Patents

Literature

2345results about "Plungers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

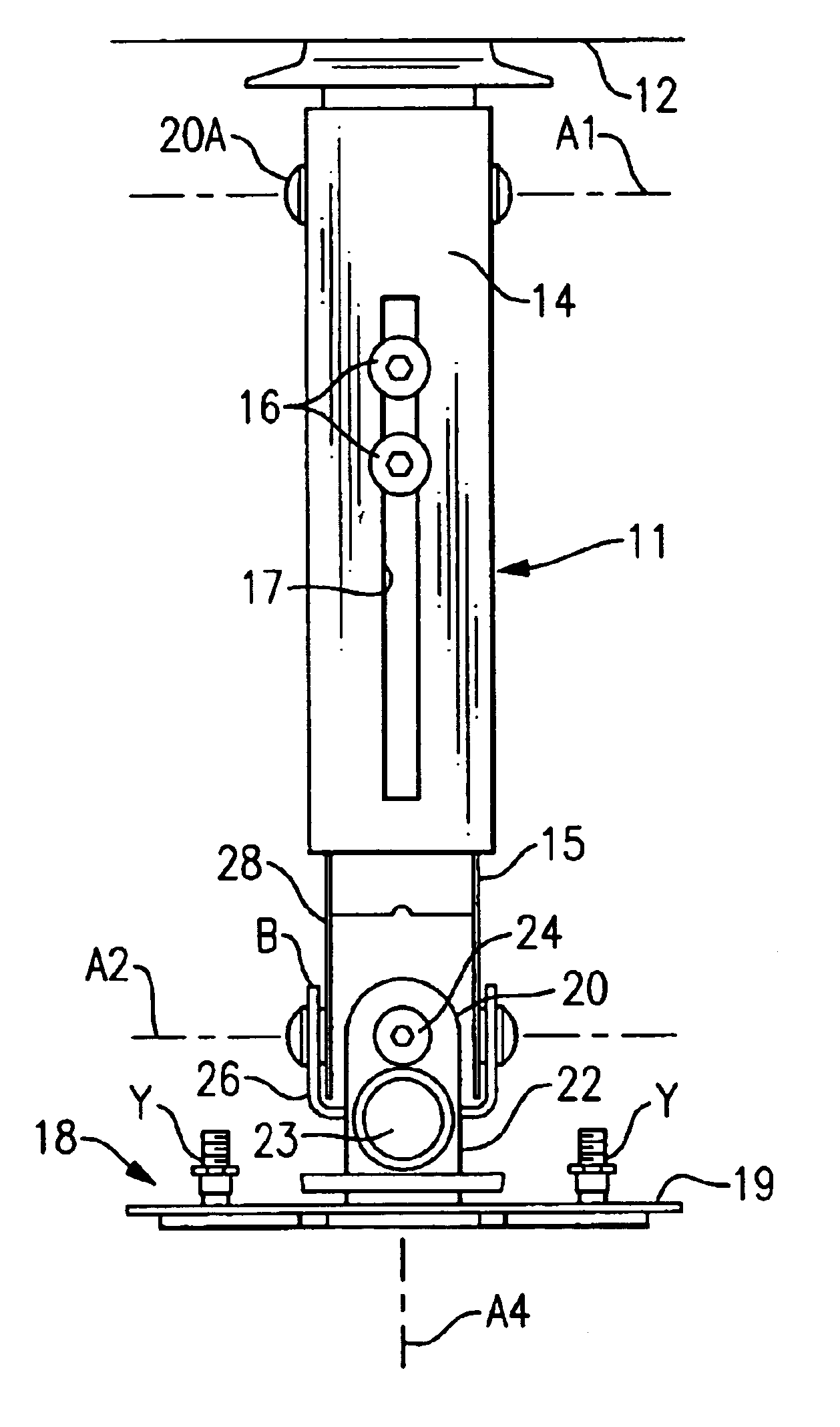

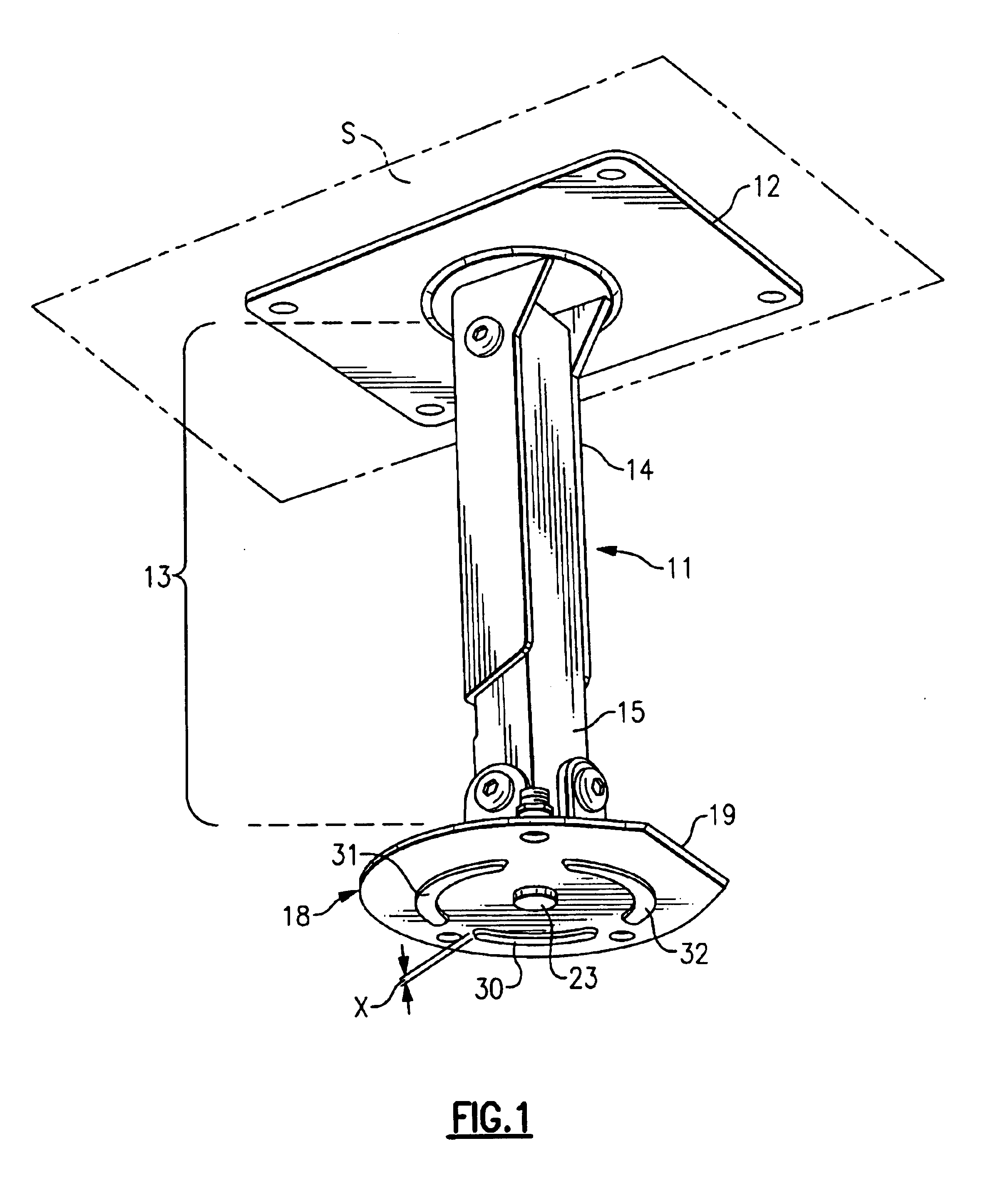

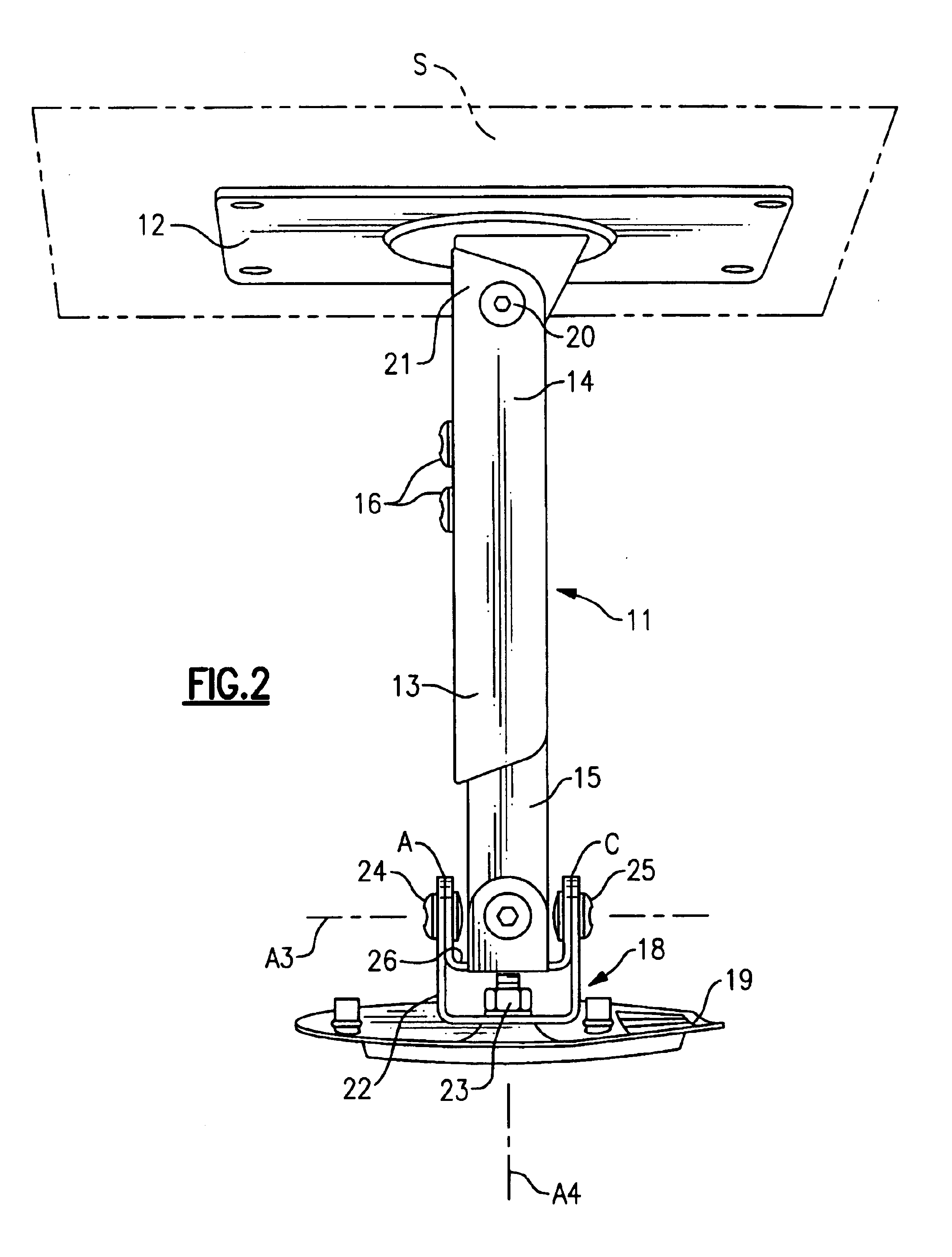

Mounting bracket

A mounting unit (11) for a attaching a working unit such as a video projector to a mounting surface which can be horizontal or vertical or at some angle intermediate the horizontal and the vertical comprising: an anchorage (12) whereby the unit can be attached to the mounting surface; a beam (13); a carrier (18) comprising in combination a holding plate (19) and a mounting plate; the carrier being adapted to provide for the attachment of a working unit to the mounting plate; a first pivot (20a) whereby a first end of the beam is pivotably attached to the anchorage to enable the beam to pivot about a first axis (a1); a second pivot whereby the other end of the beam to the first end is pivotably attached to the holding plate to enable the holding plate to pivot about a second axis (a2) parallel to the first axis; a third pivot (24) whereby the holding plate can pivot about a third axis perpendicular to the second axis; a fourth pivot (23) whereby the holding plate can pivot about a fourth axis (a4) perpendicular to the second and third axes; the carrier including mechanism whereby the mounting plate can be rotated about an fifth axis parallel to the holding plate.

Owner:LIGERTWOOD PETER

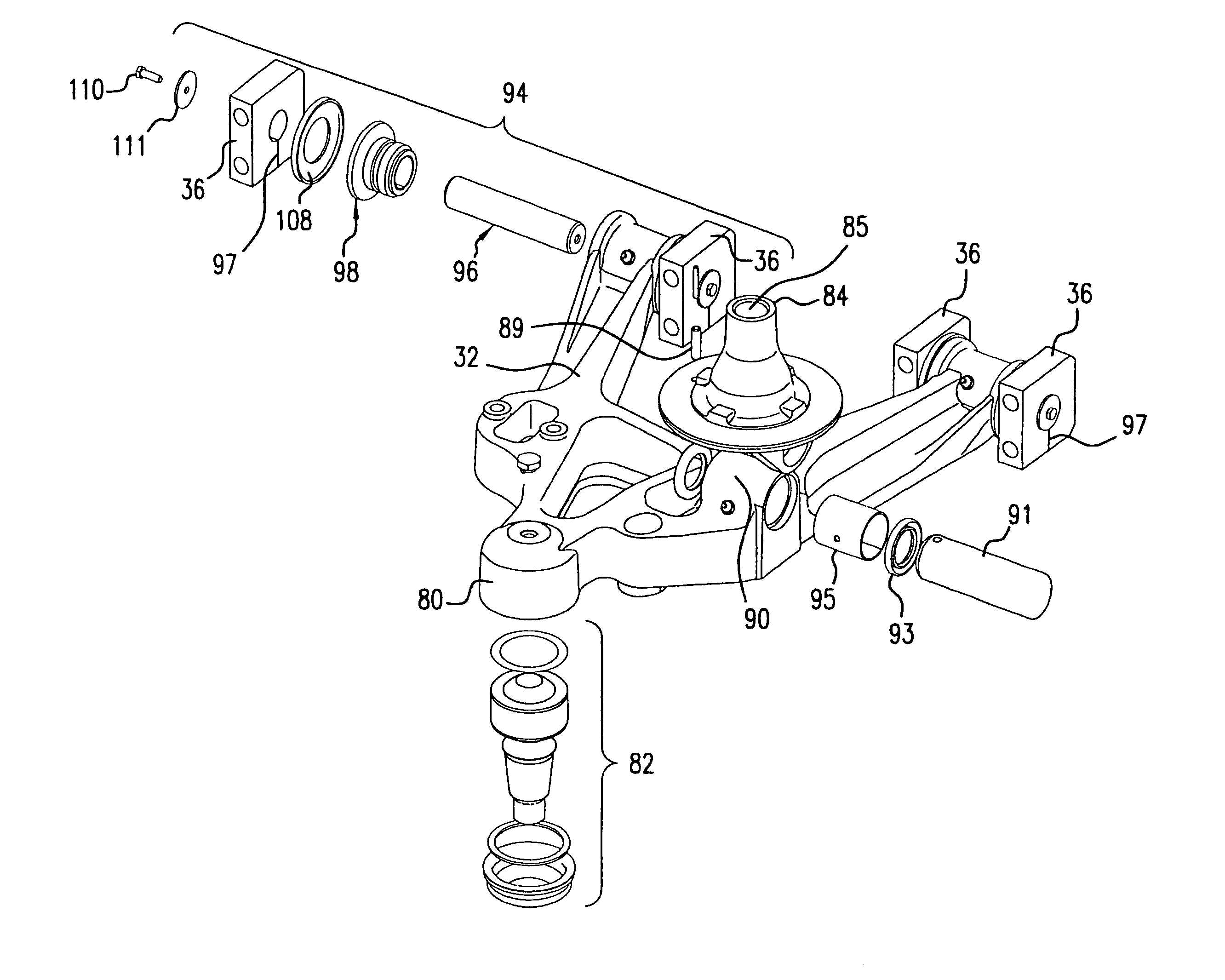

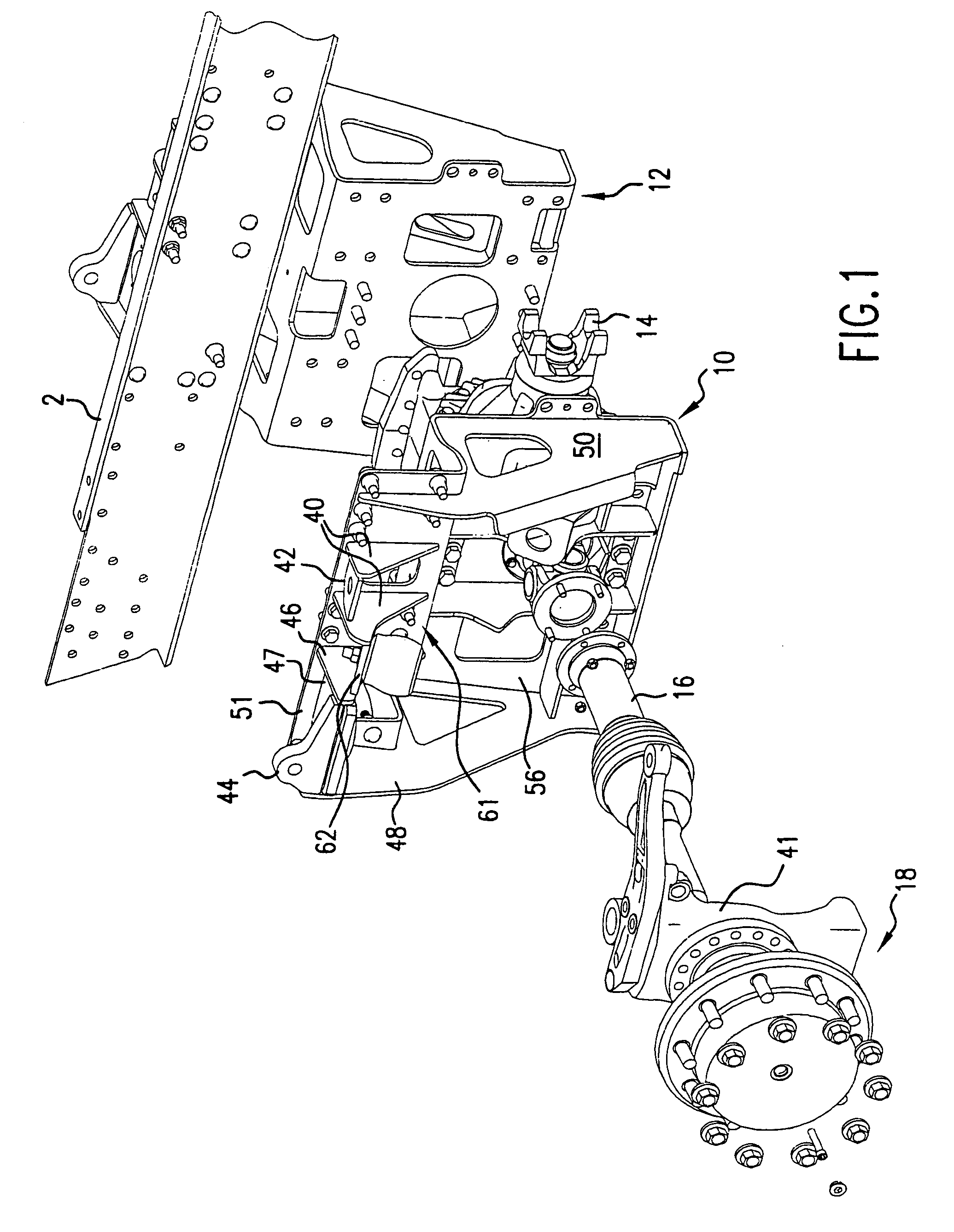

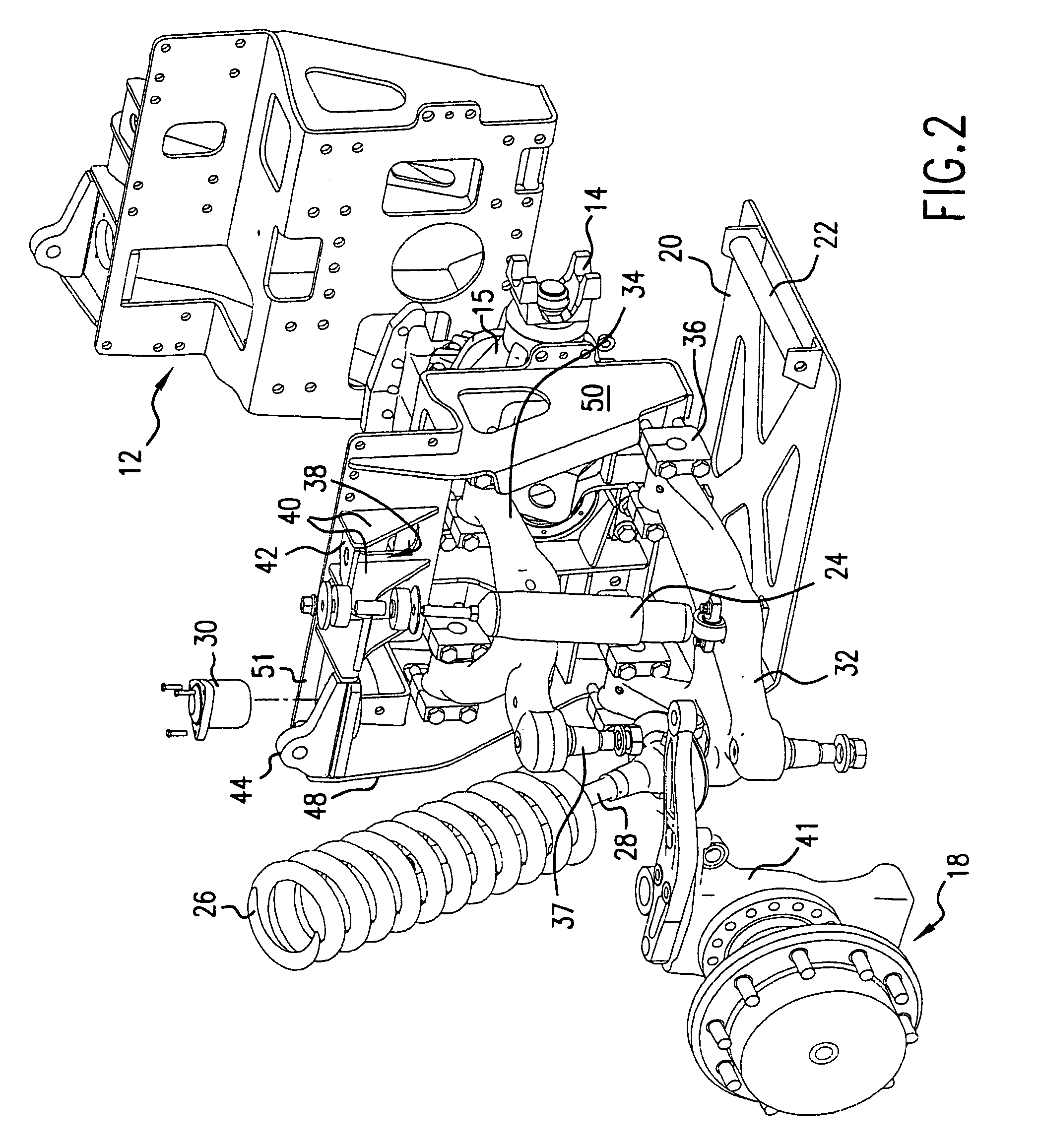

Mounting assembly for a vehicle suspension arm

A mounting assembly for use with a mounting surface includes an arm, a pin, a pair of clamping blocks and a fastener. The arm has a cylindrical bore at one end. The pin extends through the bore. Each block of the pair of clamping blocks includes a central opening and is circumferentially discontinuous about the central opening. Each clamping block further includes a slot defined by portions of the block. The slot is dimensioned to allow the pin to pass through the slot when the block is in an unclamped position and to tightly grip the pin when the block is in a clamped position. The fasteners extend across the slots and are configured to engage the mounting surface to mount the blocks to the mounting surface.

Owner:OSHKOSH CORPORATION

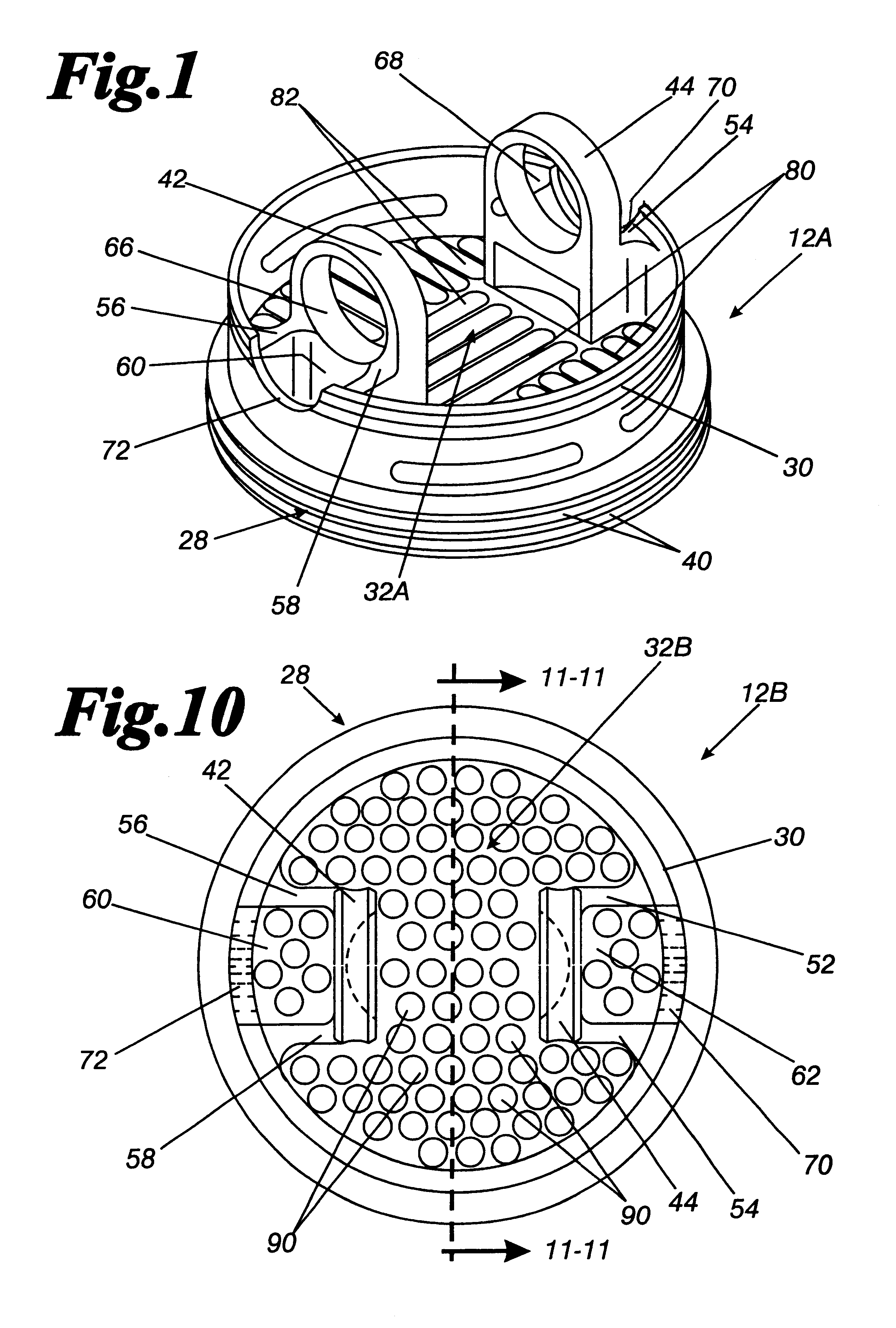

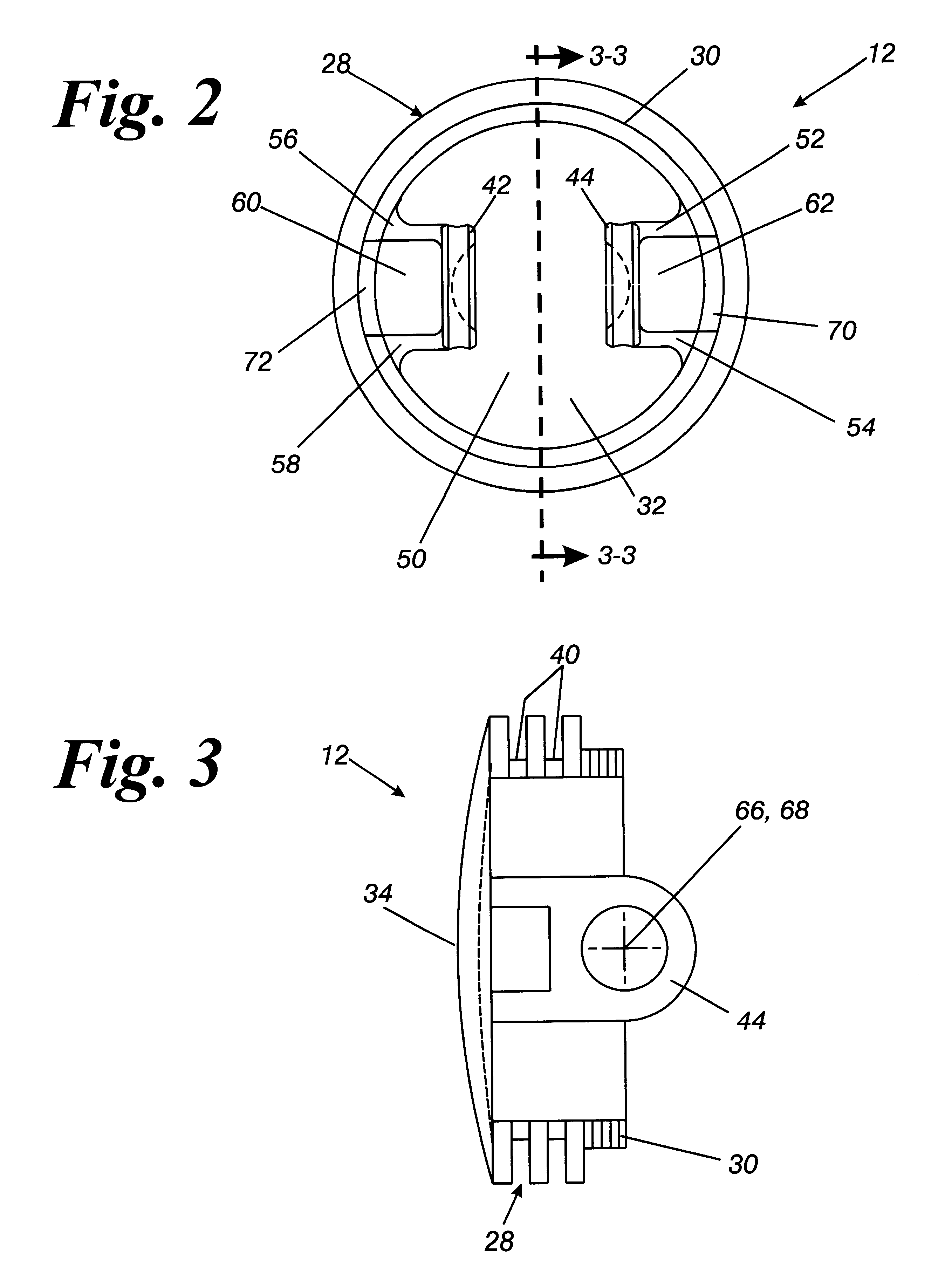

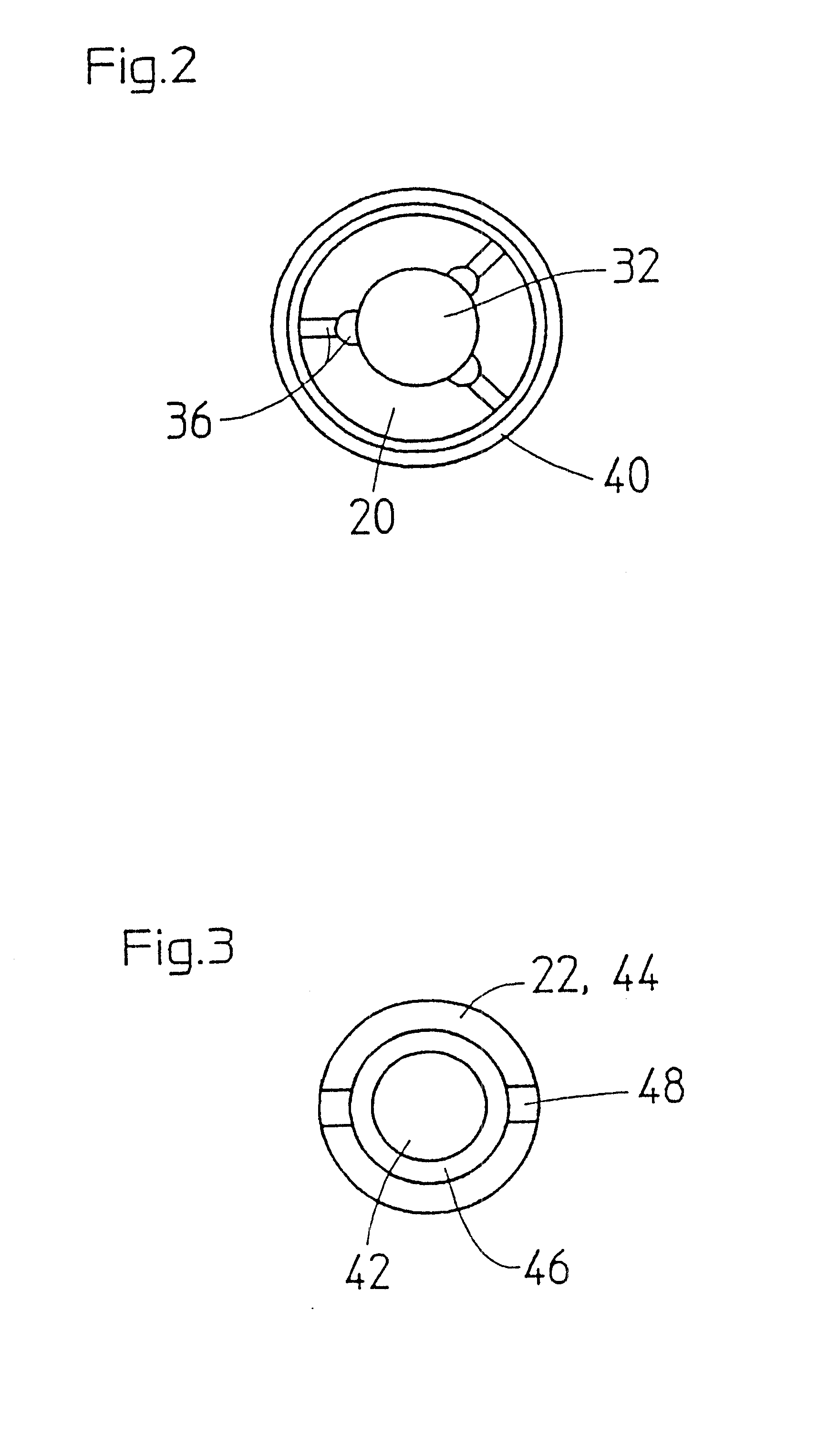

Cartridge piston

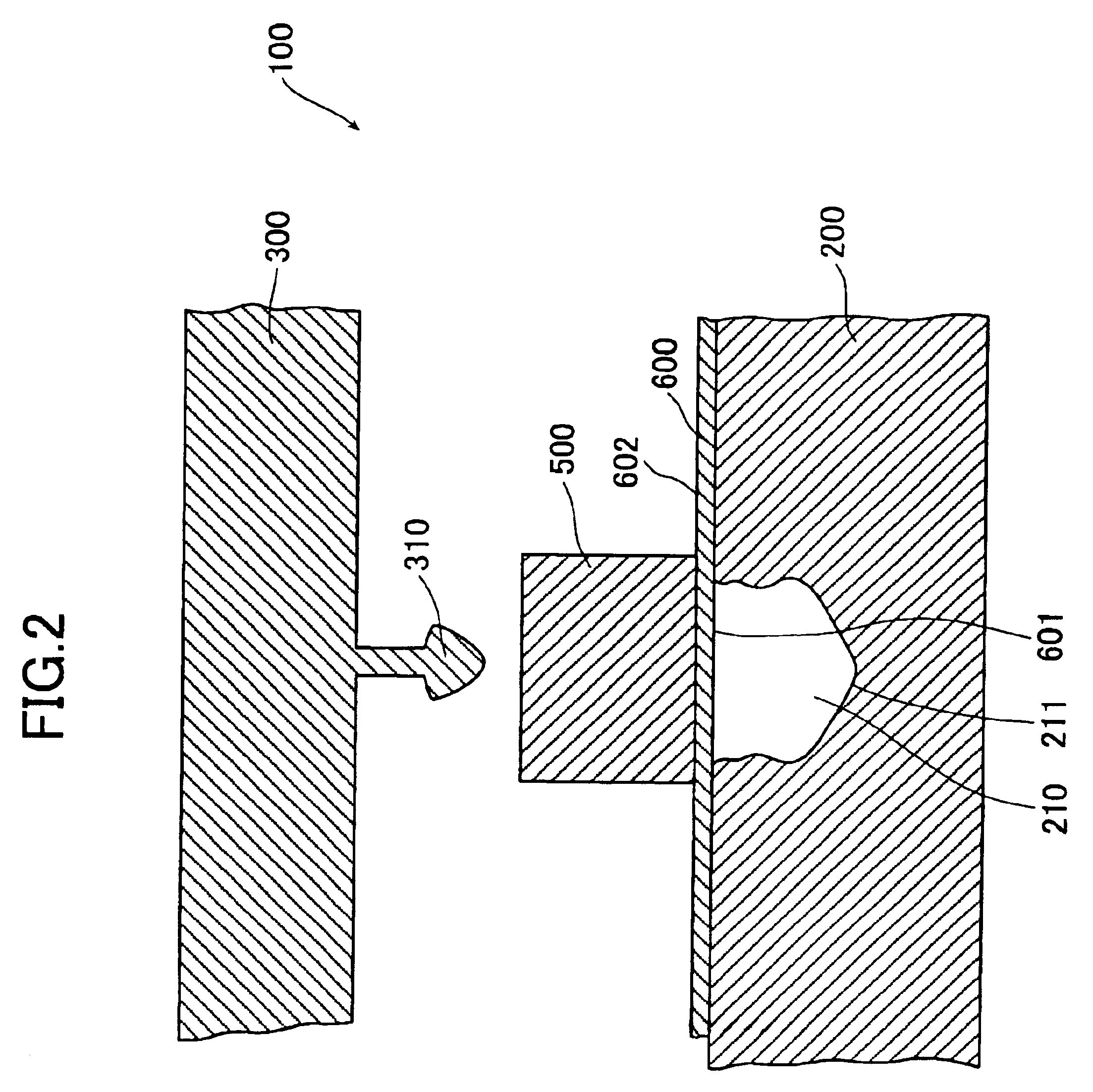

ActiveUS8919616B2Convenient guidanceAvoid skewLiquid surface applicatorsPlungersSolid particleEngineering

The piston includes a piston body having a conveying side, an oppositely disposed drive side and, at the circumferential side, a piston jacket forming a connection between the conveying side and the drive side. The piston jacket has a projection that carries a guide element for the guidance of the piston in a cartridge containing a filling with solid particles and for forming a sealing contact with a wall of the cartridge. The projection also carries a scraper element in front of the guide element for scraping solid particles from the cartridge wall back into the filling during discharge.

