Split joint type large-area field emission planar light source

A planar light source and field emission technology, applied in the direction of fluorescent screen lamps, etc., can solve the problems of poor vacuum degree, difficulty in obtaining large-area planar light source, and inability to meet the level of field emission planar light source, so as to achieve the effect of improving uniformity and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

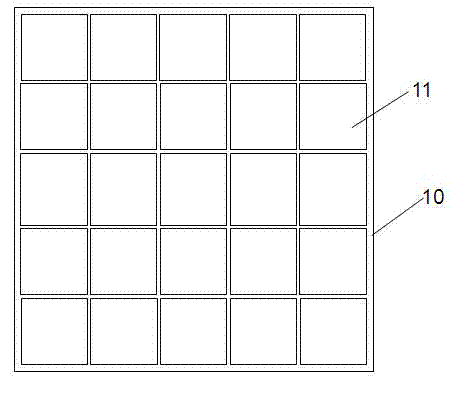

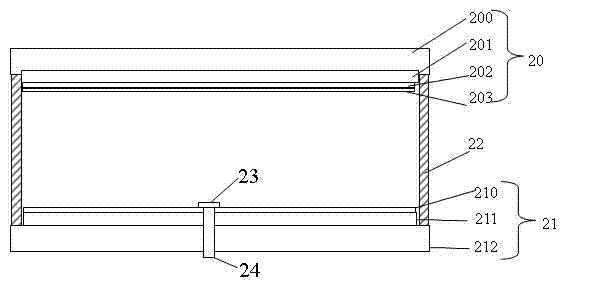

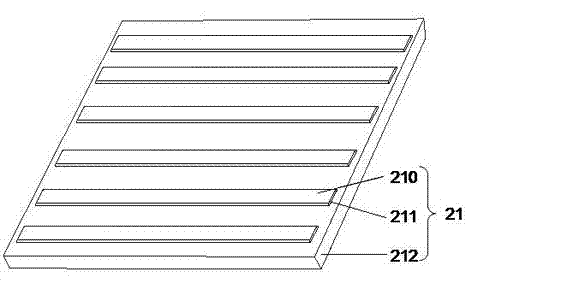

[0030] refer to Figure 4 and Figure 5 , Figure 4 It shows a schematic diagram of a spliced large-area field emission planar display light source in Embodiment 2 of the present invention, Figure 5A three-dimensional exploded schematic diagram showing a single circular field emission light source unit. In this embodiment, the spliced large-area field emission flat display light source 40 includes 40 field emission light source units 41 without vacuum isolation pillars, and the 40 field emission light source units 41 without vacuum isolation pillars are independently arranged on a plane , and arranged in 5 rows and 8 columns, combined into a splicing large-area field emission backlight 40; wherein there is no field emission light source unit 41 for vacuum isolation pillars; the field emission light source unit 41 without vacuum isolation pillars includes a cathode plate 51 , an anode plate 50 corresponding to the cathode, an edge sealing body 52 and a getter 53 for enc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com