Patents

Literature

51results about How to "High hardness properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

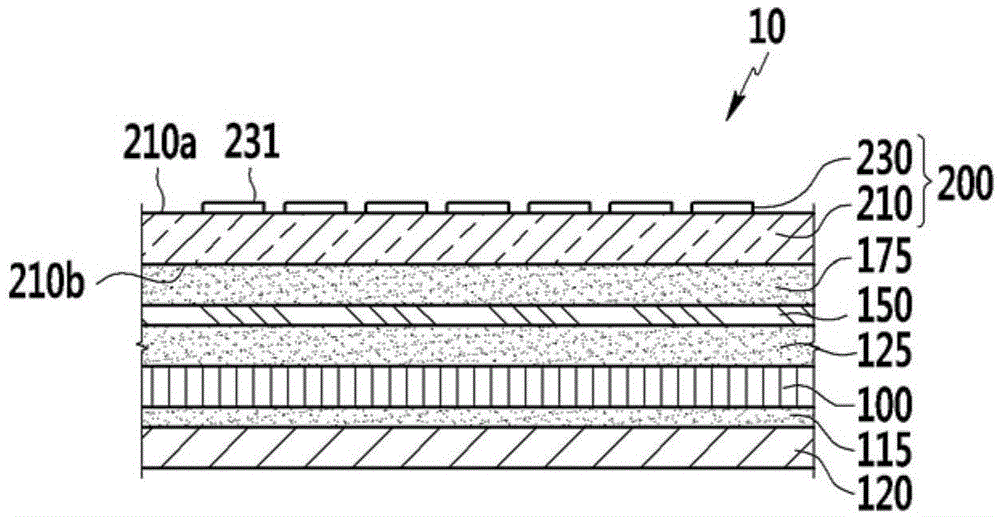

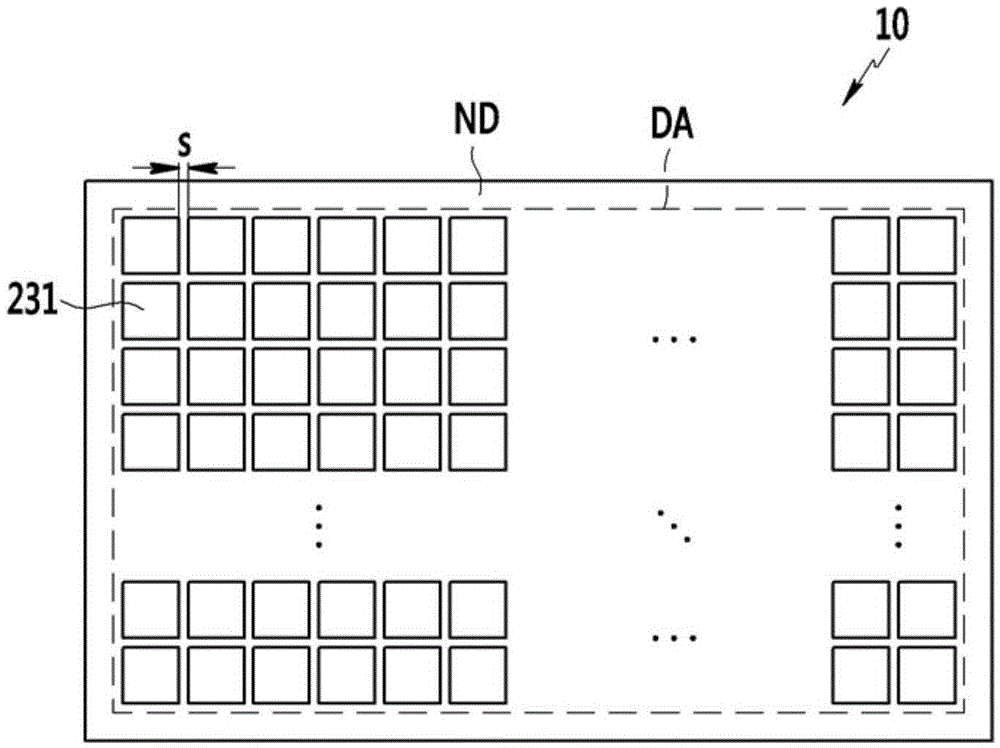

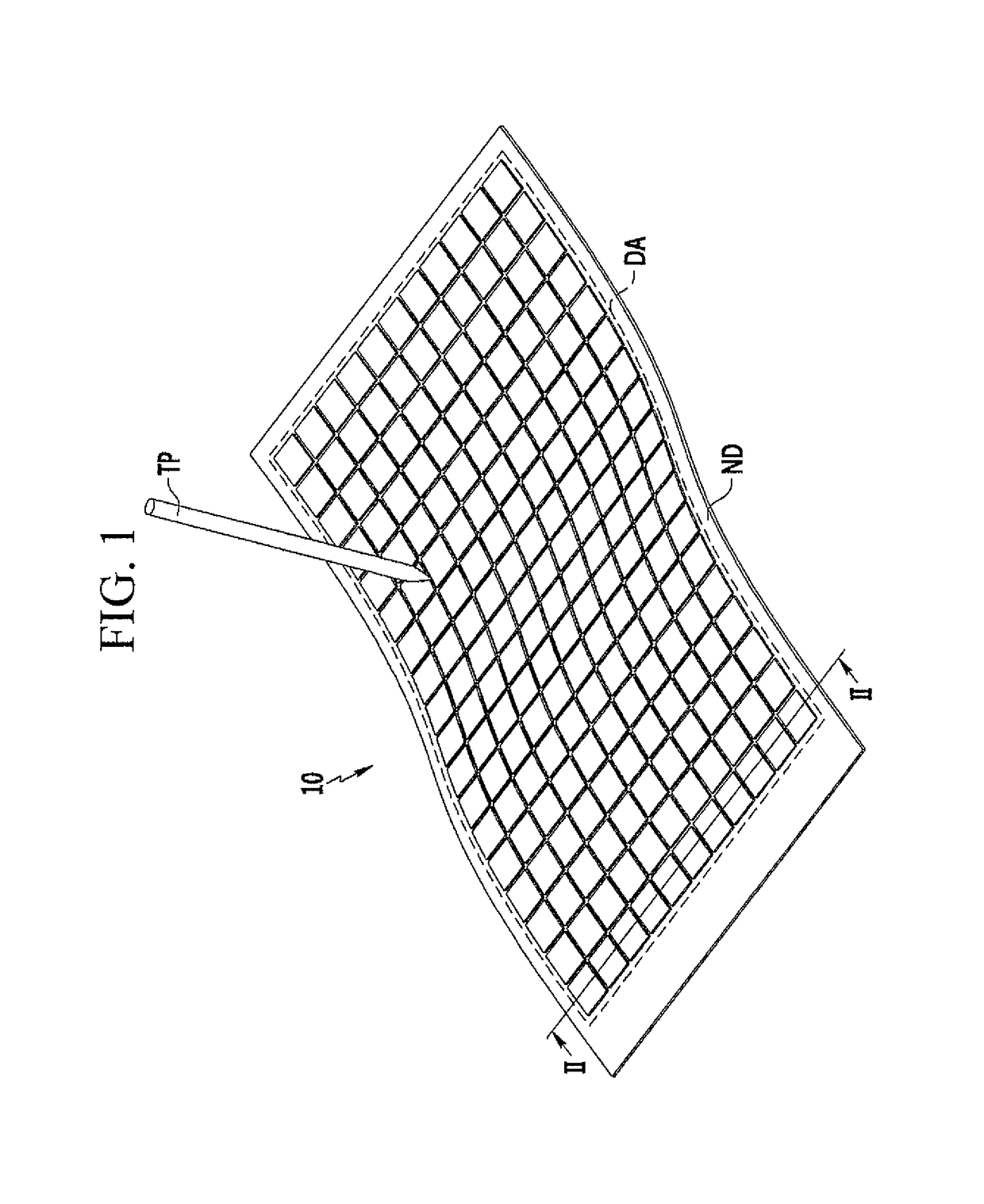

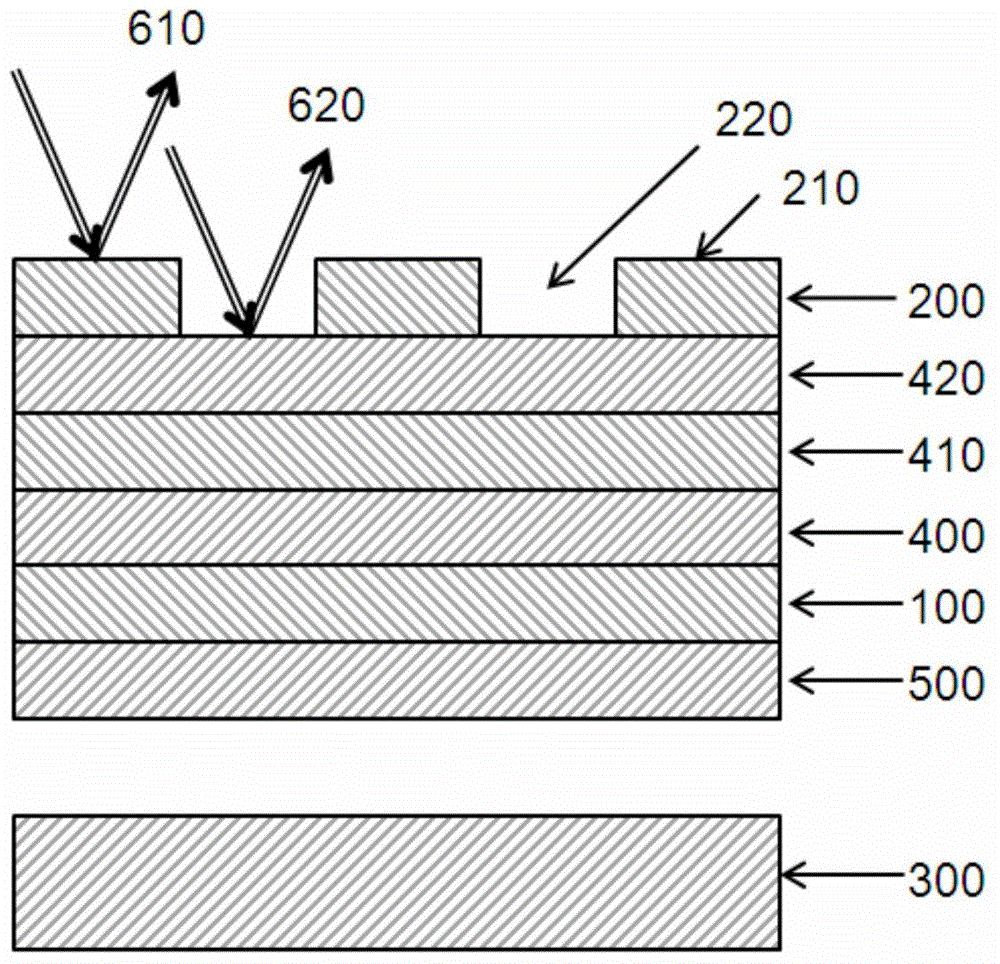

Flexible window substrate and flexible display device having the same

ActiveUS20160320803A1Implement flexibilityImplement high hardness characteristicDigital data processing detailsSynthetic resin layered productsSelf-healing materialEngineering

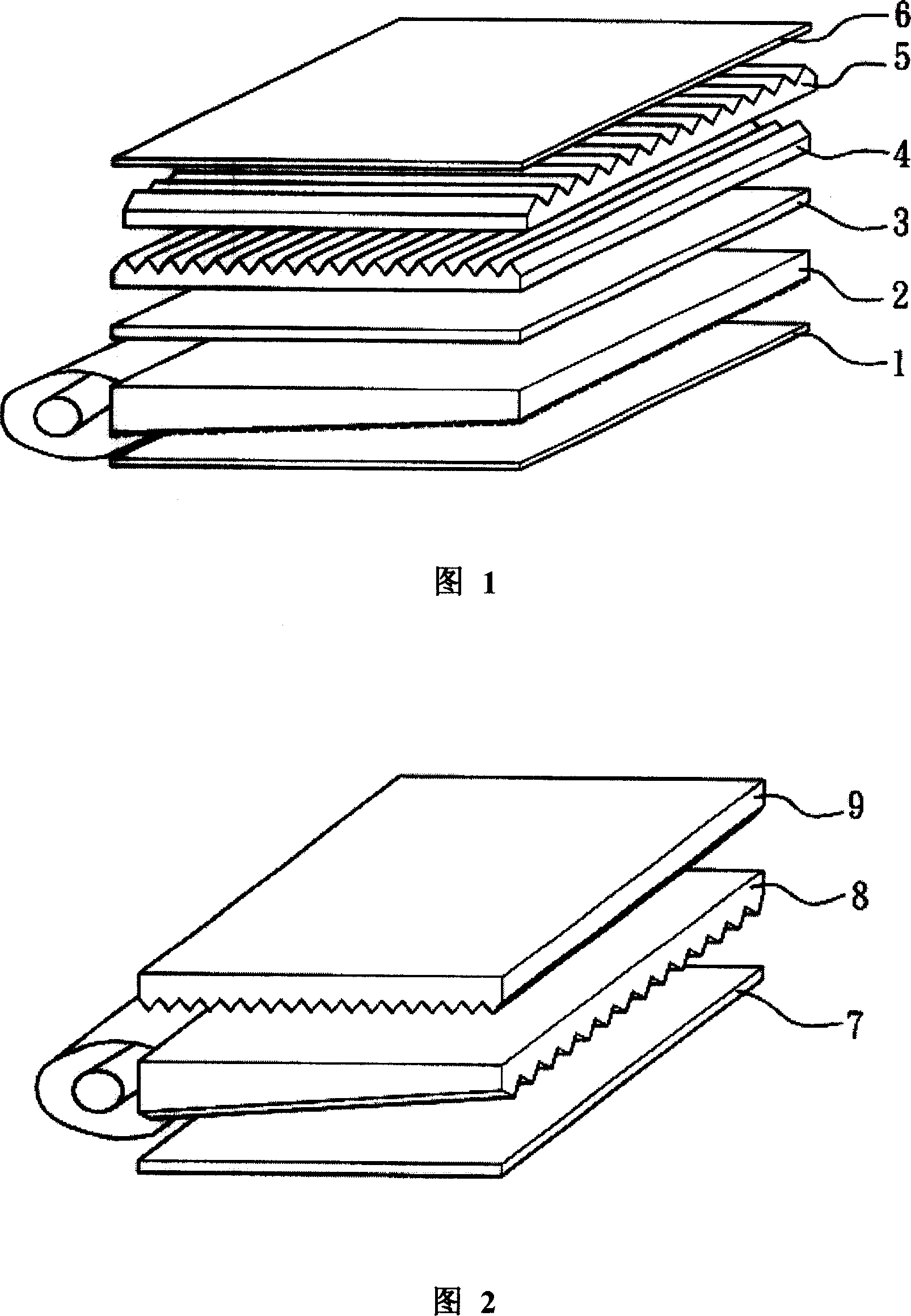

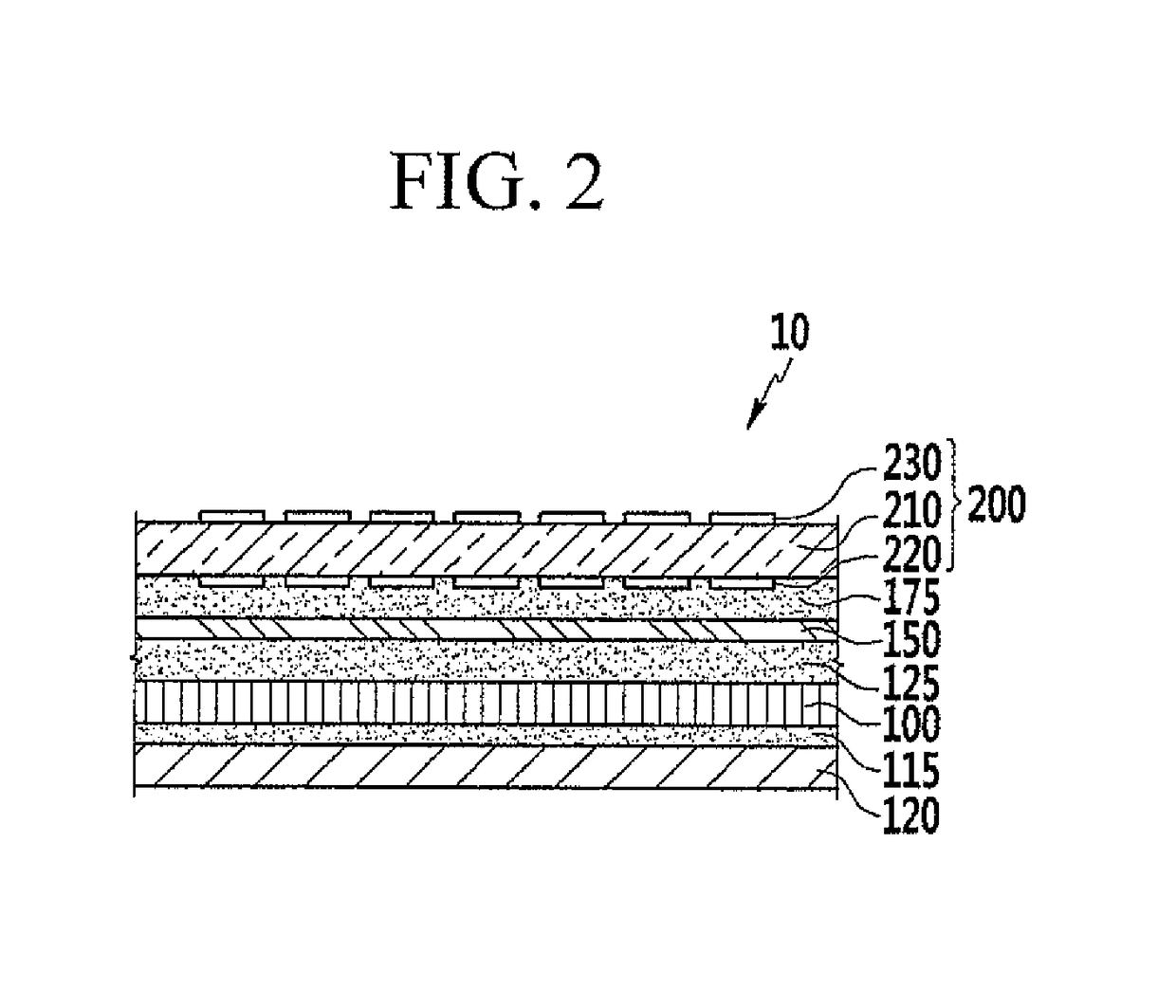

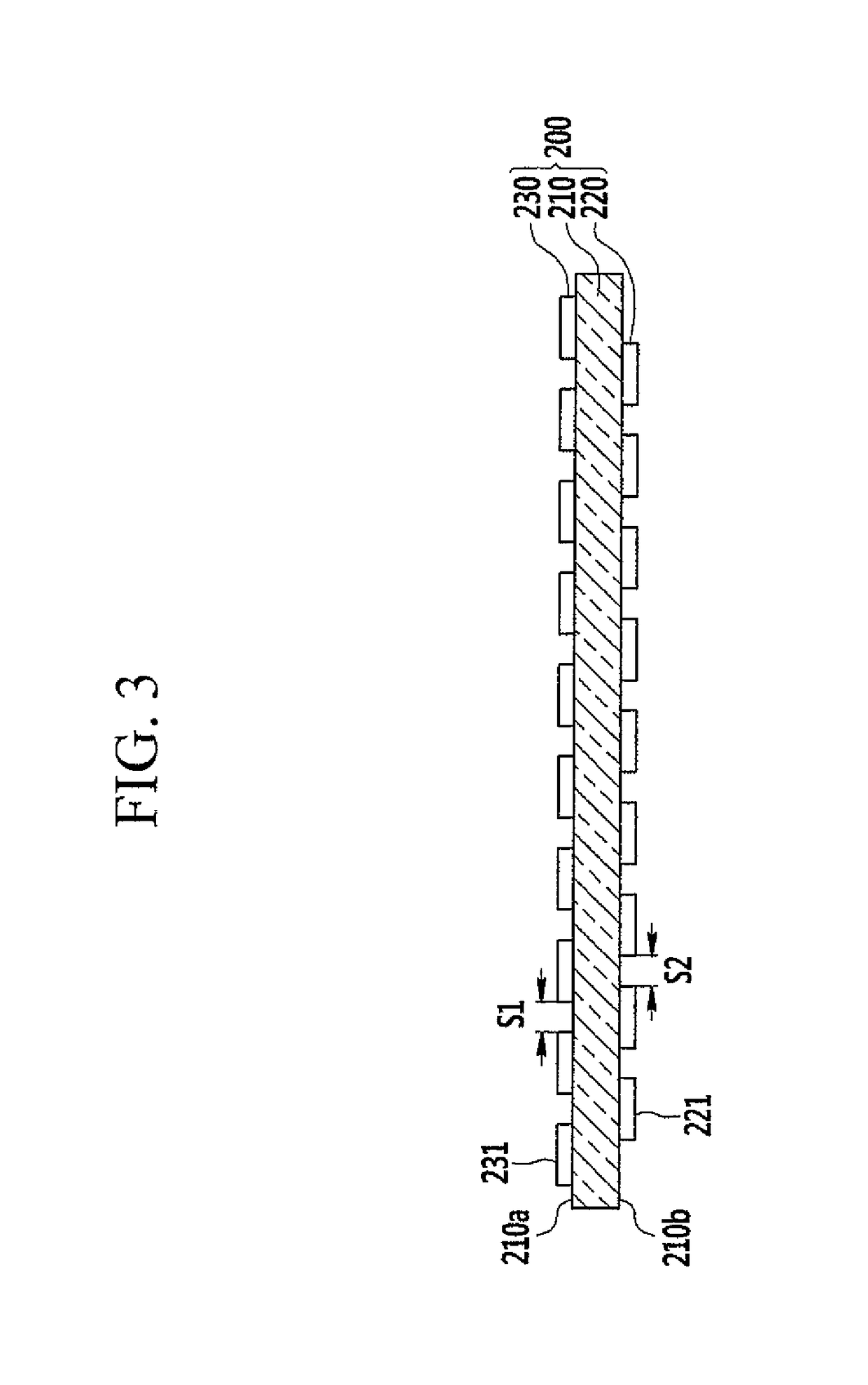

There is provided a flexible display device including a display panel for displaying an image, and a window substrate covering the touch screen panel, the widow substrate including a flexible base layer including an externally facing first surface, and a second surface opposite the first surface and facing the display panel, a hard coating layer having a hardness that is larger than that of the base layer, and including a plurality of coating tiles on the first surface of the base layer that are spaced to have a gap between adjacent ones of the coating tiles, and a self-healing coating layer including a self-healing material and covering the hard coating layer on the base layer.

