Patents

Literature

136results about How to "High coating hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cemented carbide cutting tool for multi-component coating

ActiveCN101407905AHigh coating hardnessImprove antioxidant capacityVacuum evaporation coatingSputtering coatingAlloyHigh intensity

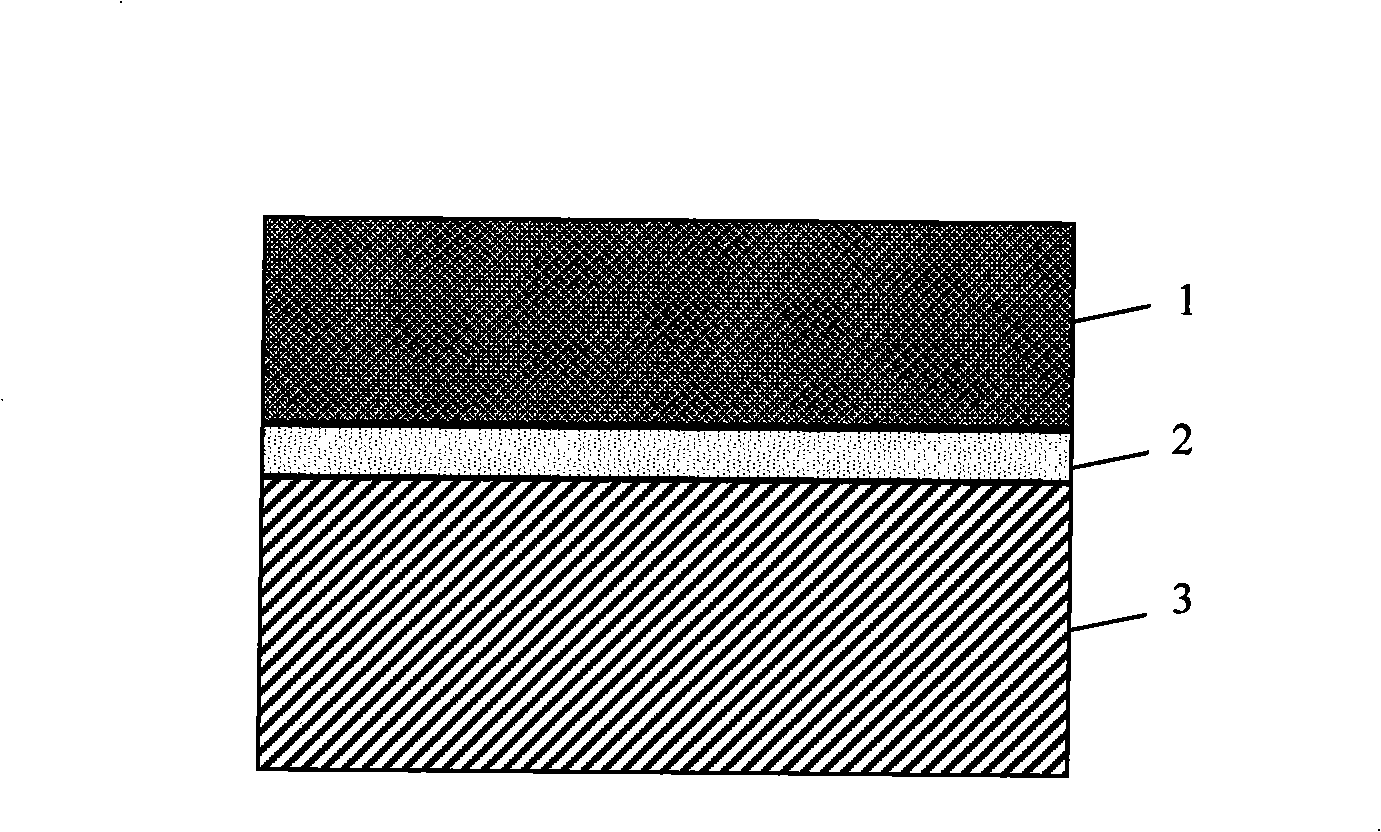

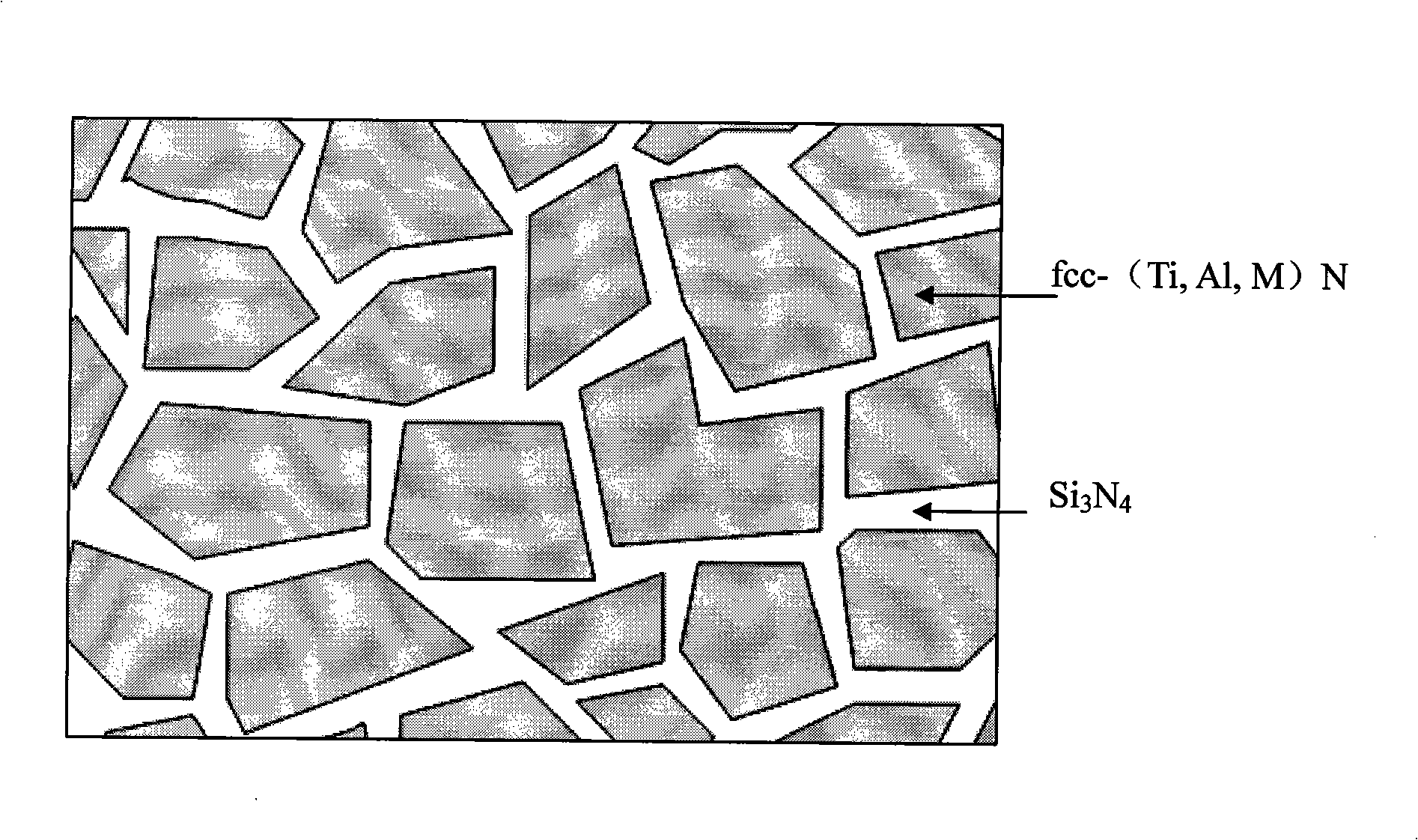

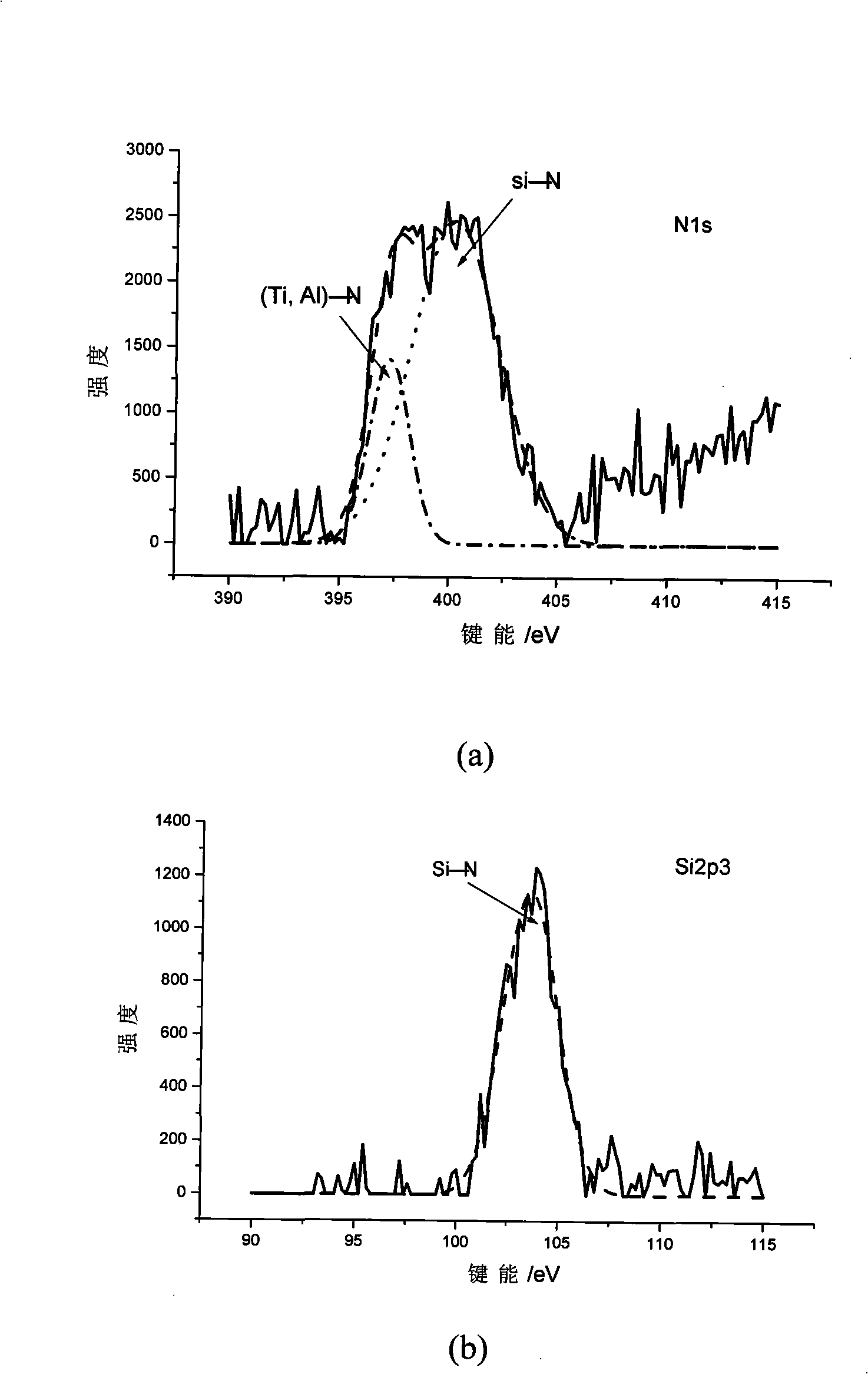

The invention discloses a cemented carbide cutting tool of a multi-component coating, which comprises a matrix and a coating coated on the matrix by a PVD method; wherein, the coating comprises a matrix binding layer coated on the matrix and a composite mixed crystal structural layer which is coated on the matrix binding layer and contains nano crystalline / amorphous composition; the matrix binding layer comprises at least a Ti-based metal layer which comprises at least one of metal elements of Al, Si and groups of IVB, VB and VIB; the composite mixed crystal structural layer comprises elements of Ti1-a-b-cAlaMbSicN, wherein M is one or a plurality of metal elements of Ta, Nb, Zr, Cr, Hf and W. The cemented carbide cutting tool has the advantages of high wearing resistance, high intensity, high temperature resistance, impact resistance, good binding of the coating and matrix, etc.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

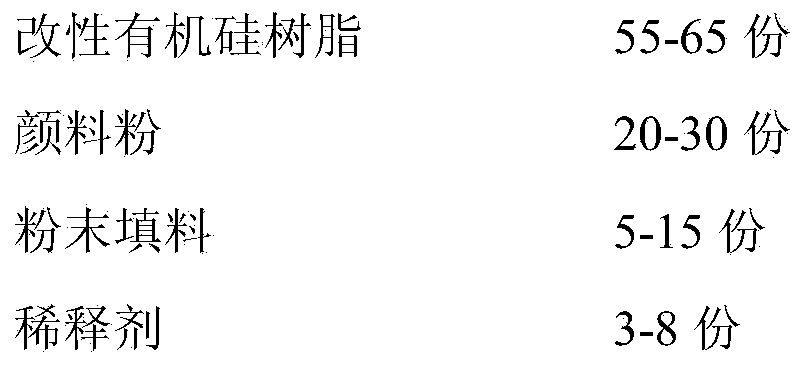

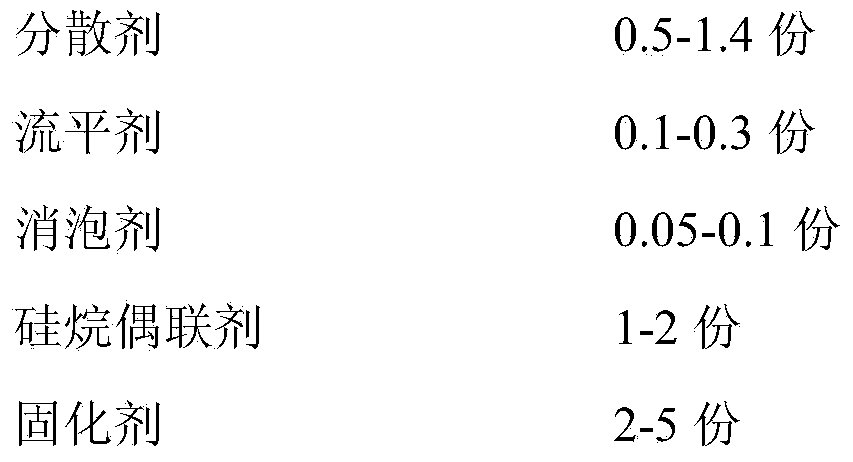

Thermosetting high temperature resisting printing ink for touch screen as well as preparation method of printing ink

