High-temperature-corrosion-resistant paint, preparation method thereof, high-temperature-corrosion-resistant coating and preparation method thereof

A high-temperature corrosion-resistant and coating technology, applied in anti-corrosion coatings, metal material coating processes, coatings, etc., can solve the problems affecting the wide application of supercritical thermal power units, limiting the effective operation of supercritical thermal power units, etc., to improve smoke resistance. Gas erosion performance, good surface condition, effect of improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides a preparation method of the high-temperature corrosion-resistant coating described in the above technical solution, comprising the following steps:

[0039] (1) mixing ceramic powder and metal powder, and carrying out high-energy ball milling to obtain cermet powder;

[0040] (2) mixing chromium, nickel and the cermet powder obtained in the step (1) to obtain a high-temperature corrosion-resistant coating.

[0041] The invention mixes the ceramic powder and the metal and performs high-energy ball milling to obtain the cermet powder. The present invention has no special requirements on the method of mixing the ceramic powder and the metal, and the material mixing method well known to those skilled in the art can be used. In an embodiment of the present invention, the mixing of the ceramic powder and the metal is specifically stirring and mixing; the rotation speed of the stirring and mixing is preferably 100-300r / min, more preferably ...

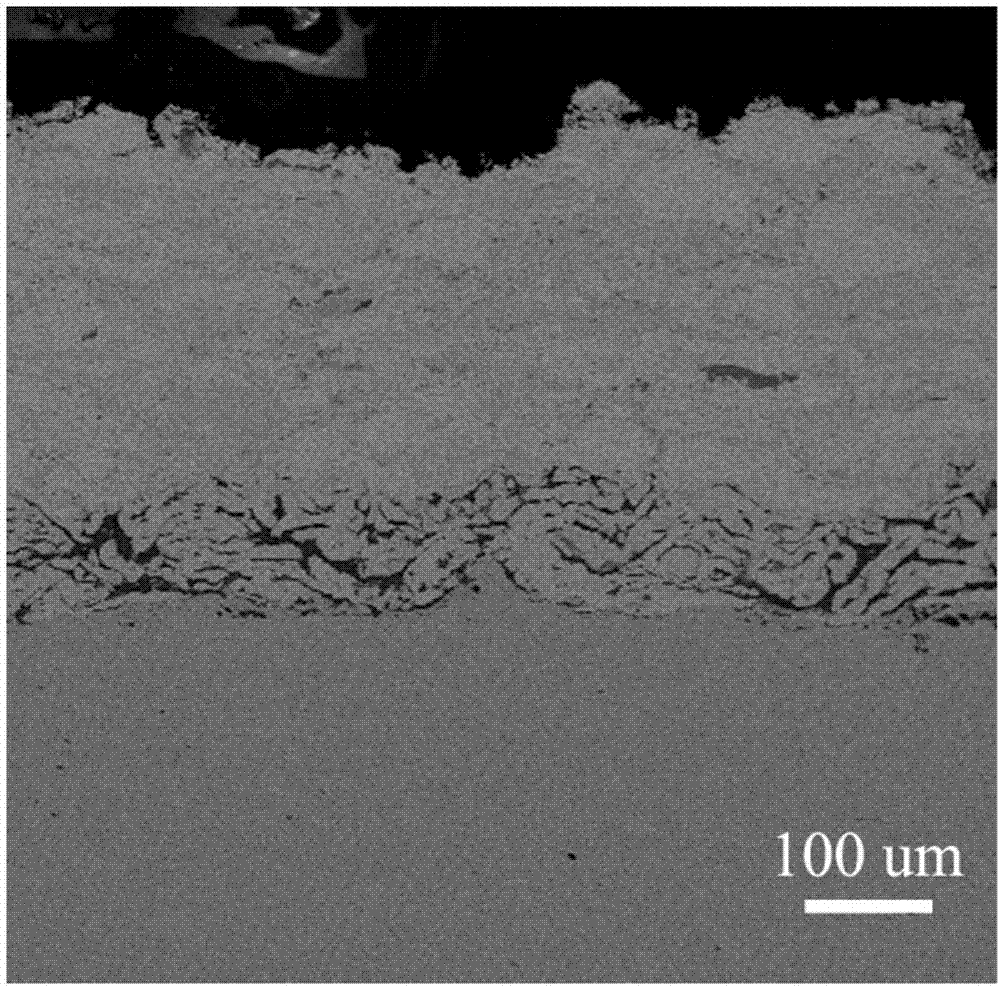

Embodiment 1

[0064] (1) Cr with a particle size of 0.5 microns 3 C 2 Powder and spherical CeO with a particle size of 5 nm 2 The powder is mixed in a mass ratio of 4:1 to make a uniformly mixed ceramic powder, and the aluminum with a particle size of 3 μm and the titanium with a particle size of 3 μm are mixed in a mass ratio of 3:1 to obtain a metal powder; ceramic powder and metal The powder is mixed according to the mass ratio of 1:1, and the high-energy ball milling is carried out under the protection of argon for 5 hours, and the ball milling time of the high-energy ball mill is 4.5h, the speed is 350r / min, and the ball-to-material ratio is 30:1 to make titanium and / or aluminum Encapsulated ceramic powder. According to the mass percentage, 50% of chromium, 36% of nickel, and 14% of metal-wrapped ceramic powder are uniformly mixed to obtain thermal spray powder, that is, a high-temperature corrosion-resistant coating.

[0065] (2) Taking No. 20 carbon steel with a specification of 6...

