Patents

Literature

31 results about "Test weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Test weight refers to the average weight of a cereal as measured in pounds per bushel (1bu. = 8 gallons or 2150.42 cu. inches). Test weight is an important predictor of milling yield for rice and flour extraction rate for wheat. USDA’s official weight per bushel for the highest grade for major cereals and oilseeds include: wheat and soybeans (60 lbs./bu.); corn, sorghum, and rye (56 lbs./bu.); barley (48 lbs./bu.); oats (32 lbs./bu.); and rice (45 lbs./bu.). When producers deliver grain that is significantly below the official weights the prices are discounted. Official U.S. Grain Standards (developed and used under authority of the United States Grain Standards Act, USGSA) include test weight criteria.

Detection method of plated layer corrosion rate in steel wire or steel wire rope

InactiveCN103353432AJudging the anti-corrosion abilityThe service life is easy to judgeWeighing by removing componentWeather/light/corrosion resistanceAlcoholSalt spray test

The invention relates to a detection method of plated layer corrosion rate in a steel wire or a steel wire rope. The method comprises the process steps that: 1, a sample is prepared, wherein a plated steel wire or steel wire rope is cut into N segments; the surfaces are cleaned by using alcohol cotton; and the ends are sequentially sealed by using a solid sealant (AB composite adhesive), such that N samples are prepared; 2, the samples are weighed; 3, a salt spray test is carried out, wherein the weighed samples are subjected to a neutral salt spray test in a salt spray box; 4, the surfaces of the samples are cleaned, wherein the samples after the salt spray test are washed in a container with a prepared chromic acid cleaning agent, such that residual salt and corrosives on the surface of the samples are completely removed; the samples are washed by using water, and are dried; and 5, weighing and calculation are carried out, wherein the dried samples are weighed, and the weights are adopted as after-test weights; and the corrosion rate is calculated according to the weight loss before and after the test. With the method provided by the invention, corrosion-resistant rates of various plated layers can be easily determined, and the service lives of the plated layer samples in the environment can be inferred.

Owner:JIANGSU FASTEN MATERIAL ANALYSIS & INSPECTION

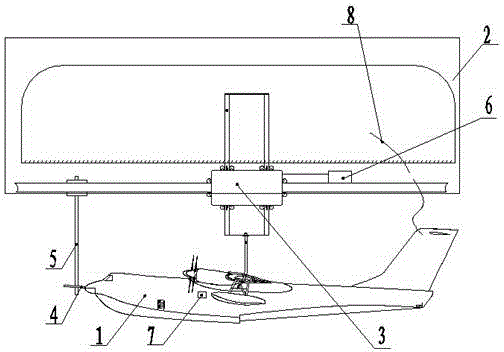

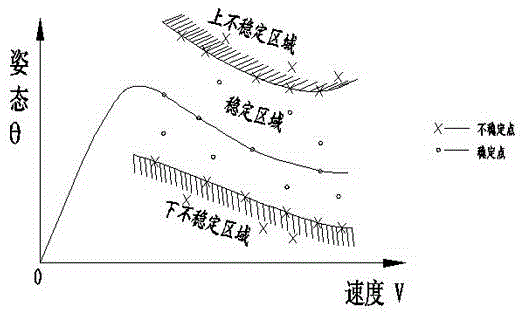

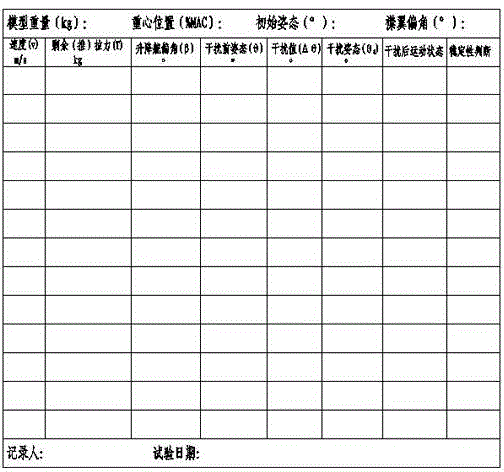

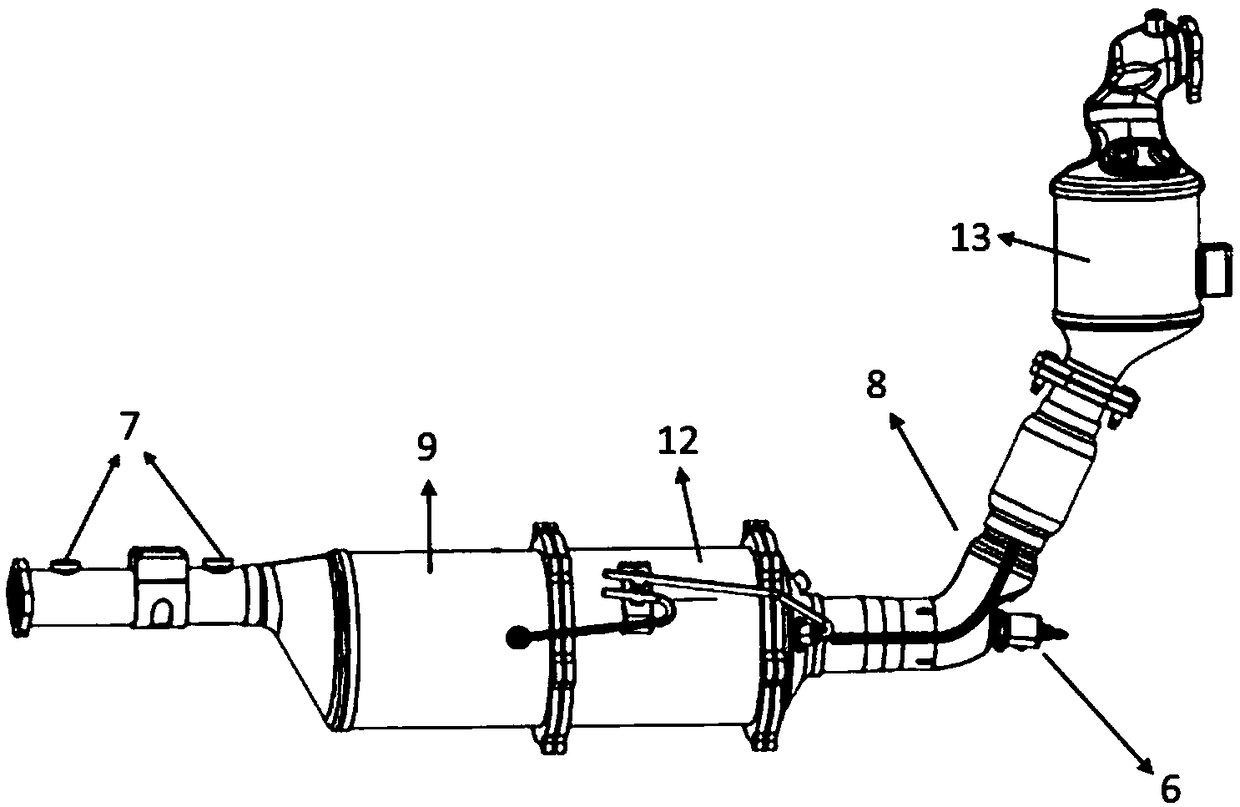

Surface aircraft stability whole-machine power model basin test method

ActiveCN104596732APractical methodMethod is feasibleHydrodynamic testingFlight vehicleData collecting

Disclosed is a surface aircraft stability whole-machine power model basin test method. The surface aircraft stability whole-machine power model basin test method comprises the test steps of a, installation of a whole-machine power model and a test device; b, installation of a data collecting device. Specifically, the method comprises observing and recording the motion state and the motion process of the whole-machine power model (1) under disturbance; during the test, recording the state of the whole-machine power model (1) as well parameters such as the angle of deflection of flaps, the angle of deflection of an elevator, test weight and center of gravity and test speed. After finishing the test, data analyzing personnel should perform comprehensive analysis on the collected data according to the collected data and test phenomena as well as validity evaluation on test data. The surface aircraft stability whole-machine power model basin test method has the advantages of being practical, feasible, simple in operation and reliable in test results.