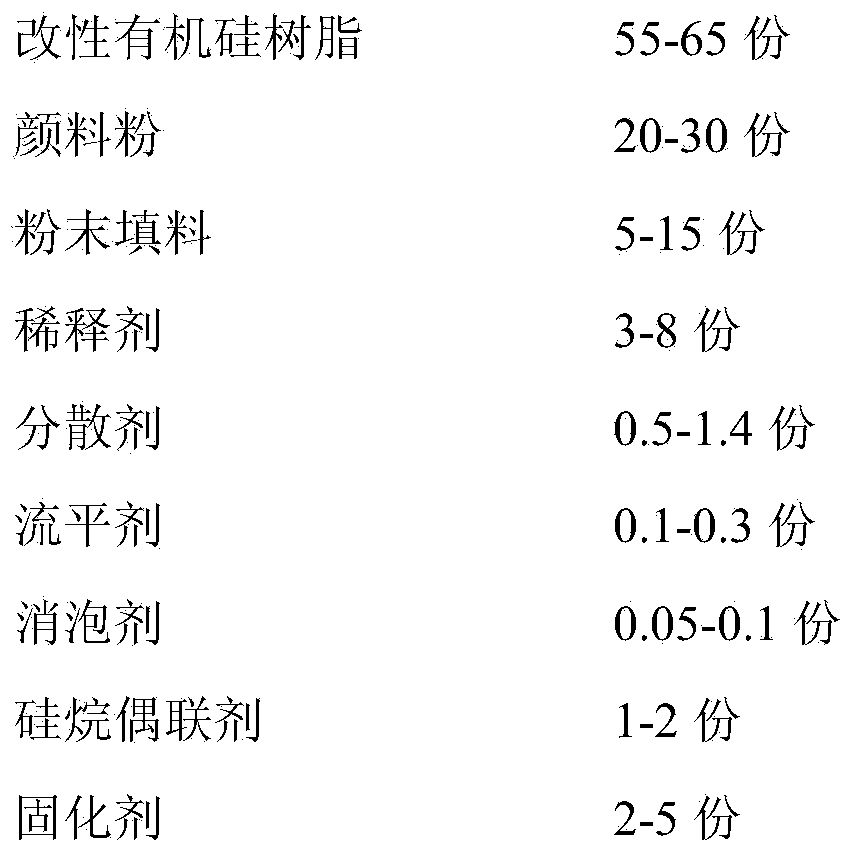

The invention discloses thermosetting high temperature resisting printing ink for a touch screen as well as a preparation method of the printing ink. The formula of the printing ink comprises the following raw materials in parts by weight: 55-65 parts of modified organic silicon resin, 20-30 parts of titanium dioxide, 5-15 parts of powder packing, 3-8 parts of a diluent, 0.5-1.4 parts of a dispersant, 0.1-0.3 part of a leveling agent, 0.05-0.1 part of a defoamer, 1-2 parts of a silane coupling agent and 2-5 parts of a curing agent. The preparation method comprises the following steps: mixing the modified organic silicon resin, a pigment, the powder packing, 0.35-0.95 part of the dispersant, 0.05-0.15 part of the leveling agent and 2-5.4 parts of the diluent to obtain a main agent; and adding the curing agent, the defoamer, the silane coupling agent as well as remaining leveling agent, dispersant and diluent into the main agent, and dispersing, filtering and discharging. The printing ink coating is high temperature- resisting in coating, excellent in color retention at a high temperature of 300 DEG C, good in adhesion to a base material, high in hardness, resistant to acetone wiping and resistant to ITO (Indium Tin Oxides) etching liquids.

Owner:深圳市卓联电子有限公司

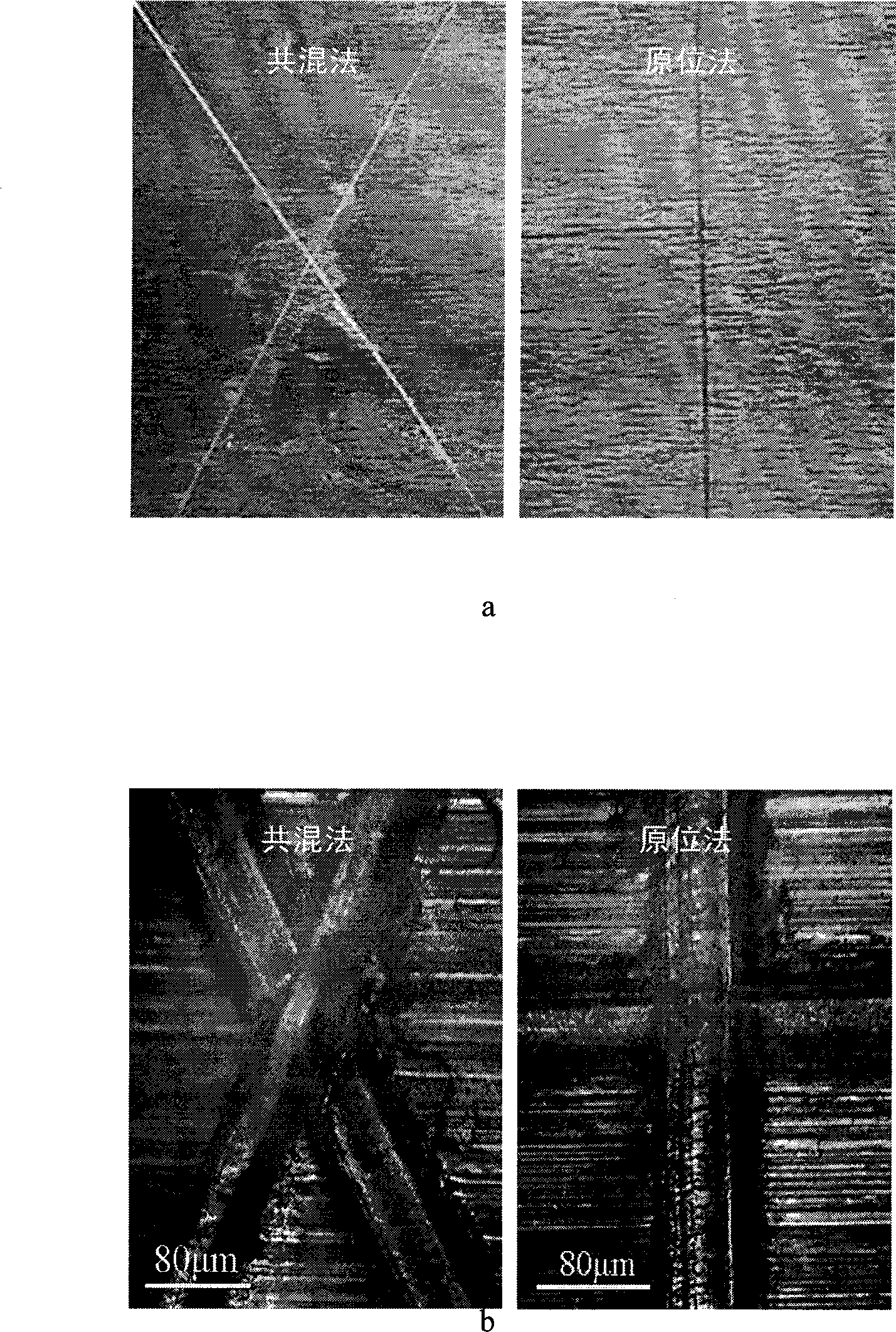

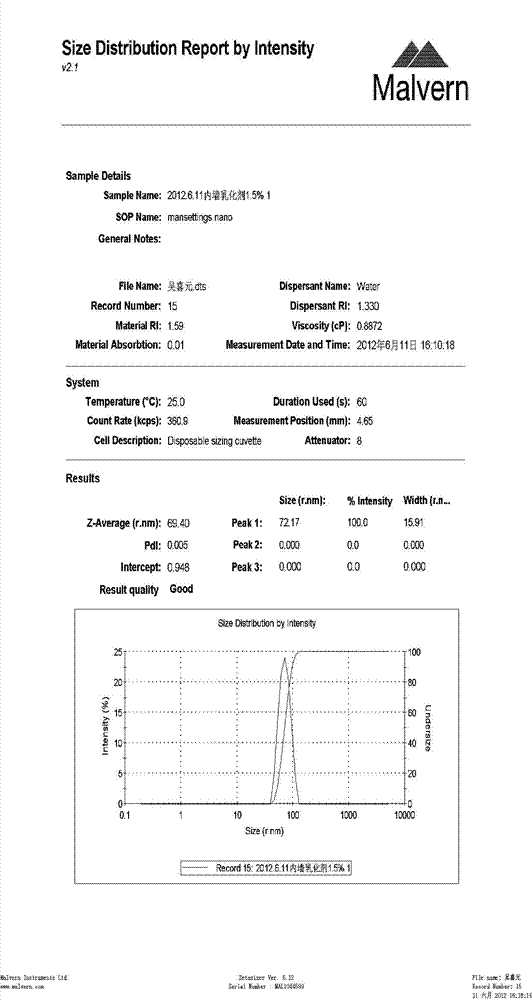

Preparation of high performance metal protection nano coating

InactiveCN101486869AHigh coating hardnessImprove adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyIn situ polymerization

A method for preparing a high-performance metal protection nanometer coating includes the following steps of: ball-milling diluter and nanometer oxide particles according to the weight ratio of 40-100:1 to obtain nanometer oxide suspension; measuring acrylic ester and remaining copolymerization monomers according to the weight ratio of 2-3:1 to obtain a mixed monomer, adding the nanometer oxide suspension accounting for 80 percent of the total weight of the mixed monomer and adding reaction additives to obtain a mixture which is stirred for 10min to obtain in-situ polymerization precursor liquid. Under nitrogen protection, 10 percent of the in-situ polymerization precursor liquid is added into a reaction container, within the reaction time of 1-8h, the rest 70-90 percent of the in-situ polymerization precursor liquid is dipped, and after the dripping is over, the temperature of the reaction system is raised to 90 DEG C and kept for 0.5-2h; and nanometer oxide-acrylics is obtained after adding pH regulator and stirring for 5-10min. With epoxy resin and assistant and the like added, the metal protection nanometer coating is prepared in a ball milling method.

Owner:NANJING UNIV

Magnesium alloy non-chromium dacro solution paint and its preparation method

InactiveCN1786091AStrong adhesionGood weather resistanceLiquid surface applicatorsAnti-corrosive paintsCross-linkHeat resistance

The present invention discloses a magnesium alloy chrome-free dyclo solution coating and its production method. It is characterized by that the organic silicon and nano powder body undergone the process of nano dispersing liquor treatment are dispersed in the resin made up by using several resins through the process of polymerization and cross-linking reaction to make modification, and mixed with zinc powder and aluminium powder so as to obtain the invented acid-resistant, alkali-resistant, salt fog resistant, impact-resistant and corrosion-resistant magnesium alloy chrome-free dyclo solution coating.

Owner:长春吉大化学有限公司

Preparation method of waterproof and whiting-resistant silicon-acrylic composite emulsion for interior wall latex coatings

InactiveCN102924646AGood weather resistanceImprove adhesionEmulsion paintsPolymer scienceLatex rubber

The invention relates to a preparation method of a waterproof and whiting-resistant silicon-acrylic composite emulsion for interior wall latex coatings. The emulsion comprises the following raw materials: monomers, emulsifiers, initiators such as ammonium persulfate and deionized water. The raw materials are orderly processed through steps of pre-emulsifying the monomer, polymerizing seed emulsion, polymerizing semi-continuous emulsion and finally filtering and discharging. According to the preparation method, vinyl organic silicon, a self-crosslinking system and assistant cross-linking agents are copolymerized with acrylic esters monomers by using pre-emulsification semi-continuous seed emulsion polymerizing method to prepare the silicon-acrylic composite emulsion. Entire preparation process is stable and convenient and is beneficial to achieving mass production. The obtained composite emulsion has the advantages of monomer conversion rate of more than 96%, average emulsion particle size of less than 100 nanometers (nm), good mechanical stability and storage stability, high hardness of film, low lowest film-forming temperature and excellent whiting resistance in water and water resistance.

Owner:SHAANXI UNIV OF SCI & TECH

Wear-resistant epoxy powder coating for pipeline

InactiveCN103540220AIncrease crosslink densityHigh coating hardnessPowdery paintsEpoxy resin coatingsChemistryCarbon black

The invention relates to a wear-resistant epoxy powder coating for a pipeline. The wear-resistant epoxy powder coating comprises the following components in percentage by weight: 35-60% of epoxy resin, 5-12% of phenolic curing agent, 1-10% of latent amine type curing agent, 0.1-2% of curing accelerator, 20-45% of filler, 0.5-1% of pigment, 0.5-1% of benzoin, 0.4-1% of leveling agent, 1-30% of additive resin and 0.5-1% of gas-phase silicon dioxide. The preparation steps are as follows: (1) weighing the raw materials except white carbon black, wherein the error does not exceed 0.1%; (2) mixing the raw materials by using a high-speed dispersing machine; (3) performing twin-screw melt extrusion; (4) tabletting; (5) crushing; (6) grinding; and (7) boxing the qualified 120-mesh epoxy powder coating. The coating provided by the invention is mainly based on an epoxy system, the curing accelerator and the additive resin are added to improve the crosslinking density and the hardness of a coat and further improve the wear resistance of the coat; and the performances of the coat can reach the requirements of American Preservers Association of Engineers 0394 after the coating is cured.

Owner:SHANGHAI HILONG PETROCHEM RES INST +2

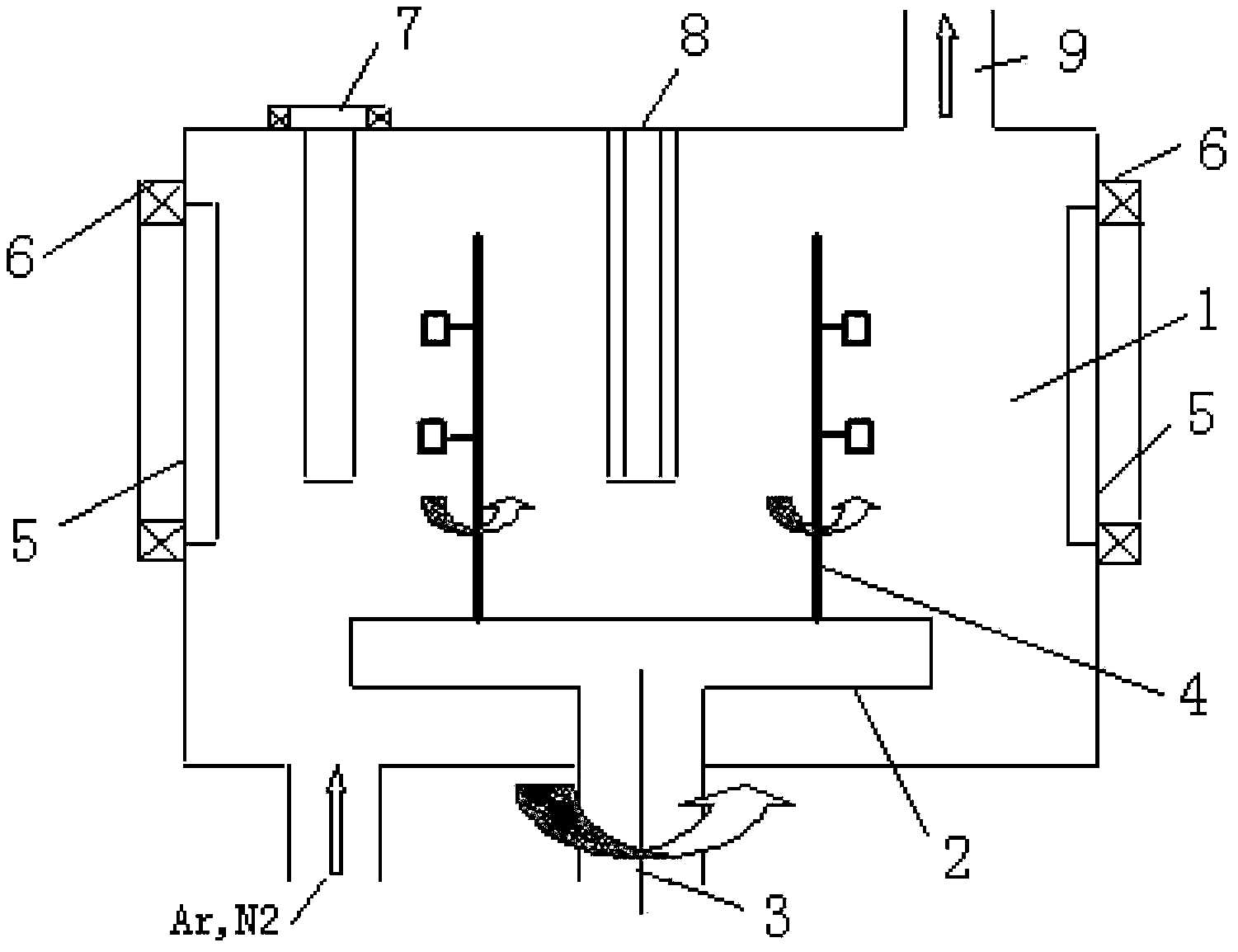

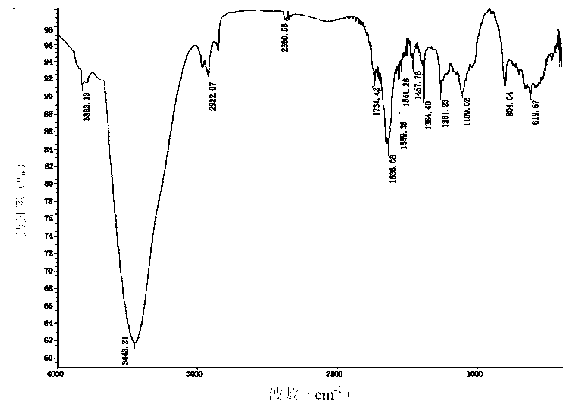

Wolframium (W) doped diamond-like coating and preparation method thereof

InactiveCN103451608AHigh coating hardnessImprove bindingVacuum evaporation coatingSputtering coatingChemical stabilityMaterials science

