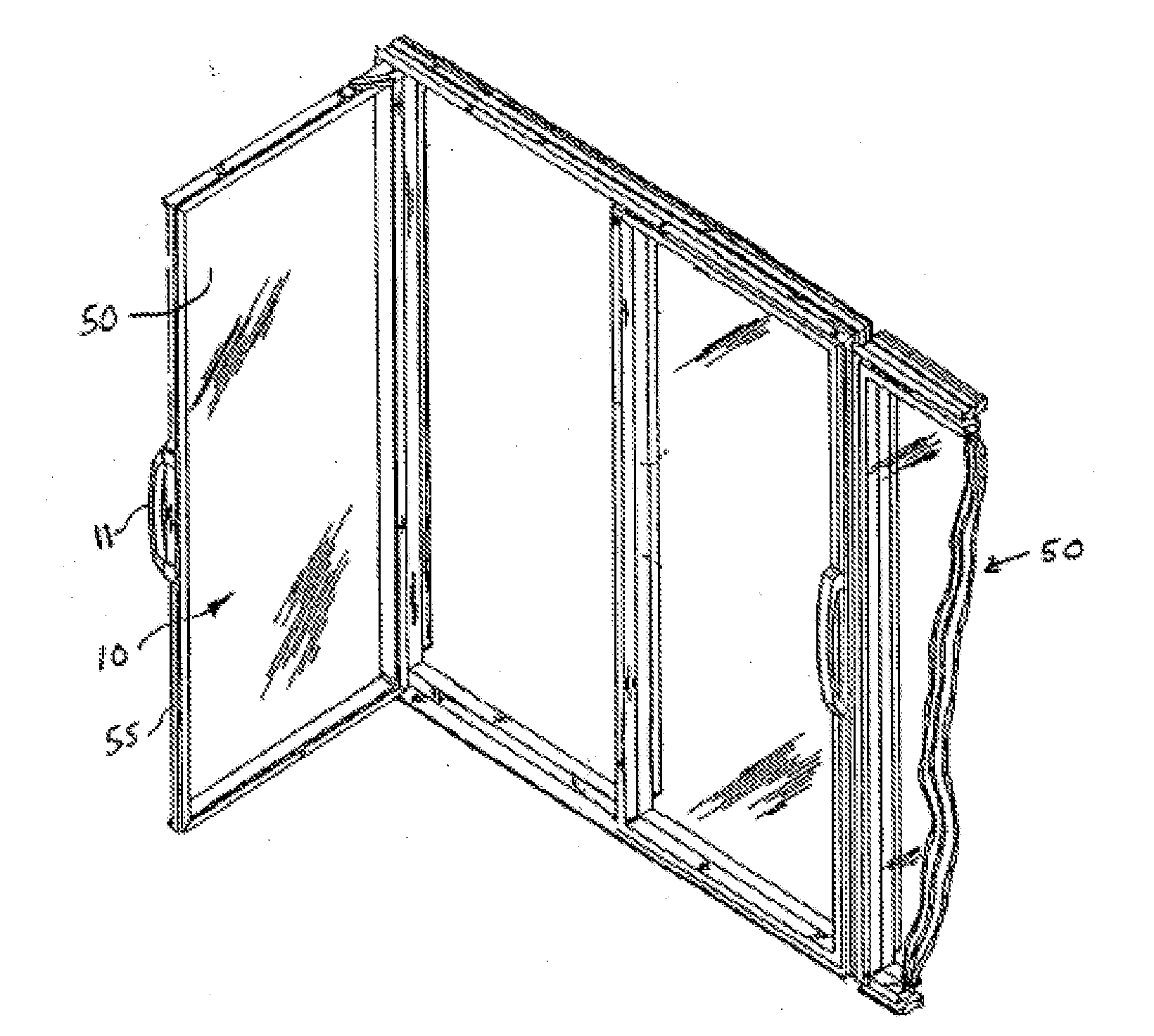

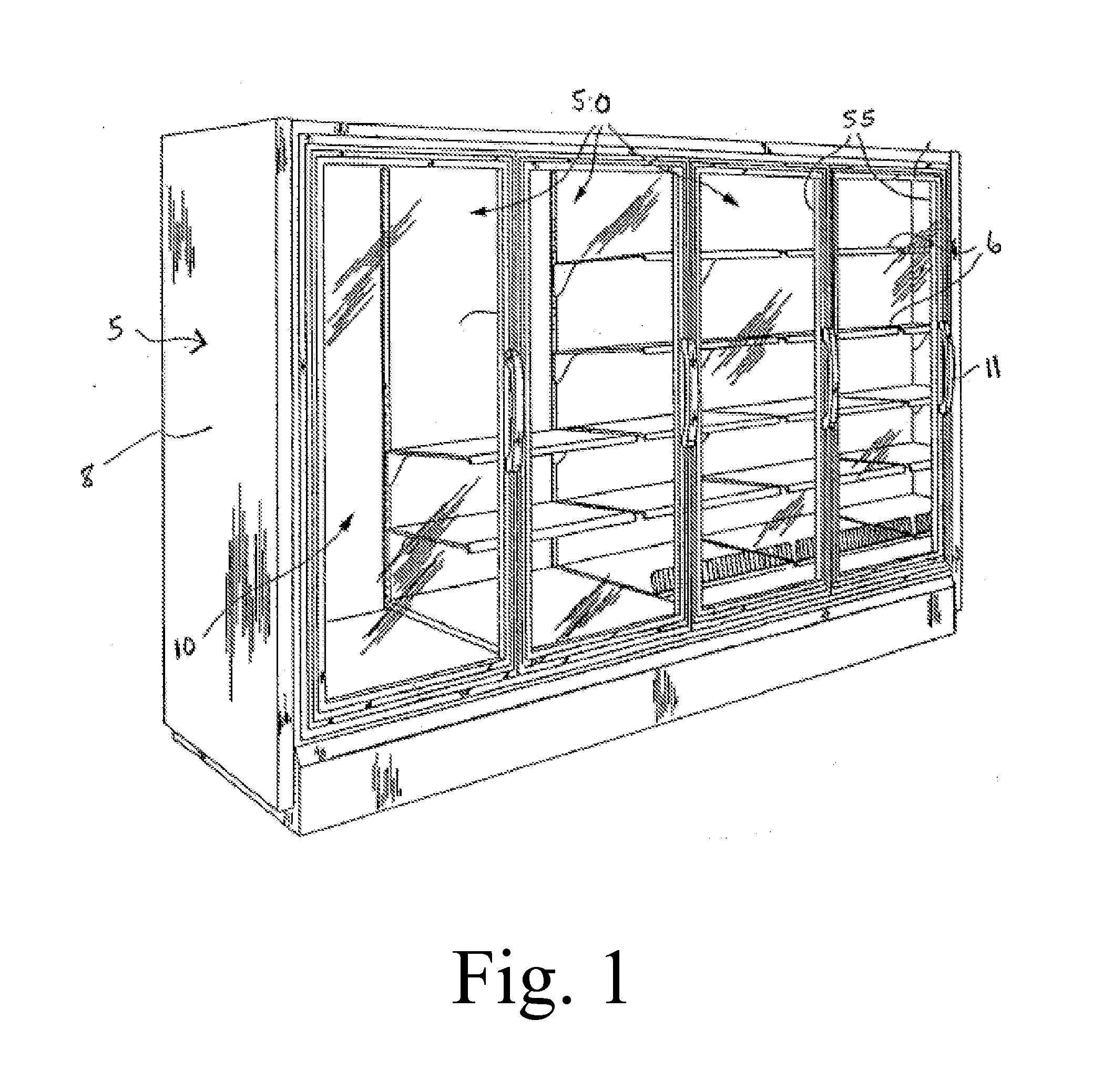

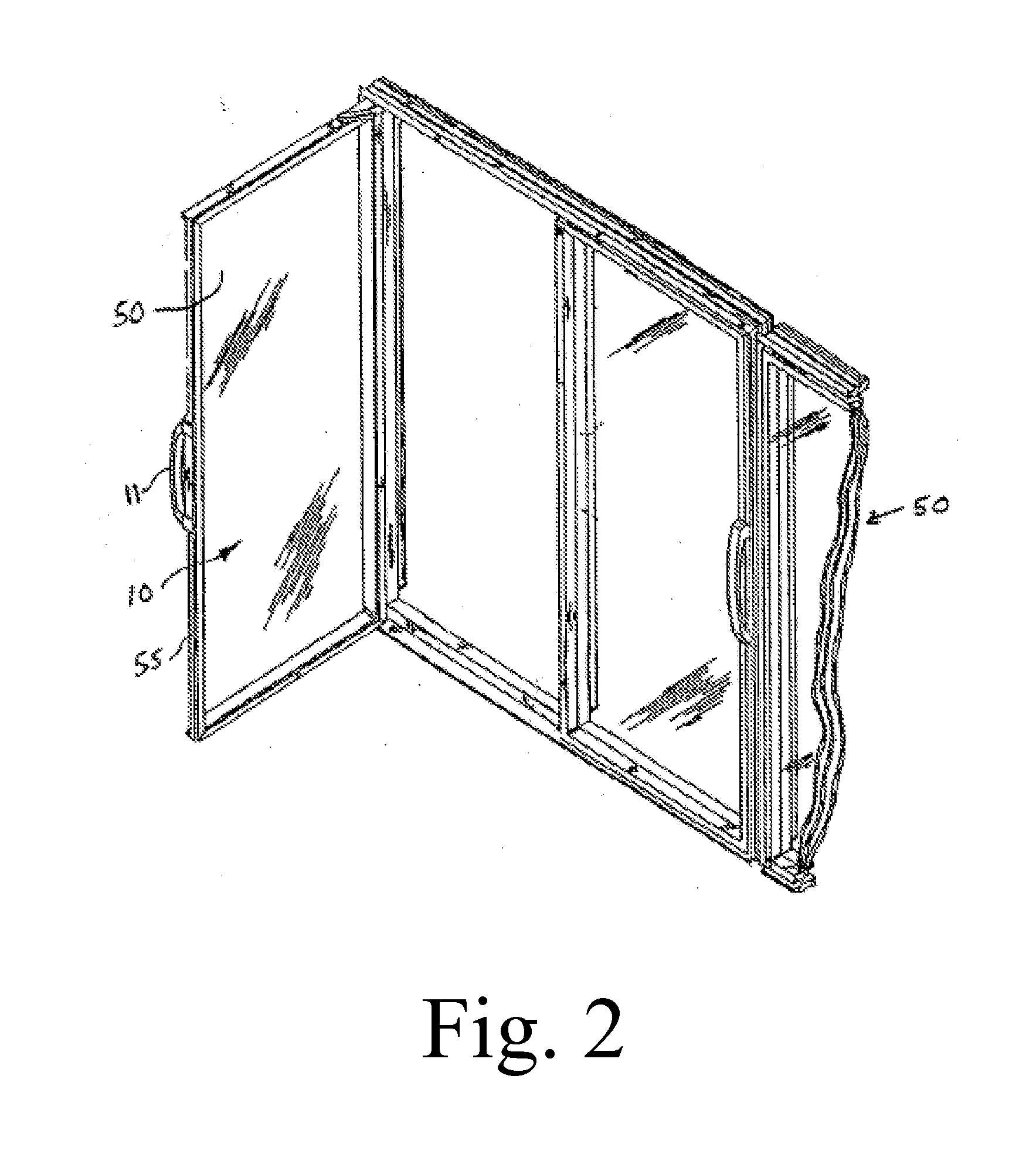

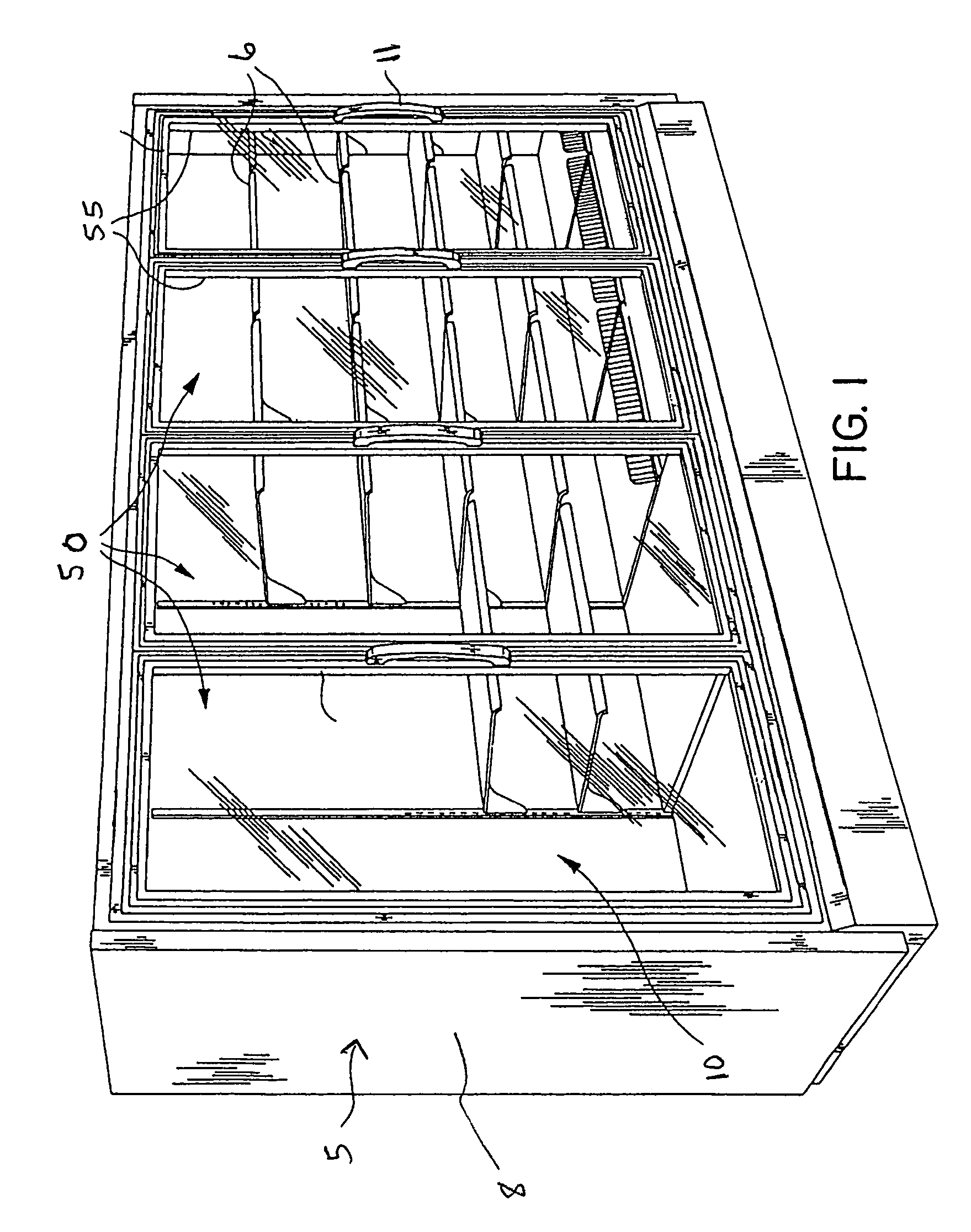

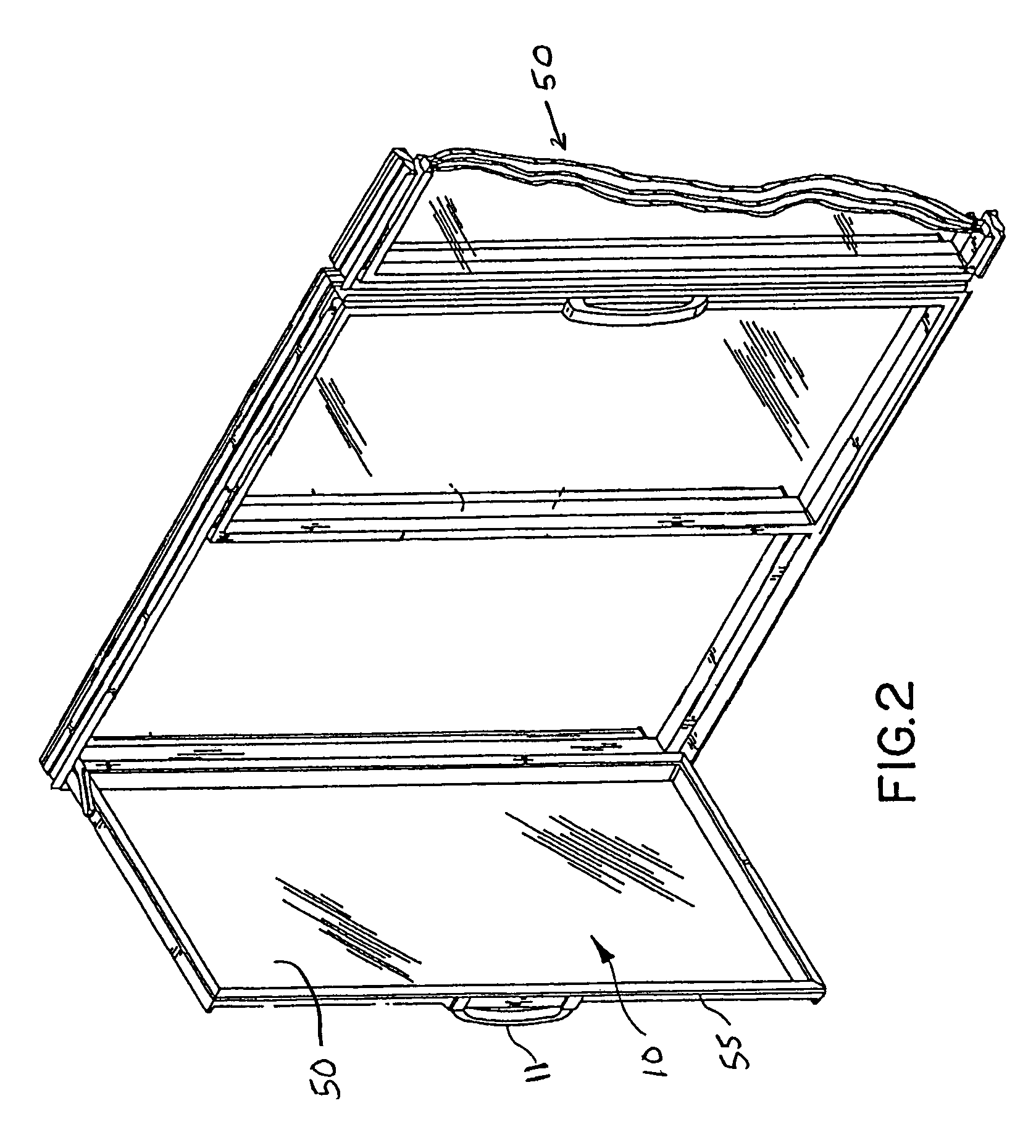

Anti-fog refrigeration door and method of making the same

InactiveUS20060265979A1BurdeningIncreased energy costShow cabinetsRailway roofsThermal insulationLow emissivity

The energy-free refrigeration door of the present application provides a way to control condensation when the door of a refrigeration unit is opened by providing thermal insulation to the door with glass panels which have a low emissivity coating. The door includes a door frame housing and an insulating glass unit comprising inner, middle and outer sheets of glass. A first sealant assembly disposed around the periphery of the inner and middle sheets of glass forms a first chamber between the inner and middle sheets of glass. A second sealant assembly disposed around the periphery of the middle and outer sheets of glass forms a second chamber between the middle and outer sheets of glass. A gas, such as krypton, air, or argon is held in the first and second chambers. The outer sheet of glass and inner sheet of glass each have an unexposed surface that faces the middle sheet of glass. A low emissivity coating is disposed on the unexposed surfaces of the inner and outer sheets of glass so that the glass door as a whole avoids formation of condensation on the outer surface of the outer sheet of the glass door, without the application of electricity to heat the door, while also providing the desired evaporation rate of condensation from the inner side of the inner sheet of the glass door. An anti-fog or anti-frost coating is included on a surface of one of the sheets of glass.

