Patents

Literature

33results about How to "Mechanical property" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

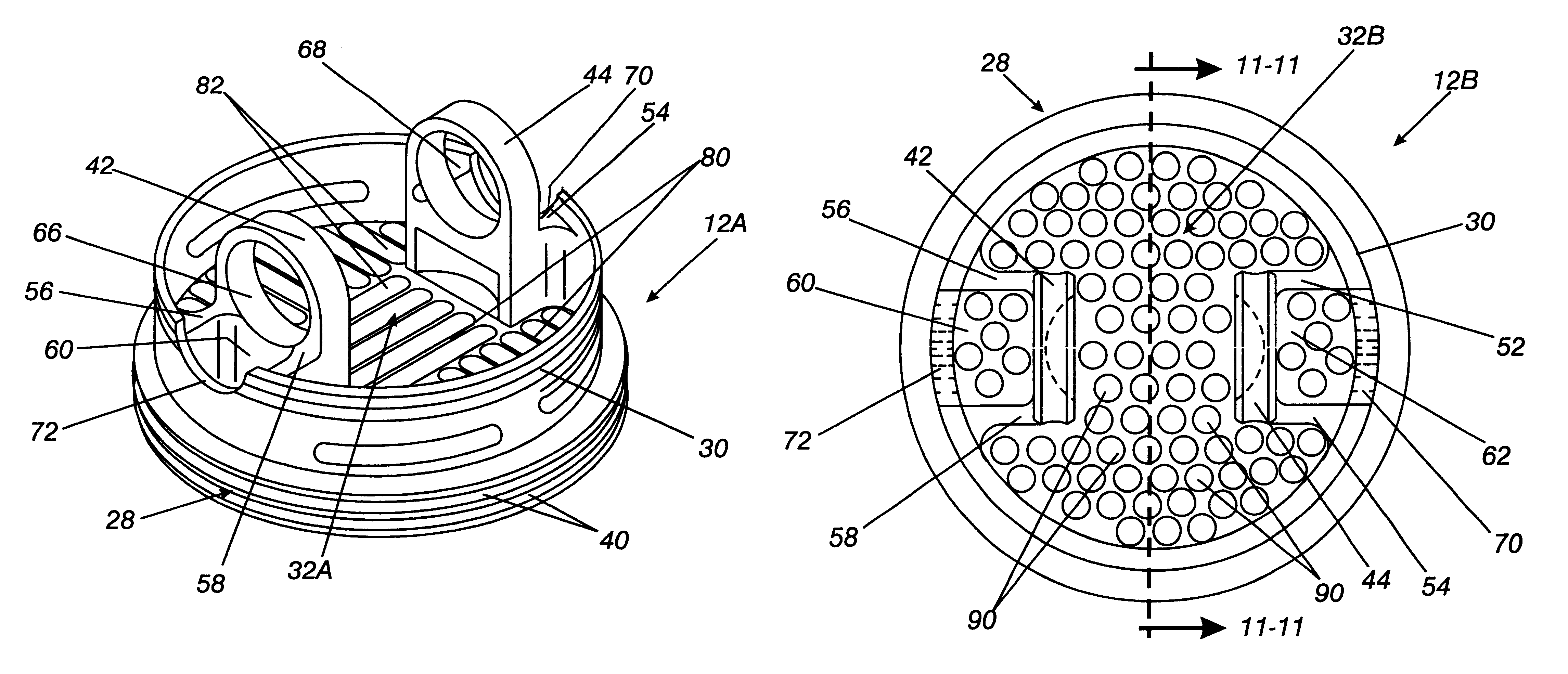

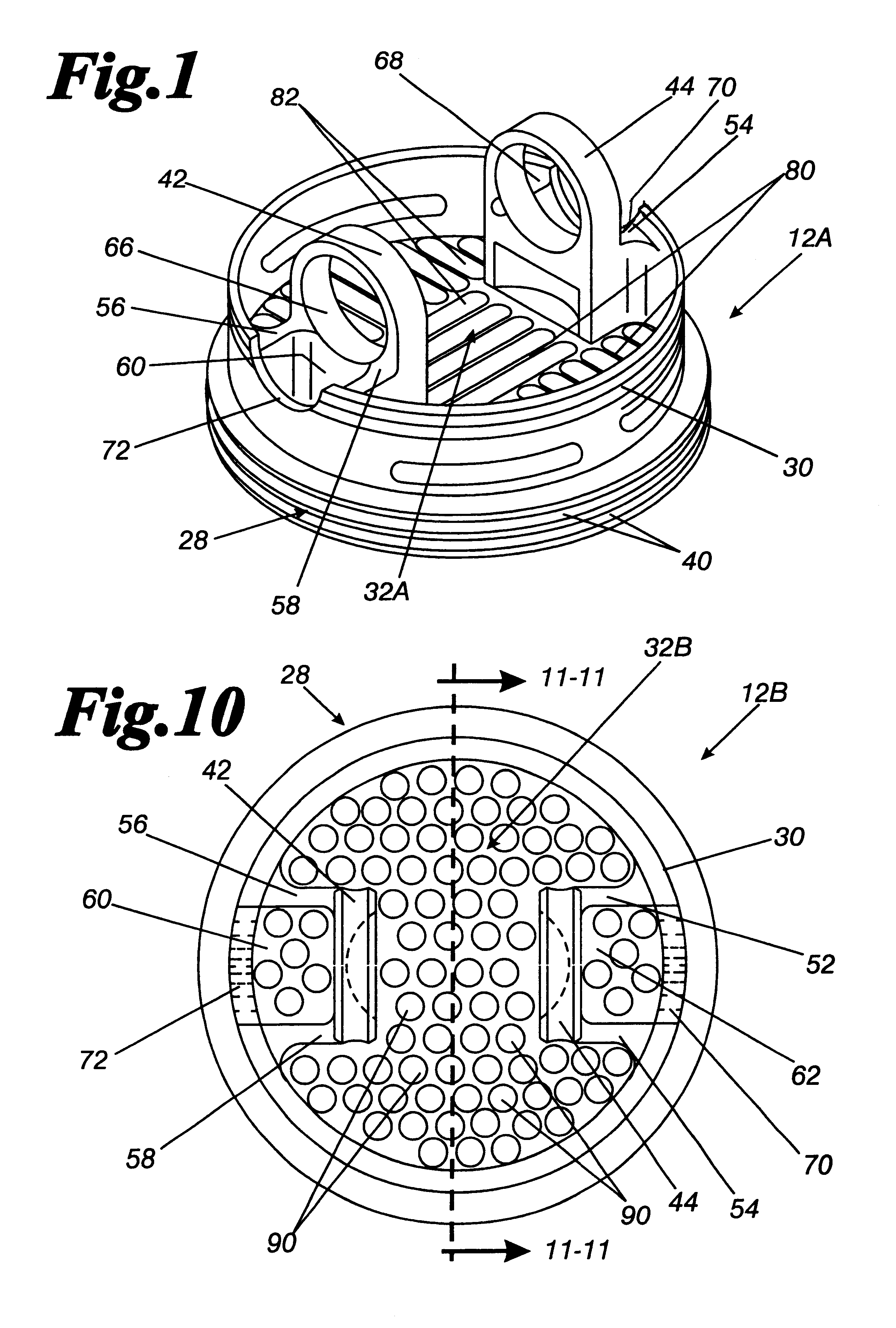

Two-piece piston assembly

InactiveUS6318243B1Mechanical propertyLight weightPlungersMachines/enginesEngineeringMechanical engineering

Owner:JONES D KENT

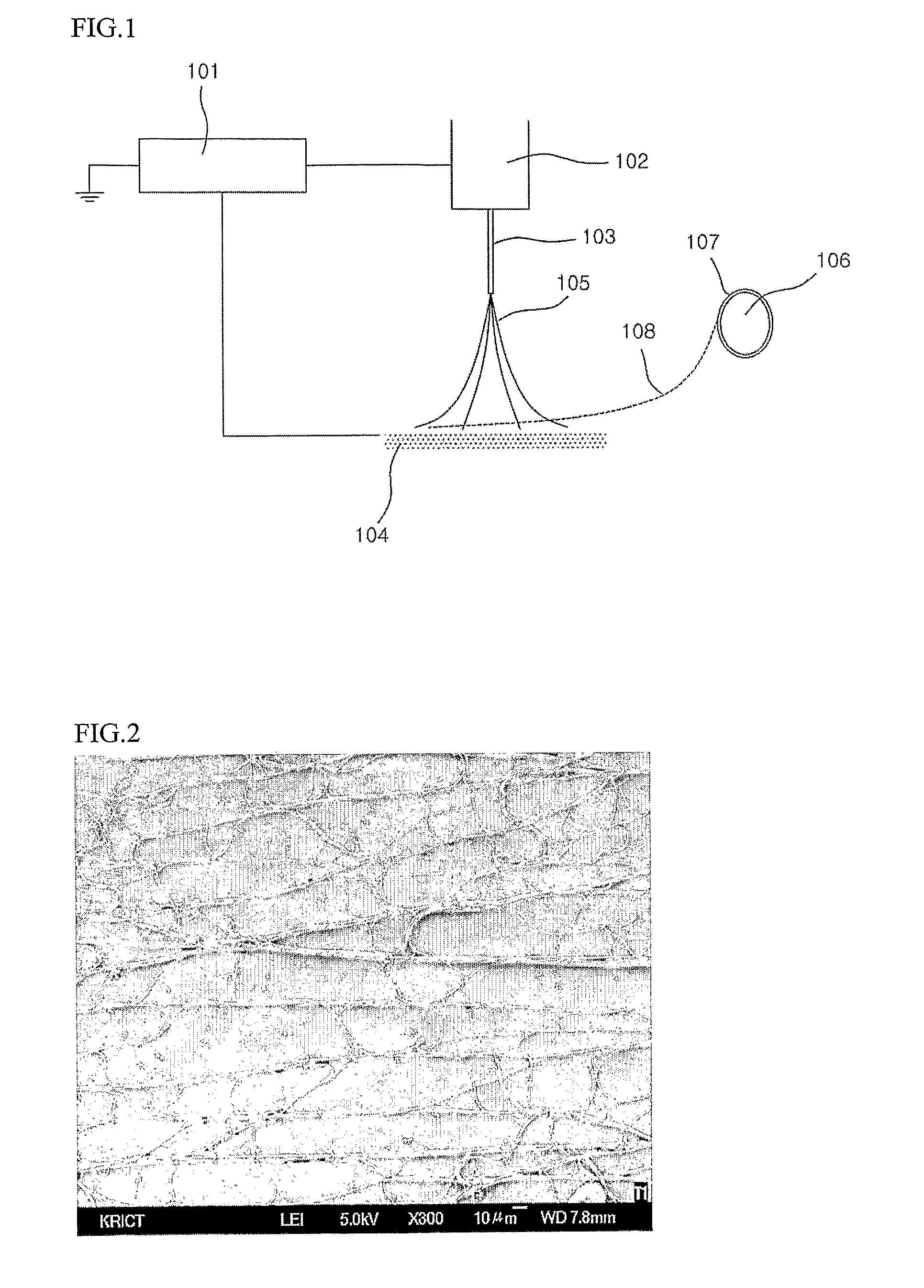

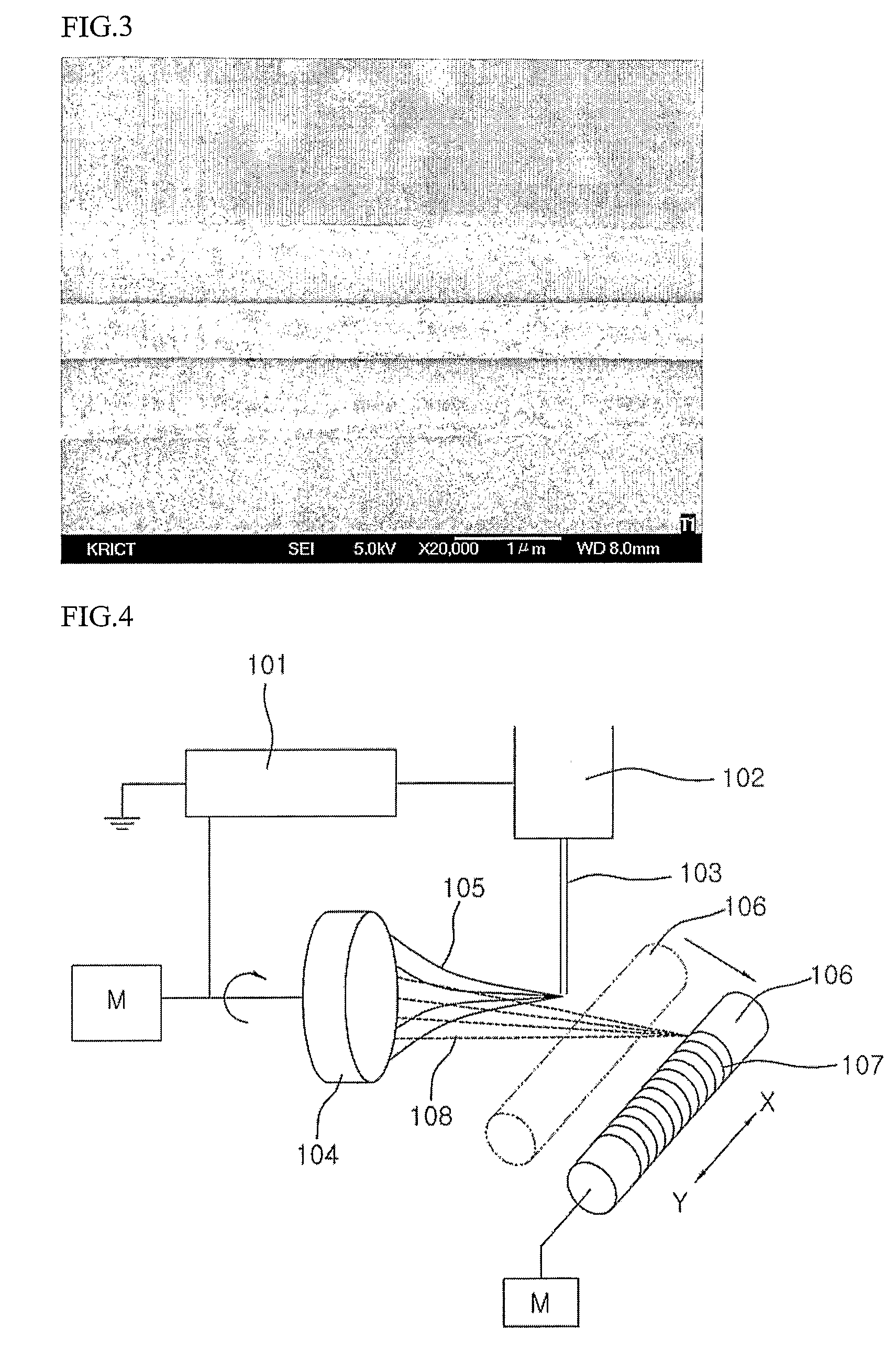

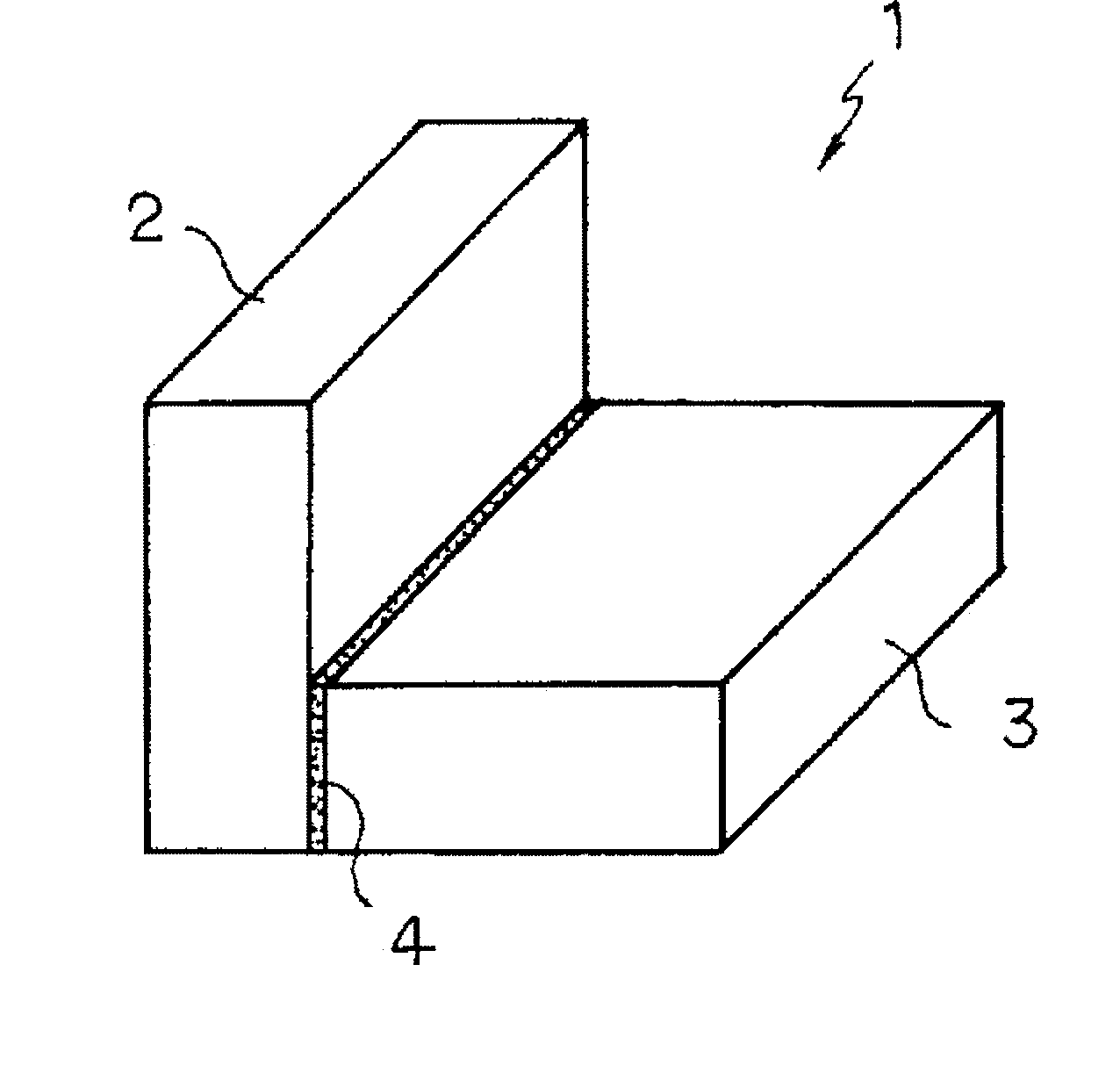

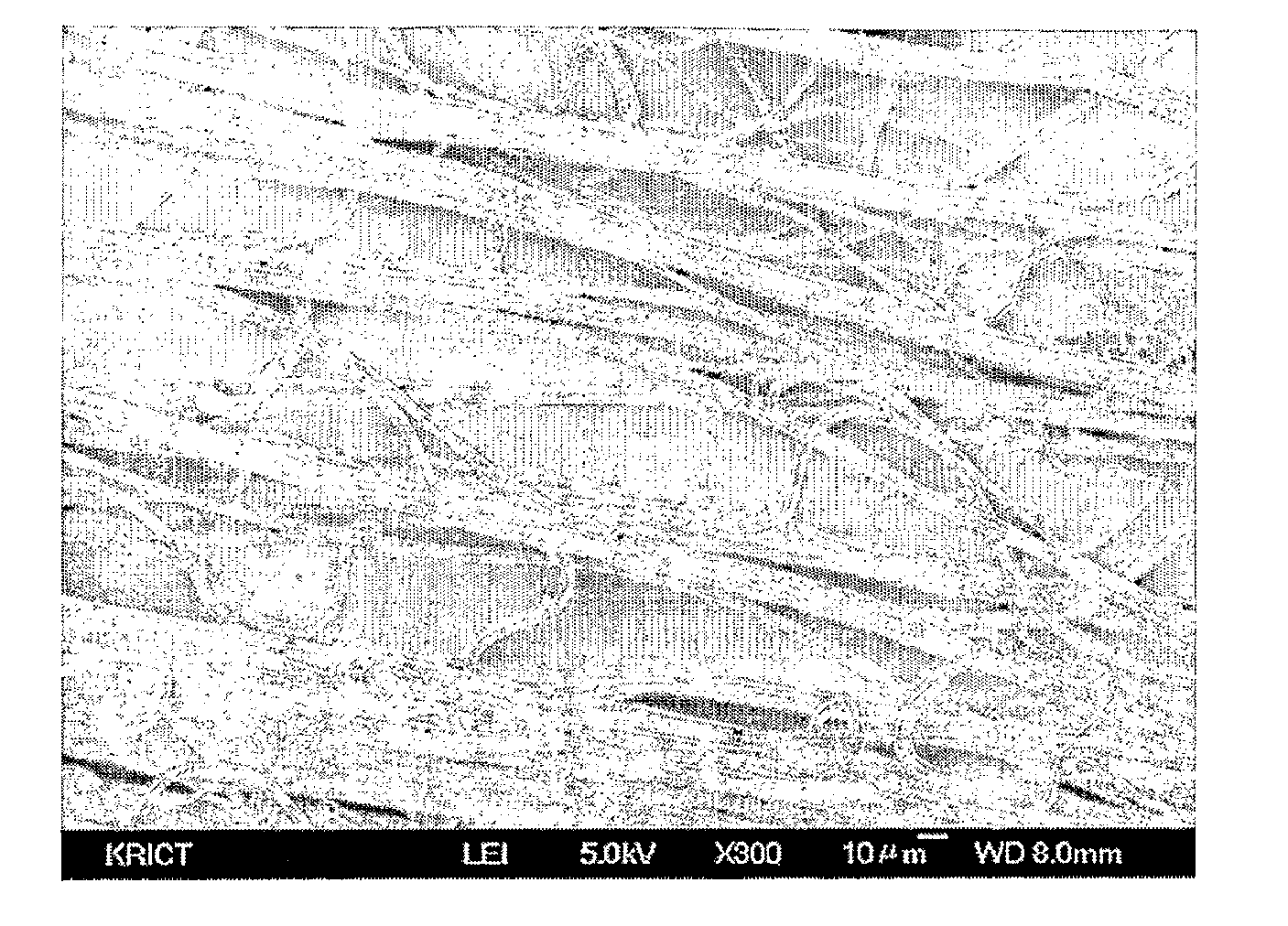

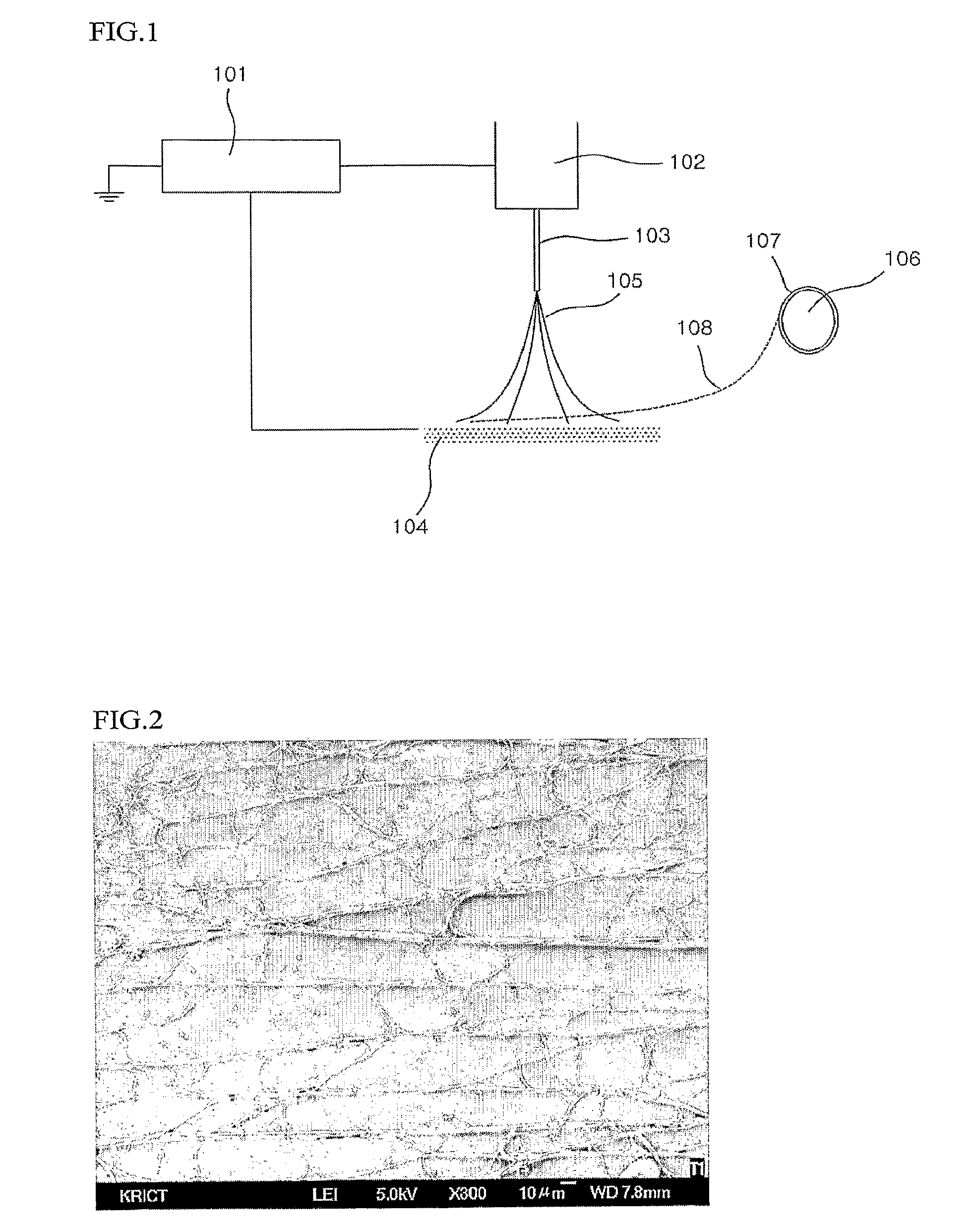

Filament Bundle Type Nano Fiber and Manufacturing Method Thereof

InactiveUS20080241538A1Improve mechanical propertiesMechanical propertyElectric discharge heatingFilament/thread formingFiberYarn

A filament type nano-sized long fiber and a method of producing the same are disclosed. In the method, a spinning solution or a spinning melt is electro-spun in drops using a spinneret to which a critical voltage is applied, and the spun drops are continuously collected on a multi-collector. The spinning solution is produced by dissolving a blend or copolymer consisting of two or more kinds of polymers in a solvent. The spinning melt is produced by melting the polymers. The multi-collector is selected from the group consisting of a plate type collector, a roll type collector, and a combination thereof. The filament type nano-sized long fiber is processed into a yarn through one step during the electrospinning process, and thus, mechanical properties are better than those of a conventional nanofiber non-woven fabric. Consequently, the filament type nano-sized long fiber can be utilized for the extended application.