Owner:CHINA SPECIAL TYPE FLIER RES INST

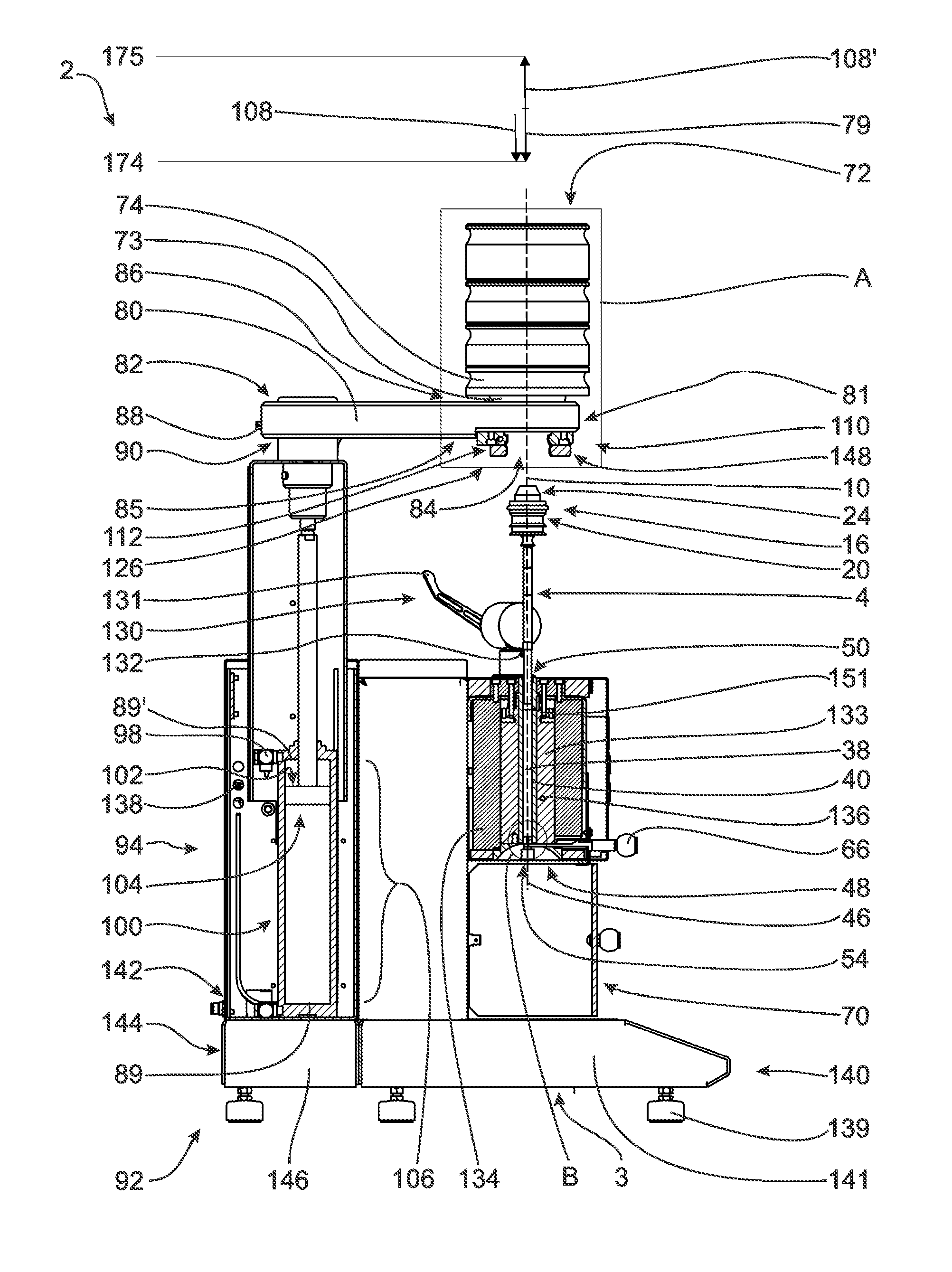

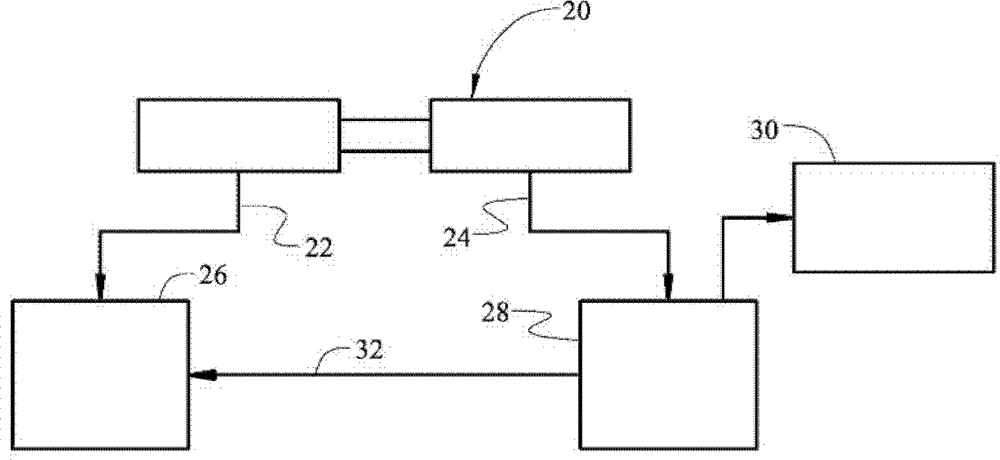

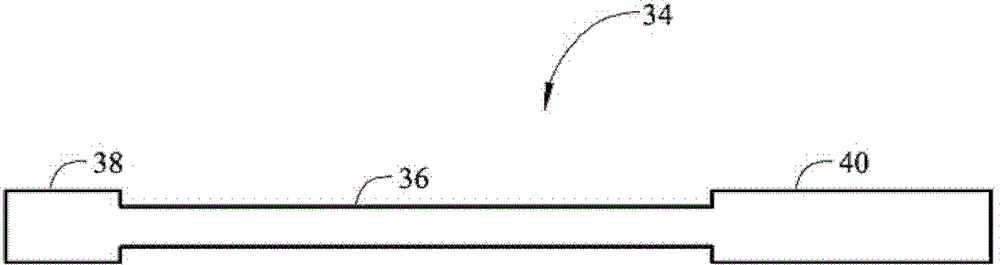

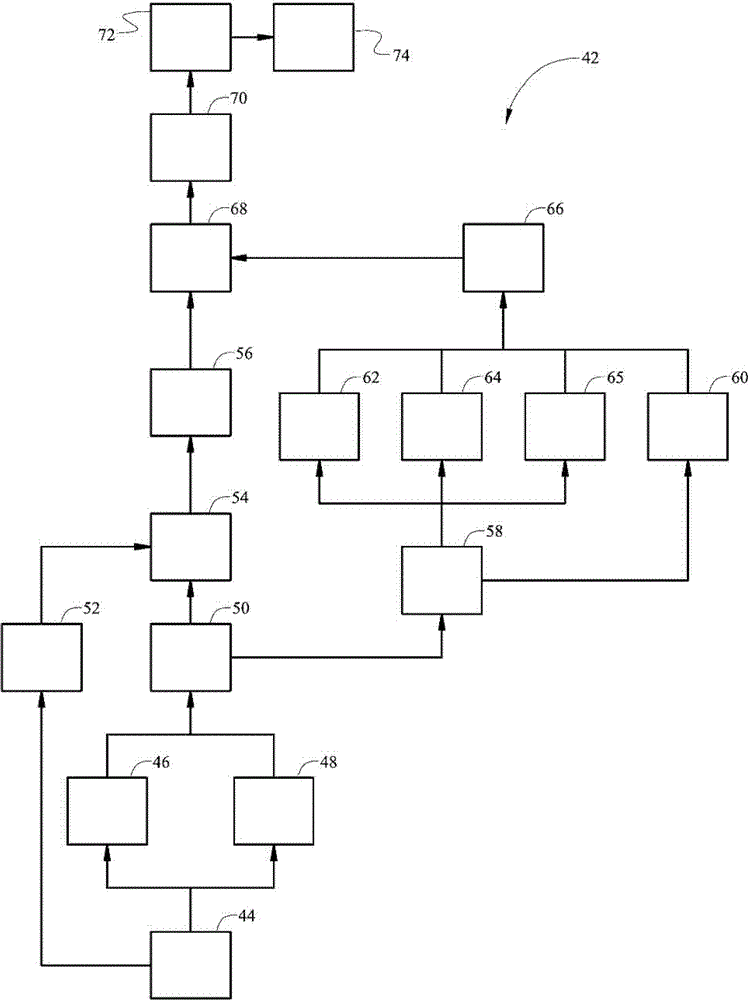

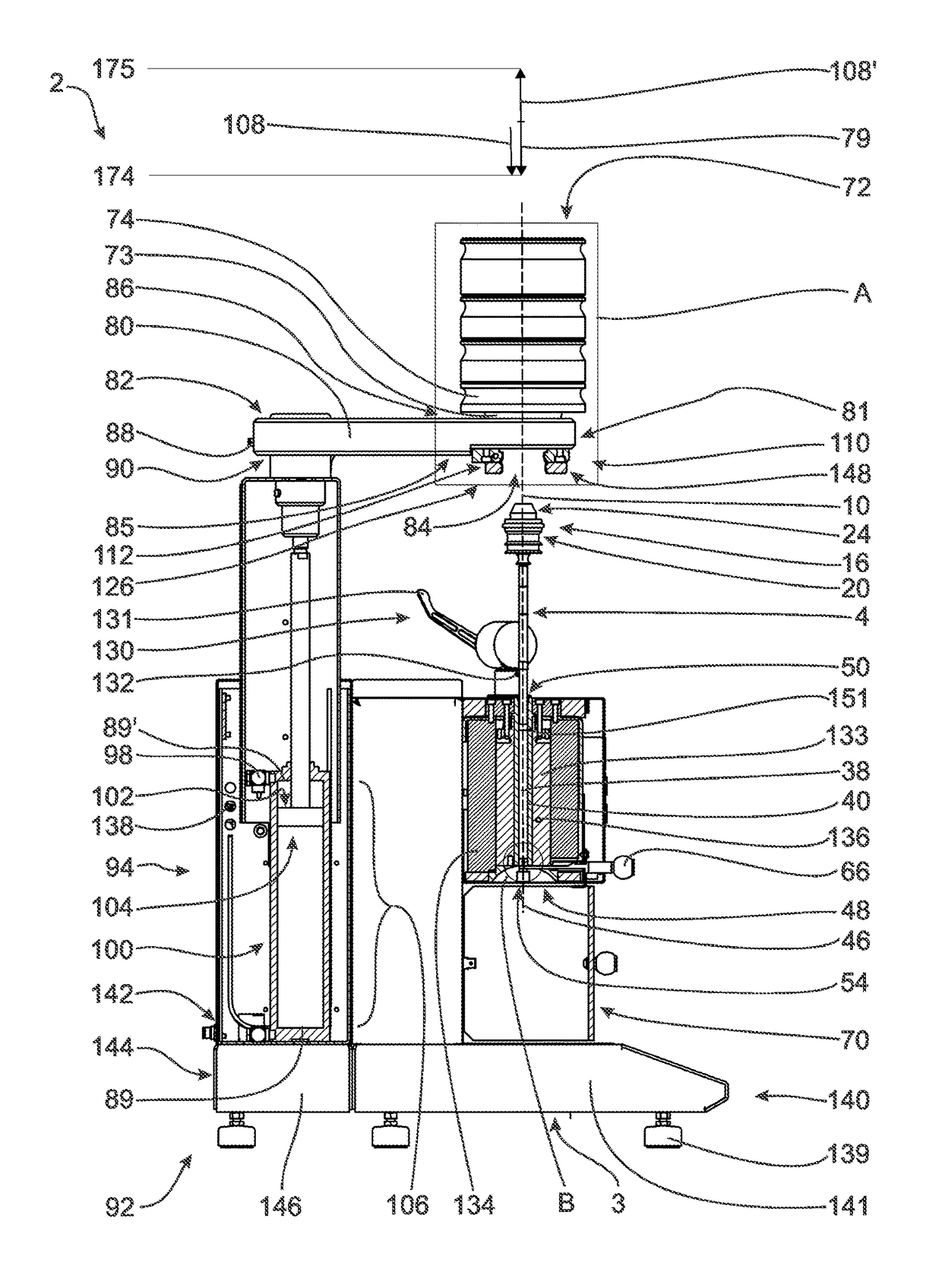

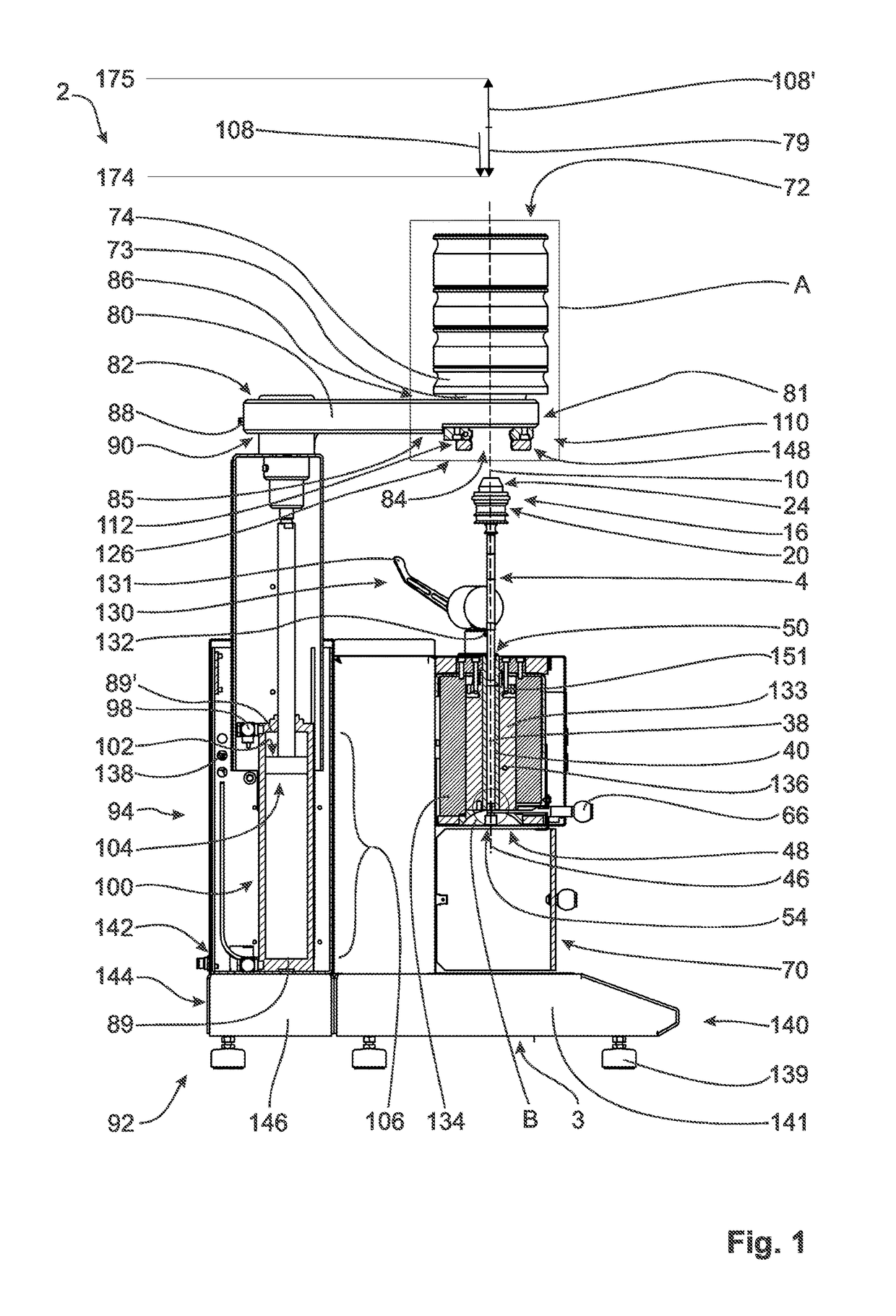

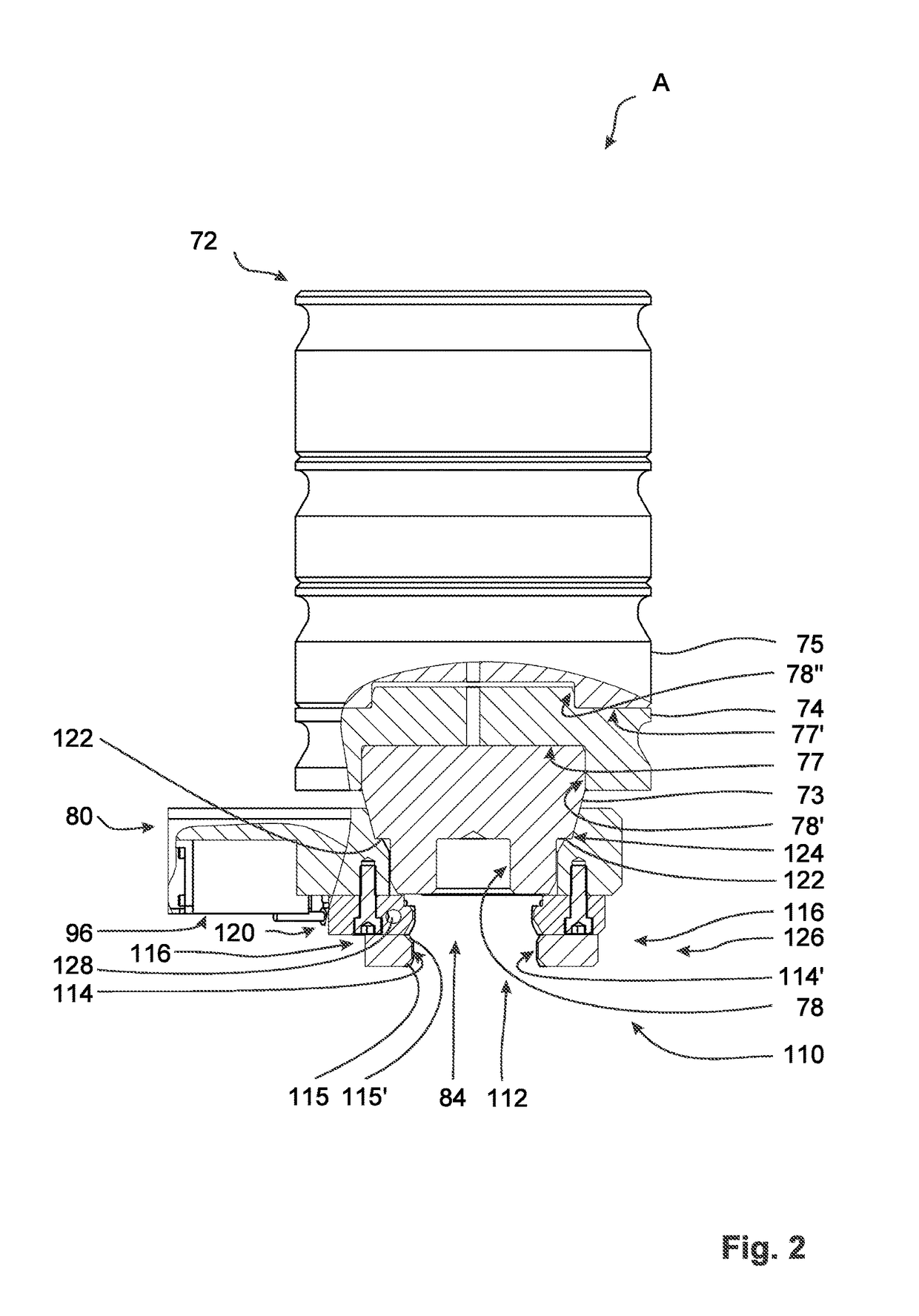

Flow test machine and an associated measurement method, as well as an associated cleaning process

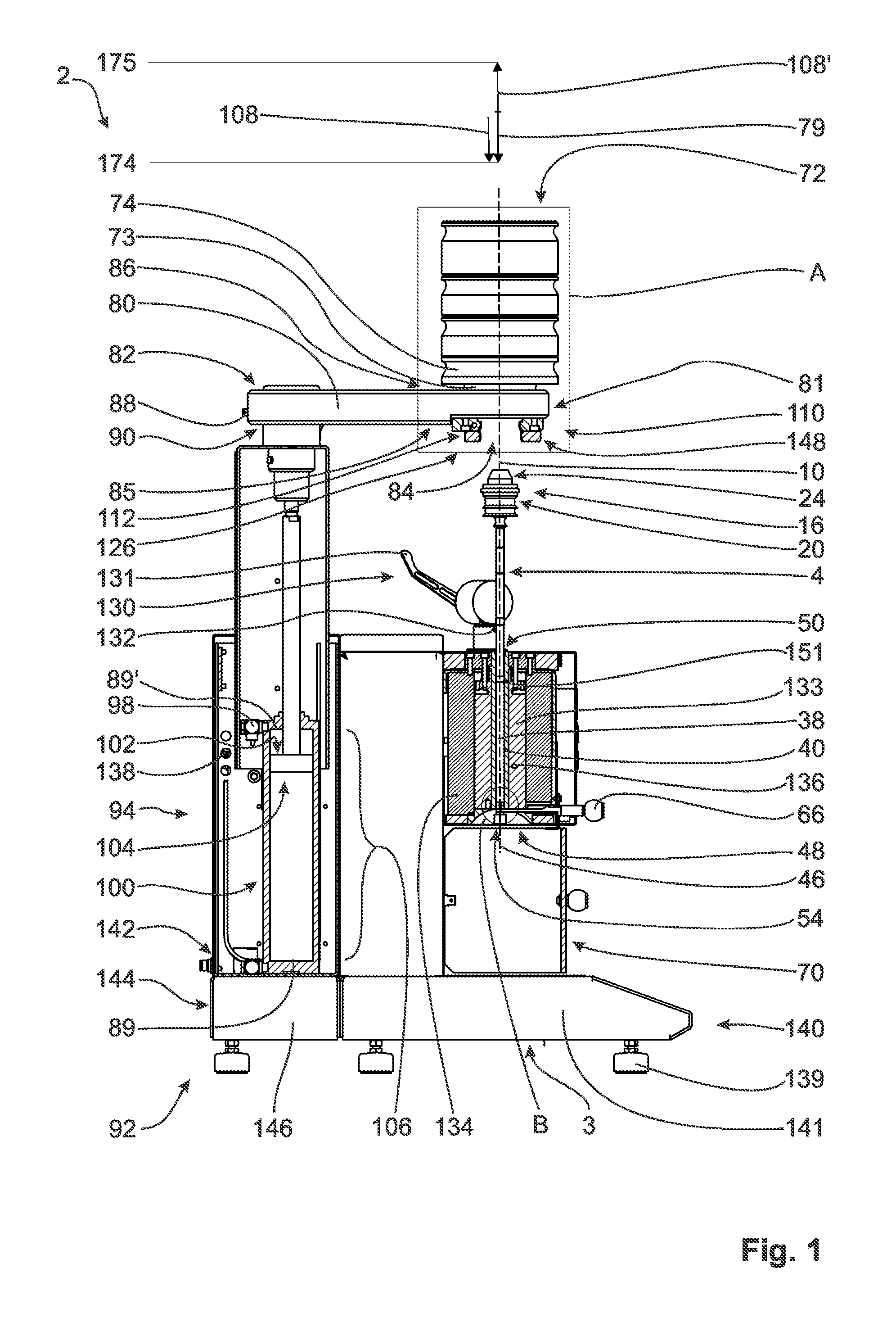

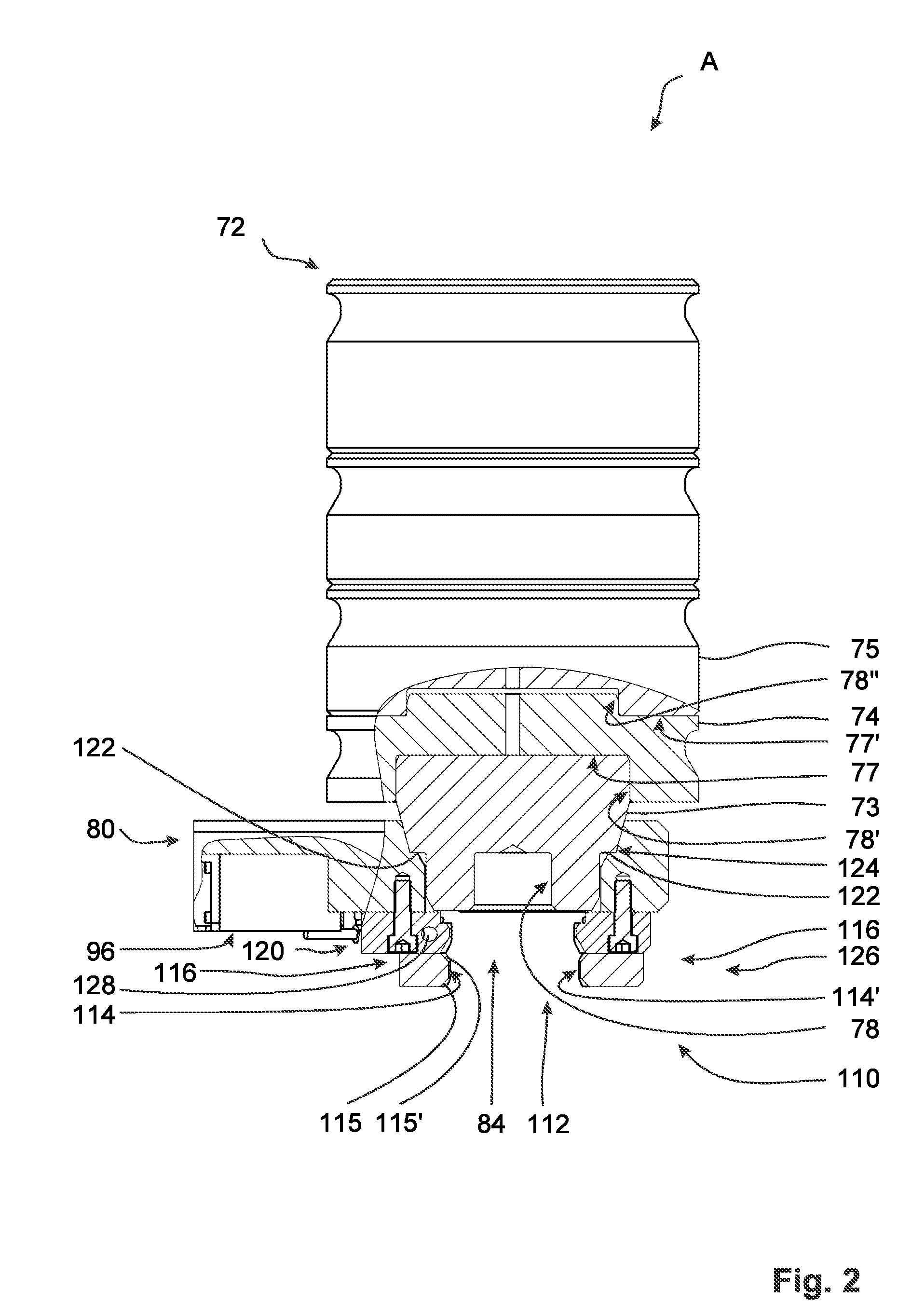

ActiveUS20160091404A1Solve insufficient heating capacityReduce the amount requiredHollow article cleaningMaterial strength using tensile/compressive forcesThermoplasticTest channel

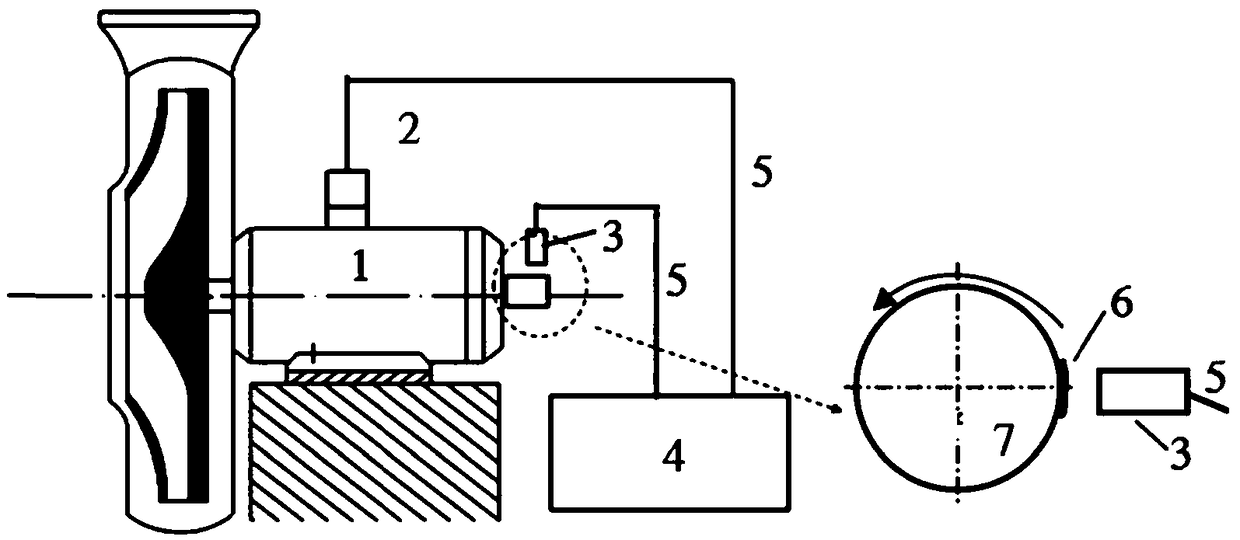

A flow test machine 2 which, for example, is able to be used for viscosity tests on plastics, comprises a test piston 4, a test channel 38, at least one test weight 72 and a drive unit 92. The test piston 4 is able to move through the test channel 38 by means of a weight force 79 of the test weight 72. The test weight 72 is able to be loaded by an actuating additional force 108, 108′ by means of the drive unit 92 between a starting position 151 and an end position. The actuating additional force 108 enables a movement of the test piston 4 in the direction of the weight force 79, said movement being accelerated in comparison with an effect of the weight force 79. In a melt viscosity test, after a heating step, a thermoplastic plastic is pressed through a test channel 38 by a test piston 4. In a measurement preparation step and / or a cleaning step, the test mass is lowered along a weight force direction 79 under the influence of an actuating additional force 108, 108′. In a method for cleaning, a cleaning step is undertaken by means of an actuating additional force 108, 108′ from the drive unit 92, said drive unit 92 serving to drive a test piston movement during a melt viscosity test.

Owner:ZWICKROELL GMBH & CO KG

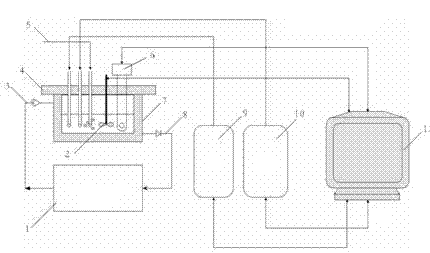

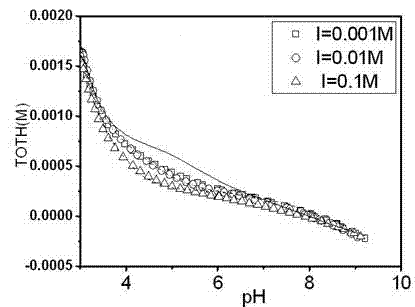

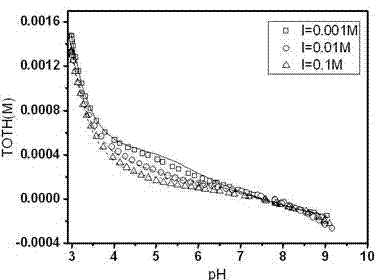

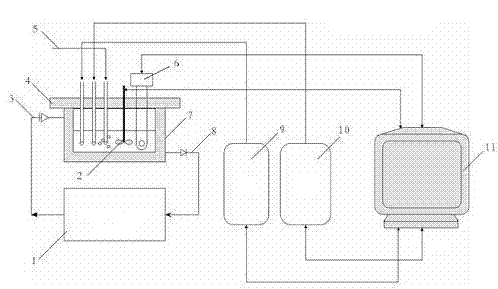

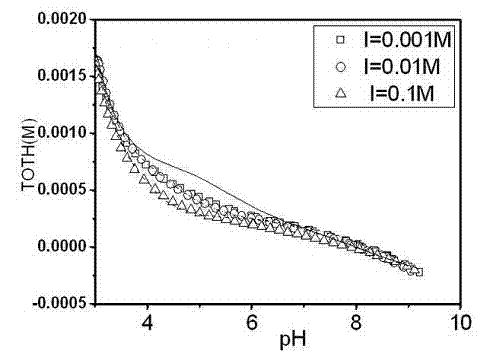

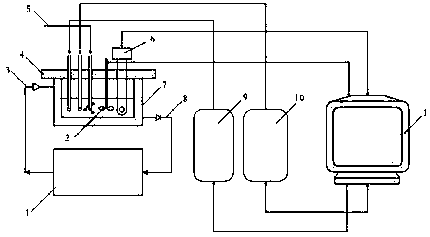

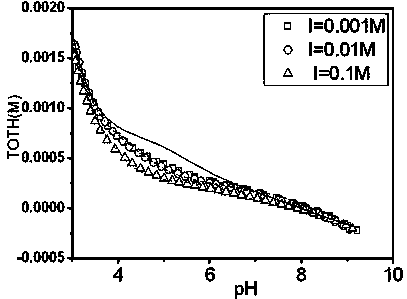

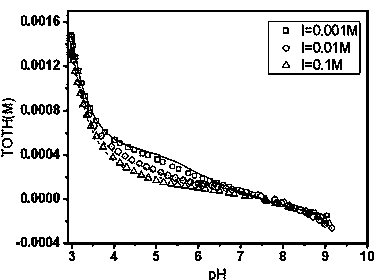

Method for determining dissolving state and adsorption state of Cd (II) in mineral soil

InactiveCN102590471ASolve the unpredictableEarth material testingMaterial electrochemical variablesCation-exchange capacitySkin complexion

The invention provides a method for determining dissolving state and adsorption state of Cd (II) in mineral soil, and belongs to the field of soil analysis. The method comprises the steps: separating clay minerals from the soil, testing the CEC (cation exchange capacity) value and the specific surface area Ss of the minerals, testing acid-base constants (namely logK(+), logK(-) and logK(Na, H)) of the surface of the clay minerals, testing metal surface complexion constants (namely logK(AlOCd) and logK(X2Cd)) of the surface of the clay minerals, testing weight percentages of organic matters, iron oxide and clay granules in the soil, and constructing a full-soil model. According to the method for determining dissolving state and adsorption state of Cd (II) in the mineral soil, the problem that the states of Cd in the soil cannot be predicated is solved, the determination method for the state and the concentration of Cd in a soil system is created, and the method can be used for predicating the effective concentration of Cd in the mineral soil.

