Patents

Literature

41results about How to "Cost reduction measures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

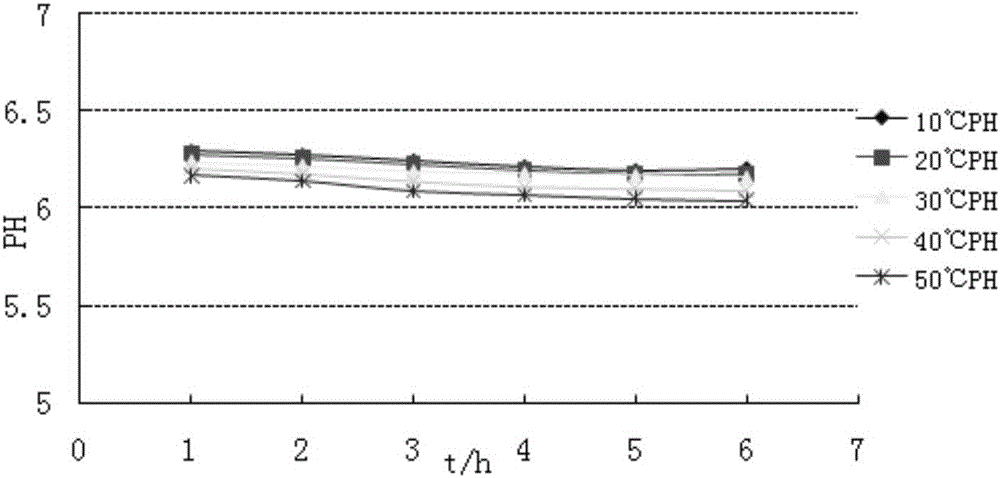

Three-in-one acidification unblocking agent for oil well unblocking and application method thereof

InactiveCN108517204AIncrease productionOn-site construction of high-efficiency acidification and plugging removalFluid removalDrilling compositionCalcium in biologyAdditive ingredient

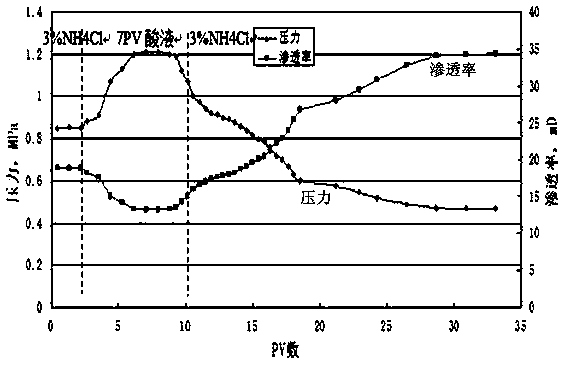

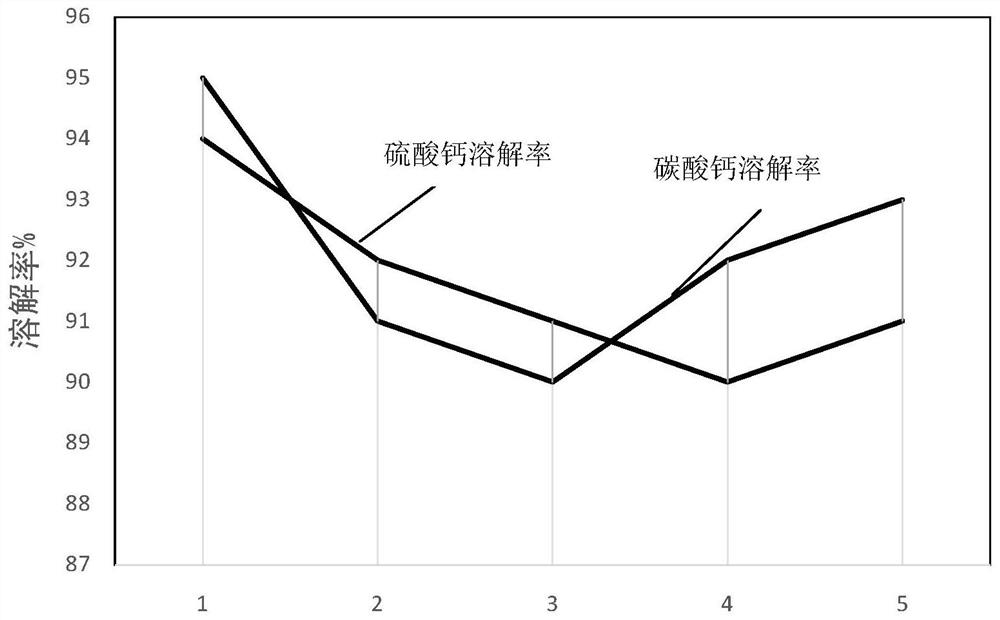

The invention relates to a three-in-one acidification unblocking agent for oil well unblocking and an application method thereof. The acid liquid formula is prepared from the following ingredients inpercentage by weight: 18 to 26 percent of polyorganic acid, 15 to 20 percent of precipitation inhibitors, 5 to 8 percent of iron ion chelating agents, 4 to 7 percent of anti-swelling agents, 6 to 9 percent of corrosion inhibitors, 3 to 6 percent of hydrogen fluoride, 2 to 5 percent of demulsifiers, 3 to 6 percent of acid sludge inhibitors, 3 to 6 percent of water locking prevention agents and thebalance of clean water. During the preparation, all ingredients are added into an anti-corrosion reactor according to the weight parts; the stirring is performed for 40 to 50 minutes at the normal temperature; a finished product is obtained after the uniform dissolution. The main functions of pre-acid, host acid and post-acid in the conventional acidification liquid are integrated; inorganic scales such as mud filtering cake, calcium matters and iron matters and organic scales such as colloid matter and asphalt matter in the stratum can be effectively dissolved; the secondary settlement damageon a reservoir cannot be caused. The three-in-one acidification unblocking agent can also be used as the acidification unblocking agent for pressure reduction and injection increase of an oil field water injection oil.

Owner:扬州润达油田化学剂有限公司

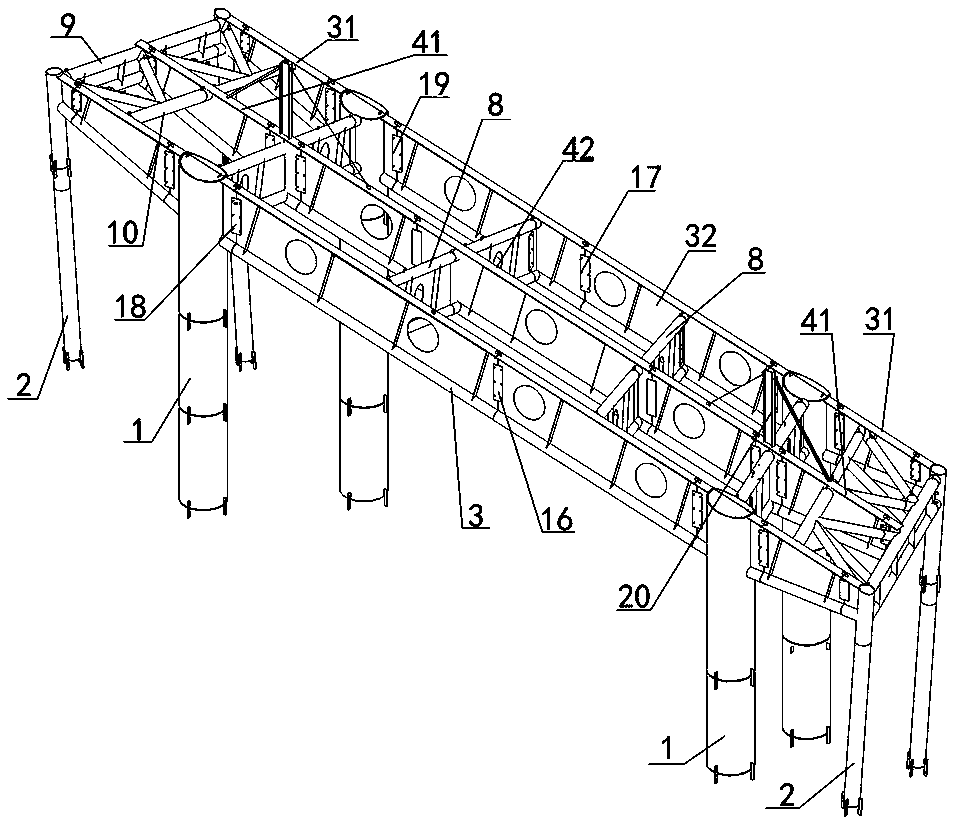

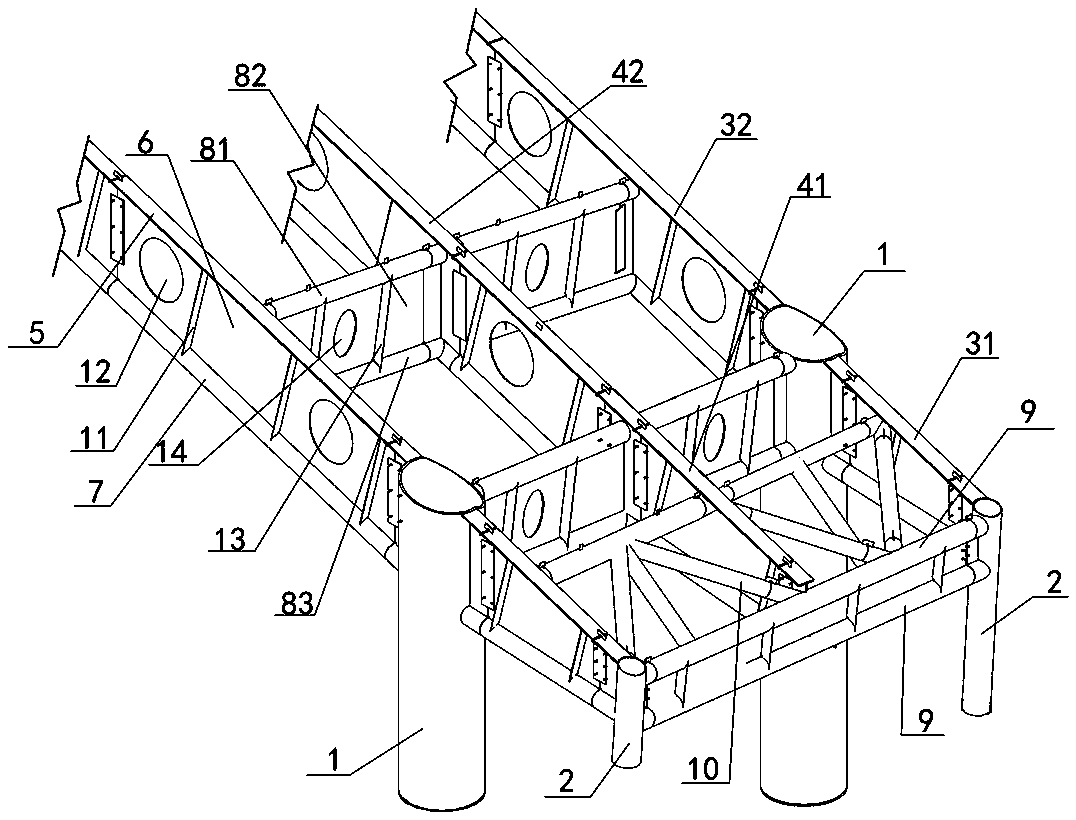

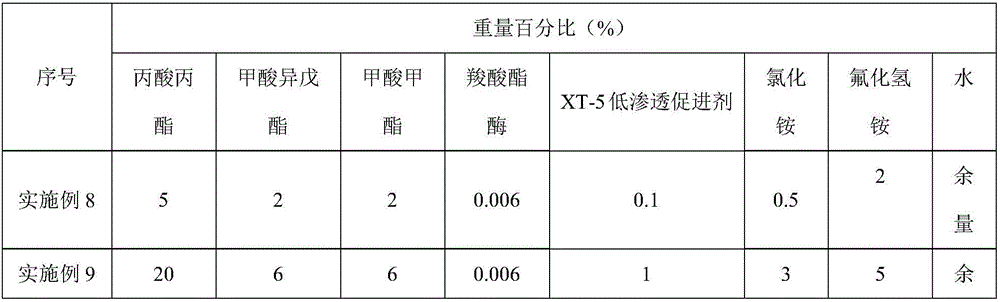

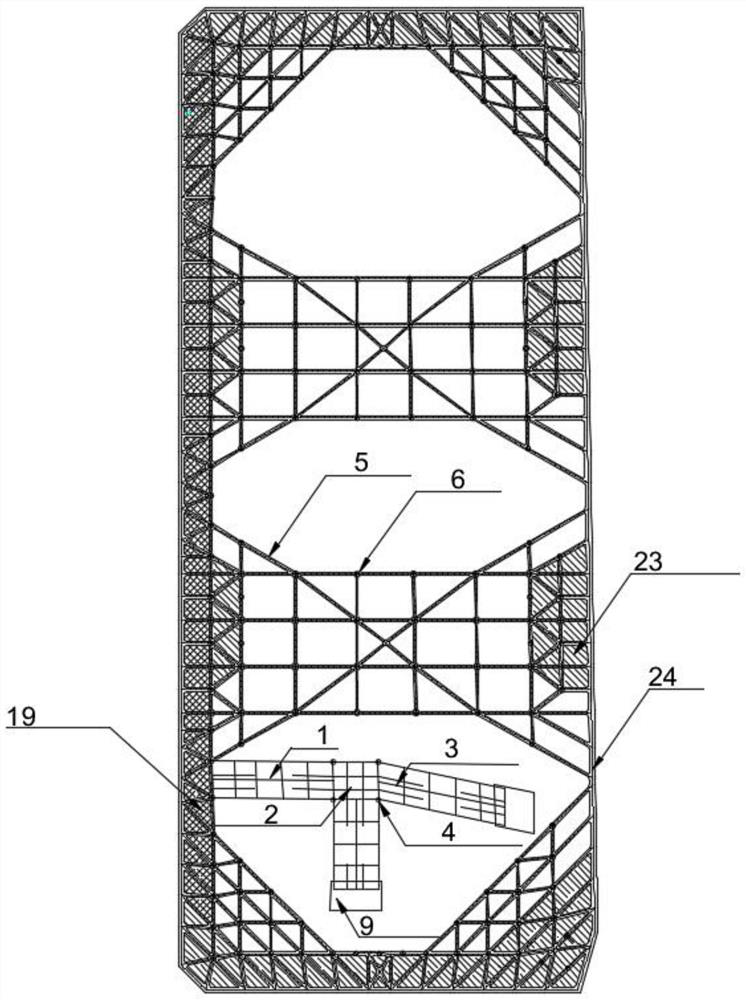

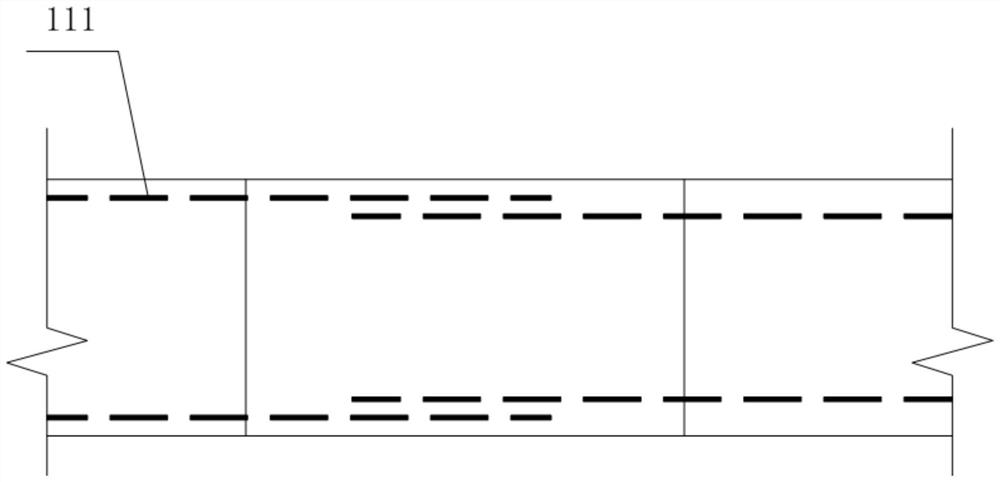

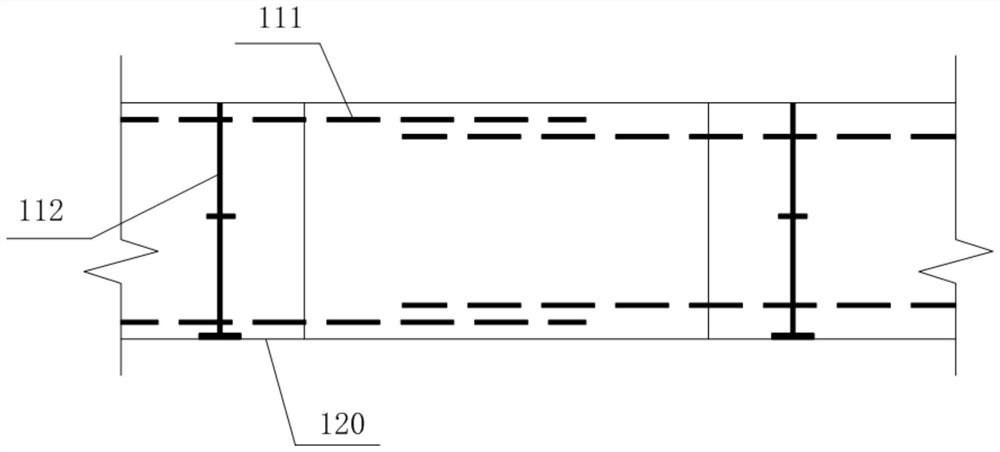

Long-span multi-section combined truss roof structural system and construction method thereof

The invention relates to a long-span multi-section combined truss roof structural system and a construction method thereof. The structural system comprises structural columns and a roof truss, whereinthe structural columns include middle columns and side columns; the roof truss comprises main trusses and secondary main trusses, the main trusses comprise side main trusses and side main trusses, the main trusses are formed by splicing main truss units, and the head end surface and tail end surface of the main truss units are oblique end surfaces and are parallel to each other; and column connecting brackets which used for connecting the roof truss and are adapted to components of the corresponding roof truss are arranged in node regions of the structural columns. According to the construction method, the roof truss and the structural columns are sectionally lifted by virtue of the cooperation with a temporary reinforcing measure. Under the condition that the construction stress is met,the structural system is improved, the construction procedure is optimized, the construction cost is saved, the mounting efficiency is improved, and the measure cost is saved.

