Burster block of composite structure and manufacturing method of burster block

A composite structure and manufacturing method technology, applied to the structure of armor plates, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of increased weight of bullet-proof plates, armor plate weight, and energy-absorbing deformation of fiber fabrics, etc., to achieve Excellent fracture toughness and impact resistance, high impact resistance and multiple impact resistance, good rigid support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

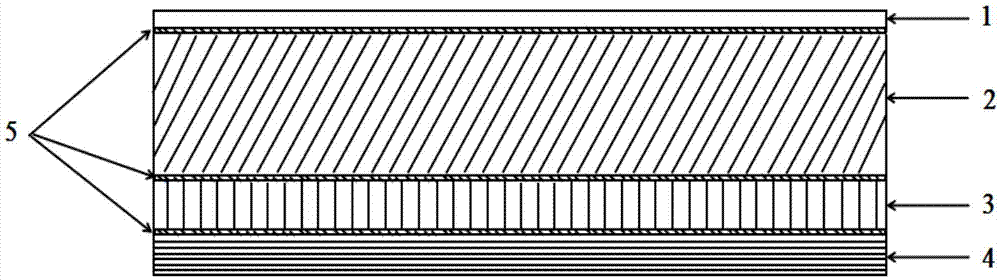

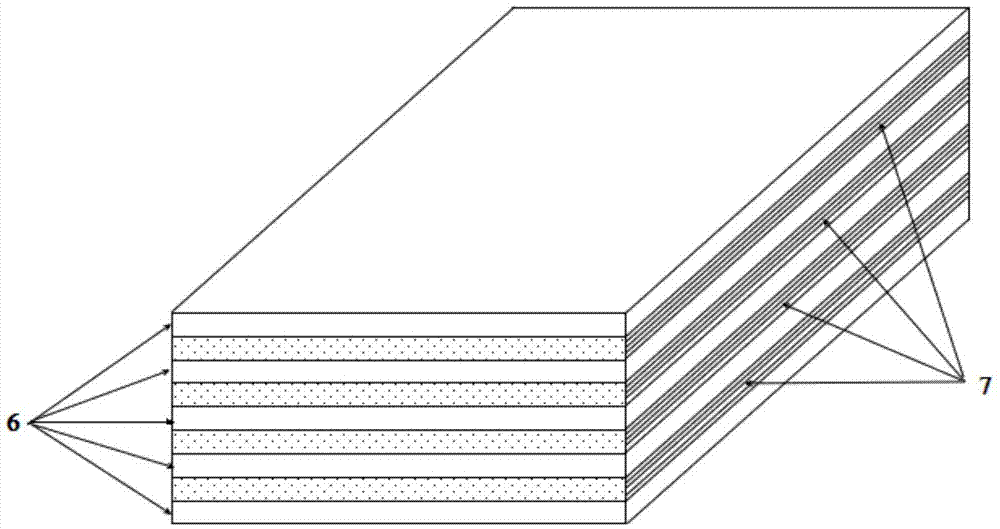

[0034] Wherein, the preparation method of the fiber metal composite laminate of the support layer 4 comprises the following steps:

[0035] Step 1: Select the type, size, thickness and quantity of materials for the metal plate 6 and the fiber prepreg 7 according to the needs of the support layer 4 .

[0036] Step 2: Surface treatment of the metal plate 6 is carried out by a sandblasting process. First put the metal plate 6 in an acetone solution at 50-60°C for 20-30 minutes in a water bath for degreasing treatment; then take out the metal plate 6 and rinse it with clean water; use a pressure-feeding sandblasting machine with a particle size of 150 mesh The bauxite fine sand is evenly blown on the surface of the metal plate 6 under the air pressure of the spray gun of 0.6-1 MPa, and lasts for 20-30 seconds until the surface of the metal plate 6 becomes matte.

[0037] Step 3: Lay the surface-treated metal plate 6 and fiber prepreg 7 in an alternating manner of multiple layers ...

Embodiment 1

[0042] A composite structure bulletproof plate, the size of which is a flat plate of 300×300mm. The protective layer is aramid fiber non-weft cloth with a thickness of 0.2mm and a surface density of 2.88kg / m 2 ;The ceramic layer is a 15mm thick boron carbide board with a surface density of 37.65kg / m 2 ; The energy-absorbing layer is aramid fiber non-weft cloth, the thickness is 5mm, and the surface density is 7.2kg / m 2 The support layer is a fiber-metal composite laminate formed by compounding carbon fiber prepreg and magnesium alloy metal plate through the process of the present invention, and the density of the fiber-metal composite laminate is 1.64g / cm 3 , surface density is 3.28kg / m 2 , tensile strength ≥ 810MPa, tensile modulus ≥ 82.0GPa; Among them, there are five magnesium alloy metal plates, the thickness of a single magnesium alloy metal plate is 0.2mm, four layers of carbon fiber prepreg, and the thickness of a single layer of carbon fiber prepreg 0.15mm. The pro...

Embodiment 2

[0044] A composite structure bulletproof plate, the size of which is a flat plate of 300×300mm. The protective layer is a carbon fiber non-weft cloth with a thickness of 0.2mm and an area density of 3kg / m 2 ;The ceramic layer is a whole plate of alumina ceramics with a thickness of 18mm, and the surface density is 52.4kg / m 2 ;The energy-absorbing layer is ultra-high molecular weight polyethylene fiber without weft cloth, the thickness is 7mm, and the surface density is 6.44kg / m 2 The support layer is a fiber metal composite laminate formed by compounding carbon fiber prepreg and magnesium-lithium alloy metal plate through the process of the present invention, and the density of the fiber metal composite laminate is 1.50g / cm 3 , surface density is 6kg / m 2 , tensile strength ≥ 1100MPa, tensile modulus ≥ 78.0GPa; Among them, there are five magnesium-lithium alloy metal plates, the thickness of a single magnesium-lithium alloy metal plate is 0.2mm, four layers of carbon fiber pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com