Owner:MEDMIX SWITZERLAND AG

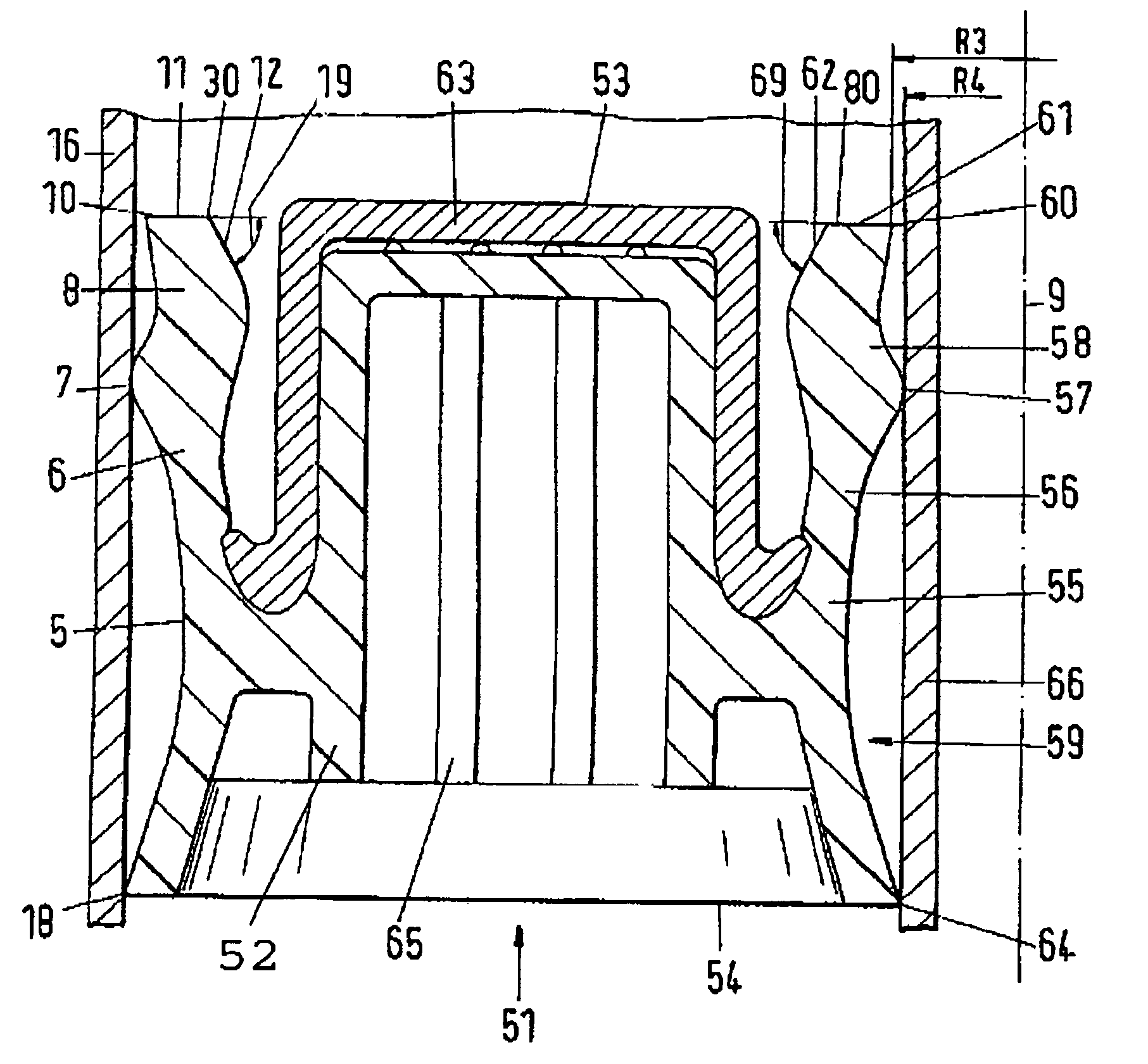

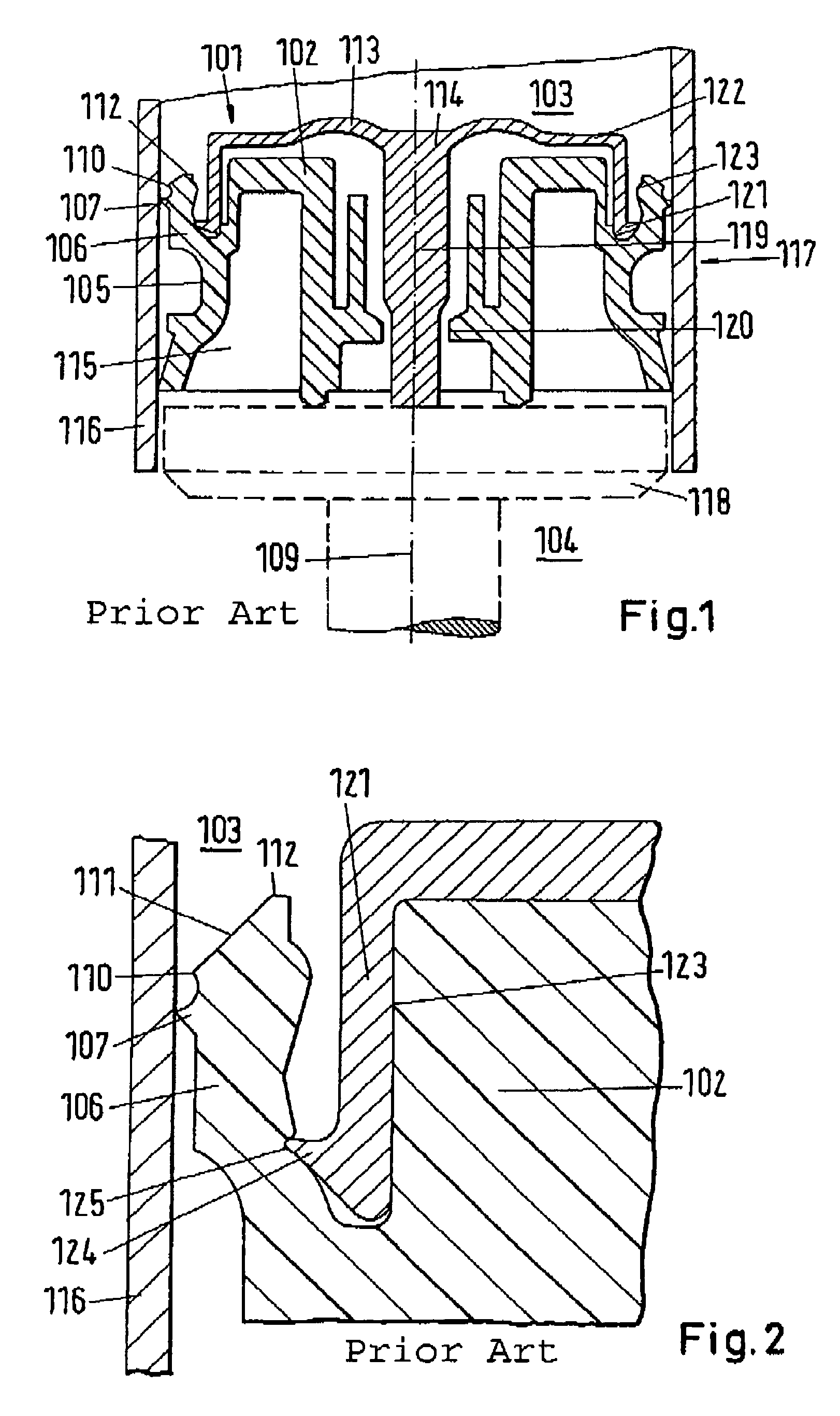

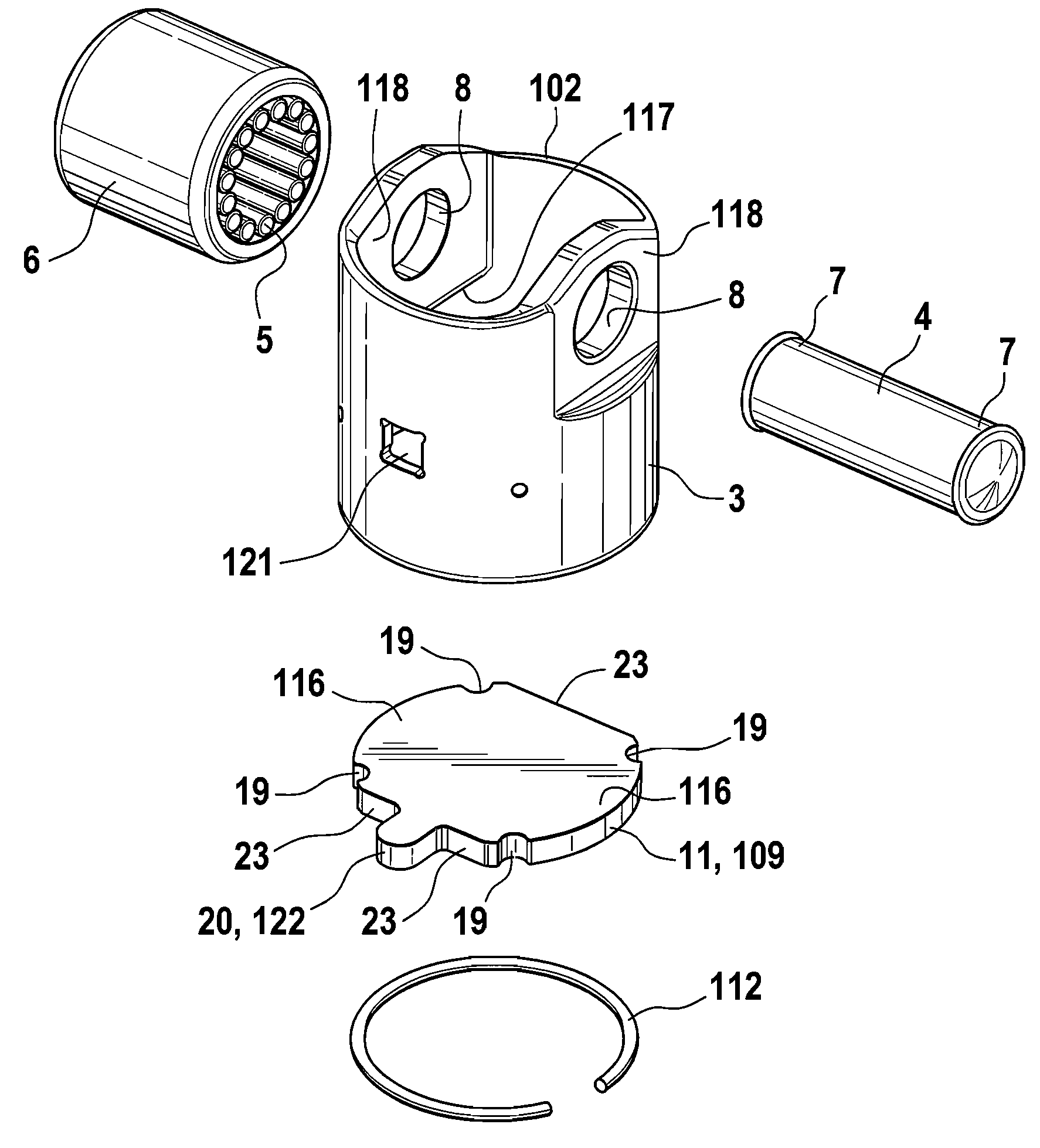

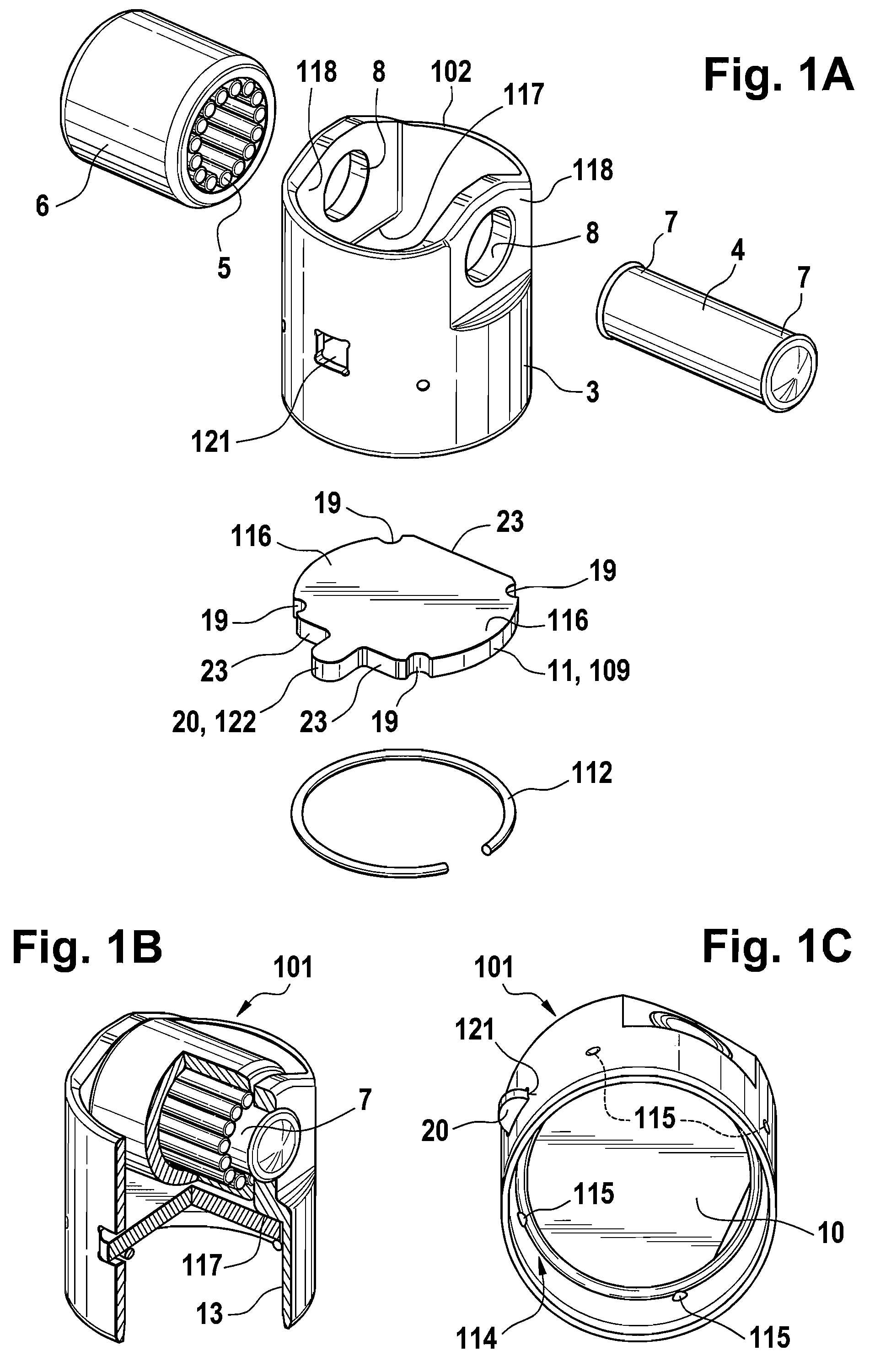

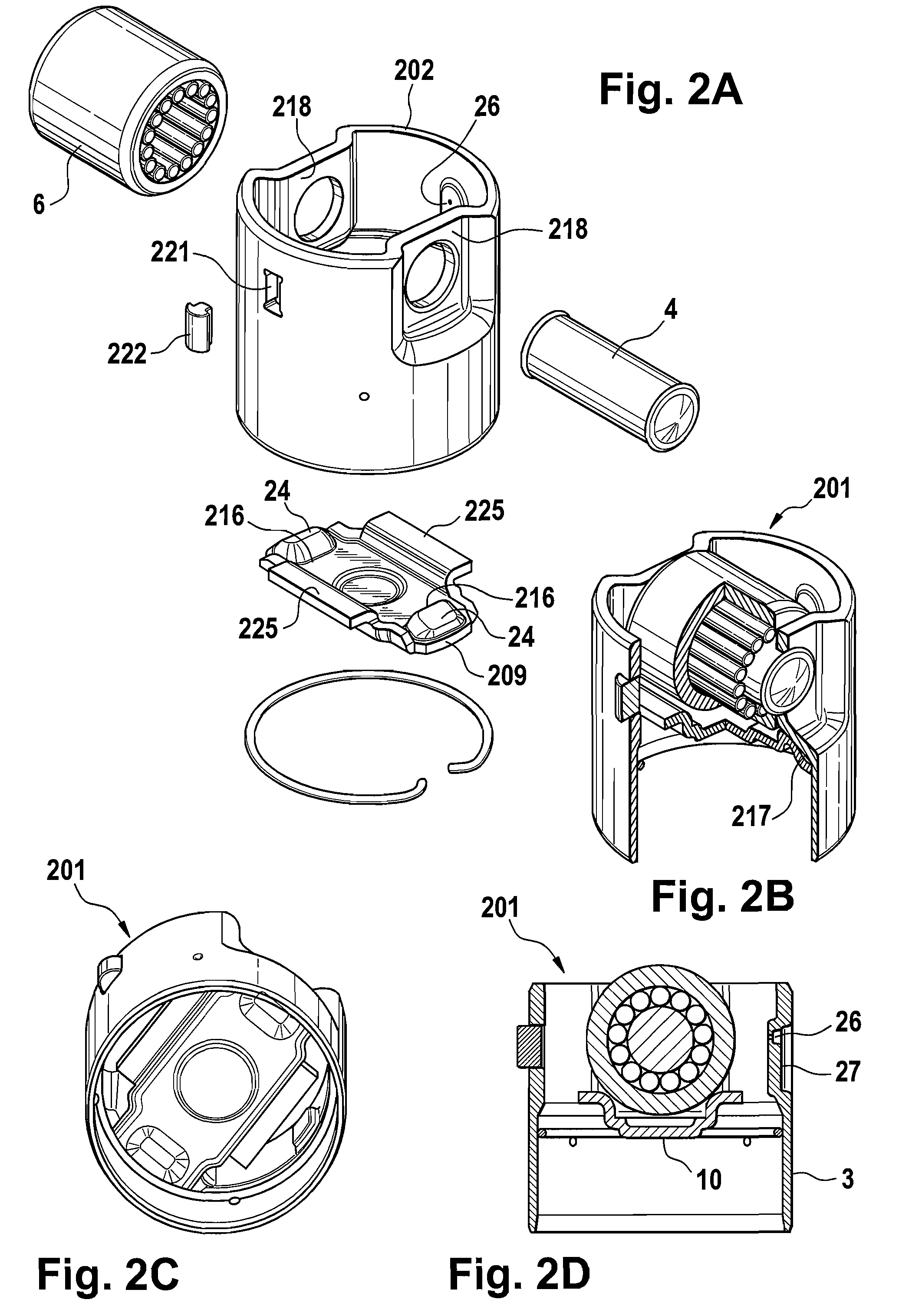

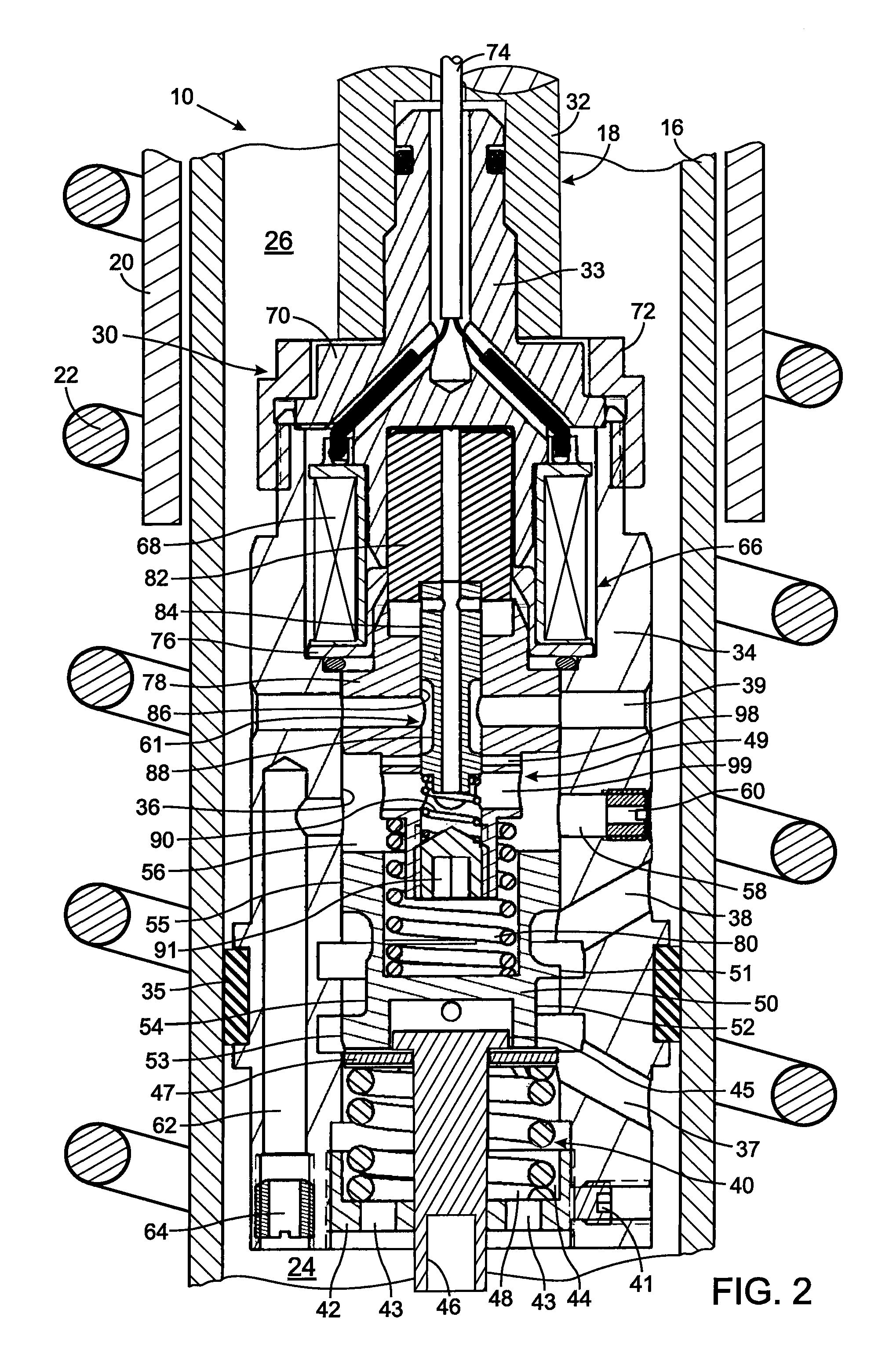

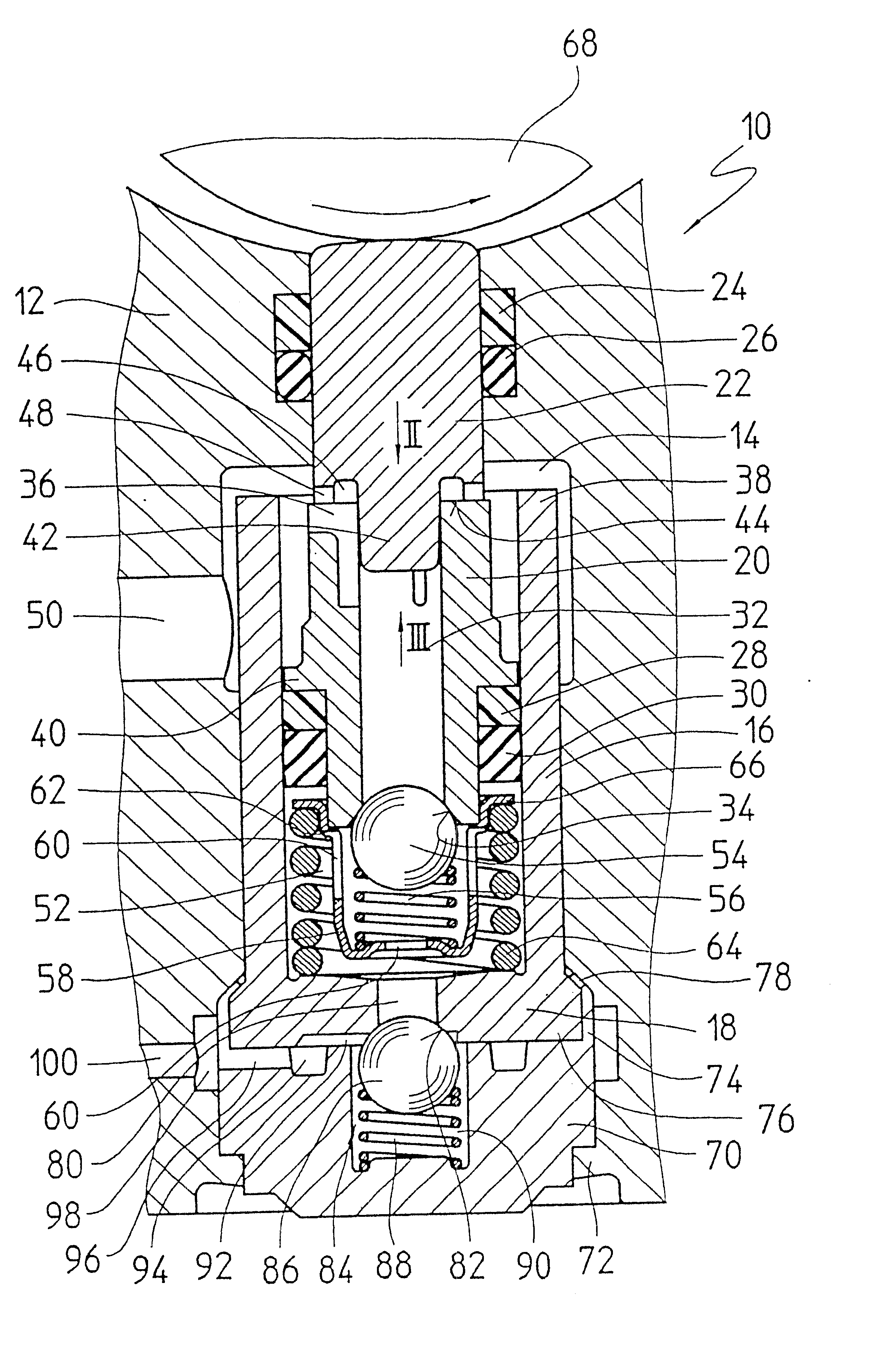

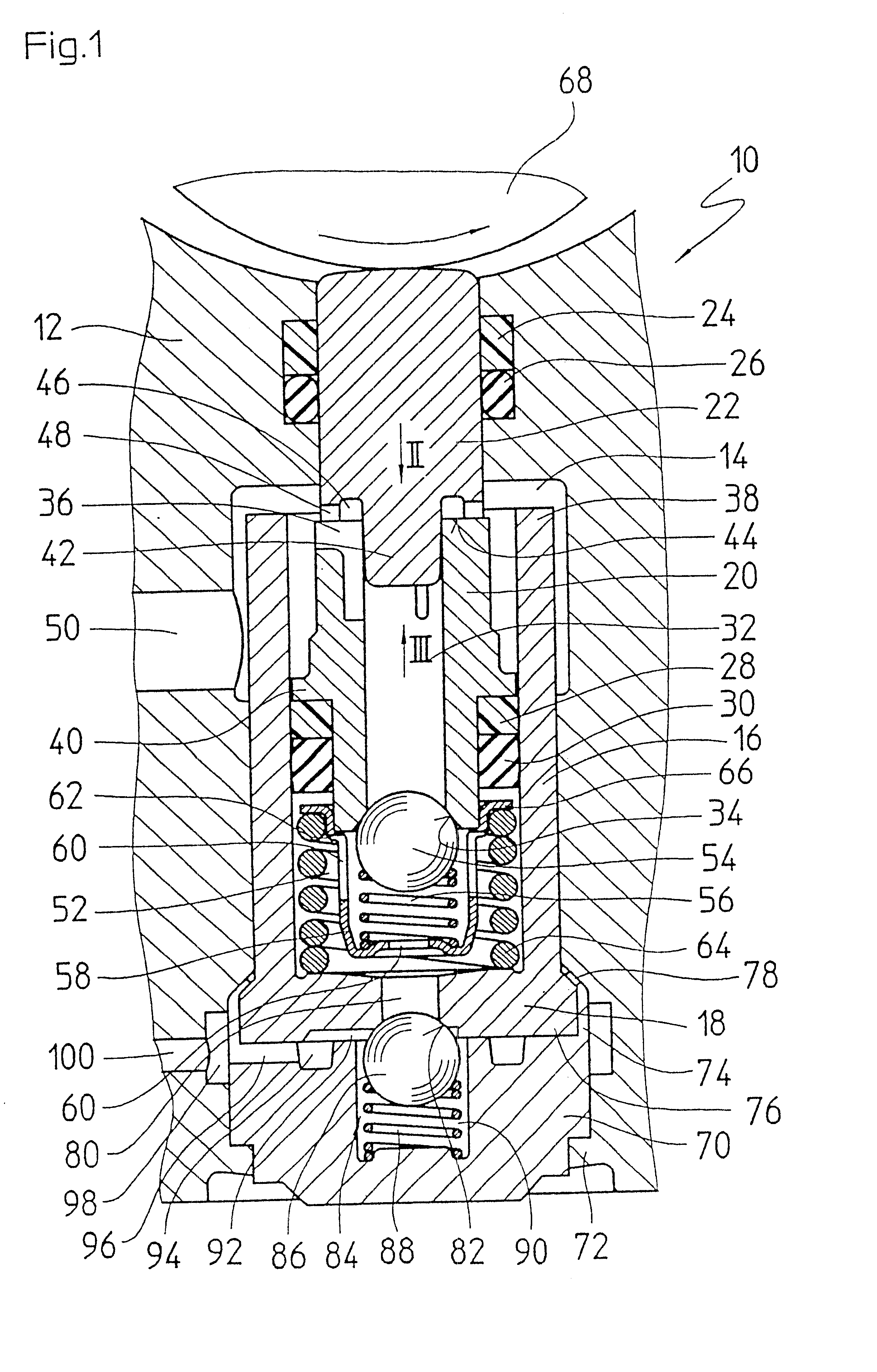

Mechanical tappet in particular for a fuel pump of an internal combustion engine

InactiveUS7793583B2High potential lightweight constructionSave on high costsValve arrangementsEngine sealsInternal combustion engineTappet

A mechanical tappet (101, 201, 301, 401, 501, 601, 701, 801, 901, 1001) is provided, in particular for actuating the lifting of a pump piston (39) of a fuel pump of an internal combustion engine, with a sleeve-shaped tappet housing (102, 202, 302, 402, 502, 602, 702, 902, 1002) constructed as a shaped sheet-metal part and with a driving roller (6) supported so that it can rotate. Here, a bolt (4) supports the driving roller so that it is centered, and end sections (7) of the bolt projecting from the driving roller are supported in bolt eyes (8) of the tappet housing.

Owner:SCHAEFFLER TECH AG & CO KG

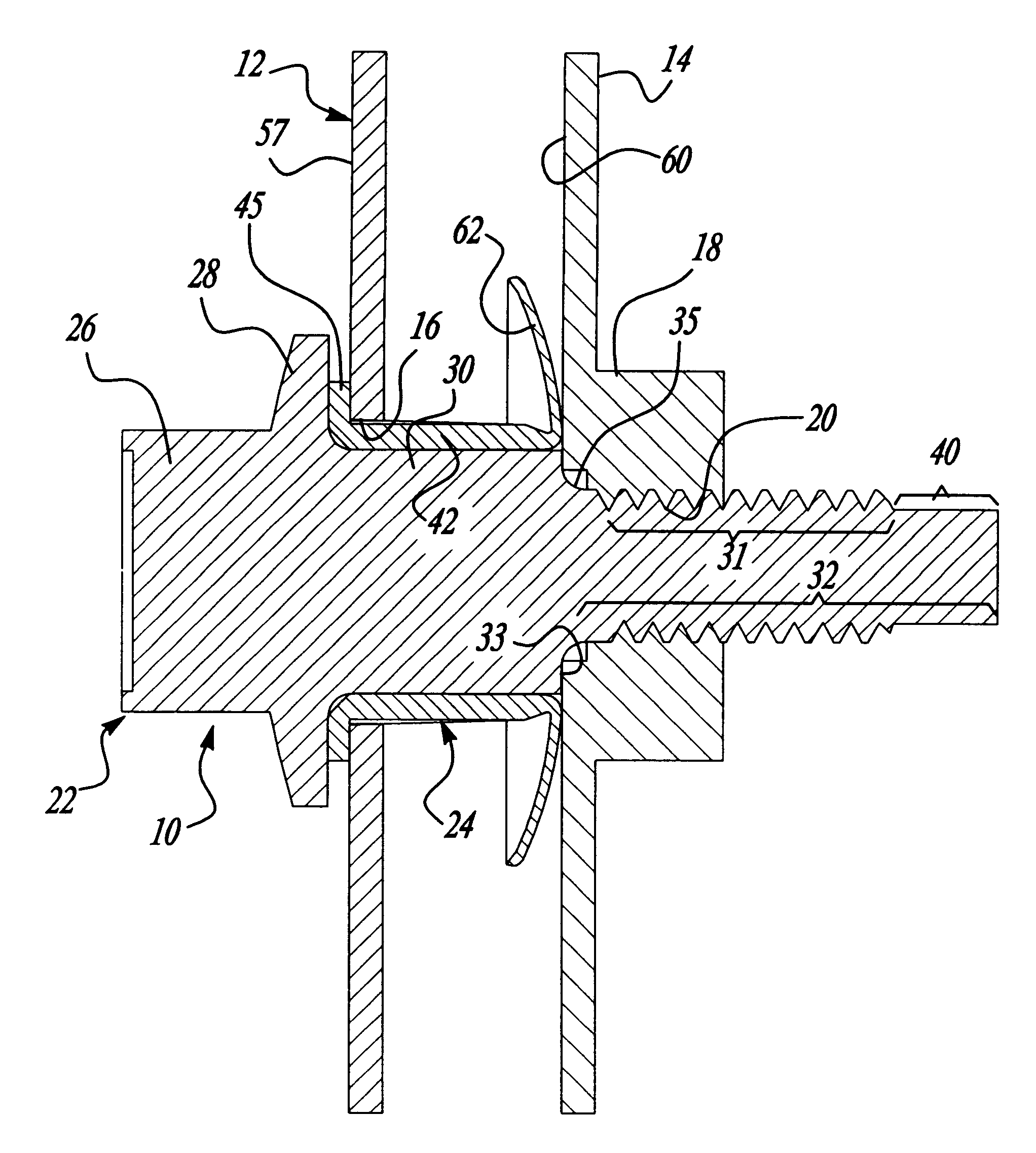

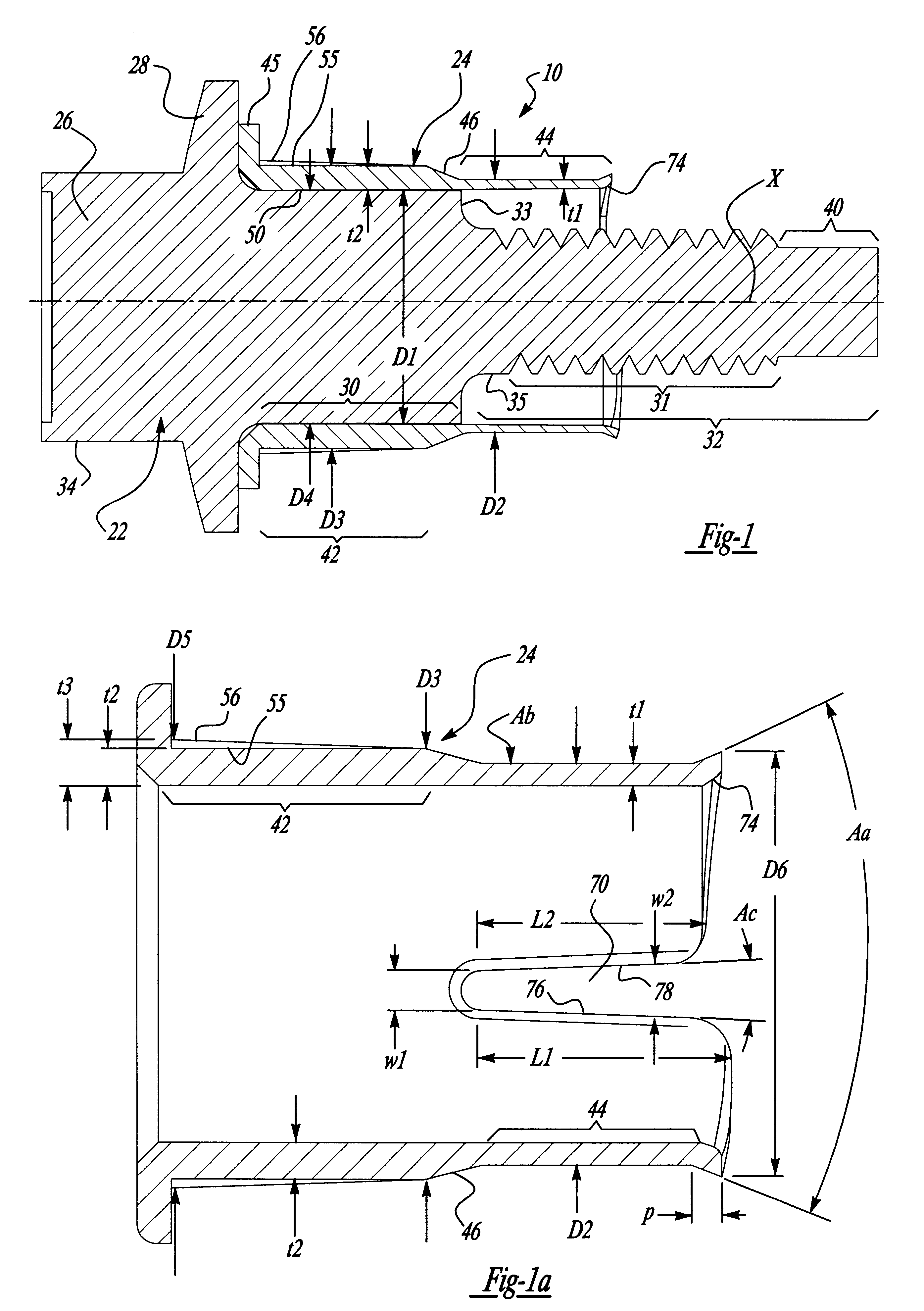

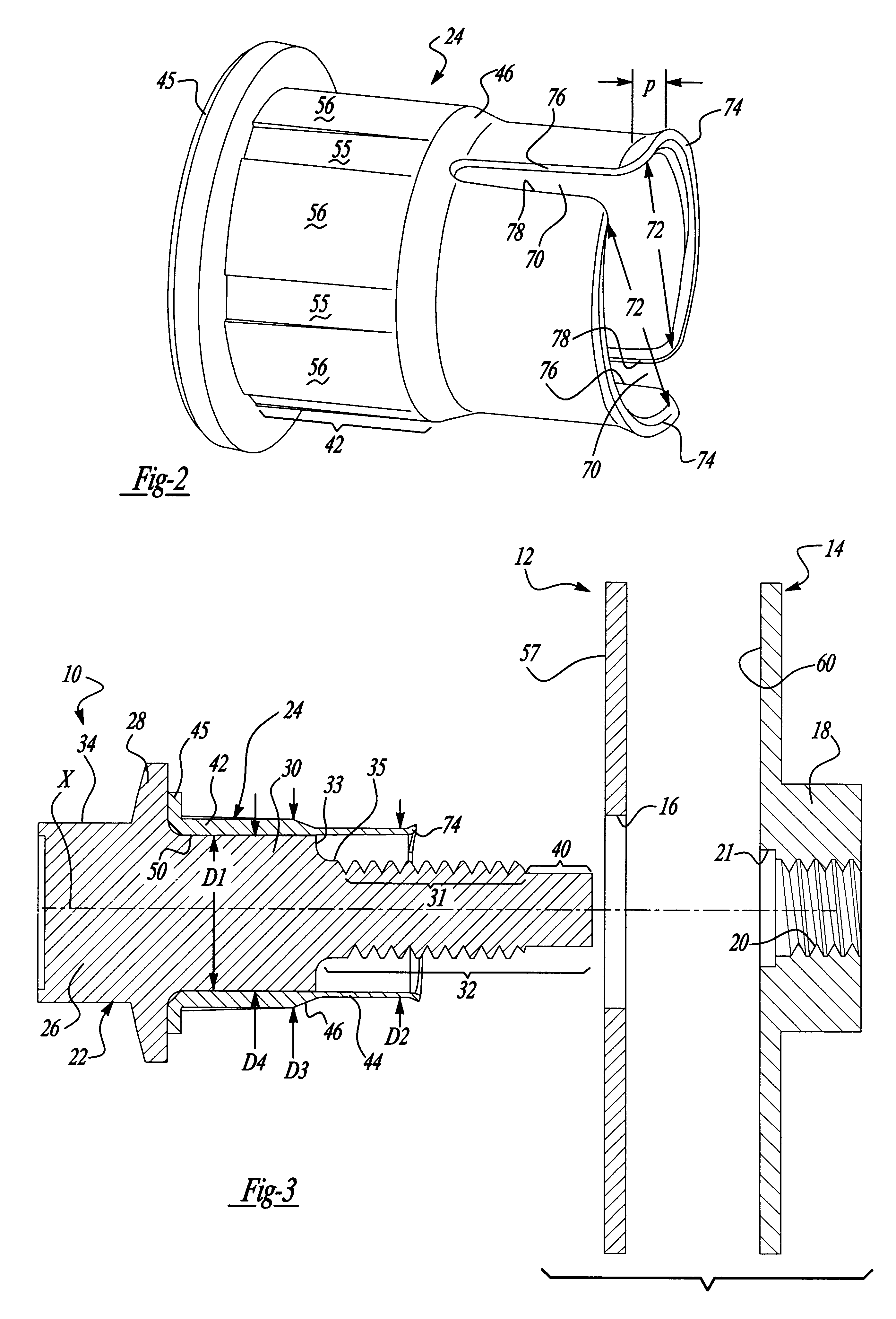

Pivot apparatus including a fastener and bushing assembly

A fastening assembly for use as a pivot joint for a first member and a second member which have alignable openings therethrough. The fastening assembly comprises a fastener having a longitudinal axis and a bushing mounted on the fastener with the bushing having a first end and a second end. The second end of the bushing being formed wherein upon the combined fastener and bushing being mounted within the aligned openings the second bushing end extends only through the opening of the first member whereby upon its engagement with the second member during installation it flares radially outwardly from the longitudinal axis of the fastener and between the first and second members thereby providing automatic retention of the bushing and, resilient spacing between the first and second members.