Owner:CHINA CONSTR SECOND BUREAU INSTALLATION ENG

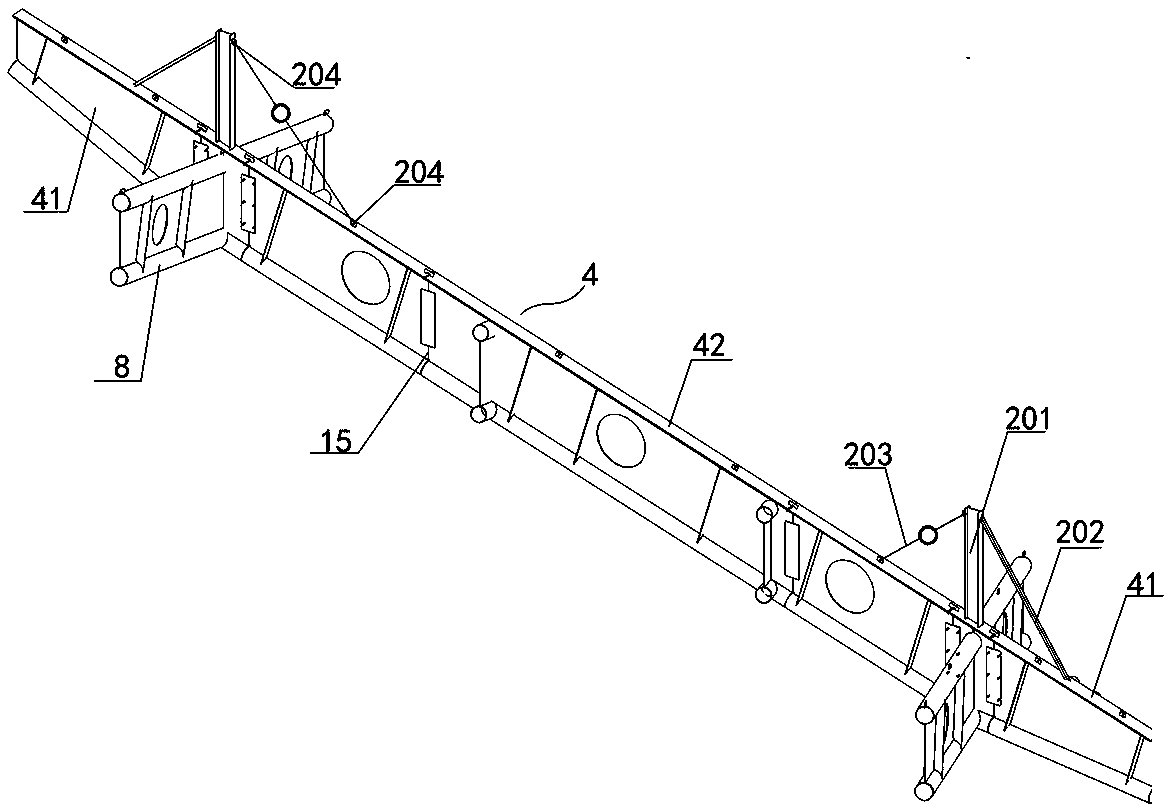

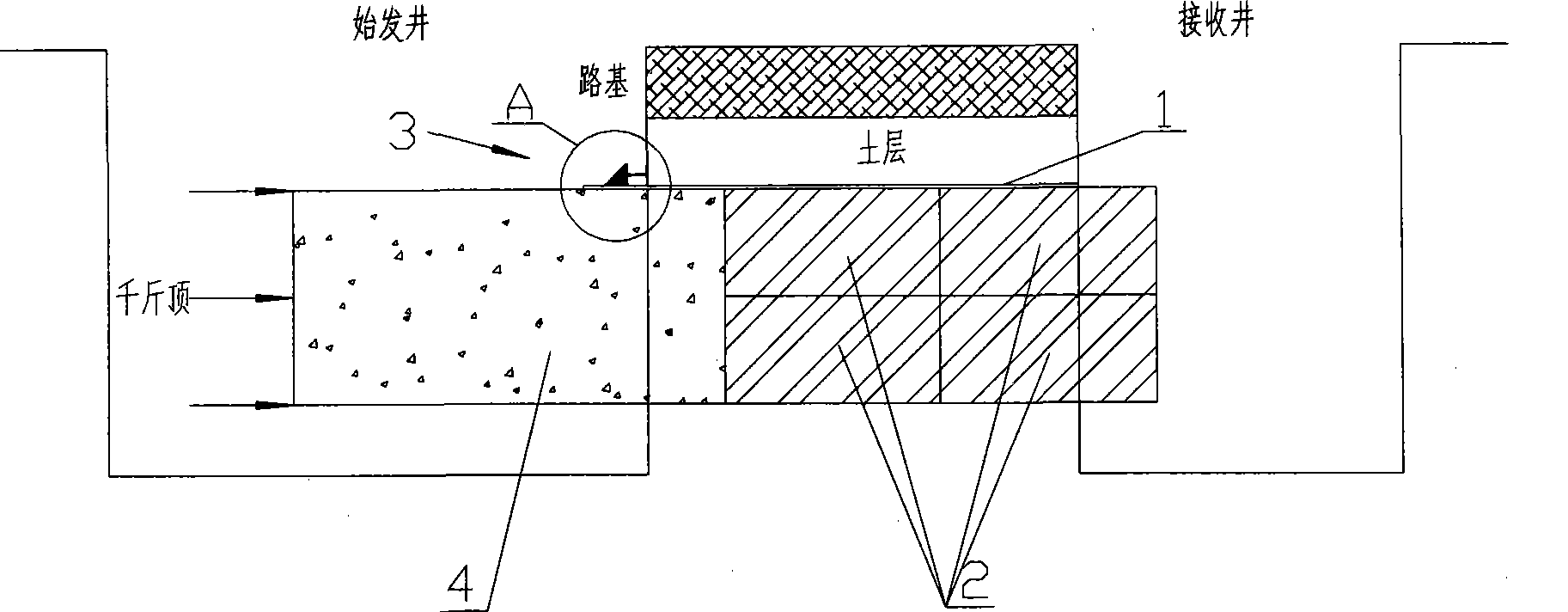

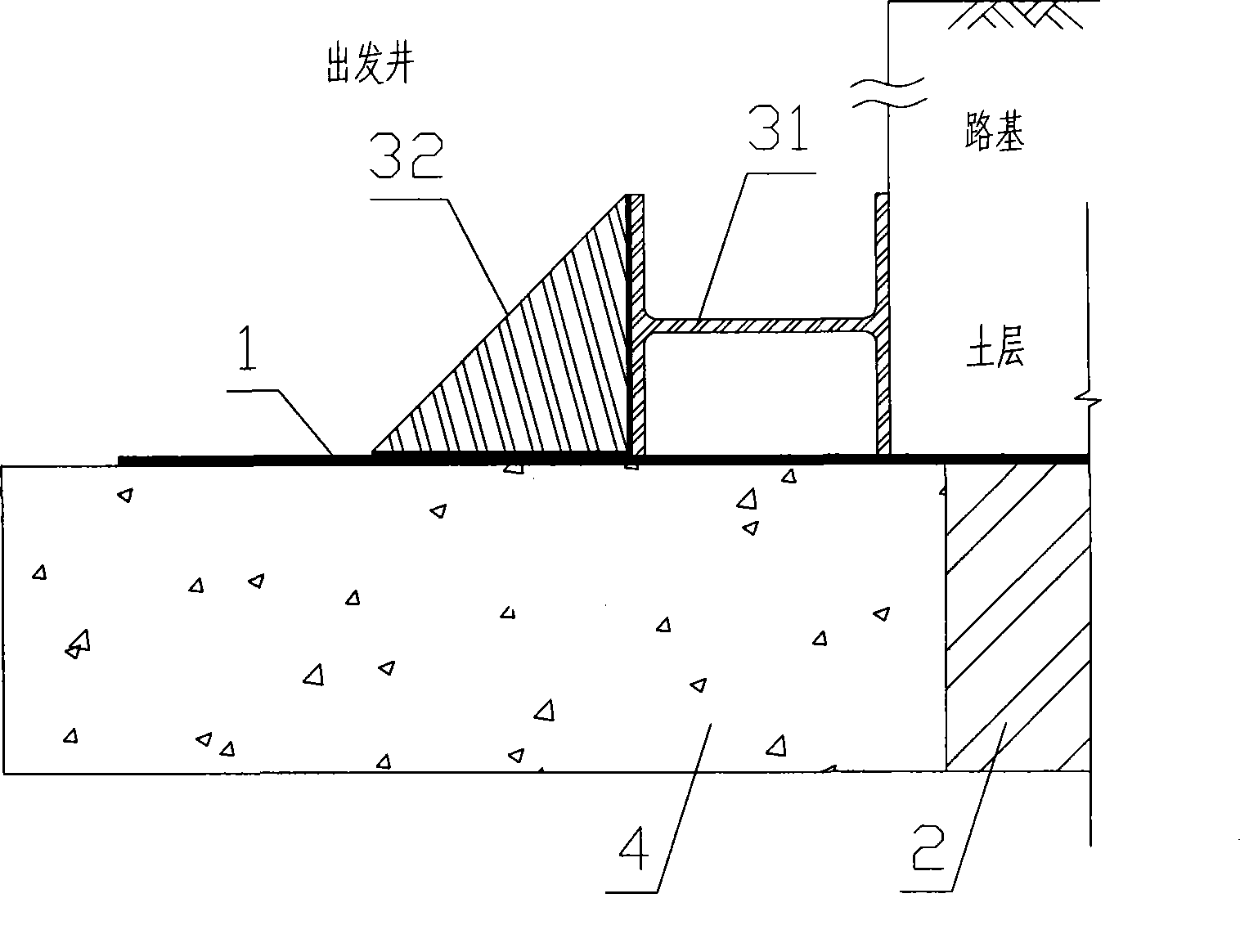

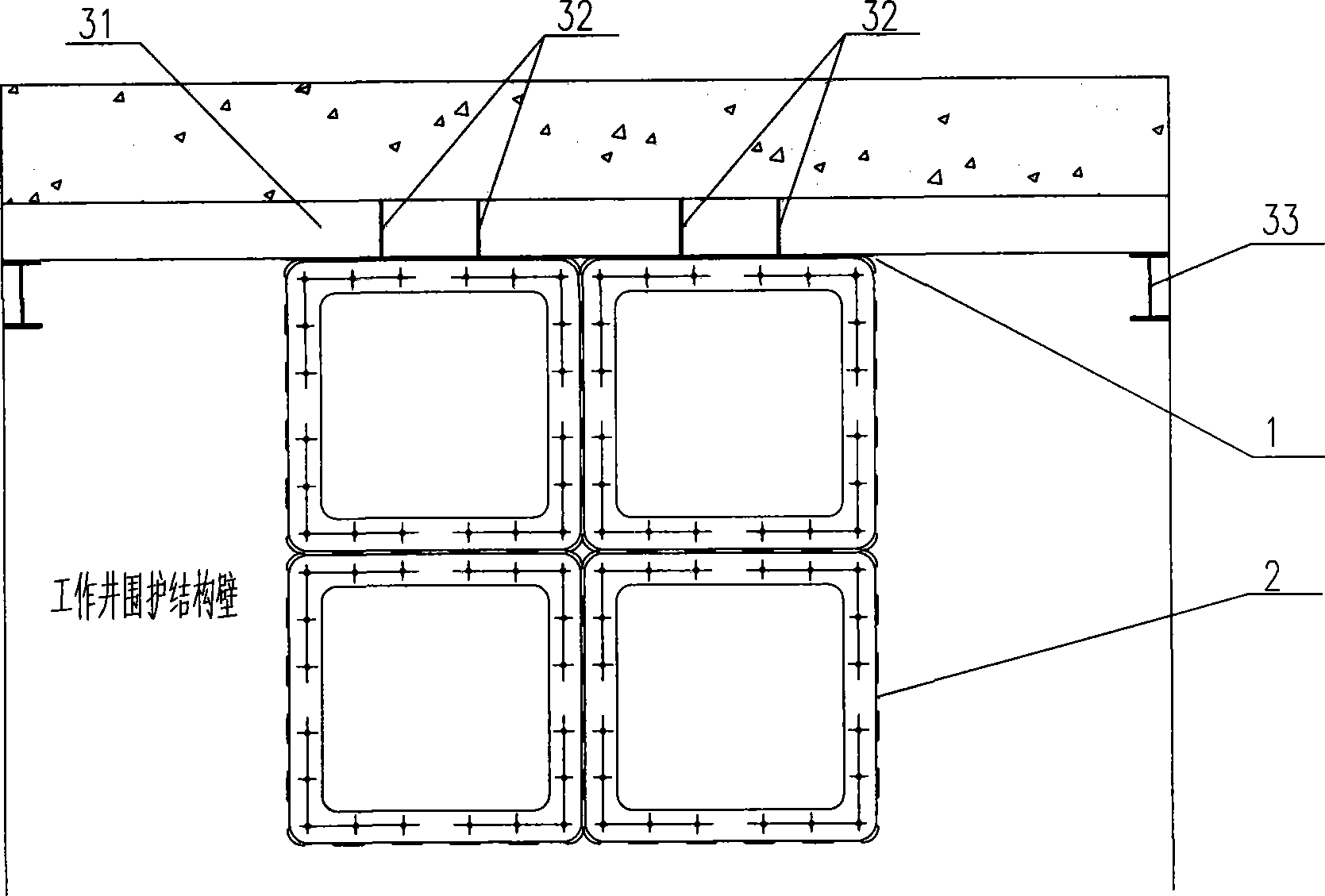

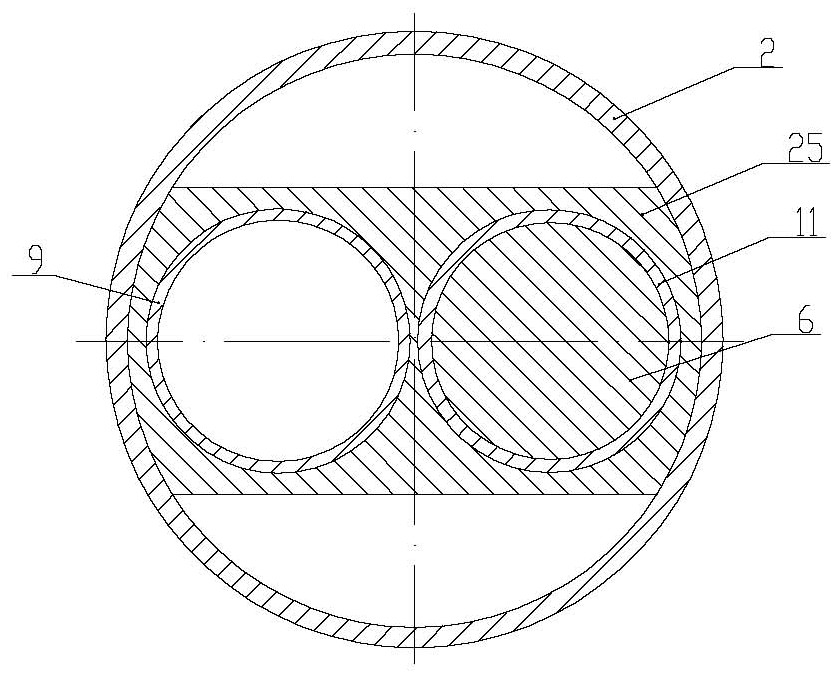

Method and device for underpinning antifriction separator for shallow underground space construction

ActiveCN101532386AEasy to modularizeAdaptableUnderground chambersTunnel liningMeasurement costUnderground space

The invention provides a method for underpinning an antifriction separator for shallow underground space construction. The method comprises the following steps that: firstly, the antifriction separator and a supporting tube are arranged on jacking construction equipment; secondly, when the construction equipment is jacked in, the antifriction separator and the supporting tube are driven to the right position gradually; thirdly, a fixing device is used for fixing the antifriction separator; fourthly, the jacked equipment exits; finally, a prefabrication structure is jacked from a start working well by a synchronous jack so as to underpin the supporting tube in underpinning space under the antifriction separator. The invention also discloses an antifriction separator underpinning device for the shallow underground space construction, comprising the antifriction separator, the supporting tube and the fixing device, wherein the antifriction separator separates an upper overburden layer from the top surface of the supporting tube; and the antifriction separator is fixed on a space enclosing structure through the fixing device. The device and the method solve the problem of earthback pressure effect generated by rectangular jacking method and box culvert jacking method in underground space construction, can smoothly complete construction under a condition that earth covering is hardly disturbed, thereby achieving the aims of protecting periphery environment, reducing measurement cost and reducing the whole working period.

Owner:SHANGHAI CONSTRUCTION GROUP

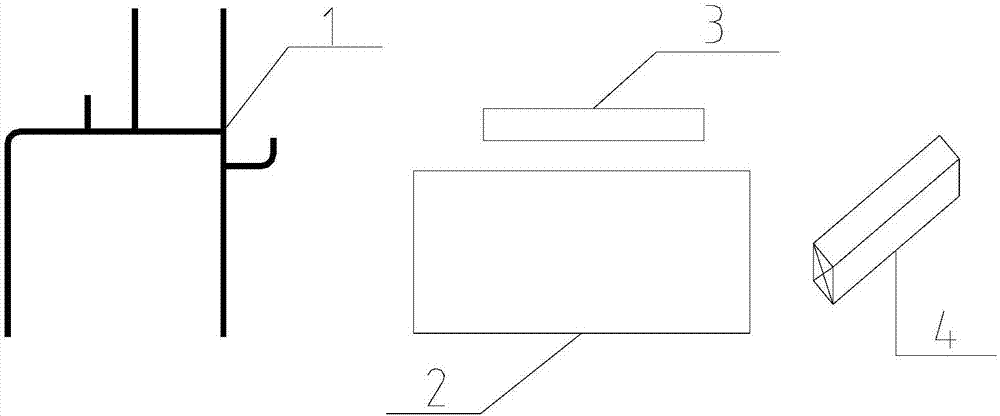

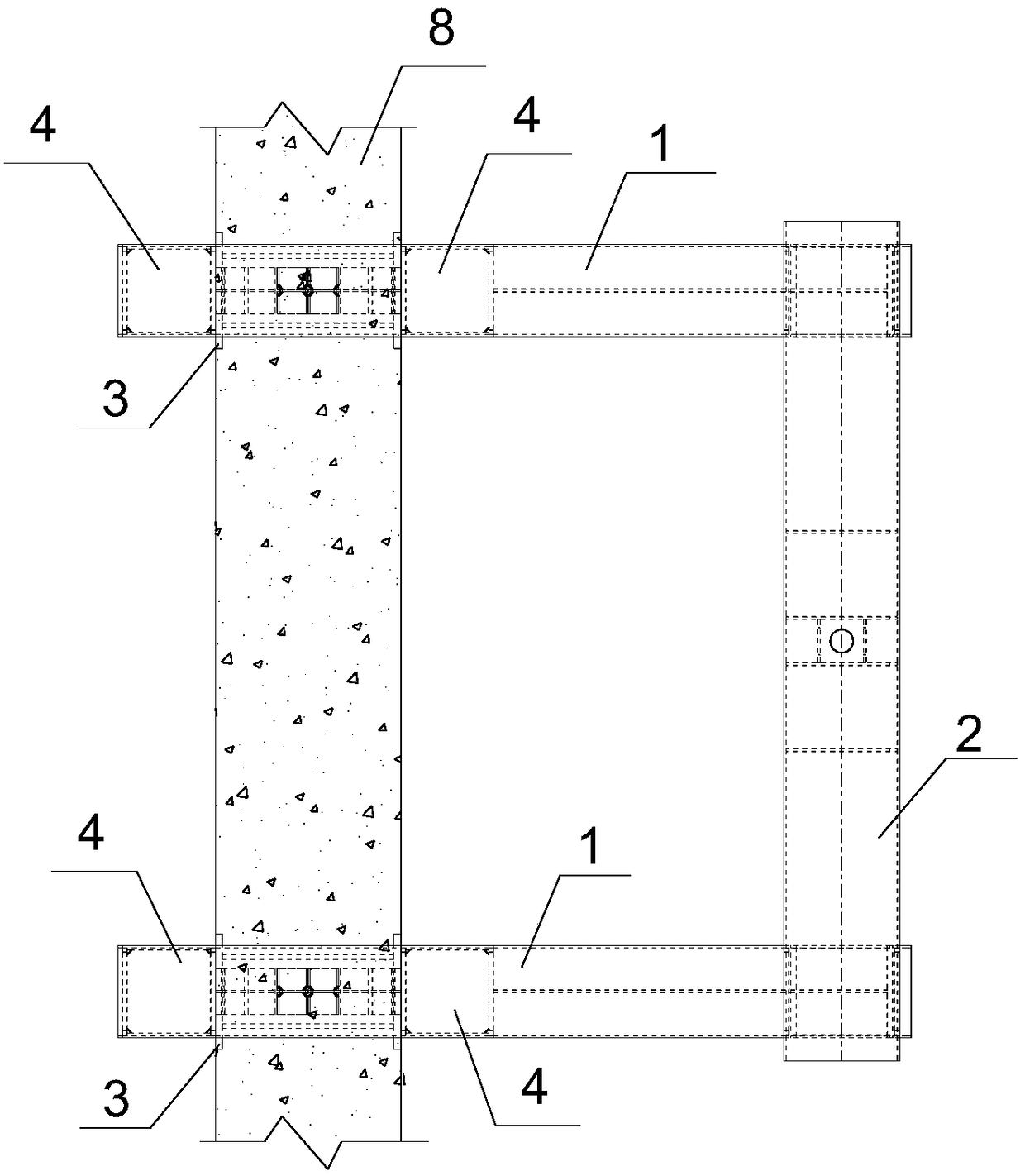

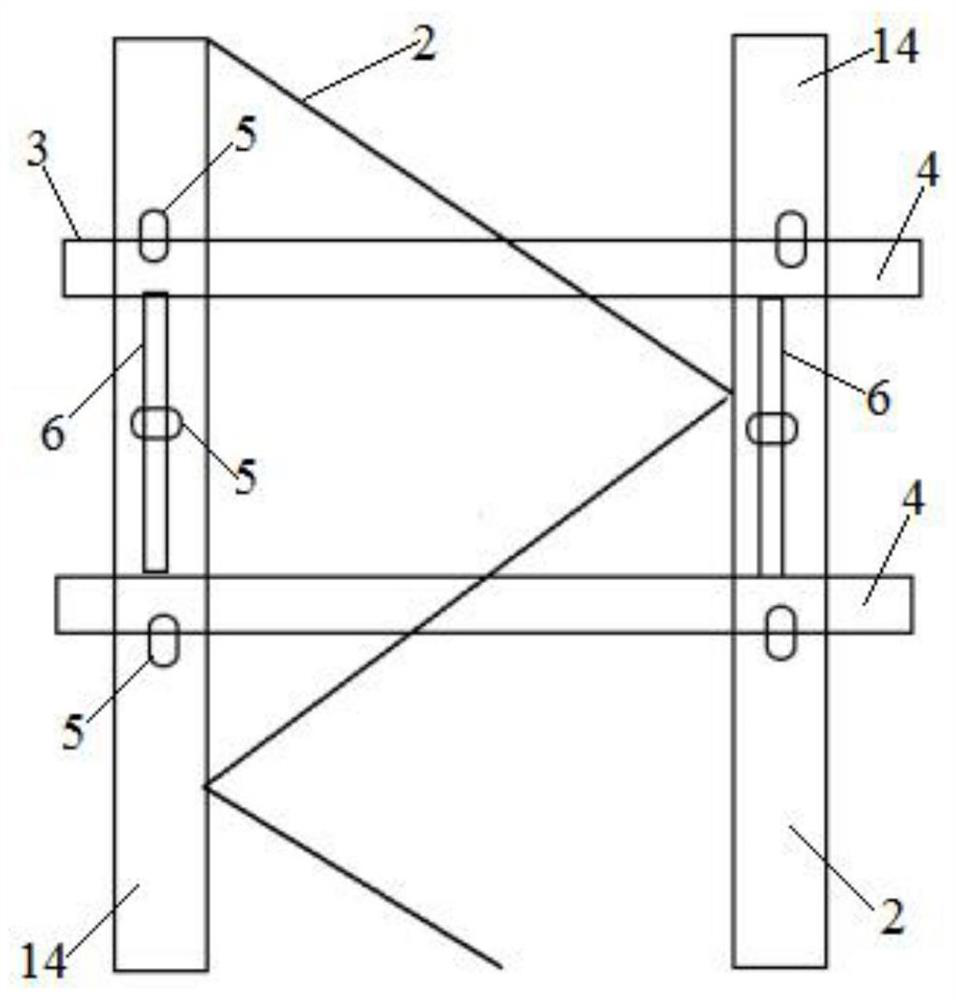

Bathroom inverse bank one-time forming template supporting method

InactiveCN107083840AFirmly connectedEasy to makeForms/shuttering/falseworksTime structureConcrete beams

The invention discloses a bathroom inverse bank one-time forming template supporting method and belongs to the technical field of bathroom inverse bank construction. Firstly, a reinforced bar supporting framework (1) is vertically fixed to a stirrup and a main rib of a one-time structure beam, then, an inverse bank side template (2) is installed at the corresponding position, an inverse bank lower square pillar (4) is installed between the inverse bank side template (2) and the reinforced bar supporting framework (1) so that the reinforced bar supporting framework (1) and the inverse bank side template (2) can be fixed firmly, and the dimension of a lower opening is ensured; and finally, a batten (3) for fixing an upper opening of an inverse bank and an inverse bank upper square pillar (4) are used for reinforcing to fix the size of the upper opening of the side template (2), then the template can be reinforced, accordingly, an inverse bank template is fixed, and the section size of the inverse bank is ensured. The bathroom inverse bank one-time forming template supporting method has the advantages of not occupying much space and being capable of recycling waste reinforced bars. The degree of bonding between inverse bank concrete beams and plates is ensured, the construction progress can be accelerated, and the cost of measures can be reduced.