The invention provides a wolframium (W) doped diamond-like coating and a preparation method thereof. The coating comprises a Cr bottom layer, a CrC transition layer and a W doped diamond-like layer, wherein the Cr bottom layer is deposited on the surface of a substrate, the CrC transition layer is prepared on the Cr bottom layer, and the W doped diamond-like layer is prepared on the CrC transition layer. The preparation method comprises the following steps: firstly carrying out plasma cleaning on the substrate, opening a column electric arc Cr target to prepare the Cr bottom layer on the surface of the substrate, opening a plane magnetron sputtering C target to prepare the CrC transition layer on the Cr bottom layer, and finally closing the column electric arc Cr target and opening a plane magnetron sputtering W target to prepare the W doped diamond-like layer on the CrC transition layer. According to the preparation method provided by the invention, the electric arc and magnetron sputtering composite coating technology is adopted, so that the prepared coating is smooth and compact in surface, high in hardness, high in film bonding strength, low in friction coefficient and good in oxidization resistance and chemical stability, and can meet relatively high requirements for oxidization resistance, wear resistance and antifriction performance, therefore the coating has wide application prospects.

Owner:XI AN JIAOTONG UNIV

Water-based fluorine-containing polyurethane paint and preparation method thereof

InactiveCN102977762AHigh hardnessHigh glossPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses a water-based fluorine-containing polyurethane paint and a preparation method thereof. The water-based fluorine-containing polyurethane paint comprises the following raw materials in parts by weight: 5-8 parts of BayhydurXP2655, 60-70 parts of water-based hydroxy fluorine-containing polyurethane resin, 0.05-0.1 part of leveling agent, 1-10 parts of wetting agent, 1-3 parts of thickening agent, 0.2-1 part of defoaming agent, 2-5 parts of film-forming assistant, 0.02-1.0 part of catalyst A and 20-40 parts of deionized water. After being coated, the water-based fluorine-containing polyurethane paint has high film coating hardness, high gloss and high water contact angle, so that the water-based fluorine-containing polyurethane paint can be used in the traditional application fields of the conventional solvent polyurethane paint, such as the high-performance technical fields of automobiles, woodware, industrial maintenance, plastics, wind-driven generator vanes, solar cells and the like.

Owner:佛山市顺德区金冠涂料集团有限公司

Process for preparing functional heat transfer surface

ActiveCN1748877AImprove performanceHigh temperature resistance and good thermal stabilityChemical industrySpecial surfacesResistWater vapor

The present invention relates to heat transfer and energy saving technology, and is especially technology of modifying metal surface with functional coating and applying the modified metal surface in heat exchanger. The present invention features that paint is coated in the surface of heat exchanger and high temperature heat treated to resist corrosionú¼resist scale and raise heat efficiency. The coating contains fluoro resin in 60-70 wt%, adhesion promoting resin 20-25 wt%, heat conducting stuffing 5-10 wt%, and nanometer particle 0.5-3 wt%, and has thickness of 5-15 micron and thermal conductivity of 0.3-1.5 W / m.K. The coating makes condensed water in the heat exchange surface form drops with high heat conductance, and results in high anticorrosion and long service life of the coated heat exchanger.

Owner:DALIAN UNIV OF TECH

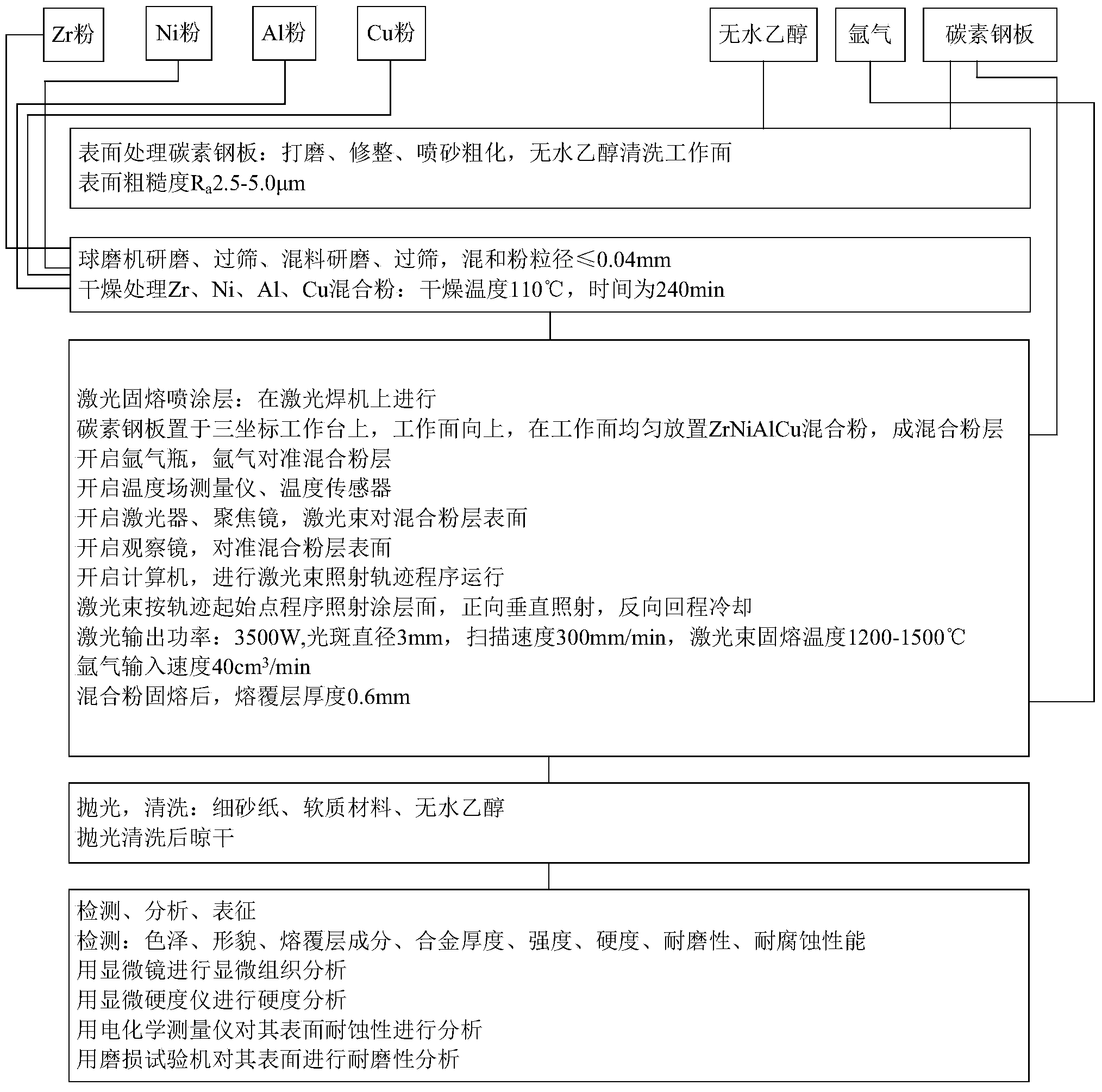

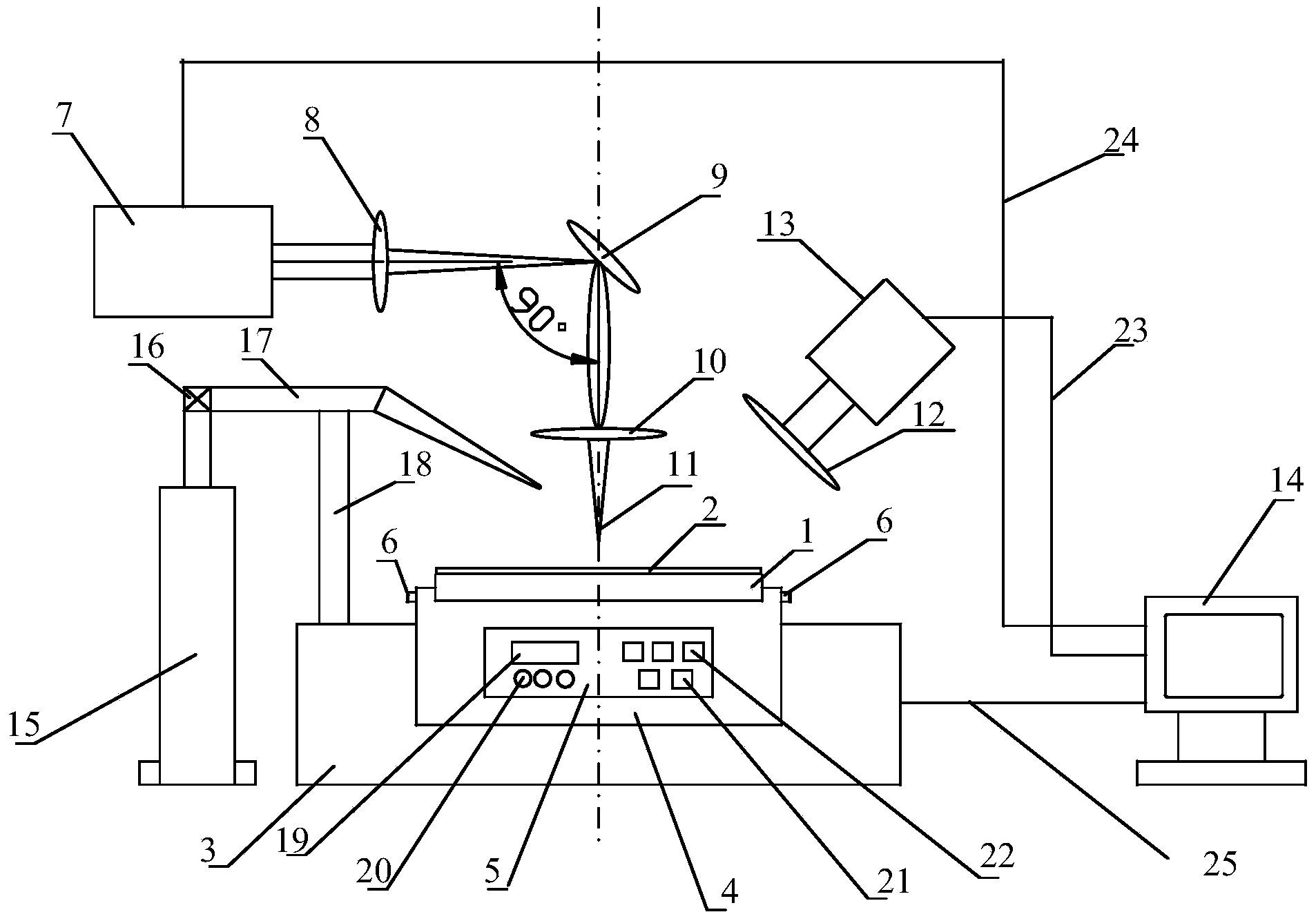

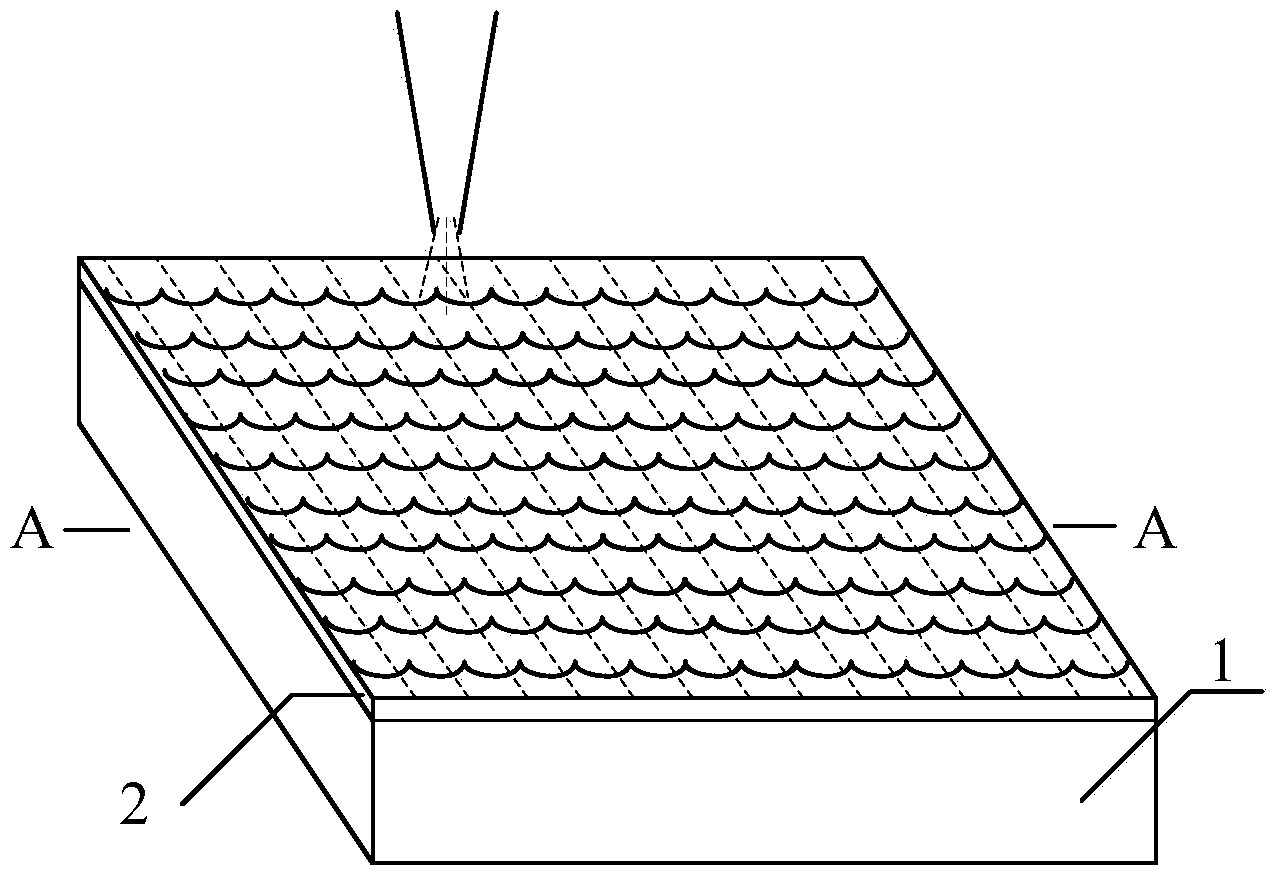

Method adopting laser cladding to form amorphous alloy coating on surface of carbon steel

ActiveCN103668177AEnhanced Amorphous Formation AbilityShort processMetallic material coating processesAlloy coatingLaser beams

The invention relates to a method adopting laser cladding to form an amorphous alloy coating on the surface of carbon steel, and as the laser cladding method is adopted on a laser welder, the carbon steel plate is intensified. The technical scheme comprises the following steps: sand blasting the surface of the carbon steel; preparing mixed powder of zirconium, nickel, aluminum and copper; cladding the surface of the carbon steel by utilizing a laser beam, and enabling the laser beam to perform all-directional irradiation along a locus curve set by a computer program; forming the amorphous alloy coating after amorphous alloy powder is fused and cured on the surface of the carbon steel. By the adoption of the method, the surface hardness, abrasion resistance and corrosion resistance of the carbon steel are greatly improved; compared with the performances before treatment, the surface hardness of the carbon steel is increased by four times, the abrasion resistance is increased by four times, and the corrosion resistance is increased by 1000%; the intensifying method has the advantages of advanced process, detailed and accurate data, short technological process and simplicity in realization, and is safe, stable and reliable; the cladding coating is solid and not easy to drop off; the method is ideal in intensifying the surface of the carbon steel.