Owner:SOUTHCO

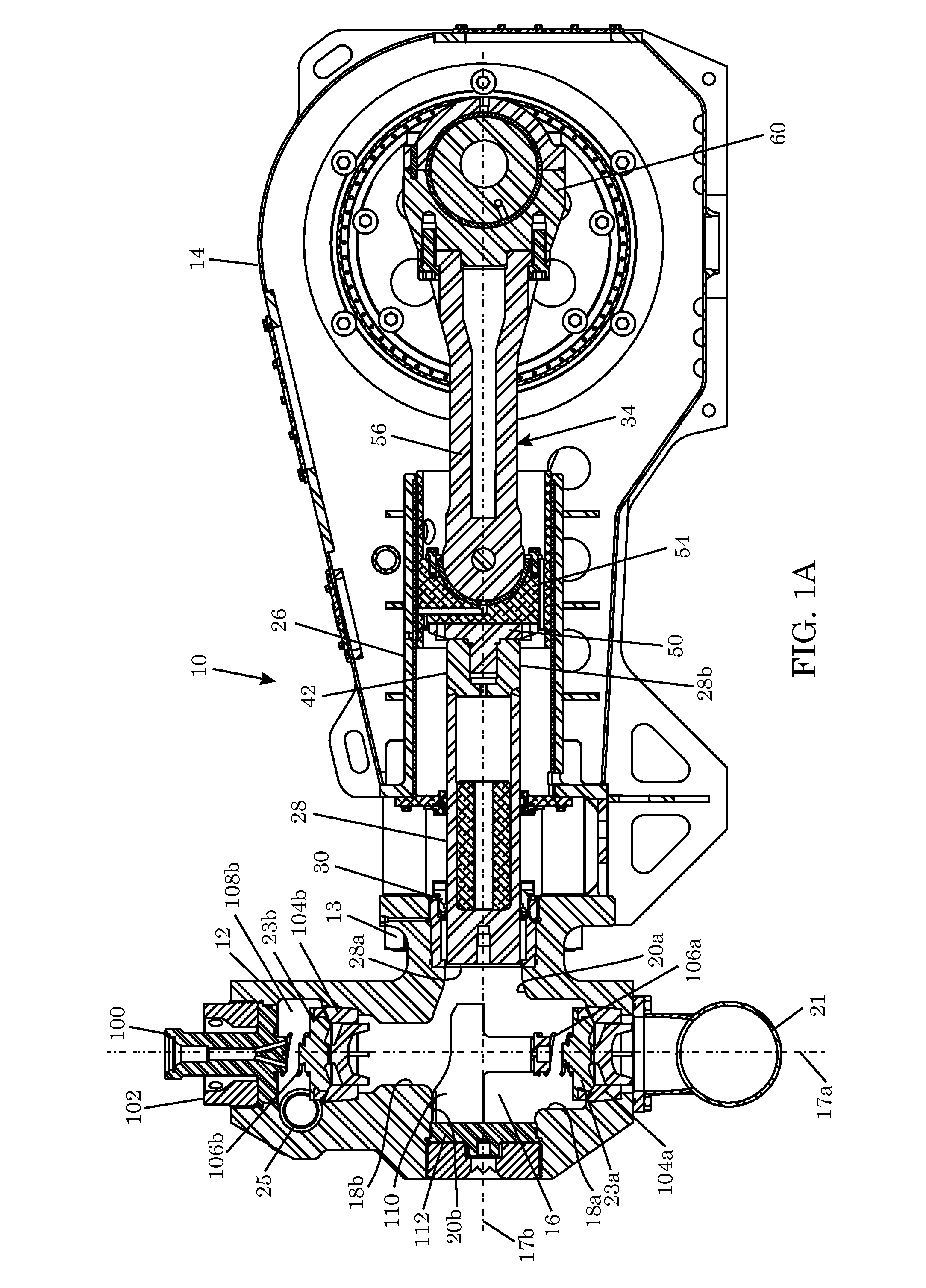

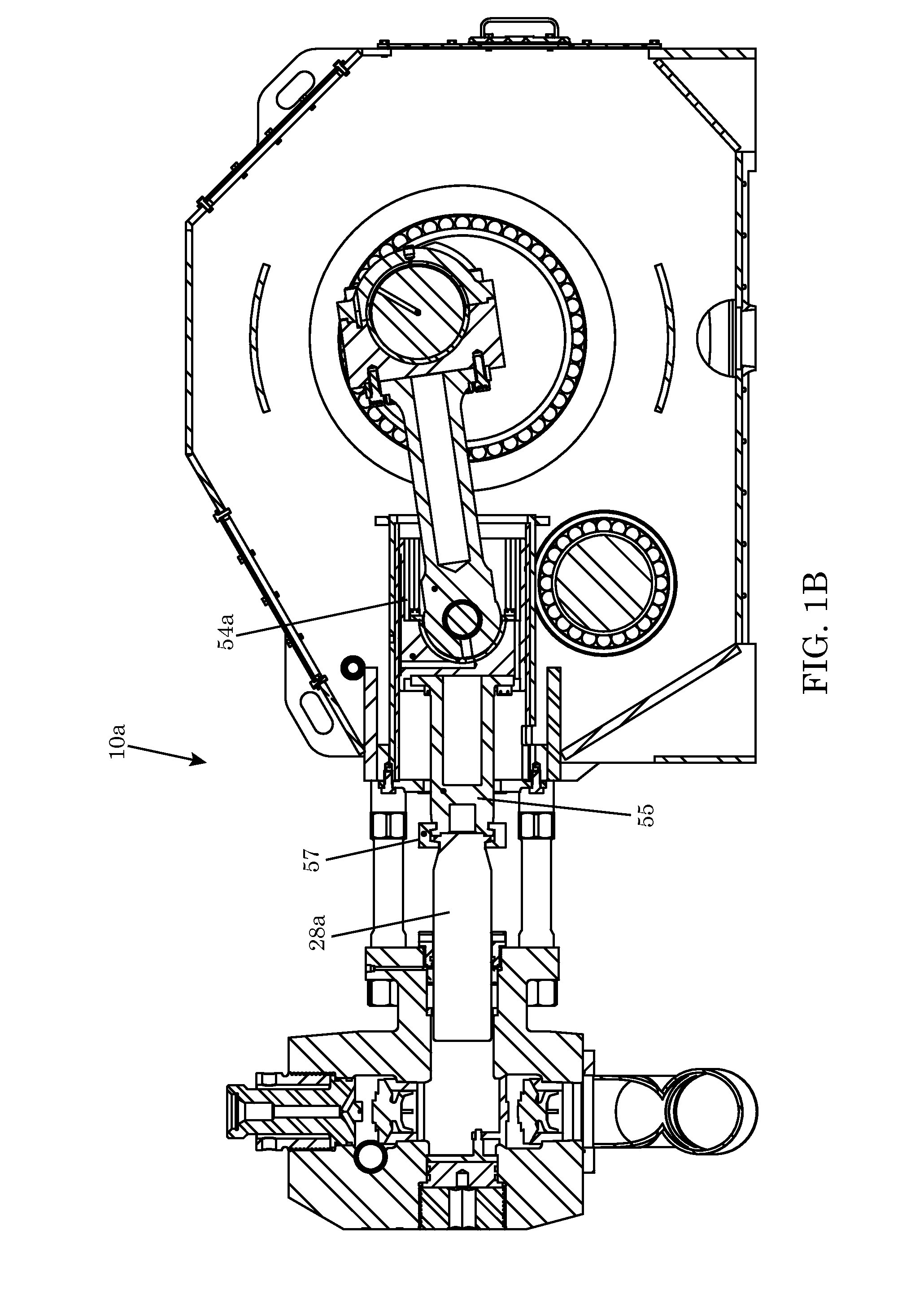

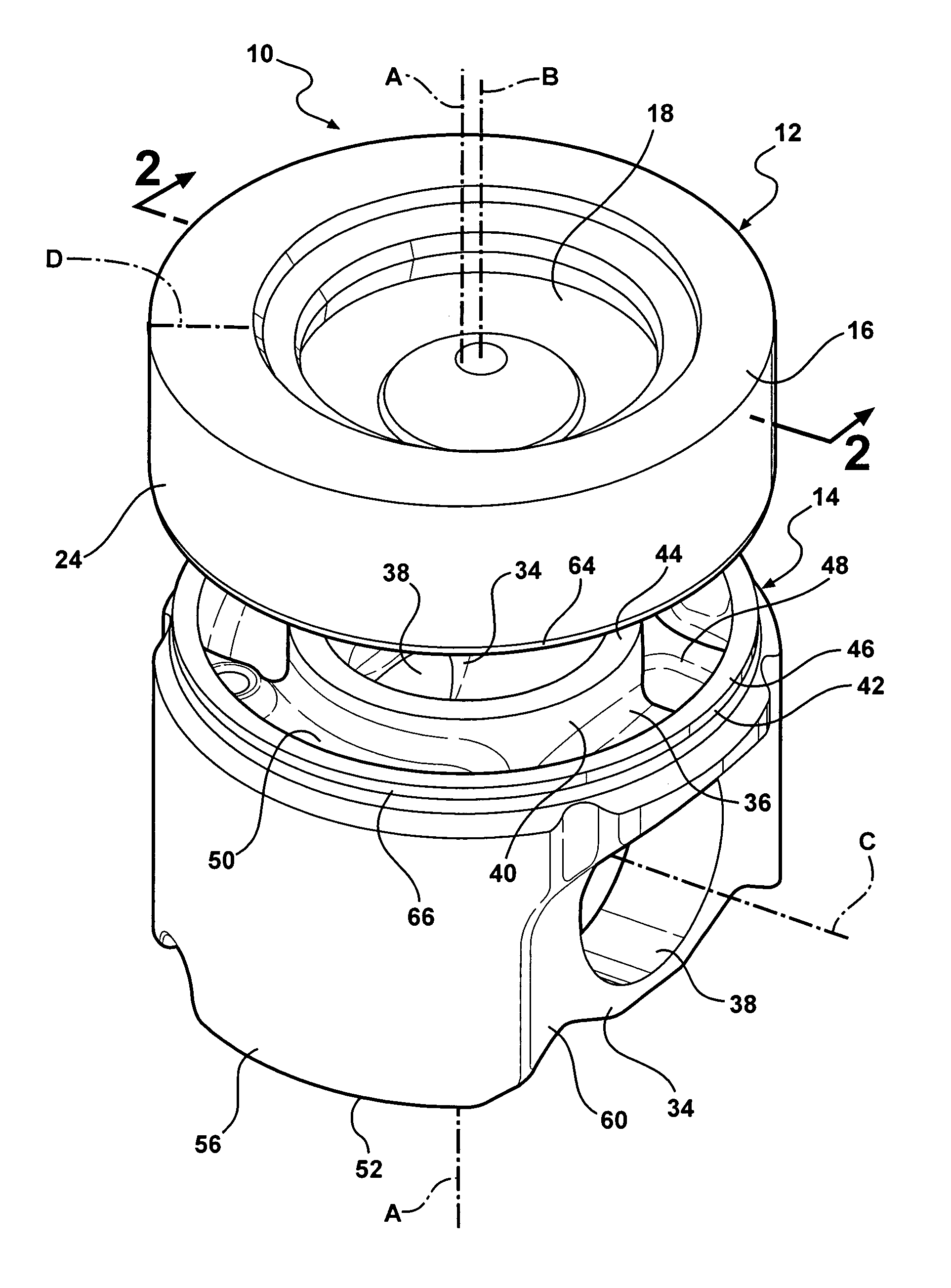

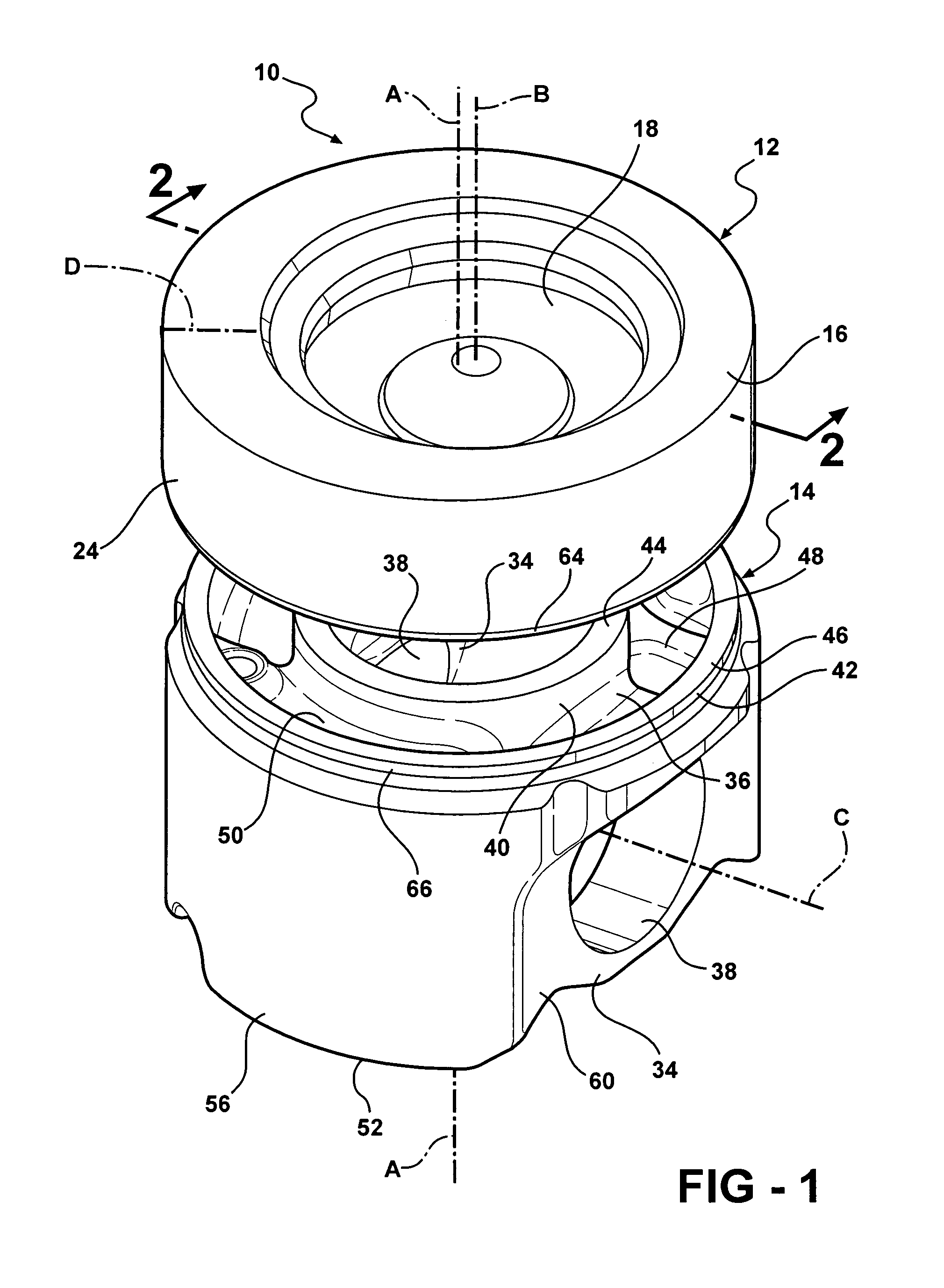

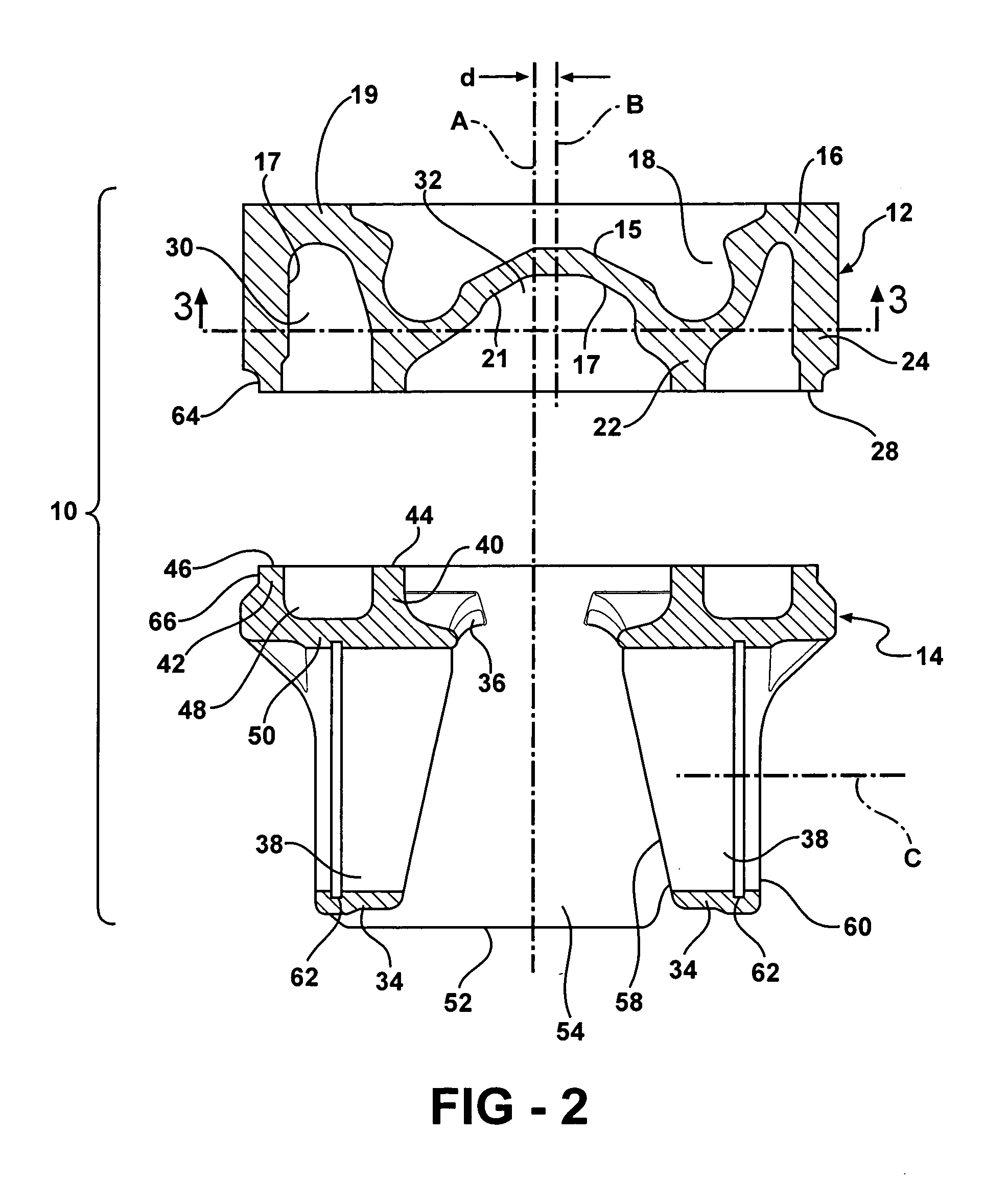

Plunger Pump, Plunger, and Method of Manufacturing Plunger Pump

InactiveUS20150132157A1Increase stiffnessImprovements in a plunger pumpPositive displacement pump componentsPlungersBiomedical engineeringPlunger pump

A plunger pump includes a pump fluid end having a fluid chamber and a suction bore, discharge bore, and plunger bore in communication with the fluid chamber. A plunger is arranged to reciprocate into and out of the fluid chamber through the plunger bore. The plunger has a plunger body with an inner cavity and an insert disposed in the inner cavity such that the combined stiffness of the insert and plunger body is greater than the stiffness of the plunger body. A crank mechanism is coupled to the plunger and operable to reciprocate the plunger.

Owner:NAT OILWELL VARCO LP

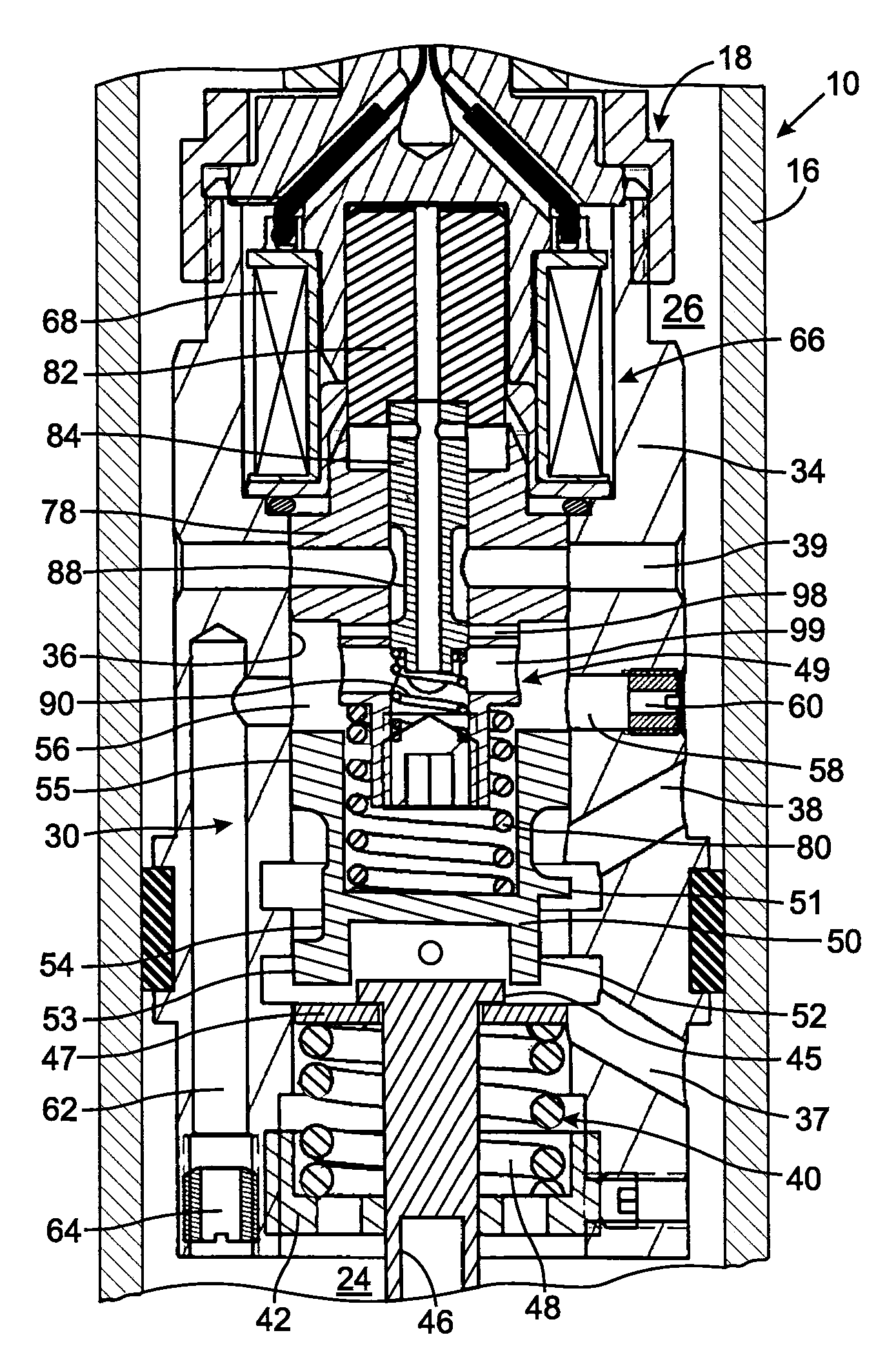

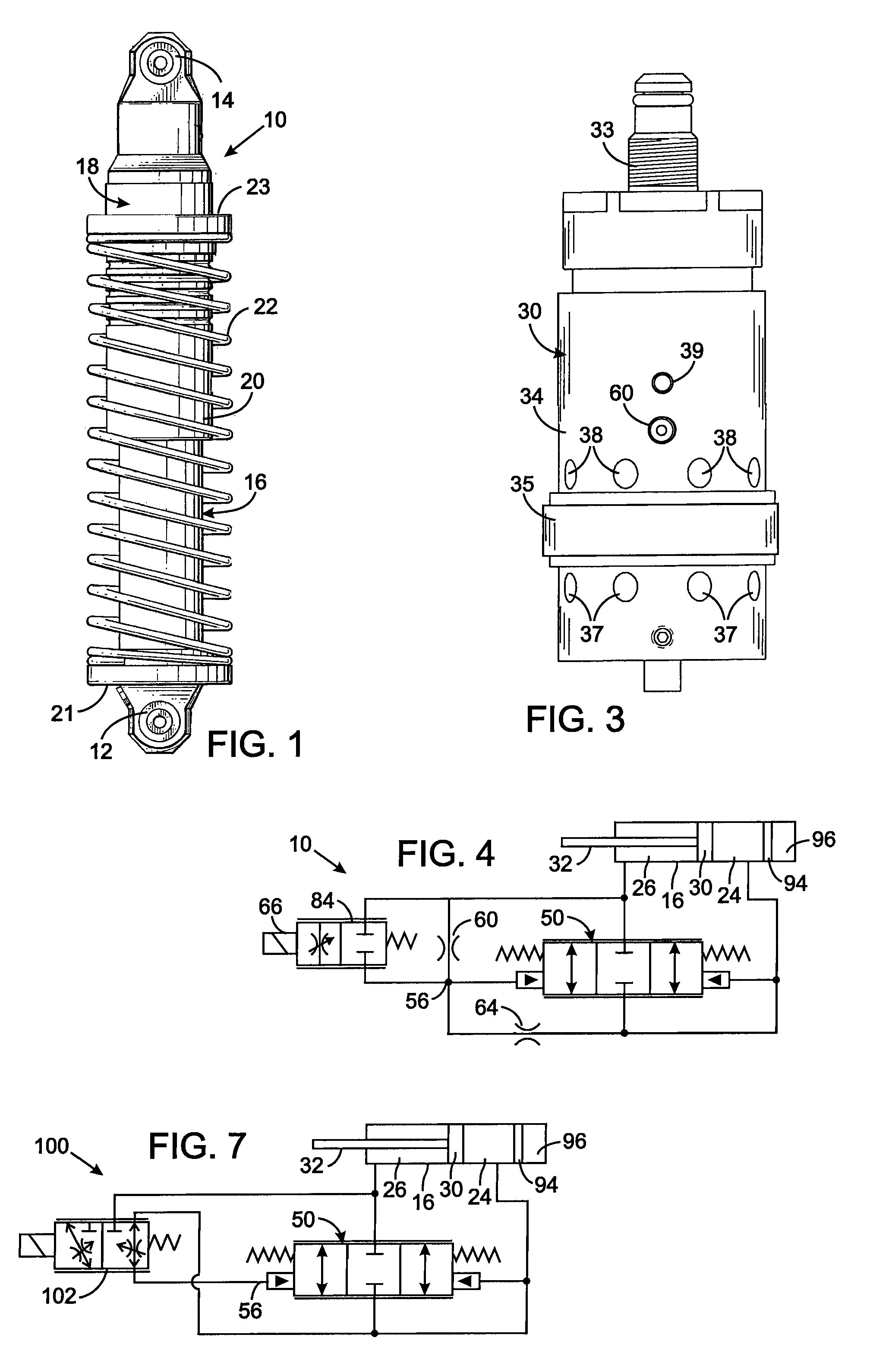

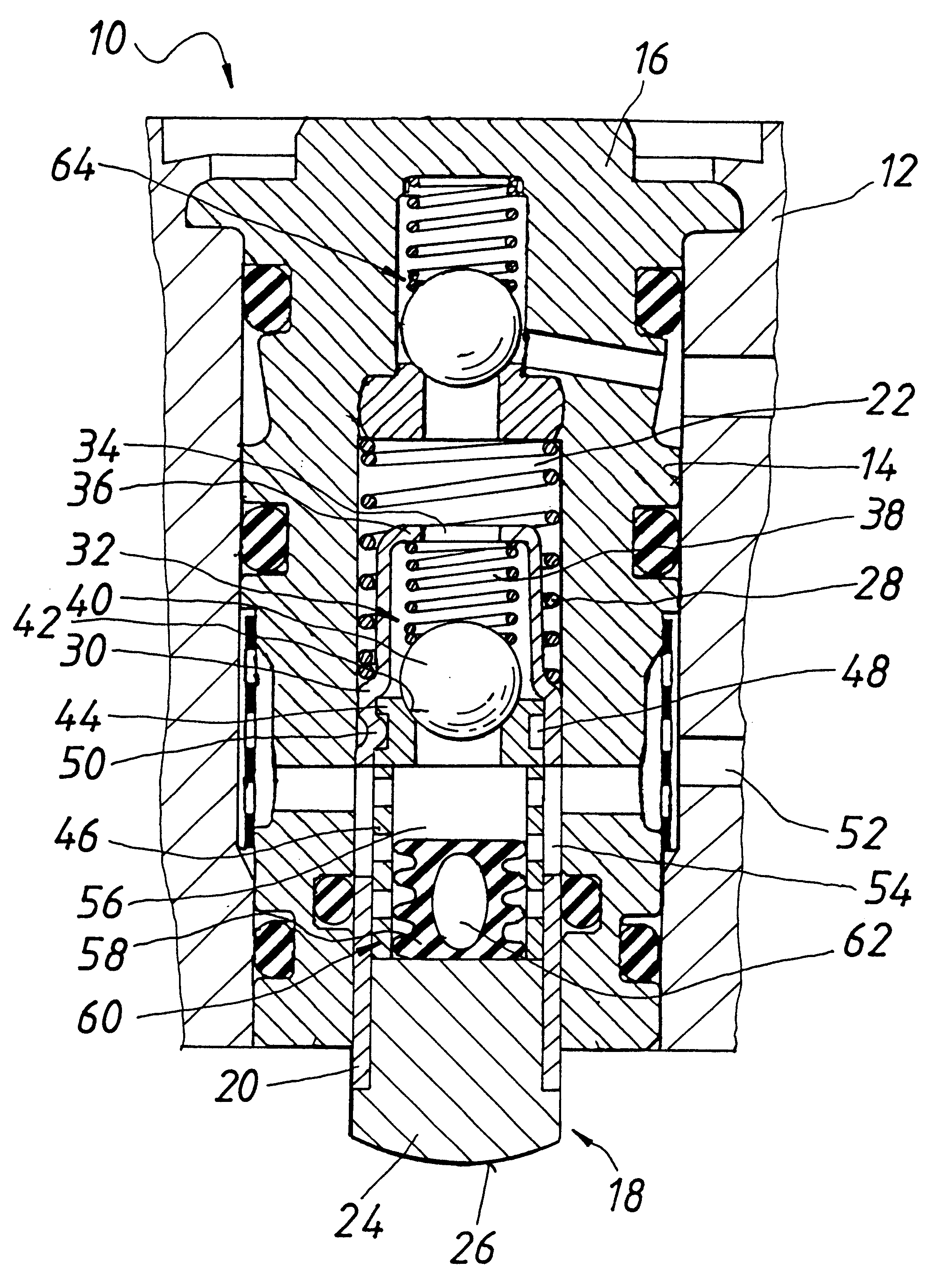

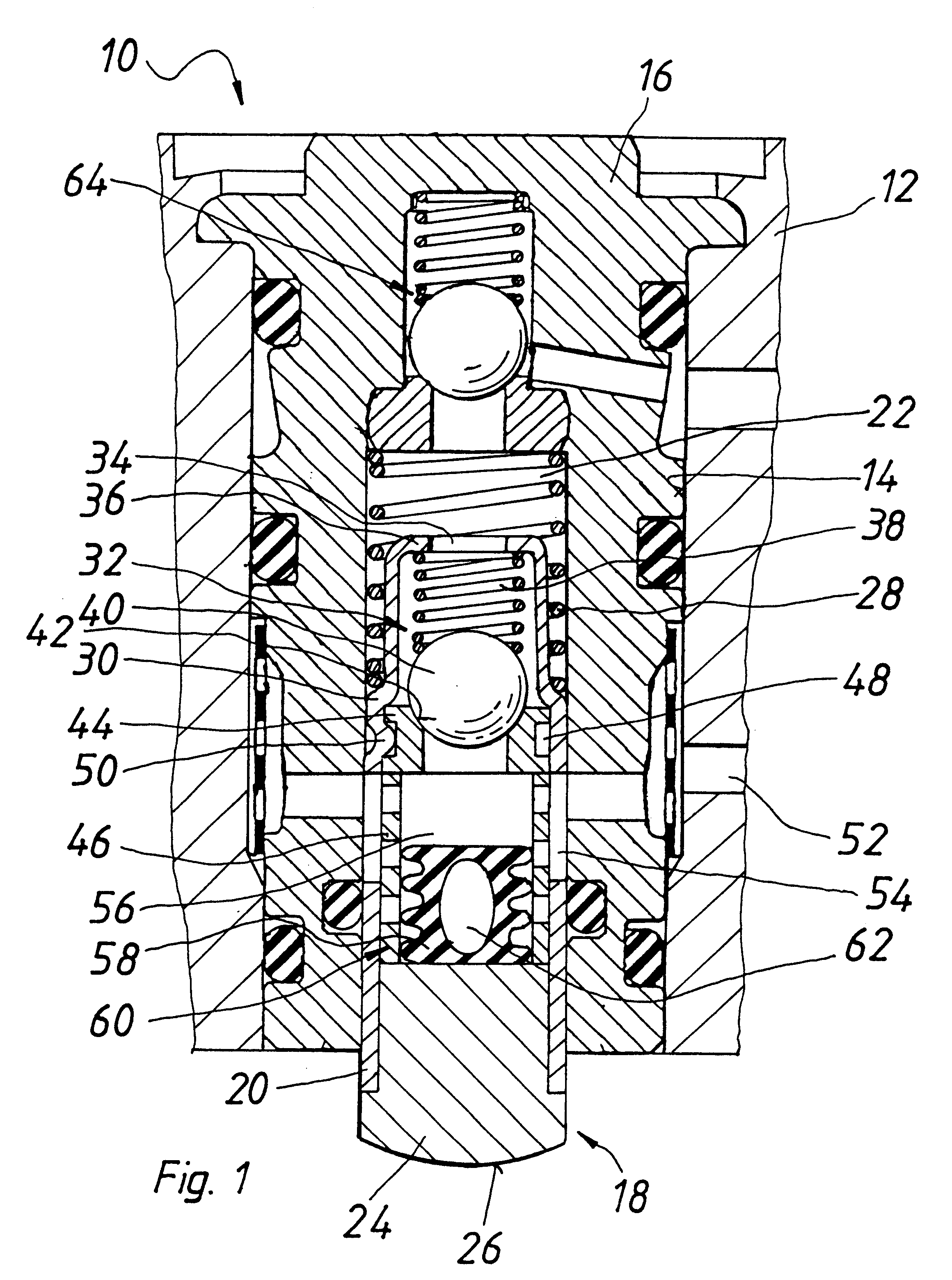

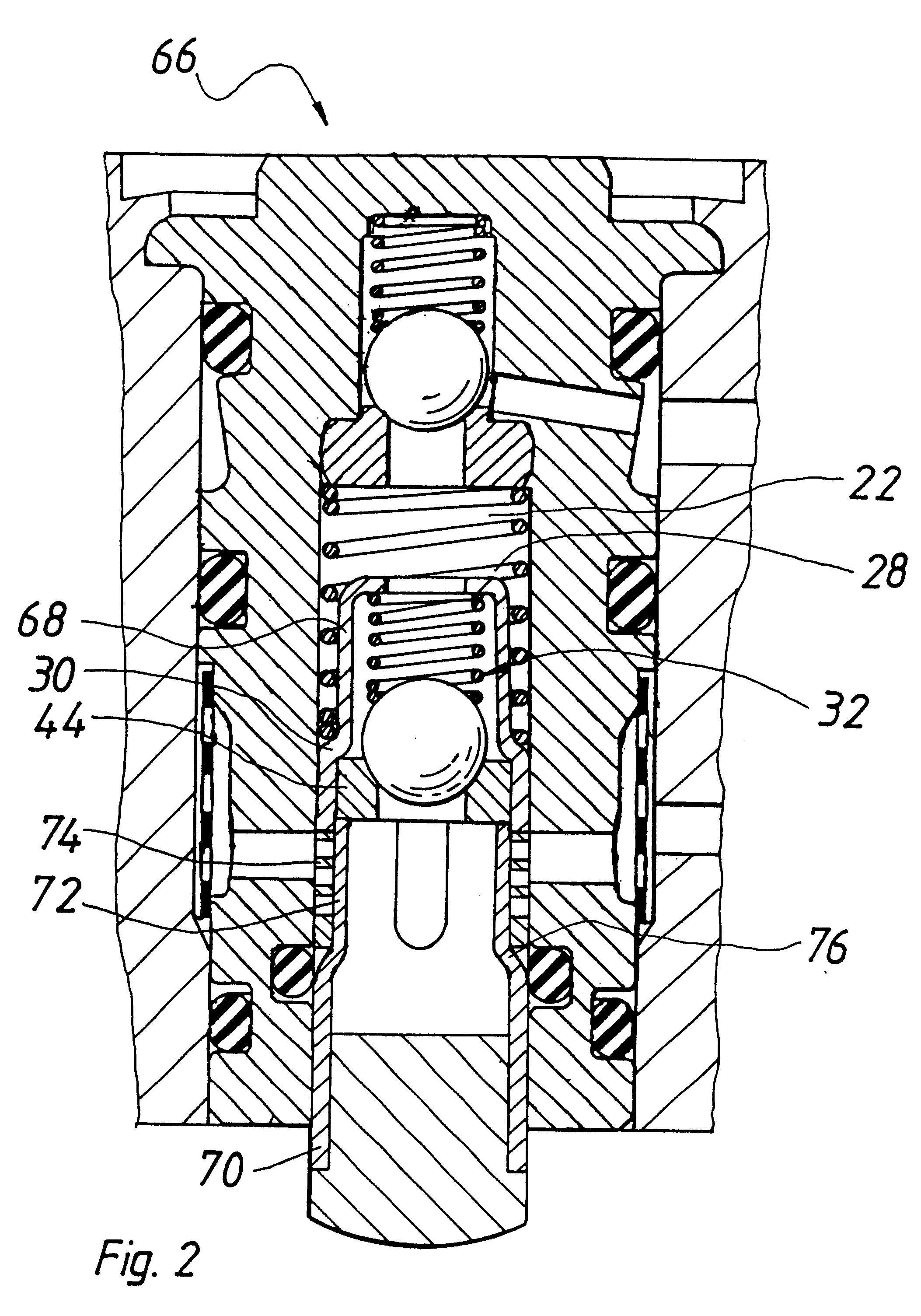

Hydraulic vibration damper piston with an integral electrically operated adjustment valve

A vibration damper piston includes a piston body with a bore from which first and second apertures respectively provide paths to first and second chambers of the vibration damper. A valve spool in the bore defines a pilot chamber and controls fluid flow between the first and second apertures. First and second springs bias the valve spool in opposing directions. A control orifice provides a continuous fluid path between the first chamber and the pilot chamber, and a variable orifice provides another fluid path between the second chamber and the pilot chamber. An actuator is operably connected to adjust the variable orifice in response to a control signal.

Owner:HUSCO AUTOMOTIVE HLDG

Piston and method of manufacture

A piston particularly adapted for heavy-duty diesel engine applications is fabricated from a separate head portion and base portion having circumferentially extending joining surfaces that are heated prior to bonding to an elevated temperature sufficient to enable bonding of the joining surfaces, and thereafter the joining surfaces brought into contact with one another and twisted to attain a permanent metallurgical weld at the interface of the joining surfaces. The head portion has an eccentric combustion bowl and crown. The joined head portion and base portion together form a monobloc piston having a closed gallery which is adapted to receive a cooling fluid, such as oil. The combustion bowl has a substantially uniform bowl sidewall thickness. The piston and method are particularly adopted for use with steel alloys and other high temperature metal alloys.