Owner:BEIJING SHOUGANG CONSTR GROUP

Delaying controlled-release acid for acidizing unblocking, preparation method of acid and acidizing unblocking method

InactiveCN105950126ALess corrosiveImprove the blocking effectDrilling compositionHydrogen fluorideControlled release

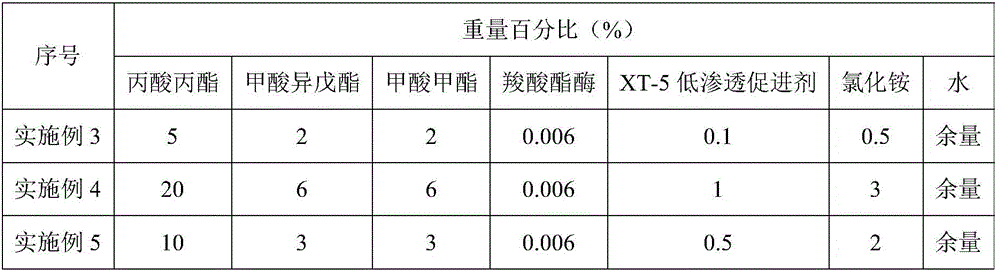

The invention discloses delaying controlled-release acid for acidizing unblocking, a preparation method of the acid and an acidizing unblocking method. The delaying controlled-release acid is prepared from components in percentage by weight as follows: 5%-20% of propyl propanoate, 2%-8% of isoamyl formate, 2%-8% of methyl formate, 0.006% of carboxylesterase, 0.1%-1% of a discharge aiding agent, 0.5%-3% of ammonium chloride, 0-8% of ammonium hydrogen fluoride and the balance of water. According to the delaying controlled-release acid, an acid producing precursor is formed by propyl propanoate, isoamyl formate and methyl formate and catalyzed under the action of carboxylesterase to generate H<+>, and the reaction time is controllable; H<+> is combined with F<-> in ammonium hydrogen fluoride to generate HF acid, the stratum structure can be effectively improved, and the purpose of unblocking and reconstructing the stratum is achieved on the basis that oil well equipment is free of corrosion.

Owner:CHINA PETROLEUM & CHEM CORP +1

Overhanging support system attached to rectangular beams and columns

ActiveCN111173249ASimple structureEasy to assemble and disassembleScaffold accessoriesBuilding support scaffoldsSupporting systemArchitectural engineering

The invention specifically discloses an overhanging support system attached to rectangular beams and columns, and particularly relates to a support structure suitable for lateral installation and decorative construction of frame structure beams and columns. The overhanging support system is characterized by comprising a clamp, a supporting module and a safety fence which are in a full assembly mode; the overhanging system is fixedly connected to the beams or the columns or other firm rectangular structure bodies of a main structure through the clamp and the supporting module, the safety fenceis arranged on the supporting module, and therefore, the overhanging system attached to the rectangular beams and columns is formed. The overhanging support system can meet construction requirements simply by at least two supports, can meet local construction requirements, and can also meet large-range construction requirements, the flexibility and mobility are high, the circulation utilization rate is high, the wastage rate is low, and the measurement cost can be effectively controlled and reduced. The overhanging support system is particularly suitable for the construction of specially shaped structures, the technology is high in adaption, and the direction can be adjusted at random along with buildings.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

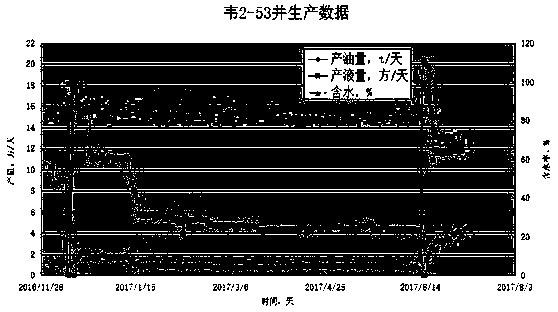

Profile control and sand fixing integrated technology for heat oil production well

InactiveCN1587638ABlocking to prevent steam channelingIntegration of sand consolidationSealing/packingSection planeActive agent

The invention relates to a kind of integrated technology of profile control and fixing sand in the thermal production well. The invention has adopted proportionate mixture of the blast furnace water garrulous slay (BFS), activator, expanding agent, outer active agent, and dispersed packing, then mix them evenly with mixer thruogh mixing, crushing, finally screen to form to profile control sand-proof agent. Mix with clear water to form 30%-50% floating distributed system when applying, then inject it into the stratum to form integrated technology of profile control and fixing sand in the thermal production well. It is mainly used in the mining of compacted oil gas injection well. It can effectively control the surfacing of thermal production well, adjust gas-absorbing section, plug vapor and water fleeing, meanwhile prevent the oil well from producing sands. It has realized the integration of adjusting plug in high temperature and fixing sands, and solved the contradiction between adjusting plug and helping discharge when the two constructed separately, thus save the costs of the measures.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

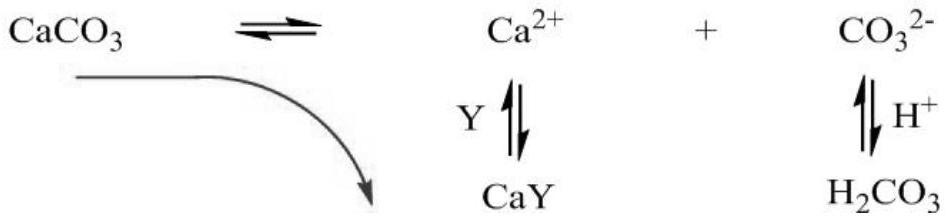

Chemical blocking remover for immovable string of oil-water well and preparation method and application thereof

InactiveCN113214813AAchieve decompositionTo achieve the purpose of increasing productionDrilling compositionDodecaneTridecane

The invention belongs to the technical field of chemical materials, and relates to a chemical blocking remover for an immovable string of an oil-water well and a preparation method and application thereof, the chemical blocking remover comprises the following raw materials in percentage by mass: 15-30% of a chelating scale dissolving agent, 0.5-1.5% of a permeation solubilizer, 2.0-4.0% of an anti-scale stabilizer, 4.0-8.0% of a viscous stable discharge aiding agent and water, wherein the chelating scale dissolving agent is one or a mixture of more than two of 1, 4, 7, 10-tetraazacyclododecane N-tetraacetic acid, ethylenediamine tetraacetic acid and 3-methyl 1, 5, 8, 11-tetraazacyclotridecane N-tetraacetic acid. The blocking remover is a neutral system and has environmental protection performance; the blocking remover can be prepared and used on site, the construction technology is effectively simplified, the operation efficiency is improved, the cost is reduced, swabbing and liquid discharging are not needed, and the purpose of stably increasing the yield of the oil producing well is achieved.

Owner:XI'AN PETROLEUM UNIVERSITY

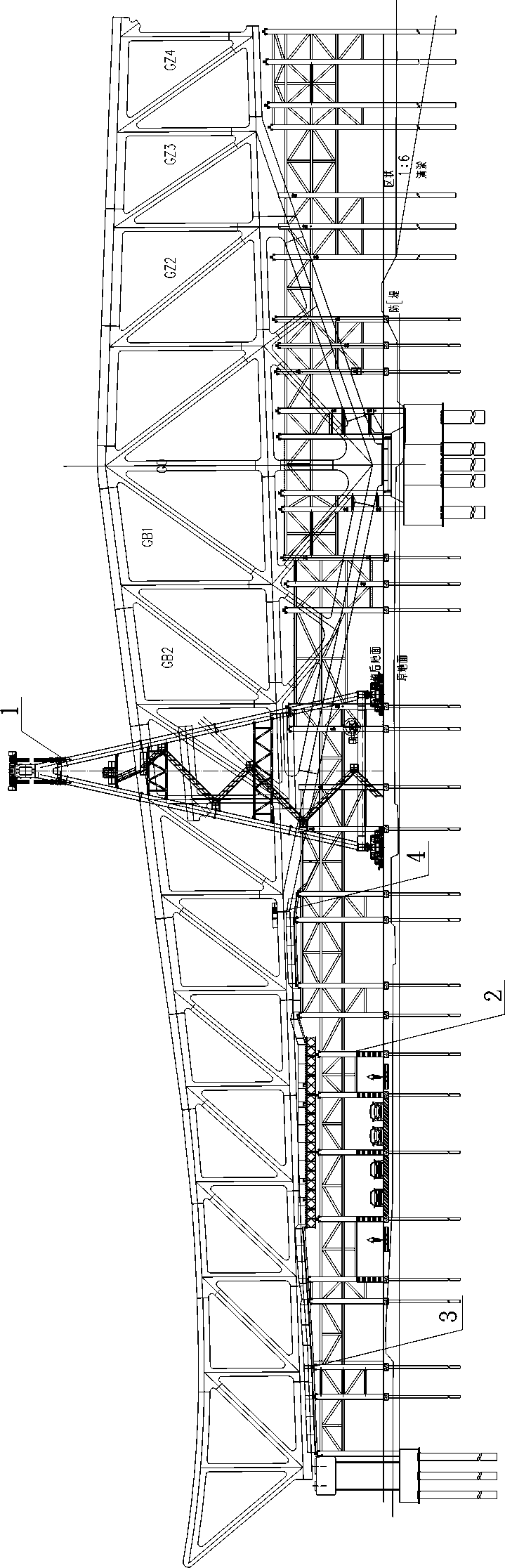

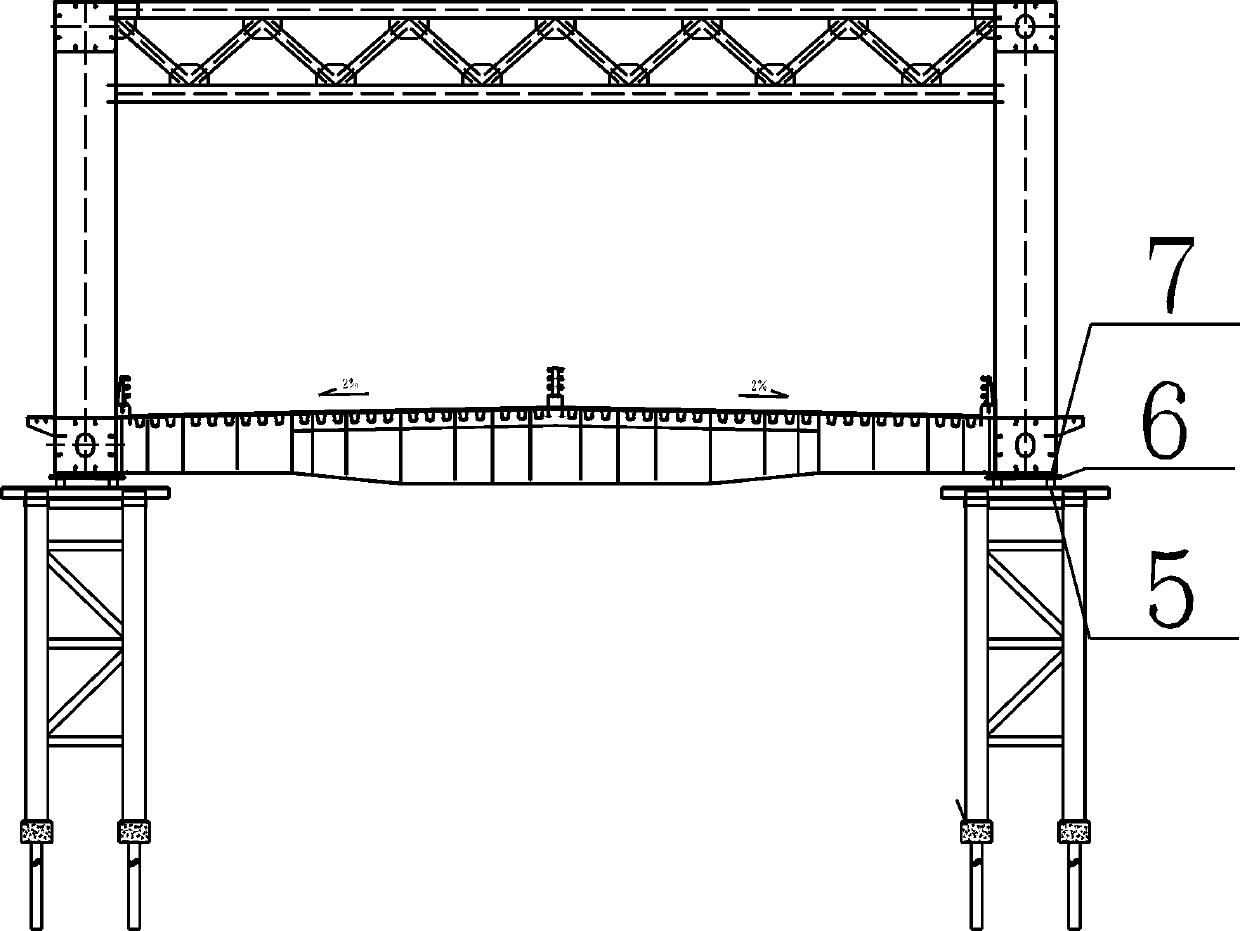

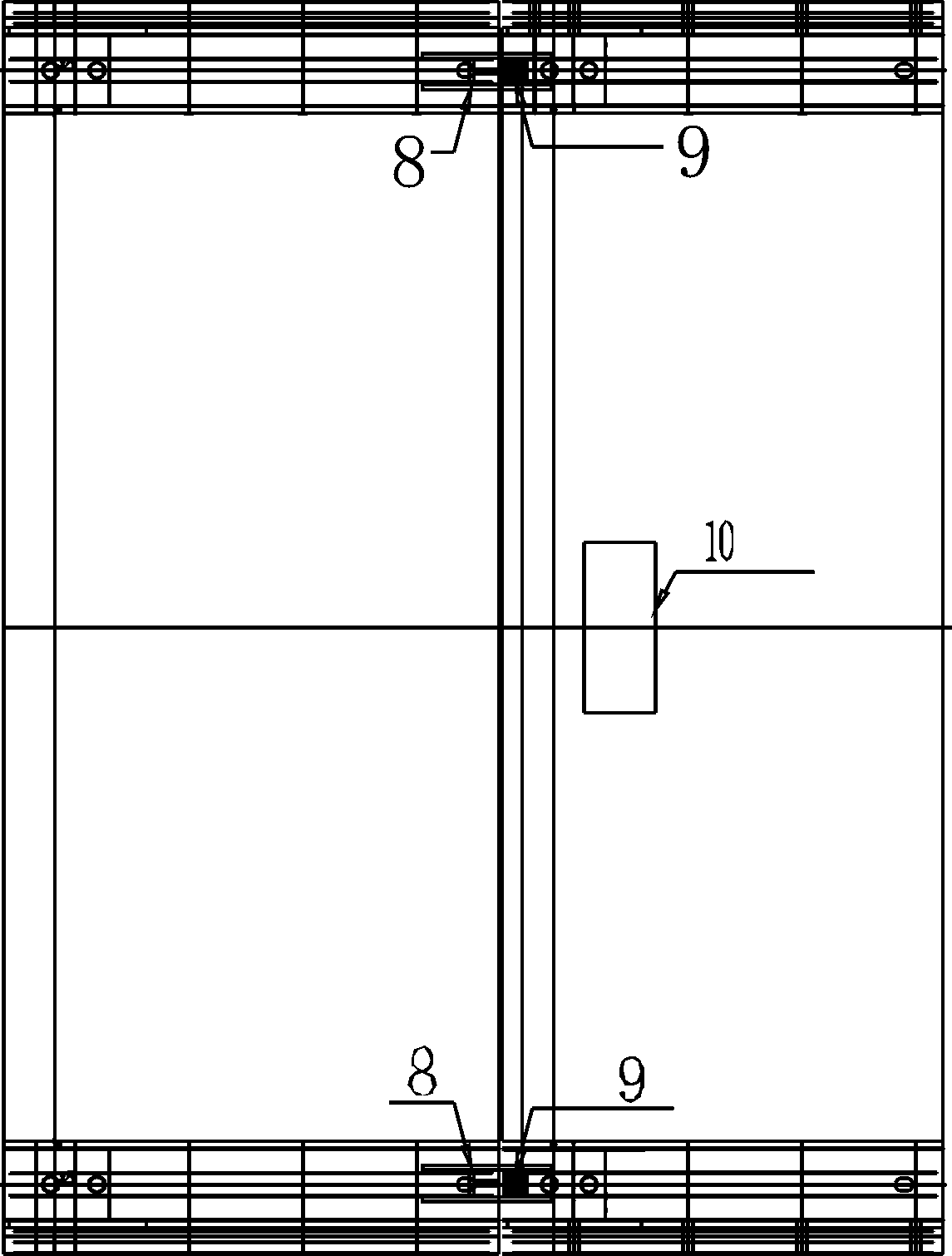

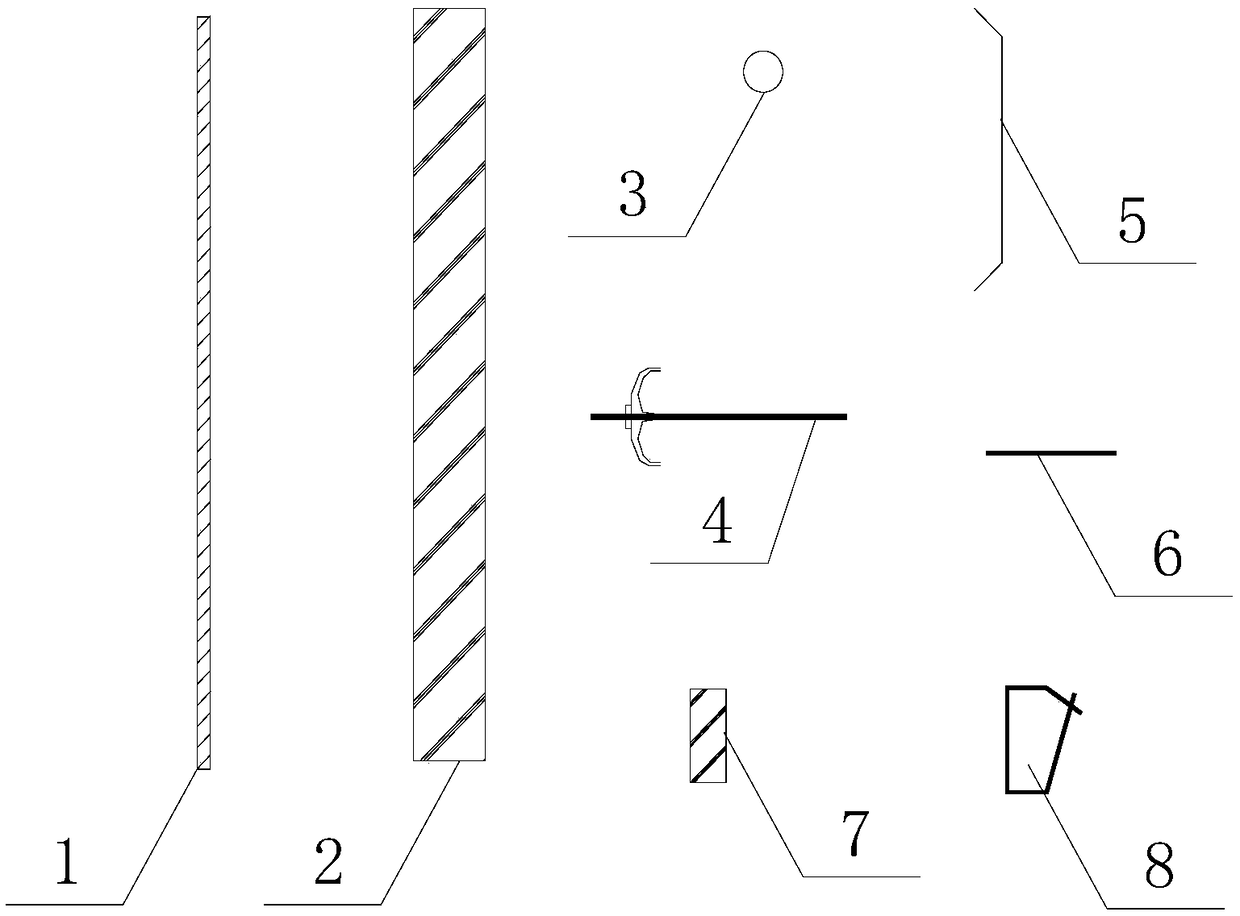

Continuous steel truss bridge side span rapid closure construction system and construction method