Owner:大同市森源激光再制造技术有限公司

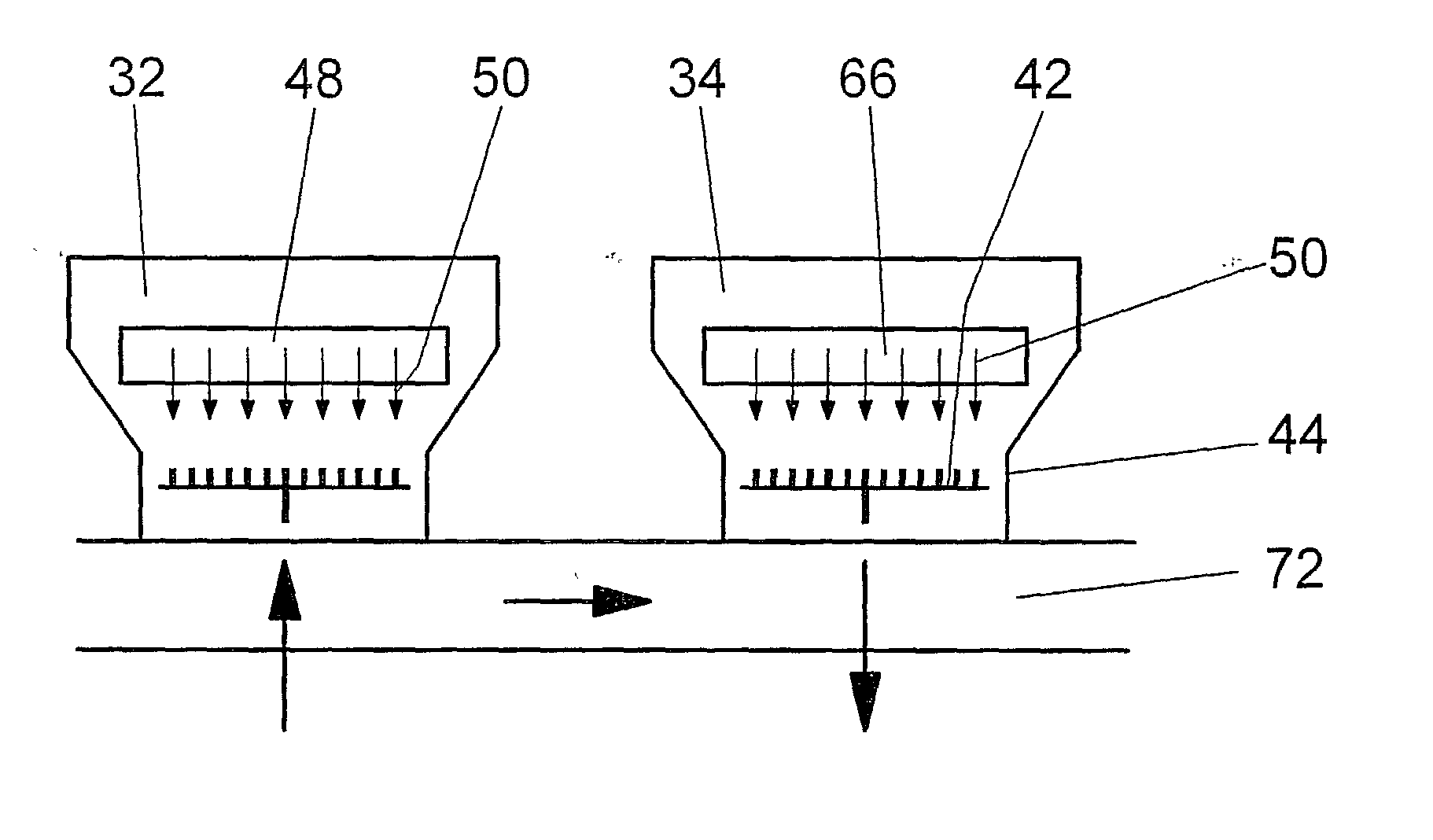

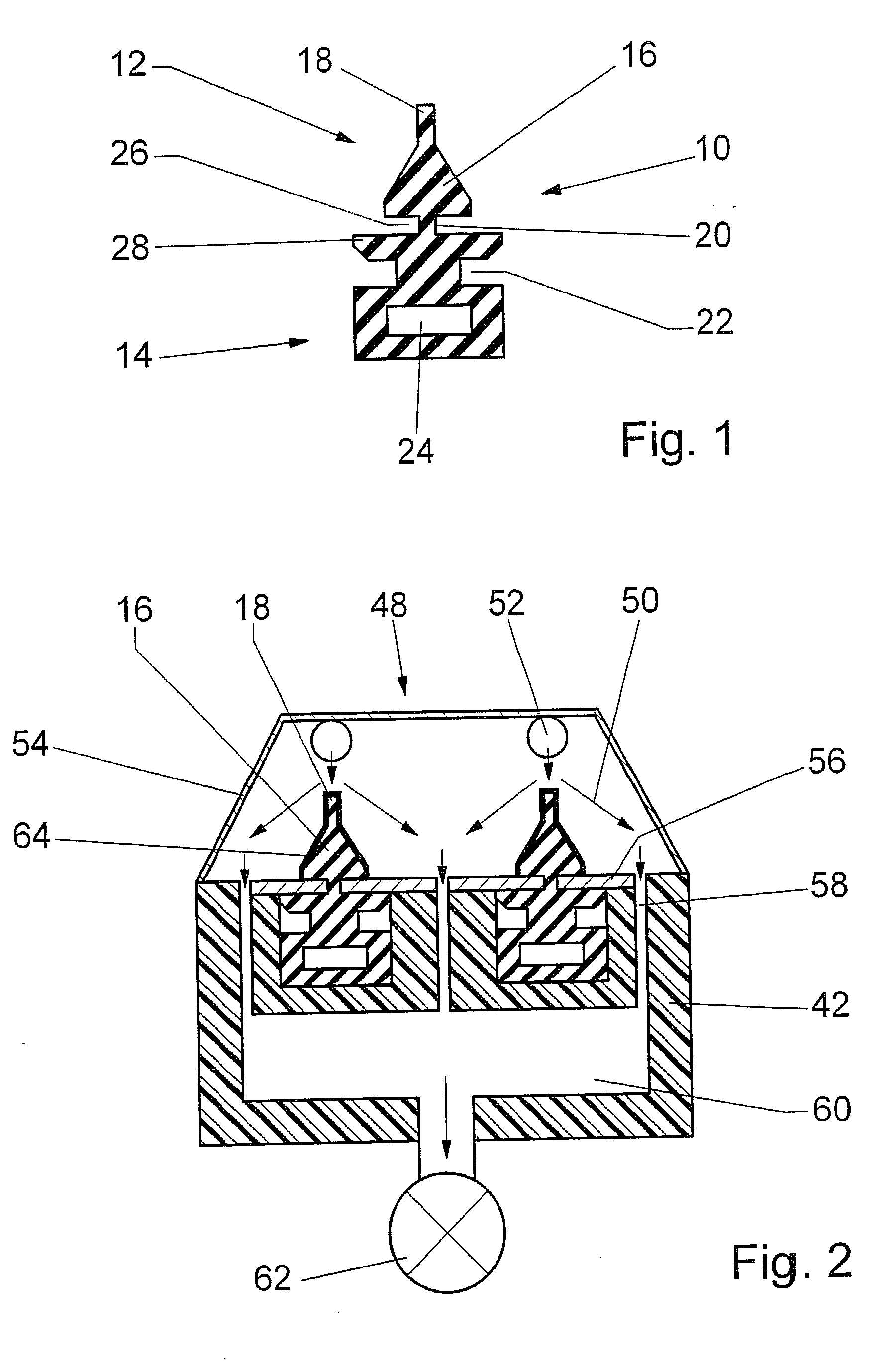

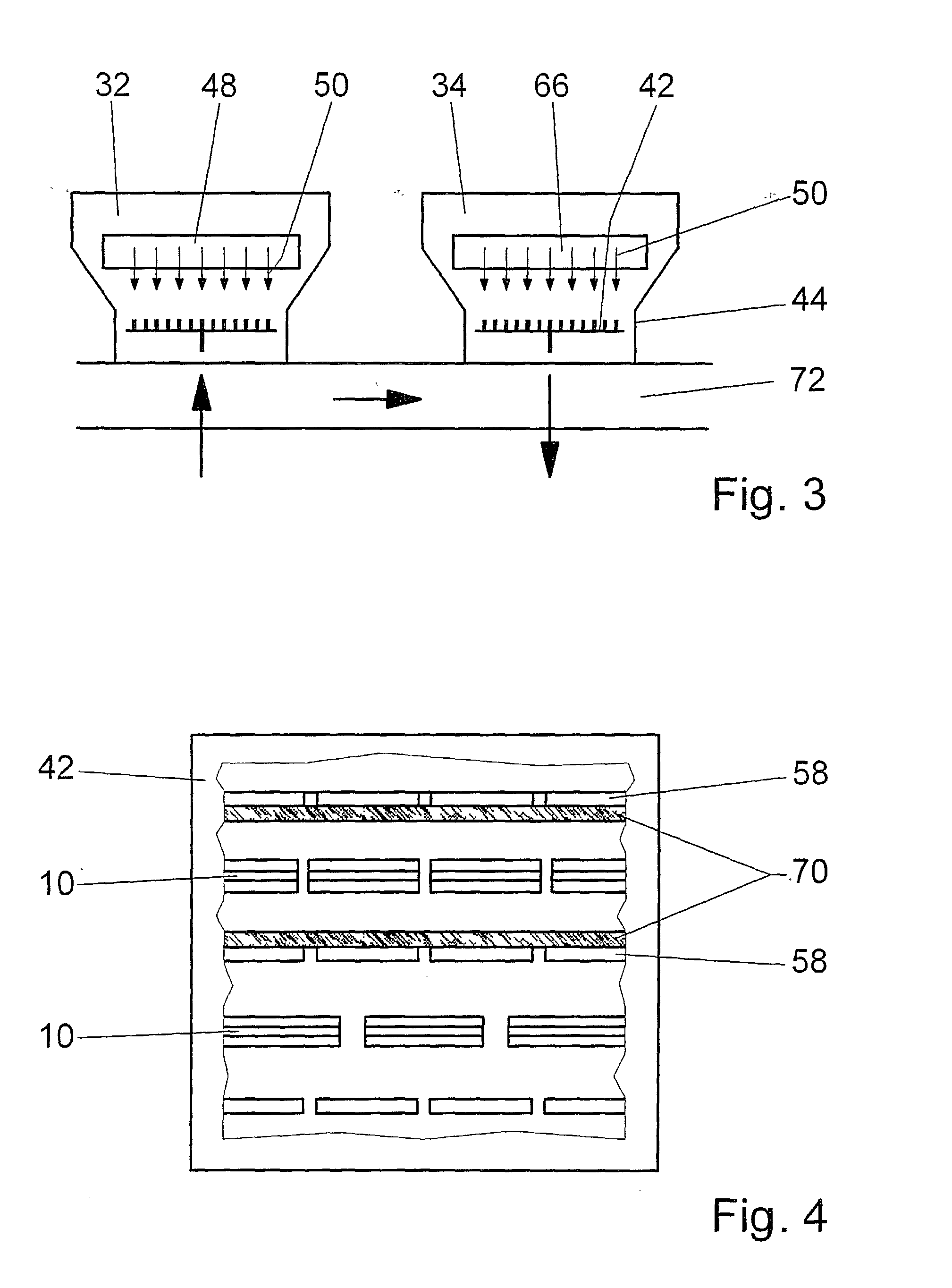

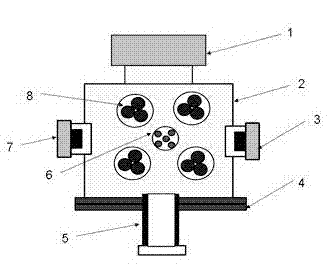

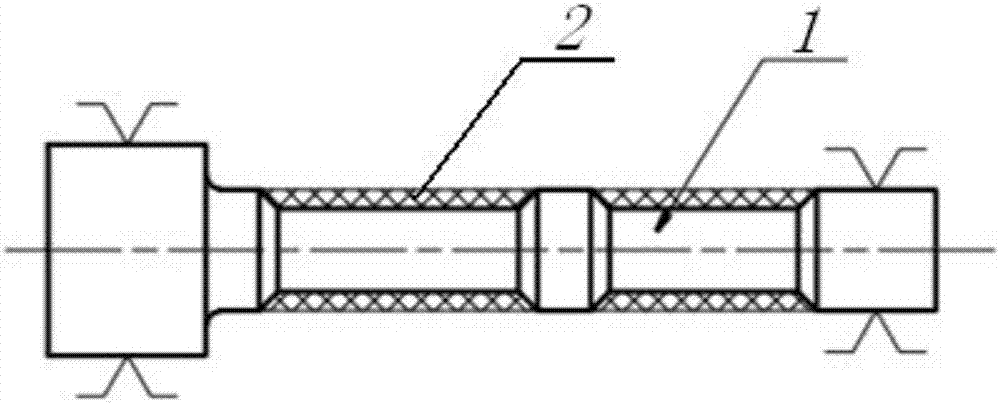

Method and device for coating at least one wiper-blade element

InactiveUS20020164422A1Good pricePositive resultVacuum evaporation coatingSputtering coatingElastomerEngineering