Owner:NANJING UNIV

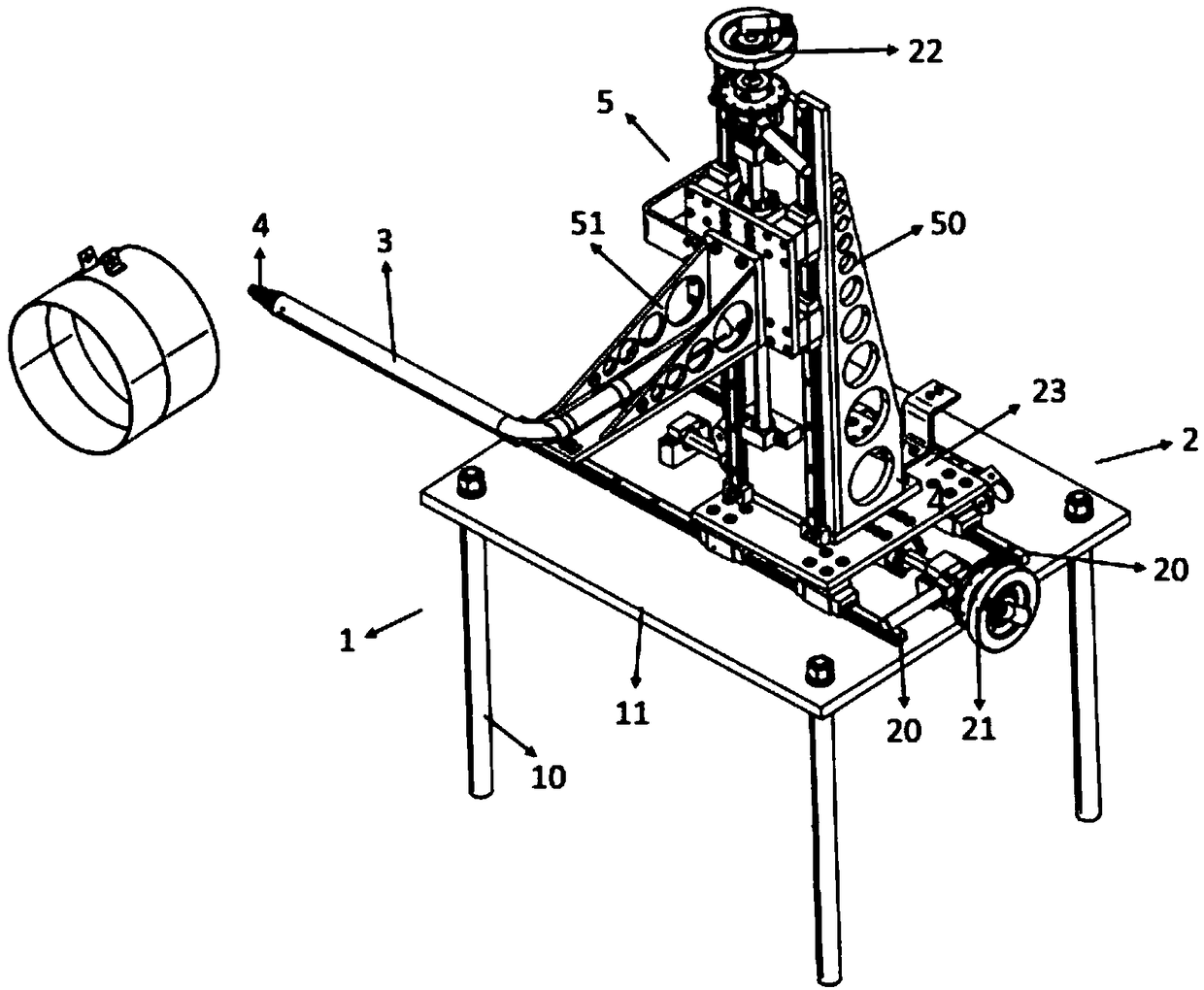

Auxiliary ammonia uniformity testing equipment and testing method thereof

PendingCN109252929AEasy to operateLow failure rateInternal combustion piston enginesExhaust apparatusFailure rateHeat flow

The invention provides auxiliary ammonia uniformity testing equipment and a testing method thereof. The testing method includes: firstly, testing weight of crystallization state test part of a postprocessing system of a diesel vehicle; secondly, performing a urea heat flow test; finally, testing a weight variation of the crystallization state test part again, testing ammonia concentrations of different positions of the crystallization state test part through the auxiliary ammonia uniformity testing equipment, and evaluating to obtain urea uniformity. The auxiliary ammonia uniformity testing equipment is capable of testing the ammonia concentrations of different positions of a tested object, and has the advantages of simplicity in operation, low failure rate, accuracy in test points and lowcost.

Owner:SHANGHAI GOTEK CATALYST +1

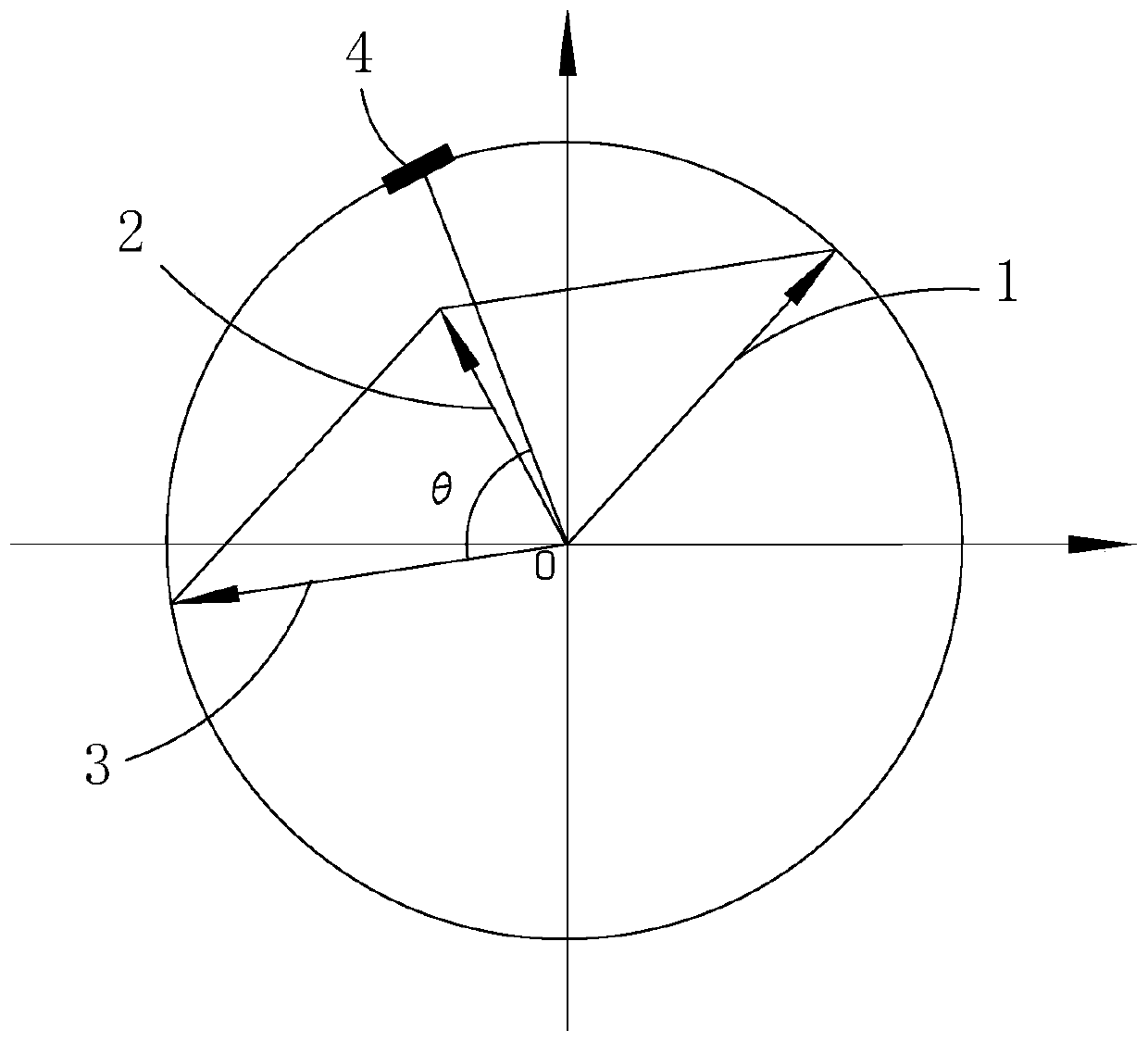

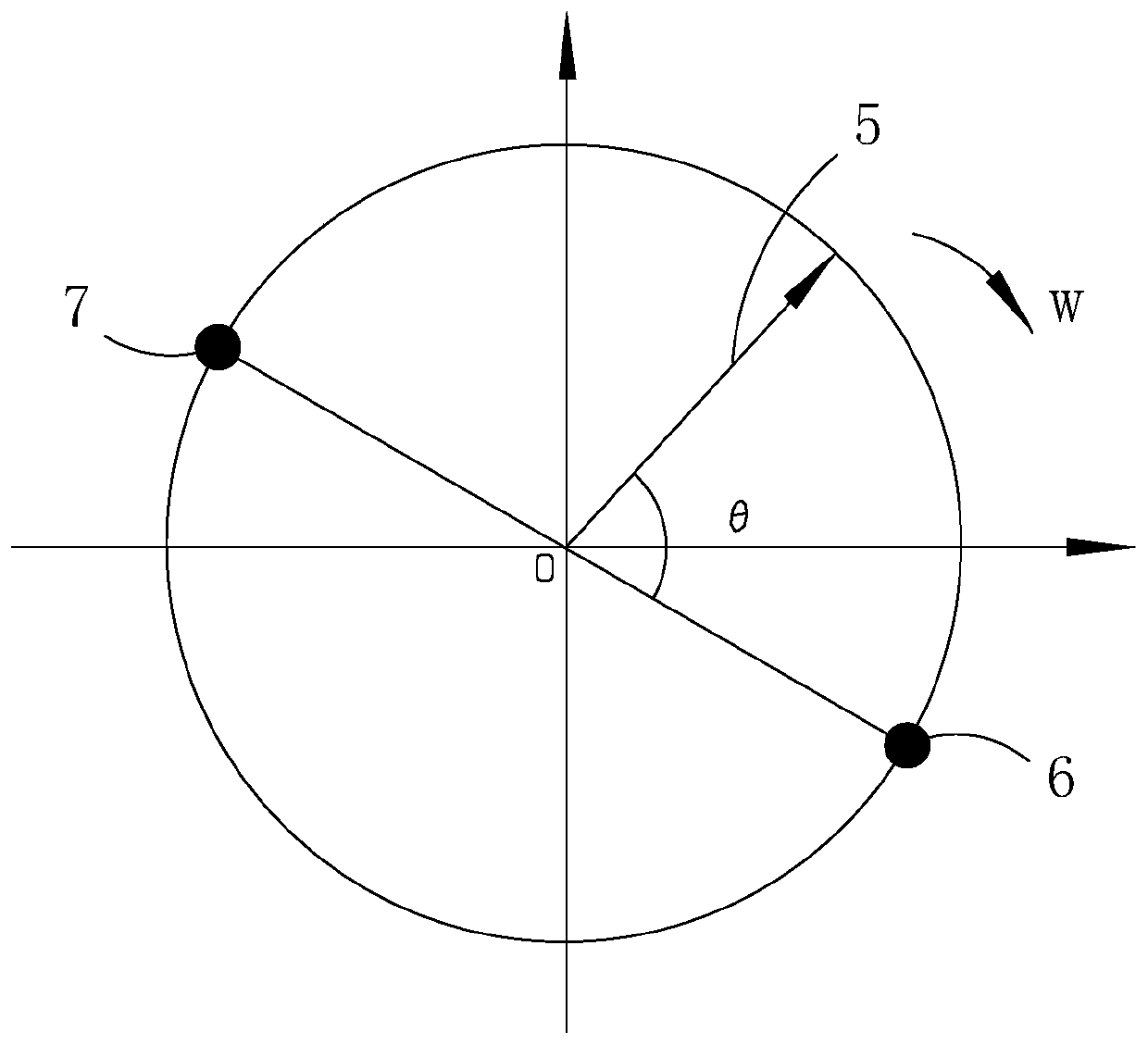

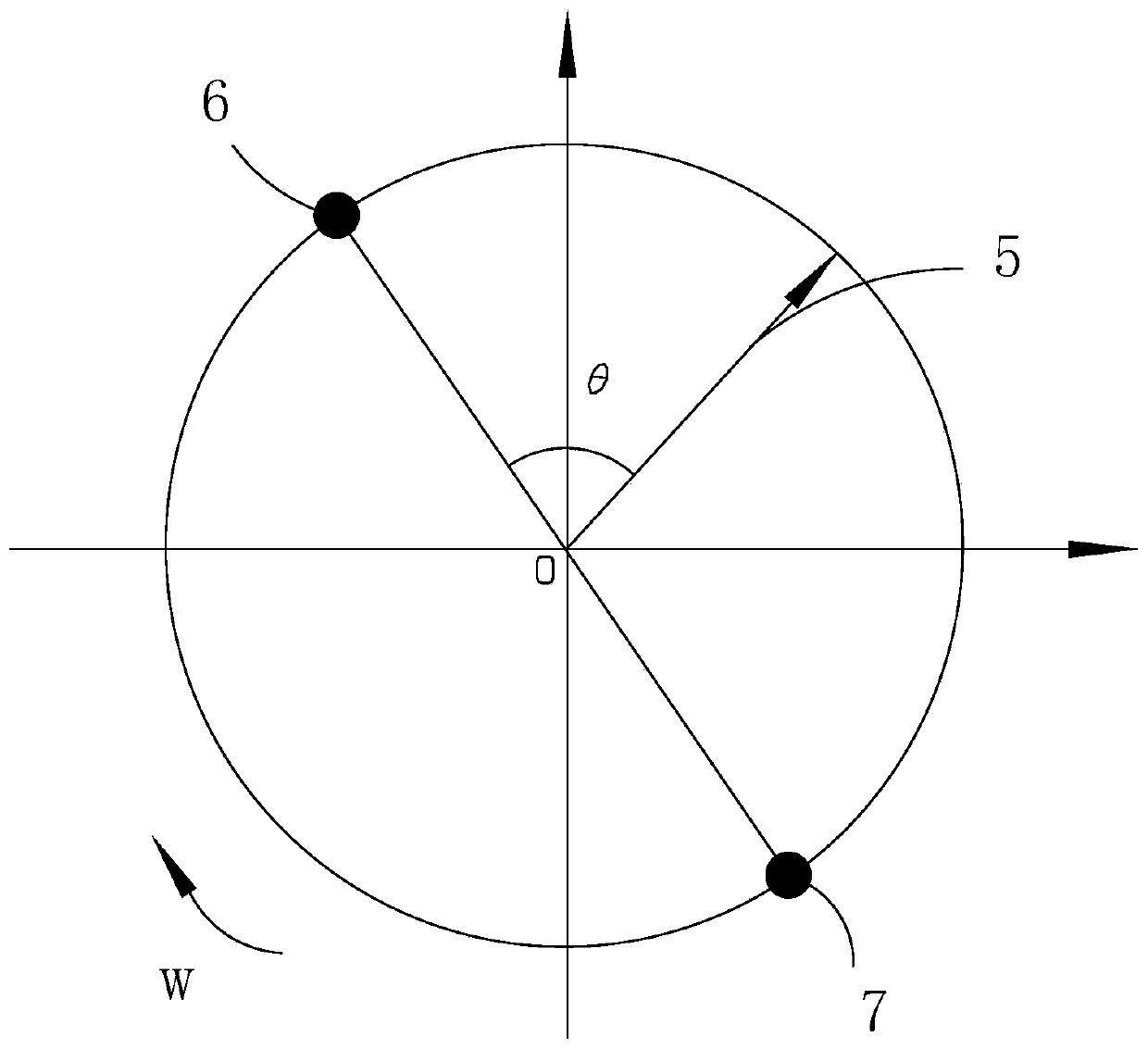

Calculation method of on-line dynamic balance of fan

InactiveCN110243541AImprove efficiencyShorten the timeStatic/dynamic balance measurementDynamic balanceEngineering

The invention provides a calculation method of on-line dynamic balance of a fan, and belongs to the technical field of dynamic balance of fans. The calculation method comprises the following steps of measuring an initial vibration vector, performing shutdown, adding a test weight, measuring a test weight vibration vector, dividing the weight of the test weight by the vibration magnitude of the test weight vibration vector to obtain a counterweight ratio of increase or decrease unit vibration quantity, determining the magnitude of a lag angle theta, measuring a target vibration vector of the same fan, obtaining the weight of a to-be-mounted balance weight by the vibration quantity in the target vibration vector, rotating the corresponding lag angle theta based on a phase angle in the target vibration vector to obtain a non-balance position point, performing rotation by 180 degrees at the non-balance position point to obtain a balance weight position point, and mounting the balance weight to the balance weight position point. The calculation method of the on-line dynamic balance of the fan does not require machine start or stop for many times; the time consumption of a dynamic balance experiment is low; and great manpower and material resources are saved.

