Bevel gear pair detection and assembling method

An assembly method and bevel gear technology, applied in the field of gear processing, can solve the problems of low production efficiency, high manufacturing cost, unsuitable for small and medium-sized production enterprises, etc., and achieve the effect of reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0042] A detection and assembly method of a bevel gear pair, which is used to detect a pair of bevel gear pairs that have been processed, so that when the bevel gear pair is installed on the corresponding gear box, the meshing state of the bevel gear pair Meet the design requirements. It should be noted that the bevel gear pair includes two bevel gears that are paired and meshed with each other. For the convenience of description, the two bevel gears are respectively referred to as the first bevel gear and the second bevel gear in this embodiment. Specifically include the following steps:

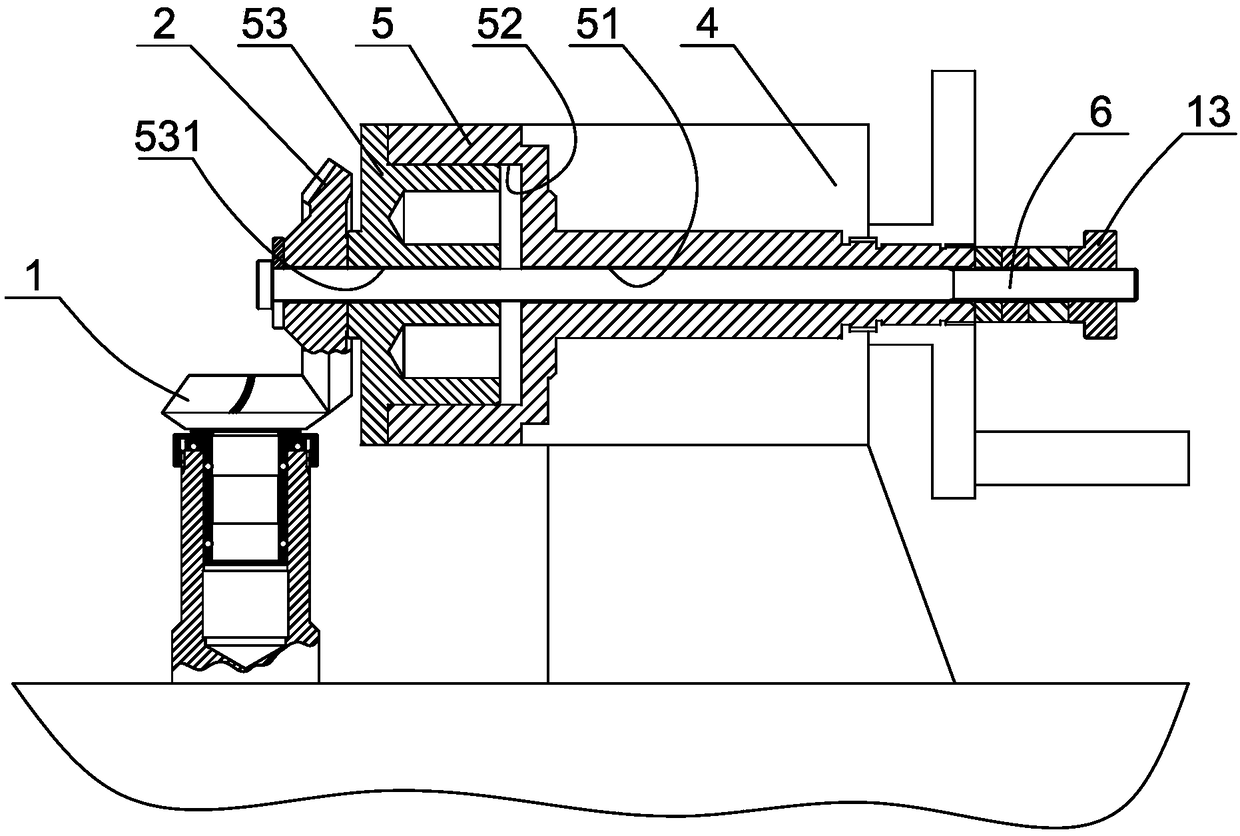

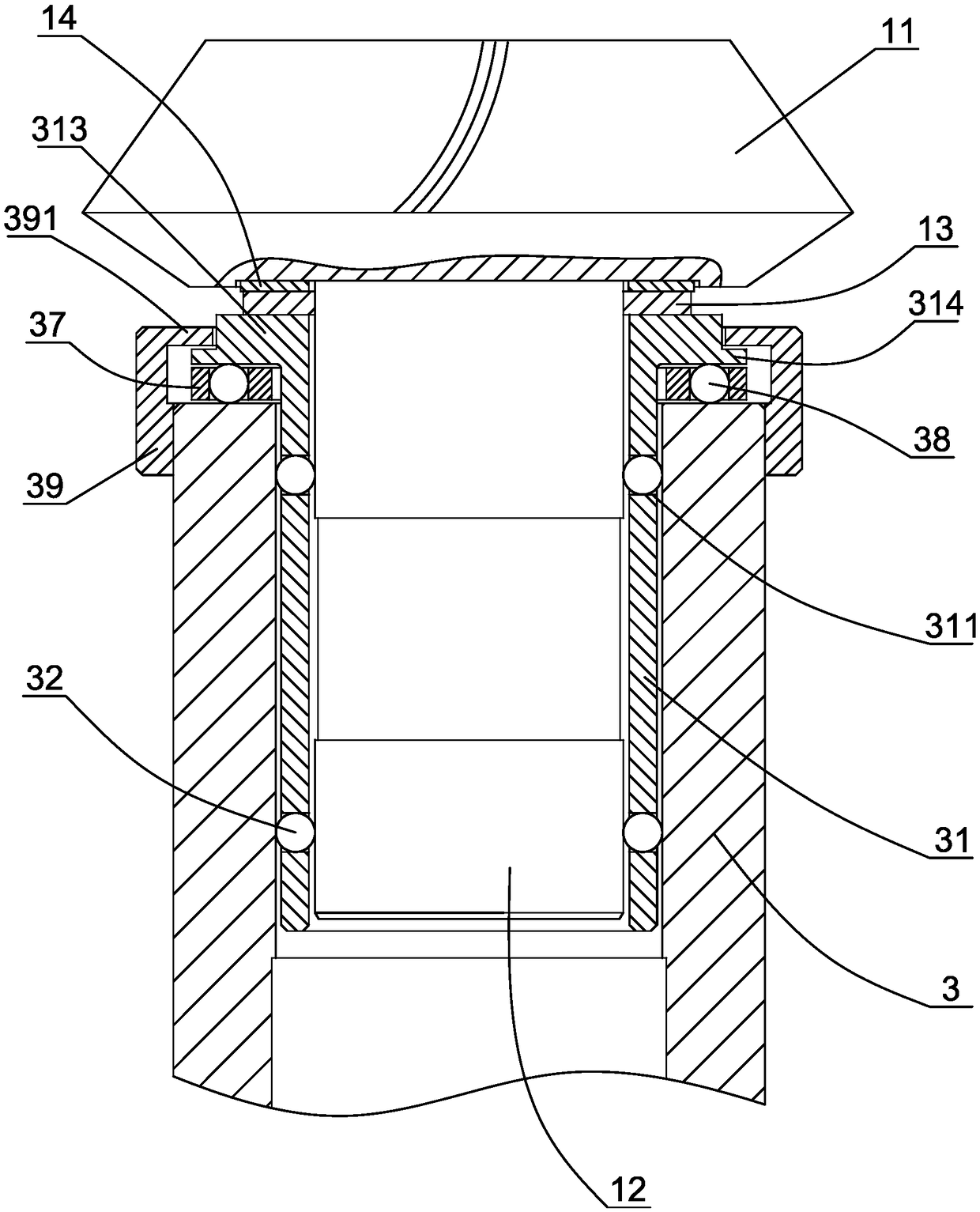

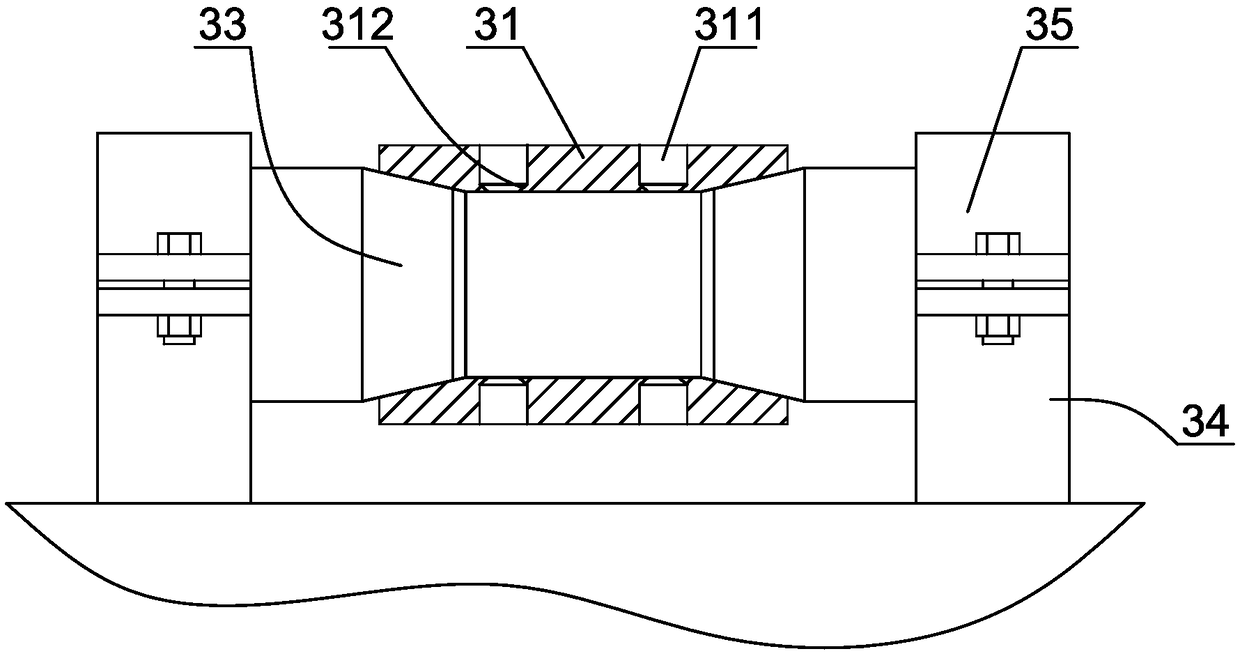

[0043] a. If figure 1 As shown, the first bevel gear 1 that has been processed is rotatably connected to a vertical socket on a detection device. At this time, the axis of the first bevel gear is in a vertical state, and the first bevel gear Can rotate ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com