Owner:AGC FLAT GLASS NORTH AMERICA INC

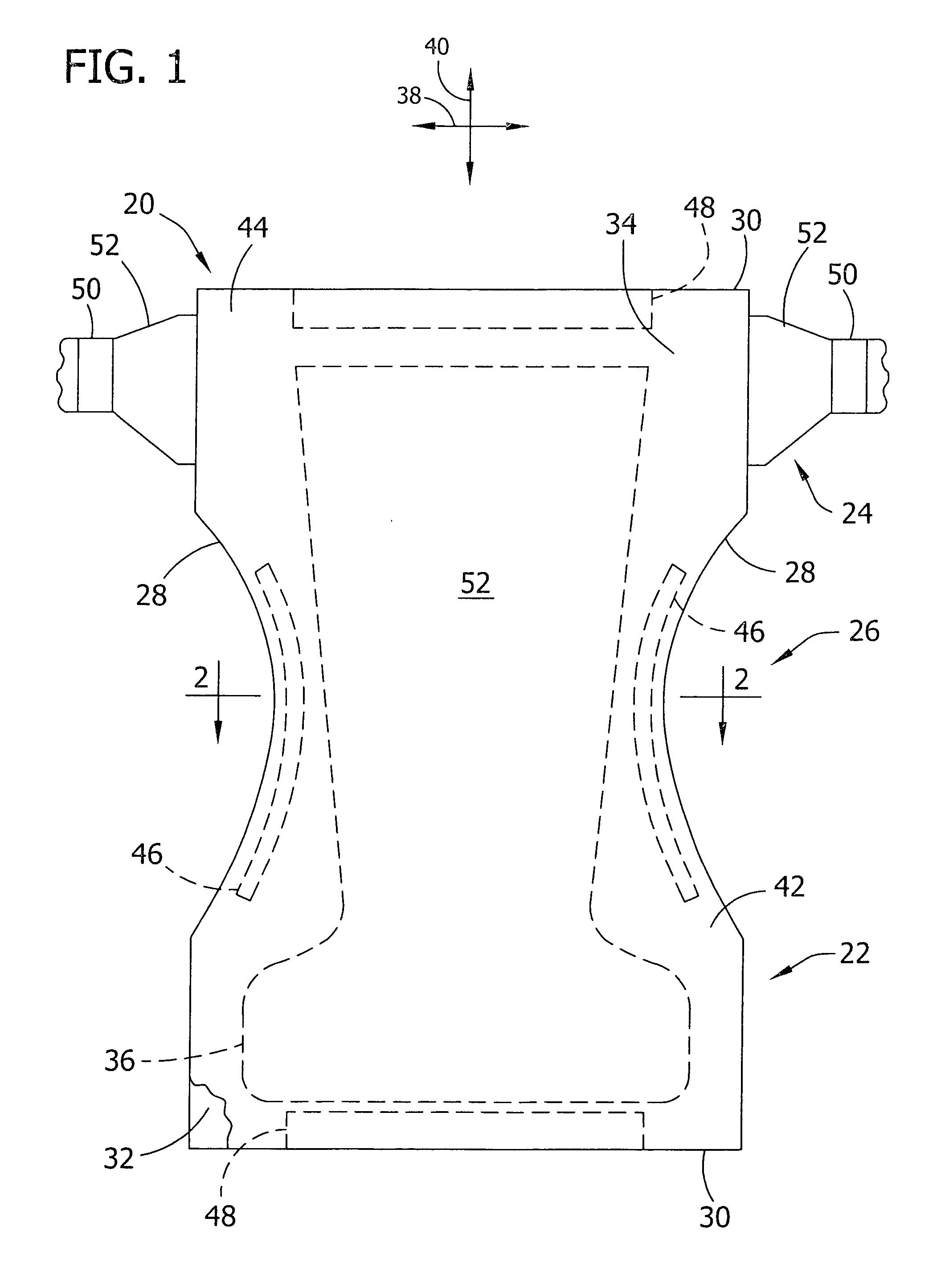

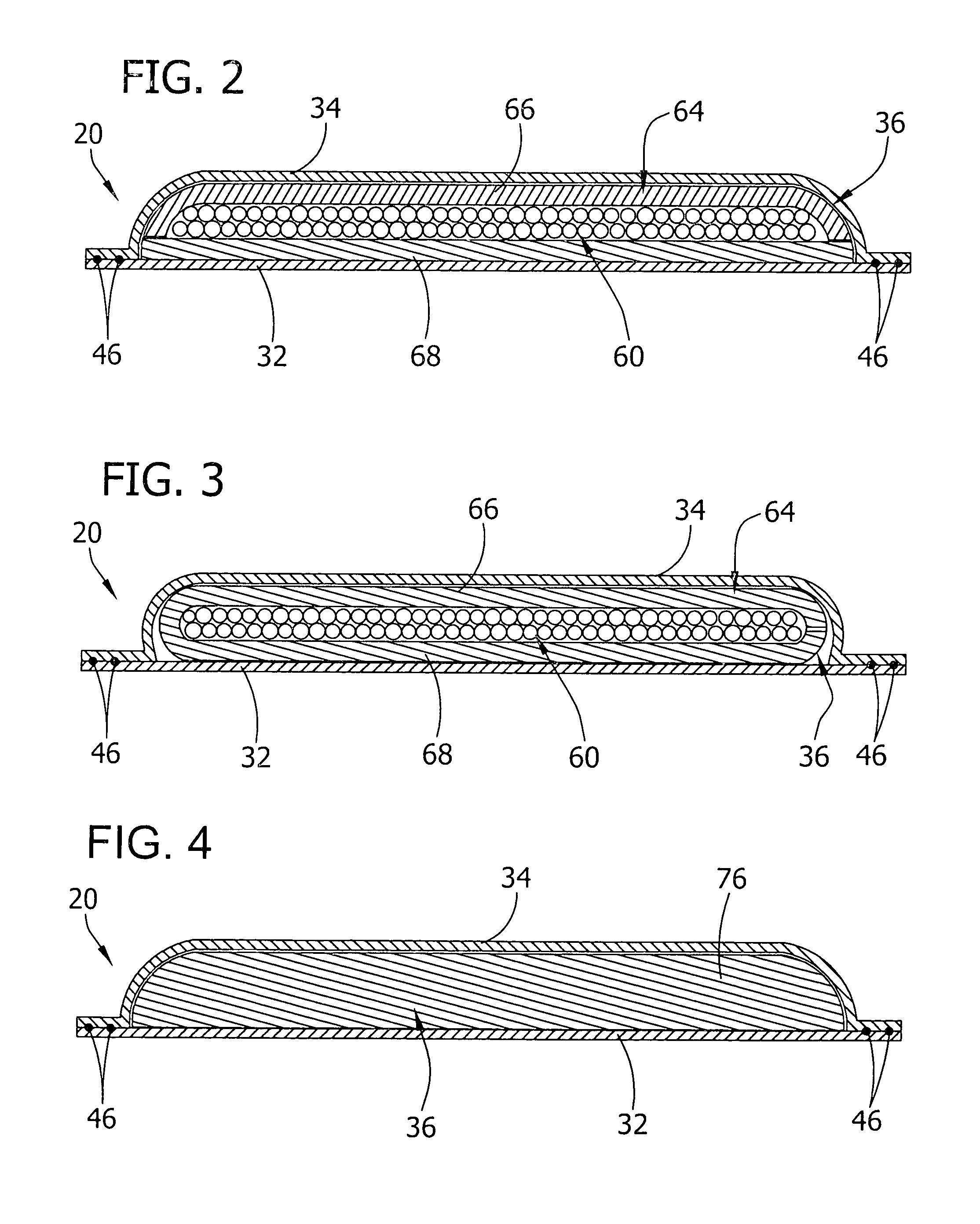

Evaporative disposable garment

A disposable garment having a liquid permeable liner, a liquid impermeable / vapor permeable outer cover in opposed relationship with the liner and an absorbent body disposed between the liner and the outer cover. The outer cover has a water vapor transmission rate (WVTR) as determined by a Water Vapor Transmission Rate Test of at least about 6,000 g / m2 / 24 hours. The disposable garment has an evaporation rate as determined by an Evaporation Rate Test of at least 0.15 g / hr / in2. A disposable garment is also disclosed having an absorbent body with an evaporation rate as determined by the Evaporation Rate Test of at least 0.30 g / hr / in2, a saturation capacity ratio as determined by a Saturation Capacity Test of at least about 17 grams / gram, and a saturation capacity as determined by the Saturation Capacity Test of at least about 50 grams.

Owner:KIMBERLY-CLARK WORLDWIDE INC

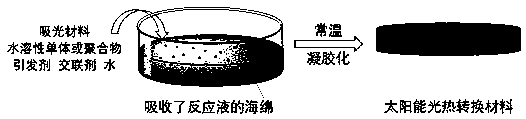

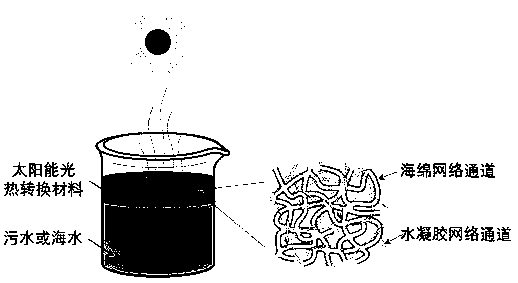

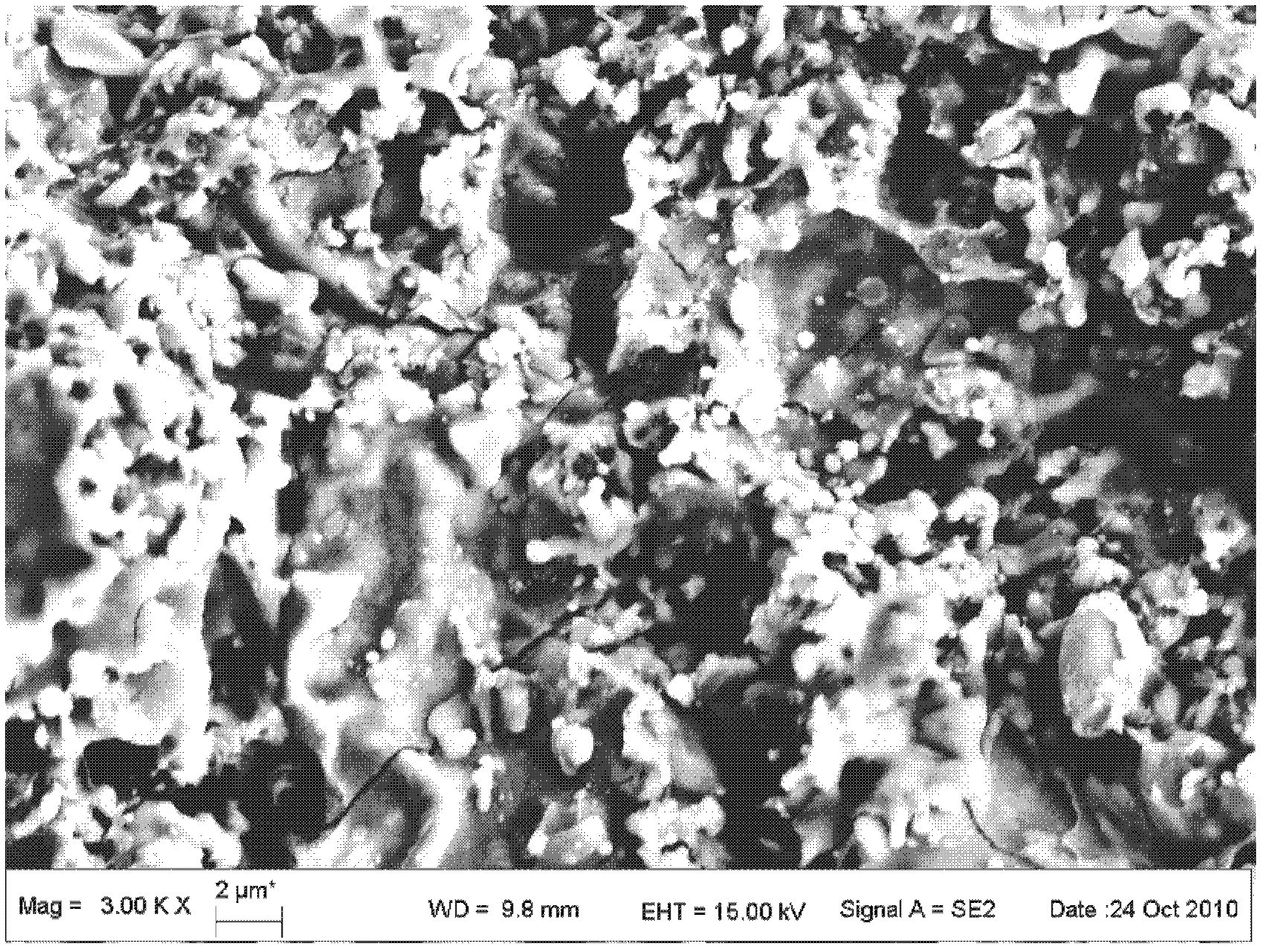

Solar photothermal conversion material and preparation method thereof

The invention discloses a solar photothermal conversion material and a preparation method thereof, wherein the method comprises the steps of: a light absorbing material, a water-soluble monomer, an initiator and a crosslinking agent are mixed and dispersed in water to obtain a reaction liquid; or the light absorbing material, a water-soluble polymer and the crosslinking agent are mixed and dispersed in the water to obtain a reaction liquid; the reaction liquid is adsorbed by a sponge, and gelatinized to obtain a hydrogel, and after several cycles of freeze-thawing, freeze-drying and dissolvingof the hydrogel in water until the hydrogel is saturated to swell, the solar photothermal conversion material is obtained. The porous property of a sponge material enhances the water absorption of the solar photothermal conversion material, and can solve the salt deposition problem, and the solar photothermal conversion material has self-cleaning property. In the solar photothermal conversion material, the light absorbing material ensures the light absorption of the solar photothermal conversion material, and the hydrogel material can reduce the latent heat required for evaporation of water,so that high photothermal conversion efficiency and high evaporation rate can be ensured.

Owner:SHENZHEN UNIV

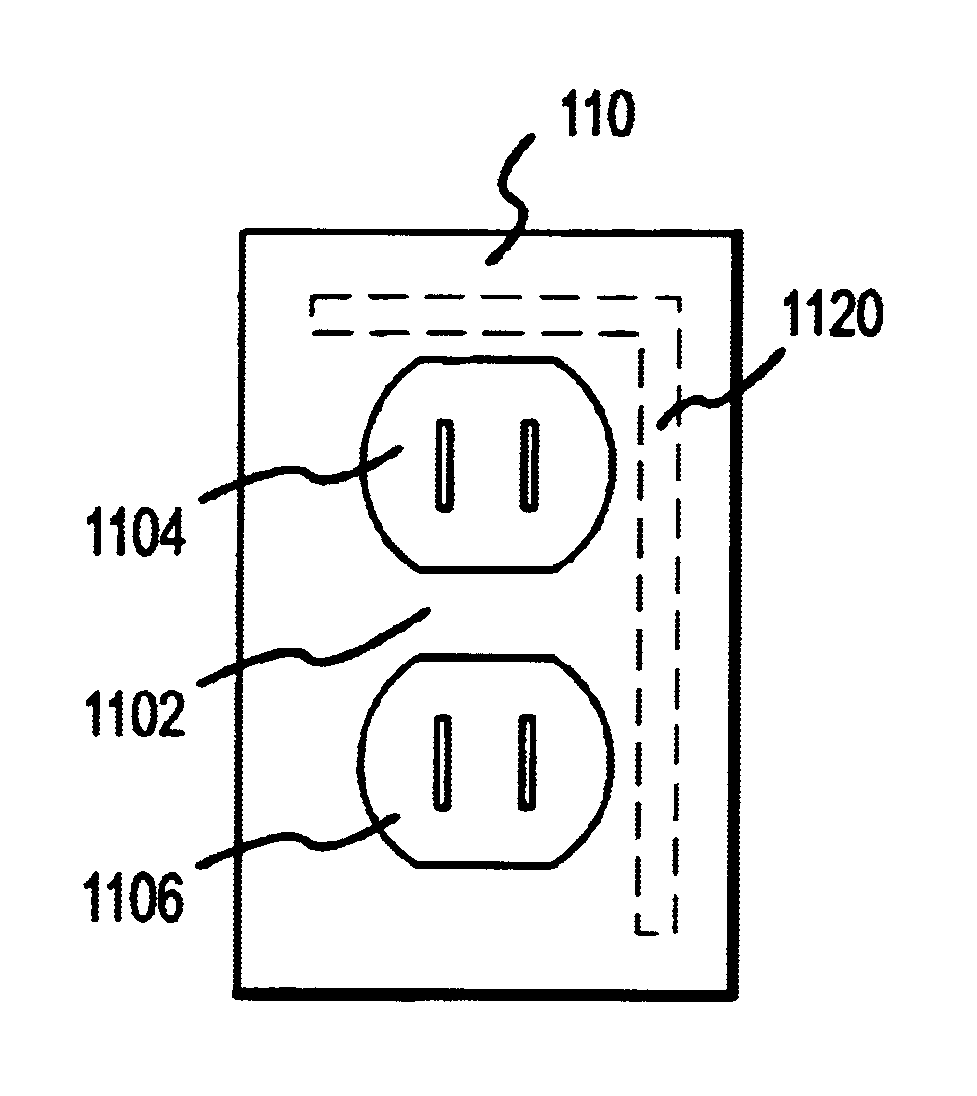

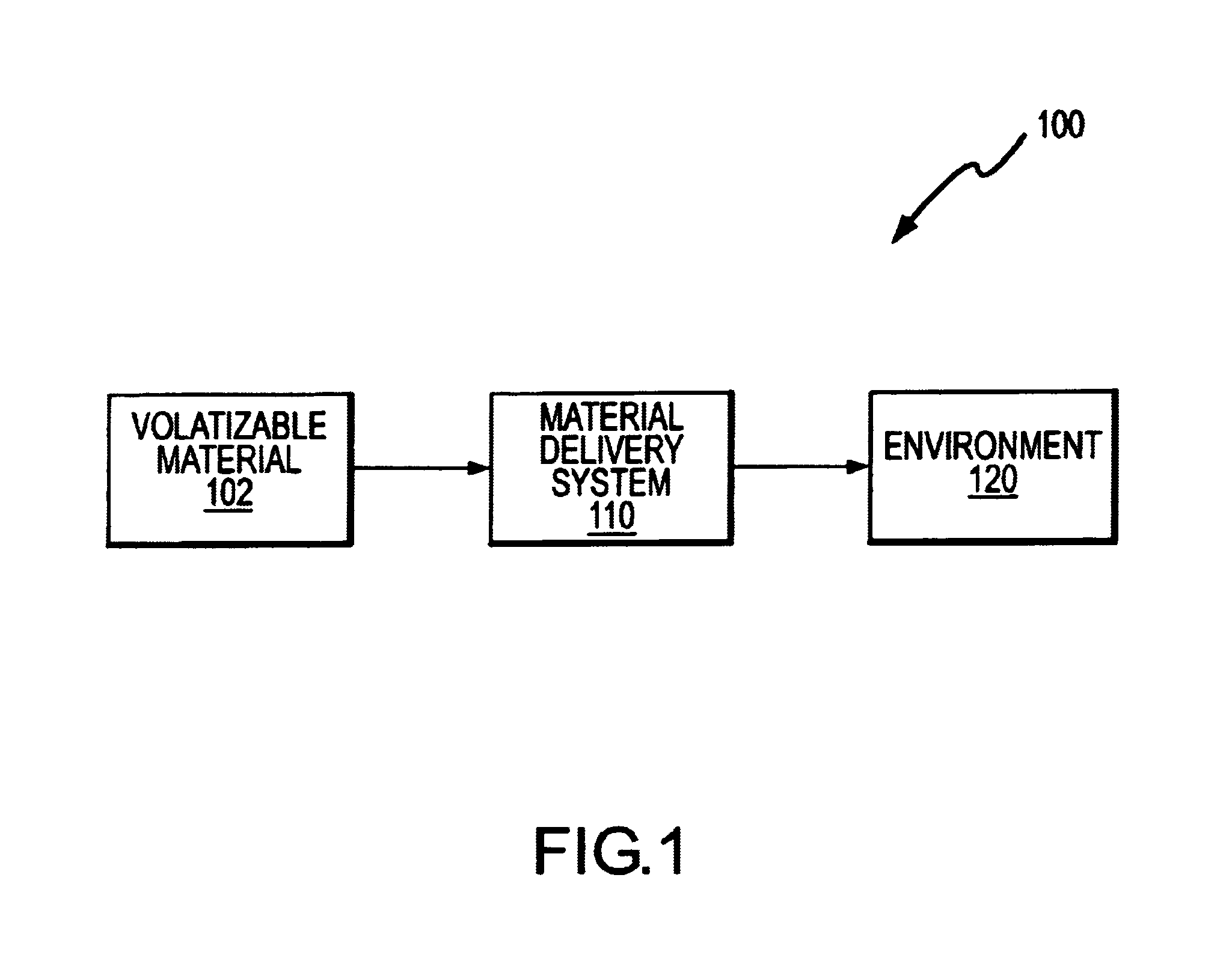

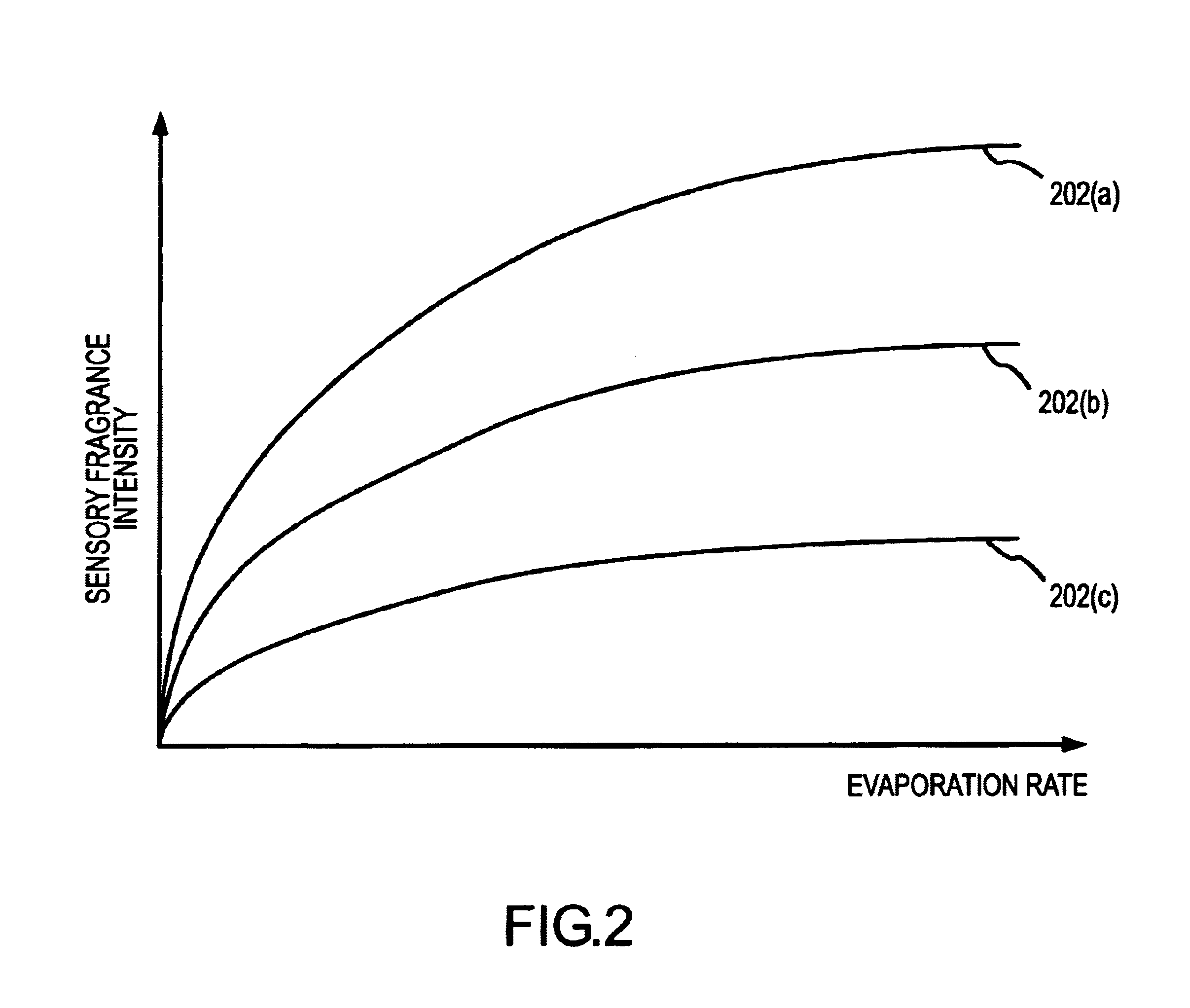

Methods and apparatus for a controllable vapor-dispensing device

A vapor-dispensing device exhibiting a range of evaporation rates corresponding to a discernable range of sensory fragrance intensity levels. The vapor-delivery device includes one or more control structure (e.g., a heat control, a vent control, and / or the like) configured to allow a user to specify the evaporation rate of the vapor-dispensing device over a continuous or discretized range of values. In accordance with another aspect of the invention, the two extremes of operation correspond to a range of sensory fragrance intensity values that span at least three minimum perceivable intensity zones.

