Mechanical locking and automatic ejection system of electric spark-prevention socket

A mechanical locking and electric spark technology, which is applied to circuits, electrical components, parts of connecting devices, etc., can solve the problems of lack of anti-shock function, and the plug is not easy to pull out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

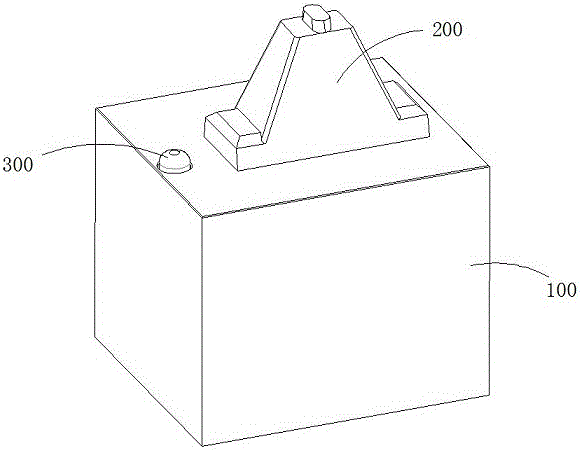

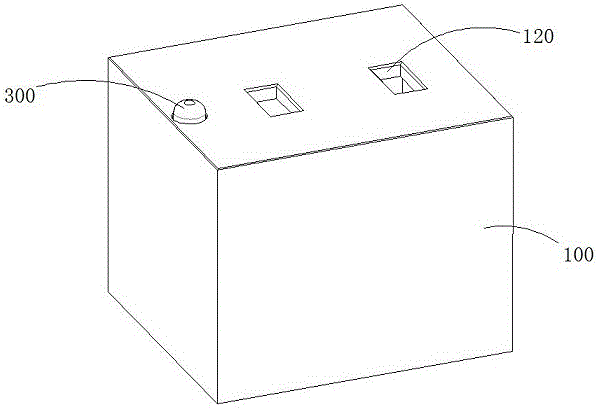

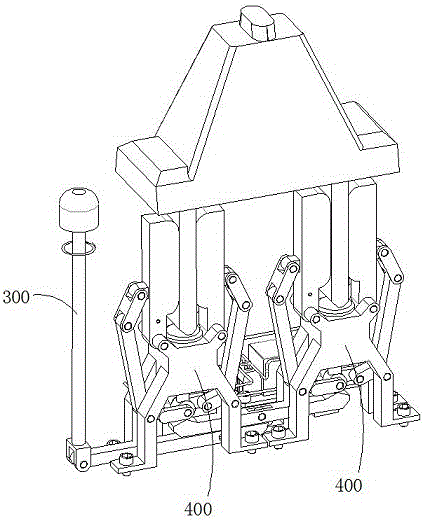

[0025] Mechanical clamping socket, which includes a shield 100, a balance control device 300 installed in the shield 100, a pair of clamping mechanisms 400, the clamping mechanism 400 includes a support body 410, a pair of splints 420, a pair of first connecting Rod 430, a pair of second connecting rods 440, contacts 450, and a pair of third connecting rods 460. The upper end of the support body 410 is hinged with a pair of splints 420 symmetrically arranged at both ends. The area between the pair of splints 420 is In the clamping area, an electrode metal sheet is arranged on the side of the splint facing the clamping area, and a pair of splints 420 are riveted to one end of the first connecting rod 430 on the side of the end that deviates from the clamping area (that is, the side opposite to the end where the electrode metal sheet is installed) The other ends of a pair of first connecting rods 430 are respectively riveted with second connecting rods 440, the middle position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com