Environment-friendly flame retardant asphalt and preparation method thereof

An environmentally friendly and asphalt technology, applied in building thermal insulation materials, building components, buildings, etc., can solve the problems of low decomposition temperature, increase working steps, and be unfavorable to construction, reduce the addition amount, improve flame retardant performance, flame retardant and smoke suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

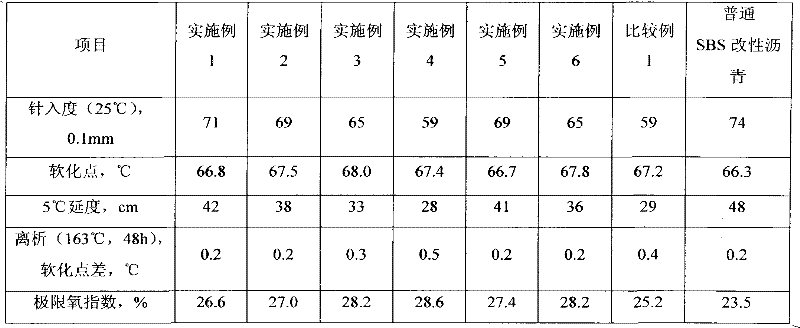

Embodiment 1

[0022] Step 1: Add magnesium aluminum carbonate hydrotalcite (particle size is 20-40nm), appropriate amount of deionized water and titanate coupling agent NDZ-201 accounting for 5% of the hydrotalcite weight into the reactor in sequence, and put it in a constant temperature water bath at 80°C. Continue stirring for 1 h, filter, wash, and dry to obtain surface-modified hydrotalcite.

[0023] Step 2: Add 3 parts of melamine phosphate and 0.6 parts of surface-modified hydrotalcite to 100 parts of 160°C 4% SBS modified asphalt, and stir and mix with ordinary stirring (450rpm / min) for 1 hour to obtain flame-retardant SBS modified asphalt .

Embodiment 2

[0025] The method for preparing the surface-modified hydrotalcite is the same as step 1 in Example 1, the coupling agent is stearic acid, and the dosage is 8% of the weight of the hydrotalcite.

[0026] Add 6 parts of melamine phosphate and 1.2 parts of surface-modified hydrotalcite to 100 parts of SBS modified asphalt at 160°C, and mix with ordinary stirring (450 rpm / min) for 1 hour to obtain flame-retardant SBS modified asphalt.

Embodiment 3

[0028] The method for preparing the surface-modified hydrotalcite is the same as step 1 in Example 1, the coupling agent is a silane coupling agent, and the dosage is 10% of the weight of the hydrotalcite.

[0029] Add 9 parts of melamine phosphate and 1.8 parts of surface-modified hydrotalcite to 100 parts of 160°C SBS modified asphalt, and mix with ordinary stirring (450rpm / min) for 1 hour to obtain flame-retardant SBS modified asphalt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com