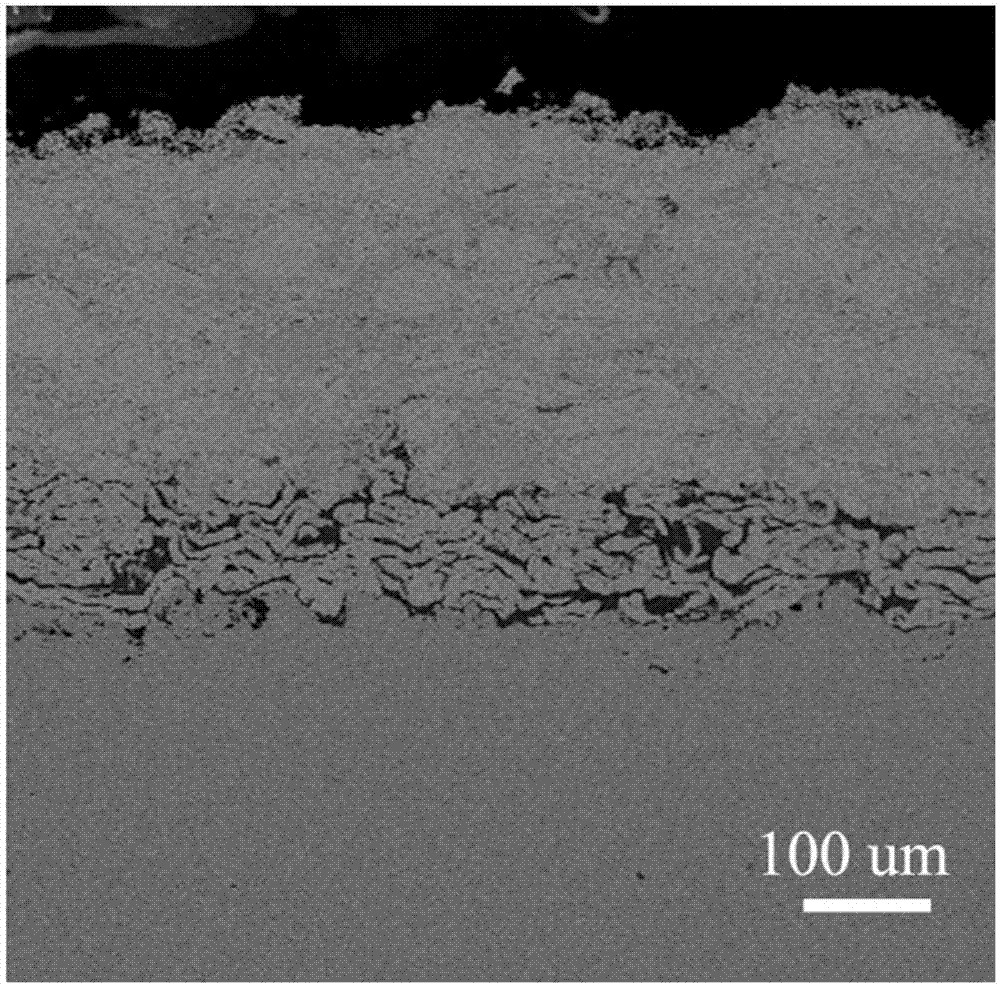

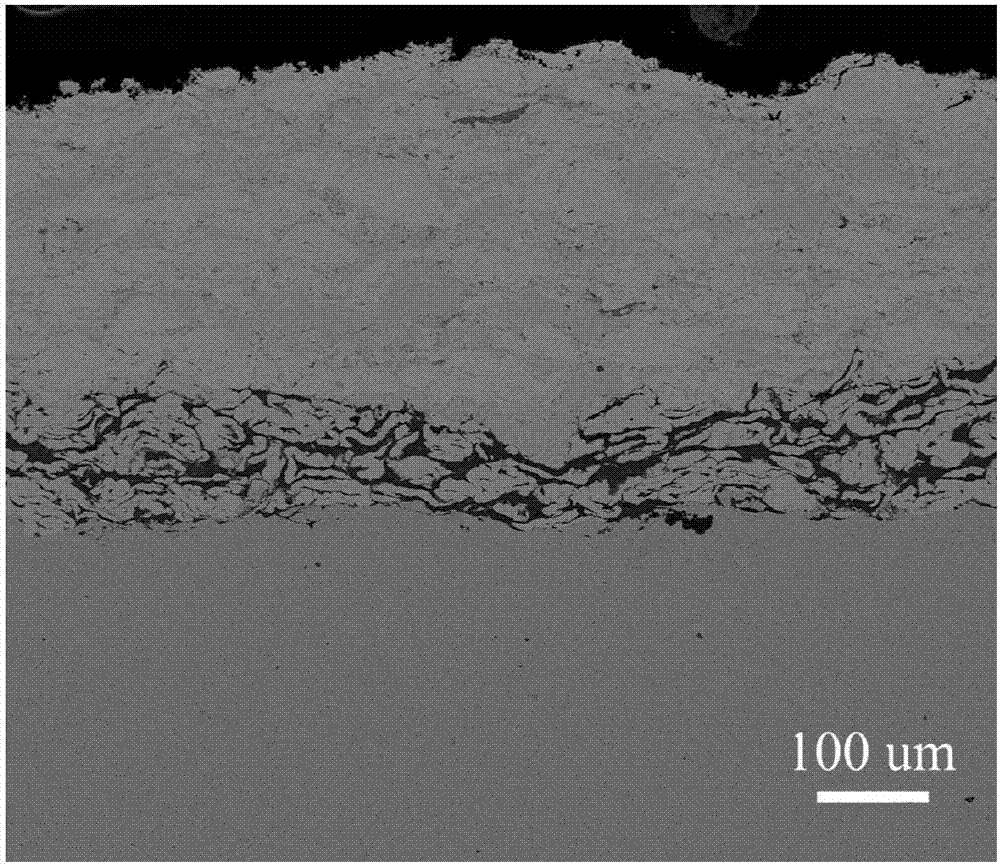

Embodiment 2

[0073] (1) Cr with a particle size of 10 microns 3 C 2 Powder and spherical CeO with a particle size of 30 nm 2 The powder was mixed mechanically at a mass ratio of 3:1 and at a speed of 150r / min for 10 minutes to obtain ceramic powder; aluminum with a particle size of 1 μm and titanium with a particle size of 1 μm were configured at a mass ratio of 2.2:1, and mechanically mixed at a speed of 150r / min Mix for 10 minutes to obtain metal powder; mix ceramic powder and metal powder according to the mass ratio of 1:1, and perform high-energy ball milling under the protection of argon for 5 hours, wherein the rotation speed is 320r / min, and the ball-to-material ratio is 25:1 to obtain titanium and / or aluminum coated ceramic powder. According to the mass percentage of 54% chromium, 33% nickel, and 13% ceramic powder wrapped in titanium and / or aluminum, the three powders were mechanically mixed at 150r / min for 10 minutes, and mixed evenly to prepare a thermal spray powder, that i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com