Owner:KOREA RES INST OF CHEM TECH

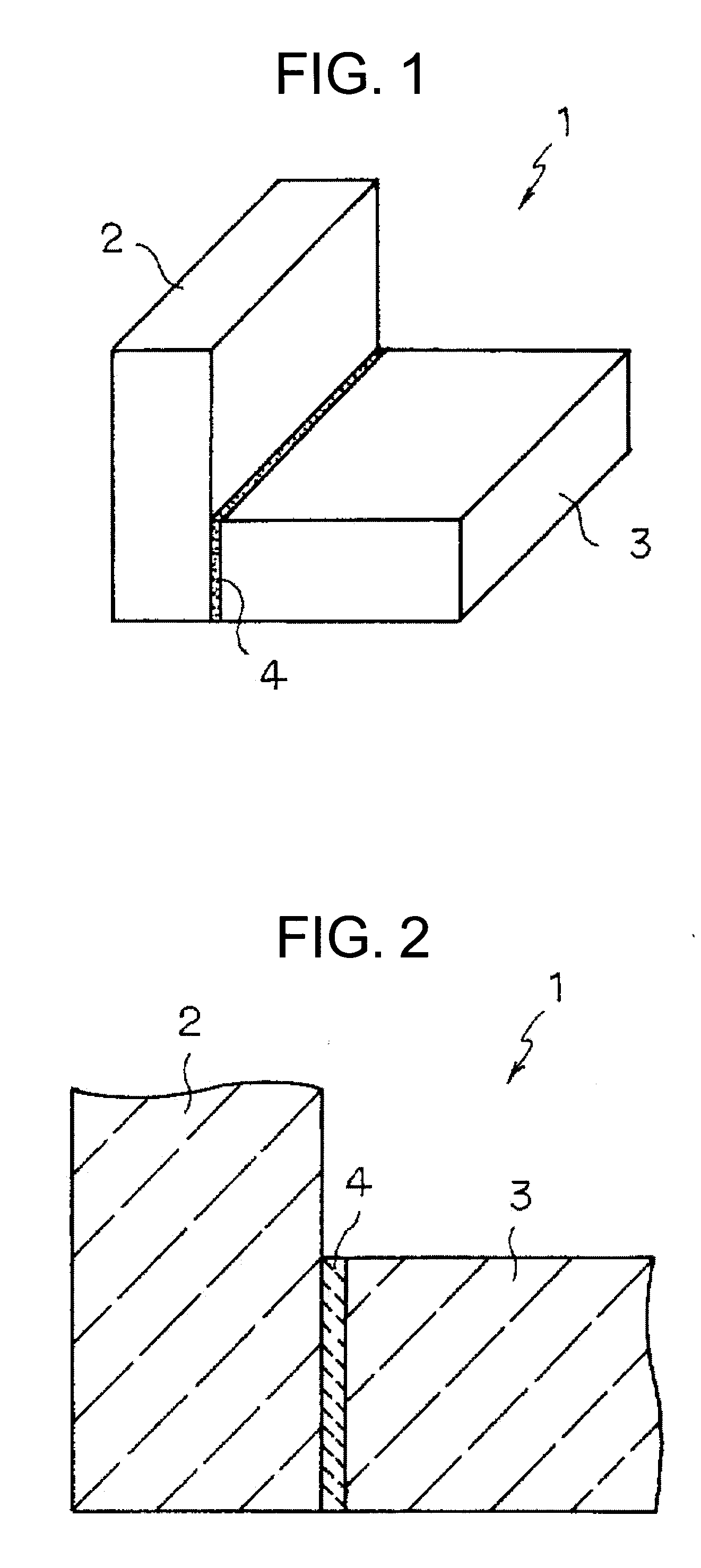

Ceramics composite member and method of producing the same

InactiveUS20080131665A1Good reproducibilityMechanical propertyMaterial nanotechnologyProjectorsSiliconMaterials science

A ceramics composite member includes a structure in which a first ceramic member and a second ceramic member are integrated with a joint portion. The joint portion has a texture in which a silicon phase having an average diameter of 0.05 μm or more and 10 μm or less is continuously provided in a network form in interstices of silicon carbide particles having an average particle diameter of 0.1 μm or more and 0.1 mm or less.

Owner:KK TOSHIBA

Lignin Enhanced Wood-Plastic Material and Preparation Method thereof

It discloses a lignin enhanced wood-plastic composite, belonging to the field of polymer based composites. The wood-plastic composite is composed of one or more of plant fiber, lignin, a recycled thermoplastic plastic, mineral powder and a processing aid, and is processed by a screw granulating extrusion process. Compared with the prior art, the mechanical properties, heat stability and aging resistance of a wood-plastic material are improved by adding lignin into the wood-plastic material according to the present invention.

Owner:NANJING UNIV OF TECH

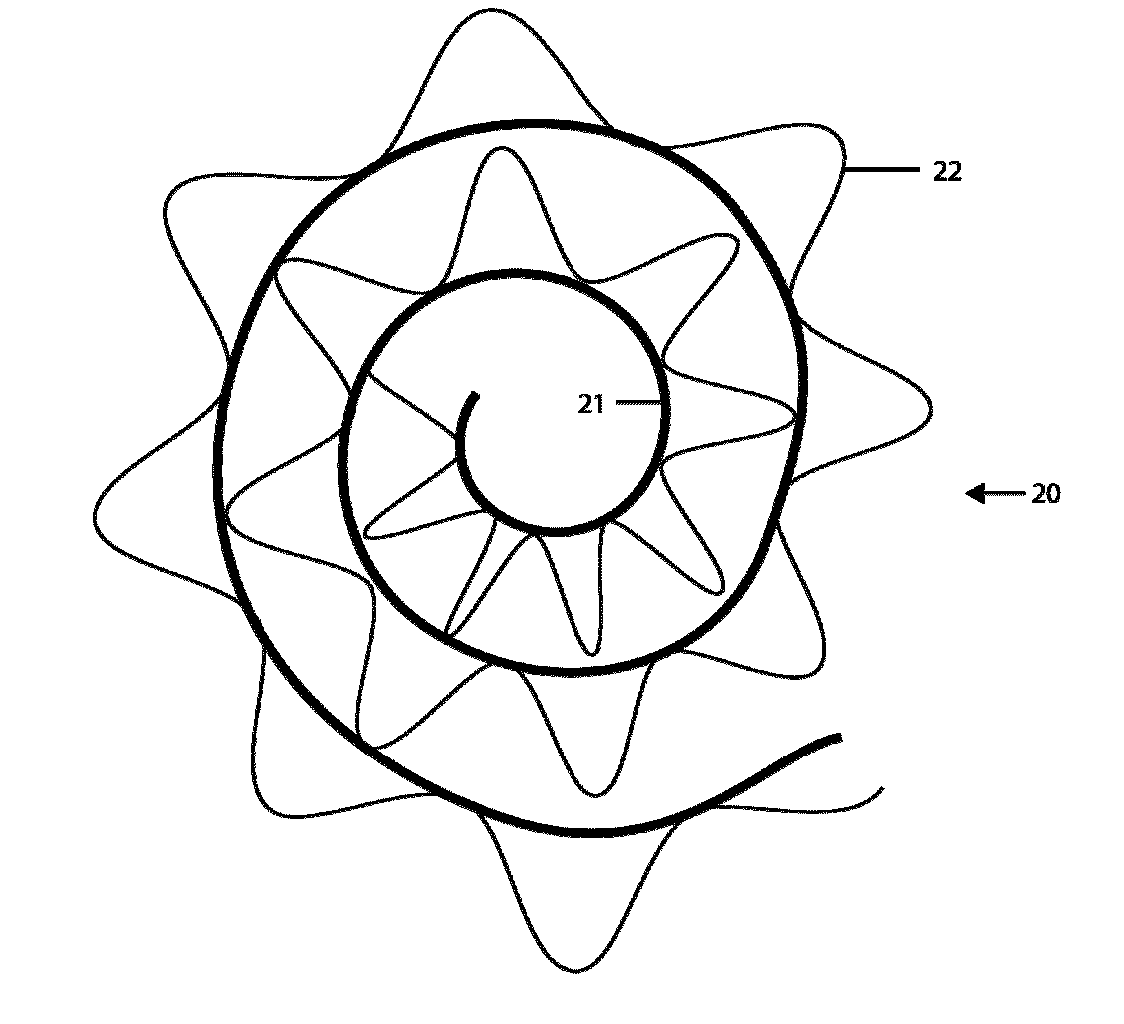

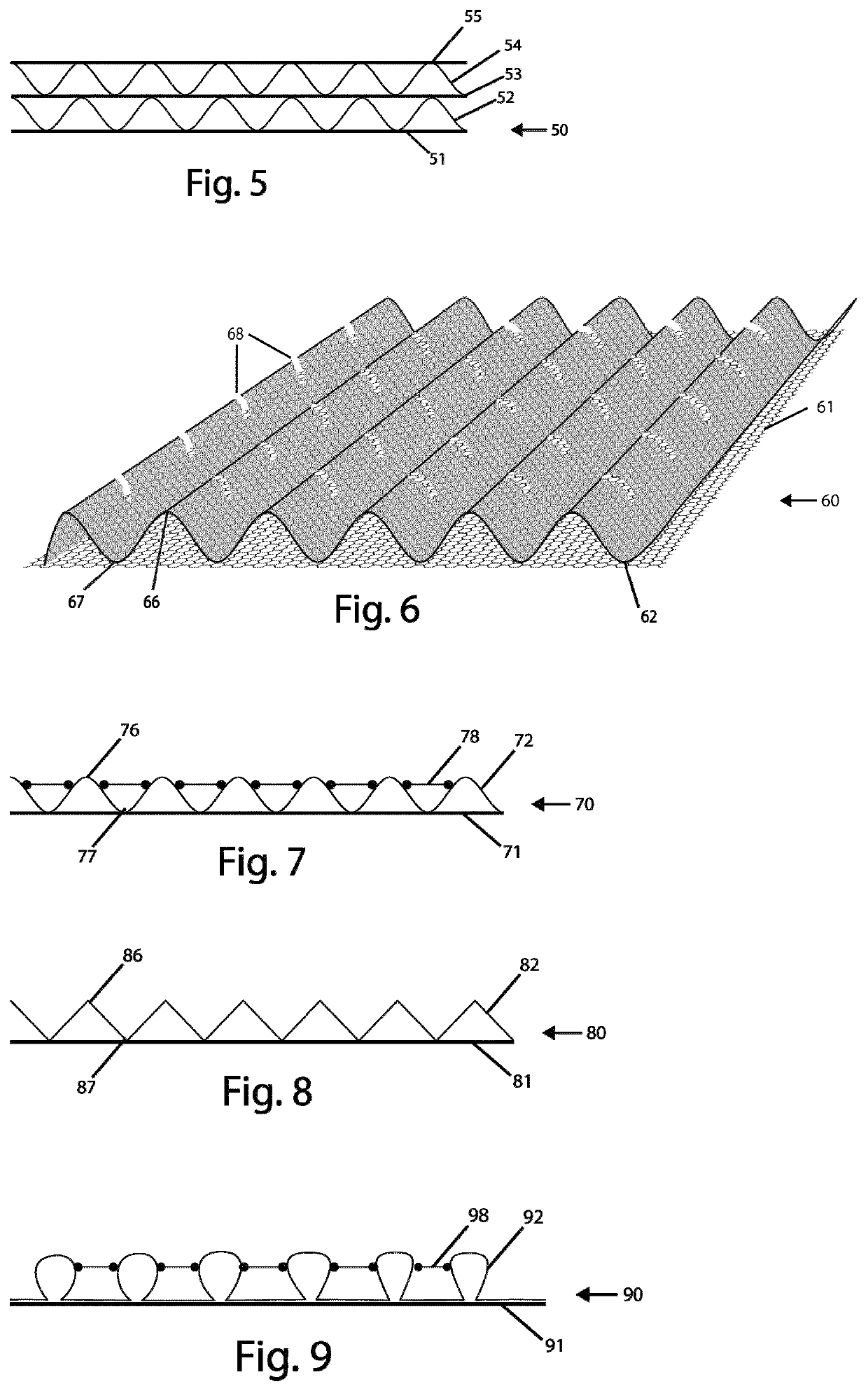

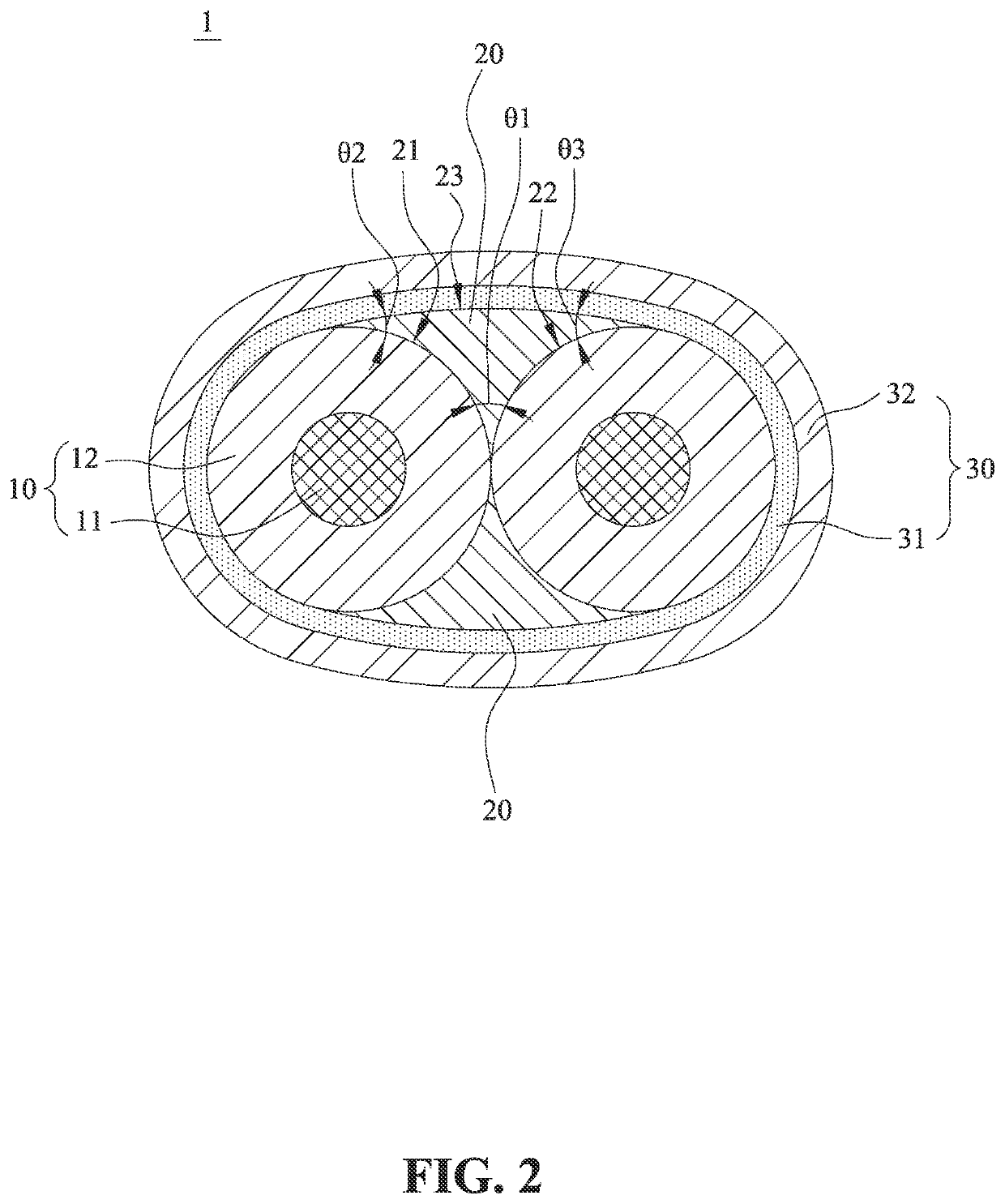

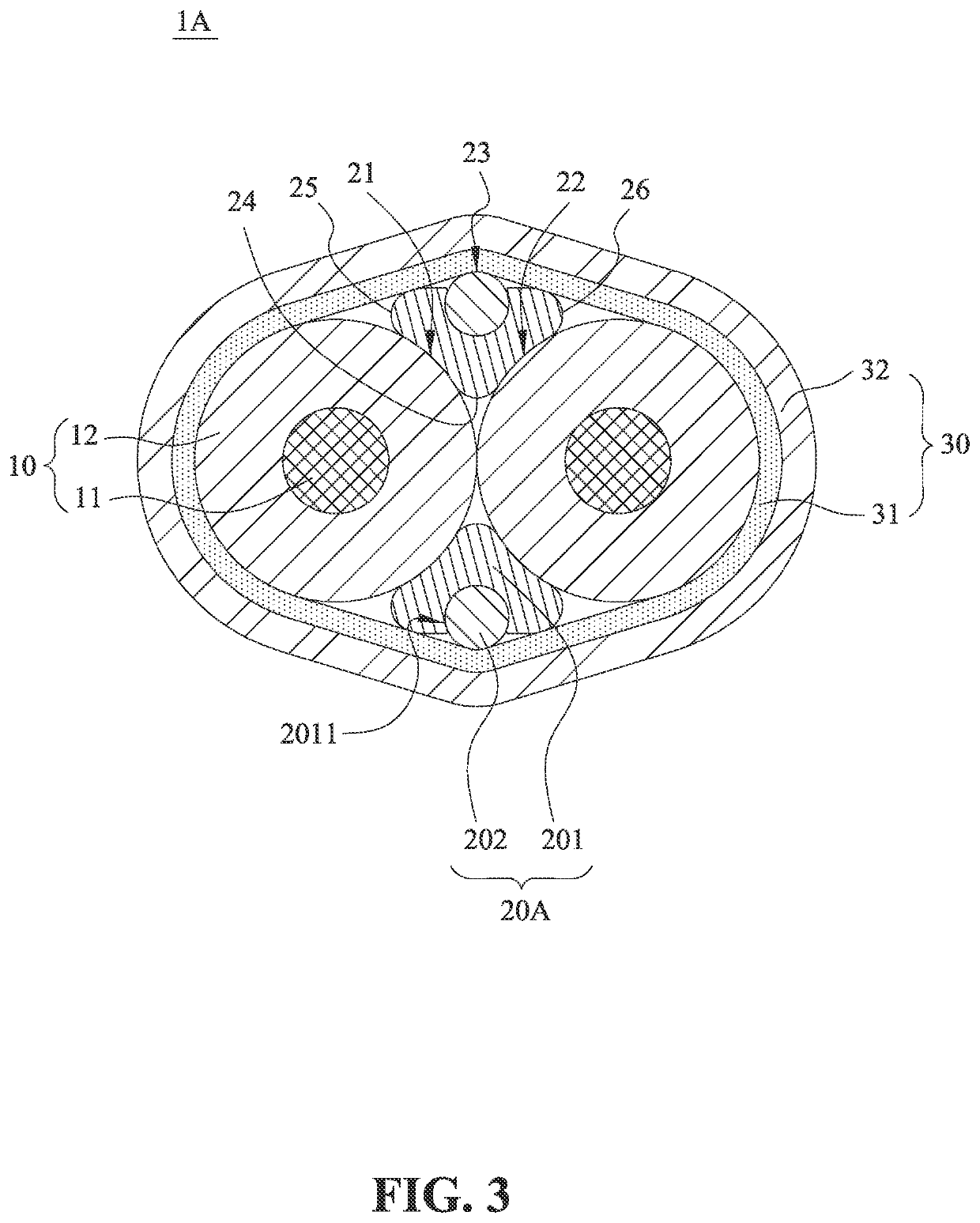

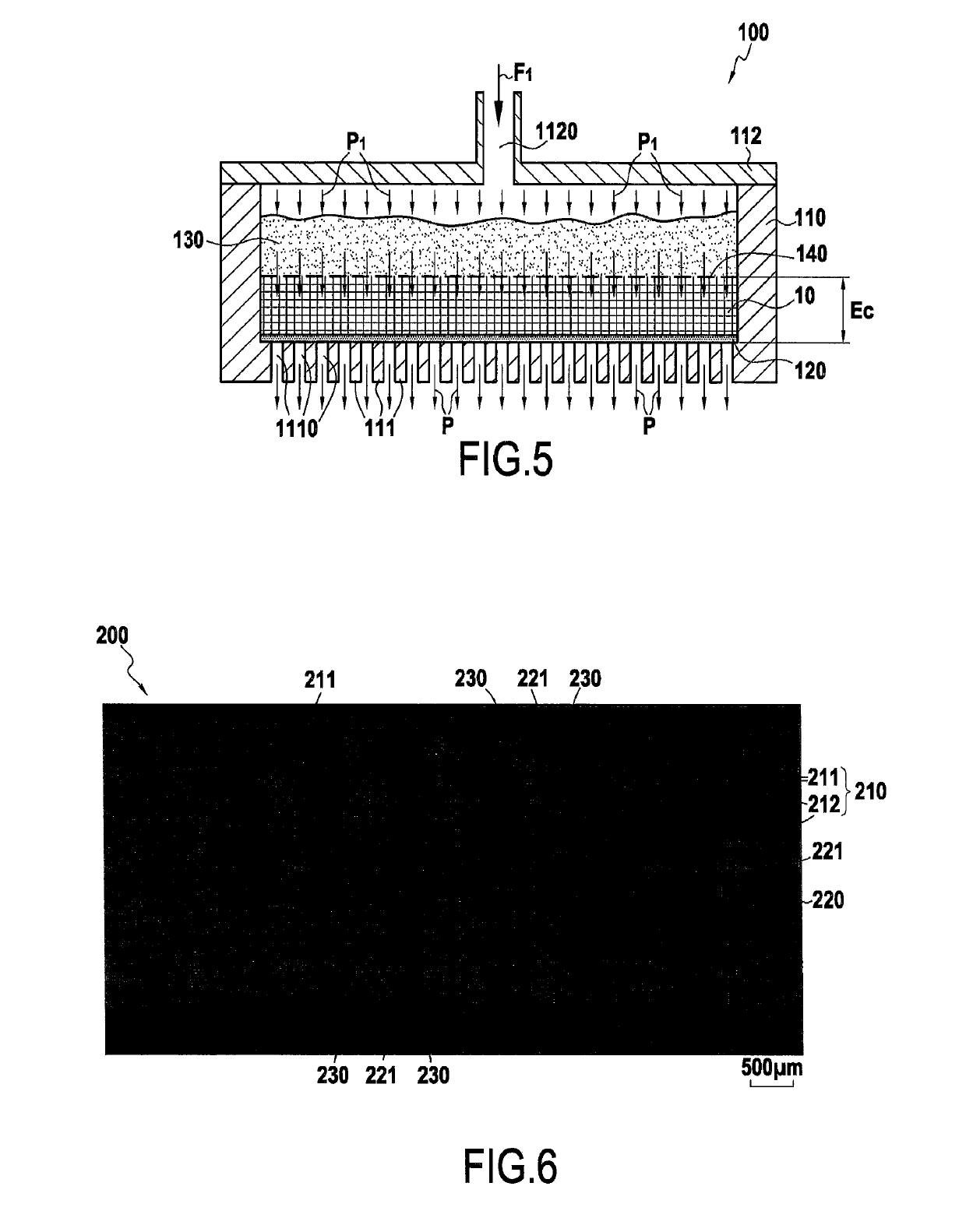

Three-dimensional polymeric medical implants

ActiveUS20140222161A1Rapid tissue in-growthSufficient mechanical propertyMammary implantsBiomedical engineeringMedical treatment

The invention relates to a three-dimensional medical implant, comprising a first thin porous component, and a first load-bearing and volume-creating component, which is connected to the first thin porous component; wherein the load-bearing and volume-creating component comprises an organized structure.

Owner:NOVUS SCI

Cellulosic inorganic-filled plastic composite

The present invention is a plastic composite reinforced by cellulosic material and talc. The composite preferably includes about 20% to 40% by weight of talc, about 10% to 60% by weight of a cellulosic material, and about 20% to 70% by weight of thermoplastic polymer, wherein the total amount of talc and cellulosic material comprise about 30% to 80% by weight of the composite. The present invention also includes articles made with composites of the present invention and methods for extruding such a composite.

