Patents

Literature

179results about How to "Convenient set" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mobile terminal and controlling method thereof

ActiveUS20120303603A1Easy to readConvenient setInput/output for user-computer interactionDigital data information retrievalComputer hardwareSearch words

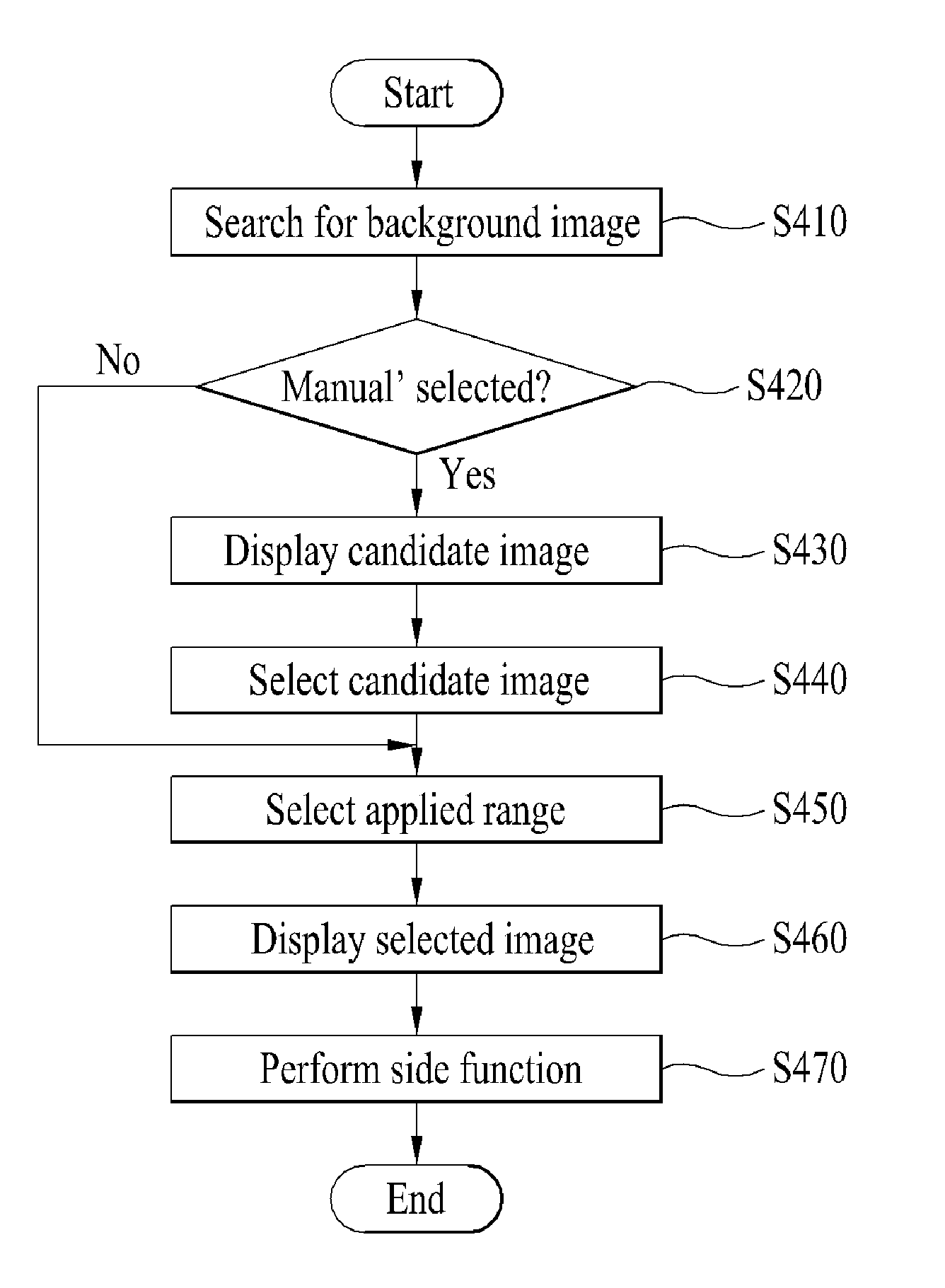

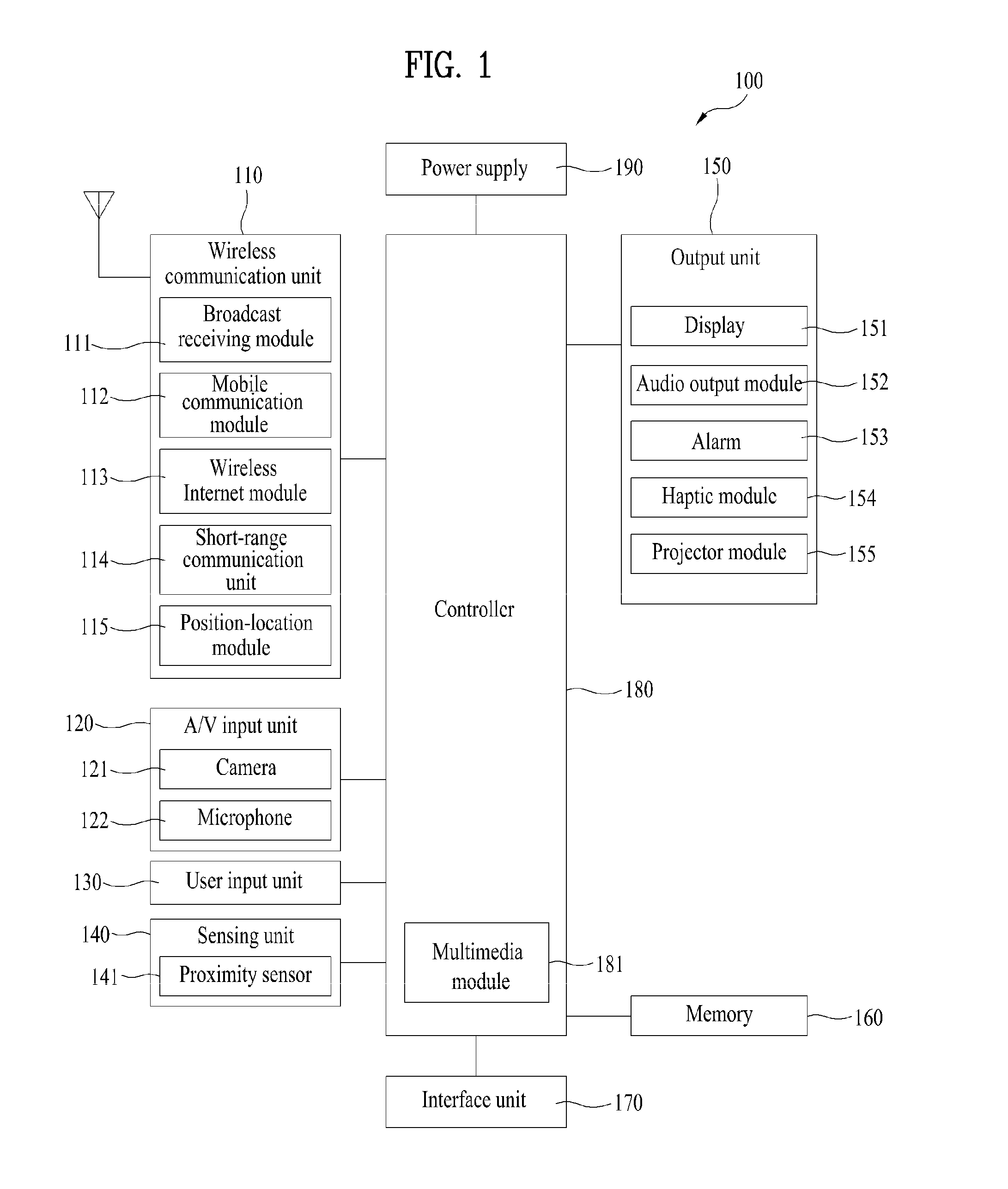

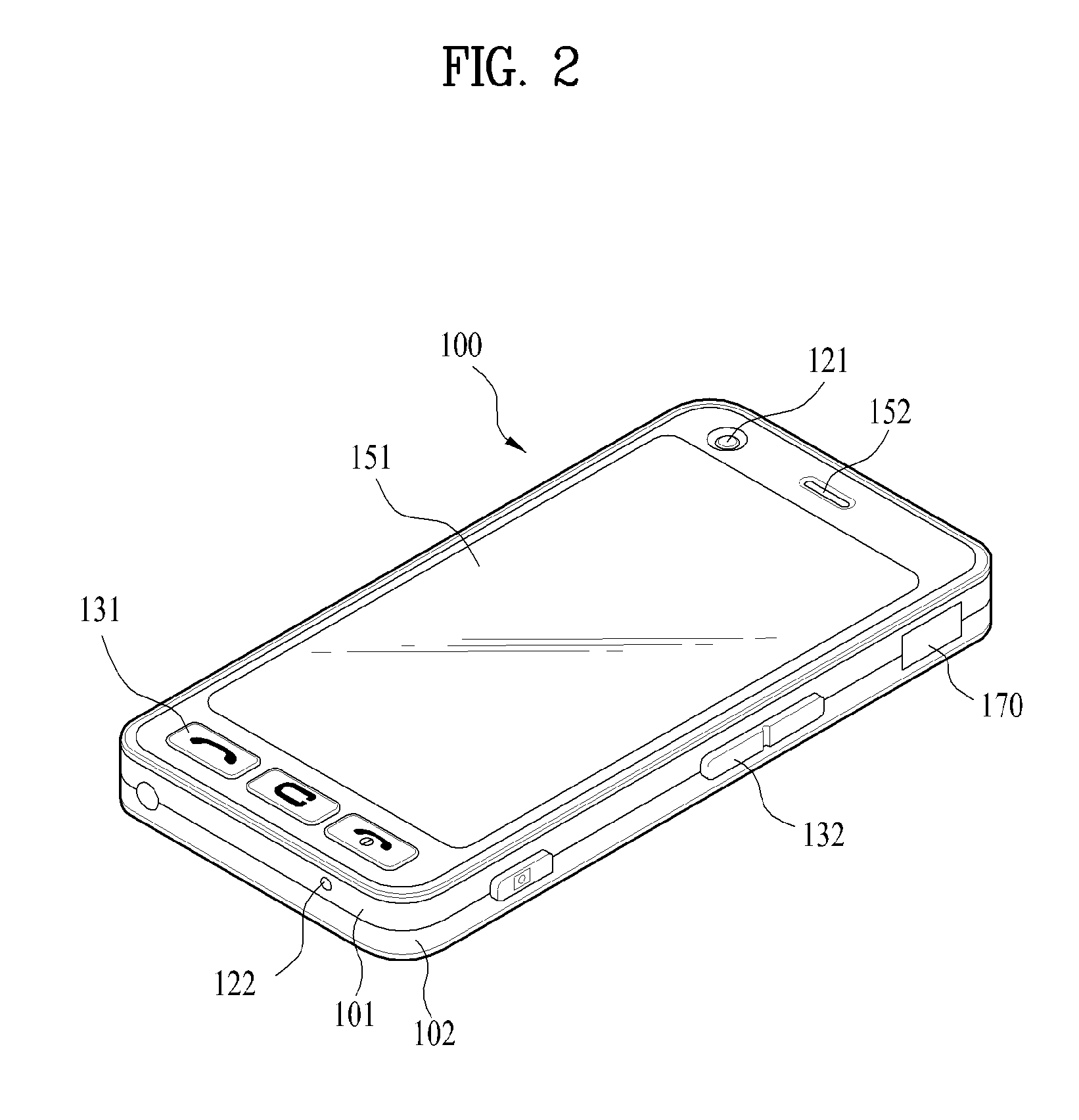

A mobile terminal and controlling method thereof are disclosed, by which a more convenient e-book reading environment can be provided through background video and / or audio settings. The present invention includes a touchscreen configured to display a first page of an e-book including at least one or more pages, a memory unit configured to store the e-book and at least one image, a communication unit configured to exchange data with an external device by wire / wireless, and a controller searching at least one of the memory unit and a search server connected via the communication unit for at least one or more candidate images with a search word determined using at least one portion of a content of the first page, the controller controlling a first one of the found at least one or more candidate images to be displayed as a background image of the first page.

Owner:LG ELECTRONICS INC

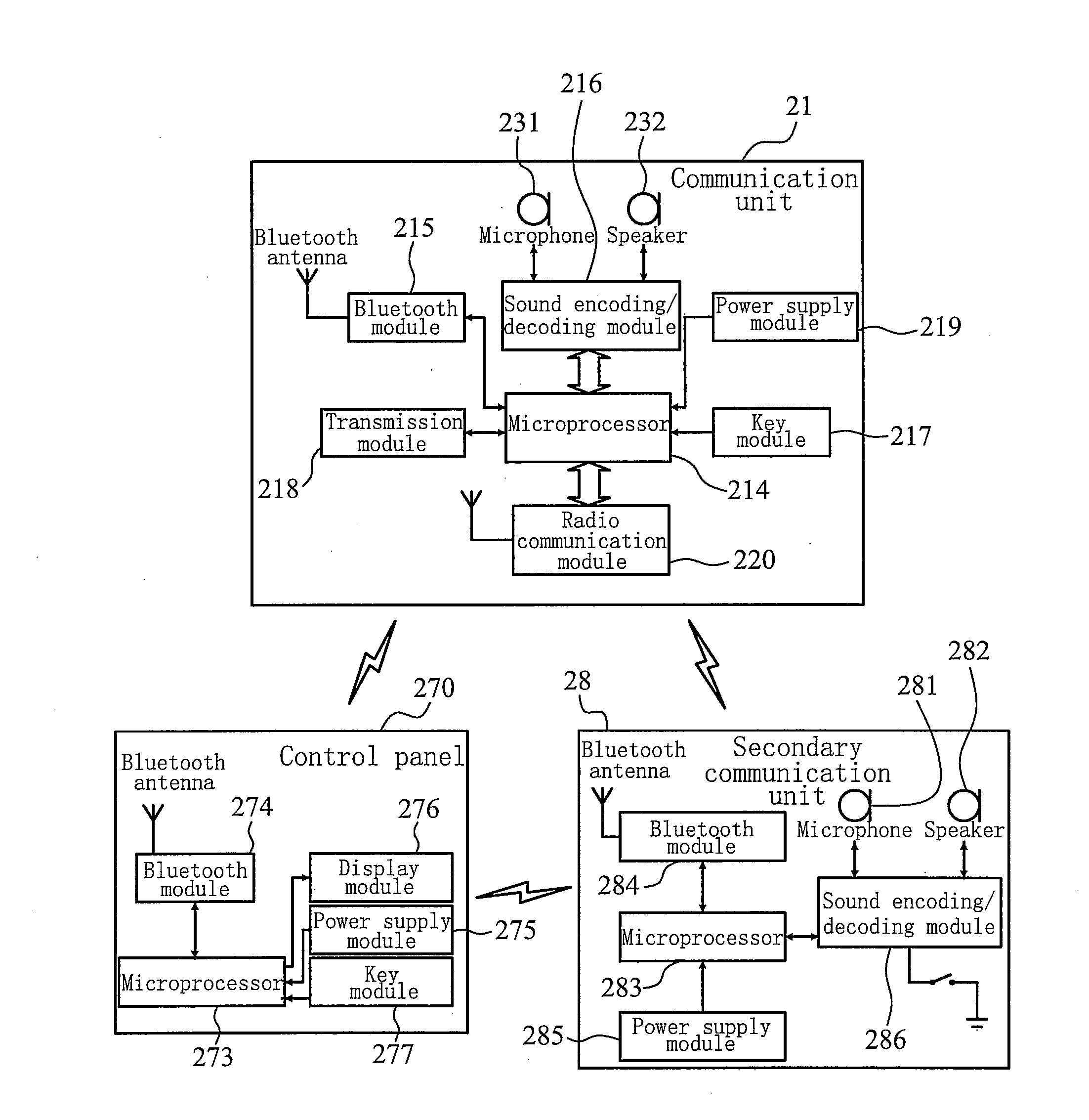

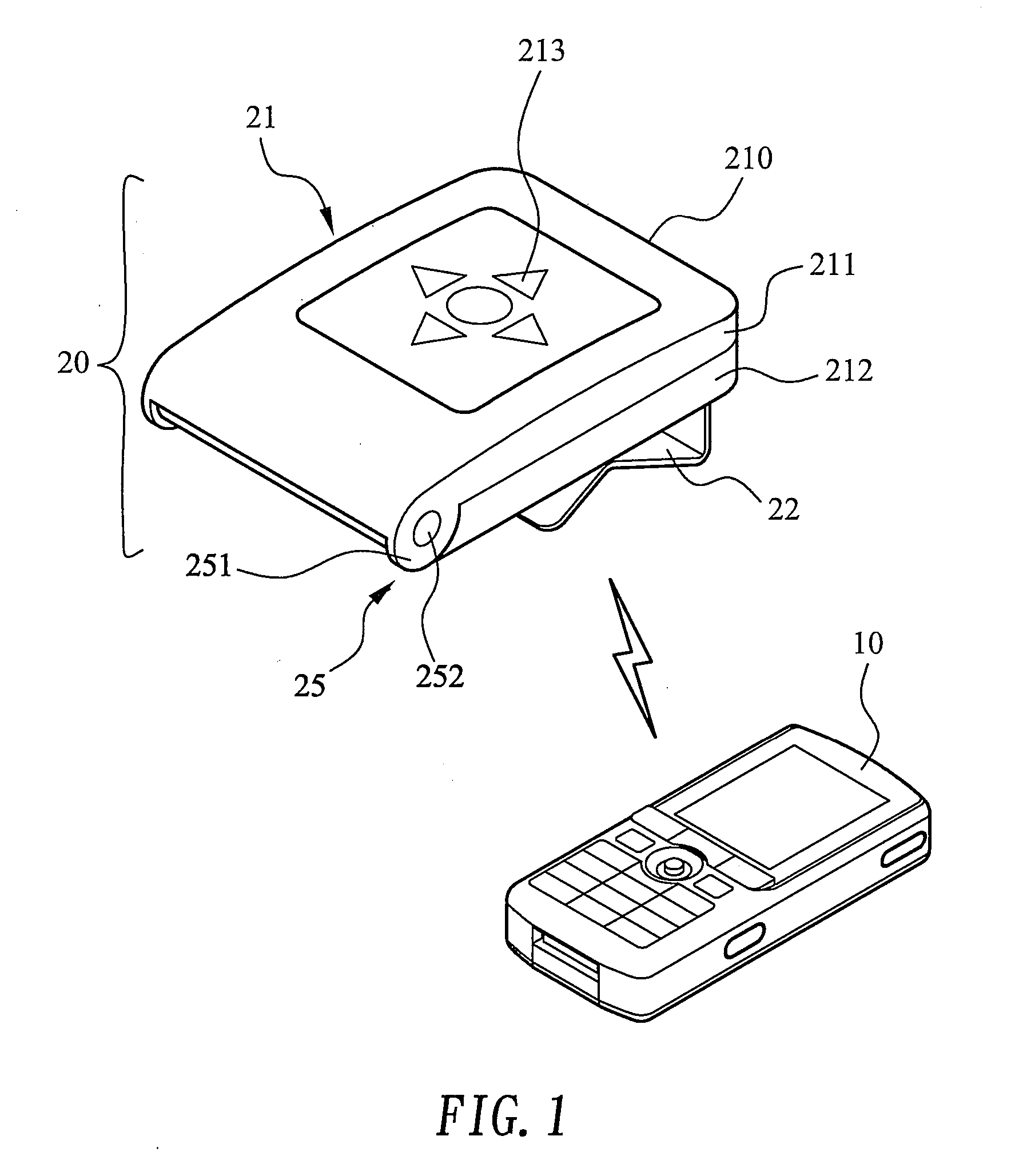

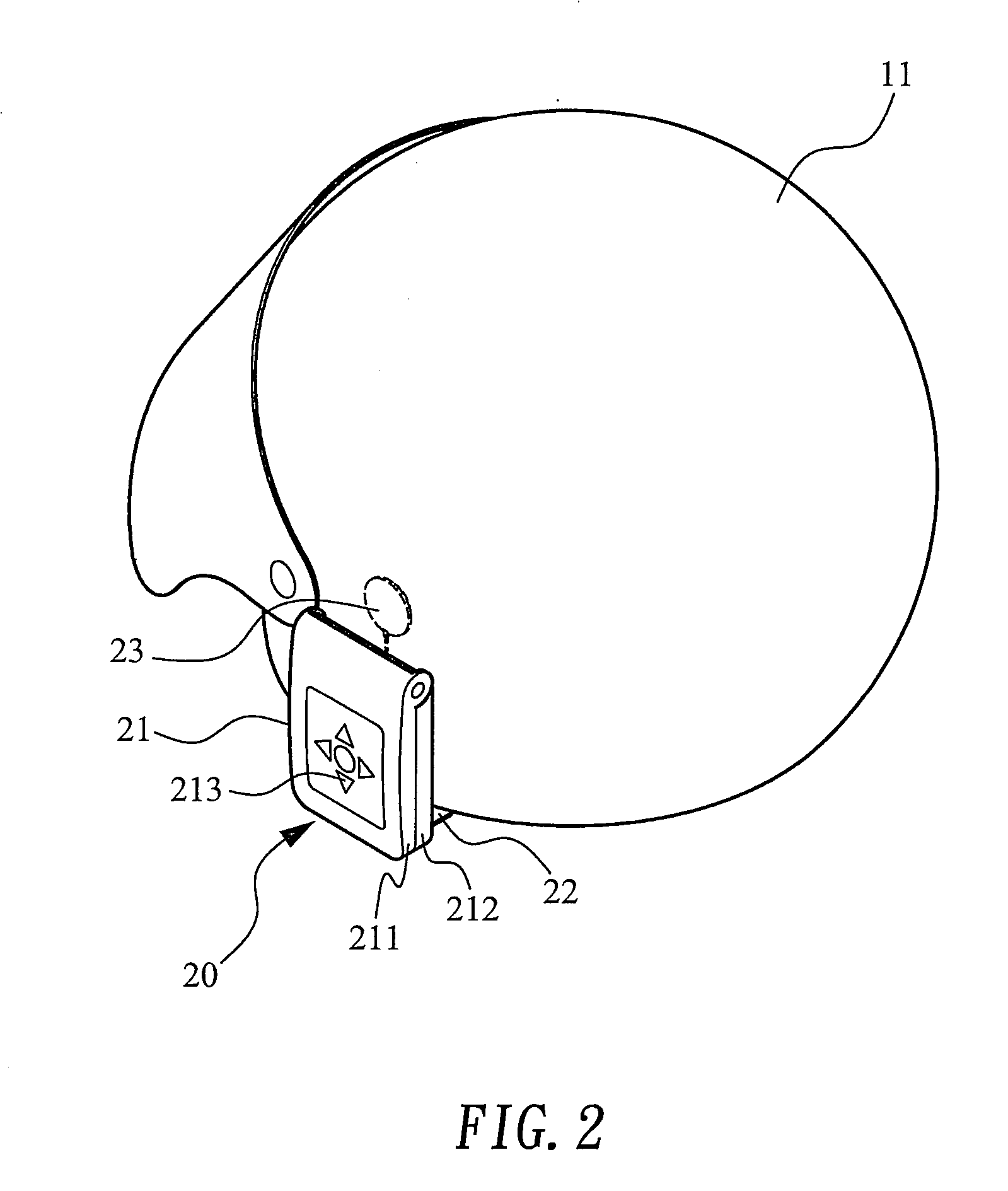

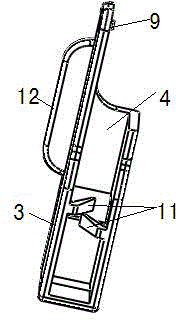

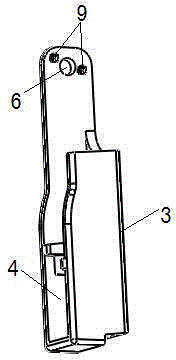

Helmet-attachable communication device

InactiveUS20110081861A1Improve functionalityImprove practicalityTransmission control/equalisingHatsCommunication unitEngineering

A helmet-attachable communication device includes a communication unit wirelessly connected to a mobile communication device and having a case externally provided with a plurality of keys and an expansion slot; a fixing unit externally arranged on the case for attaching the communication device to an outer side of a helmet; a microphone / speaker unit externally connected to internal circuits of the communication unit and mounted in the helmet; and an expansion unit inserted in the expansion slot. A motorcycle rider with the communication device attached to the helmet can use the mobile communication device during riding safely without the need of holding the same with one hand. With the expansion slot, other expanded functions can be added to the communication device according to the user's need, giving the communication device enhanced functionality and practicality.

Owner:CHIA SOON ELECTRONICS

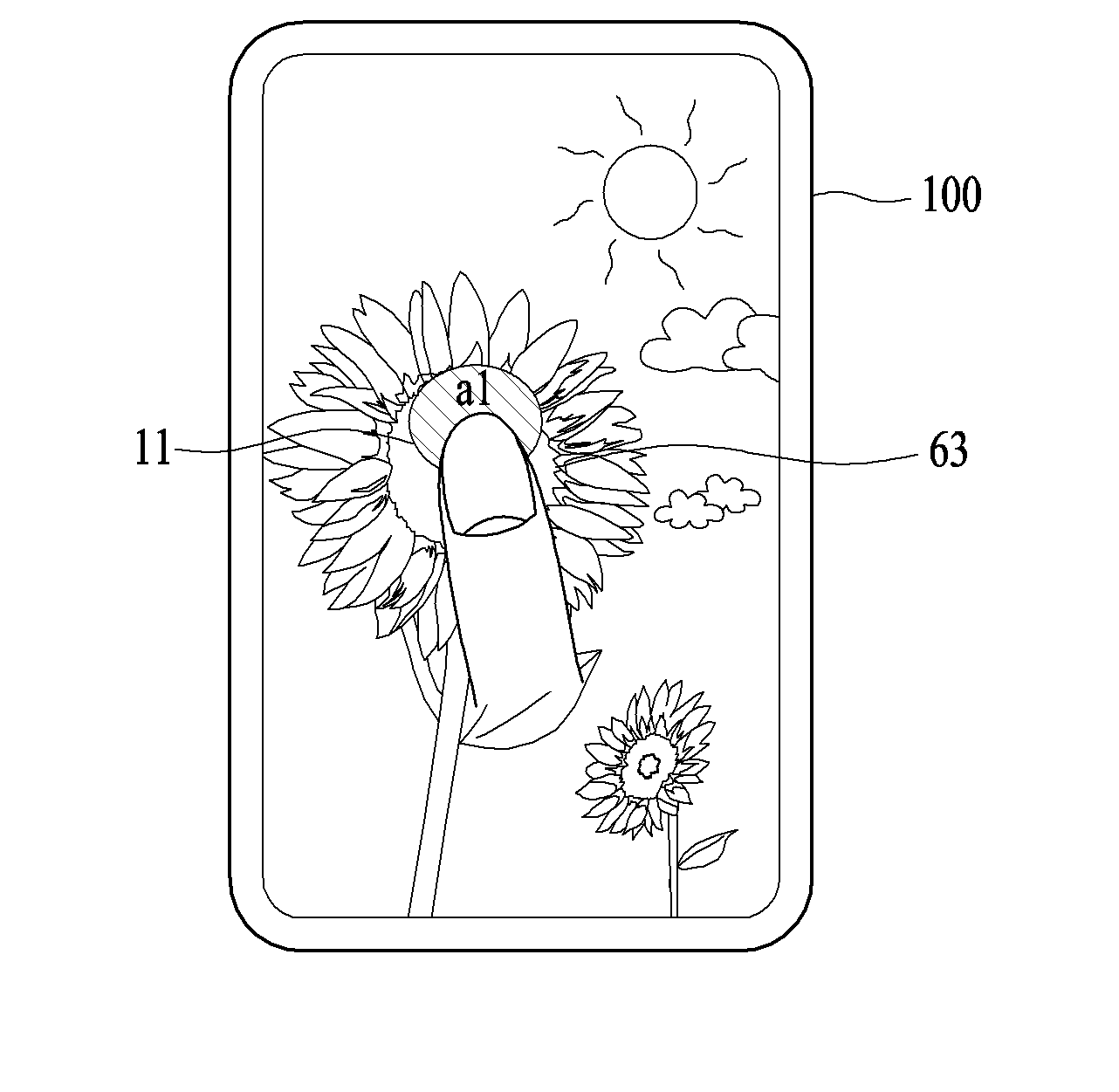

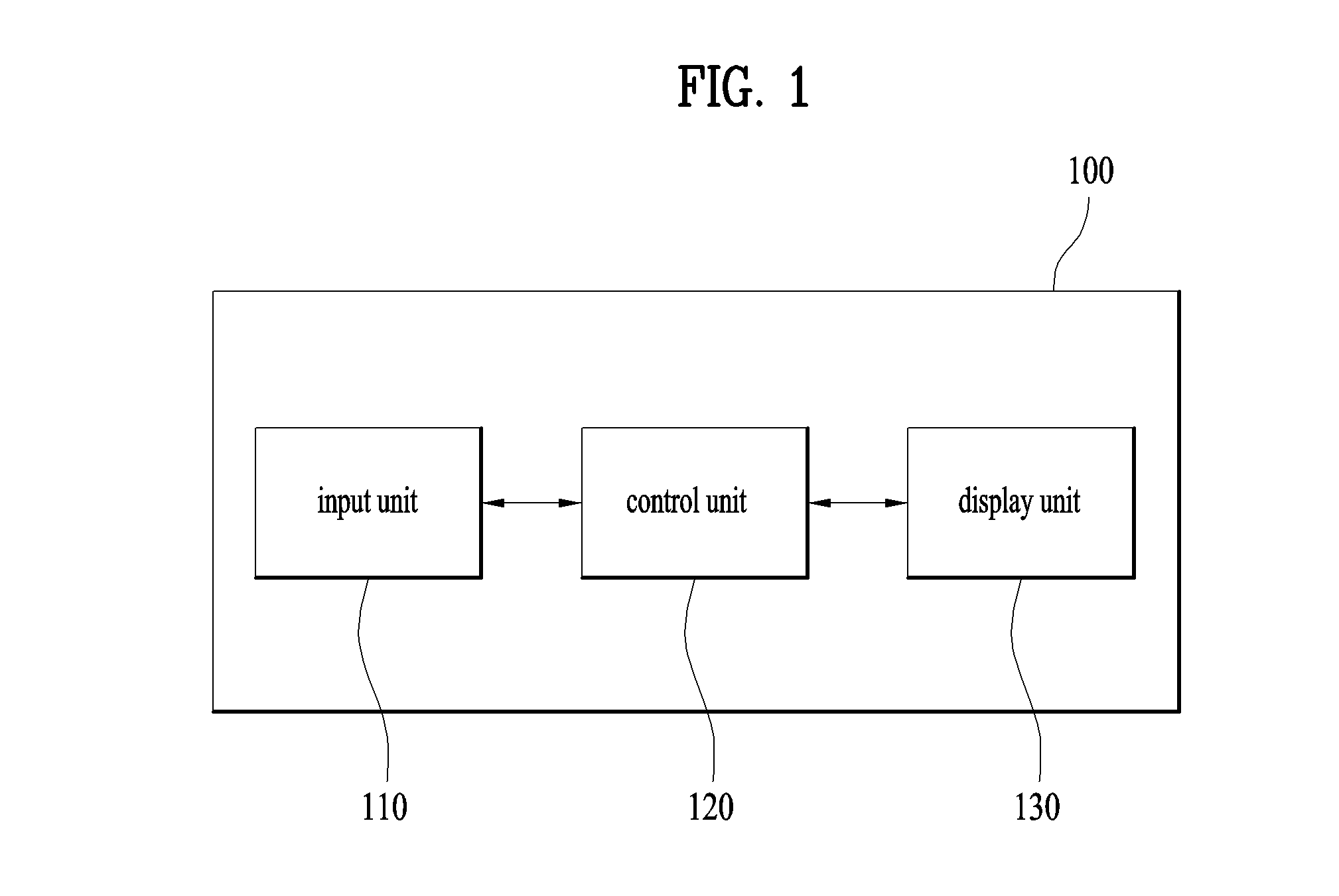

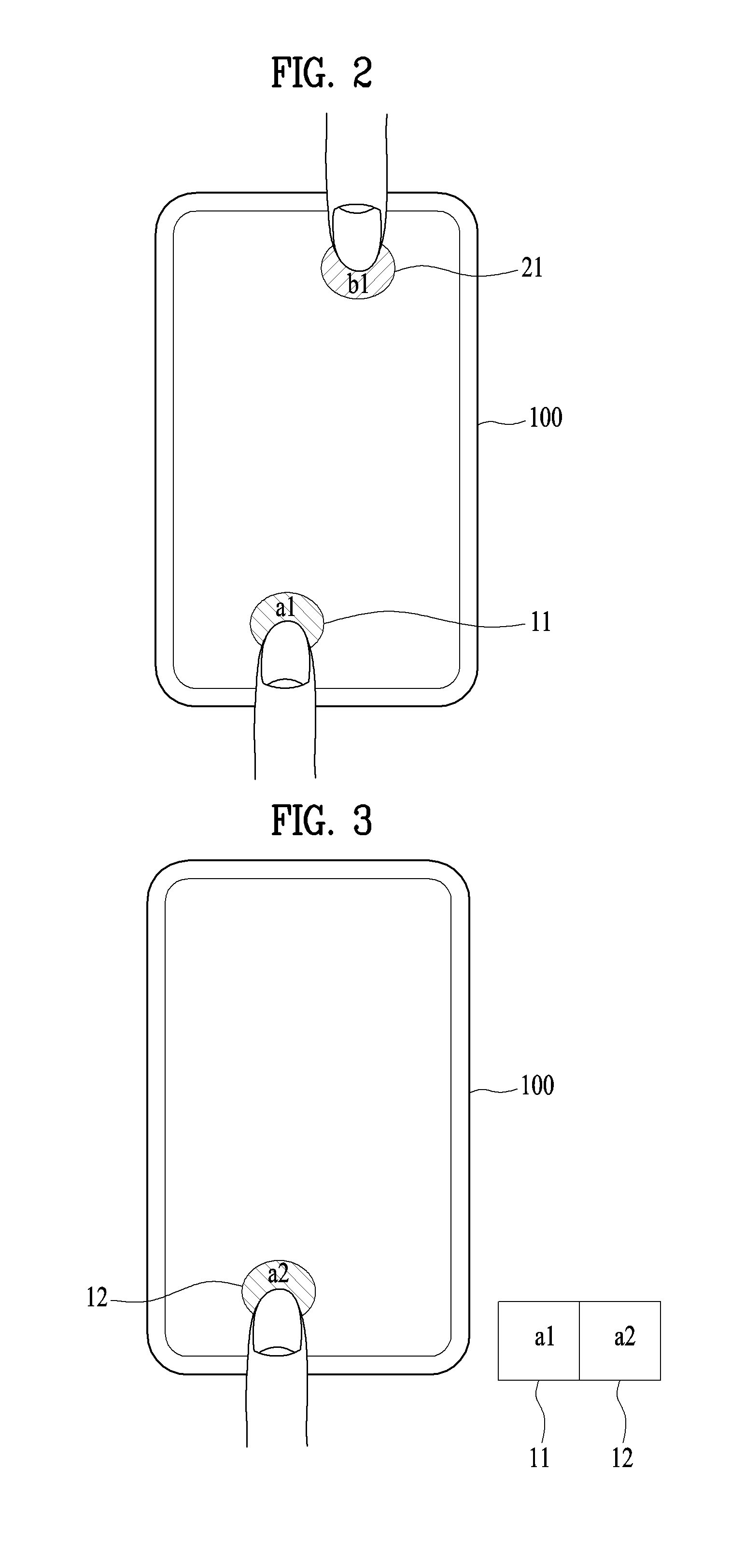

Display device and method for controlling the same

ActiveUS20150324565A1Function provideConvenient setDigital data processing detailsUnauthorized memory use protectionDisplay deviceControl unit

A display device and a method for controlling the same are disclosed. The display device comprises an input unit configured to receive a command for generating an event and a fingerprint; a control unit configured to generate the event in accordance with the command and process the generated event; and a display unit configured to display a user menu, wherein the input unit includes a touch recognition layer for recognizing a touch input and a fingerprint recognition layer for recognizing a fingerprint, the touch recognition layer and the fingerprint recognition layer being formed in a single body with the display unit and receiving a command for generating an event of a temporary unlock fingerprint setting mode and a first fingerprint different from a registered fingerprint, the control unit implements the temporary unlock fingerprint setting mode in accordance with the command for generating the input event, sets the input first fingerprint to a temporary unlock fingerprint, and unlocks the display device if the temporary unlock fingerprint is input thereto, and the temporary unlock fingerprint is released in accordance with a predetermined condition.