The invention is based on a method for coating at least one wiper blade element (10) made of an elastomer material, in which first, the surface of the wiper blade element (10) is cleaned and activated by means of a plasma, and then in a CVD process, a coating material is brought into a plasma state and at least one protective coating (64) forms on the surface of the wiper blade element (10), where a high-frequency voltage is applied to the region of the wiper blade element (10) oriented away from the protective layer (64) by means of an electrode (56). The invention proposes that before being brought into a treatment chamber (32, 34, 36, 38, 40, 74), the wiper blade element (10) be cut to a useful length (66) from a profiled band and placed on an electrode plate (56) so that its wiper lip (18) stands approximately perpendicular to the electrode plate (56), which extends to both sides of the wiper blade element (10), and is subjected to a plasma flow (50). (FIG. 2)

Owner:ROBERT BOSCH GMBH

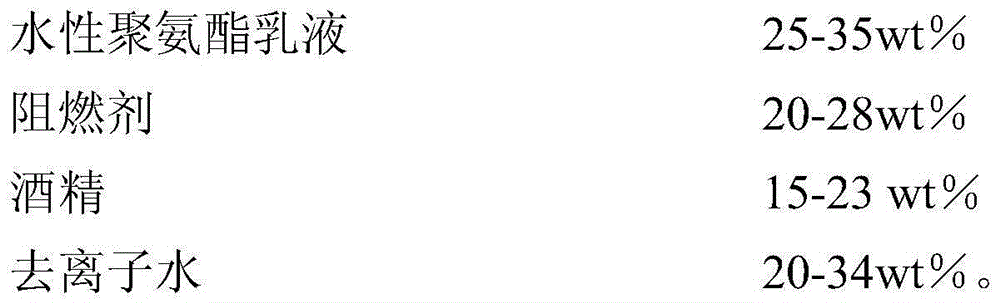

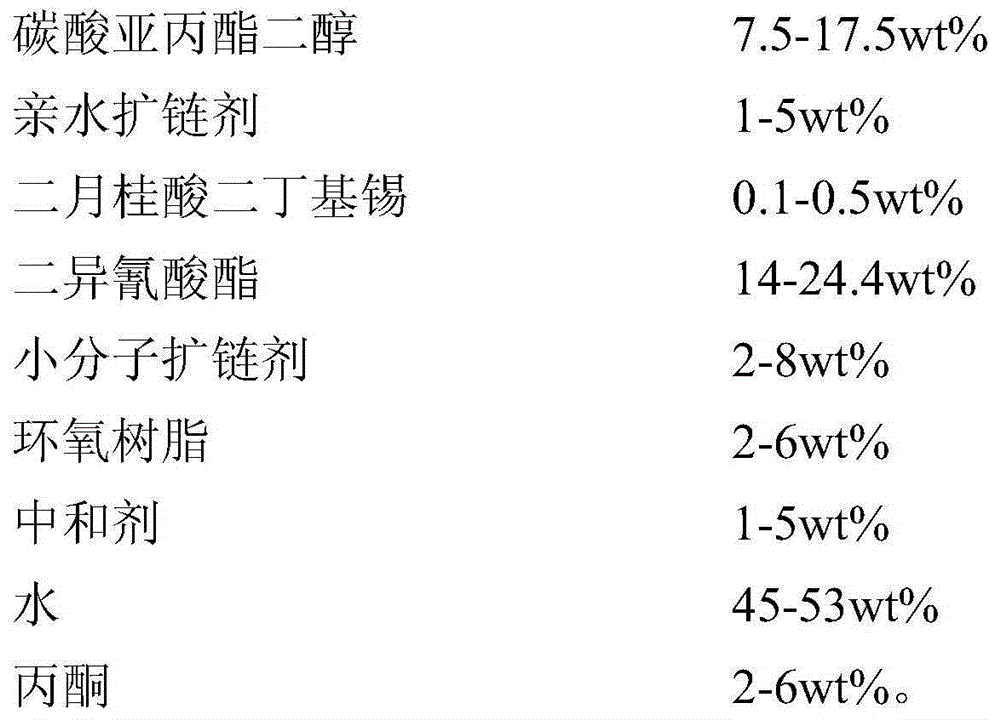

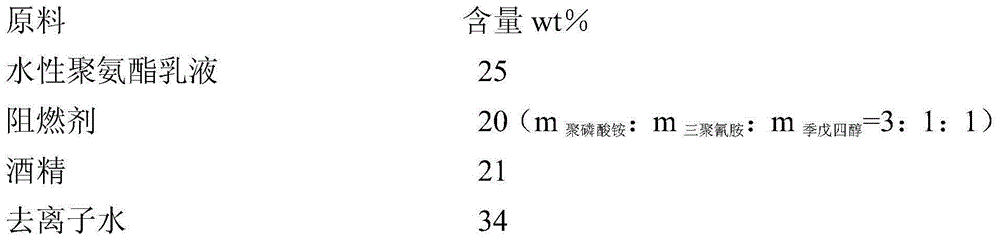

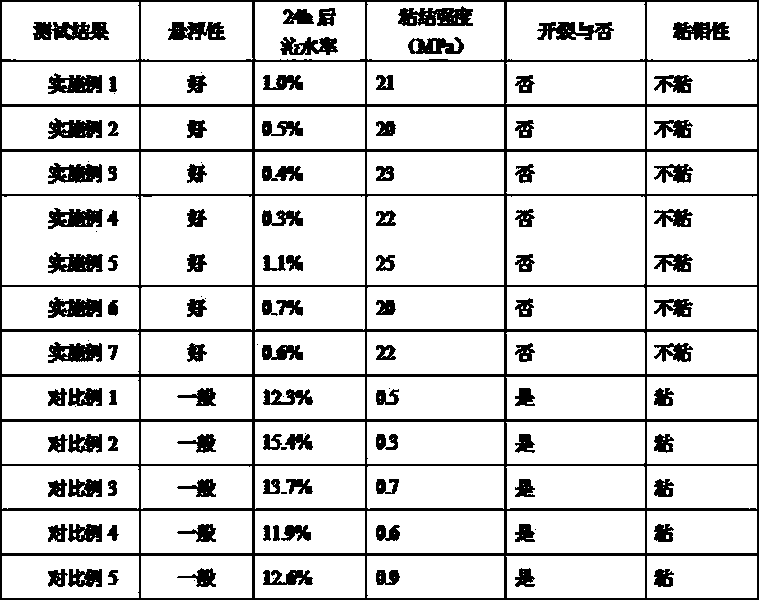

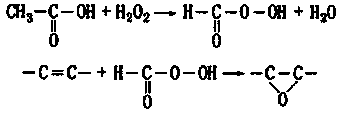

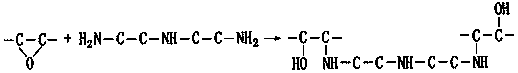

Epoxy resin modified waterborne polyurethane flame retardant paint and preparation method thereof

InactiveCN105238245AHigh coating hardnessImprove water resistanceFireproof paintsPolyurea/polyurethane coatingsEpoxyAlcohol

The invention relates to an epoxy resin modified waterborne polyurethane flame retardant paint, which is prepared from the following components by weight percentage: 25-35wt% of a waterborne polyurethane emulsion, 20-28wt% of a flame retardant, 15-23wt% of alcohol, and 20-34wt% of deionized water. The waterborne polyurethane flame retardant paint provided by the invention has the advantages of high film hardness and good water resistance, long fire resistance period, small smoke amount, good flame retardancy, no toxicity and no harm.

Owner:SKSHU PAINT

Aqueous boron nitride coating capable of binding at low temperature and being used at high temperature

ActiveCN109021628AGood adhesionImprove stabilityCoatingsEnvironmental resistanceHexagonal boron nitride

The invention discloses an aqueous boron nitride coating capable of binding at a low temperature and being used at a high temperature. The coating is prepared from 15-60 wt% of hexagonal boron nitride, 2-15 wt% of a composite high temperature binder, 1 wt% of carboxymethyl cellulose, 0.5 wt% of a thickener, 1 wt% of cobalt aluminate, 0.2 wt% of isooctanol, and the balance is demineralized water. Apreparation method of the coating comprises the following steps: mixing and stirring carboxymethyl cellulose used as a dispersant, the high-temperature binder, the thickener, cobalt aluminate used asa high-temperature pigment and demineralized water at a normal temperature to form a uniform solution, adding the hexagonal boron nitride and isooctanol used as a defoamer to the solution, and performing stirring until a uniform system is formed. The coating adopts an aqueous system, has no harmful substance volatilization during use, is clean and environmentally friendly, has good adhesion, anddoes not crack or spall in order to effectively block direct contact between a metal melt and the surface of a refractory material. Additionally, the coating has excellent stability and suspension capacity, and the stability and the suspension capacity do not change under high dilution.

Owner:SHANGQIU NORMAL UNIVERSITY

Epoxy resin curing agent and preparation method thereof

PendingCN109824869AShort curing timeImprove adhesionAnti-corrosive paintsEpoxy resin coatingsDiethylenetriaminePolyamide

The invention relates to an epoxy resin curing agent. The epoxy resin curing agent comprises, by weight , 30-50 parts of polyamine compound, 20-40 parts of benzyl alcohol, 5-10 parts of epoxy resin, 3-8 parts of propylene carbonate, 10-20 parts of polyether 400, 0.05-0.1 part of yellow-resistant auxiliary and 1-10 parts of amino-terminated hyperbranched polyamide surface grafted graphene oxide, wherein the polyamine compound comprises one or two of aliphatic polyamine and cycloaliphatic polyamine; the aliphatic polyamine is diethylenetriamine, triethylene tetramine or hexanediamine; the cycloaliphatic polyamine is m-xylylenediamine or isophorone diamine; the polyamine compound comprises isophorone diamine and triethylene tetramine, and the mass ratio of the isophorone diamine to the triethylene tetramine is (1-4):1.

Owner:XIAMEN YUANCHUANGLI TECH SERVICE CO LTD

Preparation method of novel Mannich water-based epoxy curing agent

InactiveCN102516502ASolve the problem of residual pollutionHigh molecular weightEpoxy resin coatingsEpoxyWater based

The invention discloses a preparation method of a Mannich water-based epoxy curing agent. A water-based epoxy coating has the advantages of low VOC (Volatile Organic Compound) content, low odor, safety for using and the like, and is developed quickly in recent years. The curing agent serving as an important component of the water-based epoxy coating is one of key factors for deciding coating performance. The conventional prepared water-based epoxy curing agent has the defects of poor stability, short storage life of a water-based epoxy system after mixing, and poor water resistance and low hardness of a coating film. Meanwhile, amine with low molecular weight is volatilized easily and has high toxicity, so that the development of amine is limited. The invention provides a preparation method of a Mannich water-based epoxy curing agent. A cured coating film has the advantages of high hardness and high water resistance. The curing agent has wide application prospects in the fields of coatings, adhesives, concrete and the like.

Owner:HUNAN UNIV

Waterproof coating for water-based paperboards and preparation method thereof

InactiveCN104631207AGood waterproof performanceCost comparedWater-repelling agents additionPaper coatingSolventEmulsion

The invention discloses a waterproof coating for water-based paperboards and a preparation method thereof. The coating is mainly prepared from water, an acrylate emulsion, a paraffin emulsion, an epoxy resin, a film forming additive, a flatting agent and other additives. Through the compounding of the paraffin emulsion and the acrylate emulsion, the advantages of the two emulsions are integrated, so that the glossiness, adhesion, abrasion resistance and water repellency of the waterproof coating are maximally increased; due to the addition of the epoxy resin and a drier, the water repellency, coating hardness and surface drying time of the coating can be further improved; and the waterproof coating disclosed by the invention, as a water-based resin coating, is solvent-free, non-toxic, green and environment-friendly in the process of production, and therefore, the waterproof coating has important economical and social benefits.

Owner:HUNAN HUAWANG TECH

Conductive coating

ActiveCN103587164AGood film formingImprove securitySynthetic resin layered productsElectrically-conductive paintsPhosphoric acidSulfide

The invention provides a conductive coating which comprises a bottom layer and a surface layer, wherein the bottom layer is prepared by components in parts by weight as follows: 70 parts of polytetrafluoroethylene emulsion, 6.8-7.1 parts of phosphoric acid, 6.8-7.2 parts of chromic acid, 0.7-1.0 part of lauryl sodium sulfate, 1.6-2.0 parts of chromium sesquioxide, 8-9 parts of water, 0.5-0.8 part of polyphenylene sulfide, 5-7.5 parts of graphite and 1-2.5 parts of conductive black; and the surface layer is prepared by components in parts by weight as follows: 90 parts of polytetrafluoroethylene emulsion, 0.7-0.9 part of lauryl sodium sulfate, 10-11 parts of water, 2-2.5 parts of polyphenylene sulfide, 5-7.5 parts of graphite and 1-3 parts of conductive black. The obtained conductive coating has a smooth surface and large adhesive force with a metal mold, and is high in hardness, difficult to scratch and good in conductivity; and the demolding effect is good after the metal mold is sprayed, and the quality of a finished product is guaranteed.