Owner:SAMSUNG DISPLAY CO LTD

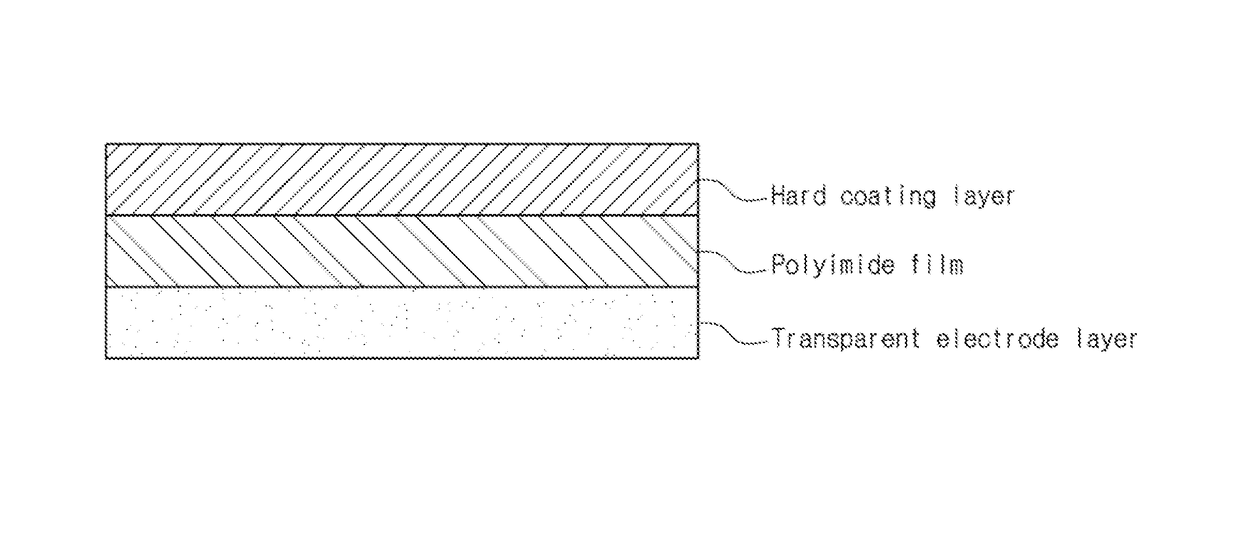

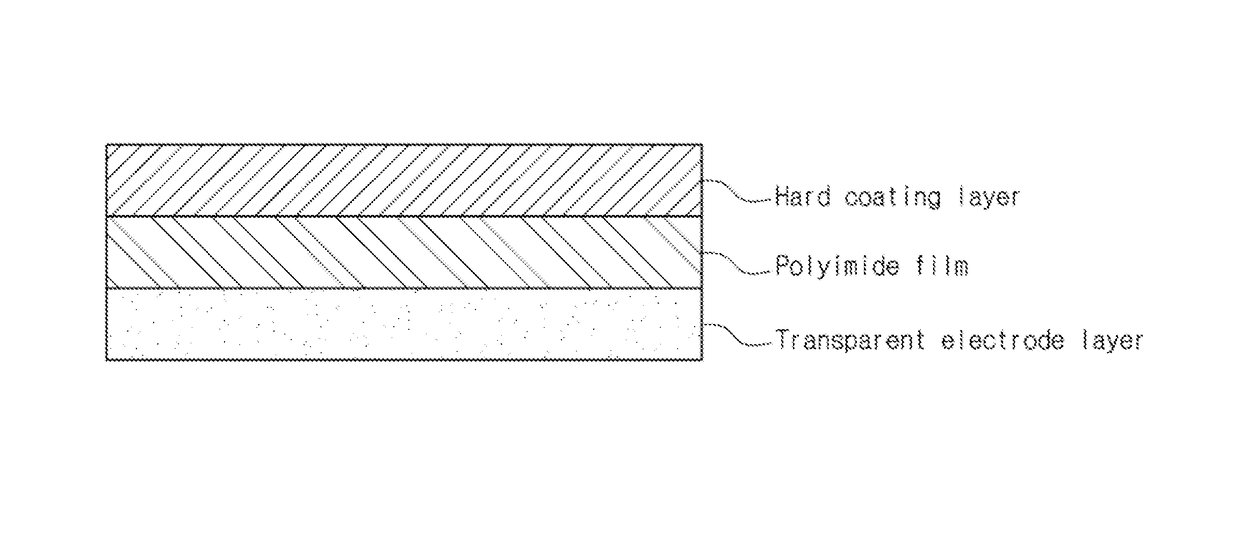

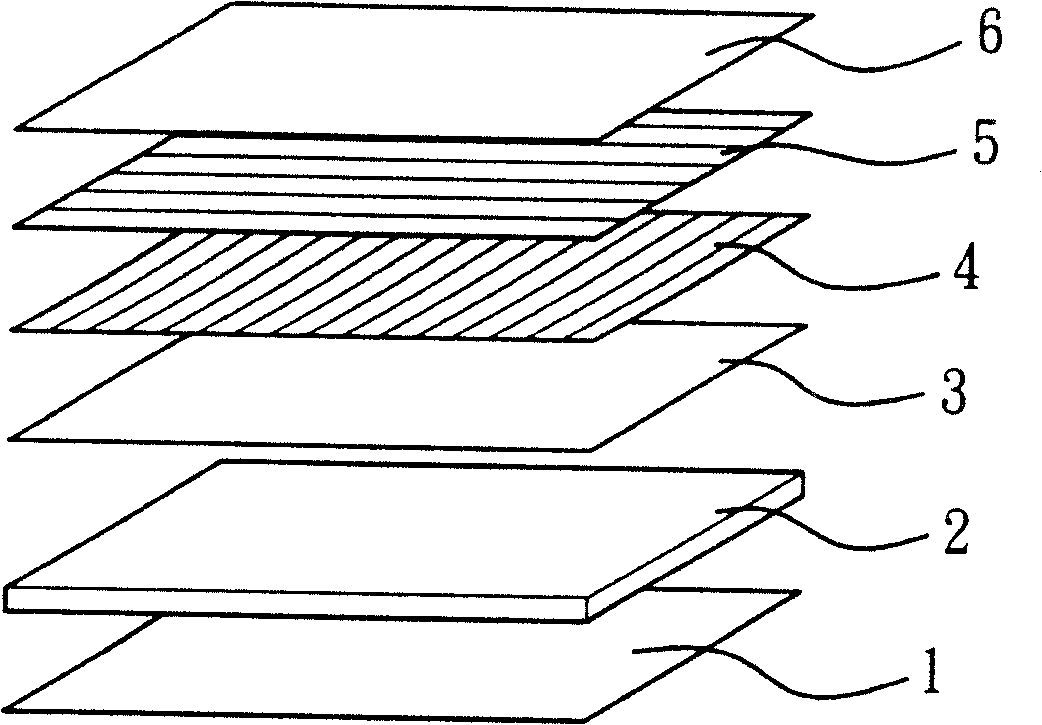

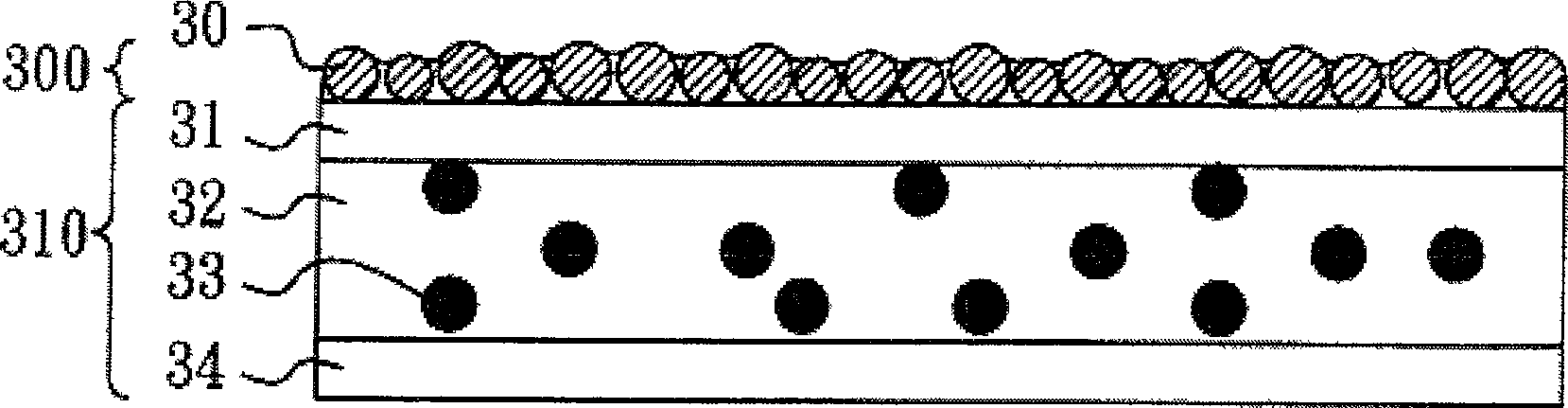

Plastic substrate

ActiveUS20140338959A1High hardness characteristicLow surface resistanceConductive layers on insulating-supportsPlastic/resin/waxes insulatorsPolyimide membraneTransmittance

The present invention provides a plastic substrate, including: a polyimide film; a hard coating layer formed on one side of the polyimide film; and a transparent electrode layer formed on the other side of the polyimide film. The plastic substrate has excellent light transmittance high hardness characteristics, superior ITO proccessability and flexibility. Further, the plastic substrate can function as both a window film and an electrode film when it is applied to a touch screen panel. Thus, the present invention provides a touch screen panel which can be slimmed by reducing the number of laminated films including the plastic substrate.

Owner:KOLON IND INC

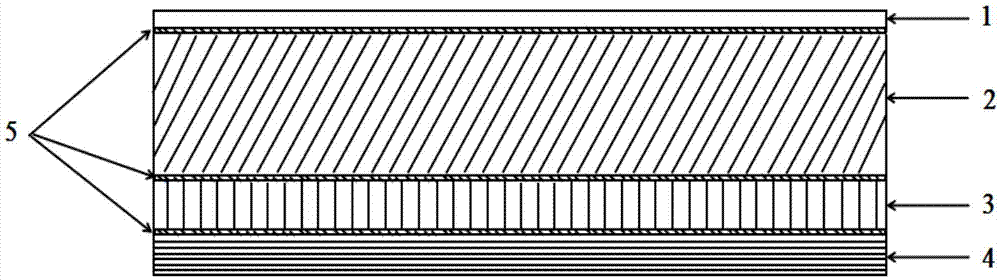

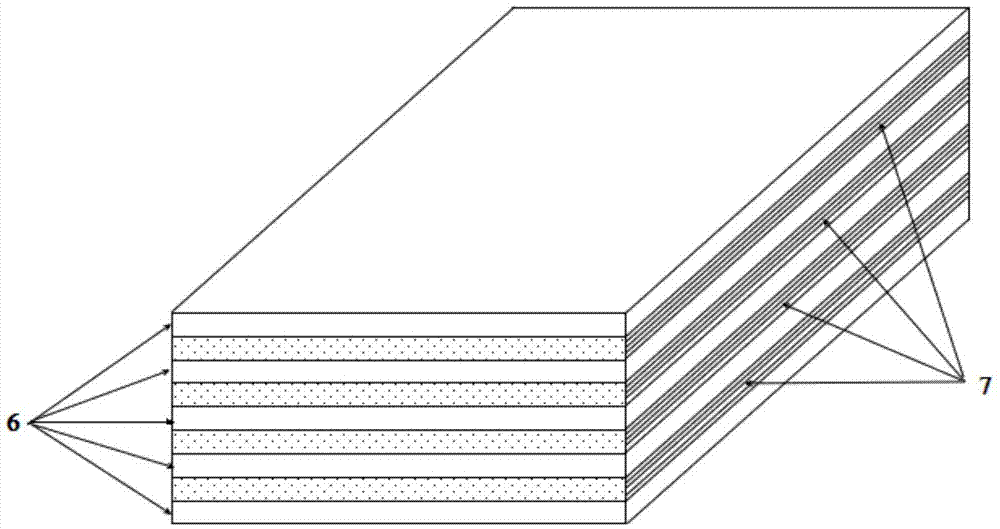

Burster block of composite structure and manufacturing method of burster block

InactiveCN105444622AImprove fracture toughnessImprove impact resistanceSynthetic resin layered productsCeramic layered productsEnergy absorptionHardness

The invention relates to a burster block of a composite structure and a manufacturing method of the burster block. The burster block comprises a protection layer, a ceramic layer, an energy absorption layer and a supporting layer, wherein the protection layer, the ceramic layer, the energy absorption layer and the supporting layer are sequentially stacked from outside to inside and bonded together through bonding agents. The surface density of the whole block is 50-80 kg / m<2>. The supporting layer is a fiber metal composite material laminated plate which is formed by alternately applying at least three metal plates and at least two layers of fiber prepreg in a combined mode. According to the burster block of the composite structure, the fiber metal composite material laminated plate serves as the supporting layer, shock resistance and multi-hit resistance of the fiber metal composite material laminated plate are far superior to those of a pure fiber reinforced resin composite material laminated plate or a metal plate, good rigid supporting can be provided for the ceramic layer, the high hardness characteristic of ceramic is given into play, bullets are broken to the greatest extent, impact energy is dispersed, and the protection capacity is greatly improved. The burster block of the composite structure can be widely applied to the field of light bulletproof armors.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +1

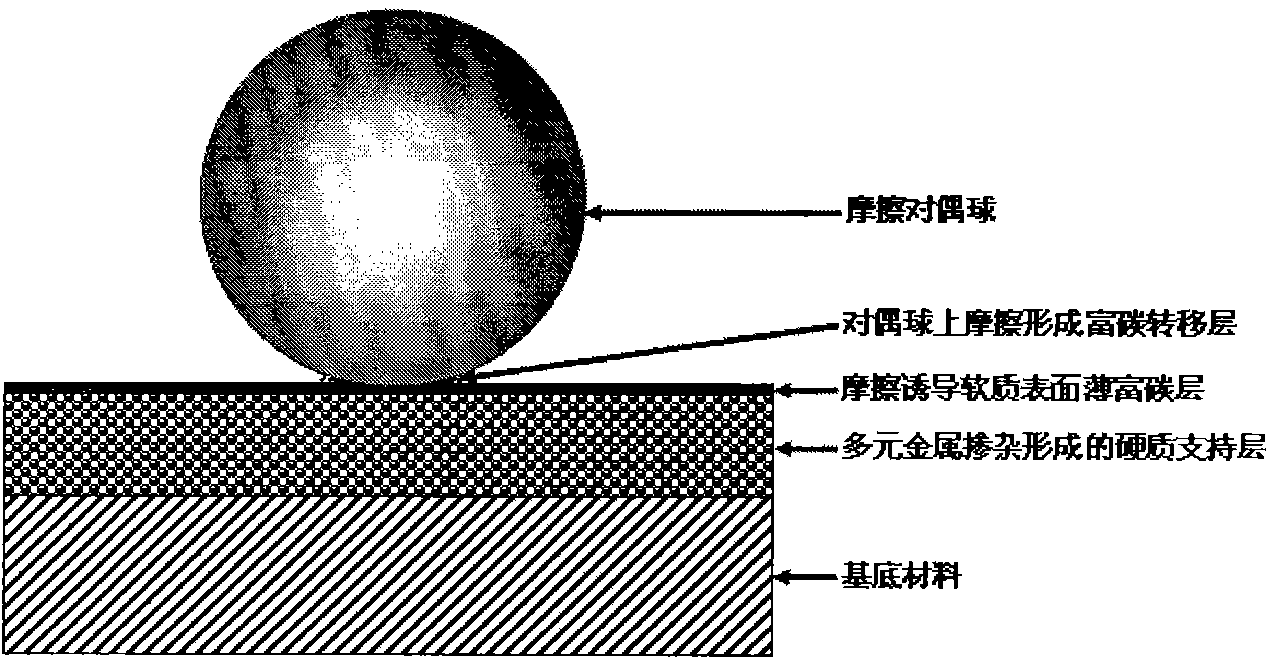

Method for preparing multi-element doped carbon-based nano composite film integrating functions of antiwear and lubrication

InactiveCN102337497AHigh hardnessReduce coefficient of frictionVacuum evaporation coatingSputtering coatingComposite filmDiamond-like carbon

The invention discloses a method for preparing a multi-element doped carbon-based nano composite film integrating functions of antiwear and lubrication. The carbon-based solid lubrication film is obtained on the surface of a metal workpiece by using a physical vapor deposition technology, the film thickness is 2.0-3.0 micrometers. Compared with a single metal doped diamond-like carbon-based composite film, the multi-element doped carbon-based nano composite film of the invention has high hardness (higher than 20GPa), low friction coefficient (the friction coefficient is 0.05-0.08), ultra low internal stress (lower than 1GPa) and excellent wear resistance (the wear resistance can be raised by 4-7 times). The multi-element doped carbon-based nano composite film can be used as a protective film integrating functions of antiwear and self lubrication, and is widely used in the precise machinery industry (bearings, gears, blades), engine industry (piston rings, piston pins, injection nozzles and the like), precise dies industry and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Plastic substrate, method for producing the same and touch screen panel containing the same

ActiveUS9706649B2High hardness propertiesReduce surface resistanceConductive layers on insulating-supportsPlastic/resin/waxes insulatorsTransmittanceHardness

The present invention provides a plastic substrate, including: a polyimide film; a hard coating layer formed on one side of the polyimide film; and a transparent electrode layer formed on the other side of the polyimide film. The plastic substrate has excellent light transmittance high hardness characteristics, superior ITO processability and flexibility. Further, the plastic substrate can function as both a window film and an electrode film when it is applied to a touch screen panel. Thus, the present invention provides a touch screen panel which can be slimmed by reducing the number of laminated films including the plastic substrate.

Owner:KOLON IND INC

Antiscraping optical film and use thereof

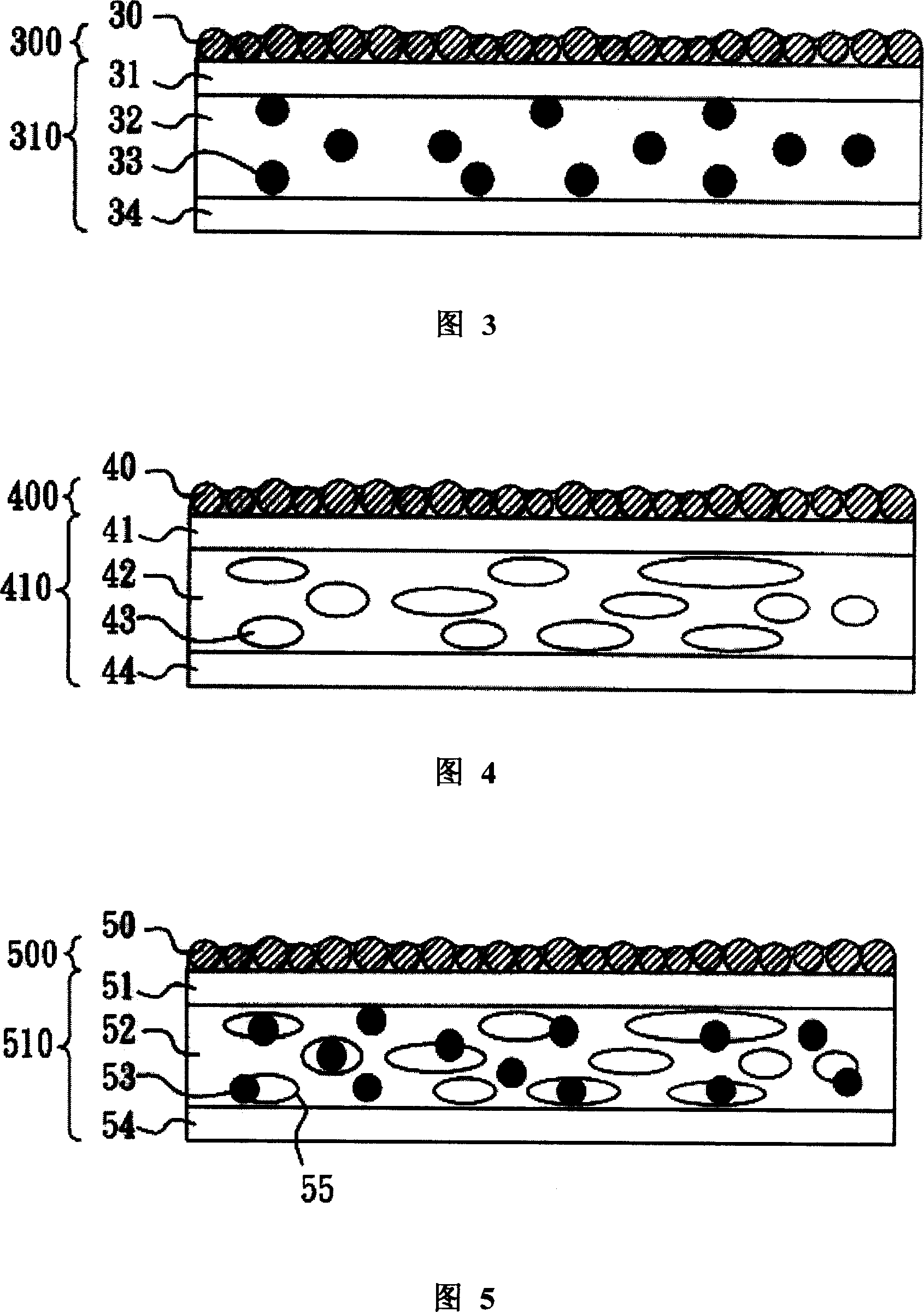

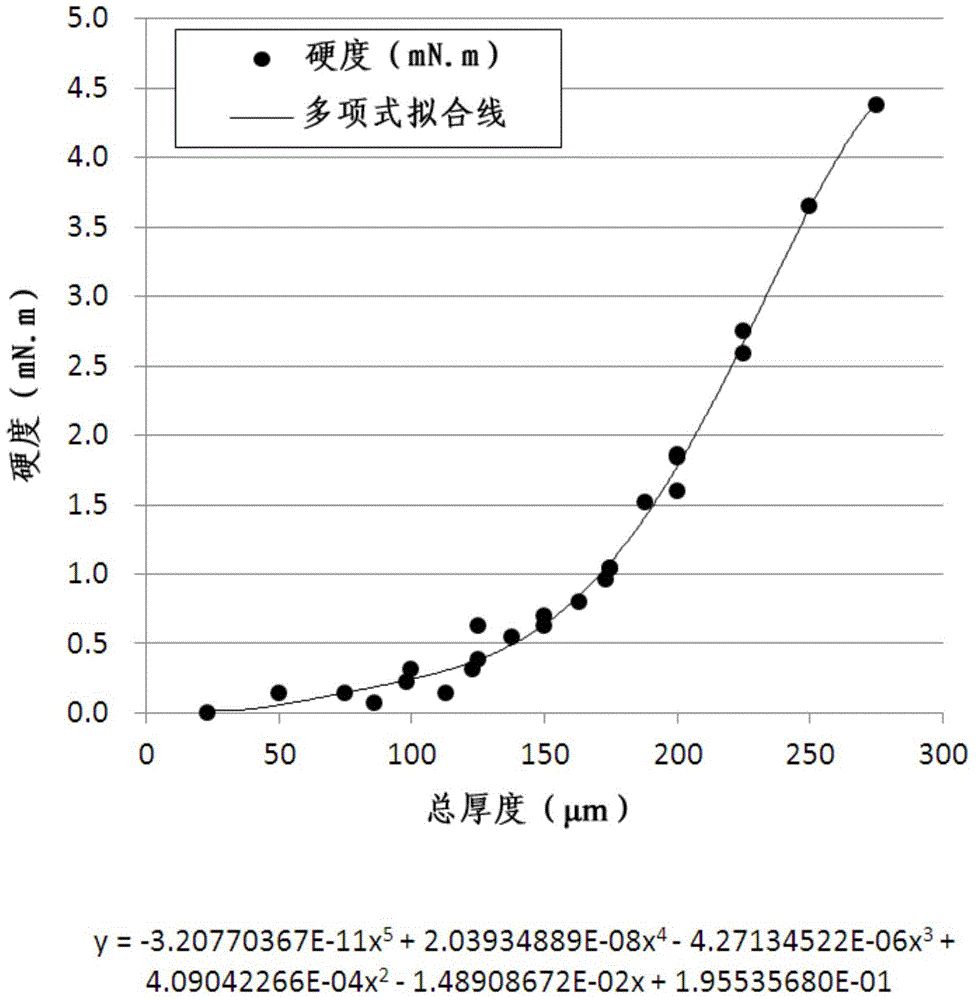

InactiveCN101021644AImprove antistatic performanceExcellent hardness propertiesNon-linear opticsOptical elementsAntistatic agentLiquid-crystal display

The invention provides an anti-scratching optical film and its use. And its characters: at least a surface of its substrate is coated with antistatic anti-scratching layer whose surface resistivity is 108-1012 Ohm / sq and which has the hardness of pencil of 3H or above, according to the measurement by JIS K5400 standard method. And it has low volumetric shrinkage, unable to warp but having good antistatic performance and high hardness, applied to advertising lamp boxes or plane displays and other light source devices, especially applied to an LCD provided with ''V-channel'' light guide plate as anti-scratching reflective film at the bottom of the light guide plate.