Owner:LG ELECTRONICS INC

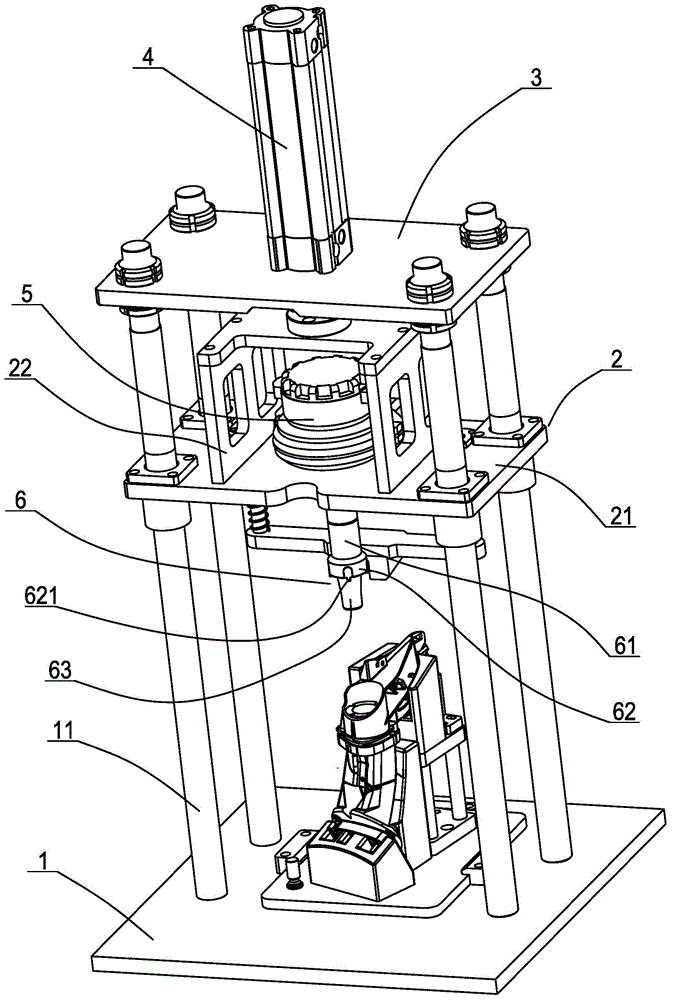

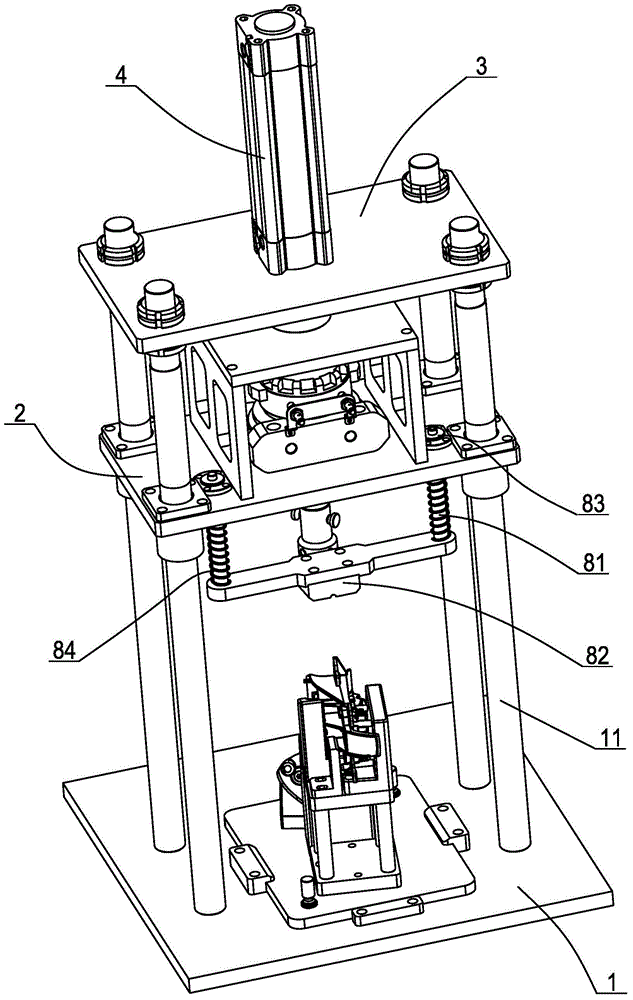

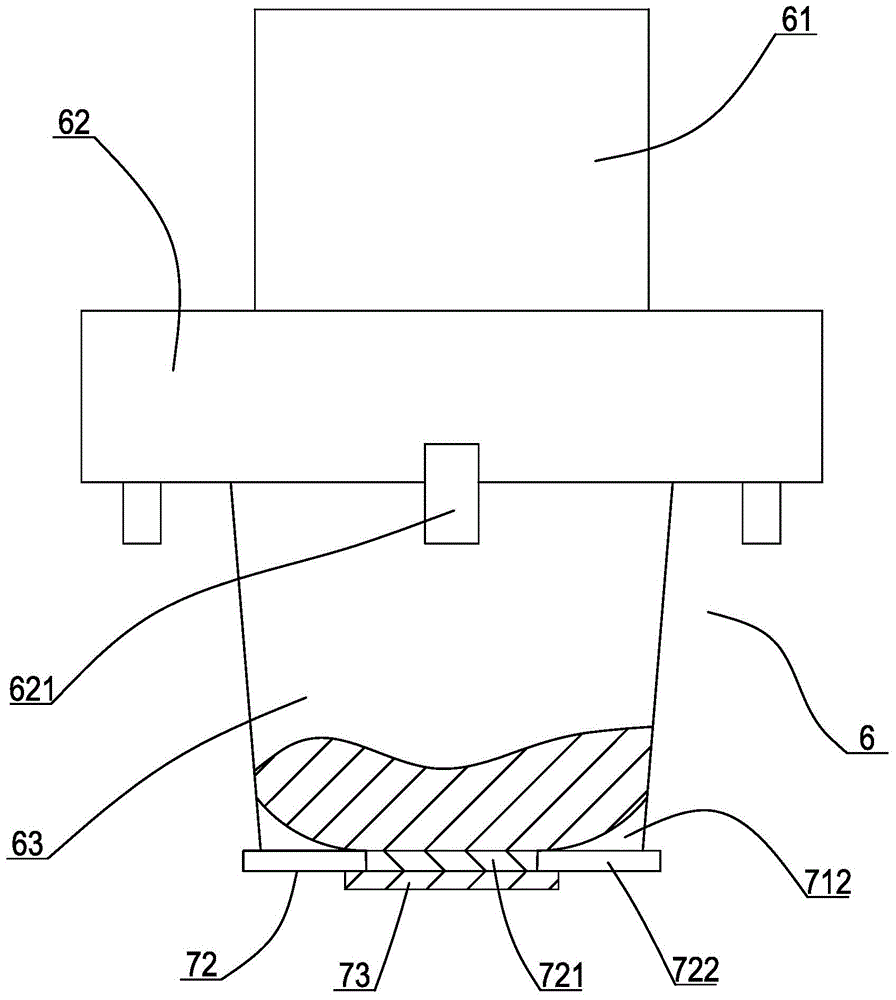

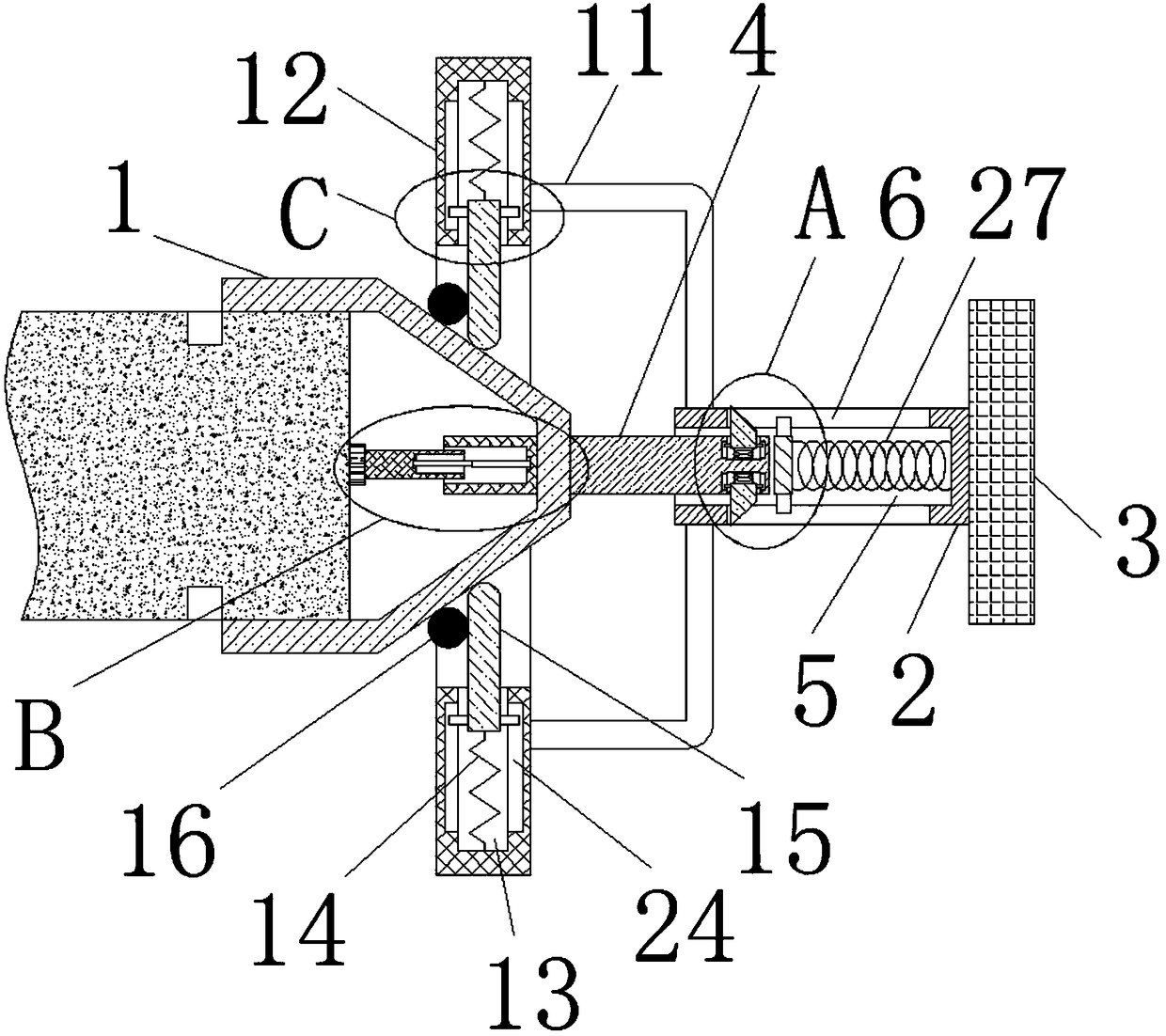

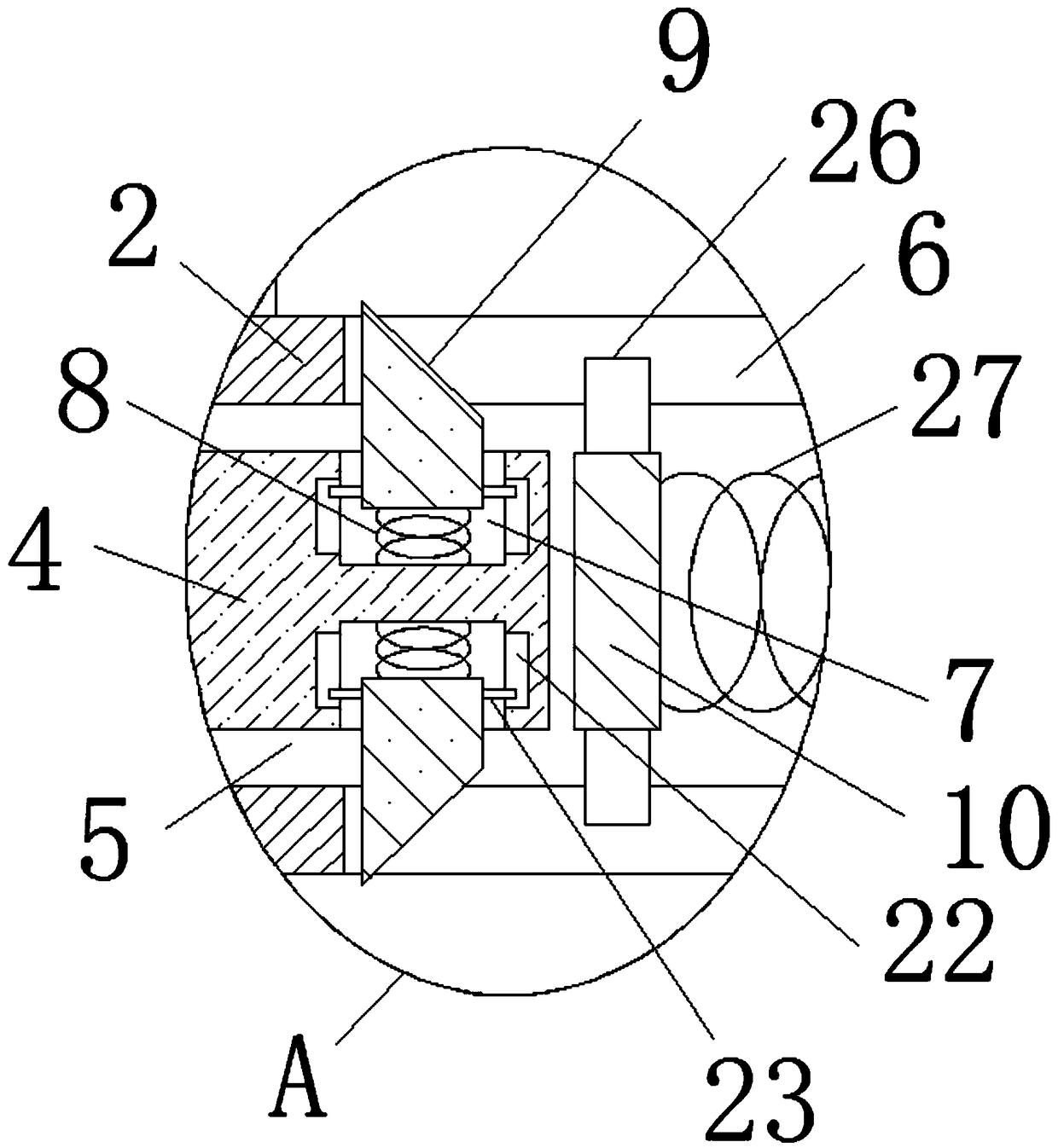

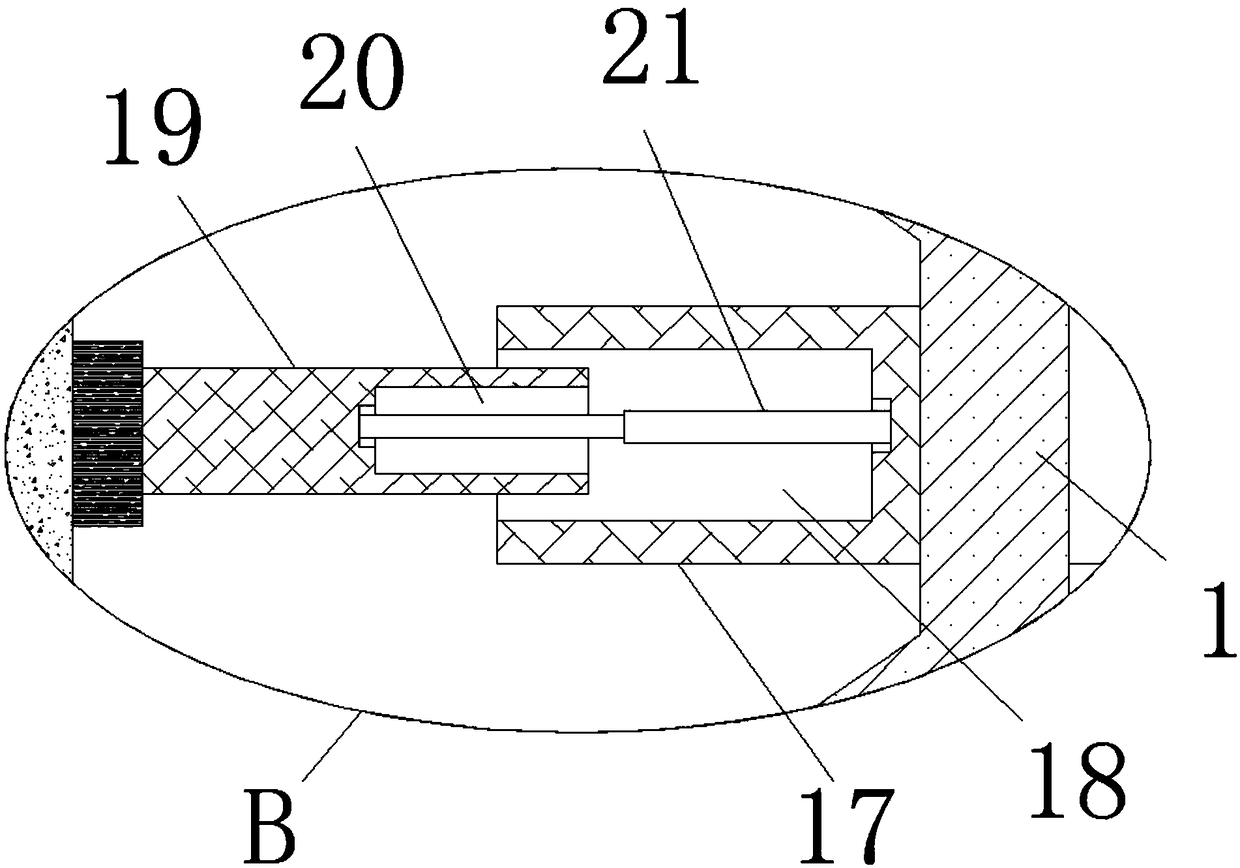

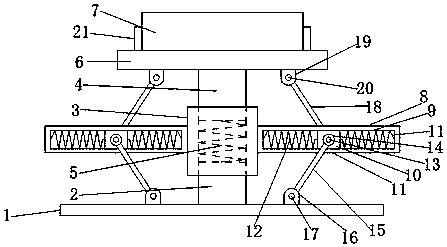

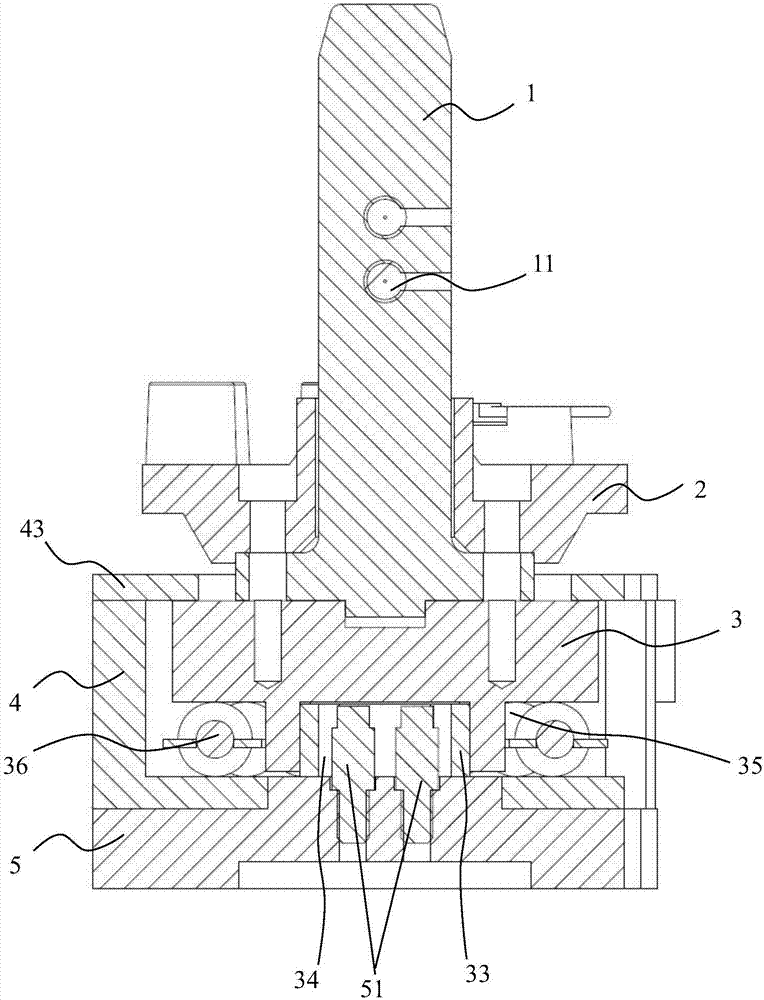

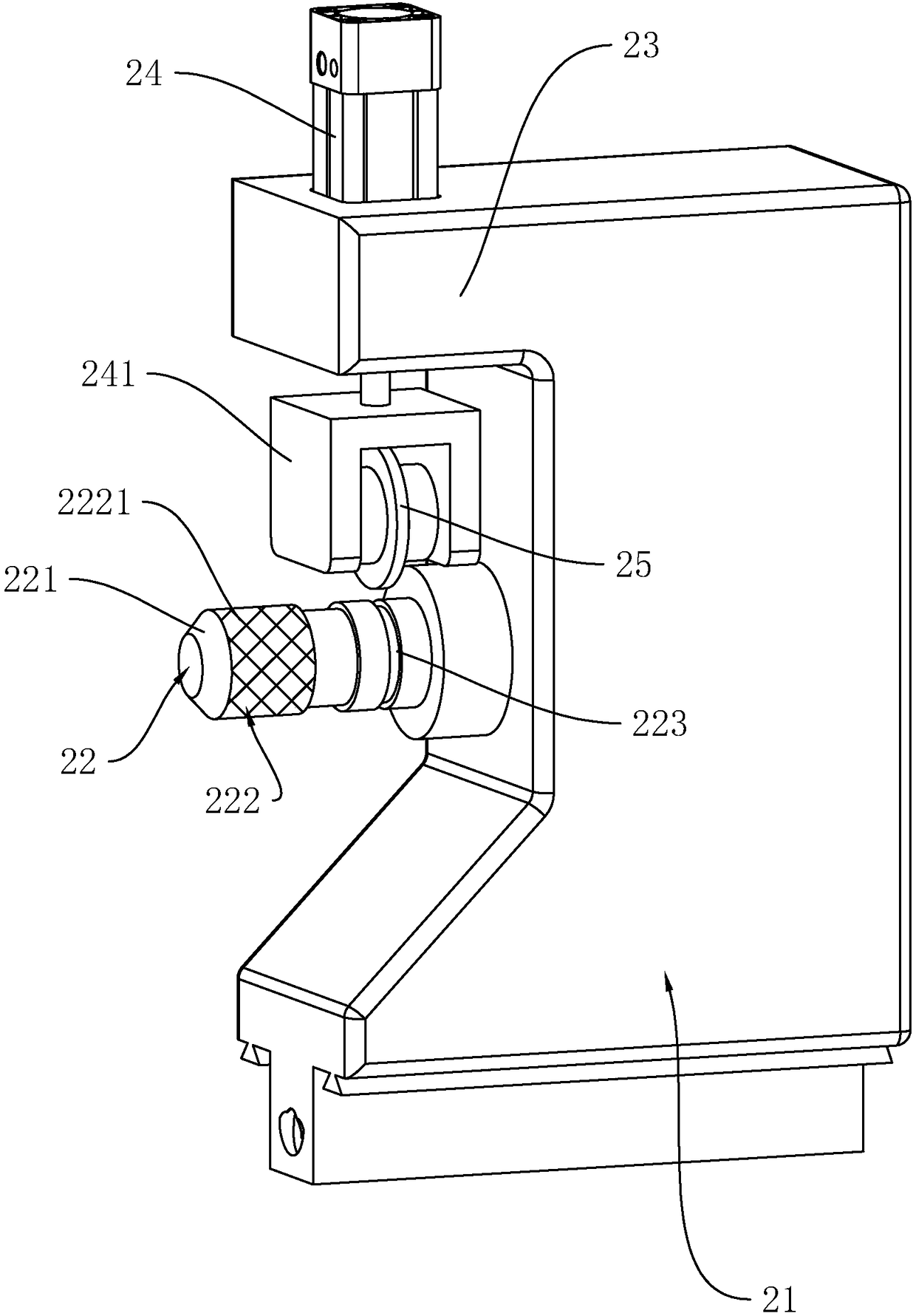

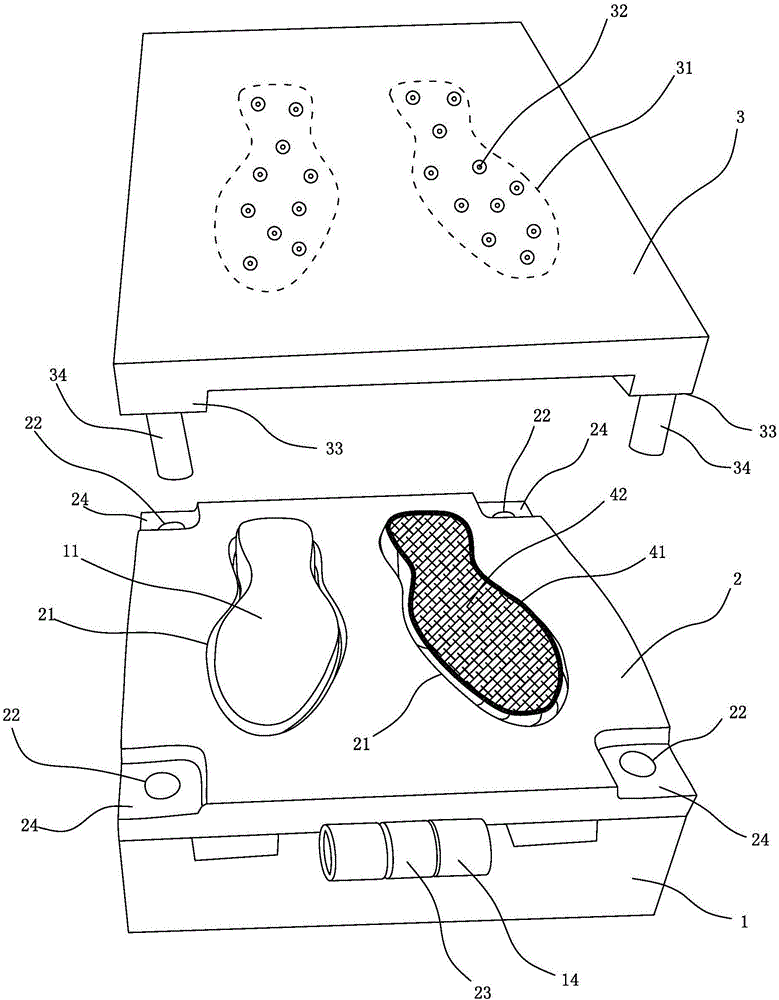

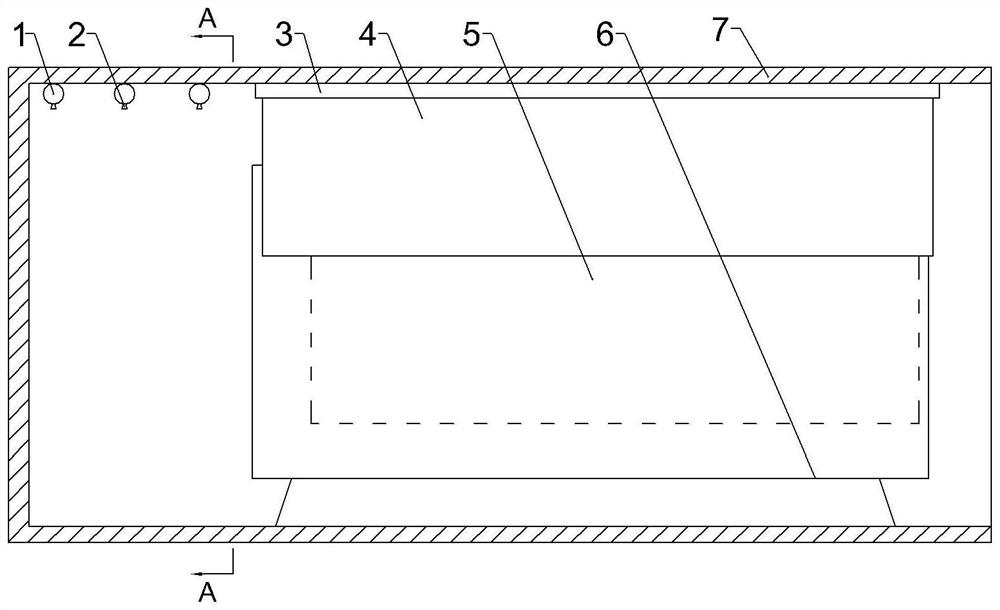

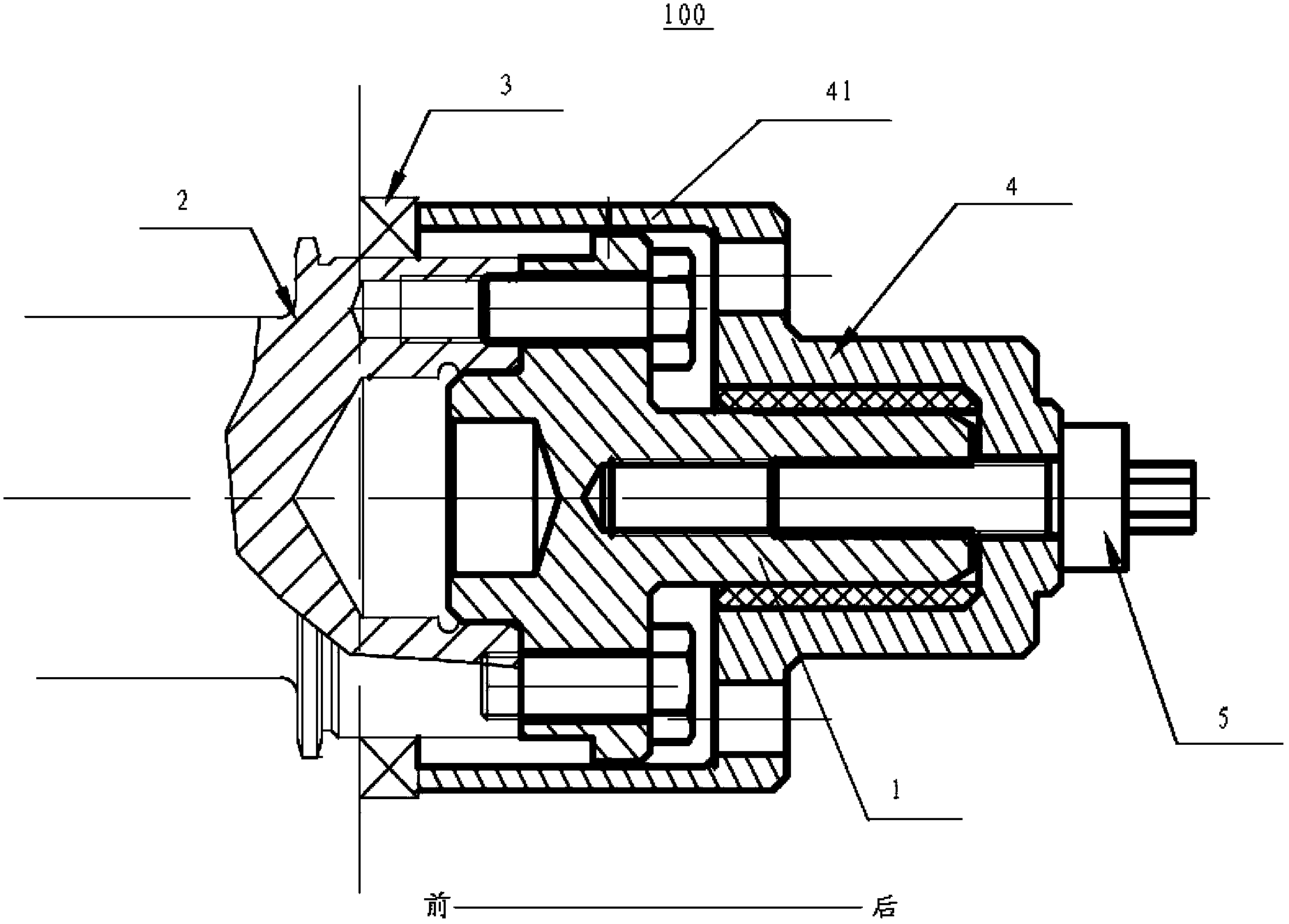

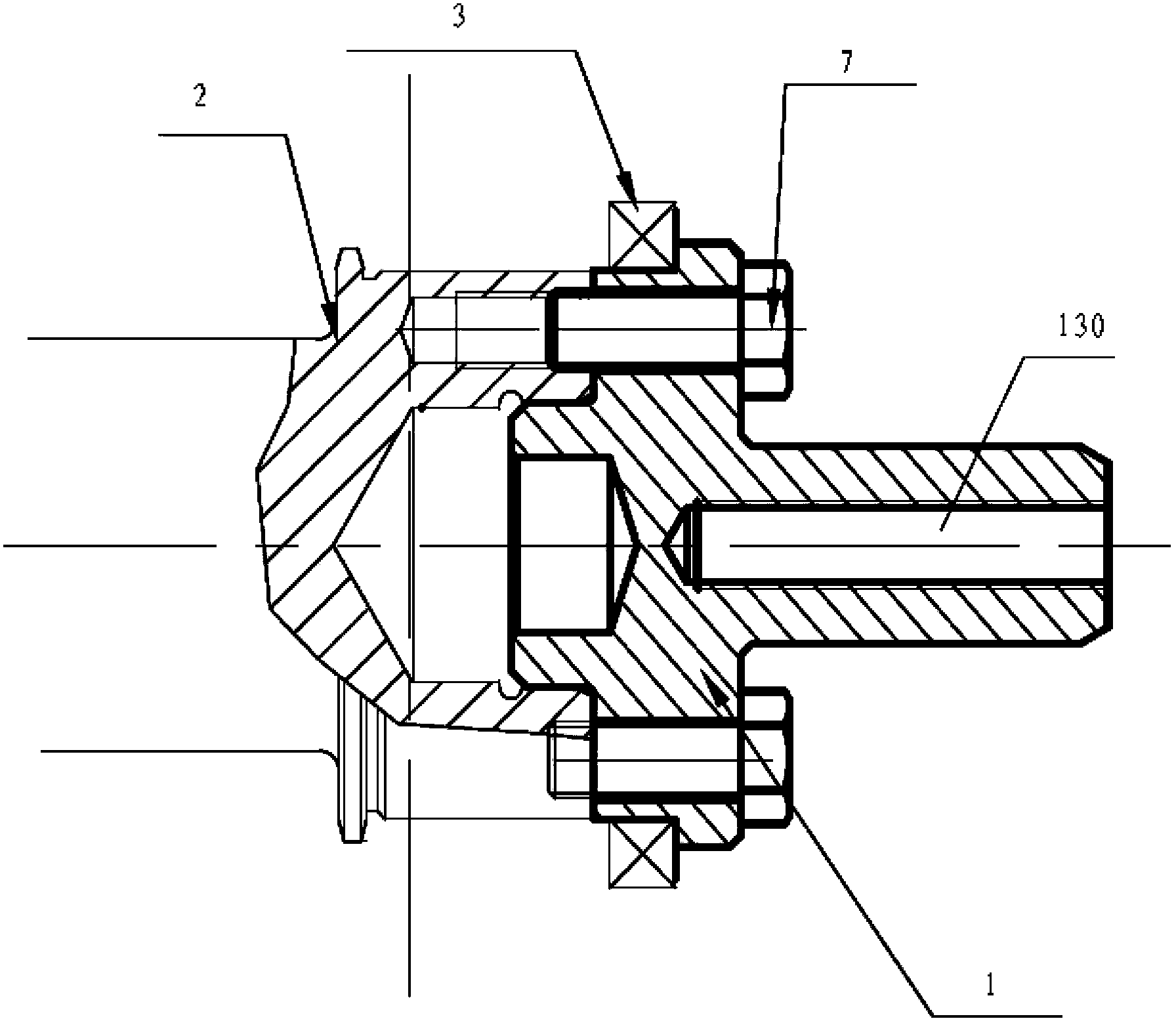

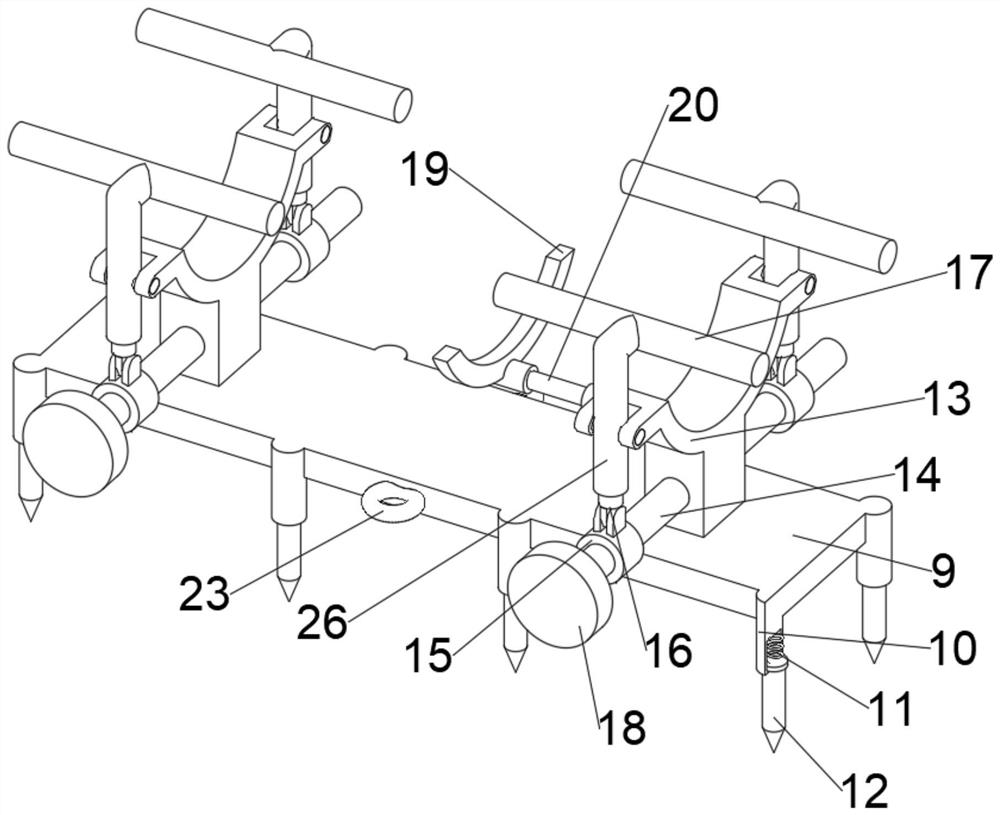

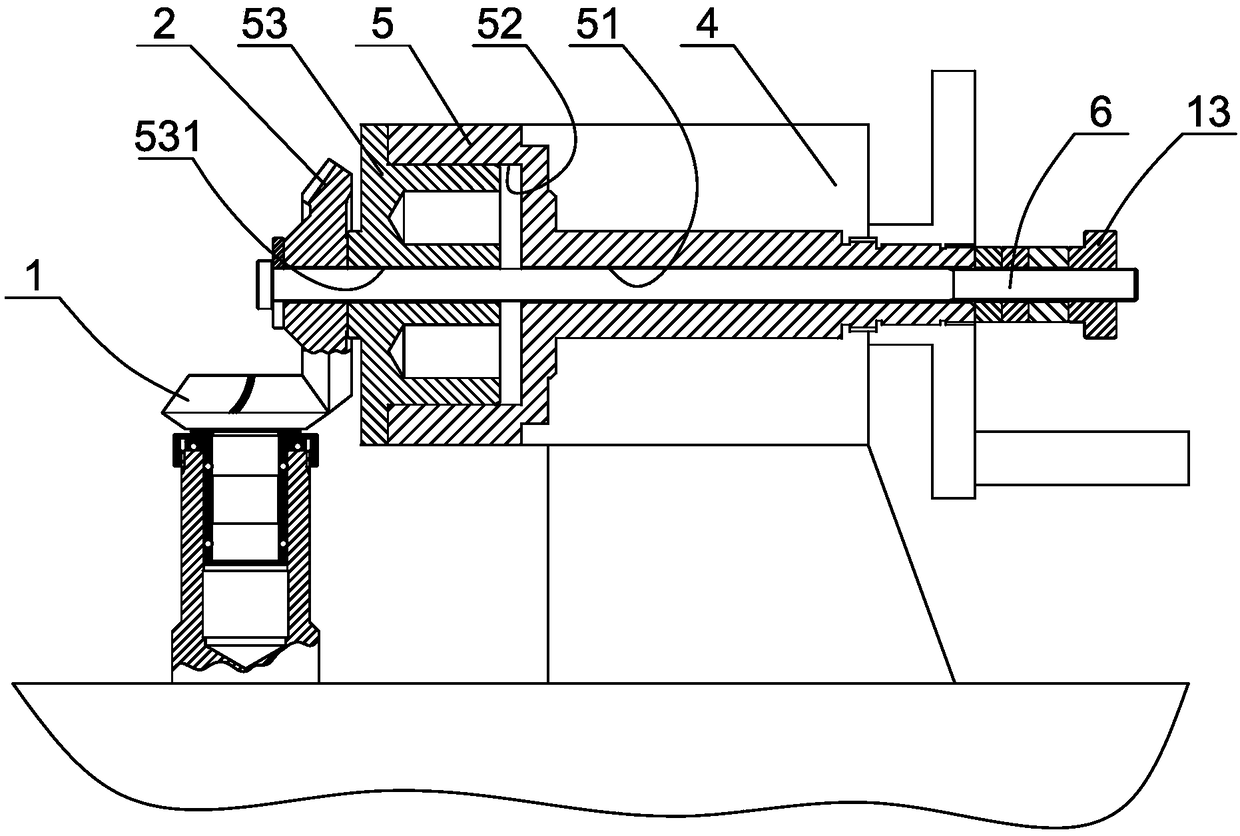

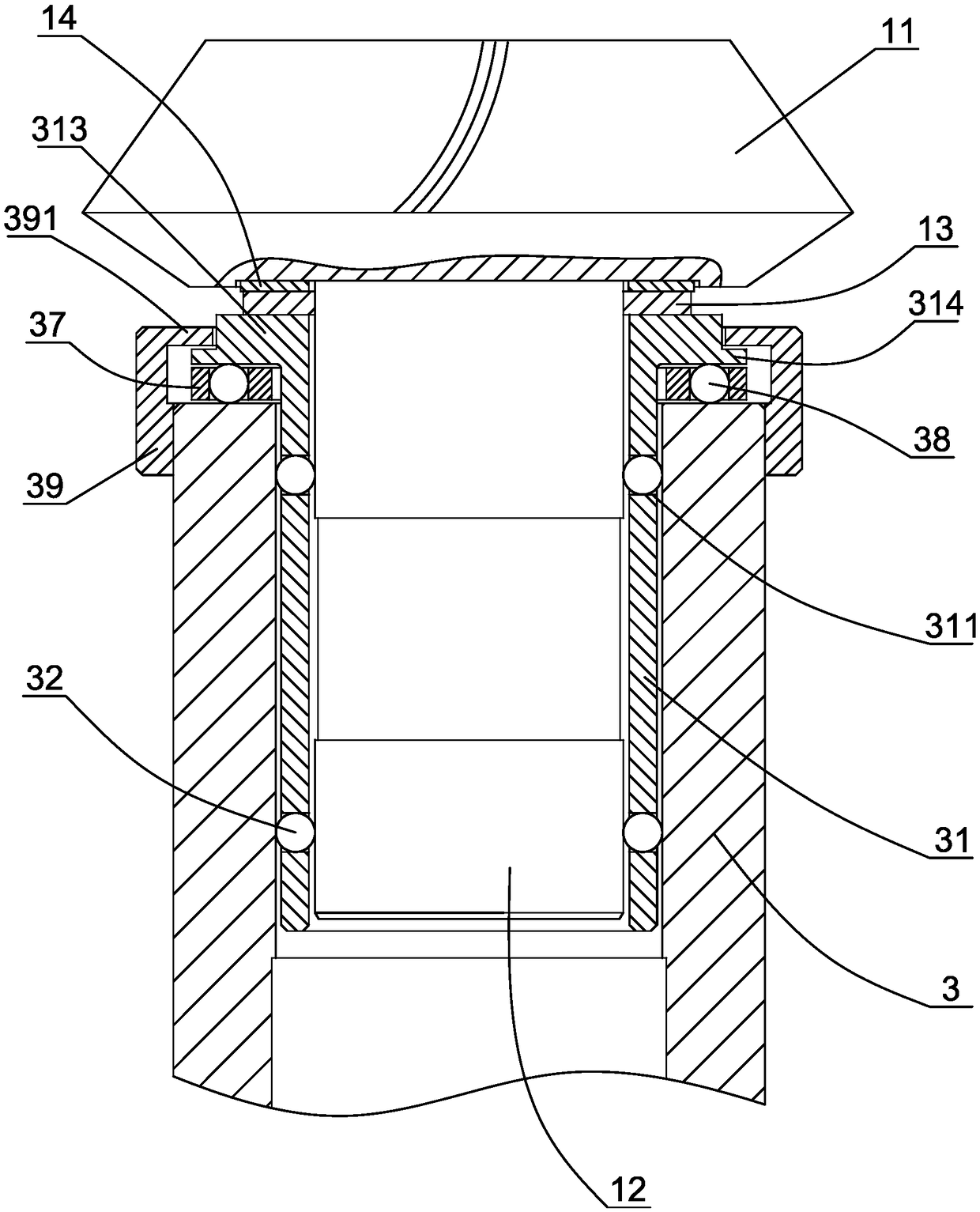

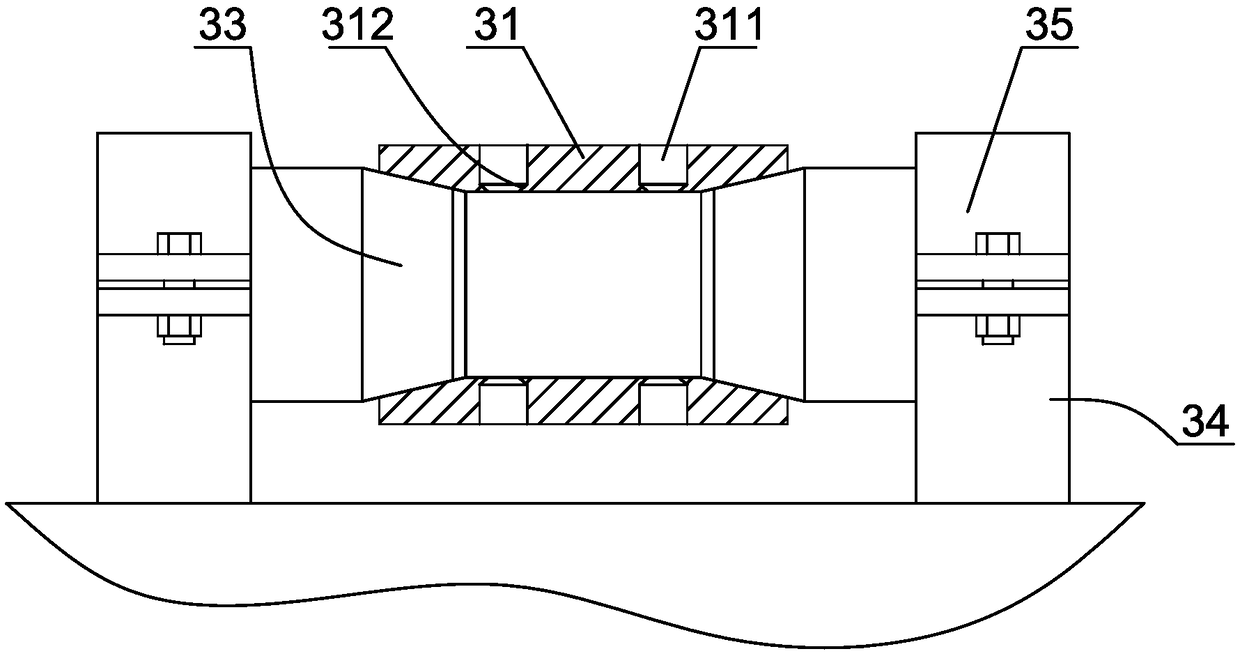

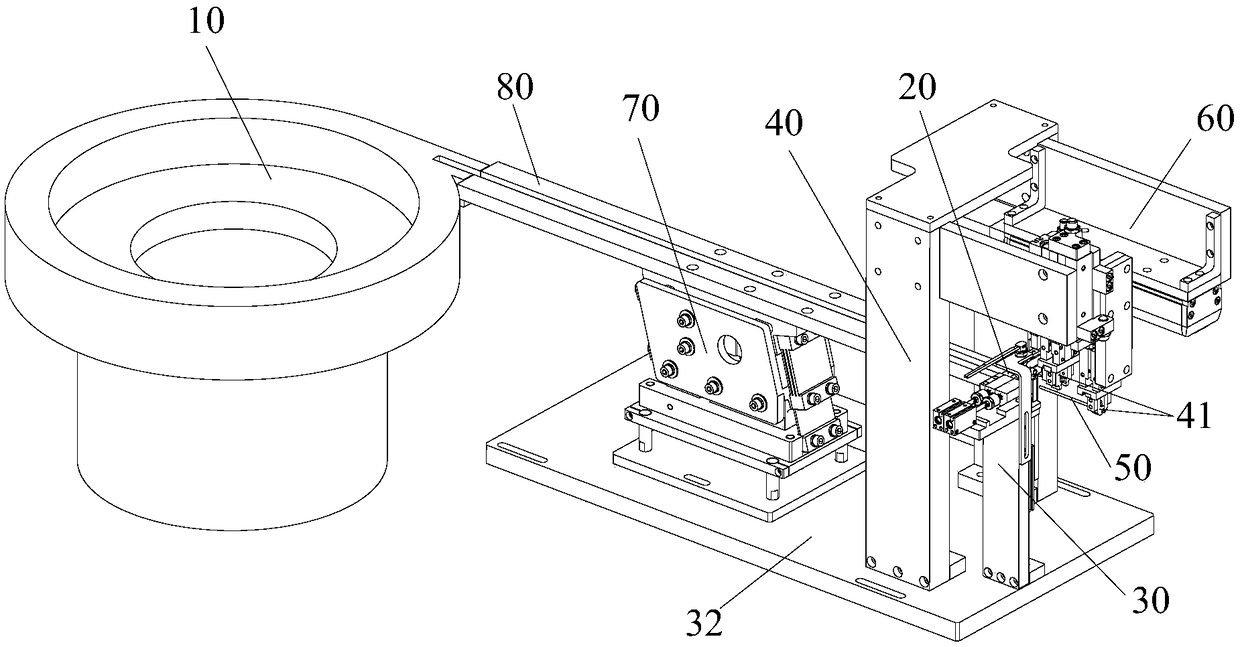

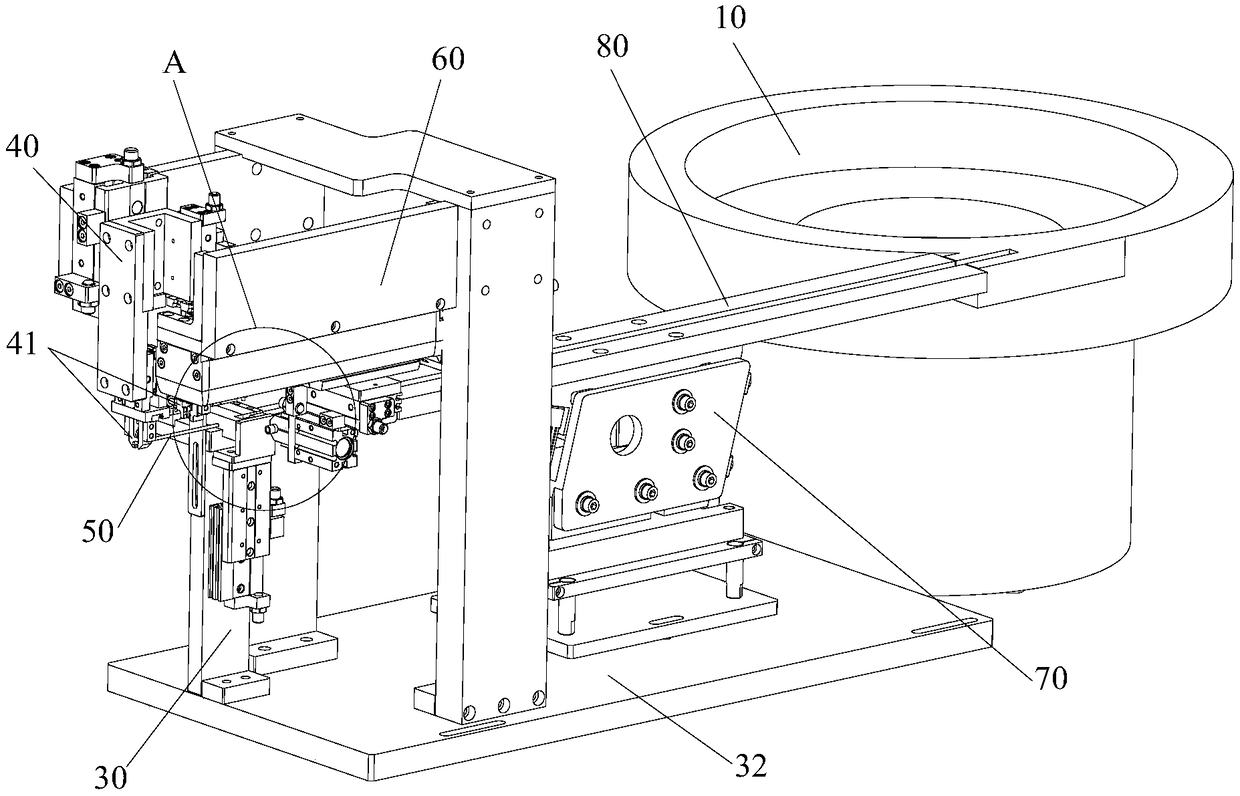

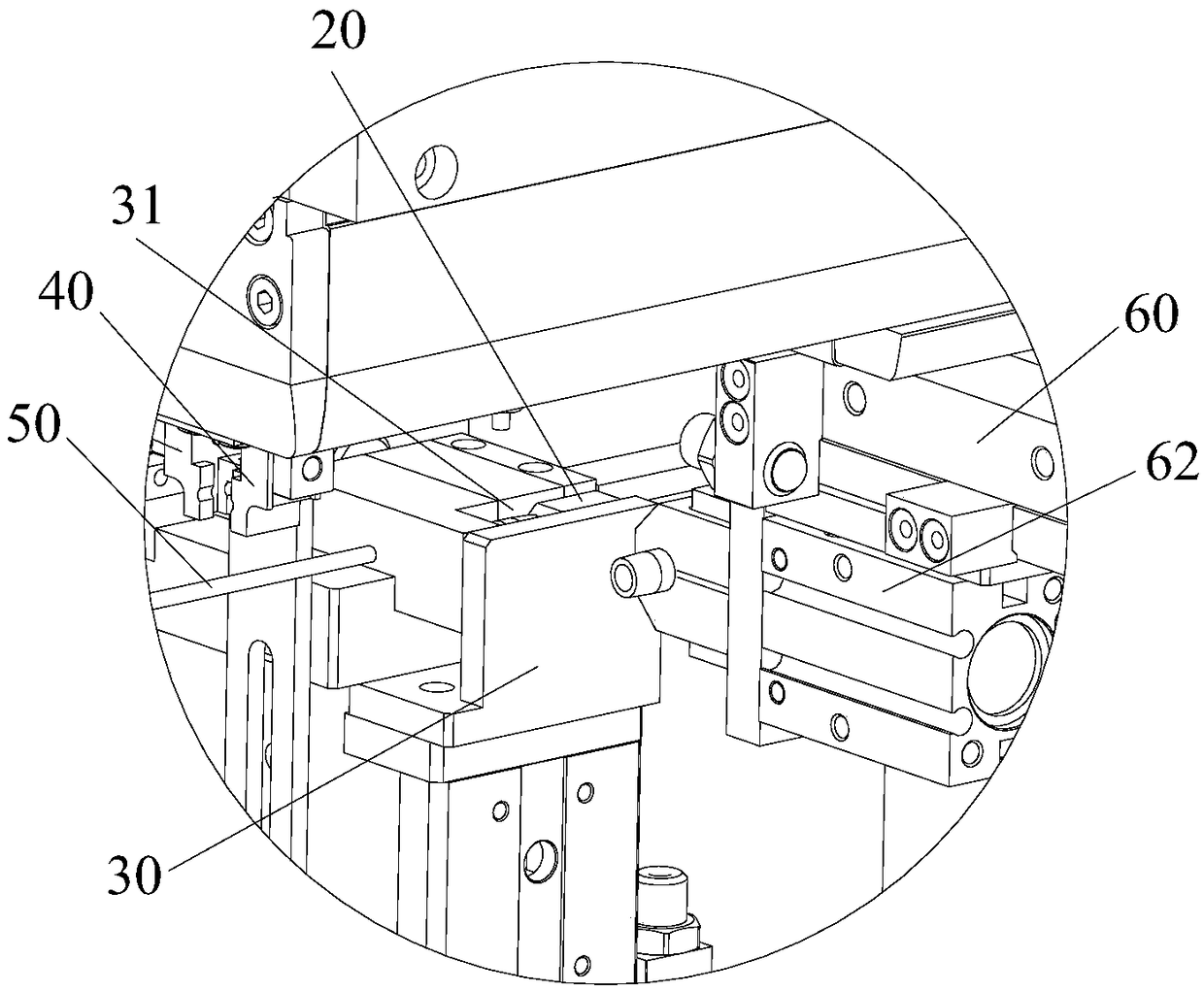

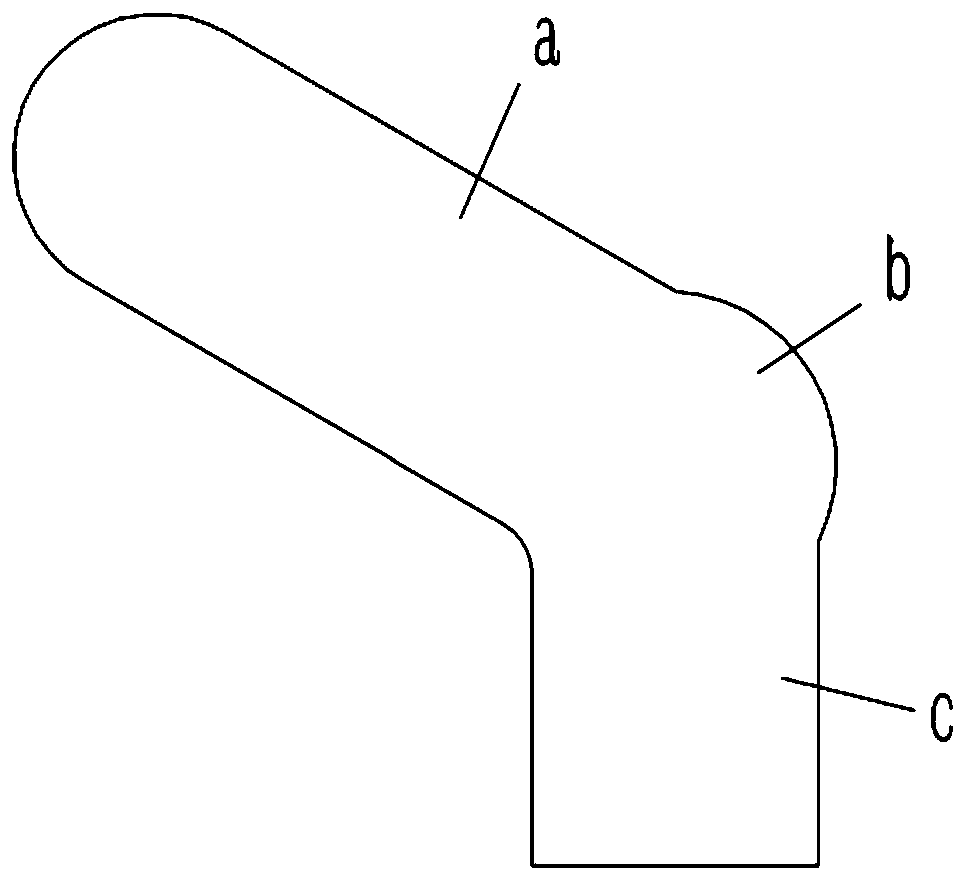

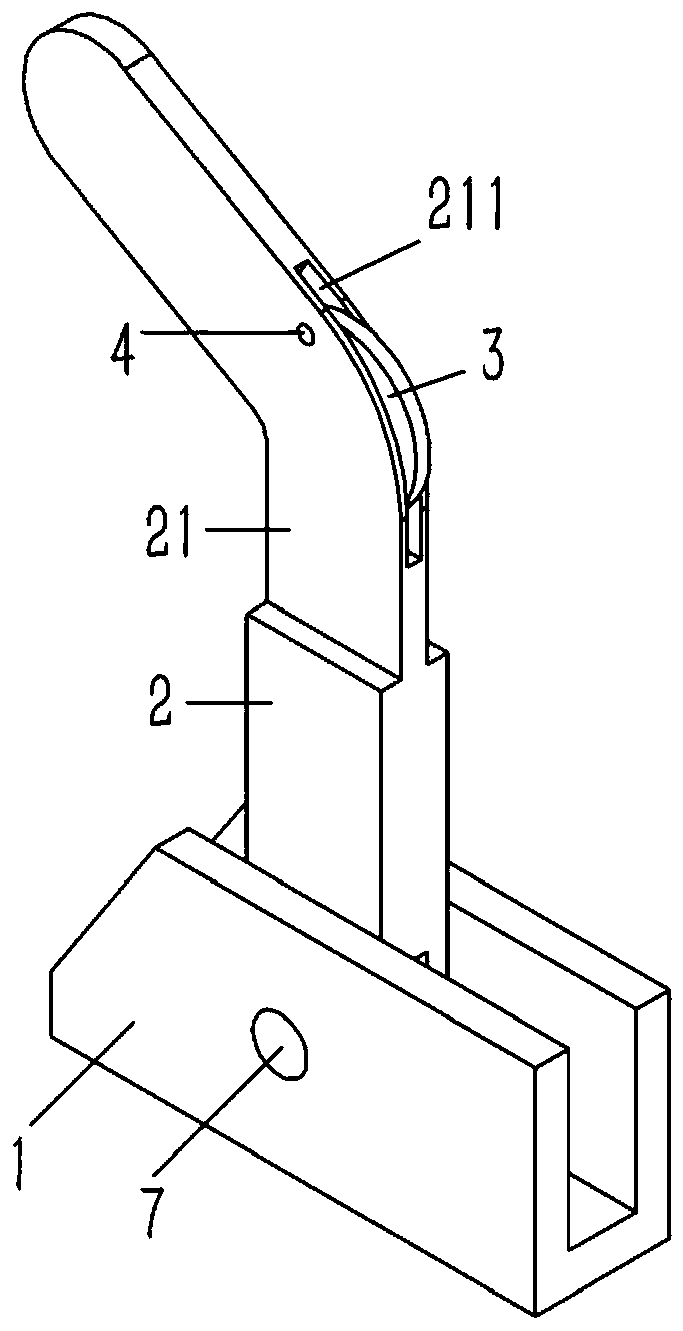

Automatic rearview mirror shaft sleeve installing mechanism facilitating installation

