Carbon-diamond cutting head

A technology of cutter head and carbon gold, applied in the direction of stone processing tools, manufacturing tools, stone processing equipment, etc., can solve the problem that the cutter body and cutter head do not have long-term use function, the manufacturing difficulty of cutter body and cutter head, and the increase of stone products, etc. problem, to achieve the effect of low production cost, light weight, and reduced stone waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

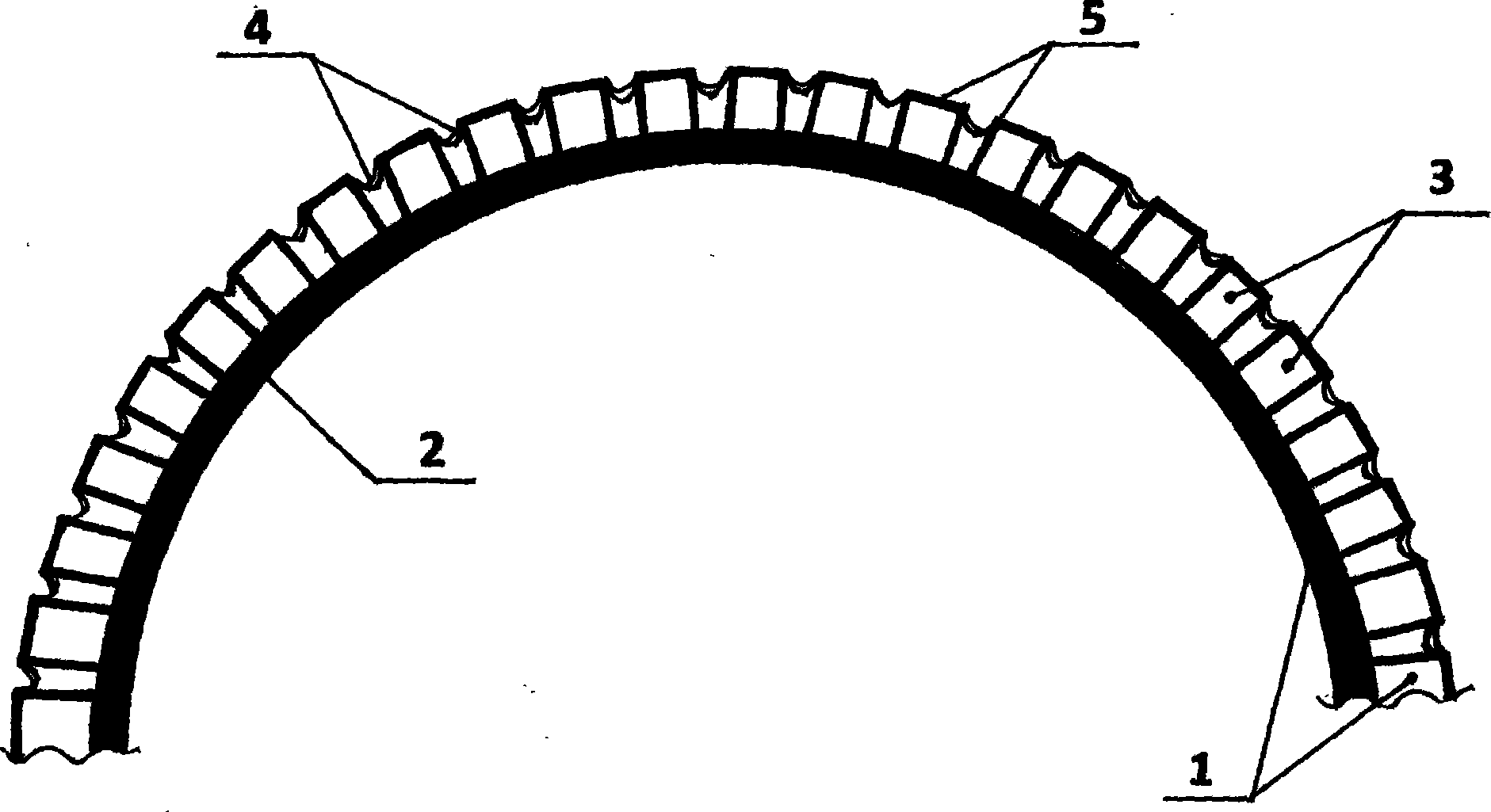

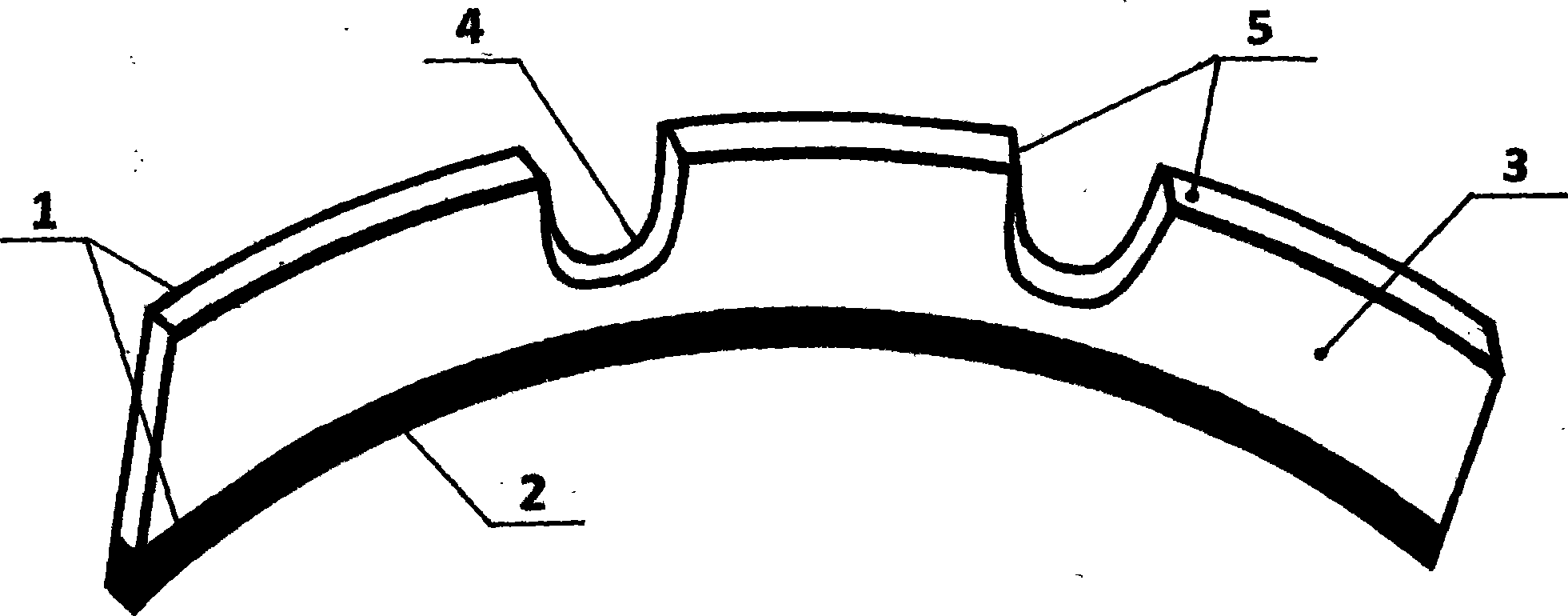

[0016] The structure of a kind of carbon-gold cutter head is described in detail hereby in conjunction with accompanying drawing:

[0017] see figure 1 , 2 , First, the cutting surface corresponding to the basic blade of the cutter head is coated with a hard film coating. The hard film coating includes diamond, graphite, cubic boron nitride, titanium nitride, silicon nitride, and aluminum oxide (one of them), and its thickness is between 0.0009-0.18 mm. Because the invention adopts a material with high hardness and is combined with a hard alloy cutter head through a coating process, the wear resistance of the cutter head is greatly improved, and the service life of the saw blade is also improved at the same time. 2. Mix carbon nitride particles, graphite diamond powder, cubic boron nitride particles, titanium carbonitride powder and carcass powder by hot pressing and sintering, wherein the carcass powder consists of Cu65-75wt%, Sn10-25wt%; The body weight is 2.2-2.8wt% of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com