Owner:XINXING DUCTILE IRON PIPES CO LTD

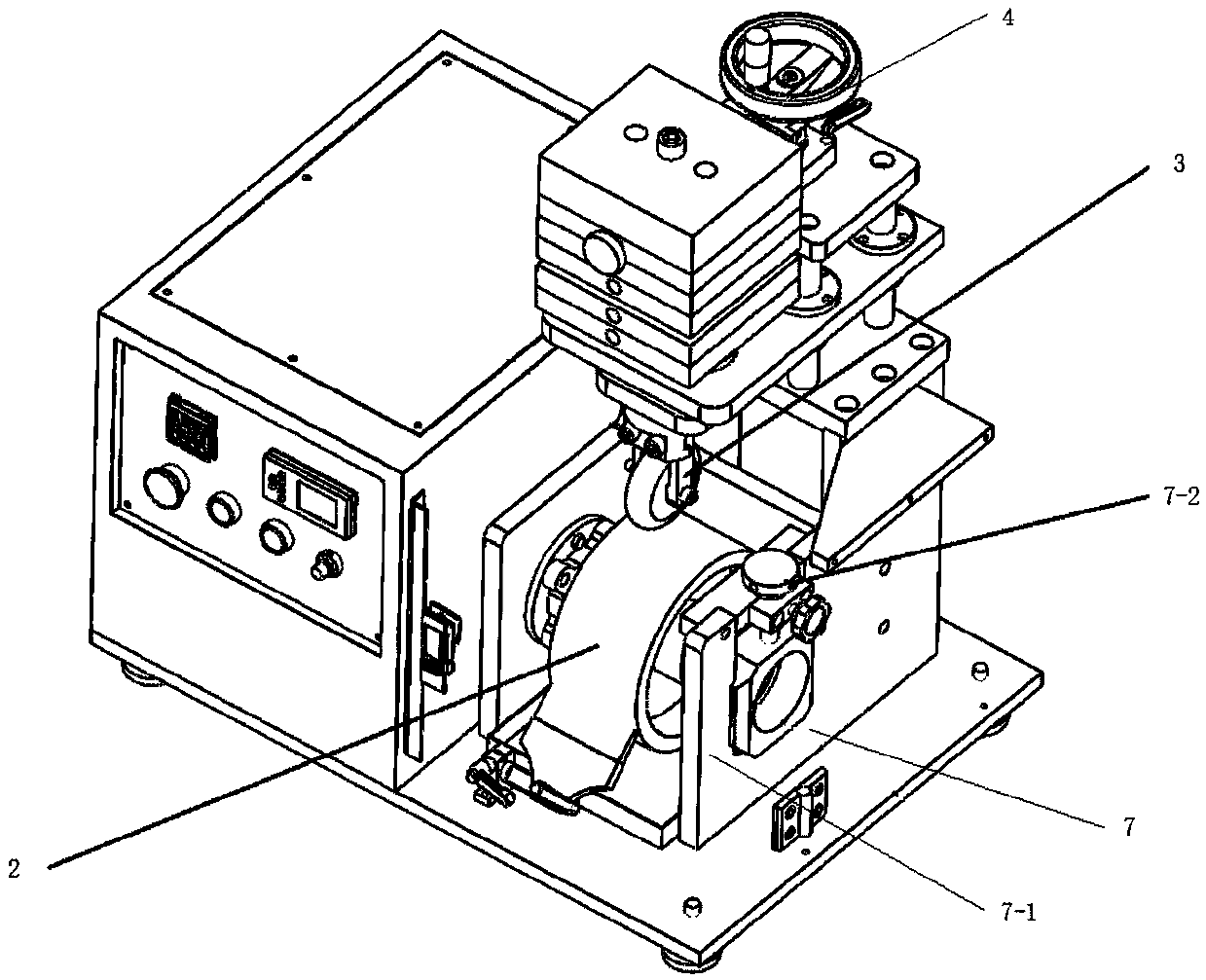

Digital type tear strength tester

InactiveCN105910907AEliminates the hassle of manual setupSimple structureMaterial strength using tensile/compressive forcesEngineeringGravitational potential

The invention discloses a digital type tear strength tester which comprises an energy conversion mechanism for converting gravitational potential energy into kinetic energy, a clamping mechanism for clamping a test sample and a measurement mechanism for measuring energy loss, wherein the energy conversion mechanism comprises a swing device and a test weight; the test weight is hung on the swing device, and the swing device swings to convert the gravitational potential energy of the test weight into the kinetic energy of the swing device; the clamping mechanism comprises a movable part and a fixed part; the movable part of the clamping mechanism is connected with the swing device; the fixed part is fixed on a stander of the tester; under the action of the swing device, the movable part and the fixed part of the clamping mechanism are separated, so that the test sample clamped on the movable part and the fixed part is torn away; the measurement mechanism comprises an angle encoder; the angle encoder is connected with the swing device; and the swing device swings, so that the angle encoder reads an angle variable. The digital type tear strength tester has the advantages of simple structure, simplicity and convenience in operation, small test error, high test accuracy, high test efficiency and the like.

Owner:SHENZHEN REFOND EQUIP CO LTD

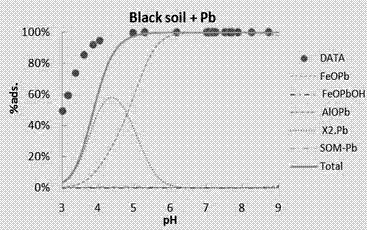

Method for determining dissolving state and adsorption state of Pb (II) in mineral soil

InactiveCN102590470ASolve the unpredictableEarth material testingMaterial electrochemical variablesSkin complexionCation-exchange capacity

The invention provides a method for determining dissolving state and adsorption state of Pb (II) in mineral soil, and belongs to the field of soil analysis. The method comprises the steps: separating clay minerals from the soil, testing the CEC (cation exchange capacity) value and the specific surface area Ss of the minerals, testing acid-base constants (namely logK(+), logK(-) and logK(Na, H)) of the surface of the clay minerals, testing metal complexion constants (namely logK(AlOPb) and logK(X2Pb)) of the surface of the clay minerals, testing weight percentages of organic matters, iron oxide and clay granules in the soil, and constructing a full-soil model. According to the method for determining dissolving state and adsorption state of Pb (II) in the mineral soil, the problem that the states of Pb in the soil cannot be predicated is solved, the determination method for the state and the concentration of Pb in a soil system is created, and the method can be used for predicating the effective concentration of Pb in the mineral soil.

Owner:NANJING UNIV

Corrosion testing system for multiphase environments using electrochemical and weight-loss methods

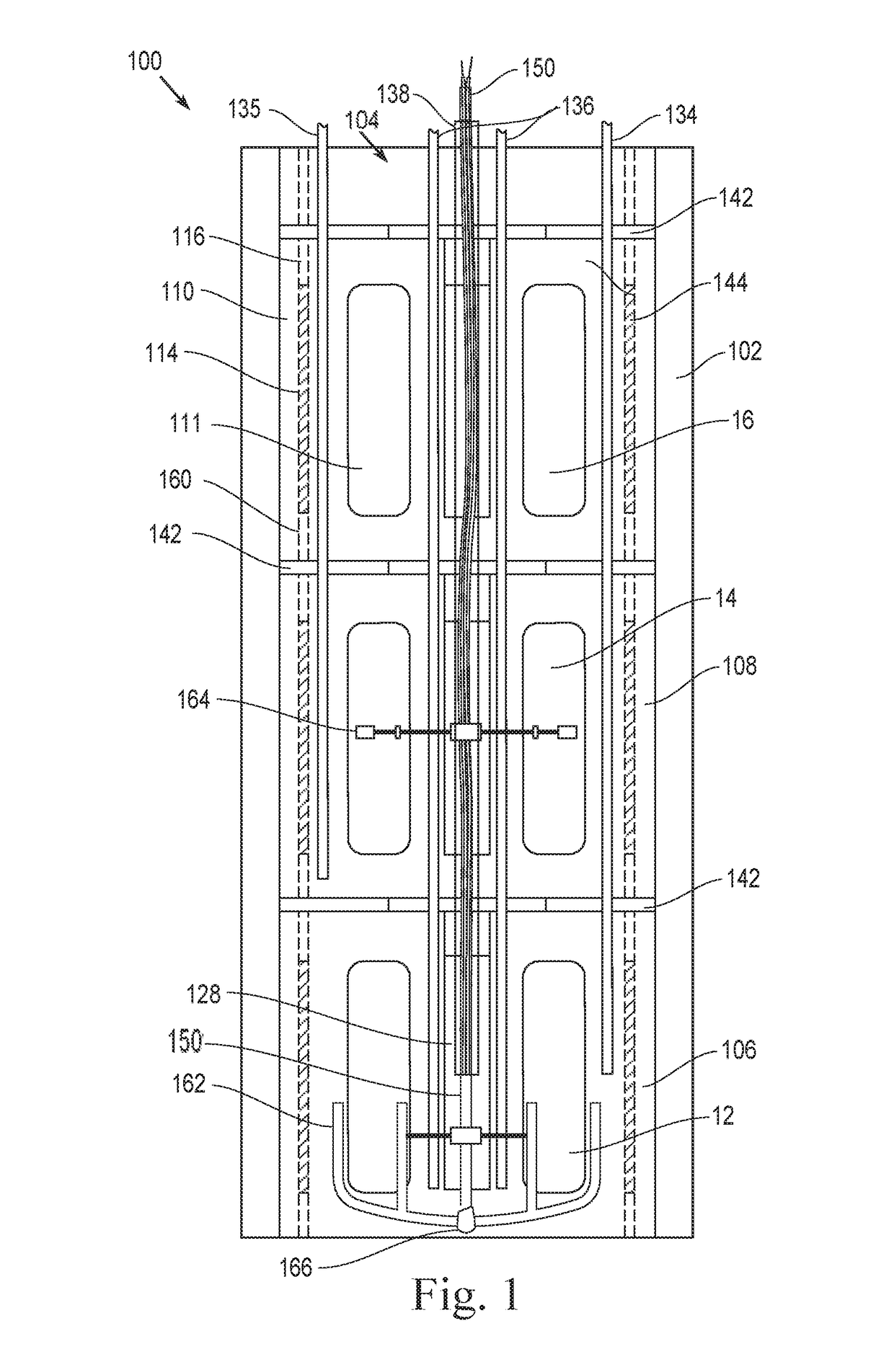

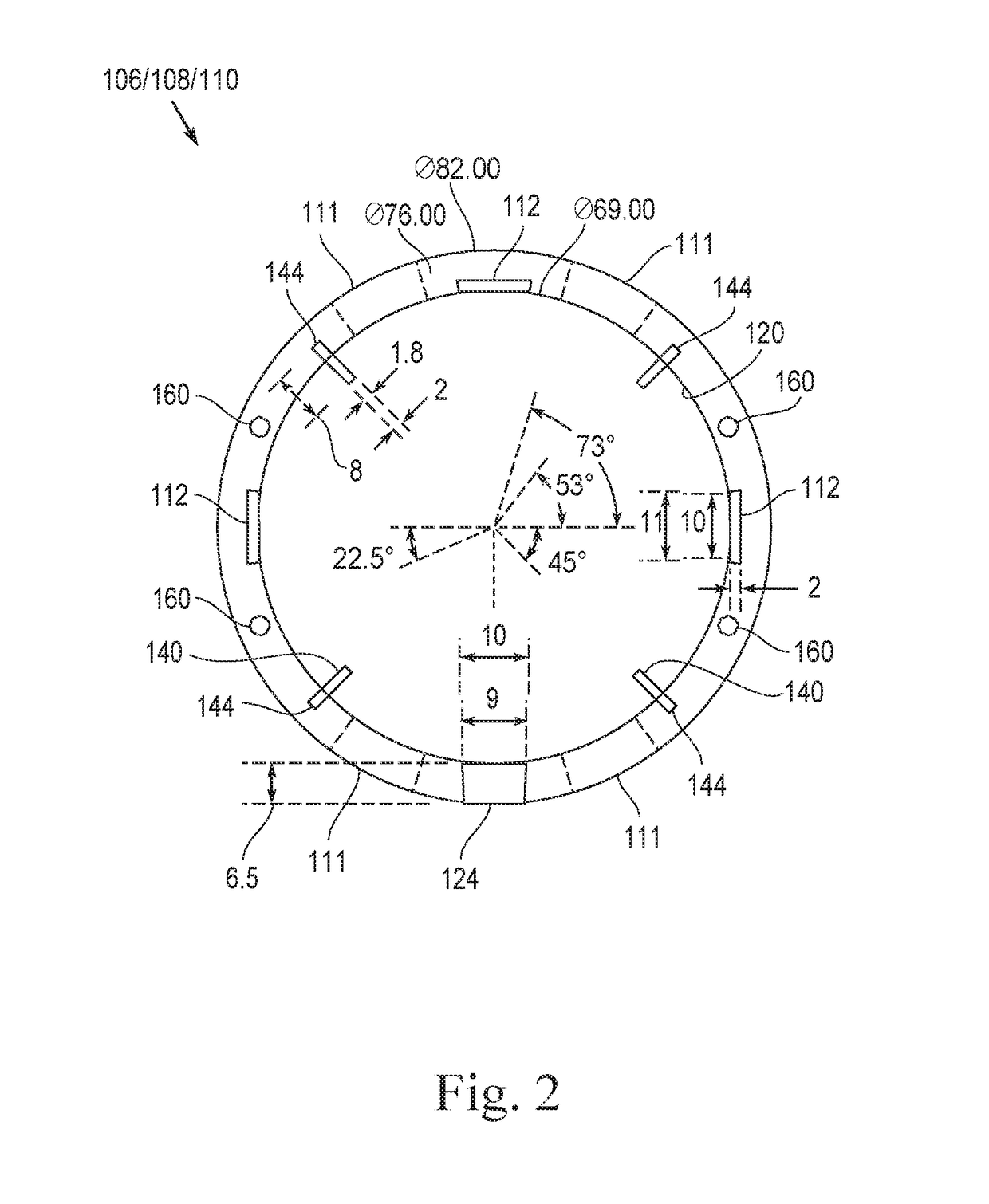

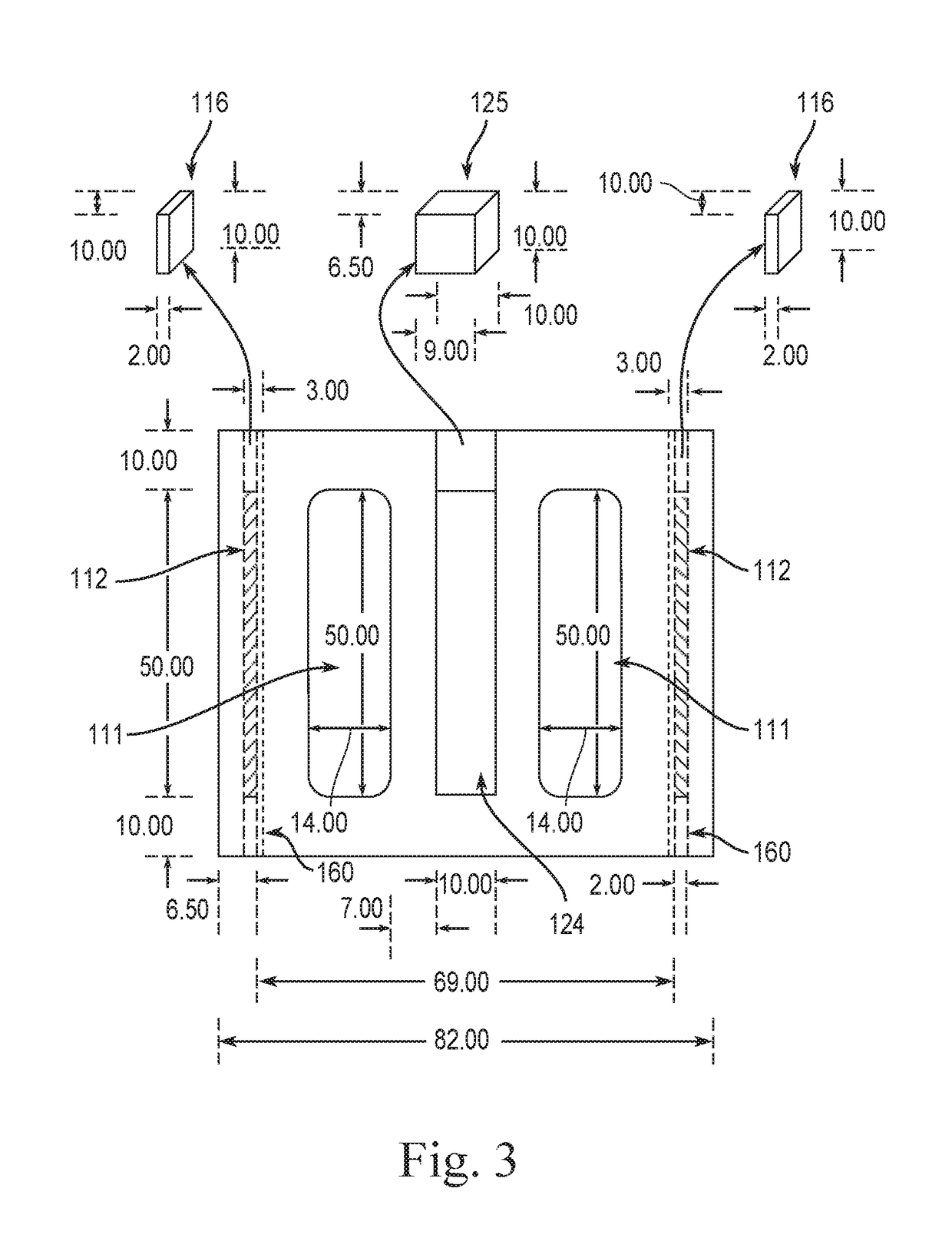

A system for conducting measuring corrosion rates in a multiphase environment using electrochemical and weight-loss measurement methods on test coupons is provided. A plurality of inserts is disposed within a test vessel in a vertical arrangement. Each insert is provided with at least one test coupon and at least one working electrode that are exposed to the corrosive test environment within vessel. A test fluid mixture is added to the vessel and the temperature and pressure is maintained such that the mixture exists in a multiphase condition that has a vertical stratification such that each insert is exposed to a different phase of the fluid. Electrical signals from the working electrode is measured to determine the corrosion rate using an electrochemical method. The pre-test weight of the coupon is compared to the post-test weight to determine the corrosion rate using a weight-loss method.

Owner:SAUDI ARABIAN OIL CO

Rotor dynamic balancing method without weight removal

ActiveCN109406053AHigh technical requirementsLabor intensiveStatic/dynamic balance measurementDynamic balanceEngineering

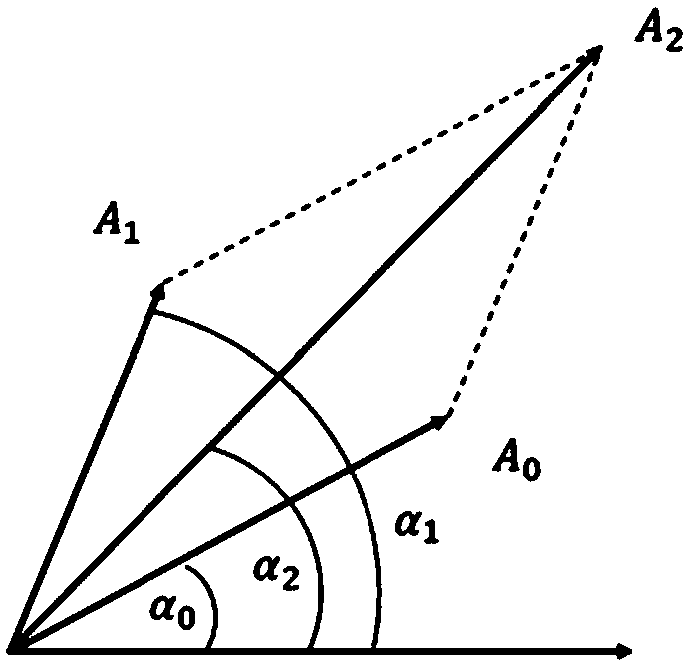

The invention discloses a rotor dynamic balancing method without weight removal, and belongs to the technical field of rotor dynamic balance. The rotor dynamic balancing method without weight removalprovided by the invention can achieve balance just by adding weights twice, eliminates a weight removal process, greatly improves balance precision, reduces balance cost, improves balance efficiency,and avoids accidents. The method comprises steps of a, installing a vibration sensor horizontally on a rotor bearing seat to acquire a vibration signal, attaching reflective paper to a rotor shaft, measuring a rotational speed signal by using a speed sensor facing the reflective paper, and measuring the amplitude and the phase of the unbalanced vibration of the rotor by a dynamic balancer; b, after a test weight is added, measuring the amplitude and the phase of the unbalanced vibration again; and c, solving the magnitude and the position of the unbalanced weight according to a formula, addingthe same correcting weight to an opposite side so as to greatly reduce the vibration and achieve balance.