ActiveCN104786041AConvenient setImplement automatic installationVehicle componentsMetal working apparatusEngineeringMechanical engineering

Owner:NINGBO NINGRUN MACHINERY

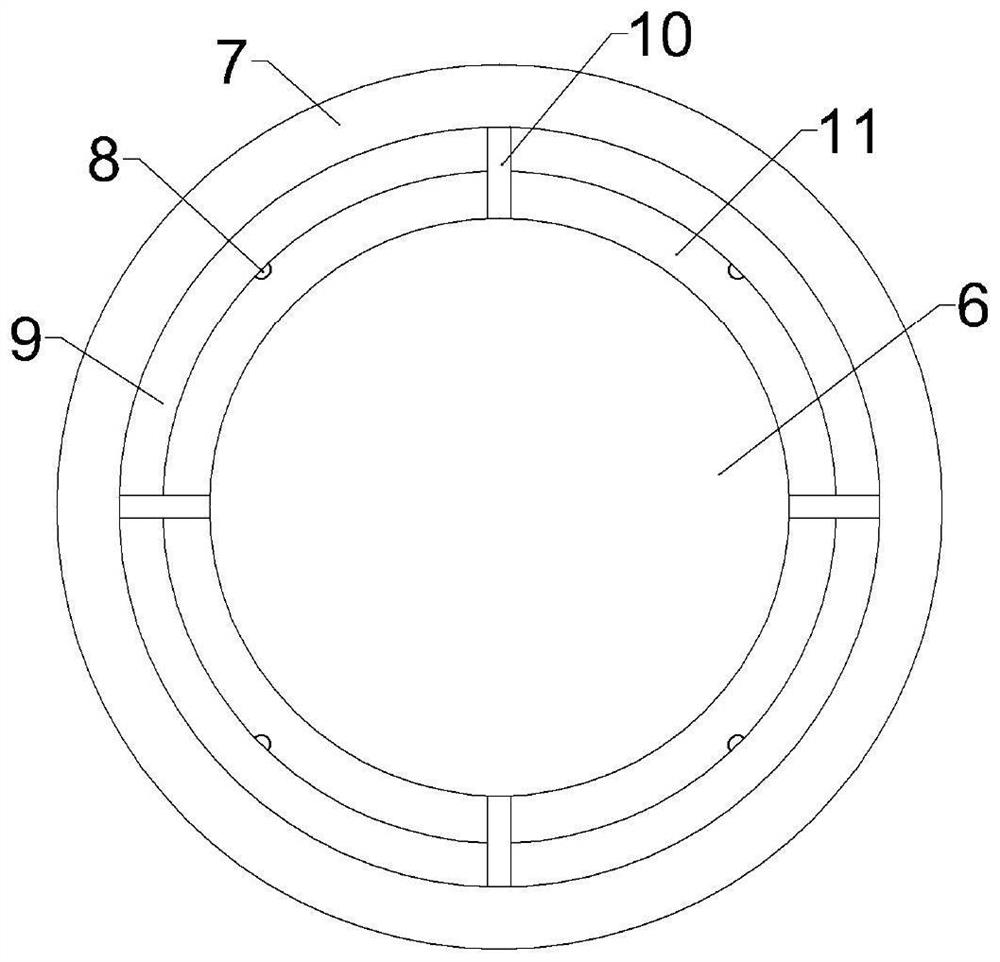

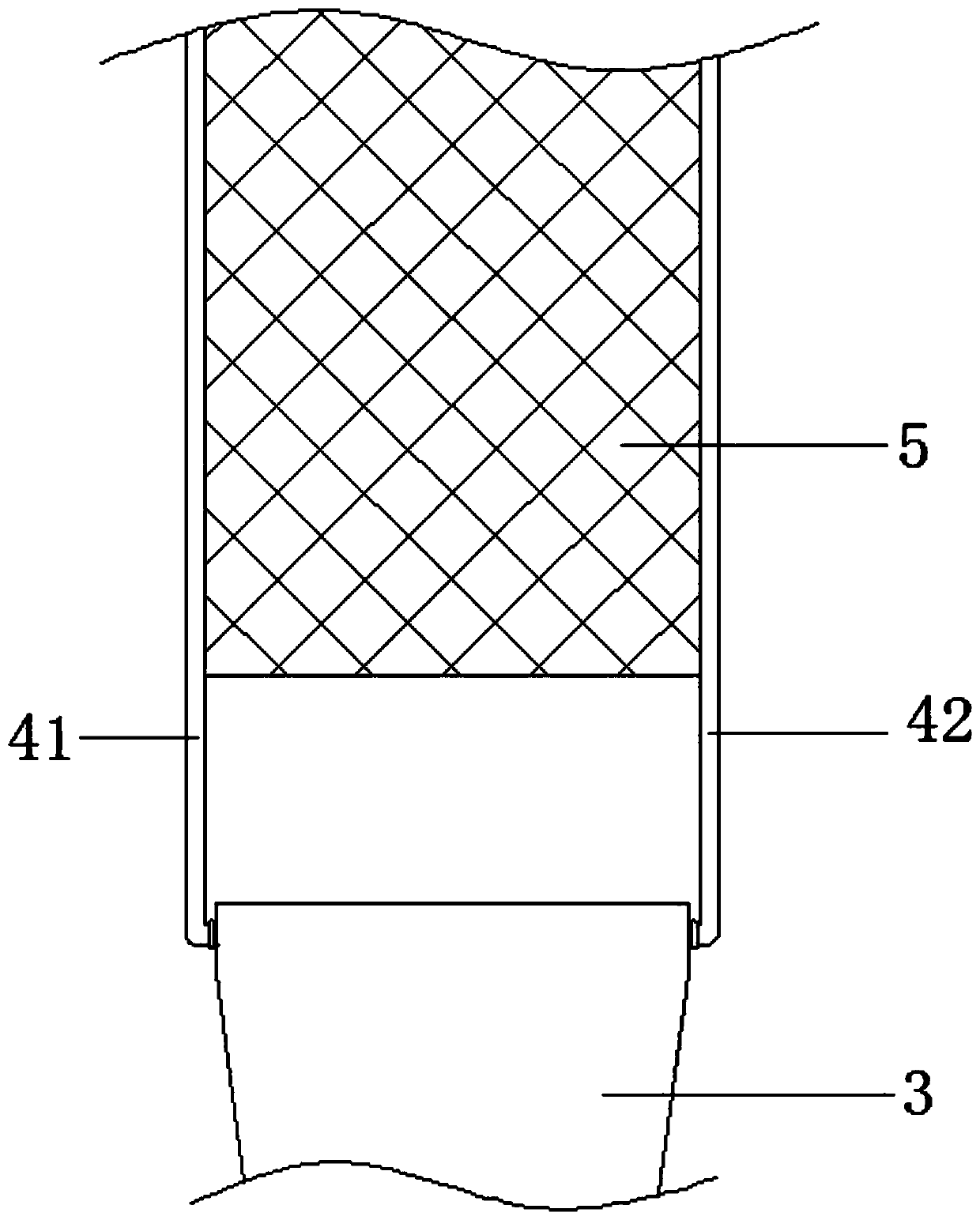

Disposable circumcision anastomat and auxiliary device for sheathing annular elastic ring

The invention discloses a disposable circumcision anastomat and an auxiliary device for sheathing an annular elastic ring. The disposable circumcision anastomat comprises an inner ring and the annular elastic ring, wherein, the inner ring is provided with an upper end surface and a lower end surface, and the size of the annular elastic ring is matched with the inner ring. The supporting auxiliarydevice is a sleeve the size of which is matched with the annular elastic ring. The novel disposable circumcision anastomat provided by the invention has the advantages of novel structure, safety, sanitation and is convenient and comfortable to use; and the auxiliary device is used for sheathing and fastening the ring.