Owner:湖北三江航天江河橡塑有限公司

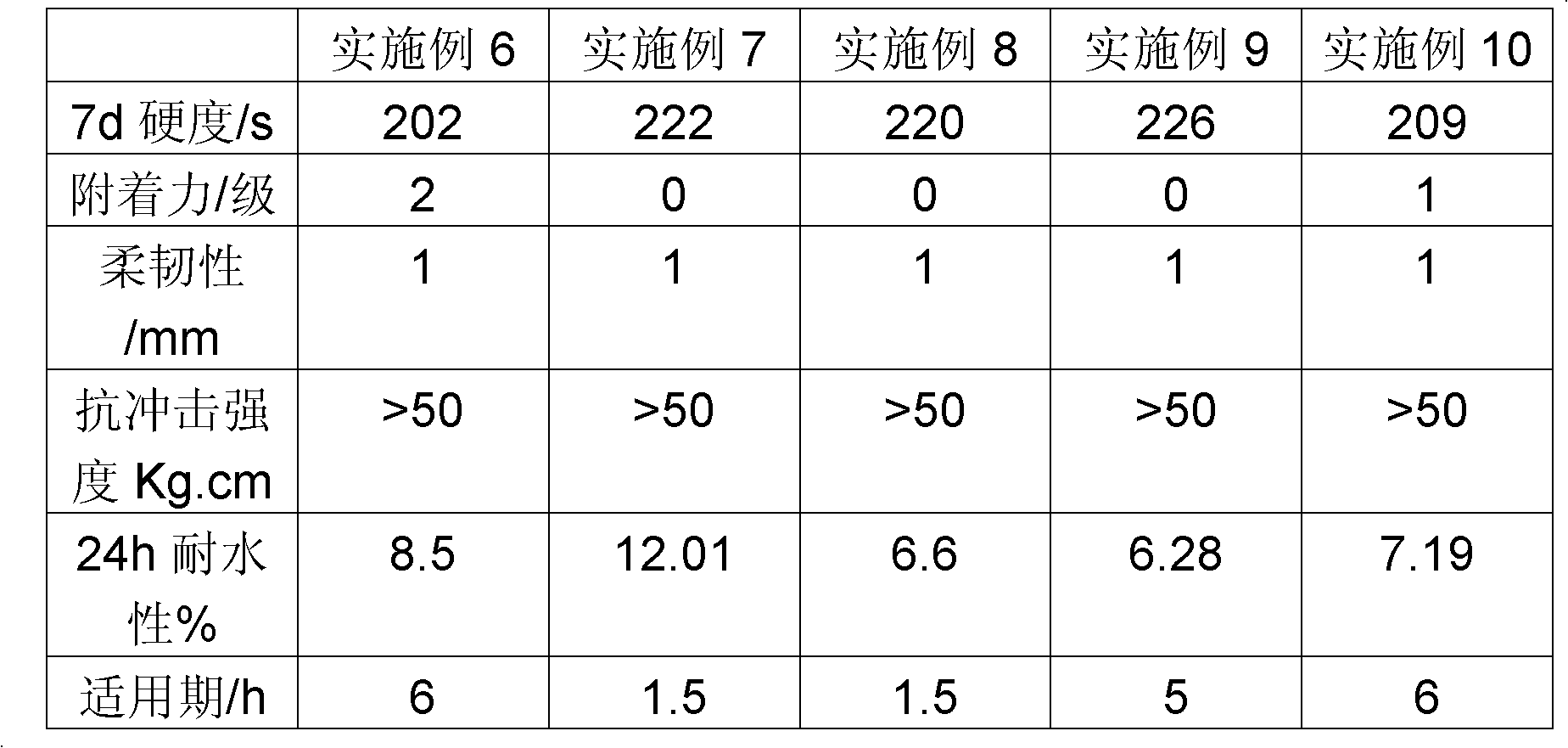

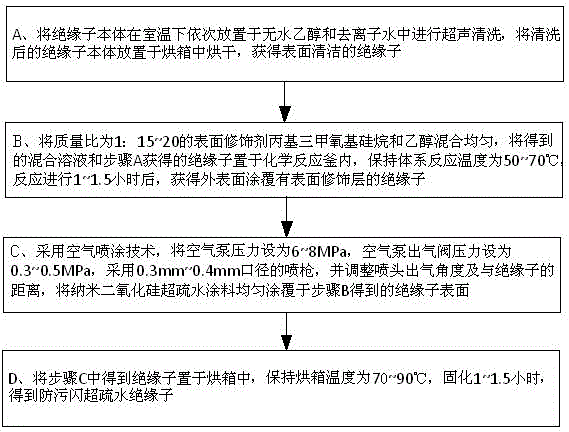

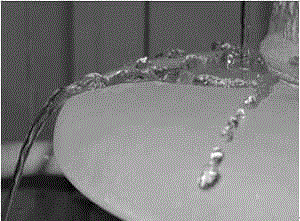

Superhydrophobic coating, anti-pollution-flashover superhydrophobic insulator and preparation technique thereof

InactiveCN105820644AReduce the accumulation of pollutionExcellent superhydrophobic propertiesInsulatorsCoatingsSilanesReaction temperature

The invention discloses a superhydrophobic coating, an anti-pollution-flashover superhydrophobic insulator and a preparation technique thereof. The superhydrophobic coating comprises a finishing coat arranged on the external surface of the insulator and the superhydrophobic coating arranged on the finishing coat. The finishing coat is prepared from a surface modification solution which is composed of a surface modifier propyltrimethoxy silane and ethanol in a mass ratio of 1:(5-20), and the superhydrophobic coating is prepared from a nano silicon dioxide superhydrophobic paint. The anti-pollution-flashover superhydrophobic insulator comprises an insulator body and the superhydrophobic coating applied to the external surface of the insulator body. By setting the reaction temperature in the finishing coat application process and the pressure, angle and other parameters in the superhydrophobic coating spraying process, the obtained anti-pollution-flashover superhydrophobic insulator has the advantages of long service life, high aging resistance and excellent hydrophobicity, can effectively reduce the filth accumulation volume on the insulator surface under haze and heavy dirt conditions, has higher pollution flashover resistance, and ensures the long-term reliability of the electric system external insulation.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

CN-MCN superhard self-lubricating nano-composite coating and preparation method thereof

InactiveCN102864411AHigh hardnessReduce internal stressVacuum evaporation coatingSputtering coatingHardnessIonization

The invention discloses a CN-MCN superhard self-lubricating nano-composite coating and a preparation method thereof. An electric arc discharge method and a hollow cathode electric arc discharge carbon source combination method are adopted to generate a combination layer, a transition layer, a supporting layer and a lubricating layer to sequentially form the nano-composite coating. The preparation method has the advantages of being high in ionization rate, simple in coating device structure, high in deposition rate and the like. The prepared CN-MCN superhard self-lubricating nano-composite coating is high coating hardness, strong in adhesive power, good in self-lubricating property, high in coating growing speed and production efficiency, low in production cost and friction coefficient and good in coating toughness and can remarkably improve the abrasion-resisting and lubricating performance of processing cutters, dies and mechanical parts. In addition, the preparation method is simple, industrial production is easily achieved, and the CN-MCN superhard self-lubricating nano-composite coating has good application prospect.

Owner:SHENZHEN YUANSIDACHENG TECH

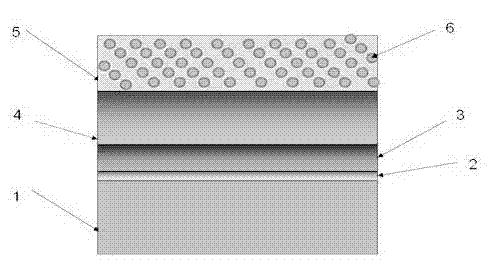

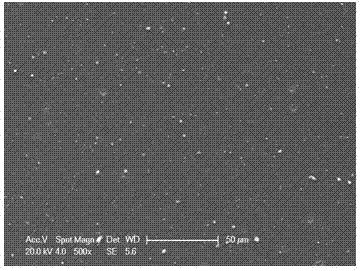

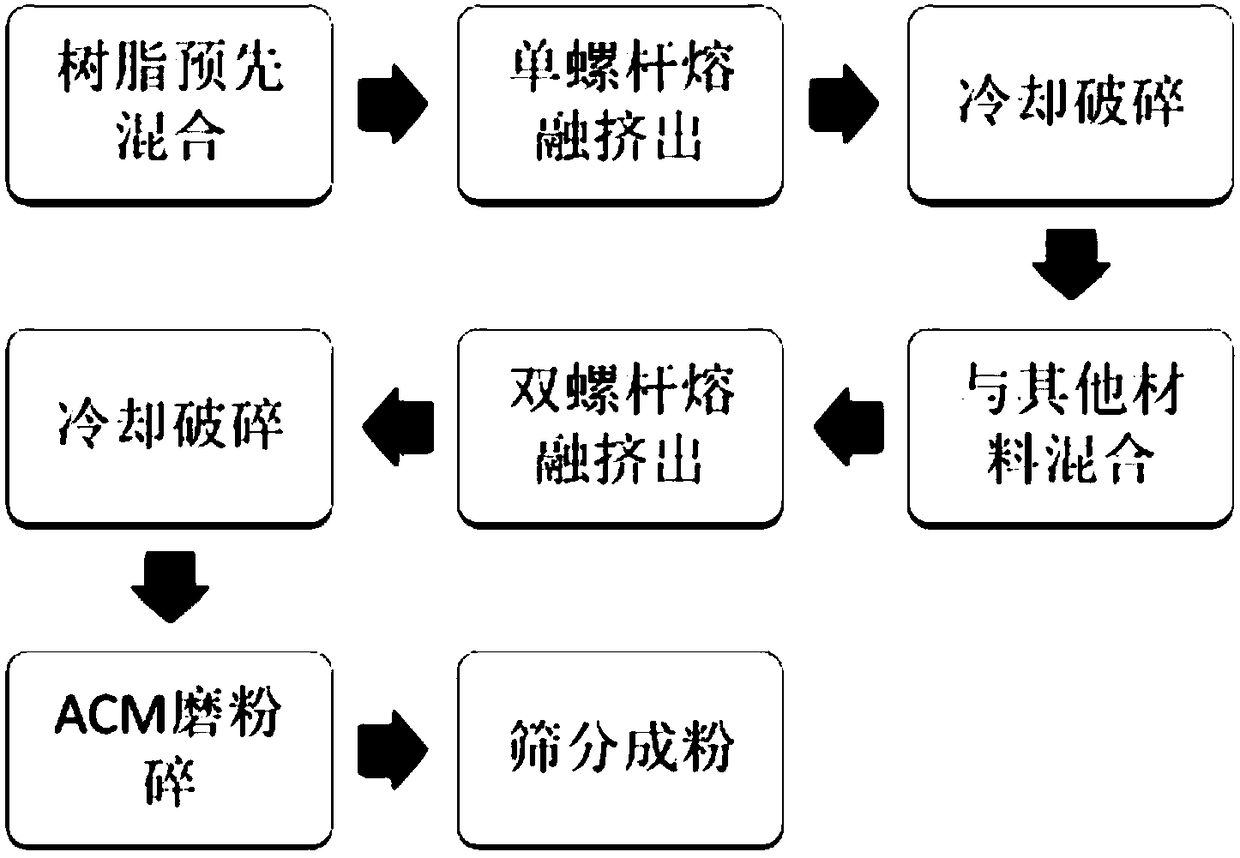

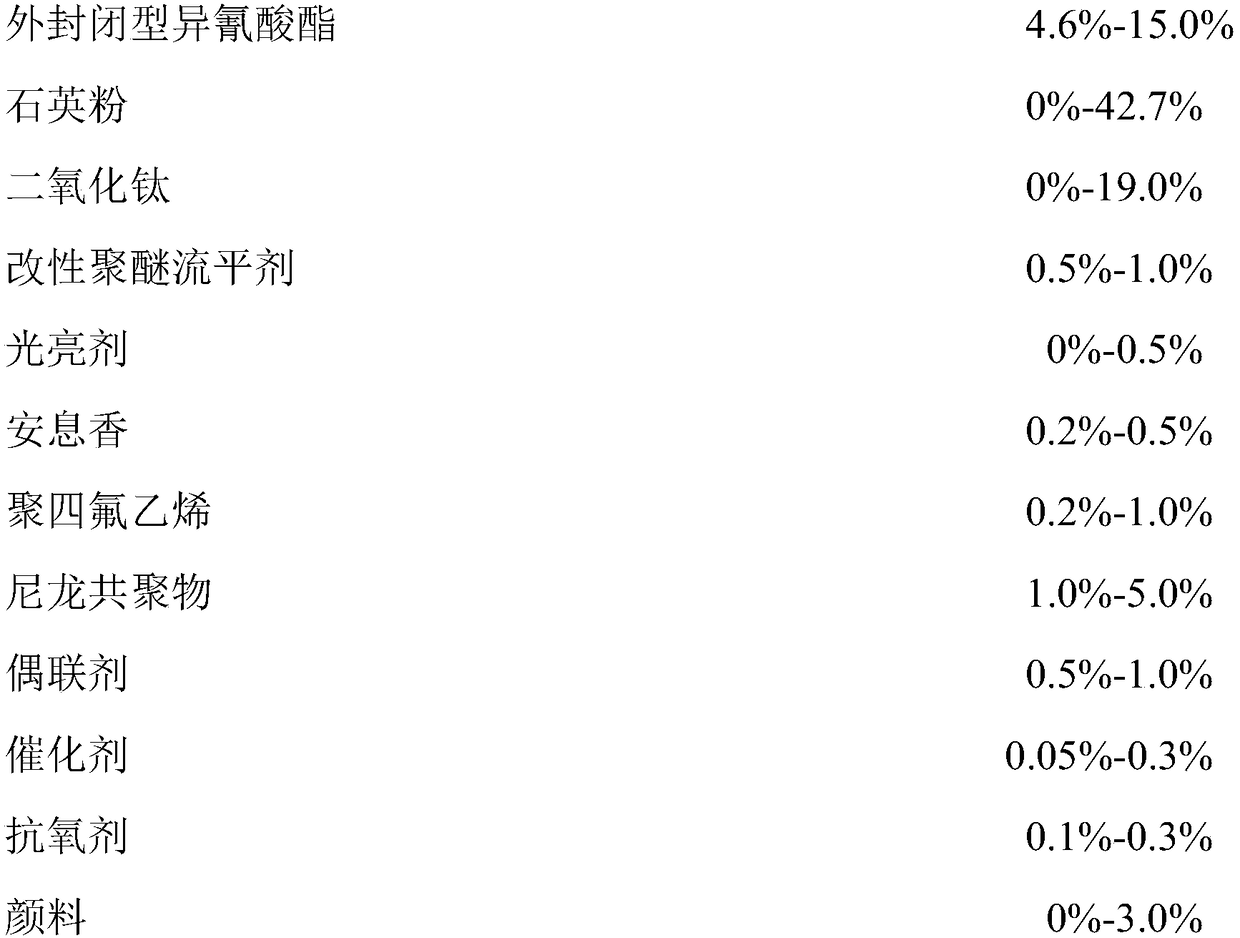

Heat transfer printing powder coating used for aluminum floor, and preparation method and application of heat transfer printing powder coating

ActiveCN108250918AGood flexibilityIncrease crosslink densityAntifouling/underwater paintsPaints with biocidesPolyesterMechanical property

The invention discloses a heat transfer printing powder coating used for an aluminum floor, and a preparation method and application of the heat transfer printing powder coating. The heat transfer printing powder coating used for the aluminum floor takes a terminal carboxyl polyester and terminal hydroxy polyester mixture as a film formation substance, and materials, including quartz powder, titanium dioxide, a modified polyether flatting agent, polytetrafluoroethylene, nylon copolymer, a coupling agent, a catalyst, an antioxygen and the like, are matched to be subjected to melt extrusion to prepare the powder coating. The heat transfer printing powder coating used for the aluminum floor is the powder coating which has the advantages of high hardness, high abrasive resistance and excellentmechanical performance, contamination resistance, water resistance and abrasion resistance, and can be widely applied to the field of aluminum floor coating.

