Device for testing performance of low-temperature vacuum multilayer heat-insulation material based on thermal protection

A multi-layer thermal insulation material, low temperature vacuum technology, applied in the direction of material thermal development, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

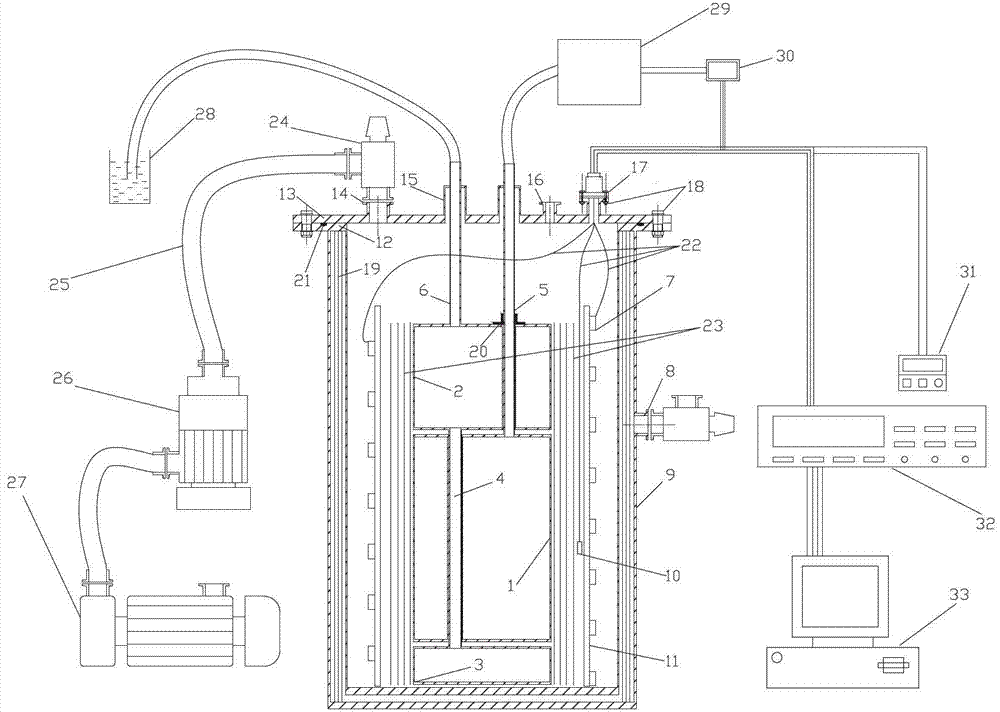

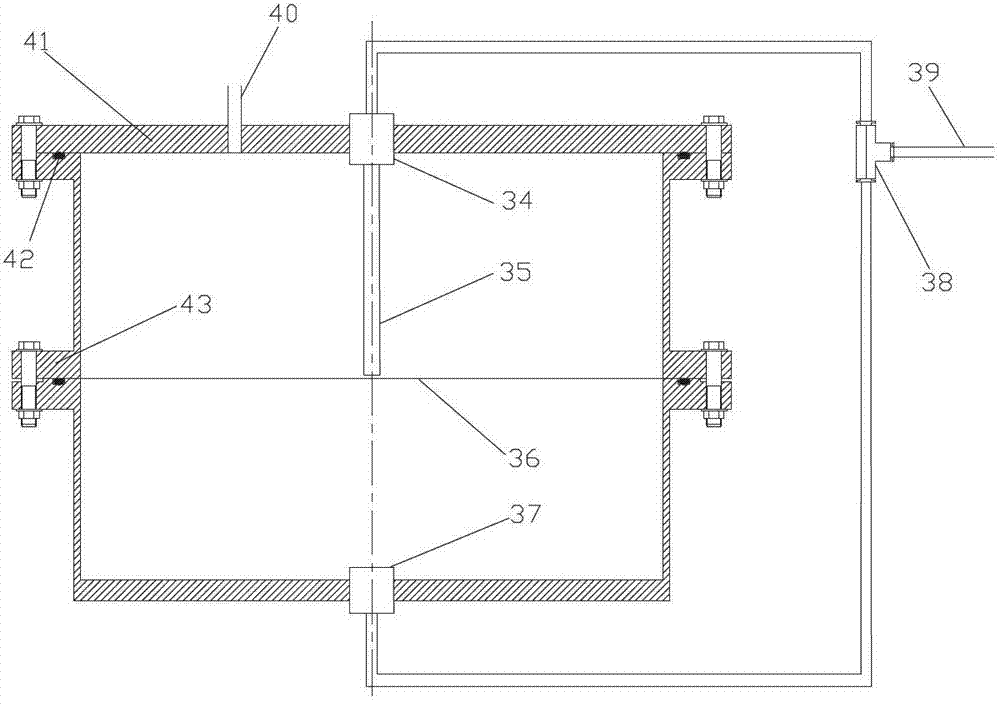

[0021] The present invention is realized through the following technical schemes, the present invention includes: a vacuum cover, an upper protection chamber, a test chamber, a lower protection chamber, a back pressure stabilization device, a controllable electric heating system, a temperature and flow sensing system, and liquid nitrogen filling System, data acquisition and processing system, vacuum pumping system, wherein: the upper and lower protective chambers are connected in space by using stainless steel pipes, and are connected to the blind end cover flange of the vacuum housing through thin-walled steel pipes. The test chamber is the main part to test the performance of multi-layer insulation, and the connecting pipe between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com