PendingCN110485300AImprove construction efficiencyShort construction periodTruss-type bridgeBridge erection/assemblyNumerical controlTraction system

The invention provides a continuous steel truss bridge side span rapid closure construction system and a construction method. The system is provided with a 600t pier-crossing gantry crane, a temporarysupport, a temporary support pad and a reaction frame traction system, wherein the temporary supporting pad is composed of a sand barrel, a steel sleeper and a tetrafluorohydrazine sliding plate, thetemporary supporting pad is integrally located on the temporary support, and a reaction frame traction system is installed on a lower chord of a corresponding temporary closure point and is composedof a reaction frame, a 200t double-acting jack and a PLC synchronous numerical control hydraulic terminal. The method and the system can effectively solve the problem that a temporary closure sectionneeds a matching and cutting process or needs to repeatedly adjust the installation position and the line type of a steel truss girder, reduce the equipment investment, shorten the construction period, save the measure cost and reduce the construction safety risks.

Owner:四川路桥华东建设有限责任公司

Chemical regulator for stratified waterflooding in water injection well and stratified water amount regulating construction method

InactiveCN1730902AReduce dosageReduce injection volumeFluid removalWater insolubleEnvironmental engineering

The laminated water injection amount chemical regulator for water injecting well is hot molten re-compounded solid resin comprising main chemical and assistant, and is water insoluble, acid insoluble, oil soluble and thermoplastic. It is processed into grains and injected into water injecting well together with pumped carrying liquid. It is absorbed in more quantity in the well water absorbing stratum than in the less water absorbing stratum and is thermoplastic, so that it can regulate water injecting quantity in different stratums automatically. The present invention has the advantages of no need of tool set to well, expanded application range, no entering and no contamination to stratum while blocking holes, low cost and easy unblocking.

Owner:孙广森 +1

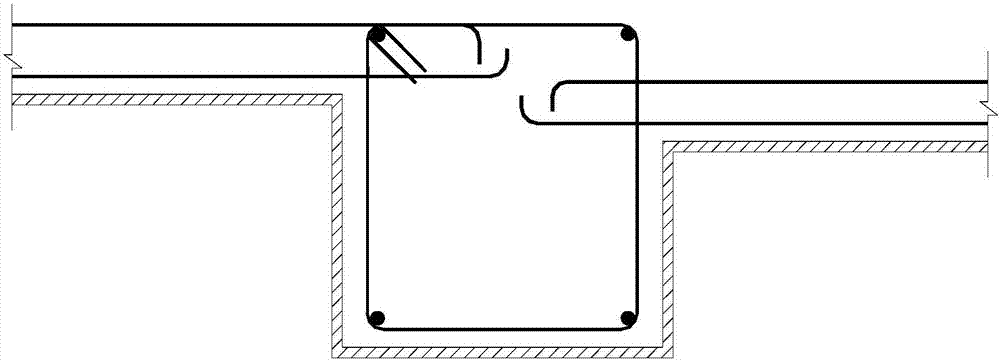

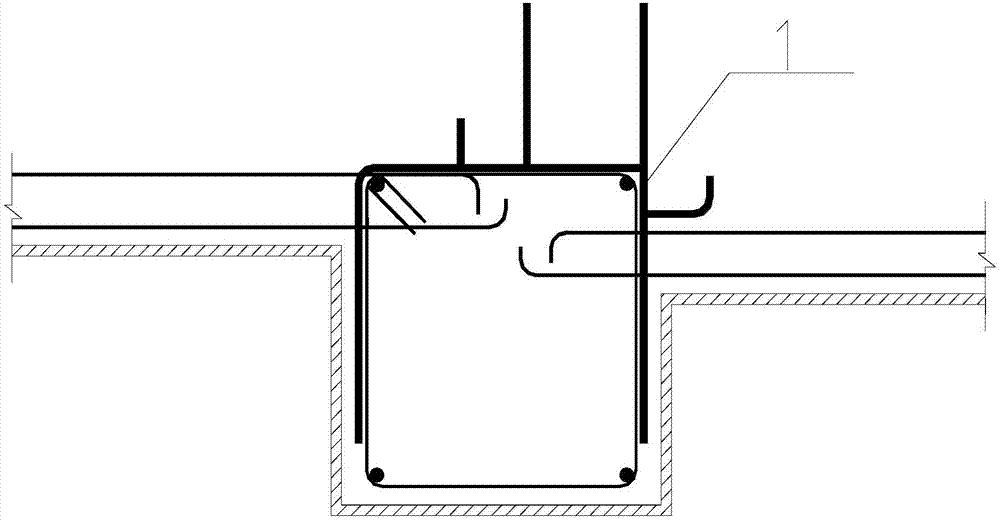

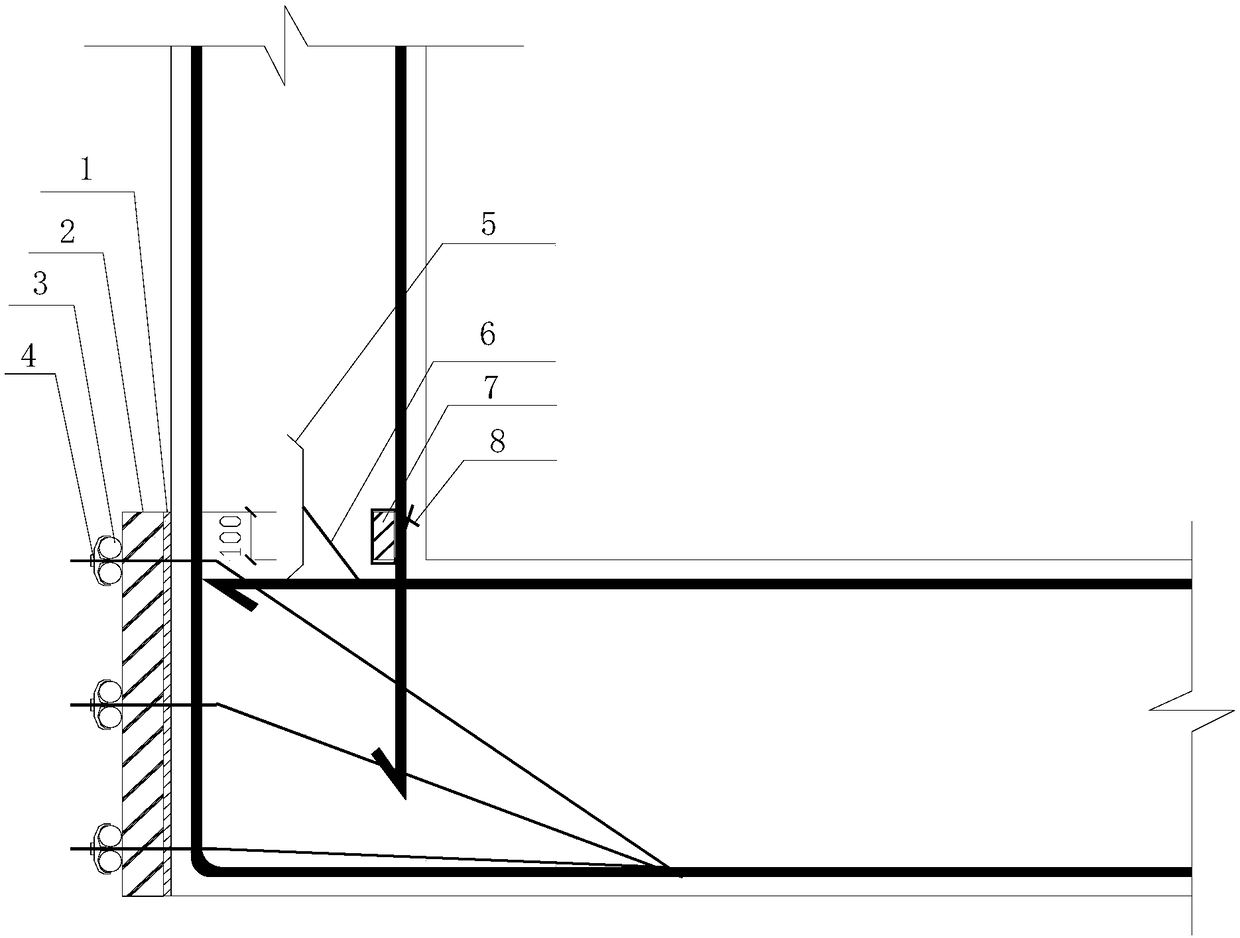

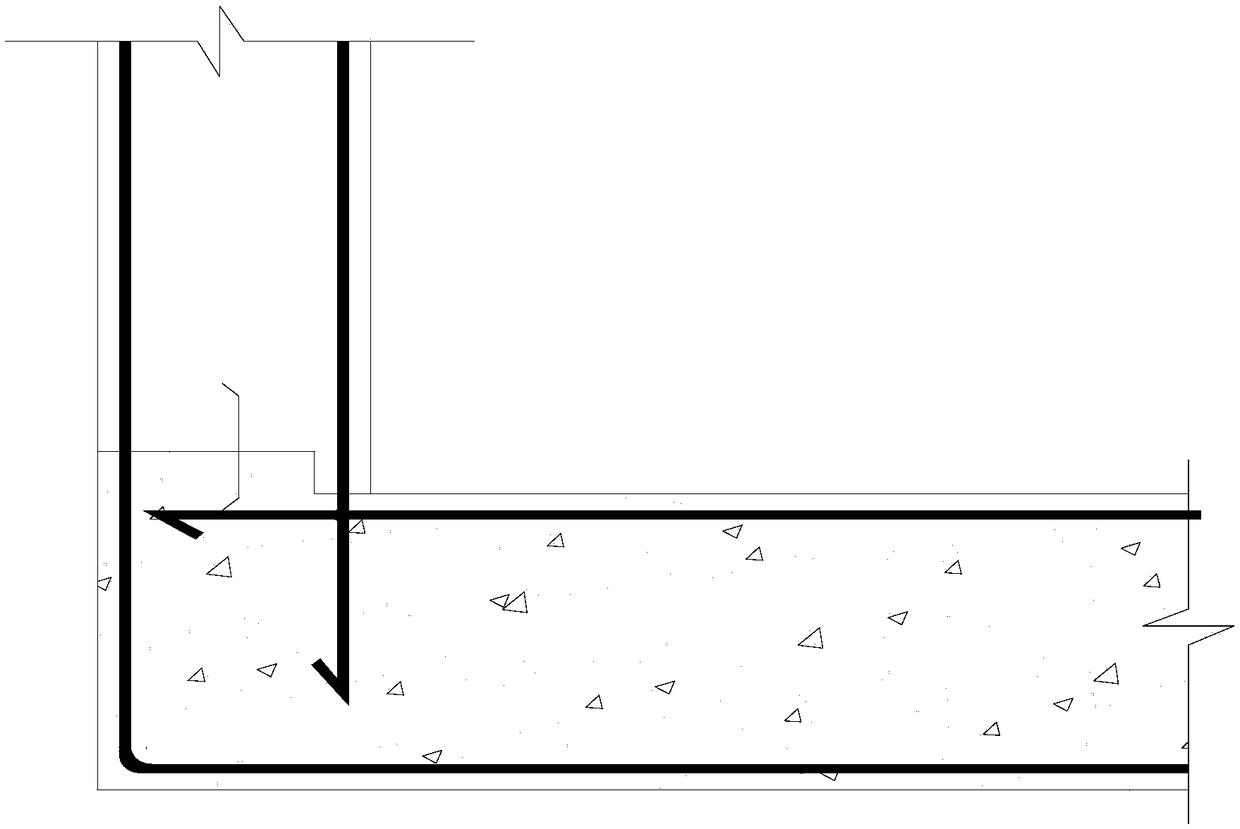

Construction method for leaving construction joint at the intersection of waterproof concrete exterior wall and foundation

InactiveCN109025290AGuarantee the appearance qualityEasy to makeBuilding material handlingBuilding insulationsRebarExternal cladding

A construction method for leaving a construction joint at the intersection of a waterproof concrete exterior wall and a foundation belongs to the technical field of construction joints in building engineering. The construction steps include that after the foundation and wall reinforcing steel bars are tied up, firstly, an upstream wall formwork is set up, an upstream formwork (1) and an upstream battens (2) are placed in sequence, and then steel pipes (3) are installed to fix the upstream formwork (1) with tension bolts (1), wherein the upstream formwork (1) is 100mm higher than the top surface of the foundation concrete; a water-stop steel plate (5) is mounted, the water-stop steel plate (5) is placed on the upper surface of the main reinforcement on the upper part of the foundation and is fixed with the steel bars (6); an inner wall face batten (7) is installed on the inner side of the wall main reinforcement, the bottom of the inner wall batten (7) is flush with the top surface of the foundation concrete, and the batten (7) is bound and fixed to the wall main reinforcement with iron wires (8). Therefore, a hanging formwork on the inner side of the outer wall is saved. The methodhas the advantages of being convenient in installation and high in construction efficiency, and ensuring the appearance quality of concrete, accelerating the construction progress and saving measurecost.

Owner:BEIJING SHOUGANG CONSTR GROUP

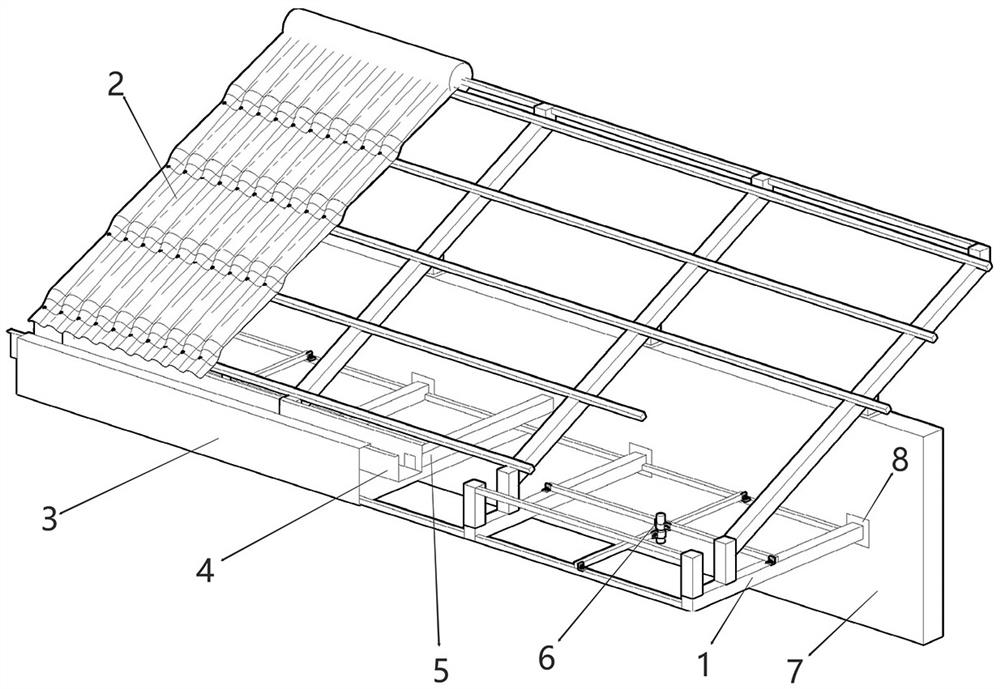

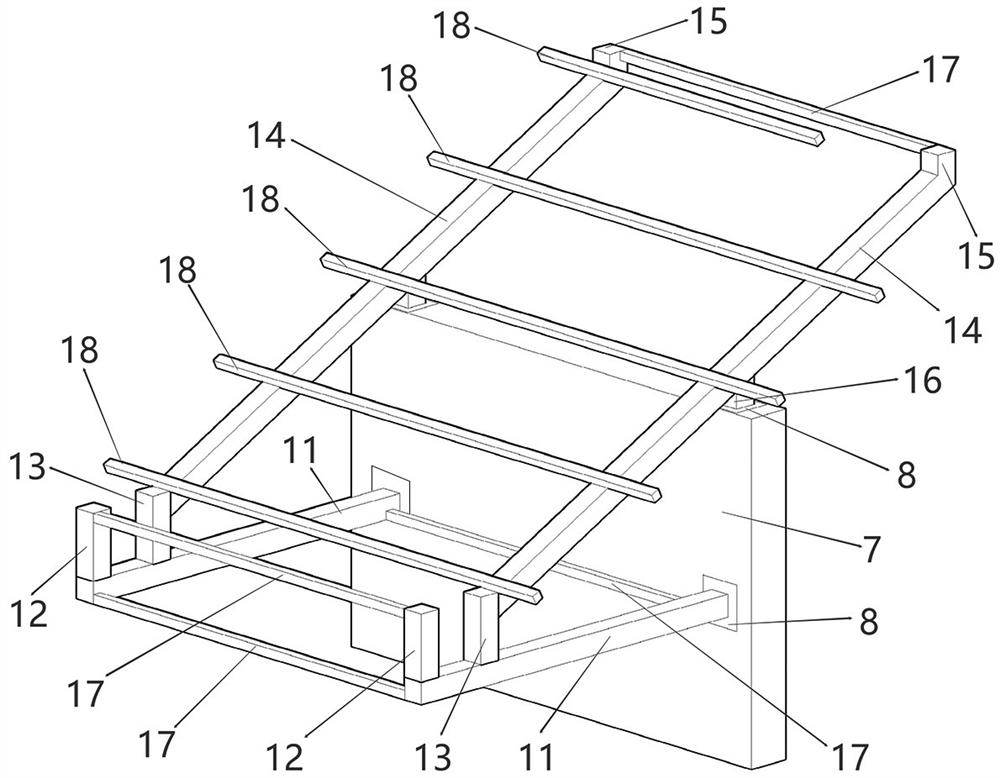

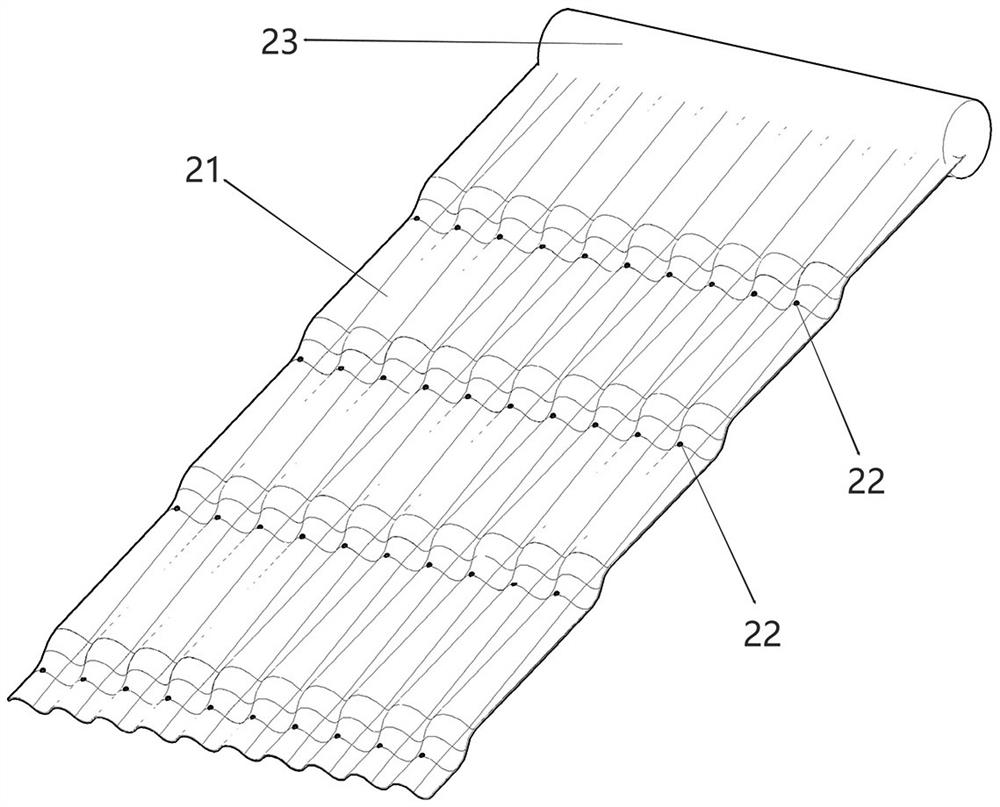

High-rise building steel structure antique eave and construction method thereof

ActiveCN113653272ASimple processGuarantee the construction qualityRoof drainageRoof toolsFalseworkEaves