Owner:ZHEJIANG UNIV

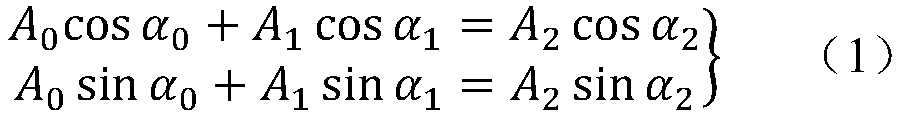

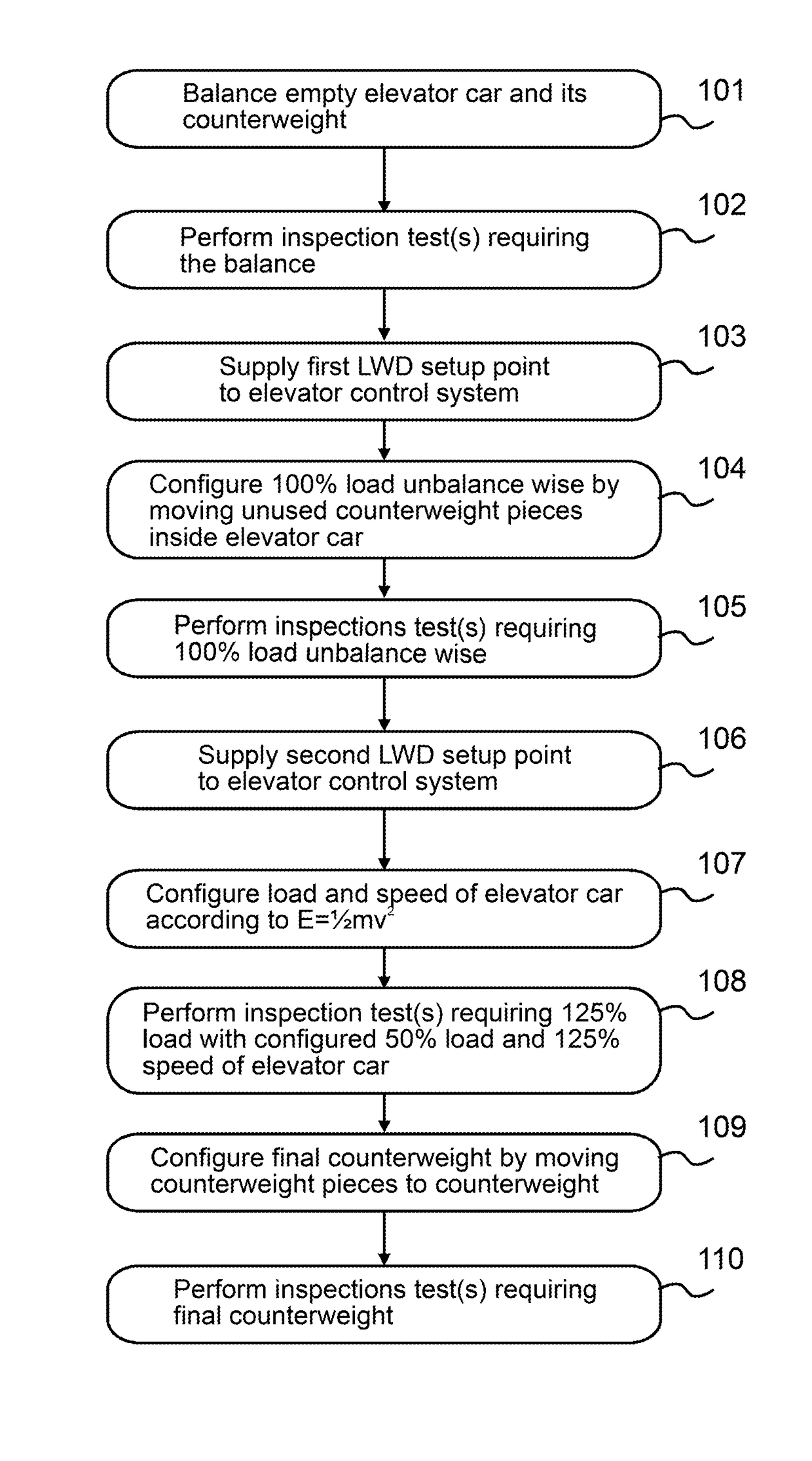

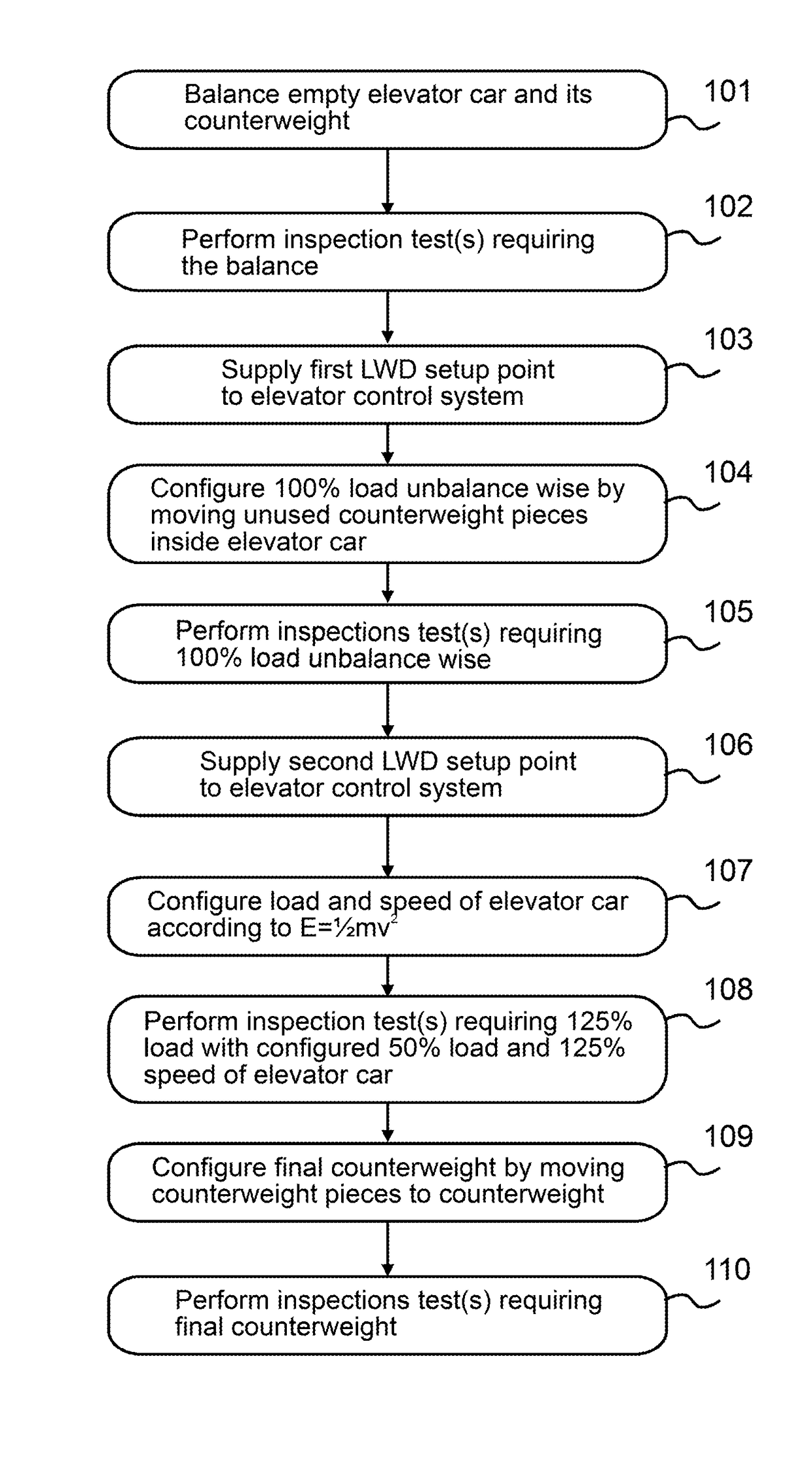

Inspection tests for an elevator without additional test weights

The invention allows inspection tests for an elevator without additional test weights. An empty elevator car and its counterweight are balanced by filling in weight pieces to the counterweight. 100% load of the elevator car in regard to unbalance is configured by moving unused counterweight pieces inside the elevator car. Inspection tests requiring the 100% load in regard to unbalance are performed. 125% load of the elevator car is simulated with 50% load and 125% speed of the elevator car. Inspection tests requiring the 125% load in regard to unbalance are performed. A final counterweight is configured by moving its weight pieces from the elevator car to the counterweight. Inspection tests requiring the final counterweight are performed.

Owner:KONE CORP

Method and system for testing weight balance of racket and ball arm

ActiveCN102305691AShow weight distributionCompact structureStatic/dynamic balance measurementEngineeringTest platform

The invention discloses a method and a system for testing the weight balance of a racket and a ball arm. The system comprises a test platform and an upper control host, wherein the test platform has a box body structure; the top of the box body is provided with a horizontal mounting surface; the horizontal mounting surface is provided with at least one head contact base and one tail contact base;the positions at which the head contact base and the tail contact base are arranged are opposite, and the top end faces of the head contact base and the tail contact base are positioned on the same horizontal plane; the bottom parts of the head contact base and the tail contact base are connected with pressure sensors; a control chip is arranged inside the test platform; and the control chip processes signals transmitted by the pressure sensors and outputs related data to the upper control host. The system has a compact structure, is convenient to use and has high automation degree. The weight and the balance points of objects to be tested can be acquired after the objects to be tested are arranged as required during operation, the weight distribution of measured parts can be displayed, the measurement speed is high, and the method and the system are suitable for testing mass products.

Owner:XIAMEN BAOSHENG COMPOSITES TECH

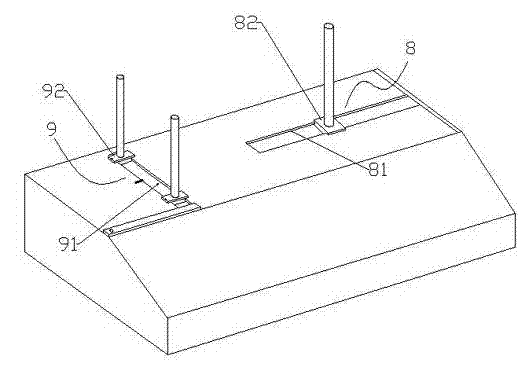

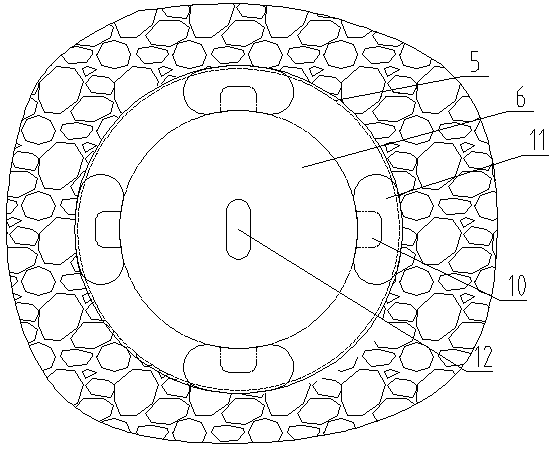

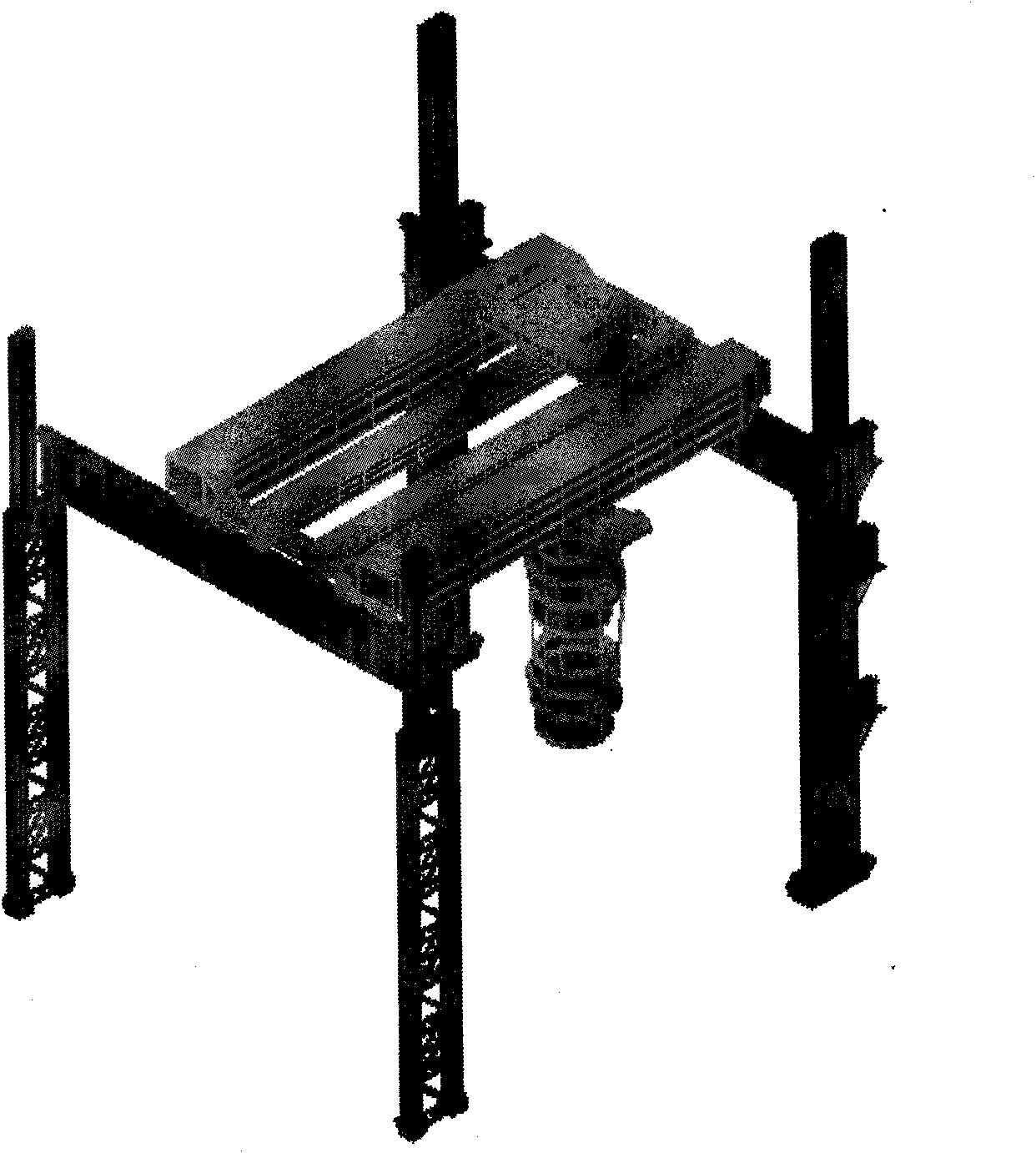

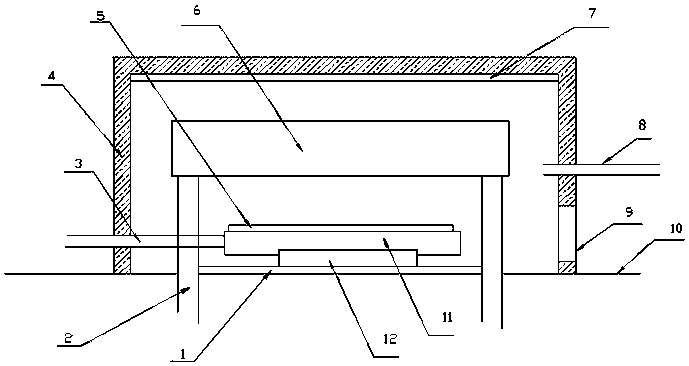

Load test device and method for chain hoist

PendingCN110118653AMeet the needs of the loadReduce cost inputMachine part testingEngineeringFactor of safety

The invention discloses a load test device for a chain hoist. The device comprises a weight and a pit for placing the weight, wherein the bottom of the pit is provided with a weight bottom support, the middle portion of the weight bottom support comprises an upwardly disposed positioning rod, and the middle portion of the weight is provided with a positioning hole adapted to the positioning rod. The invention also discloses a load test method specifically comprising the following steps of (1) load test of a 0.5t chain hoist; (2) load test of a 1t chain hoist; and (3) load test of a 2t chain hoist. In the load test provided by the invention, the load test of 0.5t, 1t and 2t chain hoists can be realized by switching different hanging points, the weight utilization rate is high, the operationis simple and the work efficiency is high. By arranging the test weight in the pit, the safety factor is greatly improved.

Owner:NUCLEON XINXIANG CRANE

Inbred corn line KWU7104

ActiveUS7041885B2Quality improvementBryophytesOther foreign material introduction processesAgricultural scienceNorth central

Owner:KLEINWANZLEBENER SAATZUCHT

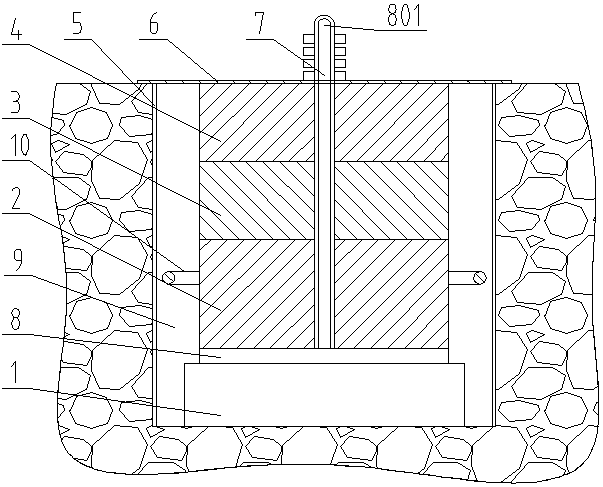

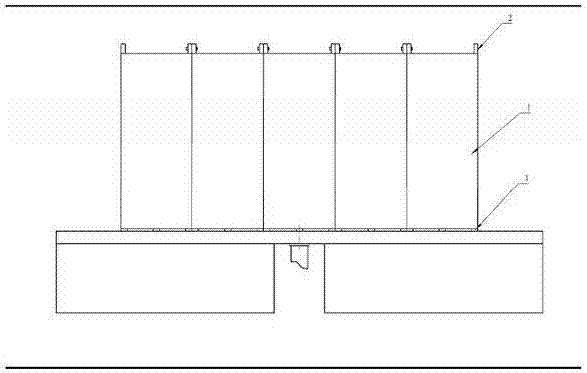

Vertical compression resistance static loading test large base pile ground weight pile-loading method for civil engineering

The invention relates to a vertical compression resistance static loading test large base pile ground weight pile-loading method for civil engineering. The method is applied to vertical compression resistance static loading test weight counter force in civil engineering base pile detection. The method is executed according to the following steps that (a) weight platform buttresses are put up, (b) weight pile-loading hollow tank columns are hoisted on the weight platform, the first weight pile-loading hollow tank column and the axis line of a test pile are overlaid, other weight pile-loading hollow tank columns are hoisted around the first weight pile-loading hollow tank column are completely filled on the whole platform, and when the weight pile-loading hollow tank columns are hoisted, every two adjacent weight pile-loading hollow tank columns are fixedly connected through fixing pieces; (c) jumbo bags are hoisted in the first weight pile-loading hollow tank column, or the first weight pile-loading hollow tank column is filled with clear water, and around the first weight pile-loading hollow tank column, bulk jumbo bags are hoisted between every two adjacent weight pile-loading hollow tank columns sequentially, or clear water is filled between every two adjacent weight pile-loading hollow tank columns sequentially; and (d) a hydraulic jack between a weight platform main beam and the test pile is started to conduct detection.

Owner:张宗毅

Roller abrasion resistance testing device for roller skate

PendingCN107941642AComprehensive detection effectGuarantee product qualityMaterial weighingInvestigating abrasion/wear resistanceAgricultural engineeringSpeed test

The invention provides a roller abrasion resistance testing device which comprises an electric control cabinet, an abrasive wheel, a roller fixture, upper and lower roller adjusting rods and a testingweight, wherein a motor is arranged inside the electric control cabinet; a control panel is arranged outside the electric control cabinet; the rotation speed and time of the motor can be controlled by the control panel; a rotating shaft of the motor is connected with a shaft of the abrasive wheel; the roller fixture is arranged above the abrasive wheel; the roller fixture is connected with the upper and lower roller adjusting rods by a connecting rod; the testing weight is arranged on a platform of the electric control cabinet; the testing weight refers is a weight set of different standard weights; a through hole is formed in each of the weights in the horizontal direction; and the weights are connected with the upper and lower roller adjusting rods by virtue of pins penetrating throughthe through holes. According to the device disclosed by the invention, the angles of the roller and the abrasive wheel can be respectively adjusted, the operation is simple, and positioning is accurate; and meanwhile, front and rear wear mass of one wheel, the angle of the abrasive wheel, the test weight, the testing speed and other parameters can be totally considered, and the device has significances for perfecting the roller skate detection capacity, improving the detection level and ensuring the quality of roller skate products in the market.

