A Method for Predicting Oil Well Fluid Level Based on Dynamic Integrated Modeling

A prediction method and dynamic liquid level technology, applied in the information field, can solve problems such as poor generalization ability, poor model performance, and poor real-time performance, and achieve the effect of improving generalization ability, shortening update time, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

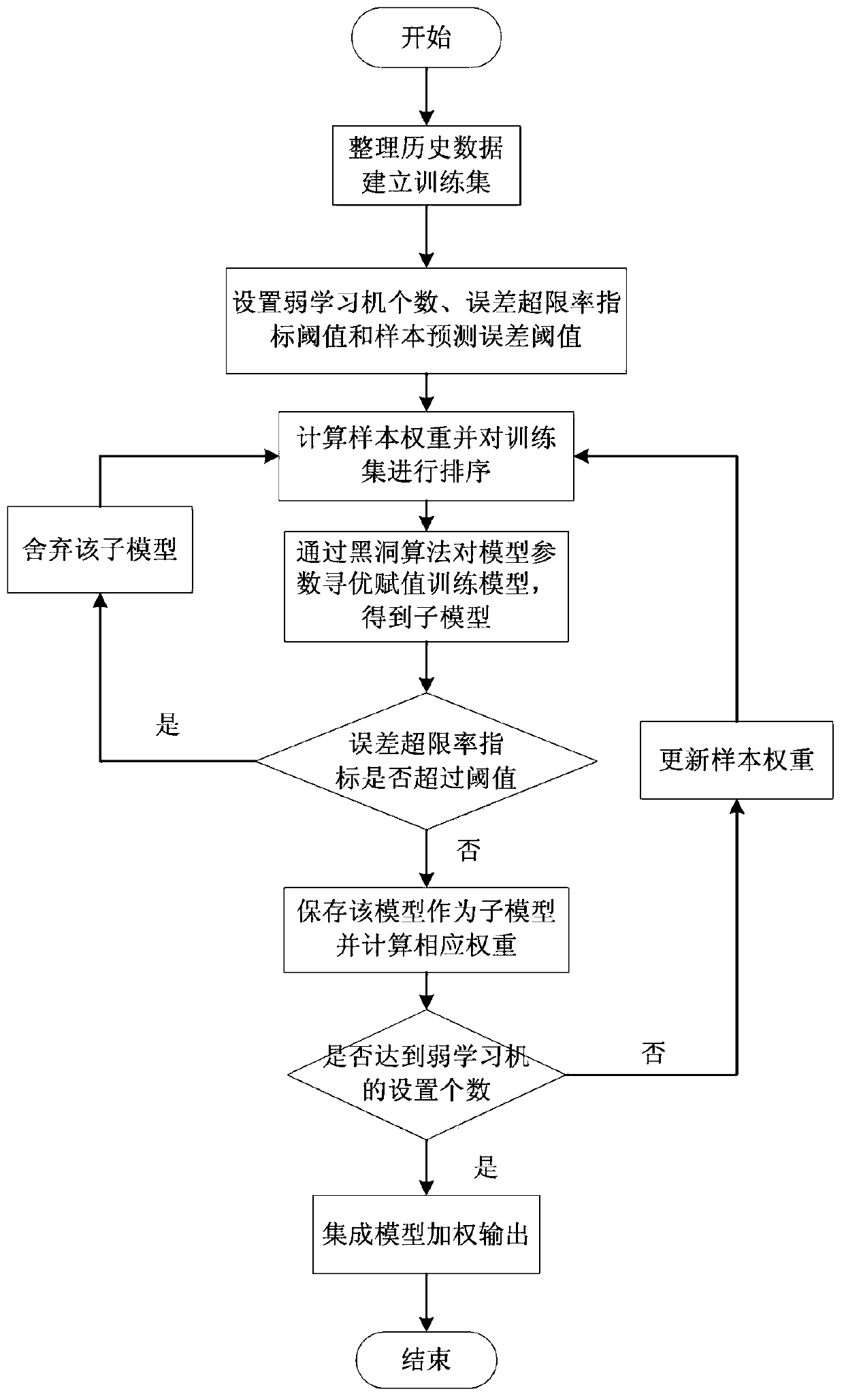

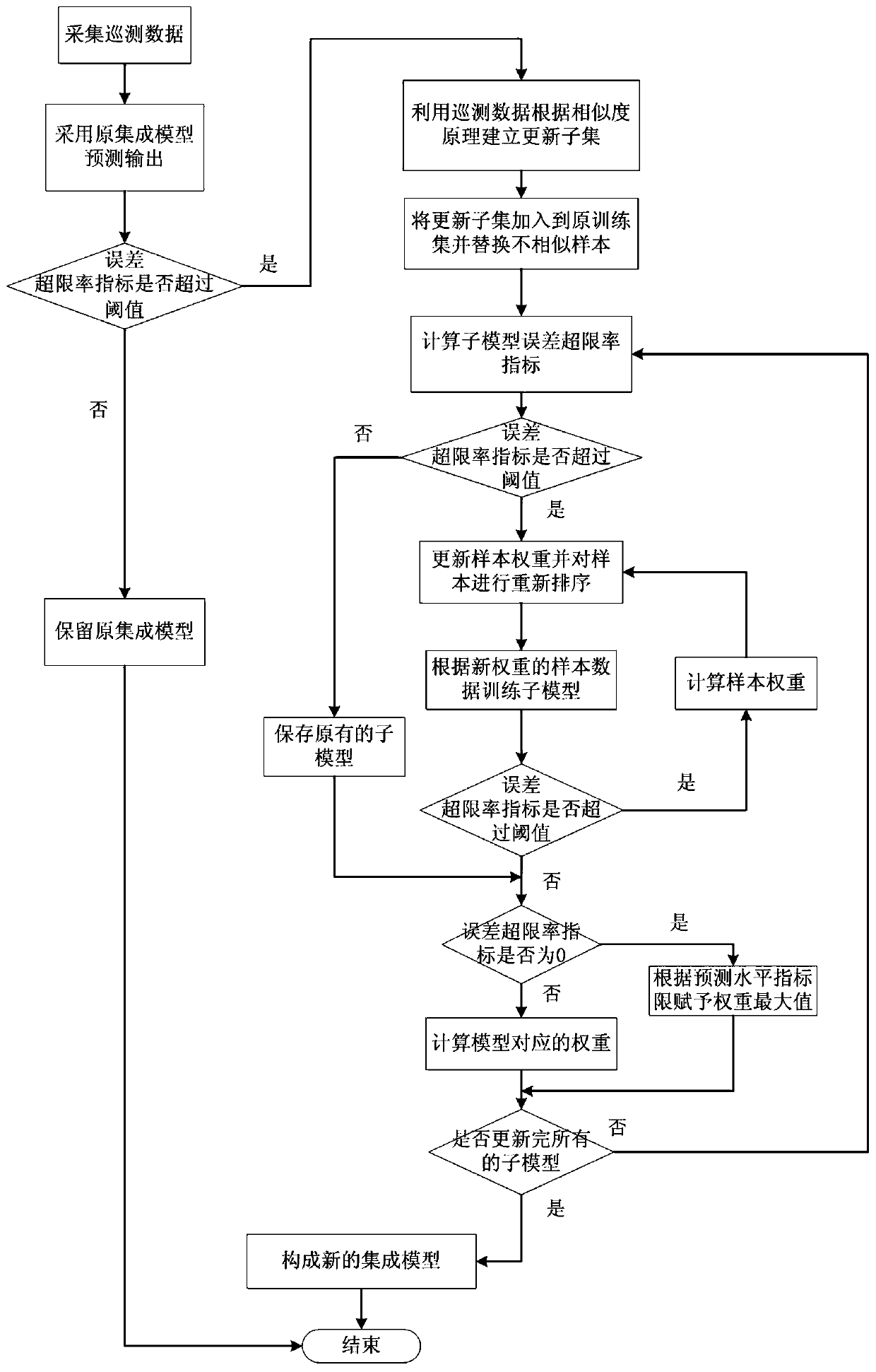

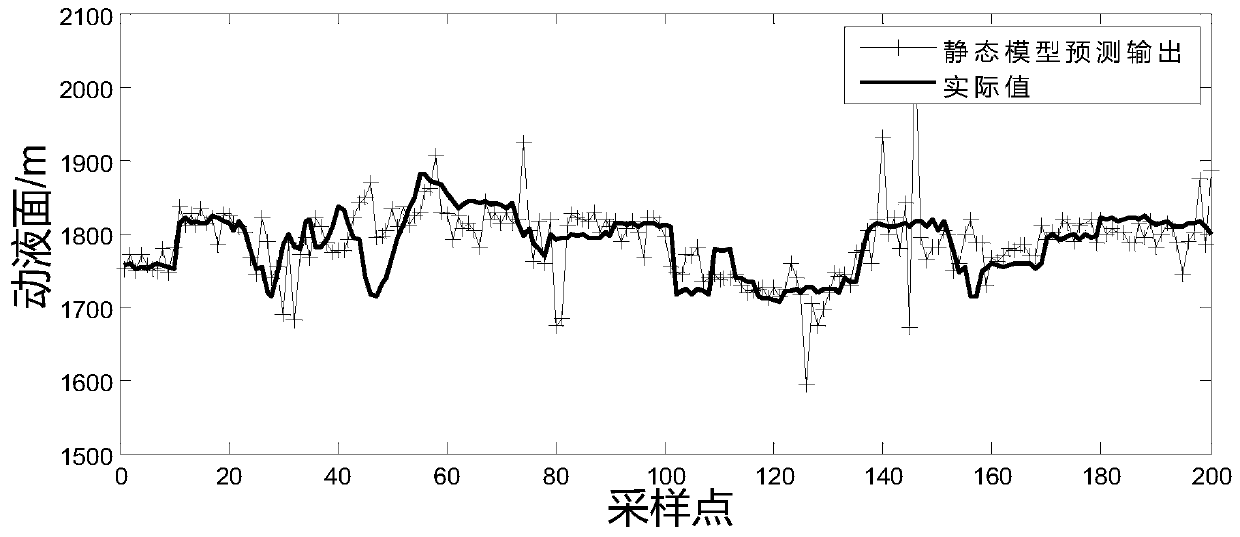

[0037] Such as Figure 1-2 As shown, a dynamic modeling-based prediction method for fluid level in oil wells includes the following steps:

[0038] Step 1: If figure 1 As shown, to obtain the dynamic liquid level data y in the process of oil well production i And dynamic fluid level data y i The corresponding auxiliary variables, the auxiliary variables form the auxiliary vector x i , the dynamic fluid surface data and its auxiliary vector constitute the historical data (x i ,y i ), wherein, i=1,2,...,m, m is the number of historical data, and is historical data (x i ,y i ) to assign weights to the median Divide historical data into training set TR for training the model t and a test set TE for testing the model t , where TR t +TE t = m, t indicates that the current model is the tth sub-model, t=1, 2, ..., T; the auxiliary variables include: oil well casing pressure, pump efficiency and flow;

[0039] Step 2: Set the number T of weak learning machines and the samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com