Leacheate generation device used in ion chromatography system

An eluent generation and ion chromatography technology, which is applied in the field of eluent generation devices, can solve the problems of uneven electrolyte, affect the stability of the baseline, increase costs, etc., and achieve the effects of uniform electrolyte, simple structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

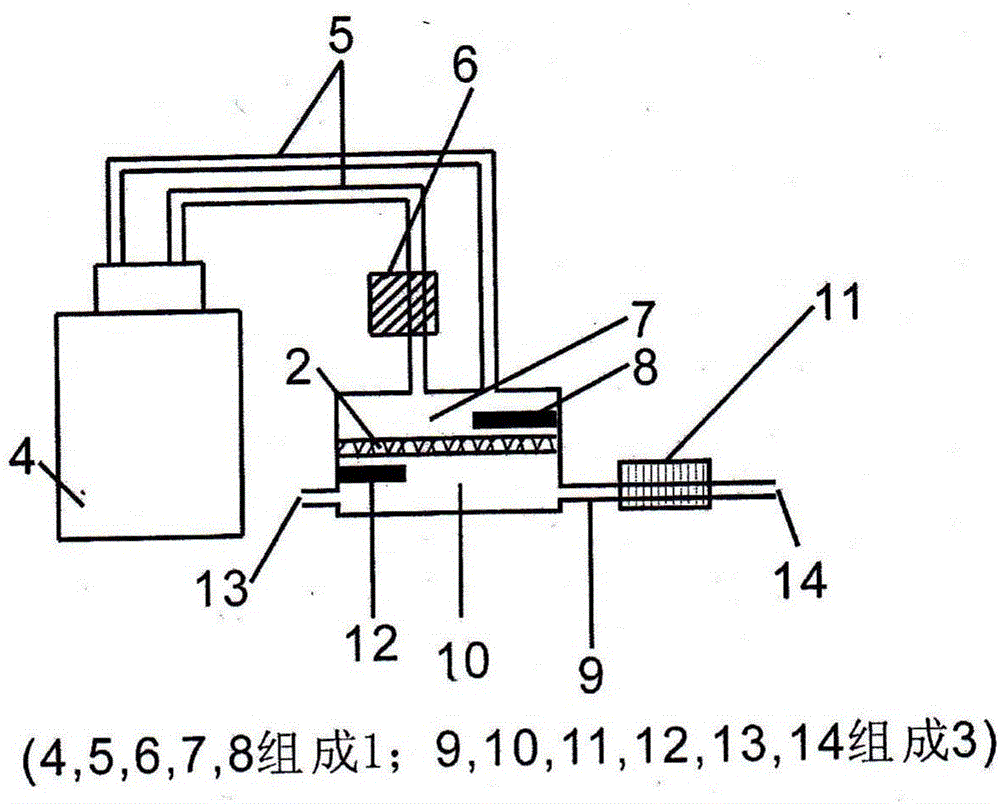

[0021] The high-concentration potassium hydroxide solution in the electrolyte mother liquid storage chamber is circulated in the eluent mother liquid circulation channel through a peristaltic pump. The eluent mother liquid passes through the ion electrolysis chamber and is electrolyzed by the Pt anode installed to generate hydrogen ions. The pump drives pure water to pass through the eluent buffer to create a channel, and electrolysis generates hydroxide ions. The hydrogen ions generated at the anode replace the potassium ions in the electrolyte solution, and the potassium ions cross the cation exchange membrane and enter the eluent buffer to create a channel. . Potassium ions and hydroxide ions entering the eluent generation channel are mixed to generate eluent; then, the eluent is further buffered by a high-pressure pump through a fluid flow device such as a catheter, thereby providing a stable hydroxide for the ion chromatography system Potassium eluent. If the potassium h...

Embodiment 2

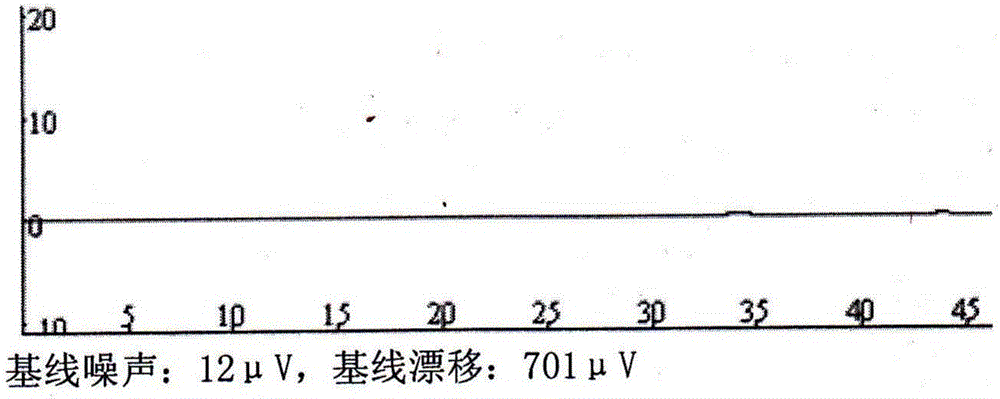

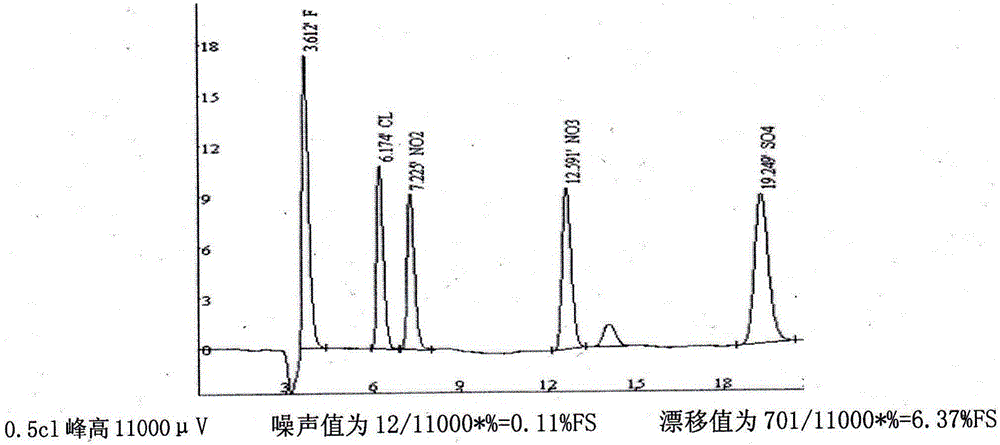

[0023] When the eluent generating device of the present invention is installed in the ion chromatography system to start running, such as figure 2 As shown, when no sample is injected, the baseline is basically in a straight line state, the baseline noise value is 12µV, and the baseline drift value is 701µV. image 3 As shown, the peak height value is 11000µV. According to the calculation, the noise value of the present invention is 12 / 11000×100%=0.11%FS, and the drift value is 701 / 11000×100%=6.37%FS; The same ion chromatographic system is installed with an eluent generator produced by an imported brand during the start-up process, when no sample is injected, such as Figure 4 As shown, the baseline is wavy, the baseline noise value is 0.0065µS, and the baseline drift value is 0.30µS. When the sample is injected, such as image 3 As shown, the peak height value is 4.345µS. According to the calculation, the noise value of the present invention is 0.0065 / 4.345×100%=0.15%FS, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com