High-altitude spraying device for venue type circular stand column

A spraying device and a circular-like technology, which is applied to the field of high-altitude spraying devices for circular columns in venues, can solve the problems of high risk factor for workers, increasing workload of workers, and increasing the danger of workers' work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

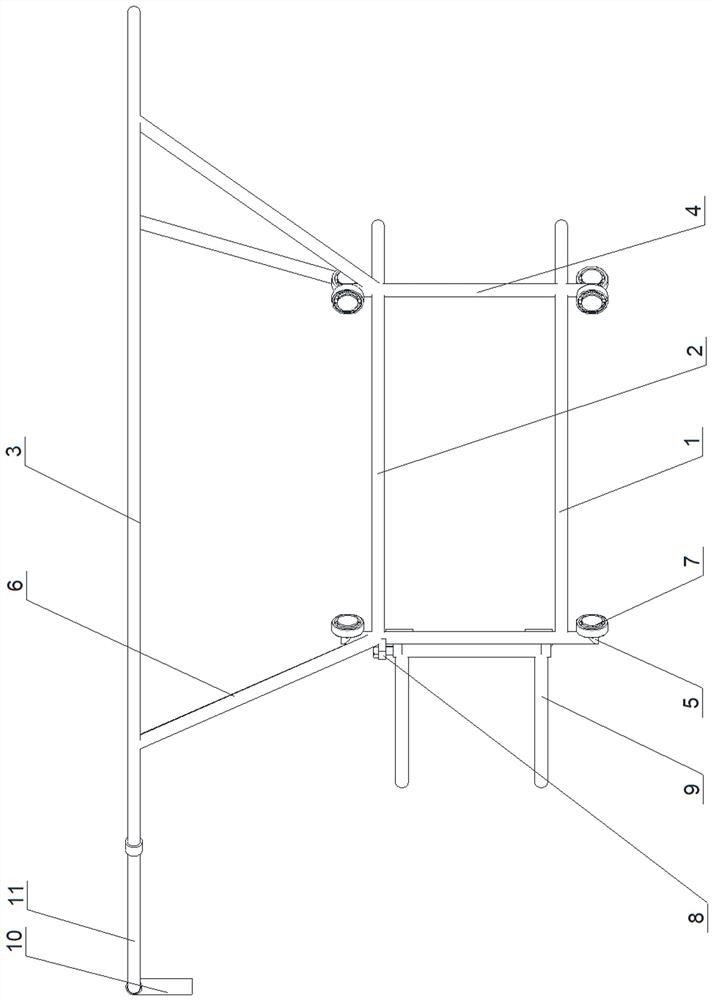

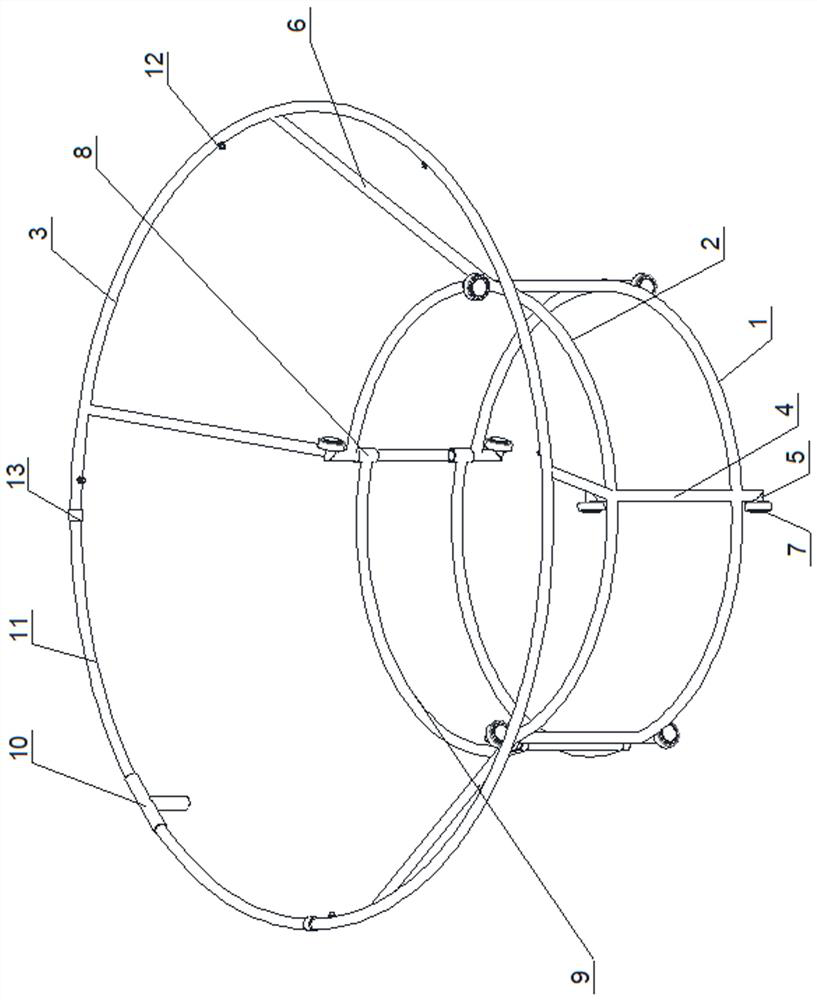

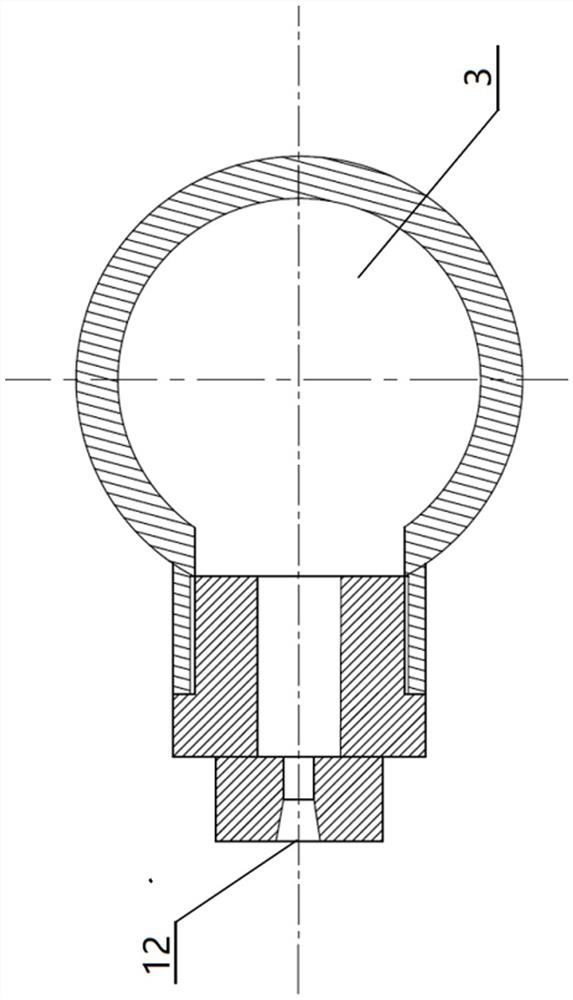

[0023] Such as figure 1 and figure 2 As shown, a high-altitude spraying device for a stadium-like circular column, including a support mechanism that is sleeved on the column and slides downward relative to the column, is fixedly connected to the top of the support mechanism and is sleeved on the column, and the outer surface of the column is sprayed. The spraying mechanism for spraying paint, the inner surface of the supporting mechanism is in contact with the outer surface of the column, the supporting mechanism drives the spraying mechanism to move down and sprays the paint on the column from top to bottom, and the supporting mechanism moves down by its own gravity or the pull rope, then During the downward movement of the support mechanism, the support mechanism drives the spraying mechanism to move from top to bottom and sprays the outer surface of the column. The setting of the support mechanism in the present invention is convenient to be sleeved on the column and rely...

Embodiment 2

[0028] Such as figure 1 and figure 2 As shown, a high-altitude spraying device for a stadium-like circular column, including a support mechanism that is sleeved on the column and slides downward relative to the column, is fixedly connected to the top of the support mechanism and is sleeved on the column, and the outer surface of the column is sprayed. The spraying mechanism for spraying paint, the inner surface of the supporting mechanism is in contact with the outer surface of the column, the supporting mechanism drives the spraying mechanism to move down and sprays the paint on the column from top to bottom, and the supporting mechanism moves down by its own gravity or the pull rope, then During the downward movement of the support mechanism, the support mechanism drives the spraying mechanism to move from top to bottom and sprays the outer surface of the column. The setting of the support mechanism in the present invention is convenient to be sleeved on the column and rely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com