Owner:DIAL CORPORATION

Carbon/carbon composite material ultrahigh temperature oxidation resistant coating and preparation method thereof

The invention discloses a carbon / carbon composite material ultrahigh temperature oxidation resistant coating. The coating comprises the following components, by volume, 40-60% of ZrB2, 15-25% of SiC, 15-20% of TaB2 and 10-15% of Sc2O3. In addition, the invention also provides a preparation method of the coating. According to the invention, TaB2 and Sc2O3 are added to make the melting point of an external layer oxidation product borosilicate glass be risen, the viscosity of the borosilicate glass be risen, the evaporation rate of the borosilicate glass be reduced, the oxygen dispersion coefficient of the borosilicate glass be reduced, an internal layer oxidation product ZrO2 phase be stable, the melting point of ZrO2 be risen, and the oxygen diffusion coefficient of ZrO2 be reduced, so thecoating can satisfy requirements of the ultrahigh temperature oxidation resistance of a carbon / carbon composite material, the coating can be sintered without applying a pressure through adding TaB2 and Sc2O3, the coating has the advantages of high combination strength, compactness, and good ultrahigh temperature mechanical property, and the preparation process has no damages to matrixes.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Energy-free refrigeration door and method for making the same

InactiveUS20110089802A1Reduce condensationBurdening the cooling systemShow cabinetsDomestic cooling apparatusElectricityLow emissivity

Owner:AGC FLAT GLASS NORTH AMERICA INC

Inks for use in membrane image transfer printing process

The present invention involves an ink for transferring a printed image from a membrane to a substrate. The ink comprises a hydrocarbon solvent, a synthetic resin, and a thixotrope for forming a thixotropic network in the ink. The hydrocarbon solvent has a predetermined evaporation rate and the thixotropic network of the ink has a thixotropic network magnitude of between about 3×104 and 6×105 dynes / cm2-sec−1 and a thixotropic network strength of at least about 35.0 gm-cm.

Owner:EXATEC LLC

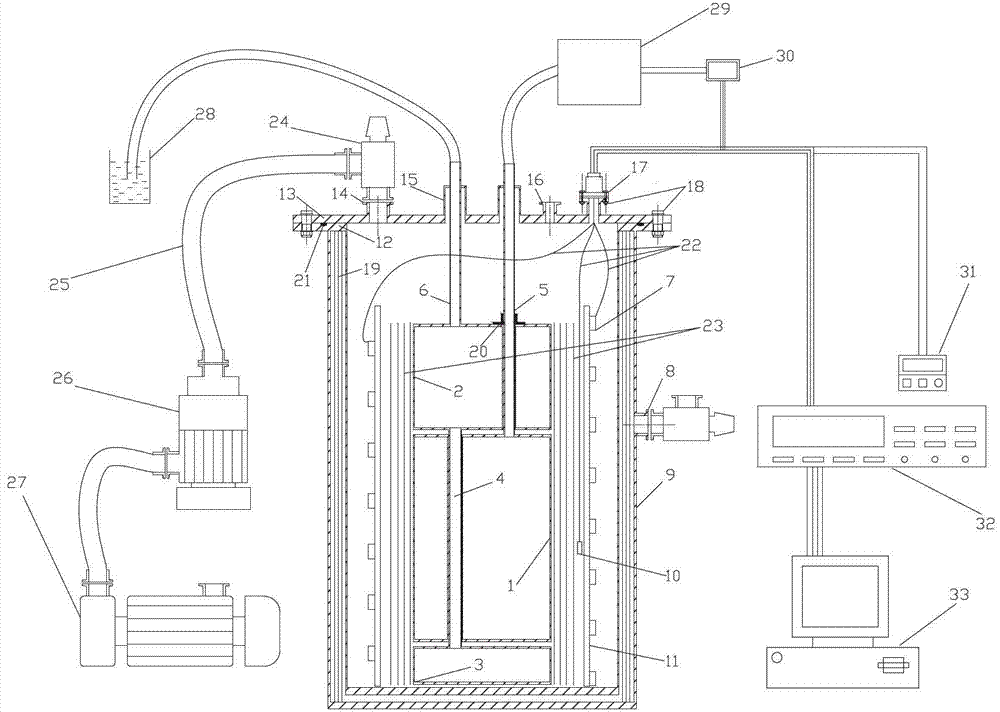

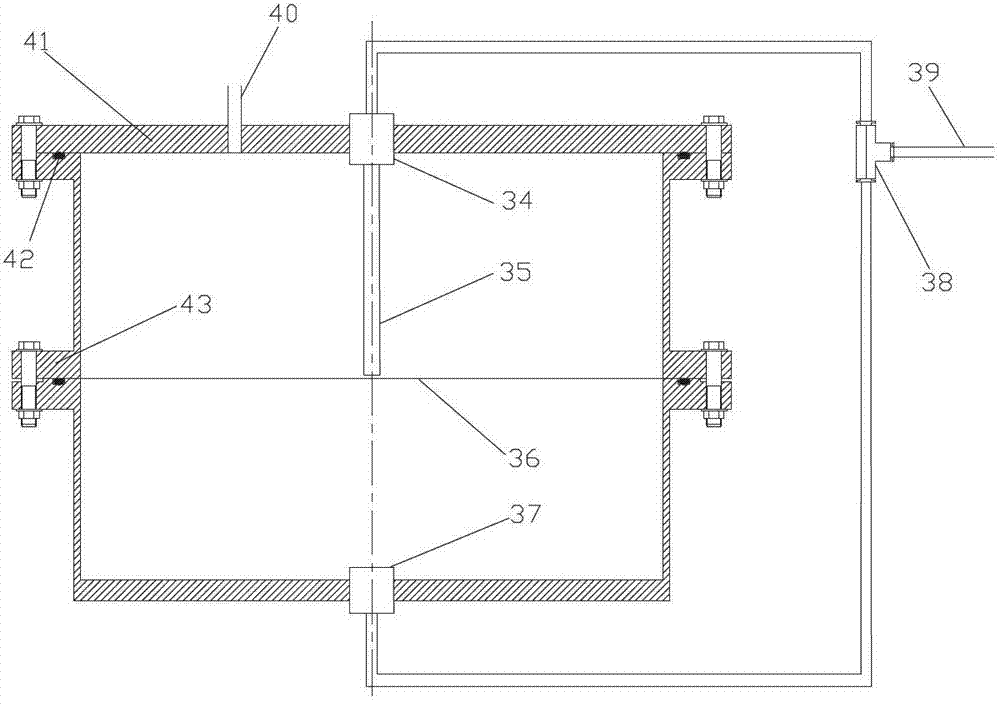

Device for testing performance of low-temperature vacuum multilayer heat-insulation material based on thermal protection

The invention discloses a device for testing performance of a low-temperature vacuum multilayer heat-insulation material based on thermal protection. The device comprises a vacuum outer cover, a blind plate end cover flange, an upper protective cavity, a testing cavity, a lower protective cavity, a back pressure stabilizing device, a controllable electric heating system, a temperature and flow-rate sensing system, a liquid nitrogen filling system, a data collecting-processing system and a vacuum pumping system, wherein the upper protective cavity and the lower protective cavity are used for insulating heat leakage in the vertical direction and connected with the blind plate end cover flange of the vacuum outer cover through thin-wall steel tubes; the testing cavity is connected with the blind plate end cover flange through the same thin-wall steel tube structure as the protective cavities. An insulating material testing sample of the device can be replaced at will, the temperature distribution inside the insulating material and the evaporation rate of stored liquid under different thermal boundary temperature conditions can be measured, and the heat leakage percentage and the material apparent thermal conductivity can be further obtained by the evaporation rate.

Owner:SHANGHAI JIAO TONG UNIV

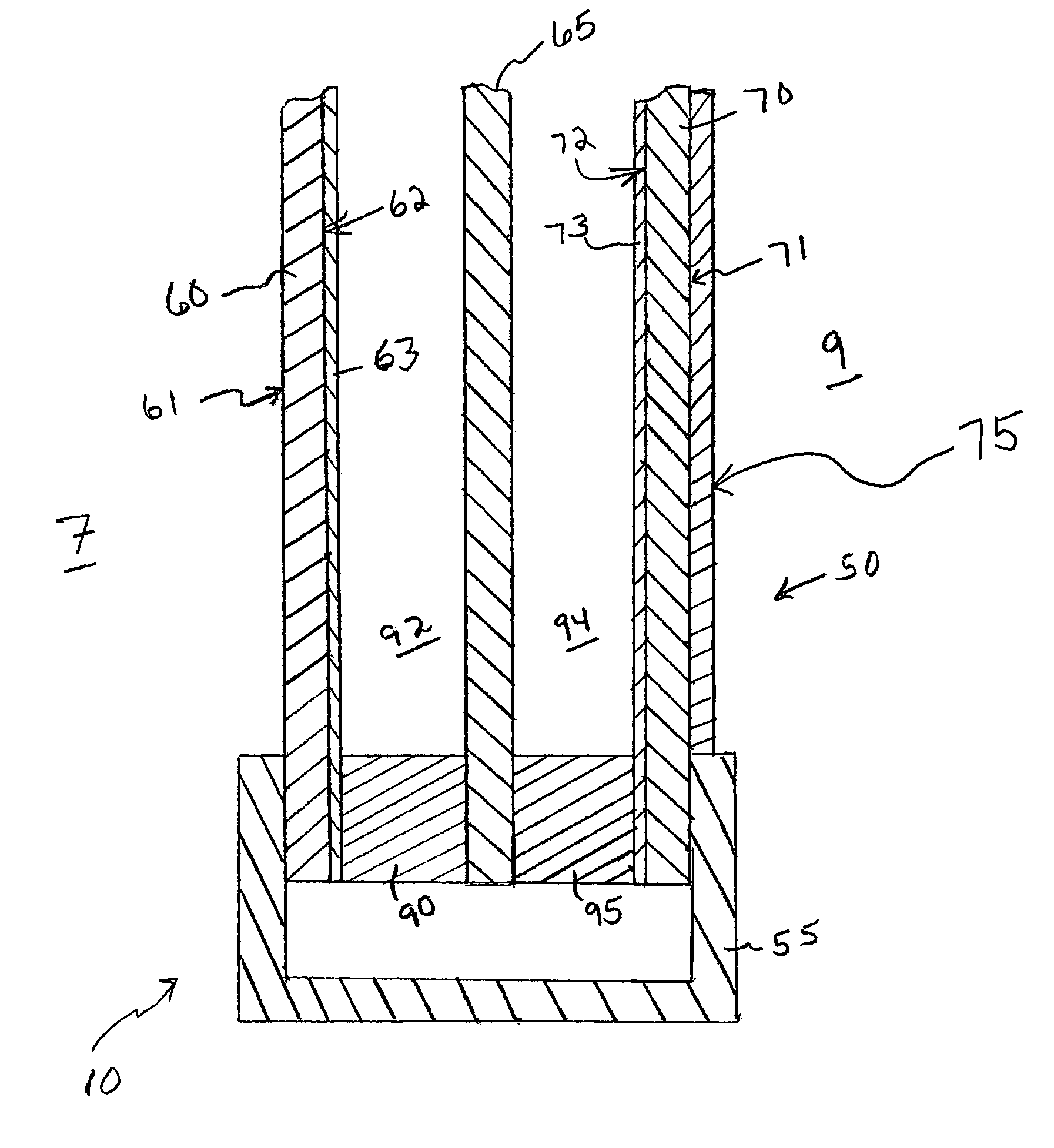

Anti-fog refrigeration door and method of making the same

InactiveUS7891154B2Burdening the cooling systemEasy and economical to manufacture and operate and maintainShow cabinetsRailway roofsElectricityFrost

The energy-free refrigeration door of the present application provides a way to control condensation when the door of a refrigeration unit is opened by providing thermal insulation to the door with glass panels which have a low emissivity coating. The door includes a door frame housing and an insulating glass unit comprising inner, middle and outer sheets of glass. A first sealant assembly disposed around the periphery of the inner and middle sheets of glass forms a first chamber between the inner and middle sheets of glass. A second sealant assembly disposed around the periphery of the middle and outer sheets of glass forms a second chamber between the middle and outer sheets of glass. A gas, such as krypton, air, or argon is held in the first and second chambers. The outer sheet of glass and inner sheet of glass each have an unexposed surface that faces the middle sheet of glass. A low emissivity coating is disposed on the unexposed surfaces of the inner and outer sheets of glass so that the glass door as a whole avoids formation of condensation on the outer surface of the outer sheet of the glass door, without the application of electricity to heat the door, while also providing the desired evaporation rate of condensation from the inner side of the inner sheet of the glass door. An anti-fog or anti-frost coating is included on a surface of one of the sheets of glass.

Owner:AGC FLAT GLASS NORTH AMERICA INC

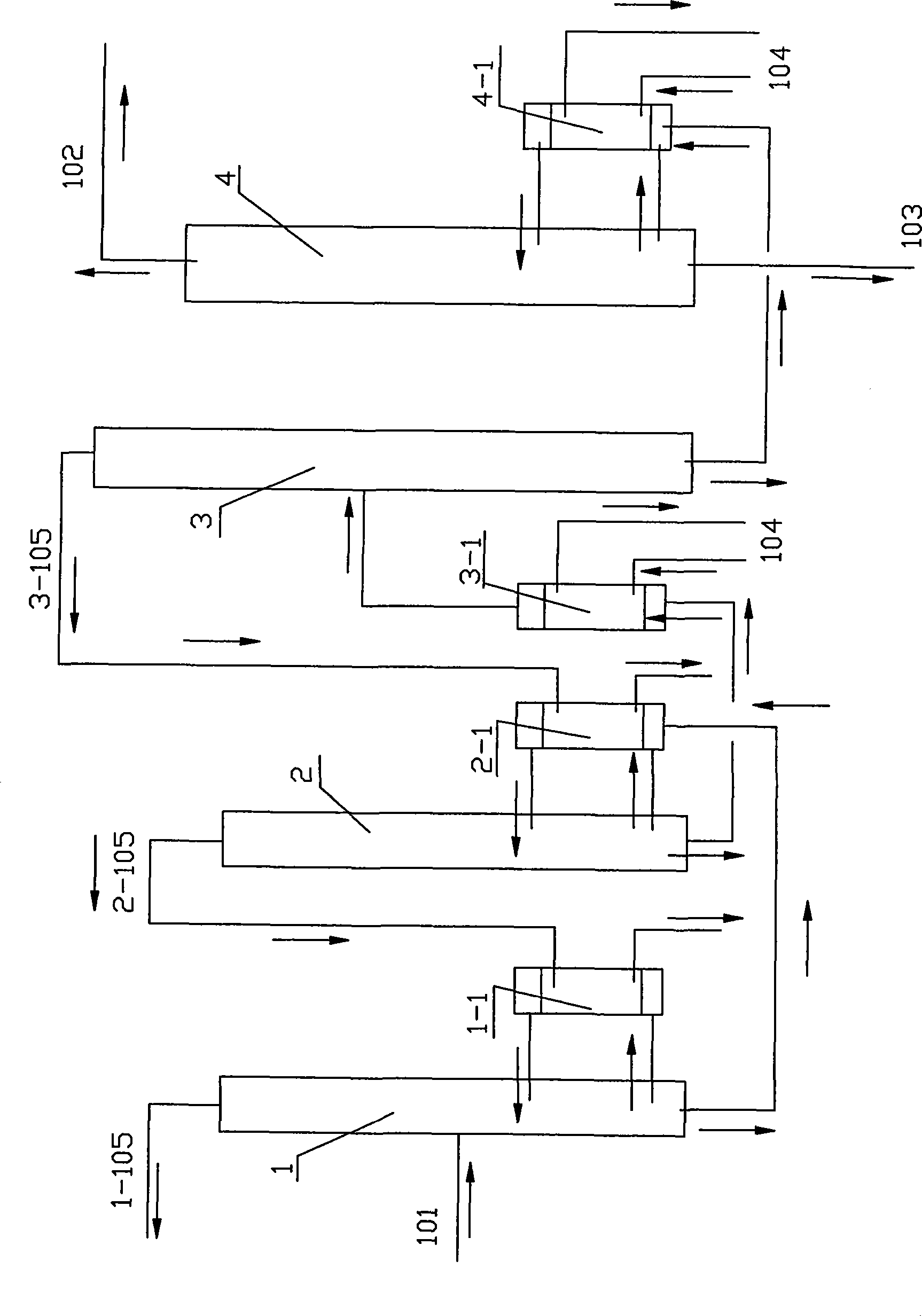

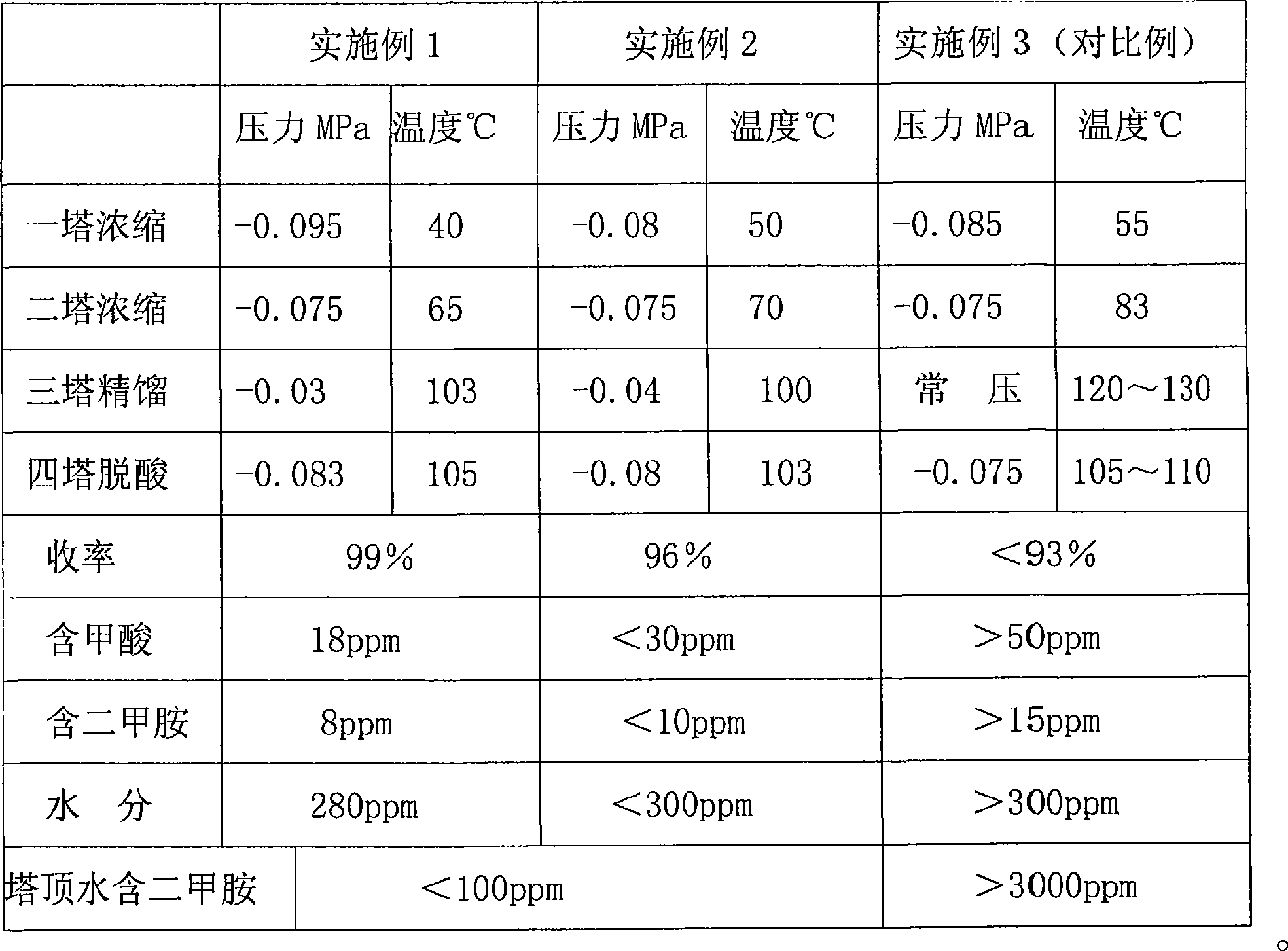

Method for recovering dimethyl formamide

ActiveCN101519362AReduce decomposition rateReduce return steam rateCarboxylic acid amide separation/purificationMultistage water/sewage treatmentDecompositionWastewater

A method for recycling dimethyl formamide relates to a method for recovering dimethyl formamide from waste water by an all-subpressure operation method. The method includes the steps of utilizing conduction oil or low-pressure steam as a heat source, sequentially leading the waste water containing DMF to four subpressure operation towers, and performing subpressure concentration in the first tower and the second tower, subpressure fractionating in the third tower and deacidification in the fourth tower, thereby obtaining finished DMF and methanoic acid. Due to the great decrease of stable operating temperature, the recovery rate of the DMF can reach over 99 percent, and the rate of purity reaches 99.99 percent; the resolution ratio of the DMF and the back evaporation rate of the peracid DMF are obviously reduced, a methanoic acid decomposition tower is cancelled, almost no DMF contains peracid, repeated rectification is not needed, and energy sources are saved by over 10 percent; and meanwhile, the dimethylamine quantity generated by decomposition is little and is completely absorbed by a boiler screen dust collection system without emission.