Owner:WUHU SHANGRING TECH CO LTD

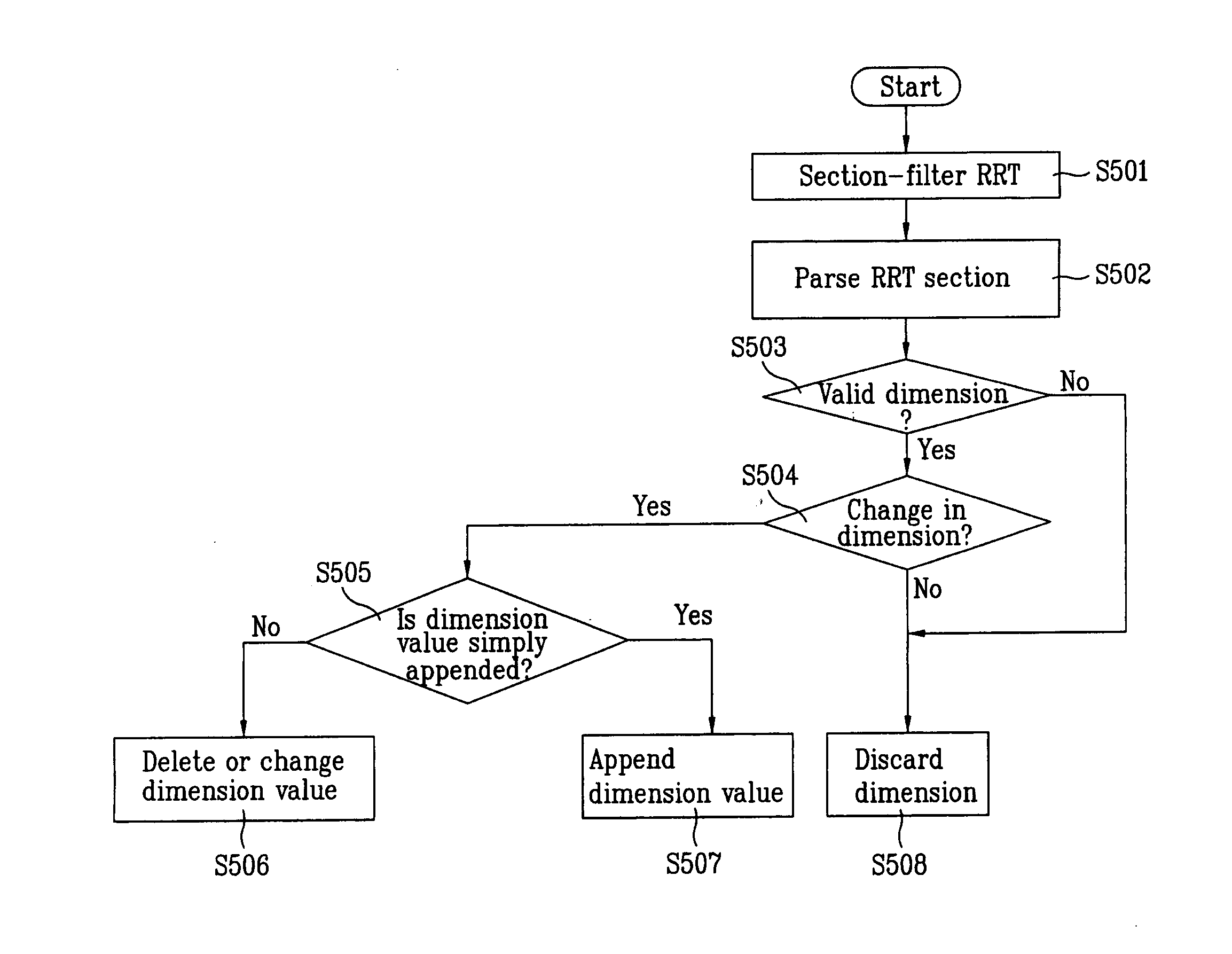

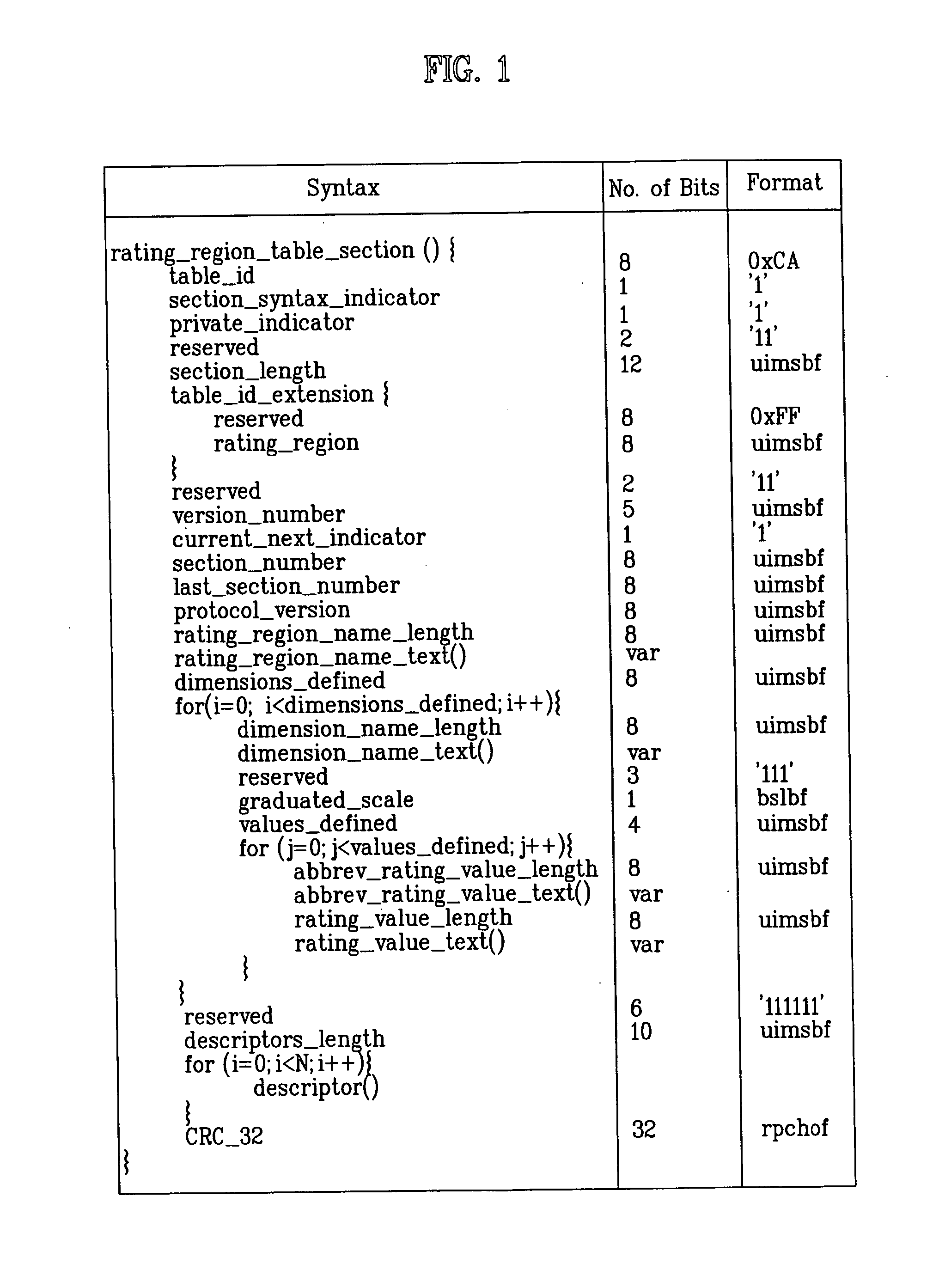

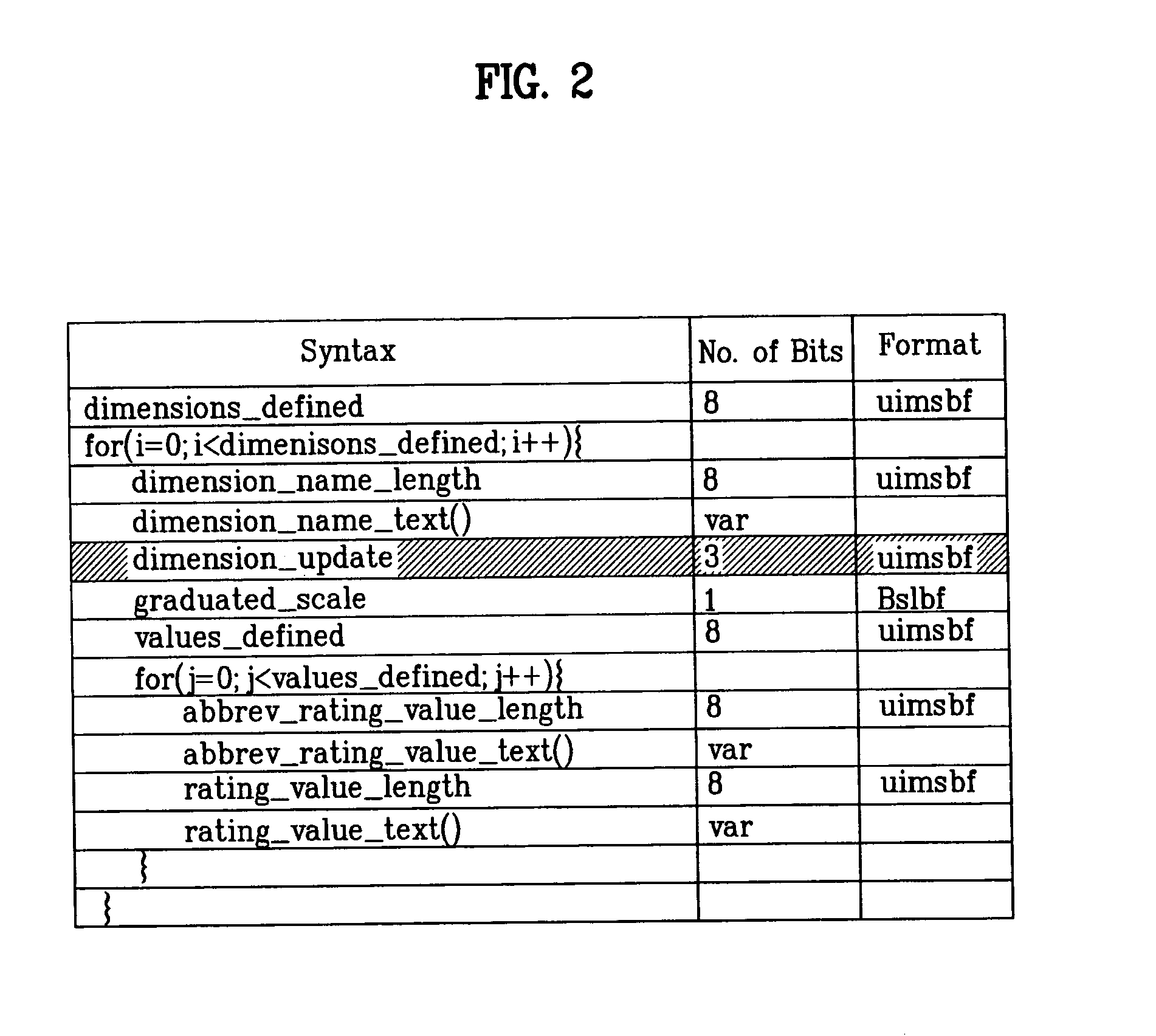

Digital television signal, method of processing digital television signal, and digital television receiver

InactiveUS20070204289A1Easy to identifyConvenient setTelevision system detailsPulse modulation television signal transmissionData fieldDTV receiver

A digital television signal for use in a digital television receiver includes a rating region table carrying rating information for multiple geographical regions. The rating region table includes a multiple string structure containing a multiple string structure which represents a name of a dimension, rating value information defining one or more rating values associated with the dimension, and a data field including information specifying a change mode of the rating value information. The change mode indicates whether and how the rating value information is changed. For example, it may indicate whether there is a change in the rating value information. If there is, it may further indicate whether a new rating value is simply appended or any existing rating value has been changed or deleted. In addition, it may further indicate whether the dimension is a valid dimension.

Owner:LG ELECTRONICS INC

High efficient hand-pressing type piston ring rapid installation device

PendingCN109352588AEasy to set upConvenient setMetal-working hand toolsBiochemical engineeringPiston ring

The invention relates to the technical field of piston ring installation, and discloses a high efficient hand-pressing type piston ring rapid installation device. The high efficient hand-pressing typepiston ring rapid installation device comprises a guide tank and an extrusion rod, wherein the guide tank and the extrusion rod sleeve a piston. The extrusion rod is located on the side, away from the piston, of the guide tank, and a handle is fixedly connected to the end, away from the guide tank, of the extrusion rod. The tank bottom of the guide tank is arranged in the shape of a circular truncated cone, and a connecting rod is fixedly connected to the tank bottom outside the guide tank. The connecting rod and the extrusion rod are connected through a clamping structure, and the clamping structure includes a connecting groove. The connecting groove is formed in the end, close to the guide tank, of the extrusion rod, sliding holes are symmetrically formed in the opposite groove walls ofthe connecting groove, and the end, away from the guide tank, of the connecting rod penetrates through a groove opening of the connecting groove and extends into the connecting groove. According to the high efficient hand-pressing type piston ring rapid installation device, clamping blocks are matched with the sliding holes for use, the connecting rod and the extrusion rod are disassembled conveniently, a piston ring sleeves conveniently, and the installation efficiency is improved.

Owner:安庆海威尔机械有限公司

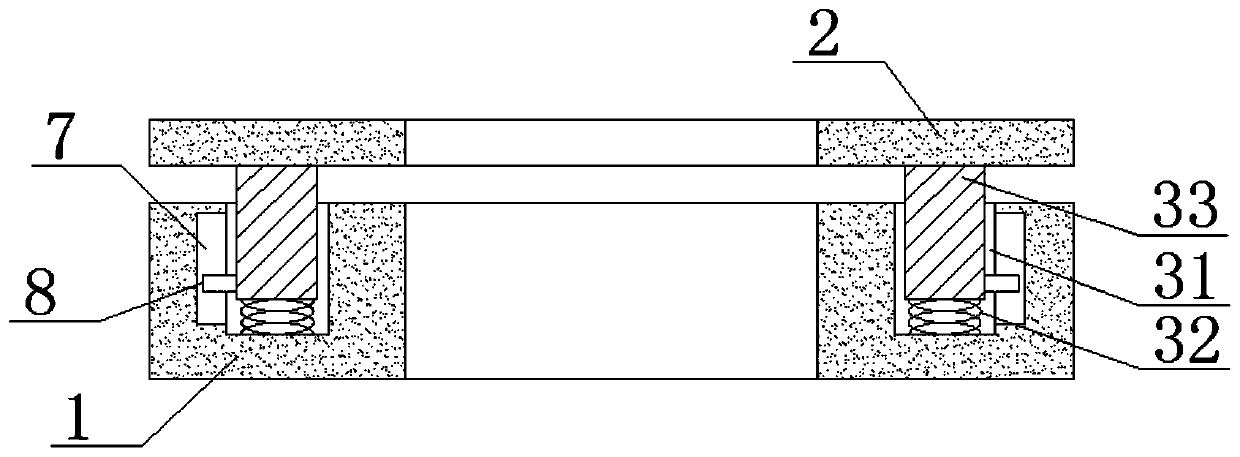

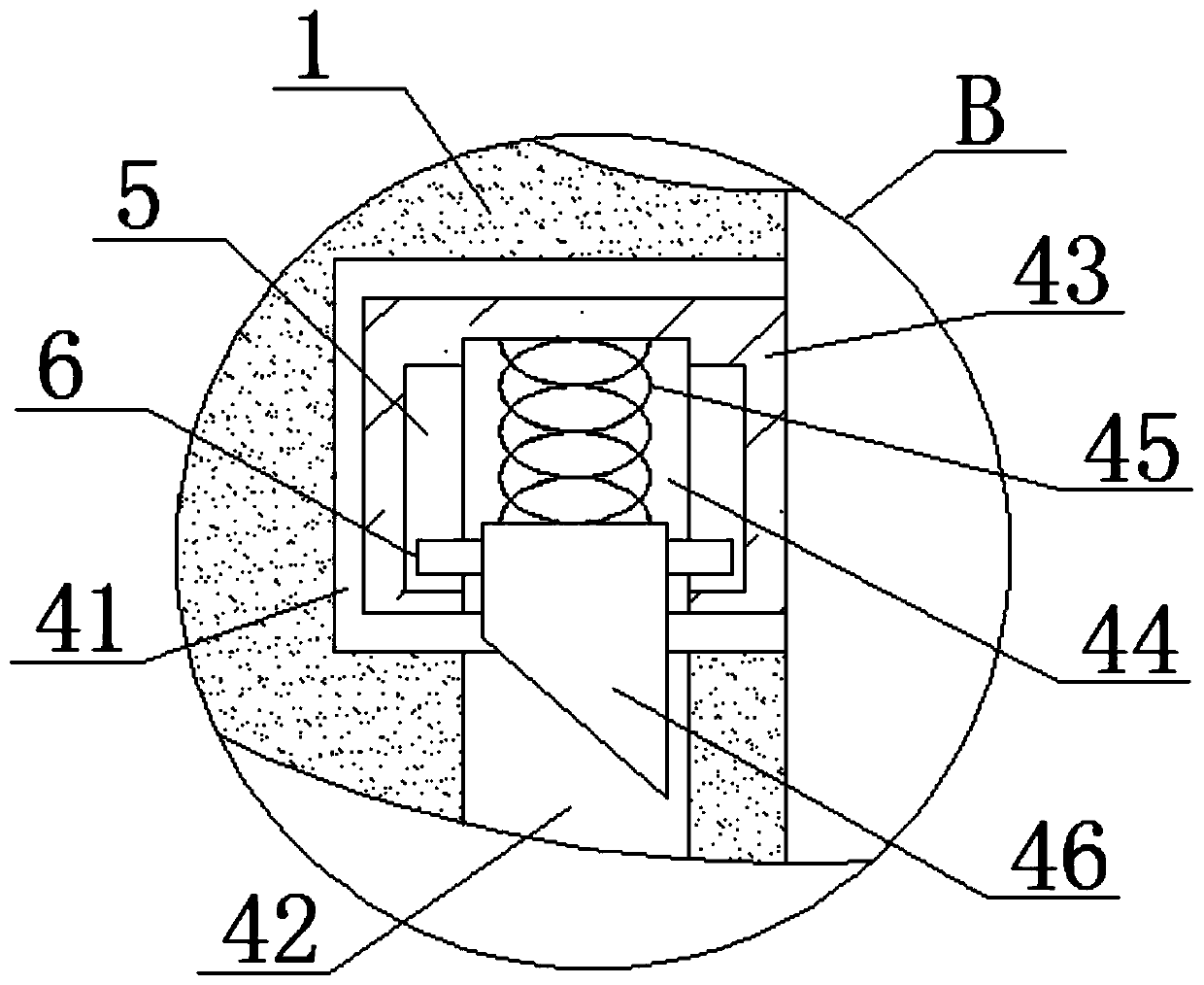

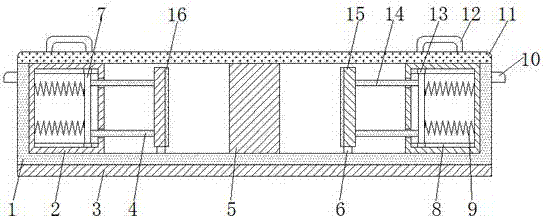

Vibration reduction base for intelligent equipment

InactiveCN108679157APlay the role of the first bufferImprove shock absorptionNon-rotating vibration suppressionEngine bedsEngineeringIntelligent equipment

The invention discloses a vibration reduction base for intelligent equipment. The vibration reduction base comprises a base body. A first fixing rod is arranged at the upper end of the base body. A sleeve is arranged at the upper end of the first fixing rod. A second fixing rod is arranged at the upper end of the sleeve. The upper end of the first fixing rod and the lower end of the second fixingrod are both located in the sleeve. A first spring is arranged at the position, located inside the sleeve, between the first fixing rod and the second fixing rod. The end, away from the sleeve, of thesecond fixing rod is provided with a support plate. The upper end of the support plate is provided with an intelligent equipment body. The two ends of the sleeve are each provided with a connecting plate. Each connecting plate is provided with a limiting groove. A sliding block is arranged in each limiting groove, wherein each sliding block is matched with the corresponding limiting groove. A second spring is arranged at the position, located inside the corresponding limiting groove, of one side of each sliding block. A third spring is arranged at the position, located inside the corresponding limiting groove, of the other side of each sliding block. A first rotating shaft is arranged on each sliding block in a penetrating and inserted manner. Connecting rings are arranged at the two endsof each first rotating shaft in a sleeving manner correspondingly. A first connecting rod is arranged at one side of each connecting ring.

Owner:HEFEI SHULI ELECTRONICS INFORMATION TECH CO LTD

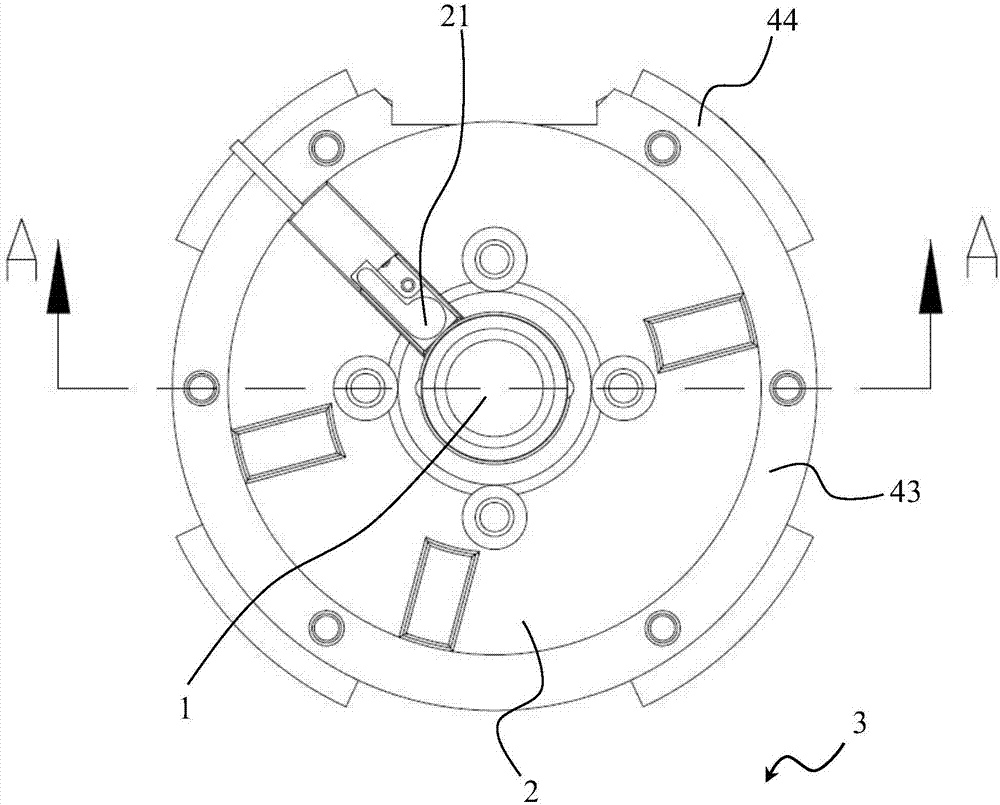

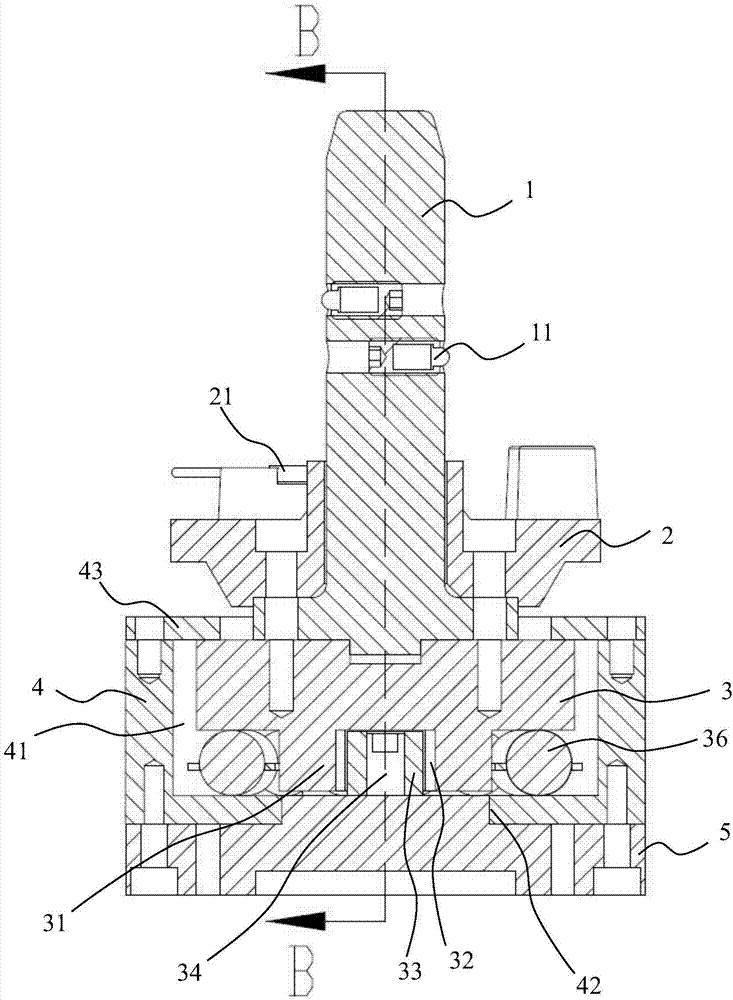

Pressing and floating device for liner bushing

PendingCN107052781AAvoid the phenomenon of force tiltAvoid the phenomenon of jumping out of the sliding cavityMetal working apparatusScrapManufacturing engineering

The invention discloses a pressing and floating device for liner bushing. The device comprises a positioning mandrel, a liner bushing phase position base, a sliding base, a fixed base and a bearing base, wherein the liner bushing phase position base is sheathed on the outer side of the positioning mandrel; the liner bushing phase position base and the positioning mandrel are fixed at the upper end of the sliding base by bolts; a sliding chamber is formed in a hollow part inside the fixed base and is placed in the sliding chamber; an annular boss is arranged in the middle part of the lower end of the sliding base; a longitudinal sliding chamber is arranged on the annular boss; a longitudinal sliding block is arranged in the longitudinal sliding chamber of the annular boss; a transverse sliding pin is fixedly mounted in the middle part of the upper end of the bearing base; and a transverse sliding groove matched with the transverse sliding pin is arranged at the lower end of the longitudinal sliding block. According to the device, the concentricity of the device and a liner bushing hole which is deviated on a workpiece can be realized, and then the liner bushing is pressed into the liner bushing hole which is deviated on the workpiece, so that scraps of the workpiece caused by deviation of the liner bushing are avoided, the machining difficulty of the liner bushing hole of the workpiece is reduced, and the manufacturing cost is reduced.