Owner:长兴光学材料(苏州)有限公司

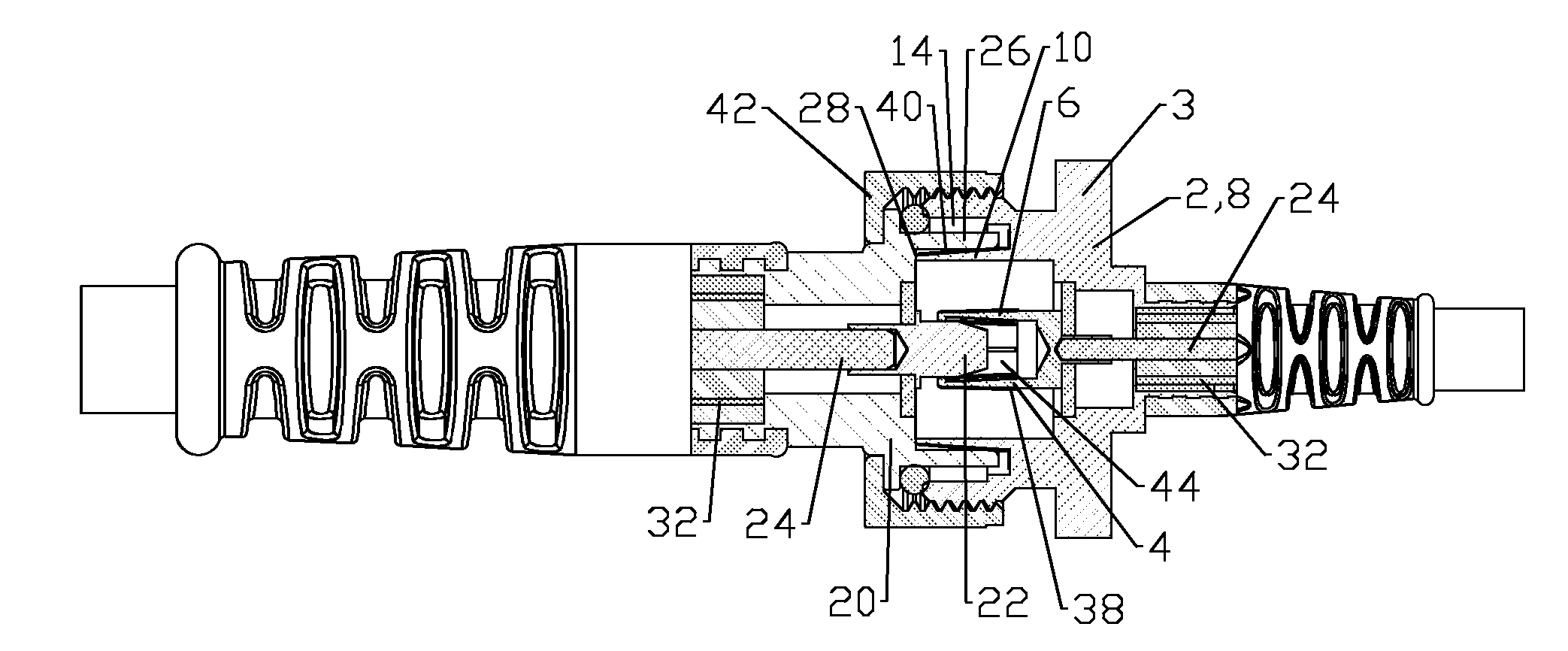

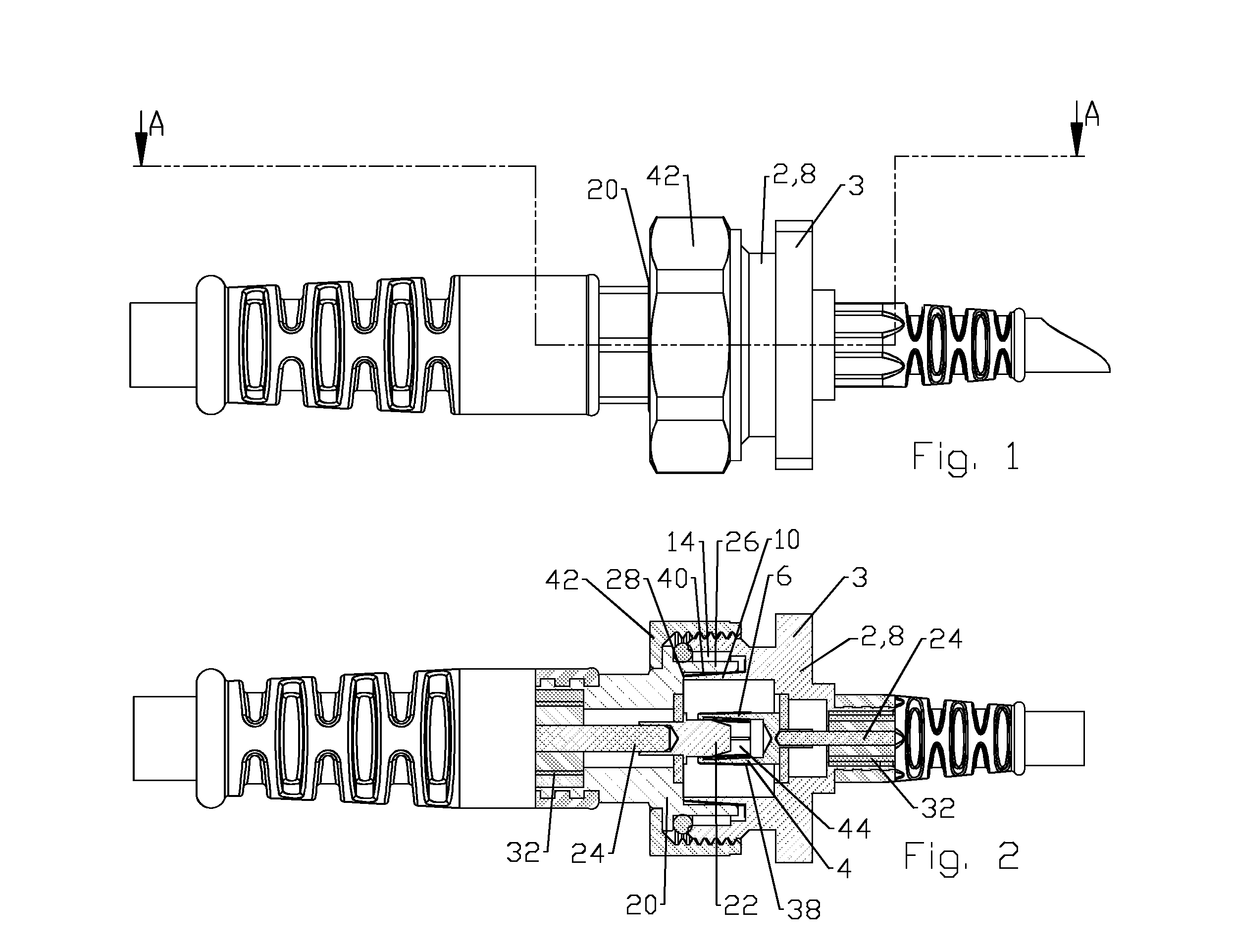

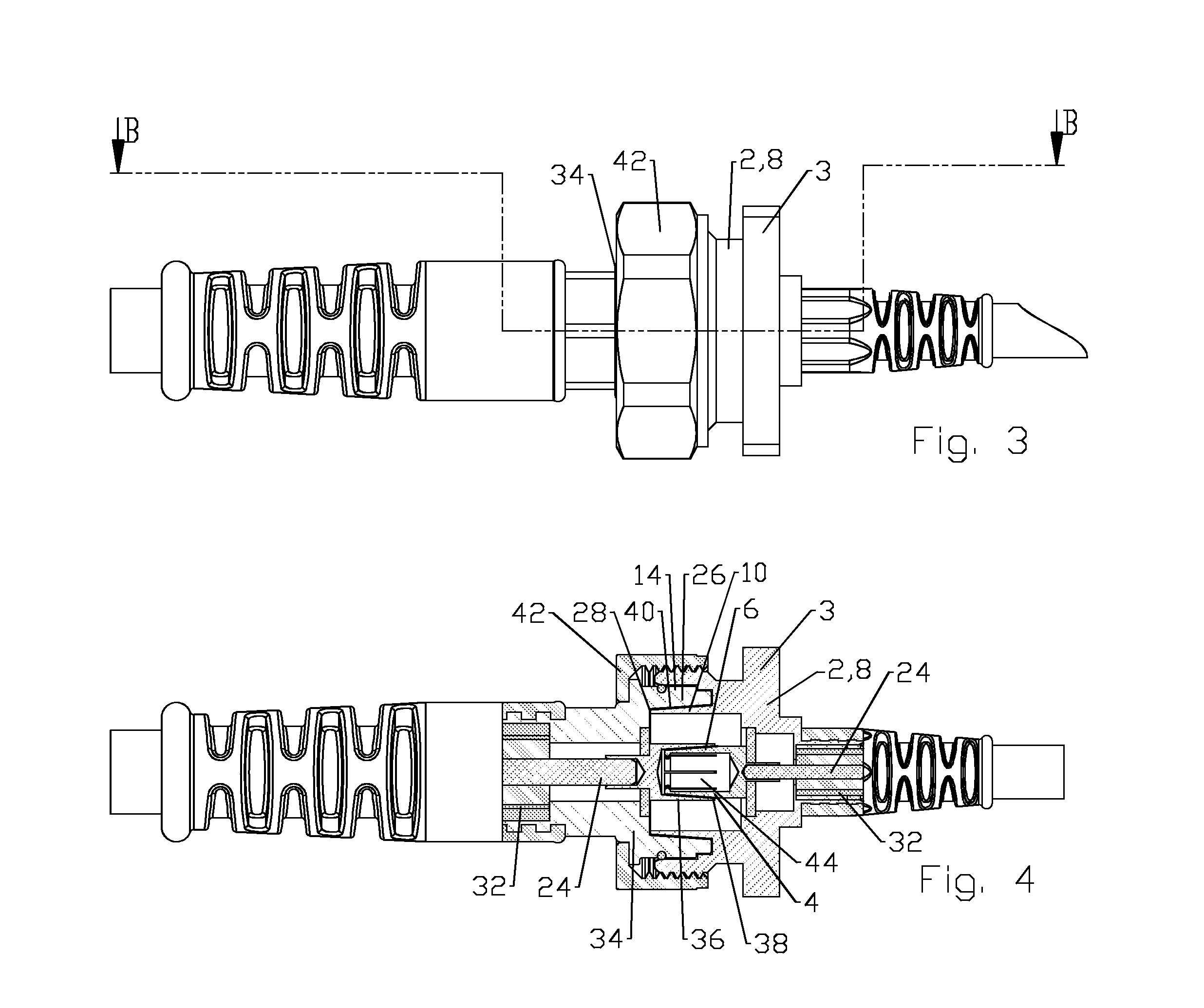

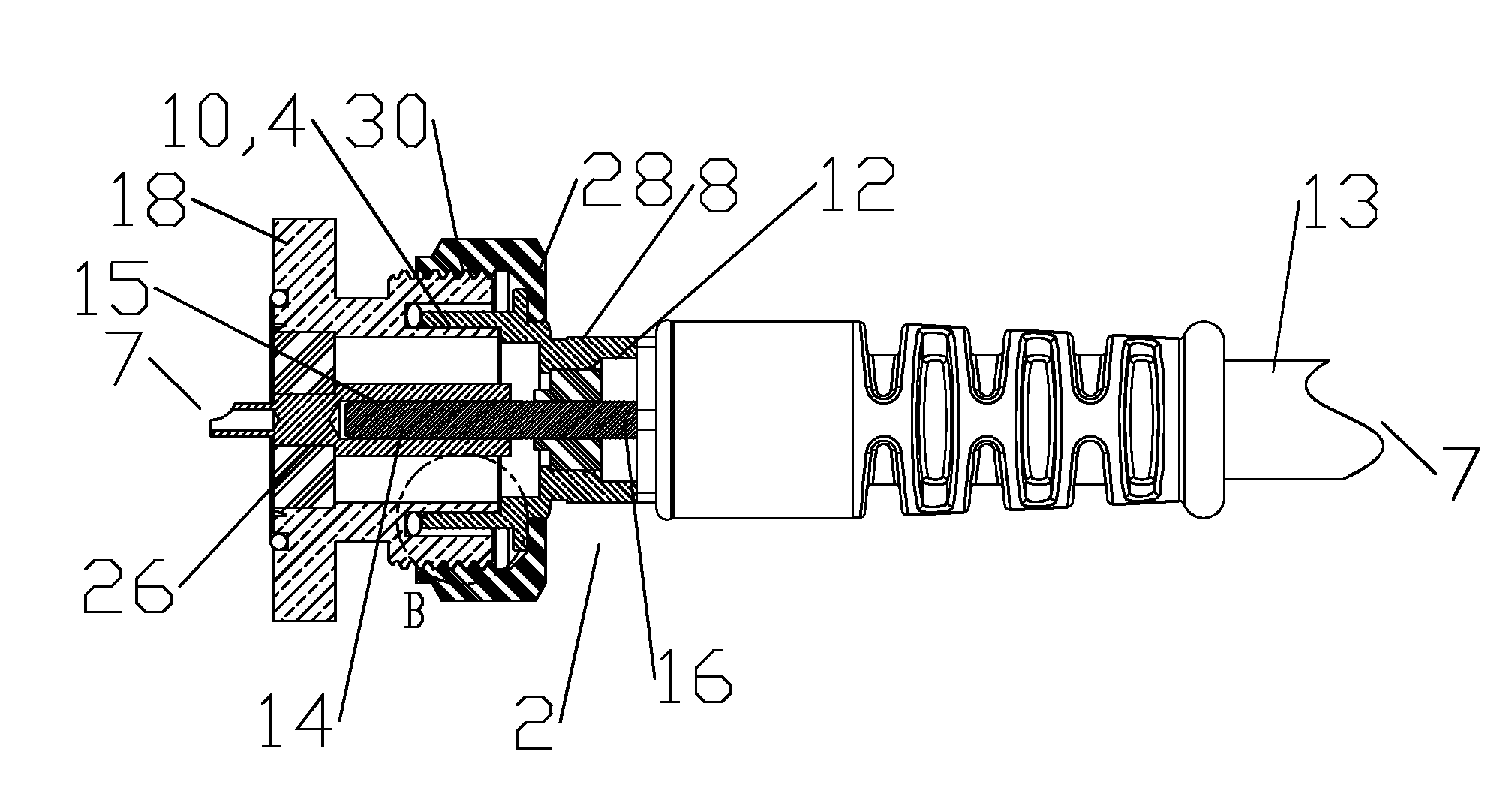

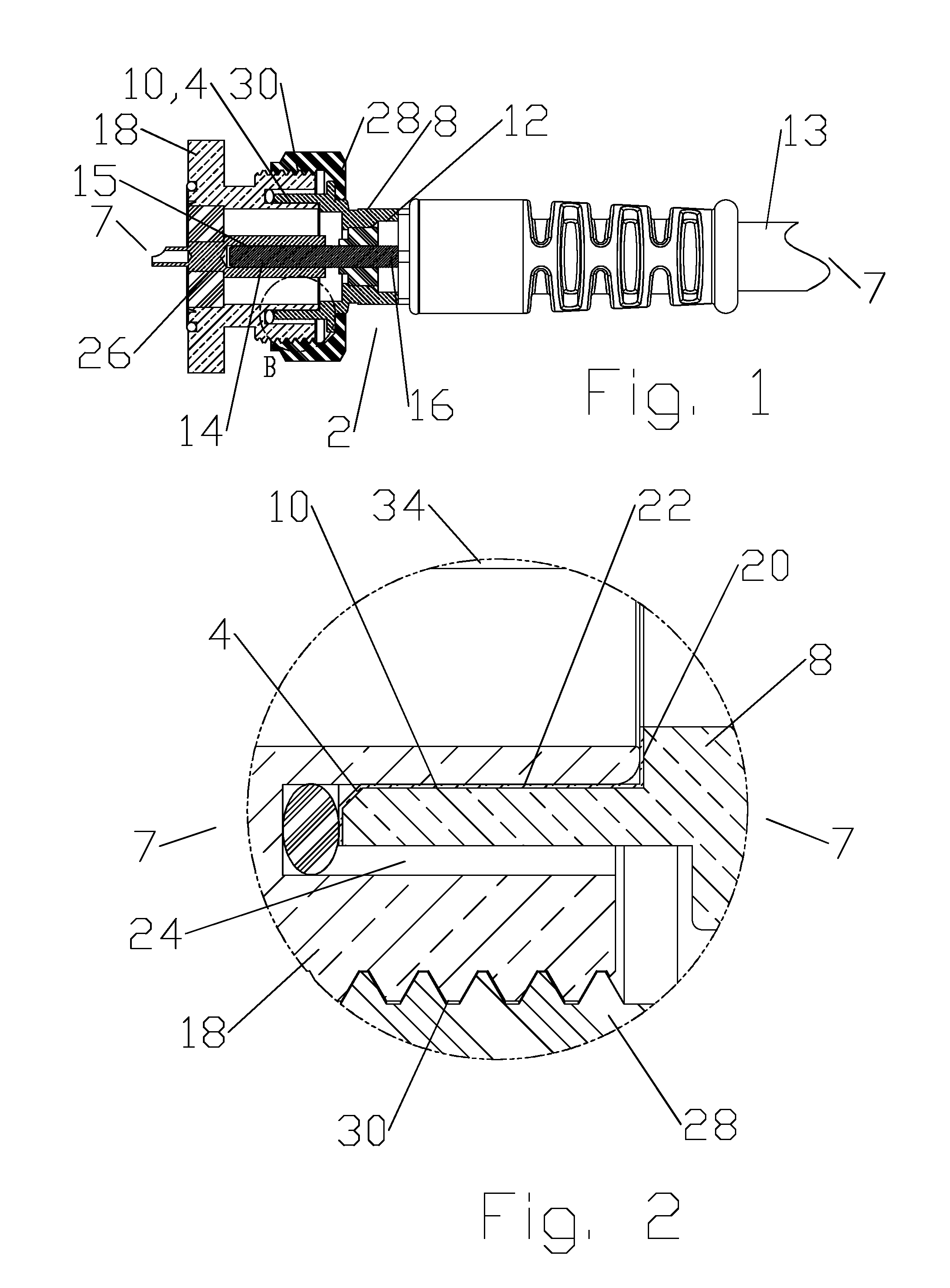

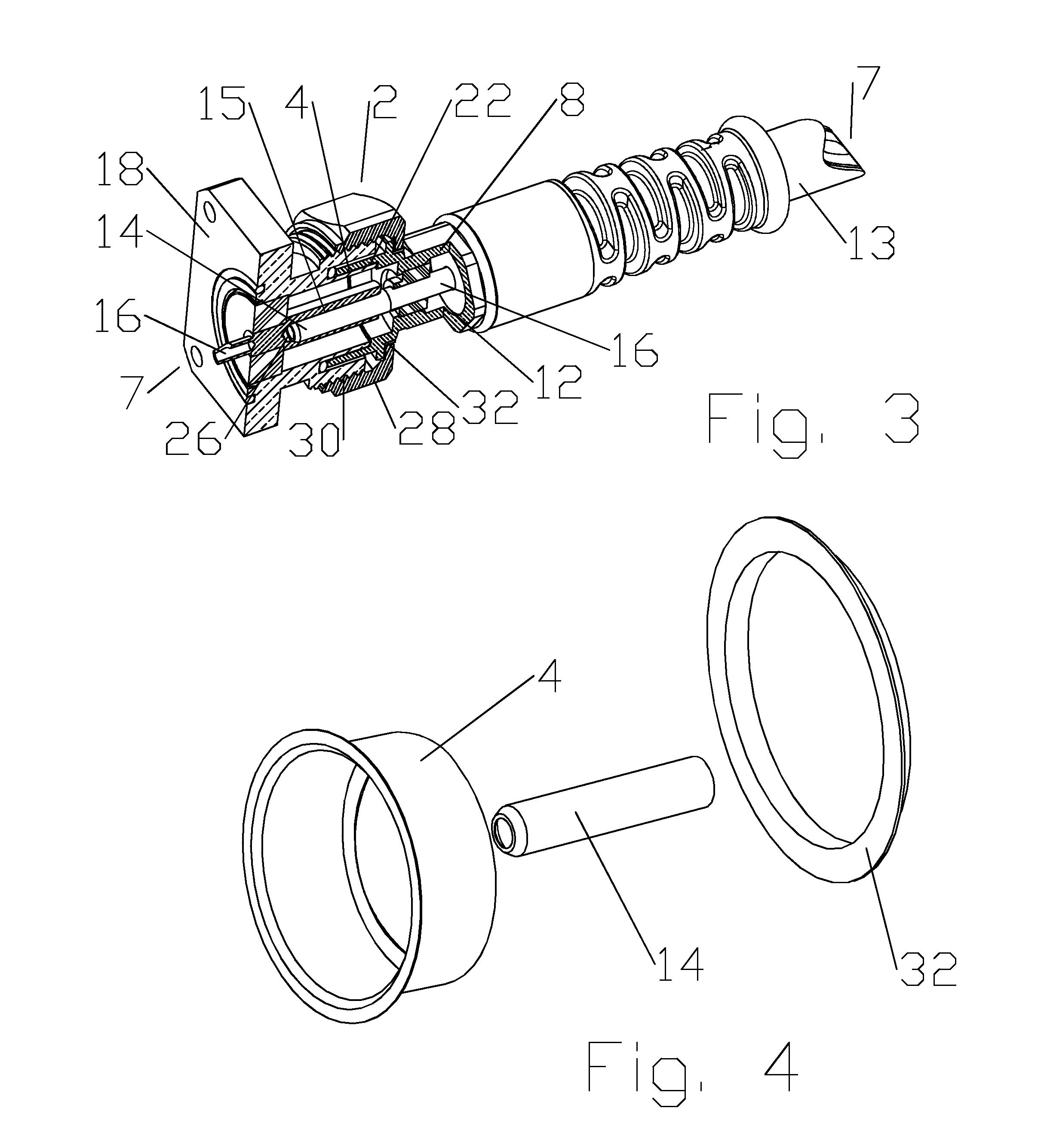

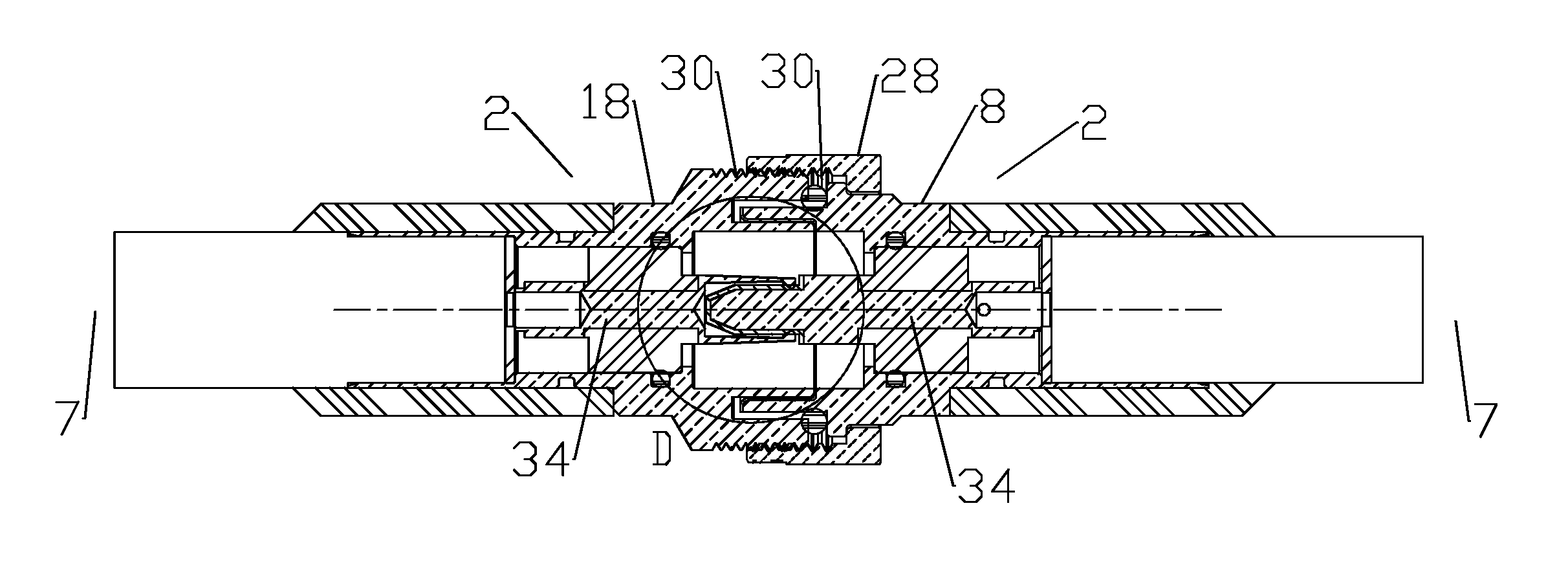

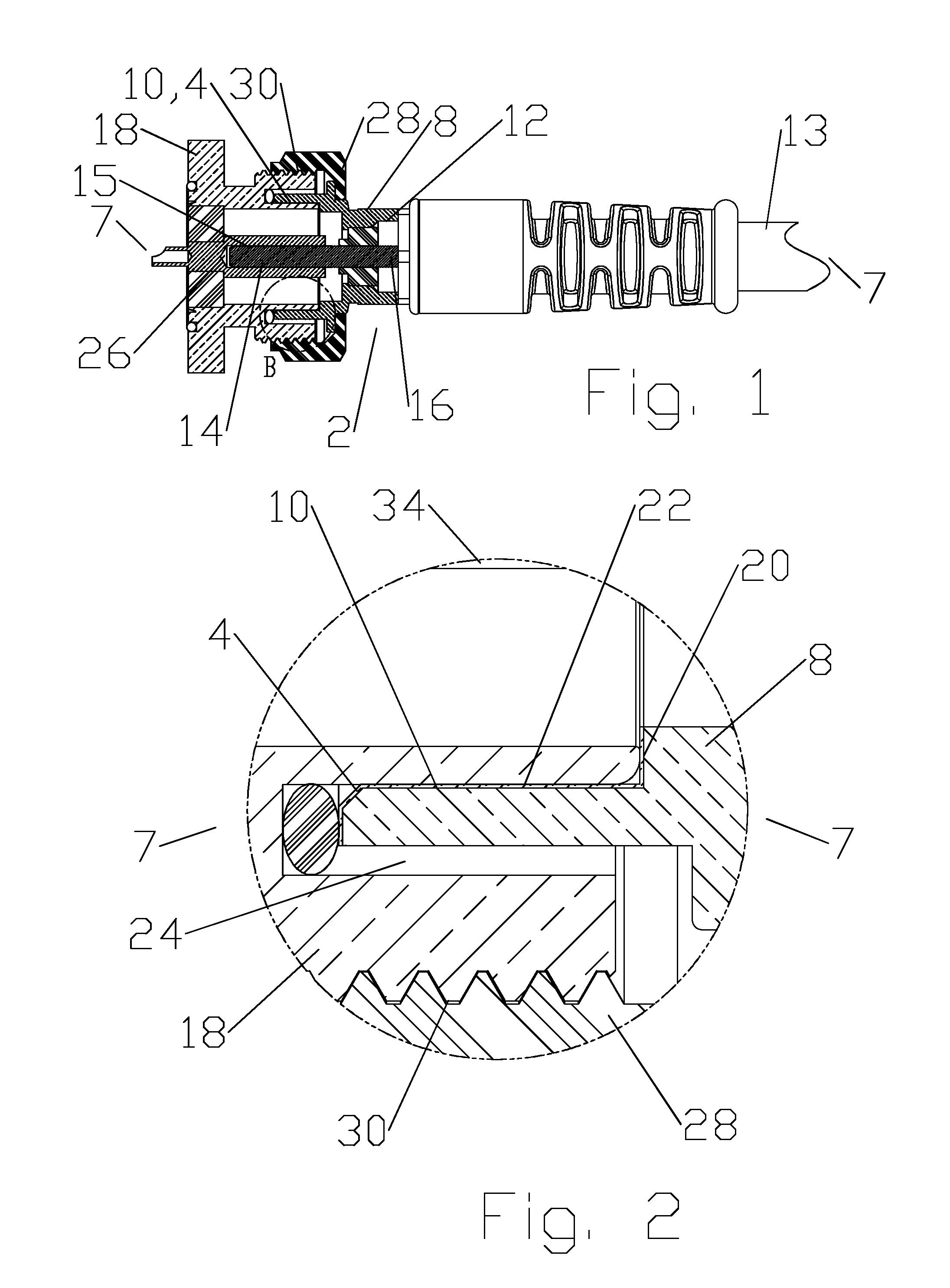

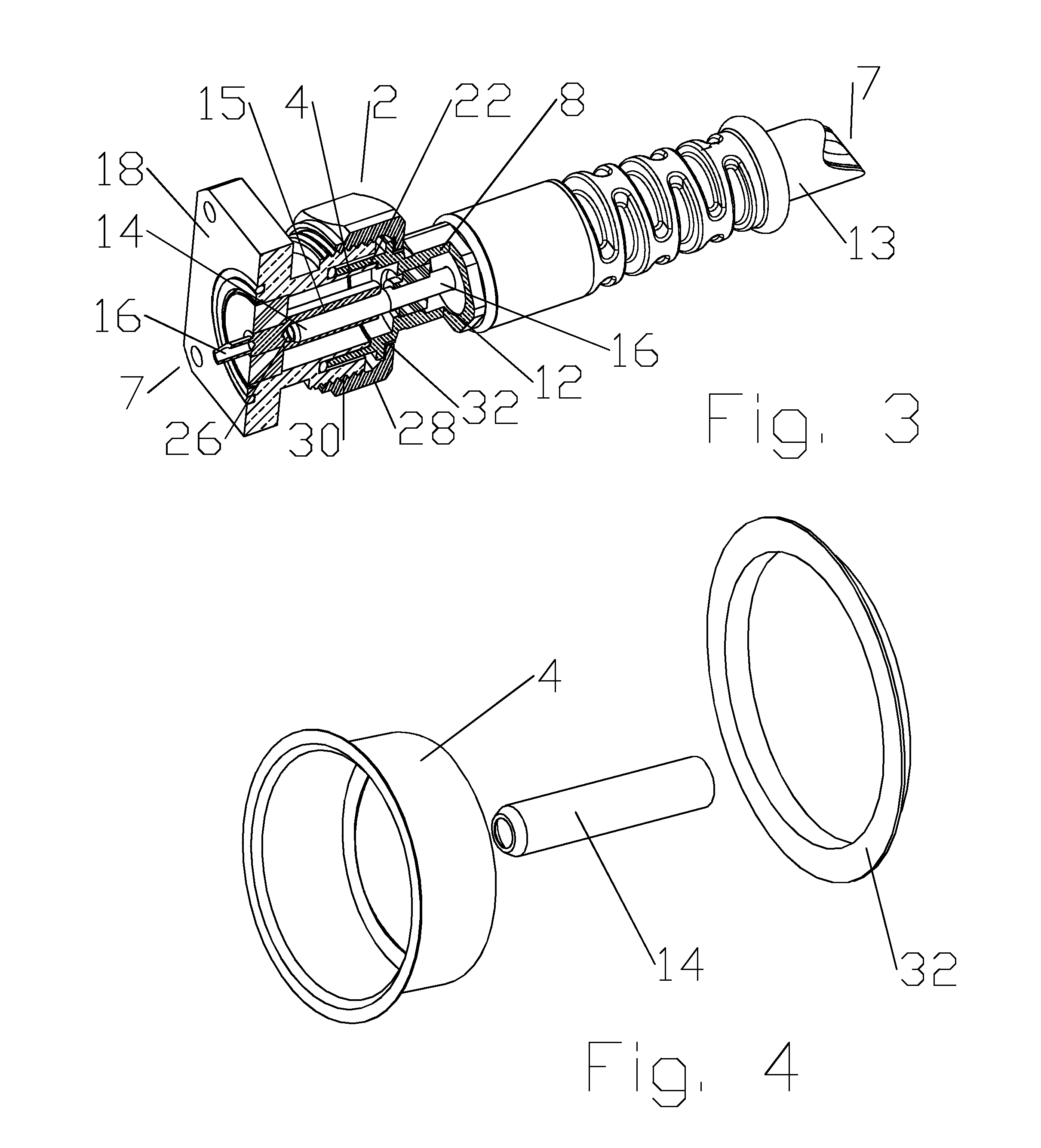

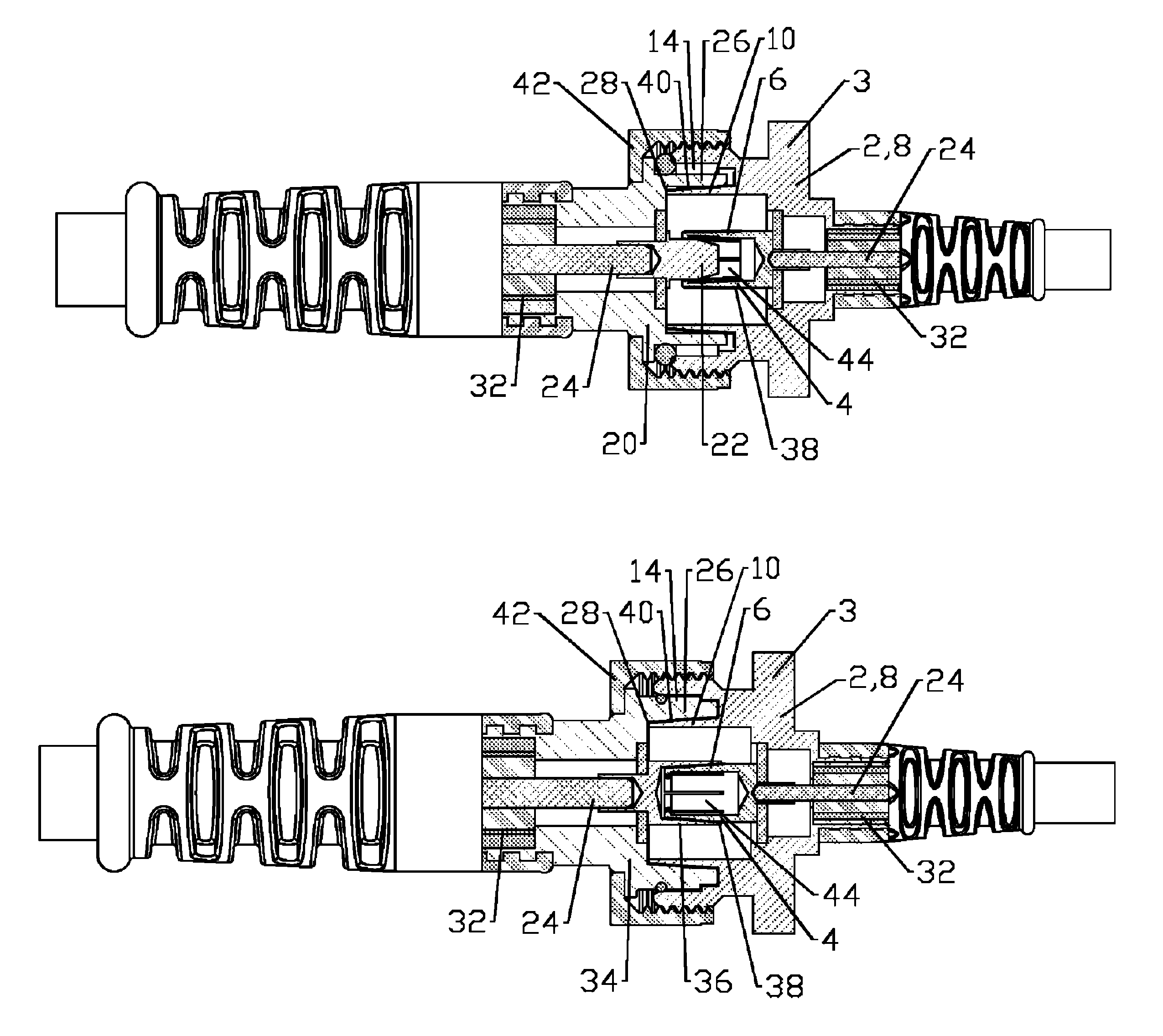

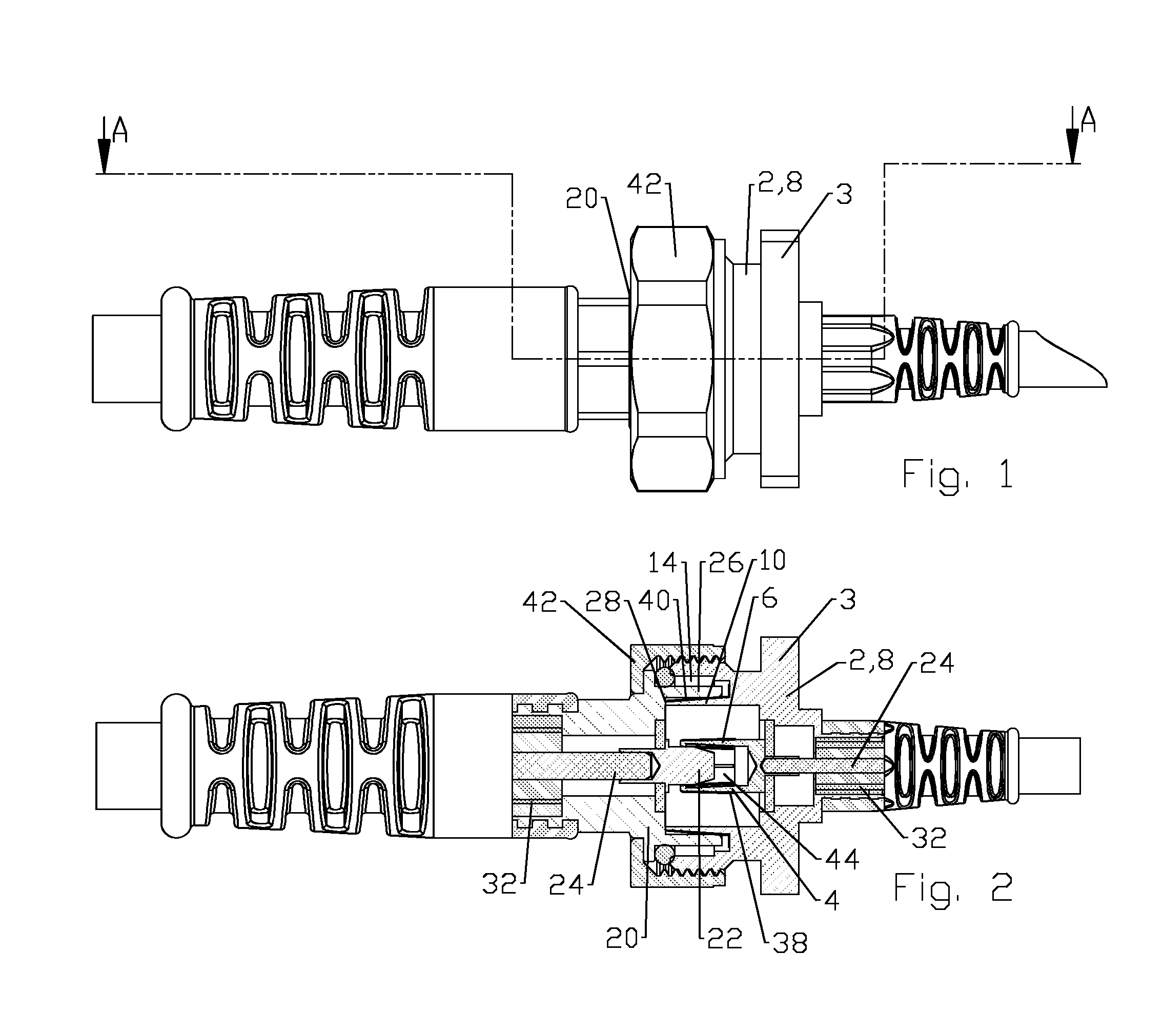

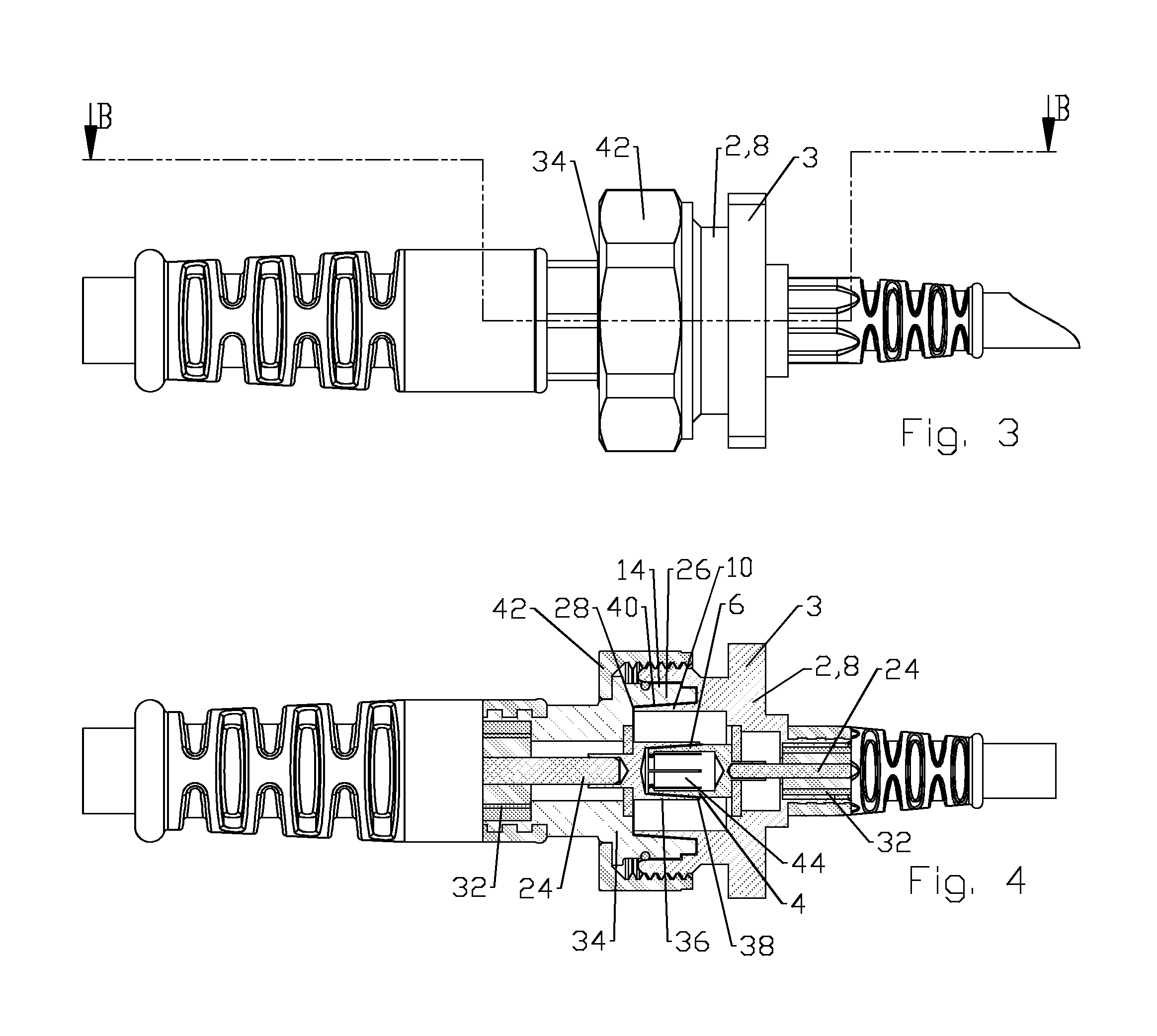

Dual connector interface for capacitive or conductive coupling

InactiveUS20140134863A1Suitable compression and thermal resistance characteristicMeet cutting requirementsElectrically conductive connectionsTwo-part coupling devicesDielectricCapacitance

A connection interface with a female portion for interconnection with a conductive male portion or a capacitive coupling male portion interface provides conductive coupling when interconnected with the conductive male portion and capacitive coupling when coupled with the capacitive coupling male portion. The female portion may include a spring basket dimensioned to receive a pin of the conductive male portion and to seat within a socket of the conductive male portion, separated by an inner conductor dielectric spacer.

Owner:COMMSCOPE TECH LLC

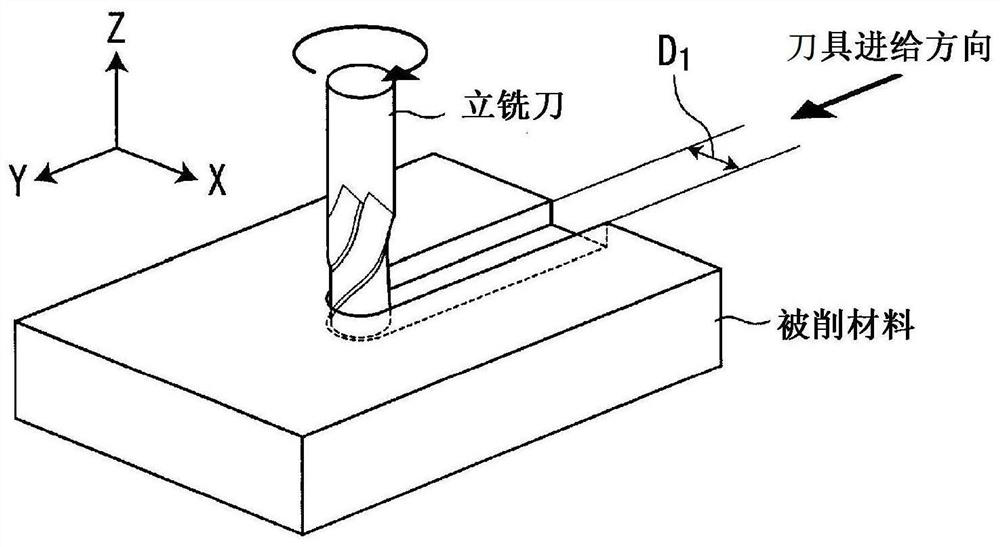

Cutting tool

PendingUS20100083583A1High hardness propertiesAvoid plastic deformationMaterial nanotechnologyPigmenting treatmentCrystalliteUltra high pressure

Owner:SUMITOMO ELECTRIC IND LTD +2

Coaxial connector with capacitively coupled connector interface and method of manufacture

ActiveUS20140134876A1Suitable compression and thermal resistance characteristicMeet cutting requirementsElectrically conductive connectionsTwo-part coupling devicesCapacitanceEngineering