Owner:INTERTEK TESTING SERVICES

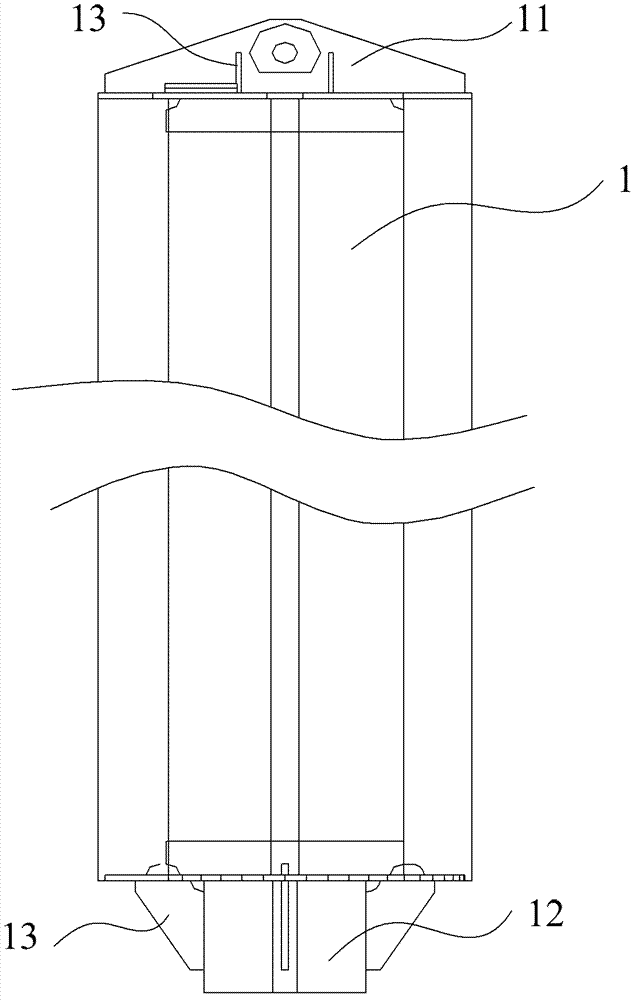

Test weight method of lifting ladle for large steel-making casting bridged crane

InactiveCN101566532AThe trial weighing process is simpleCost reduction measuresStructural/machines measurementSteelmakingNacelle

The invention provides a test weight method of lifting ladle for a large steel-making casting bridged crane, belonging to the technical field of converter steelmaking, in particular to a large casting bridged crane. Without adopting normal nacelle test weight method, the method adopts a test weight method of taking a plurality of ladle iron blocks as counterweights and comprises the following steps of: determining the quantity of the ladles and the weight of the iron blocks needed by each ladle; preparing for counterweight; checking before running-in of the crane; running-in at empty load; and testing on static load; and running-in at dynamic load. The method has the advantages of leading the test weight procedure to be simple and greatly reducing the measure costs of the test weights.

Owner:BEIJING SHOUGANG CONSTR GROUP +1

Air purifying device performance dynamic calibration method

InactiveCN106092810AEasy to chooseImprove satisfactionWeighing by absorbing componentAir cleaningIndustrial engineering

The invention relates to the field of indoor air purification, and especially relates to an air purifying device performance dynamic calibration method. The air purifying device performance dynamic calibration method comprises the following steps: selecting a standard test space, and weighing an air purifying device to obtain an initial weight; placing the air purifying device in the standard space, allowing the air purifying device to work for a certain time, and weighing the air purifying device to obtain a post-test weight, selecting several air purifying devices to be calibrated, and repeating above steps to obtain the purifying weight of every air purifying device to be calibrated according to the following formula: the purifying weight = the post-test weight - the initial weight; and comparing all purifying weights to obtain five star levels. The air purifying device with the best performances in the market is used as a standard to carry out five star evaluation on all the air purifying devices in order to measure the quality of the air purifying devices, and a user can directly know the purifying ability of every air purifying device according to the star level without knowing performance parameters, so the user can conveniently choose the air purifying device, and the user's satisfaction is effectively improved.

Owner:薛景森

Method of detecting an in-range failure of a brake pedal position sensor

A method of detecting an in-range failure of a brake pedal position sensor includes calculating the difference between a minimum position and a maximum position of the brake pedal position sensor. The calculated difference is weighted to define a fast test weighted input value and / or a full test weighted input value. A cumulative test result value is incremented by the fast test weighted input value and / or the full test weighted input value. The cumulative test result value is filtered to define a moving average of the cumulative test result value after each incremented occurrence. The moving average of the cumulative test result value is tracked to determine if the brake pedal position sensor is functioning properly.

Owner:GM GLOBAL TECH OPERATIONS LLC

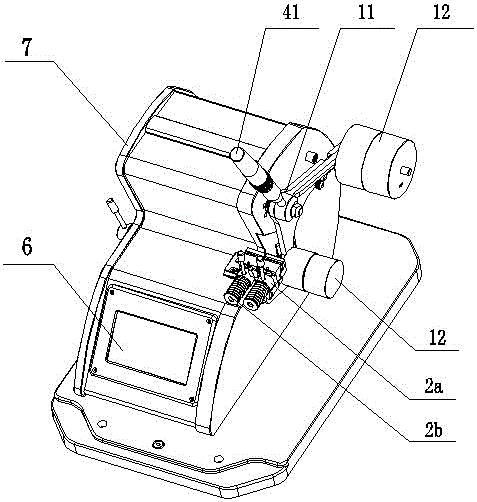

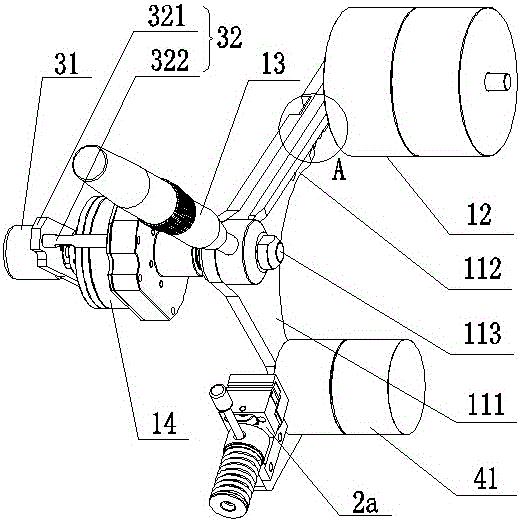

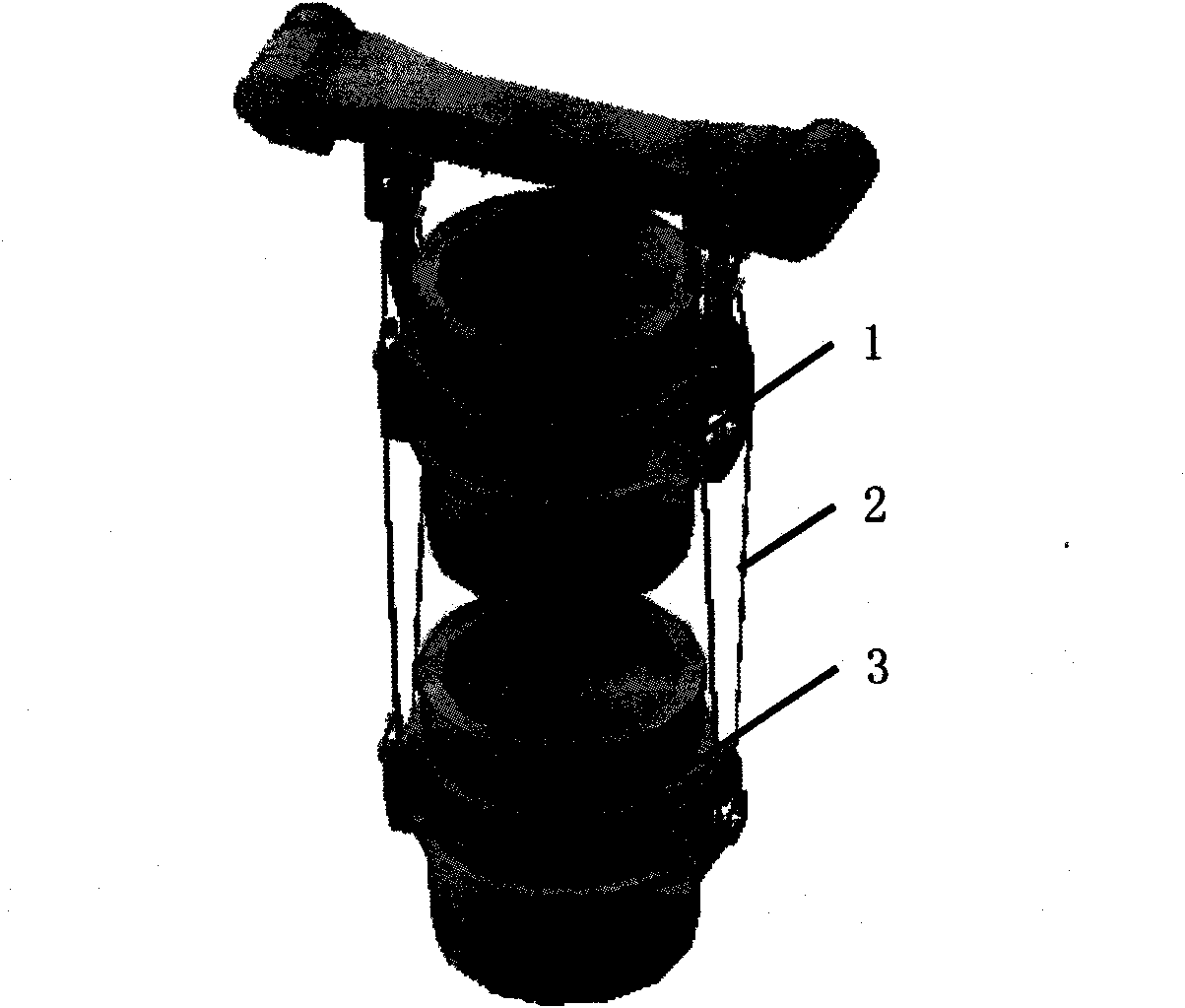

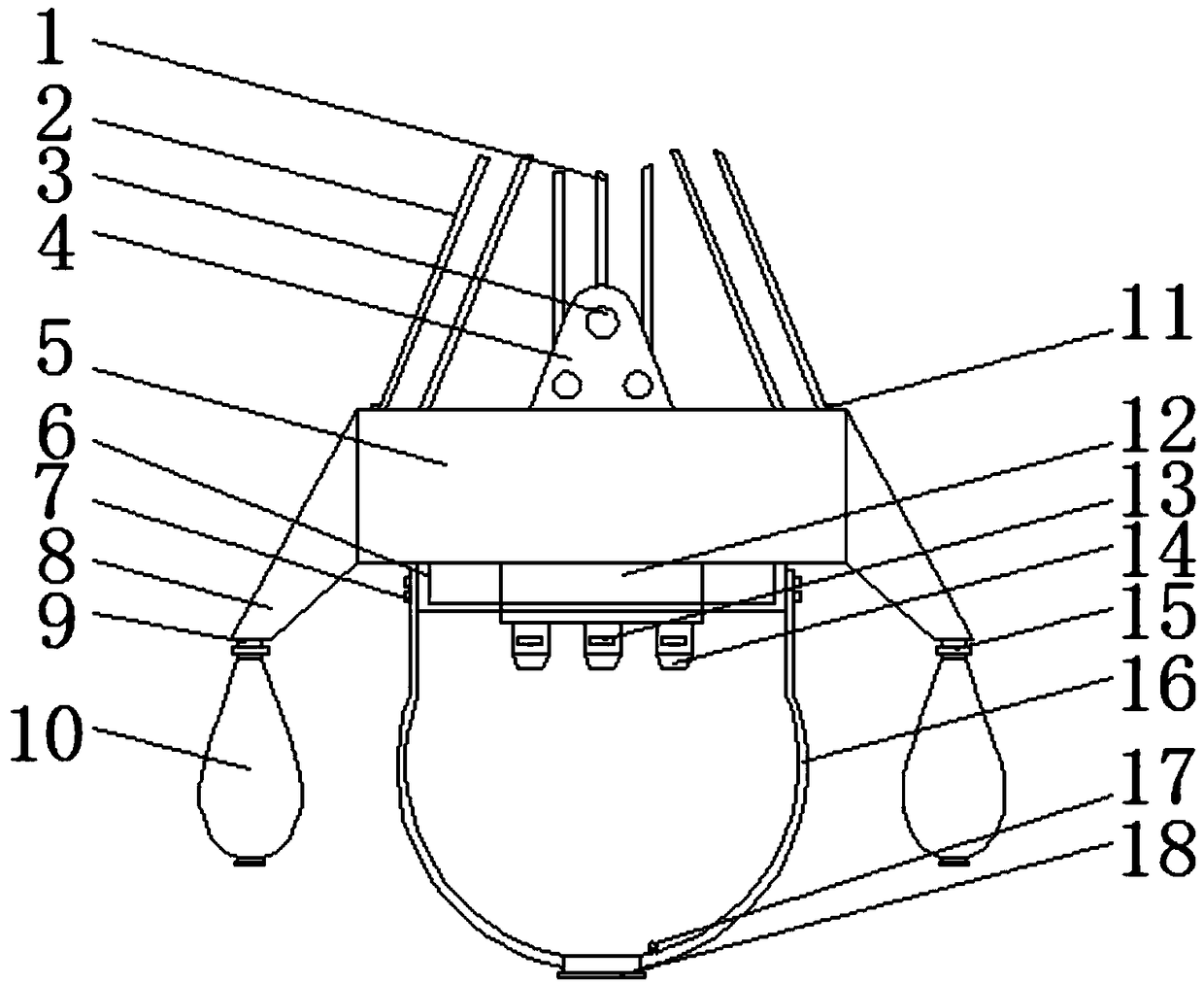

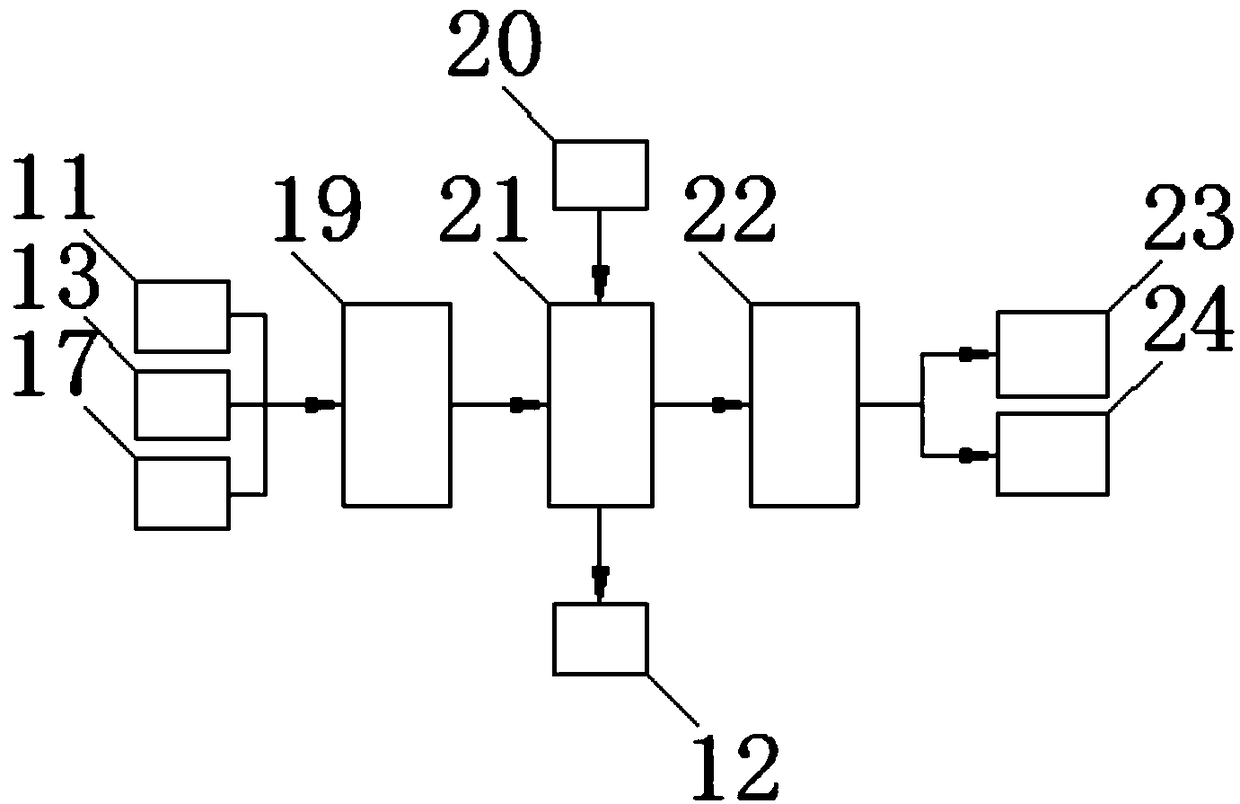

crane test device

ActiveCN107758511BTrial weight operation is goodEasy to detectLoad-engaging elementsEngineeringLoudspeaker

The invention discloses a crane weight testing device. A plurality of pin shafts are installed on a hanging block which is fixedly installed at the top end of a hanging beam main body; main steel wireropes are connected to the pin shafts respectively; auxiliary steel wire ropes are installed on the hanging beam main body; tension sensors which are arranged on the outer sides of the correspondingauxiliary steel wire ropes are installed on the hanging beam main body; auxiliary hanging beams are fixedly installed on the two sides of the hanging beam main body; a water pipe is fixedly installedat the bottom of each auxiliary hanging beam and is provided with an electromagnetic valve and an auxiliary water bag; the output end of a processor is electrically connected with the input end of a water pump and the input end of an alarm module; and the output end of the alarm module is electrically connected with the input end of a loudspeaker and the input end of an alarming lamp. The crane weight testing device provided by the invention adopts simple and reasonable structure design, is novel in modeling and practical in function, can well perform weight testing operation on a crane, is good in structure design and liable in balance grasping and can well perform fine adjustment, so that the safety performance is improved while the work difficulty is lowered.