The invention discloses a high-rise building steel structure antique eave and a construction method thereof, and relates to the technical field of antique building design and construction. The high-rise building steel structure antique eave comprises an antique eave steel structure framework arranged around a building outer wall, an antique tile pitched roof connected to the top of the antique eave steel structure framework, decorative plates connected to the bottom and the outer side of the antique eave steel structure framework, a gutter drainage system connected into the antique eave steel structure framework and a drainage hole protection device arranged in the antique eave steel structure framework. The antique eave steel structure framework is blanked and welded on site, and other structures are prefabricated in factories and installed on site; construction is convenient, and maintenance is easy; and compared with a traditional concrete structure antique eave, a cantilever structure construction formwork and a scaffold do not need to be erected again, the process is simple and convenient, operation is safe, the construction period can be greatly shortened, environment friendliness is achieved, materials are saved, and cost is reduced.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

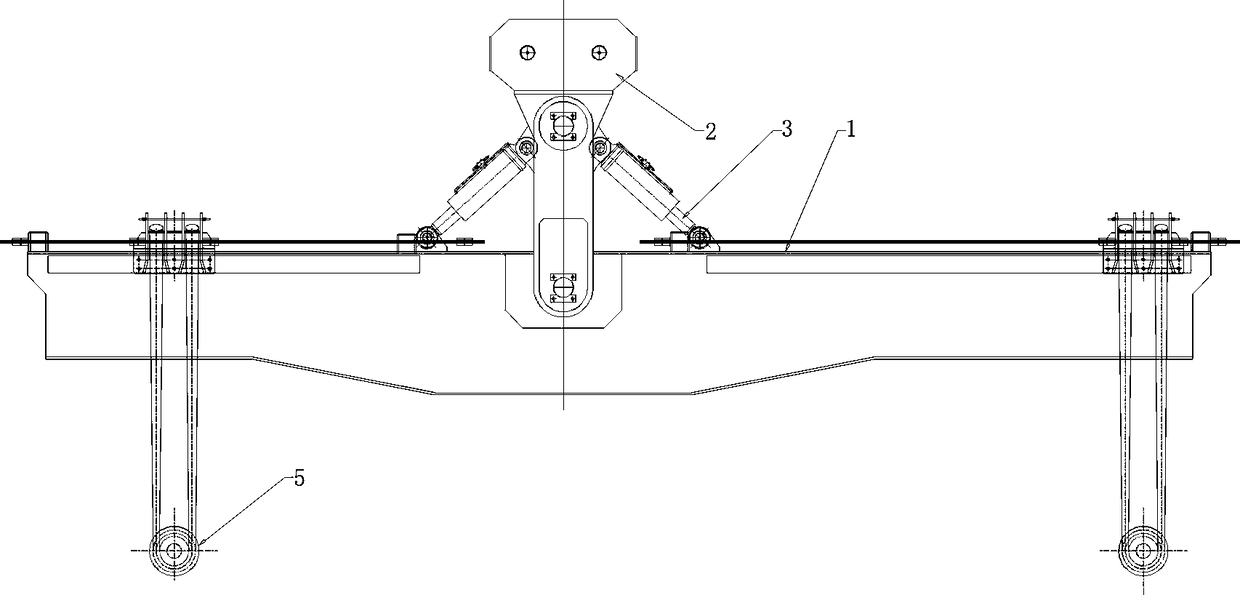

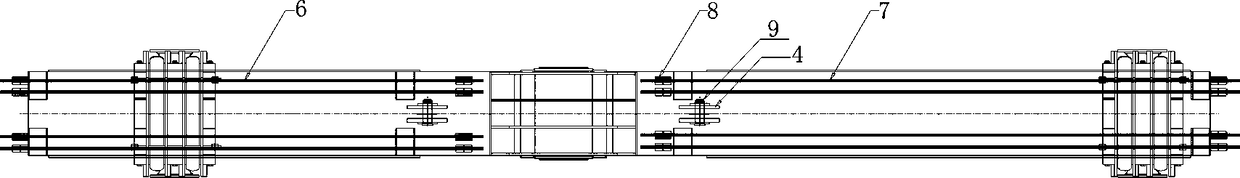

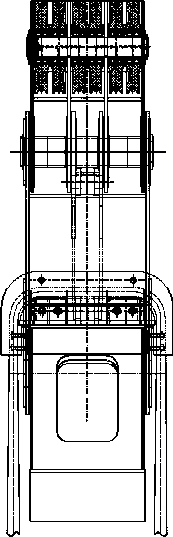

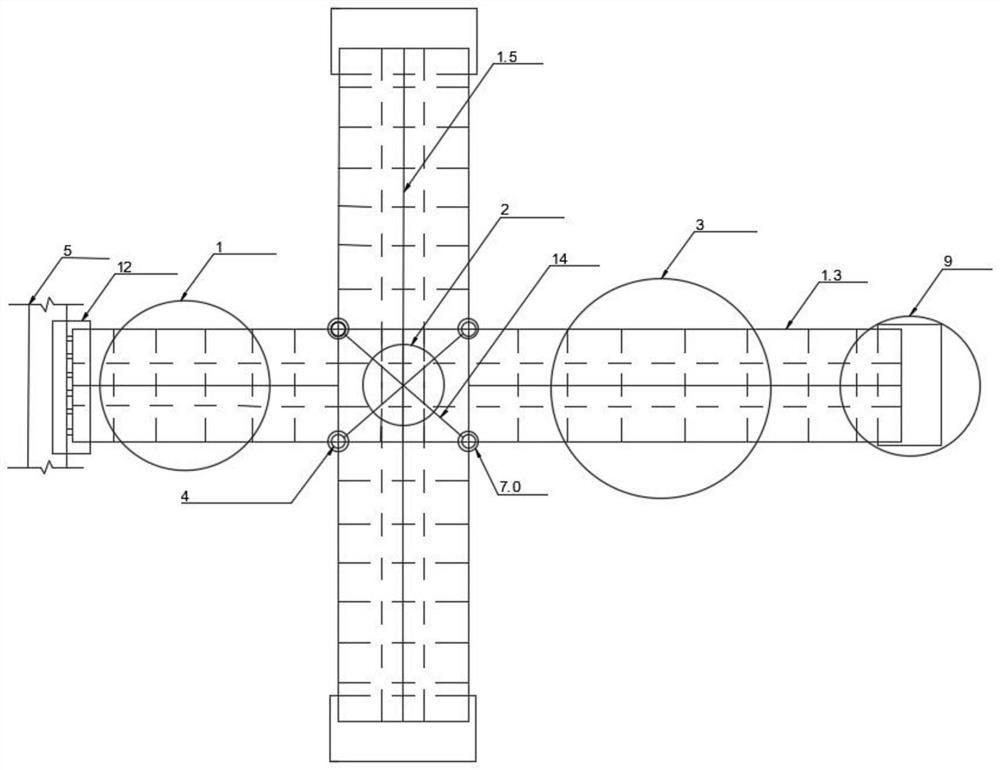

Self-adaptive steel truss girder gravity center and installation inclination angle change hoisting lifting appliance and construction method

PendingCN108275574ACost reduction measuresReduce installation difficultyBridge erection/assemblyLoad-engaging elementsArchitectural engineeringGravity center

The invention discloses a self-adaptive steel truss girder gravity center and installation inclination angle change hoisting lifting appliance and a construction method. The main structure comprises alifting appliance main beam, a movable pulley assembly, an oil cylinder, a fixed base, a suspender assembly, a high-strength finish rolling thread steel A, a high-strength finish rolling thread steelB, a high-strength finish rolling thread steel bar matching nut and a cotter pin; the lifting belt assembly is located on the lifting appliance main beam, and the movable pulley assembly is located on the lifting appliance main beam; the two sides of the movable pulley assembly are correspondingly provided with oil cylinders, the high-strength finish-rolled threaded steel A and the high-strengthfinish-rolled threaded steel B penetrate through the suspender assembly and the corresponding high-strength finish-rolled threaded steel rod matched nut correspondingly. According to the gravity center and the hoisting lifting appliance and the method, after being improved, the change of the center of gravity of the large-section hoisting of the structural object can be effectively applied, the lifting appliance is reduced, the measure cost is reduced, the construction process is simple and rapid, the installation difficulty is reduced, the total construction period is saved, and the measure cost is greatly reduced.

Owner:四川路桥华东建设有限责任公司

Cooling type oil-based selective water plugging method

ActiveCN108035697ACost reduction measuresNo pollution in the processSealing/packingThermal waterViscosity

The invention provides a cooling type oil-based selective water plugging method. The Cooling type oil-based selective water plugging method comprises the steps that heavy oil is preheated, so that thefluidity of the heavy oil is restored, and the heavy oil is injected into the formation; after squeezing injection of the heavy oil is finished, displacement is conducted with hot water, the heavy oil is totally squeezed into the formation, heat transfer at immediate vicinity of wellbore is conducted with cold water, so that the temperature of the heavy oil is reduced to the turnover temperatureor below, and plugging is formed. The viscosity of the heavy oil in a water layer can keep basically unchanged, while the viscosity and the flowback resistance of the heavy oil in an oil layer are reduced because the heavy oil in the oil layer makes contact with thin oil, and the selective aim of water plugging without oil plugging is achieved. The squeezed crude oil can be slowly produced from the formation finally, and the measure cost is low.

Owner:PETROCHINA CO LTD

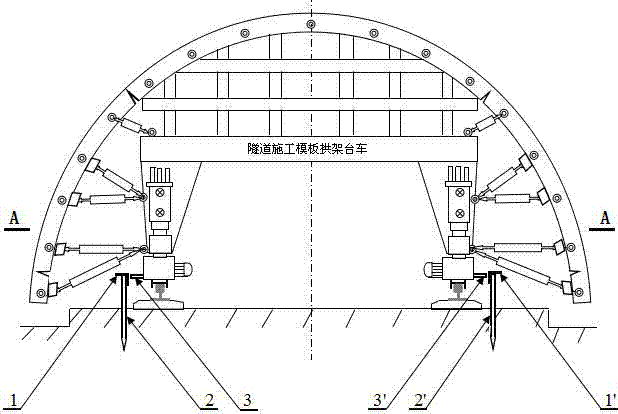

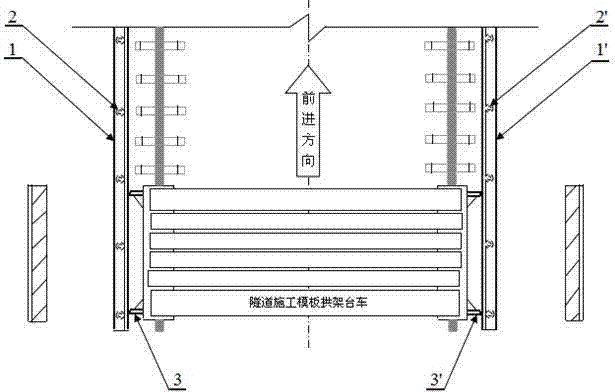

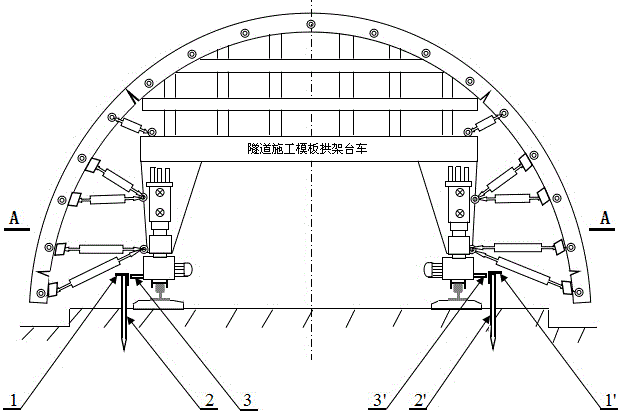

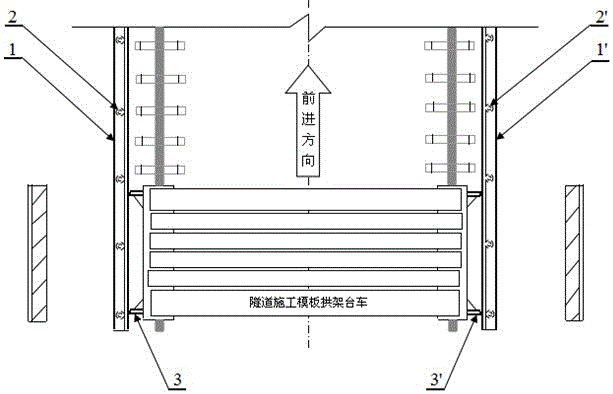

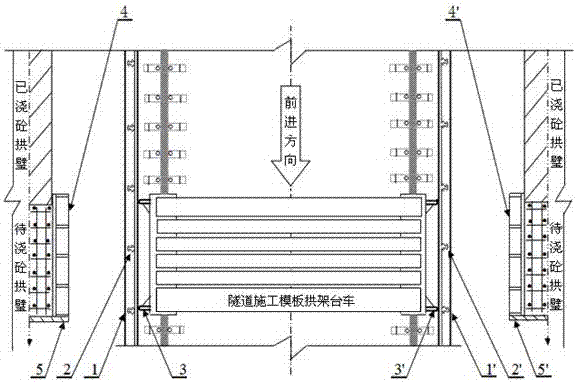

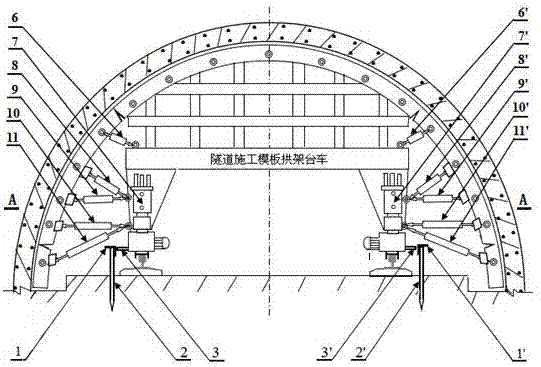

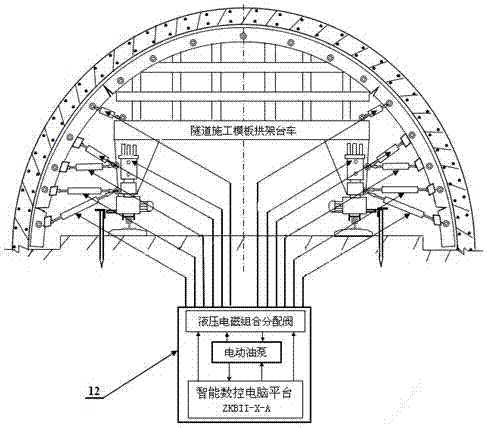

Tunnel construction template arch centering trolley guiding rule positioning method

The invention discloses a tunnel construction template arch centering trolley guiding rule positioning method, which comprises the following steps: in the advancing direction of a tunnel under tunneling construction, according to the process requirements, parallel position lines needing guiding rules to be installed are symmetrically determined by being parallel to the midline of the tunnel under the tunneling construction; a plurality of steel piles are distributed on the position lines, and are fixedly connected by adopting angle iron, thus forming tunnel construction template arch centering trolley positioning guiding rules; installation calibration contacts are arranged on the left and right sides of a template arch centering trolley; by virtue of the gap between the calibration contacts and the positioning guiding rules, the position of the template arch centering trolley in the tunnel under the tunneling construction is determined. According to the positioning method disclosed by the invention, for dynamic change errors generated after track installation, fixing errors of traveling wheel grooves and balance errors generated by an arch centering trolley mechanism, when the arch centering trolley travels or is fixed, process control and master control can be favorably realized; the travelling dynamic state and positioning in fixation of the arch centering trolley are easily observed and controlled, thus the work efficiency can be improved, and the measure cost is low.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