Owner:ZHONGSHAN CLG AUTOMATION EQUIP

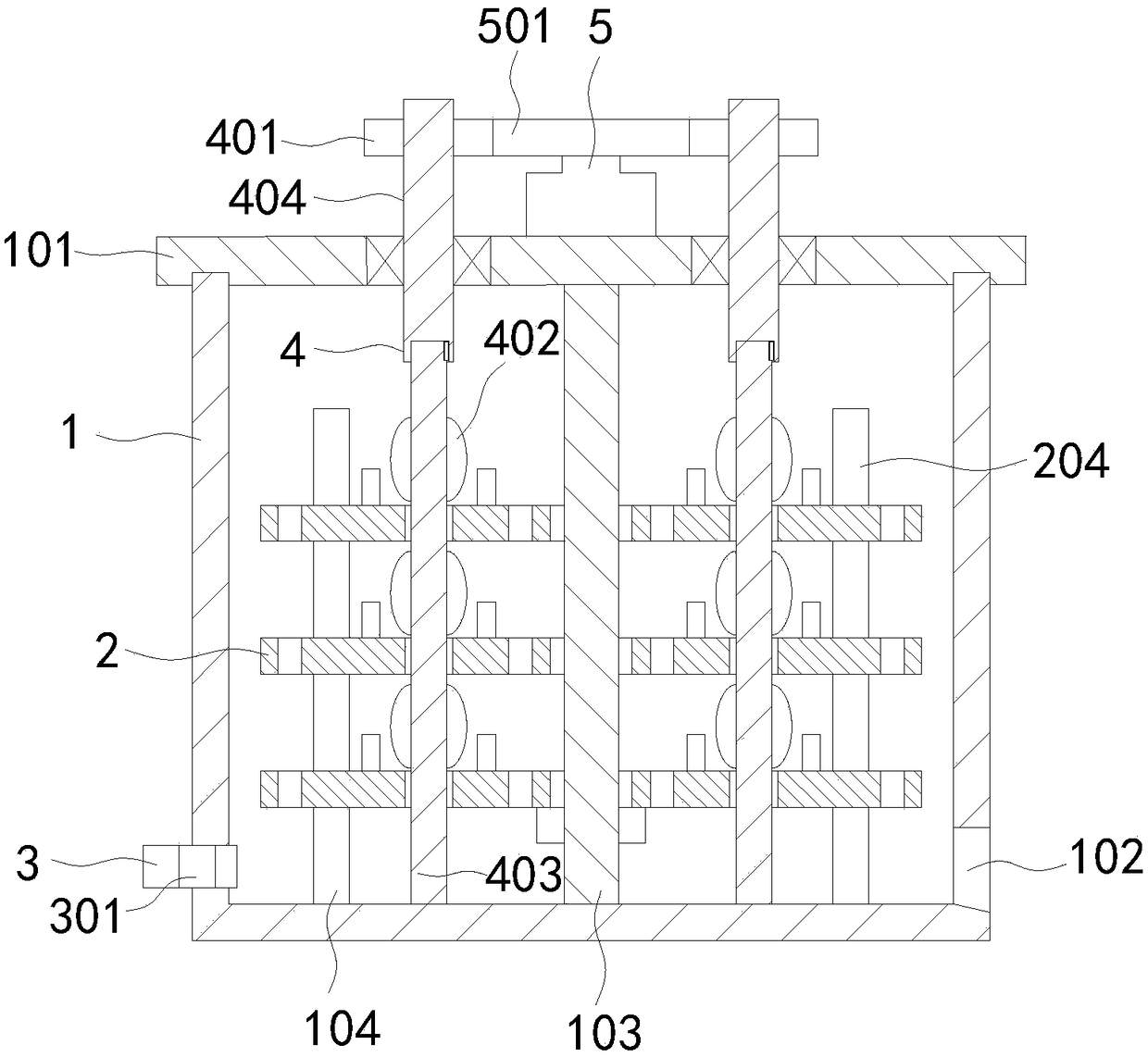

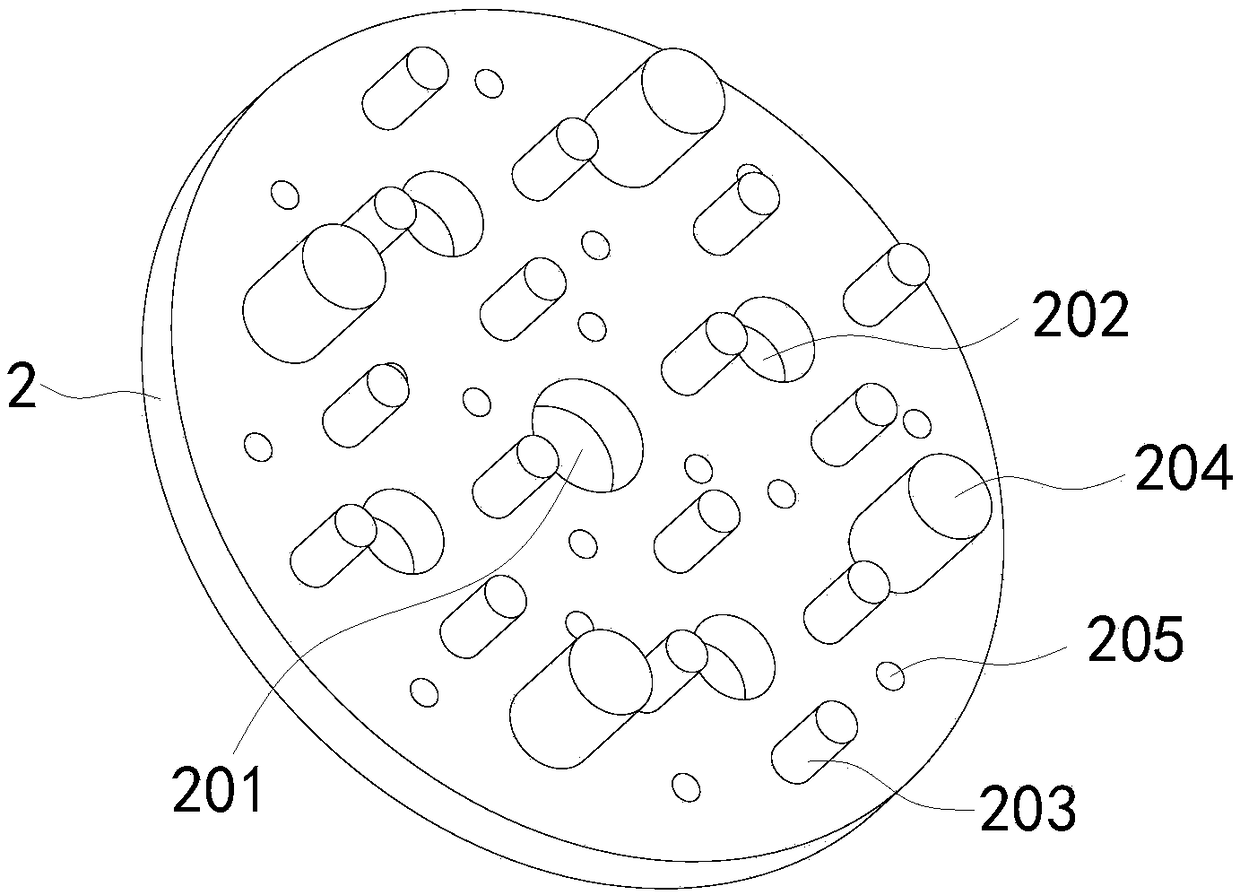

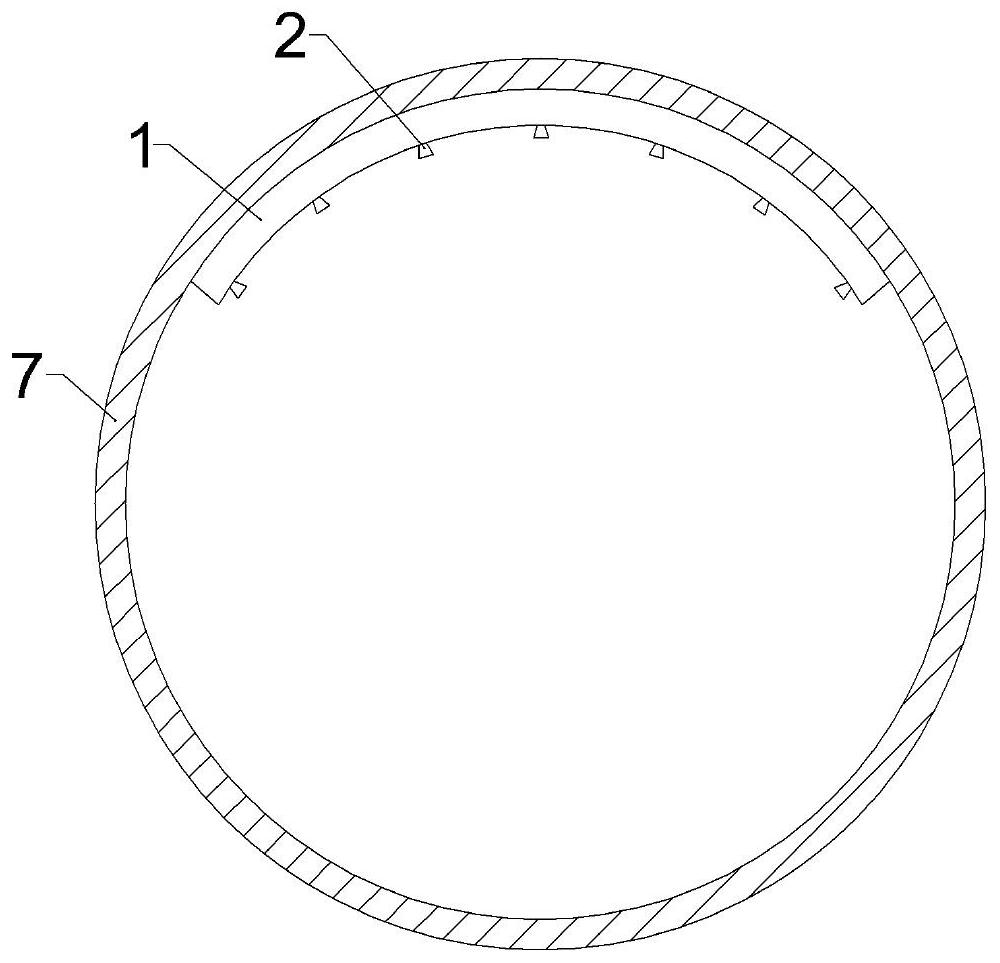

Immersion type bearing cleaning device

The invention discloses an immersion type bearing cleaning device, relating to the technical field of bearing processing equipment. The immersion type bearing cleaning device comprises a box body, anda box cover is buckled on the top surface of the box body. A slag outlet and a liquid inlet are respectively formed in the peripheral side faces of the bottom of the box body, and a fixed pillar is fixedly arranged in the middle of the inner wall of the bottom surface of the box body. A plurality of first support pillars are uniformly and fixedly arranged on the inner wall of the bottom surface of the box body, and a plurality of cleaning discs are arranged in the inner part of the box body. The liquid inlet communicates with the liquid outlet of a water pump through a connecting pipe, and the liquid inlet of the water pump is inserted into a cleaning solution. A first through hole being in clearance fit with the fixed pillar is formed in the middle of the upper surface of each cleaning disc, and a plurality of second through holes arranged on a circumferential direction and about the first through hole are uniformly distributed on each cleaning disc. The cleaning solution is poured into the box body, a bearing sleeved on a fixed rod is disturbed by an airbag under the rotation of a transmission rod, and finally the bearing is cleaned. The cleaning efficiency of the bearing is improved, and the damage to the bearing is avoided.

Owner:界首市皖俊轴承有限公司

Sealing rubber pad convenient to disassemble and assemble

InactiveCN111043312AEasy to installEasy to disassembleEngine sealsStructural engineeringMechanical engineering

Owner:TIANJIN HONGRUI RUBBER

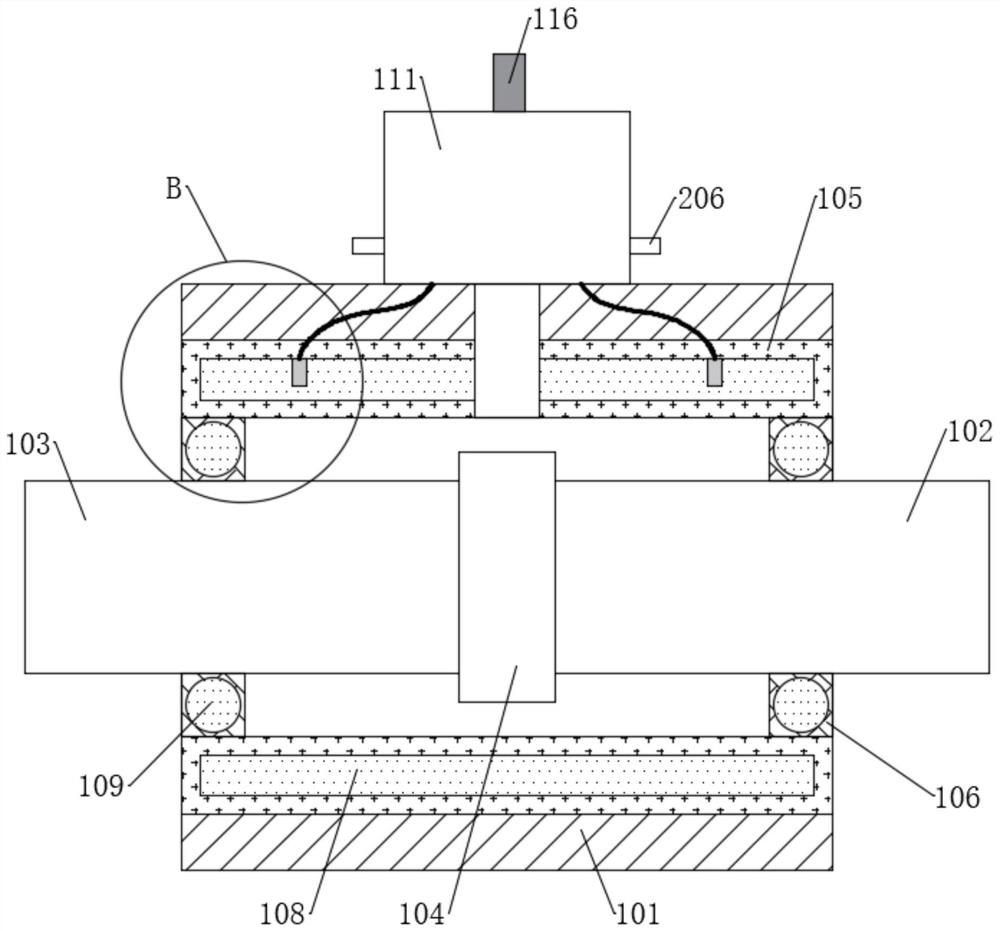

Double-way pipe fitting groove pressing machine

InactiveCN108311569AEasy to operateEasy to useMetal-working feeding devicesPositioning devicesPipe fittingPulp and paper industry

The invention discloses a double-way pipe fitting groove pressing machine and relates to the technical field of processing of a groove of a pipe fitting. The double-way pipe fitting groove pressing machine comprises a fixed pedestal; the two ends of the fixed pedestal are in slip connection with movable pedestals correspondingly; the sides, close to each other, of the two movable pedestals are rotatably connected with supporting rollers correspondingly; the two supporting rollers are coaxial; driving mechanisms for driving the supporting rollers to rotate are arranged at the ends, far away from each other, of the two supporting rollers correspondingly; groove pressing wheels which are in slip connection with the pedestal are arranged on the circumferential outer sides of the supporting rollers; the axis direction of the groove pressing wheels is as same as that of the supporting rollers; and the pressing wheels can abut against the circumferential surfaces of the supporting rollers. The double-way pipe fitting groove pressing machine solves the problems of high labor intensity, tedious operation and low processing efficiency when the two ends of the pipe fitting need to be subjected to groove processing in the prior art, and achieves the advantages of capability of processing grooves at the two ends of the pipe simultaneously, low labor intensity, simplicity in operation and convenience in use.

Owner:青岛世纪翔通管业有限公司

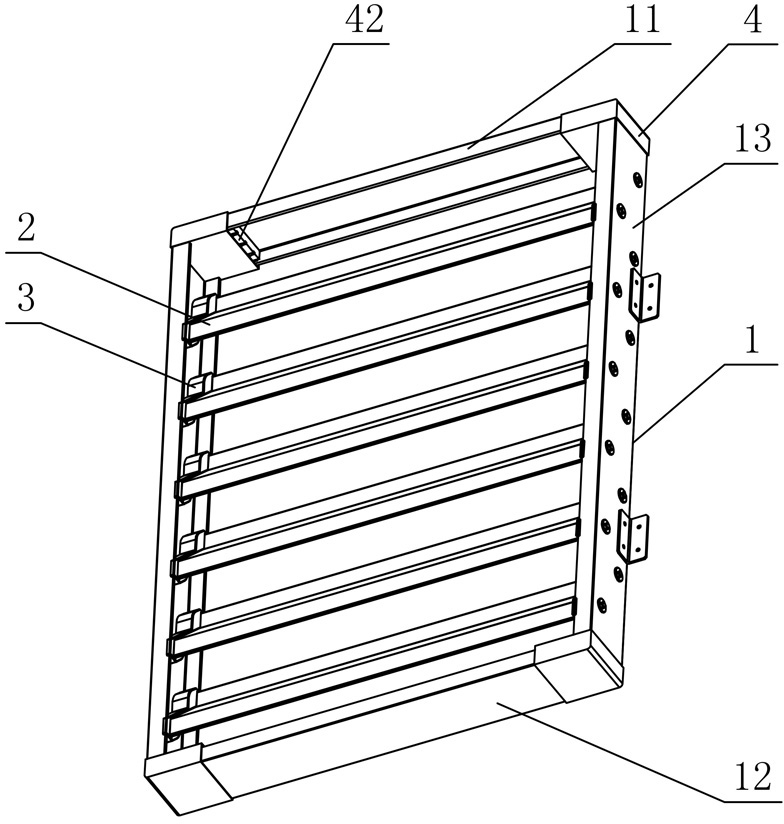

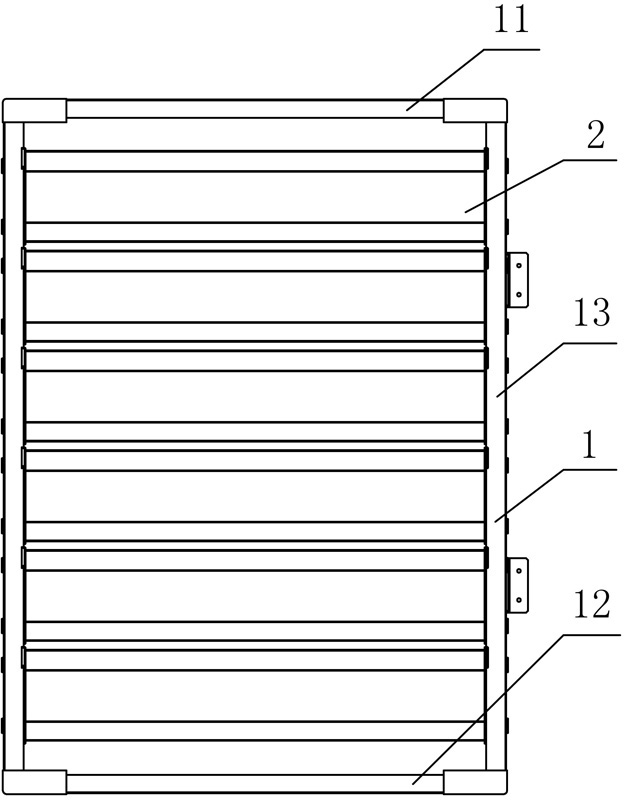

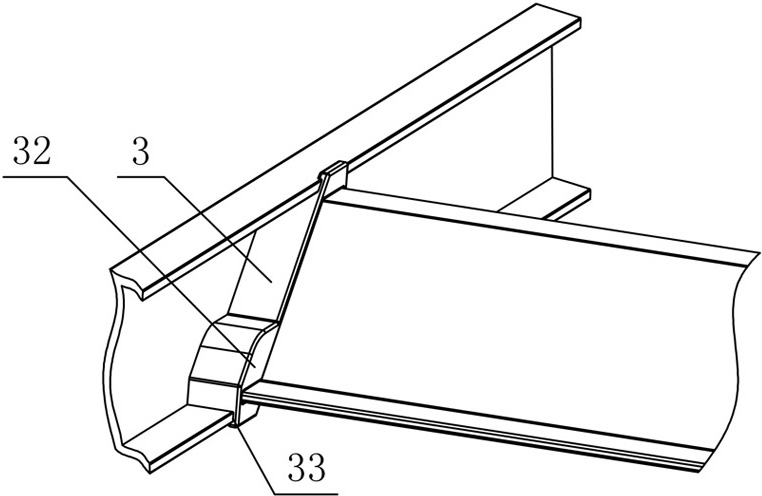

Method for assembling surface coating galvanized steel sheet shutter and shutter

InactiveCN101892798AImprove installation efficiencySimple structureSpecial door/window arrangementsSheet steelEngineering

The invention discloses a method for assembling a surface coating galvanized steel sheet shutter. The shutter comprises a top beam, a bottom beam, two side beams, a plurality of vanes and a plurality of vane fixing pads, wherein the two side beams are channel beams. The assembling method comprises the following steps of: sleeving a vane fixing pad at two ends of each vane respectively, placing the vane fixing pads at two ends of the vane into the notches of the side beams, regulating the position of the vane, then connecting and fixing the vane fixing pads and the side beams by fasteners so as to finish the assembly of one vane, and connecting and fixing the side beams, the top beam and the bottom beams to form a frame body after all the vanes are assembled. The method has simple operation and high assembling efficiency. The invention also discloses the shutter manufactured by the method. The vane fixing pad is sleeved at the two ends of each vane of the shutter respectively, the vane fixing pads are placed into the notches of the side beams, and the vane fixing pads are connected and fixed with the side beams by the fasteners. The shutter has the advantages of simple structure, convenience for assembling hinges on sides and strong adaptability.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

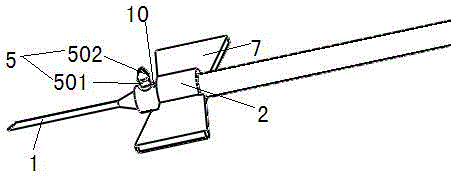

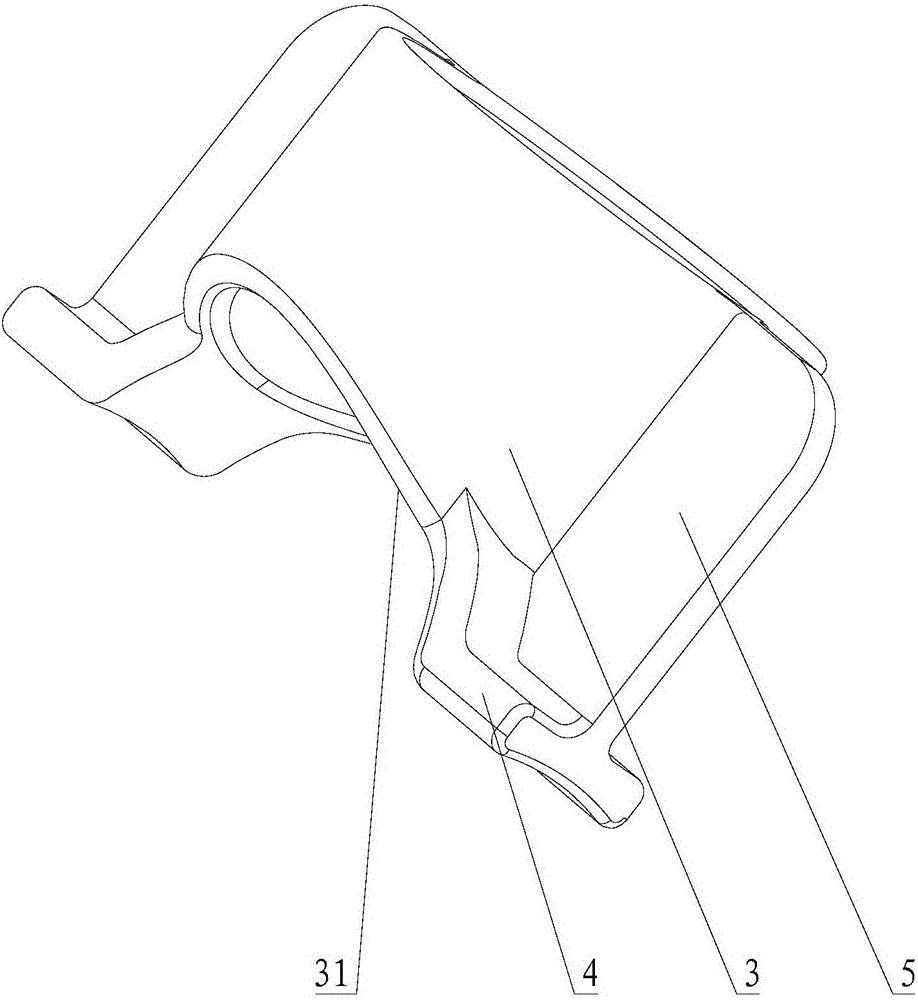

Blood sampling needle protective sleeve and multi-tube blood sampling device

InactiveCN104055528AVersatilityEase of mass productionDiagnostic recording/measuringSensorsBlood samplingSyringe needle

The invention discloses a blood sampling needle protective sleeve which comprises a needle base provided with a needle base and a protective sleeve rotatably connected with the needle base by virtue of a first connecting structure, wherein the first connecting structure comprises a connecting convex column molded at the needle base and a connecting hole formed in the connecting end of the protective sleeve, and the connecting hole is rotatably buckled with the connecting convex column; the blood sampling needle protective sleeve further comprises a locking structure capable of locking the protective sleeve at an initial position; the locking structure comprises a lateral wing and a clamping slot, the lateral ring is molded at the needle base and radially extends, and the clamping slot is formed in the side wall of one side, adjacent to the lateral ring, of the protective sleeve and can be buckled with the lateral ring at the initial position. According to the blood sampling needle protective sleeve, the protective sleeve can be connected with any needle base by virtue of the first connecting structure, so that the protective sleeve has commonality and can be produced in batches; the locking structure can be used for locking the protective sleeve at the initial position, so that the protective sleeve is prevented from rotating randomly, further influencing the visual lines of medical care personnel and reducing the working efficiency in a needle head use process.

Owner:汪贤宗 +2

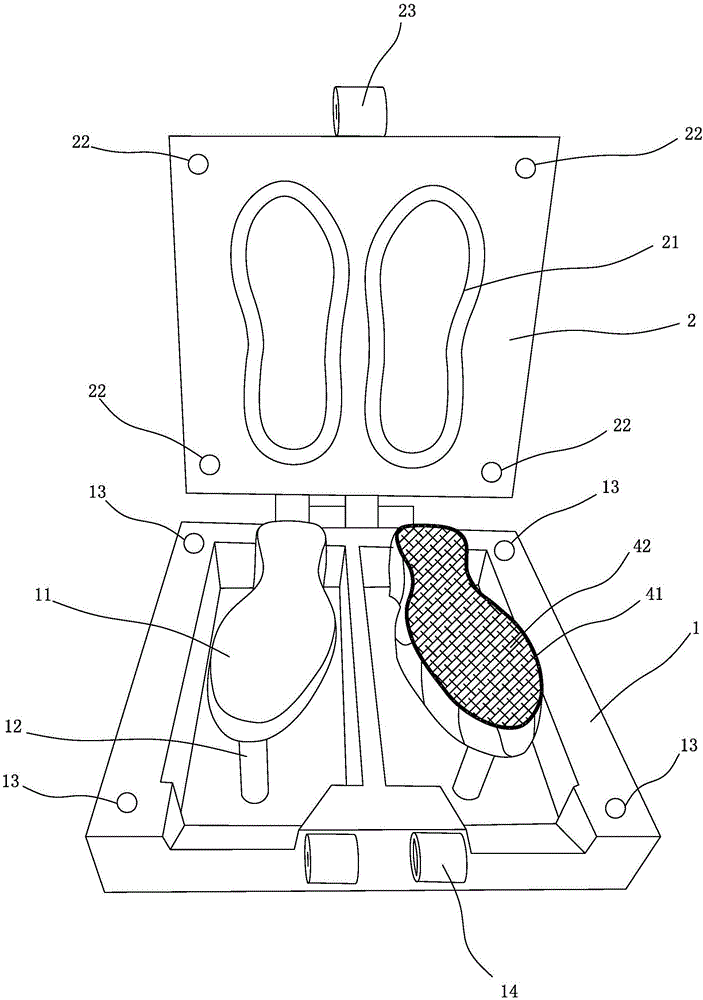

Rubber sole injection mold and injection molding method

ActiveCN106739055ASave fitting stepsReduce labor costsDomestic footwearInjection molding machineMaterials science

The invention provides a rubber sole injection mold and an injection molding method. The injection mold comprises an upper mold body, a middle mold body and a lower mold body which are sequentially combined. A shoe tree capable of being sleeved with an upper is arranged on the lower mold body. An up-down-through upper peripheral banding hole is formed in the middle mold body. A sole forming groove and injection holes communicating with the sole forming groove are formed in the upper mold body. During mold combination, the upper periphery is banded by the upper peripheral banding hole and the shoe tree, a closed sole mold cavity is defined by the middle mold body, the shoe tree, the upper periphery and the sole forming groove, one-time injection combination of the rubber sole and the sewed upper can be achieved by means of the rubber sole injection mold, and the fit step of the rubber sole and the upper is omitted, so that the labor cost is saved, and the production efficiency is improved.

Owner:HUIAN WEISHENG SHOES

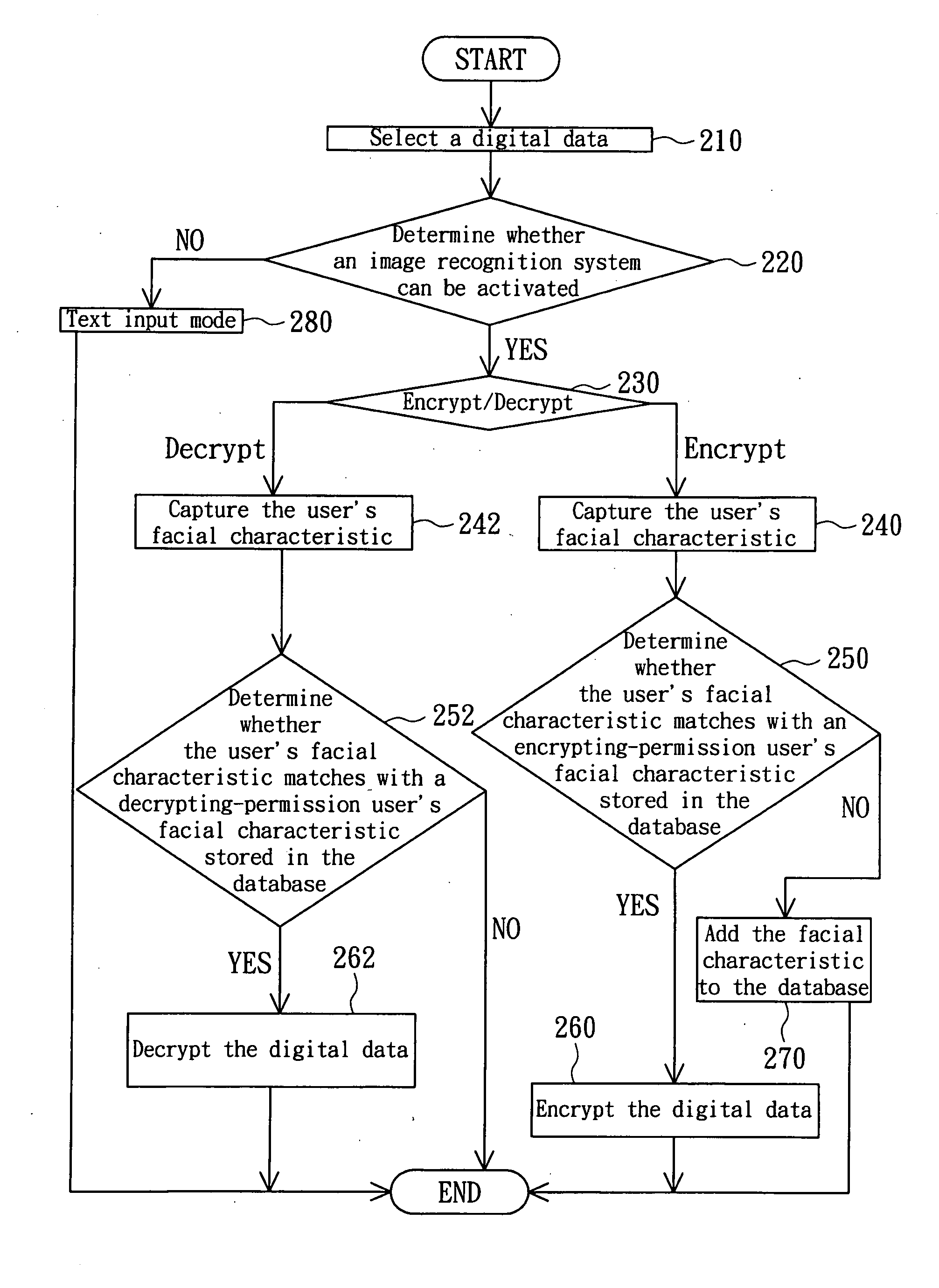

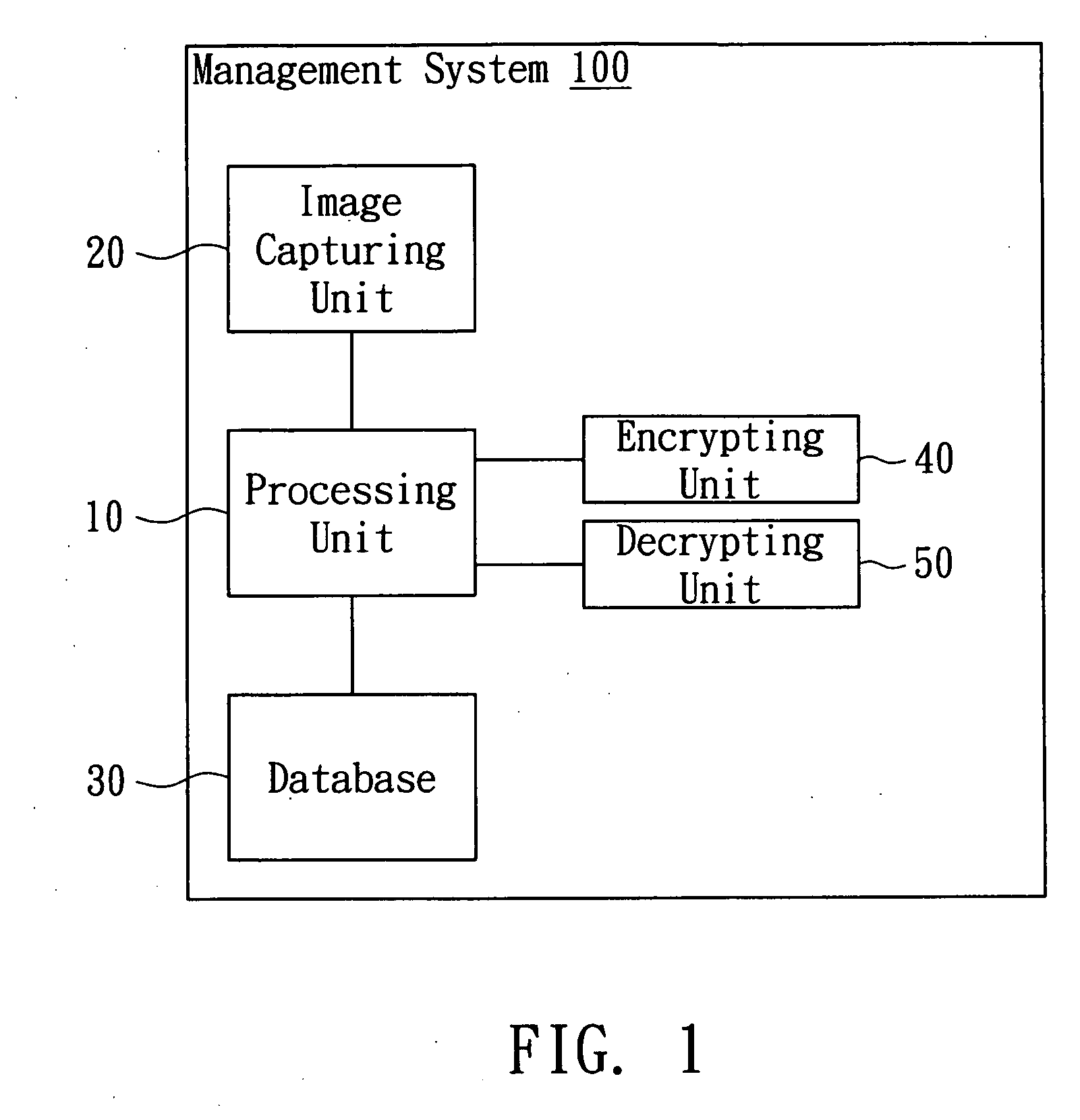

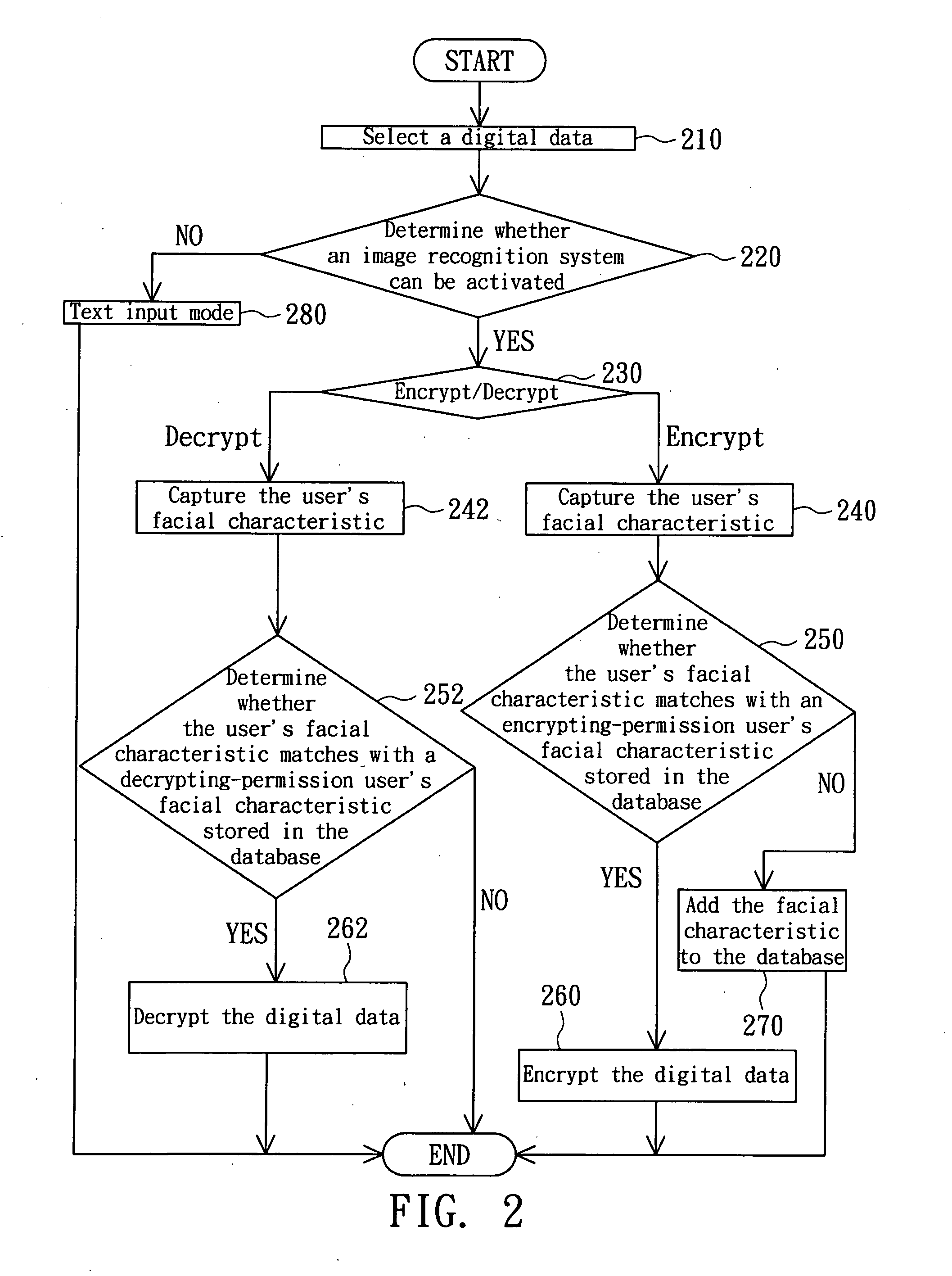

Computerized data management method and computerized data management system using the same

InactiveUS20090055653A1Easy to manageConvenient setUser identity/authority verificationComputer security arrangementsDigital dataPattern recognition

A computerized data management method and a computerized data management system using the same are provided. The computerized data management method is used for encrypting / decrypting a digital data of an electronic device. The computerized data management method comprises the following steps. Firstly, a user's facial characteristic is captured. Next, whether the user's facial characteristic matches with an encrypting-permission user's facial characteristic stored in a database is determined in an encrypting process. If the user's facial characteristic matches with the encrypting-permission user's facial characteristic stored in the database, then the user is allowed to encrypt a digital data. Then, whether the user's facial characteristic matches with a facial characteristic of a decrypting-permission user corresponding a digital data is determined in a decrypting process. If the user's facial characteristic matches with the facial characteristic of the decrypting-permission user corresponding the digital data, then the user is allowed to decrypt the digital data.