Owner:HUALUN LEATHER & PLASTIC SUZHOU

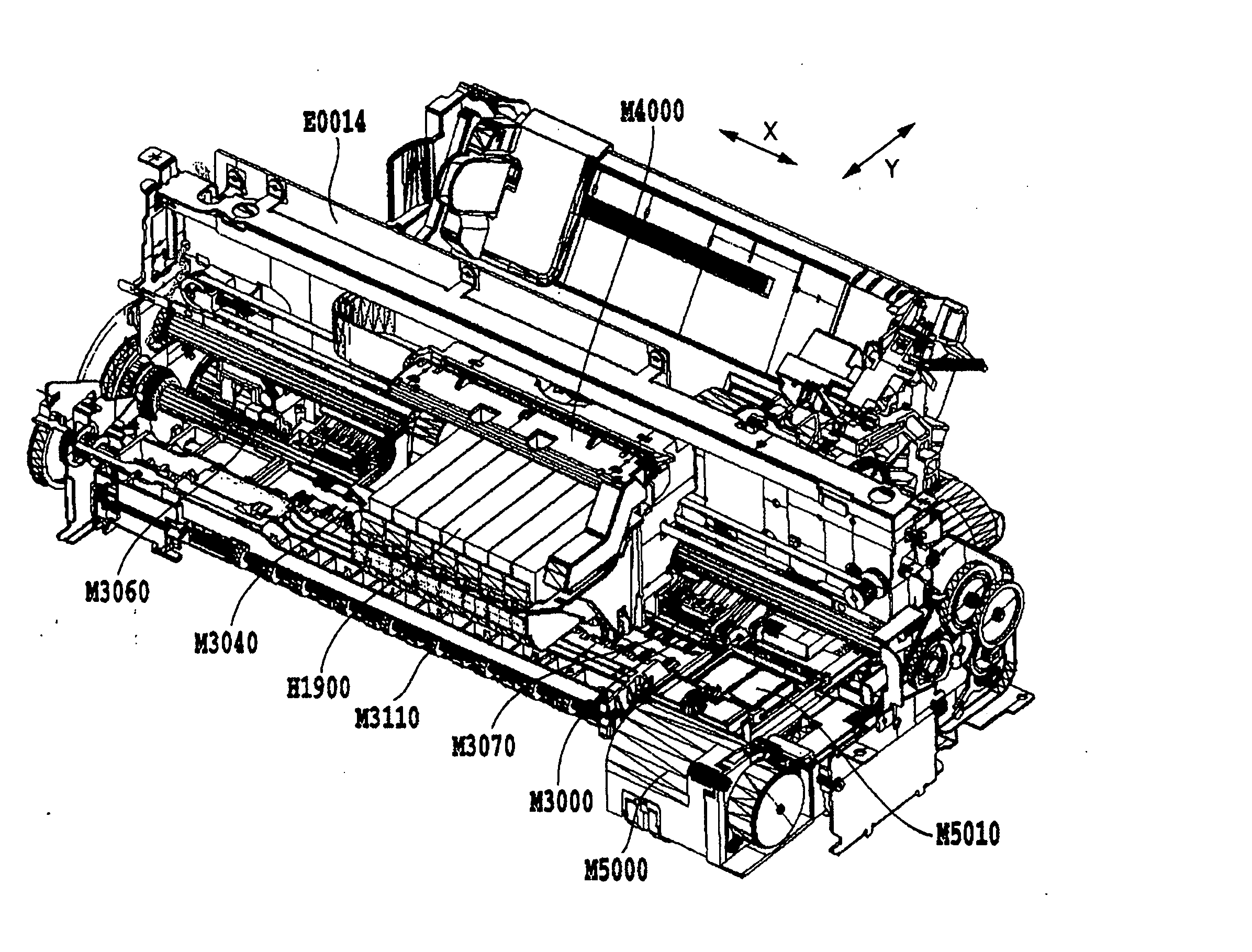

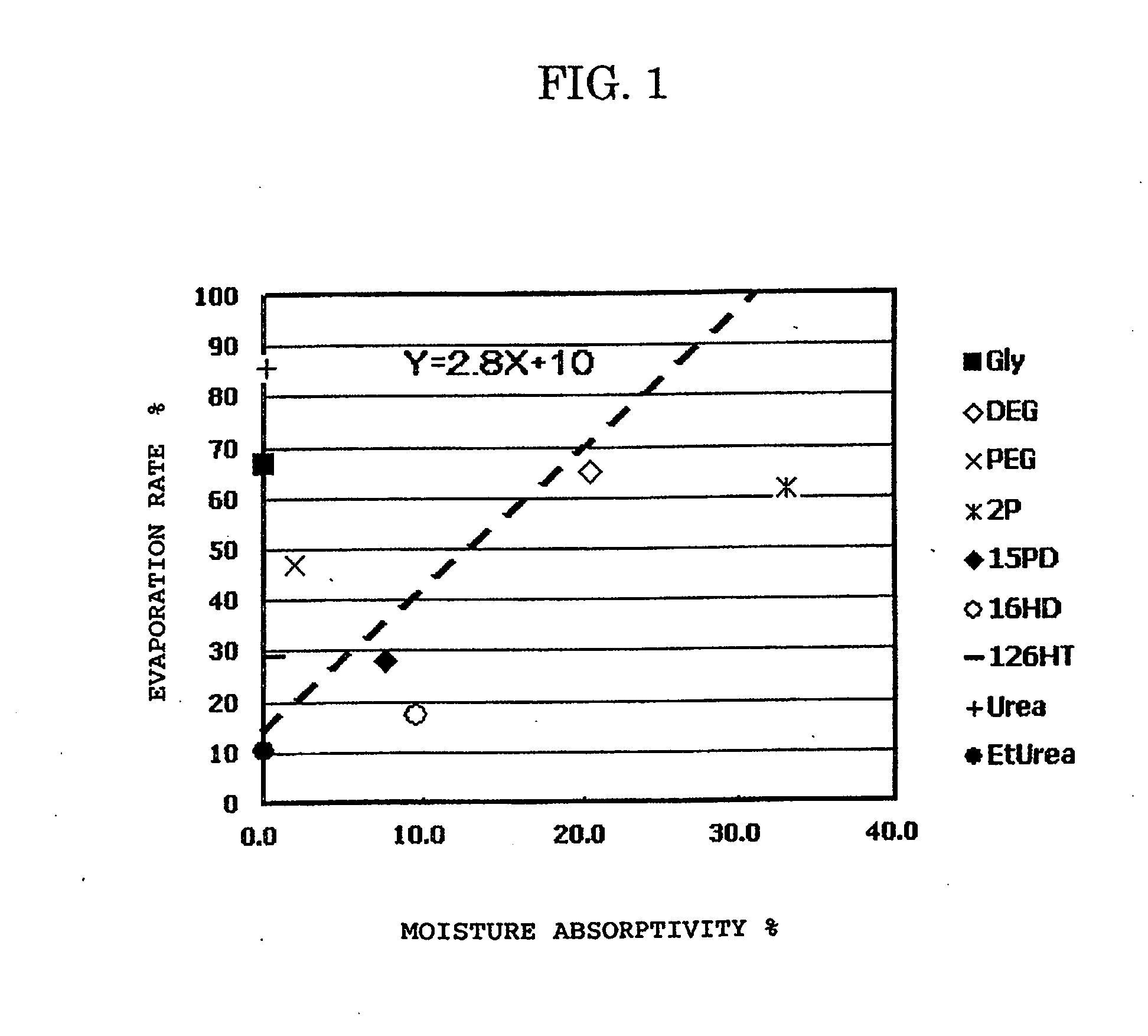

Ink, ink jet recording method, recording unit, ink cartridge, and ink jet recording apparatus

InactiveUS20060103705A1Improve moisture resistanceSatisfies color developabilityMeasurement apparatus componentsDuplicating/marking methodsOrganic solventWater soluble

An ink jet ink contains at least a coloring material and a specific water-soluble organic solvent and has both excellent color developability and excellent humidity resistance. The coloring material exhibits a small (9 or less) color difference ΔE value which is determined by a method including a series of specific steps and is represented as the square root of (L1-L2)2+(a1-a2)2+(b1-b2)2. The specific water-soluble organic solvent has an evaporation rate X smaller than that of water and a moisture absorptivity Y, the values of X and Y satisfying the relation of Y≦2.8X+10. The content of the specific water-soluble organic solvent is 50 mass % or more of the total amount of water-soluble organic solvents contained in the ink.

Owner:CANON KK

Medium for a color changer

A flexible medium for a scrolling color changer and method of making thereof. The medium is made by applying an ink using a Meyer Rod which has varying cell lengths along its length. This leaves varying size cells of ink at different locations along the length of the medium. The ink has special characteristics whereby its evaporation rate and viscosity are carefully controlled. The viscosity is such that an amount of levelling will occur will be equal to the distance between any cells, but that cell to cell levelling will not, in general, occur.

Owner:PRODN RESOURCE GROUP L L C

Produced water disposal method

A method and apparatus useful for disposing of the high volumes of produced water associated with coal bed methane natural gas wells. The method taught is to create steam from the produced water and vent the steam into the atmosphere. The apparatus taught utilizes the available natural gas sources as heat energy sources to produce heat for enhancing water evaporation rates and may incorporate a pre-heater system and / or a mineral separation system.

Owner:WALKER WELDON EUGENE

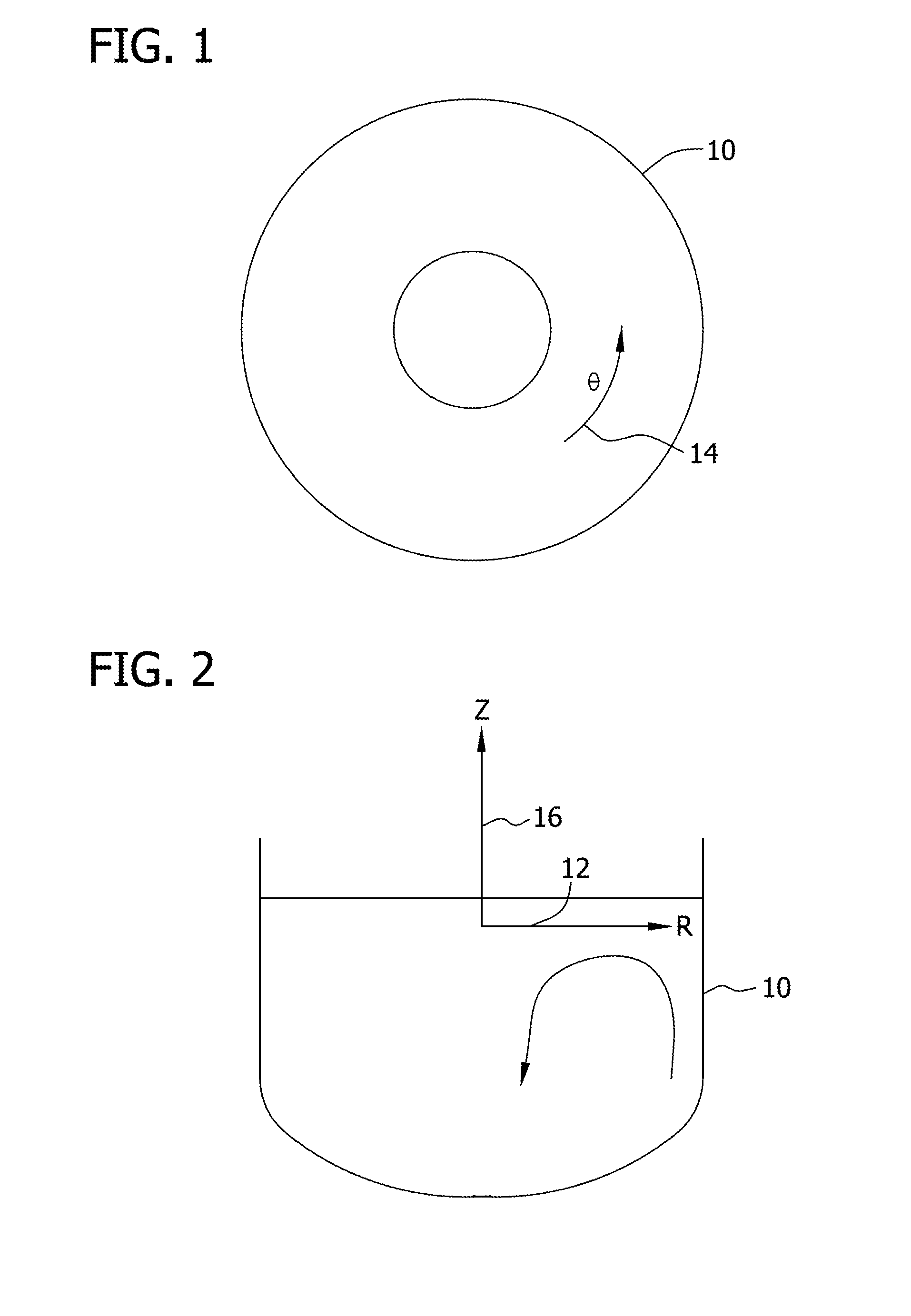

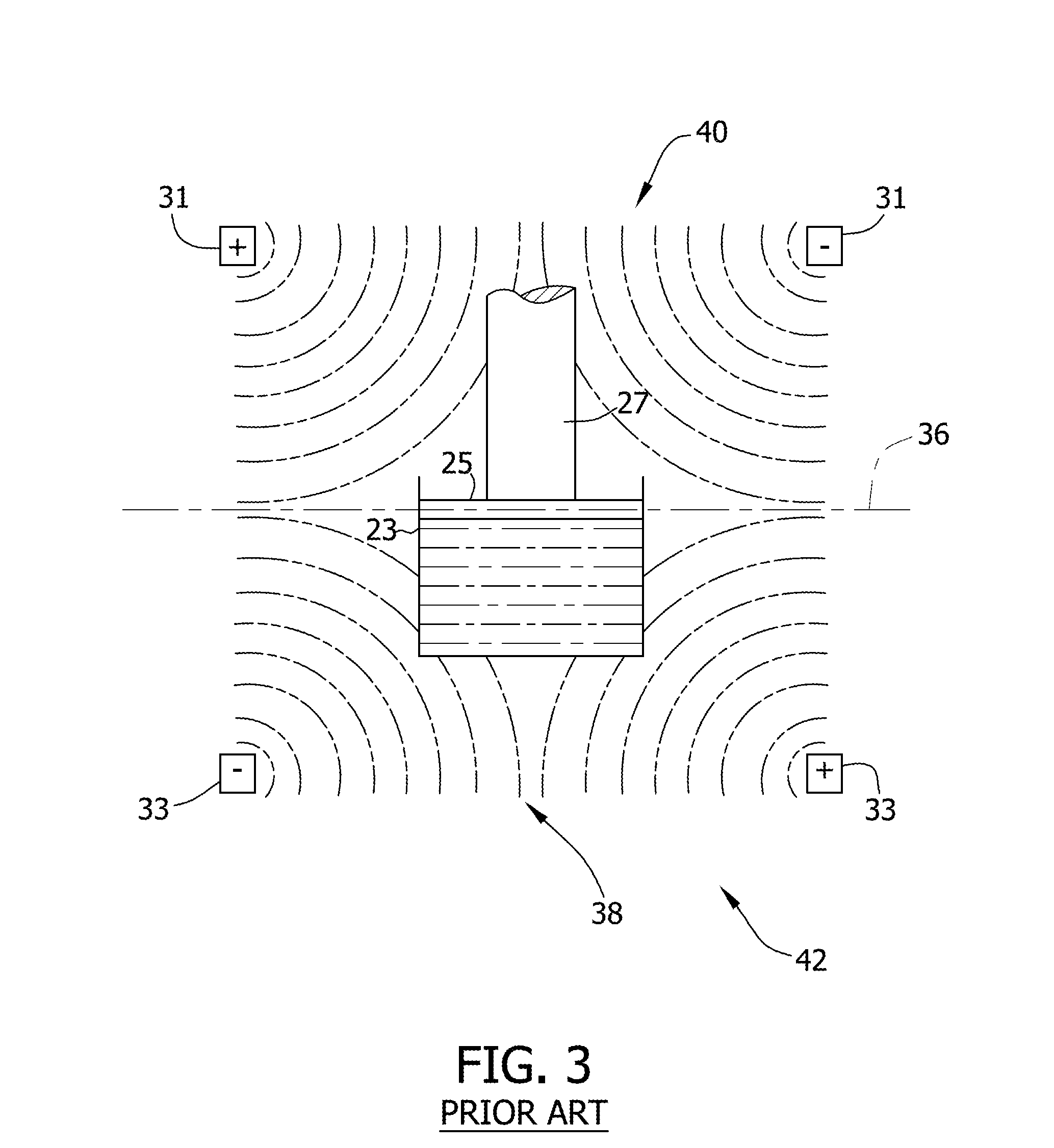

Methods for producing low oxygen silicon ingots

An method for producing a silicon ingot includes melting polycrystalline silicon in a crucible enclosed in a vacuum chamber to form a melt, generating a cusped magnetic field within the vacuum chamber, dipping a seed crystal into the melt, withdrawing the seed crystal from the melt to pull a single crystal that forms the silicon ingot, wherein the silicon ingot has a diameter greater than about 150 millimeters (mm), and simultaneously regulating a plurality of process parameters such that the silicon ingot has an oxygen concentration less than about 5 parts per million atoms (ppma). The plurality of process parameters include a wall temperature of the crucible, a transport of silicon monoxide (SiO) from the crucible to the single crystal, and an evaporation rate of SiO from the melt.