Owner:IMERYS TALC AMERICA INC

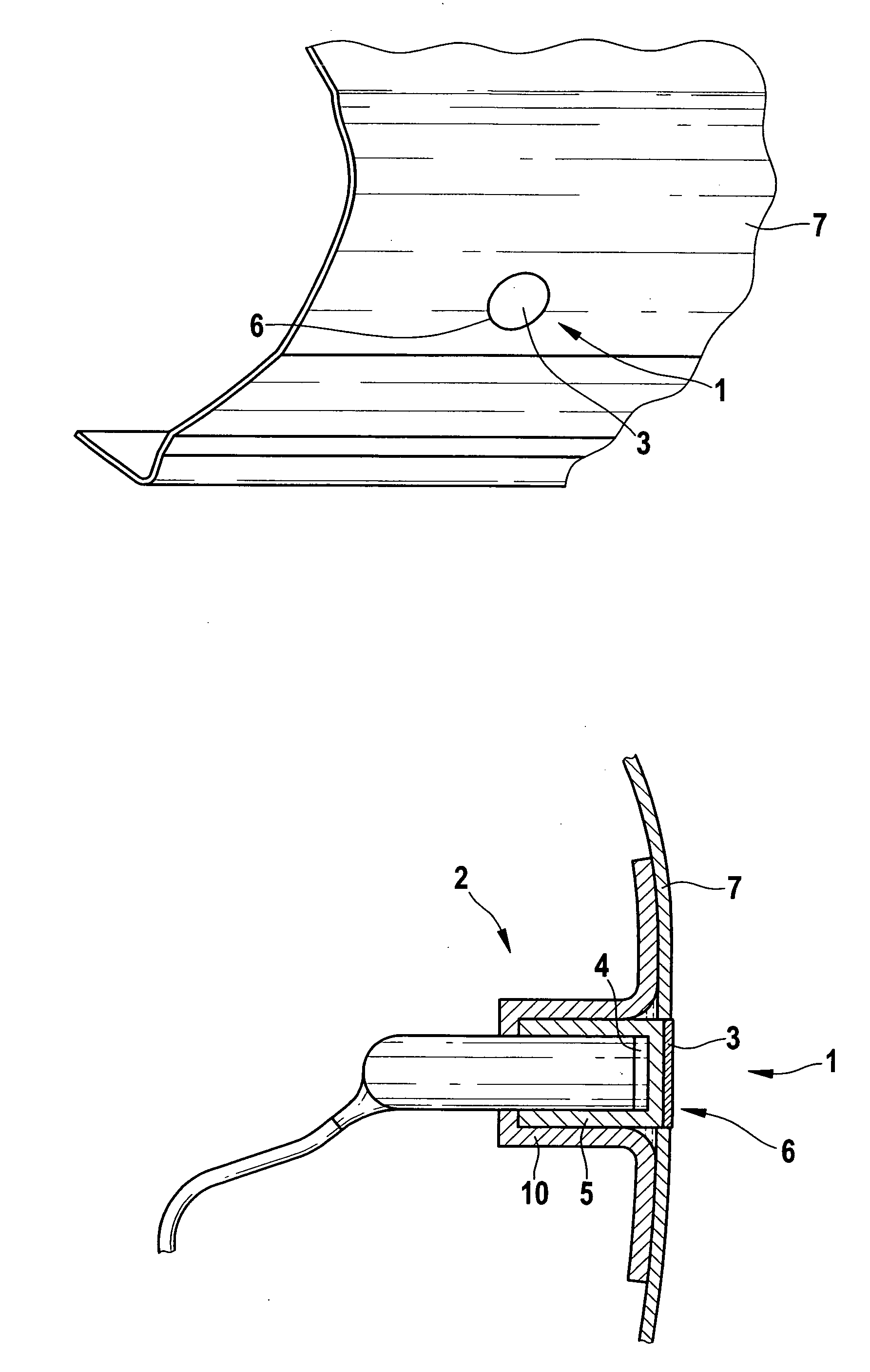

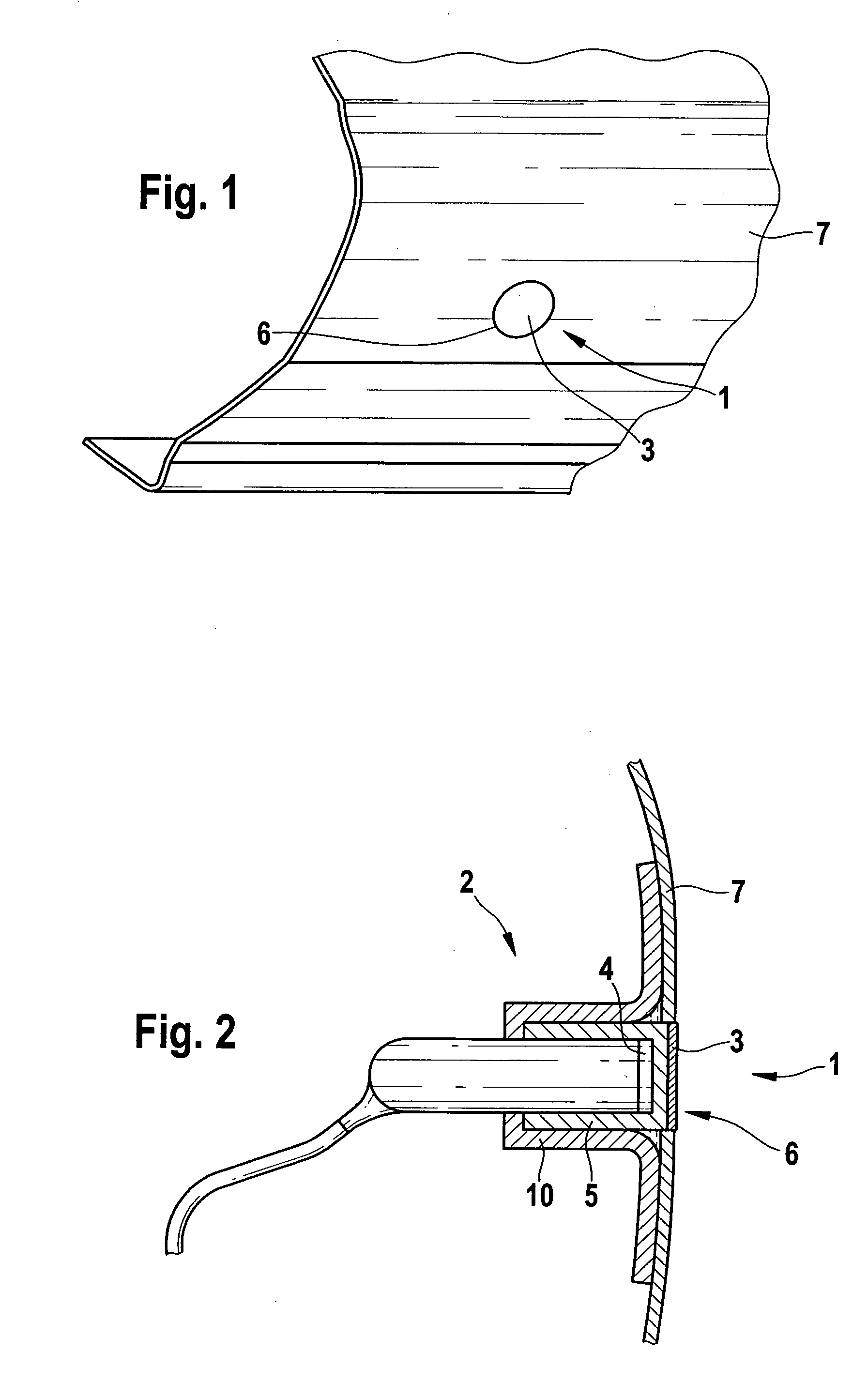

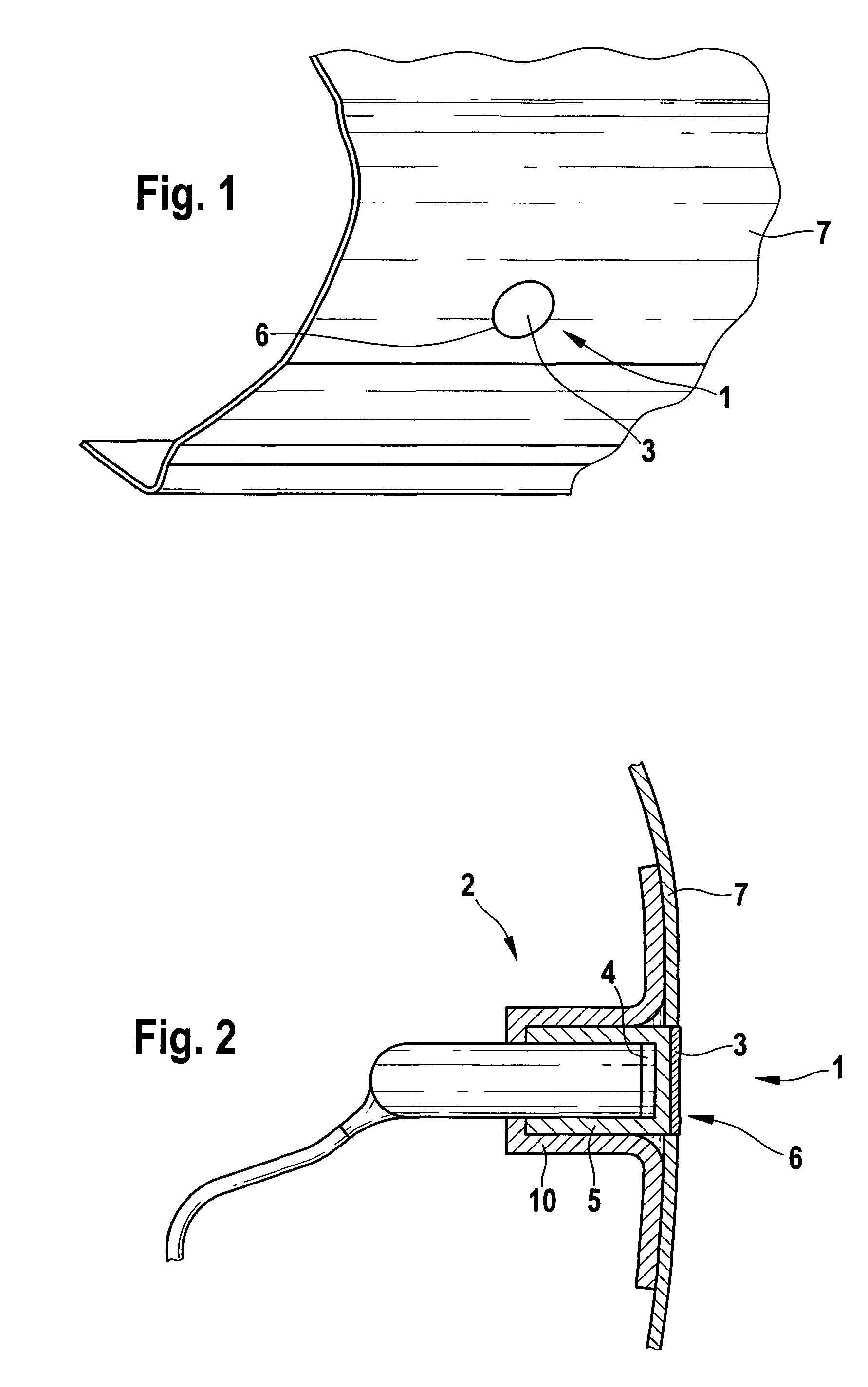

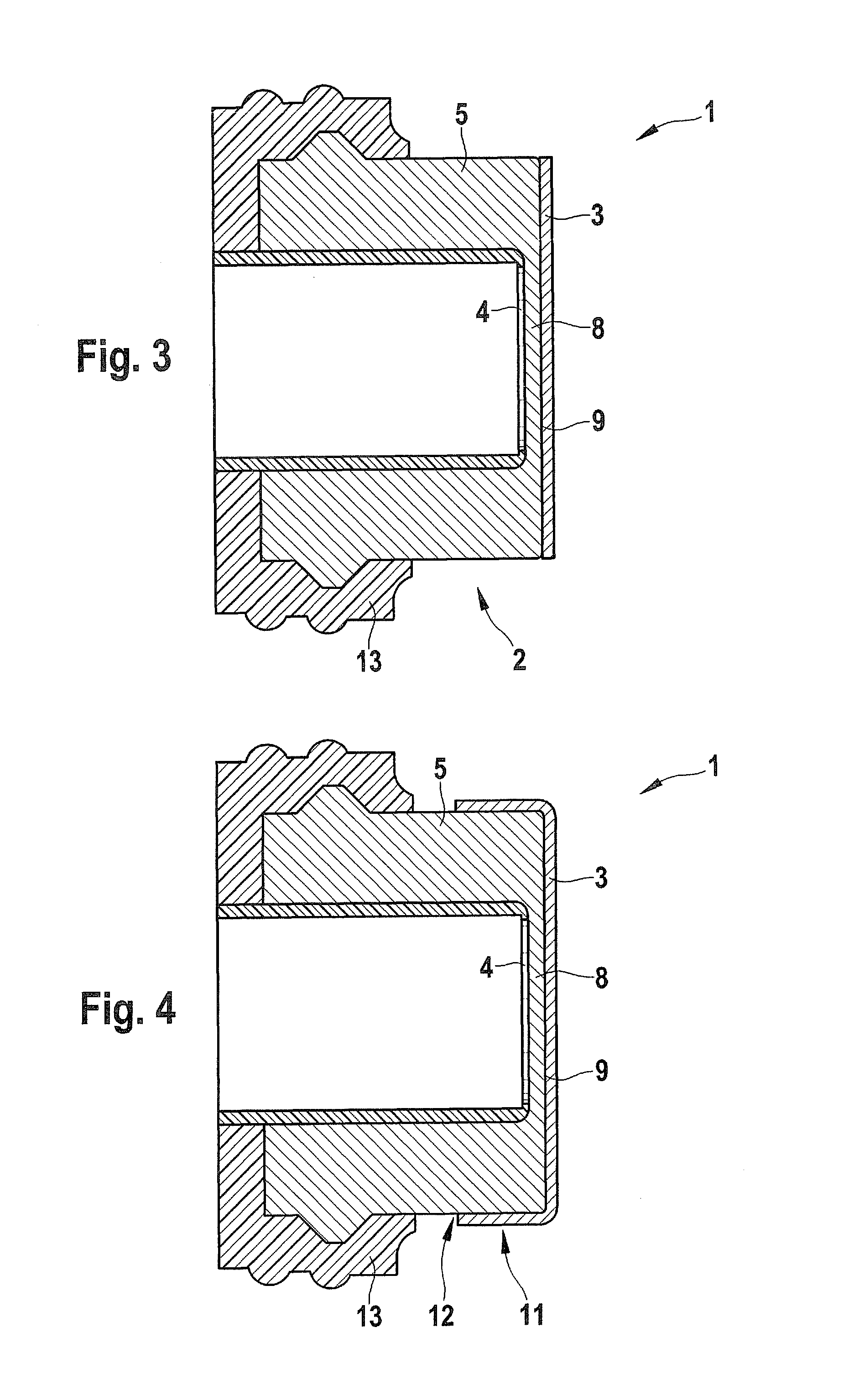

Sensor device for vehicles

ActiveUS20070194892A1Excellent visual adaptationMinimal detuningVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic sensorEngineering

A sensor device includes an ultrasonic sensor and a sensor cover in the form of a foil, the ultrasonic sensor having an oscillatory sensor element, which is affixed inside a housing, having an end face, of the ultrasonic sensor, the ultrasonic sensor being able to be accommodated in a recess or bore hole of an external vehicle component, and the sensor element and the housing being able to be covered by the sensor cover on the outside, the sensor cover being mountable directly on the ultrasonic sensor and forming an at least essentially planar surface whose outline is adapted to the outline of the end face of the housing and coincides in an essentially flush manner with the end face of the housing of the ultrasonic sensor, and the sensor cover reflecting light having a color spectrum in the range of chrome color and a reflection capacity in the range of polished chrome.

Owner:ROBERT BOSCH GMBH

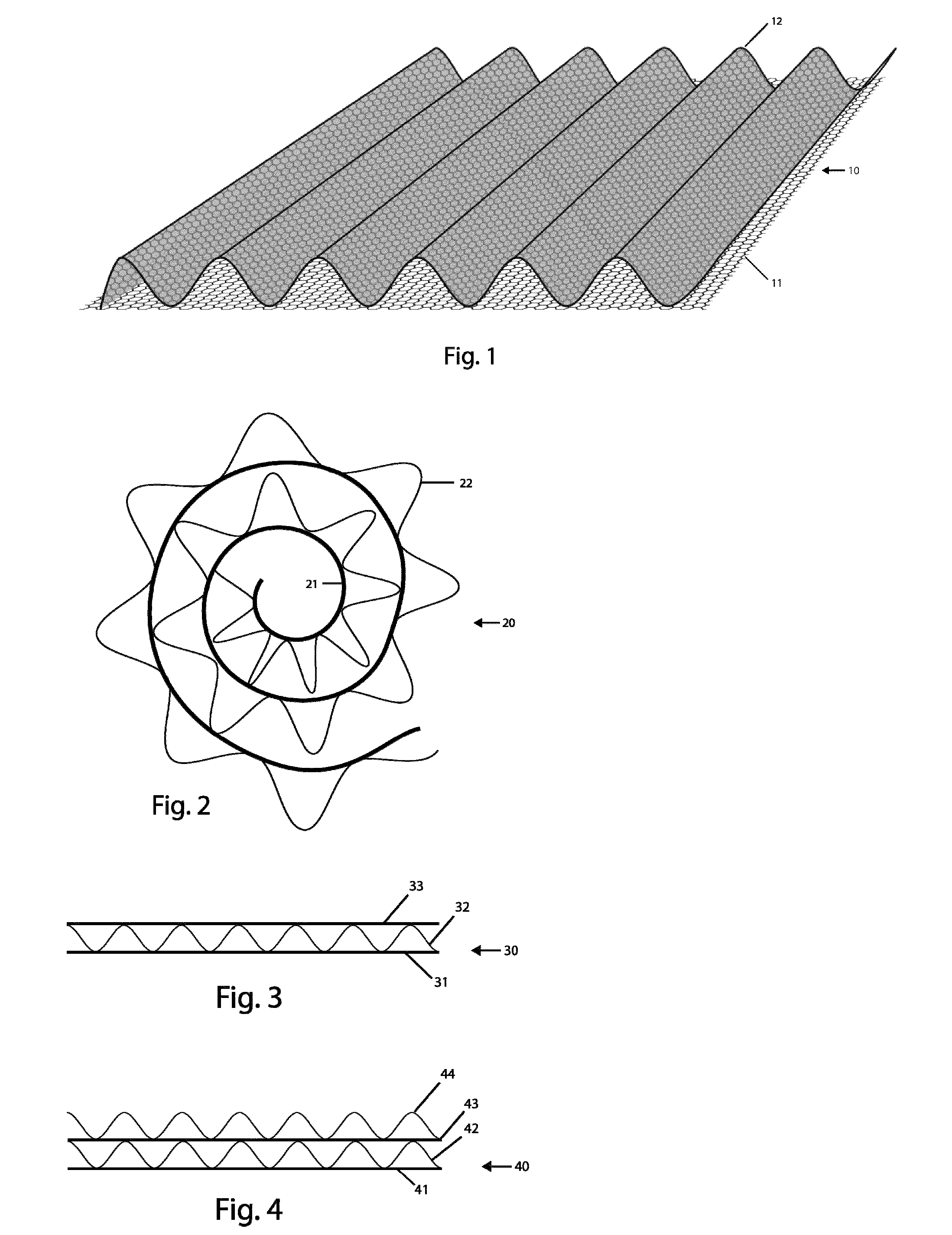

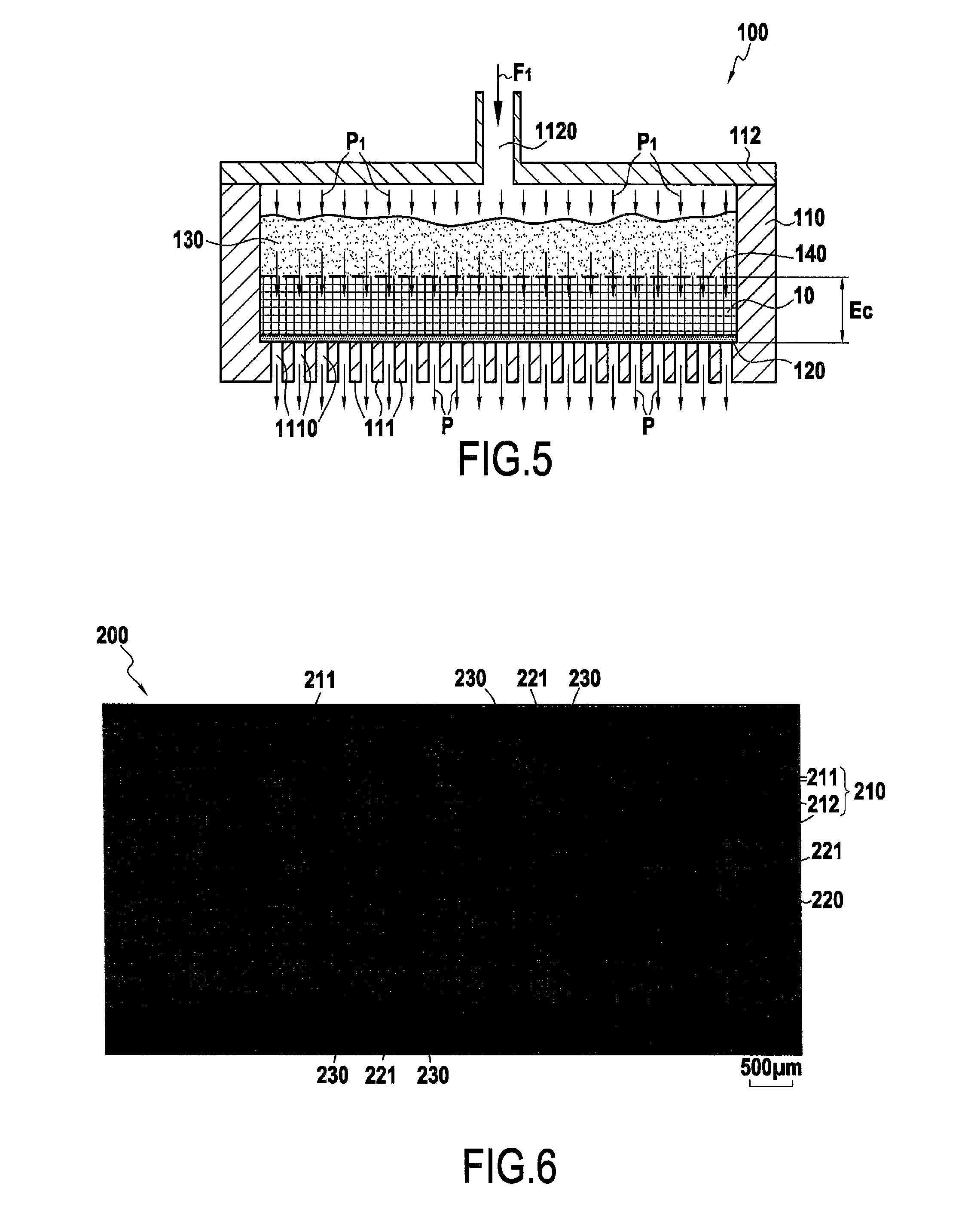

Method of producing a thick, thermoformable, fiber-reinforced semi-finished product

InactiveUS7132025B2Mechanical propertyExcellent and highly reproducibleLaminationLamination apparatusWork in processEngineering

The invention relates to a continuous method of producing a thick, thermoformable, from a thermoplastic material and reinforcing fibers. The inventive method comprises the following steps: A) blending thermoplastic fibers and reinforcing fibers to give a dry-laid blended web, B) consolidating the blended web by needle felting, C) heating the consolidated blended web, and D) compacting it to give a semi-finished product.