A connector with a capacitively coupled connector interface for interconnection with a mating portion with a sidewall. A connector body has an outer conductor coupling surface at an interface end, covered by an outer conductor dielectric spacer. The outer conductor coupling surface is dimensioned to seat, spaced apart from the sidewall by the outer conductor dielectric spacer, when the connector body and the mating portion are in an interlocked position. A releasable retainer may be provided, the releasable retainer dimensioned to secure the connector body and the mating portion in the interlocked position.

Owner:COMMSCOPE TECH LLC

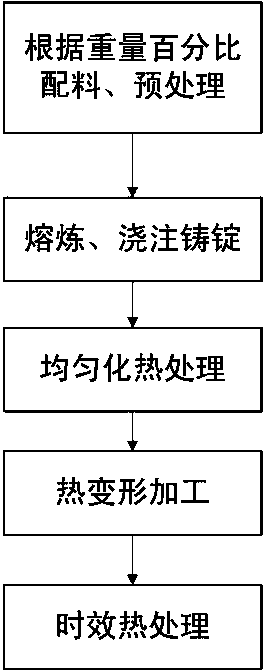

High-strength and high-hardness magnesium alloy in controllable reaction with water, and manufacturing method of component thereof

The invention belongs to the technical field of metal materials, and discloses a high-strength and high-hardness magnesium alloy in controllable reaction with water, and a manufacturing method of a component thereof. The magnesium alloy comprises the ingredients in percentage by weight: 9.0 to 15.0 percent of Gd, 3.0 to 5.0 percent of Y, 0.4 to 1.4 percent of Cu, 0.4 to 1.2 percent of Zn, 0.05 to 1.8 percent of the total content of mixed reaction accelerating elements (MRAE) such as Si, Fe, Ni, Ga and In, the balance Mg, and less than 0.01 percent of impurity elements such as Be, Zr and Ca in total. Compared with the prior art, the component manufactured by the magnesium alloy provided by the invention has high strength and high hardness, can be in controllable reaction with the water at room temperature or during heating at the same time, and is suitable to be applied in the industrial field with the requirement on integration of rigorous structure functions such as high strength, high hardness, environmental protection and degradation.

