Filament Bundle Type Nano Fiber and Manufacturing Method Thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

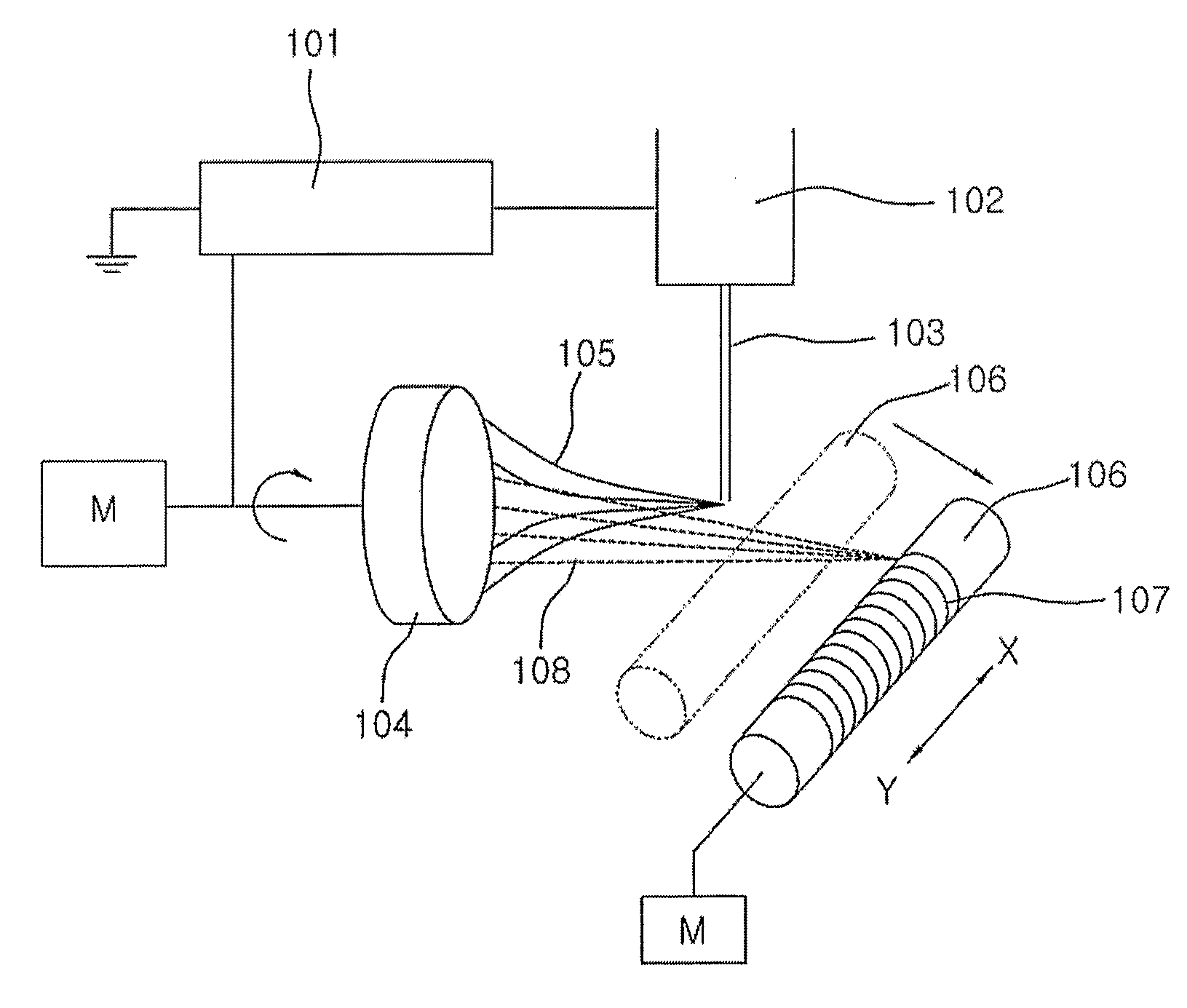

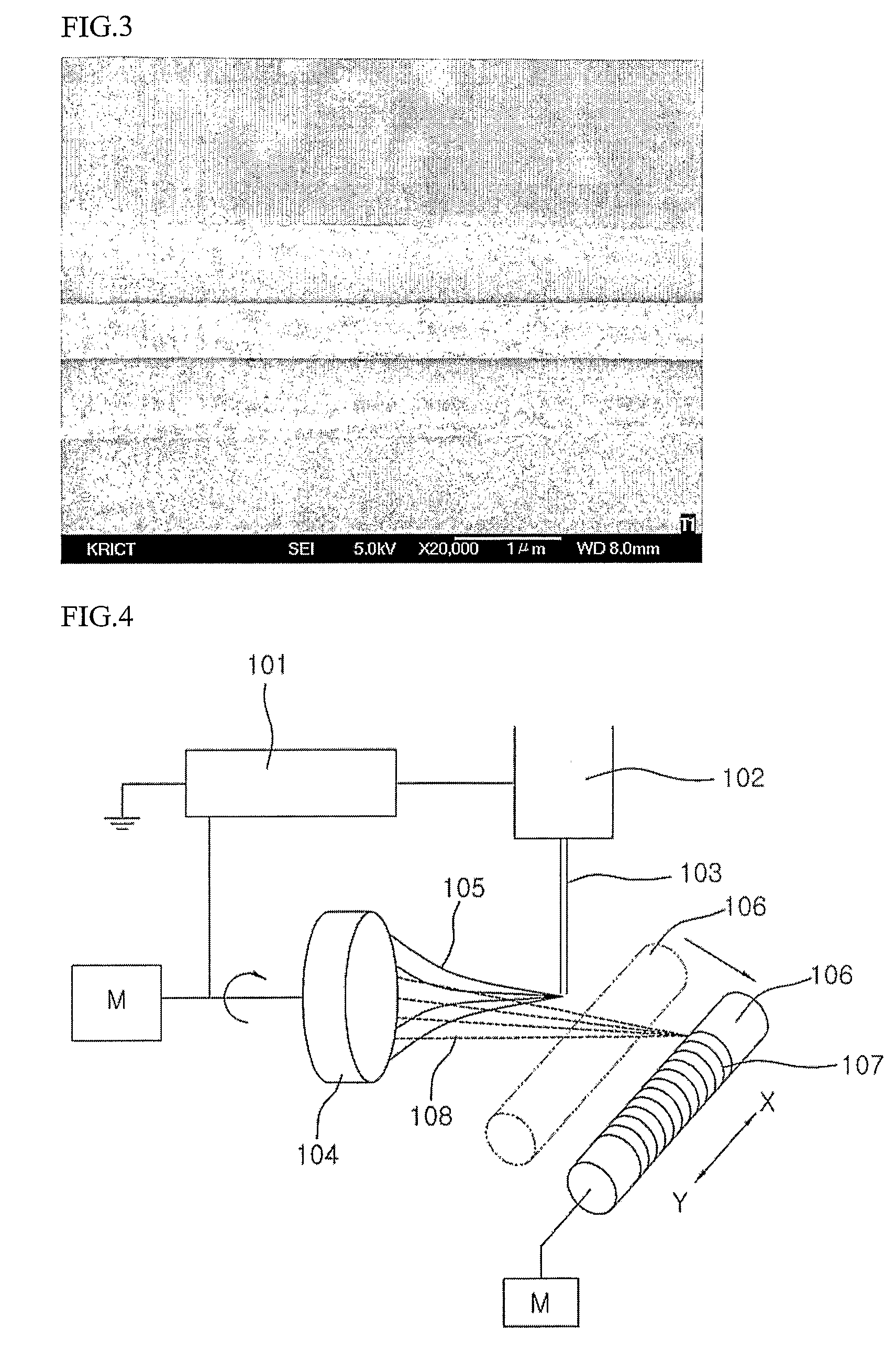

Method used

Image

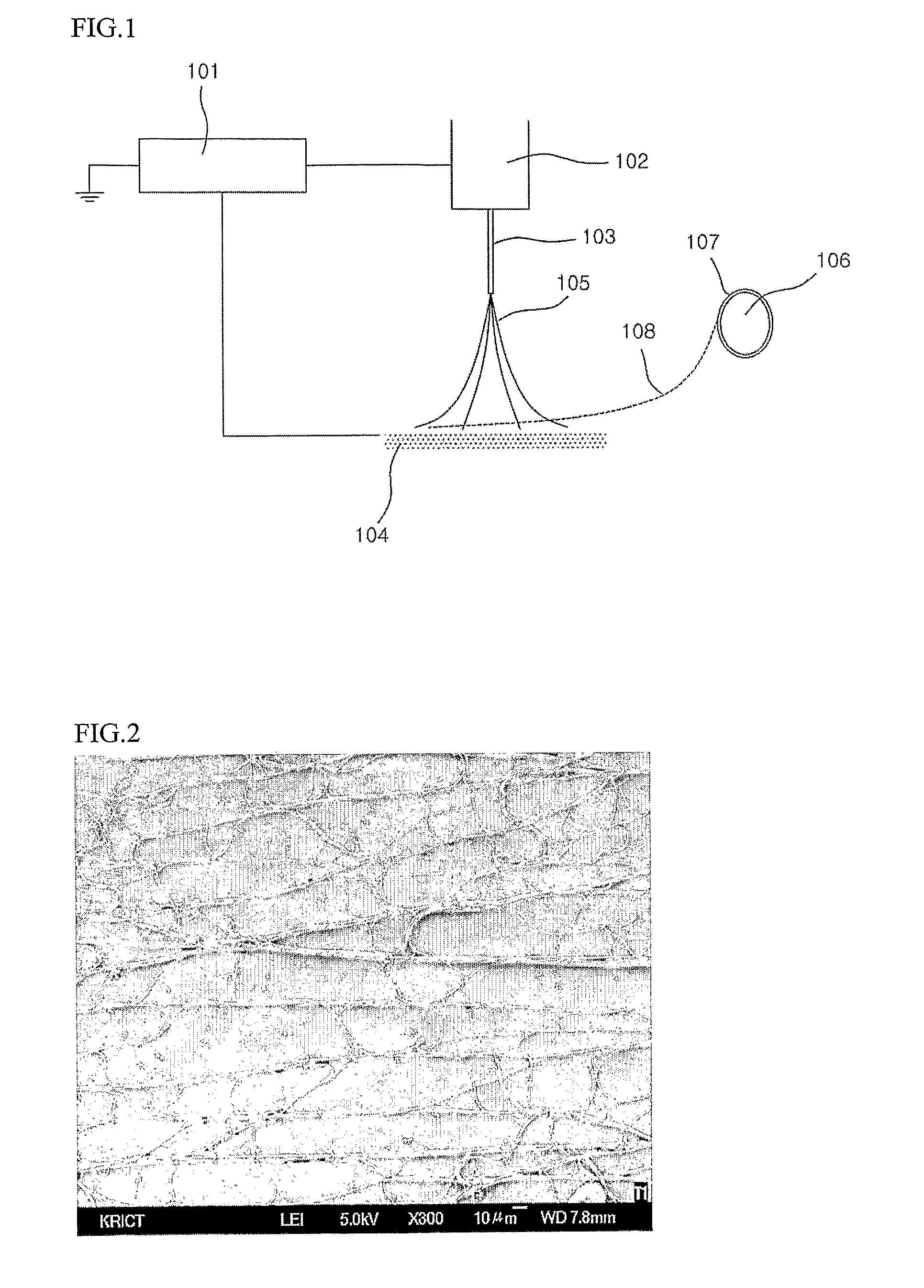

Examples

preparation example 1

First Preparation of Spinning Solution

[0055]A polymer copolymer, which consists of 30 mol % of polyamide-based polymer with an average molecular weight and 70 mol % of polyimide-based polymer with an average molecular weight, was added to a N-methyl-2-pyrrolidine solvent, and sufficiently dissolved at room temperature for 20-30 min using a ultrasonic device. In this regard, a spinning solution contains 25 wt % of polyamide-polyimide copolymer with a number average molecular weight of 1000 based on the solvent.

preparation example 2

Second Preparation of Spinning Solution

[0056]Polyethylene terephthalate having an intrinsic viscosity of 0.64 was mixed with a polyester copolymer, which contains 30 mol % of isophthalic acid and 15 mol % of diethylene glycol and which has an intrinsic viscosity of 0.60, in a weight ratio of 75:25, and then dissolved in a mixed solvent (50:50) of trifluoroacetic acid and methylene glycol to produce a spinning solution containing 15 wt % of solids.

preparation example 3

Preparation of Spinning Melt

[0057]A mixed composition, which consists of 30 mol % of polyamide-based polymer with an average molecular weight and 70 mol % of polyimide-based polymer with an average molecular weight, was melted in an electric furnace at 350° C. to produce a spinning melt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

| Angular velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com