Owner:FEDERAL MOGUL WORLD WIDE

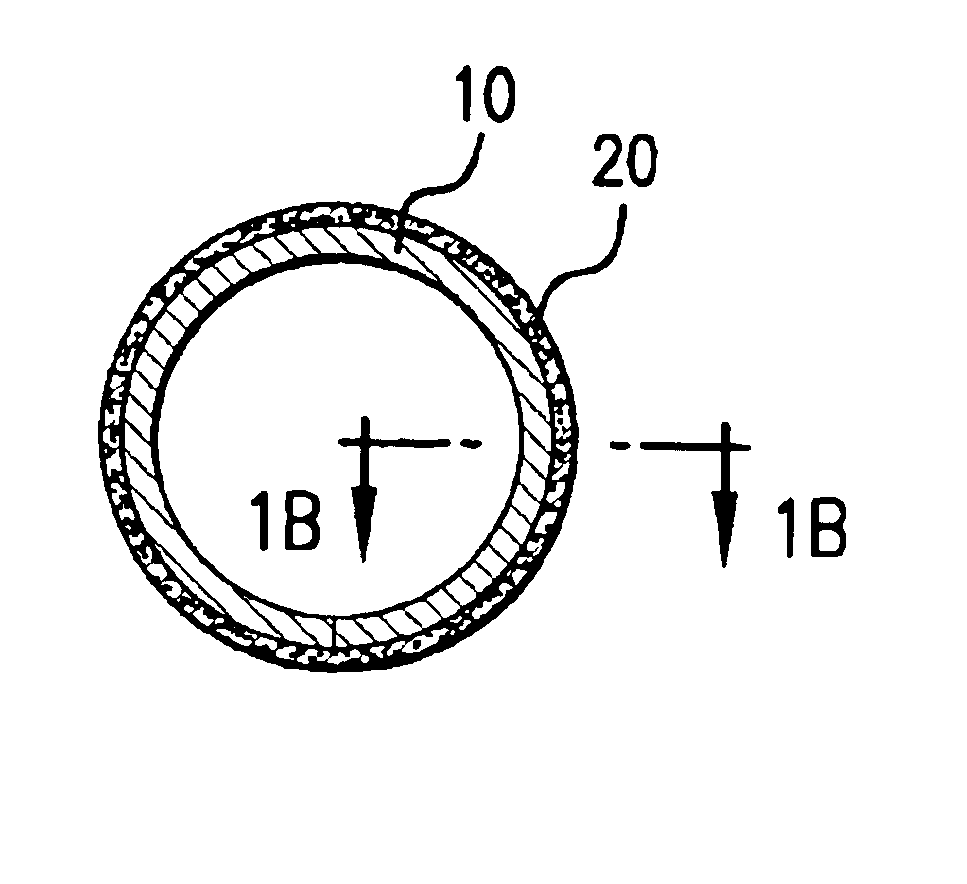

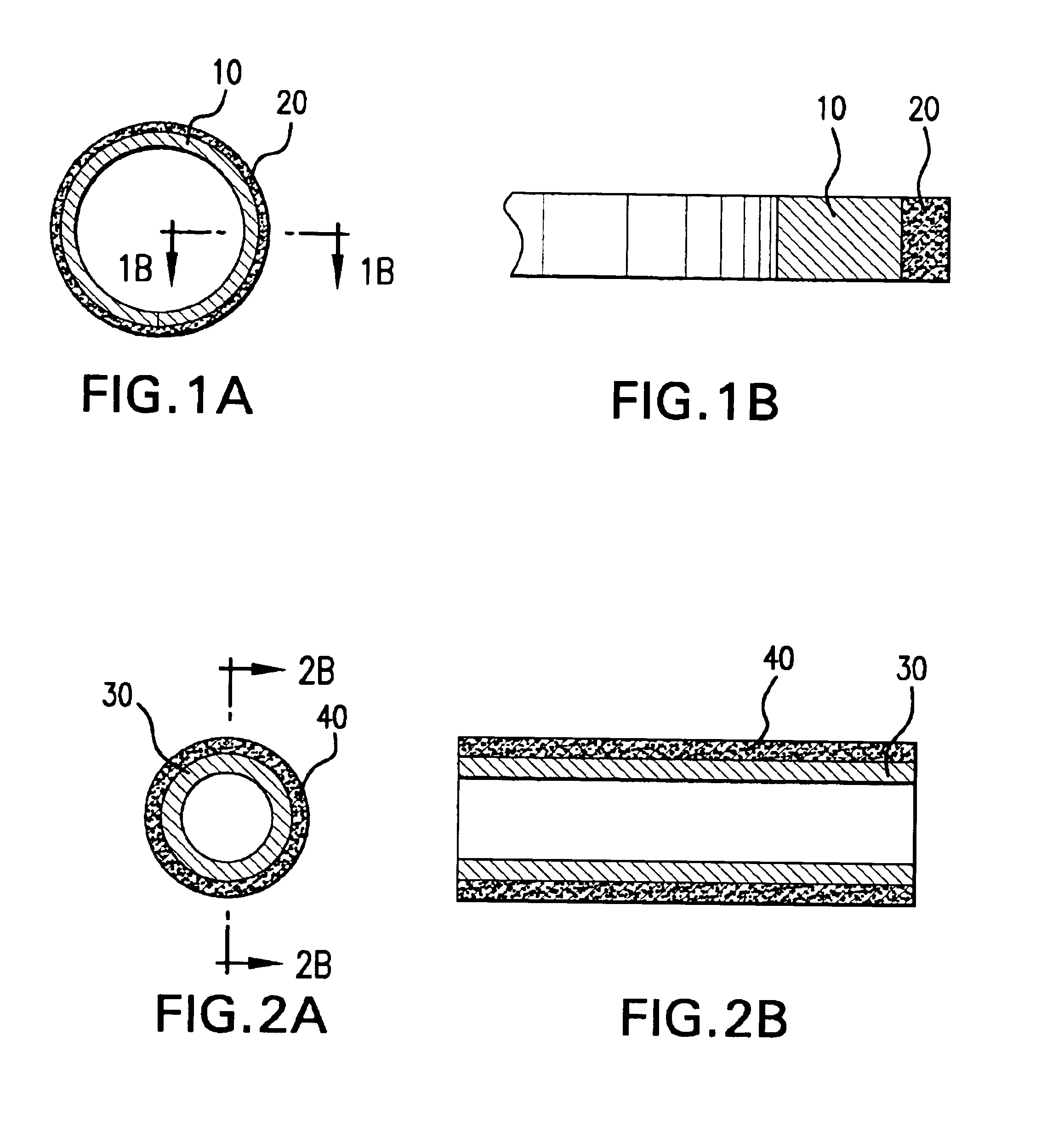

Gasket and method of manufacturing the gasket

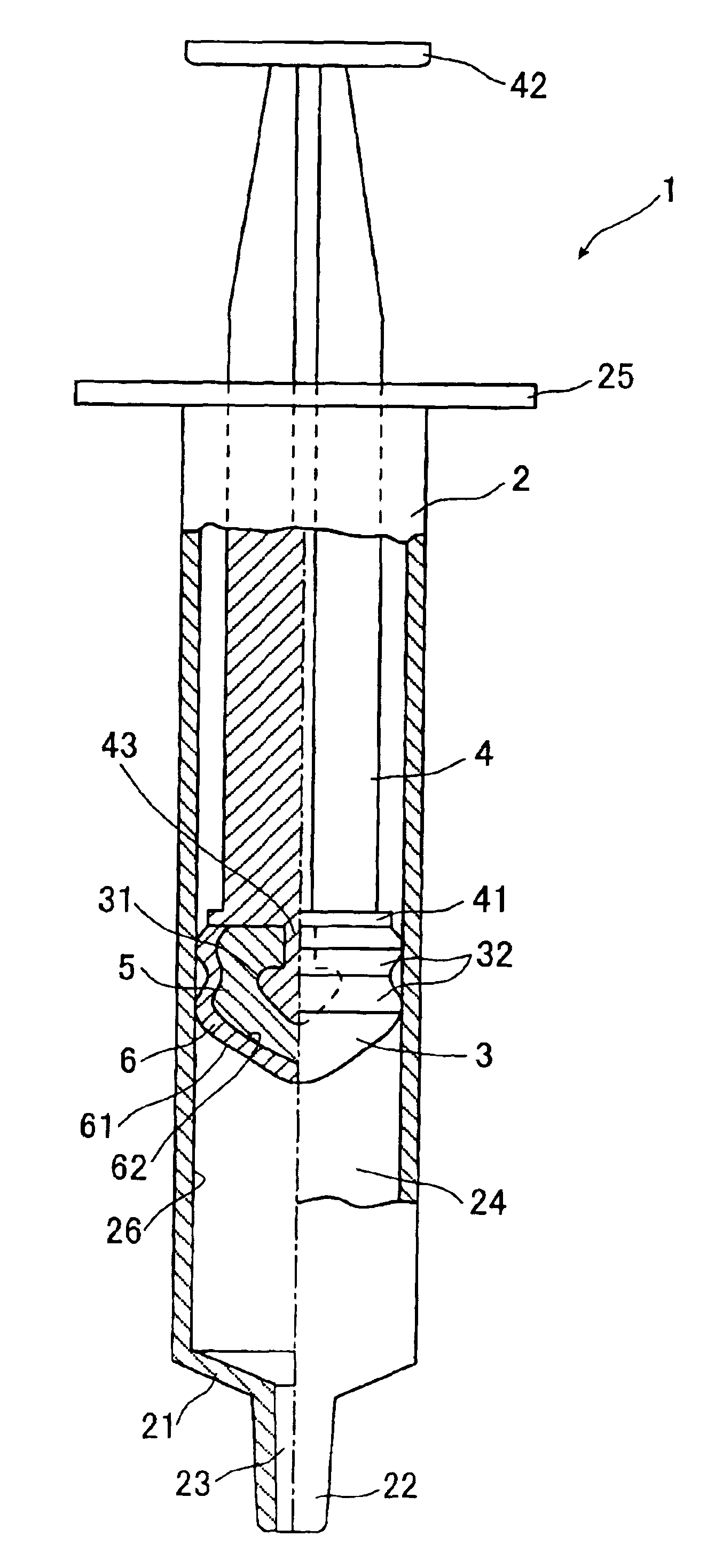

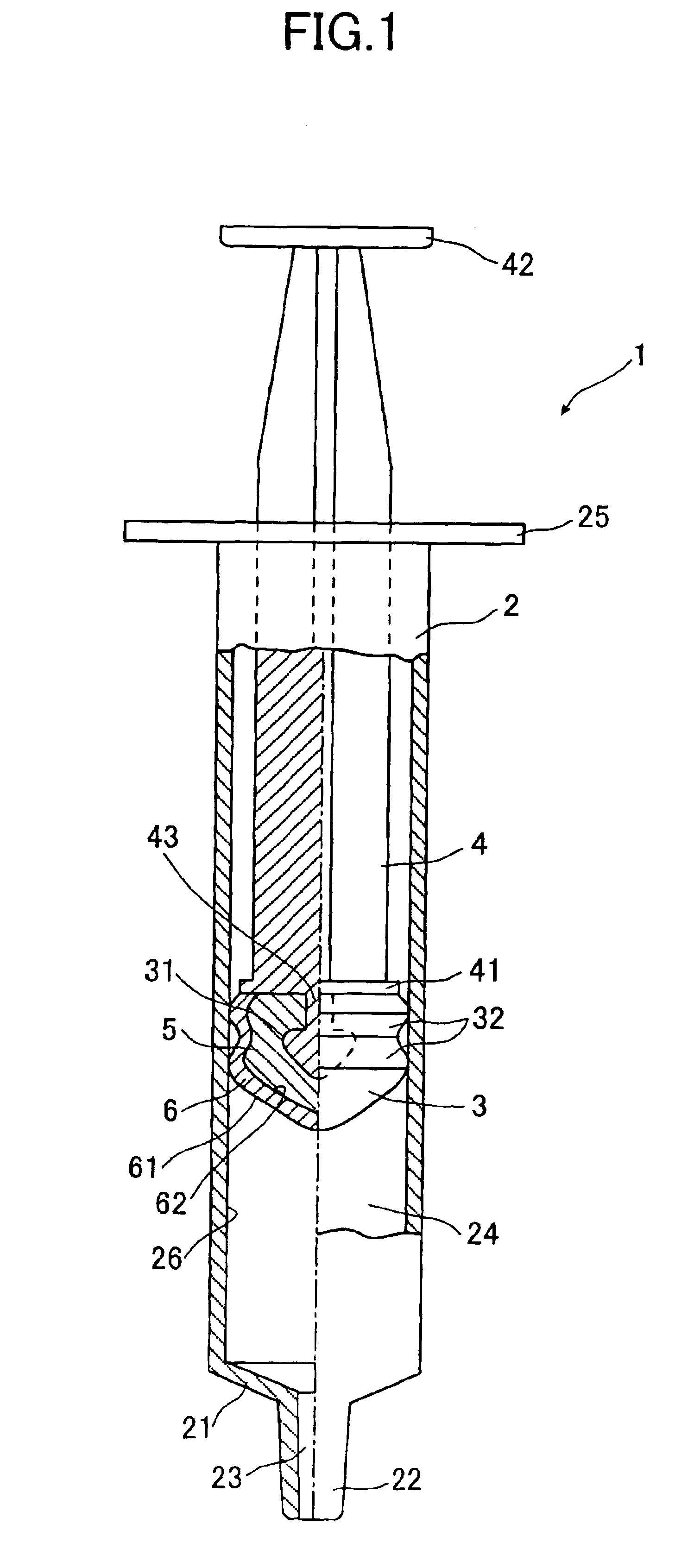

InactiveUS7111848B2Easy to slideHolding its sealabilityEngine sealsPositive displacement pump componentsSurface roughnessEngineering

A gasket is capable of providing an excellent slidabiity and holding its sealability without applying lubricant and a gasket that can prevent a resin film from being peeled off of a gasket body and prevent the generation of a molding defect such as pinholes. The gasket can be installed slidably in a outer tube of a syringe, including a gasket body and a resin film formed of a material lower in coefficient of friction than a material of the gasket body, which covers at least an outer periphery of the gasket body, in which when a surface roughness of the resin film on the outer tube side is defined as Ra1 and a surface roughness of the resin film on the gasket body side is defined as Ra2, a relationship of 1.5 Ra1≦Ra2 is satisfied.

Owner:TERUMO KK +1

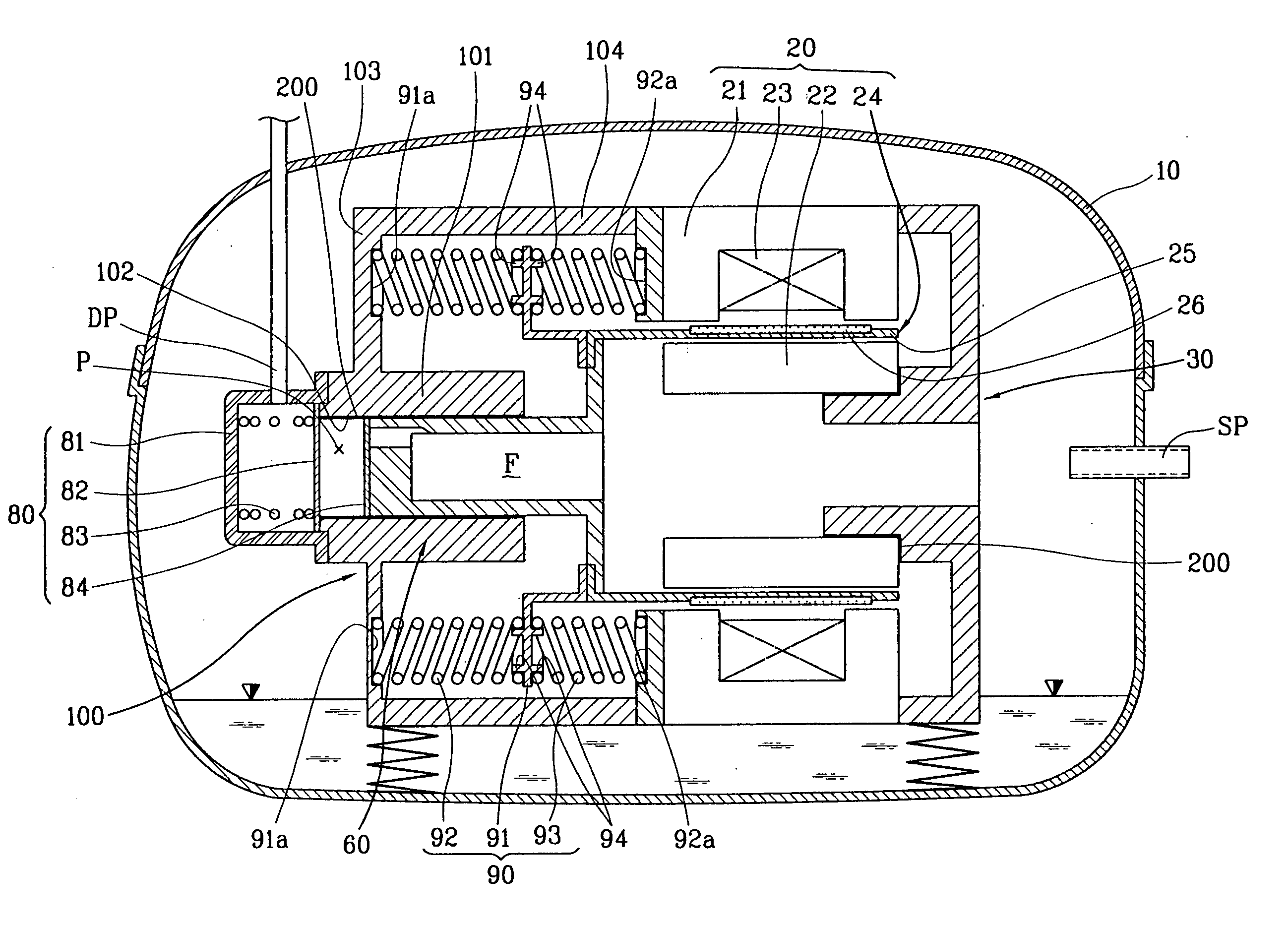

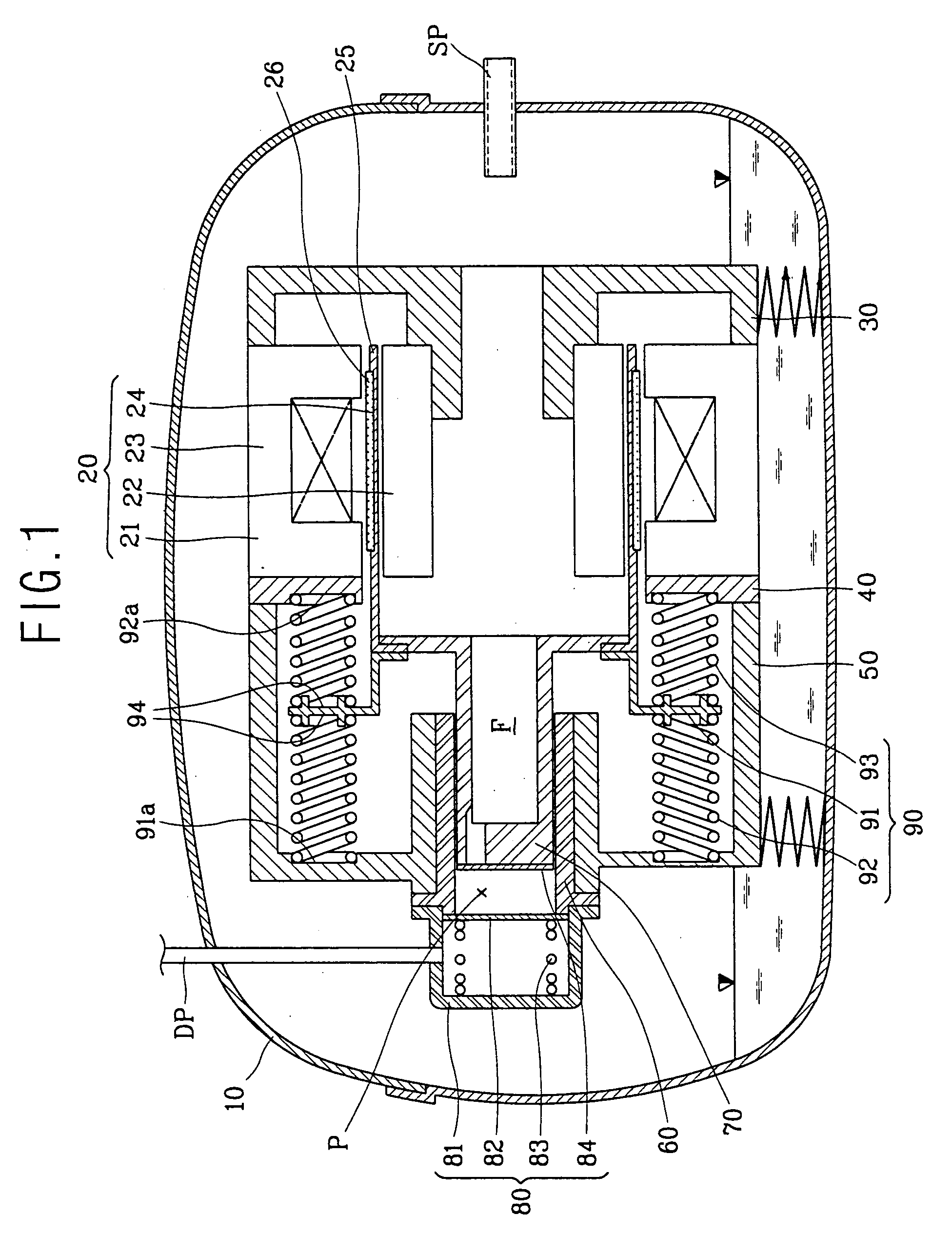

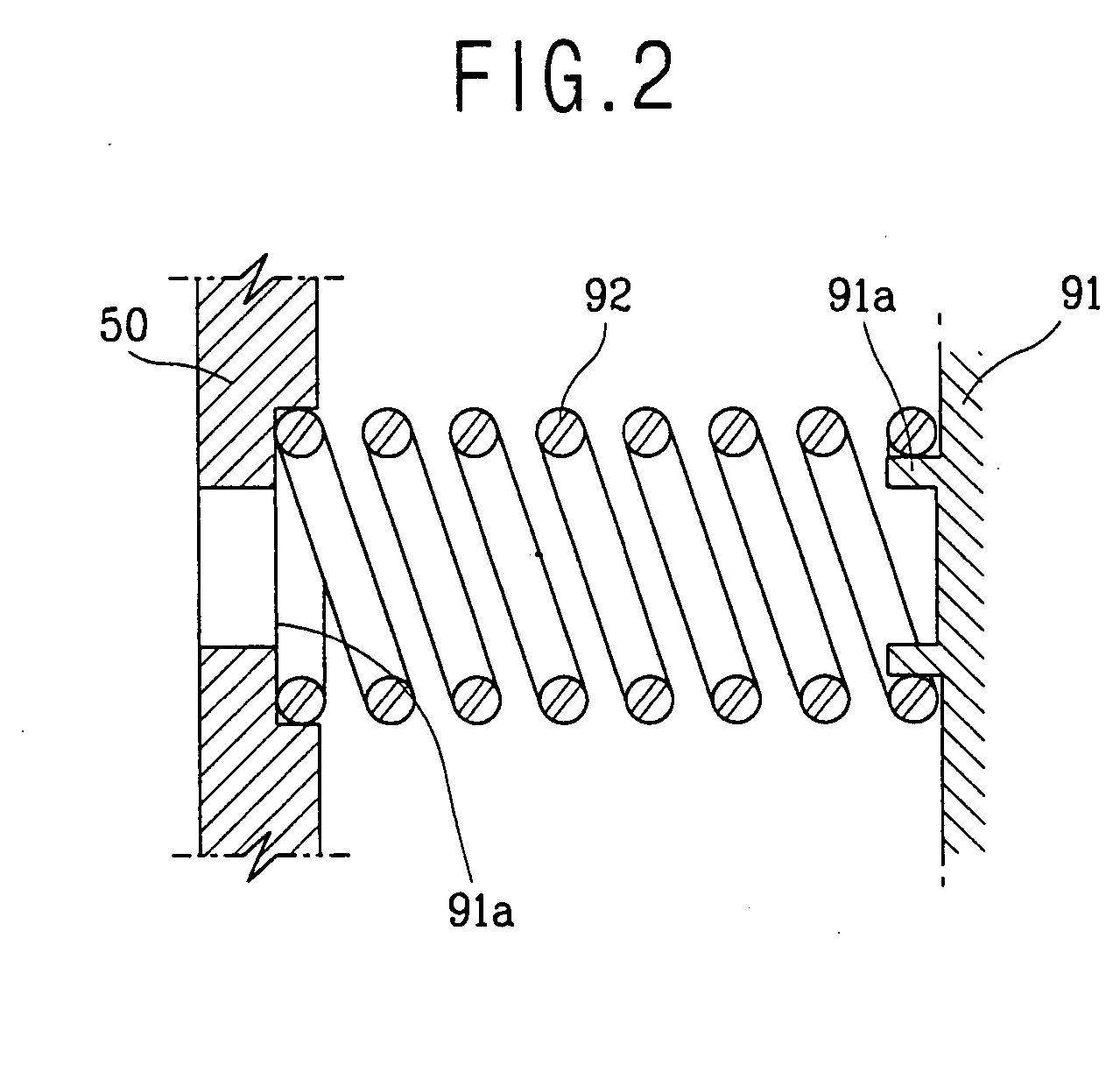

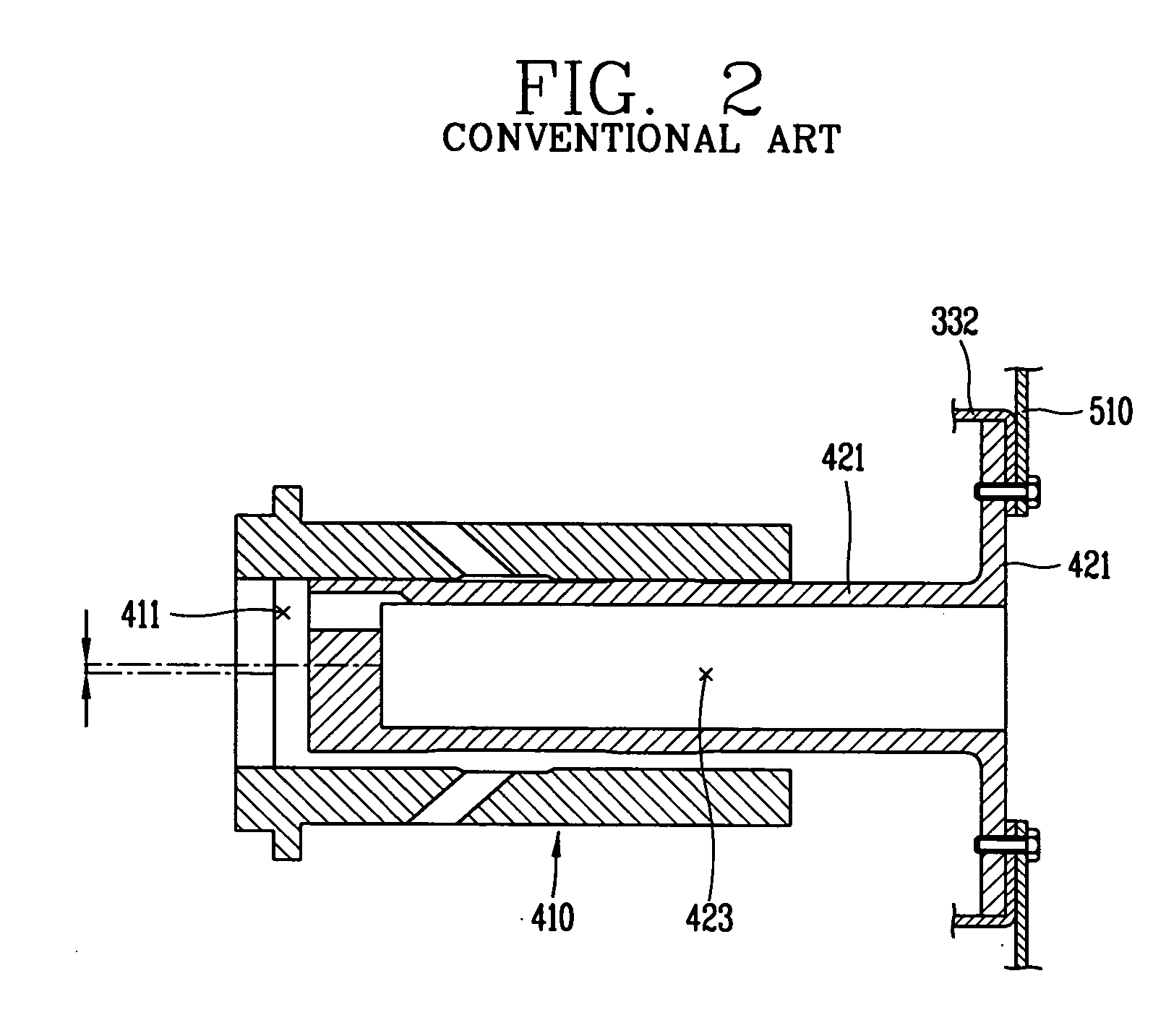

Abrasion preventive structure of reciprocating compressor

In an abrasion preventive structure of a reciprocating compressor, by forming a coating layer made of Ni—P alloy material having high hardness onto the surface of a frame at which front (92) and rear (93) resonance springs are contacted or spring mounting grooves (91a, 92a) of a spring supporting rod (91) or spring fixation protrusions or the inner circumference of a cylinder built-in type frame, although each resonance spring (92, 93) is rotated while repeating compression / relaxation, it is possible to prevent abrasion of the spring mounting grooves (91a, 92a) or the spring fixation protrusions, and accordingly reliability of the compressor can be improved.

Owner:LG ELECTRONICS INC

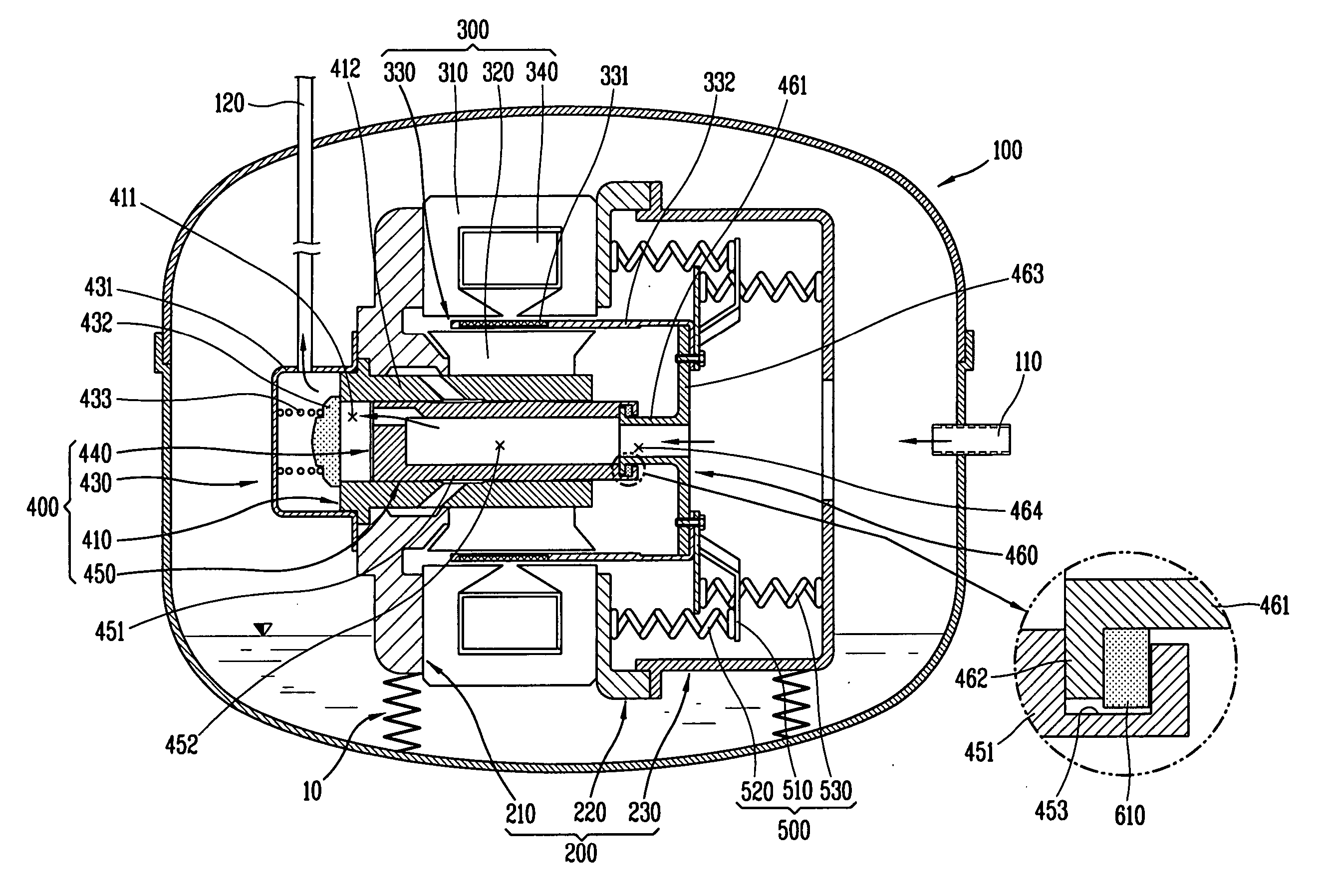

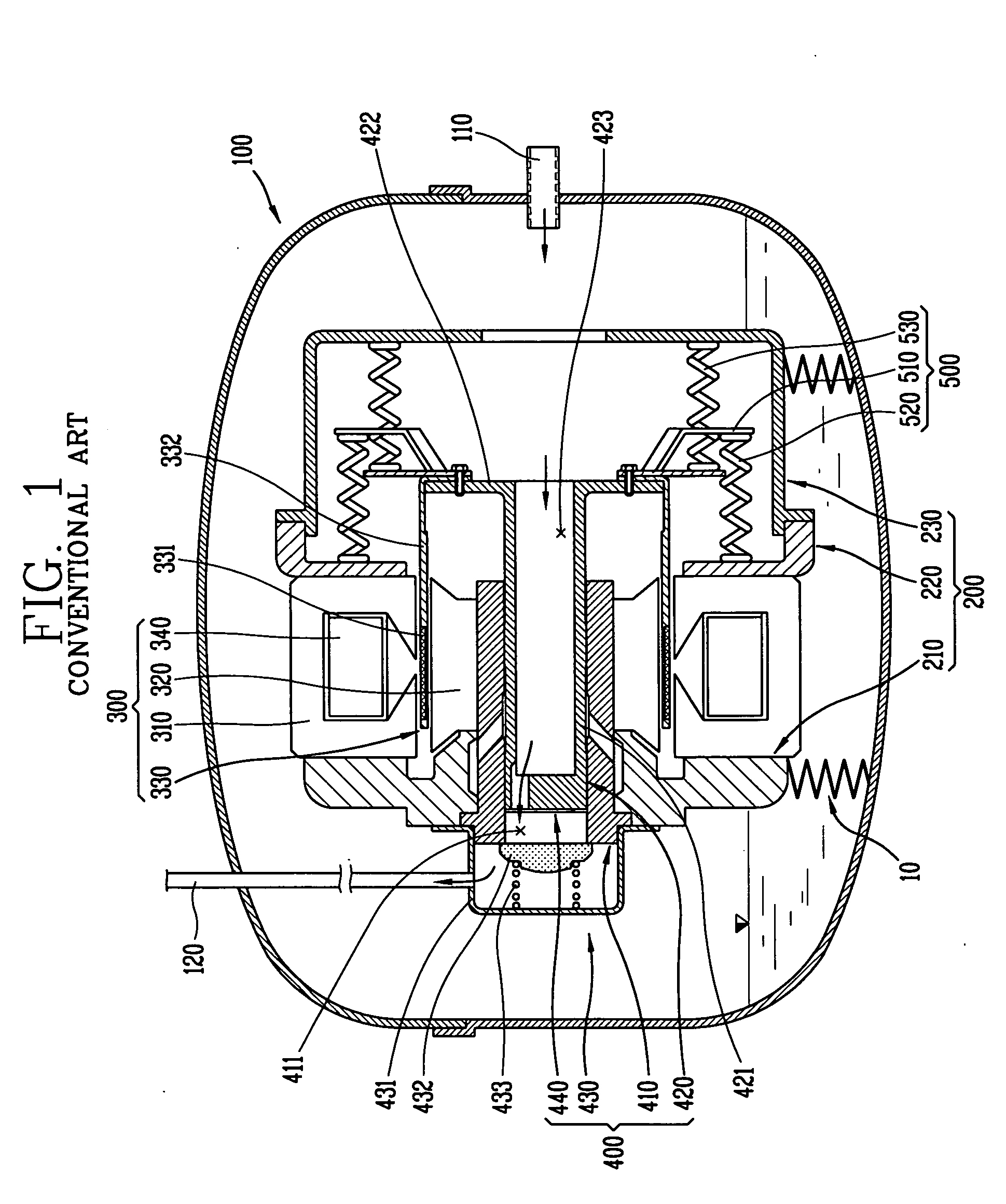

Apparatus for preventing abrasion in reciprocal compressor

InactiveUS20050142007A1Avoid scratchesPositive displacement pump componentsPlungersInterior spaceRelative motion

The present invention discloses an apparatus for preventing abrasion in a reciprocal compressor, including a cylinder, a reciprocal motor having a stator and a mover, and generating a linear reciprocation driving force, a piston inserted into an inside space of the cylinder to be linearly movable, a piston rod coupled to the piston to be movable in the radial direction of the piston, and coupled to the mover of the reciprocal motor, for transmitting the linear reciprocation driving force of the reciprocal motor to the piston, and a concentricity control means coupled to a junction between the piston and the piston rod, for fixing the piston and the piston rod in the axial direction, and allowing a relative motion thereof in the radial direction. The apparatus for preventing abrasion in the reciprocal compressor prevents abrasion from being generated between the cylinder and the piston due to processing errors and assembly errors of components of the reciprocal compressor.

Owner:LG ELECTRONICS INC

Copper-base sintered sliding material excellent in slipperiness and machaniability

InactiveUS6165246AImprove machinabilityImproved sliding characteristic and machinabilityPlungersShaftsHardnessAlloy

PCT No. PCT / JP98 / 04685 Sec. 371 Date Jun. 16, 1999 Sec. 102(e) Date Jun. 16, 1999 PCT Filed Oct. 16, 1998 PCT Pub. No. WO99 / 20806 PCT Pub. Date Apr. 29, 1999In order to make the wear-resistance and machinability of the copper-based sliding material, in which such particles as AlN, Al2O3, NiB, Fe2B, SiC, TiC, WC, Si3N4, Fe3P, Fe2P and / or Fe3B are dispersed in the matrix consisting of sintered Cu or Cu alloy, the dispersion is performed such that the weight proportion and the average particle diameter of the medium-hardness particles of Hv 500 or more and 1000 or less are greater than those of the high-hardness particles having Hv 1100 or more.