Owner:GLOBALWAFERS CO LTD

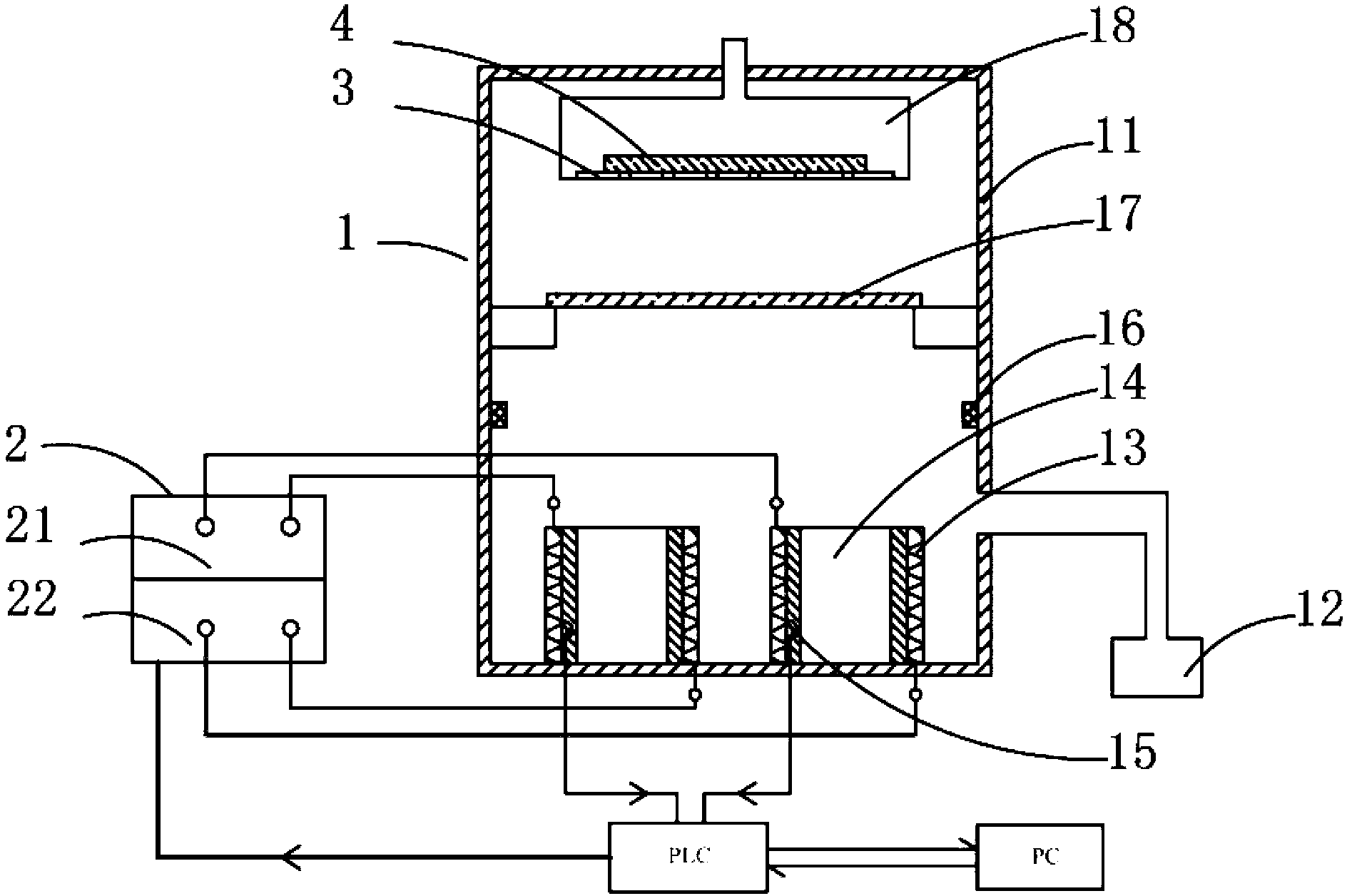

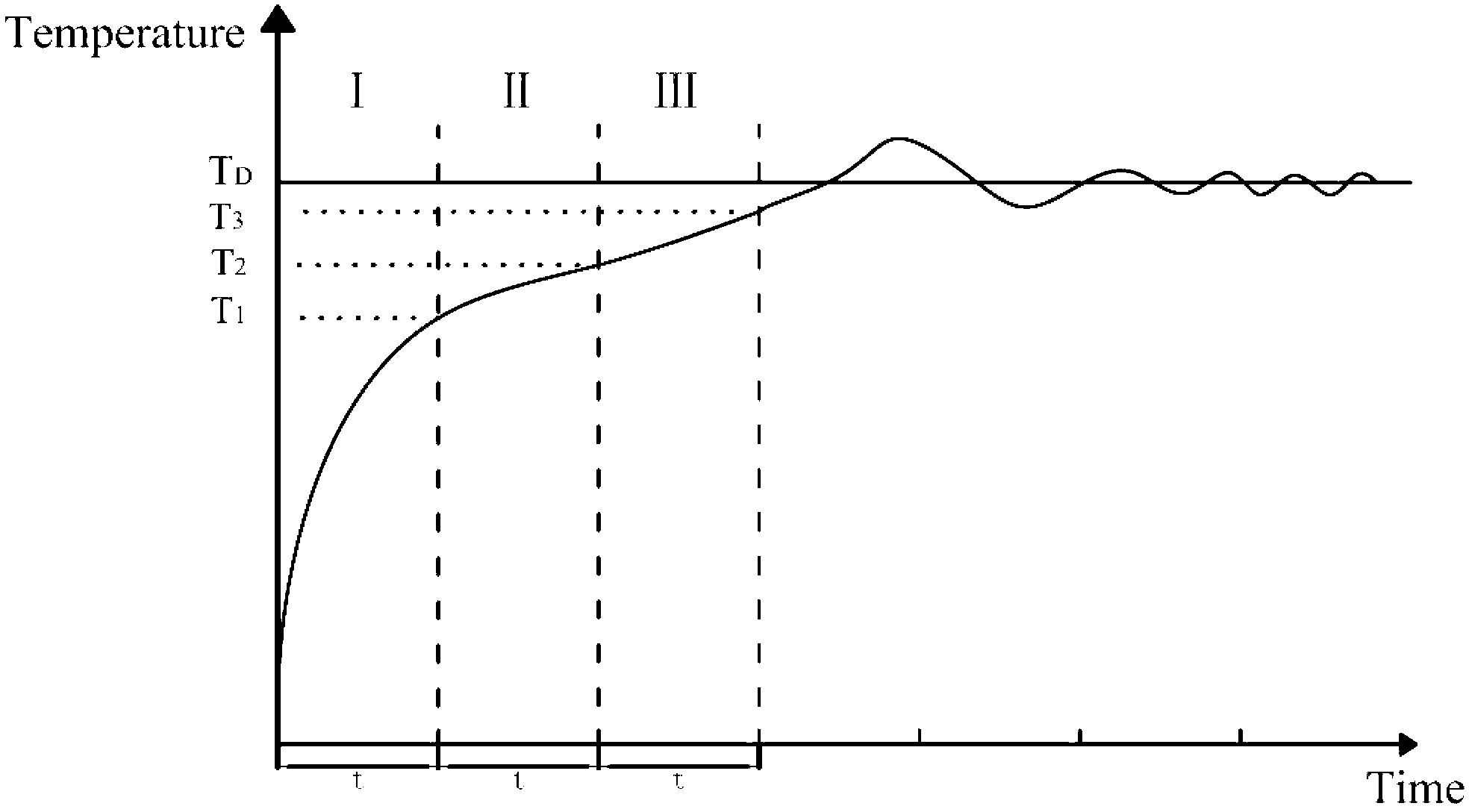

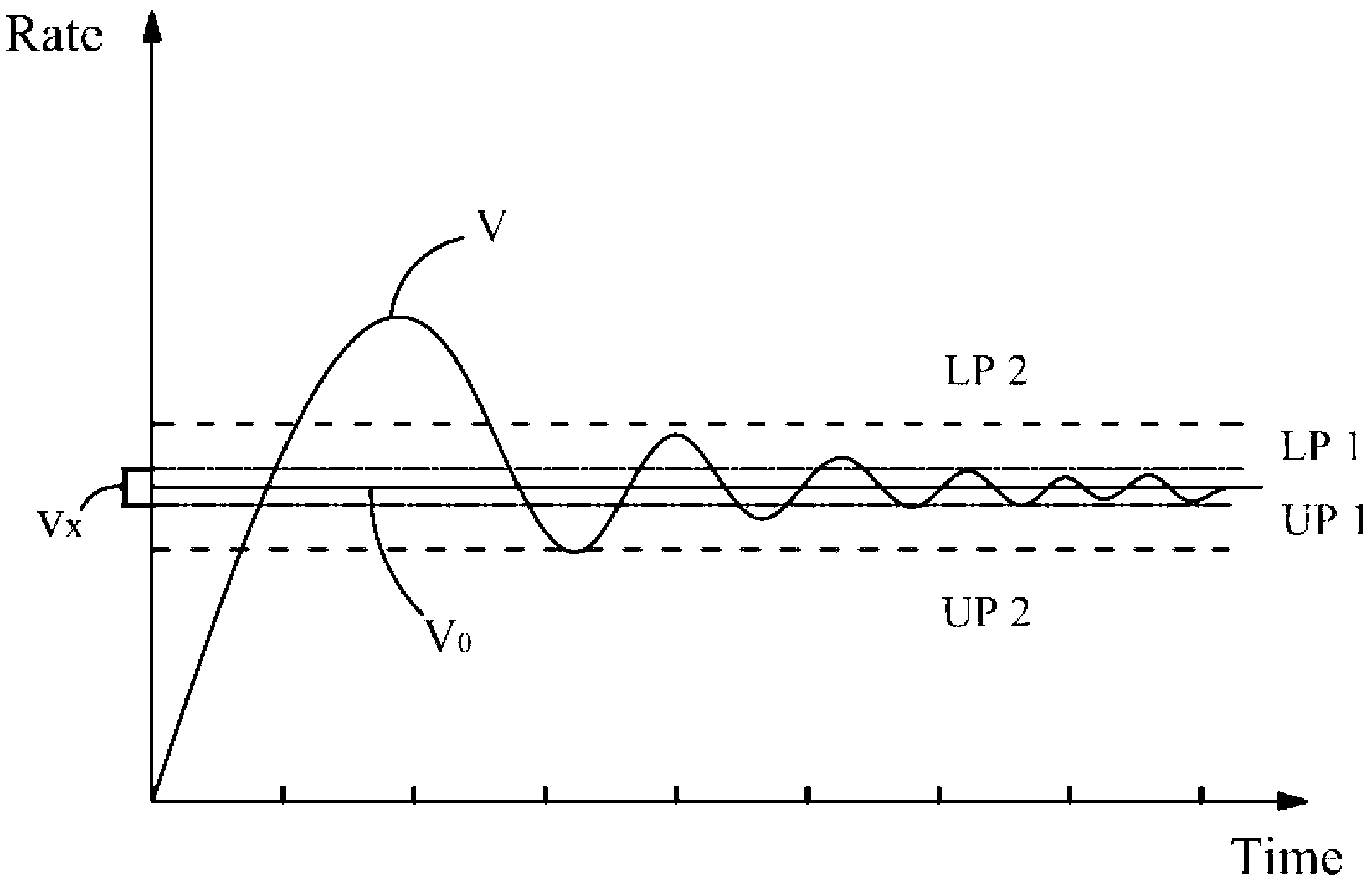

Temperature control system-based evaporation temperature control method for OLED (Organic Light Emitting Diode) organic layer

InactiveCN103305803AIncrease profitImprove uniformityVacuum evaporation coatingSolid-state devicesTemperature controlControl system

The invention discloses a temperature control system-based evaporation temperature control method for an OLED (Organic Light Emitting Diode) organic layer. The evaporation temperature control method comprises a preheating process and an evaporation process, wherein the preheating process is divided into three temperature-rise processes with temperature gradients; the evaporation process comprises a step of controlling the temperature of an evaporation source by controlling the power of an evaporation power supply on the basis of an actually-measured deposition rate curve. According to the temperature control system-based evaporation temperature control method for the OLED organic layer, the stabilization time of the temperature of the evaporation source and the deposition rate is shortened, the use ratios of the organic materials of the evaporation source are improved, meanwhile, the degradation, the degeneration and the like of the organic materials caused when the temperature rise is too fast or the risen temperature is too high are avoided, and the production cost is lowered; by utilizing a characteristic that the evaporation rate is changed by 20-30% when the evaporation temperature is changed by 1%, the accuracy of the temperature control is improved, the stability of evaporation temperature is maintained, and the uniformity of evaporated films is improved.