Owner:QUADRANT PLASTIC COMPOSITES

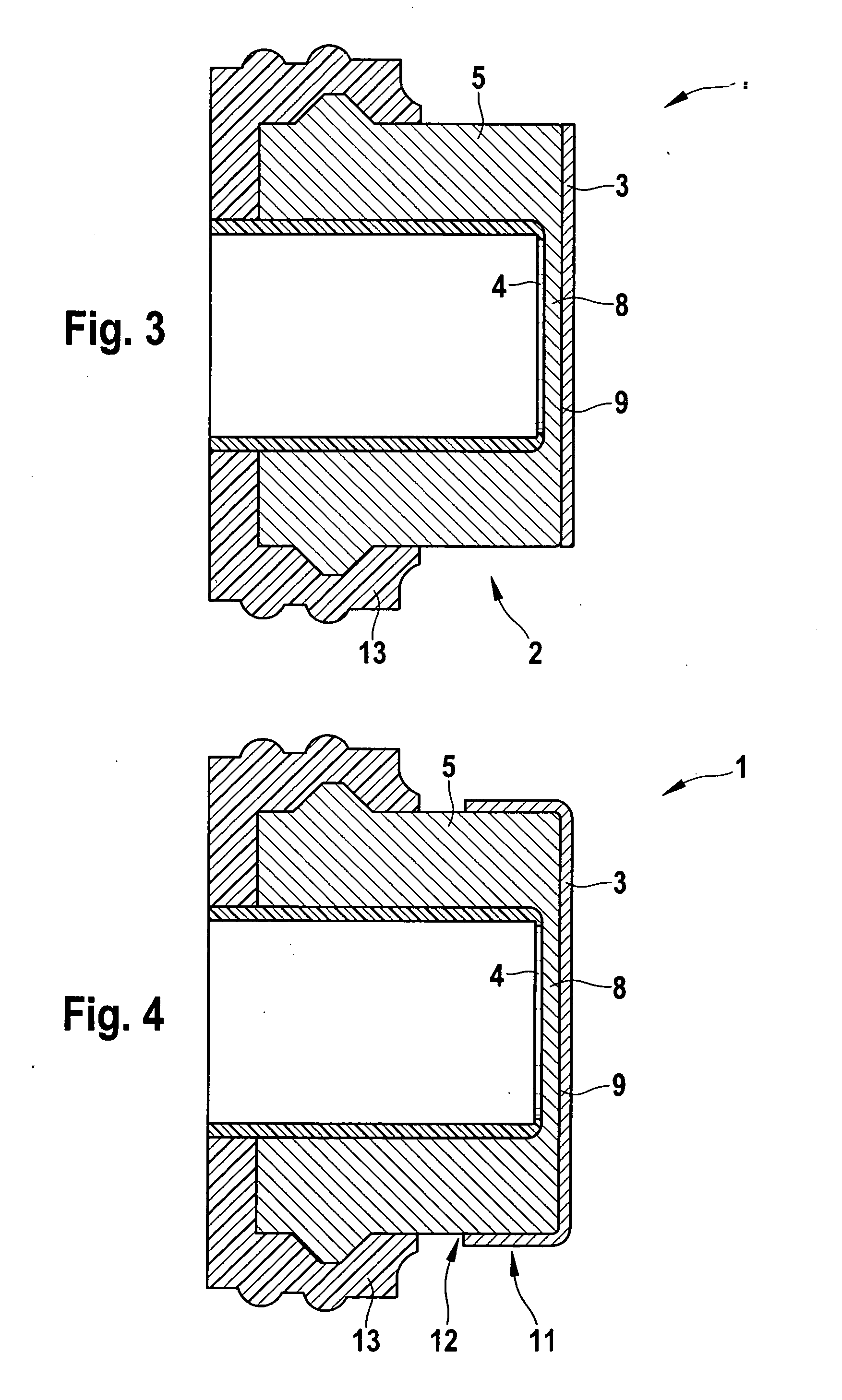

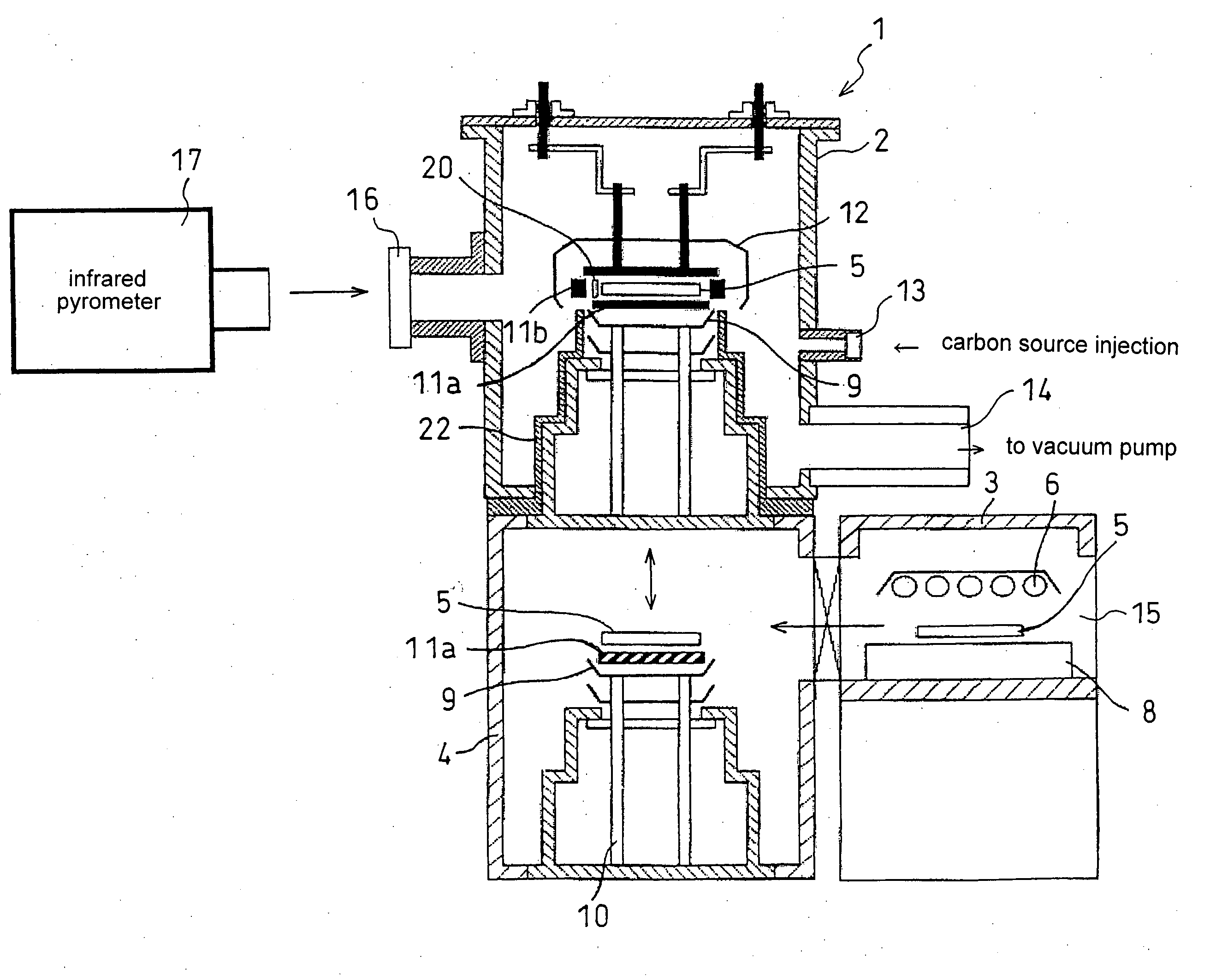

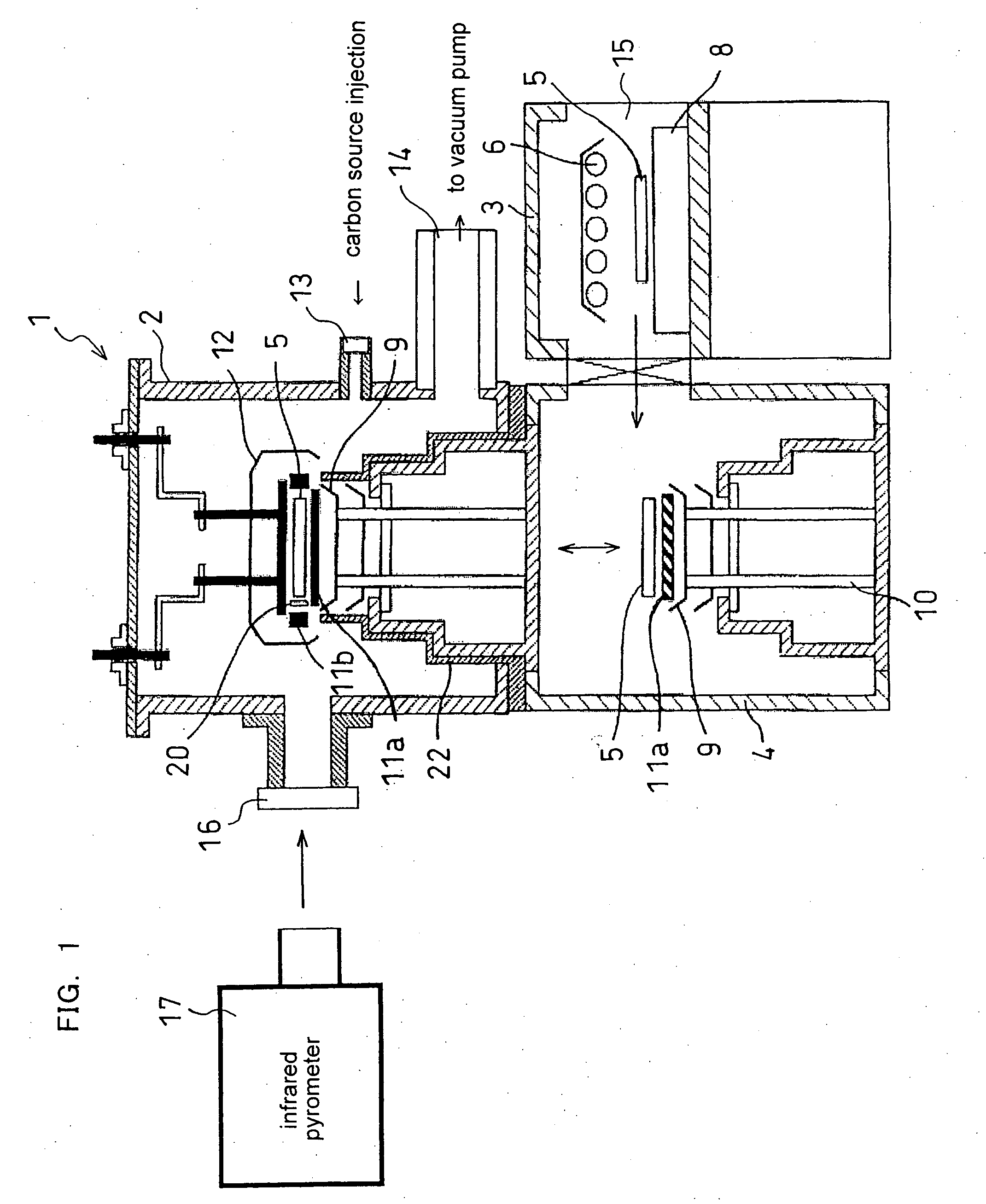

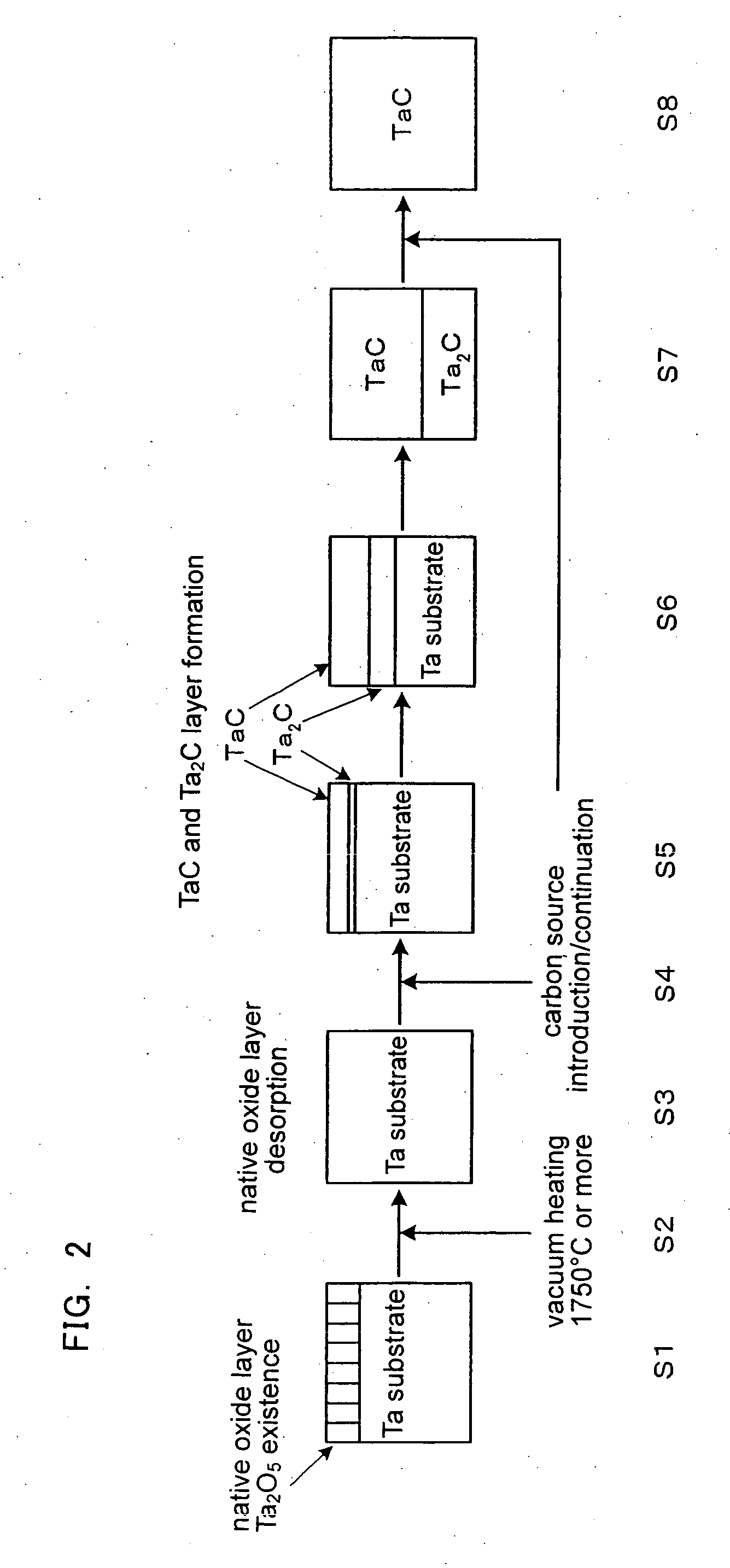

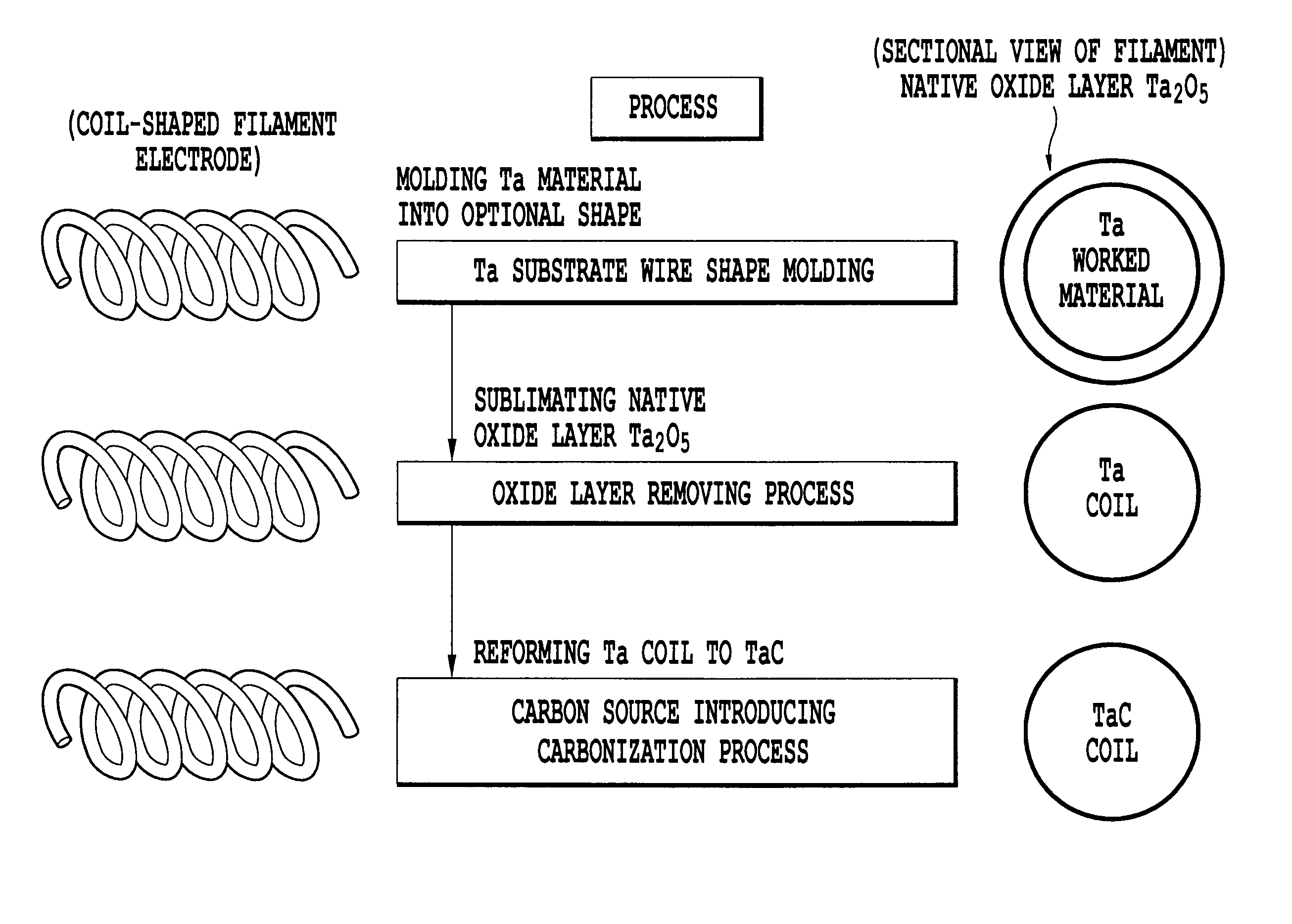

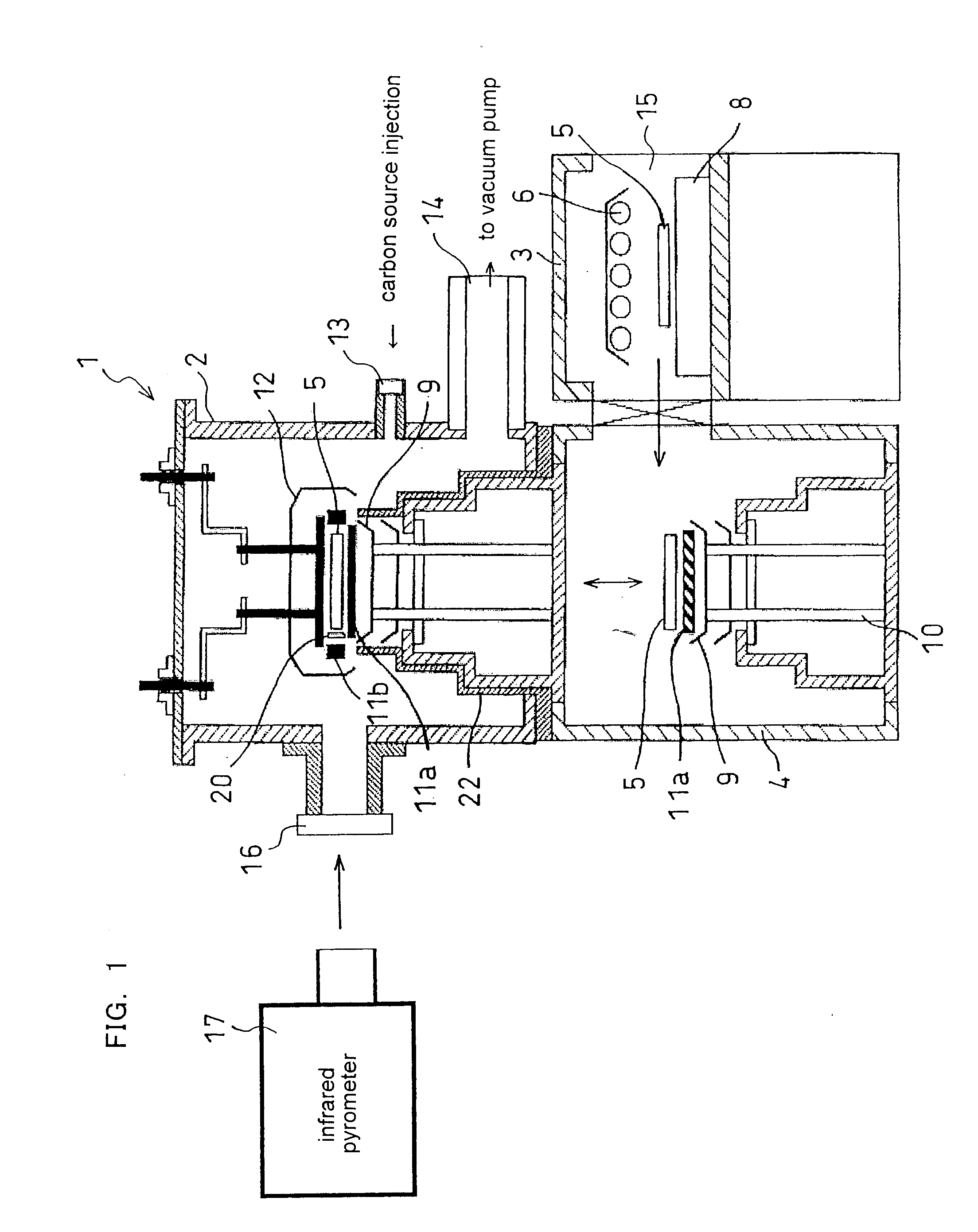

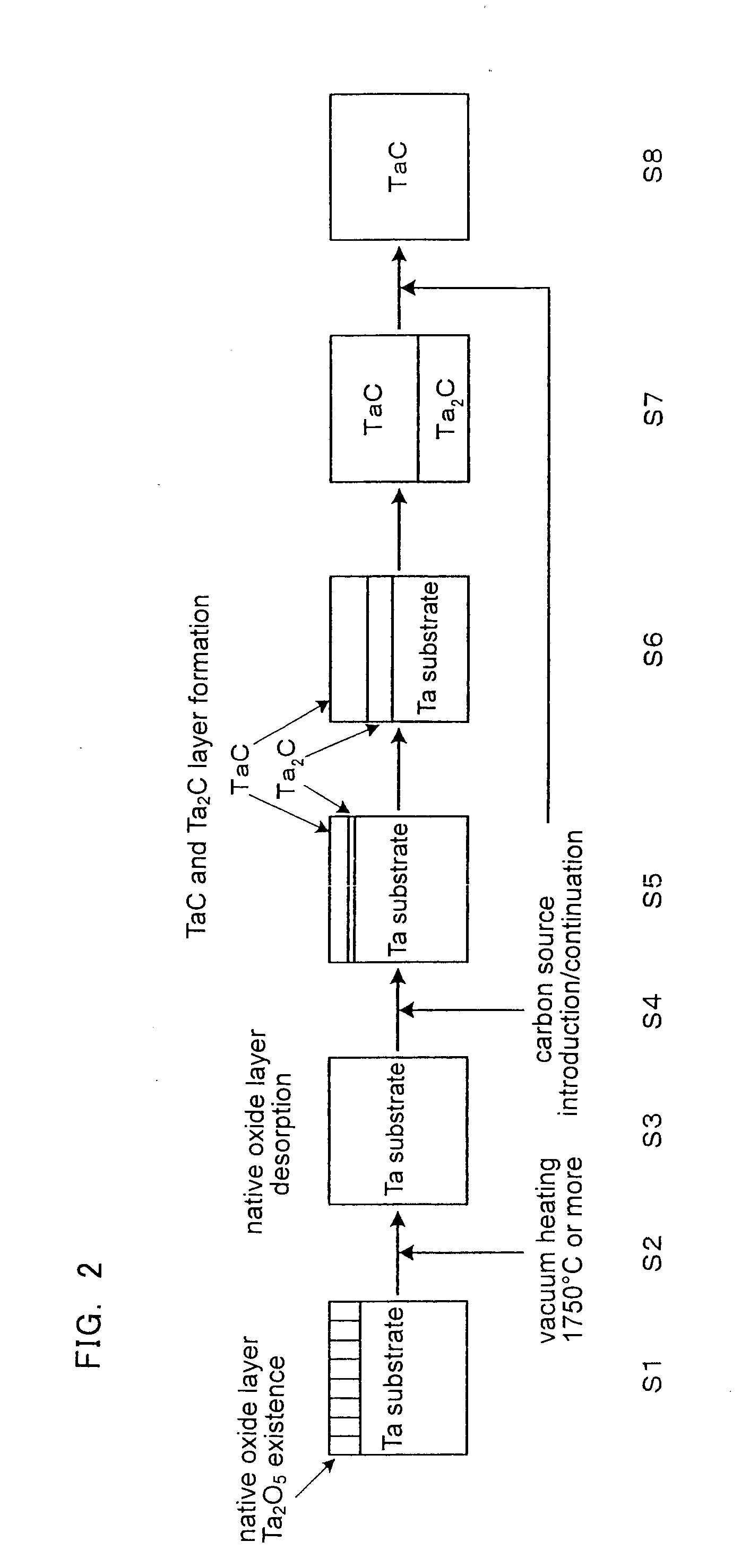

Tantalum carbide, method for producing tantalum carbide, tantalum carbide wiring and tantalum carbide electrode

InactiveUS20070059501A1High melting pointHigh hardness propertiesSolid state diffusion coatingCeramic layered productsTantalum carbideCarbon source

It is an object of the present invention to provide a method for manufacturing tantalum carbide which can form tantalum carbide having a prescribed shape using a simple method, can form the tantalum carbide having a uniform thickness even when the tantalum carbide is coated on the surface of an article and is not peeled off by a thermal history, tantalum carbide obtained by the manufacturing method, wiring of tantalum carbide, and electrodes of tantalum carbide. The tantalum carbide is formed on the surface of tantalum or a tantalum alloy by placing the tantalum or tantalum alloy in a vacuum heat treatment furnace, heat-treating the tantalum or tantalum alloy under a condition where a native oxide layer of Ta2O5 formed on the surface of tantalum or tantalum alloy is sublimated to remove the Ta205, introducing a carbon source into the vacuum heat treatment furnace, and then heat-treating.