Owner:肖旅

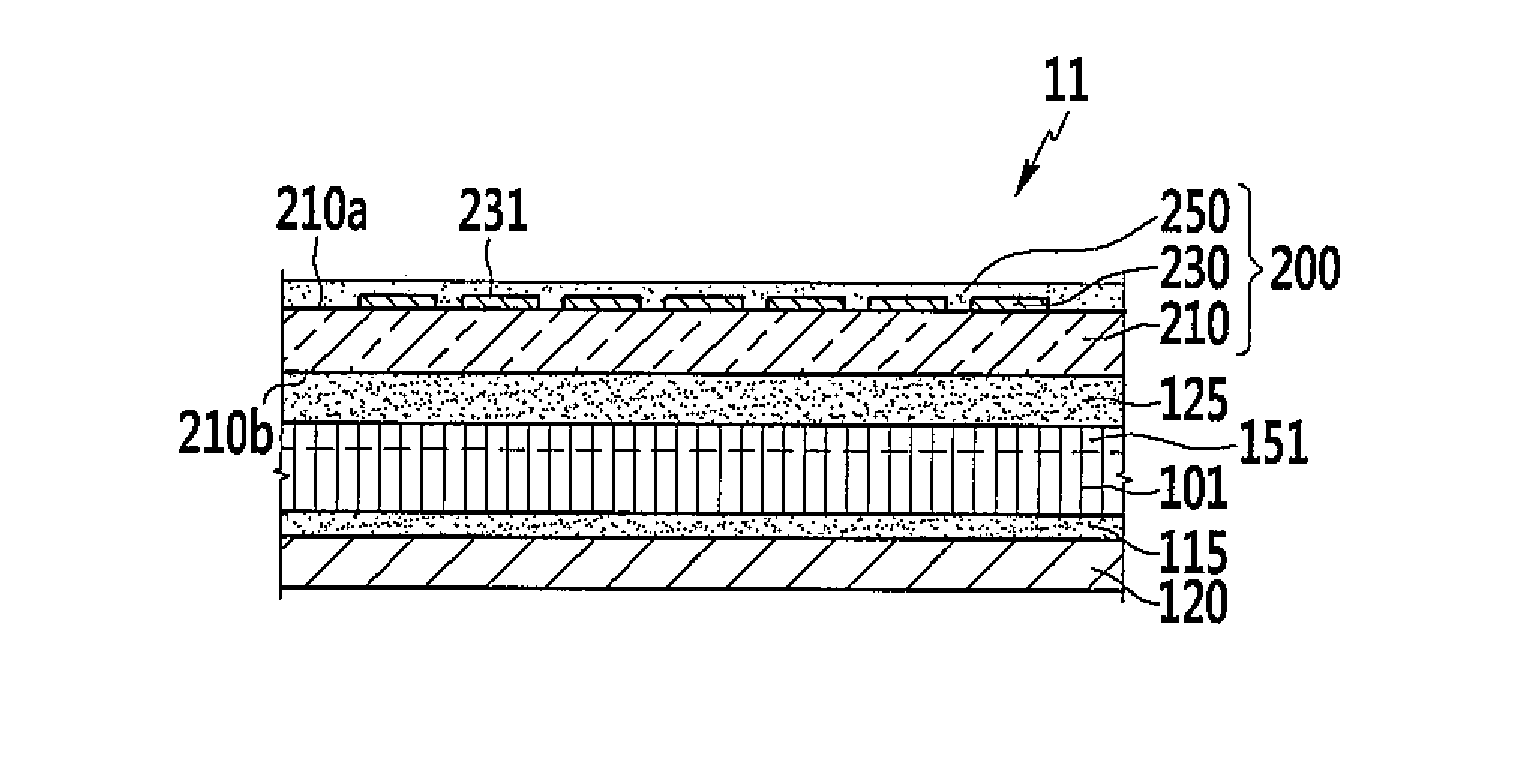

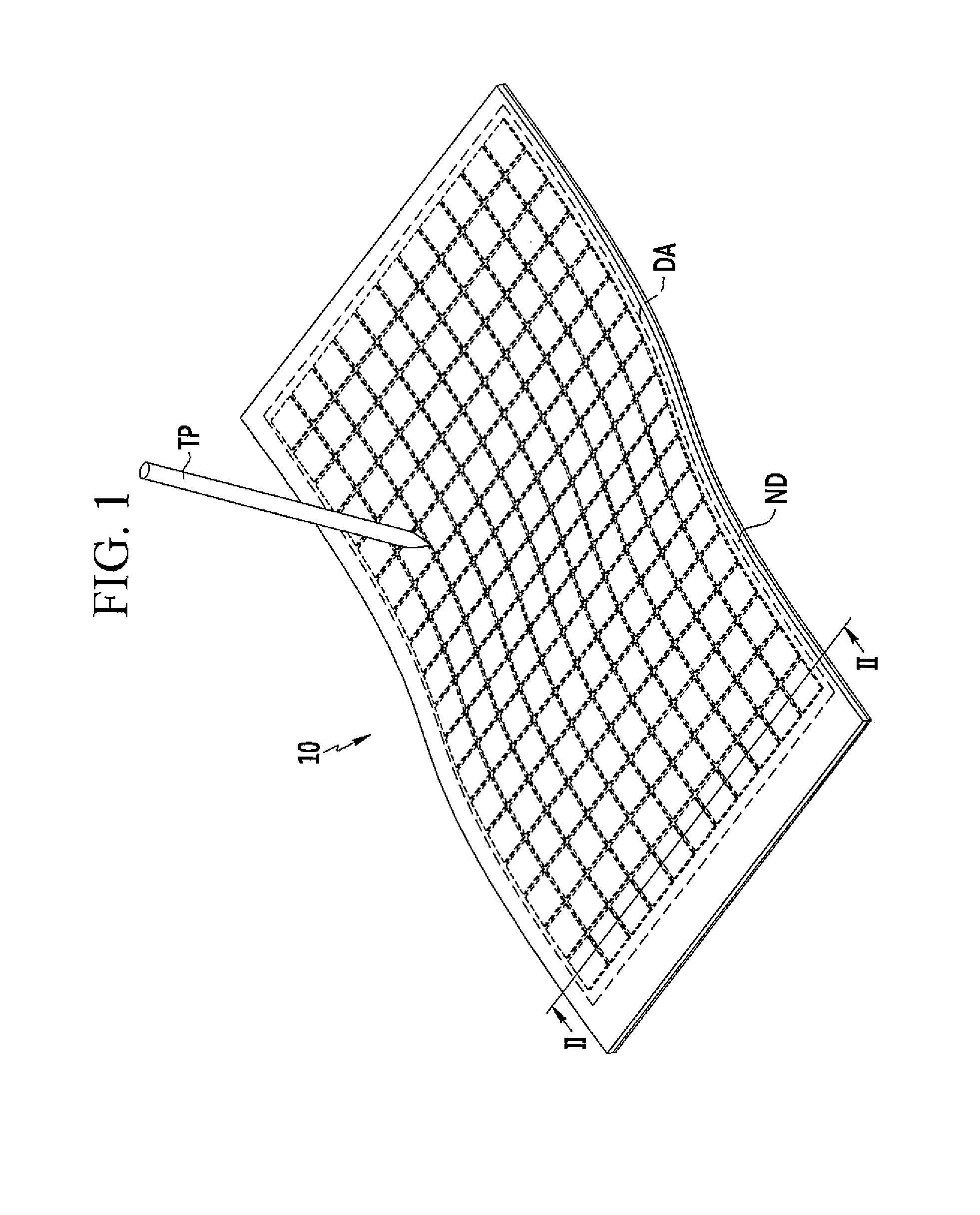

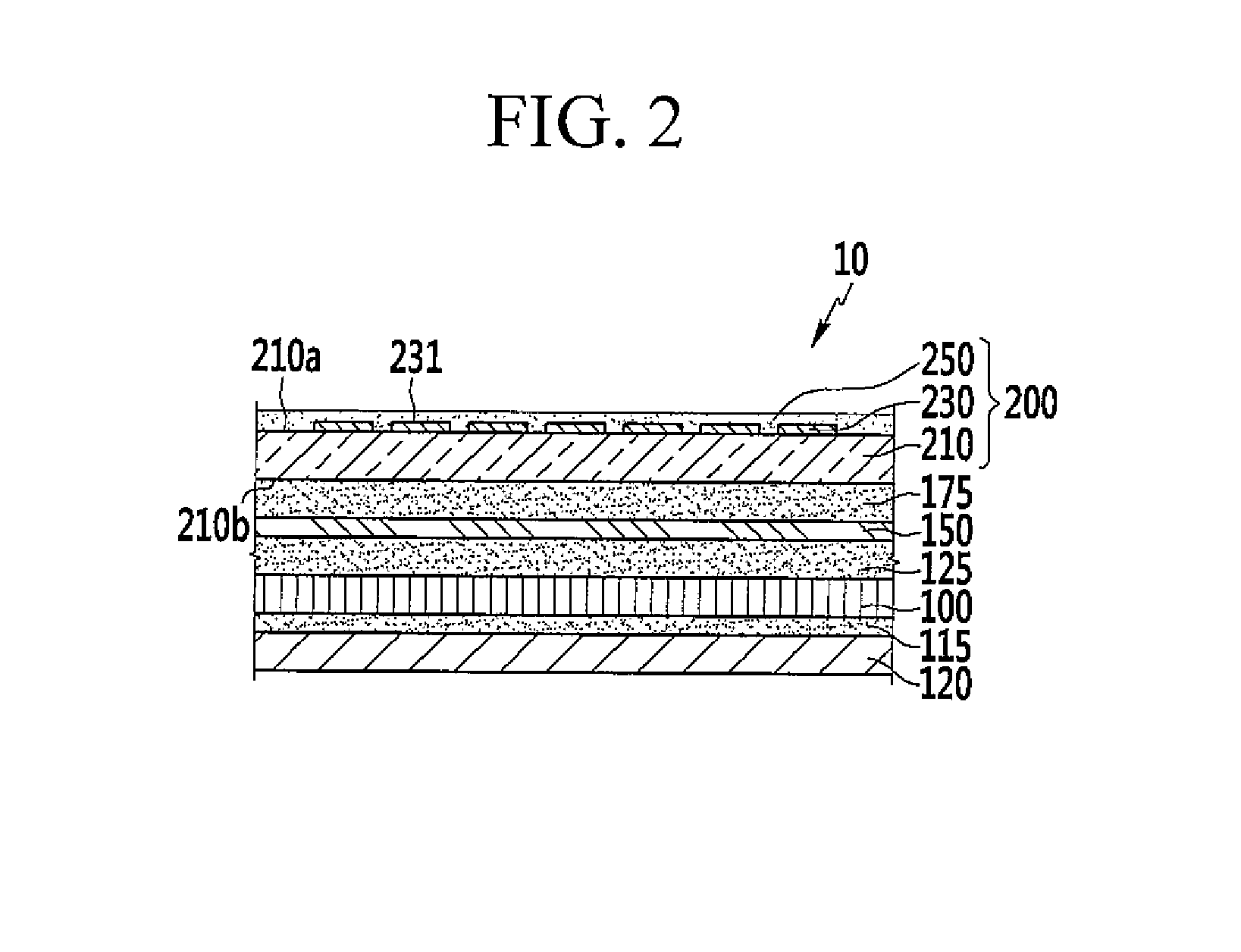

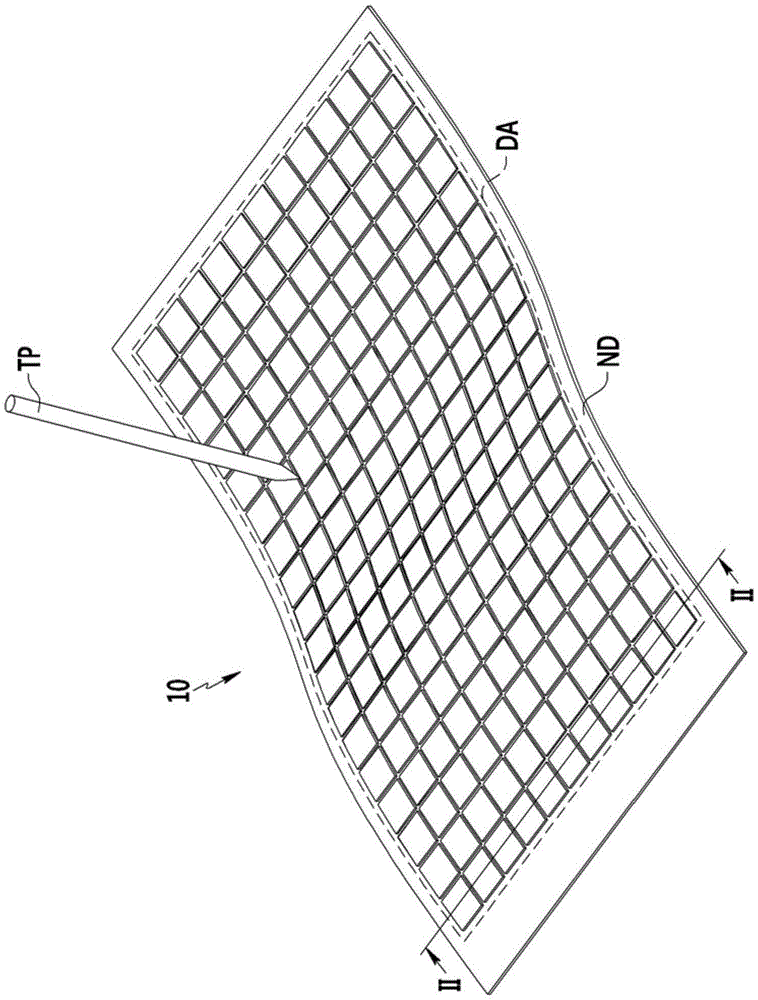

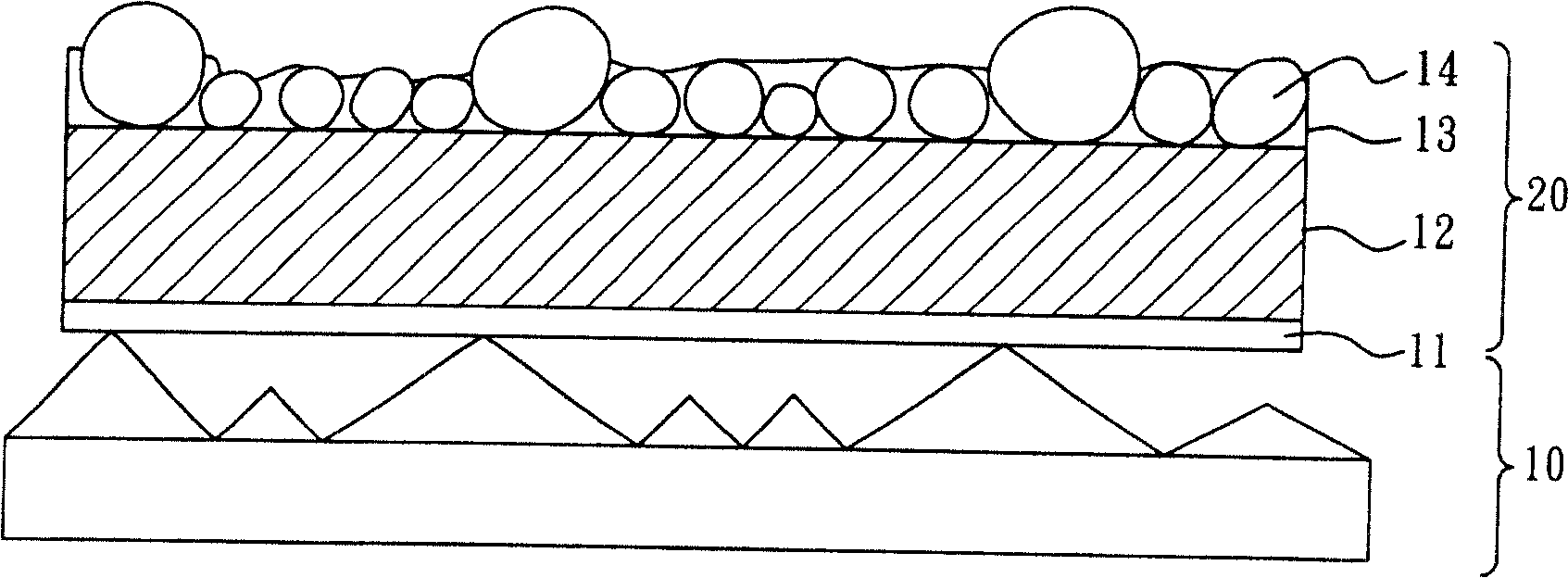

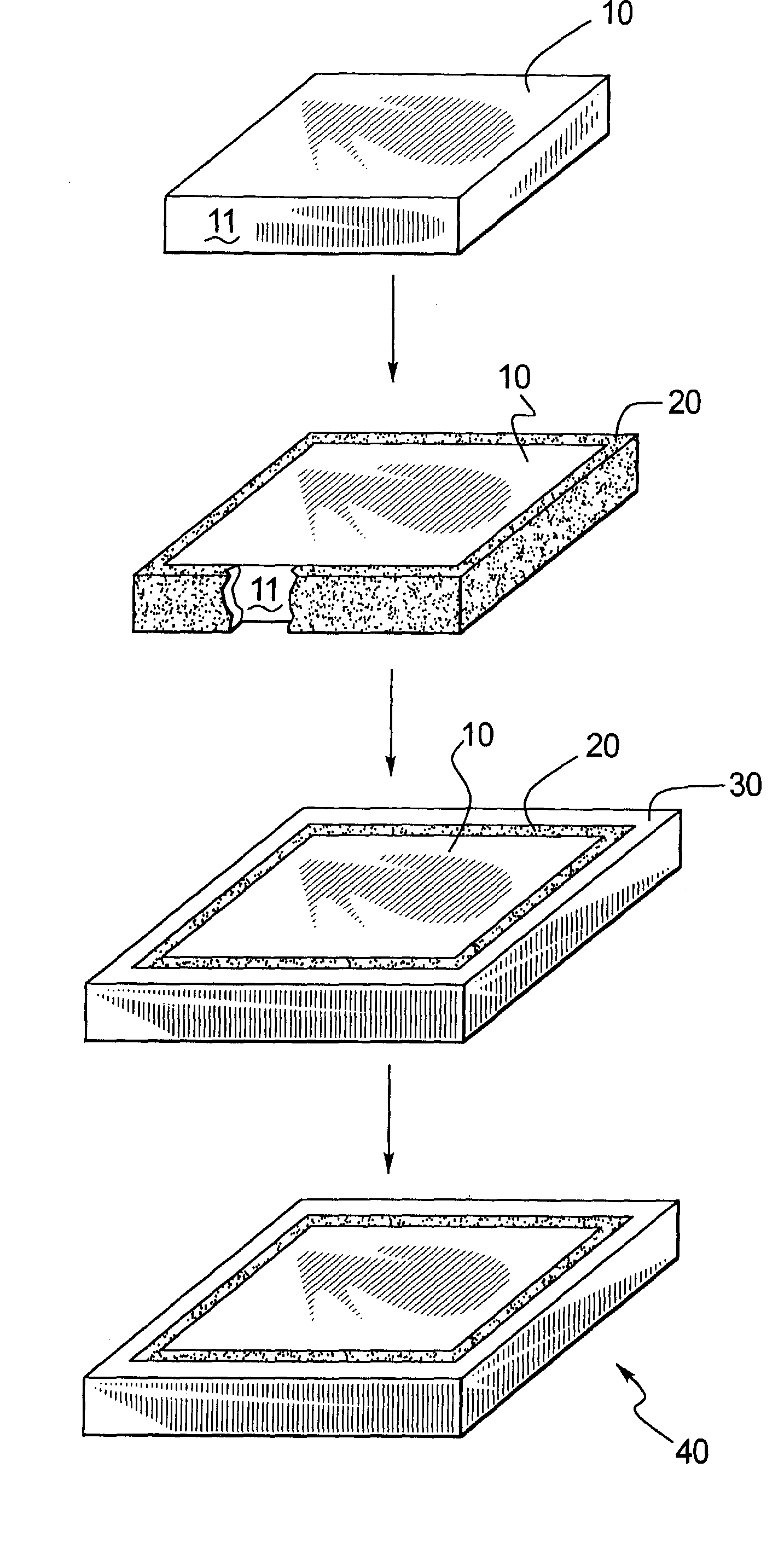

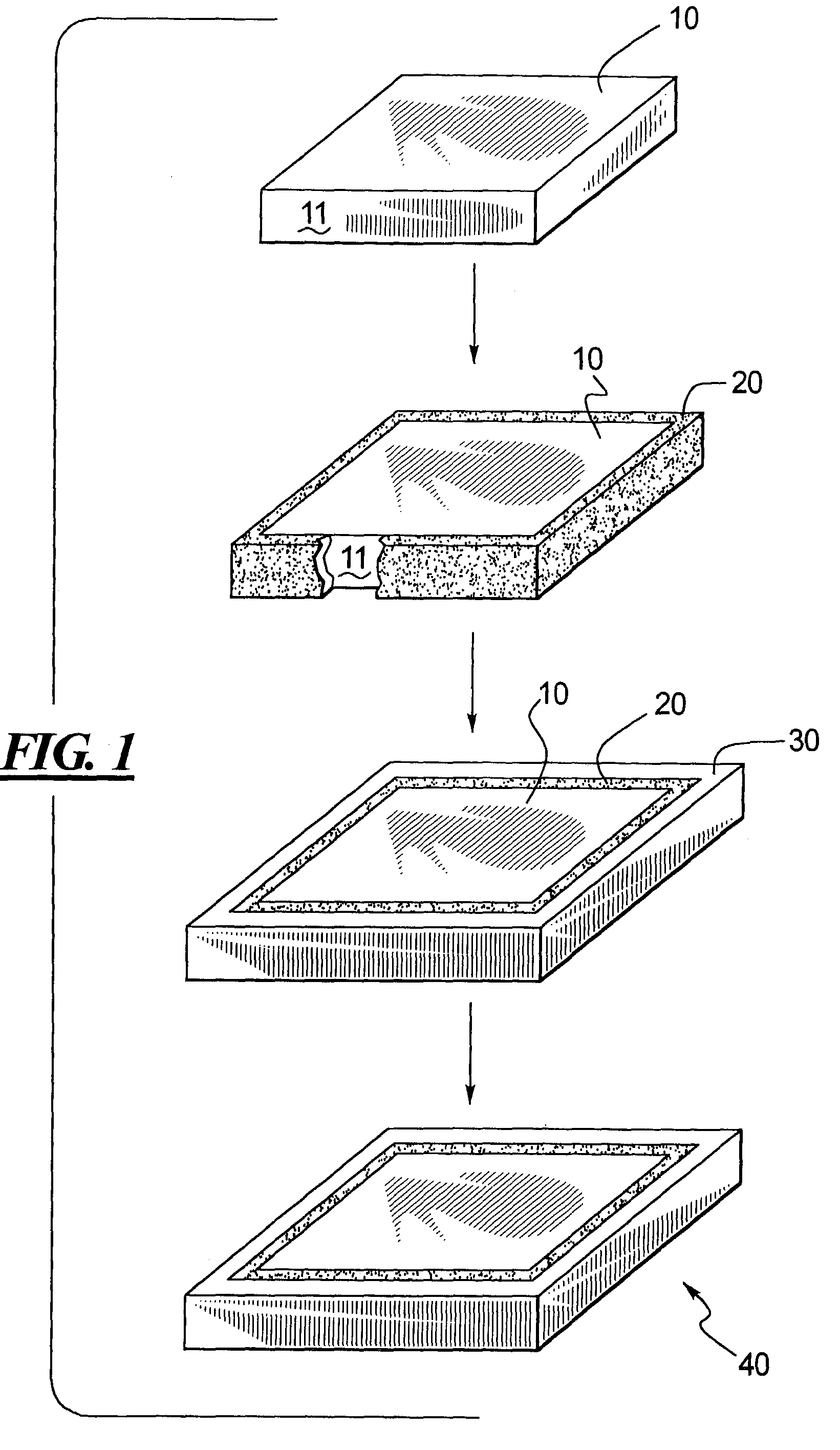

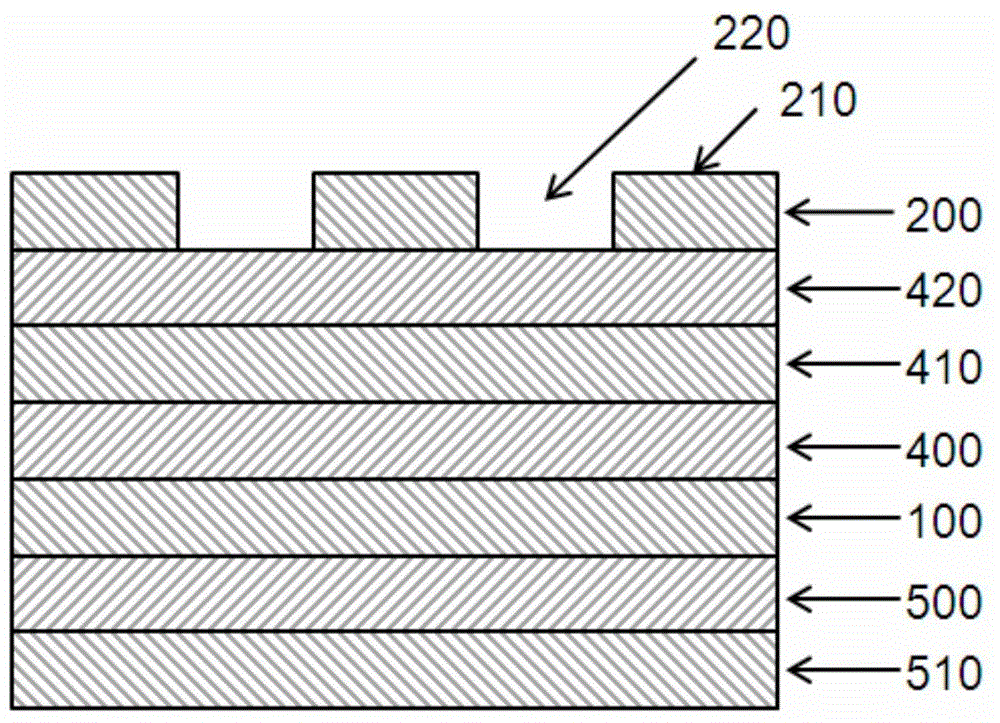

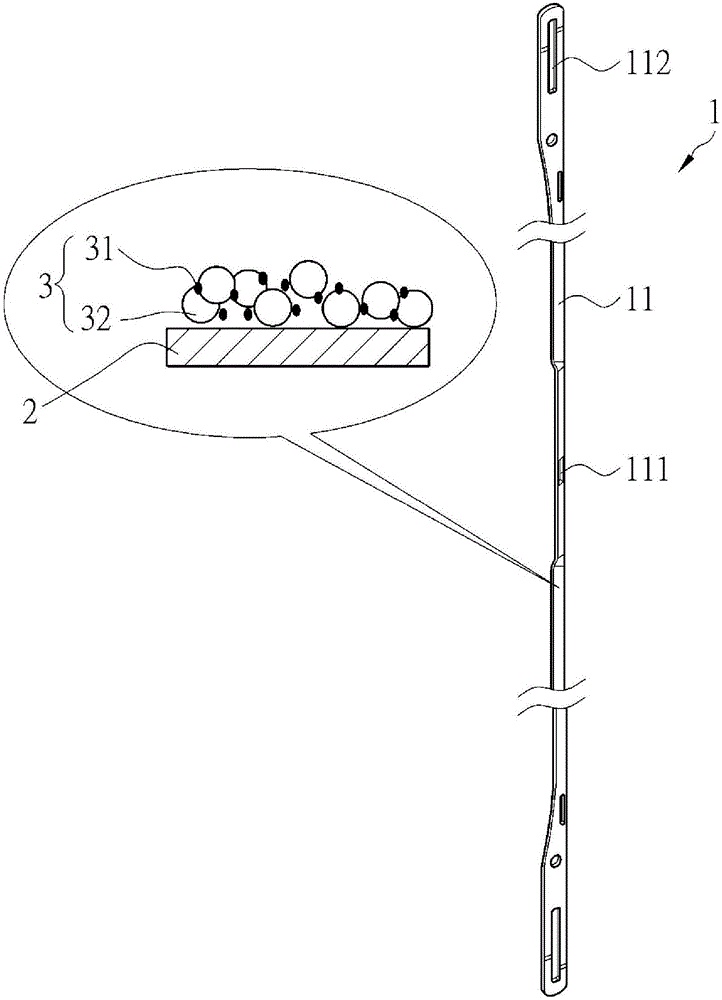

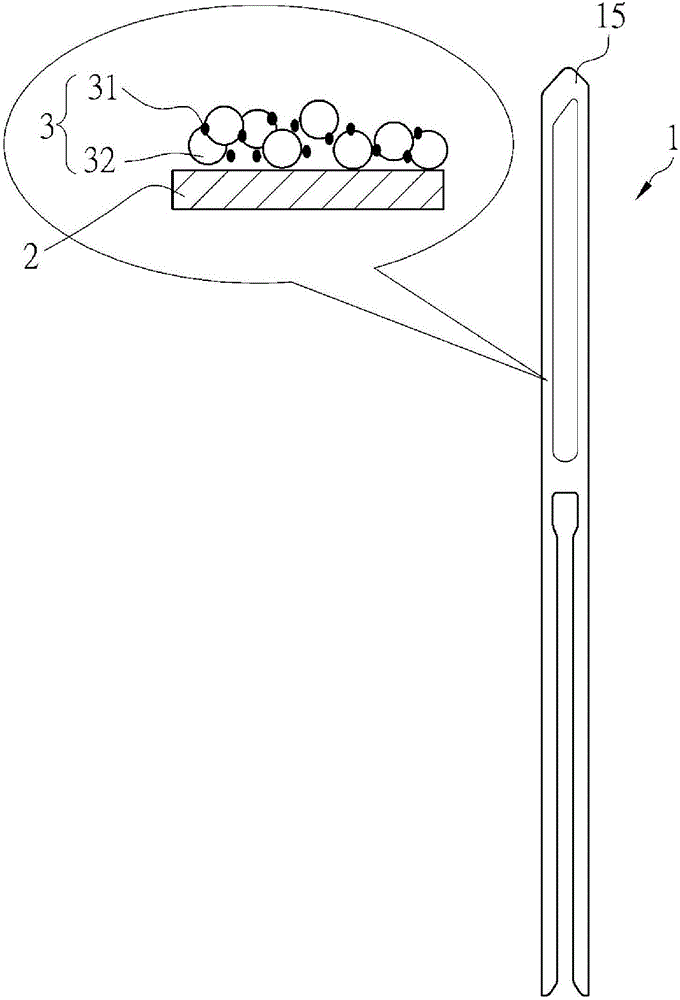

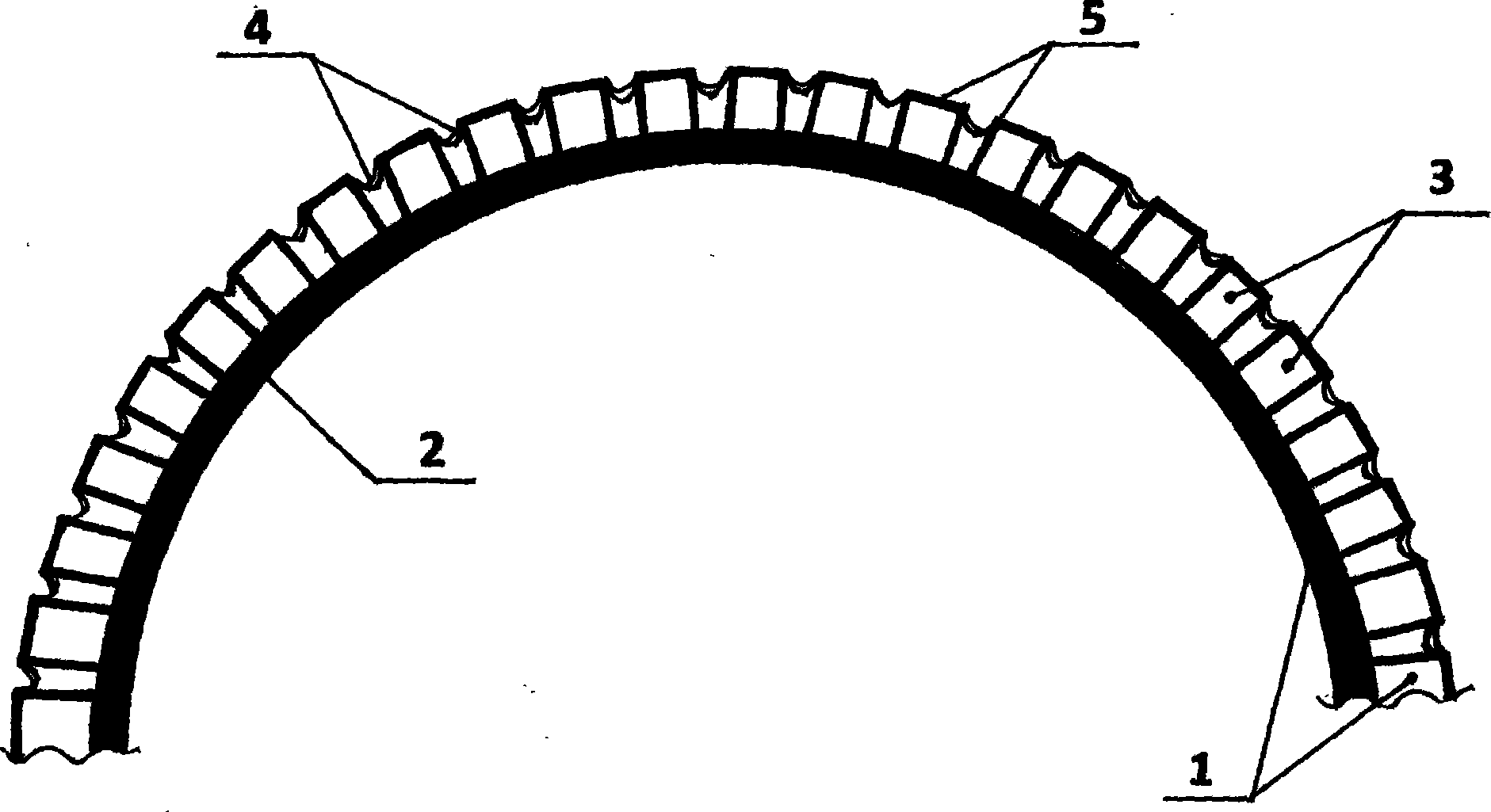

Flexible display device having flexible window substrate

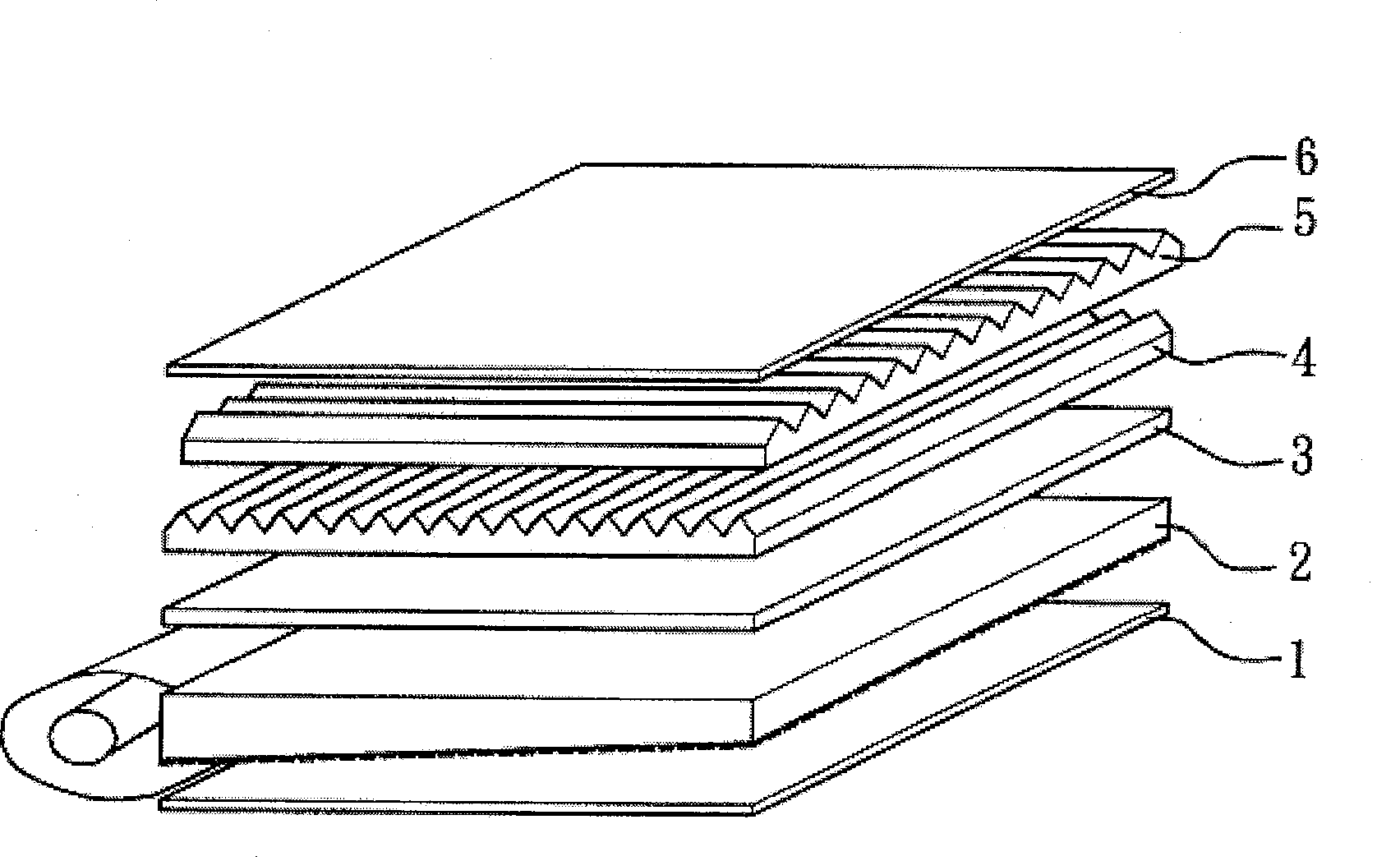

ActiveCN105843434AHigh hardness propertiesGood flexibilitySynthetic resin layered productsElectrical equipmentFlexible displayComputer science

Disclosed herein is a flexible display device including a display panel displaying an image, a touch screen panel on the display panel, and a window substrate covering the touch screen panel. The window substrate includes: a flexible base layer including a first surface facing an outside and a second surface facing the display panel in an opposite direction to the first surface; and a coating layer having hardness higher than that of the base layer and having a plurality of coating tiles arranged on the first surface of the base layer thereof, each coating tile being spaced from adjacent ones of the coating tiles.

