Method for obtaining a foamed laminar product

A foam layer and product technology, applied in the field of obtaining foam layer products, can solve problems such as increasing production costs and increasing manufacturing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

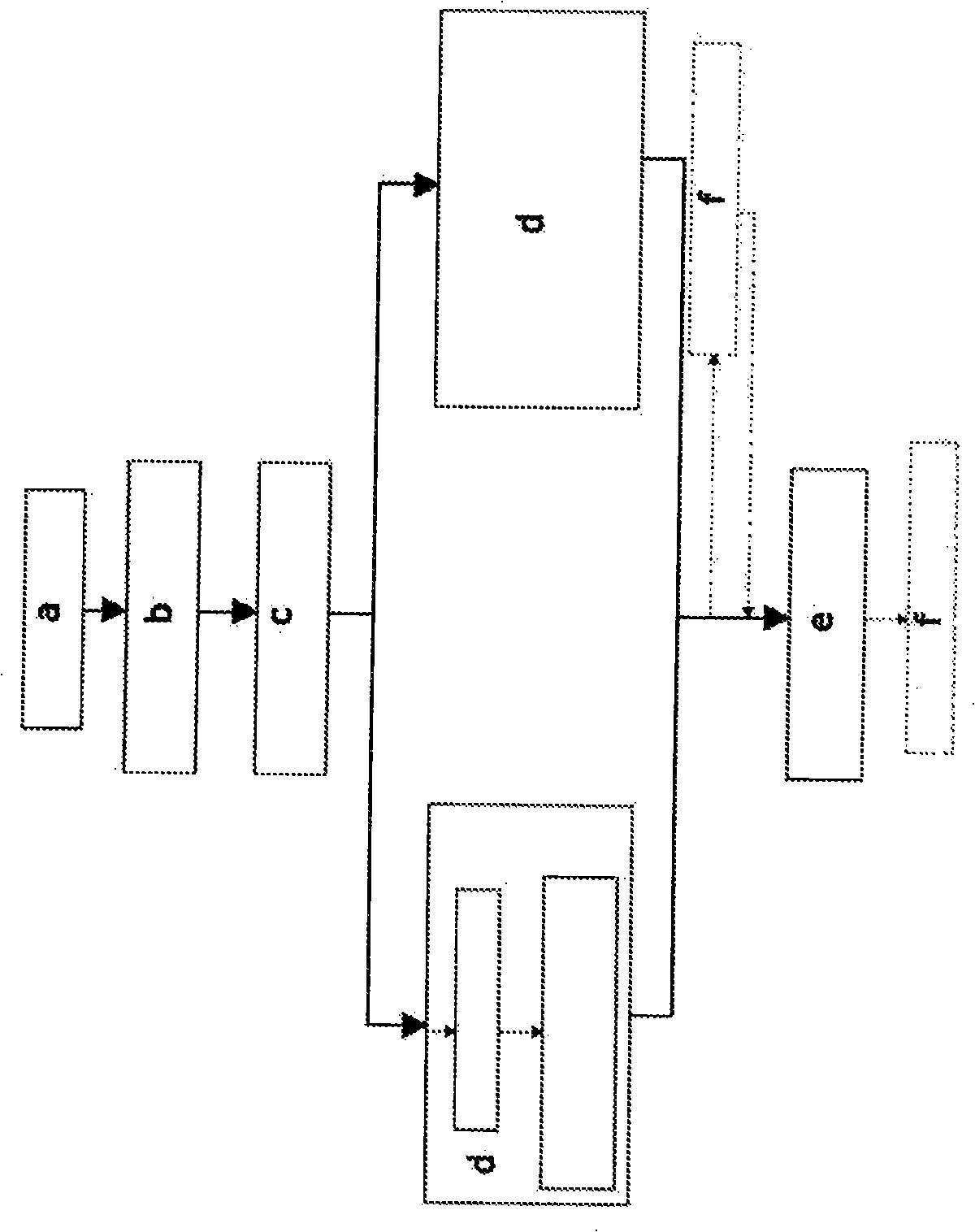

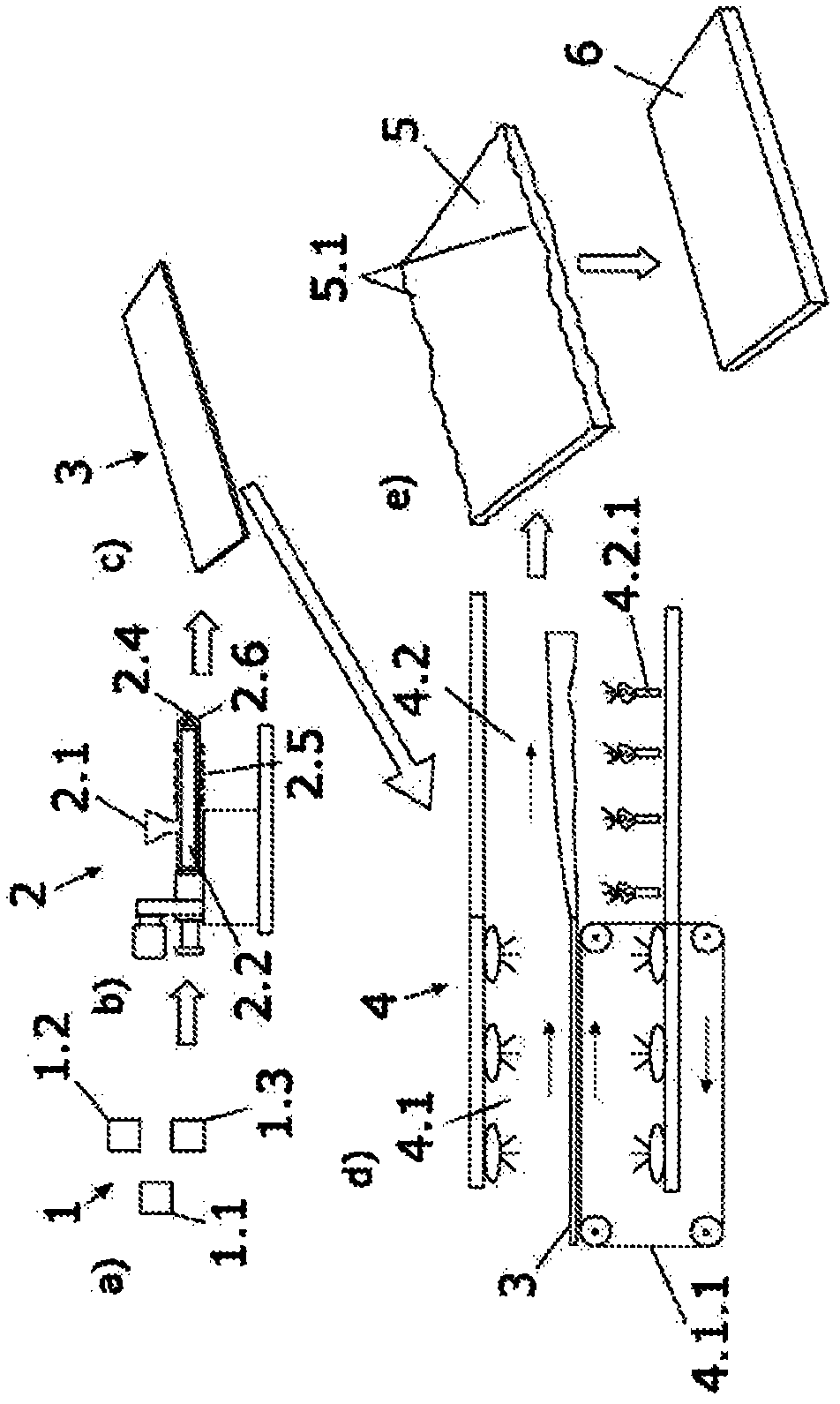

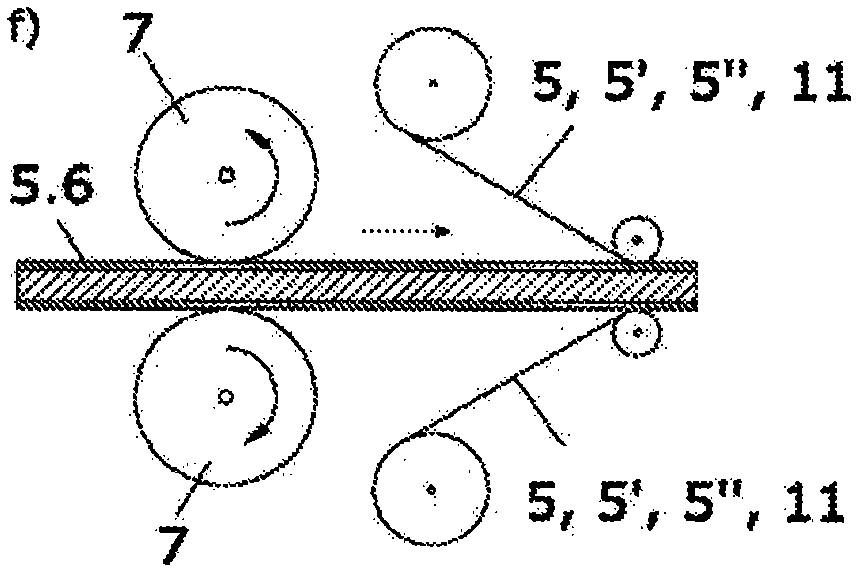

[0040] Based on the above, the present invention relates to a method for obtaining foamed layer products based on a homogeneous mixture of at least one polyolefin and additives incorporating fiber reinforcement, all these components forming an integral part of the foamed layer product.

[0041] Before starting to describe the steps constituting the method for obtaining the foamed laminar product (6), the components (1) making up the above laminar product (6) are: polyolefin, additives and fibrous reinforcement.

[0042] Polyolefin (1.1) is the main constituent of the layer product, ie forms the basis of the mixture of component (1).

[0043] The polyolefin (1.1) can be, for example, polyethylene or polypropylene or a mixture of the two aforementioned polymers.

[0044] The second component which forms the ply and which is also the main cause of the stiffness of the ply is the fiber reinforcement (1.2).

[0045] Fiber reinforcement (1.2) is used as a loading for the mixture of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com