Owner:TOYO TANSO KK

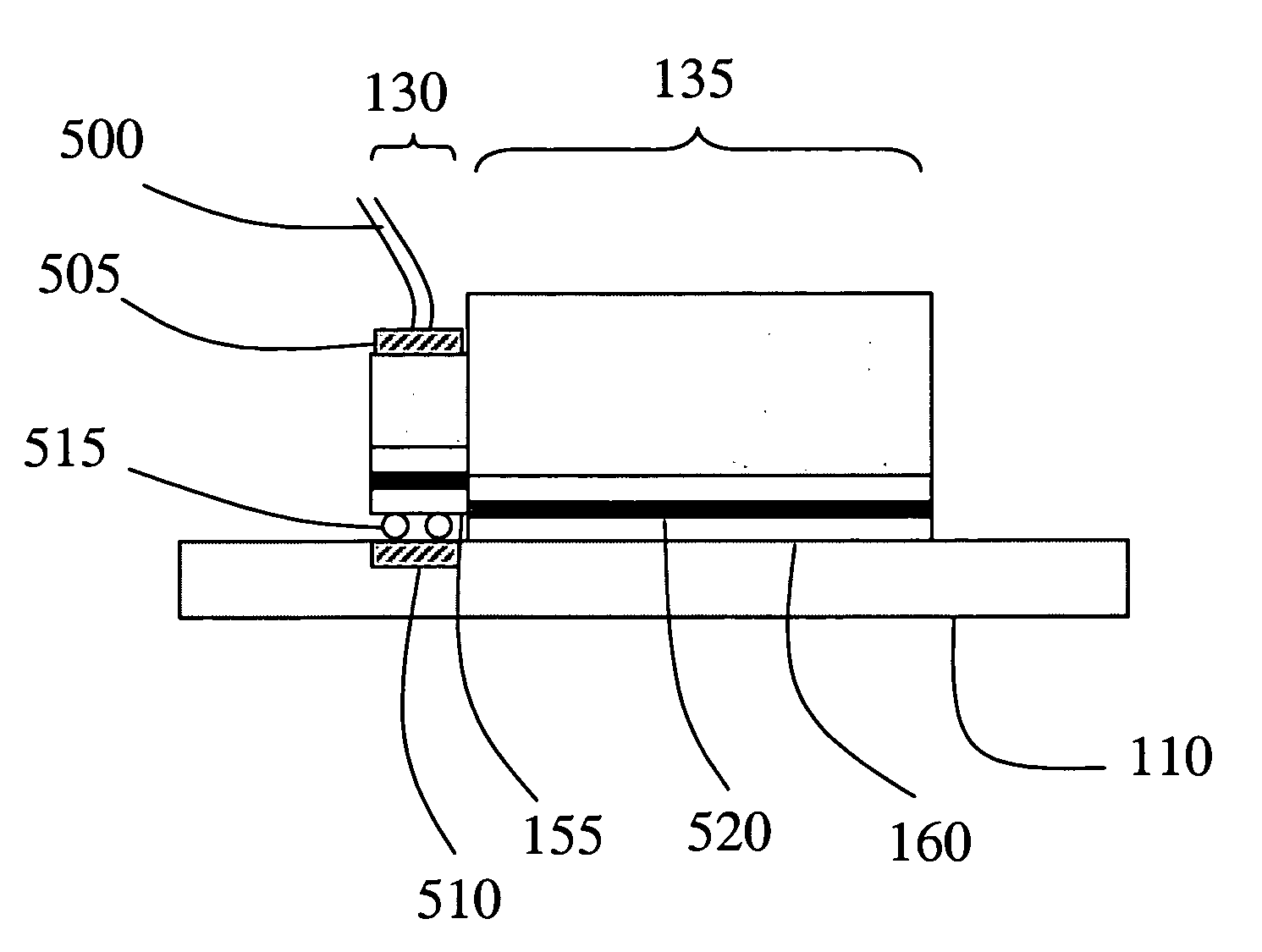

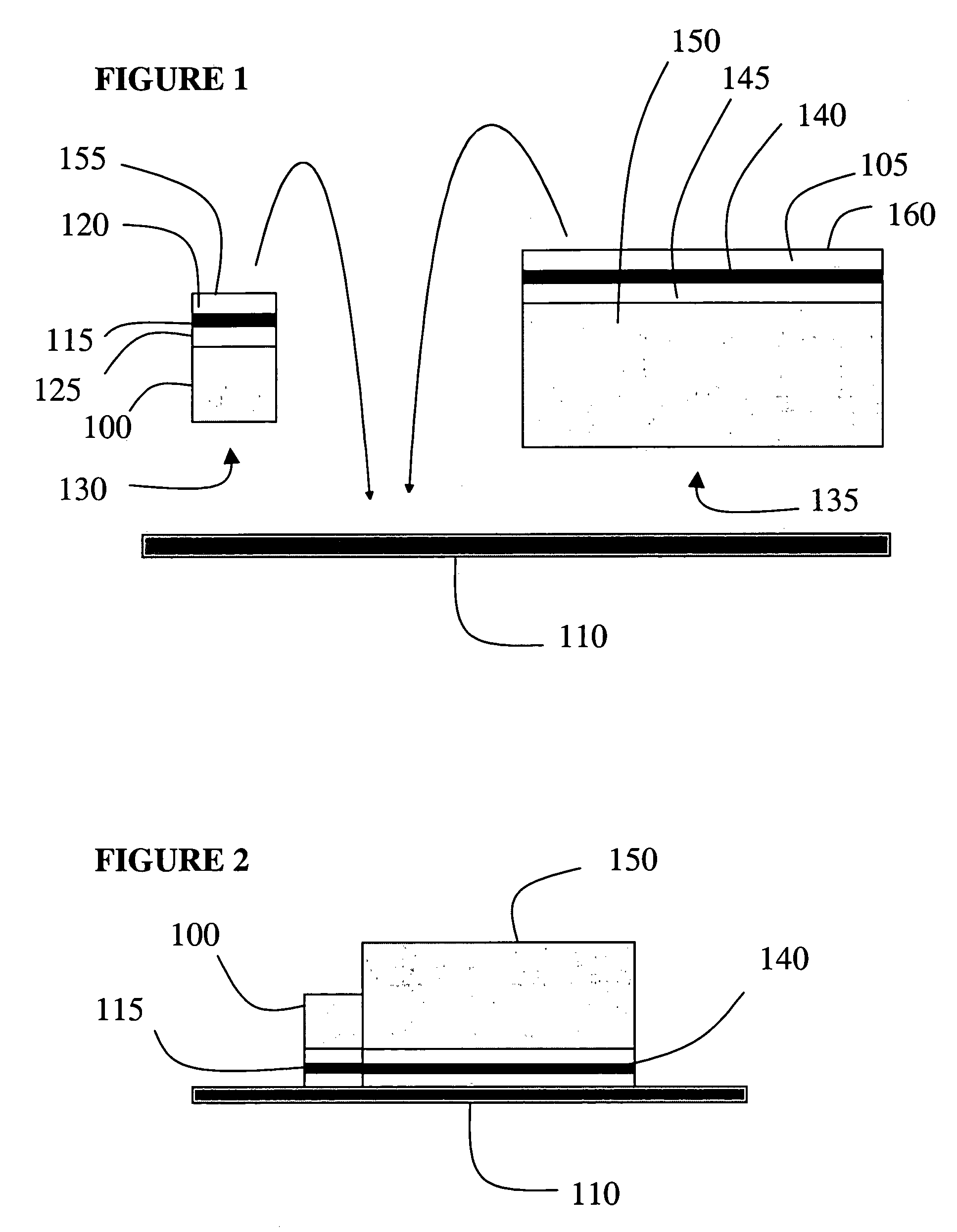

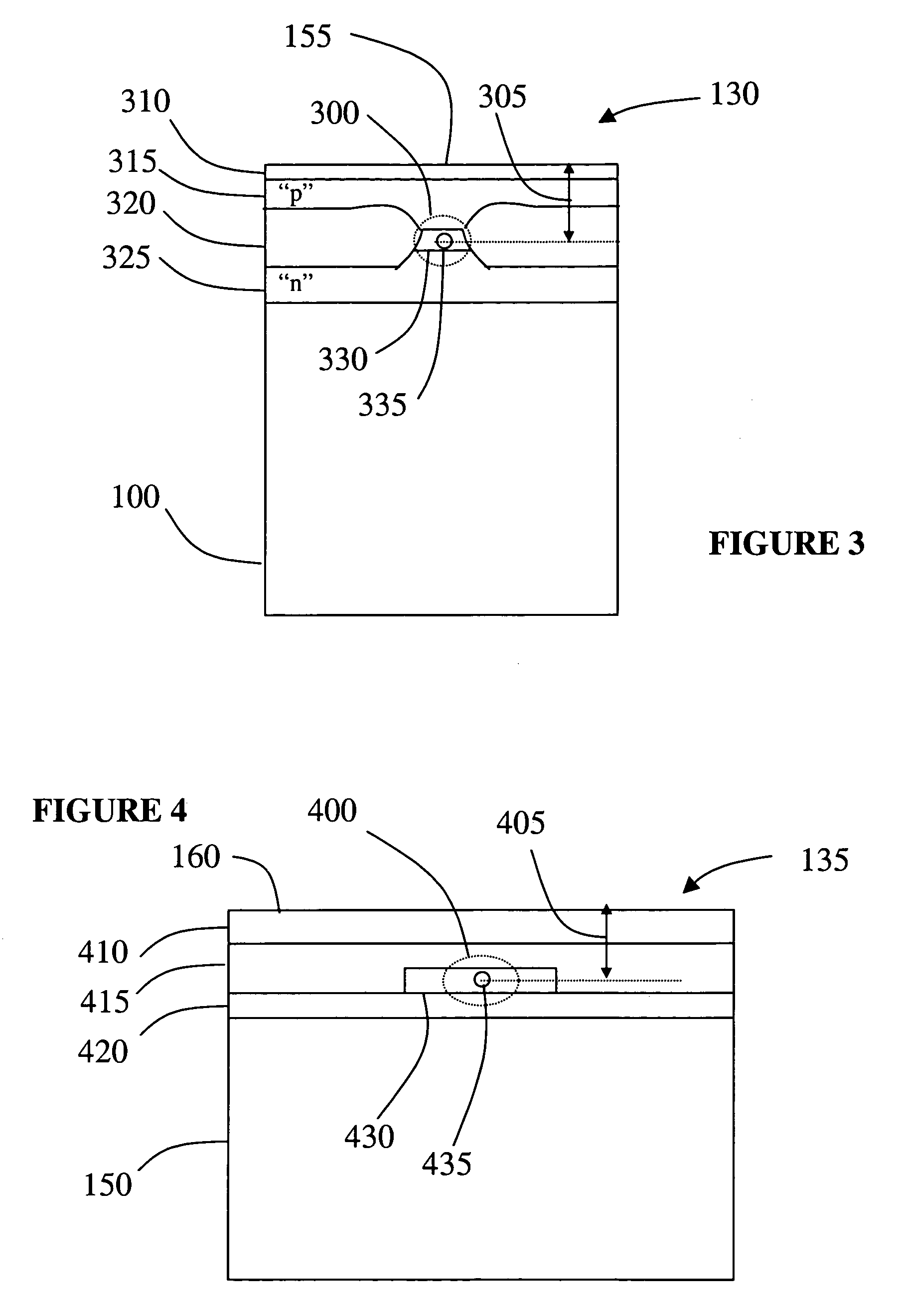

Optical component assembly

InactiveUS7663210B2Easy and cheap and reliableIncrease flexibilityLaser detailsSemiconductor/solid-state device detailsOptical radiationOptical limiting

Optical components are flip chip mounted onto a substrate for improved alignment. Each device is fabricated using “build-up” layers above a substrate. Each has an optical confinement region in which optical radiation travels in use, and a bonding surface. The overall depth of the layers above the optical confinement region is closely controlled during fabrication, for instance by the use a “spacer” layer, so that when the devices are subsequently flip chip mounted adjacent one another on a shared substrate by means of their bonding surfaces, they can be passively positioned so that their optical confinement regions abut and optical radiation can be coupled from one to the next in use.

Owner:OPTITUNE

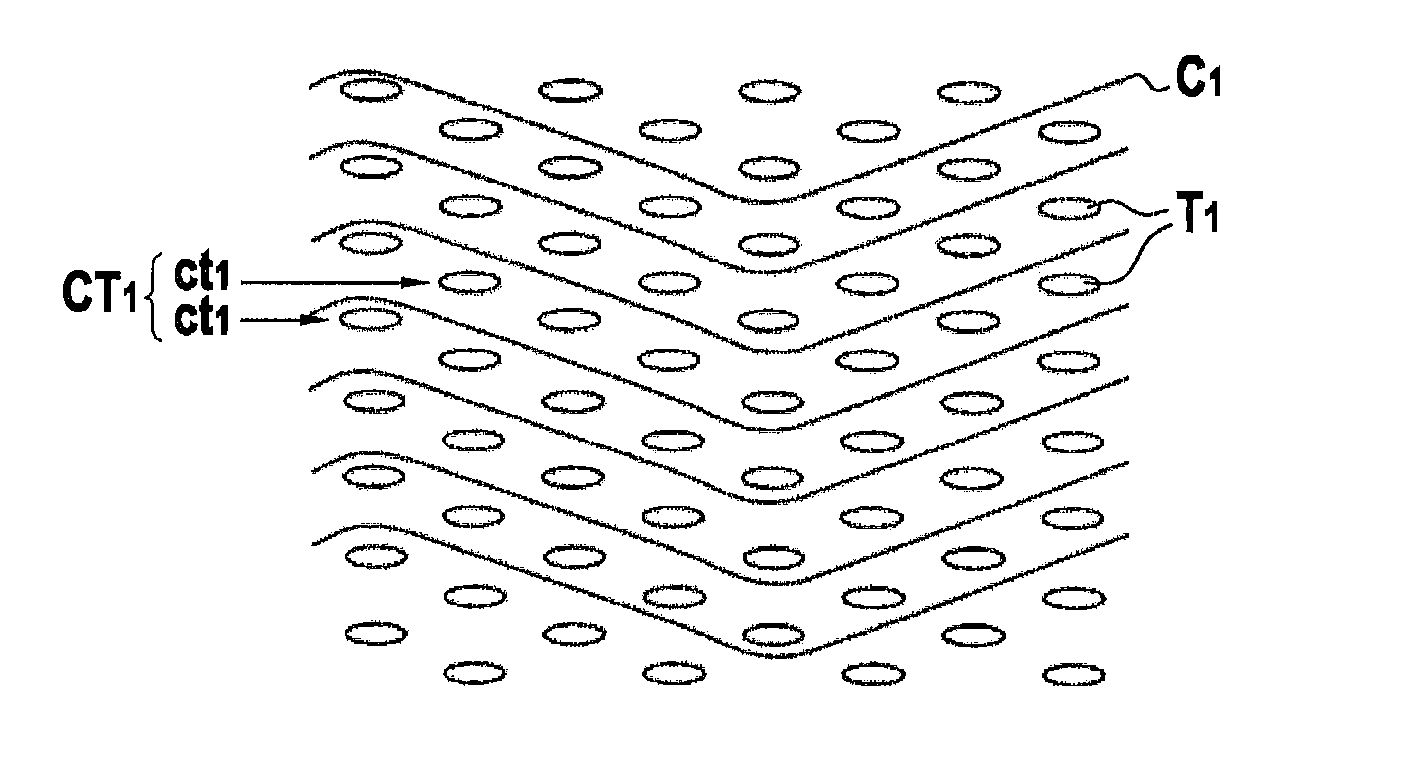

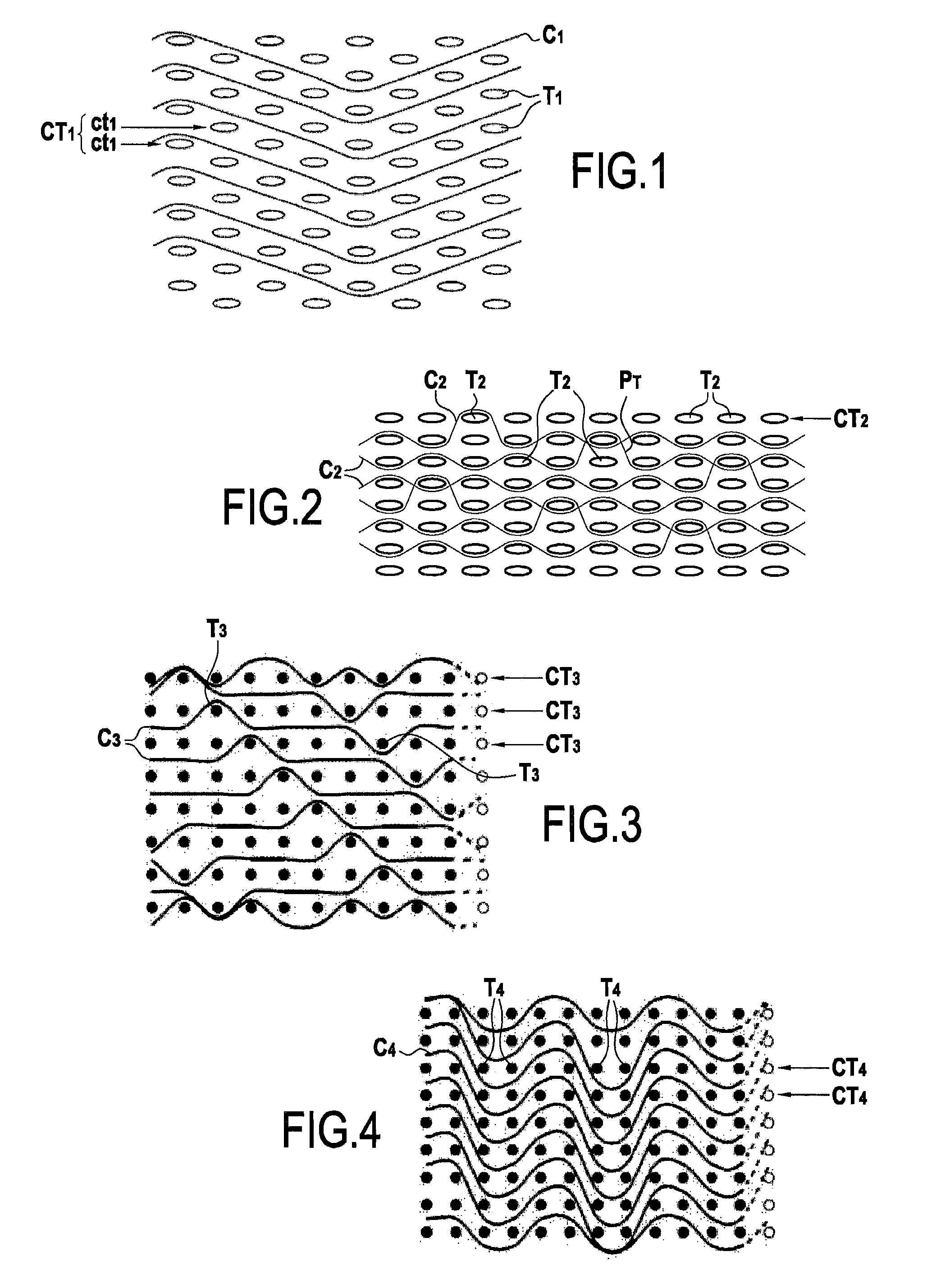

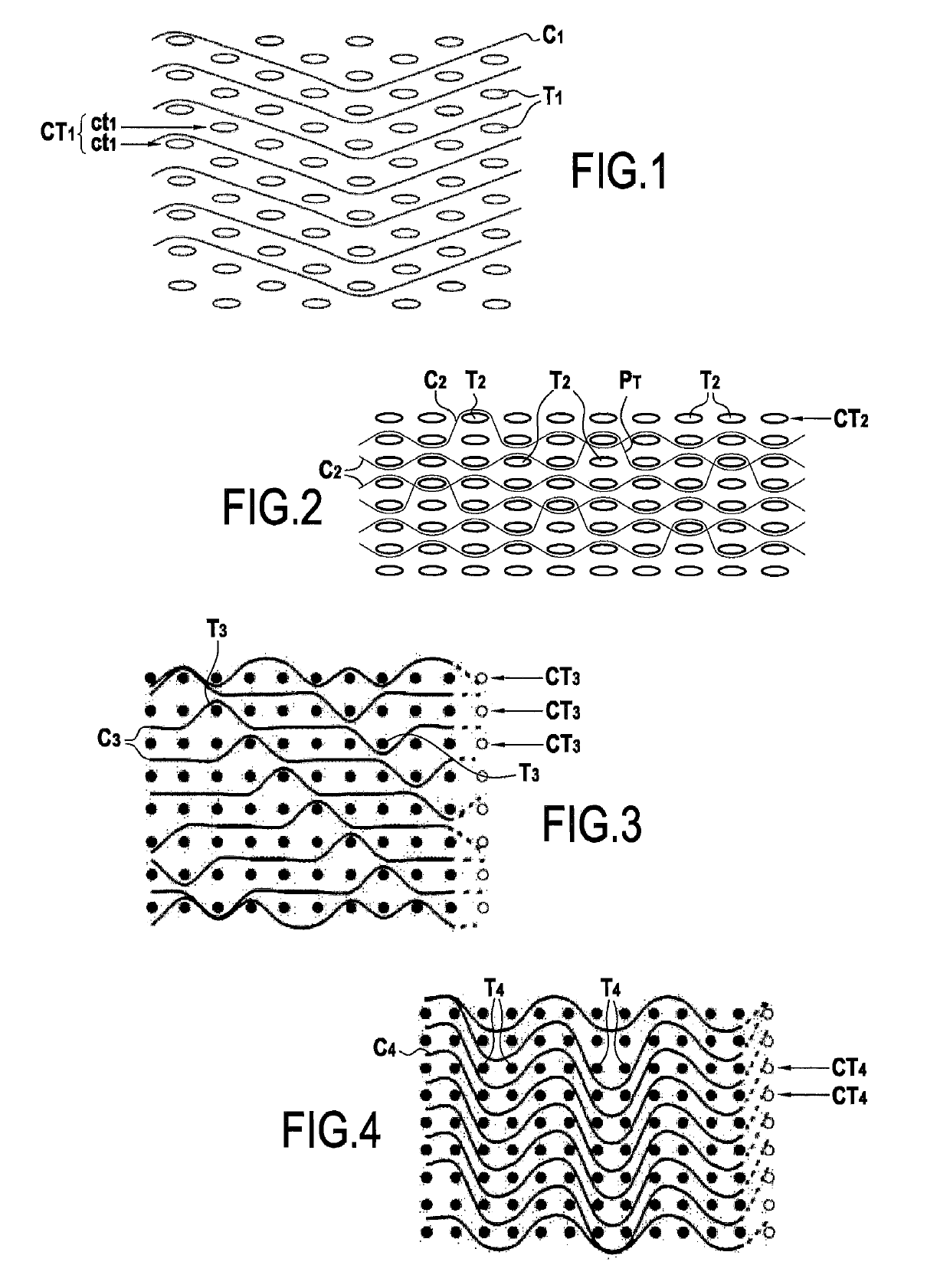

Part made from oxide/oxide composite material for 3-d reinforcing and method for manufacture of same

ActiveUS20160362822A1Mechanical propertyImprove mechanical propertiesFeeding arrangmentsMulti-ply fabricsOxide matrixOxide composite

A part made of oxide / oxide composite material includes fiber reinforcement constituted by a plurality of warp yarn layers and of weft yarn layers interlinked by three-dimensional weaving, with the spaces present between the reinforcing yarns being filled with a refractory oxide matrix. The fiber reinforcement presents a weave selected from the following weaves: interlock; multi-plain; multi-satin; and multi-serge, with warp and weft thread counts lying in the range 4 yarns / cm to 20 yarns / cm. The fiber reinforcement also presents a fiber volume fraction lying in the range 40% to 51%.

Owner:SAFRAN CERAMICS SA

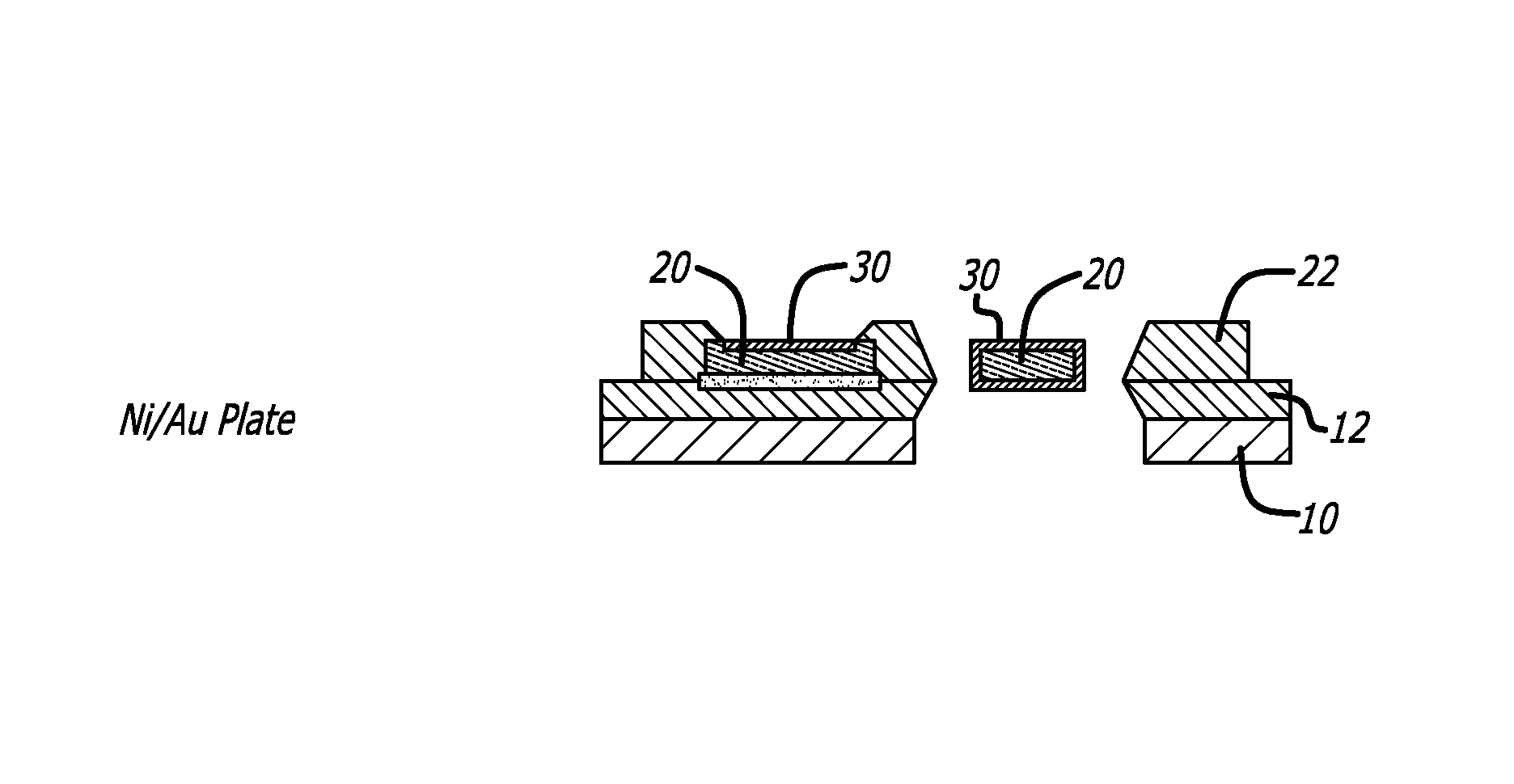

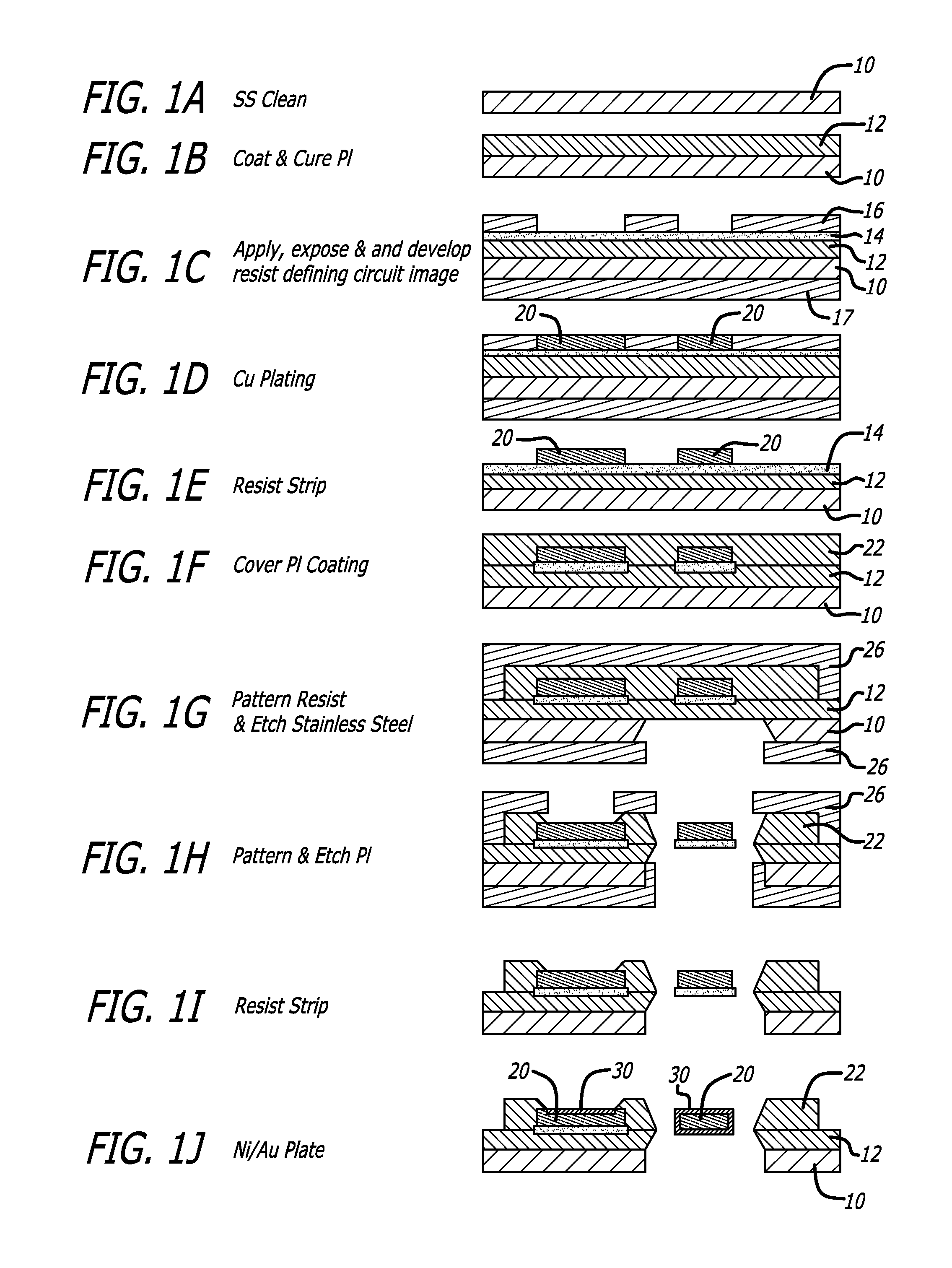

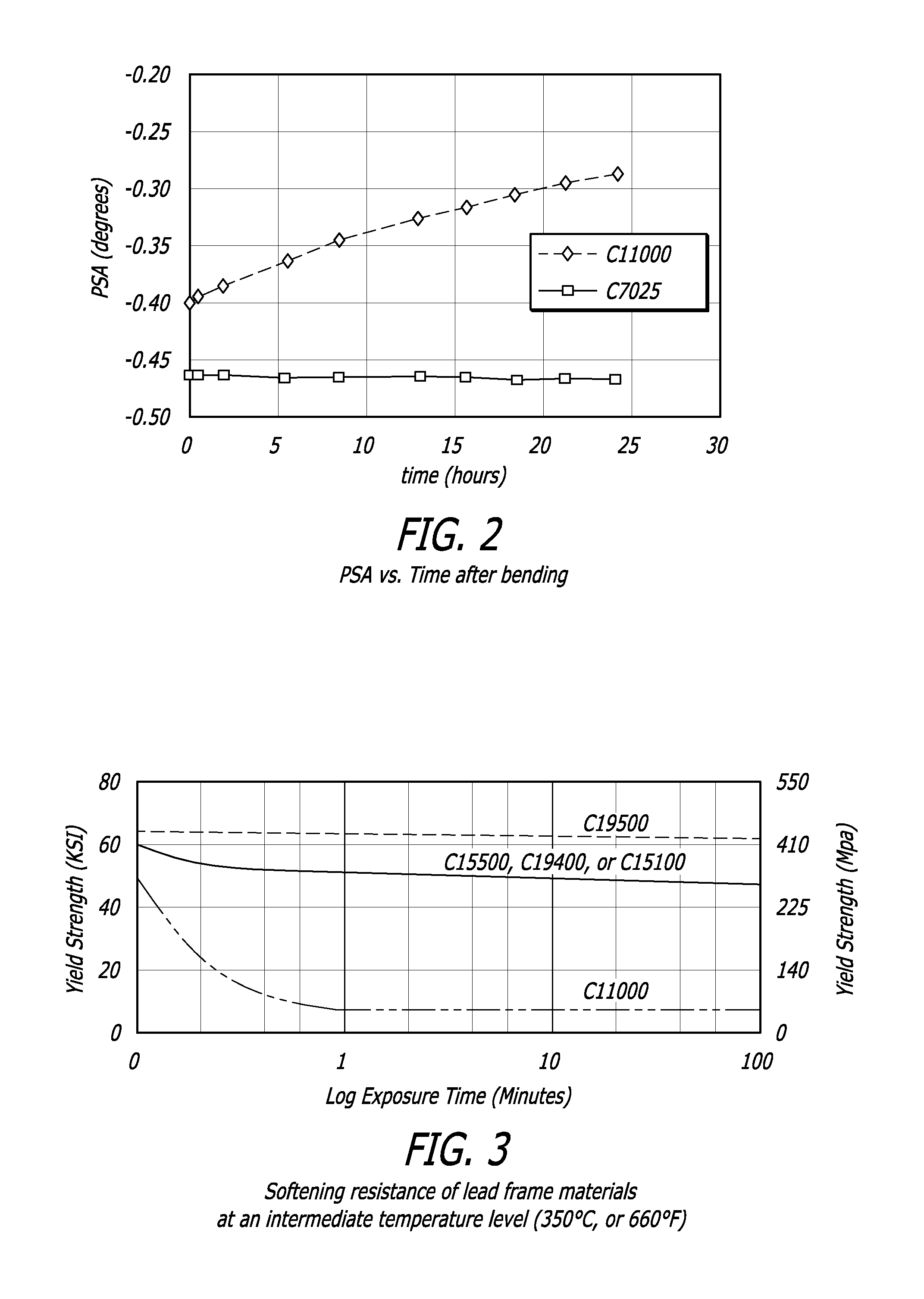

High strength electrodeposited suspension conductors

ActiveUS8303792B1High copper conductor toughnessHigh yield strengthPrinted circuit aspectsSuperimposed coating processHard disc driveElectrical conductor

A method of preparing an additive suspension circuit for a hard disk drive suspension includes electrodepositing an alloy of copper using an electrolytic bath containing copper sulfate, tin, iron, sulfuric acid, and hydrochloric acid, using pulsed current of about 10-45 amperes per square foot.