Owner:SAMSUNG DISPLAY CO LTD

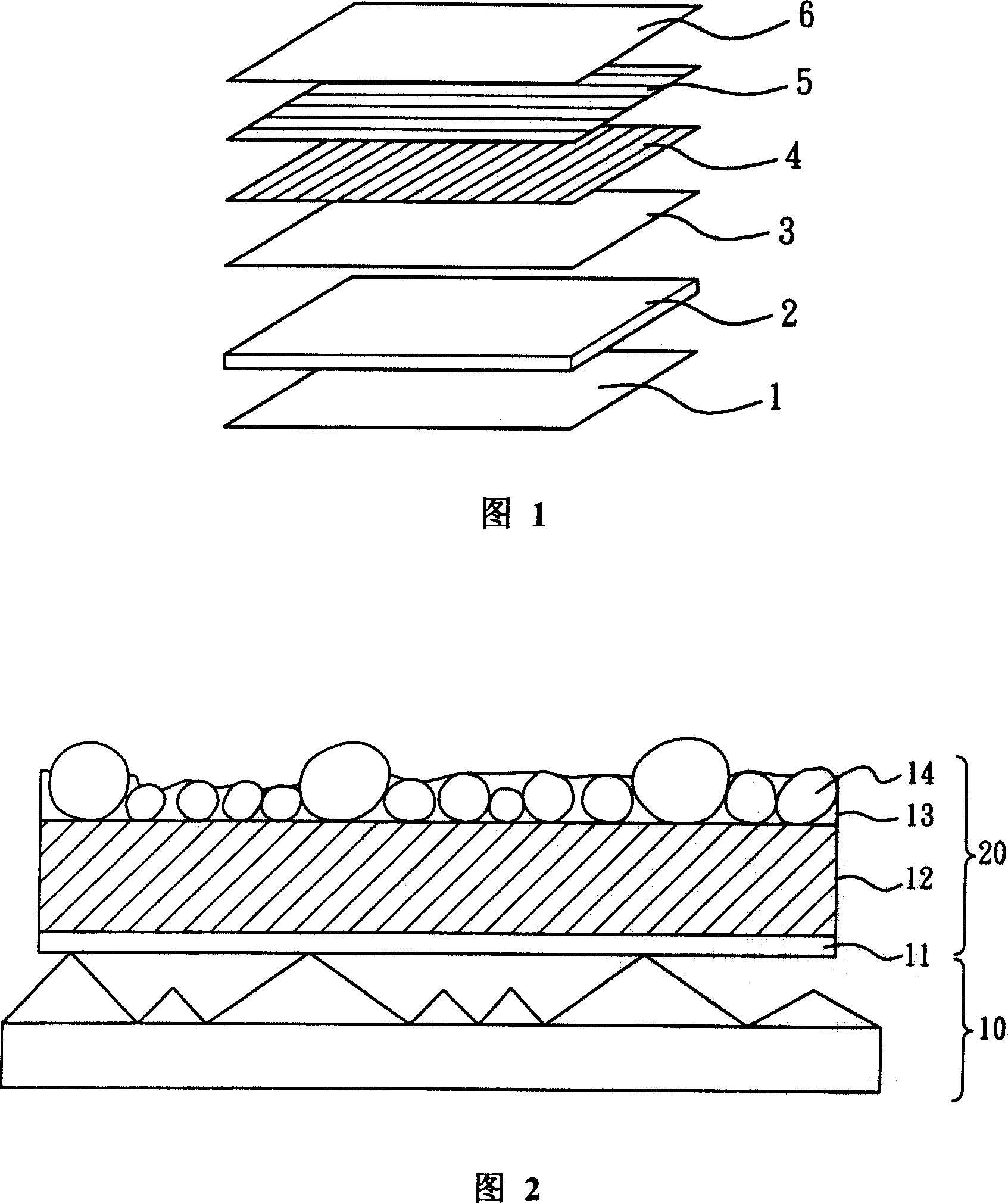

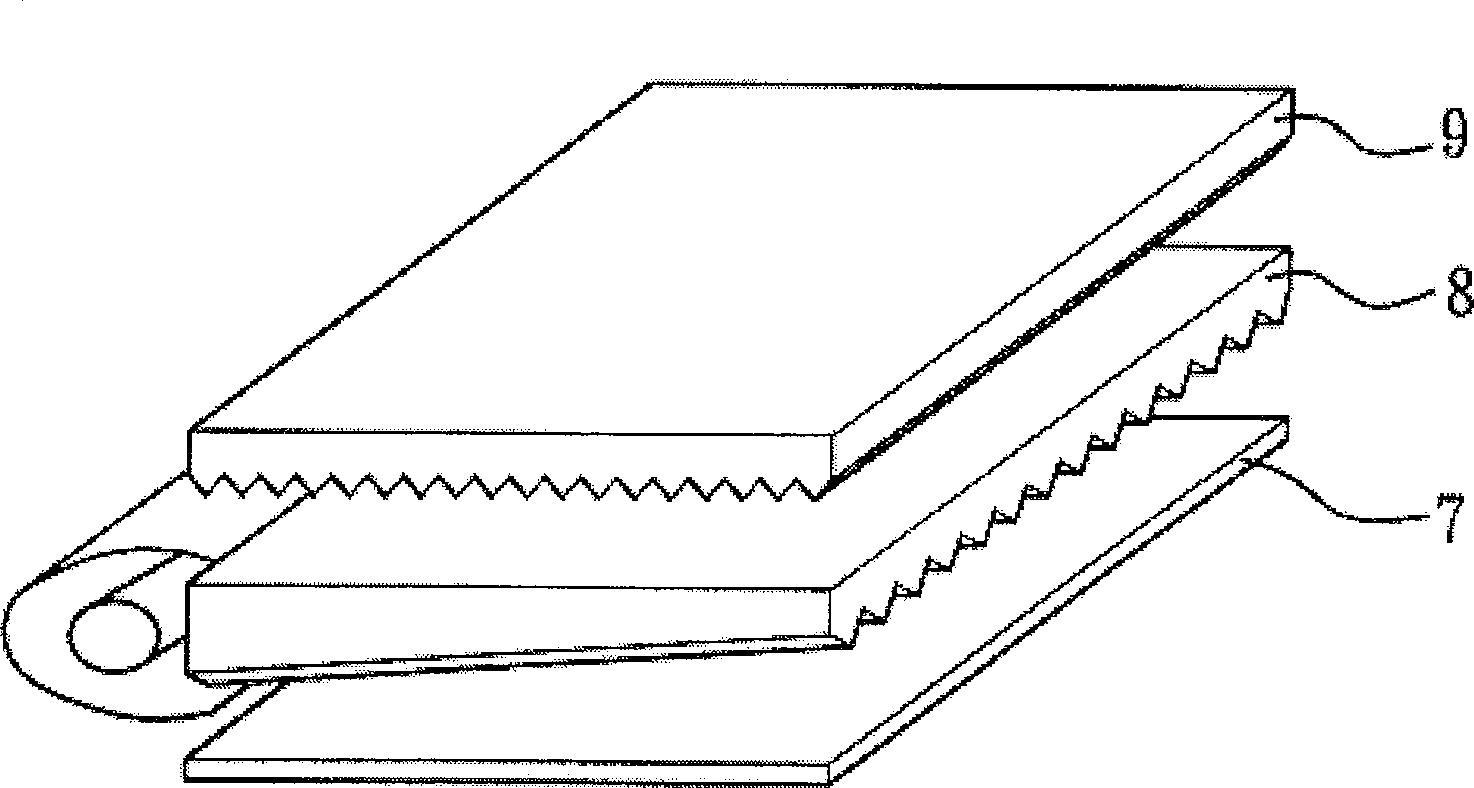

Antiscraping optical film and use thereof

InactiveCN101021573AImprove antistatic performanceHigh hardness propertiesOptical elementsConvex structureDisplay device

The invention provides an anti-scratching optical membrane and its use. And it comprises a three-layered structure, where a transparent substrate is in the middle, and two hard cover layers are on and under the transparent substrate, respectively, the first hard cover layer on the substrate is a diffusion layer and the second on under the substrate is an anti-scratching layer, the top surface of the diffusion layer has a concave-convex structure, the bottom surface of the anti-scratching layer is a smooth surface, and its characters: selecting novel hard cover liquid to form hard cover layers on the substrate surfaces, and after curing, intensifying its hardness; the surface resistivities of the two hard cover layers are between 10<8> and 10<12> Ohm / sq, and according to the measurement with JIS K5400 standard method, the two hard cover layers both have hardness of pencil of 3H or above. And it has high hardness and can prevent being scratched in operation, and when used as a protective diffusion membrane for the backlight module of a display, can not damage the prism structure of a light gathering membrane.

Owner:长兴光学材料(苏州)有限公司

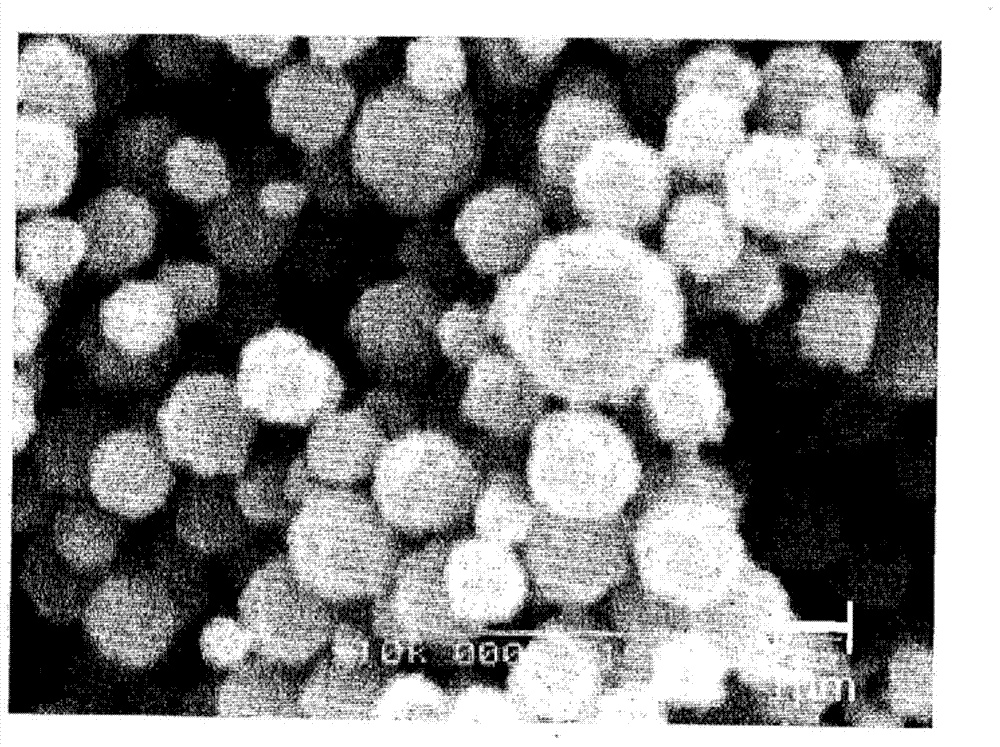

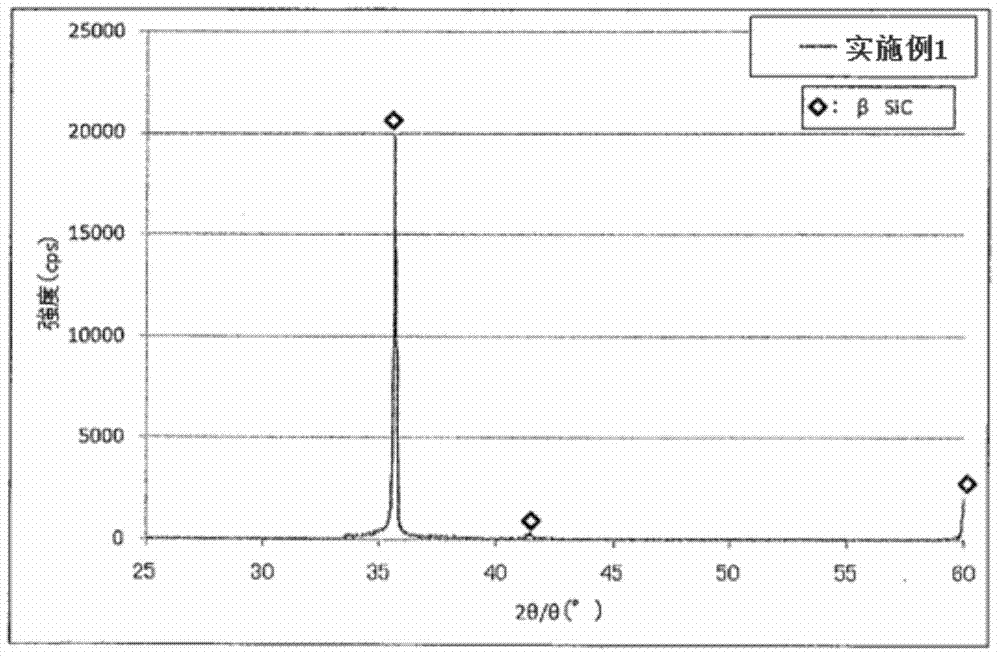

Spherical crystalline silicon carbide powder and method for manufacturing same

InactiveCN104512893AHigh temperature heat resistanceExcellent dielectric propertiesSilicon carbideThin material handlingMean diameterMicrometer

A spherical crystalline silicon carbide powder as well as its manufacturing method are proposed; the new powder mean grain size is 0.5 - 5 micrometers, its specific volume of interior pores having a mean diameter of 0.003 through 0.1 micrometer is 0.000007 cm 3 / g through 0.01 cm 3 / g, and its specific surface area is 0.5 m 2 / g through 8.0 m 2 / g.

Owner:信浓电气制錬株式会社

Antiscraping optical film and use thereof

InactiveCN100426008CImprove antistatic performanceHigh hardness propertiesOptical elementsConvex structureDisplay device

The invention provides an anti-scratching optical membrane and its use. And it comprises a three-layered structure, where a transparent substrate is in the middle, and two hard cover layers are on and under the transparent substrate, respectively, the first hard cover layer on the substrate is a diffusion layer and the second on under the substrate is an anti-scratching layer, the top surface of the diffusion layer has a concave-convex structure, the bottom surface of the anti-scratching layer is a smooth surface, and its characters: selecting novel hard cover liquid to form hard cover layers on the substrate surfaces, and after curing, intensifying its hardness; the surface resistivities of the two hard cover layers are between 10<8> and 10<12> Ohm / sq, and according to the measurement with JIS K5400 standard method, the two hard cover layers both have hardness of pencil of 3H or above. And it has high hardness and can prevent being scratched in operation, and when used as a protective diffusion membrane for the backlight module of a display, can not damage the prism structure of a light gathering membrane.

Owner:长兴光学材料(苏州)有限公司

Flexible window substrate and flexible display device having the same

ActiveUS10168740B2High hardness propertiesHigh materialDigital data processing detailsIlluminated signsHardnessFlexible display

A flexible display device including a display panel configured to display an image, a touch screen panel on the display panel, and a window substrate covering the touch screen panel. The window substrate includes: a flexible base layer including a first surface facing an outside and a second surface facing the display panel in an opposite direction to the first surface; a first coating layer having hardness higher than that of the base layer and having a plurality of first coating tiles arranged on the first surface of the base layer thereof, at a first gap from each other; and a second coating layer having hardness higher than that of the base layer and having a plurality of second coating tiles arranged on a layer different from the first surface of the base layer thereof, at a second gap from each other.

Owner:SAMSUNG DISPLAY CO LTD

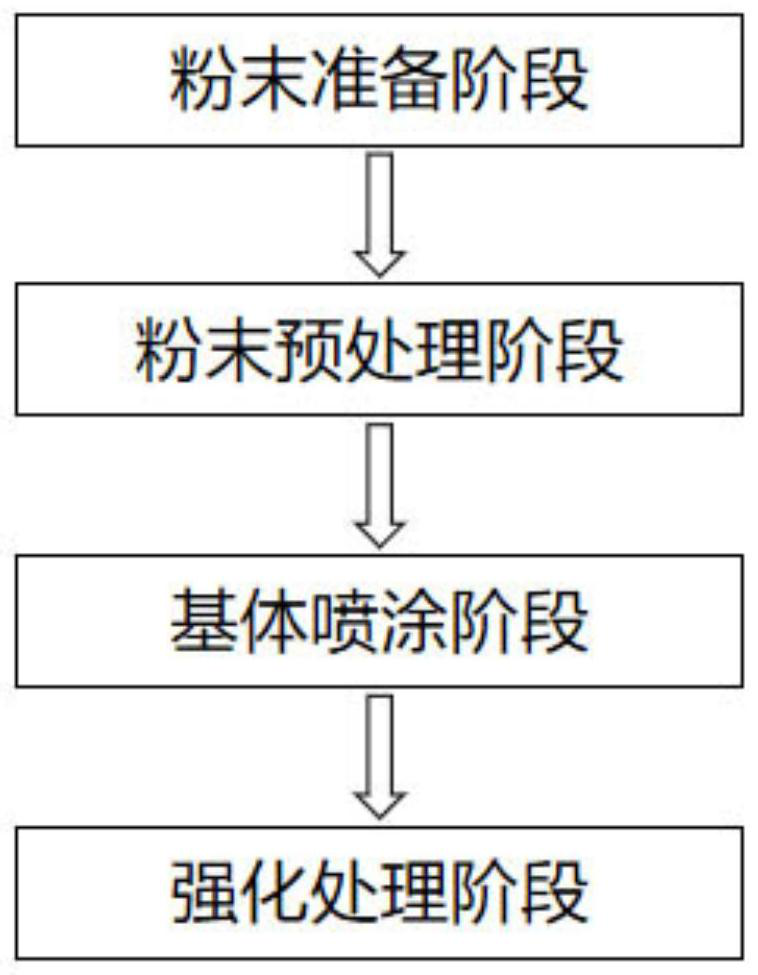

High-temperature-corrosion-resistant paint, preparation method thereof, high-temperature-corrosion-resistant coating and preparation method thereof

ActiveCN107236331AReduce decompositionImprove compactnessFireproof paintsLiquid surface applicatorsTitanium metalDecomposition

The invention provides high-temperature-corrosion-resistant paint, a preparation method thereof, a high-temperature-corrosion-resistant coating and a preparation method thereof. The high-temperature-corrosion-resistant paint comprises chromium, nickel and metal ceramic powder, the metal ceramic powder is ceramic powder with the surface coated with aluminum and / or titanium metal powder, and the ceramic powder comprises Cr3C2 and CeO2. The preparation method of the paint includes: mixing the ceramic powder comprising Cr3C2 and CeO2 with metal comprising titanium and aluminum, performing high-energy ball milling to obtain the metal ceramic powder, and then mixing the metal ceramic powder with chromium and nickel to obtain the high-temperature-corrosion-resistant paint. The preparation method of the paint includes: spraying the paint to the surface of a substrate at supersonic speed to obtain the coating. High-energy ball milling is adopted to realize coating of ceramic by metal, so that decomposition of Cr3C2 in the process of thermal spraying is reduced effectively; titanium and aluminum are low in melting point and are wrapped on the surfaces of Cr3C2 and CeO2, so that improving of compactness of the coating is facilitated; Cr3C2 and CeO2 are hard in texture, so that improving of smoke washout resistance of the coating is facilitated.

Owner:国家能源集团科学技术研究院有限公司武汉分公司 +3

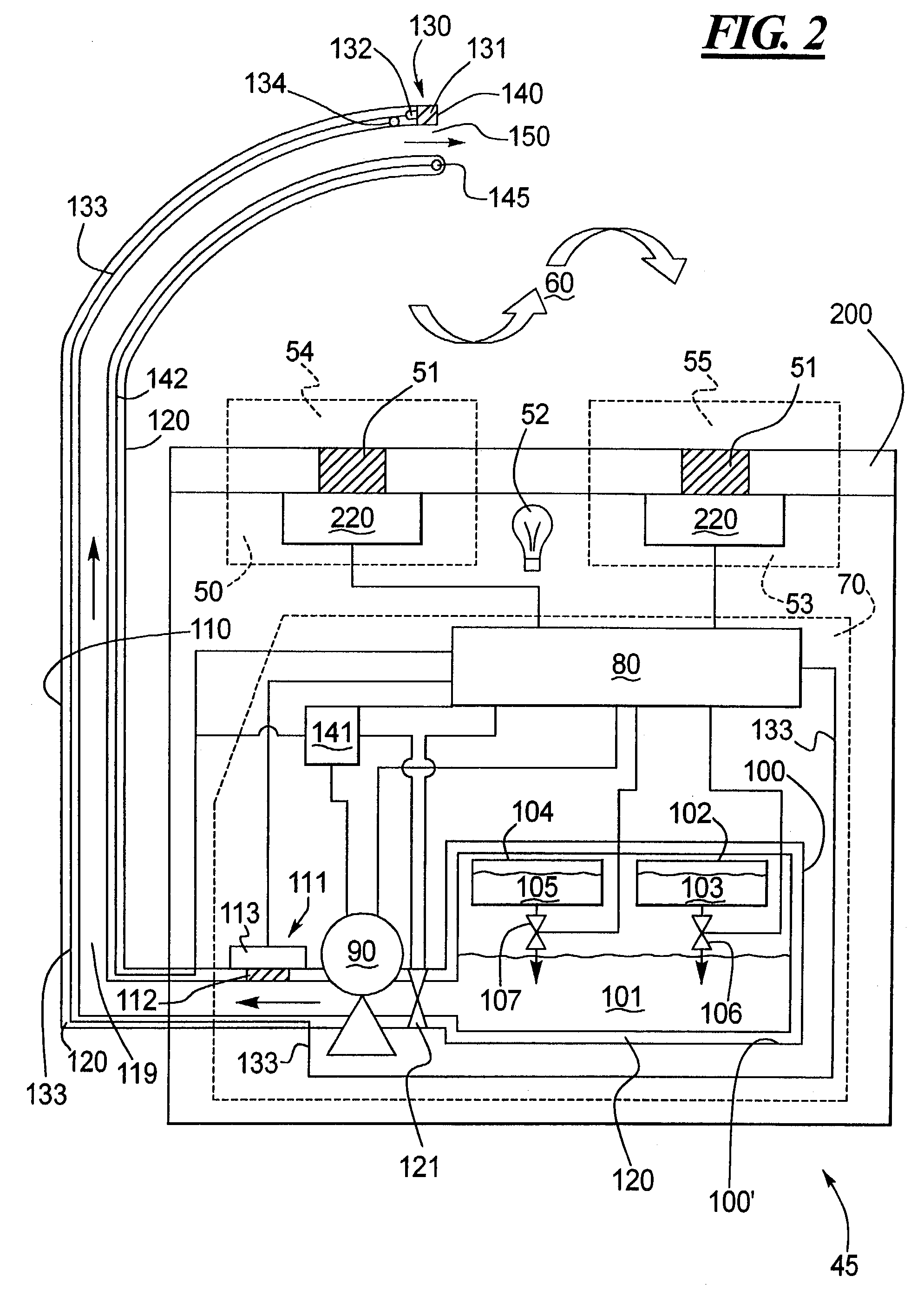

Method of manufacture of smart microfluidic medical device with universal coating

InactiveUS7279112B2Simple preparation procedureEasy to manufactureDecorative surface effectsSurgeryCarbideMedical device

A method of applying a universal coating for a medical device comprising a medical device component, the medical device component having an outer surface and an inner surface, the universal coating applied to at least the outer surface or the inner surface of the medical device component, wherein the coating is made from a material selected from the group consisting of diamond, diamond-like, borosilicate glass, carbides and nitrides. The medical device can further be a smart medical device by incorporating a sensor placed capable of measuring chemical and / or electrical conditions. A method of applying the coating inside complicated 3D structures without the need for bonding diamond to diamond or DLC to DLC layers is also provided.

Owner:MEDTRONIC INC

Method for obtaining a foamed laminar product

InactiveCN102171014AHigh hardness propertiesSimplify the manufacturing processThin material handlingEngineeringHardness

The invention comprises a method for manufacturing a foamed laminar product wherein the foam is obtained using thermoplastic material and additives. With a view to improving the rigidity of the foamed laminar product, reinforcing fibre is added to the mixture formed by the thermoplastic material and additives, such that the reinforcing fibre forms an integral part of the foamed sheet.

