Aluminum alloy having improved oxidation resistance, corrosion resistance, or fatigue resistance, and die-cast material and extruded material prepared by using the aluminum alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Technical Problem

[0004]The present invention provides an aluminum (Al) alloy prepared environment friendly and having improved chemical-mechanical properties such as oxidation resistance, corrosion resistance, or fatigue resistance, and a die-cast material and an extruded material prepared by using the Al alloy. The above problem to be solved is provided as an example and the scope of the present invention is not limited thereto.

Technical Solution

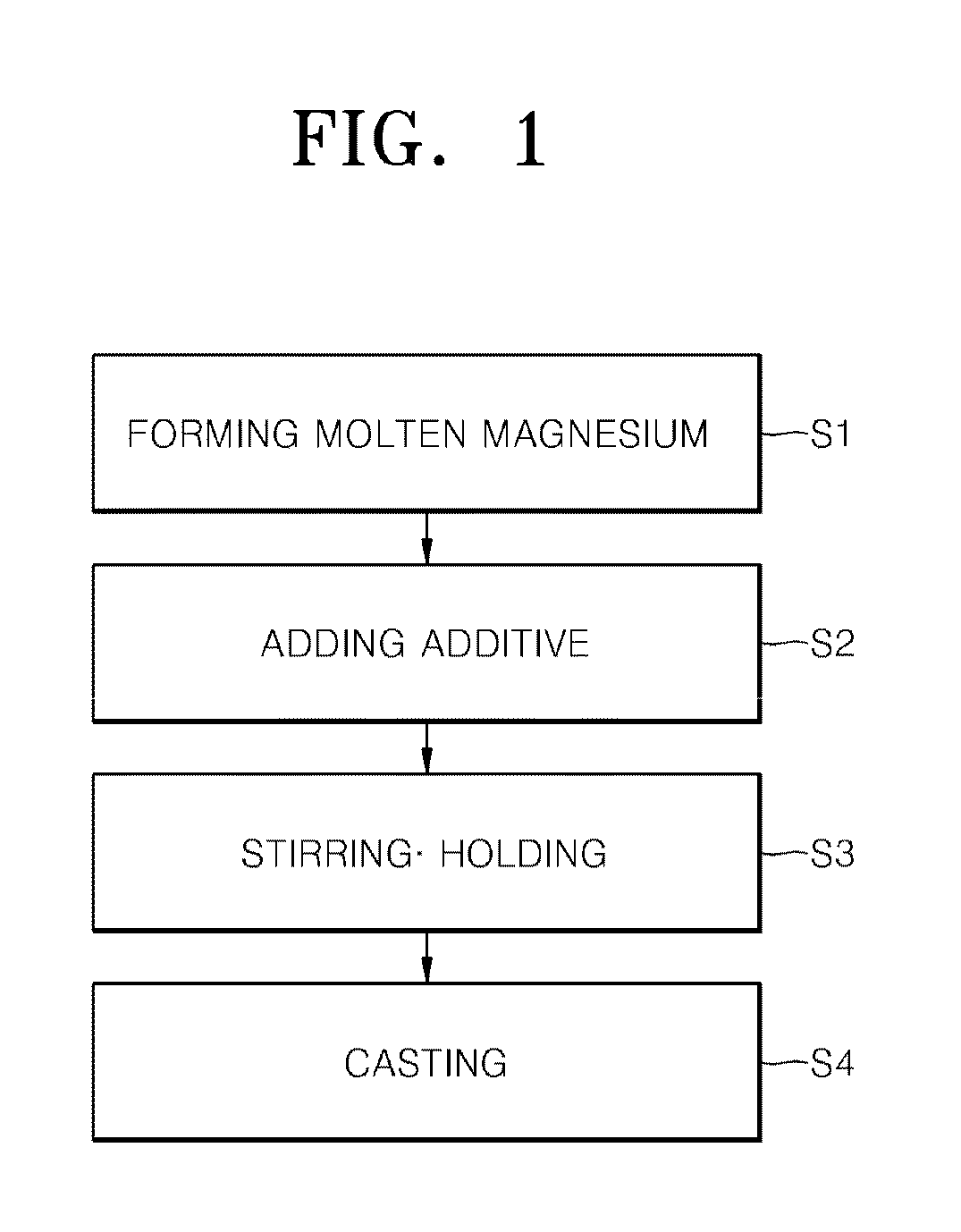

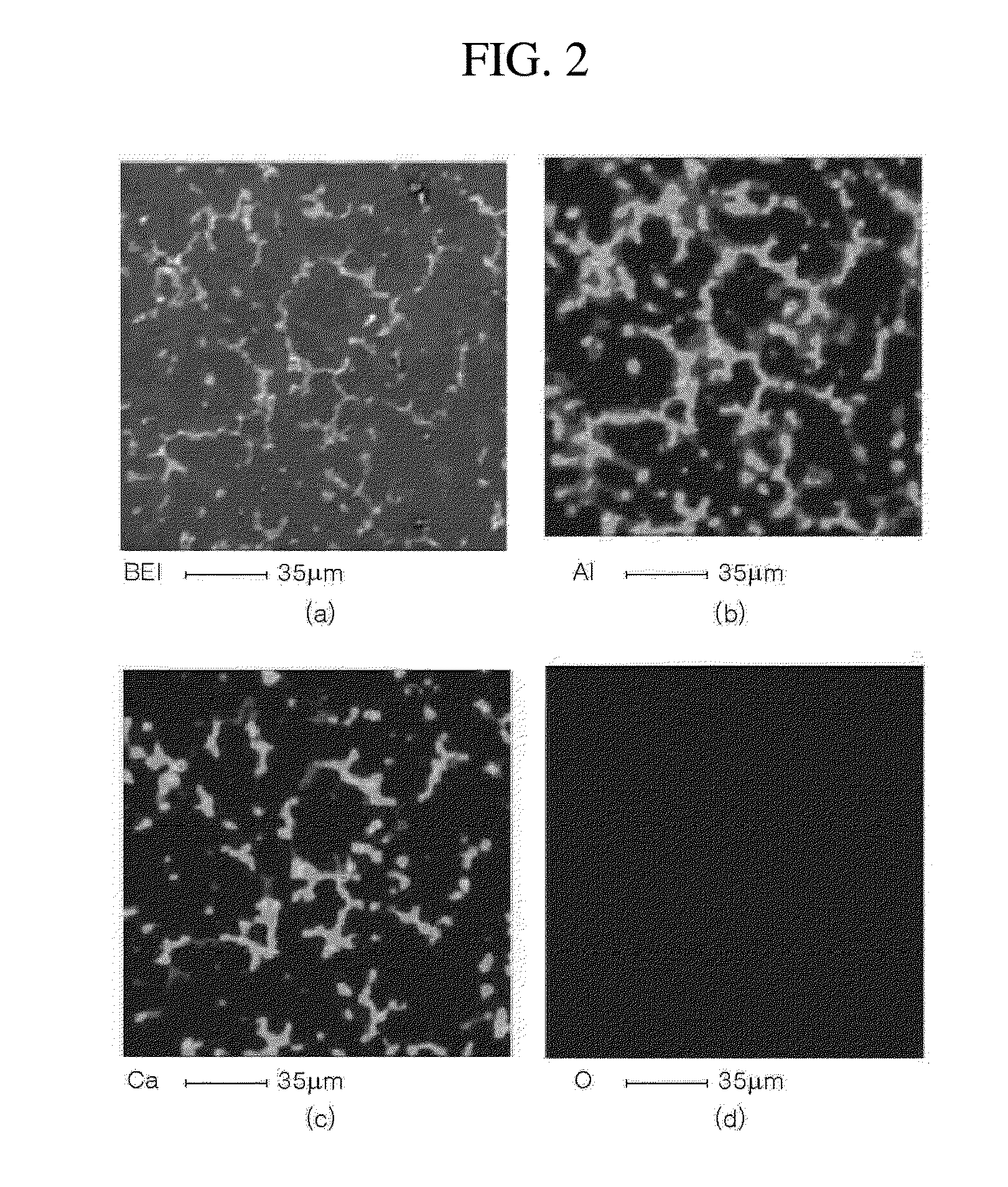

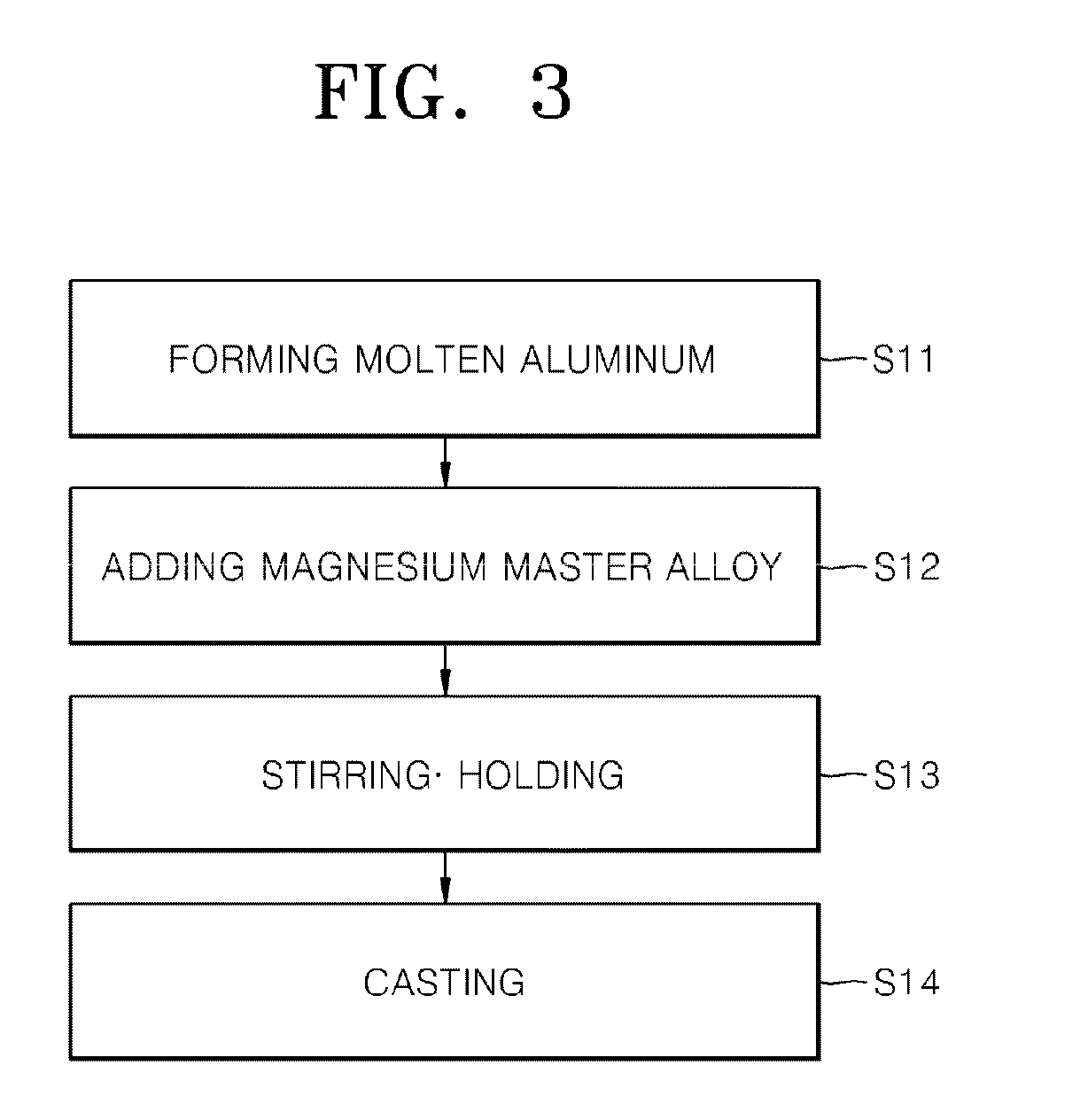

[0005]According to an aspect of the present invention, there is provided an aluminum (Al) alloy casted by adding a magnesium (Mg) master alloy, in which a calcium (Ca)-based compound is distributed in an Mg matrix, into molten Al, wherein an Al matrix includes the Ca-based compound, and wherein the Al alloy has superior oxidation resistance, corrosion resistance against salt water, or fatigue resistance to a corresponding Al alloy not including the Ca-based compound.

[0006]In this case, the Ca-based compound may include at least one of an M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com