Owner:MAGNECOMP

Sensor device for vehicles

ActiveUS7832273B2Excellent visual adaptationMinimal detuningVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic sensorEngineering

Owner:ROBERT BOSCH GMBH

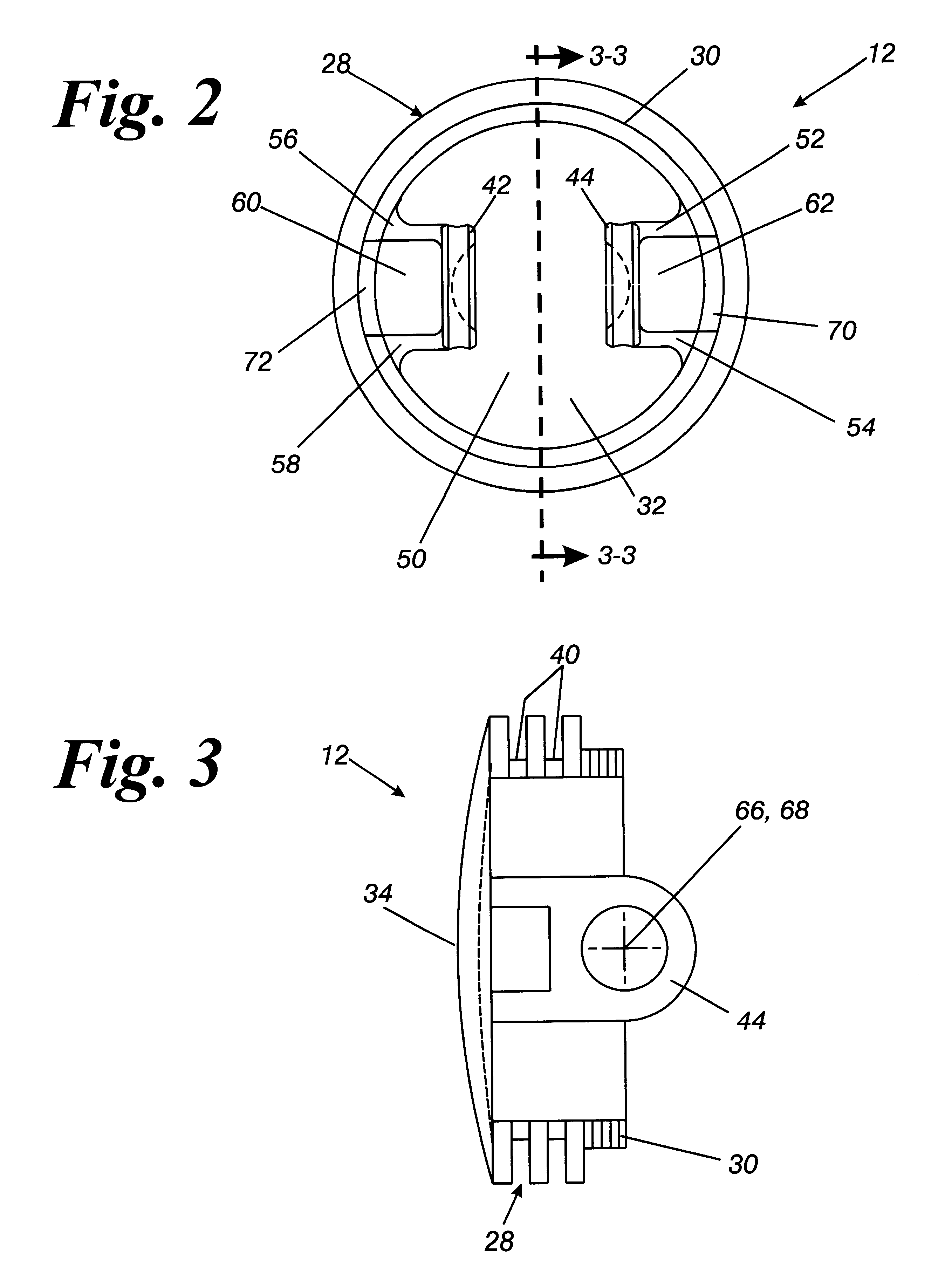

Filament bundle type NANO fiber and manufacturing method thereof

InactiveUS20100021732A1Mechanical propertyNon-fibrous pulp additionFilament/thread formingYarnElectrospinning

A filament type nano-sized lone fiber and a method of producing the same are disclosed. In the method, a spinning solution or a spinning melt is electro-spun in drops using a spinneret to which a critical voltage is applied, and the spun drops are continuously collected on a multi-collector. The spinning solution is produced dissolving a blend or copolymer consisting of two or more kinds of polymers in a solvent. The spinning melt is produced by melting the polymers. The multi-collector is selected from the group consisting of a plate type collector, a roll type collector, and a combination thereof. The filament type nano-sized long fiber is processed into a yarn through one step during the electrospinning process, and thus, mechanical properties are better than those of conventional nanofiber non-woven fabric. Consequently, the filament type nano-sized long fiber can be utilized for the extended application.

Owner:KOREA RES INST OF CHEM TECH

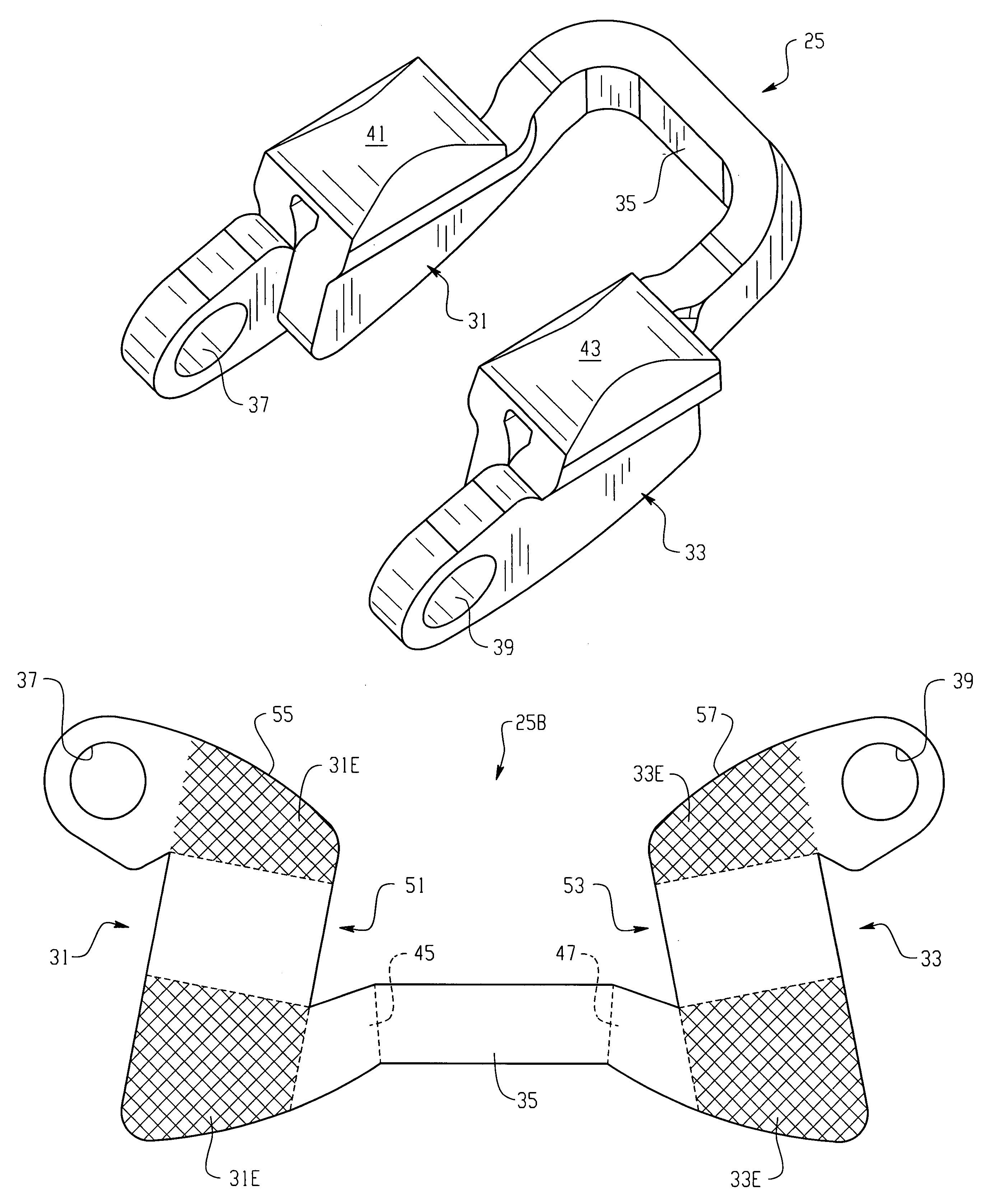

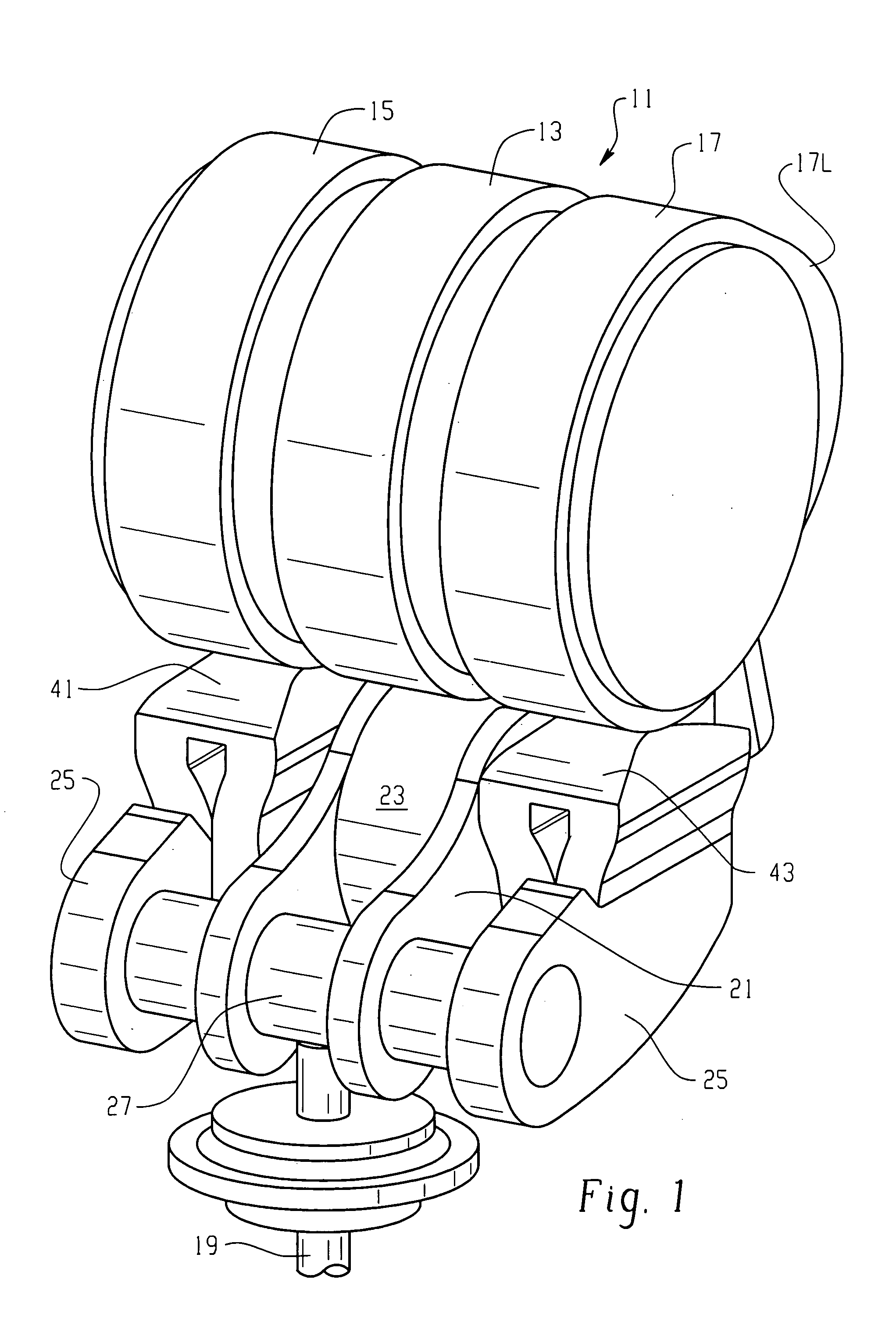

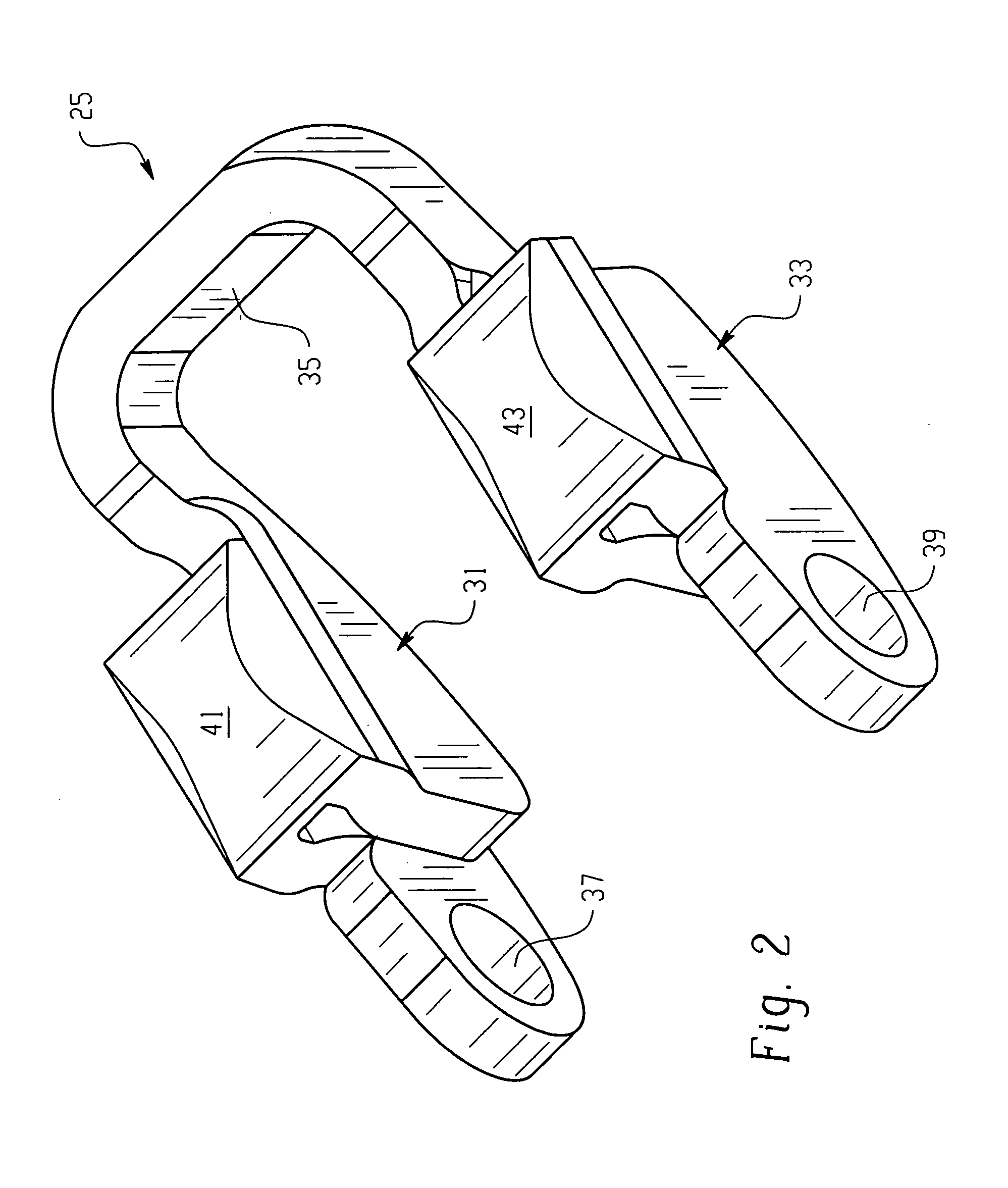

Stamped two-step rocker arm component

ActiveUS7089899B1Reduce manufacturing costMechanical propertyValve arrangementsMetal-working apparatusEngineeringCam

A rocker arm (25) adapted to engage a pair of cam lobes (15,17), the rocker arm having first (31) and second (33) sidewall portions, and being formed from a flat sheet metal blank (25B) having a nominal thickness (T). The sidewall portions (31,33) define fold regions (51,53) whereby, after each is folded over upon itself, and the rocker arm is formed to have the sidewall portions generally parallel to each other, the fold regions provide first (41) and second (43) cam contact surfaces, each having a width (W) substantially greater than the nominal thickness of the blank.