Owner:TAIHO INDUSTRIES CO LTD

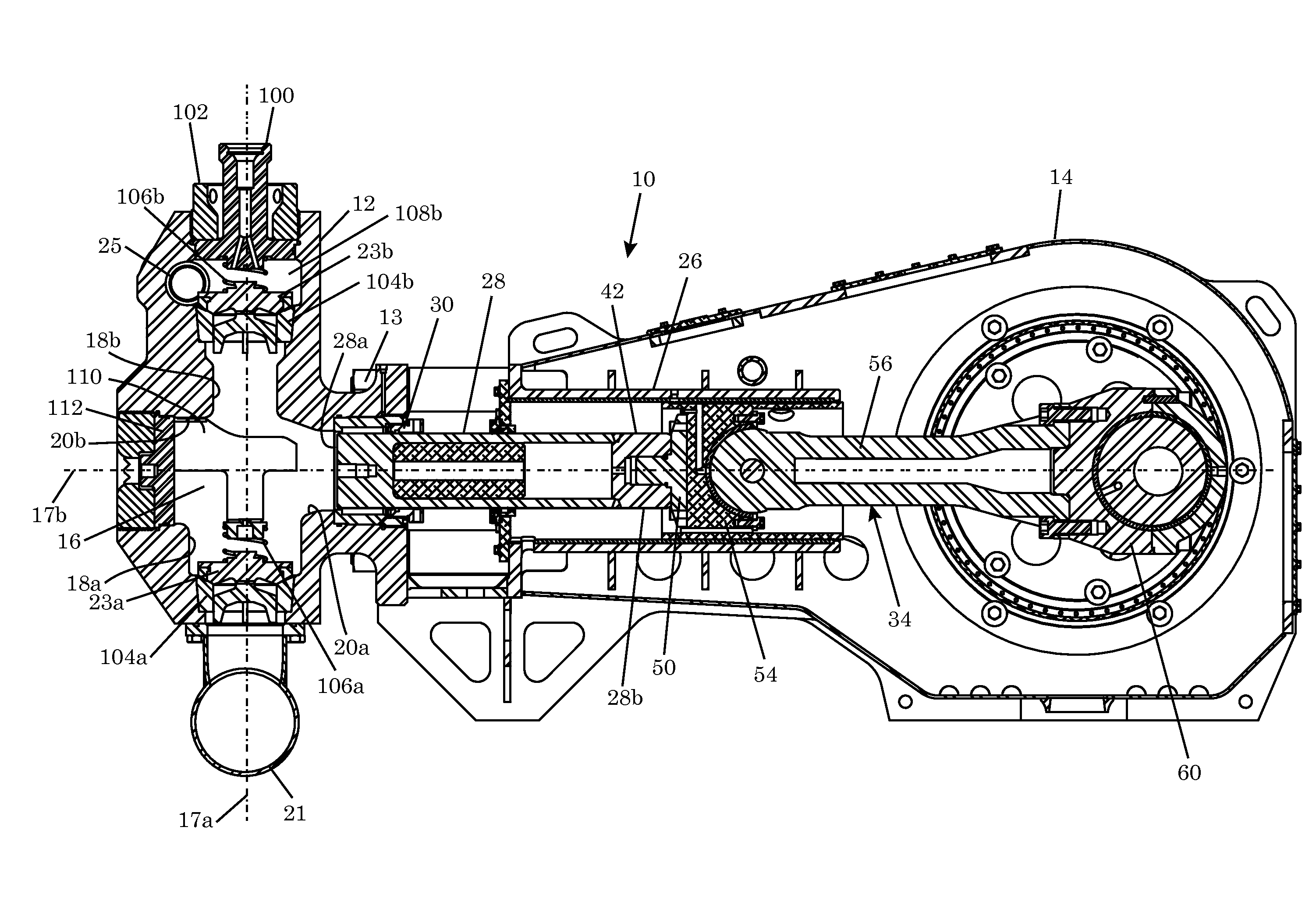

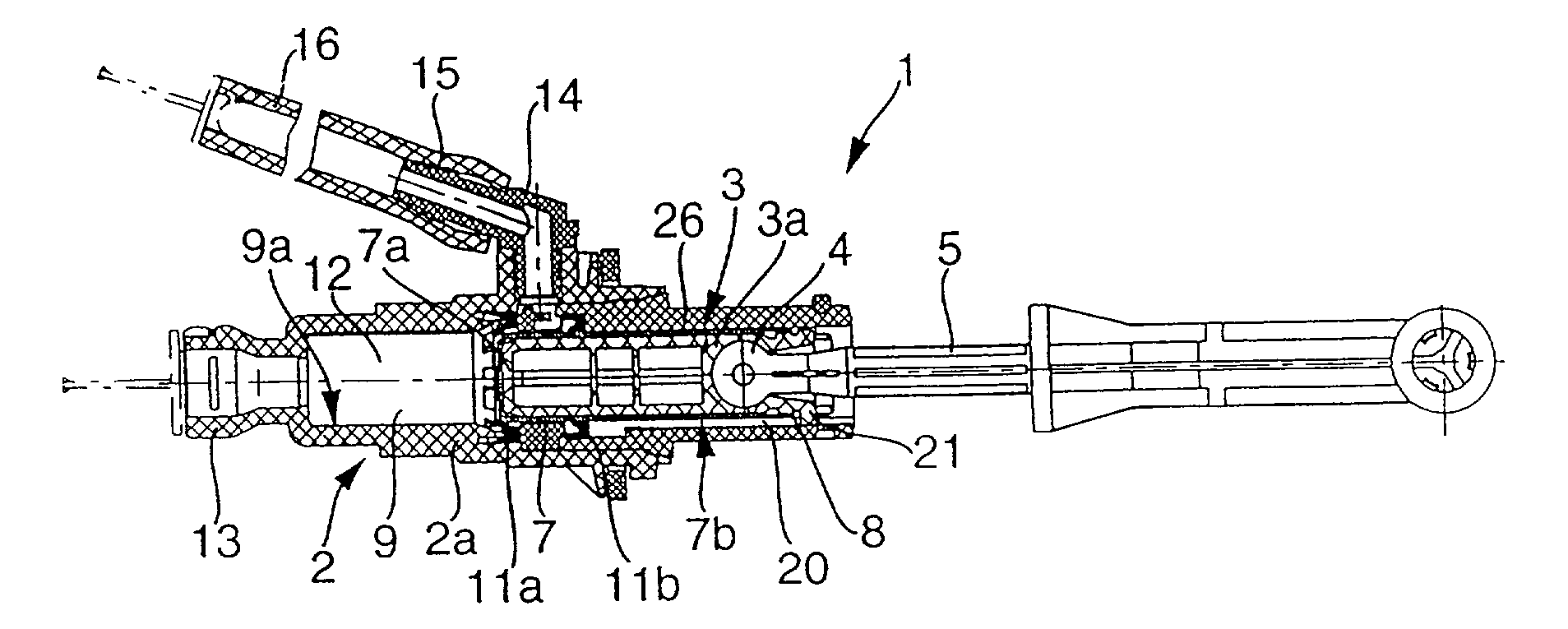

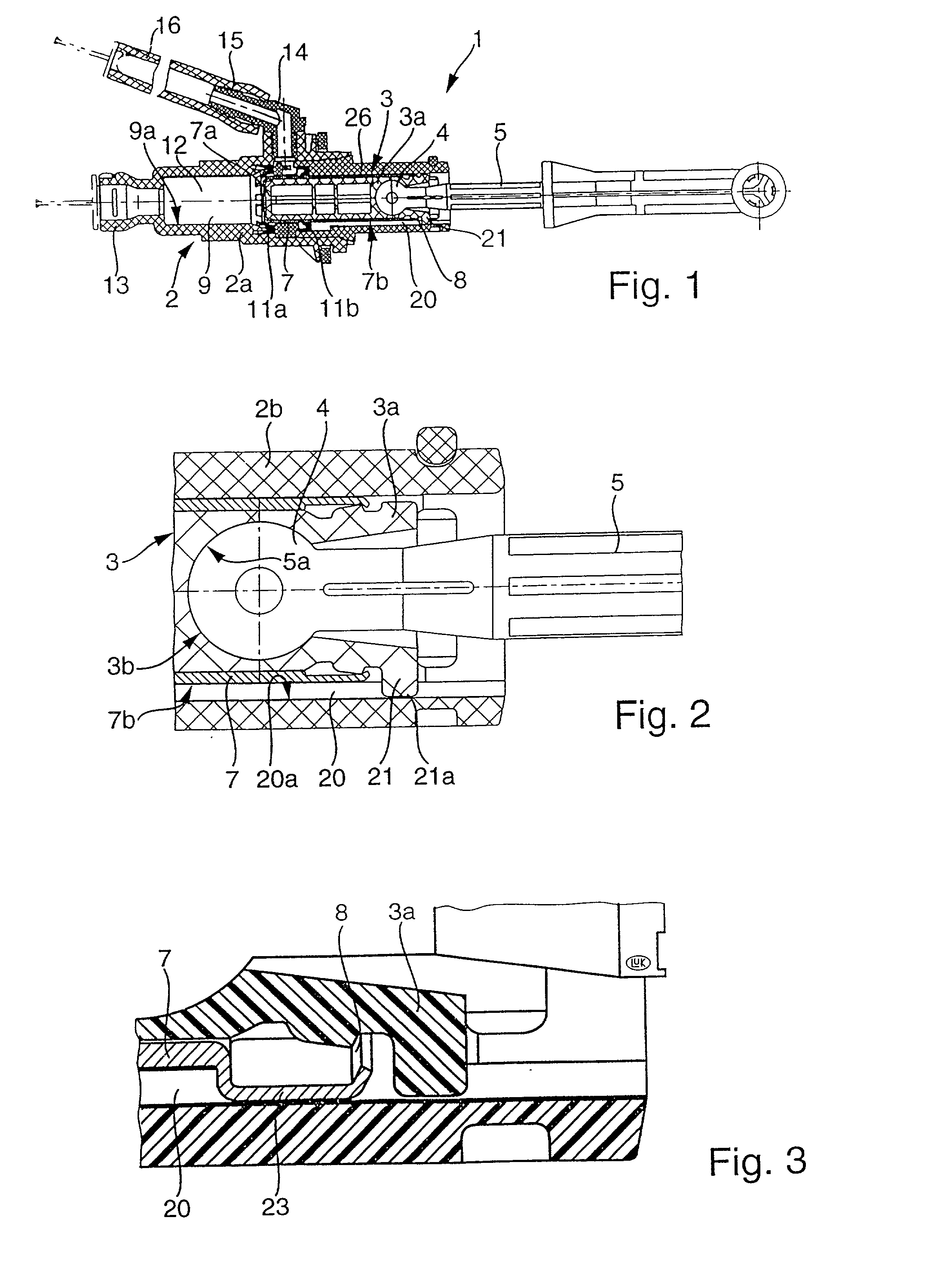

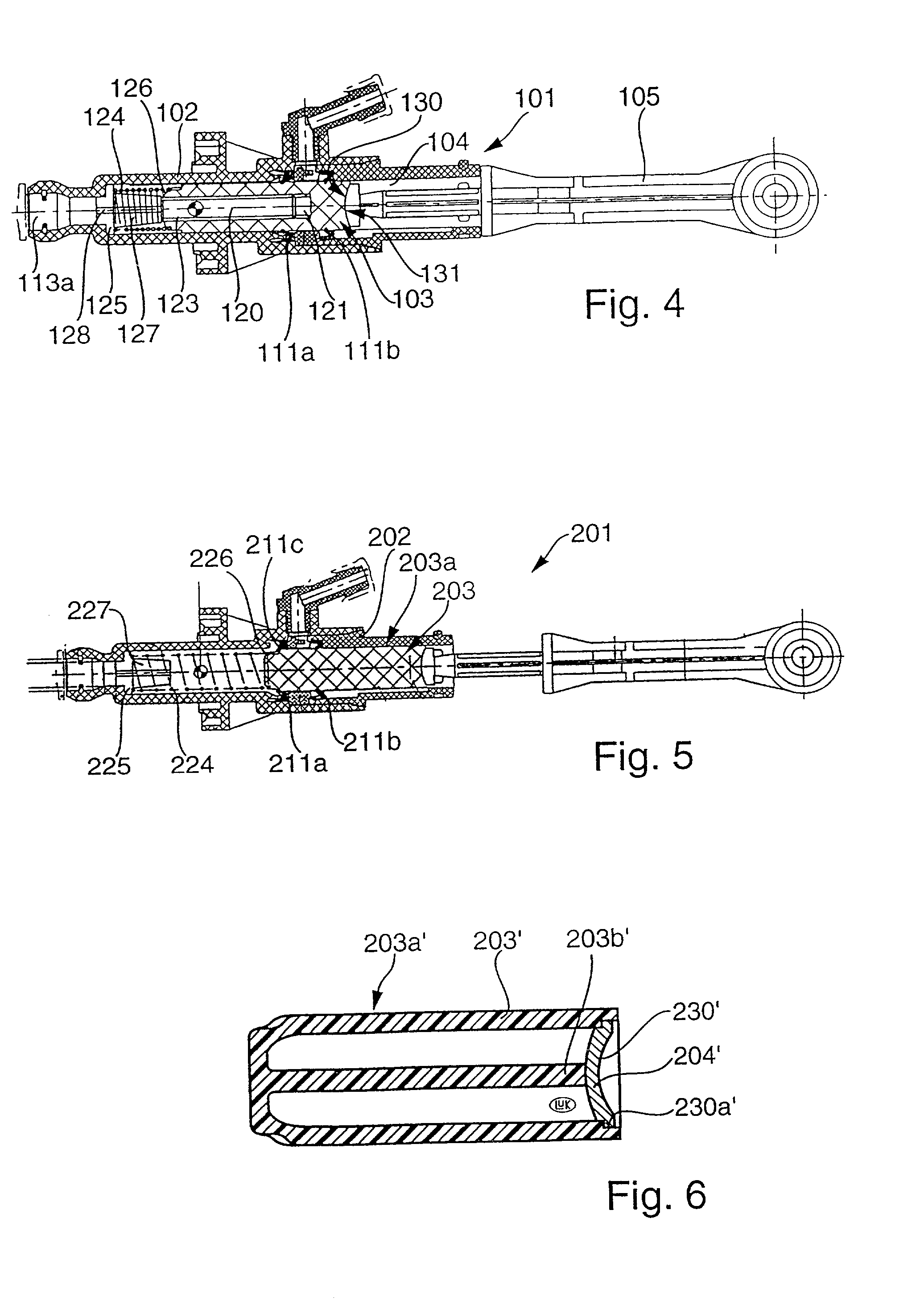

Master cylinder for use in power trains of motor vehicles

InactiveUS20020116924A1Satisfactory operationAvoid spreadingPiston ringsRotary clutchesMaster cylinderControl theory

A master cylinder for use in the power train of a motor vehicle to actuate the brakes or the friction clutch is designed to avoid the generation of screeching noise and / or the transmission of stray movements to the piston rod in response to shifting of the piston relative to the housing and relative to the sealing element(s) between the piston and the housing. This can be accomplished by causing the piston to turn relative to the housing and the sealing element(s) during axial movement in the housing and / or by installing one or more dampers between the piston and the housing and / or between the piston and the piston rod. The dampers can constitute separately produced parts and / or specially configured and / or finished surfaces provided on the piston and contacting the housing and / or the sealing element(s). The invention also relates to improvements in the configuration and / or the material(s) of the piston.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

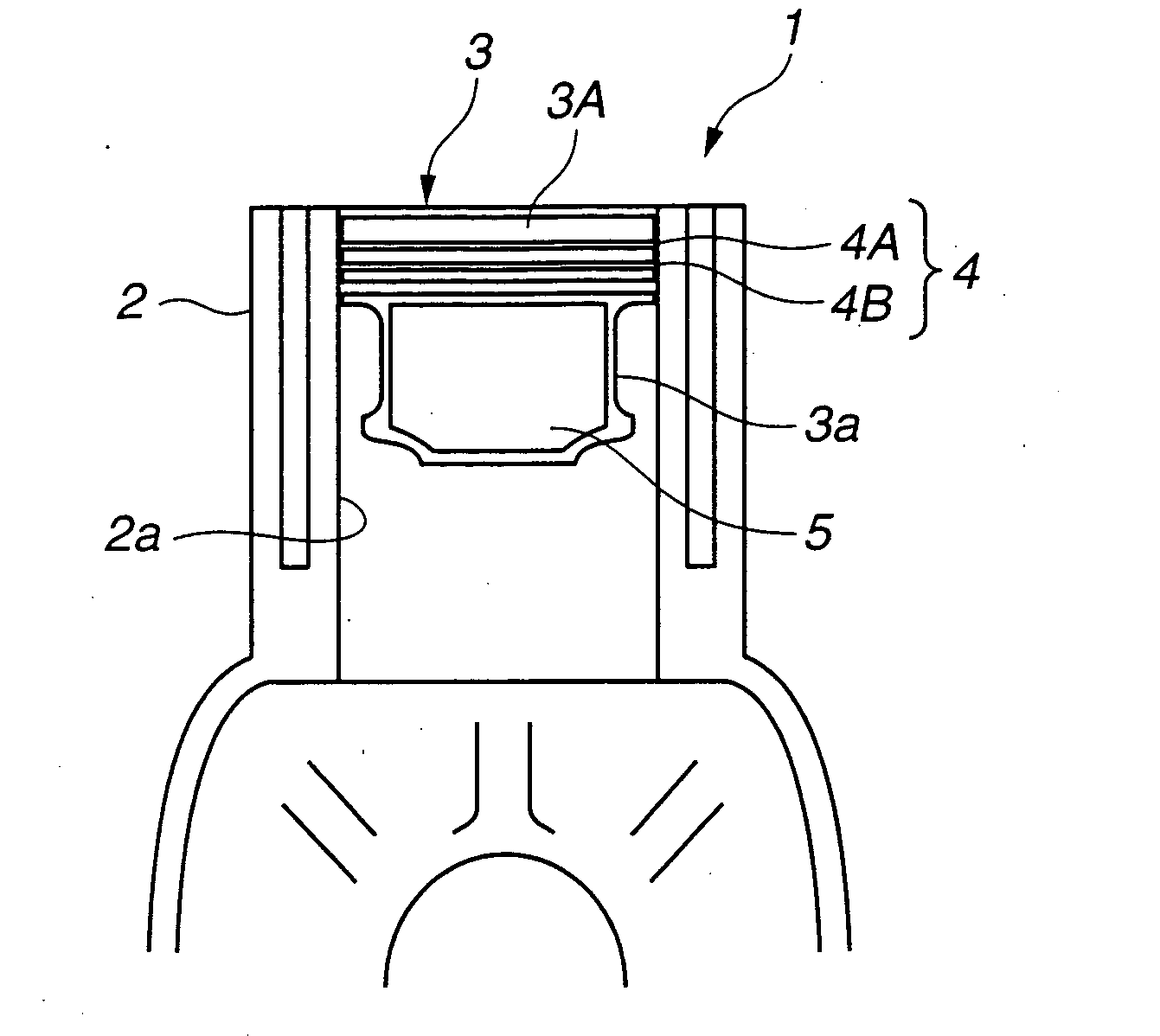

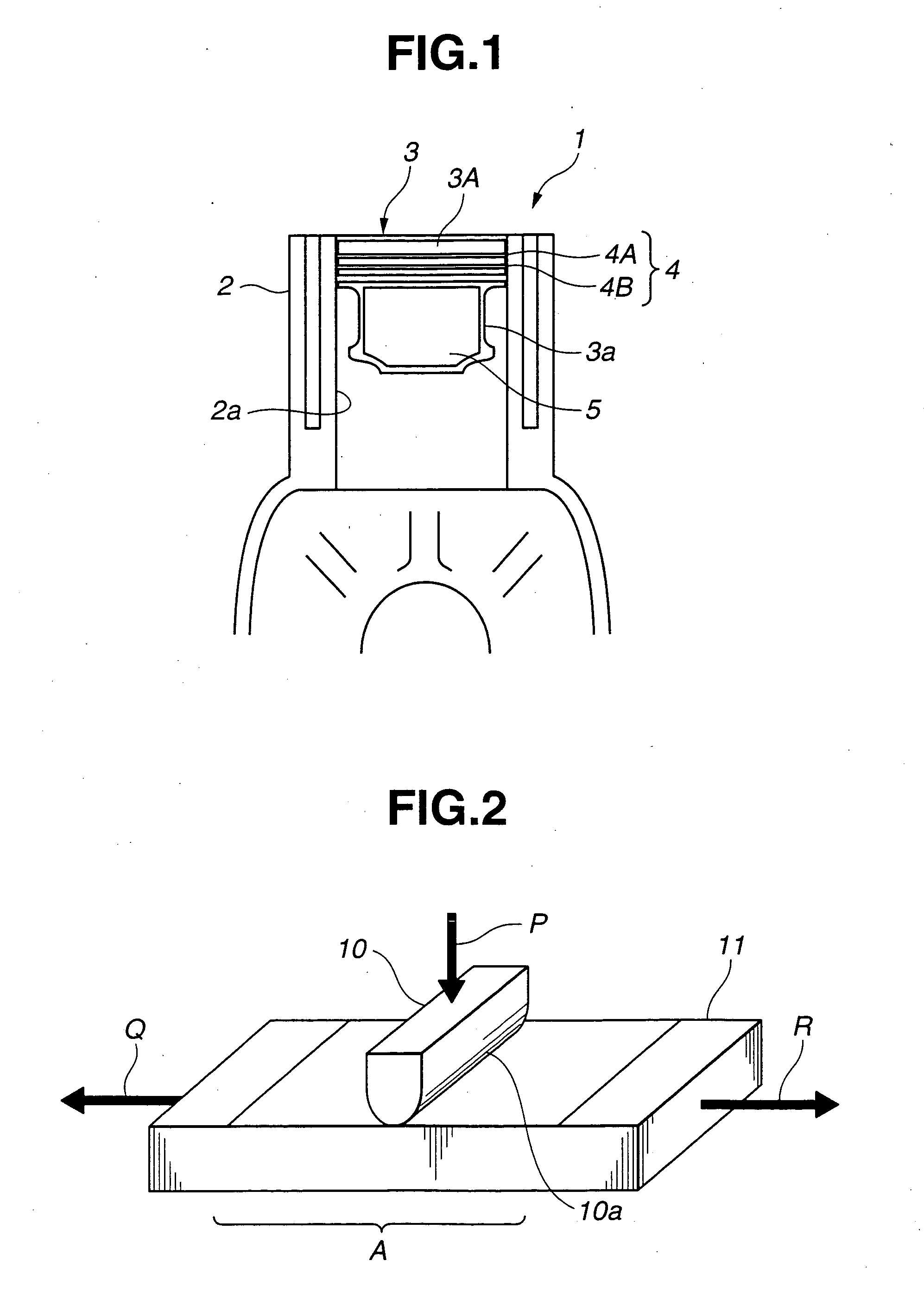

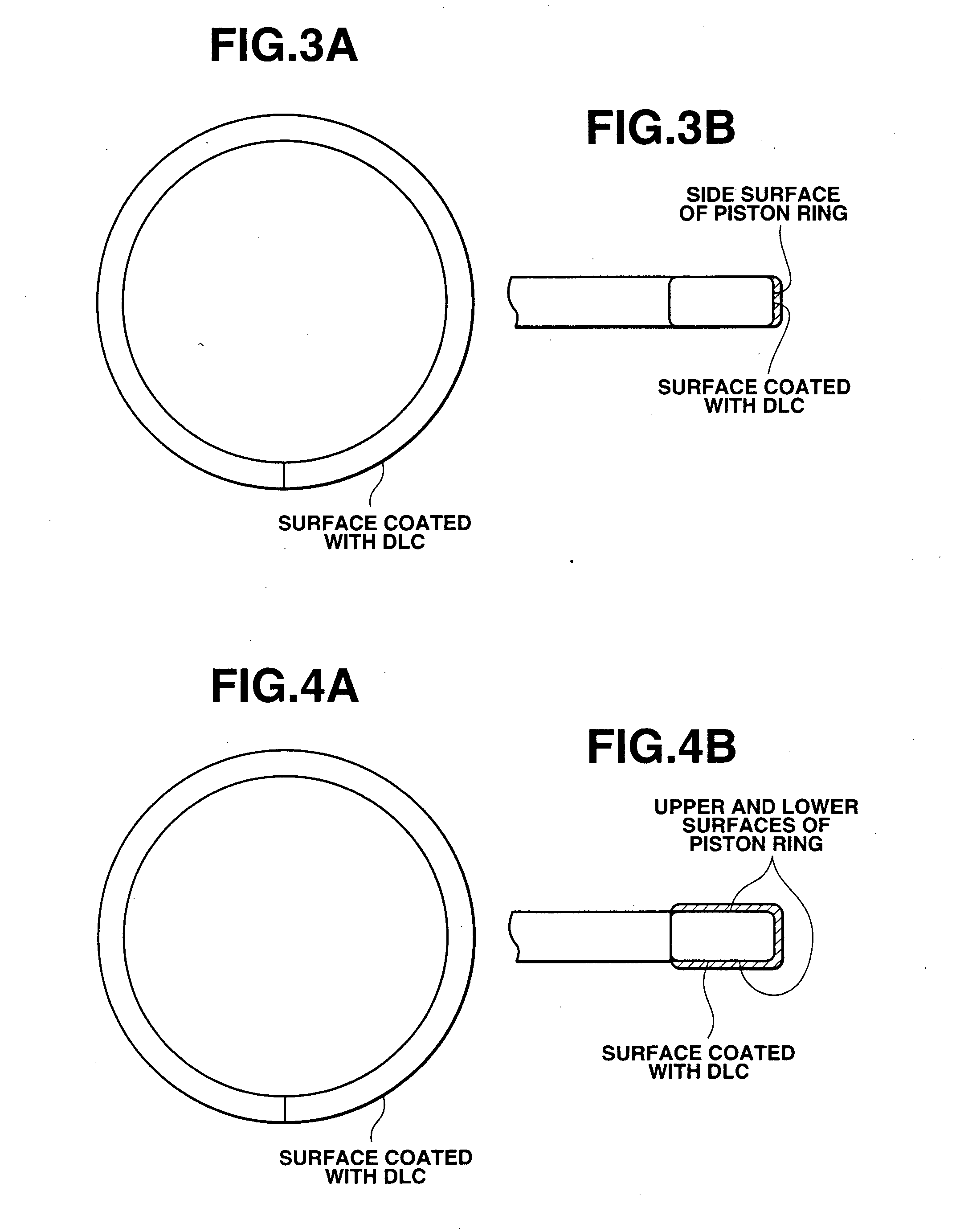

Sliding structure for automotive engine

InactiveUS6886521B2Preventing cracking and separationReduce coefficient of frictionPiston ringsMolten spray coatingCarbon filmPiston ring

A sliding structure for an automotive engine includes a sliding member with a sliding portion and a lubricant applied to the sliding portion so that the sliding portion can make sliding contact with a counterpart member via the lubricant. The sliding member is either of a piston ring, a piston pin, a cam lobe, a cam journal, a plain bearing, a rotary vane and a timing chain. The sliding portion has a base made of a steel or aluminum material and a hard carbon film formed on the base to coat the sliding portion. The hard carbon film has a thickness of 0.3 to 2.0 mum, a Knoop hardness of 1500 to 4500 kg / mm2, a surface roughness Ry (mum) satisfying the following equation: Ry<{(0.75-Hk / 8000)xh+0.07 / 0.8}, where h is the thickness (mum) of the film; and Hk is the Knoop hardness (kg / mm2) of the film.

Owner:NISSAN MOTOR CO LTD

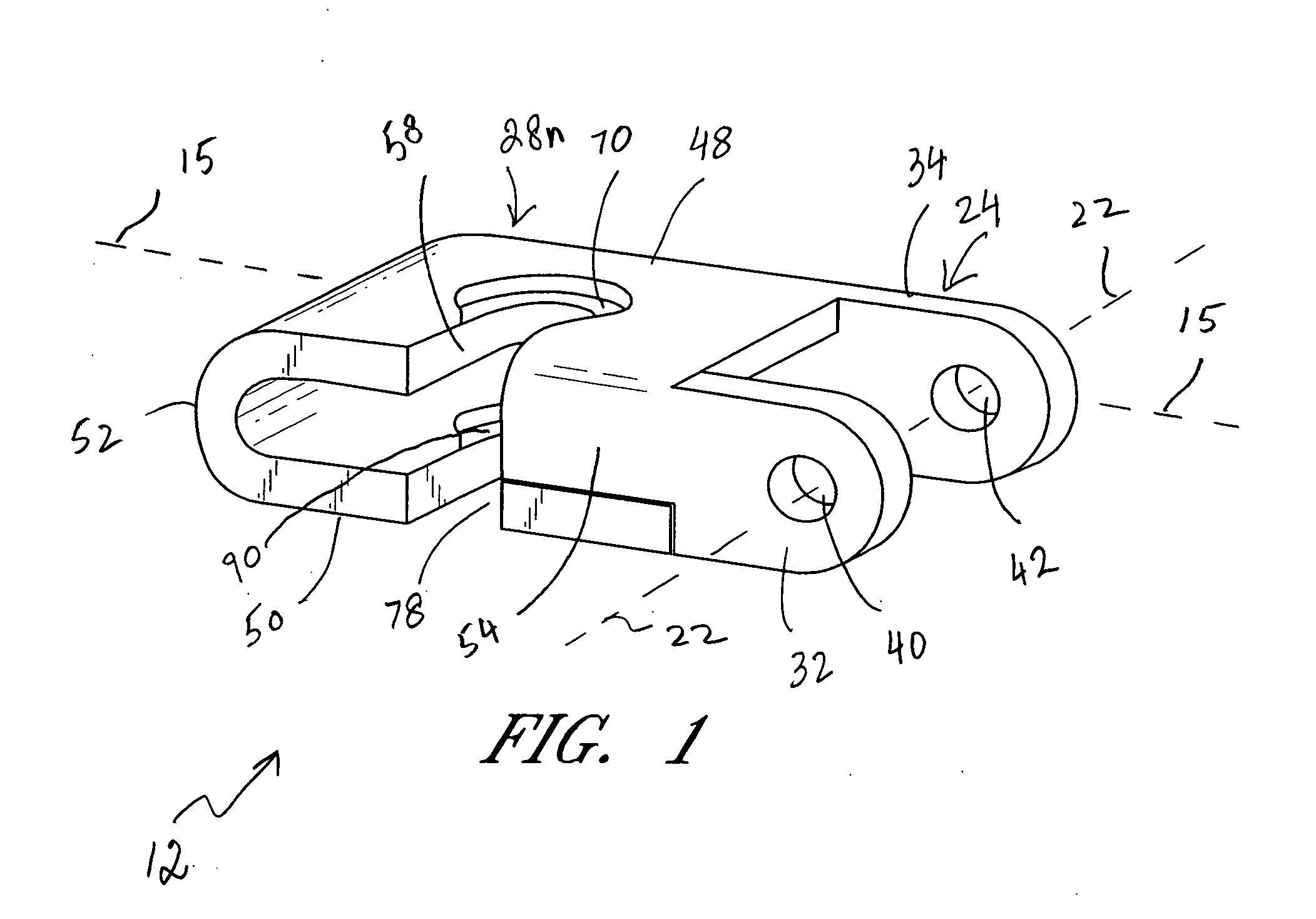

Retrofit attachment yoke

The invention relates to a retrofit connector for fast attachment to an existing system that supports a suspended load below a ceiling, beam or floor without the need to disassemble or disconnect any components of the system. Advantageously, the connector is easy to install and inexpensive to manufacture. The connector is removably or permanently attachable to a sway brace clamp or attachment to form a pivotable connector-clamp assembly. The assembly is capable of reliably supporting heavy loads against adverse sway and seismic disturbances.