Owner:GRP ANTOLIN ING SA +1

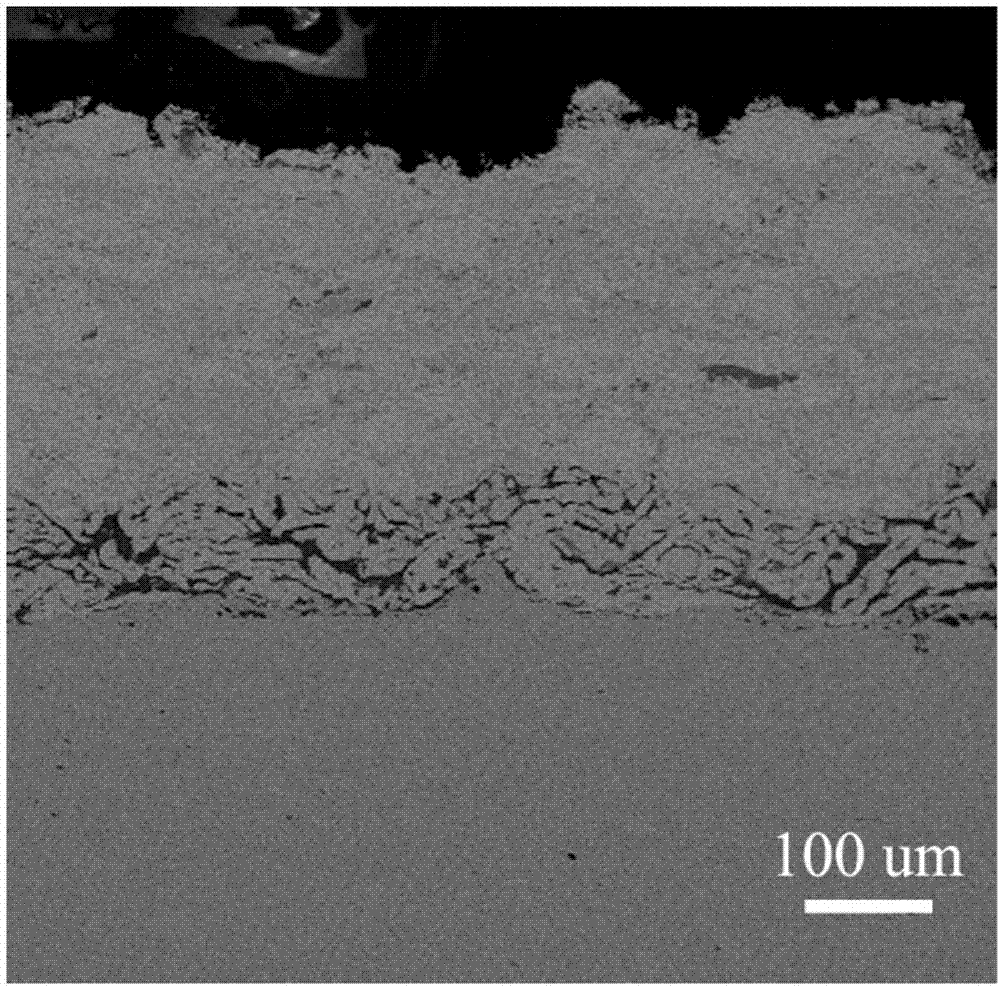

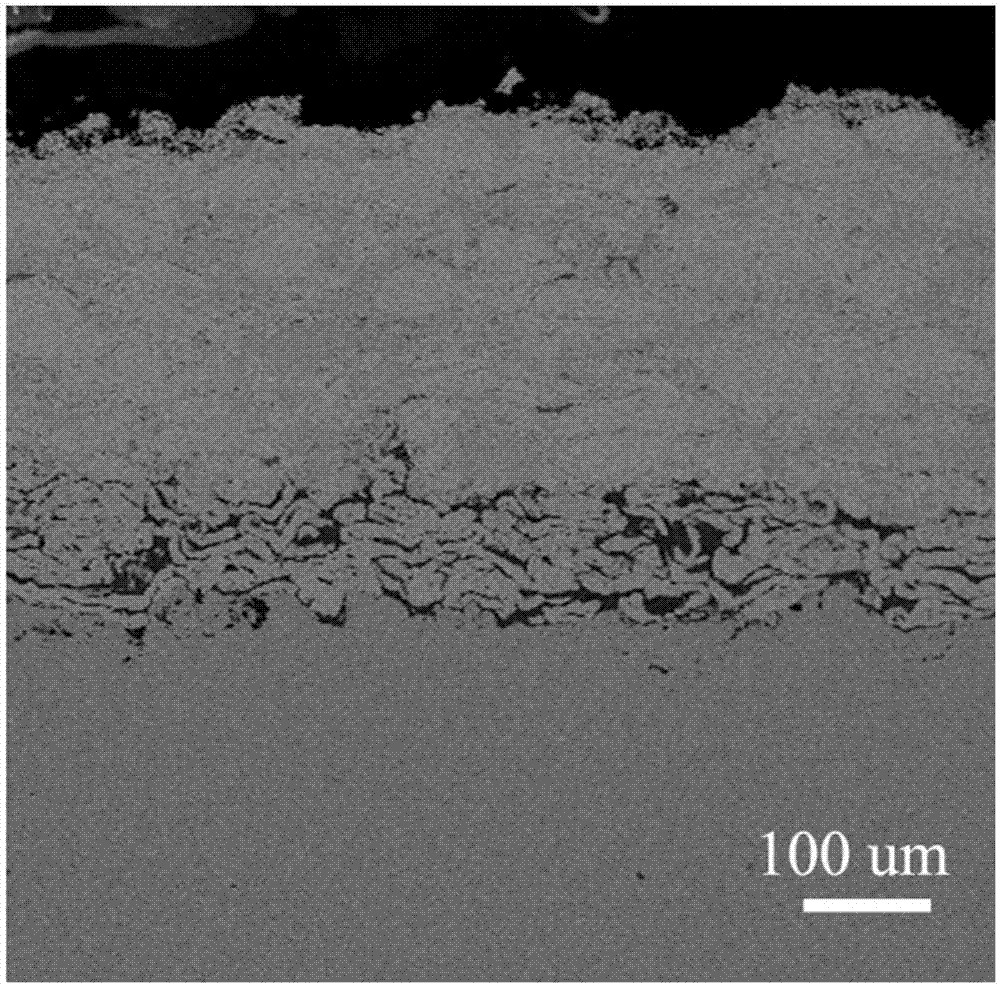

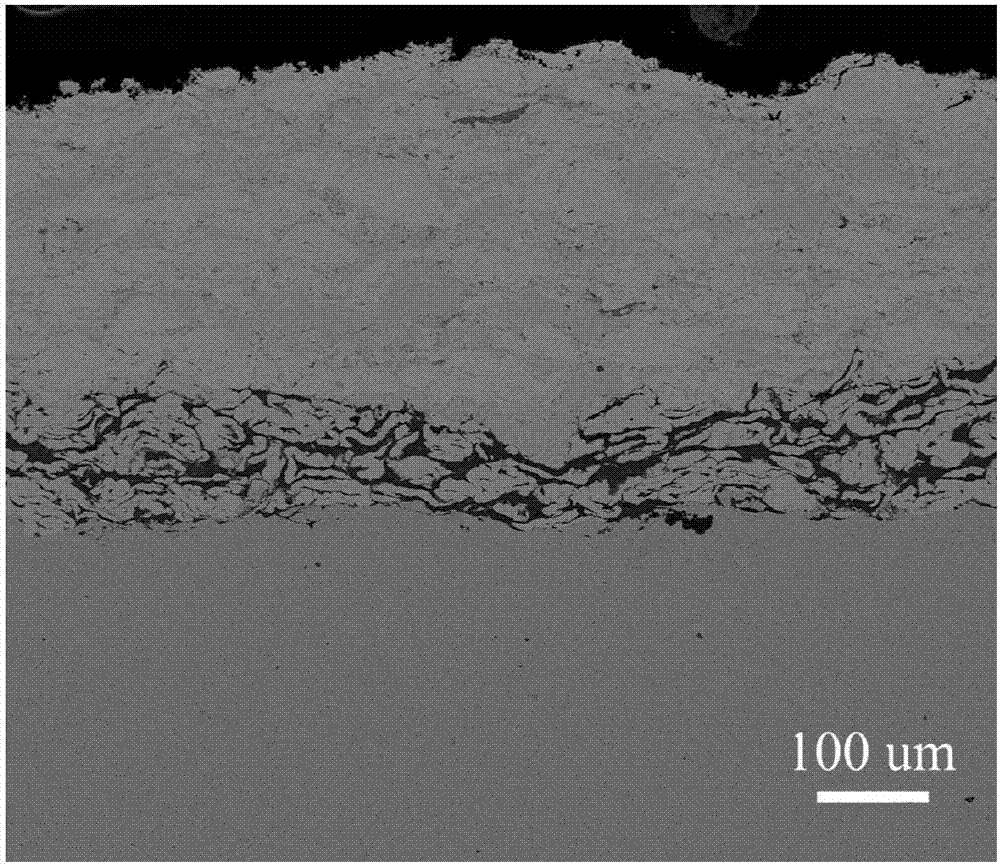

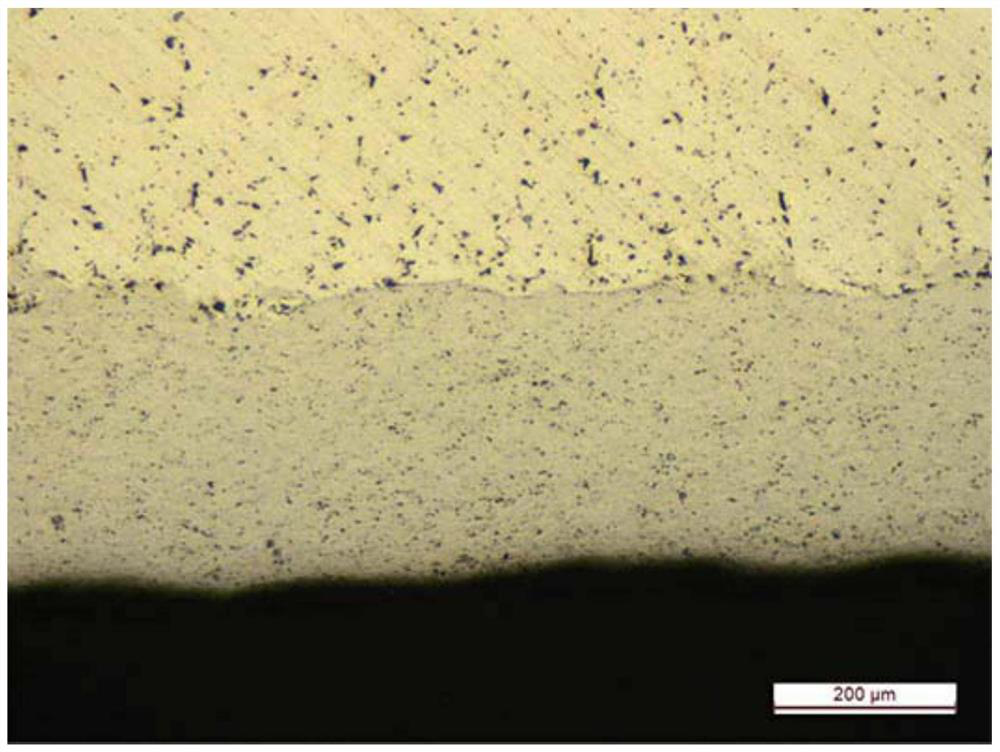

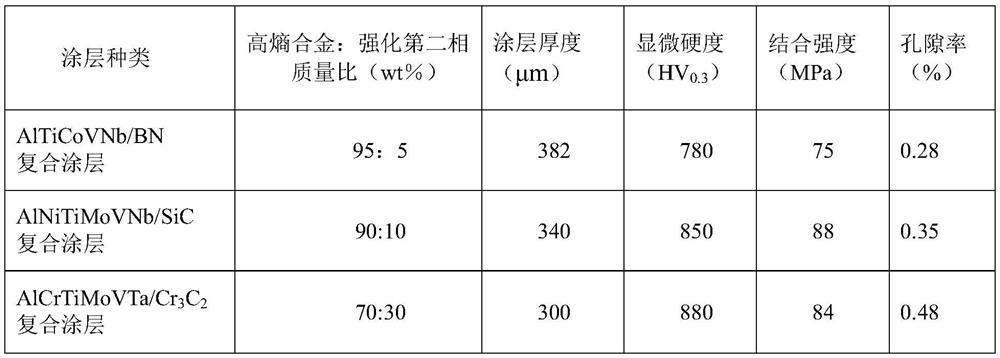

Anti-cavitation composite coating and preparation method thereof

PendingCN114231882AImprove uniformityAvoid shape changesMolten spray coatingHigh entropy alloysHydraulic machinery

The invention discloses an anti-cavitation composite coating and a preparation method thereof. The anti-cavitation composite coating is prepared from composite powder composed of a high-entropy alloy powder source and 0.01 wt%-50 wt% of a second phase strengthening powder source through hypersonic flame spraying. The high-entropy alloy powder source is composed of elements Al, Ti, V, an element represented by m and an element represented by n. After the high-entropy alloy composite powder is designed and prepared, the cavitation-erosion-resistant composite coating containing the double-phase high-entropy alloy and the dispersed second-phase structure is prepared by adopting a hypersonic flame spraying and surface strengthening method, the thickness is 100-400 microns, and the bonding strength of the coating and a matrix can reach 75 MPa or above. The preparation method is low in cost, simple and easy to control and high in production efficiency; the prepared composite coating is uniform in structure, high in bonding strength, high in strength and rigidity, good in toughness and plasticity, high in compactness and the like, the use performance of the anti-cavitation coating can be effectively improved, the service life of the anti-cavitation coating can be effectively prolonged, and the actual requirements of hydraulic machinery are met.

Owner:STATE POWER INVESTMENT CORP RES INST +1

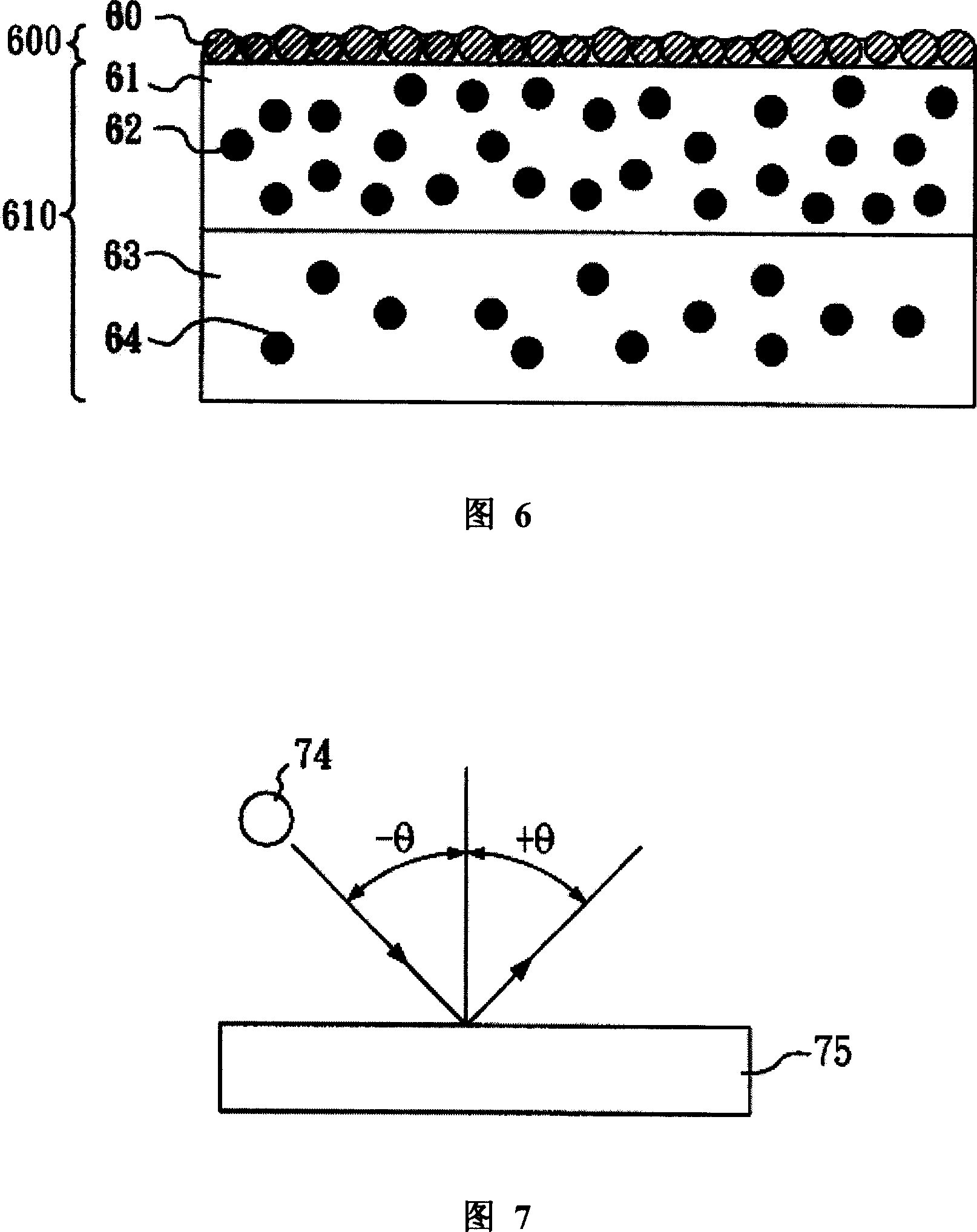

Transparent conductive optical sheet having high invisibility of pattern

ActiveCN105528107AGood dry effectNo loss of clarityInput/output processes for data processingOptical elementsElectrical devicesDisplay device

The invention relates to a transparent conductive optical sheet having high invisibility of a pattern. The transparent conductive optical sheet comprises an ITO layer via etching of a pattern. Via a thin film drying effects of a reflectivity matching layer of the optical sheet, difference between the reflectivity and reflecting color between a non-etching part and an etching part of the ITO layer is corrected, and a user is allowed to fail to recognize the non-etching part and the etching part visually, so definition for display of a display panel on a lower part will not be reduced. In particular, when thickness of the ITO layer is changed for adjustment of surface resistance, even if the reflectivity and thickness of a transparent base layer or the reflectivity matching layer are changed, the thin film drying effects can be well maintained. Thus, the optical sheet can be suitable for touch display panel field of display panels of all kinds of electrical devices.

Owner:爱思开迈克沃解决方案有限公司

Antiscraping optical film and use thereof

InactiveCN100498460CImprove antistatic performanceExcellent hardness propertiesNon-linear opticsOptical elementsLiquid-crystal displayLight guide

Owner:长兴光学材料(苏州)有限公司

Coaxial connector with capacitively coupled connector interface and method of manufacture

InactiveUS9048527B2Suitable compression and thermal resistance characteristicMeet cutting requirementsElectrically conductive connectionsTwo-part coupling devicesCapacitanceDielectric

A connector with a capacitively coupled connector interface for interconnection with a mating portion with a sidewall. A connector body has an outer conductor coupling surface at an interface end, covered by an outer conductor dielectric spacer. The outer conductor coupling surface is dimensioned to seat, spaced apart from the sidewall by the outer conductor dielectric spacer, when the connector body and the mating portion are in an interlocked position. A releasable retainer may be provided, the releasable retainer dimensioned to secure the connector body and the mating portion in the interlocked position.

Owner:COMMSCOPE TECH LLC

Dual connector interface for capacitive or conductive coupling

InactiveUS8888528B2Suitable compression and thermal resistance characteristicMeet cutting requirementsEngagement/disengagement of coupling partsElectrically conductive connectionsDielectricCapacitance

A connection interface with a female portion for interconnection with a conductive male portion or a capacitive coupling male portion interface provides conductive coupling when interconnected with the conductive male portion and capacitive coupling when coupled with the capacitive coupling male portion. The female portion may include a spring basket dimensioned to receive a pin of the conductive male portion and to seat within a socket of the conductive male portion, separated by an inner conductor dielectric spacer.

Owner:COMMSCOPE TECH LLC

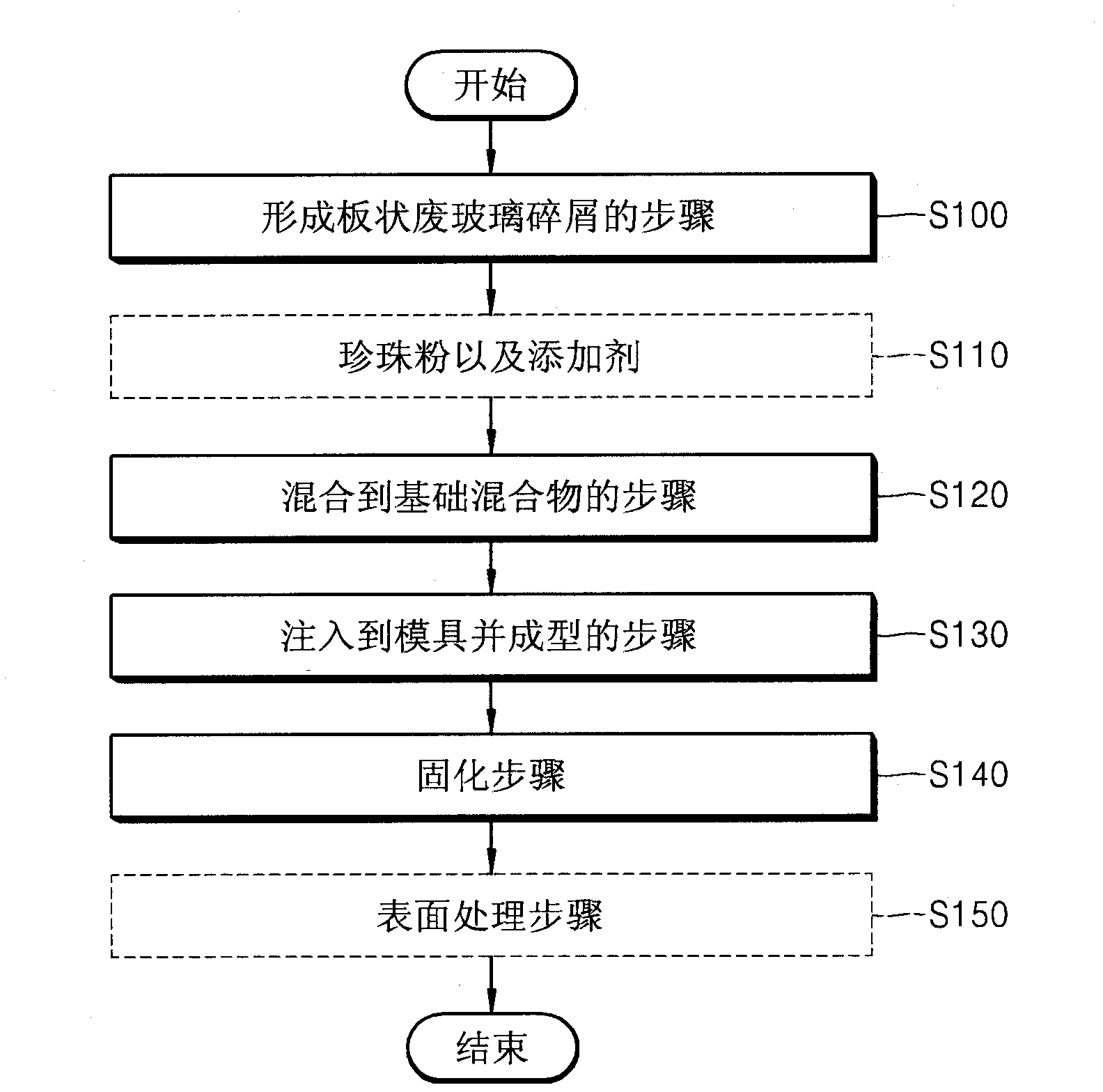

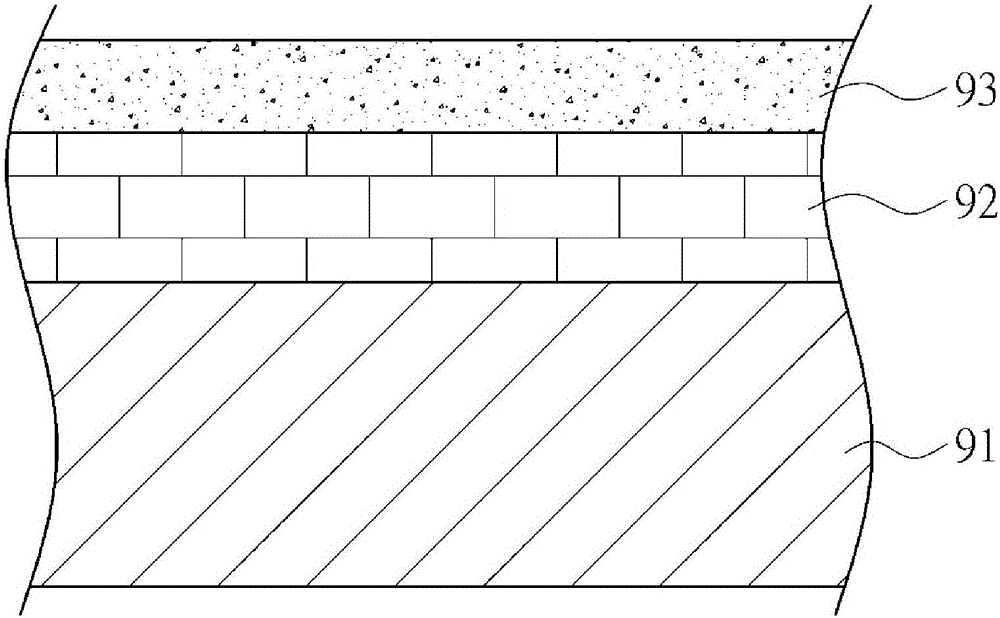

Artificial marble including plate-shaped chips of waste glass, and method for fabricating same

The present invention relates to artificial marble including plate-shaped chips of waste glass, and to a method for fabricating same. A thin glass plate recycled from an LCD backlight unit is used to form plate-shaped chips of waste glass having a thickness of 0.6 mm or less and a large particle size of 20 mm or less. The chips are added to a base compound including one or more types of polymer resin and an additive. Accordingly, the artificial marble has: an appearance resembling that of natural marble; a surface having excellent physical properties; and optimal characteristics when used as an interior material used for floors, walls, kitchens, and the like.

Owner:LG HAUSYS LTD

A woven yarn guide assembly for coating composite electroplating layer and its making method

InactiveCN106757250AHigh hardnessImprove thermal conductivityWeft knittingElectrolytic inorganic material coatingYarnCeramic coating

The present invention provides a weaving yarn guide assembly for coating a composite electroplated layer having good abrasion resistance and thermal conductivity and a method for producing the same, and a method of manufacturing a composite yarn by electrochemically coating a surface of a woven yarn guide assembly of a textile machine Carbide ceramic plating layer, the composite metal carbide ceramic plating layer hardness of 750-950Hv, the friction coefficient of 0.45 or less and the thermal conductivity of 185W / (m * K) or more, can be applied to the need for high precision, high hardness, Low-friction and friction heat is not easy to accumulate the requirements of the weaving-oriented components such as healds, Shenke tablets, reed, stop sheet, or spinning needles and other components; the invention proposed the preparation of the composite metal carbide ceramic coating Electroplating method for yarn guide assembly.