Owner:EATON INTELLIGENT POWER LIMITED

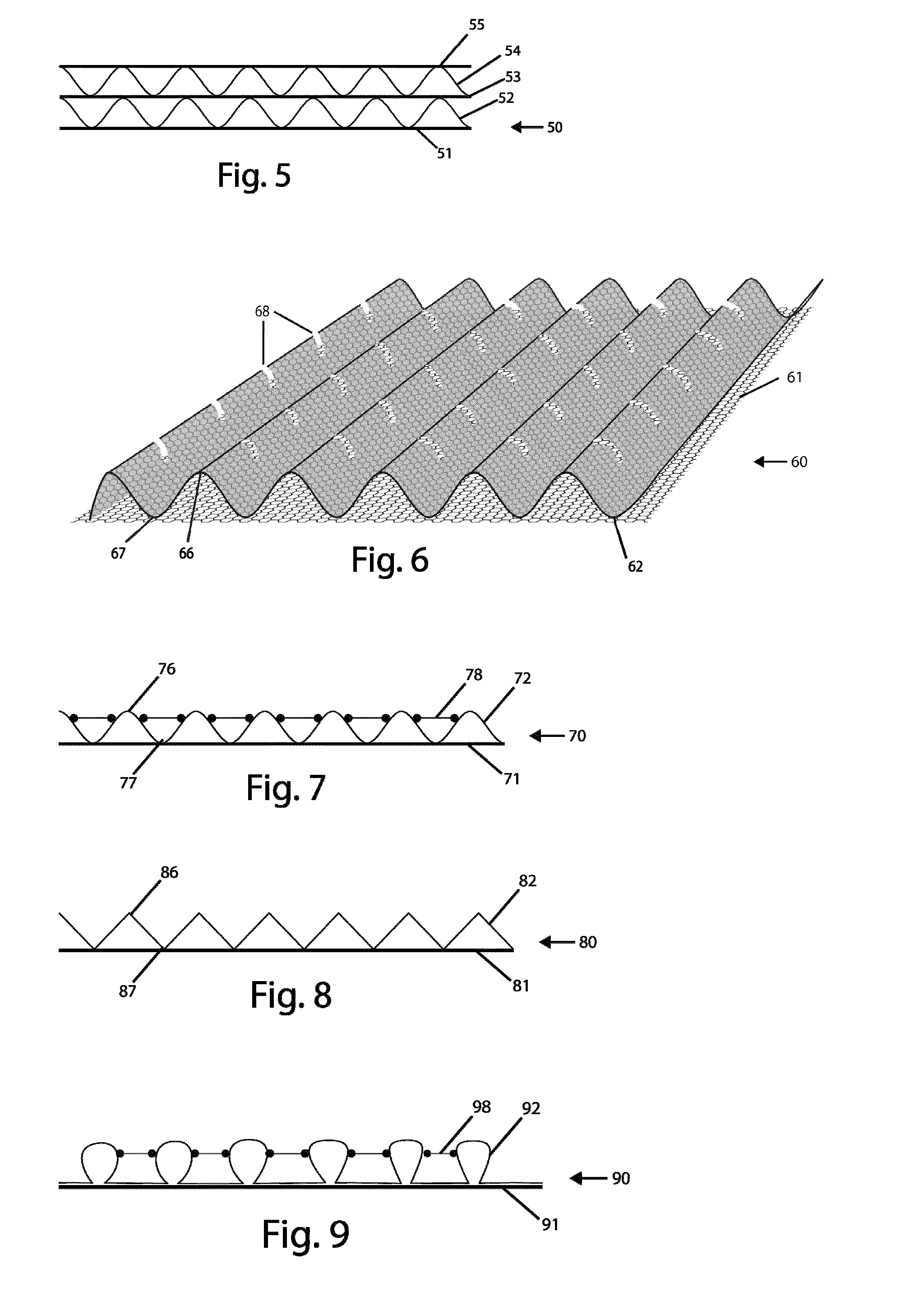

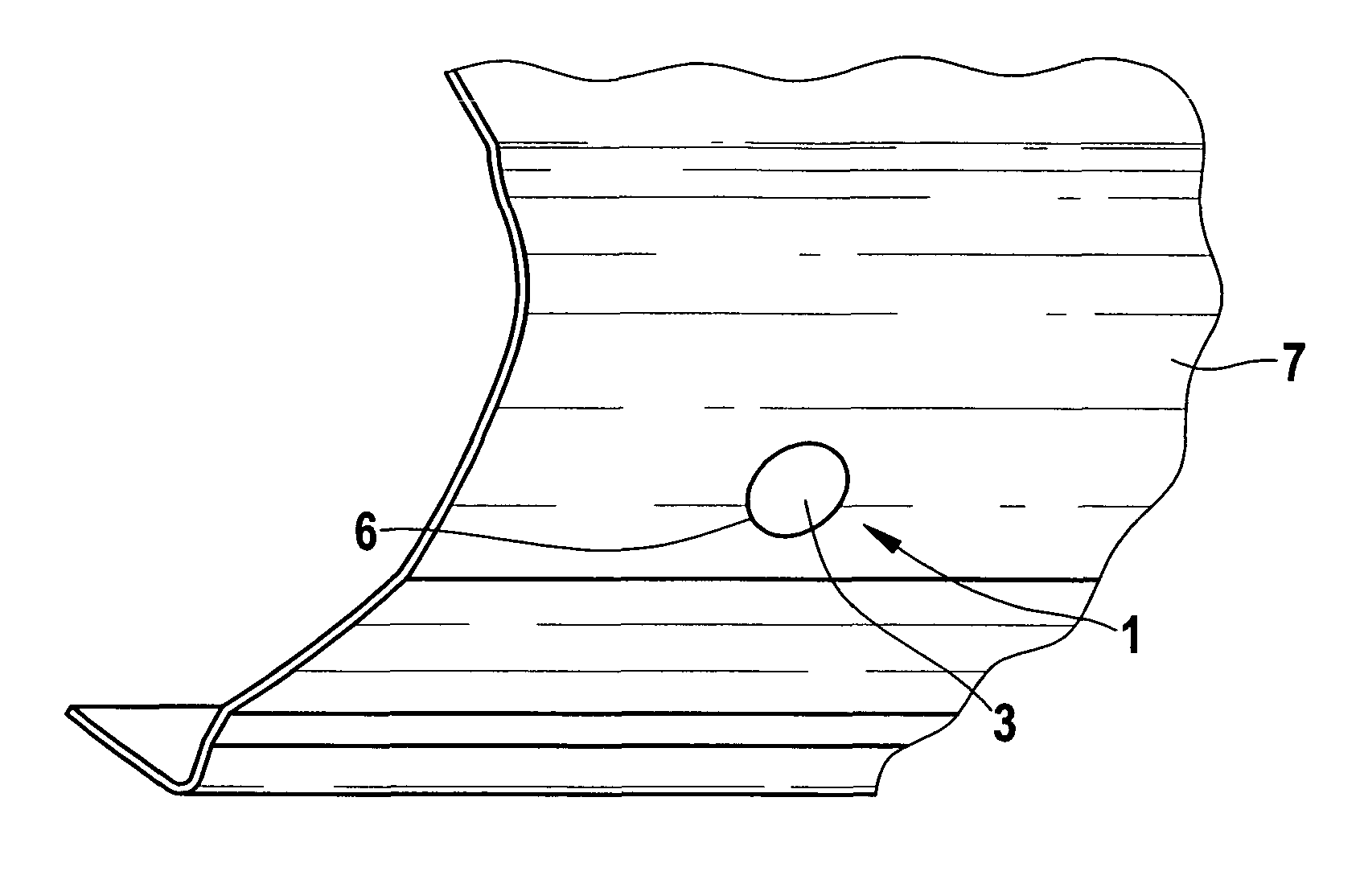

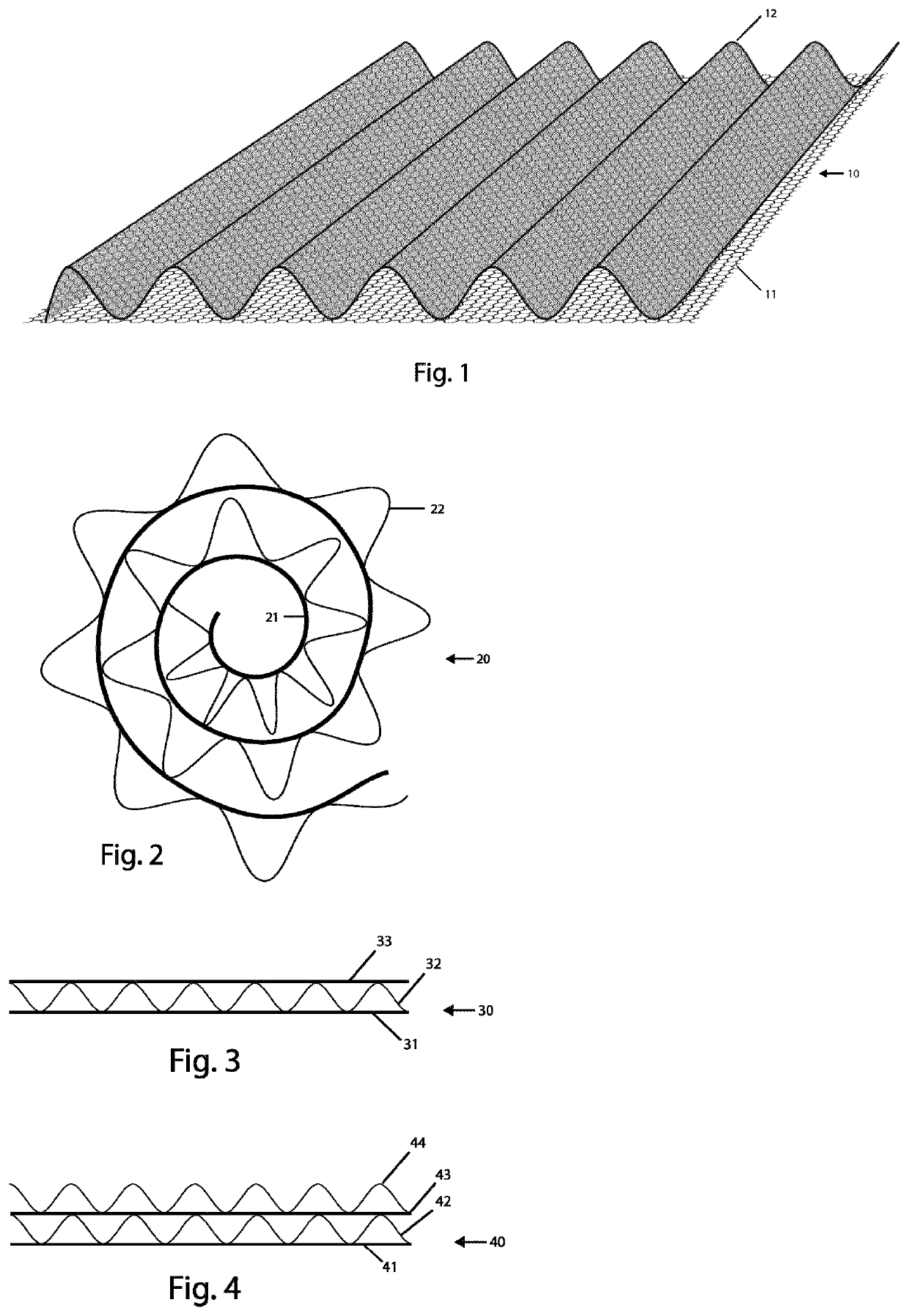

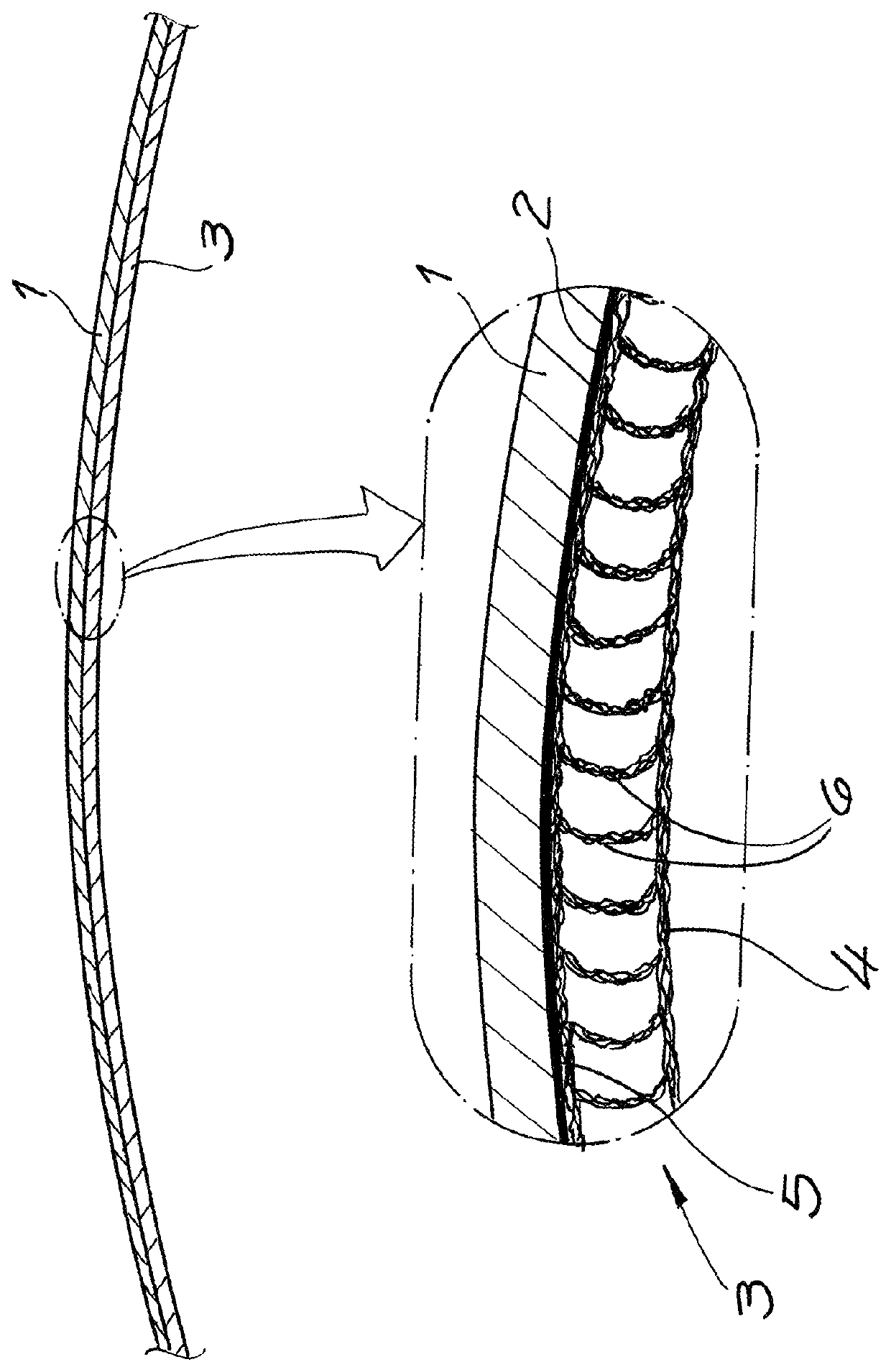

Knit spacer fabric for use as interior vehicle trim

ActiveUS20190381955A1Reduce consumptionWater contamination be reducedOrnamental textile articlesLayered productsYarnEngineering

A spacer fabric comprises a first and a second textile layer as well as spacer yarns that join the textile layers and is used to form an interior trim. The first textile layer is visible from outside on a surface of the interior trim, and the first textile layer and the spacer yarns are made entirely of polymeric multifilament yarns. At least the polymeric multifilament yarns of the first textile layer and of the spacer yarns are dyed.

Owner:MULLER TEXTIL

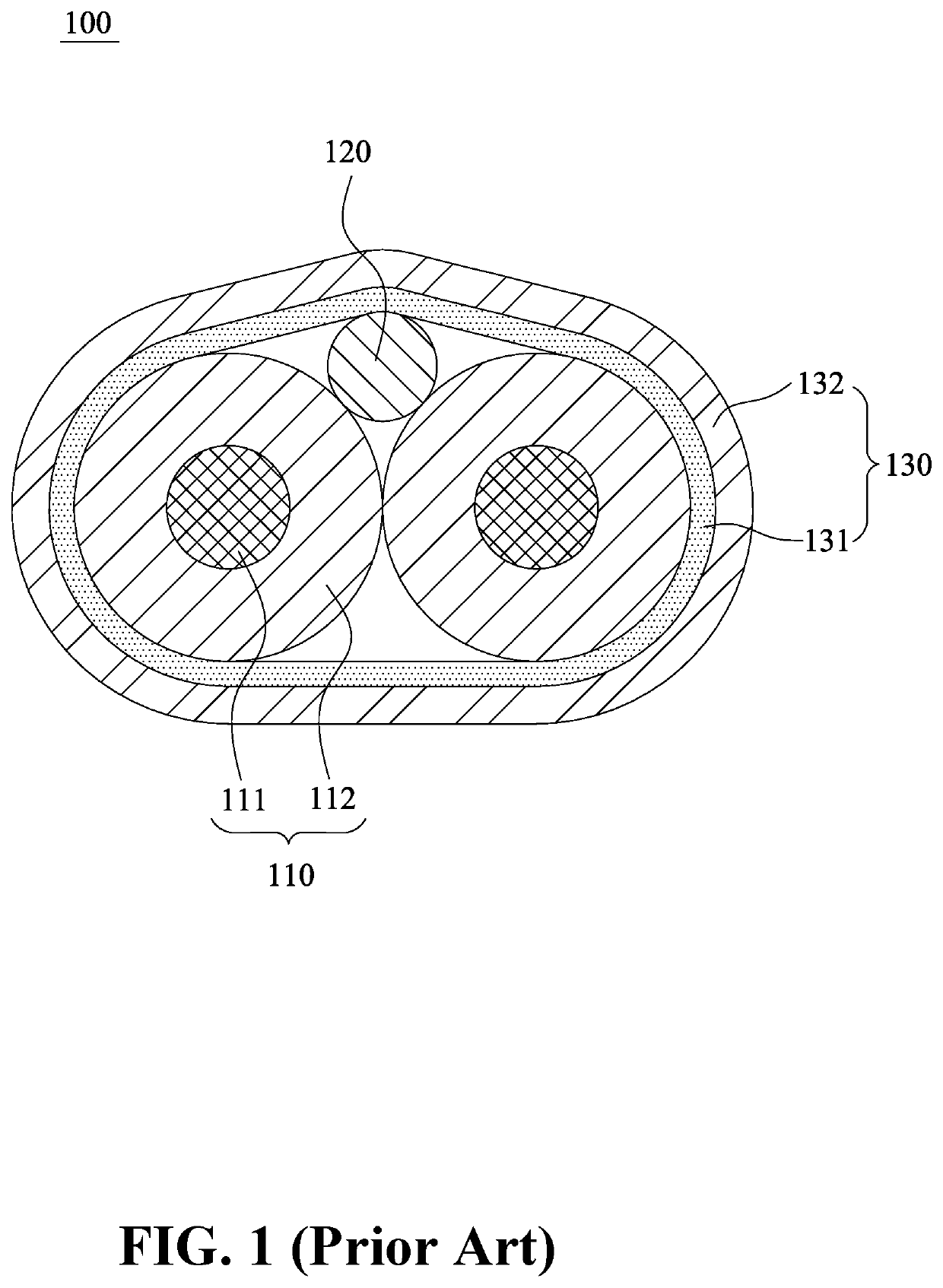

Three-dimensional polymeric medical implants

ActiveUS10709539B2Rapid tissue in-growthSufficient mechanical propertyMammary implantsBiomedical engineeringImplant

The invention relates to a three-dimensional medical implant, comprising a first thin porous component, and a first load-bearing and volume-creating component, which is connected to the first thin porous component; wherein the load-bearing and volume-creating component comprises an organized structure.

Owner:NOVUS SCI

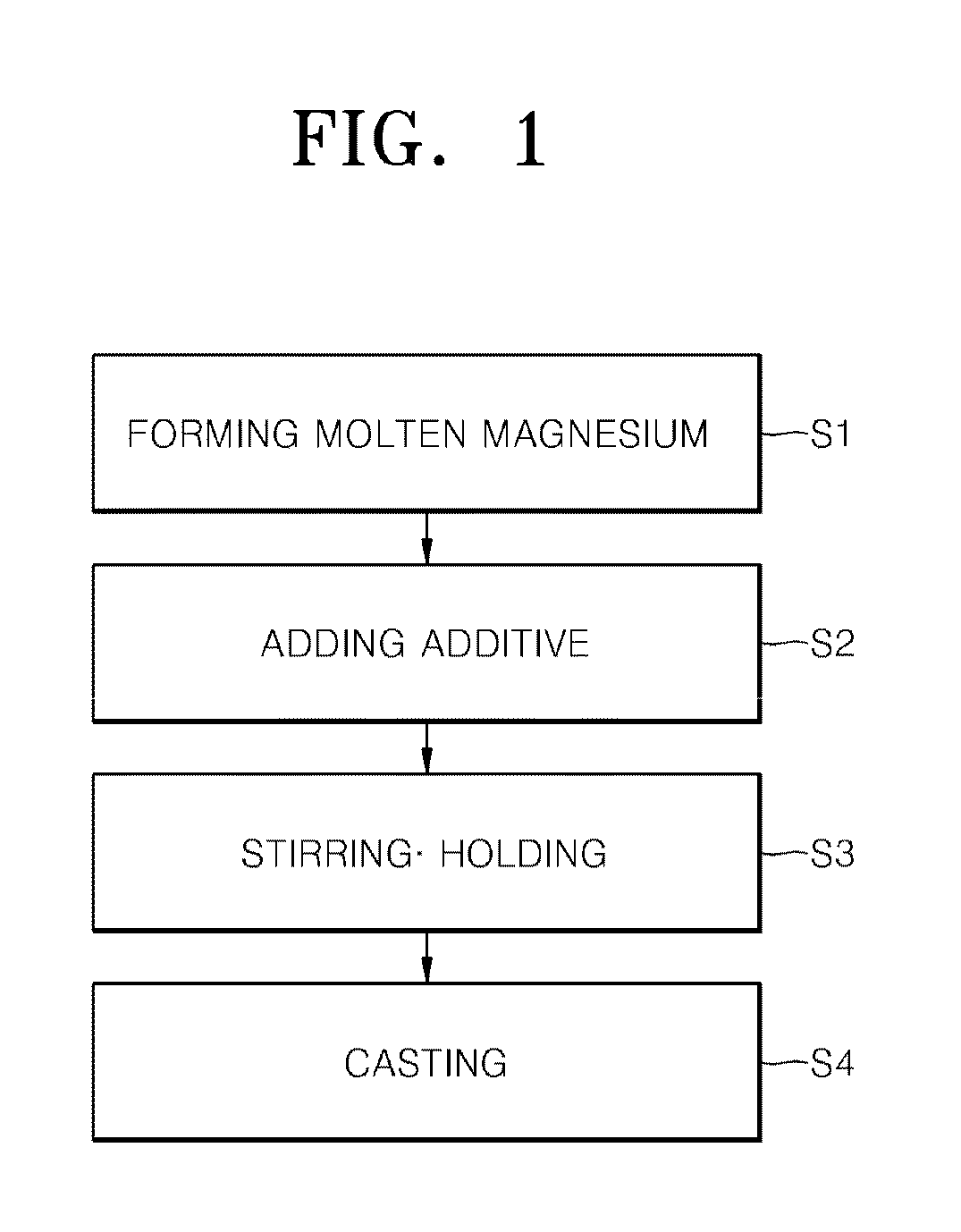

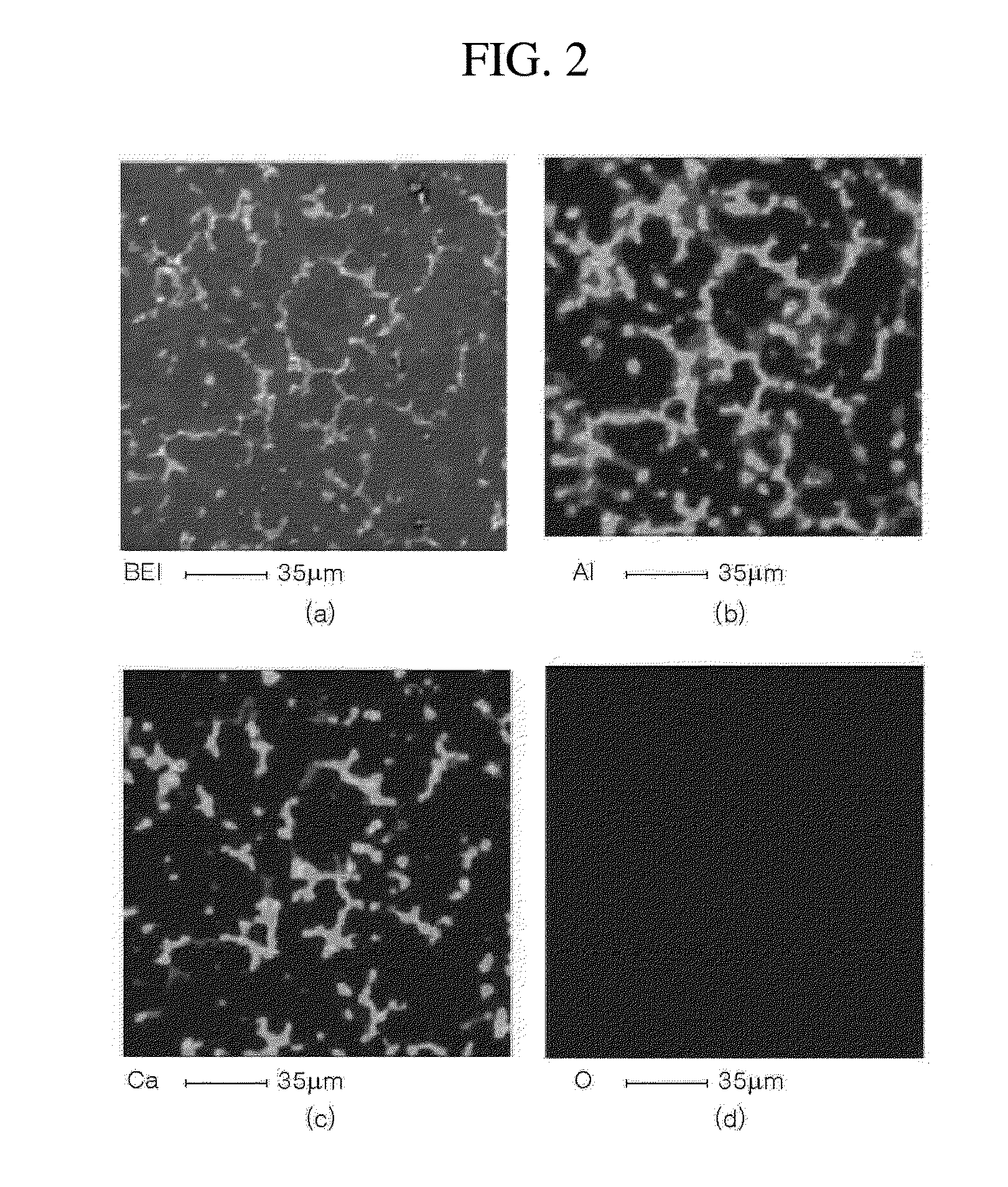

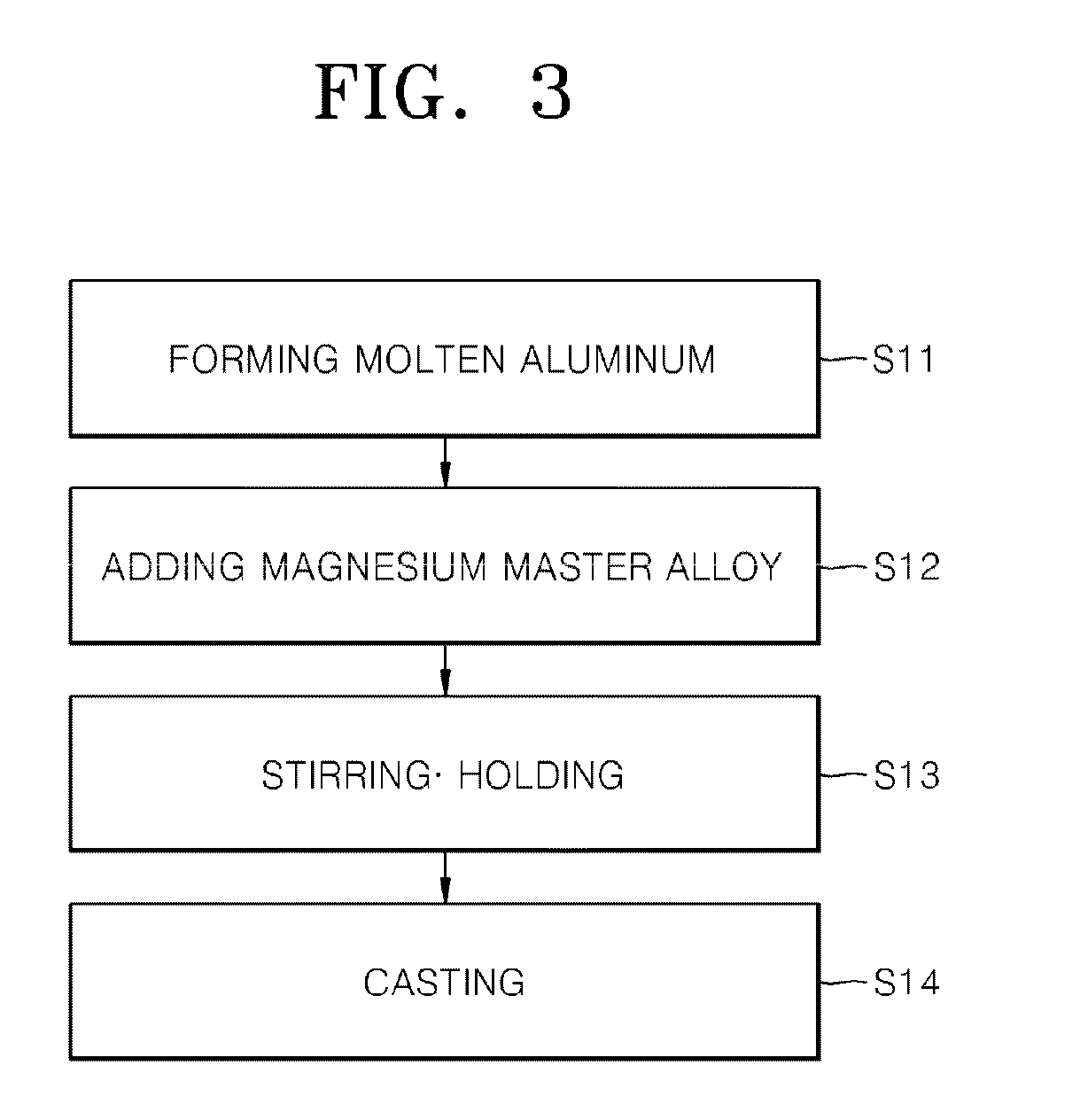

Aluminum alloy having improved oxidation resistance, corrosion resistance, or fatigue resistance, and die-cast material and extruded material prepared by using the aluminum alloy

InactiveUS20130243643A1Improve mechanical propertiesMechanical propertyFoundry mouldsFoundry coresOxidation resistantMagnesium

Provided are an aluminum (Al) alloy prepared environment friendly and having excellent oxidation resistance properties, and a method of preparing the Al alloy. An oxidation-resistant Al alloy according to an embodiment of the present invention is casted by adding a magnesium (Mg) master alloy, in which a calcium (Ca)-based compound is distributed in an Mg matrix, into molten Al. An Al matrix includes the Ca-based compound. The Al alloy has superior oxidation resistance to a corresponding Al alloy not including the Ca-based compound.