Owner:SICHUAN CCO DISPLAY TECH

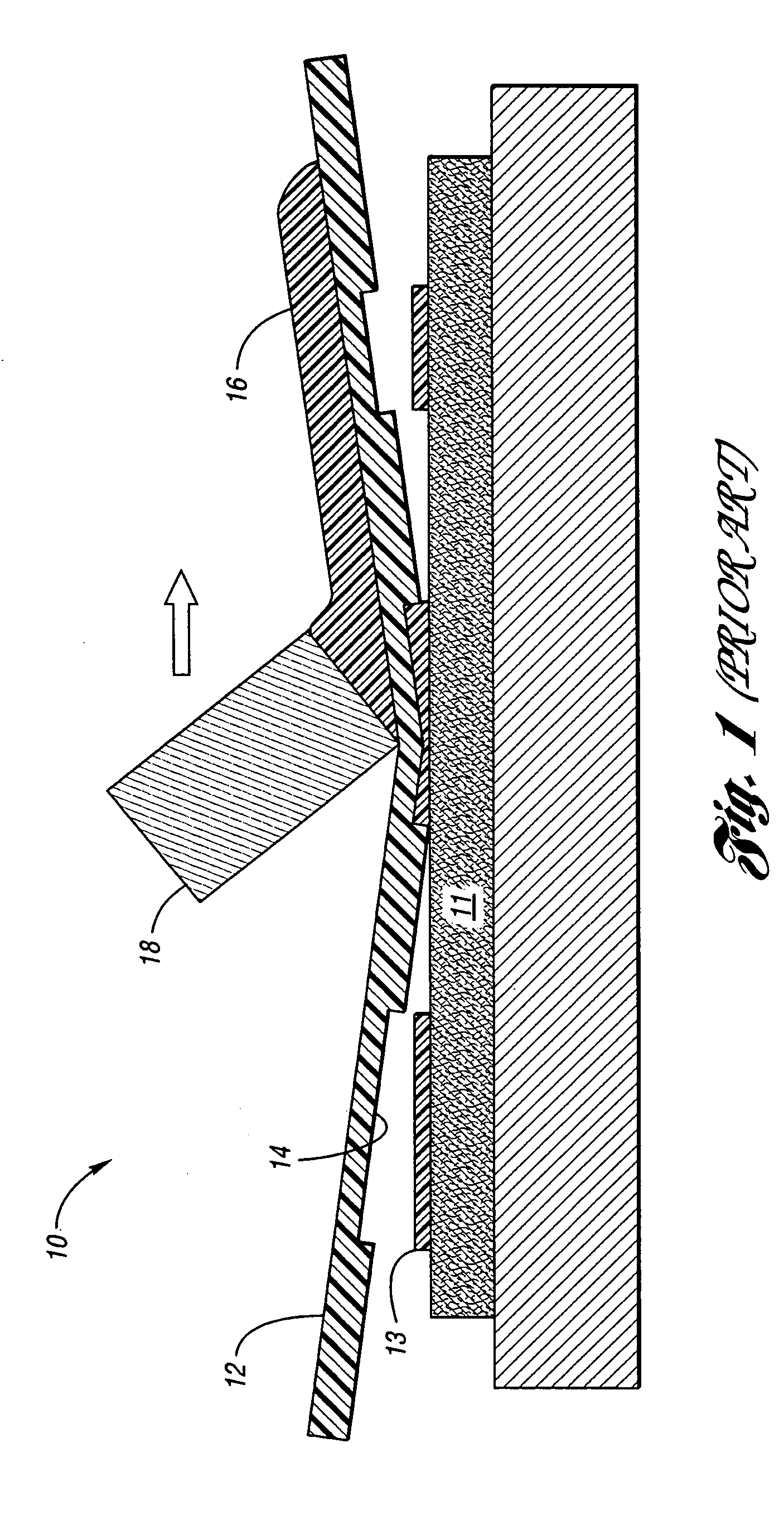

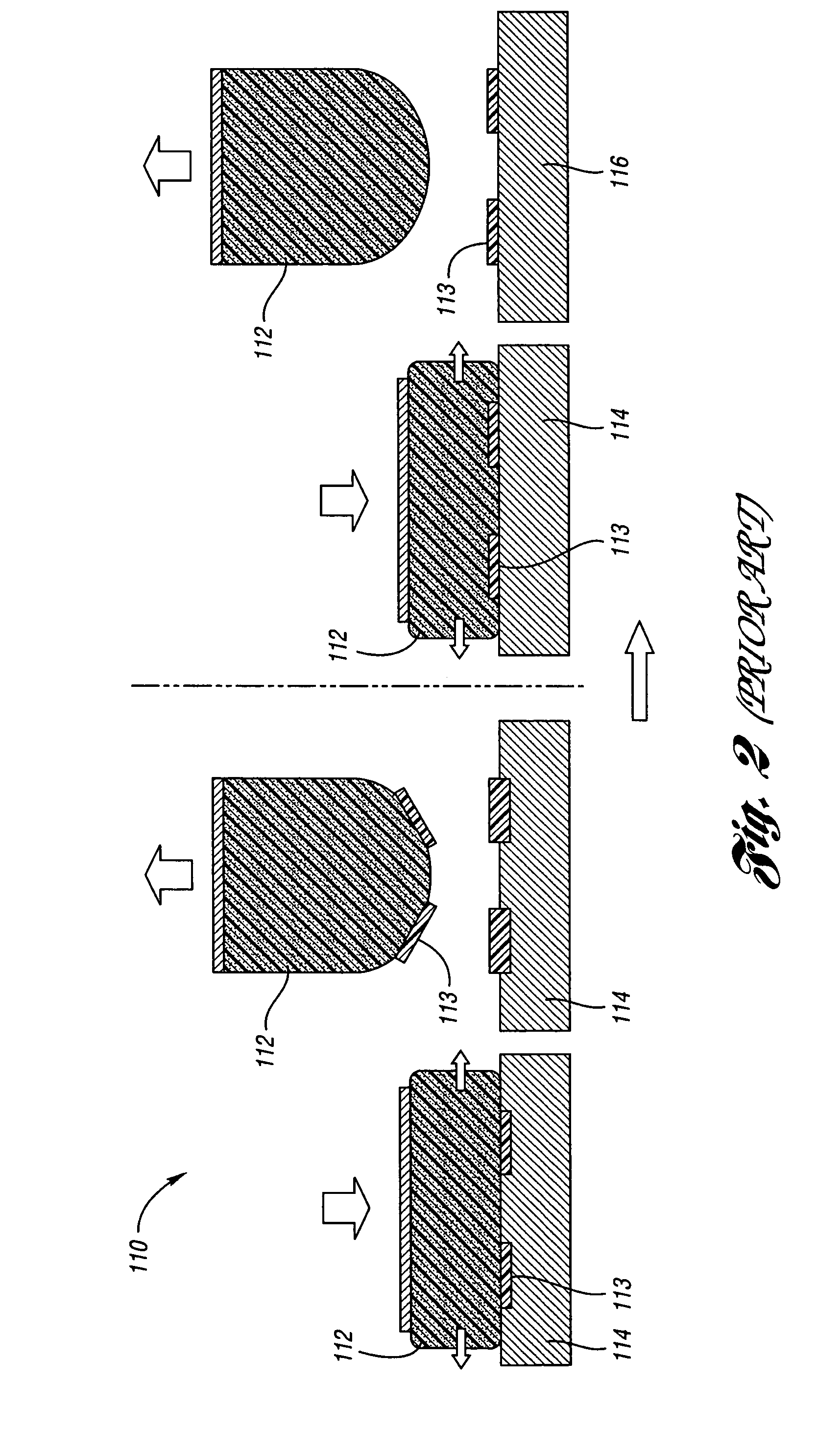

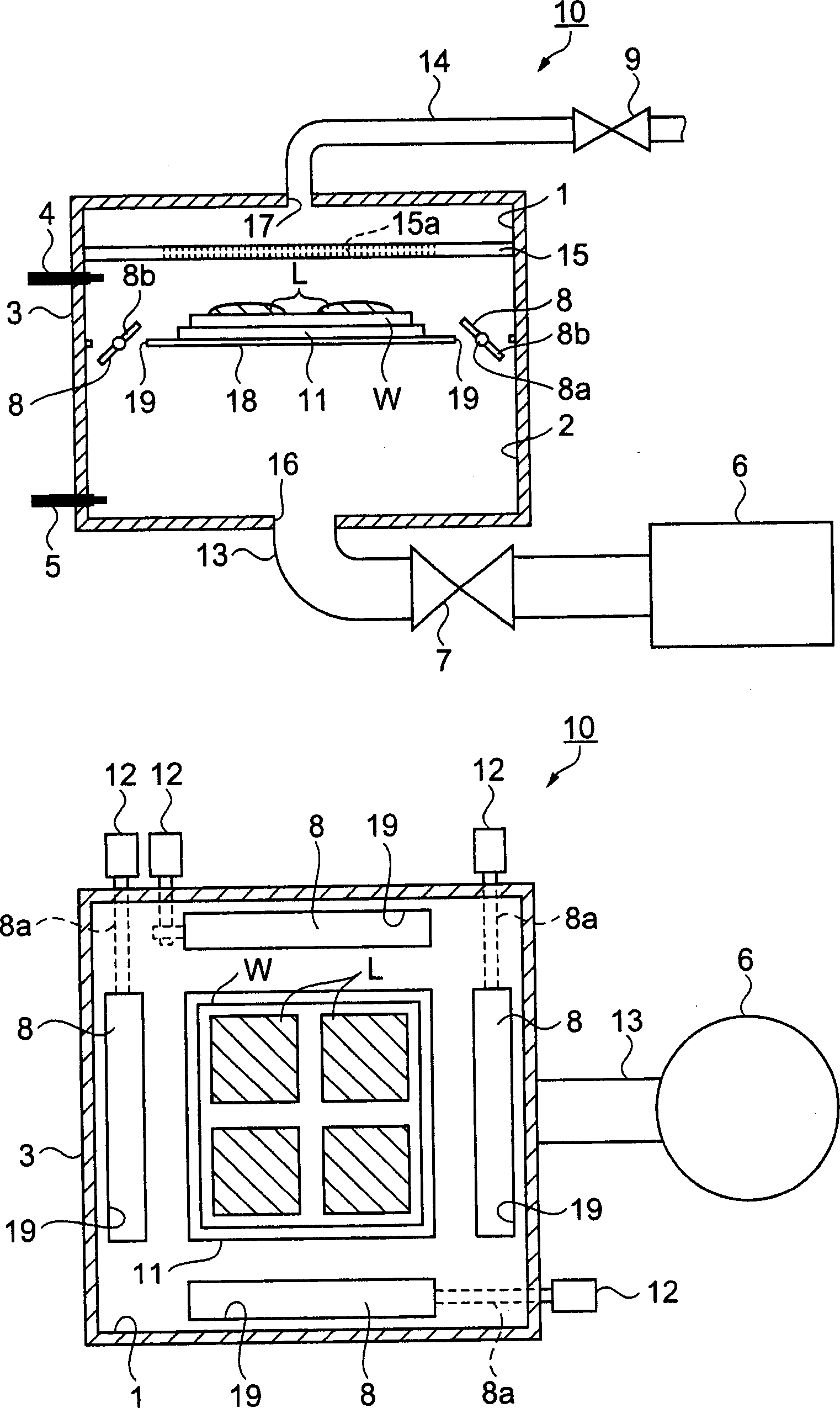

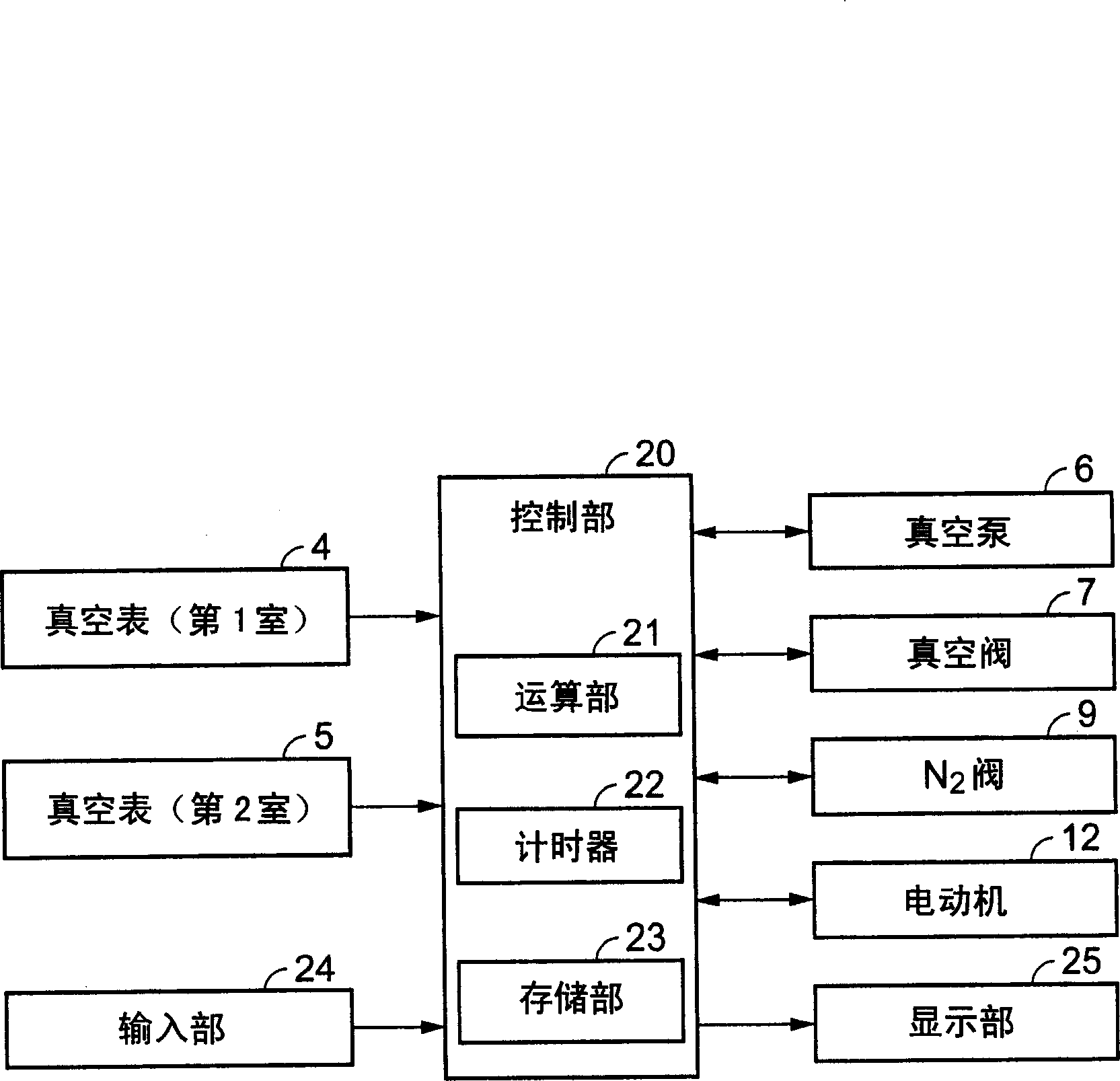

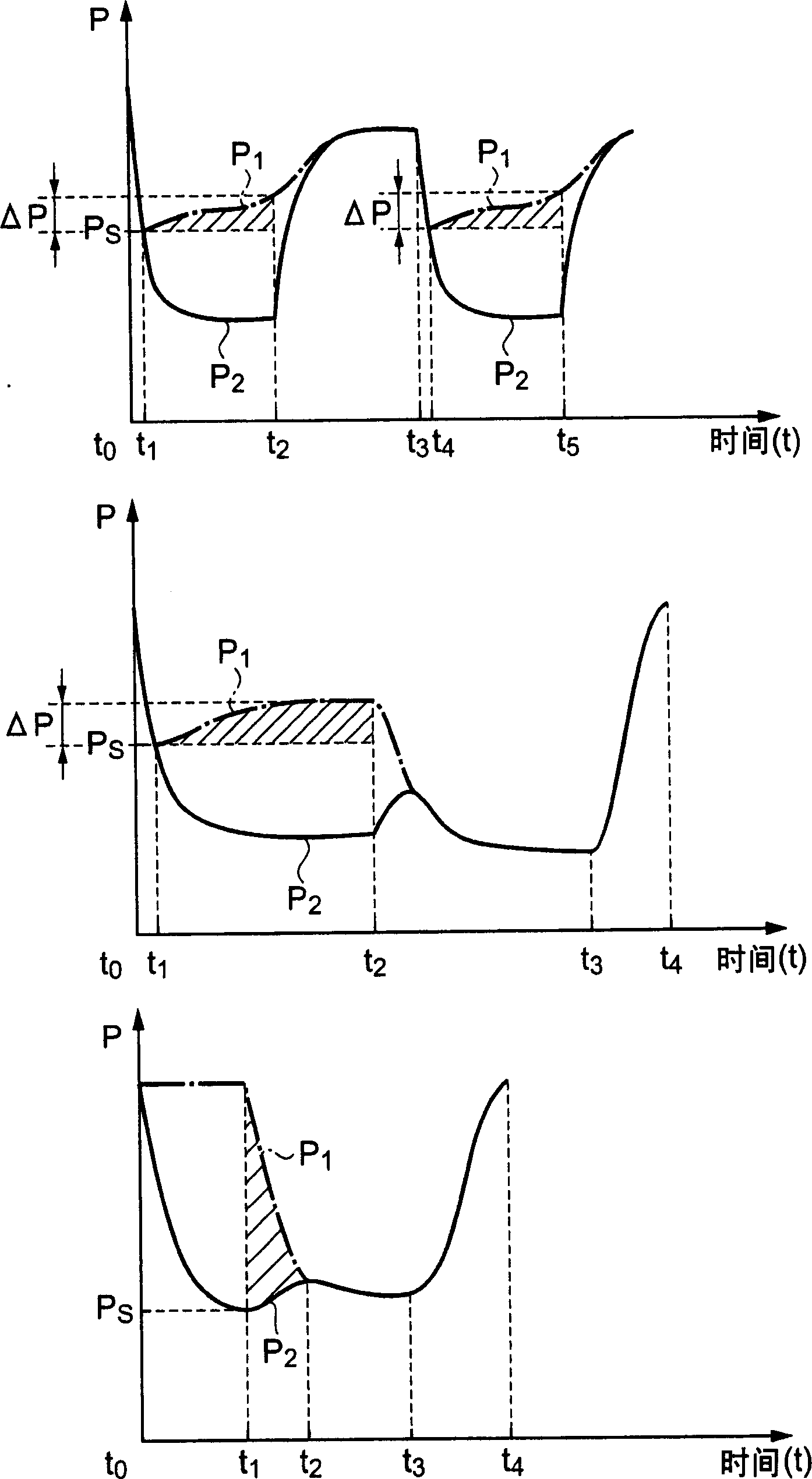

Reduced-pressure drying apparatus

A decompression drier (10) is provided with a chamber (3) housing a substrate W applied with the liquid (L) and placed on a mounting block (11), and having a first chamber (1) and a second chamber (2), and a vacuum pump (6) used as a decompressing means provided in a state capable of decompressing the second chamber (2). It is provided with a communication port (19) used as a communication part provided in a bulkhead part (18) separating the first chamber (1) and the second chamber (2), and a communication valve (8) capable of opening and closing the communication port (19); a control part provided for controlling driving of the vacuum pump (6), and opening and closing of the communication valve (8), and vacuum gauges (4, 5) provided for detecting respective pressures of the first chamber (1) and the second chamber 2. The volume of the second chamber 2 is set such that it is larger than the volume of the first chamber 1. The decompression drier capable of optimizing an evaporation rate of an applied liquid solvent in response to the type of the liquid in a drying process, and capable of carrying out drying under reduced pressure with distribution of vapor pressure of the solvent held in a substantially even state.

Owner:SEIKO EPSON CORP

Hydrophilic fouling-release coatings and uses thereof

InactiveUS20070258940A1Improve toughnessBiocideAntifouling/underwater paintsCelluloseHydrophilic coating

The present invention provides a process for obtaining a non-toxic coating suitable for preventing attachment of fouling organisms on marine structures which involves applying onto a substrate a coating composition and curing the coating composition to yield a water-insoluble hydrophilic coating wherein the coating composition includes at least one cellulose ester and at least one organic solvent which possesses a sufficiently slow evaporation rate in order to yield a coating which is substantially smooth and non-porous. The invention also pertains to the reaction of the cellulose esters in the coating compositions with crosslinkers to provide improved toughness for coatings on substrates that are submerged in water. The invention also relates to the application of the coating composition to a substrate to be subjected to a marine environment. In a further aspect, the coating composition is applied as a clearcoat to a previously coated substrate.

Owner:EASTMAN CHEM CO

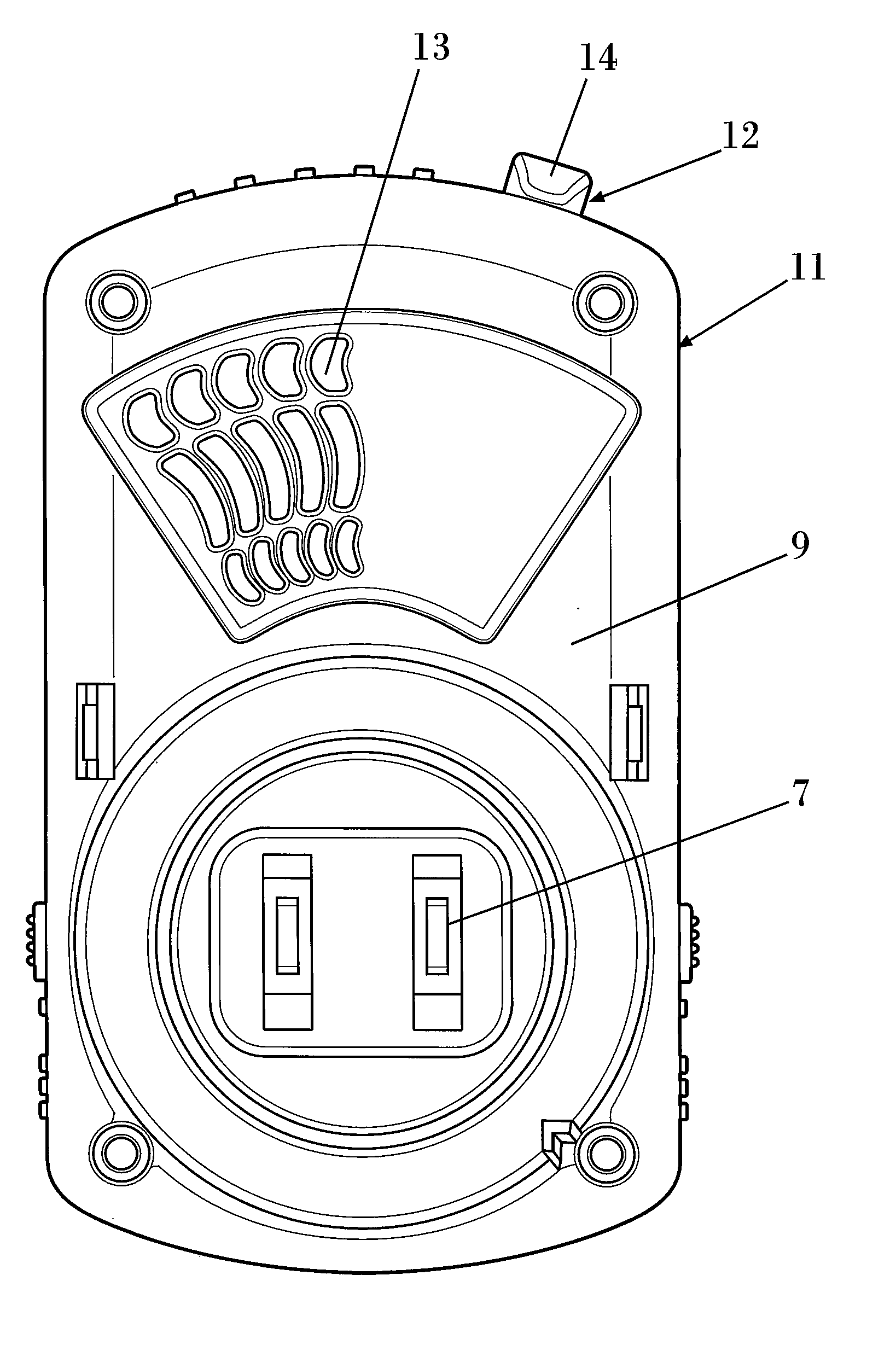

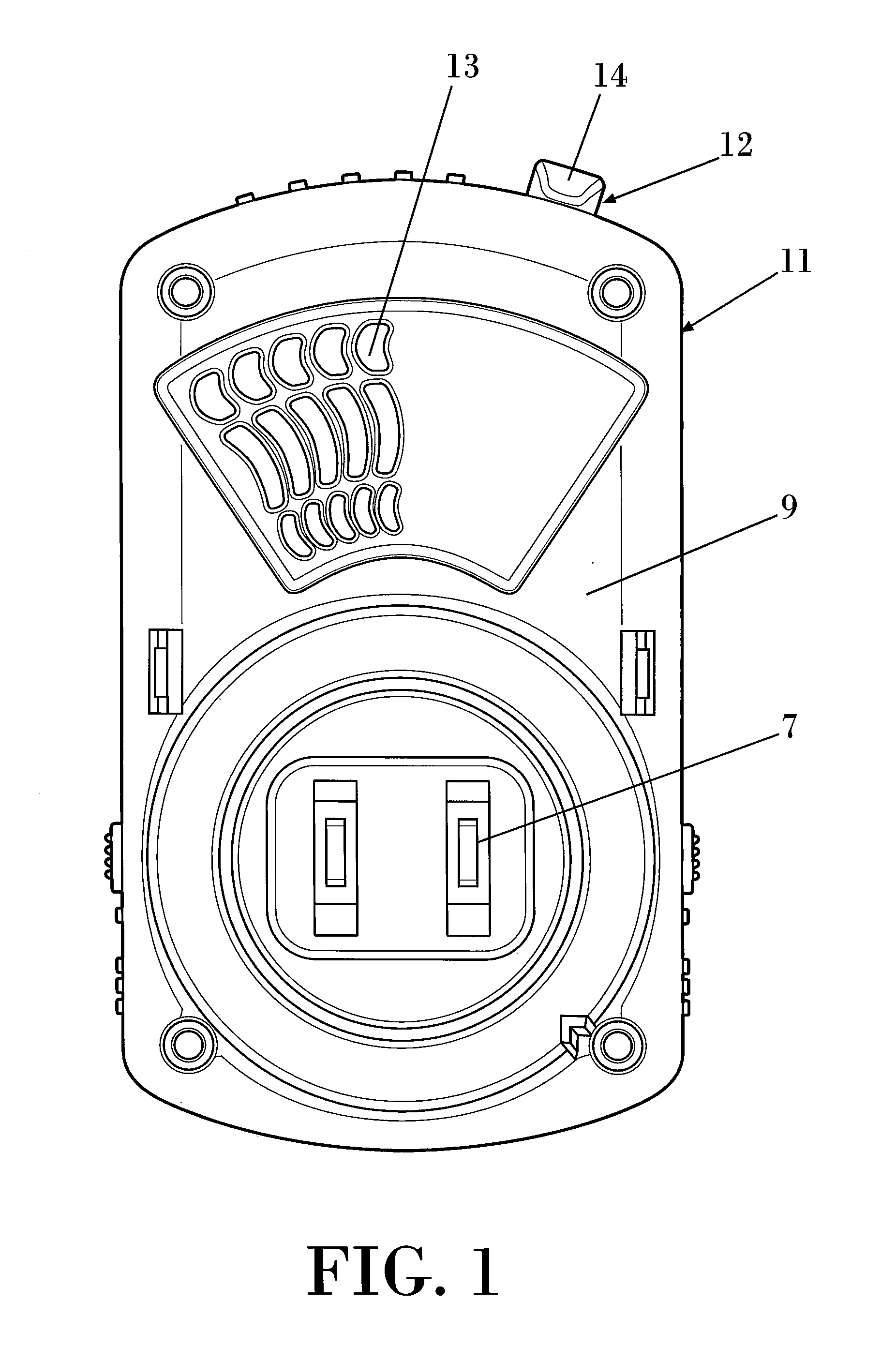

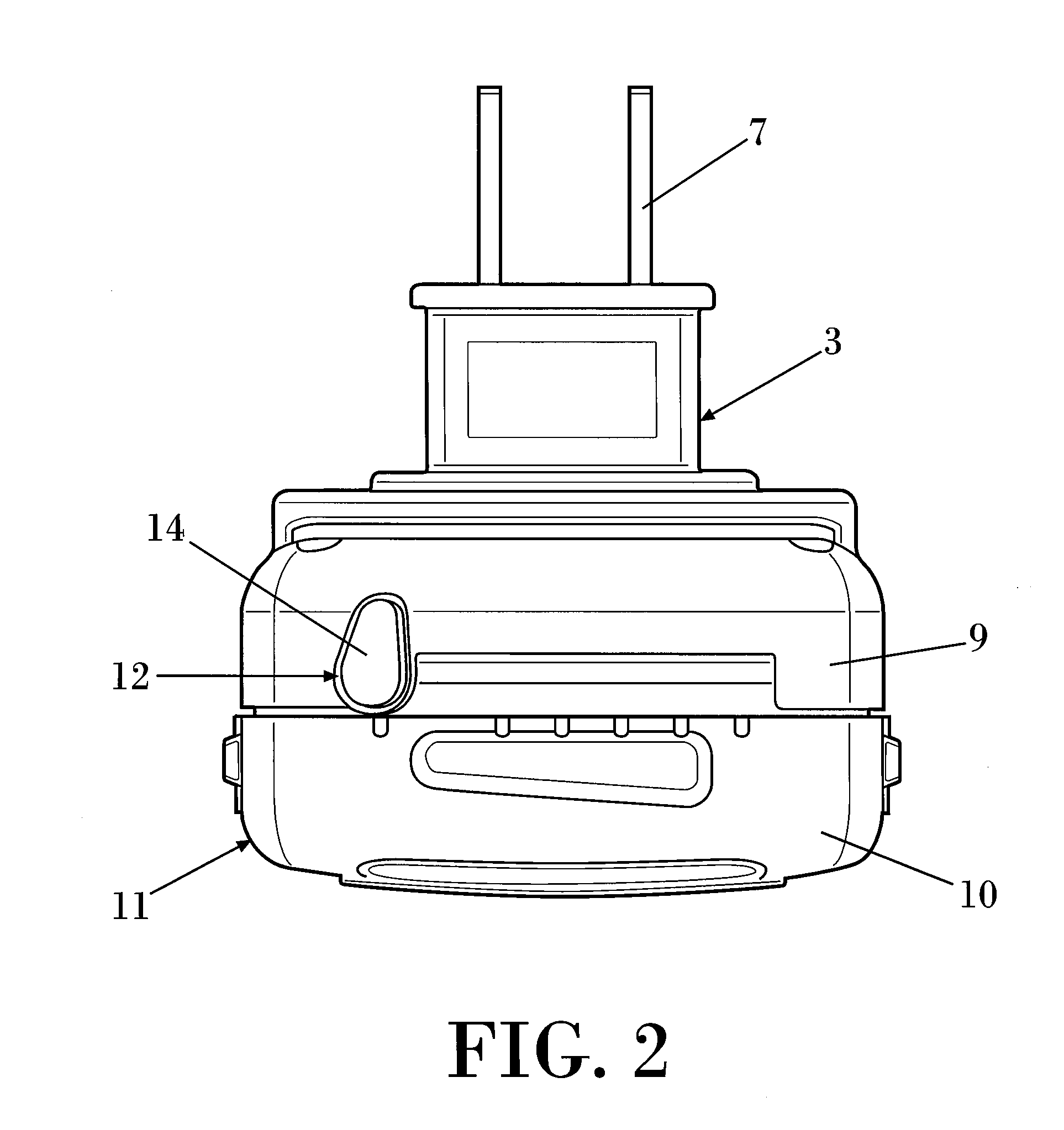

Electric evaporator device of volatile substances with adjustable evaporation intensity

ActiveUS20080095522A1Prevent escapeAvoid displacementMachines/enginesGaseous substancesElectricityEngineering

The present invention relates to an electric evaporator device of volatile substances with adjustable evaporation intensity. A heating plate (4) defines a first chamber (6) separated from a second chamber (8), wherein a heat generator (5) is located inside the first chamber (6). A regulation opening (13), located in the first chamber (6), allows the exit of a heated air flow from the first chamber to regulate the temperature both in the first chamber (6) and the heating plate (4), enabling thus the regulation of the evaporation rate.

Owner:ZOBELE HLDG SPA

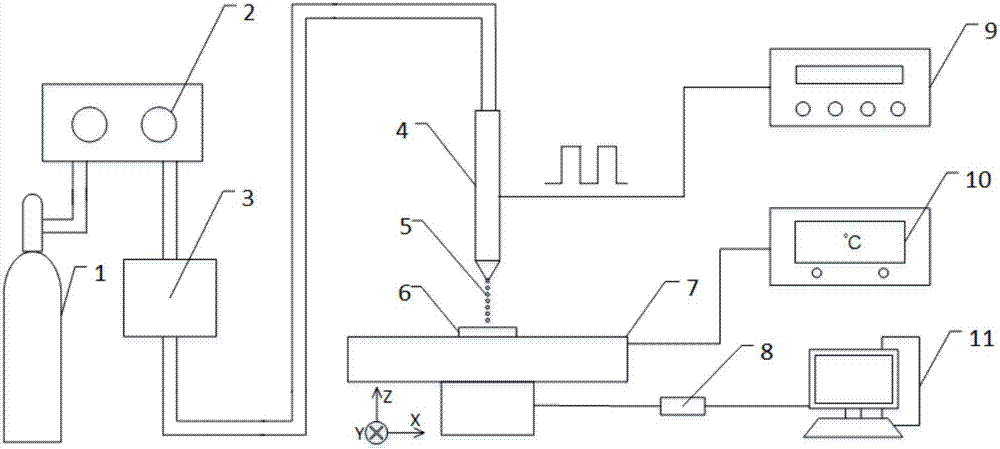

Micro-droplet jetting printing device and method for preparing graphene metamaterial microstructure through device

ActiveCN106891414AFast formingAdditive manufacturing apparatusCeramic shaping apparatusElectricityCvd graphene

The invention discloses a micro-droplet jetting printing device and a method for preparing a graphene metamaterial microstructure through the device. The micro-droplet jetting printing device and the method are used for solving the technical problem that an existing method for preparing the graphene metamaterial microstructure is complex. According to the technical scheme, the device comprises a nitrogen cylinder, pressure controllers, a liquid accumulator, a piezoelectric micro sprinkler, a microstructure substrate, a three-dimensional associated movement base plate, a three-dimensional associated movement base plate controller, a piezoelectric ceramic driver, a temperature controller and a computer. The method comprises the steps that graphene dispersion liquid is dispersed into picoliter-order uniform graphene micro-droplets through the piezoelectric micro sprinkler, and the liquid droplet diameter and the jetting frequency are adjusted through the piezoelectric ceramic driver; and then the three-dimensional associated movement base plate is controlled through the computer, the accumulation track of the graphene micro-droplets on the substrate is controlled, the graphene microstructure is obtained through point-by-point, line-by-line and layer-by-layer accumulation, meanwhile, the temperature controller is utilized for controlling the evaporation rate and solute migration in the graphene micro-droplet deposition process, and complex graphene metamaterial microstructure patterns are obtained. The method is simple and practicable.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