Owner:INVENTEC CORP

Emergency treatment device for leakage of liquid ammonia storage tank

ActiveCN113154254APrevent leakageRealize blockingContainer filling methodsFluid handling accessoriesEmergency treatmentAir pump

The invention relates to the technical field of liquid ammonia safety protection, in particular to an emergency treatment device for the leakage of a liquid ammonia storage tank. The emergency treatment device comprises a detection mechanism for detecting ammonia gas and a spraying mechanism for diluting the ammonia gas, and the emergency treatment device further comprises a sleeve sleeved outside the liquid ammonia storage tank, one end of the sleeve is sealed, the other end of the sleeve is open, and a plurality of partition plates are axially arranged in the sleeve. The free ends of the partition plates are in sliding connection with the surface of the liquid ammonia storage tank, the partition plates divide the space between the sleeve and the liquid ammonia storage tank into a plurality of blocking cavities, an air bag is arranged in each blocking cavity, the air bags are fixed to the sleeve, each air bag communicates with an air pump, and the air pumps are used for inflating and deflating the air bags; and the detection mechanism comprises an ammonia gas detector, the ammonia gas detector is arranged on the face, close to the liquid ammonia storage tank, of the air bag, the ammonia gas detector is electrically connected with a controller, the controller is electrically connected with an alarm, and the controller is further electrically connected with the spraying mechanism and the air pump. According to the emergency treatment device, the air bags are inflated to block a leakage area, and further leakage of ammonia gas is effectively avoided.

Owner:重庆安全技术职业学院

Packaging box for bearing

Owner:HUNAN MEIBEIDA TECH CO LTD

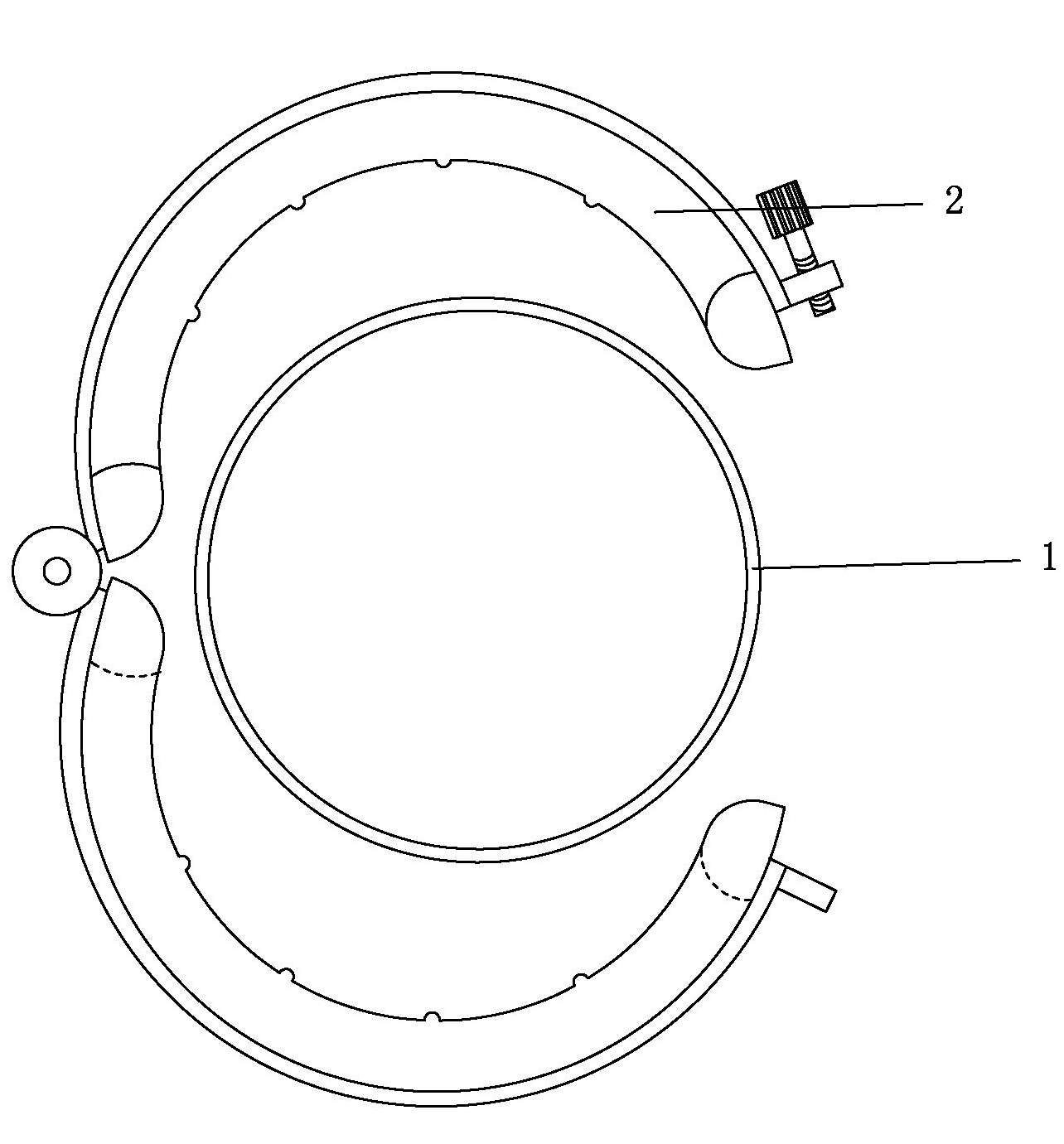

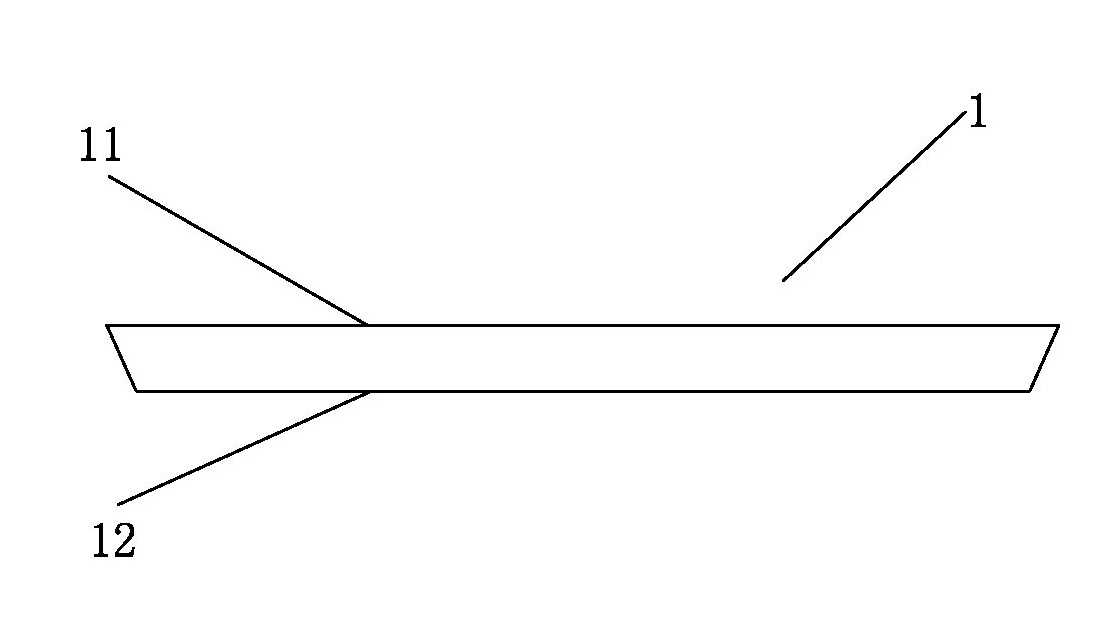

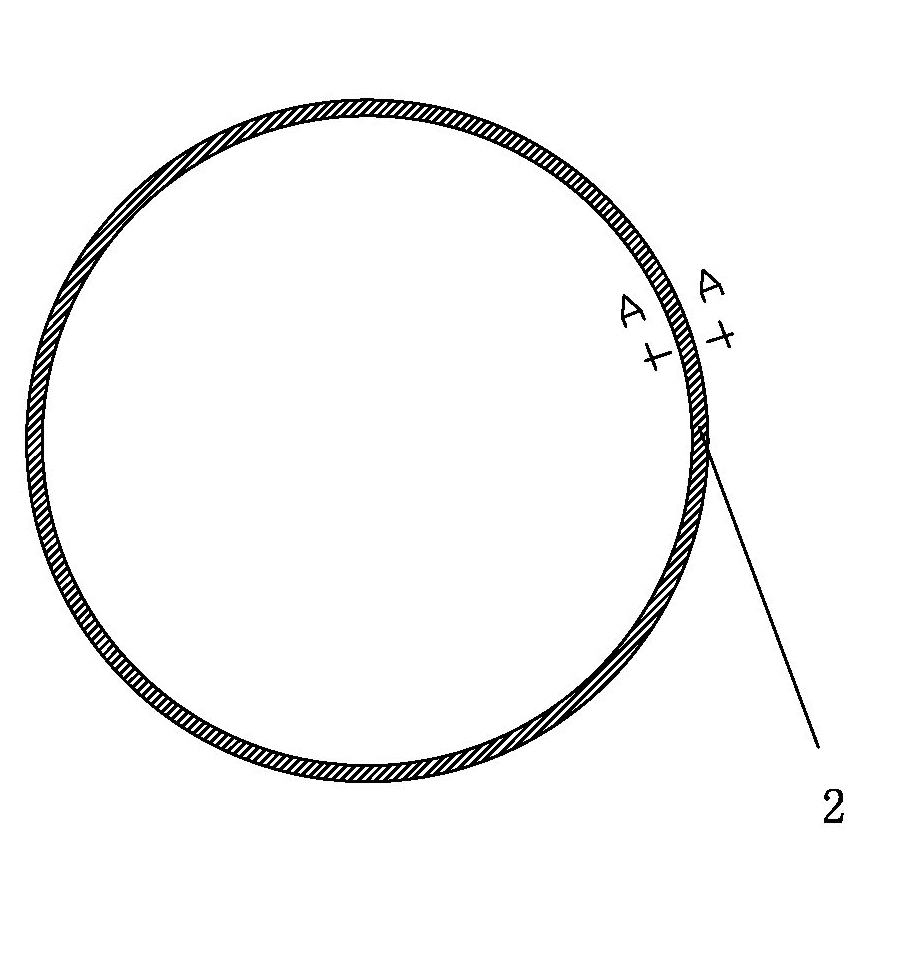

Adjustable sphincter exerciser

ActiveUS20110263396A1Convenient setSets the constriction force of the sphincterClubsResilient force resistorsMuscle strengthPower unit

An adjustable sphincter exerciser (Kegel exercise) includes a flexible tubular member, at least one sleeve mounted to the tubular member; a body inserted into the tubular member, a conductive device connected to the body and located in the tubular member, the conductive device being activated when the tubular member is compressed, a vibration unit electrically connected to the conductive device, and a power unit providing power to the conductive device and the vibration unit. The at least one sleeve can be replaced and has different hardness, when the user squeezes the at least one sleeve and the tubular member to activate the conductive device and the vibration unit, the user is acknowledged the force that sphincter is exercised. The adjustable sphincter exerciser (Kegel exercise) enhances the muscular strength and the muscular endurance of the sphincter.

Owner:BIOINFINITY (M) SDN BHD

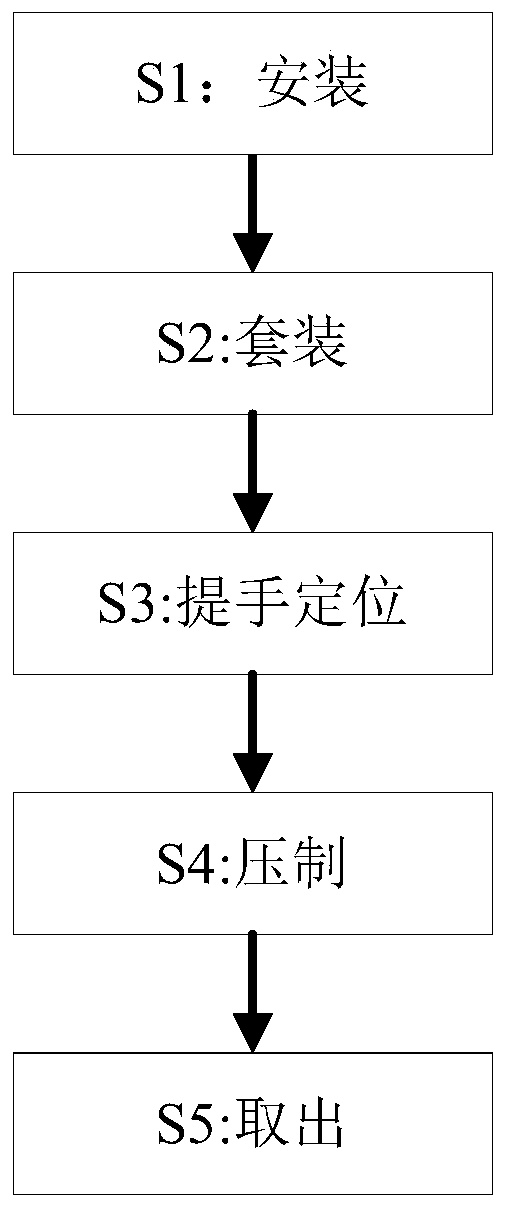

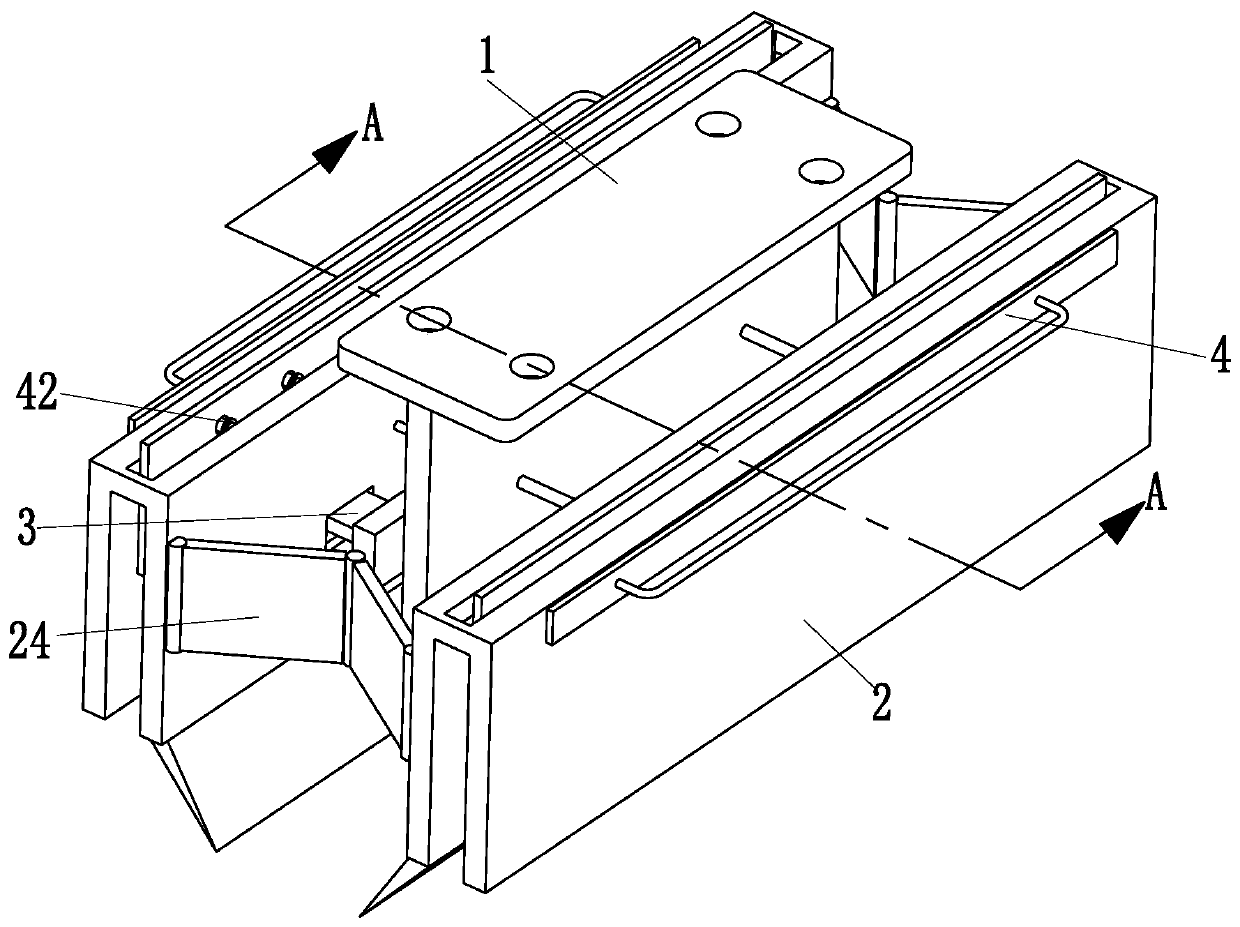

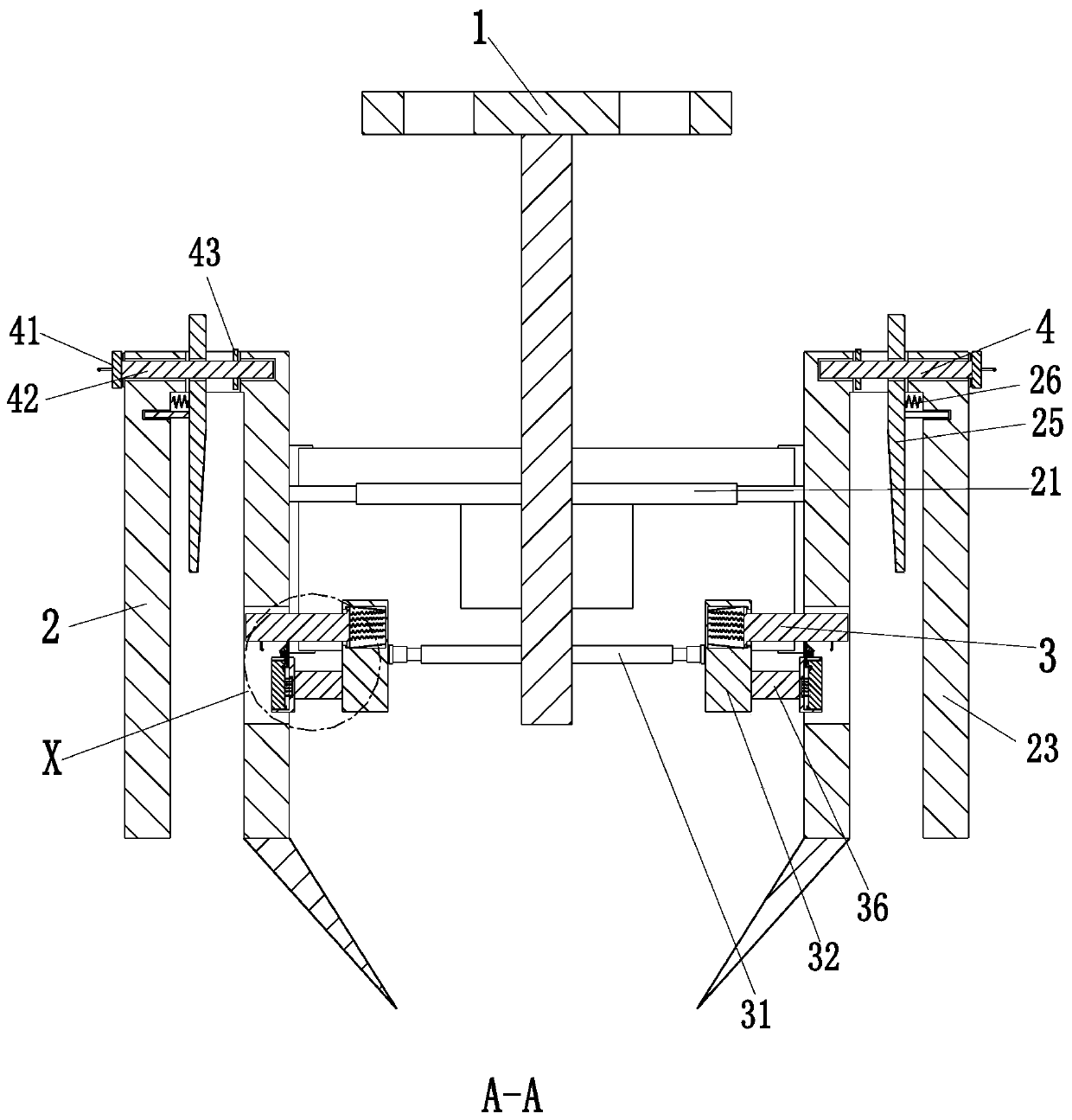

Manufacturing process of non-woven fabric hand bag

ActiveCN111016288AImprove work efficiencyImprove the suppression effectBag making operationsPaper-makingNonwoven fabricMechanical engineering

The invention provides a manufacturing process of a non-woven fabric hand bag. Operation is completed through cooperation of an installation frame, an expansion device, two pressing devices and two handle positioning devices, a problem that the traditional connection mode has many steps and is tedious can be solved, when a lifting handle is adhered to the marking position, manual operation is adopted, problems that the positions of lifting handles of various finished products are slightly different due to small-range dislocation, the lifting handles and a bag body slip due to lubricity of gluesolution during manual pressing, the manual pressing force is not large, and the lifting handles and the bag body possibly fall off in advance before the glue solution is solidified are solved.

Owner:山东绿恒无纺布制品有限公司

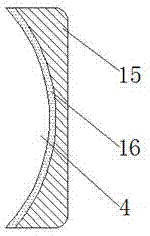

Device and method for mounting oil seal on crankshaft

ActiveCN103567950AEfficient assemblyNo deformationMetal-working hand toolsEngineeringMechanical engineering

The invention discloses a device for mounting an oil seal on a crankshaft. The device comprises a core seat, a press cover and a compression bolt, the core seat is suitable for being detachably mounted on the crankshaft, the oil seal is suitable for being sleeved on the outer surface of the core seat, the press cover is sleeved on the core seat and can be in sliding fit with the core seat, and the compression bolt penetrates the press cover, is in thread fit with the core seat and is used for compressing the press cover and the core seat to the crankshaft in order to push and assemble the oil seal onto the crankshaft. According to the device for mounting the oil seal on the crankshaft, the oil seal can be efficiently assembled onto the crankshaft in a high-precision and deformation-free manner, and the device for mounting the oil seal on the crankshaft is simple in operation and structure, convenient to use, recyclable and low in cost, and can be used in various production environments. The invention further discloses a method for mounting the oil seal on the crankshaft.

Owner:BEIQI FOTON MOTOR CO LTD

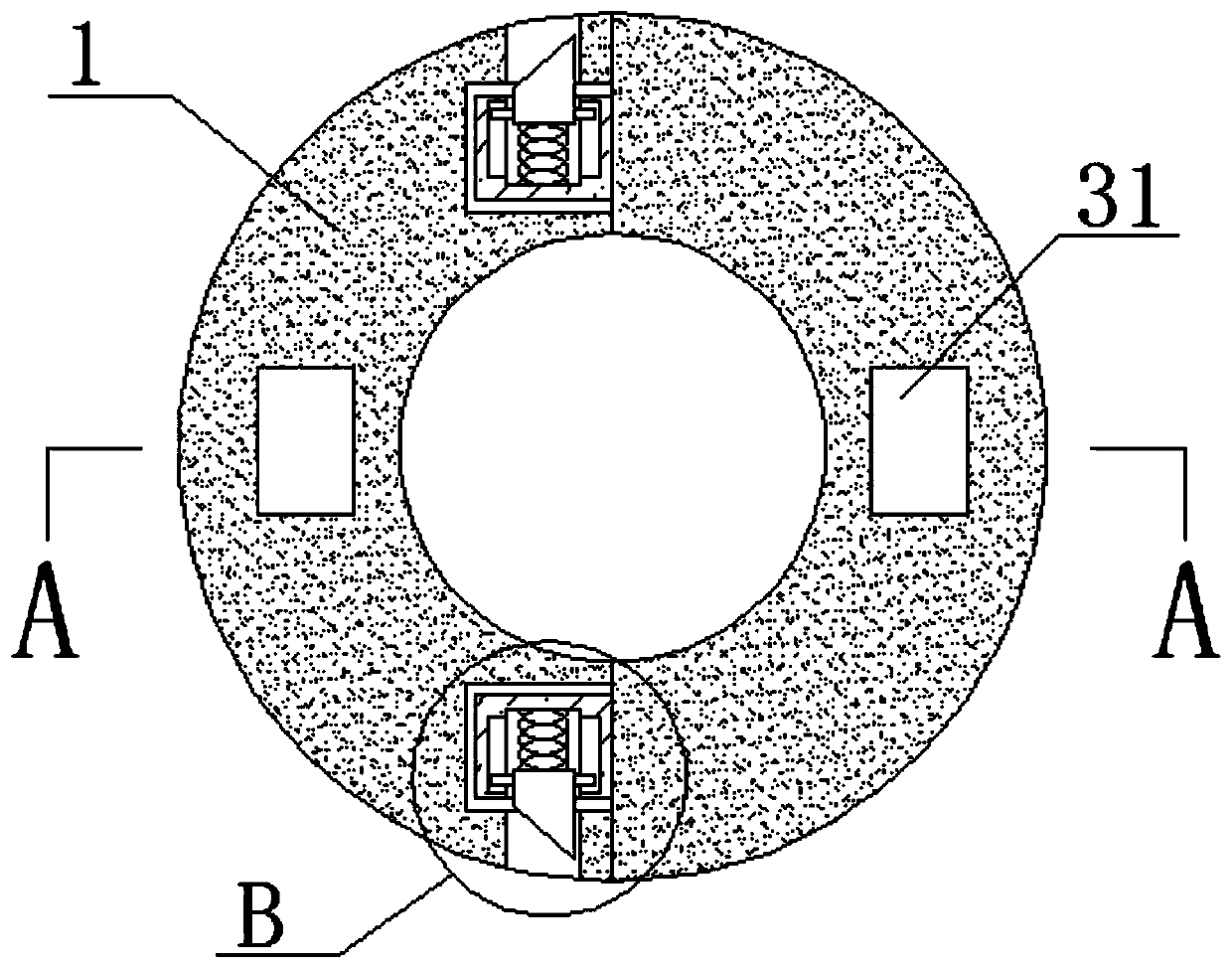

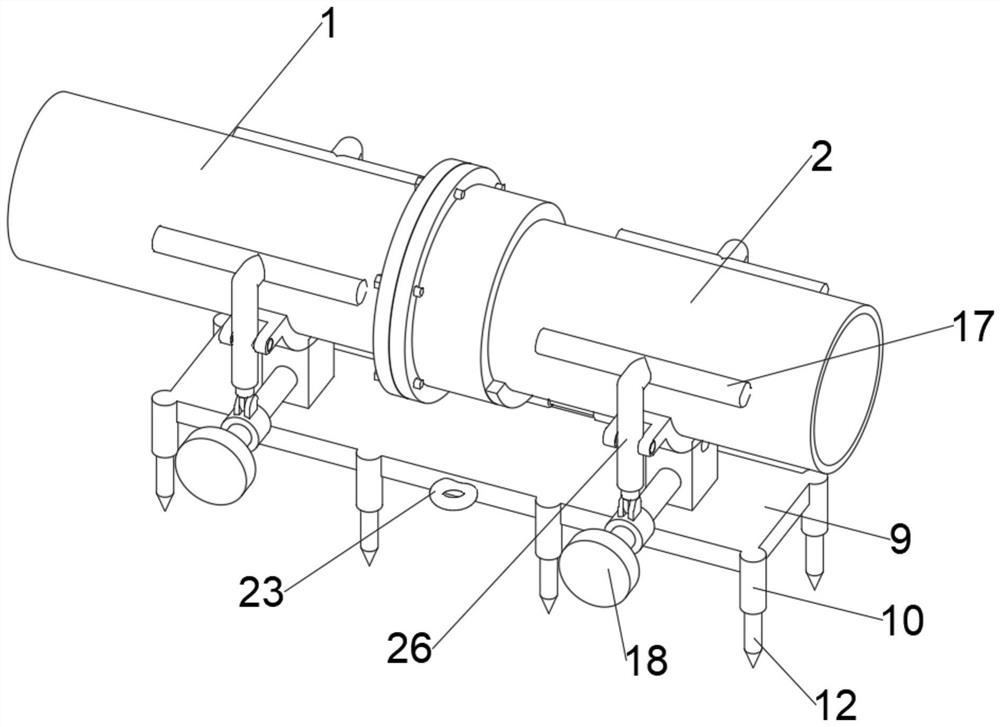

Underground pipeline installation centering device for hydraulic engineering construction

PendingCN113833906AImprove installation efficiencySolve the problem of disturbance and affect the efficiency of dockingPipe laying and repairWork holdersArchitectural engineeringStructural engineering

The invention discloses an underground pipeline installation centering device for hydraulic engineering construction, and belongs to the technical field of hydraulic engineering construction. The underground pipeline installation centering device for hydraulic engineering construction comprises a pipeline A, wherein a pipeline B is arranged at the right side of the pipeline A; a sliding groove is formed in the right portion of the pipeline A; a fixing ring is arranged in the sliding groove; a plurality of bolt holes are formed in the fixing ring; bolt rods are arranged in the bolt holes; the outer side of the left end of the pipeline B is sleeved with a connecting pipe; a wide-opening groove is formed in the right side of the connecting pipe; a limiting ring is arranged in the connecting pipe; a mounting plate is arranged below the pipeline A; a plurality of sleeves are arranged below the mounting plate; springs A and ground plugs are arranged in the sleeves; two arc-shaped plates are symmetrically arranged above the mounting plate; a threaded rod is arranged below the arc-shaped plates; two sleeve rings are symmetrically arranged on the threaded rod; sliding rods are connected to the upper portions of the sleeve rings; and the sleeves are connected to the upper portions of the sliding rods. By using the underground pipeline installation centering device, a user can conveniently install a pipeline.

