High-hardness high-scratch-resistance spraying-free highlight PC/PBT alloy material and preparation method thereof

An alloy material and scratch-resistant technology, which is used in the field of high-hardness, high-scratch-resistance, spray-free high-gloss PC/PBT alloy materials and their preparation. Low problems, to achieve the effect of scratch resistance, excellent hardness and scratch resistance, good high gloss performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

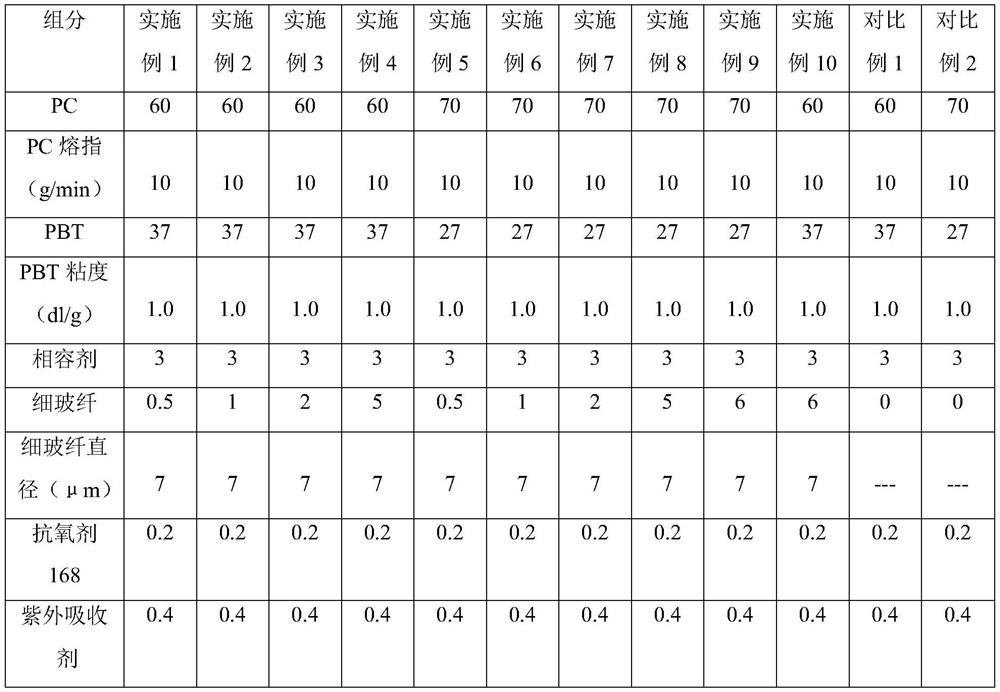

[0026] Weigh 60 parts of PC, 37 parts of PBT, 3 parts of compatibilizer, 1680.2 parts of antioxidant, 0.4 part of ultraviolet absorber UV-2340.4 part and 0.2 part of PETS according to the ratio of parts by weight and mix and stir to obtain the mixture; wherein the compatibilizer is E-MA-GMA, the melt index of PC is 10g / min, the viscosity of PBT is 1.0dl / g, and the single filament diameter of fine glass fiber is 7μm.

[0027] Put the mixture into the extrusion equipment, and at the same time feed 0.5 parts of fine glass fiber from the side feeding port, blend at a high speed of 250r / min for 10 minutes, then melt and extrude through the extruder, pelletize and cool to obtain high strength and high durability. Scratch-free spray-painted high-gloss PC / PBT alloy material.

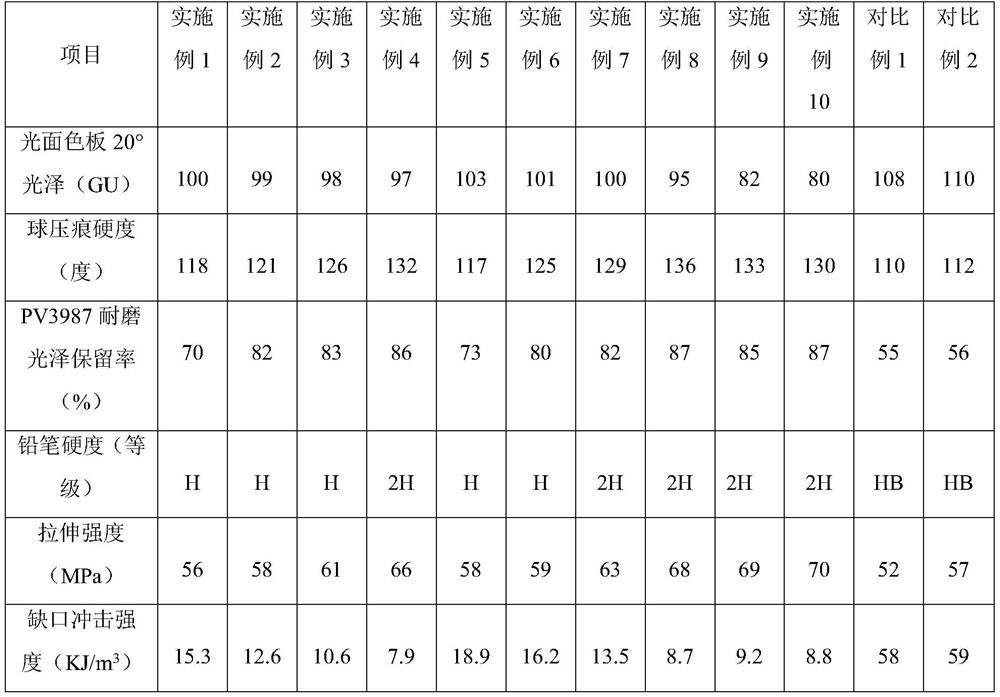

[0028] The PC / PBT alloy material that present embodiment obtains is carried out experimental detection, detects its glossy swatch 20 ° gloss (GU), ball indentation hardness (degree), PV3987 wear-resisting gloss ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

| Monofilament diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com