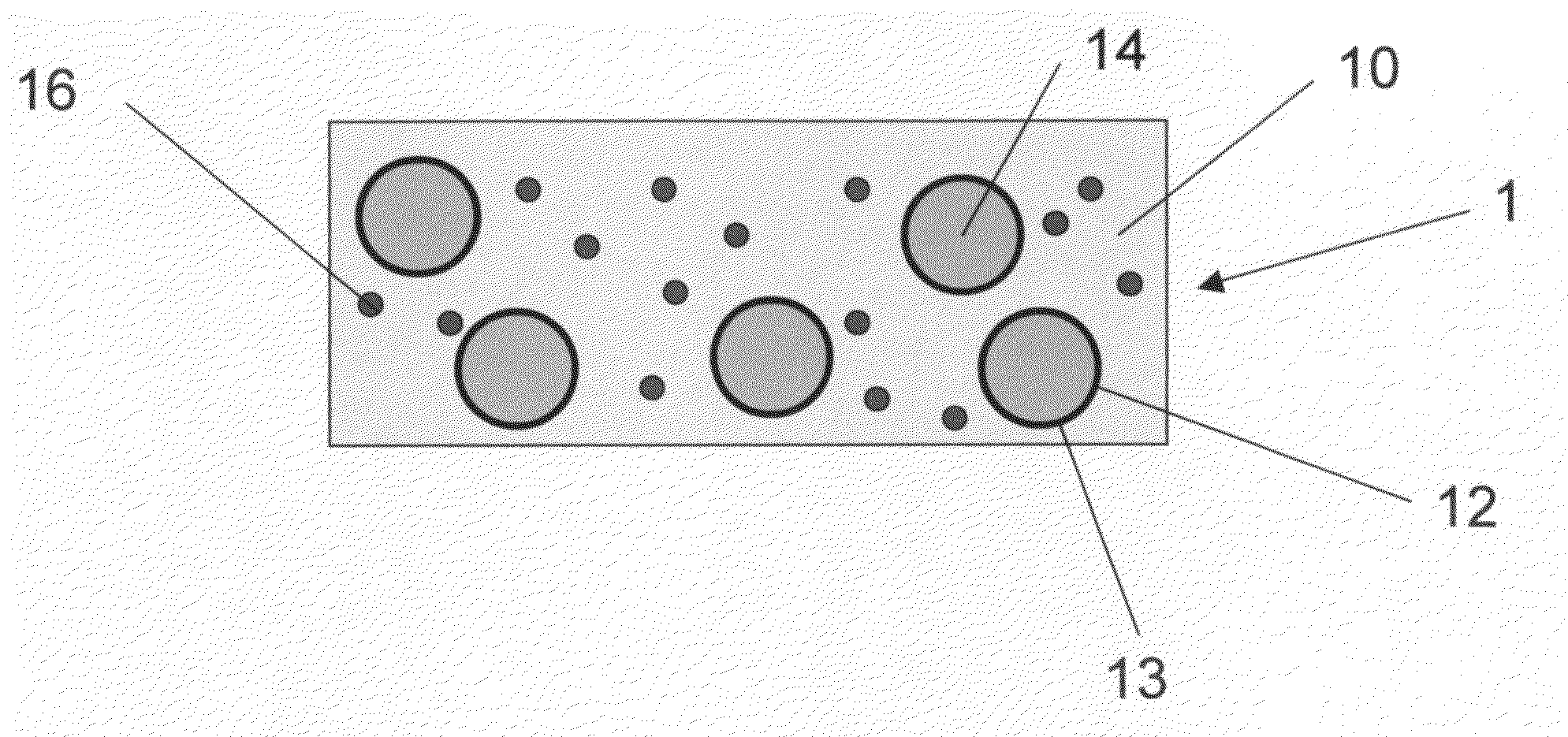

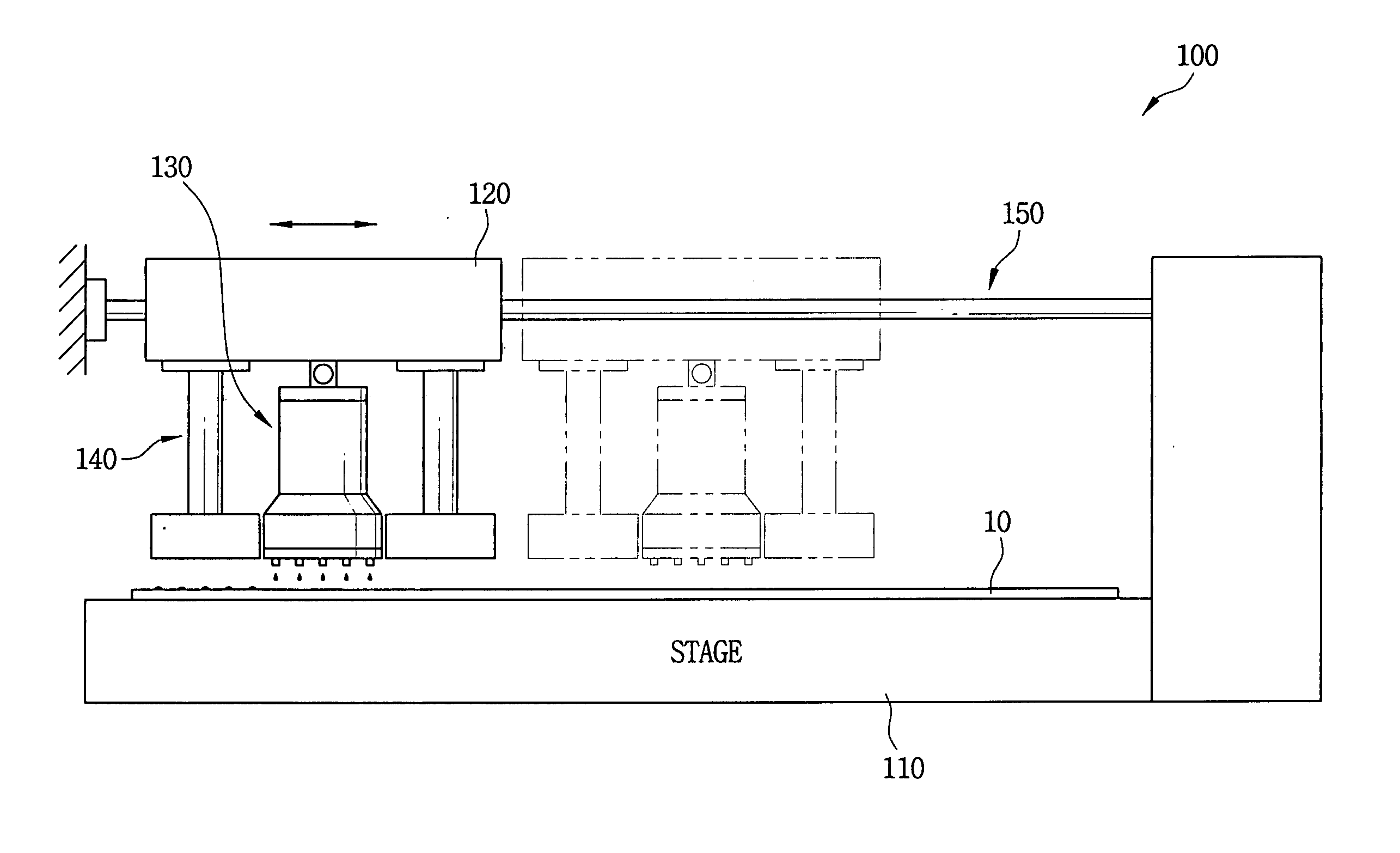

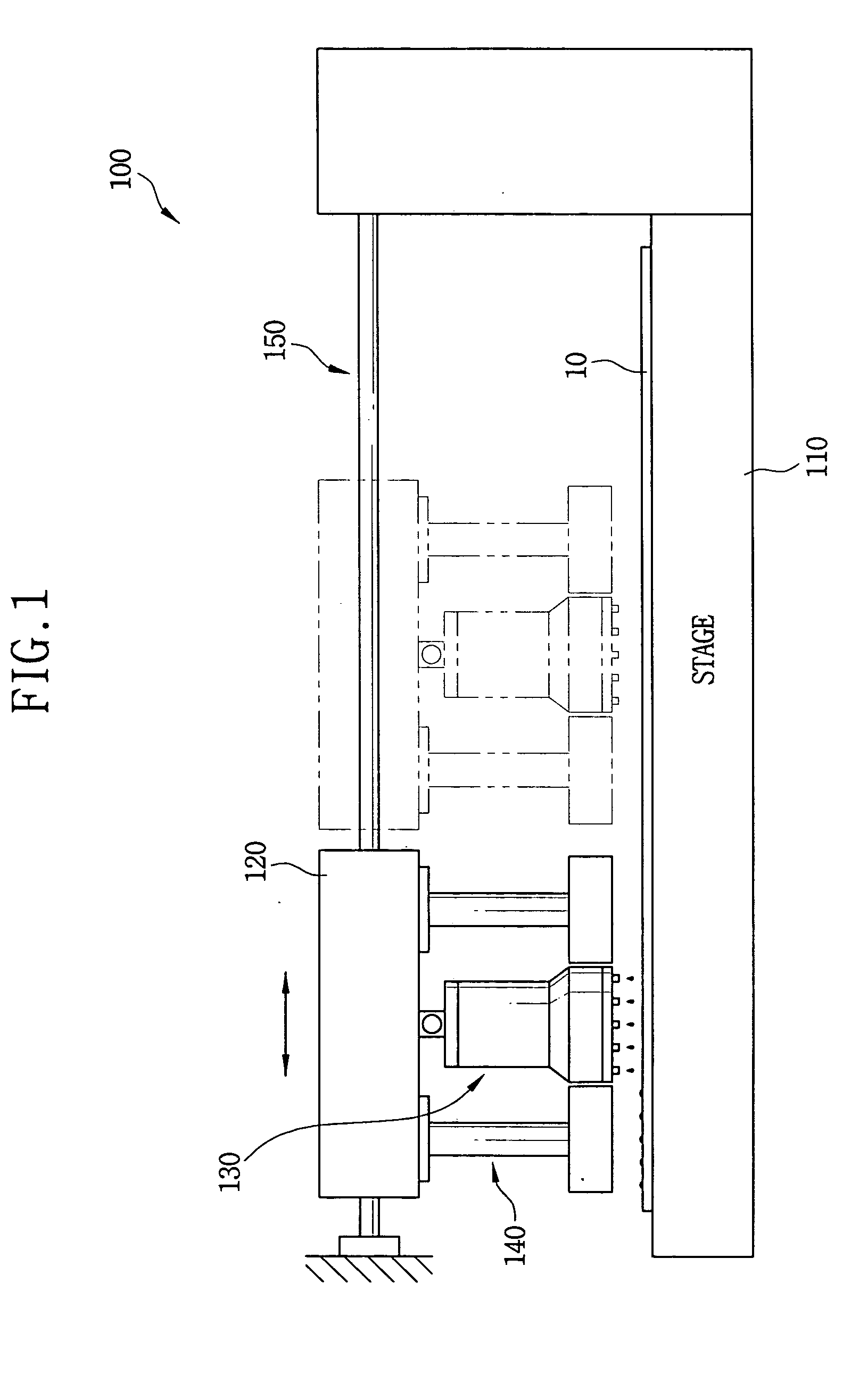

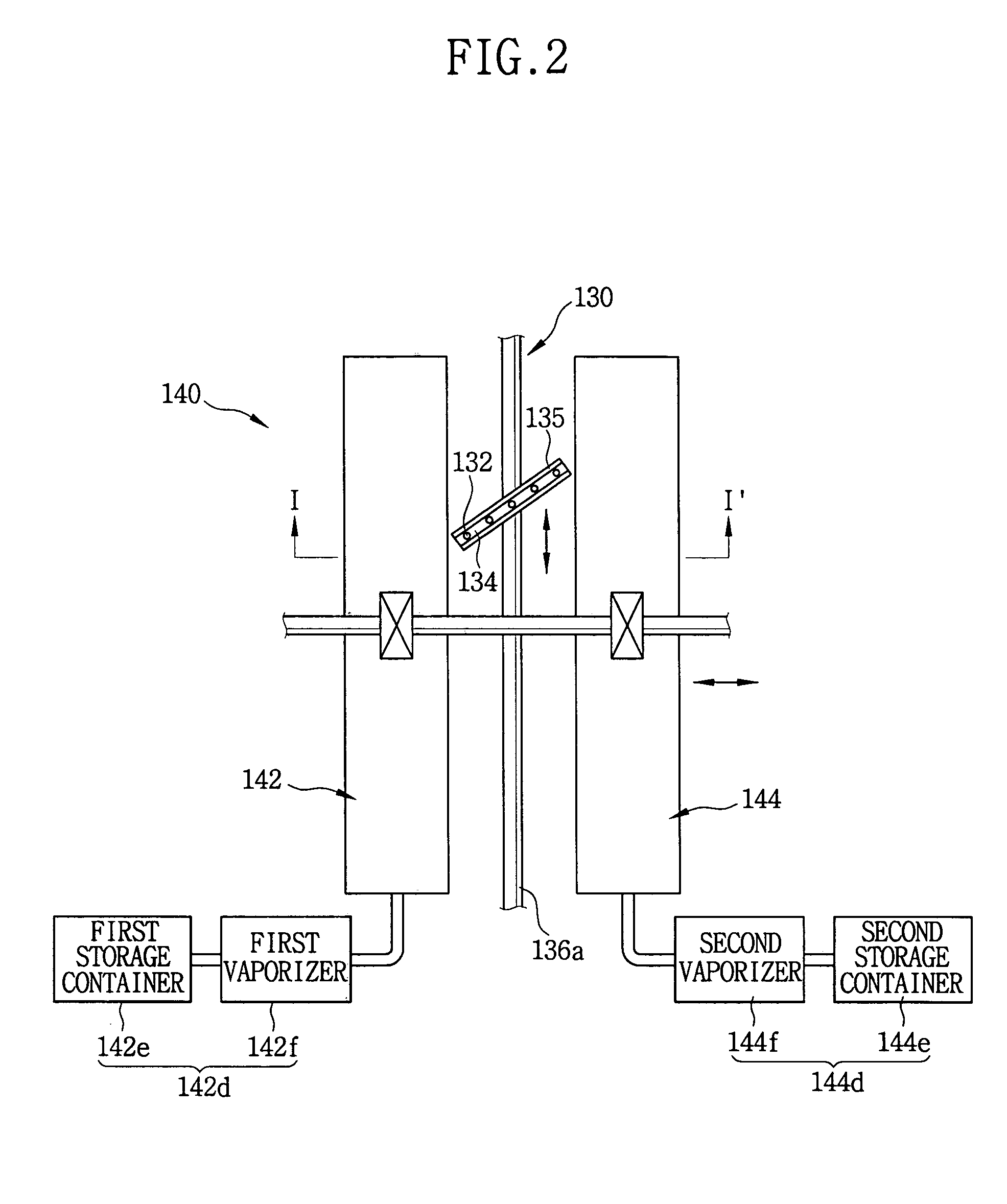

Apparatus for supplying a droplet on a substrate and method of manufacturing display apparatus using the same

ActiveUS20050110852A1Improve image display qualityLiquid surface applicatorsElectroluminescent light sourcesLiquid dropImage display

In an apparatus for supplying a droplet on a substrate and a method of manufacturing a display apparatus, the apparatus includes a base body, a dropping unit and a vapor supplying unit. The base body corresponds to the substrate disposed on a stage. The dropping unit is disposed on the base body. The dropping unit includes a nozzle to drop the droplet on the substrate. The vapor supplying unit is disposed adjacent to the dropping unit to supply the droplet dropped onto the substrate with a volatile solvent vapor. Therefore, an evaporation rate of the droplet dropped onto pixels is adjusted to uniformize a thickness of the layer, thereby improving the image display quality.

Owner:SAMSUNG DISPLAY CO LTD

Soil membrane forming mixture

InactiveUS20060257213A1Improve resistance to degradationIncrease the amount of waterClimate change adaptationGrowth substratesS oxidationPhygadeuon fumator

This invention relates to an organic, environment-friendly, preferably antioxidising and biodegradable climate, soil and growth enhancing mixture of preferably organic materials that can be applied to moist soil as dry matter or dry soil in liquid state, and which subsequently solidifies into a degradable film or membrane on top of or at a given depth in the soil. The properties of the film can be set so that the film regulates or changes the soil's oxidation ability, degradation rate, temperature, greenhouse gas respiration, combustibility, mechanical strength, evaporation rate, water runoff, nutrient conversion rate and germination conditions on and / or below the surface of the soil mass. The film or membrane can be used alone or in combination with standard plant nutrition or fertiliser.

Owner:BION AS

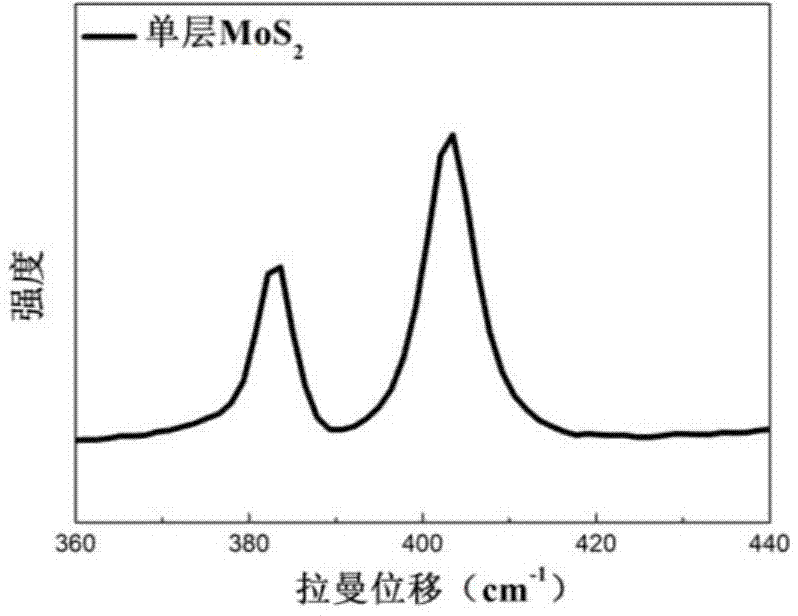

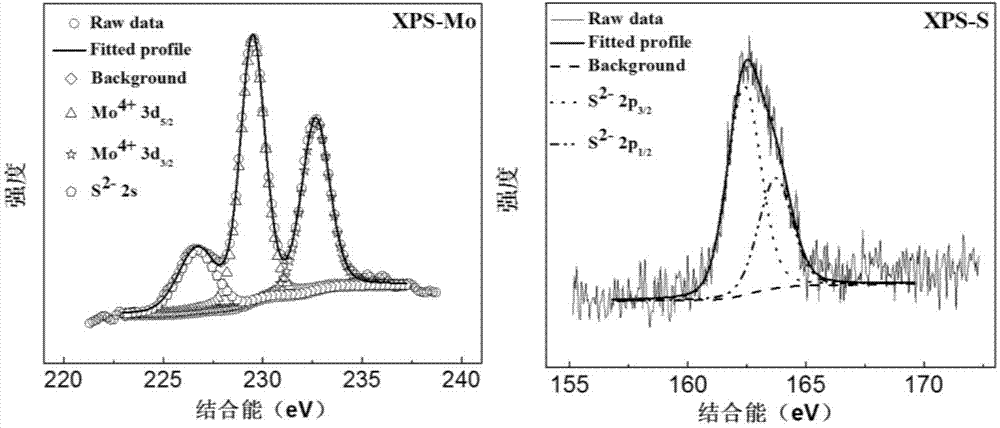

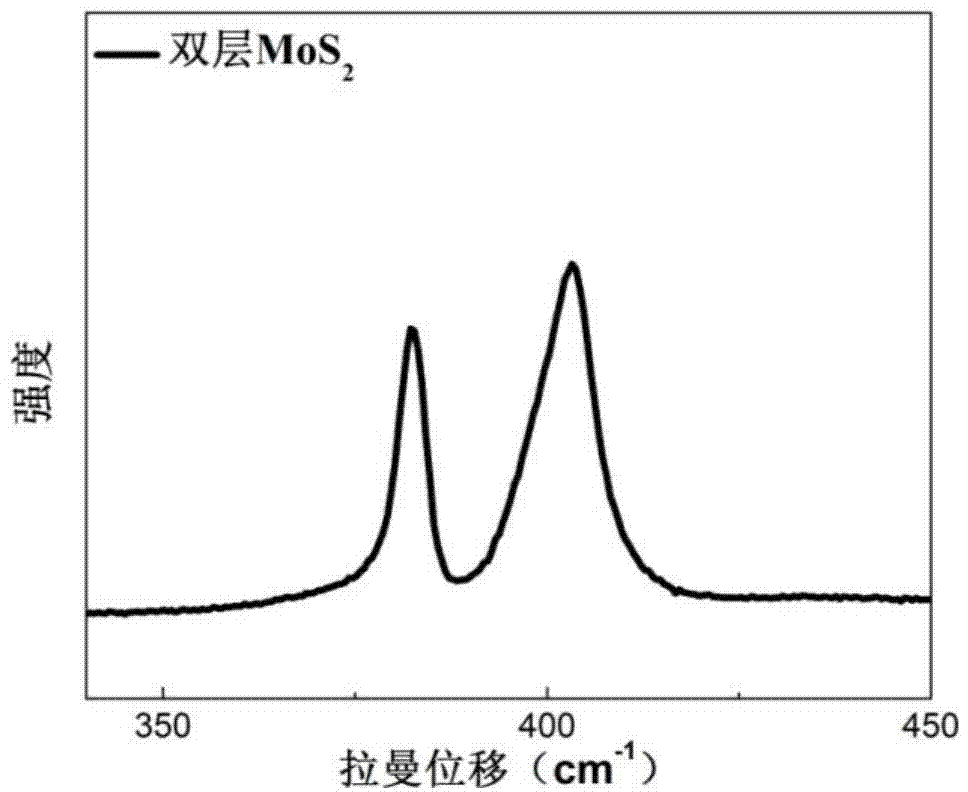

Method for preparing molybdenum disulfide thin film

InactiveCN104498878AUniform growthHigh purityVacuum evaporation coatingSputtering coatingReaction temperatureMetal particle

The invention provides a method for preparing a molybdenum disulfide thin film. The method comprises the following steps: by taking molybdenum metal particles and sulfur powder as raw materials, preparing a MoS2 thin film on a target substrate in a vacuum environment by virtue of a double source evaporation method; adjusting the evaporation rates of the molybdenum and sulfur sources, wherein the content ratio of Mo atoms and S atoms is 1: 2; and carrying out reaction on the Mo atoms and S atoms on a heated substrate to generate MoS2 molecules to obtain the layer-controlled molybdenum disulfide thin film. The method achieves controllable layers of the molybdenum disulfide thin film by controlling an electron beam, heat evaporating temperature and growing time. The method provided by the invention is simple to operate and the molybdenum disulfide thin film is controllable in thickness, so that large-area high-purity molybdenum disulfide thin films with a monomolecular layer, double molecular layers and multiple molecular layers can be prepared. The method has the characteristics of low reaction temperature, energy conservation, high efficiency, simple operation, good controllability, good repeatability and batch preparation and the invention provides a reliable sample preparation method for application of molybdenum disulfide in electric and optical fields.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

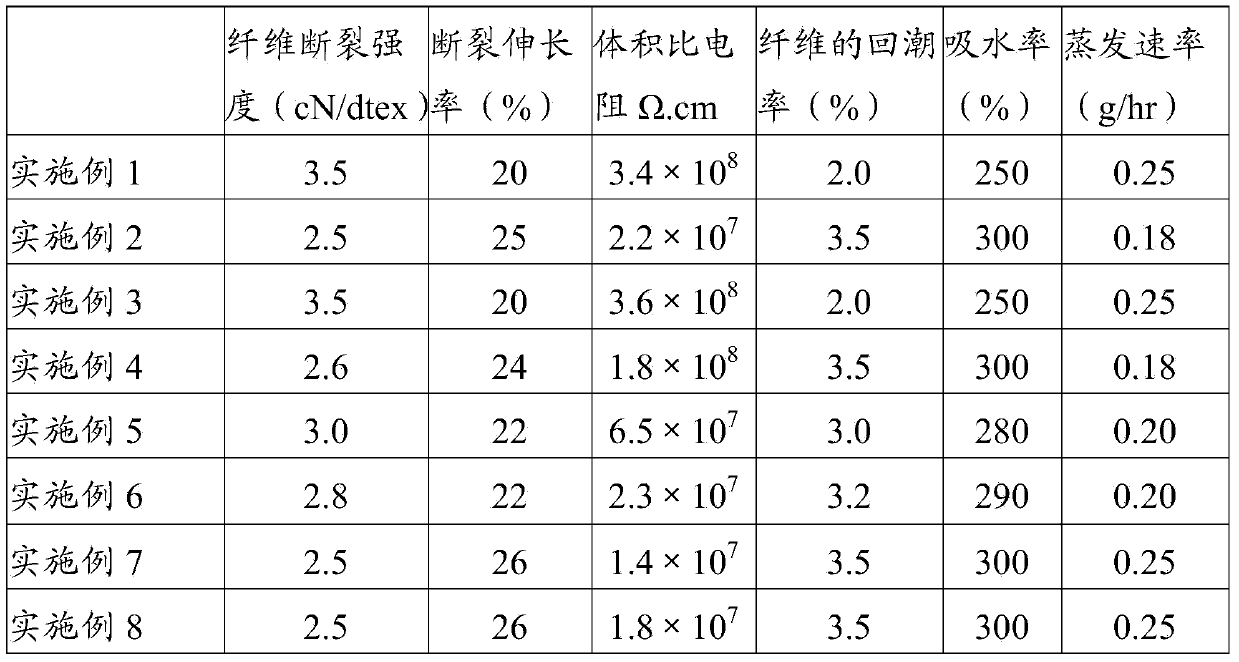

Hydrophilic polyester fiber and preparation method thereof

ActiveCN103741258AImprove thermal stabilityGood hygroscopicitySpinnerette packsMelt spinning methodsPolyesterMoisture absorption

The invention discloses a preparation method of a hydrophilic cotton-like polyester fiber. The preparation method is characterized by comprising the following steps: (1) dissolving chelate formed in a calcium chloride water solution by virtue of polyvinyl alcohol; (2) carrying out mixing granulation on polyester chips, a molecular weight modifier, an antioxidant and a lubricant so as to obtain cooled master batches; (3) carrying out blending and melt spinning on the obtained modified polyvinyl alcohol, the cooled master batches and polyester chips, and carrying out final processing to prepare the cotton-like polyester fiber. The invention further provides the hydrophilic cotton-like polyester fiber prepared by the preparation method. The fiber comprises 0.1wt%-5wt% of the modified polyvinyl alcohol, 0.005wt%-0.05wt% of the molecular weight modifier, 0.002wt%-0.02wt% of the antioxidant and 0.002wt%-0.02wt% of the lubricant; the fiber has the coefficients that the moisture regain is more than or equal to 2.0%, the water absorption rate is more than or equal to 250%, the evaporation rate is more than or equal to 0.18g / hr, the breaking strength is more than or equal to 2.5cN / dtex, the elongation at break is more than or equal to 20%, and the volume resistivity is less than or equal to 108 omega.cm. The cotton-like polyester fiber disclosed by the invention has the advantages that the moisture absorption performance is good, and the comfort level is greatly improved.