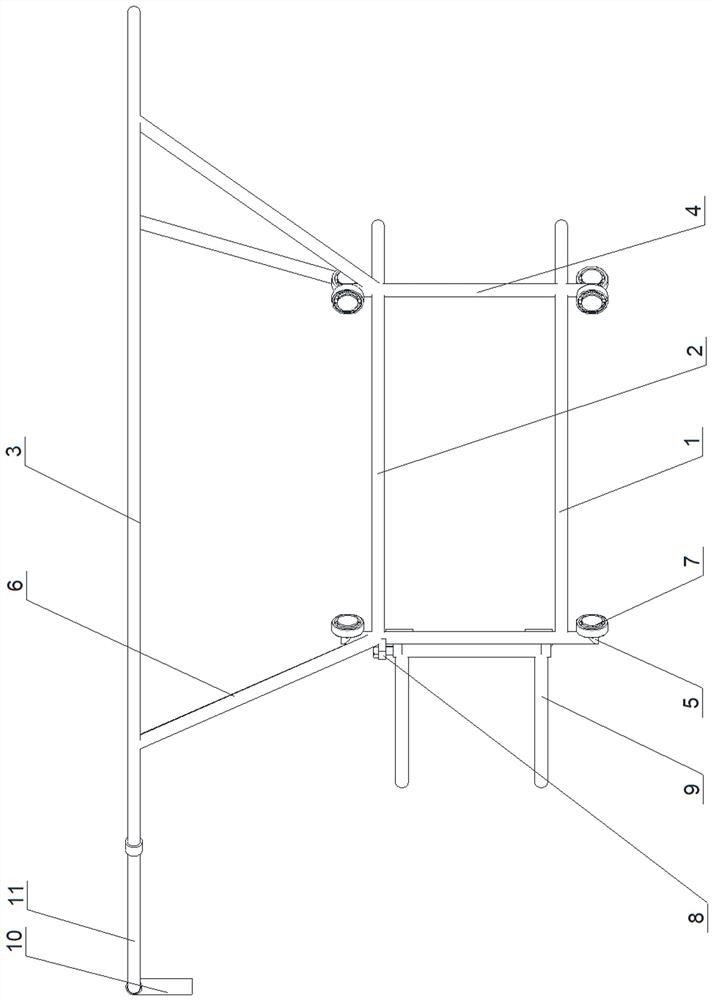

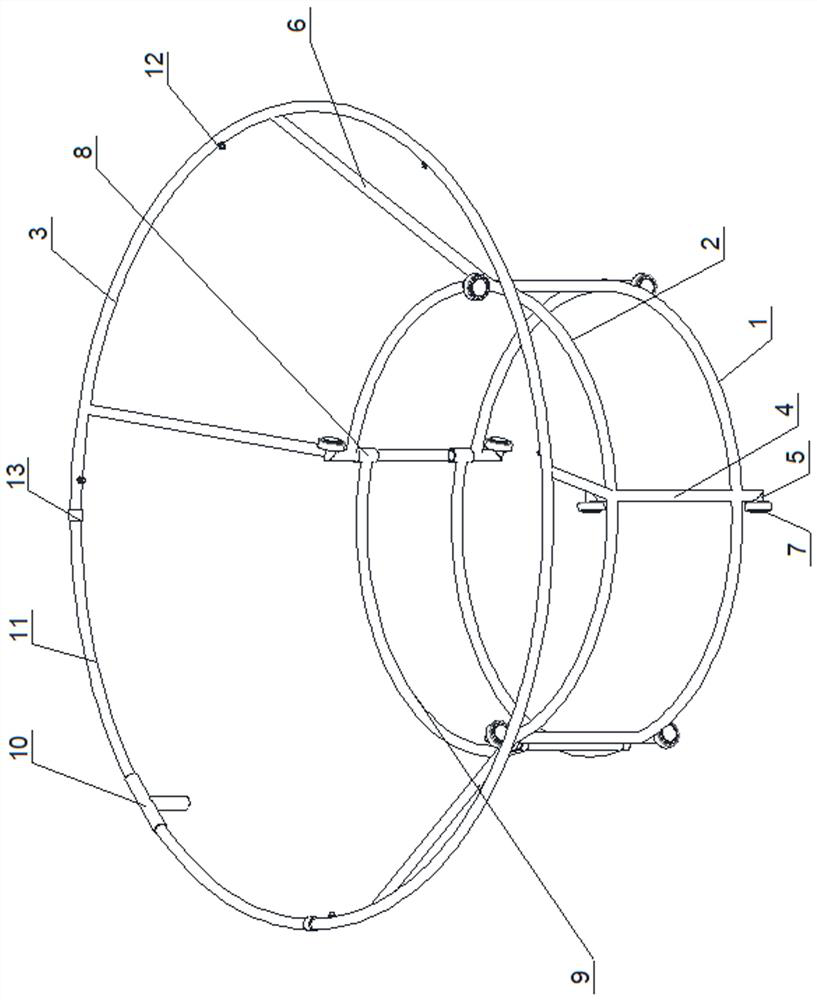

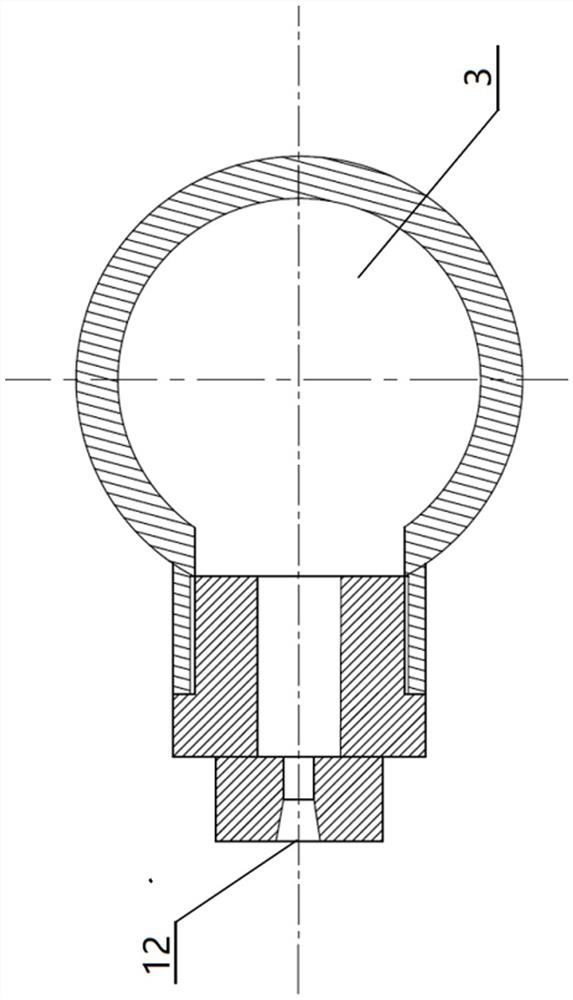

High-altitude spraying device for venue type circular stand column

PendingCN113275164AConvenient setEasy to spraySpraying apparatusStructural engineeringIndustrial engineering

Owner:SHANGHAI BAOYE GRP CORP

A method for positioning the formwork arch trolley in tunnel construction by ruler

The invention discloses a tunnel construction template arch centering trolley guiding rule positioning method, which comprises the following steps: in the advancing direction of a tunnel under tunneling construction, according to the process requirements, parallel position lines needing guiding rules to be installed are symmetrically determined by being parallel to the midline of the tunnel under the tunneling construction; a plurality of steel piles are distributed on the position lines, and are fixedly connected by adopting angle iron, thus forming tunnel construction template arch centering trolley positioning guiding rules; installation calibration contacts are arranged on the left and right sides of a template arch centering trolley; by virtue of the gap between the calibration contacts and the positioning guiding rules, the position of the template arch centering trolley in the tunnel under the tunneling construction is determined. According to the positioning method disclosed by the invention, for dynamic change errors generated after track installation, fixing errors of traveling wheel grooves and balance errors generated by an arch centering trolley mechanism, when the arch centering trolley travels or is fixed, process control and master control can be favorably realized; the travelling dynamic state and positioning in fixation of the arch centering trolley are easily observed and controlled, thus the work efficiency can be improved, and the measure cost is low.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

A correction method for tunnel construction arch formwork

ActiveCN105840212BEasy to controlSimple processUnderground chambersTunnel liningBogieNumerical control

The invention discloses a tunnel construction arch center formwork correcting method. The method comprises the steps that an arch center is moved and positioned in a tunnel; hydraulic electromagnetic combination distribution valves of a pump station provided with an intelligent numerical control computer platform on an arch center bogie are connected with hydraulic jacking oil cylinders respectively; a sensor on each hydraulic jacking oil cylinder is connected with the intelligent numerical control computer platform; a preset extending value and thrust data of each hydraulic jacking oil cylinder are determined and input, the hydraulic pump station is started, and a formwork on the tunnel construction arch center is corrected; after the arch center bogie moves forwards to a next station, the formwork on the tunnel construction arch center is corrected this time according to the data, memorized and stored in a computer, of the previous station. During arch center formwork correction and fixing, process control and master can be achieved for error gaps produced during arch center formwork installation, gap errors of a concrete arch wall which is cast again and comprehensive errors produced during arch center formwork installation, and the accurate control and correction effect on the arch center formwork on the bogie is achieved.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

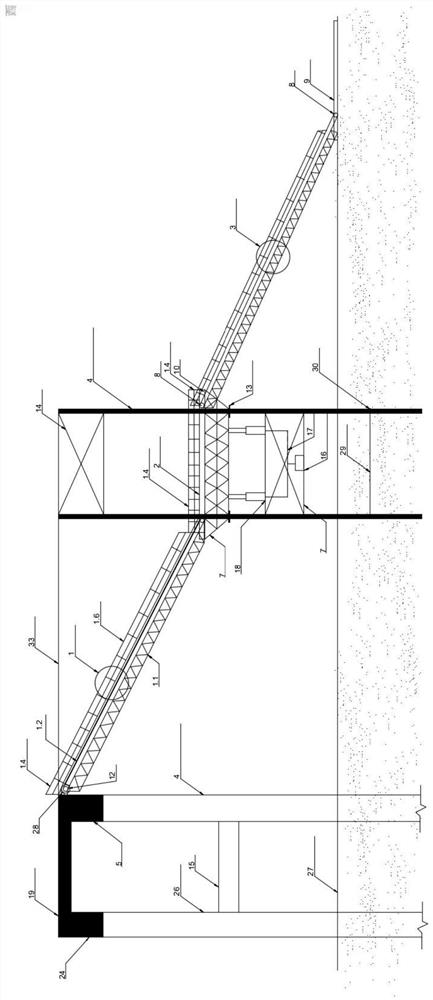

Prefabricated ultra-deep foundation pit ramp system and its construction method

ActiveCN111608429BCost reduction measuresTo achieve the purpose of cleaning and reducing dustExcavationsShaping building partsArchitectural engineeringJackscrew

The invention discloses an assembled ultra-deep foundation pit ramp system and a construction method thereof. The system includes ramp structures and vertical support structures. Among them, the ramp structure is composed of the first-level ramp and the second-level ramp connected to the transition platform through rollers and slideways, the first-level ramp and the support beam are connected through pin shafts, and the second-level ramp and the friction plate are connected through rollers and slideways. Connection; the vertical support structure is composed of concrete-filled steel tube columns, stabilizing braces, tie rod jacks, supporting trusses, control lines, jack control boxes, and supporting flanges; the four concrete-filled steel tube columns are fixed by supporting trusses and stabilizing braces, and A rod-type jack propulsion system is set in the support truss to control the transition platform up and down, thereby adjusting the slope of the ramp. The system and method of the present invention avoid problems such as drainage and anti-skid of earthwork slopes in foundation pits, affecting vehicle excavation safety and efficiency, construction progress, and the like, and reduce the cost of slope measures.

Owner:CHINA FIRST METALLURGICAL GROUP

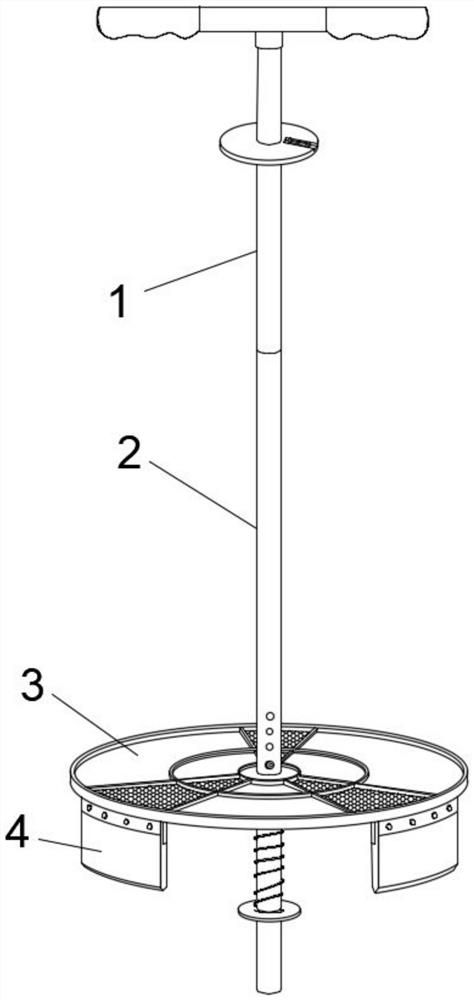

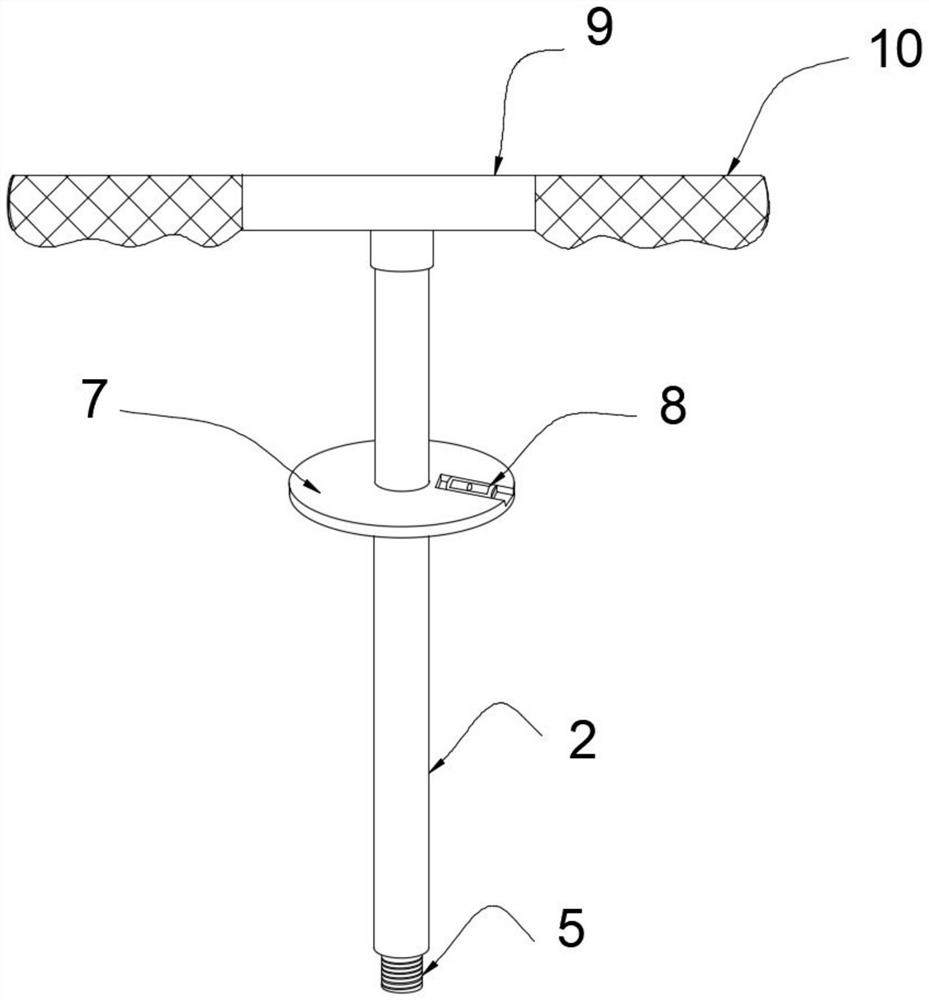

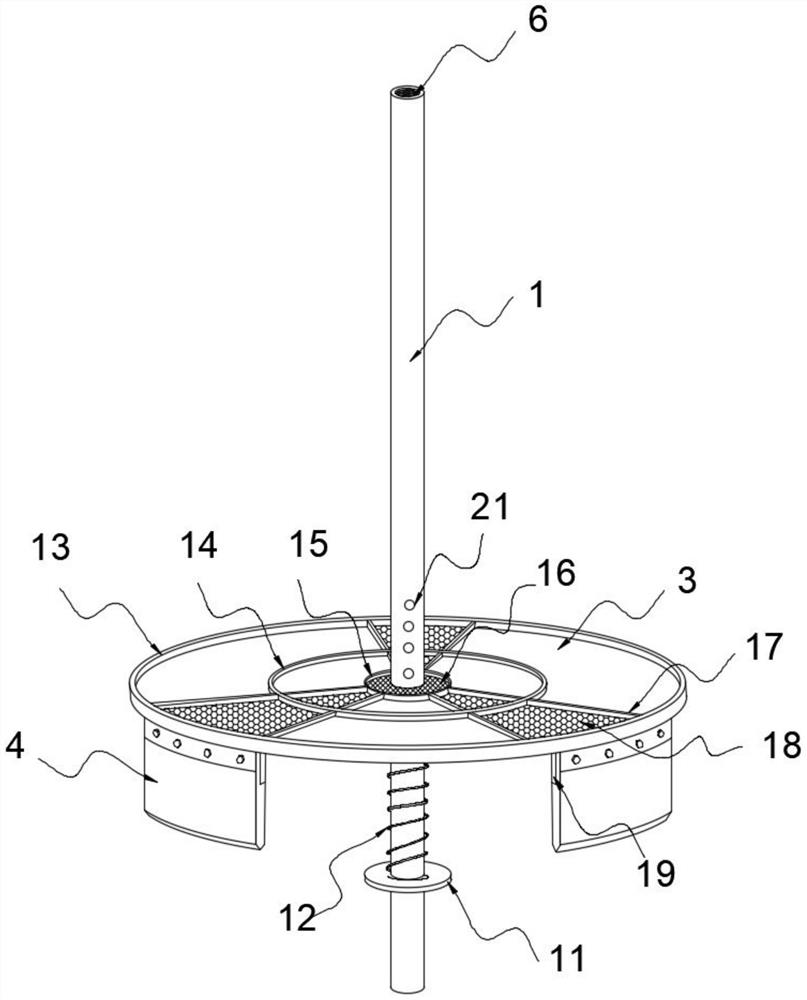

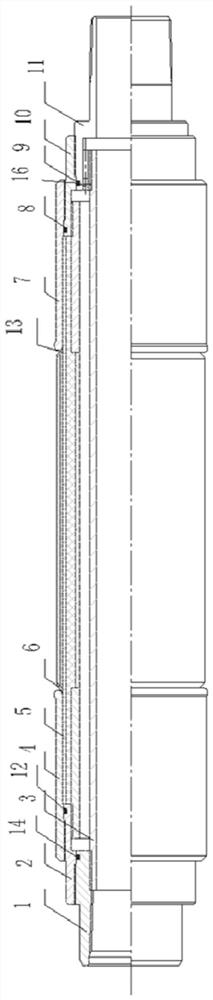

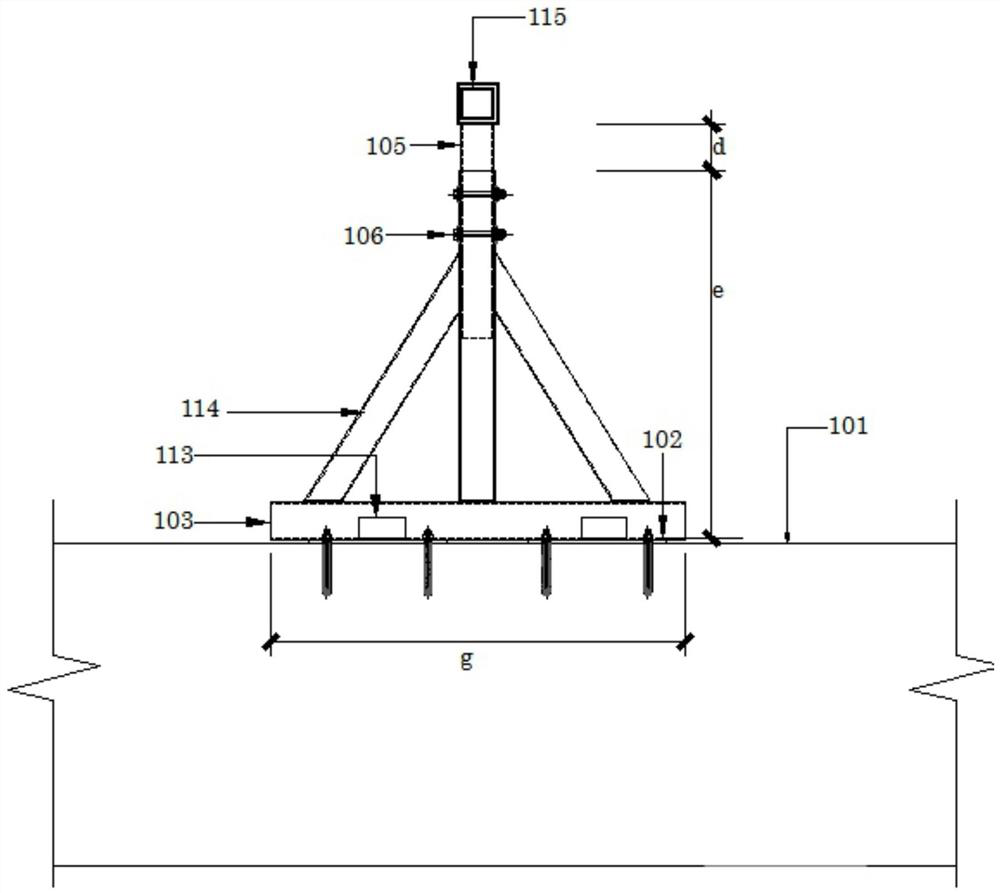

Positioning and paying-off device for pipe pile construction and construction method

ActiveCN113882379AEasy constructionImprove efficiencyGeothermal energy generationFoundation testingArchitectural engineeringStructural engineering

The invention discloses a positioning and paying-off device for pipe pile construction and a construction method, and belongs to the field of pipe pile construction. The positioning and paying-off device comprises a lower main rod and an upper main rod, wherein the upper main rod is detachably connected with the lower main rod; a measuring piece is arranged on the upper main rod; the measuring piece is detachably connected with the upper main rod; a pedal disc is mounted on the lower main rod; the outer diameter of the pedal disc is matched with the outer diameter of a pipe pile; the pedal disc sleeves the lower main rod; an elastic supporting piece is mounted below the pedal disc; the elastic supporting piece is suitable for supporting the pedal disc to be positioned on the lower main rod and move up and down along the lower main rod; a side plate is mounted below the pedal disc; the side plate is detachably connected with the pedal disc; and during working, the bottom end of the side plate is suitable for being inserted into the ground. The positioning and paying-off device solves the technical problems that the pipe pile is accurately positioned at a relatively low cost, deviation caused by inclination of the pipe pile is reduced, and later remediation cost is affected.