Owner:EATON INTELLIGENT POWER LIMITED

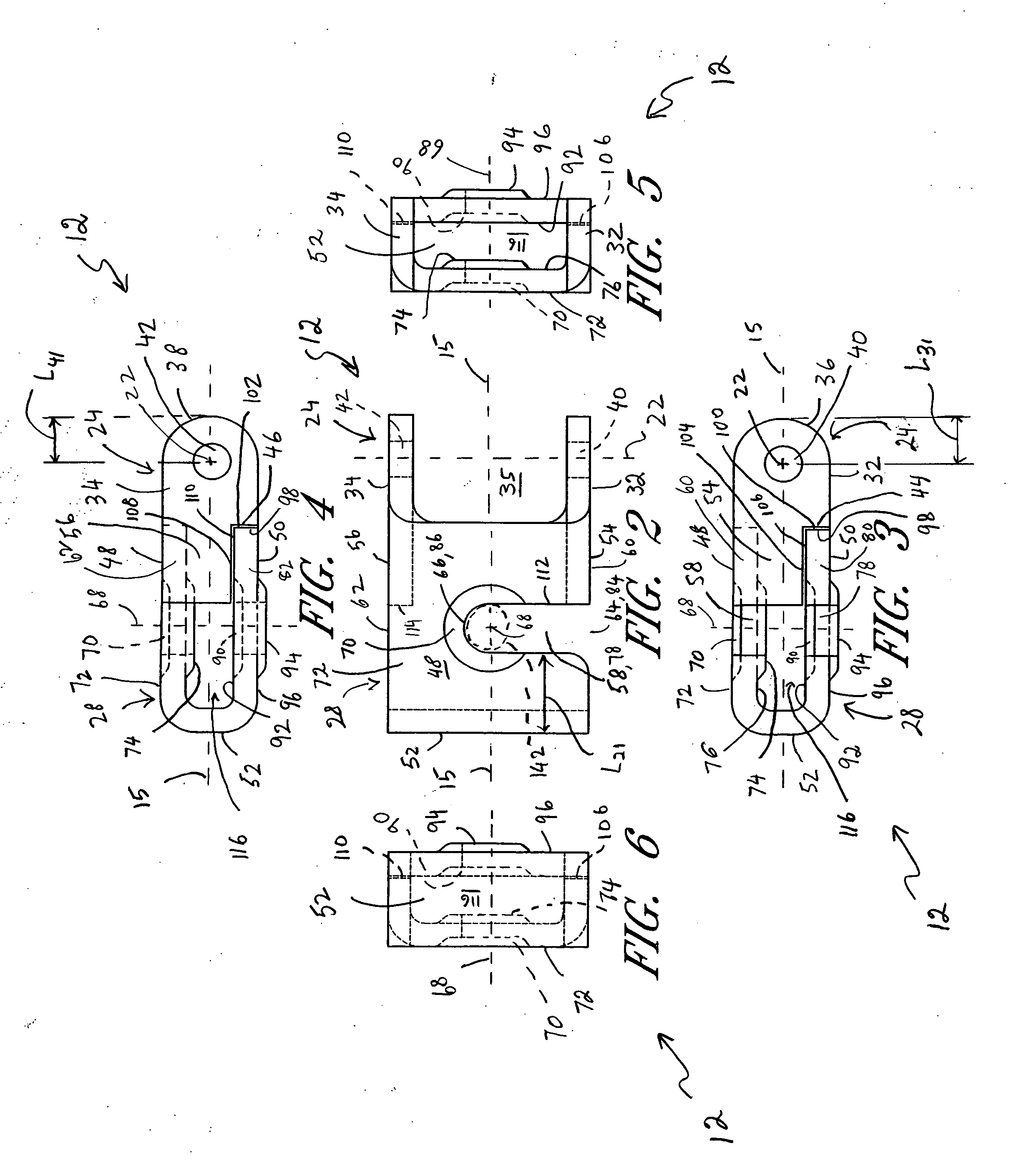

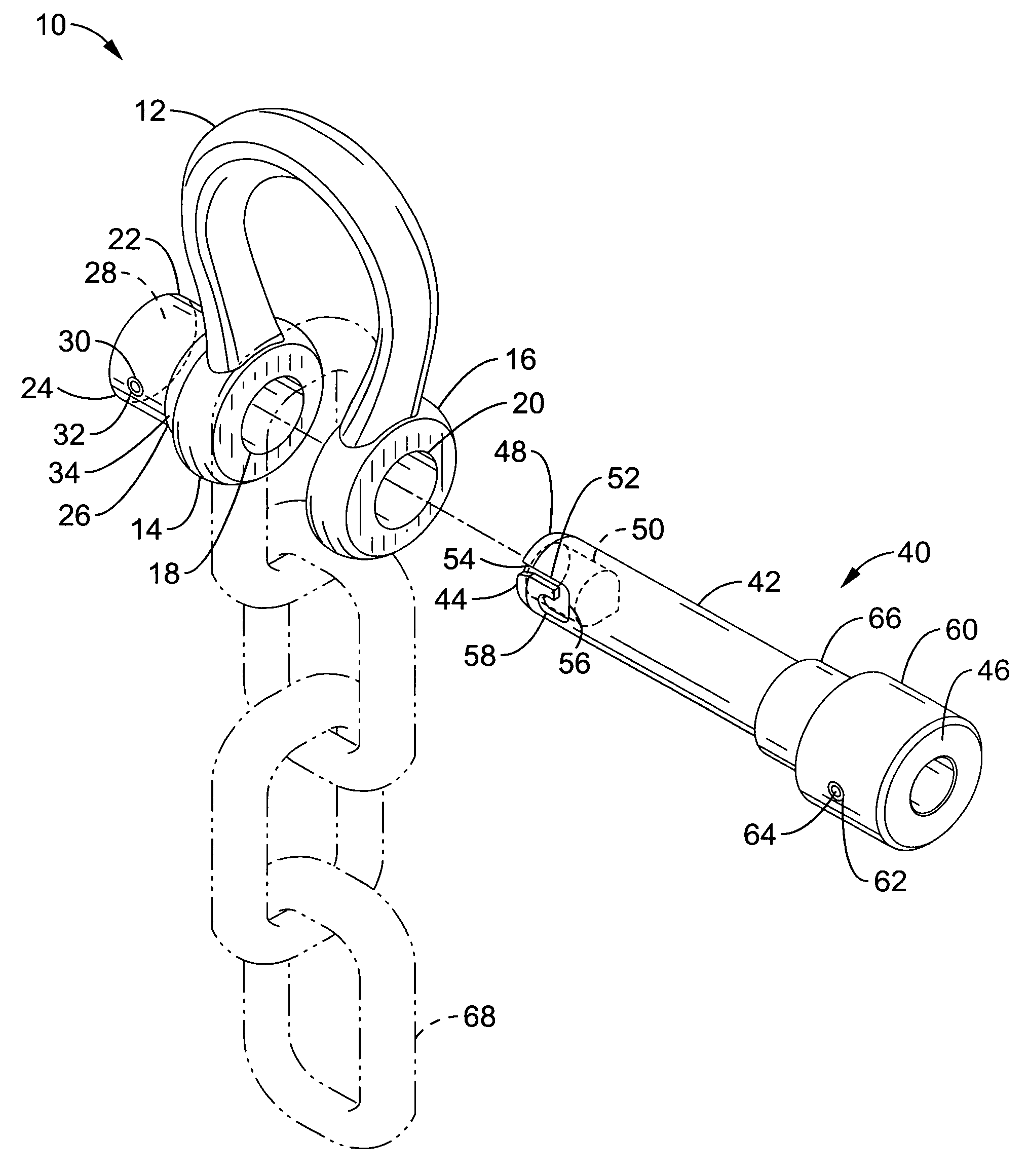

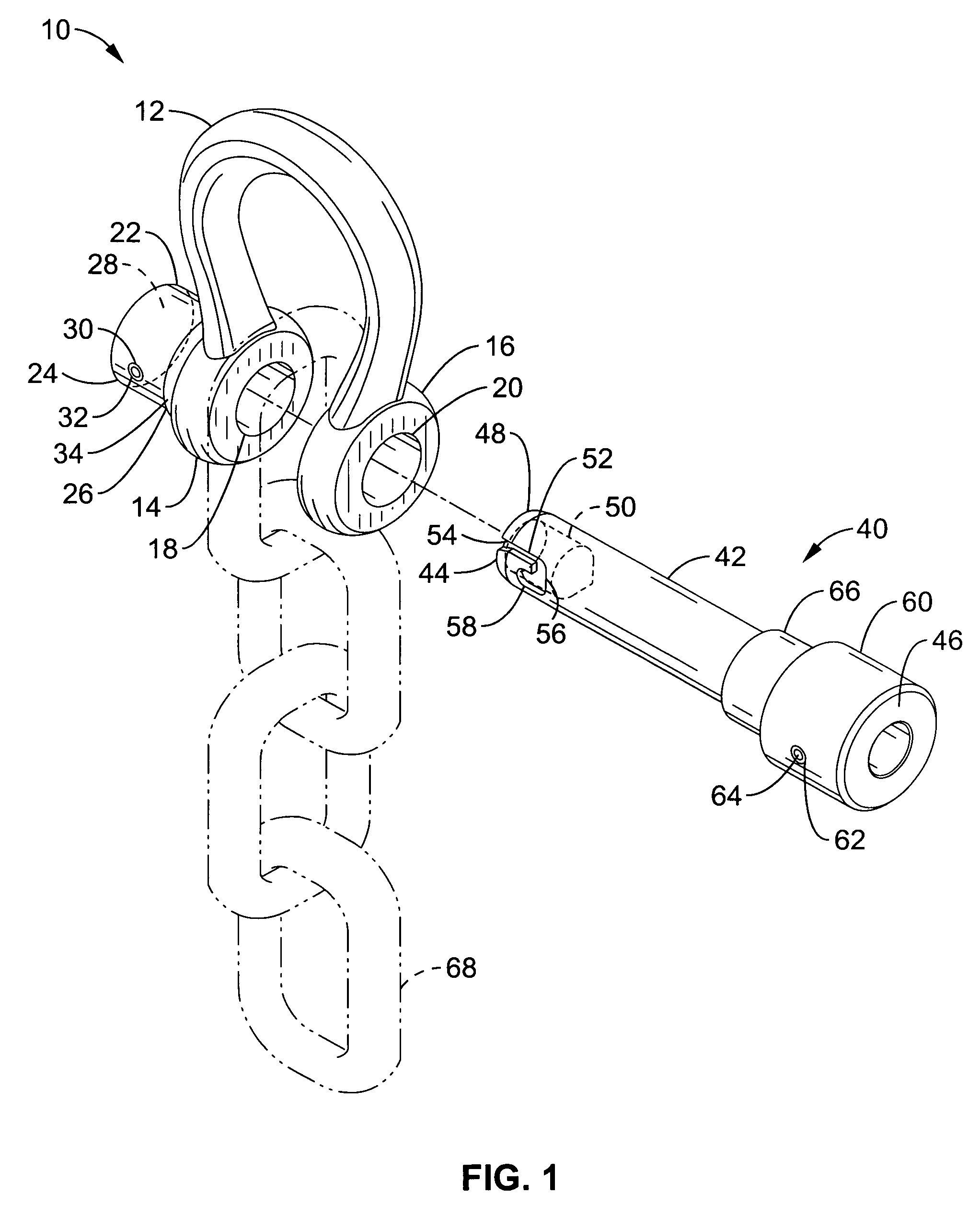

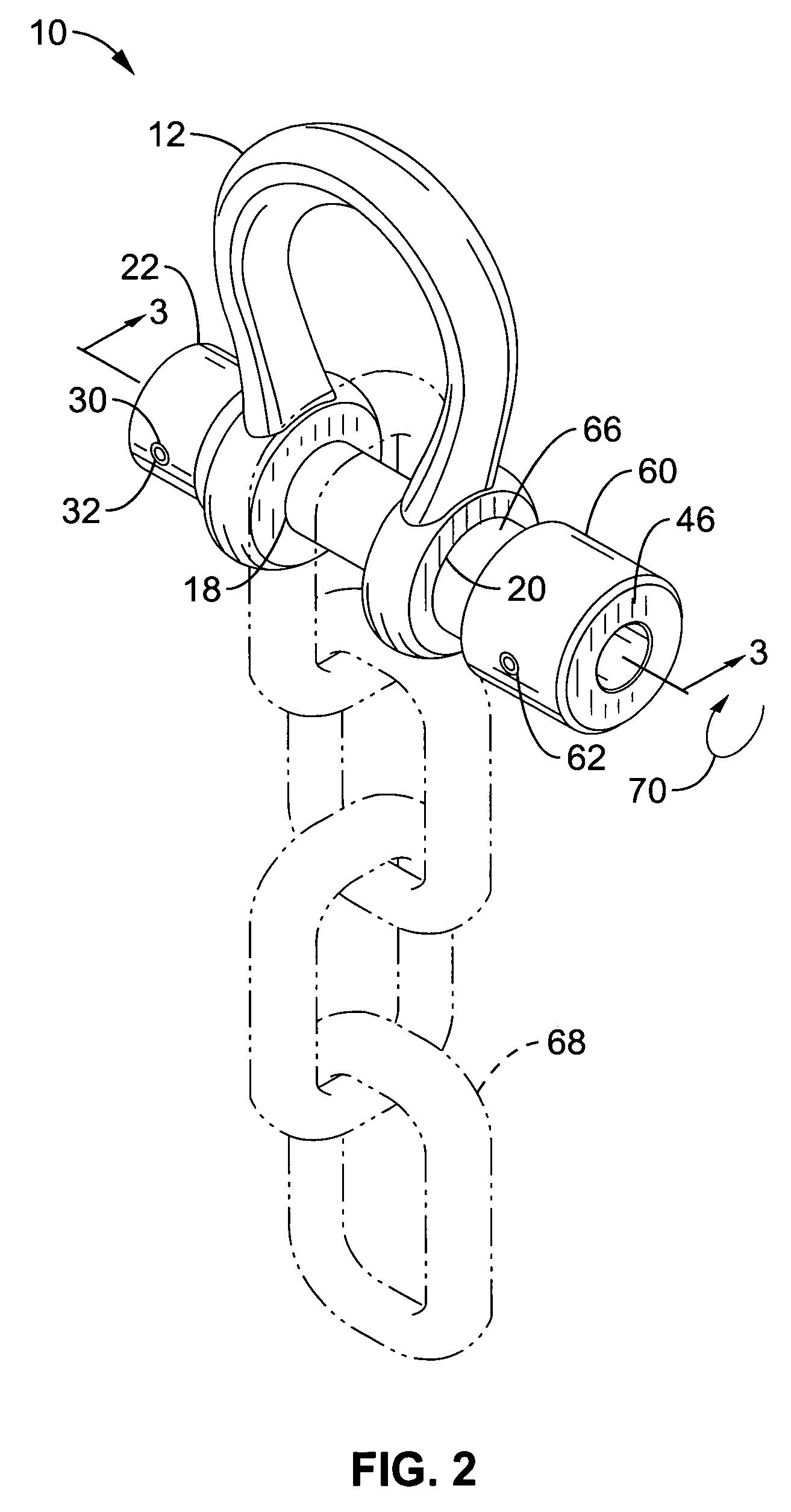

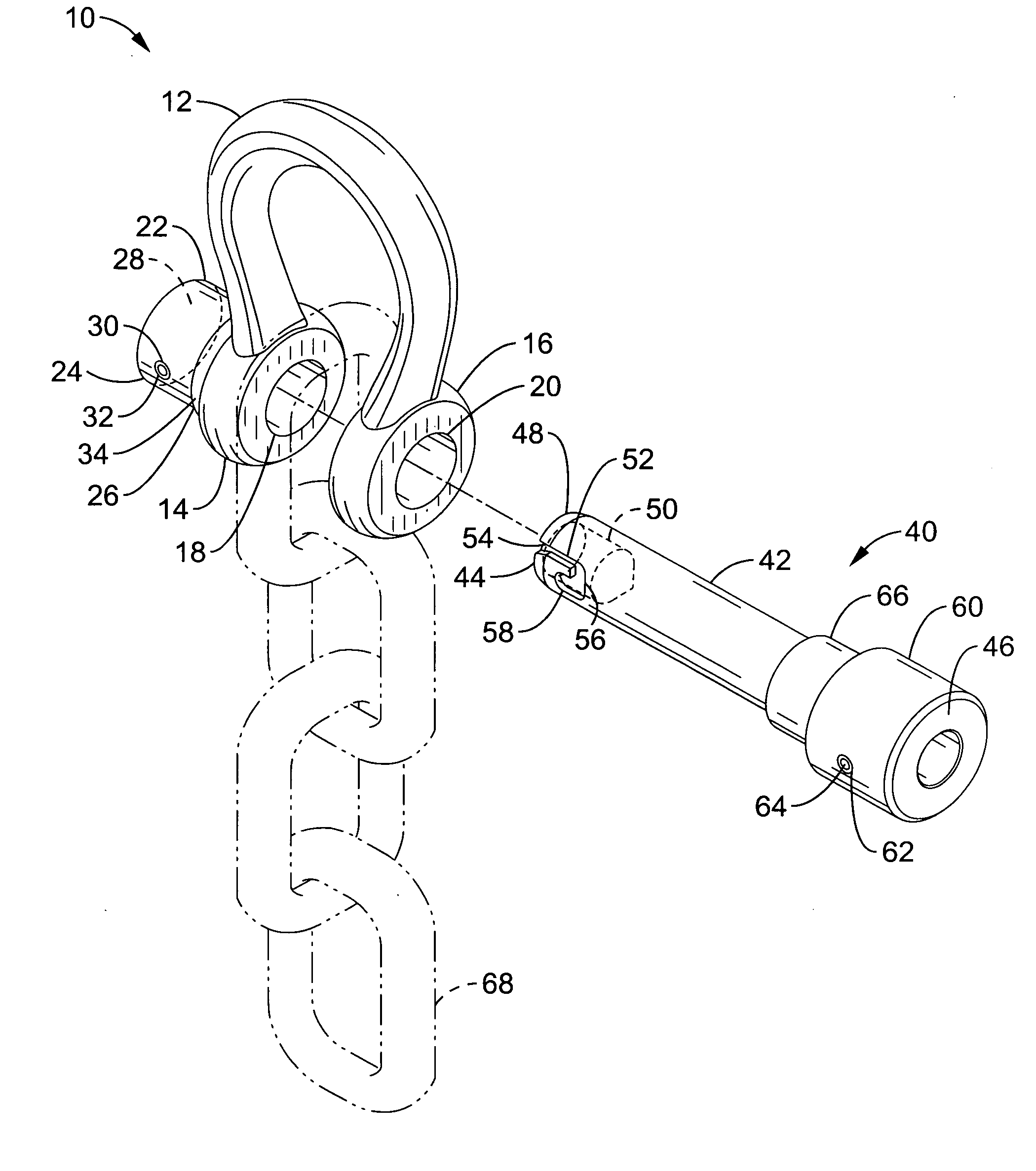

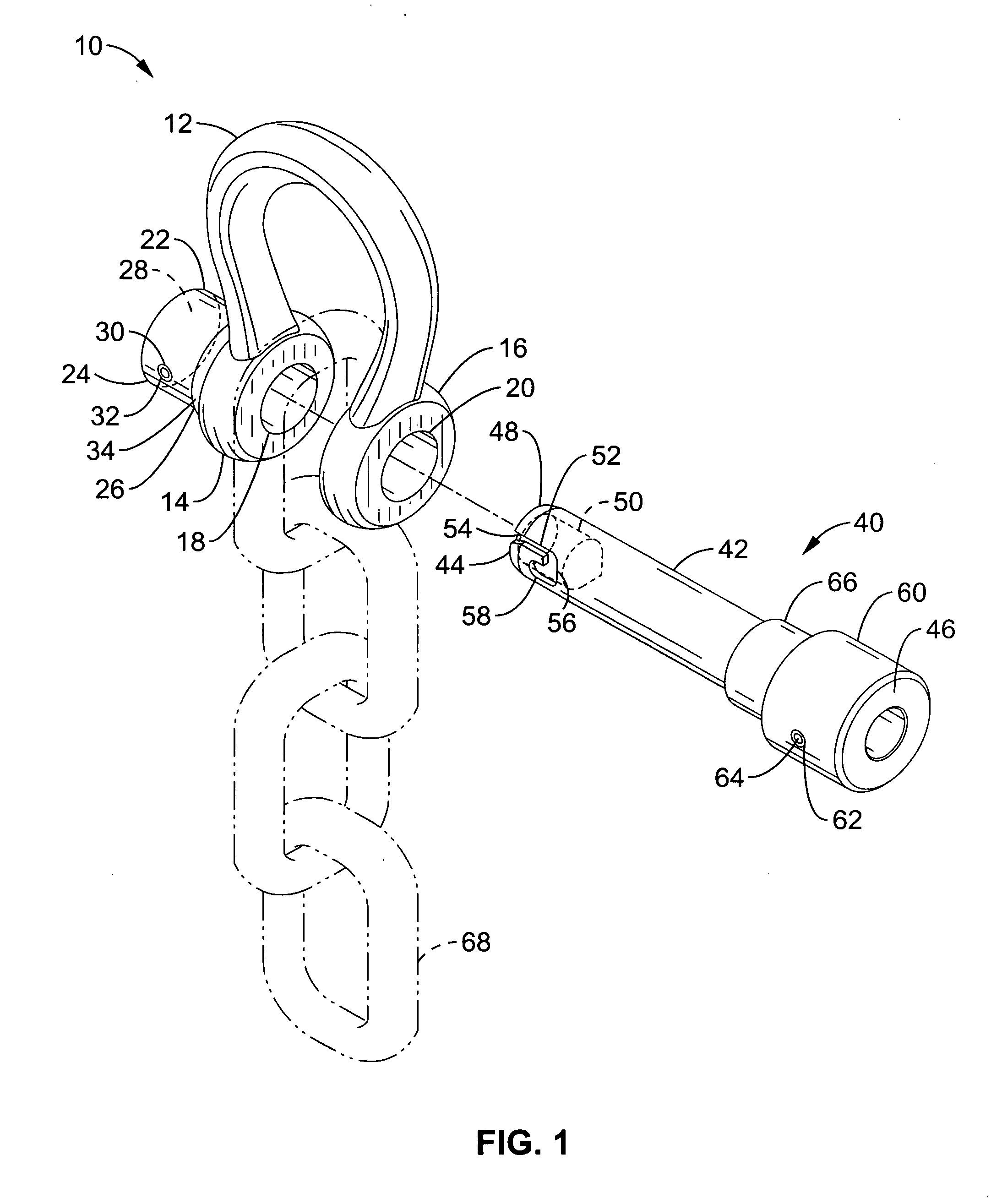

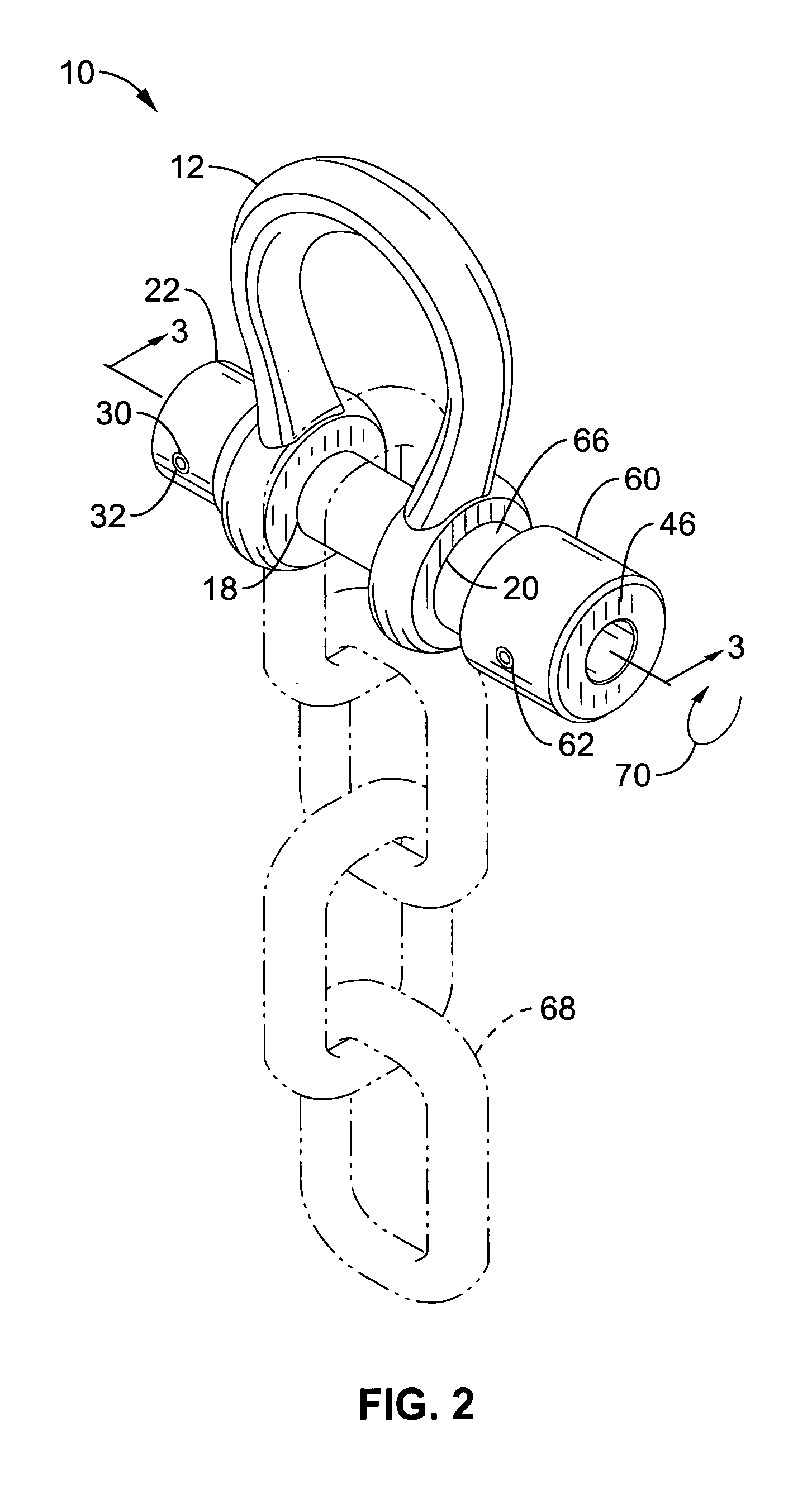

Quick release shackle pin system

A spring loaded quick release pin and tubular receiver with a retainer pin configured to secure the quick release pin in a shackle, clevis, yoke or forked rod end. The receiver is welded to a shackle or cast with the shackle as a single body. One end of the quick release pin has aligned J slots that engage the retainer pin positioned in the receiver with a clockwise twist. The other end of the quick release pin has a cap and a spring loaded sleeve that biases the cross pin against outside of the second leg of the shackle. The spring bias keeps the short leg of the J slot engaged with the retaining pin. The quick release pin is removed with a push and counter clockwise twist. The invention includes a kit with a receiver, a bushing and a quick release pin for installing or retrofitting existing shackles.

Owner:SILVA FRED

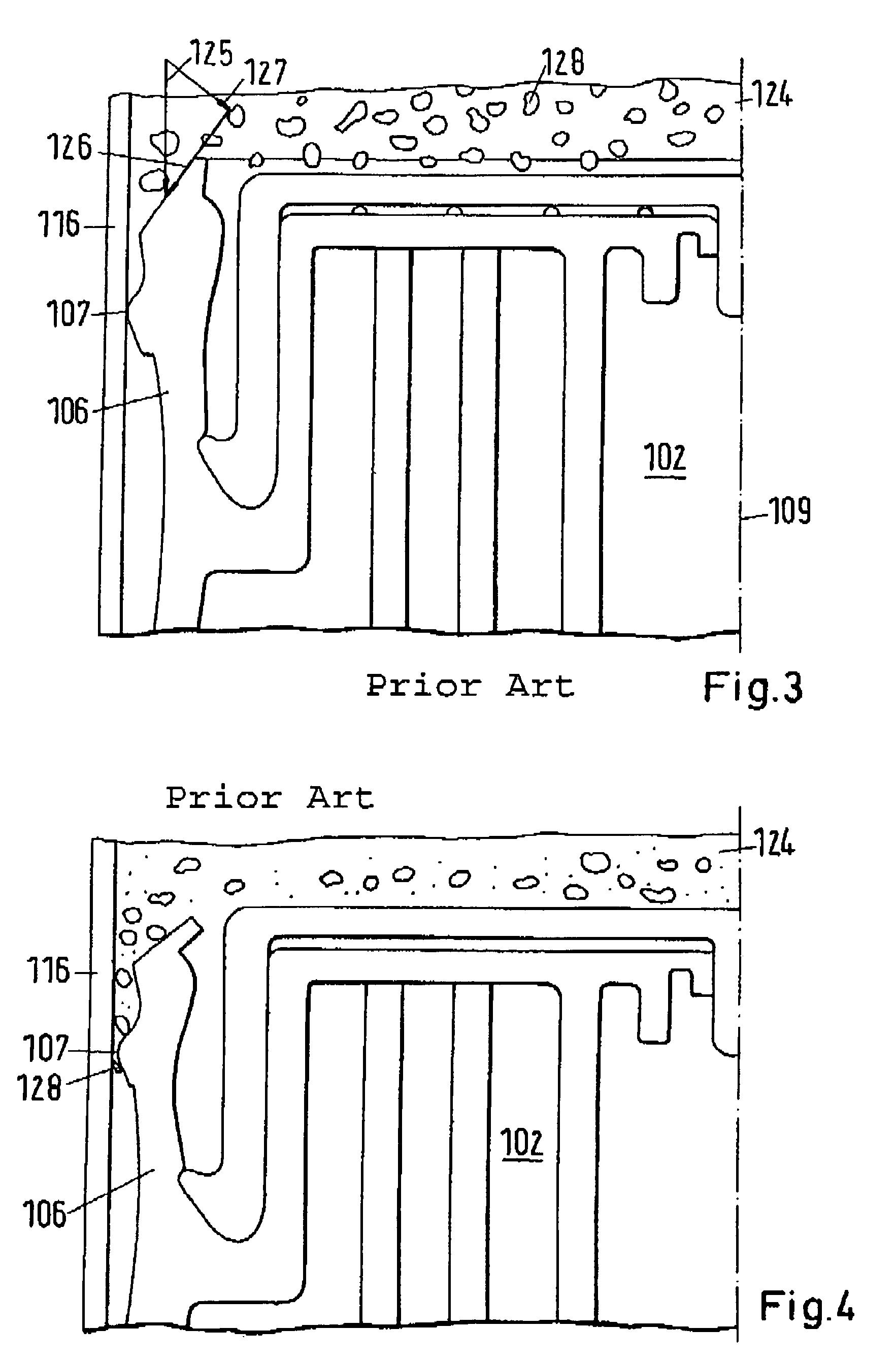

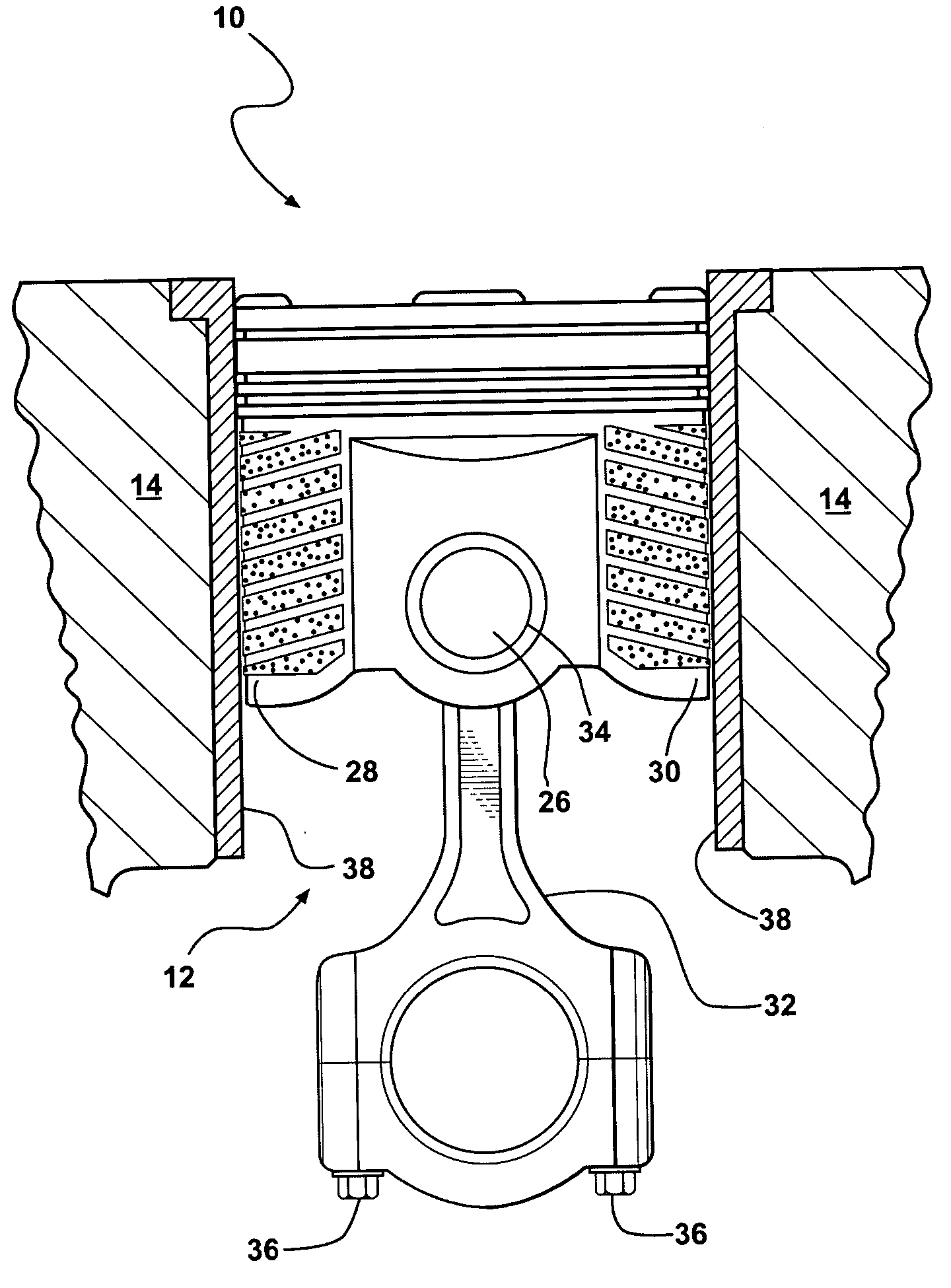

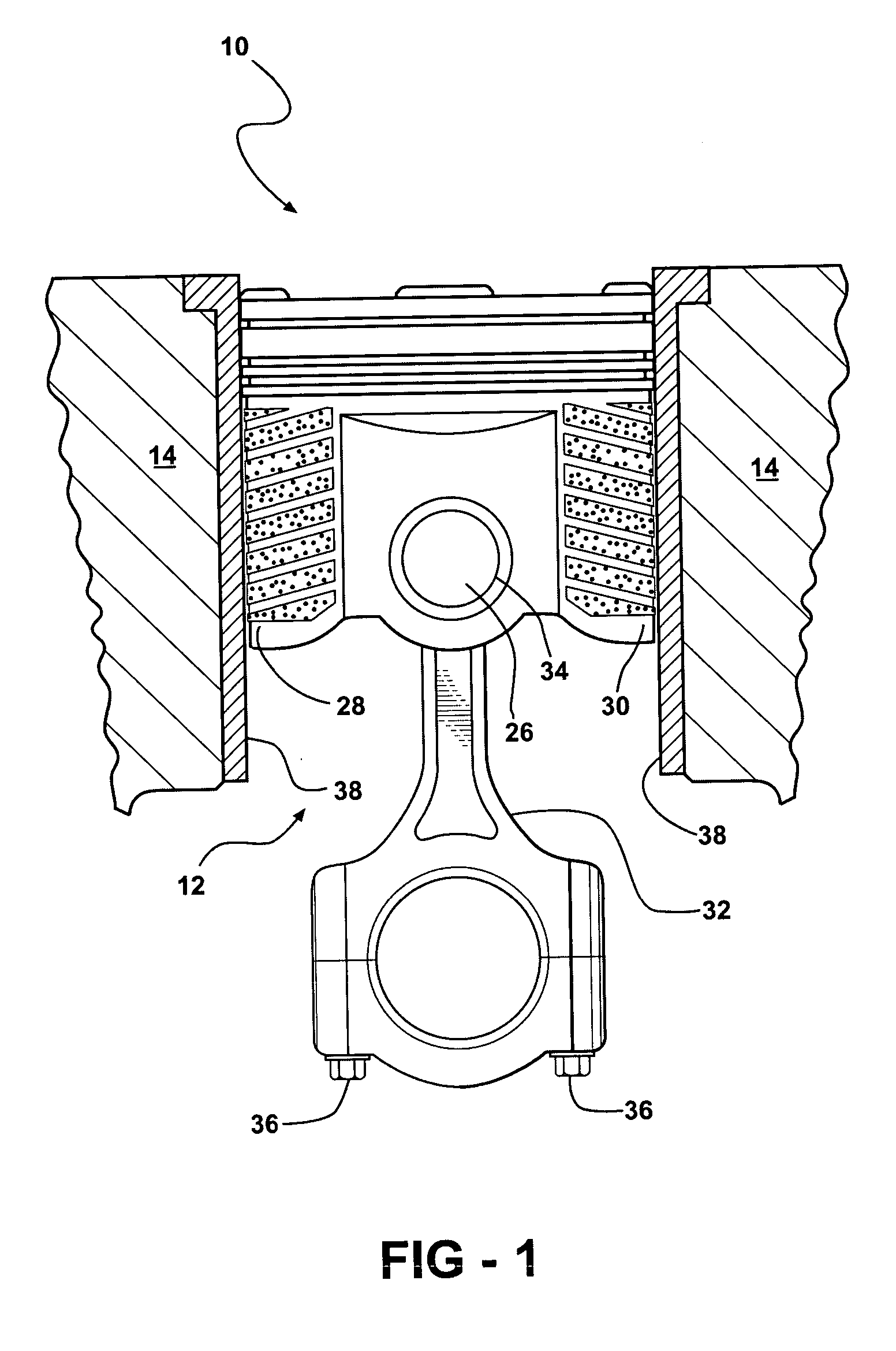

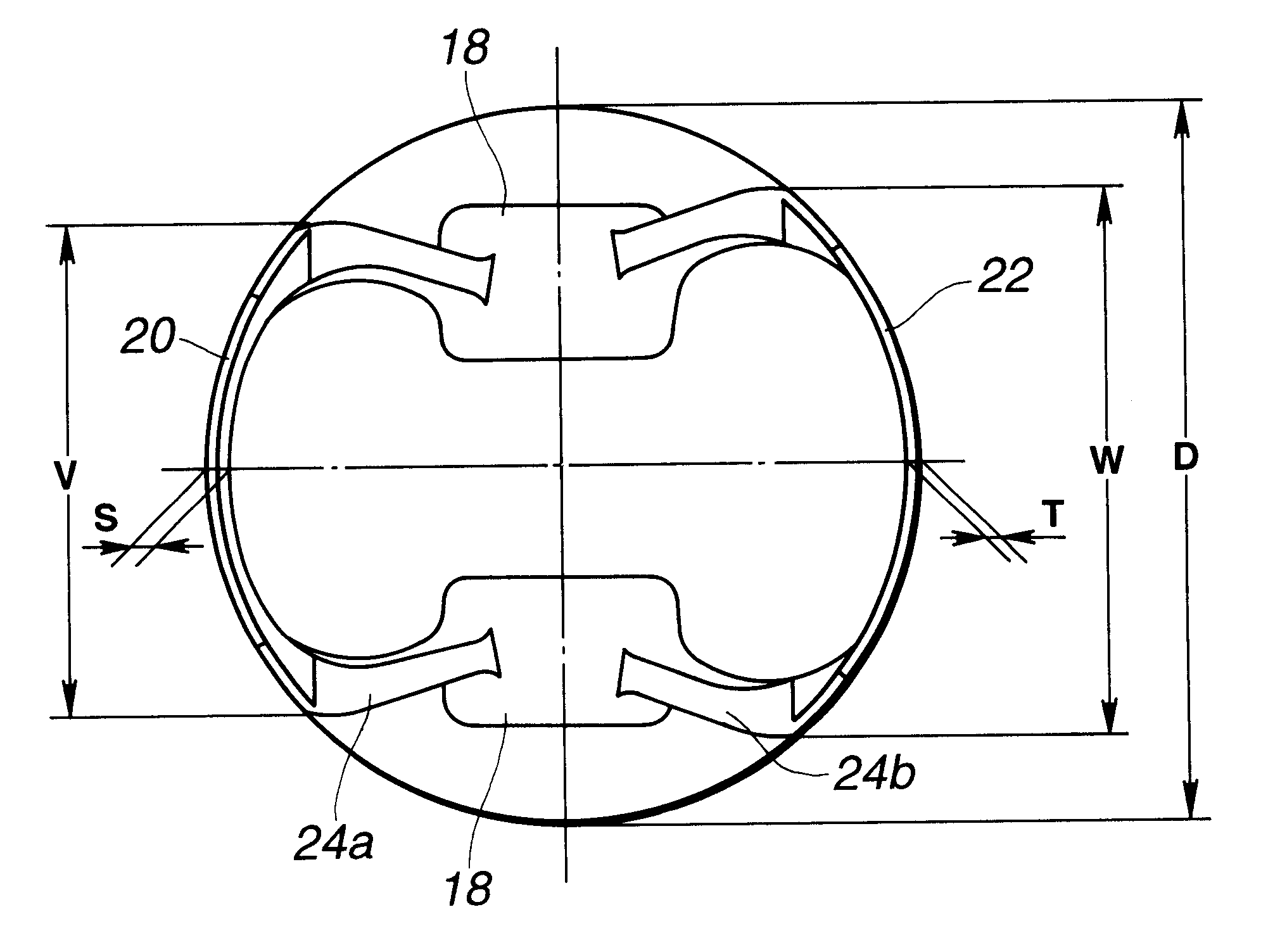

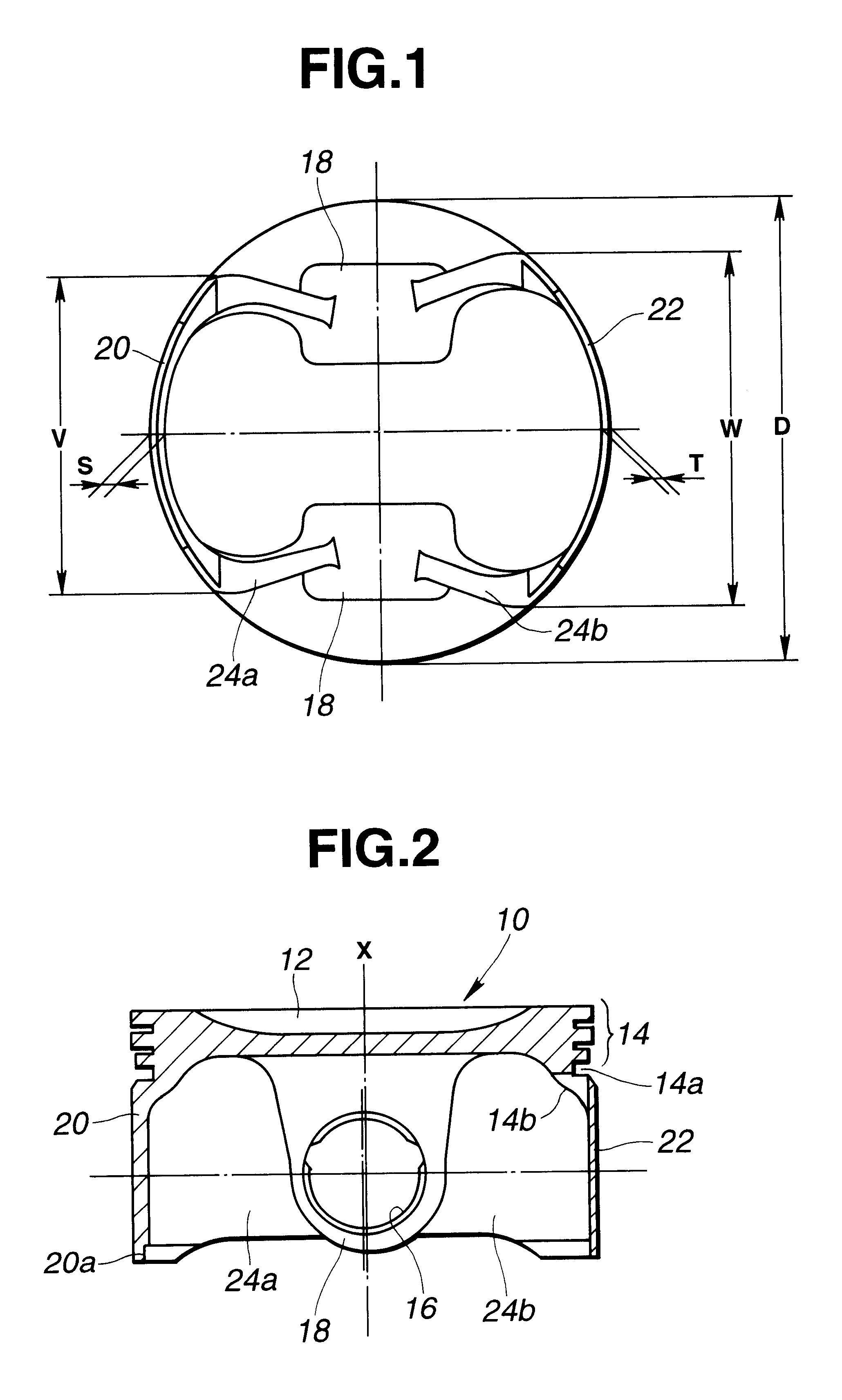

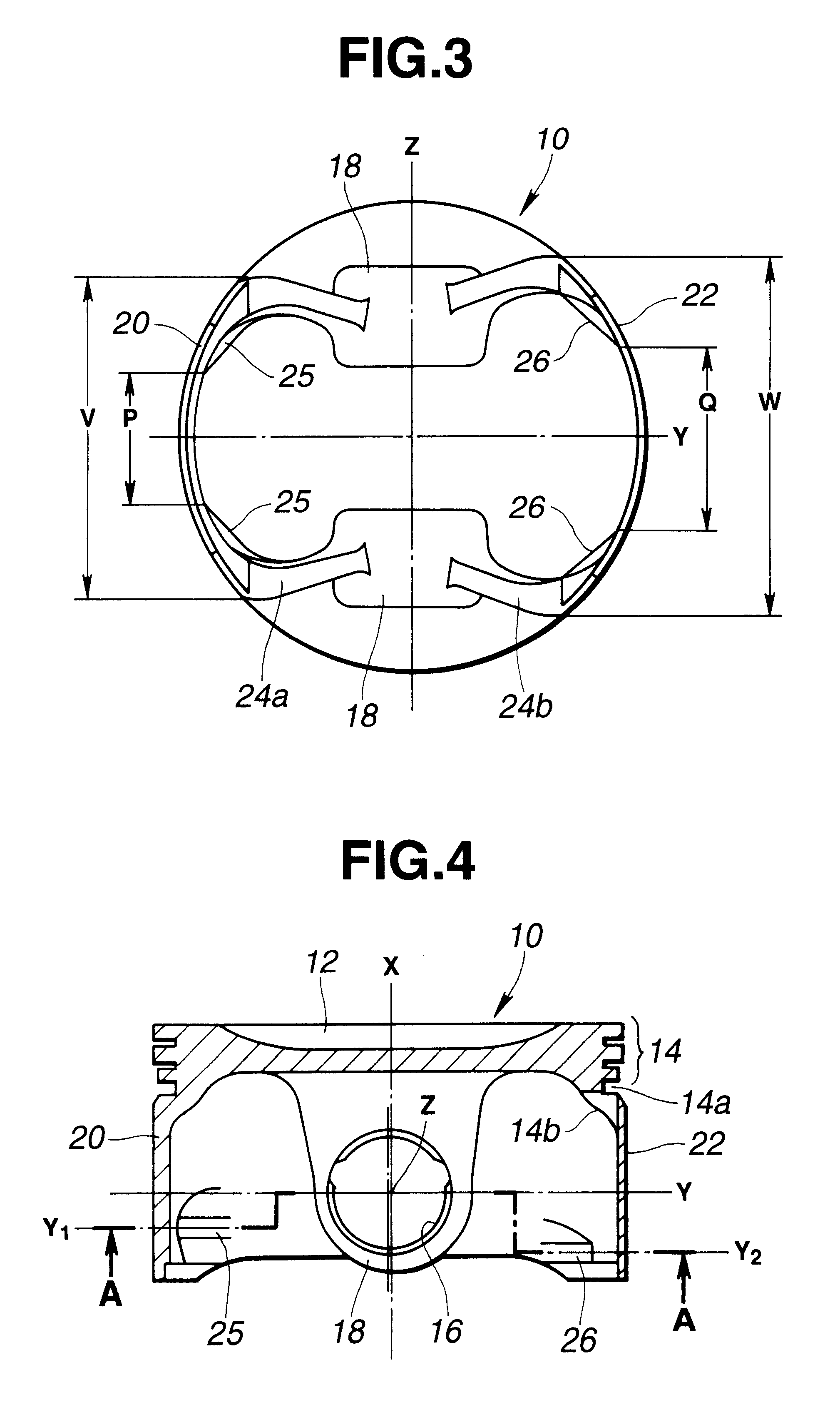

Piston having a patterned coating and method of applying same

ActiveUS20050087166A1Improve propertiesImproved propertyMolten spray coatingPlungersReciprocating motionEngineering

The present invention relates to a piston adapted for reciprocal movement within the cylinders of an internal combustion engine. The piston includes a body having a crown formed at the uppermost margins of the body and a skirt, depending from the crown, adapted for relative sliding motion with respect to the cylinder. The piston further includes a coating bonded to the piston skirt so as to be juxtaposed between the skirt and the cylinder. The coating has a plurality of recesses formed thereon so as to define a predetermined pattern of recesses on the surface of the skirt that retains lubricant between the skirt and the cylinder wall. The coating may also direct lubricant along the outer circumference of the piston skirt during reciprocal movement of the piston within a cylinder. A method of applying the coating to the piston skirt is also disclosed.

Owner:MAHLE TECH

Two-piece piston assembly

InactiveUS6318243B1Mechanical propertyLight weightPlungersMachines/enginesEngineeringMechanical engineering

Owner:JONES D KENT

Piston pump for a vehicle brake system

InactiveUS6471496B1Positive displacement pump componentsBraking action transmissionEngineeringMechanical engineering

To enable economical production of a piston for a piston pump, the piston is made from a tubular deformed part and a closure plug, which is press-fitted with a protrusion into the deformed part. The piston has the advantage that the piston can be made without metal cutting in the form of deformed parts, for instance by extrusion, and hence can be produced quickly and economically.