Owner:SUZHOU CHAOLIQUANG MACHINERY ELECTRONICS & TECH CO LTD +1

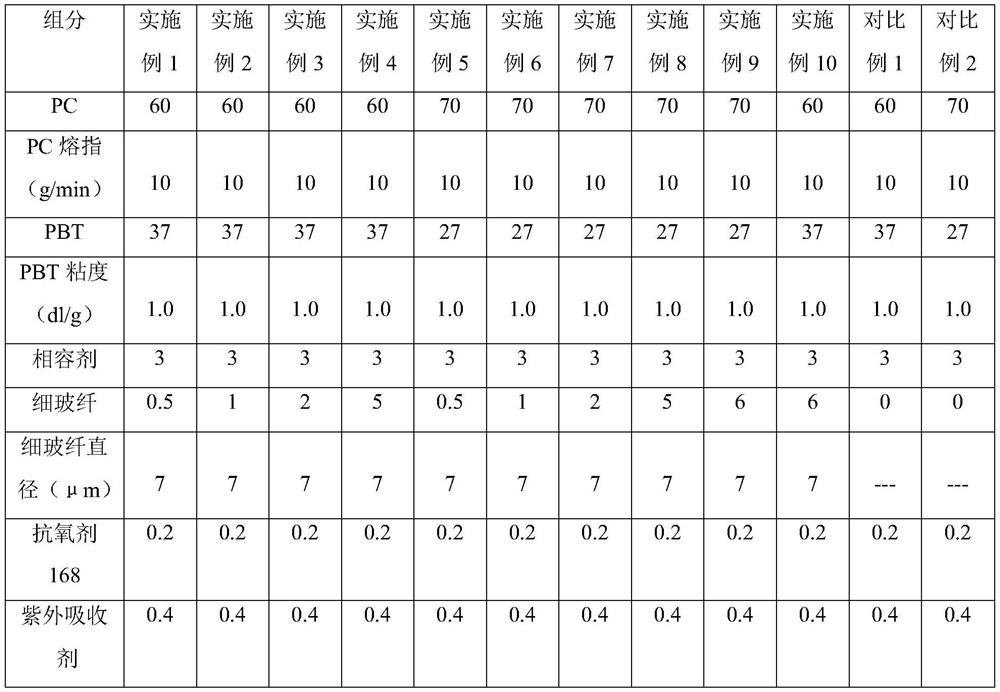

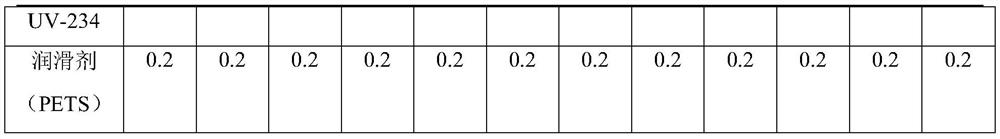

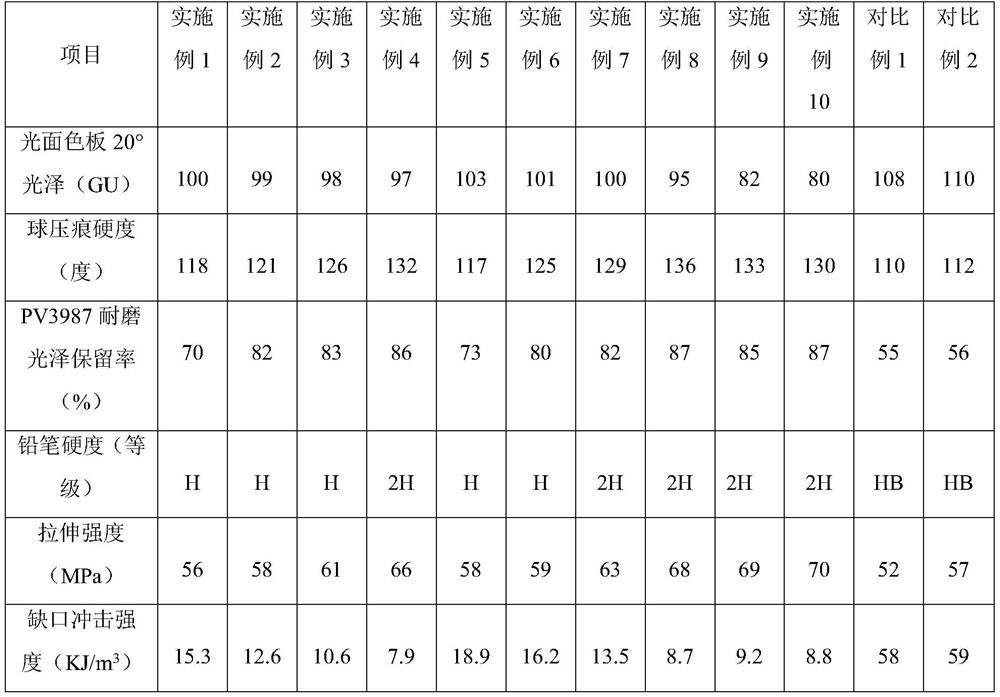

High-hardness high-scratch-resistance spraying-free highlight PC/PBT alloy material and preparation method thereof

The invention provides a high-hardness high-scratch-resistance spraying-free highlight PC / PBT alloy material. The alloy material comprises the following components in parts by weight: 60-70 parts of polycarbonate, 27-37 parts of polybutylene terephthalate, 3-5 parts of a compatilizer, 0.5-5 part of fine glass fibers, 0.1-0.5 part of an antioxidant, 0.2-1.0 part of an ultraviolet light absorbent and 0.1-0.5 part of a lubricant. According to the PC / PBT alloy material disclosed by the invention, the fine glass fibers with relatively small monofilament diameters are added to modify the PC and PBTmaterials, so that the modified PC / PBT alloy material has excellent high hardness and high scratch resistance.

Owner:南京跃贝新材料科技有限公司

High-carbon cold-rolled steel sheet, method for producing same, and high-carbon steel machine component

ActiveCN113099723AMachinability inhibitionHigh hardness propertiesFurnace typesQuenching agentsSteel platesCarbon steel

Provided is a high-carbon cold-rolled steel sheet having a sheet thickness of less than 1.0 mm. The high-carbon cold-rolled steel sheet has good impact characteristics and hardness characteristics and excellent wear resistance after shock cooling (quenching) after solution treatment and low-temperature tempering (quenching / tempering) for a short period of time, and has little reduction in secondary workability before quenching / tempering treatment. The high-carbon cold-rolled steel sheet has the steel sheet chemical composition containing, in mass%, 0.85-1.10% of C, less than 0.60% of Mn, 0.10-0.35% of Si, 0.030% or less of P, 0.030% or less of S, and less than 0.60% of Cr, with Mn+Cr satisfying less than 1.0%, and further containing 0.005-0.020% by mass of Nb, the remainder being Fe and unavoidable impurities, so that the reduction in secondary workability before quenching and tempering is reduced compared to the conventional steel materials. Furthermore, by forming a steel plate structure in which the average particle diameter of carbides is 0.2-0.7 [mu] m and the spheroidization rate is 90% or more, the machine component having excellent impact characteristics in which the impact value is 9 J / cm2 or more, sufficient hardness characteristics in the range of 600-750 HV, and excellent wear resistance can be produced even after the short time of quenching and tempering, such as 3-15 minutes.

Owner:TOKUSHU KINZOKU EXCEL +1

Carbon-diamond cutting head

InactiveCN104139460AReduce manufacturing costExtend the life cycleStone-like material working toolsDiamond cuttingEngineering

A carbon-diamond cutting head is characterized in that high-rigidity materials are combined with a cemented carbide cutting head through a coating and plating technology, so that the wear-resisting property of the cutting head is improved greatly, the service life of a saw blade is prolonged simultaneously, the cutting head and a tool rest have multipurpose cutting functions, the cutting head is quite convenient to mount, use and transport, equipment running load and weight can be reduced to the greatest extent, energy consumption can be reduced without stress deformation, the stone cutting cost can be reduced remarkably, a cutter body is strong enough for long-time use, the performance and efficiency are high, energy is saved, and the environment is protected. Compared with like products, the working efficiency can be improved by 2-4 times, and durability and an efficient using function are provided; the cutting head has high-performance cutting and the cutting function of an energy-saving and environment-friendly ultrathin saw blade, the cutting saw blade is high in running speed and sharp in cutting head, and the equipment is small in running load, light in weight and low in energy consumption, does not generate stress deformation and is not prone to wear; and the carbon-diamond cutting head has the advantages of low manufacture cost, high product operation efficiency and the like, and is quite perfect.

Owner:南光日 +2

Preparation method of titanium carbide/titanium diboride composite ceramic particle preform

The invention relates to a preparation method of a titanium carbide / titanium diboride composite ceramic particle preform. The preparation method comprises the following steps: firstly, preparing titanium carbide / titanium diboride composite ceramic particles; and then preparing a titanium carbide / titanium diboride composite ceramic particle preform. The titanium carbide / titanium diboride composite ceramic particles can be prepared by a pressure granulation method or a sol-gel granulation method. According to the pressure granulation method, titanium carbide and titanium diboride are utilized to form an eutectic phase with a low sintering temperature, then a small amount of metal sintering aid is added, and pressureless sintering can be carried out at the low sintering temperature to form the titanium carbide / titanium diboride composite ceramic particles. The sol-gel method granulation comprises the following steps: adding water, a water reducing agent and a sodium alginate solution into mixed powder formed by titanium carbide powder, titanium diboride powder and metal powder, carrying out ball milling, curing and carrying out high-temperature sintering. The obtained composite ceramic particles have high hardness and high toughness, and compared with zirconium oxide toughened aluminum oxide ceramic particles, the performance of the metal-based ceramic particle composite material can be further improved.

Owner:HENAN INST OF ENG

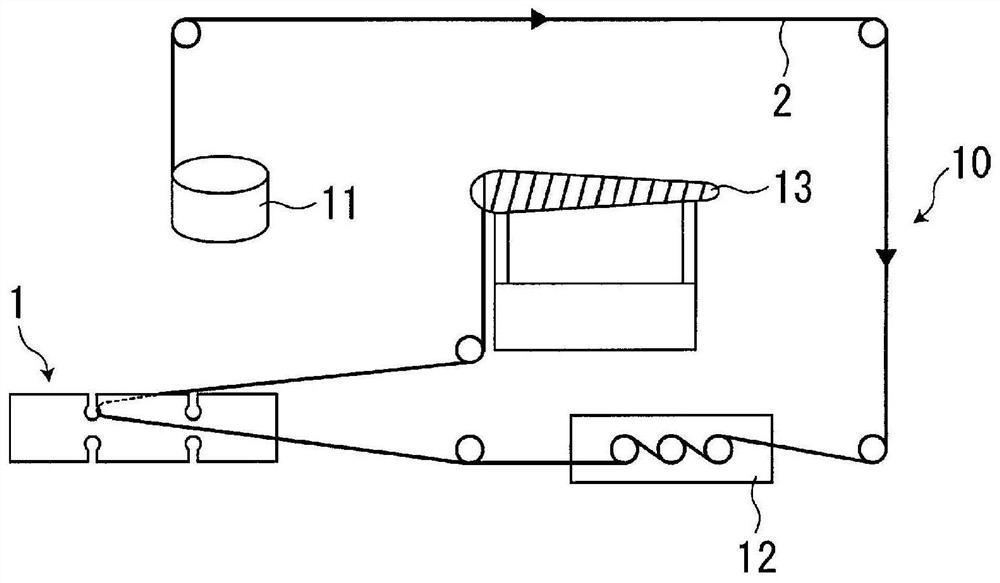

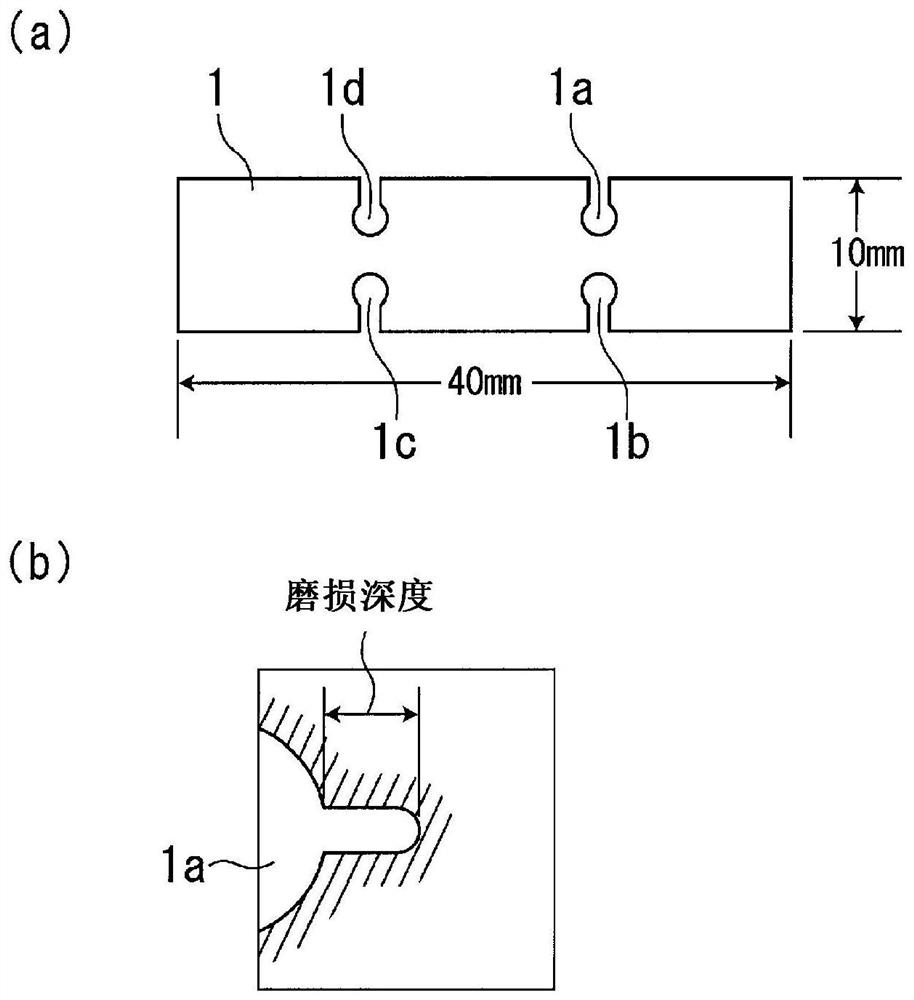

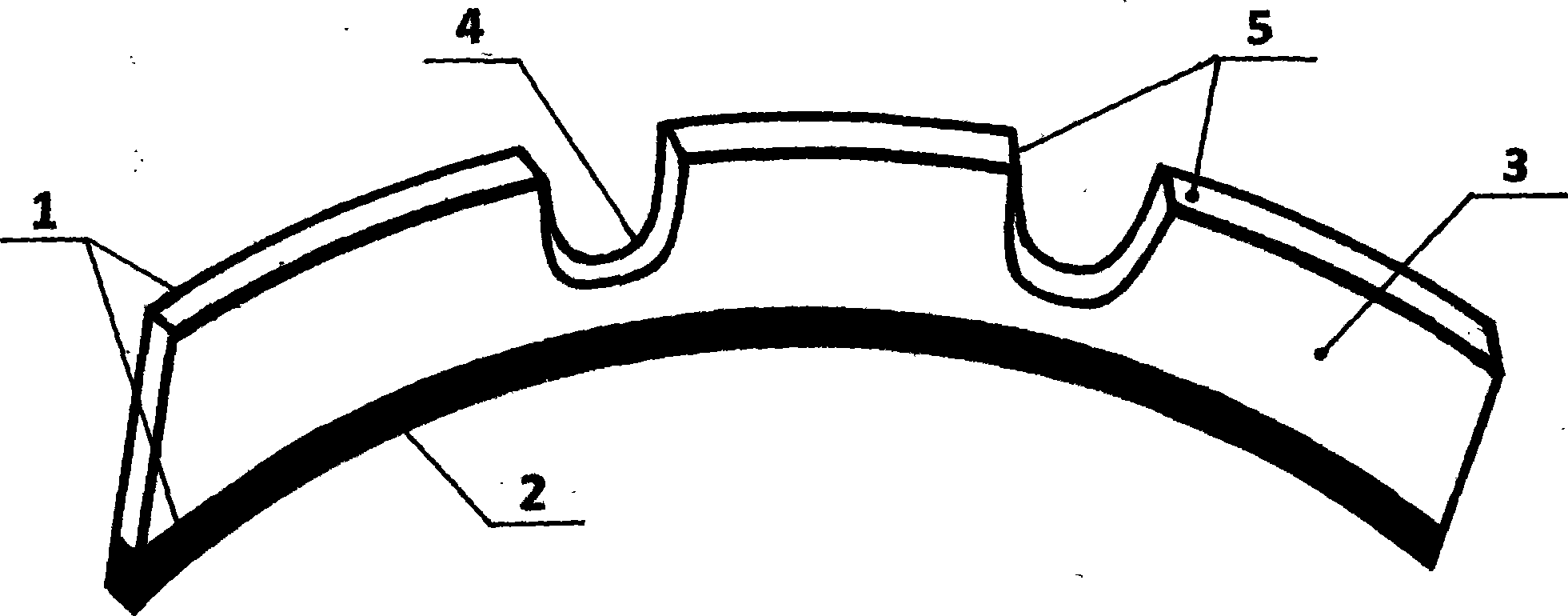

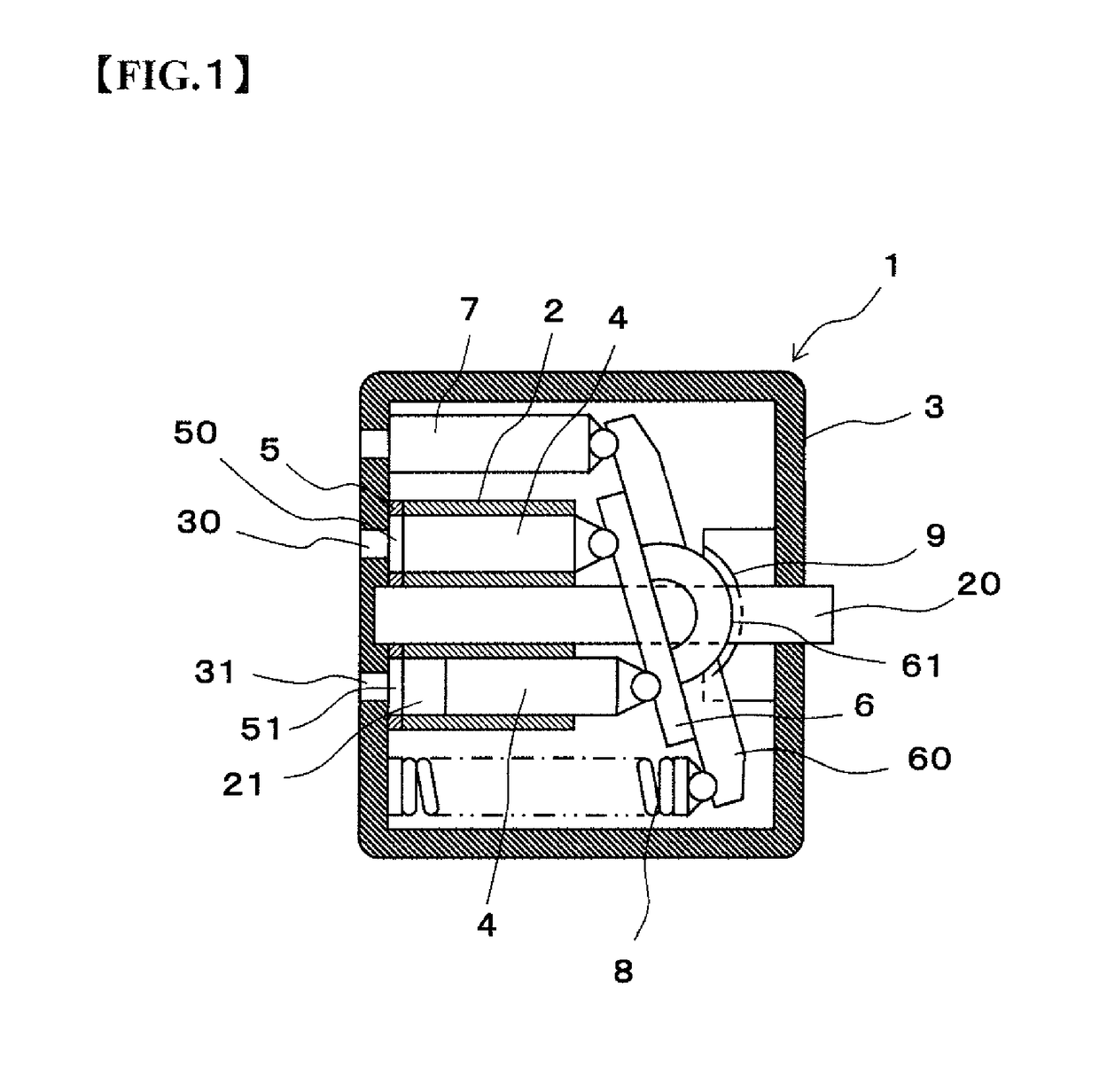

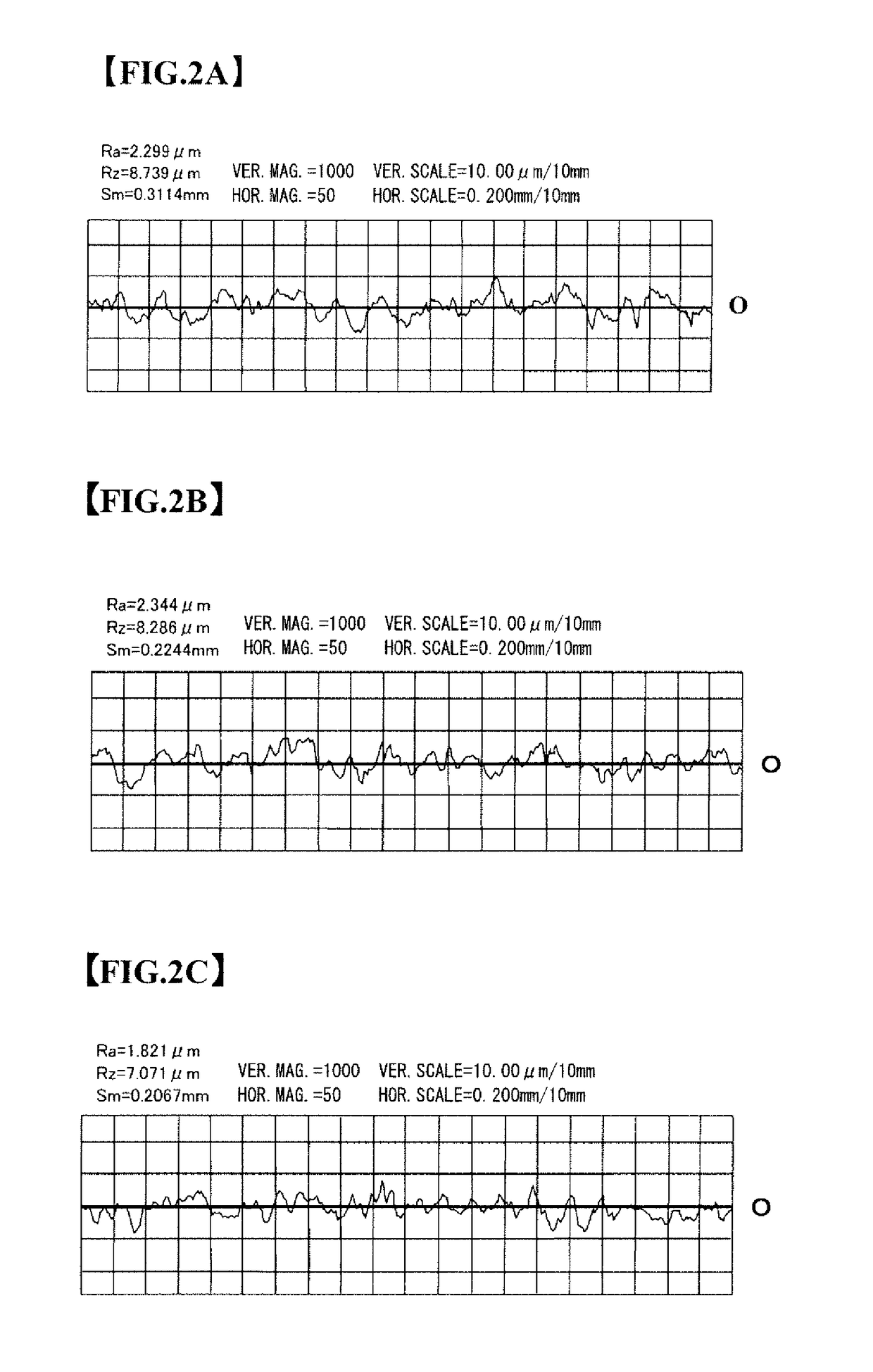

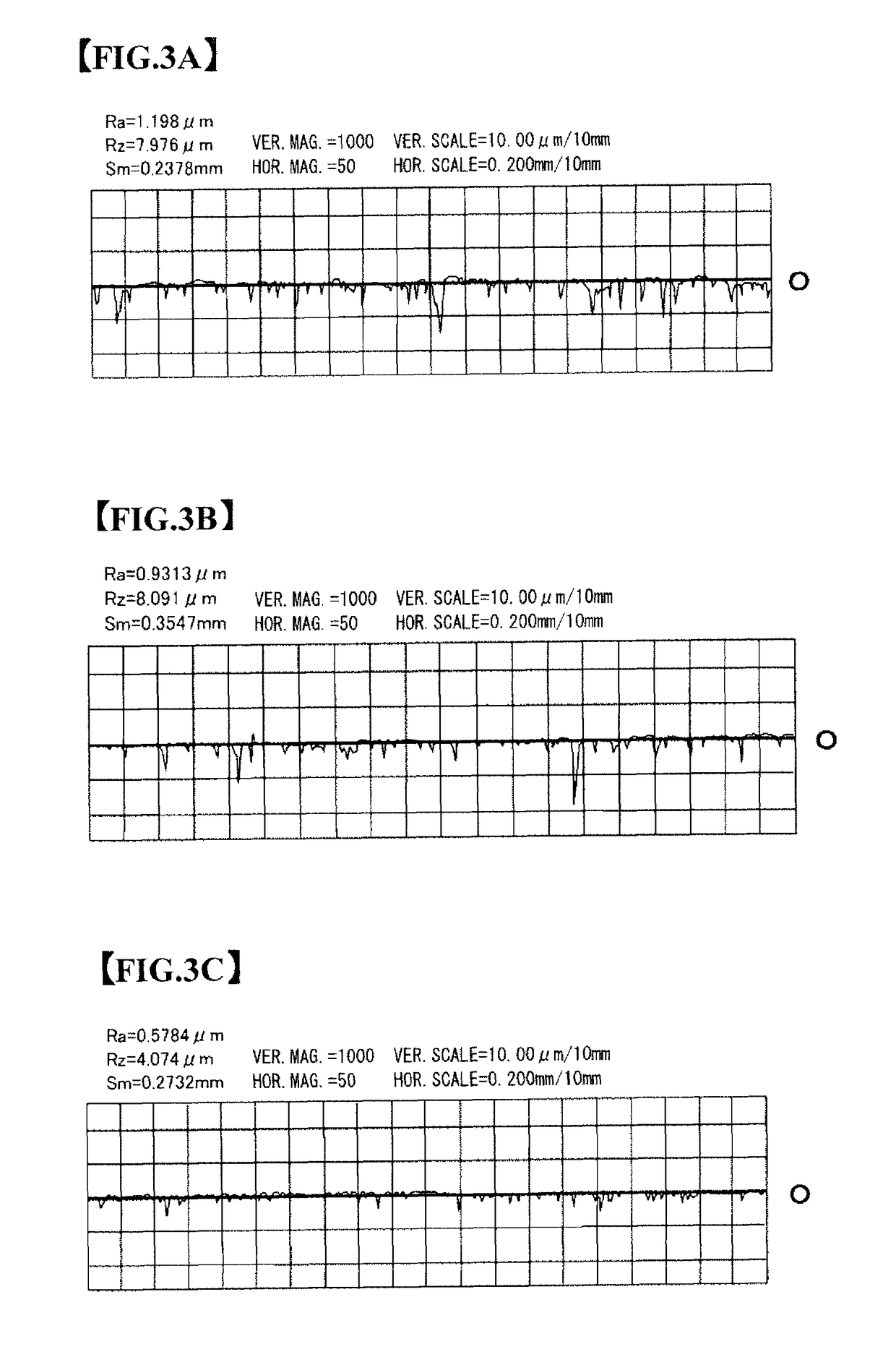

Sliding member

ActiveUS10145415B2High hardness propertiesSuppress adhesionShaftsBearing componentsHardnessHeavy load

A sliding member which has a hardness suitable for use under heavy-load conditions and which exhibits excellent abrasion resistance property. A sliding surface is formed on a surface of a sliding layer that slidably supports an object to be slid. The sliding surface is then shot-blasted and is formed to have an uneven shape exhibiting an arithmetic average roughness (Ra) of more than 0 to 2.0 μm, a ten-point average roughness (Rz) of more than 0 to 7.5 μm, and a surface hardness (Hv) of 150 to 250.

Owner:SENJU METAL IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com