Owner:ANHU WUHU CHANGJIANG JACK UP EQUIP CO LTD

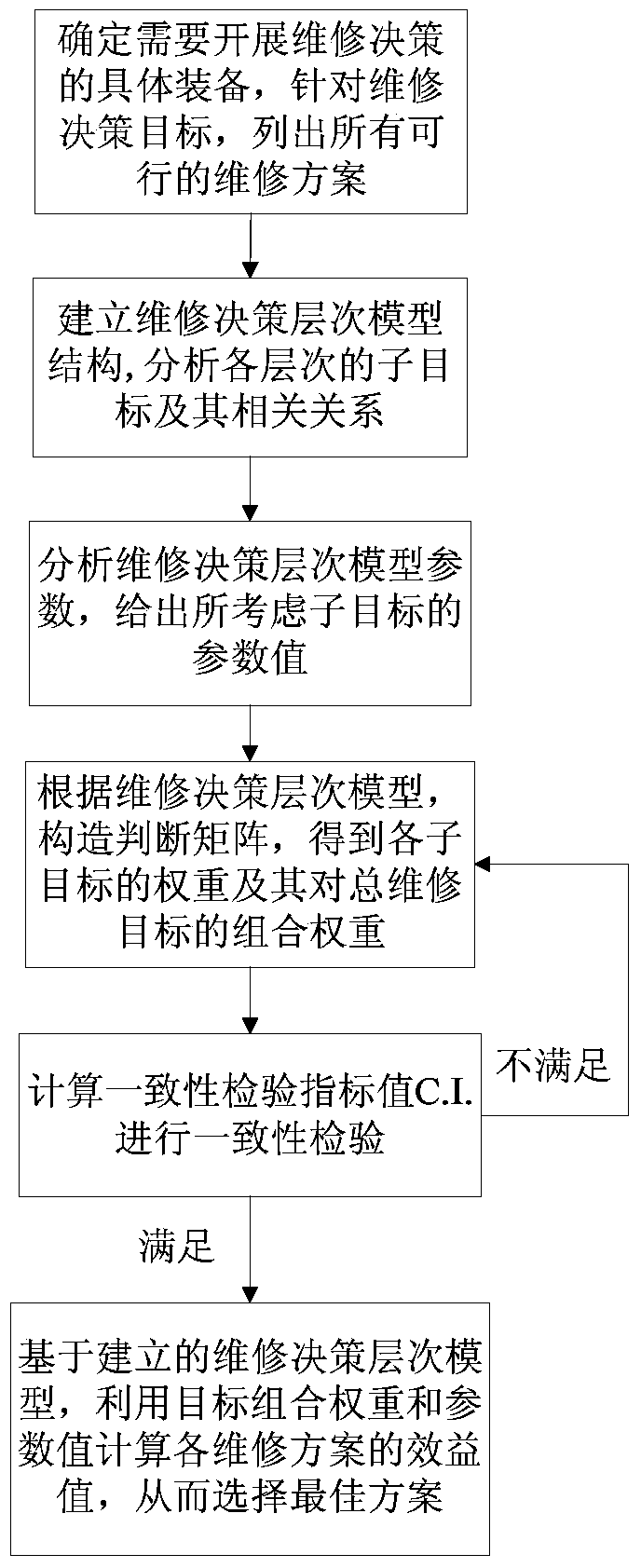

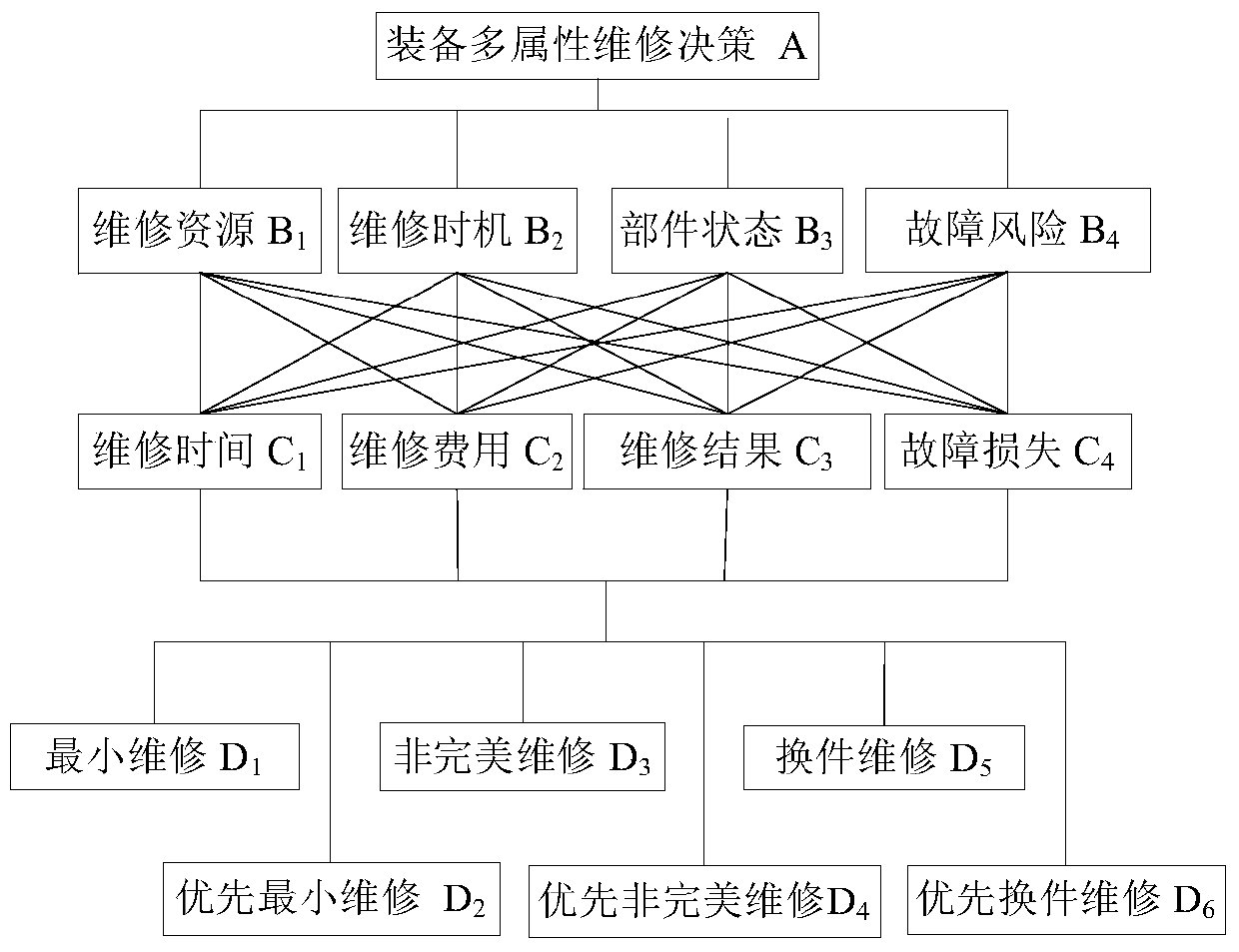

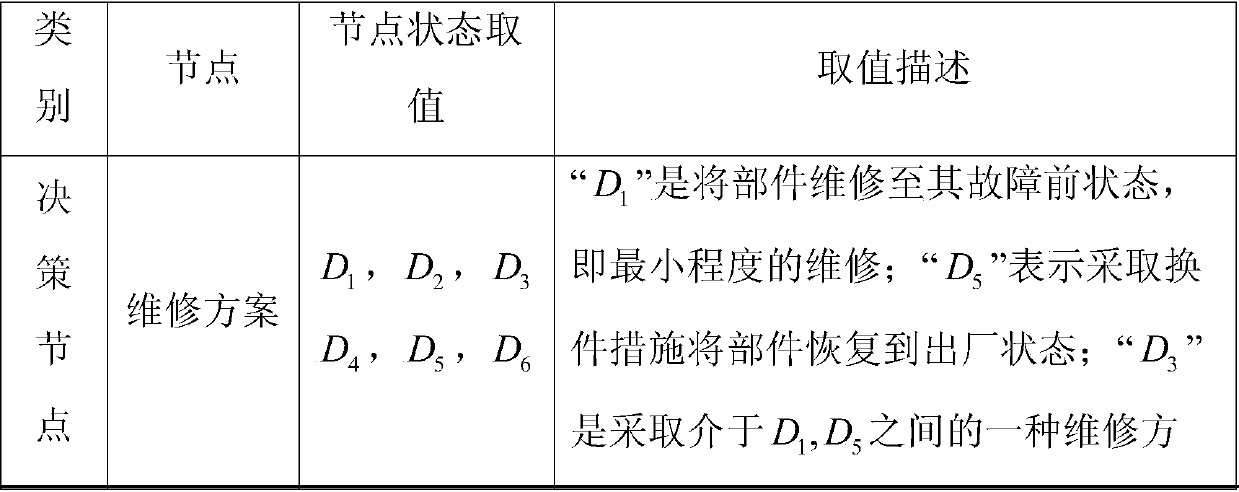

Weight-based multi-attribute maintenance decision-making method for equipment

Owner:NORTHWESTERN POLYTECHNICAL UNIV

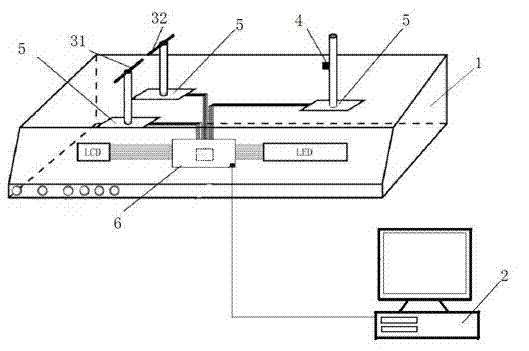

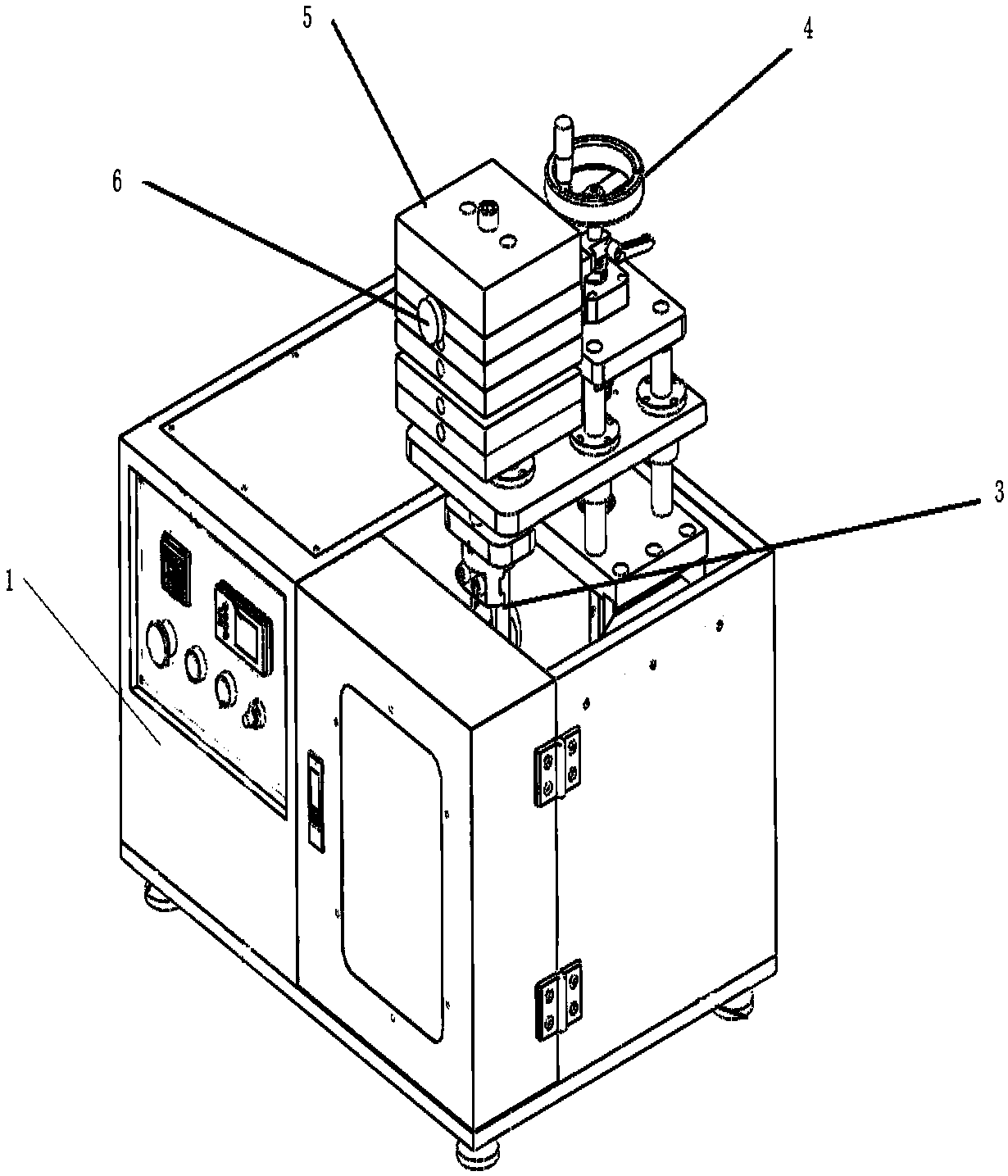

An automatic weight-bearing contact device for color fastness testing based on temperature control in a closed environment

ActiveCN104007059BLittle influence of temperatureImprove stabilityWeather/light/corrosion resistanceThermal insulationEngineering

An automatic load-bearing contact device for color fastness testing based on temperature control in a closed environment, characterized in that it includes a bottom plate and a heat-insulating shell, and an automatic load-bearing testing mechanism is arranged on the bottom plate located in the cavity of the heat-insulating shell. The translation load detection platform is composed of flat test weights. The flat test weights are controlled to move up and down by lifting cylinders arranged on the bottom plates on both sides of the load detection platform. The load detection platform is controlled by horizontal cylinders to move horizontally. An electric heating plate is arranged on the inside of the top and the bottom plate in the heat-insulation shell, and a temperature sensor is arranged in the cavity of the heat-insulation shell. The outstanding feature of the present invention is: heating is carried out by the heating plate installed inside the device, and the test sample is heated by the heat conduction of the ambient air in the heat preservation shell, so as to realize the constant temperature and load-bearing contact process in the detection of color fastness to saliva, which can be widely used Analysis and determination of color fastness to saliva in textile, paper and other industries.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +1

Flow test machine and an associated measurement method, as well as an associated cleaning process

ActiveUS9746406B2Efficient implementationShort cycleHollow article cleaningMaterial strength using tensile/compressive forcesThermoplasticTest channel

A flow test machine 2 which, for example, is able to be used for viscosity tests on plastics, comprises a test piston 4, a test channel 38, at least one test weight 72 and a drive unit 92. The test piston 4 is able to move through the test channel 38 by means of a weight force 79 of the test weight 72. The test weight 72 is able to be loaded by an actuating additional force 108, 108′ by means of the drive unit 92 between a starting position 151 and an end position. The actuating additional force 108 enables a movement of the test piston 4 in the direction of the weight force 79, said movement being accelerated in comparison with an effect of the weight force 79. In a melt viscosity test, after a heating step, a thermoplastic plastic is pressed through a test channel 38 by a test piston 4. In a measurement preparation step and / or a cleaning step, the test mass is lowered along a weight force direction 79 under the influence of an actuating additional force 108, 108′. In a method for cleaning, a cleaning step is undertaken by means of an actuating additional force 108, 108′ from the drive unit 92, said drive unit 92 serving to drive a test piston movement during a melt viscosity test.

Owner:ZWICKROELL GMBH & CO KG

Method for determining dissolving state and adsorption state of Cd (II) in mineral soil

InactiveCN102590471BSolve the unpredictableEarth material testingMaterial electrochemical variablesSkin complexionCation-exchange capacity

The invention discloses a method for determining the dissolved state and adsorption state of Cd(II) in mineral soil, and belongs to the field of soil analysis. The steps are: separate soil clay minerals, determine the CEC value and specific surface area Ss of the minerals, determine the acid-base constant values logK(+), logK(-), and logK(Na,H) on the surface of the clay minerals, and determine the acid-base constants on the surface of the clay minerals. Metal surface complexation reaction constants logK(AlOCd) and logK(X2Cd) were used to determine the weight percentage content of organic matter, iron oxides, and clay particles in the soil, and a whole soil model was constructed. The invention solves the problem that the form of heavy metal Cd in soil cannot be predicted, creates a method for determining the concentration of Cd form in the soil system, and can be used to predict the concentration of effective Cd in mineral soil.

Owner:NANJING UNIV

Non-removing rotor dynamic balancing method

ActiveCN109406053BHigh technical requirementsLabor intensiveStatic/dynamic balance measurementDynamic balanceEngineering

The invention discloses a rotor dynamic balancing method without weight removal, and belongs to the technical field of rotor dynamic balance. The rotor dynamic balancing method without weight removalprovided by the invention can achieve balance just by adding weights twice, eliminates a weight removal process, greatly improves balance precision, reduces balance cost, improves balance efficiency,and avoids accidents. The method comprises steps of a, installing a vibration sensor horizontally on a rotor bearing seat to acquire a vibration signal, attaching reflective paper to a rotor shaft, measuring a rotational speed signal by using a speed sensor facing the reflective paper, and measuring the amplitude and the phase of the unbalanced vibration of the rotor by a dynamic balancer; b, after a test weight is added, measuring the amplitude and the phase of the unbalanced vibration again; and c, solving the magnitude and the position of the unbalanced weight according to a formula, addingthe same correcting weight to an opposite side so as to greatly reduce the vibration and achieve balance.

Owner:ZHEJIANG UNIV

Inbred corn line KWU7104

ActiveUS20050097630A1Quality improvementOther foreign material introduction processesFermentationAgricultural scienceNorth central

This invention is in the field of corn breeding, specifically relating to a dent corn inbred designated as KWU7104. Inbred KWU7104 is a Lancaster-Mo17 family based inbred that is specifically bred by means of a pedigree selection method for the north central United States. As one of the parents, Inbred KWU7104 contributes superior test weight to the F1 hybrid. The specific density of the grain is referred to as test weight and is an important agronomic trait in the corn industry.

Owner:KLEINWANZLEBENER SAATZUCHT

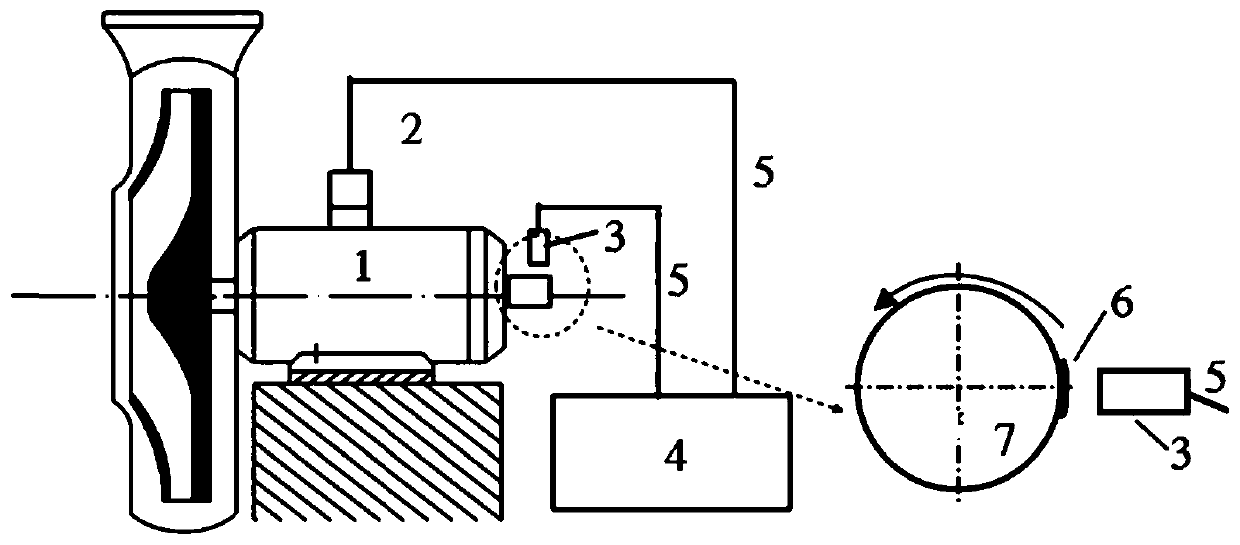

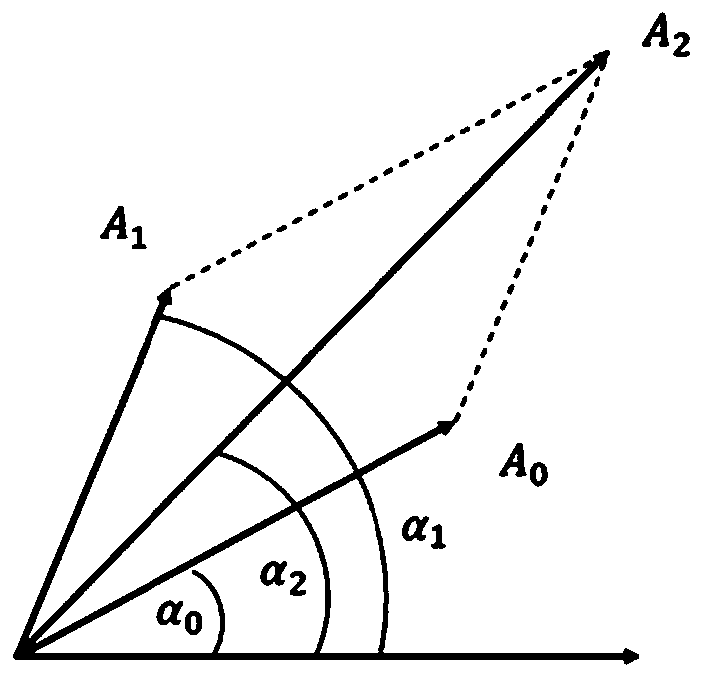

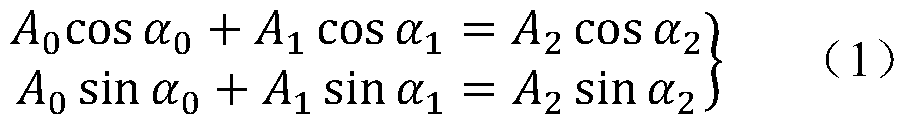

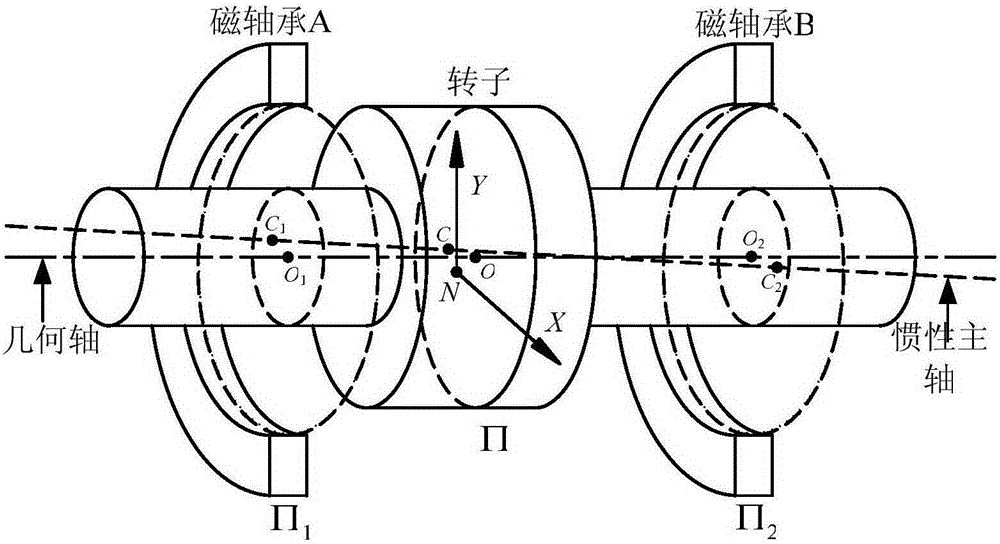

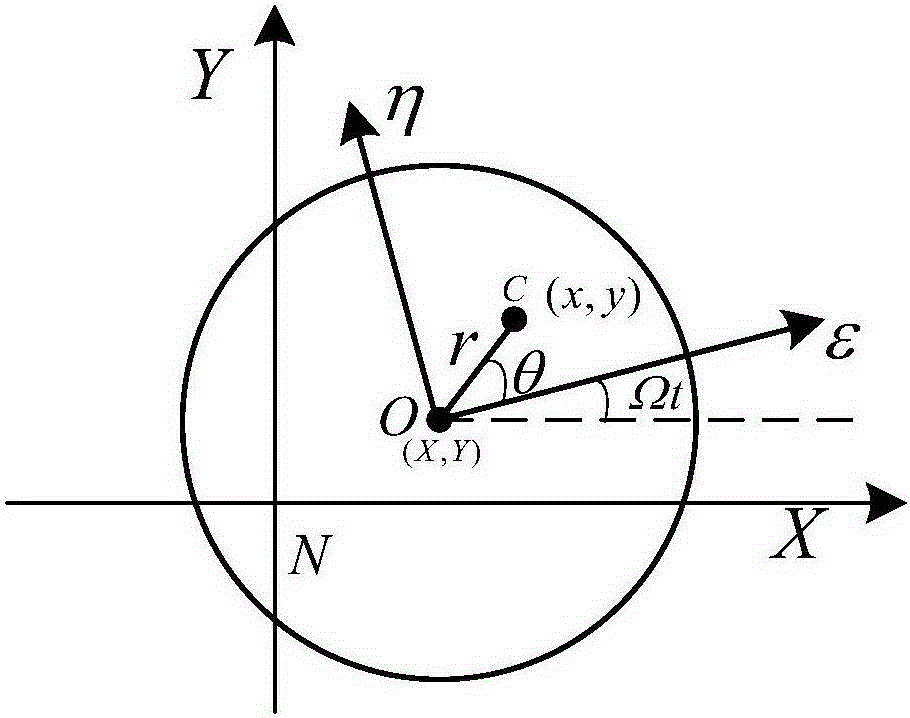

An online identification method for the unbalance of a maglev rotor based on a current test weight