Owner:ROBERT BOSCH GMBH

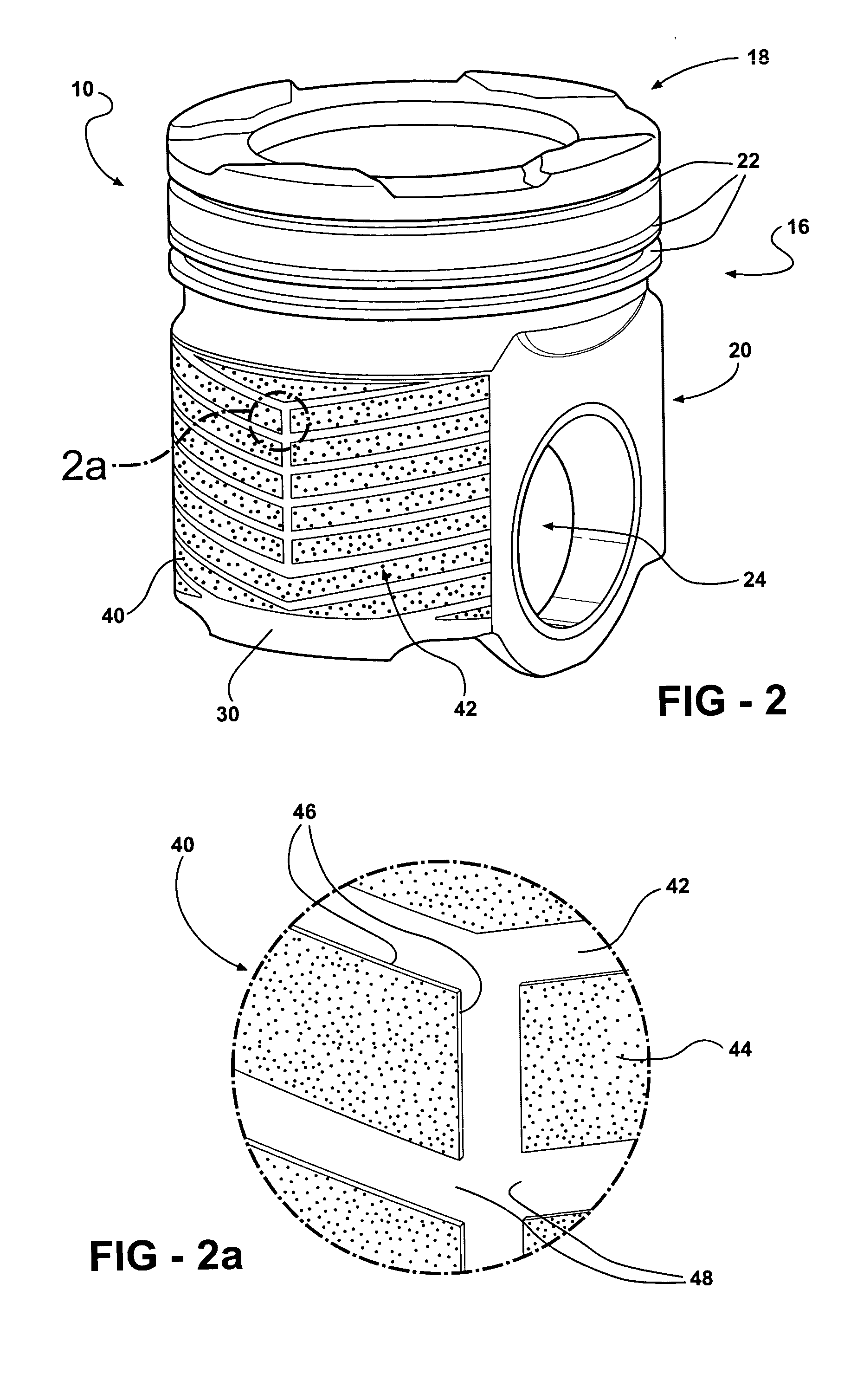

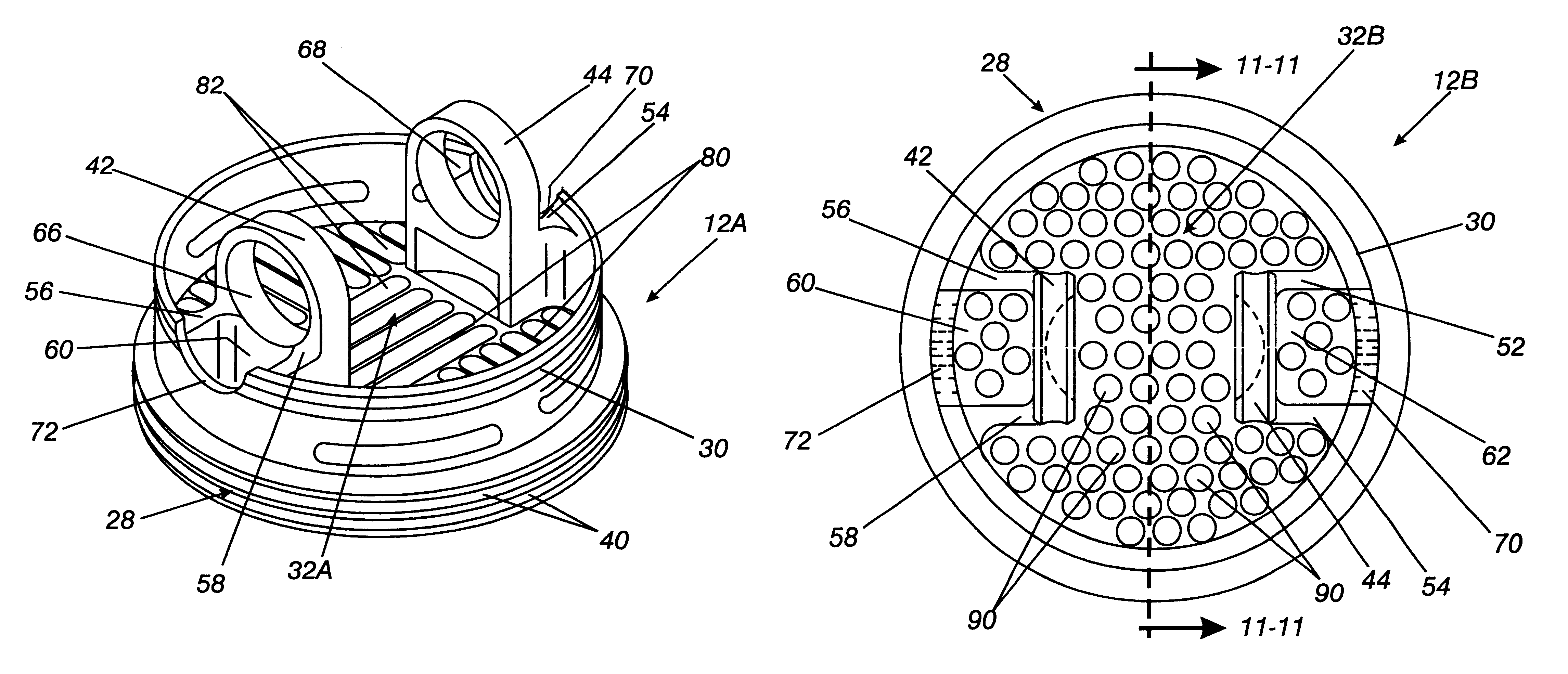

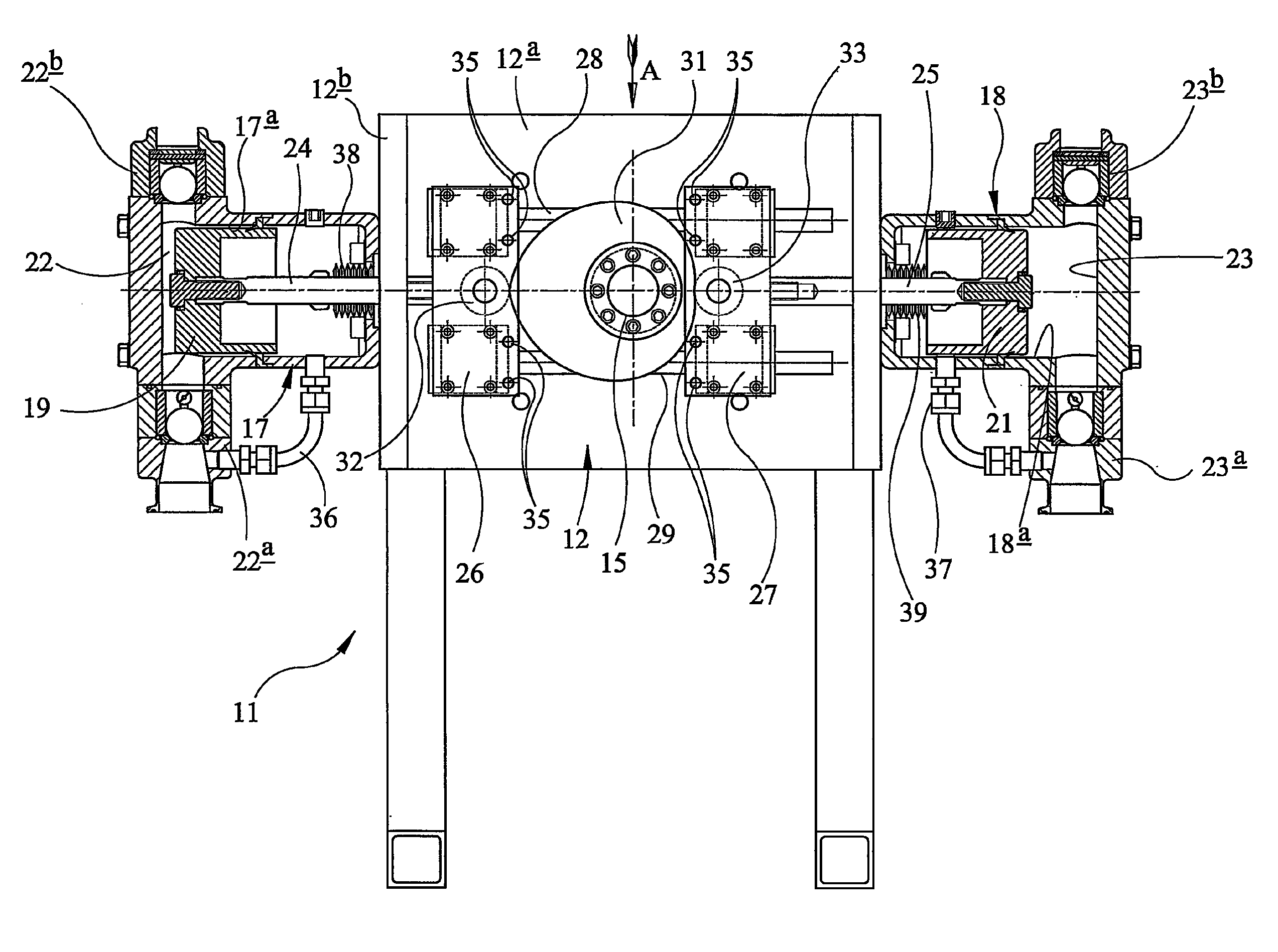

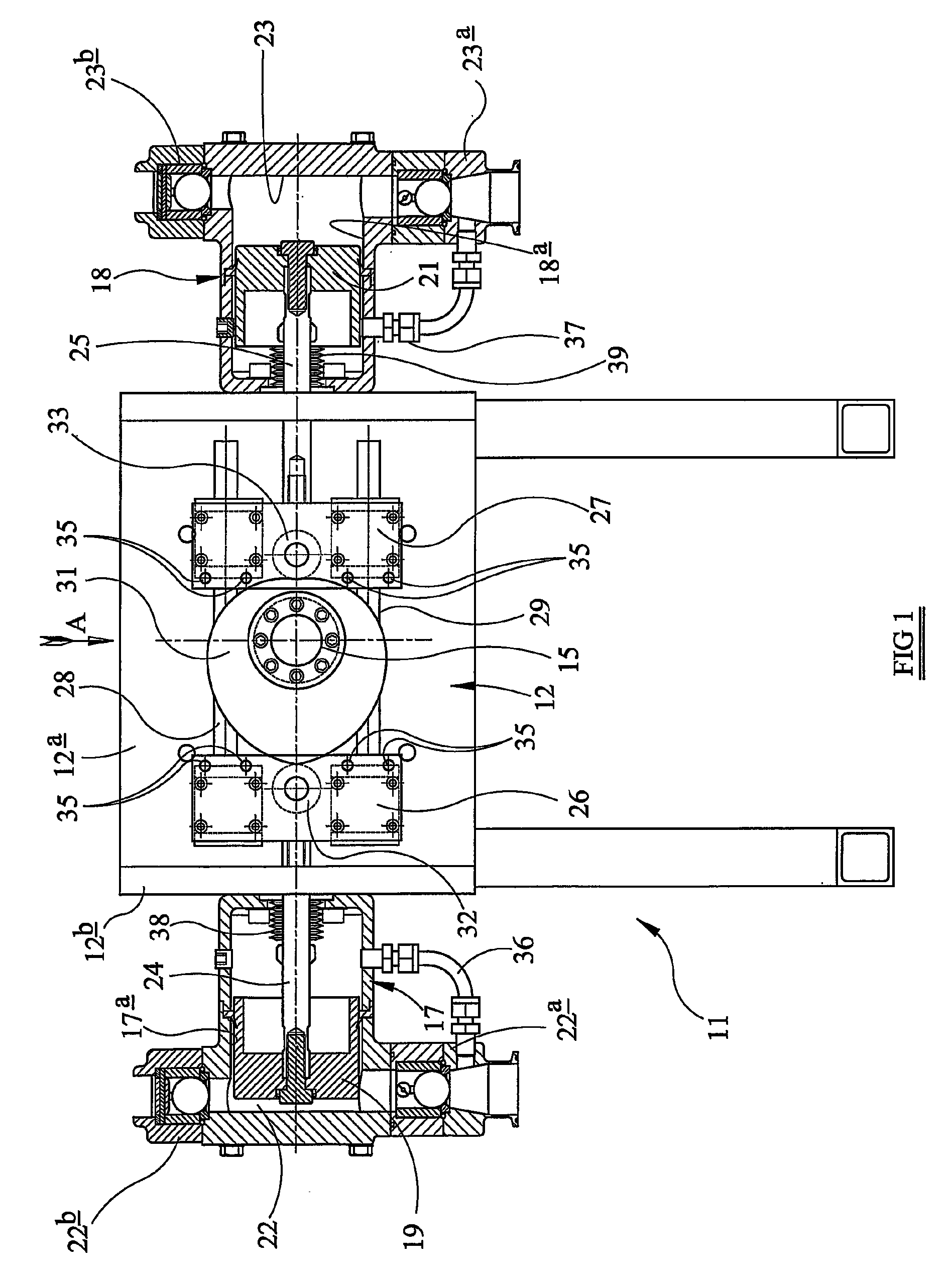

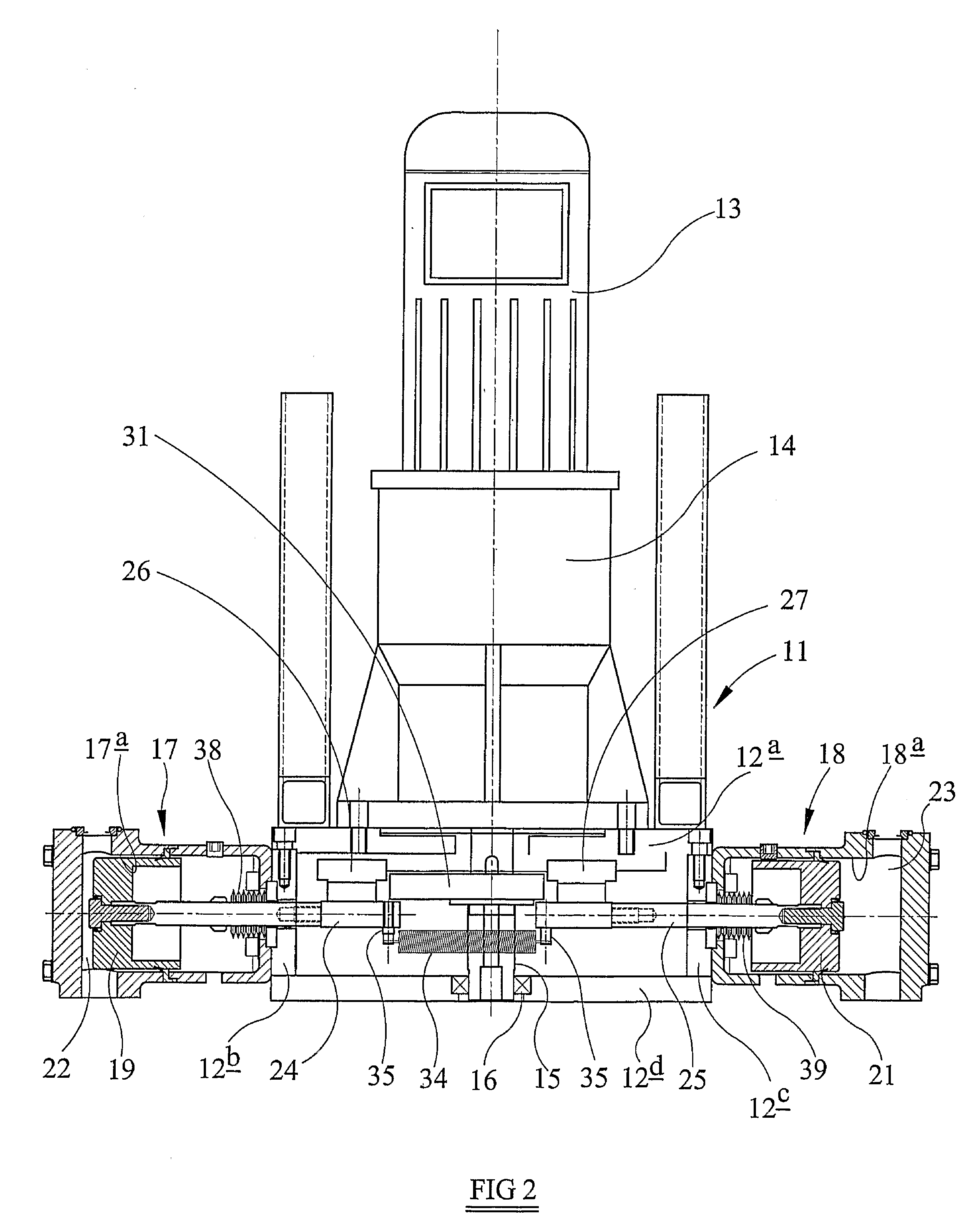

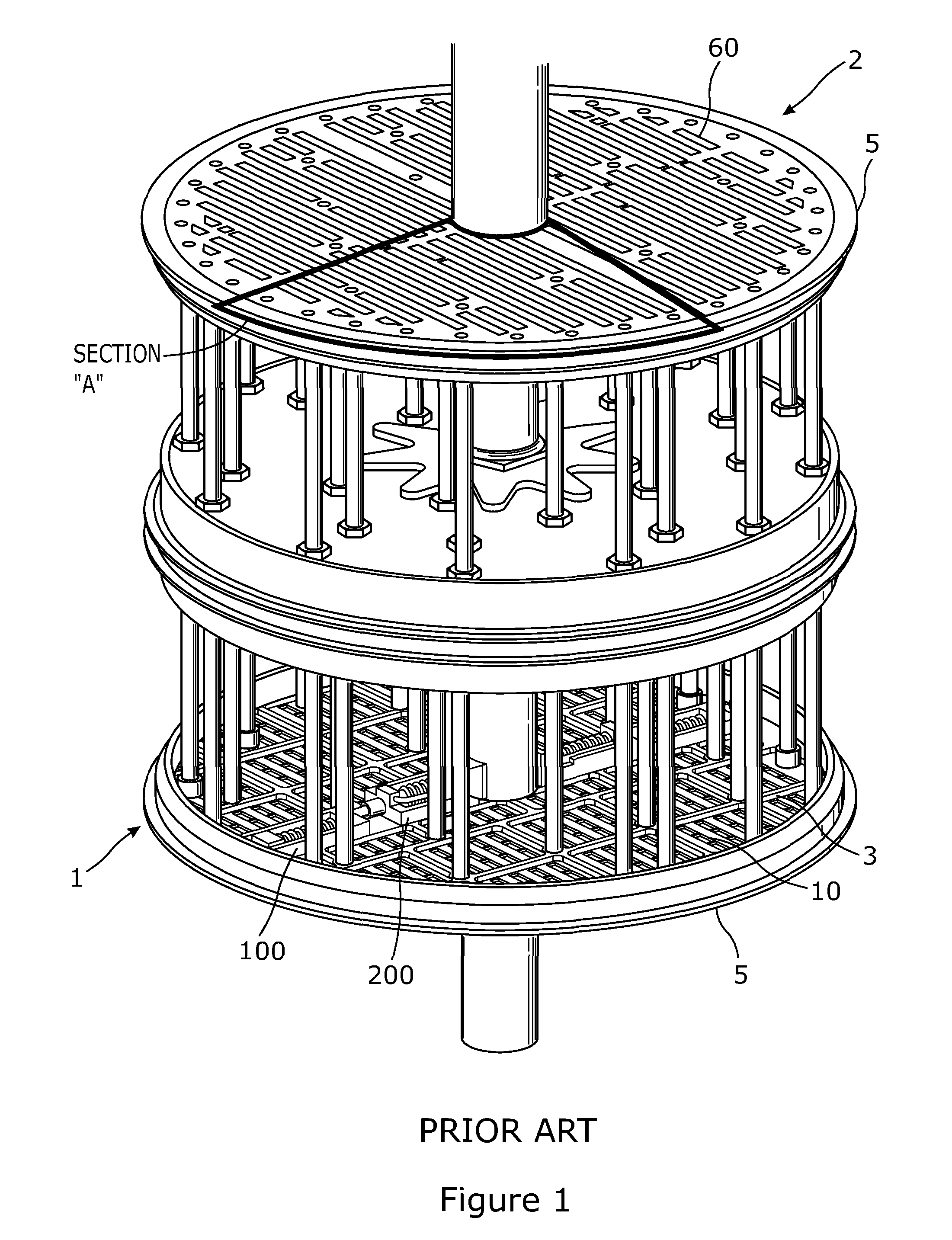

Piston pump with cam follower arrangement

A pump primarily for liquid paint includes first and second pistons reciprocable rectilinearly in respective first and second cylinders. The first and second pistons are moved relative to their respective pistons by operation of an A. C. electric motor the rotary output shaft of which is coupled to the first and second pistons by a constant velocity cam and a cam follower mechanism converting rotary motion of the output shaft into reciprocatory motion of the first and second pistons 180° out of phase with one another.

Owner:CARLISLE FLUID TECH UK LTD

Piston for internal combustion engine

ActiveUS20050005892A1Excellent abrasion resistanceReduce coefficient of frictionCasingsPlungersPiston ringAliphatic amine

A piston for an internal combustion engine of an automotive vehicle. The piston has a piston ring and a piston skirt section each of which has a sliding section in slidable contact with a cylinder bore section of a cylinder block in presence of a lubricating oil. The cylinder bore section is formed of eutectic or hyper-eutectic aluminum alloy. Additionally, a hard carbon thin film is coated on the sliding section of the piston and contains hydrogen atom in an amount of not more than 1 atomic %. Here, the lubricating oil contains at least one selected from the group consisting of ashless fatty acid ester friction modifier, ashless aliphatic amine friction modifier, polybutenyl succinimide, derivative of polybutenyl succinimide, zinc dithiophosphate, and derivative of zinc dithiophosphate.

Owner:NISSAN MOTOR CO LTD

Method of producing coated engine components

InactiveUS20050016489A1Reduce frictionProvide wear resistanceMolten spray coatingPlungersPorous coatingEngineering

To improve engine performance and reduce wear and friction, a porous coating is applied to piston skirts and cylinder bores via a thermal spray process. The porous nature of the coating allows for oil to be held on the surfaces enhancing lubrication.

Owner:WIDE OPEN COATINGS

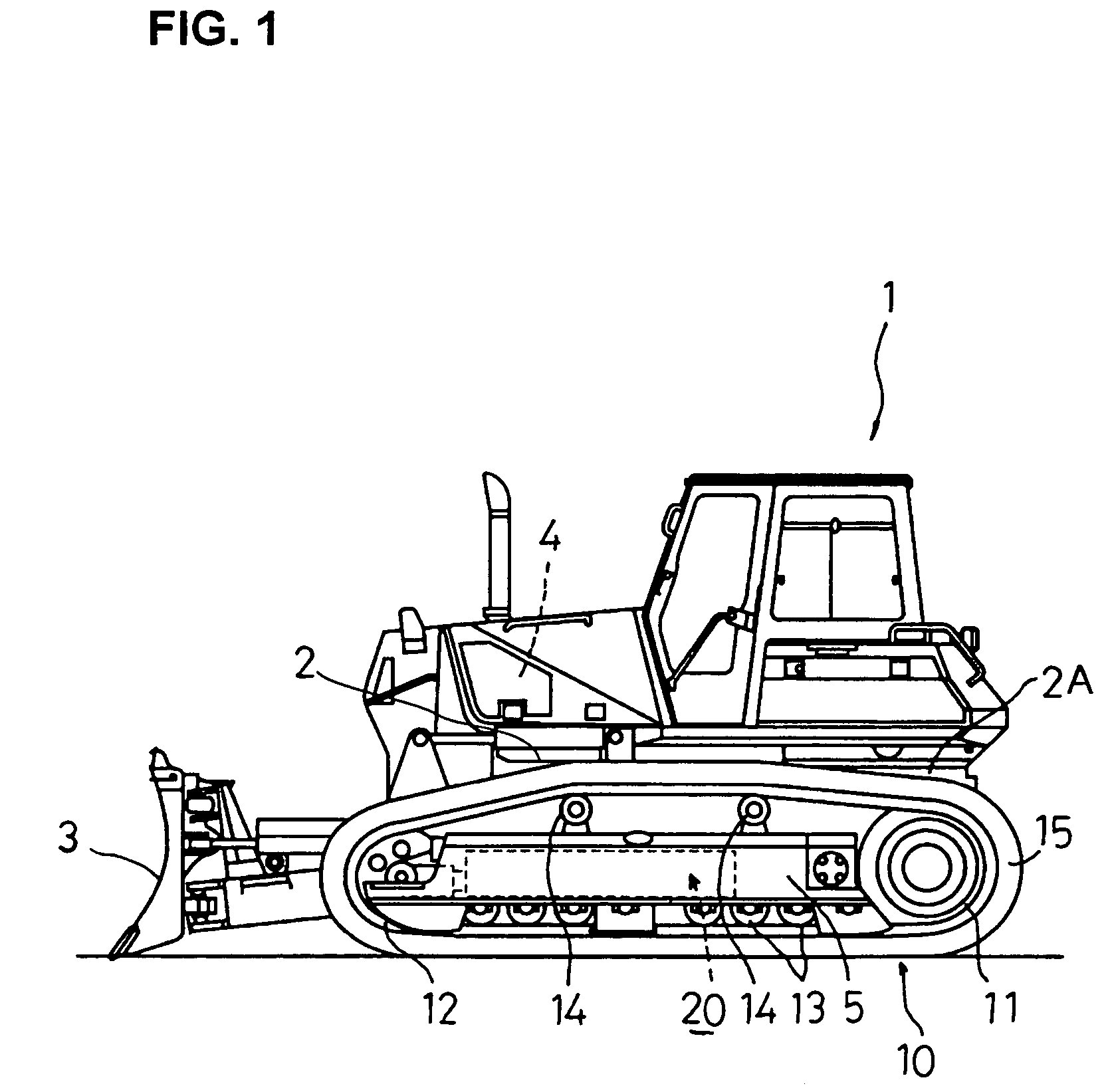

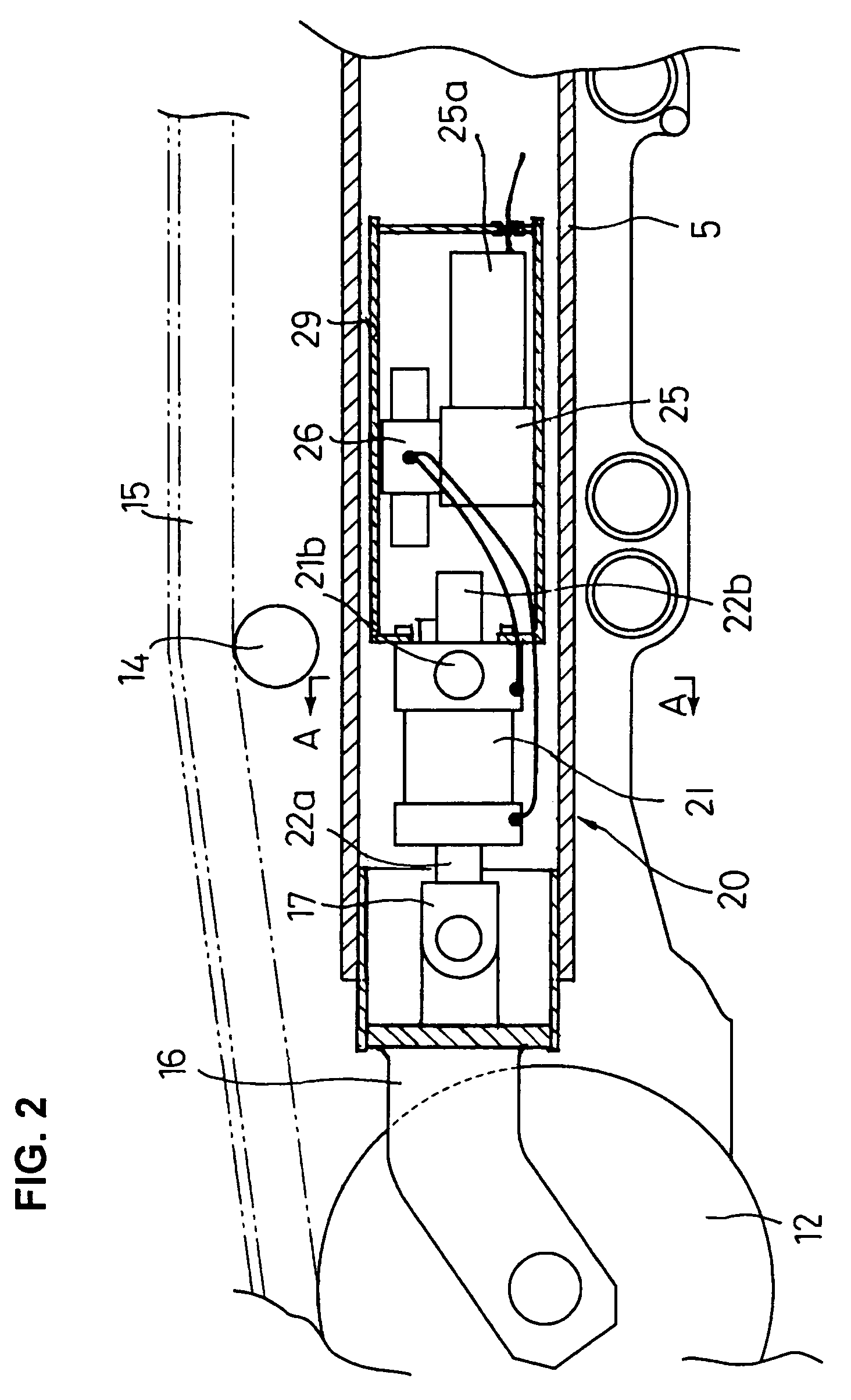

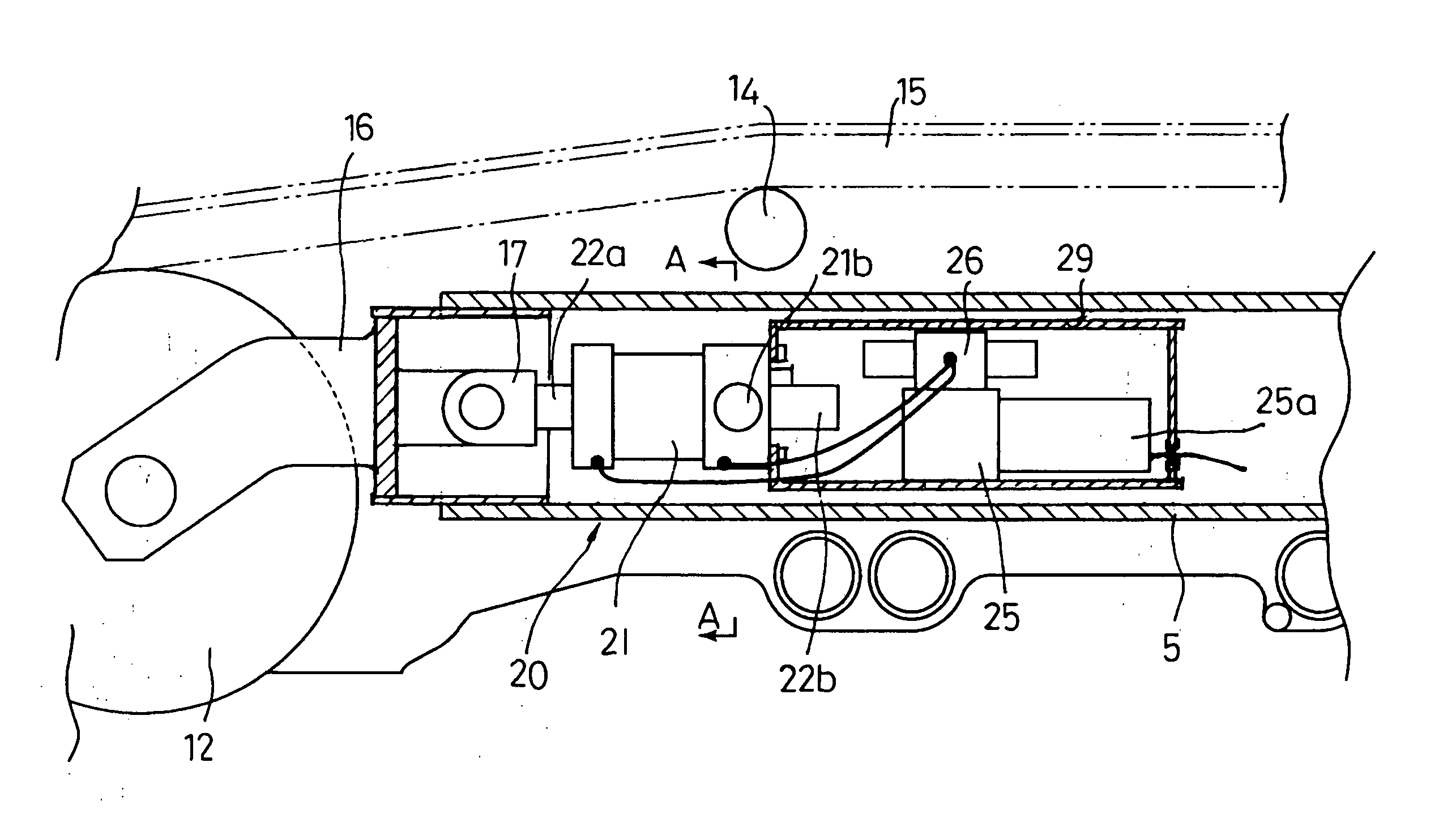

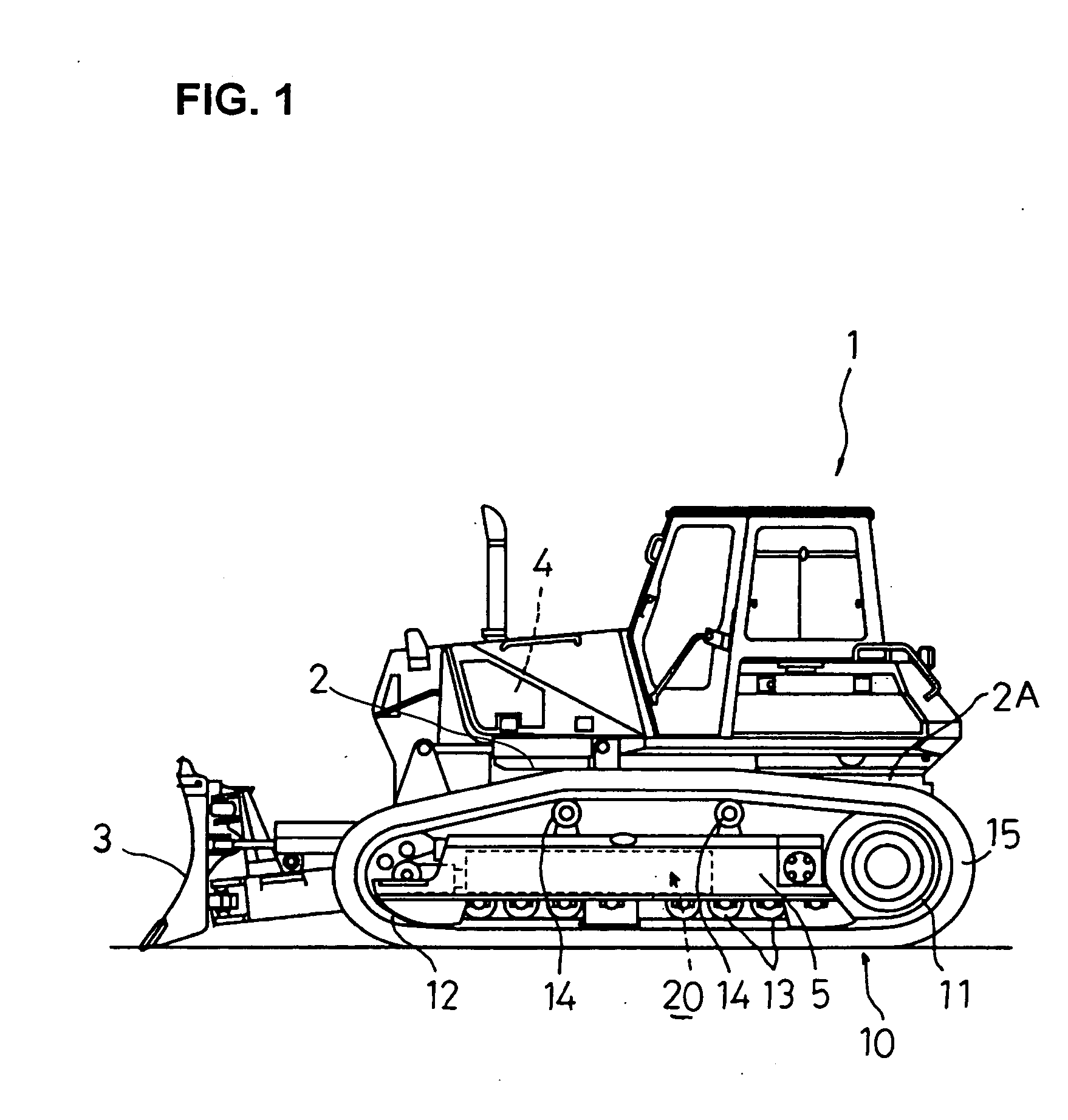

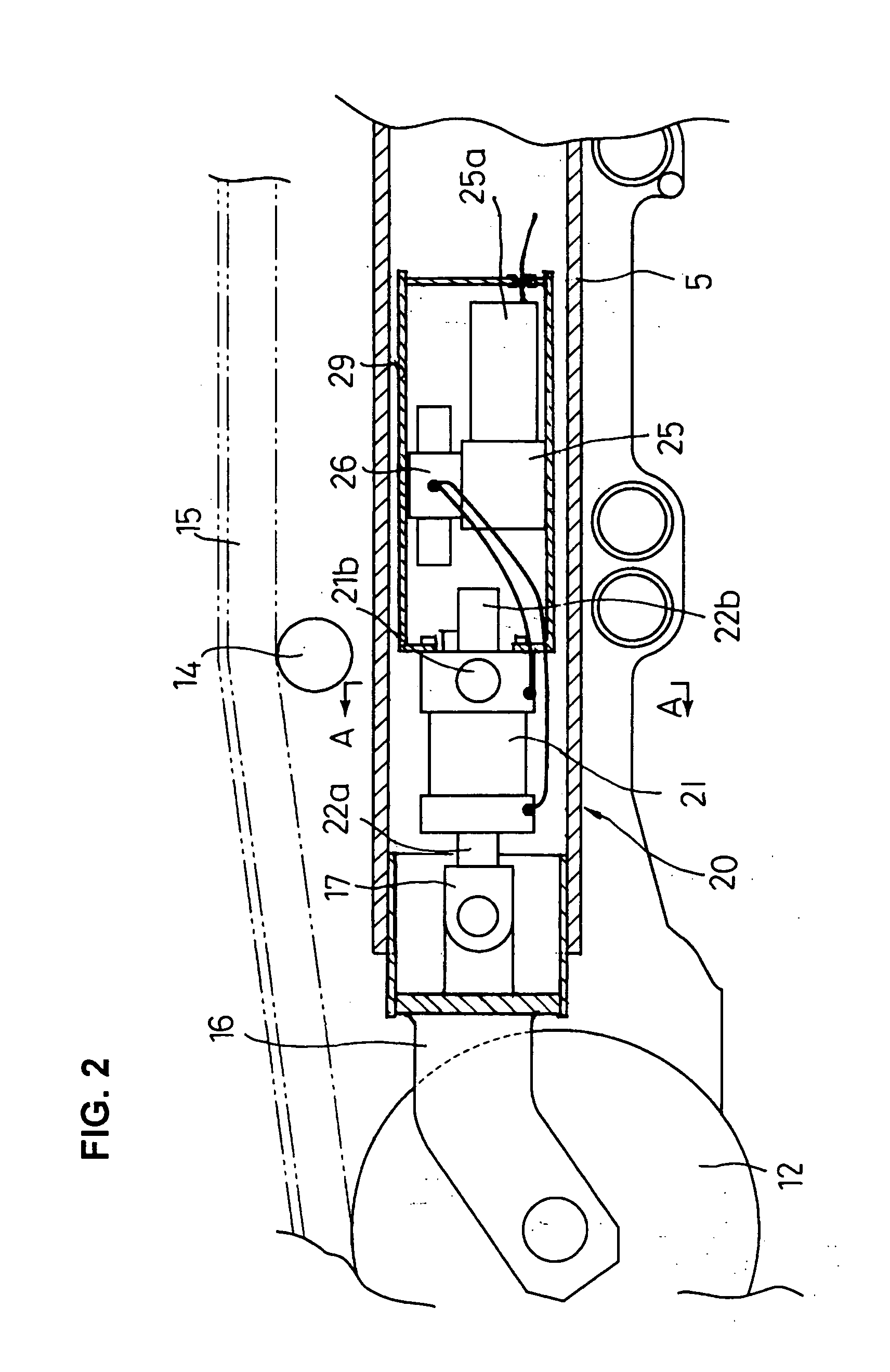

Crawler track tension adjusting device

Owner:KOMATSU LTD

Quick release shackle pin system

A spring loaded quick release pin and tubular receiver with a retainer pin configured to secure the quick release pin in a shackle, clevis, yoke or forked rod end. The receiver is welded to a shackle or cast with the shackle as a single body. One end of the quick release pin has aligned J slots that engage the retainer pin positioned in the receiver with a clockwise twist. The other end of the quick release pin has a cap and a spring loaded sleeve that biases the cross pin against outside of the second leg of the shackle. The spring bias keeps the short leg of the J slot engaged with the retaining pin. The quick release pin is removed with a push and counter clockwise twist. The invention includes a kit with a receiver, a bushing and a quick release pin for installing or retrofitting existing shackles.

Owner:SILVA FRED

Piston of internal combustion engine

InactiveUS6357341B1Reduce frictional resistanceReduce coefficient of frictionPlungersMachines/enginesEngineeringInternal combustion engine

In a reciprocating piston of an internal combustion engine comprising a piston skirt having a major-thrust-side skirt portion and a minor-thrust-side skirt portion, a projected circumferential width of the minor-thrust-side skirt portion is greater than a projected circumferential width of the major-thrust-side skirt portion. Additionally, the piston skirt is dimensioned so that the minimum thickness of the minor-thrust-side skirt portion is less than the minimum thickness of the major-thrust-side skirt portion.

