Exhaust system for gaseous film cooling central cone of turbofan aircraft engine

An exhaust system and film cooling technology, which is applied in the direction of machines/engines, jet propulsion devices, etc., can solve the problems of low mixing efficiency of annular mixers, high temperature and large proportion of hot exhaust gases in exhaust systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

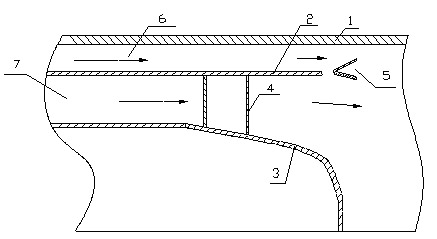

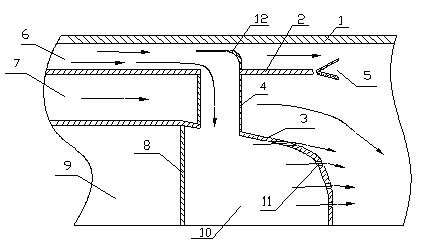

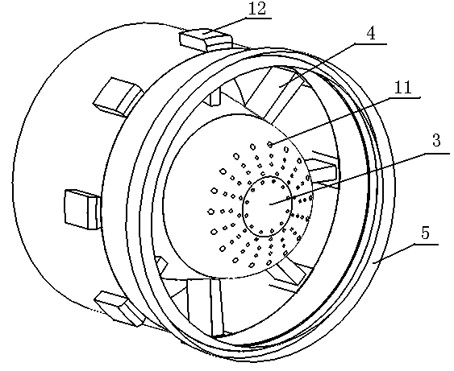

[0013] Such as figure 2 , image 3 and Figure 4 As shown, the outer culvert gas passes through 8 deflectors, and part of the outer culvert cold air enters the center cone rear cavity 10 through 8 hollow turbine rear support plates 4, and the cold air flows out from many small holes arranged on the surface of the center cone. The surface of the cone has a significant cooling effect. A model test study was carried out on the illustrated structure. The test conditions are: the gas flow rate in the inner channel is 0.9kg / s, and the temperature is 893K; the gas flow rate in the outer channel is 0.72 kg / s, and the outer temperature is 305K. The surface temperature of the central cone was measured with a thermal couple, and the backward infrared radiation intensity of the exhaust system was measured with a Fourier spectroradiometer. The test results show that the use of the air film cooling center cone proposed in this patent can reduce the surface temperature of the center con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com