Owner:CHINA MCC17 GRP

Fire flooding producing well layering gas channeling plugging technology

ActiveCN111827920AImprove the development effectIncrease the degree of vertical mobilizationFluid removalDrilling compositionPipePetroleum engineering

The invention provides a fire flooding producing well layering gas channeling plugging technology. The fire flooding producing well layering gas channeling plugging technology comprises the steps that(1) after a fire flooding producing well layering gas channeling plugging pipe column is downwards arranged at a design position, a certain amount of gel composite is fed into an oil layer from an oil pipe; (2) a certain amount of high-strength gel particles are further fed from the oil pipe; and (3) an inorganic sealing agent channeling plugging system is injected, clear water is injected in a positive flow displacing manner, and then the clear water is displaced excessively. The fire flooding producing well layering gas channeling plugging technology and the adopted pipe column solve the problems that in the prior art, the plugging effect is not ideal, construction procedures are complicated, the construction time is long, and the operation cost is high; and operation procedures and cost can be effectively reduced, and the measure effect and the production efficiency are improved.

Owner:PETROCHINA CO LTD

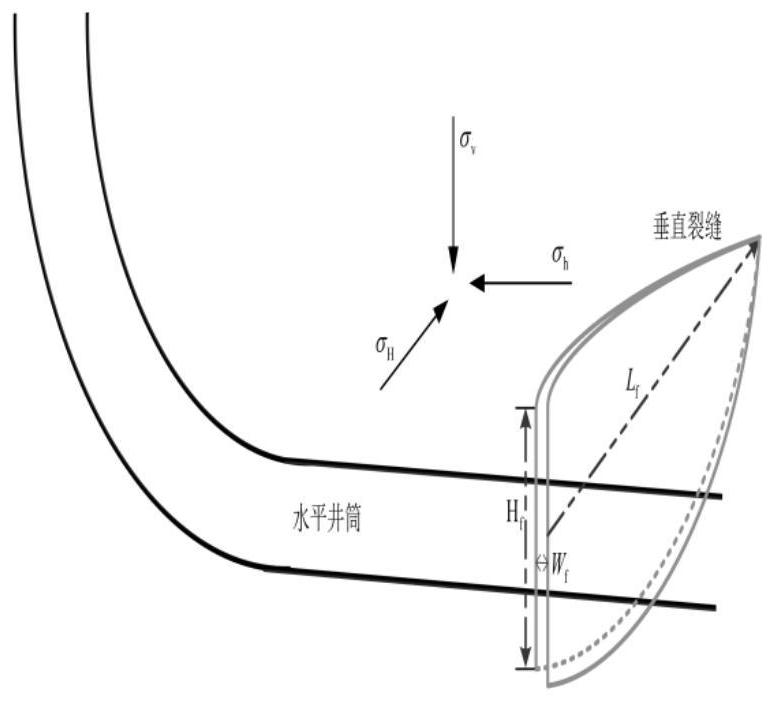

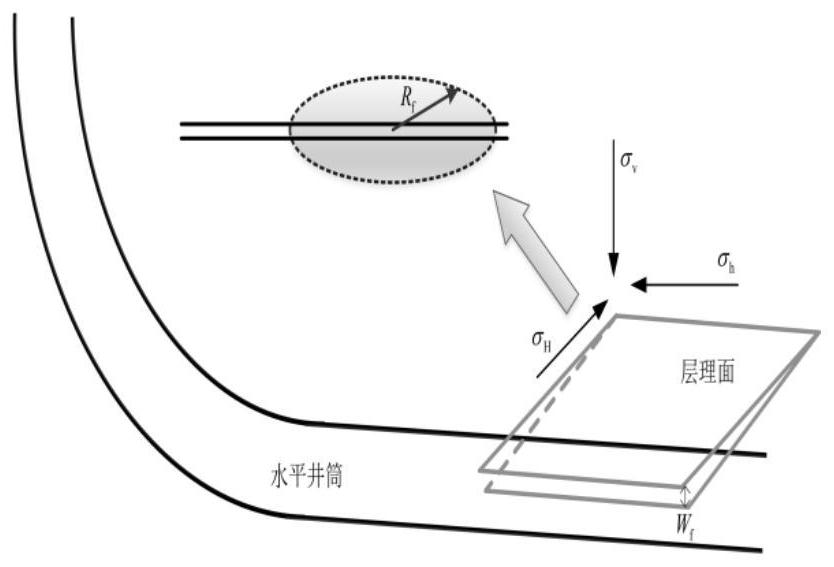

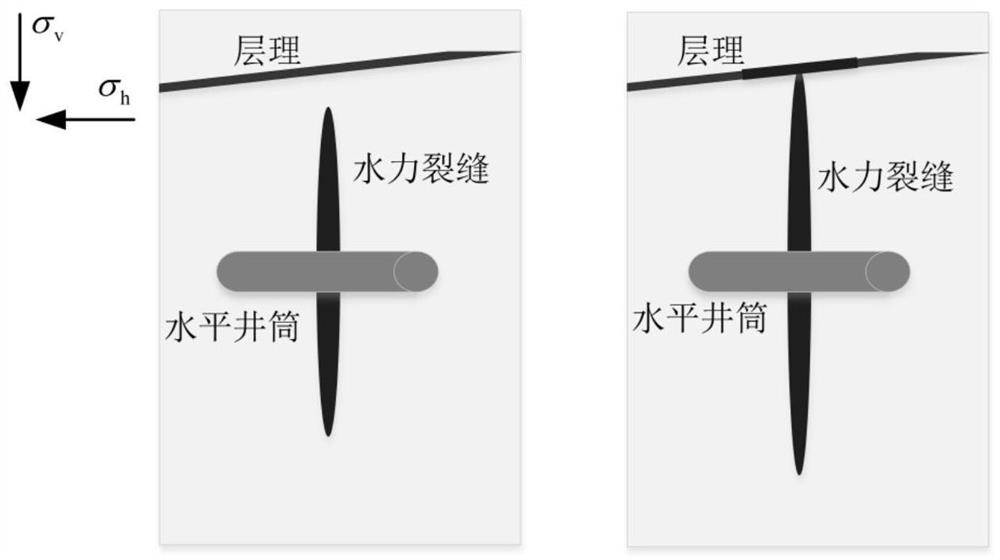

An analysis method for influencing factors of complex fracture propagation in shale fracturing process

ActiveCN110134984BTimely adjustment of fracturing optimization designAvoid invalid transformationFluid removalDesign optimisation/simulationMining engineeringShale gas

The invention discloses an analysis method for influencing factors of complex fracture expansion in the shale fracturing process, which includes the following steps: firstly, analyzing the geological characteristics of the target reservoir; The corresponding solution method calculates the net pressure of different expansion modes, and inverts the fracture parameters under different expansion modes; finally, the fracture extension law and the corresponding pressure under various factors that affect the dynamic expansion of shale fractures Response characteristics were studied to clarify the crack dynamic expansion law and main controlling factors under different construction pressure responses. The present invention can clearly grasp the dynamic expansion behavior of fractures, realize the diagnosis and analysis of different typical construction curves in shale gas fields, and is beneficial to identify various fracturing change events as early as possible, judge the fracture shape trend and construction abnormal points in advance, and adjust fracturing optimization in time Design, avoid ineffective transformation, reduce the cost of measures, thereby improving the quality and effect of fracturing.

Owner:CHINA PETROLEUM & CHEM CORP +1

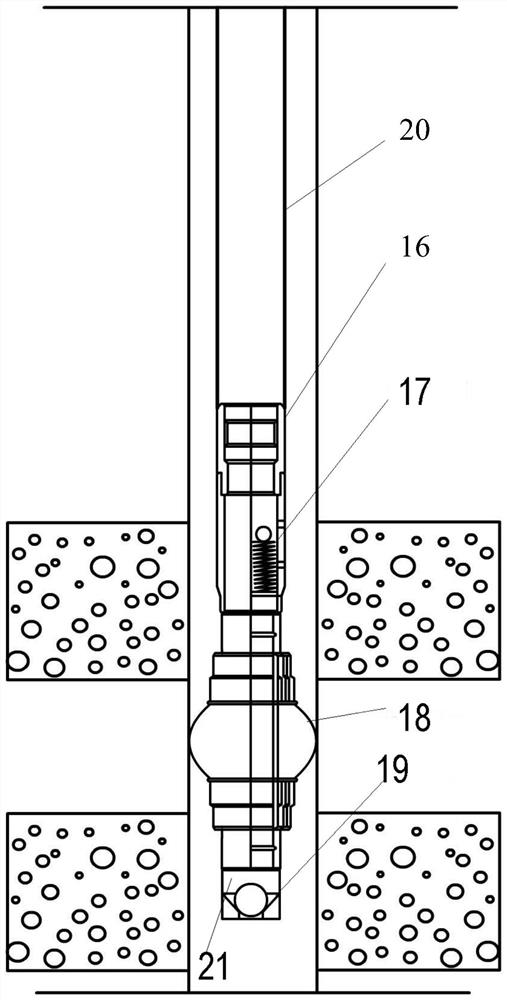

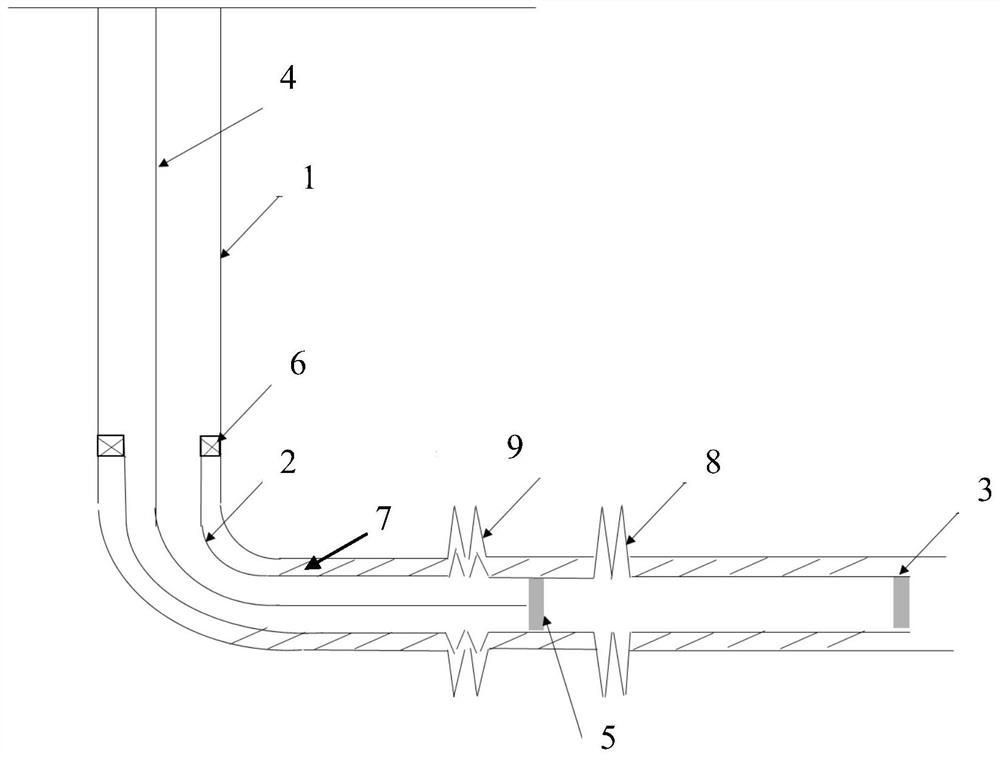

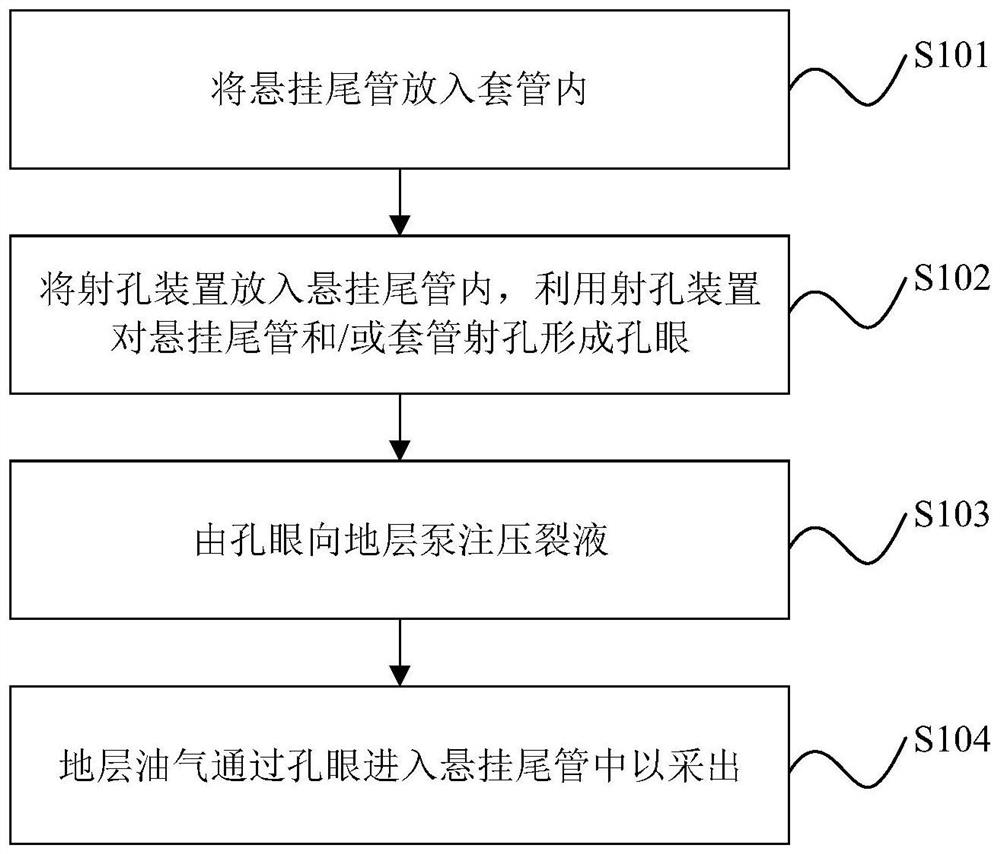

Well completion device and method for horizontal well re-fracturing

PendingCN111997578ASolving Staged Refracturing ProblemsIncrease productionFluid removalHorizontal wellsOil field

The invention provides a well completion device and method for horizontal well re-fracturing. The well completion device for horizontal well re-fracturing comprises a sleeve, a suspension tail pipe and a plugging head, wherein one end of the suspension tail pipe is suspended at the heel part of a horizontal section in the sleeve, the plugging head is arranged at the other end of the suspension tail pipe to plug the suspension tail pipe, and in the well completion operation, a perforating device is lowered into the suspension tail pipe to perforate the sleeve and / or the suspension tail pipe. According to the well completion device, the suspension tail pipe is lowered into the sleeve, repeated fracturing can be carried out on an interval already having a perforation hole but not transformed,the problem that an existing horizontal well faces staged repeated fracturing is solved, repeated fracturing with the large displacement volume is achieved, the single-well yield is increased, the measure cost is reduced, and the repeated fracturing effect and the final oilfield recovery ratio are improved.

Owner:PETROCHINA CO LTD

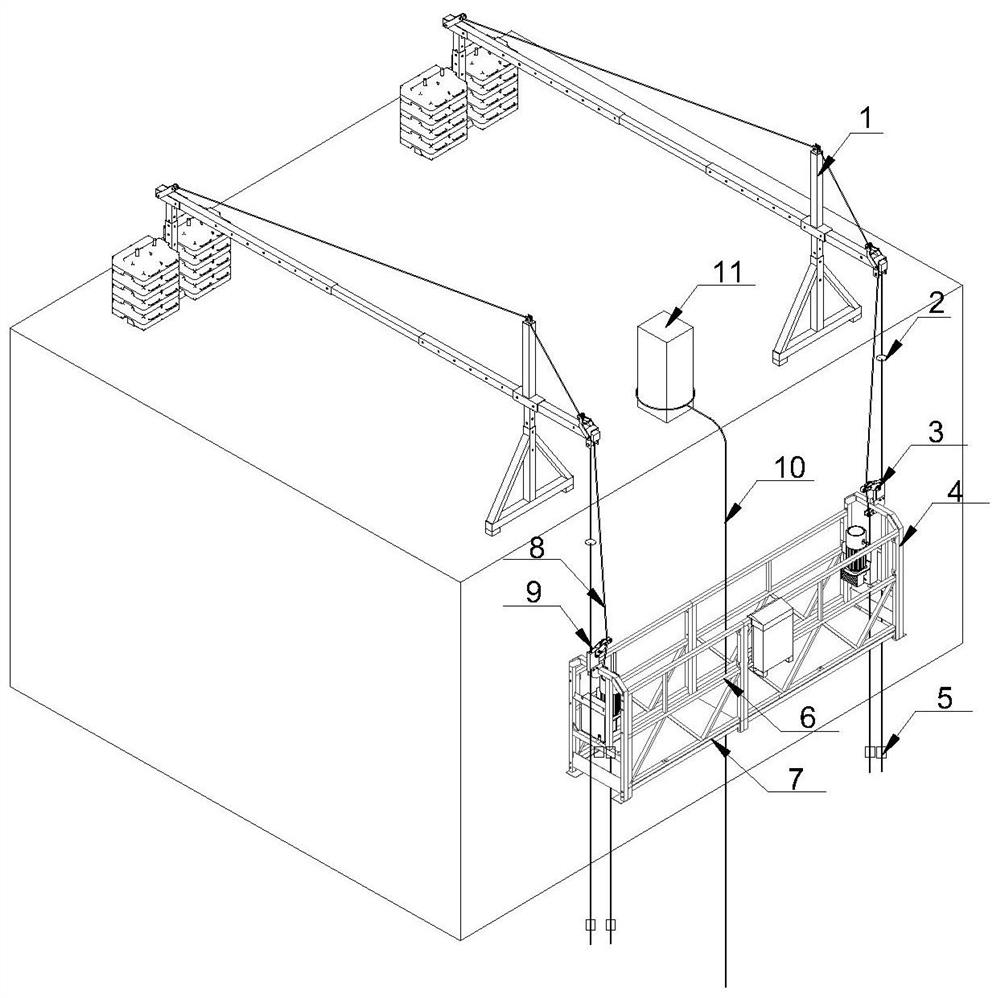

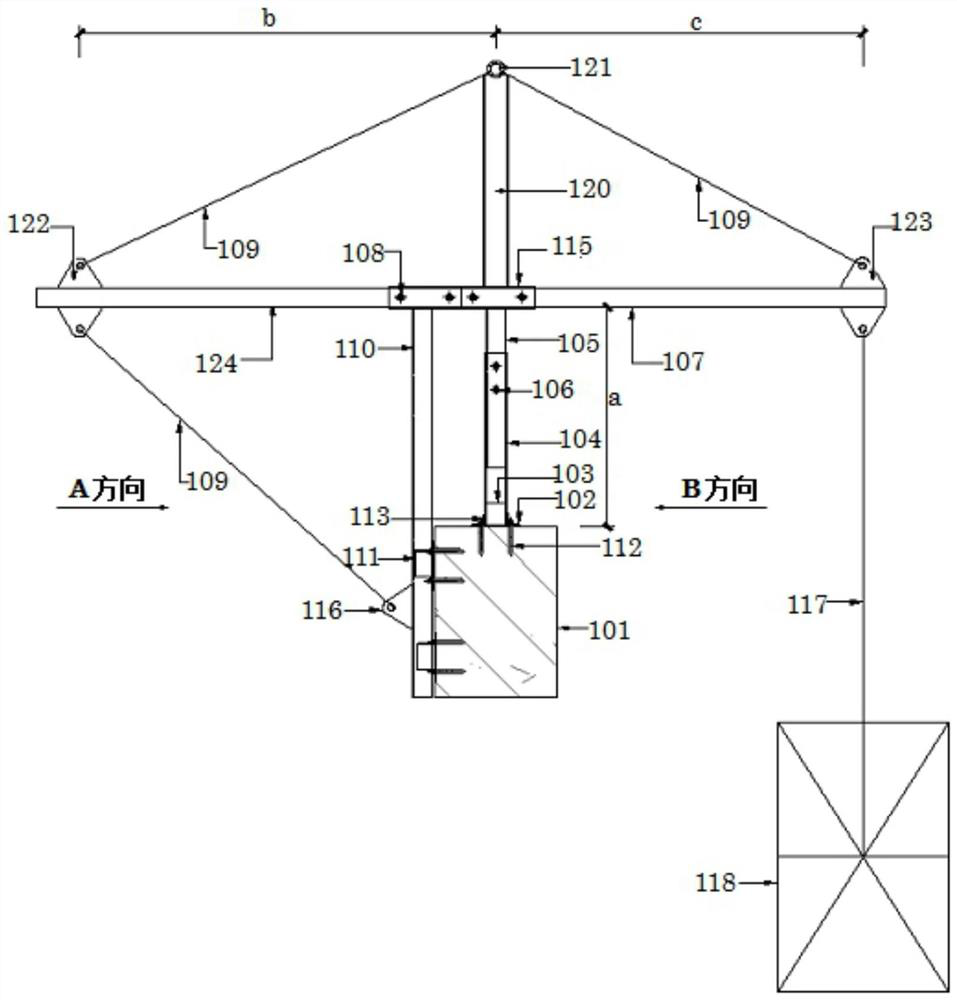

Hanging basket bracket mechanism on structural beam and installation method

PendingCN113550552AReduce construction measuresCost reduction measuresBuilding material handlingScaffold accessoriesEngineeringWire rope

The invention provides a hanging basket bracket mechanism on a structural beam. The hanging basket bracket mechanism is characterized by comprising a first fixing unit, a second fixing unit, a front bracket unit, a rear vertical rod unit, a cross beam unit, an upper supporting column unit, a steel wire rope and a hanging basket; the first fixing unit comprises a first buried plate fixed to the top face of the structural beam, and a support limiting groove is formed in the first buried plate; the front bracket unit is inserted and installed in the bracket limiting groove; the second fixing unit comprises a second buried plate fixed to the side face of the structural beam, and a clamping and fixing groove is formed in the second buried plate; the rear vertical rod unit is welded and fixed through the clamping and fixing groove; a transverse connecting sleeve of the cross beam unit is fixedly welded to the rear vertical rod and the front vertical rod; a rear beam and a hanging basket supporting arm are inserted from the two sides of the transverse connecting sleeve and fixed through bolts; the upper supporting column unit is fixed on the transverse connecting sleeve; and the steel wire rope is sequentially connected to a stand column lug plate, a rear beam lug plate, a rope wheel, a supporting arm lug plate and a hanging basket. According to the hanging basket bracket mechanism, the mounting construction of the outer curtain wall hanging basket on the non-solid roof is realized.