Owner:广东华江粉末科技有限公司

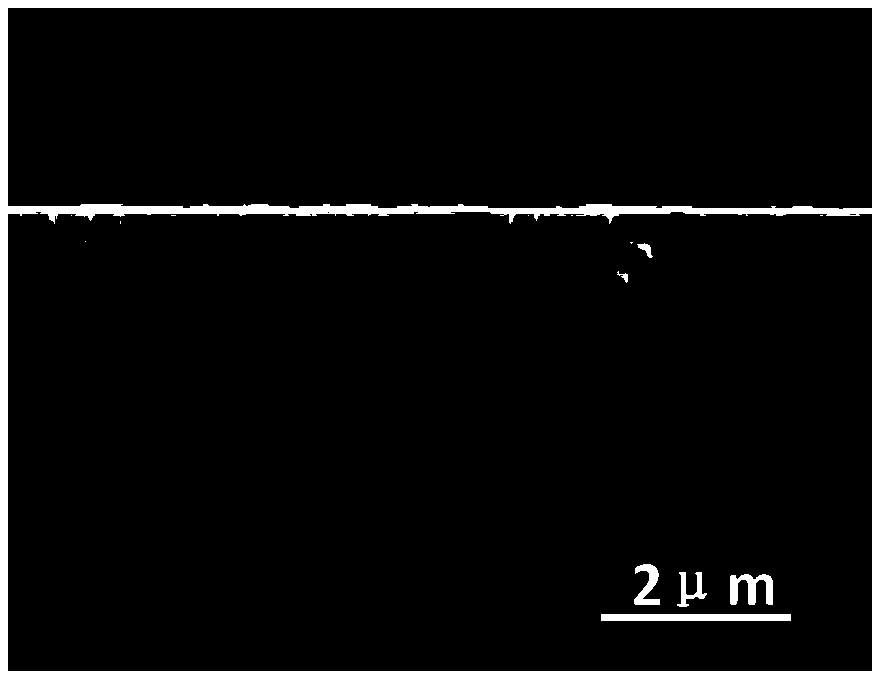

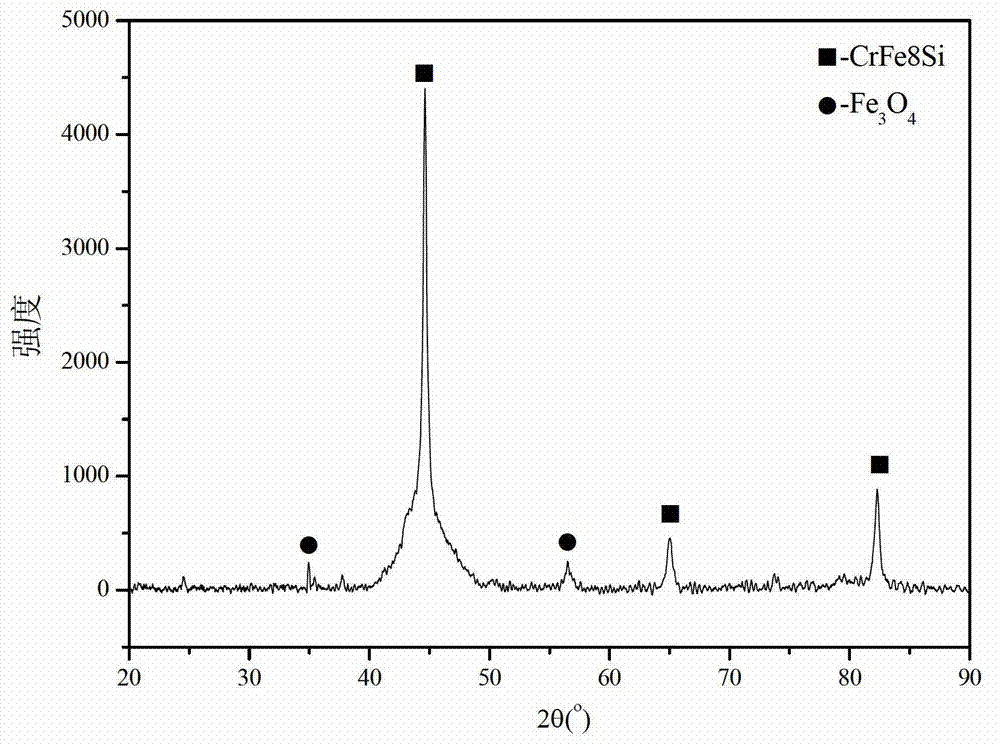

Iron-based cored wire including amorphous phase abrasion-resistant and corrosion-resistant coating prepared by utilizing electric arc spraying and preparation method of coating

InactiveCN102925789AHigh coating hardnessImprove wear resistanceMolten spray coatingCorrosion resistantElectric arc

The invention discloses an iron-based cored wire including an amorphous phase abrasion-resistant and corrosion-resistant coating prepared by utilizing electric arc spraying and a preparation method for the coating, and belongs to the field of the thermal spraying in the material processing engineering. Steel band materials for manufacturing a wire casing are stainless steel bands, and the filling rate of the cored wire is from 32% to 34%. The cored wire comprises the following elements in percentage by atoms: 15 to 26 at.% of Cr, 4 to 14 at.% of P, 9 to 18 at.% of Si and 2 to 4 at.% of C. The preparation method for the coating comprises the steps as follows: pre-grinding a matrix surface by using 180 meshes of sand paper and carrying out a blasting treatment on the matrix surface by using 60 meshes of brown aluminium oxide, thereby obtain the cored wire; and preparing the coating by using the electric arc spraying process, wherein the voltage in the spraying process is from 25V to 34V, the current is from 180A to 220A, the spraying distance is from 190mm to 210mm, and the compressed air pressure is from 0.4 Mpa to 0.6 Mpa. The prepared amorphous phase coating has the characteristics high hardness, good abrasion-resistant and corrosion-resistant performance and excellent mechanical performance.

Owner:BEIJING UNIV OF TECH

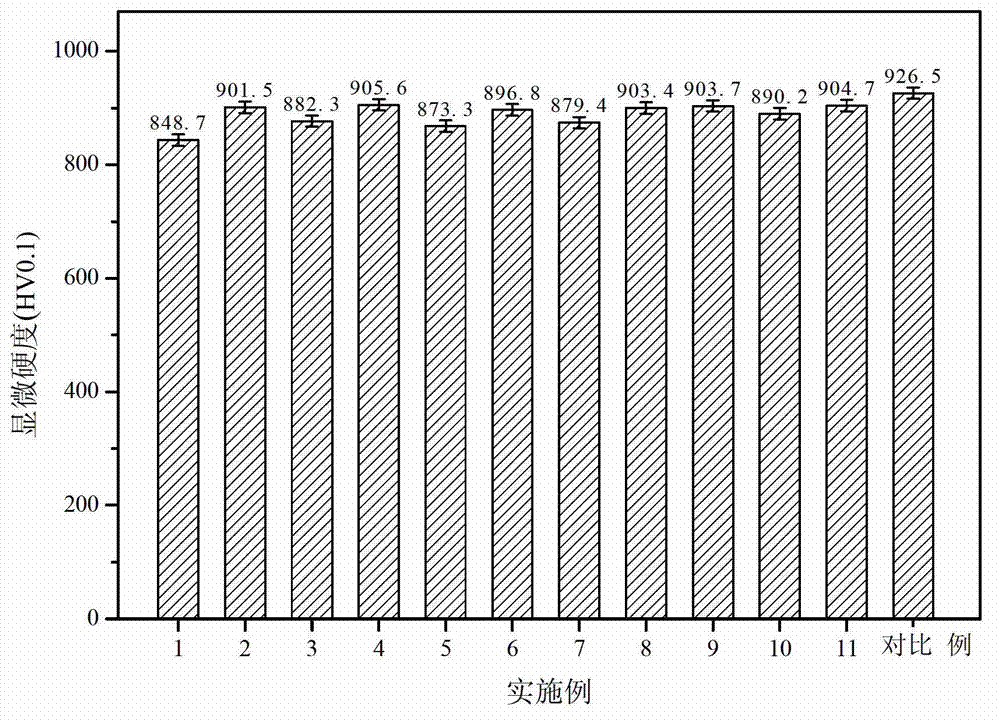

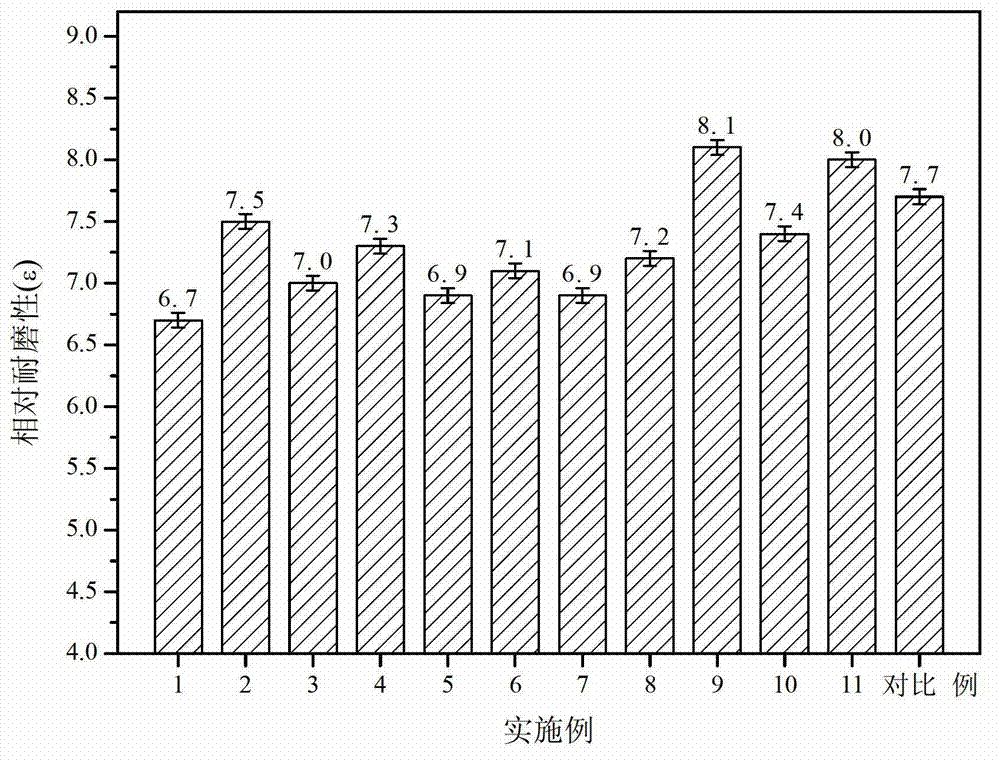

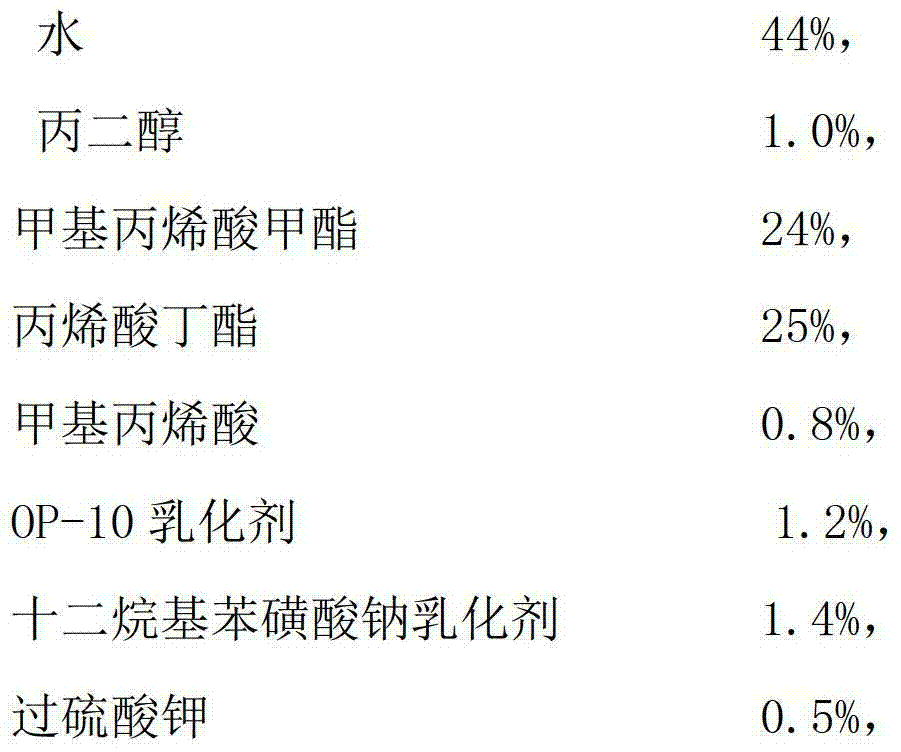

Modified pure acrylic emulsion and preparation method thereof

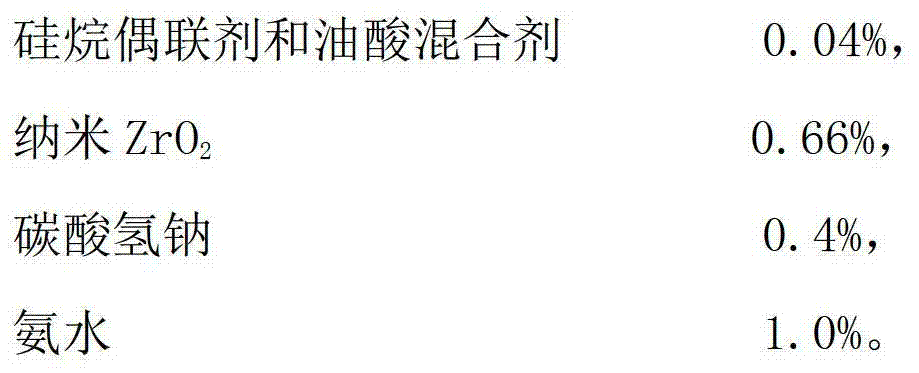

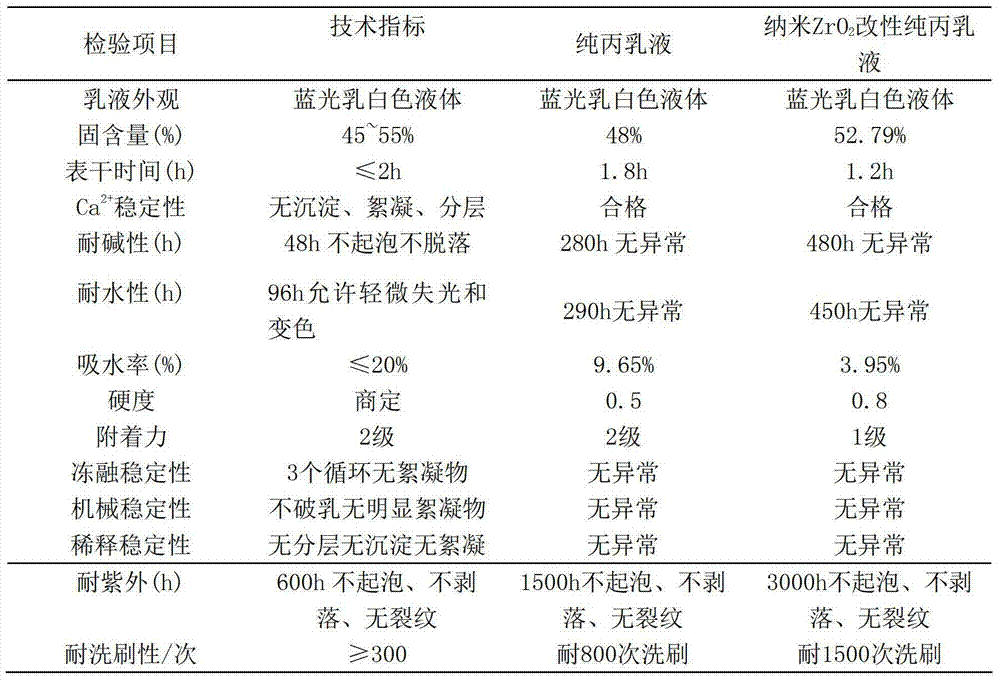

The invention discloses a modified pure acrylic emulsion and a preparation method thereof. The emulsion comprises the following components by mass percent: 42-56% of water, 1-3% of propylene glycol, 20-30% of methyl methacrylate, 15-25% of butyl acrylate, 0.8-1.2% of methacrylic acid, 1.0-1.4% of emulsifier OP-10, 1.2-1.6% of sodium dodecyl benzene sulfonate, 0.4-0.6% of sodium bicarbonate, 0.4-0.6% of potassium persulfate, 0.23-0.66% of nano ZrO2, 0.5-1.2% of ammonia water and 0.04-0.17% of mixture of silane coupling agent and oleic acid (5:1). The nano ZrO2 modified pure acrylic emulsion has the advantages of environment friendliness, aging resistance, washability, water resistance, alkali resistance, good emulsion stability, high film hardness and the like.