Owner:LI NING CHINA SPORTS GOODS

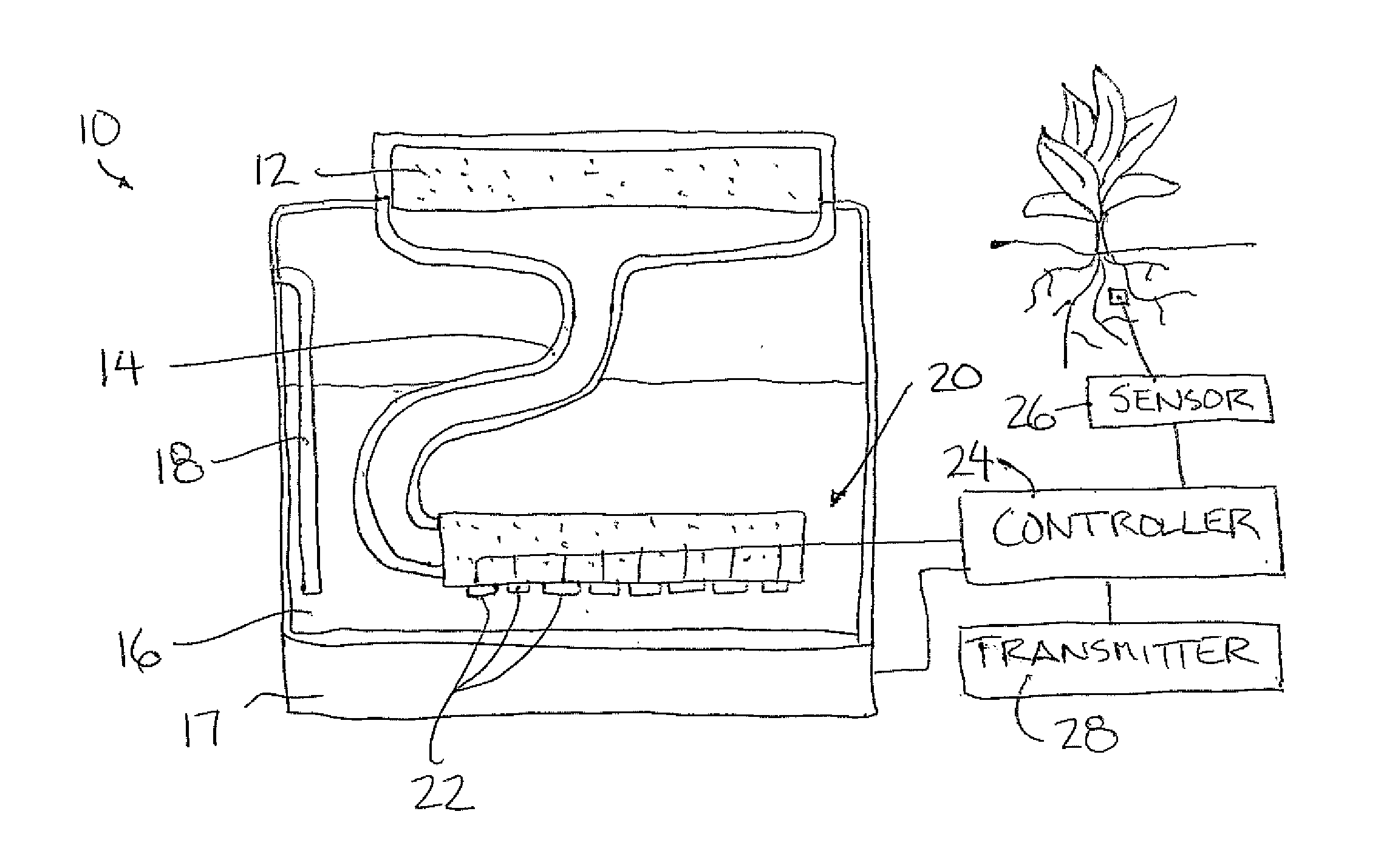

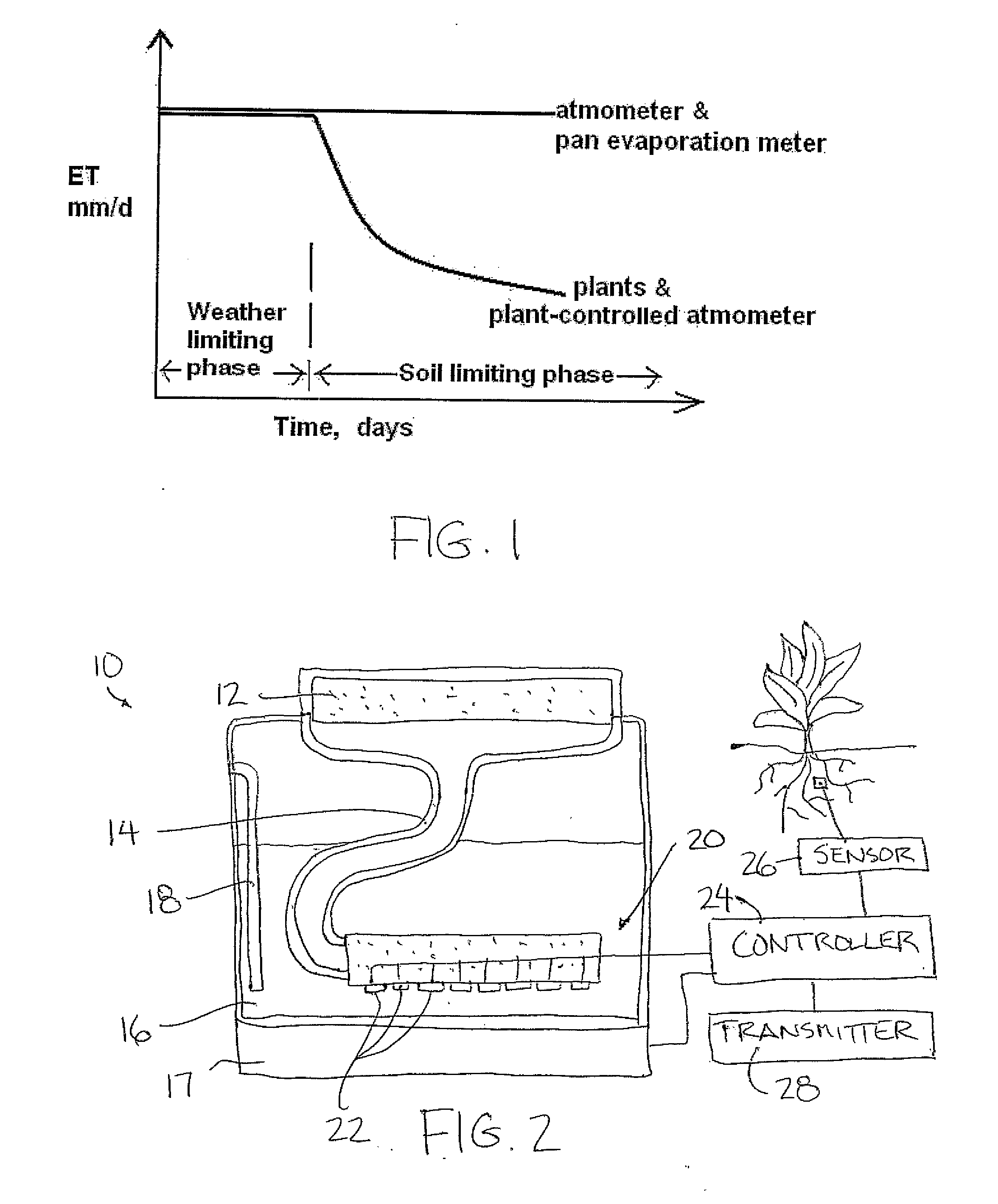

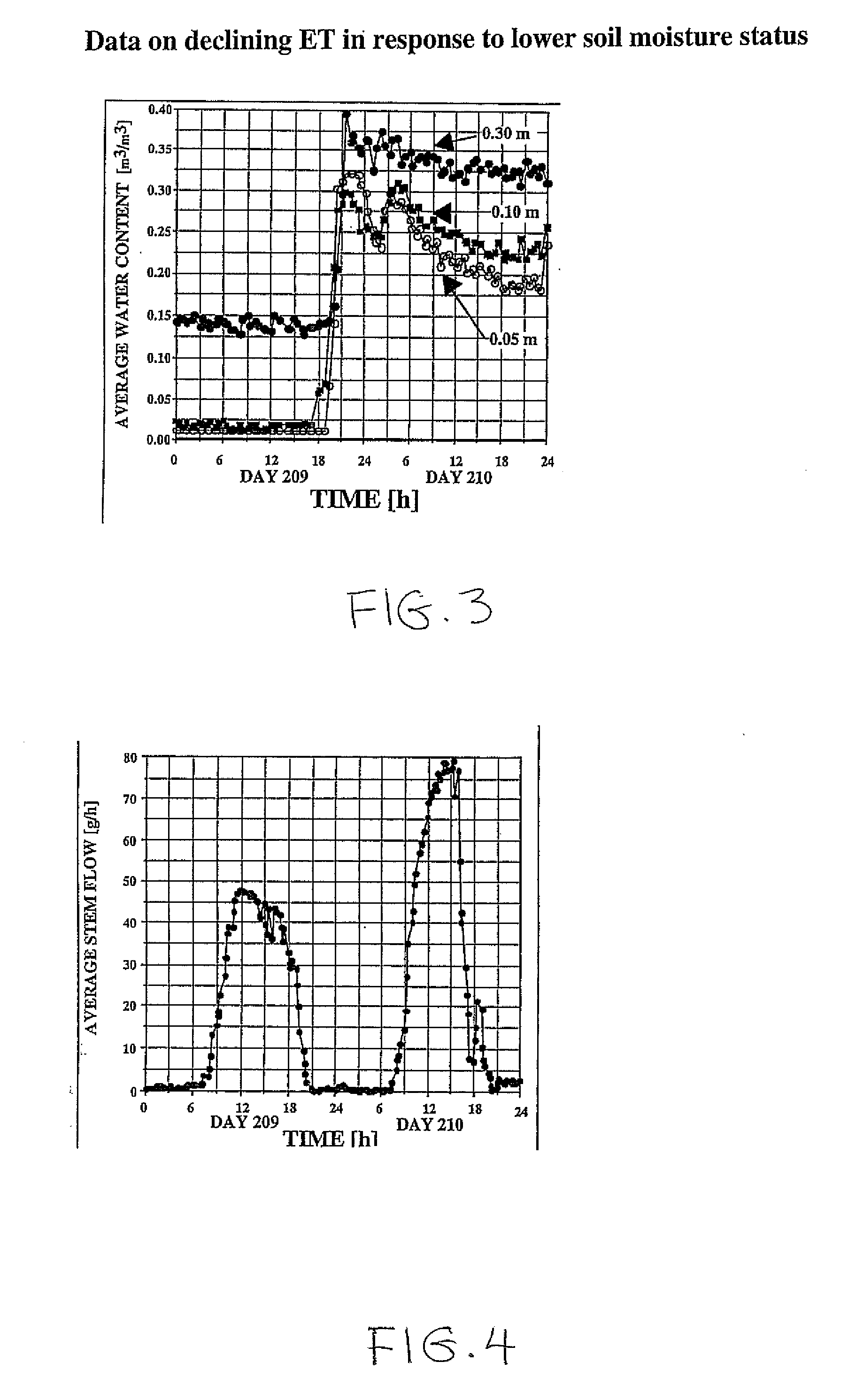

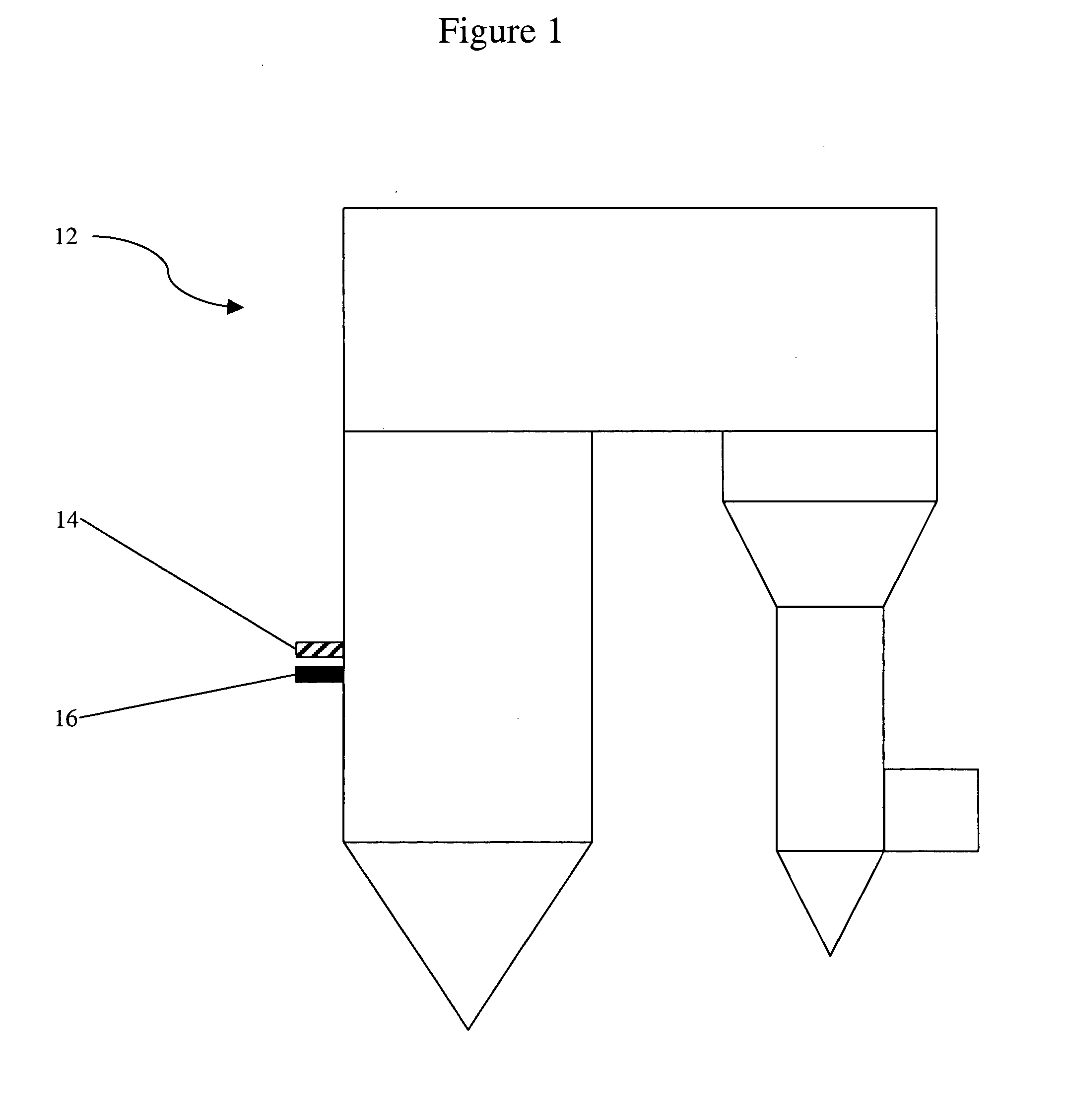

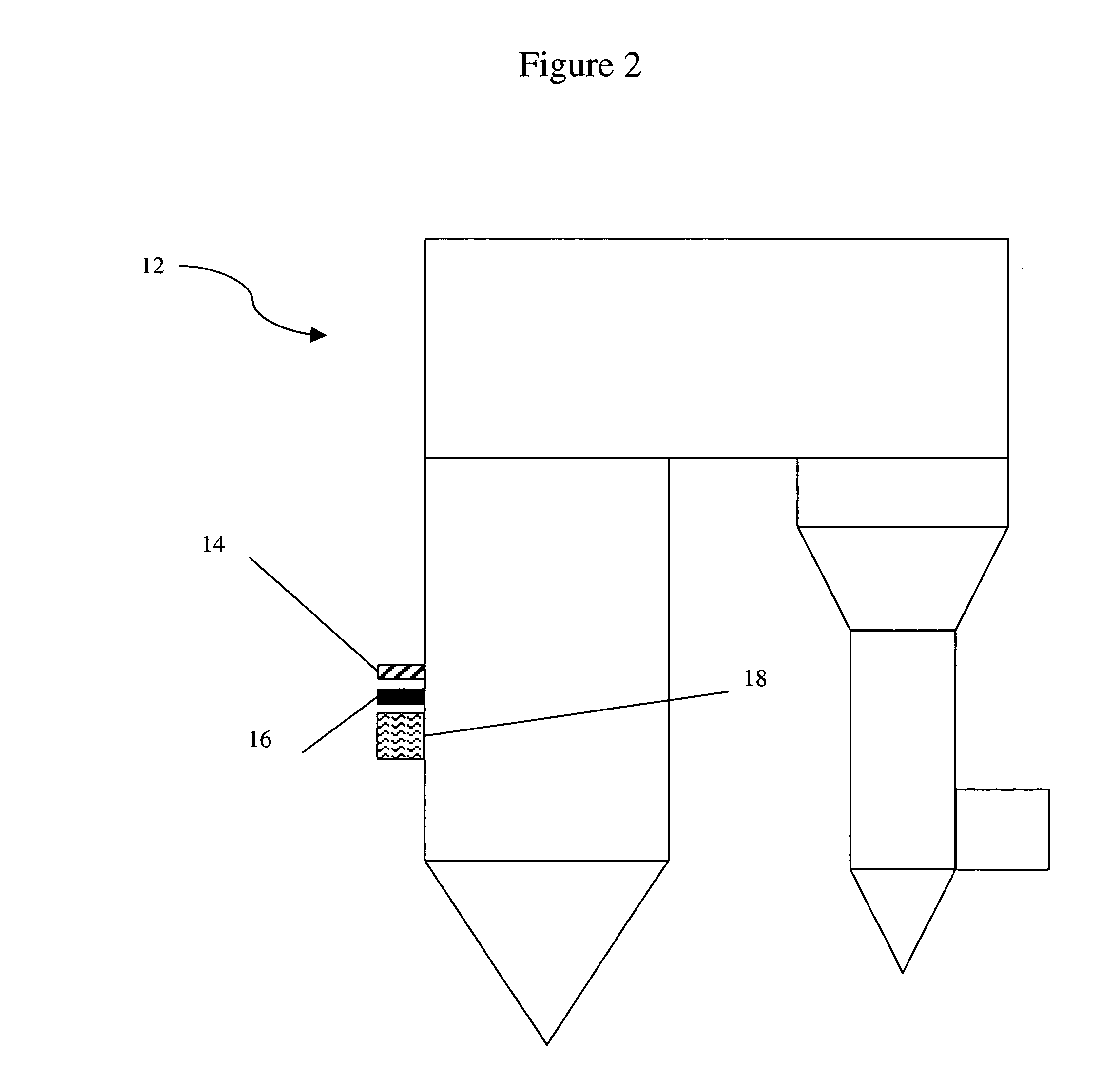

Plant-Controlled Atmometer for Measuring Crop Evapotranspiration

ActiveUS20100212409A1Low rateReduce evaporation rateMaterial moisture contentTesting plants/treesCrop evapotranspirationEngineering

An atmometer device comprises a porous evaporator member, a suction tube communicating water from a reservoir to the porous evaporator member, a sensor measuring a moisture characteristic of soil associated with a crop, a mechanism arranged for controllably varying a rate of evaporation of the water through the porous evaporator member responsive to the moisture characteristic measured by the sensor, and an indicator arranged to indicate water loss in the reservoir. By controlling rate of evaporation of the water through the porous evaporator member responsive to the measured moisture characteristic of the soil, the amount of water loss in the reservoir during the given time period more accurately reflects crop evapotranspiration.

Owner:SRI RANJAN RAMANATHAN

Combustion NOx reduction method

InactiveUS20040253161A1Combustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustionEngineering

A method of extending the droplet half-life of water droplets in a combustion furnace by increasing the relative humidity in the droplets' environment; thereby reducing the evaporation rate of the water from the droplet and increasing the half-life of the droplets in the droplets' environment.

Owner:THE POWER IND GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com