Structurally improved shaping bracket for socks

A technology for setting brackets and socks, which is applied in the direction of setting/extending circular fabrics, textiles and papermaking, fabric surface trimming, etc. It can solve the problems of steam contact, poor setting effect and influence, and achieve convenient setting and setting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

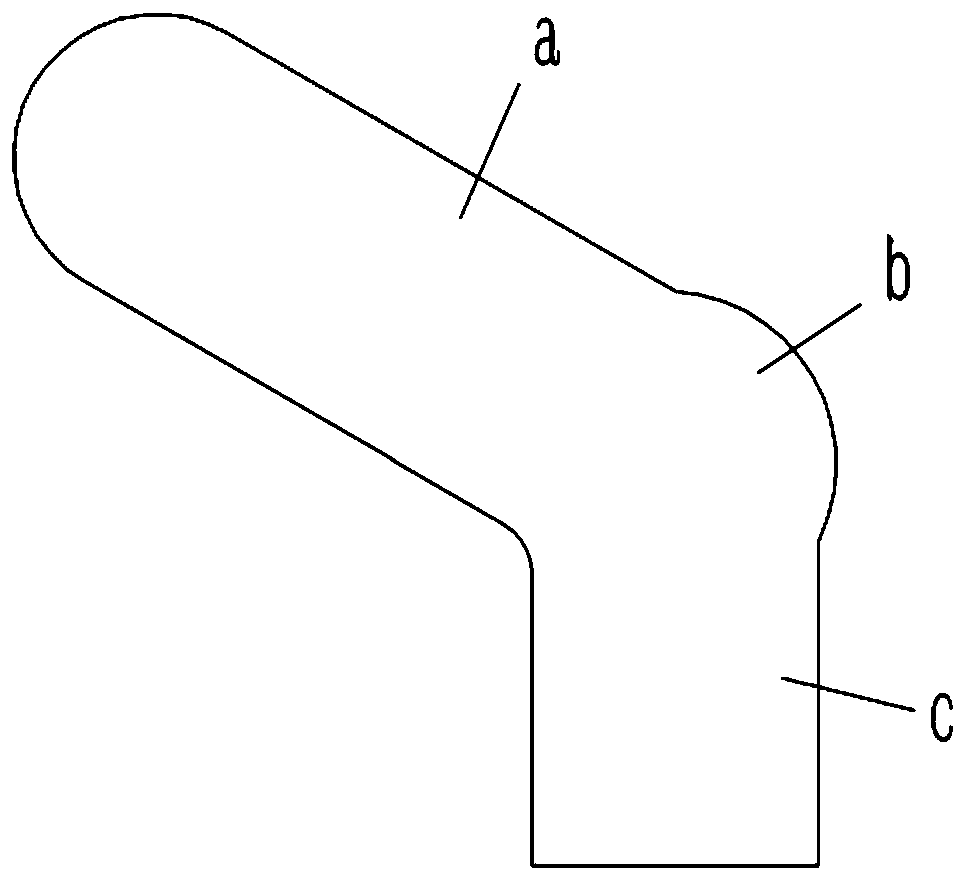

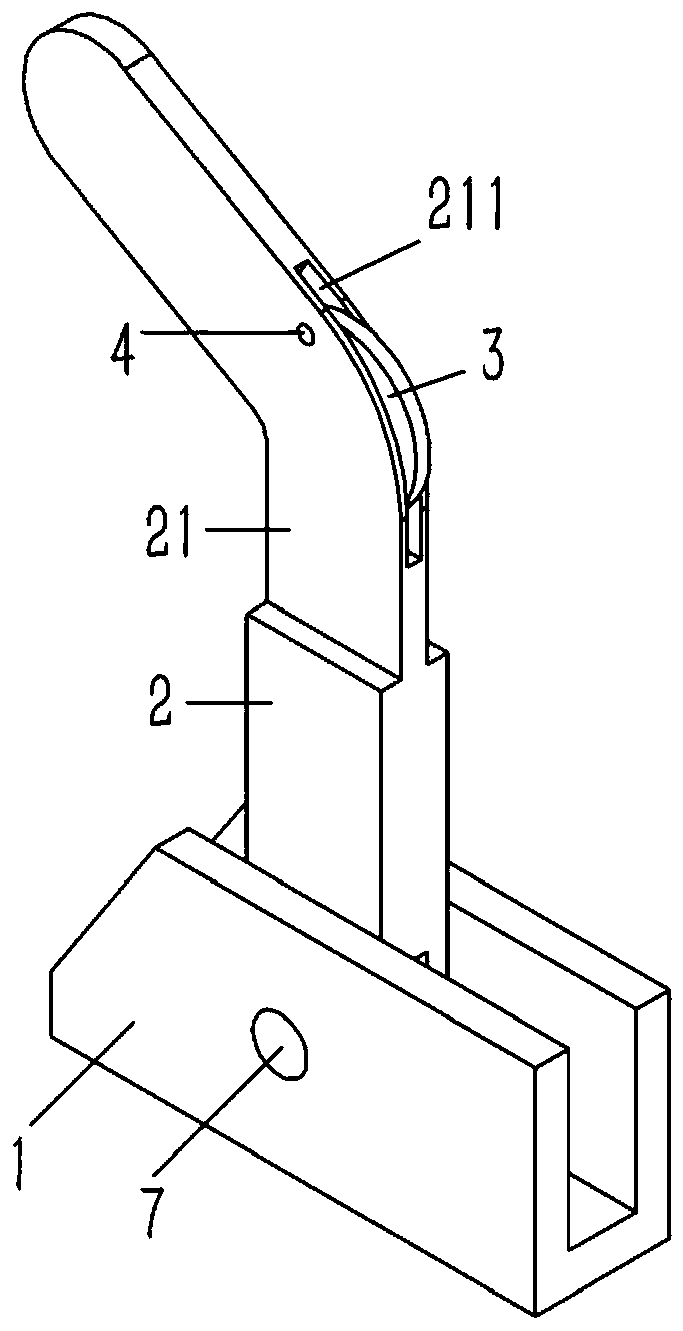

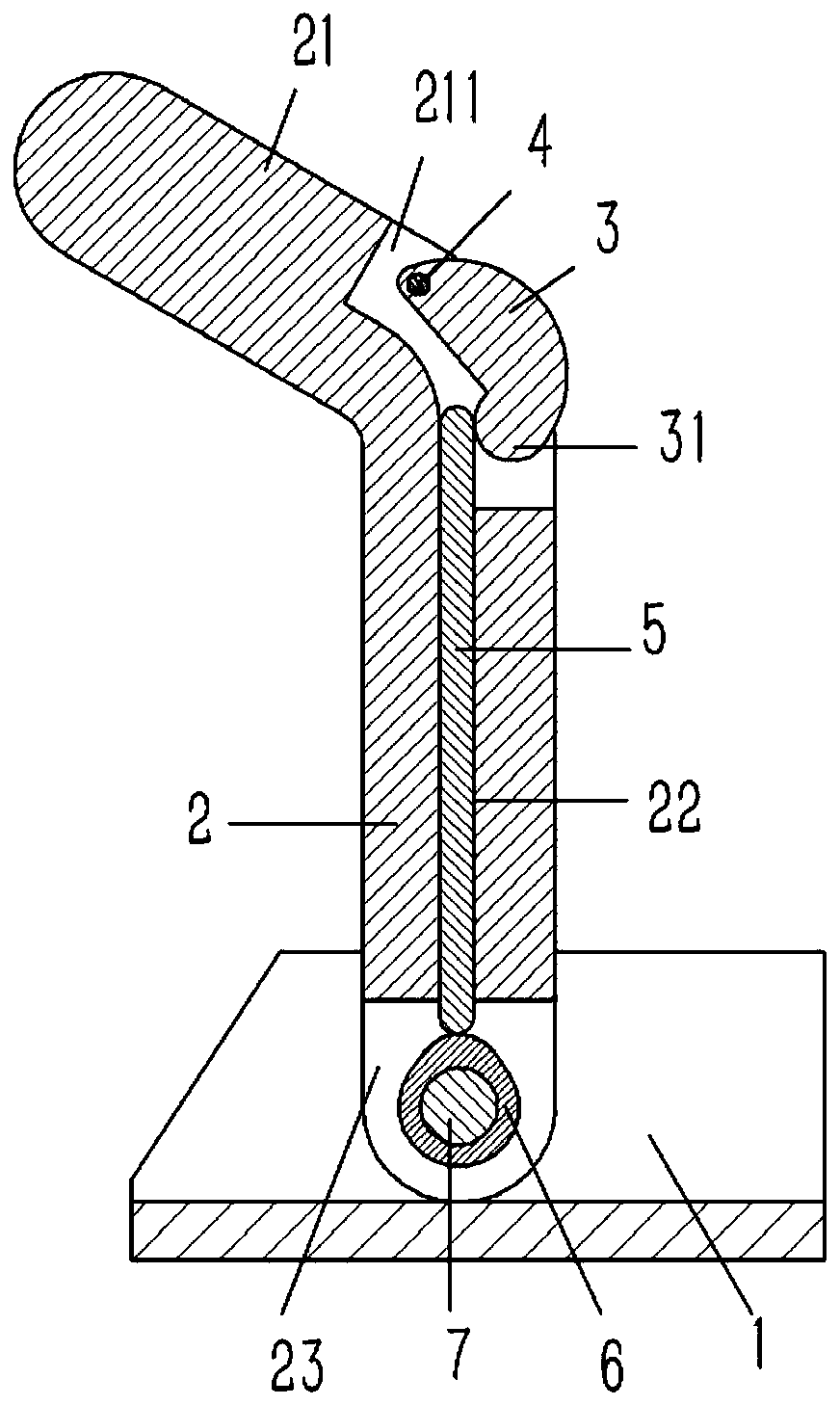

[0018] Example: see Figures 2 to 3 As shown, a structure-improved shaping bracket for socks includes a "凵"-shaped base 1 and a vertical turning plate 2. The lower end of the turning plate 2 is inserted into the base 1, and the upper end of the turning plate 2 is shaped like a sock. The sock cover plate 21, the sock heel of the sock cover plate 21 is formed with an arc-shaped slot 211, the slot 211 of the sock cover plate 21 is inserted with a fan-shaped sock heel template 3, and the upper end of the sock heel template 3 passes The hinge shaft 4 is hinged on the sock cover plate 21, and the lower end of the sock heel template 3 is formed with an arc-shaped counterweight 31; the lower end of the turnover plate 2 is formed with a positioning groove 23, and the turnover plate 2 on both sides of the positioning groove 23 Slot holes are formed on the top, and a positioning shaft 7 is inserted into the slot hole of the flip plate 2, and the two ends of the positioning shaft 7 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com