Owner:UNISIA JECS CORP

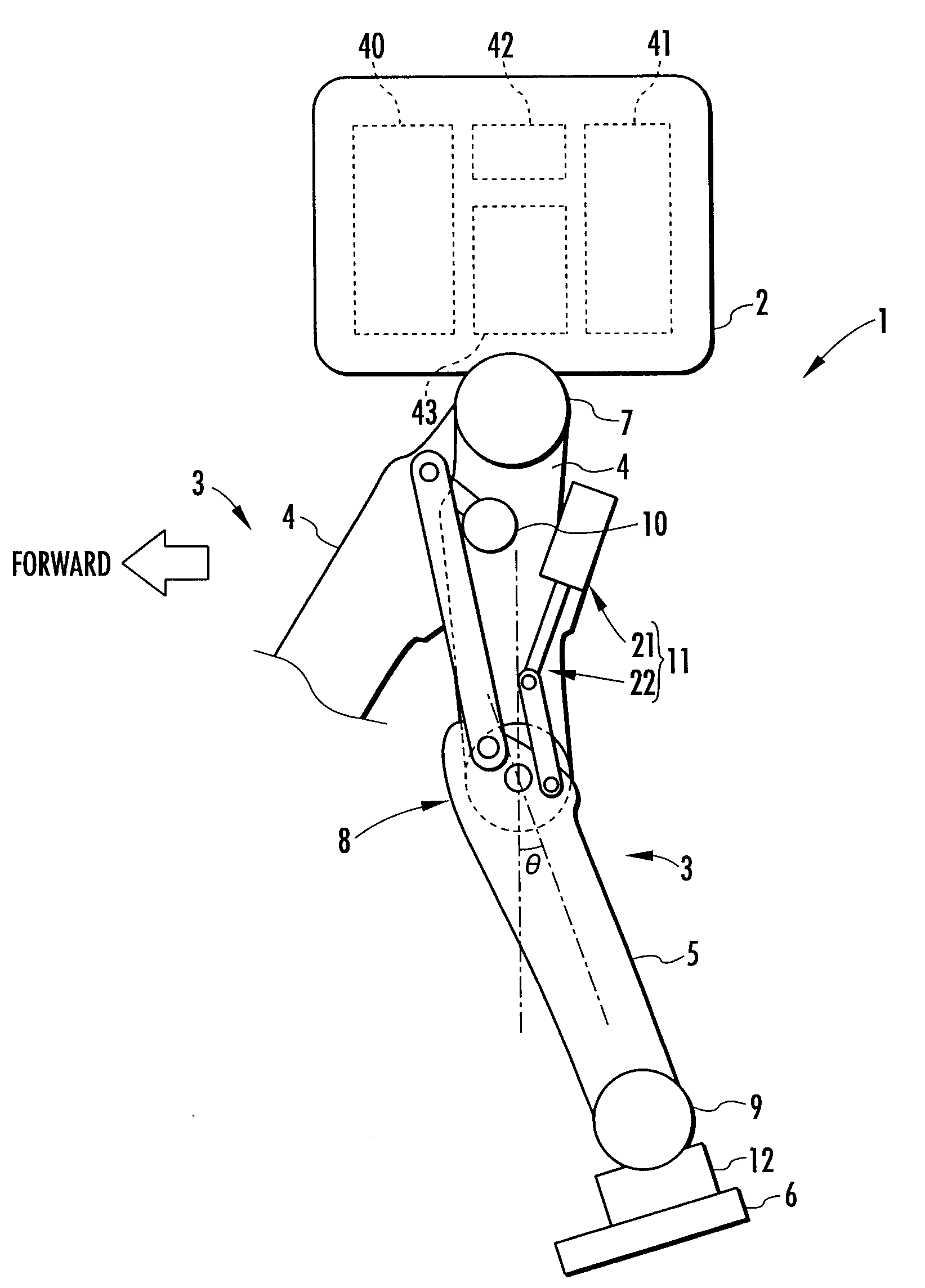

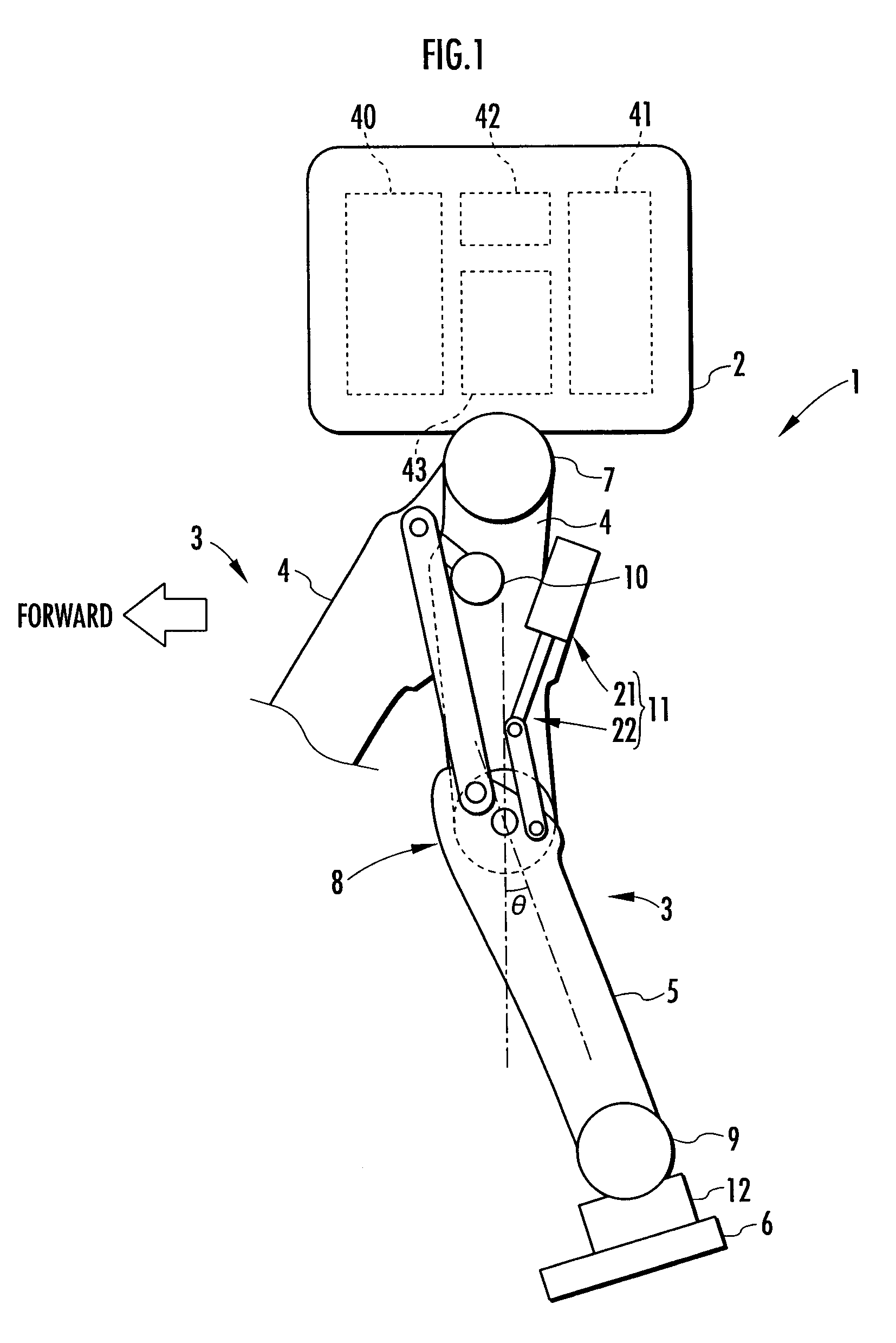

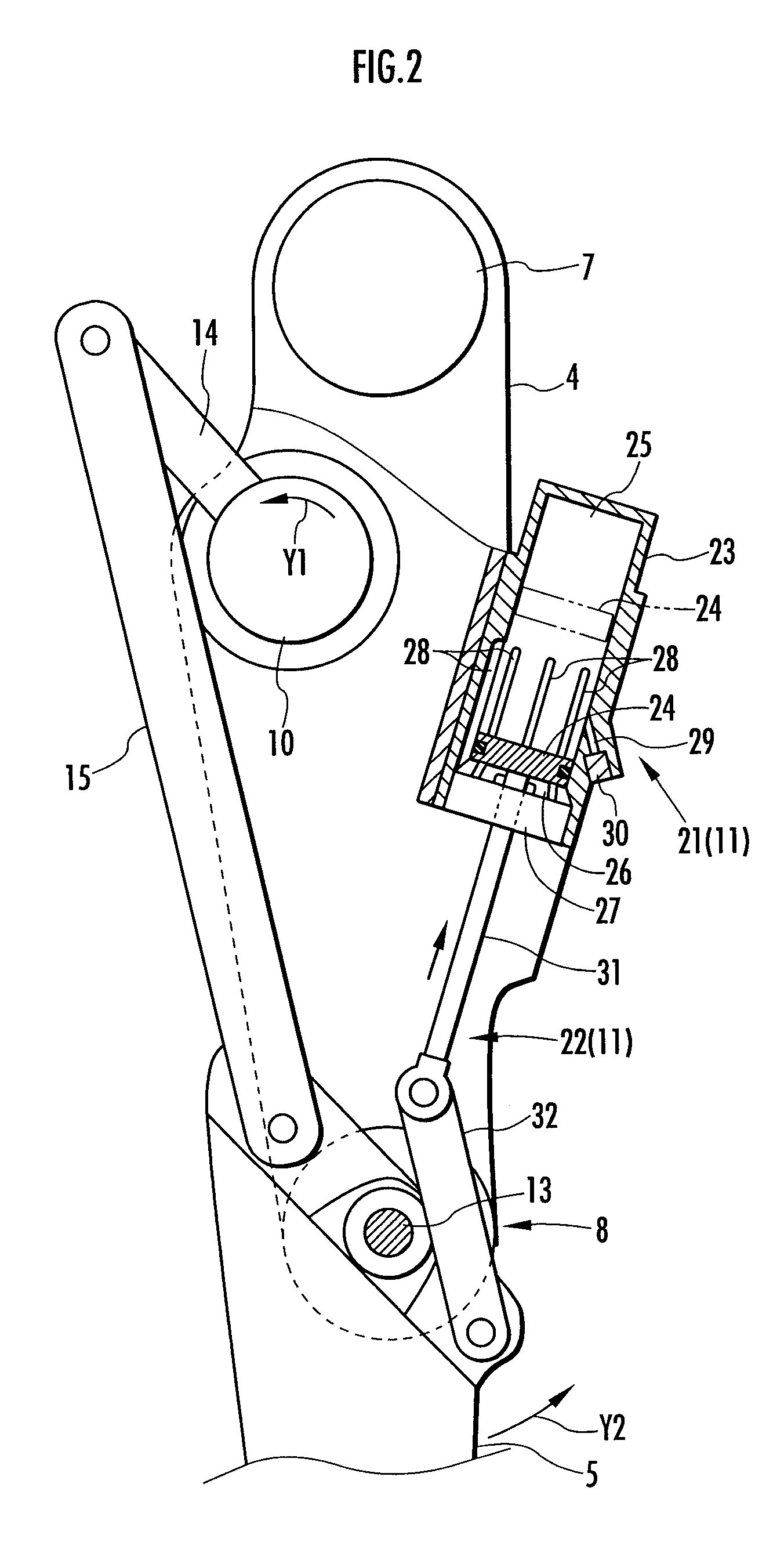

Leg Joint Assist Device of Legged Mobile Robot

An assist device 11 is equipped with a spring means 21 (gas spring), and a piston 24 in a cylinder 23 moves upward or downward according to a relative displacement motion (flexing or stretching motion) of a thigh 4 and a crus 5 at a knee joint 8 of a leg 3 of a robot. Air chambers 25 and 26 above and below the piston 24 are filled with gases. If a flexing degree at the knee joint 8 is a predetermined value or less, then the air chambers 25 and 26 are brought into communication through a groove 28 in the cylinder 23, and the spring means 21 does not generate an elastic force, but if the flexing degree exceeds the predetermined value, then the air chambers 25 and 26 are hermetically sealed from each other and the spring means 21 produces an elastic force, the elastic force acting on the knee joint 8 as assisting driving force. A burden on a joint actuator of a leg can be reduced, while reducing energy consumption of the robot by using a small and simple construction. Moreover, a change in the characteristics of an assisting driving force of the spring means 21 in response to a flexing degree of the knee joint 8 can be restrained.

Owner:HONDA MOTOR CO LTD

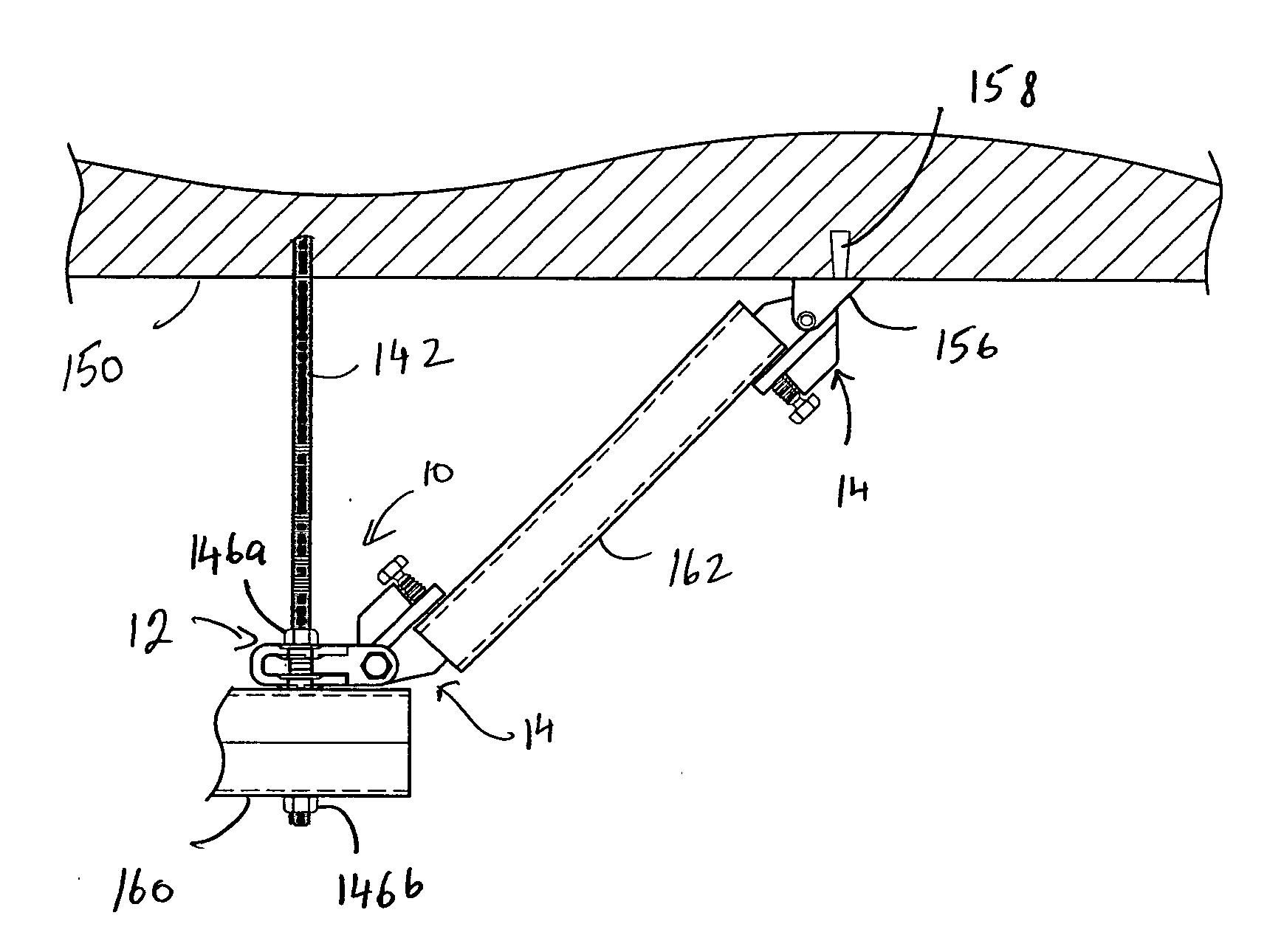

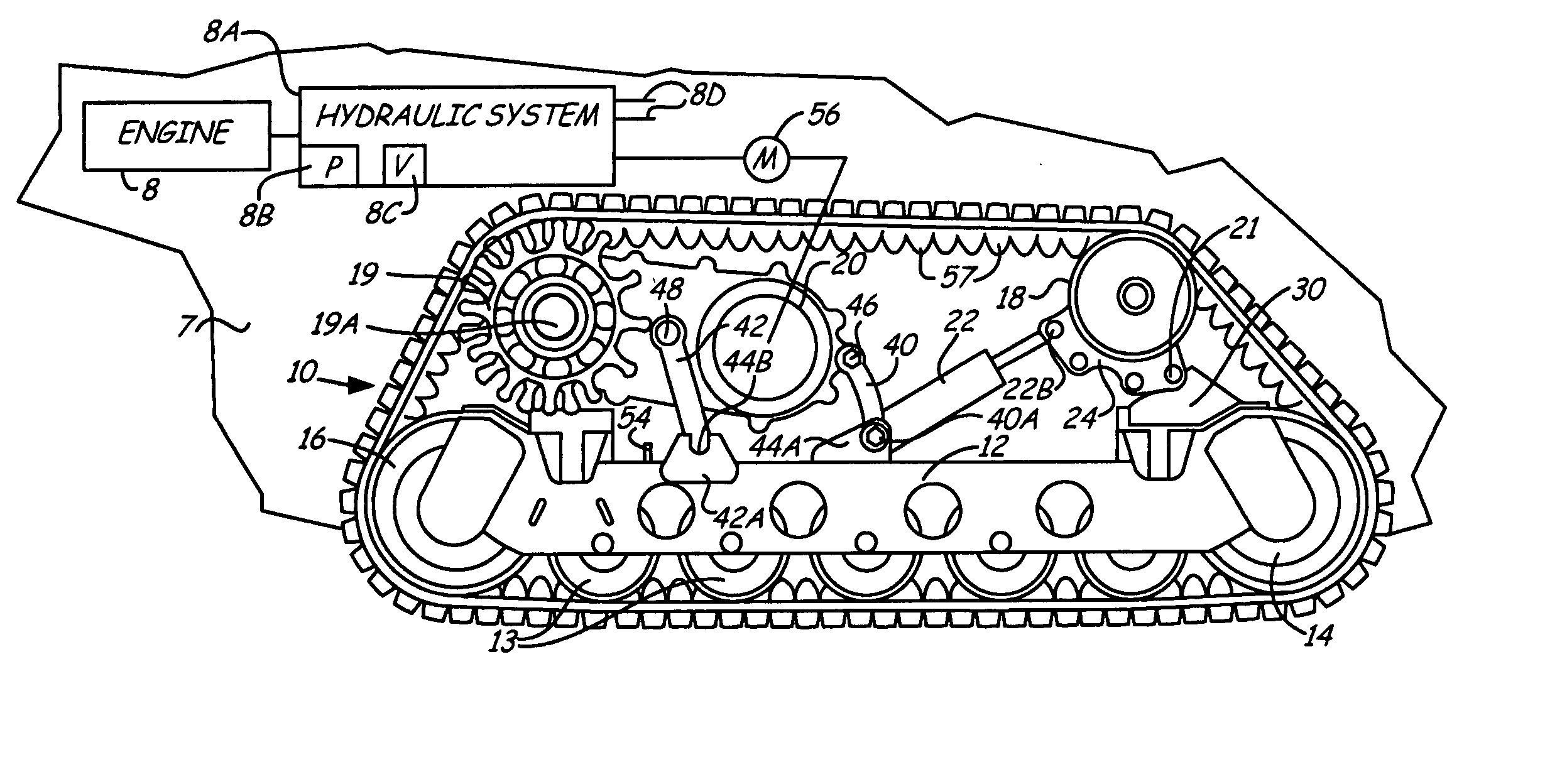

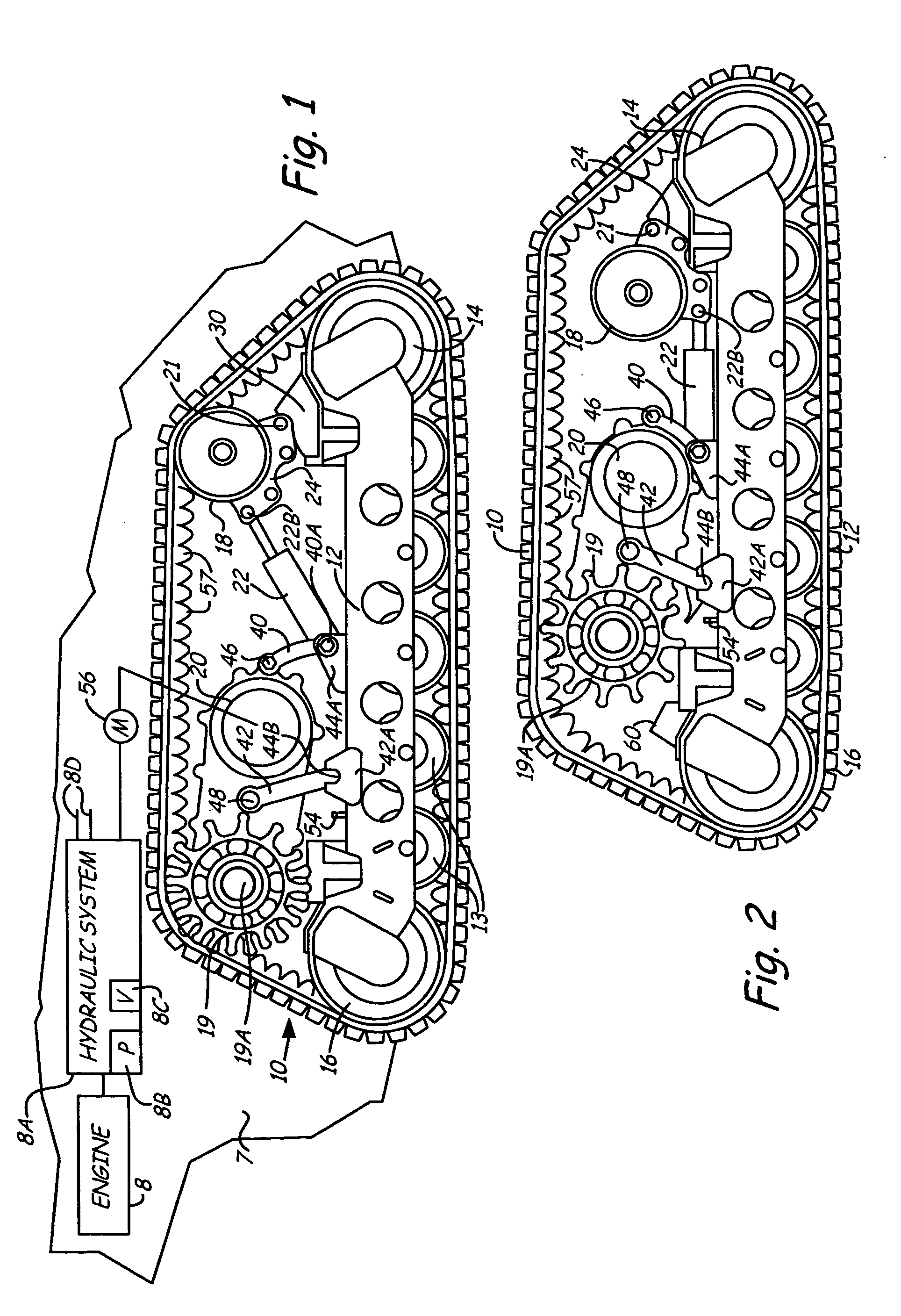

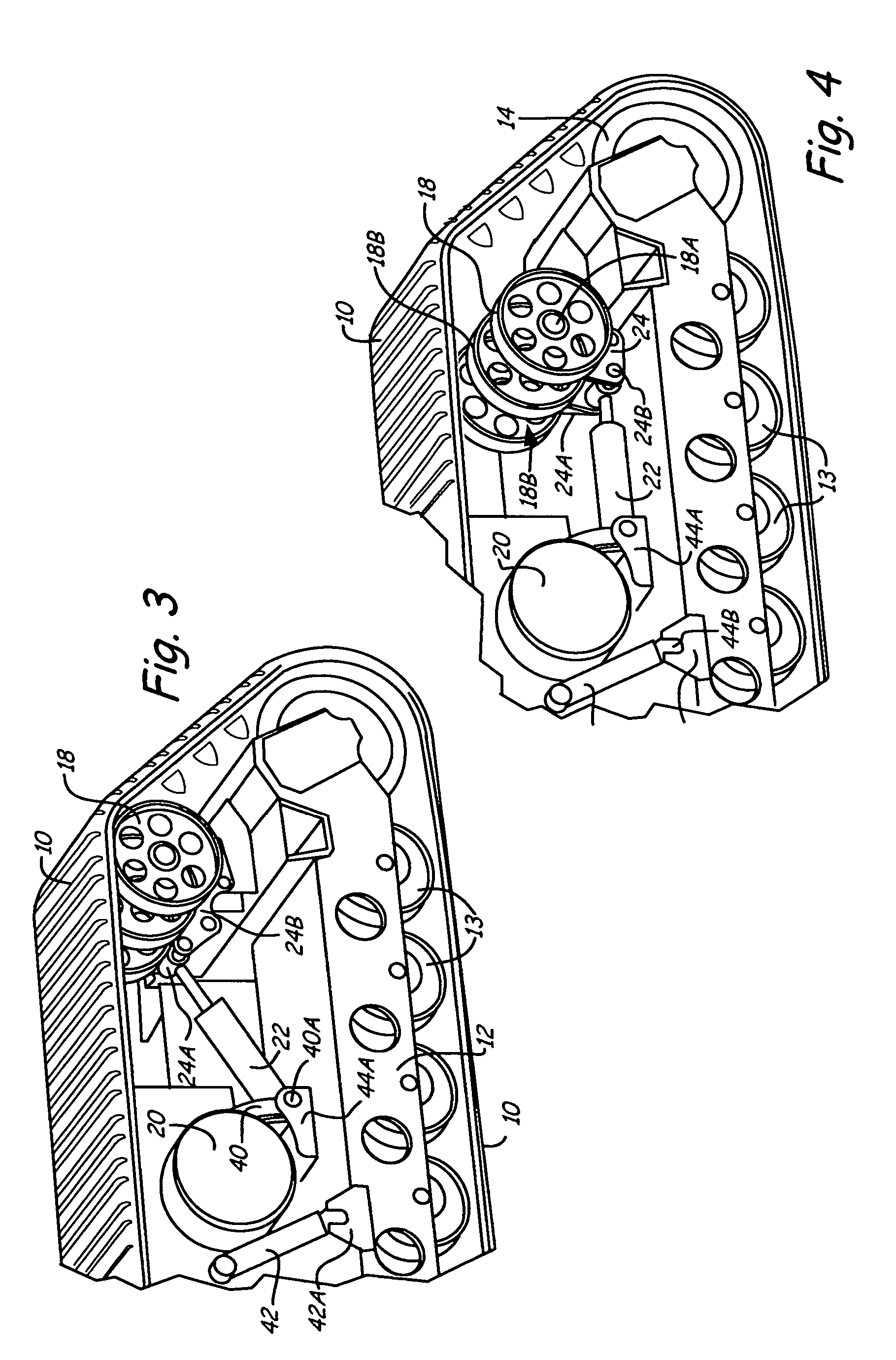

Collapsible track undercarriage for installation and tensioning

A track frame or undercarriage is made to support a rubber track on suitable guide rollers. A tensioning roller is provided as one of the guide rollers on the interior of the track and is mounted on a pivoting bracket. The pivoting bracket moves the tensioning roller to a working position for creating tension in the track. An actuator provides a known force on the pivoting bracket to move the tensioning roller to its working position, using a controlled pressure applied to the actuator. Drive sprockets for the track are mounted onto a drive case that is mounted to the frame through pivoting linkages such that the drive case and the drive sprocket can be held in a working position and retracted away from the track. The position of the tensioning roller is maintained within set limits of retractions during use, by providing a stop to limit the amount that the tensioning roller can retract.

Owner:CLARK EQUIP CO INC

Piston pump

InactiveUS6341950B1Manufactured quickly and economicallyDamp pressure pulsationPositive displacement pump componentsPlungersEngineeringMechanical engineering

The invention relates to a piston pump, which is intended for use as a return pump for a slip-controlled hydraulic vehicle brake system. To simplify the manufacture of a piston of the piston pump, the piston includes a thin sleeve.

Owner:ROBERT BOSCH GMBH

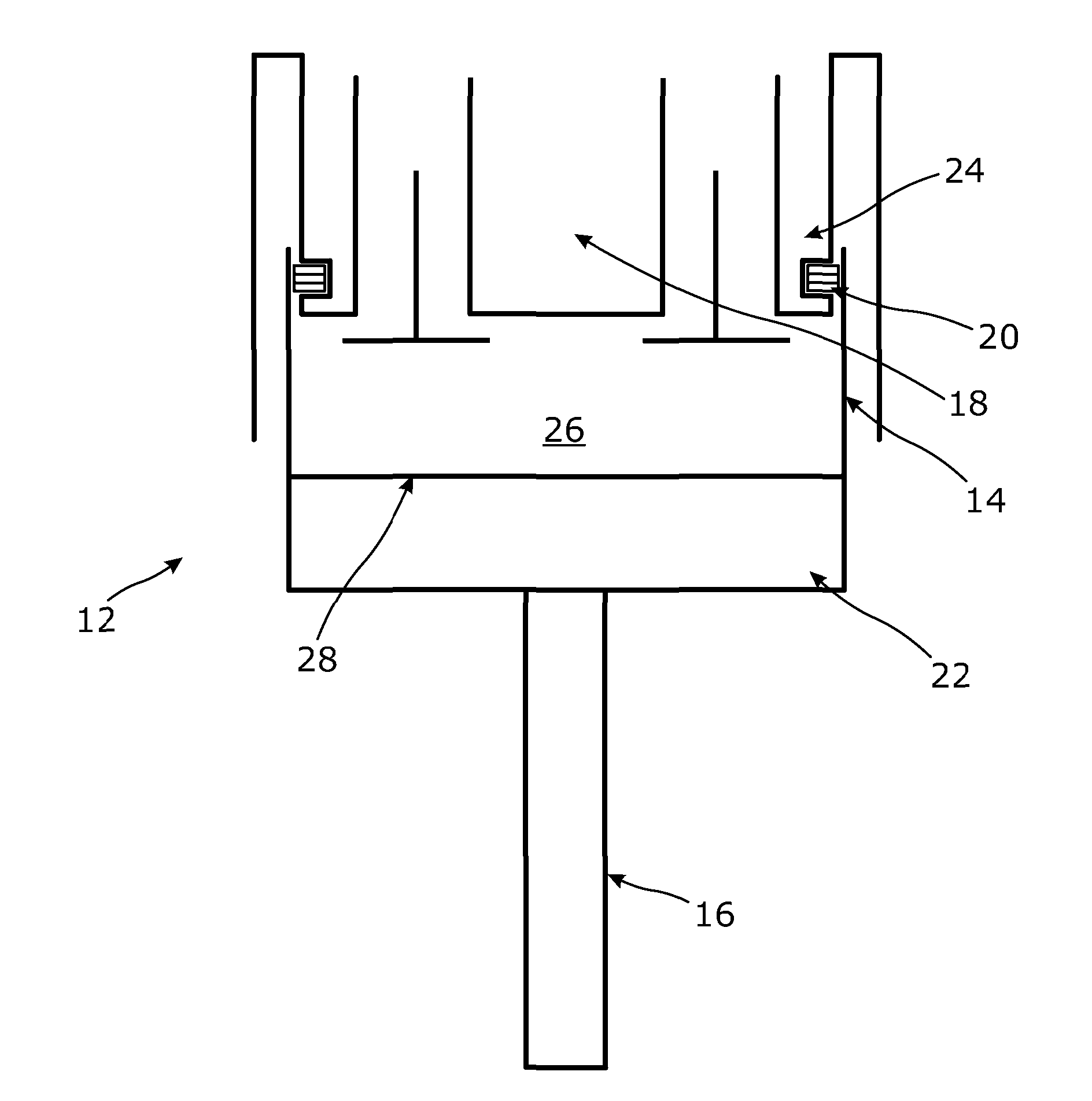

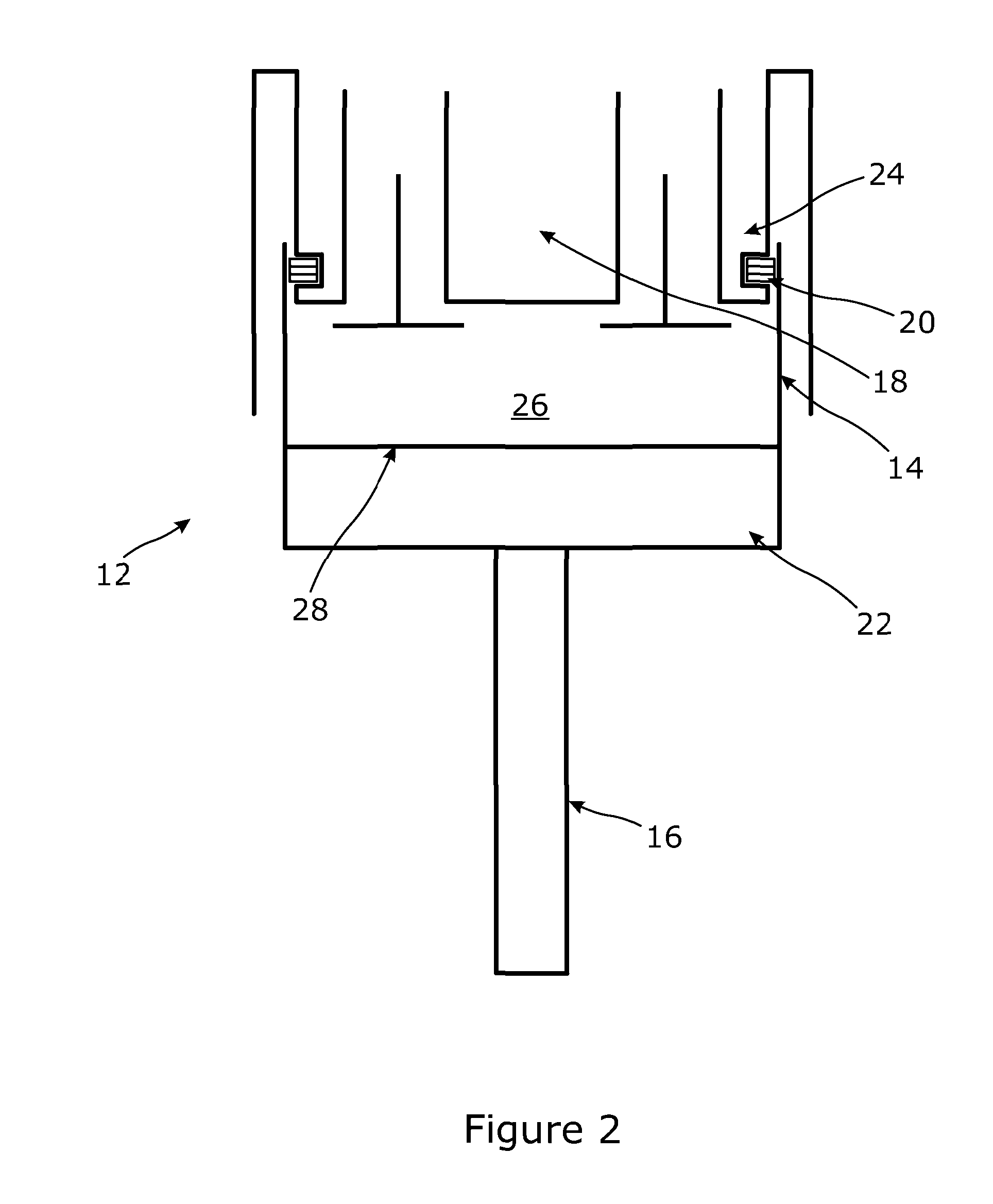

Piston Assembly

InactiveUS20150114217A1Reduce inertia forceReduce quality problemsEngine sealsPositive displacement pump componentsCylinder headGraphite

A piston assembly (12) comprising a reciprocating sleeve (14) incorporating an integral internal piston surface (28), which sleeve is slidably mounted upon a cylinder head (18) so as to define a piston chamber (26) therewith, the piston chamber being sealed in the vicinity of the cylinder head (18) by a circumferential static seal (20) that acts to seal against the reciprocating sleeve (14). The static seal (20) may occupy a horizontal plane and may include sacrificial wear zones and be formed from a graphite-based material. The piston assembly may be an oversquare assembly for use in an oil-free environment for processing high temperature gases, for example, a hot gas engine or heat pump or heat engine such as may be used in an energy storage system.

Owner:ENERGY TECH INST

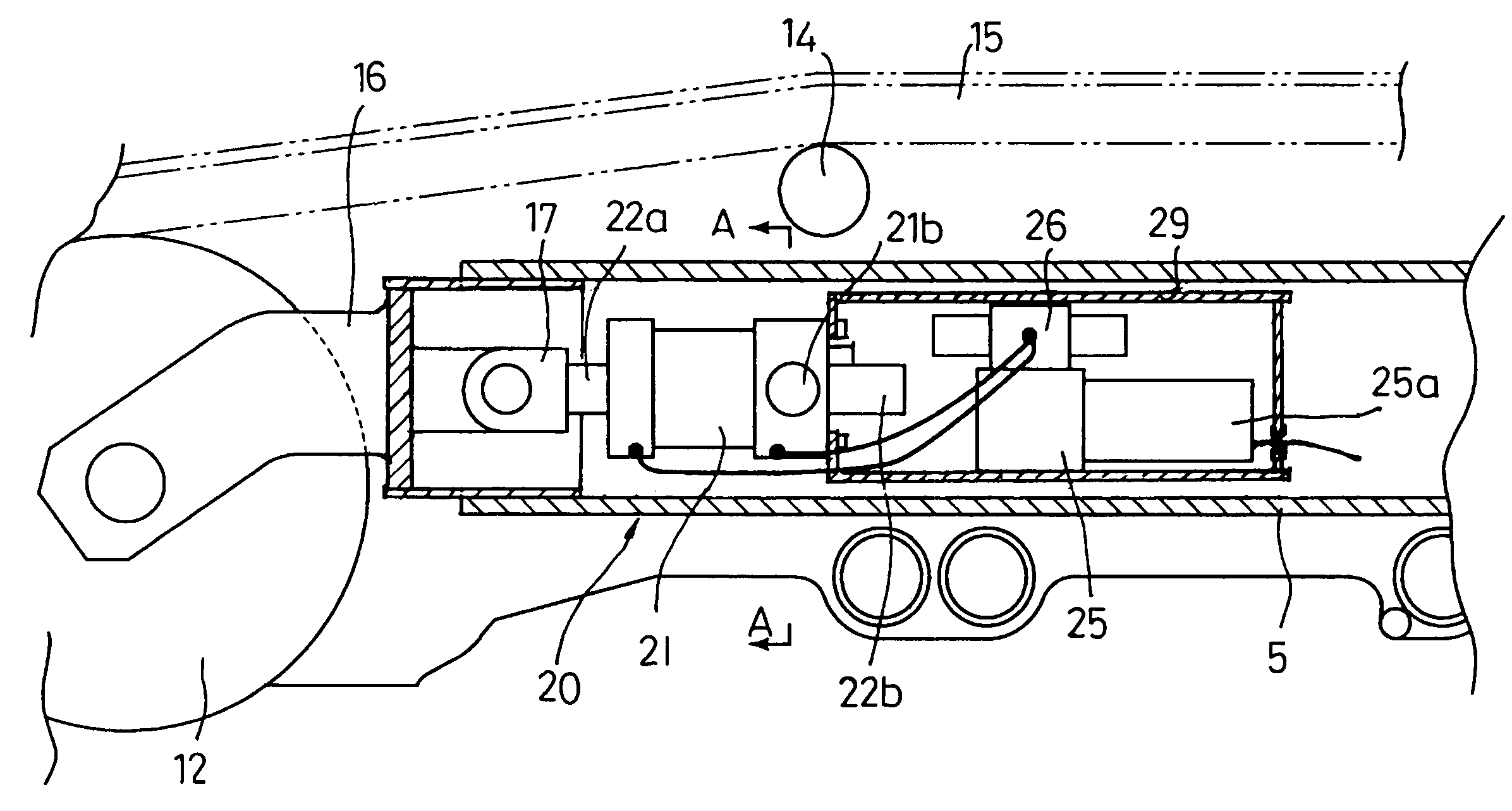

Crawler track tension adjusting device

A crawler track tension adjusting device is provided in which a driving unit of a closed structure is used as a control operation mechanism and automatic tension adjustment is carried out in response to a control signal to create optimum tension on a crawler belt. To this end, the crawler track tension adjusting device comprises: (a) a tension adjusting cylinder which is operated in a direction to increase tension and in a direction to reduce tension under the same condition; (b) a hydraulic pump driven by a motor; (c) a hydraulic circuit including an electromagnetic direction selector valve disposed in an oil pipeline for connecting the hydraulic pump to the tension adjusting cylinder; and (d) a hydraulic sensor for detecting the operating condition of the tension adjusting cylinder disposed in the hydraulic circuit. The hydraulic sensor is connected to an additionally installed controller to operate the hydraulic pump and the direction selector valve thereby controlling the tension adjusting cylinder.

Owner:KOMATSU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com