On-line identification method for unbalance of magnetic suspension rotor based on current test mass

A technology of a magnetic suspension rotor and an identification method is applied in the field where the gyro room is inconvenient to disassemble, and can solve the problems of low identification accuracy, inability to realize zero current and zero displacement state at the same time, affecting the stability of the original system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

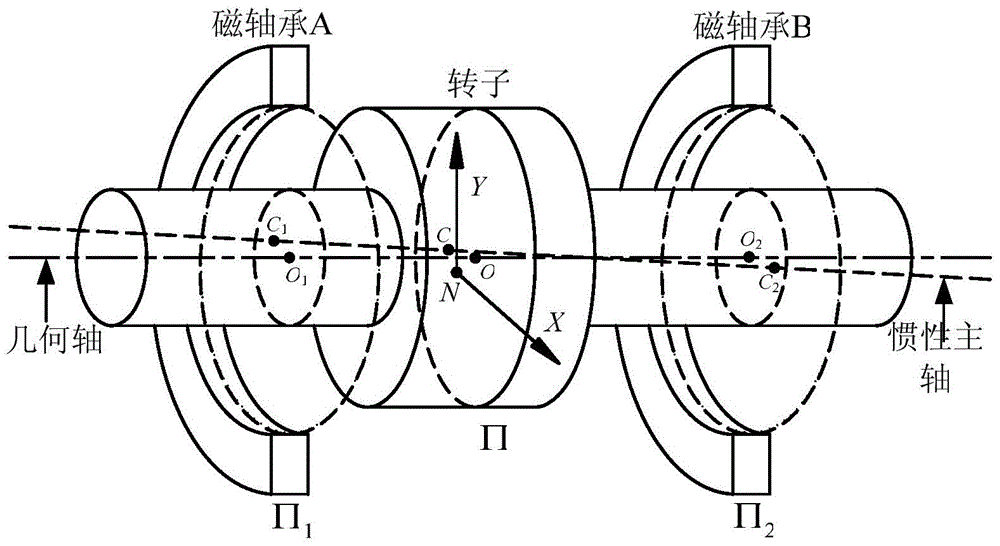

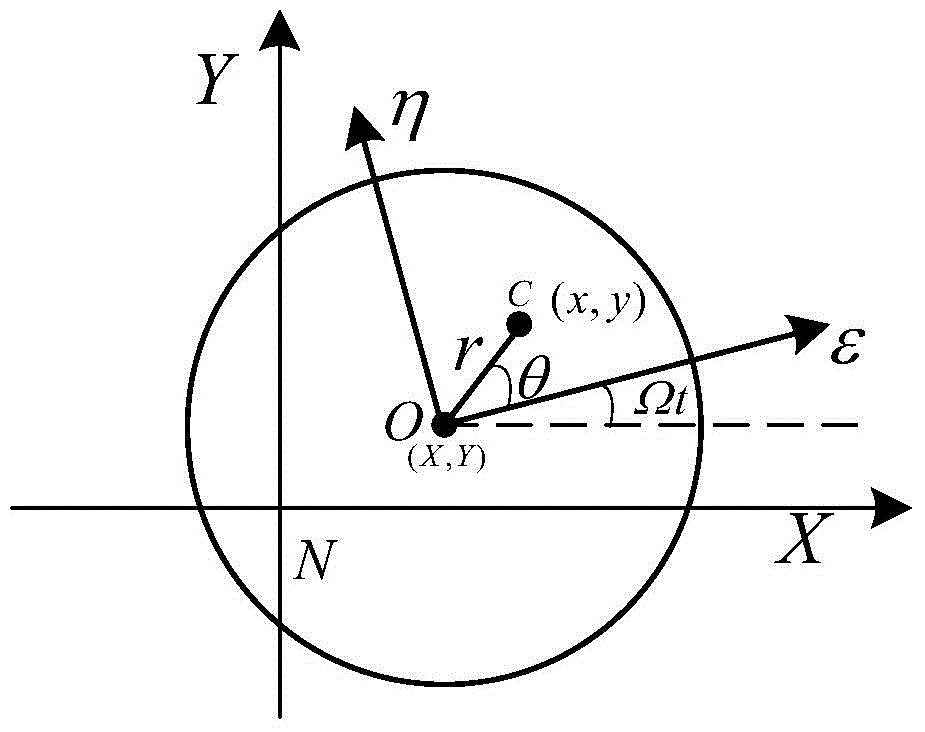

[0059] The maglev rotor system consists of a displacement sensor K s , controller C(s), power amplifier G w (s), the magnetic bearing rotor system P(s), the displacement sensor measures the rotor displacement and feeds it back to the controller, the controller outputs the control quantity to the power amplifier, the power amplifier outputs the current to the magnetic bearing coil, and the magnetic bearing generates force and torque to make The rotor is stably suspended. Due to reasons such as manufacturing and processing, the inertial axis of the rotor does not coincide with the geometrical axis. Among them, the displacement of the geometric center and the center of mass of the rotor is the static unbalance, and the torsional angular displacement of the geometrical axis relative to the inertial axis is the dynamic unbalance of the rotor.

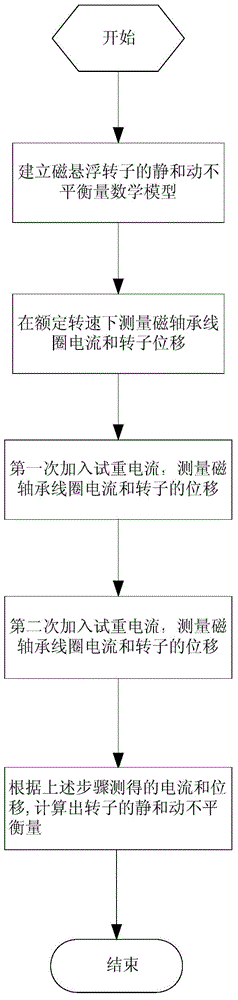

[0060] (1) Establish the static and dynamic unbalance mathematical model of the maglev rotor

[0061] Static and dynamic unbalance of mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com