Owner:中建八局装饰工程有限公司

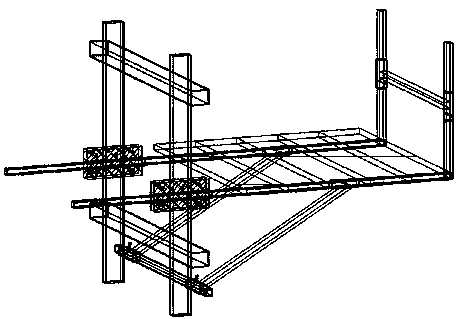

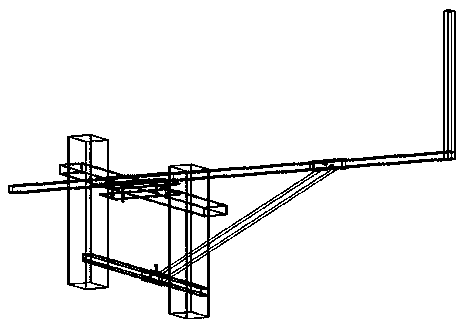

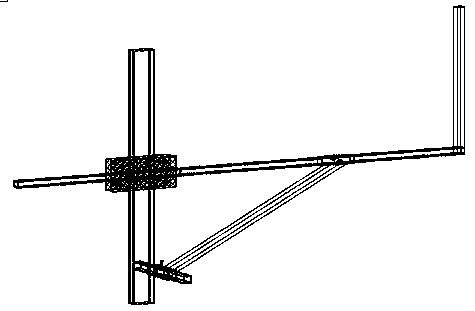

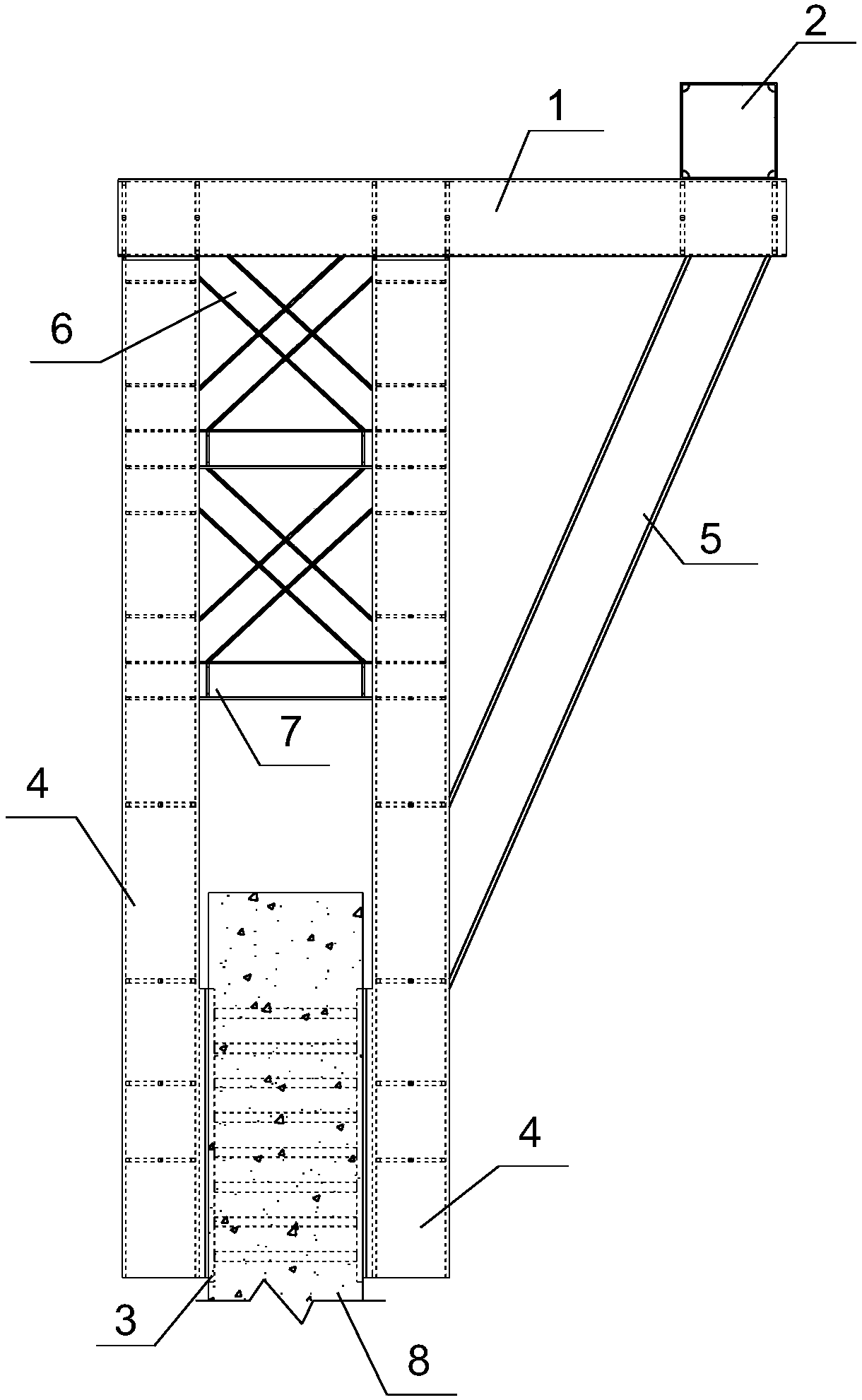

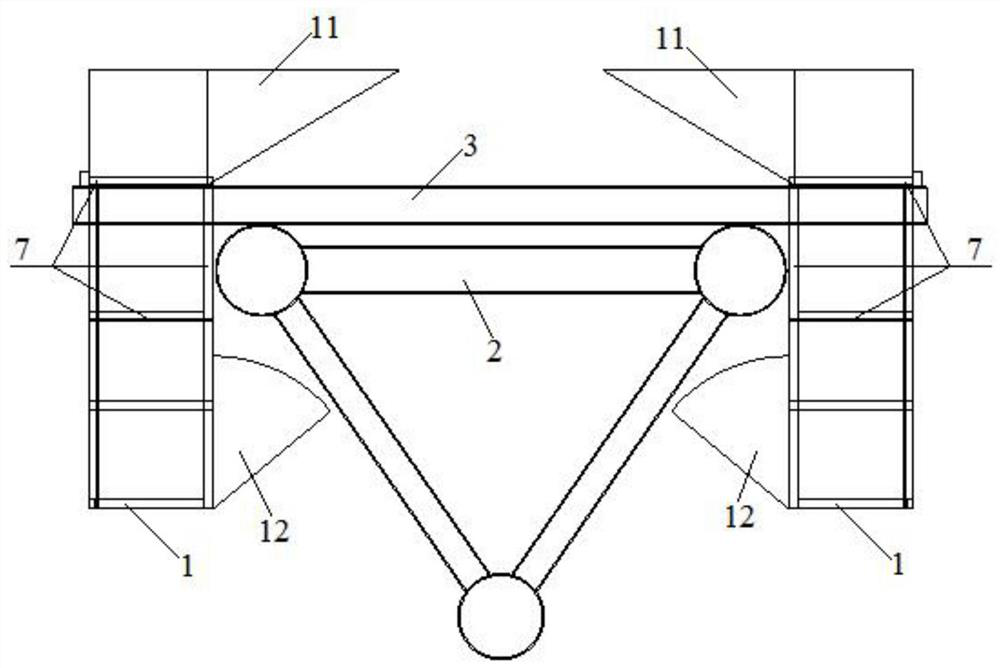

Laterally-mounted parallely-row carrying pole type lifting frame based on concrete independent beam

PendingCN108483247AEffective installationLiftingBase supporting structuresBraking devices for hoisting equipmentsEngineeringSafety risk

The invention relates to a laterally-mounted parallely-row carrying pole type lifting frame based on a concrete independent beam. The laterally-mounted parallely-row carrying pole type lifting frame comprises two built-in fittings, two supporting frames and one load transferring beam; each supporting frame is composed for two vertical columns, one cross beam, one oblique support, a plurality of oblique rods and a plurality of cross rods, and each supporting frame is characterized in that the two built-in fittings are pre-buried on the concrete independent beam, the two vertical columns in eachsupporting frame are welded to buried plates on the two sides of the same built-in fitting, and the two vertical columns of each supporting frame are connected to be a whole through the multiple oblique rods and cross rods; the cross beam is loaded at the tops of the two vertical columns of each supporting frame, one end of the oblique support is connected with the suspension end of the cross beam, and the other end is connected with the bottom of one vertical column of each supporting frame; and the two ends of the load transferring beam are lapped on the two cross beams loaded by the two supporting frames. The lifting frame mounted based on the concrete independent beam effectively improves the mounting efficiency of the truss lifting frame, reduces the investment of measure expense, reduces the construction cost and lowers the safety risks.

Owner:CHINA CONSTR THIRD ENG BUREAU INSTALLATION ENG CO LTD

A cooling oil-based selective water plugging method

ActiveCN108035697BCost reduction measuresNo pollution in the processSealing/packingThermal waterViscosity

The invention provides a cooling type oil-based selective water plugging method. The Cooling type oil-based selective water plugging method comprises the steps that heavy oil is preheated, so that thefluidity of the heavy oil is restored, and the heavy oil is injected into the formation; after squeezing injection of the heavy oil is finished, displacement is conducted with hot water, the heavy oil is totally squeezed into the formation, heat transfer at immediate vicinity of wellbore is conducted with cold water, so that the temperature of the heavy oil is reduced to the turnover temperatureor below, and plugging is formed. The viscosity of the heavy oil in a water layer can keep basically unchanged, while the viscosity and the flowback resistance of the heavy oil in an oil layer are reduced because the heavy oil in the oil layer makes contact with thin oil, and the selective aim of water plugging without oil plugging is achieved. The squeezed crude oil can be slowly produced from the formation finally, and the measure cost is low.

Owner:PETROCHINA CO LTD

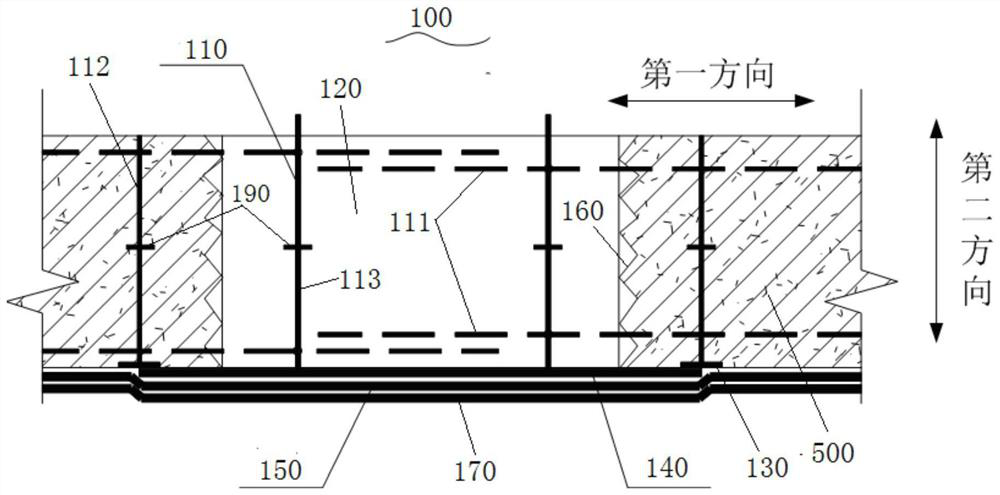

Post-cast strip wall formwork structure and construction method for advanced water stop of outer wall post-cast strip

PendingCN114809592ASpeed up the closure processCost reduction measuresForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksWater stopArchitectural engineering

The invention is suitable for the technical field of wall engineering, and provides a post-cast strip wall formwork structure and an outer wall post-cast strip advanced water stop construction method. The post-cast strip wall formwork structure comprises supporting assemblies, inner side formworks, embedded steel plates and steel cover plates, outer wall concrete is arranged on the left side and the right side of a post-cast strip, the supporting assemblies are fixedly arranged on the outer wall concrete on the two sides, and fast and easy closing-up nets or fish scale water stop pieces are arranged between the post-cast strip and the outer wall concrete; the inner sides of the embedded steel plates are welded to the supporting assembly and fixedly arranged on the outer side face of the outer wall concrete, and the embedded steel plates are located on the two sides of the post-cast strip. The inner sides of the two ends of the steel cover plate are welded to the outer sides of the embedded steel plates located on the two sides of the post-cast strip correspondingly, and the steel cover plate seals and covers an outer opening of the post-cast strip. And the waterproof layer is laid on the outer sides of the concrete and the steel cover plate. The structure is simple, the wall manufacturing period is greatly shortened, the labor cost is greatly saved, the problems of early closing difficulty and measure cost of the basement outer wall are solved, the closing progress is accelerated, and the construction period is shortened.

Owner:中建五局第三建设(深圳)有限公司

A thermal recovery sealing agent for heavy oil

ActiveCN101633835BImprove the blocking effectReduce squeeze pressureDrilling compositionSuspended particlesEthyl acetate

The invention discloses a sealing agent for thermal recovery of heavy oil, which is made of the following raw materials in percentage by weight: 10-30% of water glass, 0.5-3% of ethyl acetate, 0.3-1.3% of ammonium chloride, and 0.005% of aluminum citrate -0.015%, EDTA or EDTA salt 0.01-0.03%, the balance is water. The gelation time of the sealing agent of the present invention is 4-12 hours. After gelling, it can withstand high-temperature steam at 300°C. It can be used in conjunction with the suspended particle type sealing agent, and is used for the implementation of some thermal recovery wells with serious steam channeling. Deep channel sealing can enhance the channel sealing effect; especially it can be used in heavy oil thermal recovery sand control wells, which can directly seal channel in the presence of sand control layers or sand control tools, reducing construction costs and having good results.

Owner:CHINA PETROLEUM & CHEM CORP +1

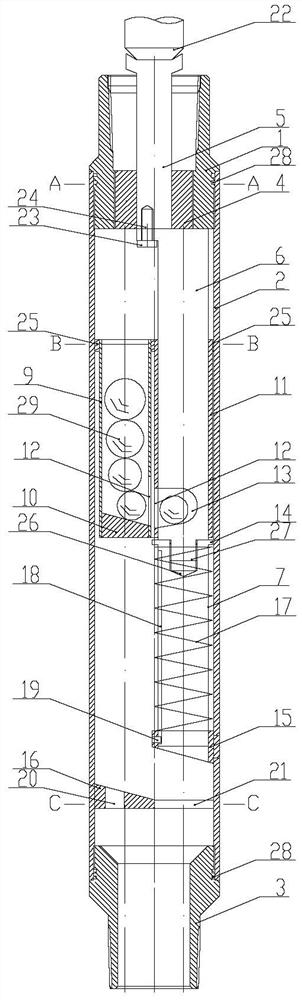

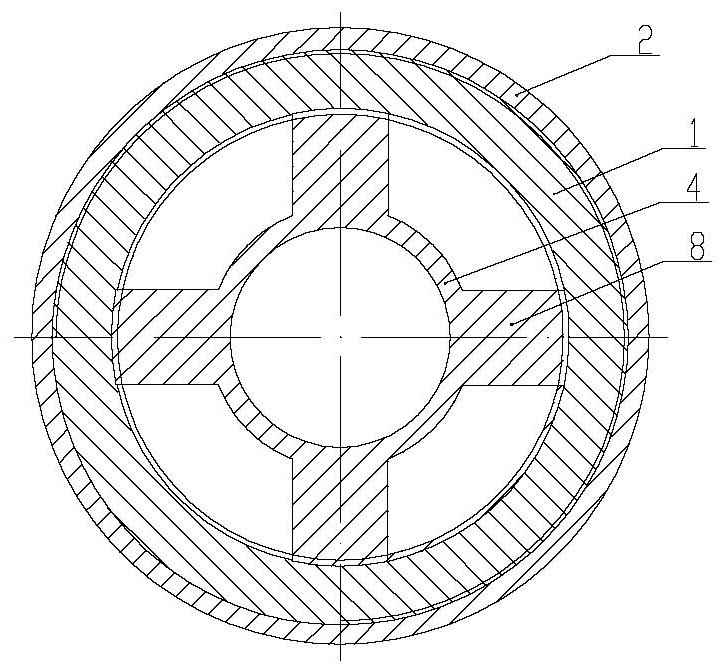

Downhole automatic ball throwing device for oil field

PendingCN111878037AReduce labor intensityCost reduction measuresFluid removalWell/borehole valve arrangementsJackshaftCrank

The invention relates to the technical field of oil field machinery, in particular to a downhole automatic ball throwing device for an oil field. The device comprises an upper connector, an outer barrel, a lower connector and a positioning sleeve, wherein the upper connector and the outer barrel are fixedly mounted together, the outer barrel and the lower connector are fixedly mounted together, and the positioning sleeve is located on the lower portion of an inner cavity of the upper connector; a ball storage barrel is fixedly mounted on the left portion of the inner cavity of the outer barrel, a bottom plug is fixedly mounted on the inner side of the lower end of the ball storage barrel, and a guide sleeve is fixedly mounted on the right portion of the inner cavity of the outer barrel; and corresponding ball holes are formed in the right side of the lower portion of the ball storage barrel and the left side of the lower portion of the guide sleeve respectively, and the lower end of acrankshaft penetrates through the positioning sleeve to be fixedly connected with the upper end of a trigger rod. The downhole automatic ball throwing device is reasonable and compact in structure andconvenient to use, well achieves the purpose of layer changing without lifting out a sucker rod, and has the advantages of being safe and reliable, operations are facilitated, work efficiency is improved, labor intensity and measure cost of operators are greatly reduced, and the requirements of an existing process can be well met.

Owner:KARAMAY HONGDU

Welding operation platform capable of being used for inverted triangular truss

PendingCN112227692AAvoid hanging problemsSafe operating platform selectionWelding/cutting auxillary devicesAuxillary welding devicesHanging basketPipe

The invention provides a welding operation platform capable of being used for an inverted triangular truss. The welding operation platform comprises two welding hanging baskets and a carrying pole beam assembly fixed to an inverted triangular circular pipe truss body, the carrying pole beam assembly comprises two pieces of first I-shaped steel, the two pieces of first I-shaped steel are fixed to the top of the inverted triangular circular pipe truss body, the length extending direction of the two pieces of first I-shaped steel is perpendicular to the length extending direction of the invertedtriangular circular pipe truss body, the two welding hanging baskets are hung between the two pieces of first I-shaped steel, and the two welding hanging baskets are located on the two sides of the inverted triangular circular pipe truss body respectively in the length extending direction of the first I-shaped steel. According to the welding operation platform suitable for the inverted triangulartruss, the problems that a common hanging cage is difficult to fix and low in safety coefficient when used for circular pipe components are solved, the welding hanging baskets are symmetrically hung on the two sides of the inverted triangular truss body, the two sides are symmetrically and simultaneously constructed, the construction period is shortened, and meanwhile the welding operation platform has the advantages that overturning is not likely to happen, and the truss is not likely to deform during welding.

Owner:THE THIRD CONSTR CO LTD OF CHINA CONSTR THIRD ENG BUREAU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com