ActiveCN103604563BImprove work efficiencyStability is not affectedStatic/dynamic balance measurementRotary gyroscopesMagnetic bearingDynamic balance

Owner:BEIHANG UNIV

Method for ground compression and heaping of large foundation piles for vertical compressive static load test in civil engineering

The invention relates to a vertical compression resistance static loading test large base pile ground weight pile-loading method for civil engineering. The method is applied to vertical compression resistance static loading test weight counter force in civil engineering base pile detection. The method is executed according to the following steps that (a) weight platform buttresses are put up, (b) weight pile-loading hollow tank columns are hoisted on the weight platform, the first weight pile-loading hollow tank column and the axis line of a test pile are overlaid, other weight pile-loading hollow tank columns are hoisted around the first weight pile-loading hollow tank column are completely filled on the whole platform, and when the weight pile-loading hollow tank columns are hoisted, every two adjacent weight pile-loading hollow tank columns are fixedly connected through fixing pieces; (c) jumbo bags are hoisted in the first weight pile-loading hollow tank column, or the first weight pile-loading hollow tank column is filled with clear water, and around the first weight pile-loading hollow tank column, bulk jumbo bags are hoisted between every two adjacent weight pile-loading hollow tank columns sequentially, or clear water is filled between every two adjacent weight pile-loading hollow tank columns sequentially; and (d) a hydraulic jack between a weight platform main beam and the test pile is started to conduct detection.

Owner:张宗毅

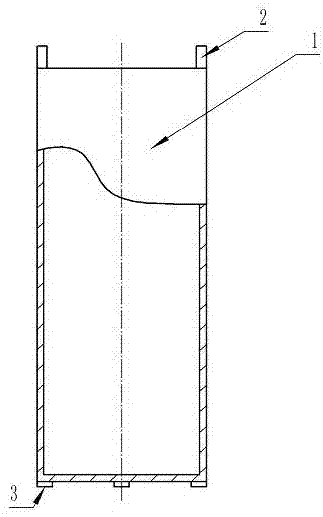

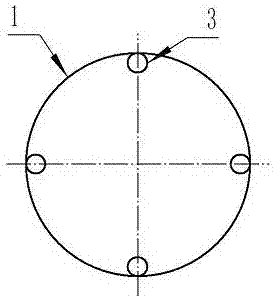

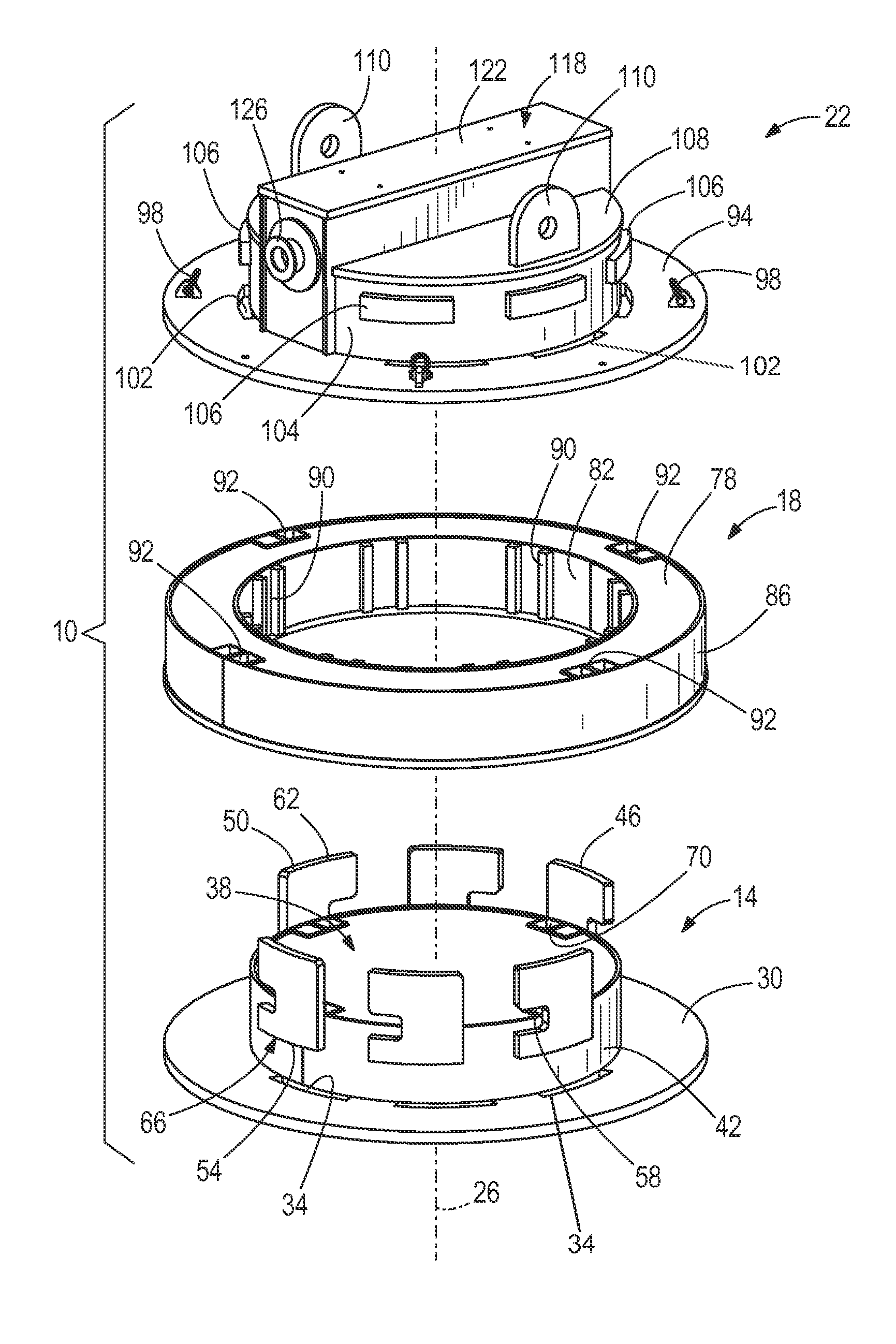

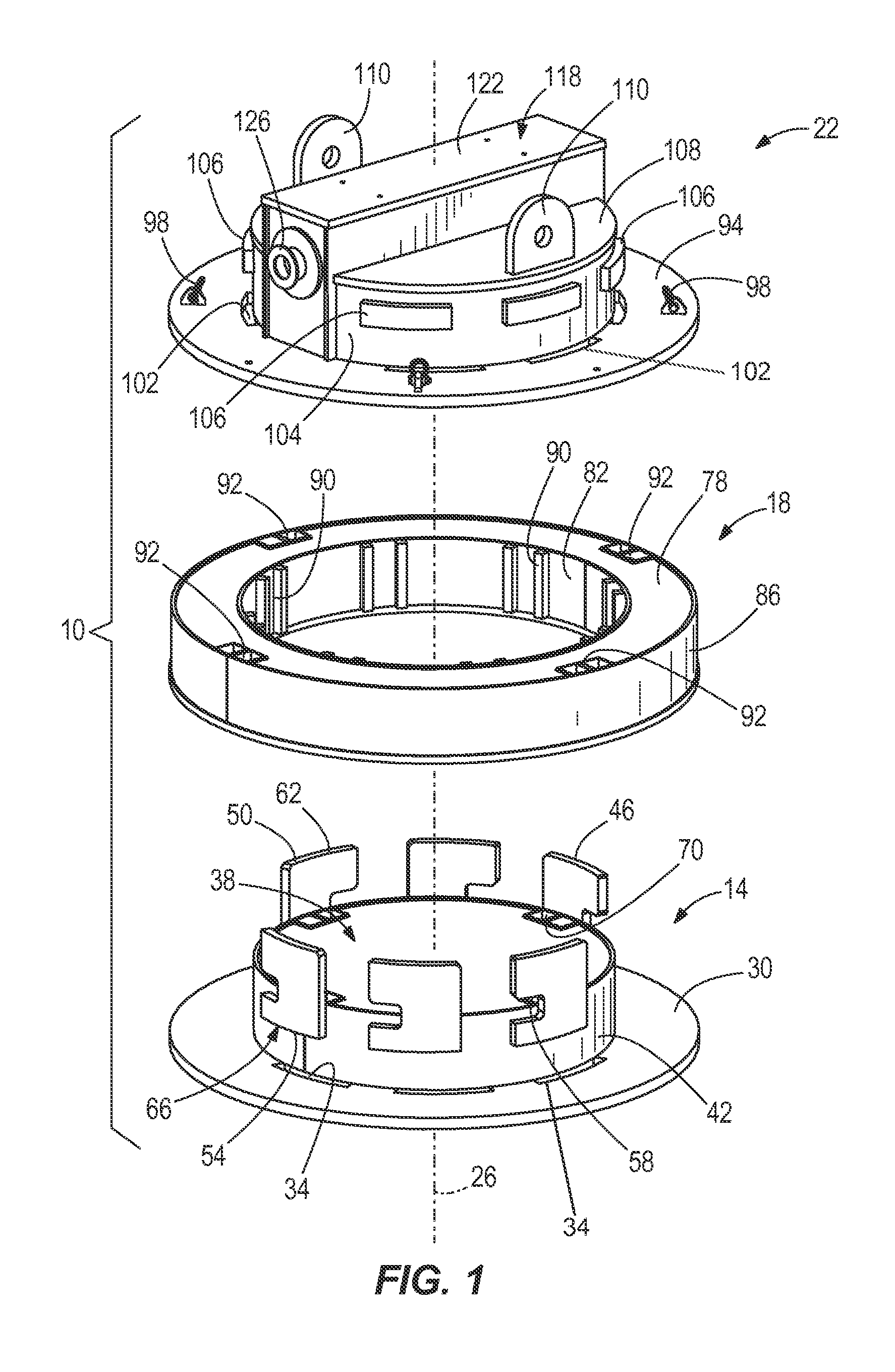

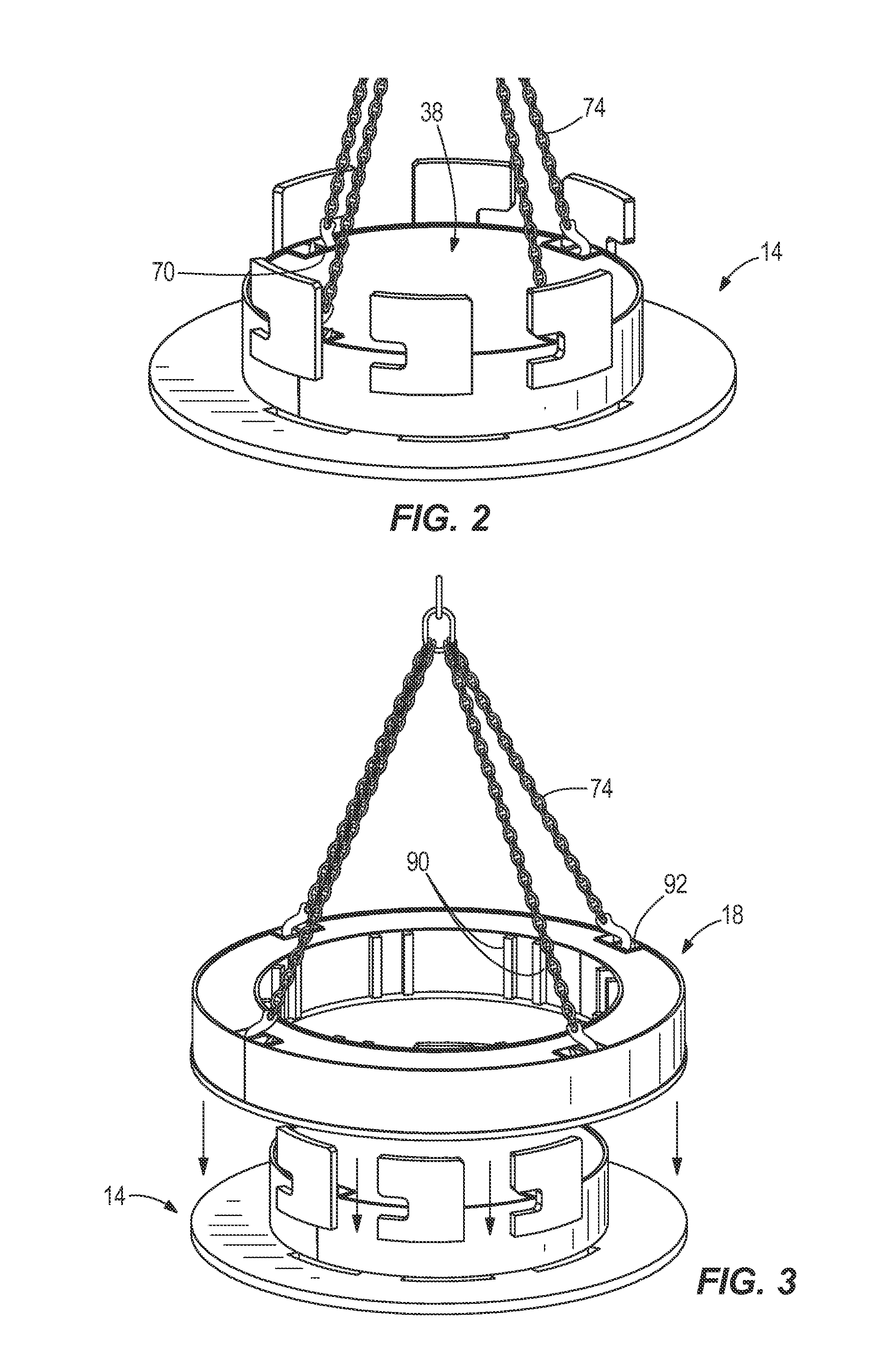

Interlocking test weight system

ActiveUS8890006B2Large containersWeighing apparatus testing/calibrationEngineeringMechanical engineering

A test weight system includes a first assembly having a first body member and a plurality of ear members arranged about the first body member. The test weight system also includes a second assembly interlocked with the first assembly, the second assembly having a second body member defining a plurality of slots. A portion of each ear member extends through one of the plurality of slots.

Owner:KONECRANES GLOBAL

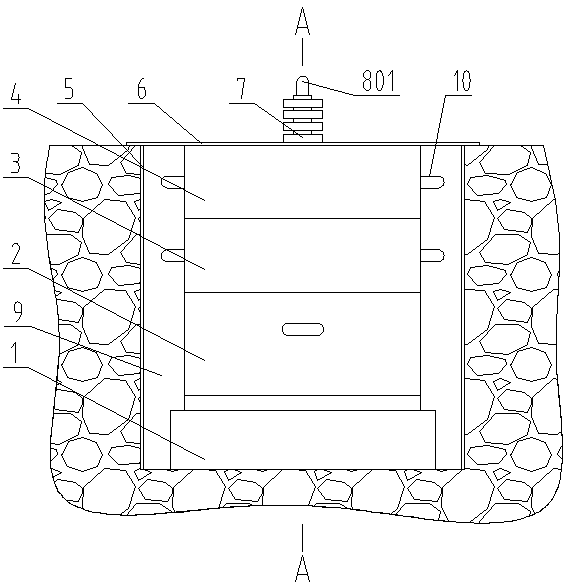

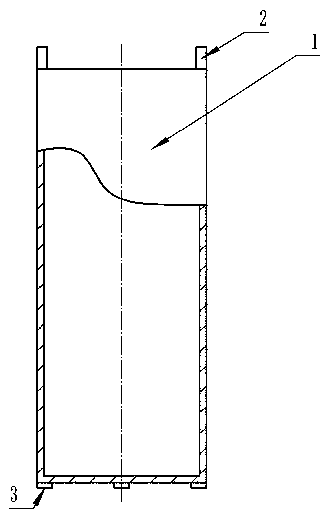

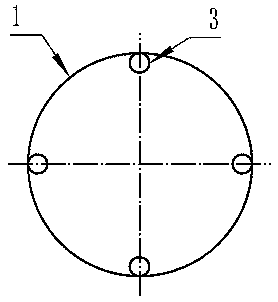

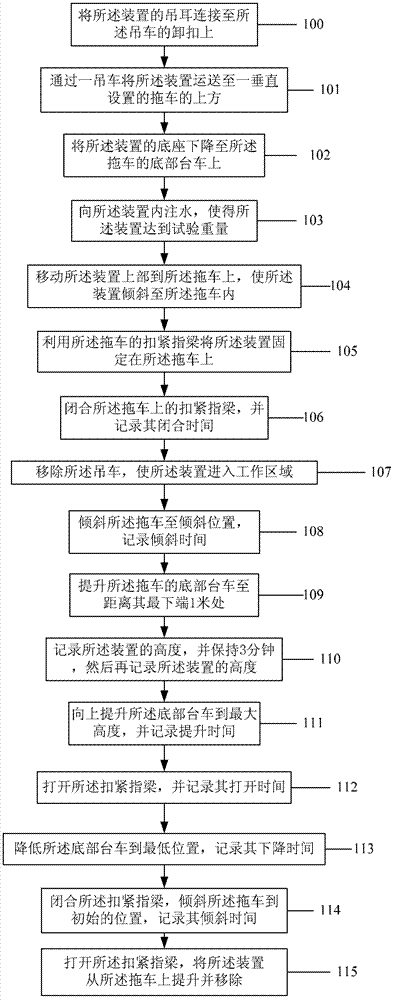

Device and method for load test of marine riser treatment system

The invention discloses a device for a load test of a marine riser treatment system. The device is a hollow cylinder with two closed ends, wherein a water injection hole is formed in the upper end face of the hollow cylinder, and a drainage hole is formed in the lower end face of the hollow cylinder. The invention further discloses a method for the load test of the marine riser treatment system. The method comprises the following steps of: S1, transporting the device above a vertical trailer with a crane, S2, lowering a base of the device onto a bottom trolley of the trailer, S3, injecting water into the device to allow the device to reach the test weight, and S4, conducting the load test on the trailer with the device. The device for the load test of the marine riser treatment system adopts the hollow cylinder filled with the water for the load test, and the method for the load test ensures the accuracy of the load test of the marine riser treatment system, and greatly lowers the load test cost.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com