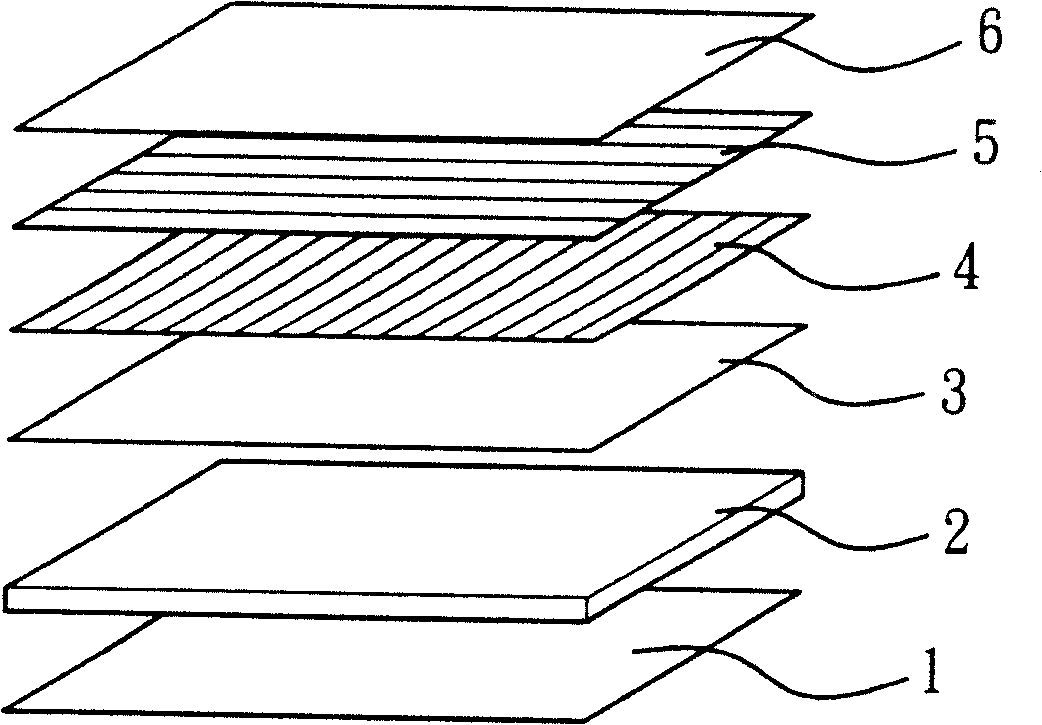

Antiscraping optical film and use thereof

A technology of optical film and anti-scratch layer, applied in the field of optical film, can solve the problems of bead shedding, film warpage, poor resin coating, etc., and achieve good antistatic properties, protection of contact components, and high hardness characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

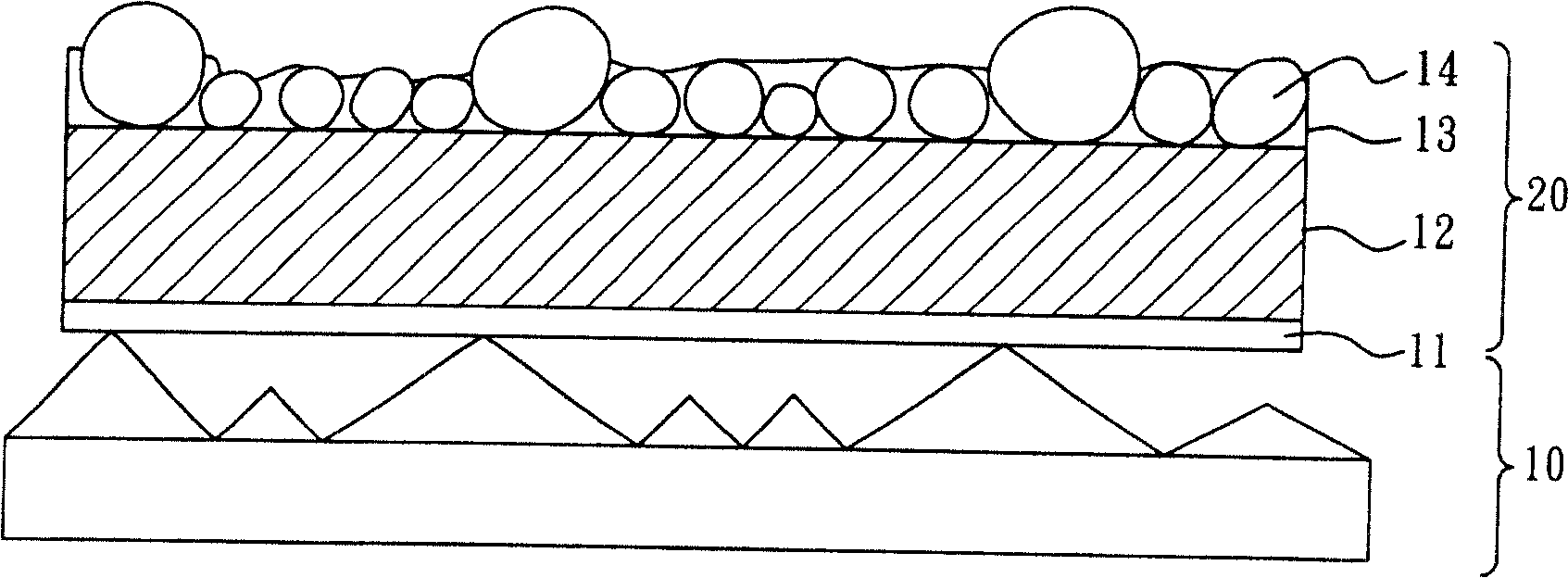

[0074] 1. The first hard mask layer (diffusion layer)

[0075] Take a 250 ml glass bottle, and add solvent: 20 grams of toluene and 6 grams of methyl ethyl ketone into the glass bottle. Under high-speed stirring, add 3 grams of acrylic microparticles [MB30X-8, Japan Sekisui Chemical Co., Ltd.] with an average particle size of 8 μm, UV-curable resin: 2-hydroxyethyl methacrylate, methyl methacrylate, A total of 12 grams of monomer mixture of butyl acrylate and pentaerythritol triacrylate, thermosetting resin: 10 grams of acrylate resin [Eterac 7363-ts-50, Eternal company] (solid content about 50%), then add 1.0 grams of hardener [ Desmodur 3390, Bayer Company] (about 75% in solid content), 2.0 g of antistatic agent [GMB-36M-AS, Marubishi oilChem.Co., Ltd] (about 20% in solid content), photoinitiator: diphenylbenzene A total of 0.6 grams of the mixture of ketone and 1-hydroxycyclohexyl phenyl ketone was finally soaked into a coating with a solid content of about 40% and a total ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com