Owner:KOREA INST OF IND TECH

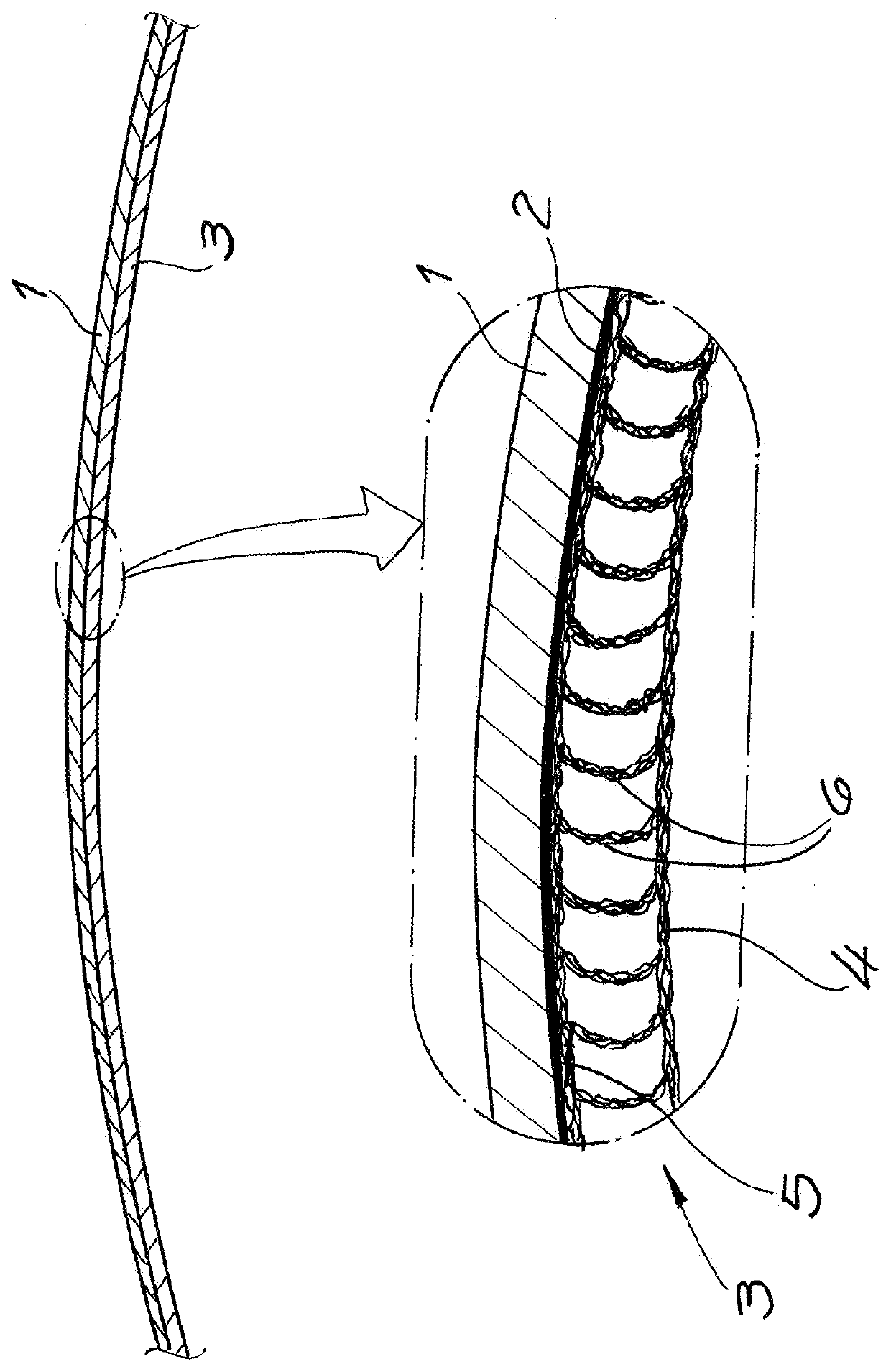

Cable with non-circular ground wires

ActiveUS11482349B1Improve fitMechanical propertySingle bars/rods/wires/strips conductorsCommunication cablesClassical mechanicsStructural engineering

A cable with a non-circular ground wire is provided, including two wires, two ground wires, and an insulating tape; wherein the inner sides of the wires are in contact with each other; the ground wires are respectively arranged on two opposite sides of the wires; each ground wire at least includes a first side surface, a second side surface, and a third side surface; the first and second side surfaces respectively contact the outer surfaces of the two wires, and the shapes of the first side surface and the second side surface respectively correspond to the shapes of the outer surfaces of the two wires; the insulating tape covers the outer surfaces of the wires and the third side surfaces of the ground wires. Thereby, the mechanical properties of the cable of the present invention, such as small impedance variation of high-frequency signal transmission, transmission stability, structural flexibility and bending, can be significantly improved.

Owner:LEE JAMES CHENG

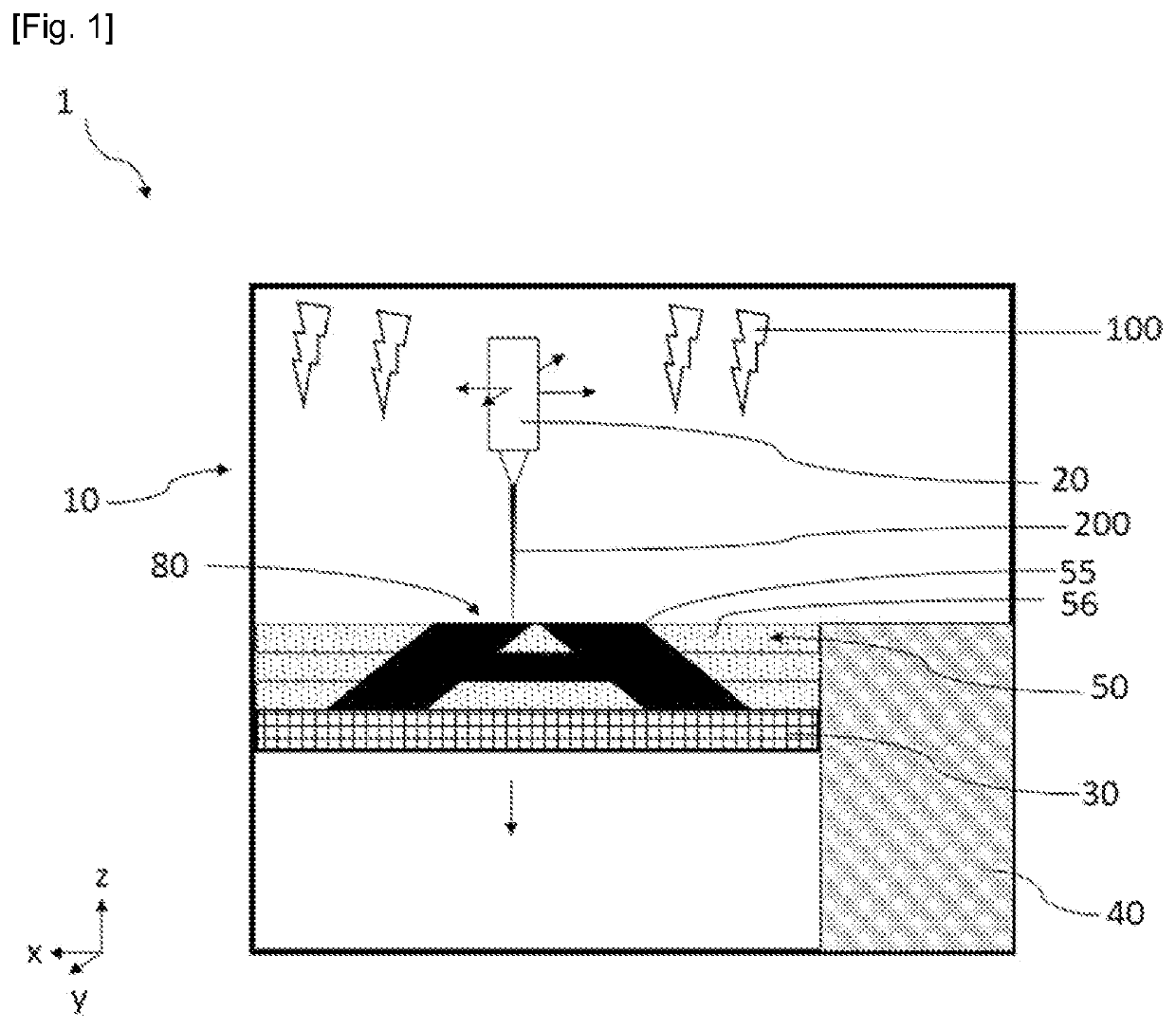

Anti-reflective film, polarizing plate, and display apparatus

ActiveUS20200309996A1Excellent abrasion resistanceImprove scratch resistanceCoatingsOptical elementsOptical propertyDisplay device

Provided are an anti-reflective film including a low-refractive layer having mechanical properties such as high abrasion resistance and scratch resistance, etc., and excellent optical properties, and a hard coating layer, a polarizing plate including the same, and a display device including the same.

Owner:LG CHEM LTD

Tantalum carbide, method for producing tantalum carbide, tantalum carbide wiring and tantalum carbide electrode

ActiveUS20100284895A1High purityAvoid layeringSolid state diffusion coatingTungsten/molybdenum carbideCarbon sourceTantalum carbide

Owner:TOYO TANSO KK

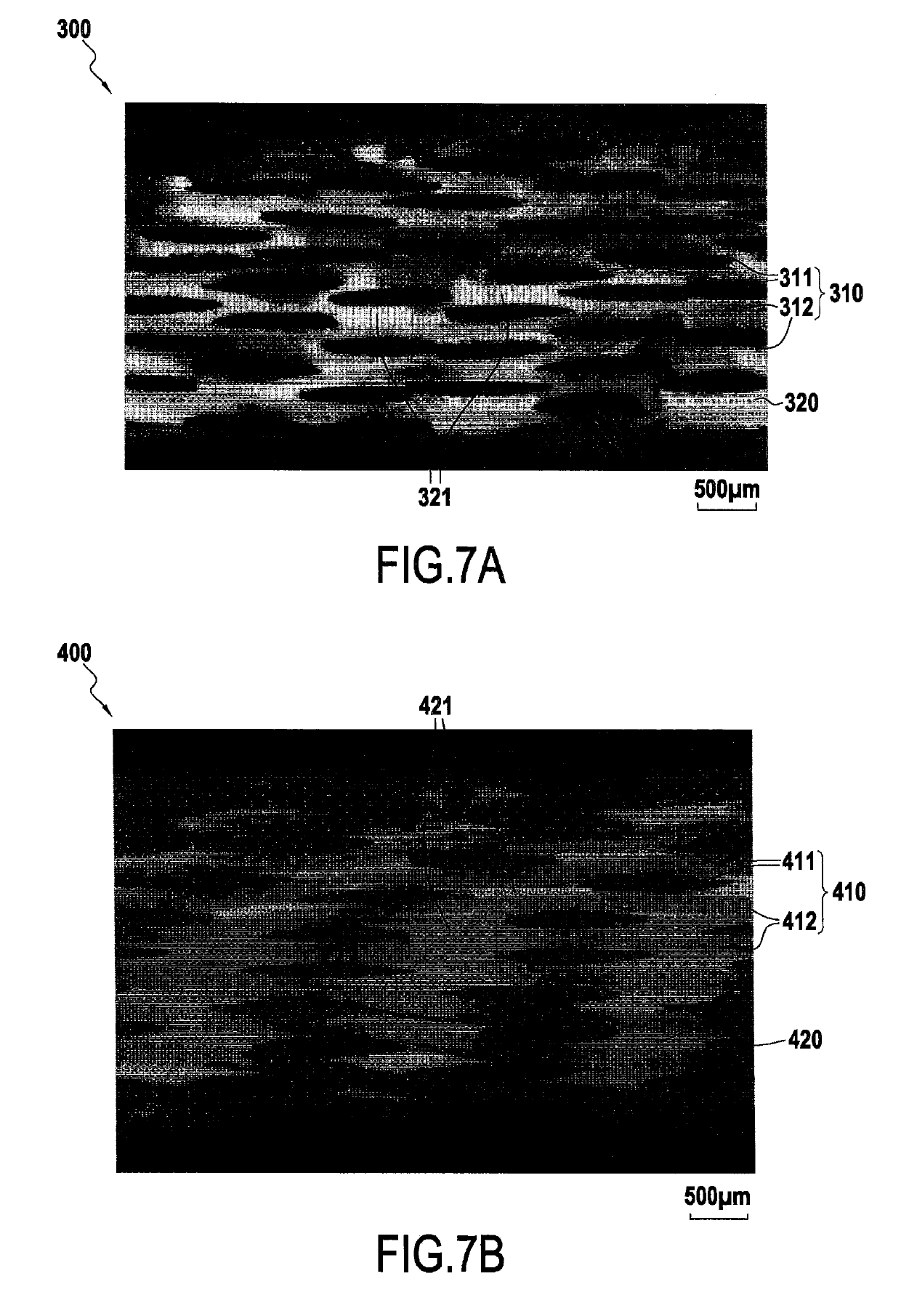

Spunbond nonwoven fabric

PendingUS20200240061A1Good flexibilityReduce production efficiencyMonocomponent polypropylene artificial filamentNon-woven fabricsPolymer scienceCrystal orientation

Provided is a spunbond nonwoven fabric which is made of a polypropylene fiber and satisfies all of the following conditions A to E: A. the average single fiber diameter of the fiber is 6-17 μm; B. the degree of crystal orientation of the fiber as obtained by wide-angle X-ray diffraction is at least 0.91; C. the crystallite size of the (110) plane of the fiber as obtained by wide angle X-ray diffraction is at least 12 nm; D. the average orientation parameter of the fiber as obtained by Raman spectroscopy is at least 8.0; and E. the complex viscosity of the spunbond nonwoven fabric at a temperature of 230° C. is 20-100 Pa·sec at an angular frequency of 6.3 rad / sec.

Owner:TORAY IND INC

Methods for applying a skin treatment

ActiveUS20170049925A1Solving the Insufficiency of ElasticityNot easy to tearCosmetic preparationsToilet preparationsSkin treatmentsBiochemical cascade

Owner:DIRECT COMPONENTS INC

Part made from oxide/oxide composite material for 3-D reinforcing and method for manufacture of same

ActiveUS10400367B2Mechanical propertyImprove mechanical propertiesFeeding arrangmentsMulti-ply fabricsOxide matrixOxide composite

A part made of oxide / oxide composite material includes fiber reinforcement constituted by a plurality of warp yarn layers and of weft yarn layers interlinked by three-dimensional weaving, with the spaces present between the reinforcing yarns being filled with a refractory oxide matrix. The fiber reinforcement presents a weave selected from the following weaves: interlock; multi-plain; multi-satin; and multi-serge, with warp and weft thread counts lying in the range 4 yarns / cm to 20 yarns / cm. The fiber reinforcement also presents a fiber volume fraction lying in the range 40% to 51%.

Owner:SAFRAN CERAMICS SA

Lignin enhanced wood-plastic material and preparation method thereof

Owner:NANJING TECH UNIV

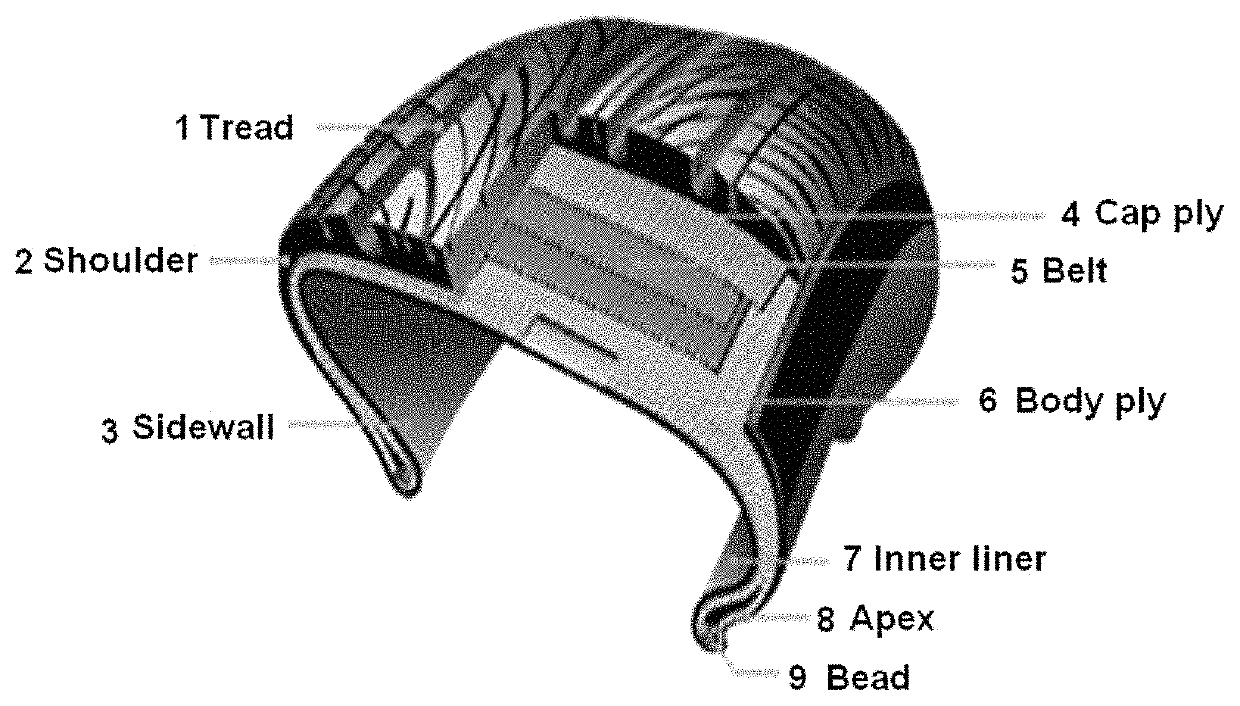

Polymer film and method for preparing polymer film

ActiveUS10533078B2Reduce weightImprove fuel efficiencyRoad vehicle tyresFilm/foil adhesivesPolymer sciencePolyamide

Owner:KOLON IND INC

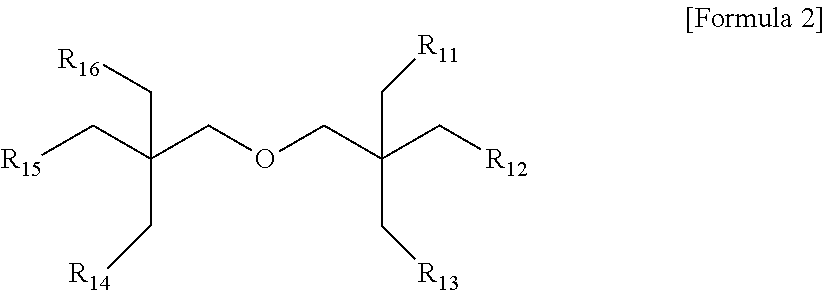

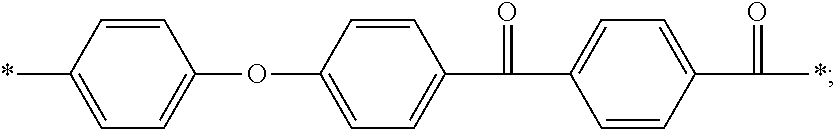

Method for preparing nitrile-based rubber

The present invention relates to a method for preparing a nitrile-based rubber, by which the nitrile-based rubber is prepared by polymerizing a monomer mixture comprising an α,β-unsaturated nitrile-based monomer and a conjugated diene-based monomer, in the presence of an initiator and an emulsifier comprising a C30 to C60 compound having two or more carboxyl groups, a nitrile-based rubber prepared thereby, and a nitrile-based rubber composition comprising the nitrile-based rubber.

Owner:LG CHEM LTD

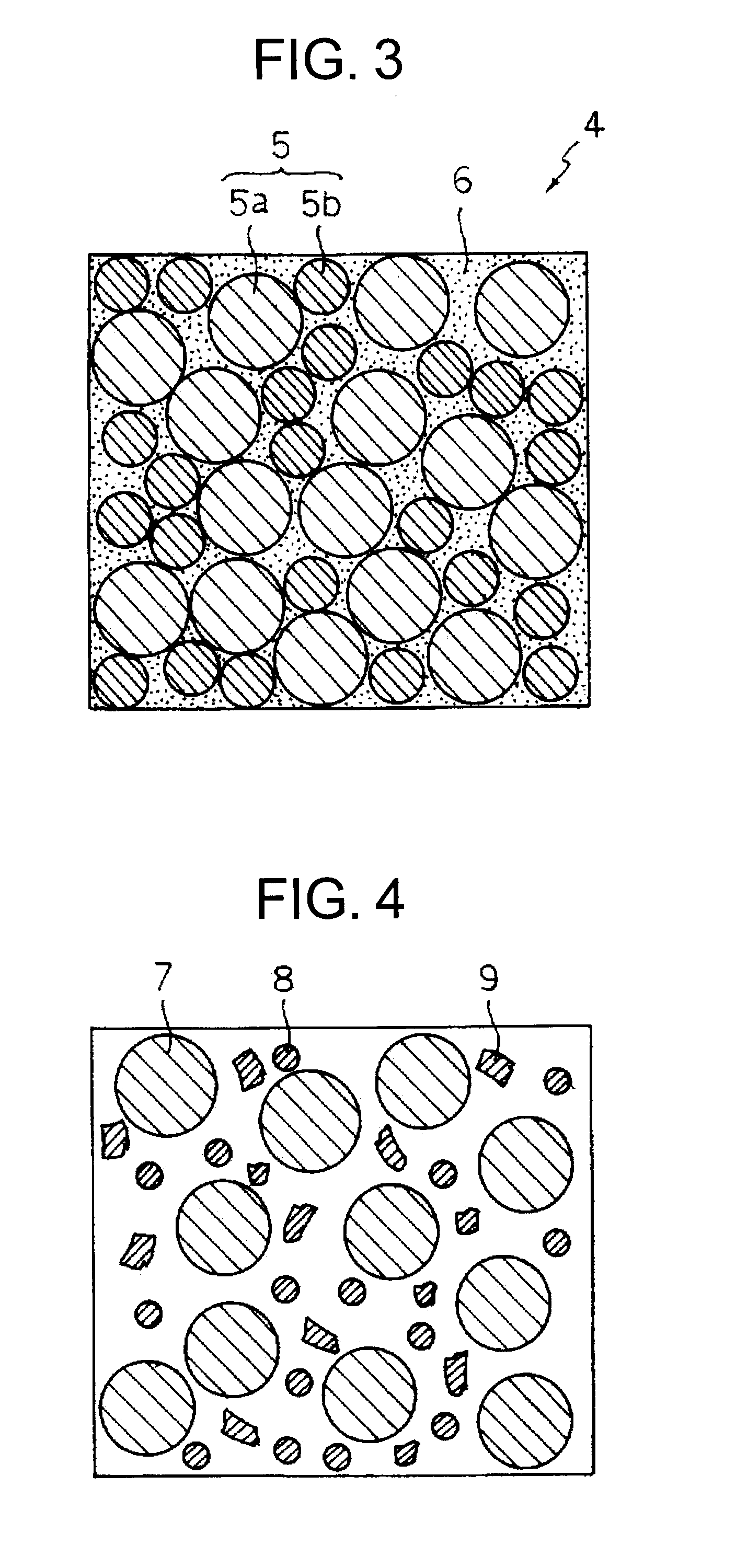

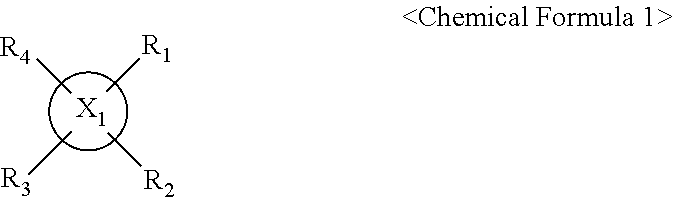

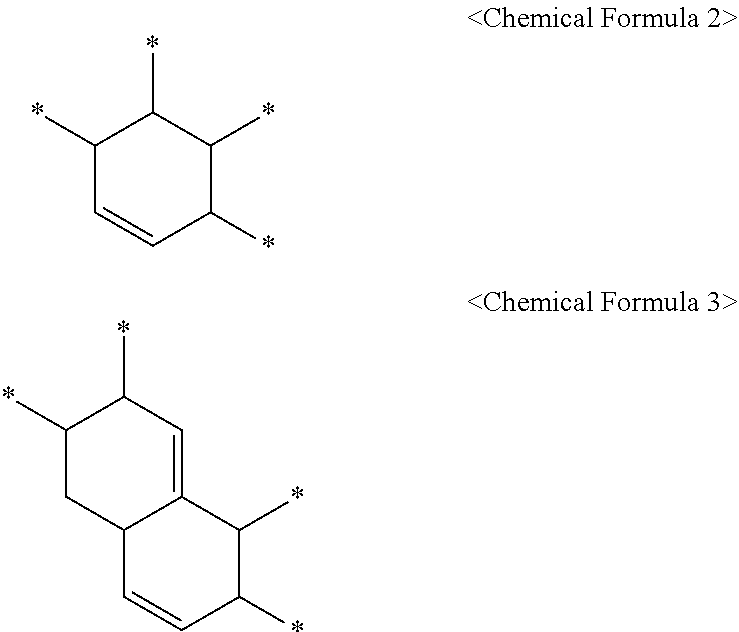

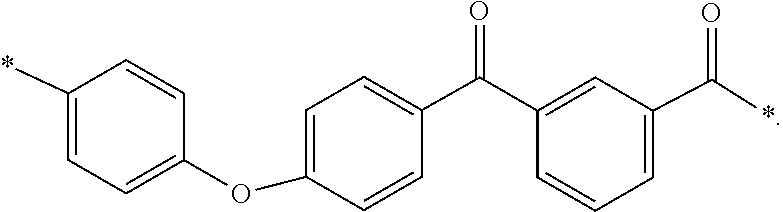

Filled polyaryl ether ketone powder, manufacturing method therefor and use thereof

PendingUS20220363842A1Improve mechanical propertiesHigh modulusAdditive manufacturing apparatus3D object support structuresPolymer scienceEther

A powder with a volume-weighted particle size distribution, with a median diameter D50 ranging from 40 to 120 micrometers, including at least one polyaryl ether ketone and at least one filler, in which: said at least one polyaryl ether ketone forms a matrix incorporating, at least partly, said at least one filler, and said filler has a Stokes equivalent spherical diameter distribution with a median diameter d′50 of less than or equal to 5 micrometers. Also a powder manufacturing process and the use thereof in a process for the layer-by-layer construction of objects by electromagnetic radiation-mediated sintering.

Owner:ARKEMA FRANCE SA

Knit spacer fabric for use as interior vehicle trim

ActiveUS11110870B2Compression hardness and elasticityMechanical propertyOrnamental textile articlesLayered productsYarnEngineering

A spacer fabric comprises a first and a second textile layer as well as spacer yarns that join the textile layers and is used to form an interior trim. The first textile layer is visible from outside on a surface of the interior trim, and the first textile layer and the spacer yarns are made entirely of polymeric multifilament yarns. At least the polymeric multifilament yarns of the first textile layer and of the spacer yarns are dyed.

Owner:MULLER TEXTIL

Acrylic rubber composition

ActiveUS10393203B2Excellent tan δ valueGood vibration isolationNon-rotating vibration suppressionSprings/dampers manufactureAcrylic rubberGrommet

An acrylic rubber composition comprising 5 to 80 parts by weight, preferably 10 to 60 parts by weight, more preferably 20 to 40 parts by weight, of a styrene acrylic-based resin containing a functional group other than a carboxyl group, based on 100 parts by weight of acrylic rubber. A vibration insulation member having an excellent tan δ value at a high temperature and improved vibration insulation properties can be molded by adding a specific ratio of a styrene acrylic-based resin to acrylic rubber. This acrylic rubber composition can be effectively used as a molding material for a mount, a grommet, or the like in the vicinity of an automobile engine used in a high temperature environment.

Owner:NOK CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com