Owner:王召

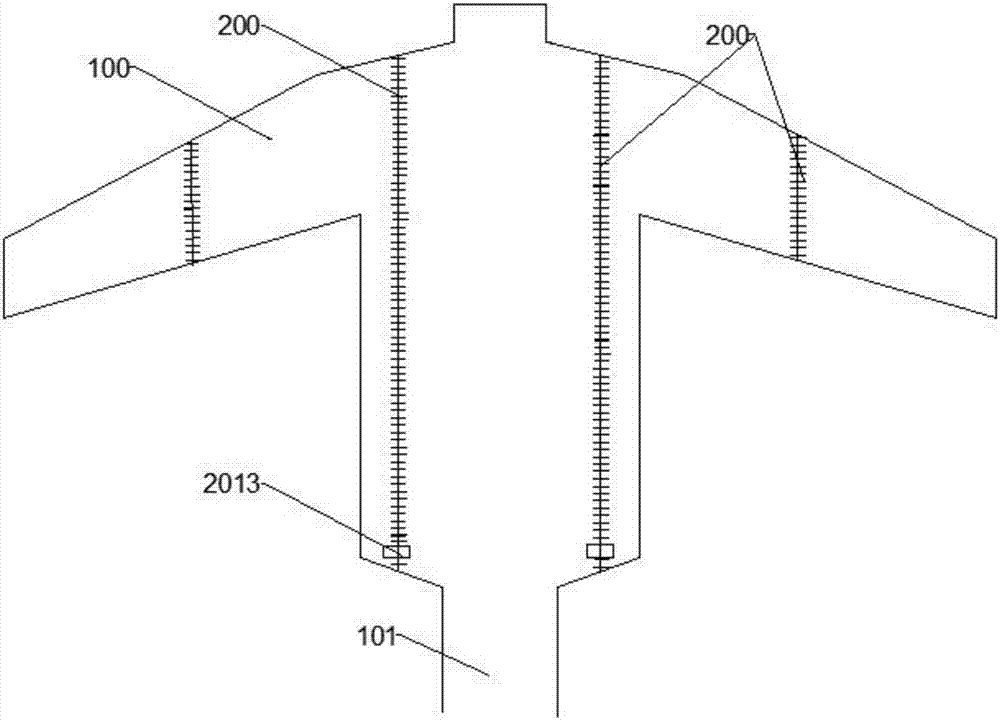

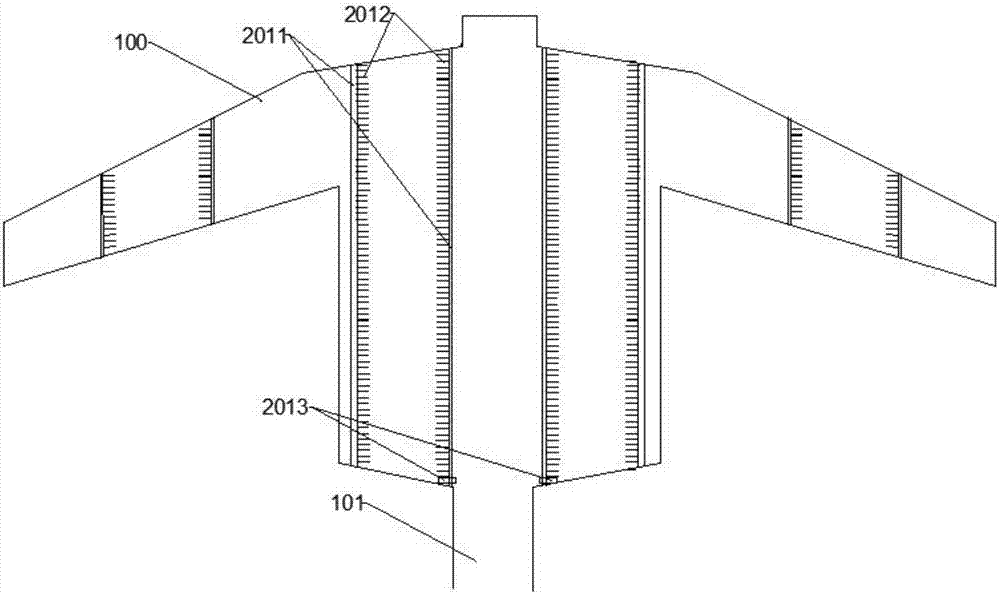

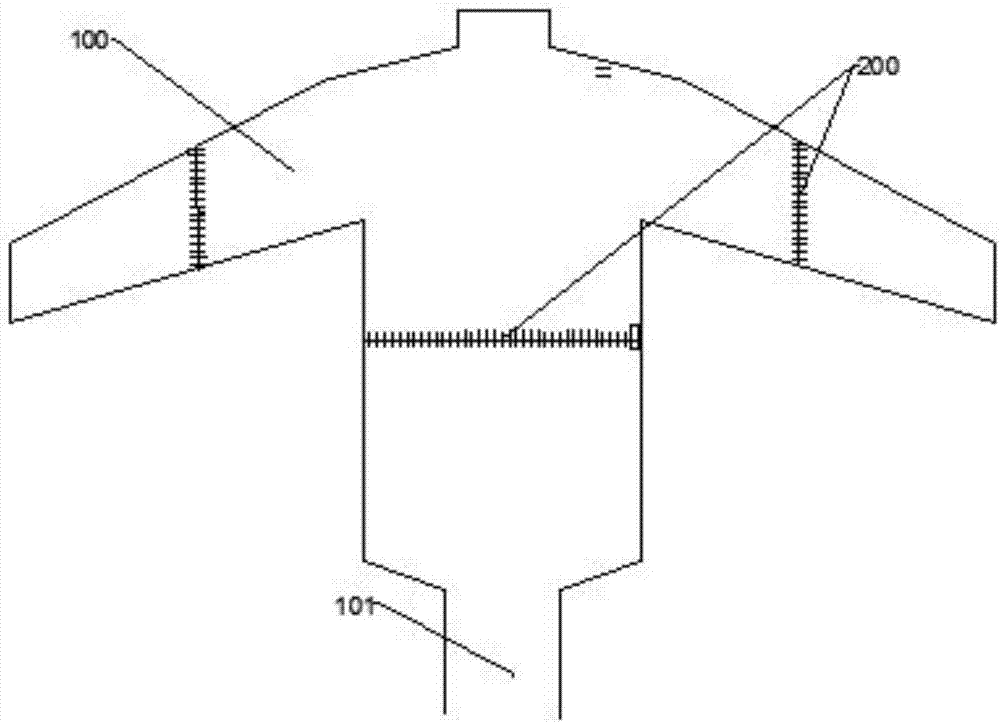

Clothes supporting device and fast clothes dryer with the clothes supporting device

ActiveCN107881737ALow costFirmly connectedOther drying apparatusTextiles and paperPulp and paper industry

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE +1

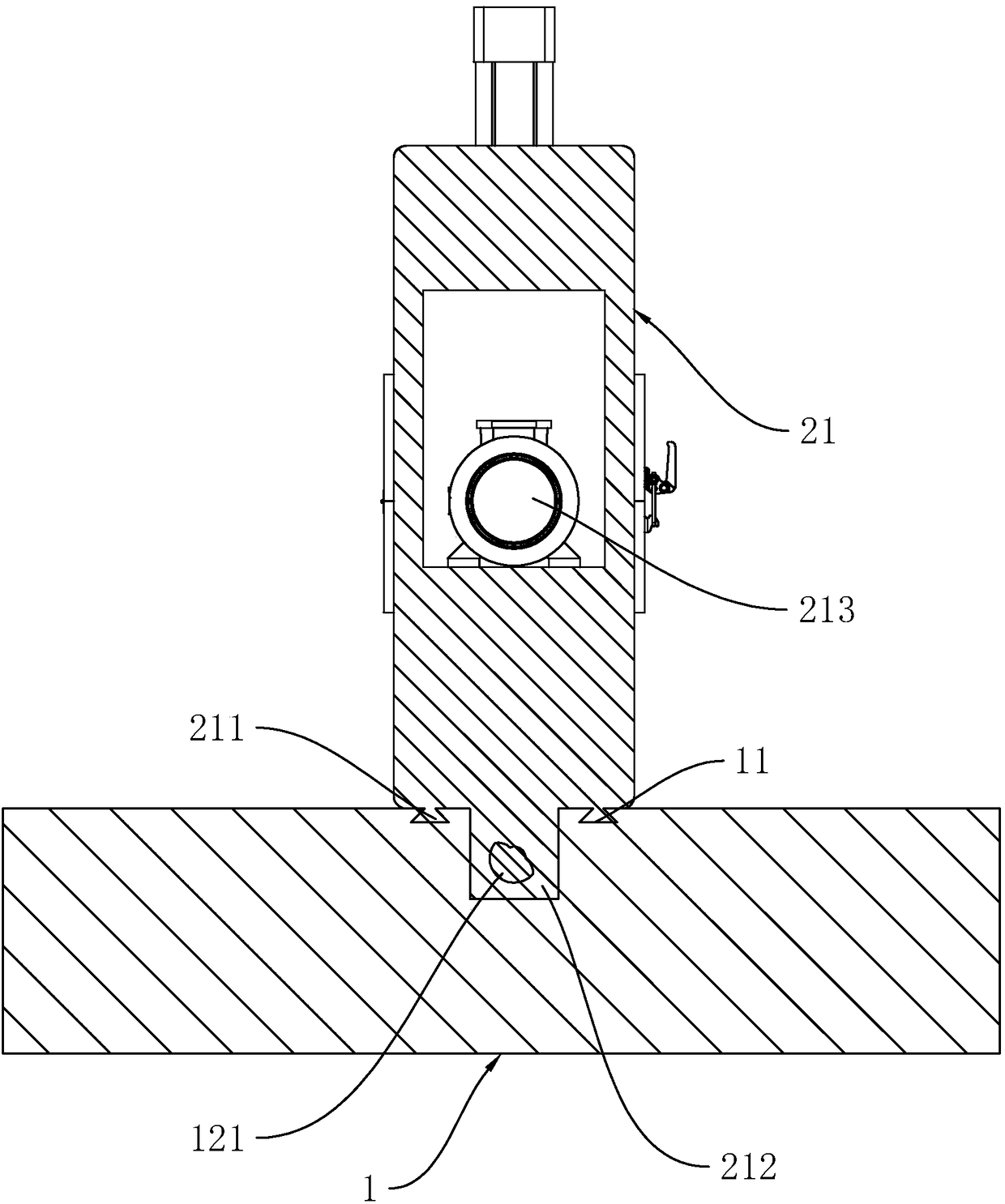

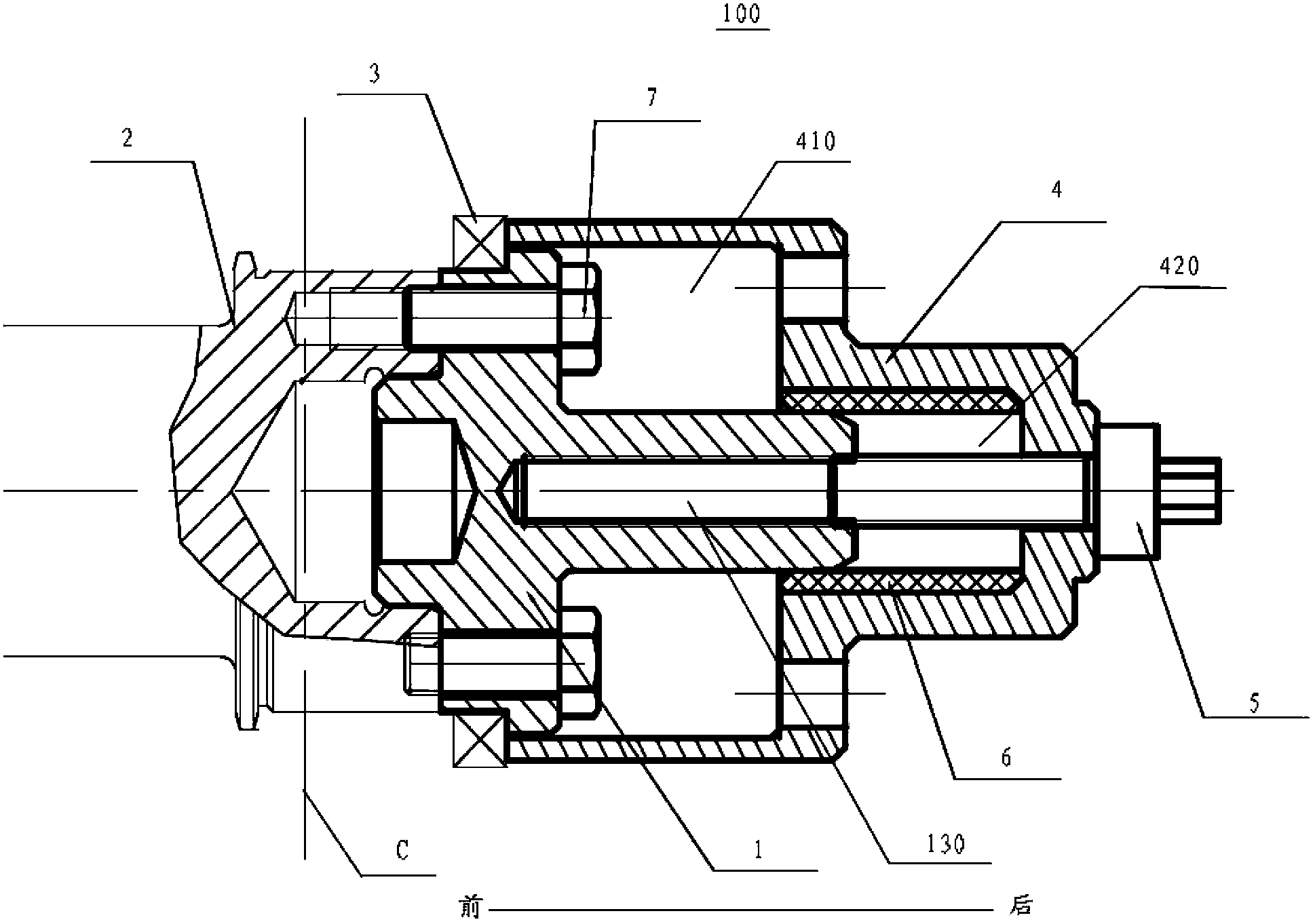

Bevel gear pair detection and assembling method

ActiveCN108871158AReduce frictional resistanceConvenient setMechanical counters/curvatures measurementsMetal working apparatusEngineeringElectrical and Electronics engineering

The invention discloses a bevel gear pair detection and assembling method comprising the following steps: connecting a first bevel gear on a vertical plug socket, connecting a second bevel gear on a horizontal plug socket, and enabling the second bevel gear to enter an engaged state; rotating the second bevel gear, and detecting the engaged state of the two bevel gears; determining the bevel gearpair to be qualified if the engaged state of the two bevel gears complies with design requirements, otherwise entering the next step; moving the bevel gear axial position, rotating the second bevel gear, detecting the engaged state of the two bevel gears until the engaged state of the two bevel gears complies with the design requirements, and correspondingly recording the axial mobile distance ofthe bevel gear; correspondingly adjusting the axial position of the bevel gear according to the detected axial mobile distance in an assembling process, and enabling the engaged state of the assembledtwo bevel gears to comply with the design requirements. The method can reduce equipment making and detection precision requirements, thus greatly reducing the making cost, and improving the production efficiency and assembling precision.

Owner:浙江恒星传动科技有限公司

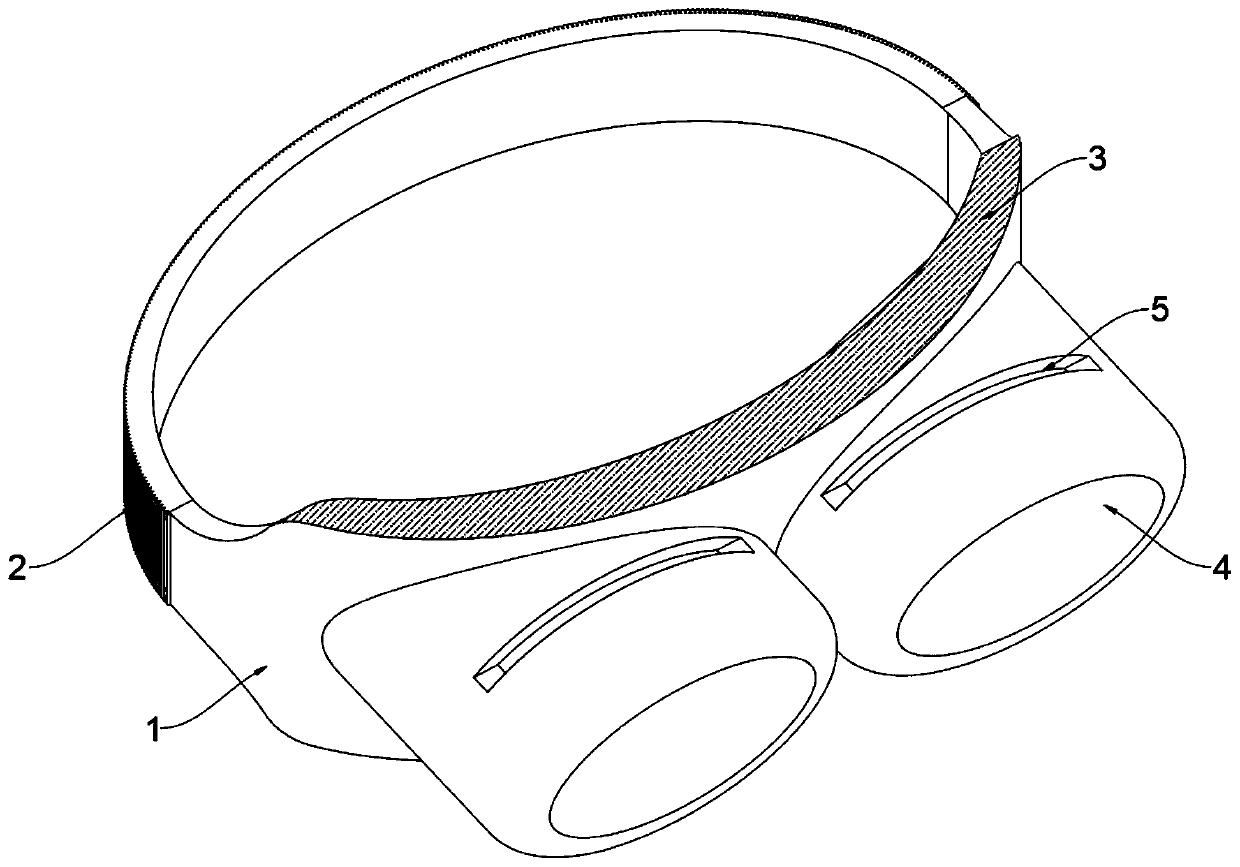

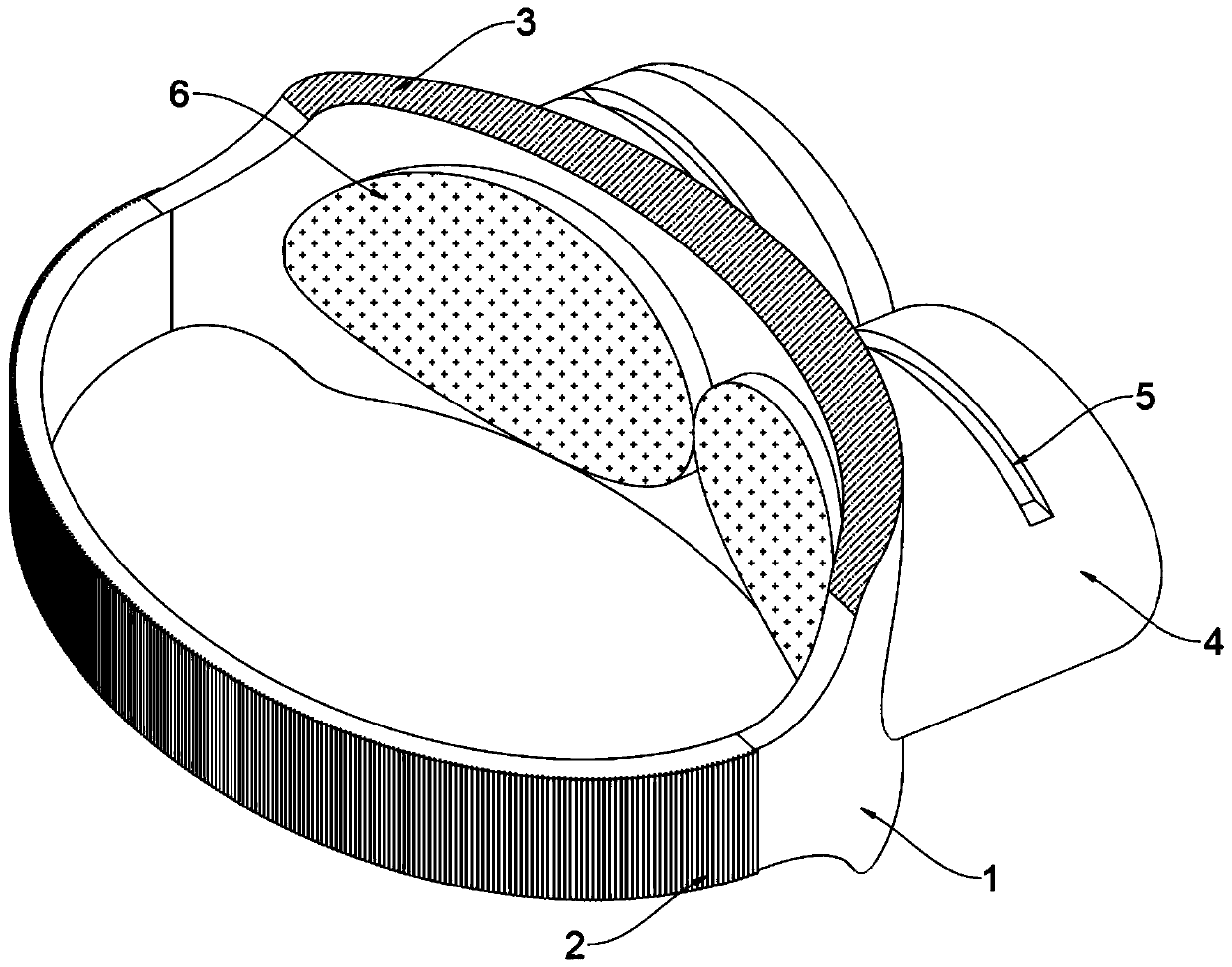

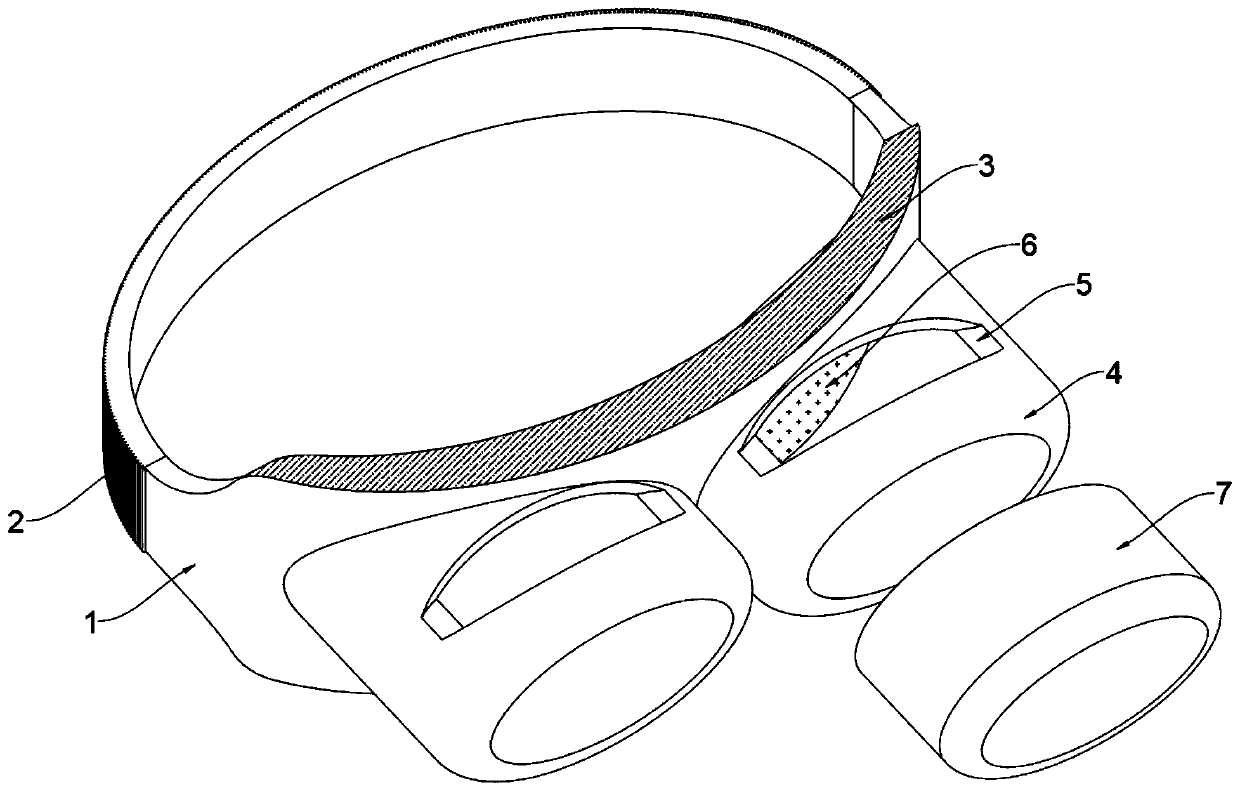

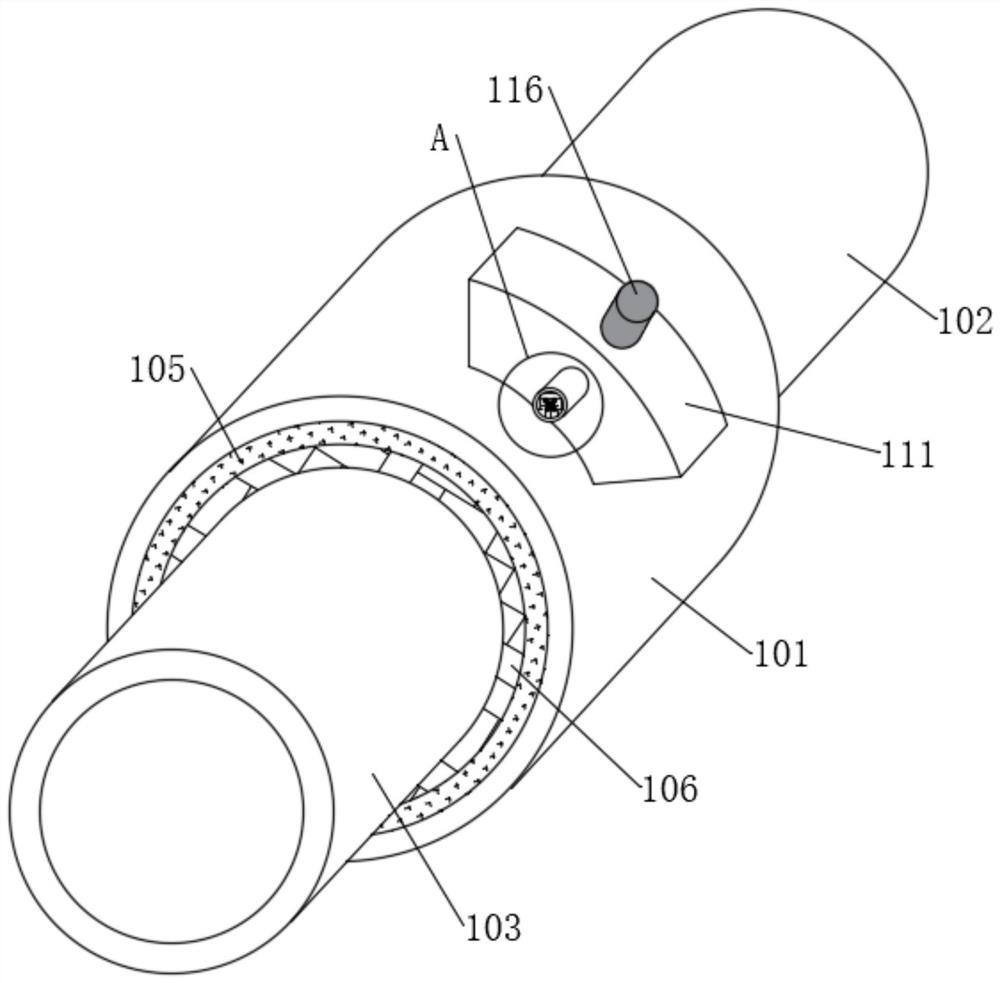

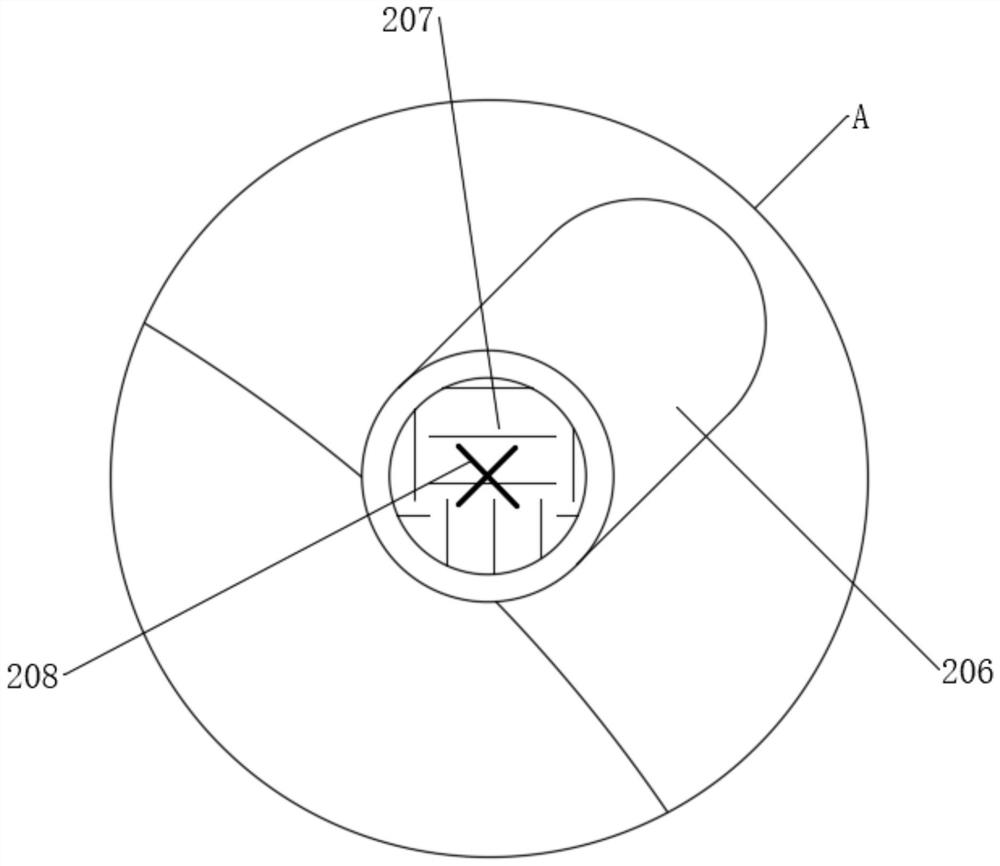

Double eyelid plasty postoperative nursing cold compress bag

The invention belongs to the technical field of cold compress bags and relates to a double eyelid plasty postoperative nursing cold compress bag. The double eyelid plasty postoperative nursing cold compress bag includes a nursing eye bag; the nursing eye bag is a flat and arc-shaped; two sides of the nursing eye bag are connected together through an elastic band; elastic binding side wings are arranged at the upper side edge and lower side edge of the nursing eye bag; cold compress bags are symmetrically arranged at the front end surface of the nursing eye bag; each cold compress bag is in a semi-arc shape and embedded into the nursing eye bag; an opening is formed in the upper portion of each cold compress bag; cotton cloth is arranged at the inner side of each cold compress bag; and a water containing rubber glove is placed in each cold compress bag. According to the double eyelid plasty postoperative nursing cold compress bag of the invention, the nursing eye bag is connected through the elastic band, and therefore, the whole double eyelid plasty postoperative nursing cold compress bag can conveniently sleeve the head of a user, and the double eyelid plasty postoperative nursingcold compress bag can stretch and contract to be suitable for different head circumferences. With the elastic binding side wings adopted, the nursing eye bag can be more tightly attached to the eyesof the patient. The water containing rubber gloves can be additionally arranged in the nursing eye bag conveniently, and the cotton cloth at the cold compress bags is used in combination with the water containing rubber gloves, and therefore, the whole nursing eye bag can be attached to the eyes more closely so as to press the eyes to realize hemostasis and cold compress.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

Leakage reminding barrel for natural gas pipeline joint

InactiveCN113432045AEliminate potential safety hazardsImprove securityPipeline systemsElectrically conductiveStructural engineering

The invention discloses a leakage reminding barrel for a natural gas pipeline joint, and belongs to the technical field of natural gas. Through the arrangement of an outer sleeve and related components, when the pipeline joint leaks, leaked natural gas can enable an elastic film to protrude upwards, so that a switch button is automatically triggered to turn on a power supply, an alarm device can be started to give an alarm, related workers can know the occurrence of gas leakage in time, thereby eliminating potential safety hazards and greatly improving the safety; meanwhile, a conductive rod can be electrified to harden a state changed filling body and shape an elastic tubular bag, so that the sealing effect of the elastic tubular bag can be greatly improved, and the amount of natural gas leaking to the outside of the outer sleeve is remarkably reduced; by arranging a shading tube, the elastic film protrudes upwards, meanwhile, a part of the light-reflecting reminding rod can be automatically exposed out of a shading tube, secondary reminding is given out, the reminding function is enhanced, and practicability is greatly improved.

Owner:胡国府

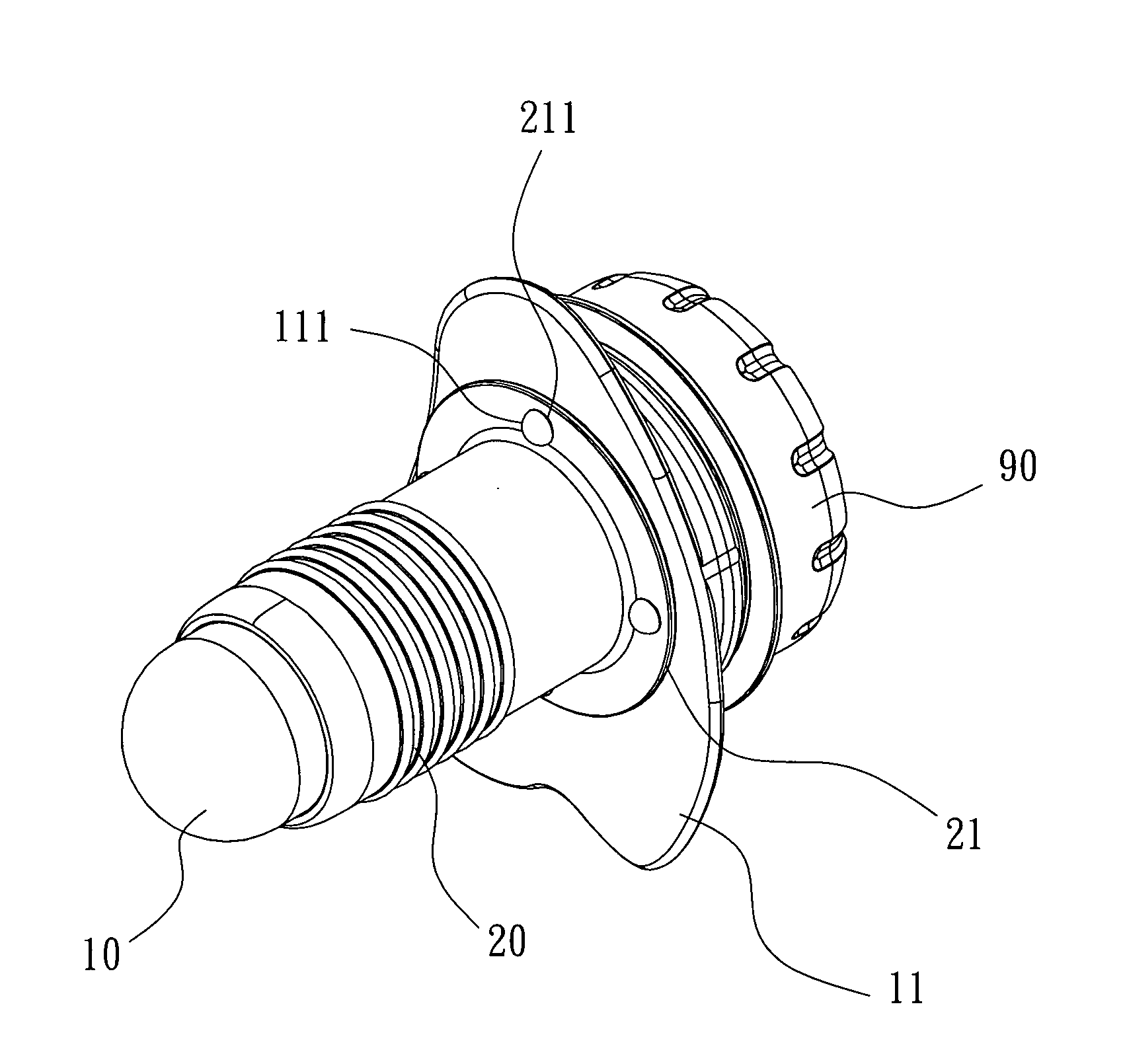

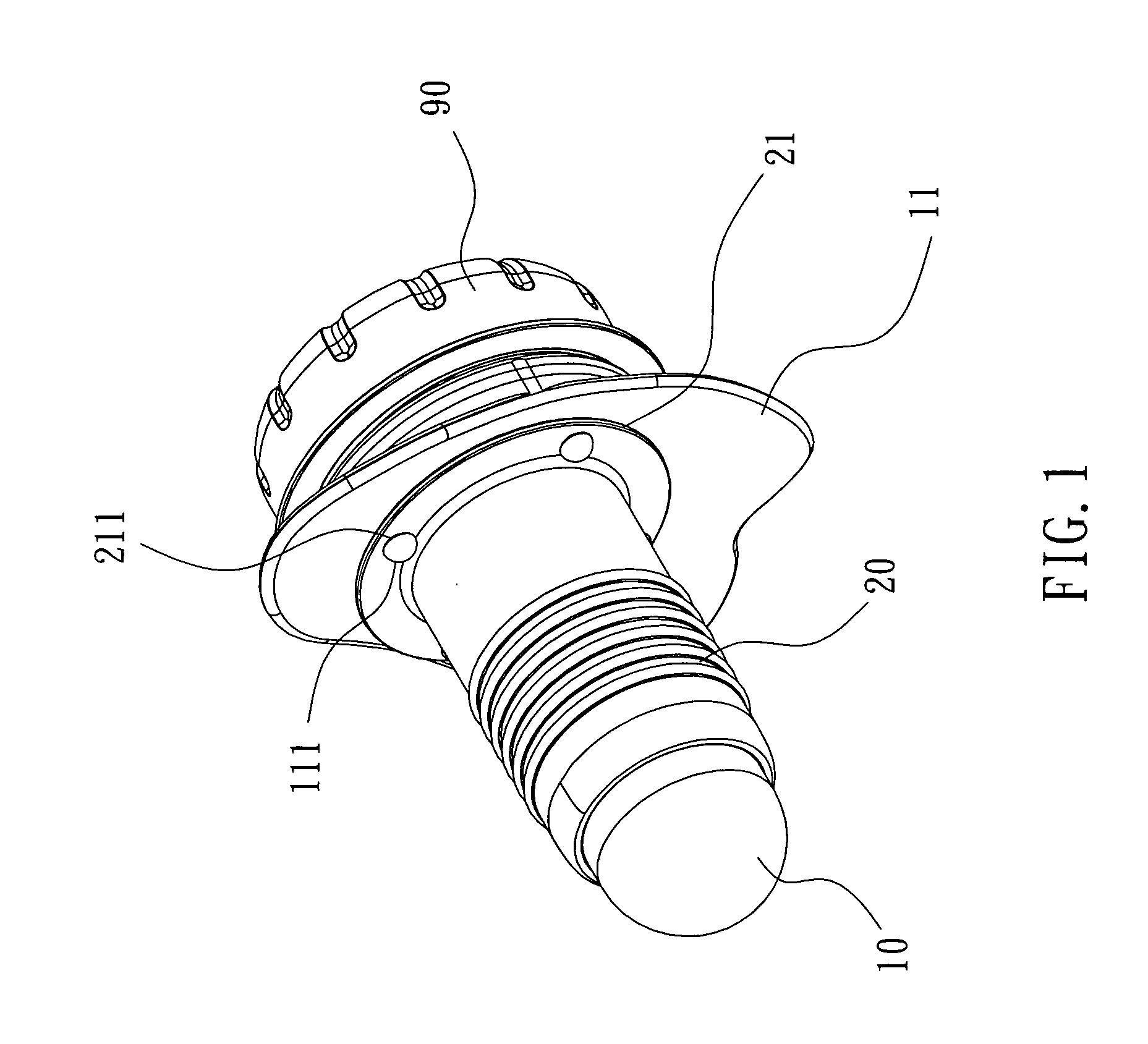

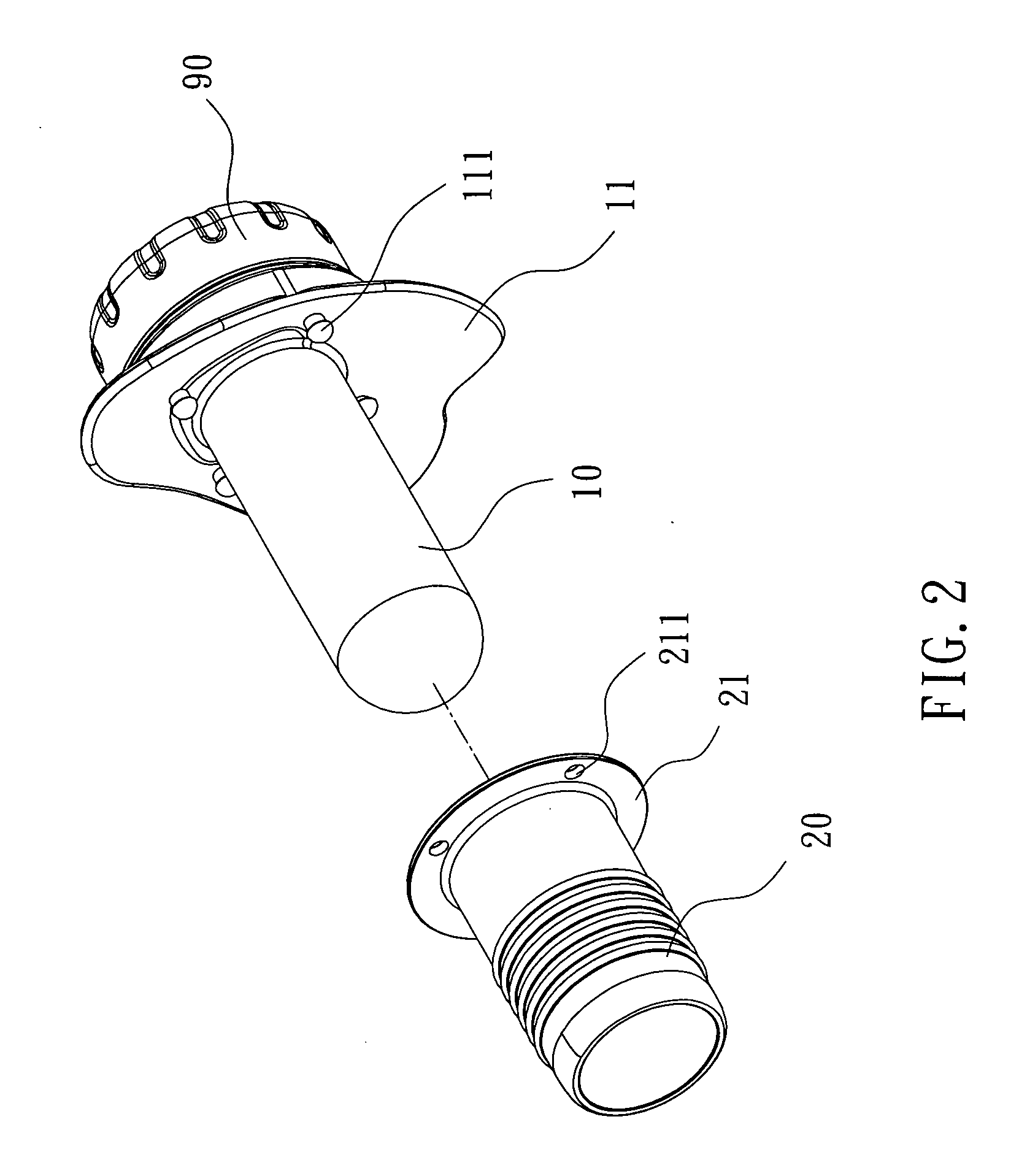

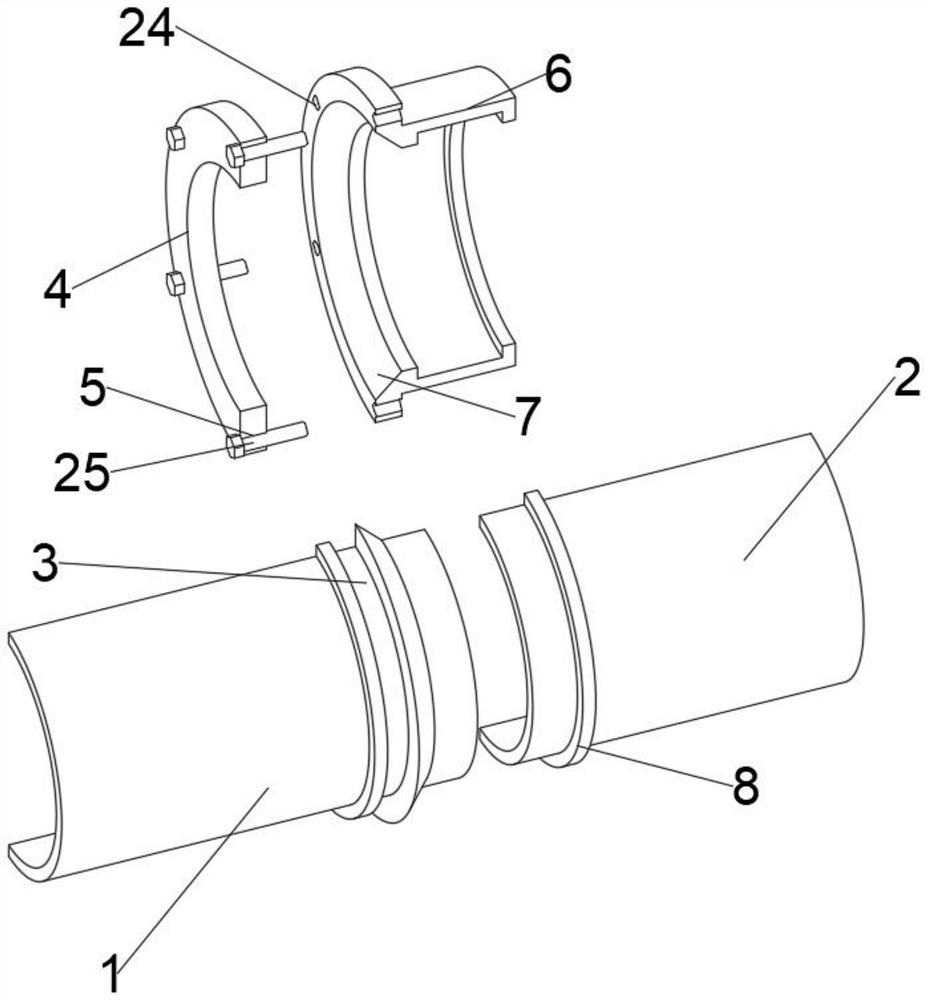

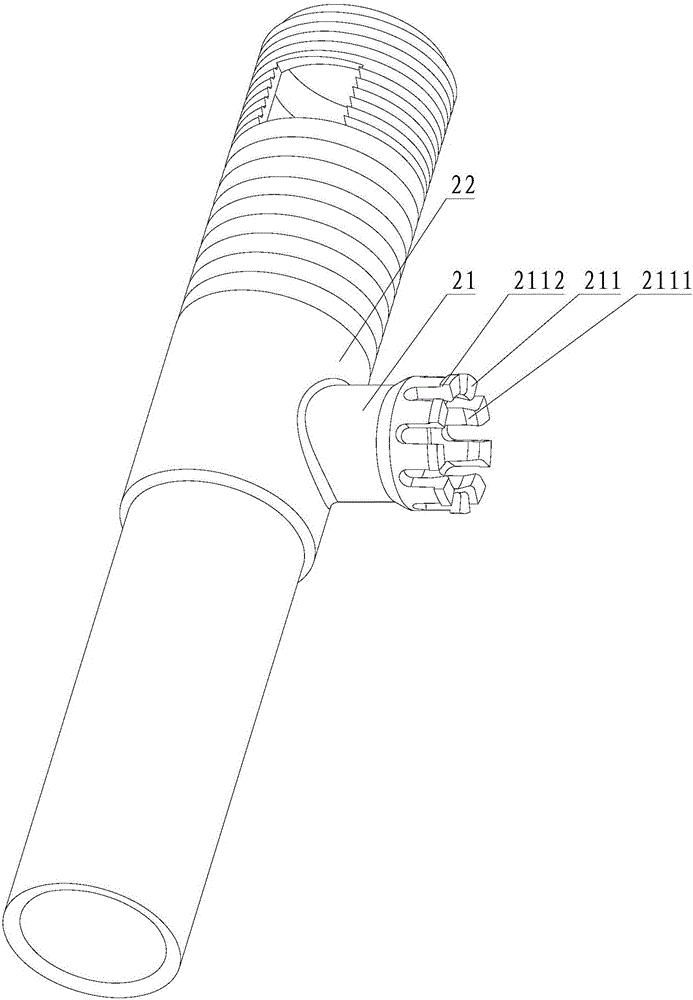

Connecting device

ActiveCN105757374AConvenient setEasy to placeSleeve/socket jointsDomestic plumbingEngineeringMechanical engineering

The invention discloses a connecting device. The connecting device comprises a first connector, a second connector and a connecting fitting, wherein the first connector is arranged on the second connector through the connecting fitting, and a first clamping part is arranged at the end, connected with the second connector, of the first connector; the second connector comprises a connecting part and limiting parts; the limiting parts are arranged on the connecting part, two or more connecting claws are arranged at one end of the connecting part, and the two or more connecting claws form an accommodating cavity with an opening; second clamping parts are arranged on the inner walls of the connecting claws, and the first connector is arranged in the accommodating cavity; the first clamping part and the second clamping parts are in clamping connection; the connecting fitting adopts a hollow structure, and concave parts are arranged on the side wall of the connecting fitting and is used for rotating in the circumferential direction so as to be jointed with or divorced from the limiting parts, so that the connecting fitting limits or releases the connecting claws in the axial direction. The connecting device provided by the invention not only is simple in structure, and firm to connect, but also convenient and fast to mount.

Owner:XIAMEN SANJUN IND & TRADE

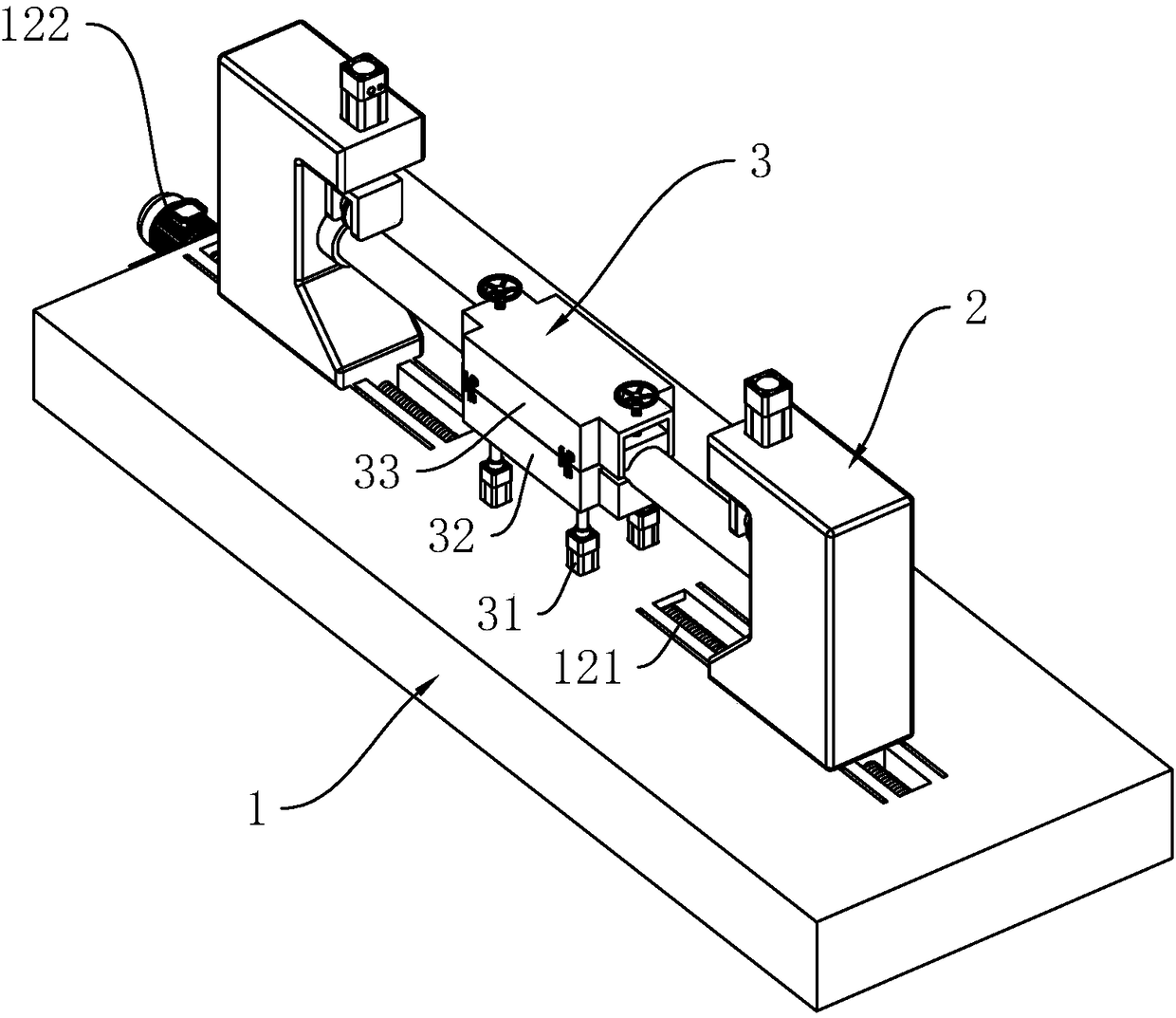

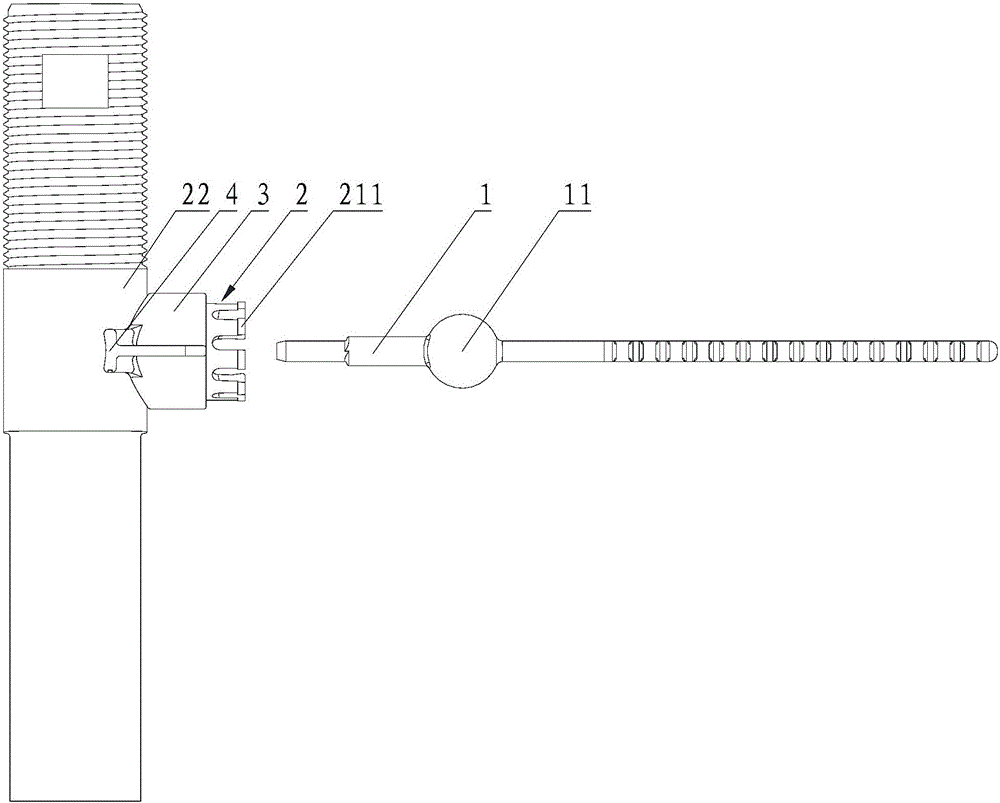

Power cord assembly apparatus

ActiveCN109088299AConvenient setEasy to assembleLine/current collector detailsEngineeringMaterial supply

The invention provides a power cord assembling apparatus. The power cord assembling apparatus includes a feeding section for providing a kit for the power cord assembling apparatus; a material storagepart disposed at a downstream position of the material supply part, the material storage part including an access part for placing the sleeve; a clamping portion including a plurality of first clamping members for clamping a part to be assembled; an assembling part comprising a first driving device and a second clamping member connected with the first driving device, the second clamping member being used for clamping the sleeve member from the access part and driving the sleeve member to move toward the first clamping member under the driving of the first driving device so as to assemble thesleeve member with the part to be assembled. Each of the first clamping members has a clamping state of clamping the part to be assembled and a releasing state of releasing the part to be assembled, and the running states of the plurality of first clamping members are independently controlled. The invention effectively solves the problem that the working efficiency of the mode of processing the power cord in the prior art is low.

Owner:GREE ELECTRIC APPLIANCES INC +1

Structurally improved shaping bracket for socks

InactiveCN111334962AEasy to set and shapeAchieve shrinkageShaping/stretching tubular fabricsEngineeringStructural engineering

The invention discloses a structurally improved shaping bracket for socks. The structurally improved shaping bracket for socks comprises a U-shaped base and a vertical turnover plate; the lower end ofthe turnover plate is in insertion connection in the base; a sock-shaped sock sleeve plate is formed on the upper end of the turnover plate; a circular arc-shaped slot is formed at the position of the heel part of the sock sleeve plate; a fan-shaped heel template is in insertion connection in the slot of the sock sleeve plate; the upper end of the heel template is hinged with the sock sleeve plate through a hinged shaft; a circular arc-shaped weight balance block is formed on the lower end of the heel template; a locating groove is formed in the lower end of the turnover plate; slot holes areformed in the turnover plate at two sides of the locating groove; a locating shaft is in insertion connection in the slot holes of the turnover plate; two ends of the locating shaft are in insertionconnection and fixed on the side wall of the base; a cam is in insertion connection and fixed in the locating groove of the turnover plate; and the flange of the cam is at the upper side of the locating shaft.

Owner:温州优巴信息技术有限公司

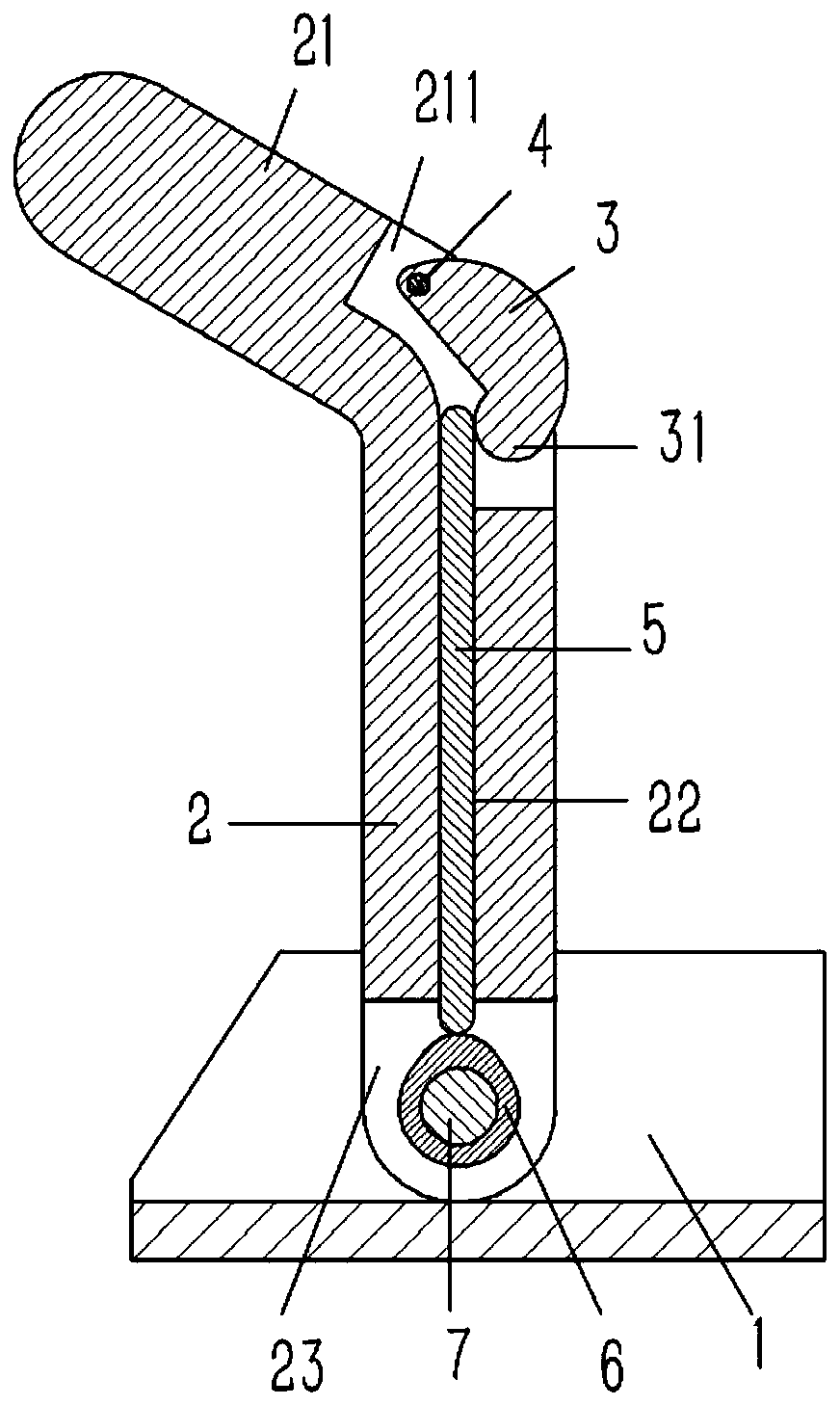

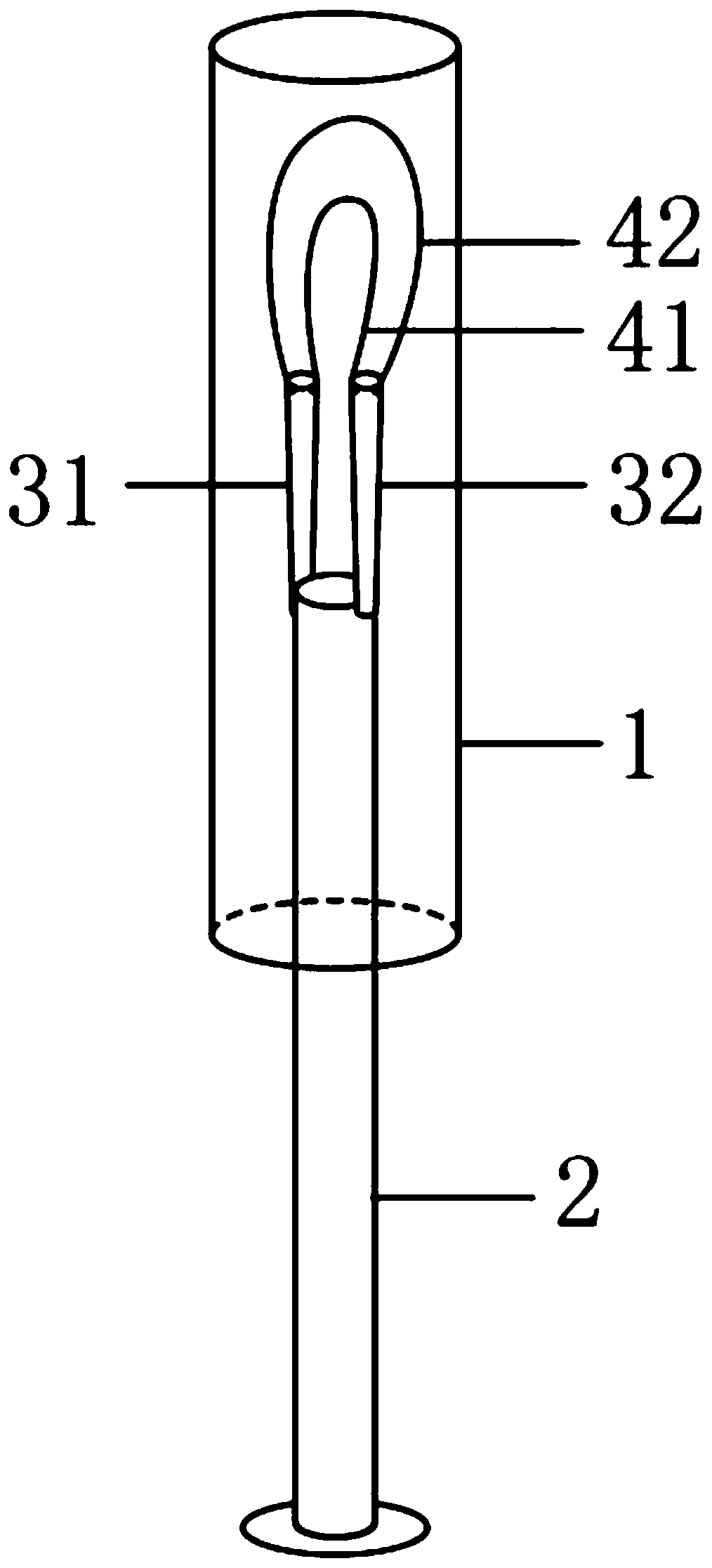

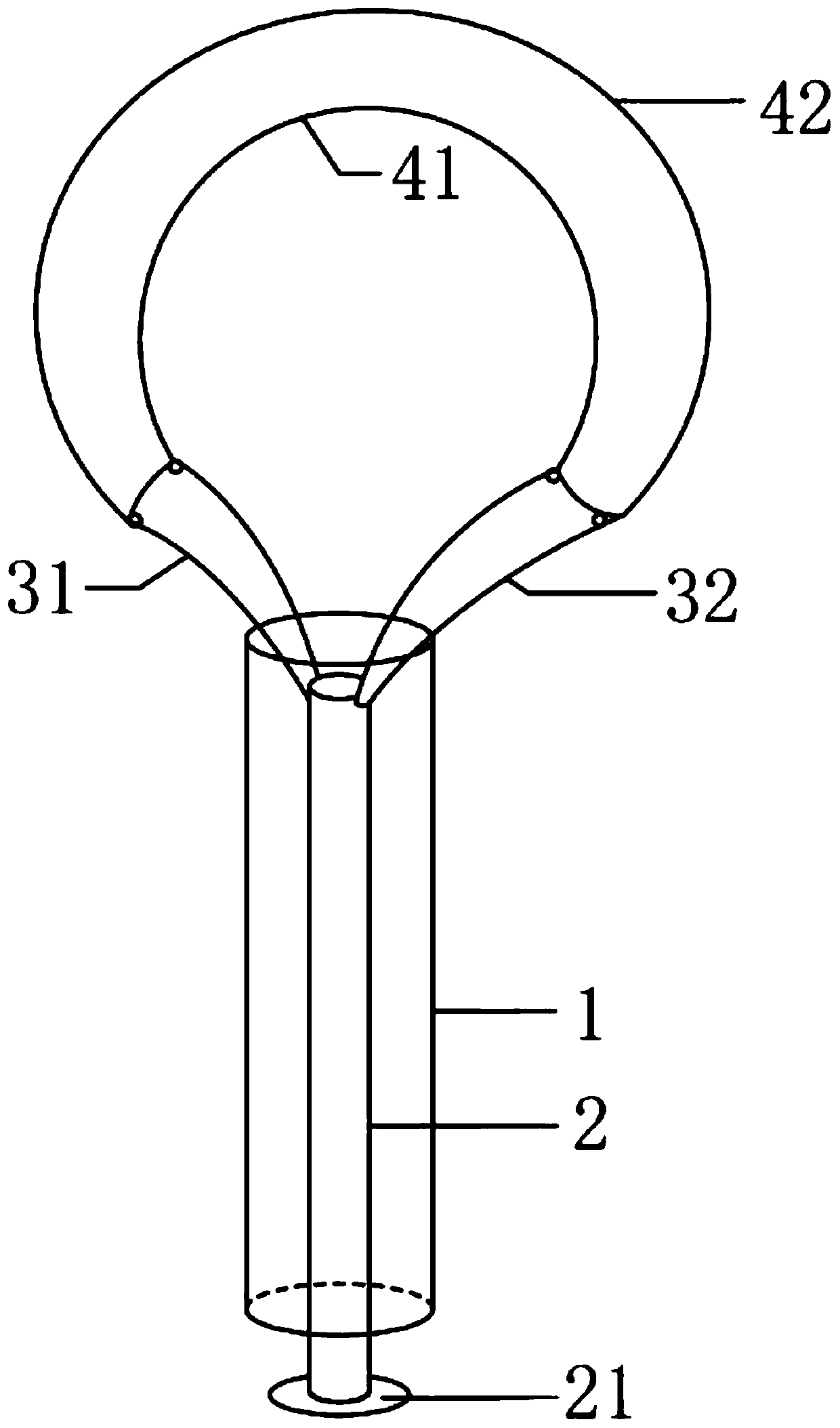

Tractor for liver operation under laparoscope

The embodiment of the invention provides a tractor for liver operation under a laparoscope, and belongs to the technical field of tractors under laparoscopes. The tractor for liver operation under thelaparoscope comprises an outer pipe, a push rod and a traction piece, wherein the two ends of the outer pipe are through, the push rod is arranged inside the outer pipe, the push rod can stretch andretract inside the outer pipe, the traction piece is arranged on the push rod, the push rod and the traction piece form a containing space, the containing space is a closed ring shape, the containingspace can act on the liver, and the liver is pulled by the push rod. The technical effects that the operation space requirement is small, and liver traction is convenient are achieved.

Owner:王珂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com