Owner:中山市天益聚合物有限公司

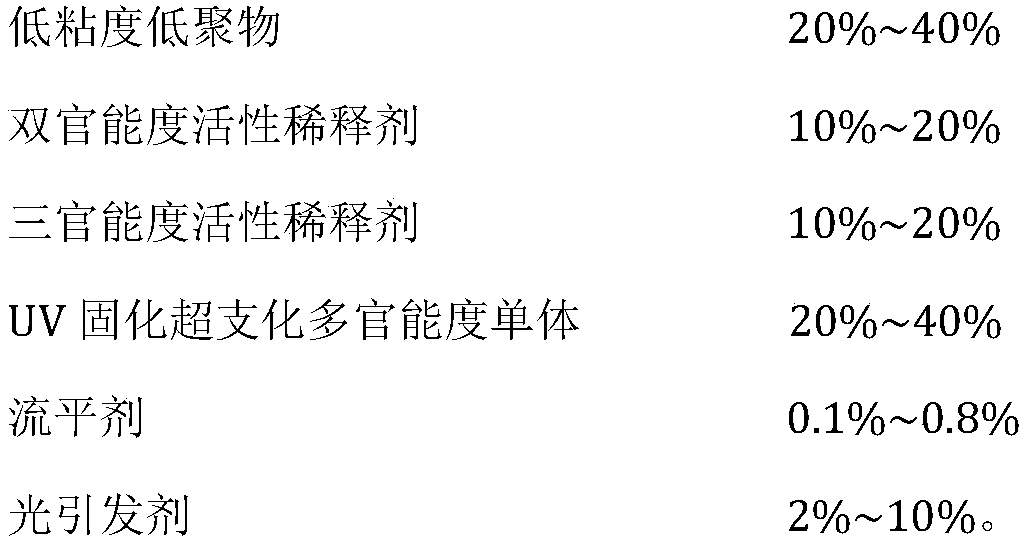

Solvent-free UV (ultraviolet) resin and application thereof

A solvent-free UV resin and application thereof belong to the technical field of environment-friendly paints. The solvent-free UV resin is composed of, by weight percentage, 20-40% low-viscosity oligomer, 10-20% of bifunctional active diluent, 10-20% of trifunctional active diluent, 20-40% of UV curing hyperbranched polyfunctional monomer, 0.1-0.8% of flatting agent and 2-10% of photoinitiator. The solvent-free UV resin can solve the problem VOC (volatile organic compounds) led by toxic organic solvent in UV curing paints.

Owner:TONGGUANG JIANGSU INFORMATION TECH CO LTD +1

Cobalt-based spray powder used for aero-engine abrasion-resistant parts and preparation method thereof

InactiveCN106975742AExcellent resistance to abrasive wearExcellent hard surface wearMolten spray coatingWear resistantSpray coating

The invention belongs to the technical field of wear-resistant coating materials, and in particular relates to a cobalt-based spraying powder for aero-engine wear-resistant parts, and also relates to a method for preparing the above-mentioned spraying powder. The composition and weight percentage of the spray powder are: chromium: 20%~30%; nickel: 7%~15%; tungsten: 5%~12%; carbon: 0.1%~1%; cobalt: 45%~65% %; the particle size range of the above spray powder is 5 μm to 45 μm; the coating obtained by using the spray powder is suitable for working at high temperature, and has excellent anti-abrasive wear, hard surface wear, fretting wear and particle erosion wear performance ;After spraying, the bonding strength is high, and it is not easy to fall off; after spraying, the coating has a uniform texture, smooth surface, no delamination and cracks; at the same time, the cobalt content in the material determines that the coating is an excellent anti-oxidation coating; in addition , the powder coating also has good coating grinding and polishing properties and high coating hardness, and can be widely used in the application of engine parts.

Owner:TIANJIN CHENGLI AVIATION TECH CO LTD

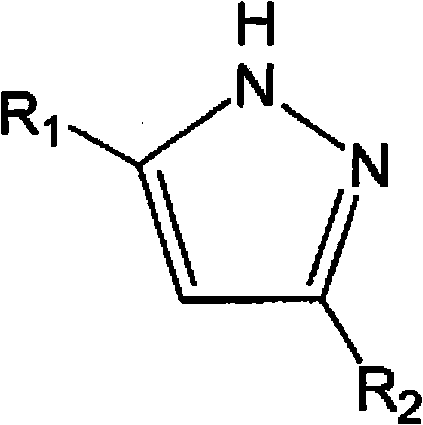

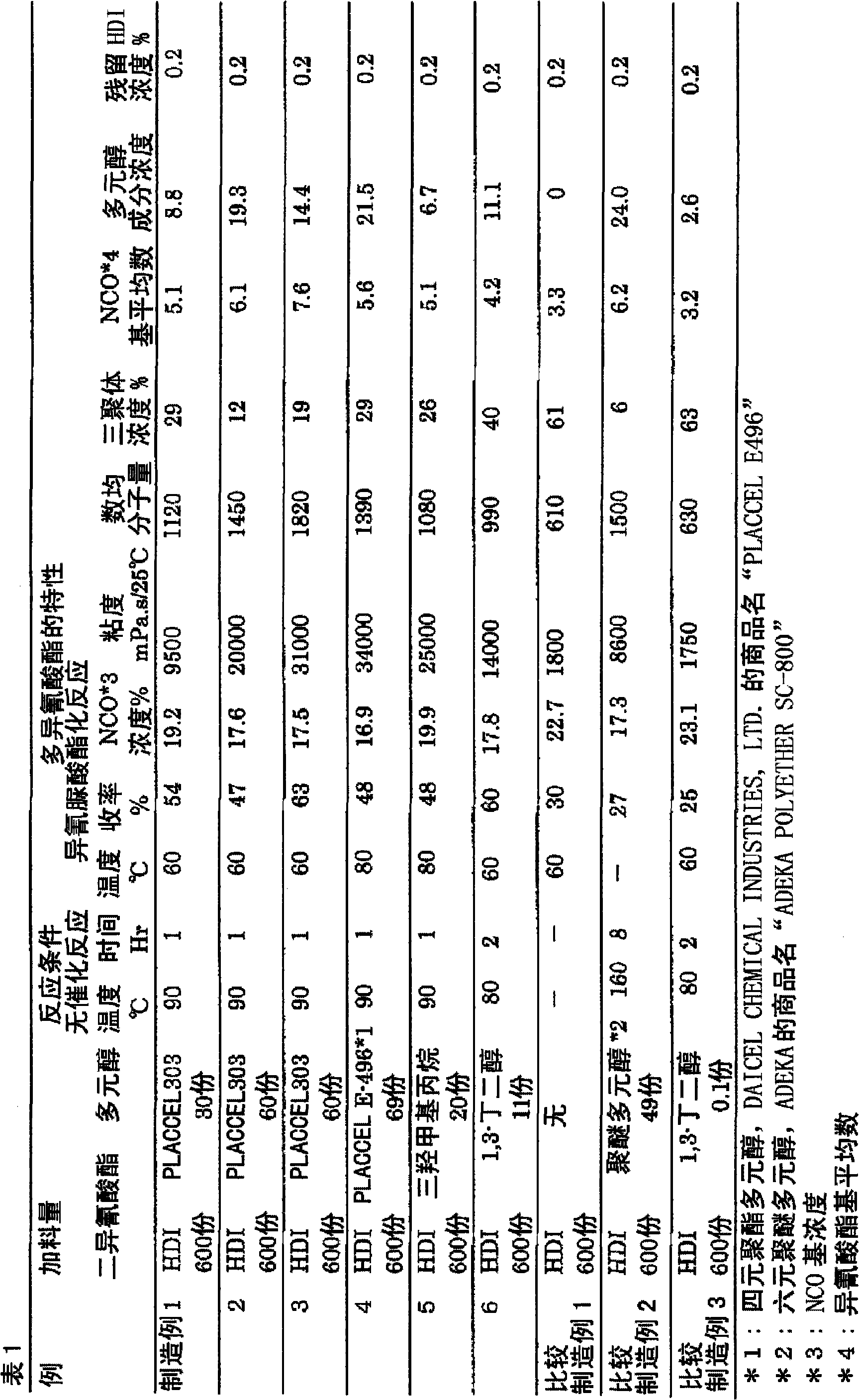

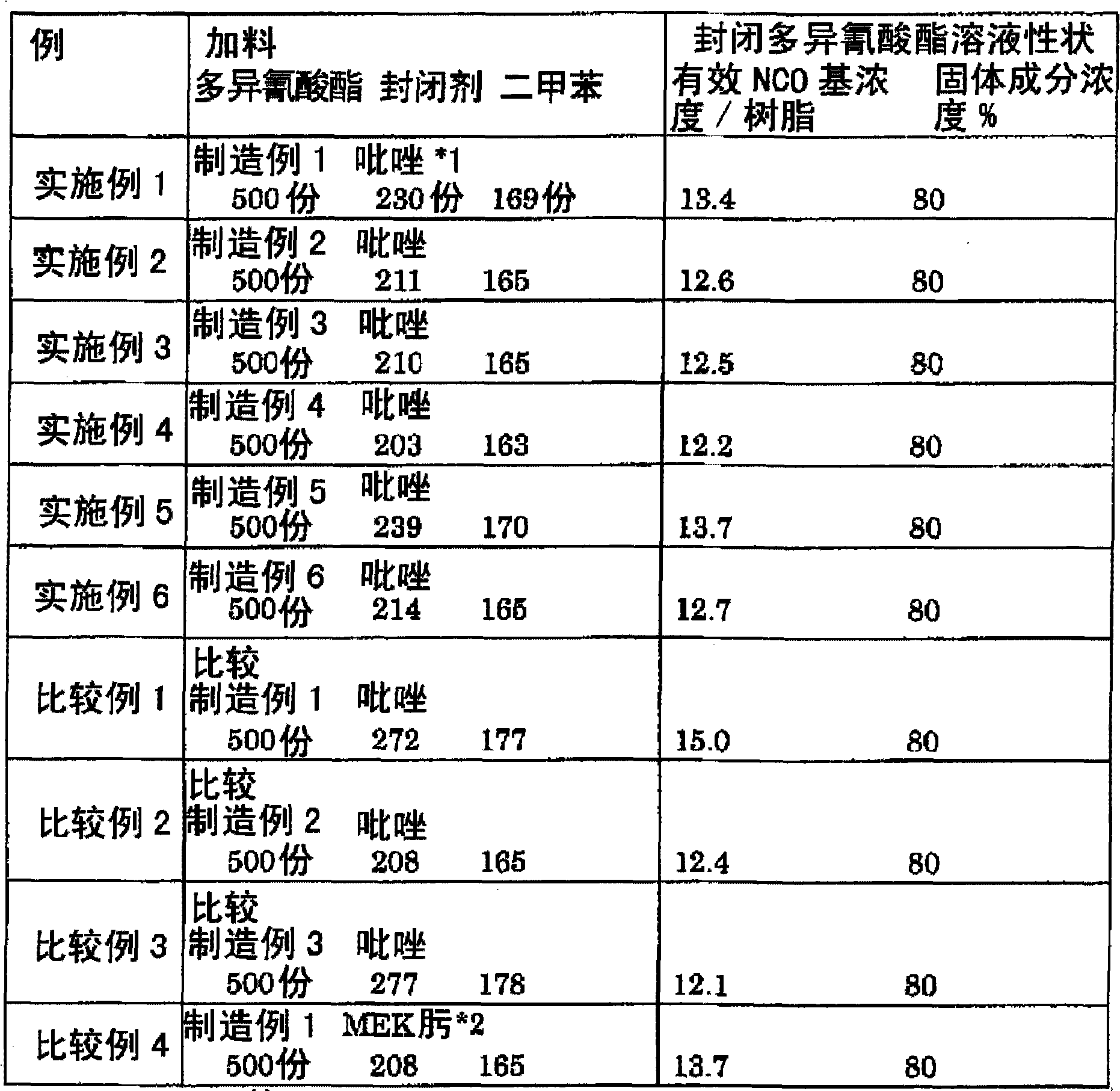

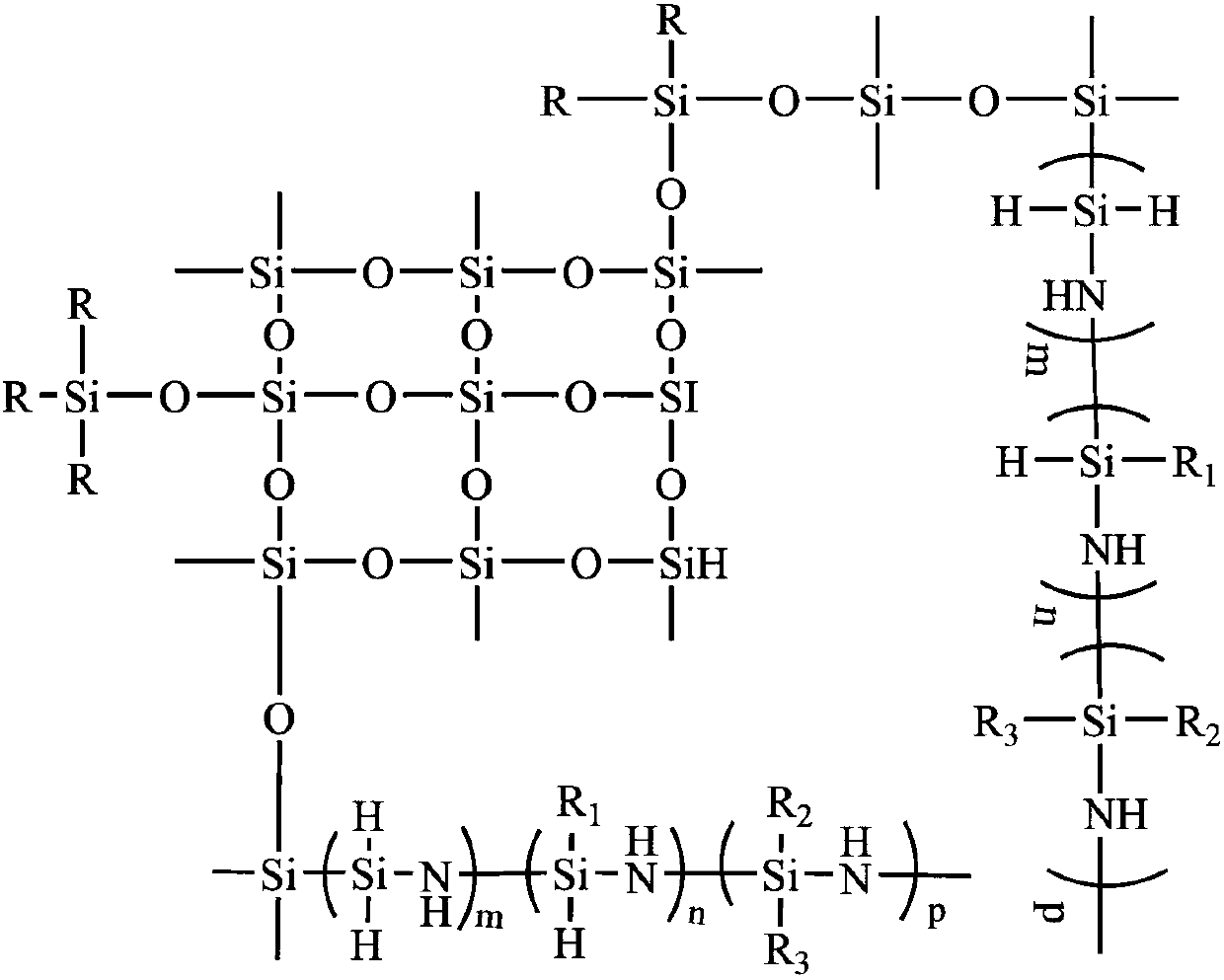

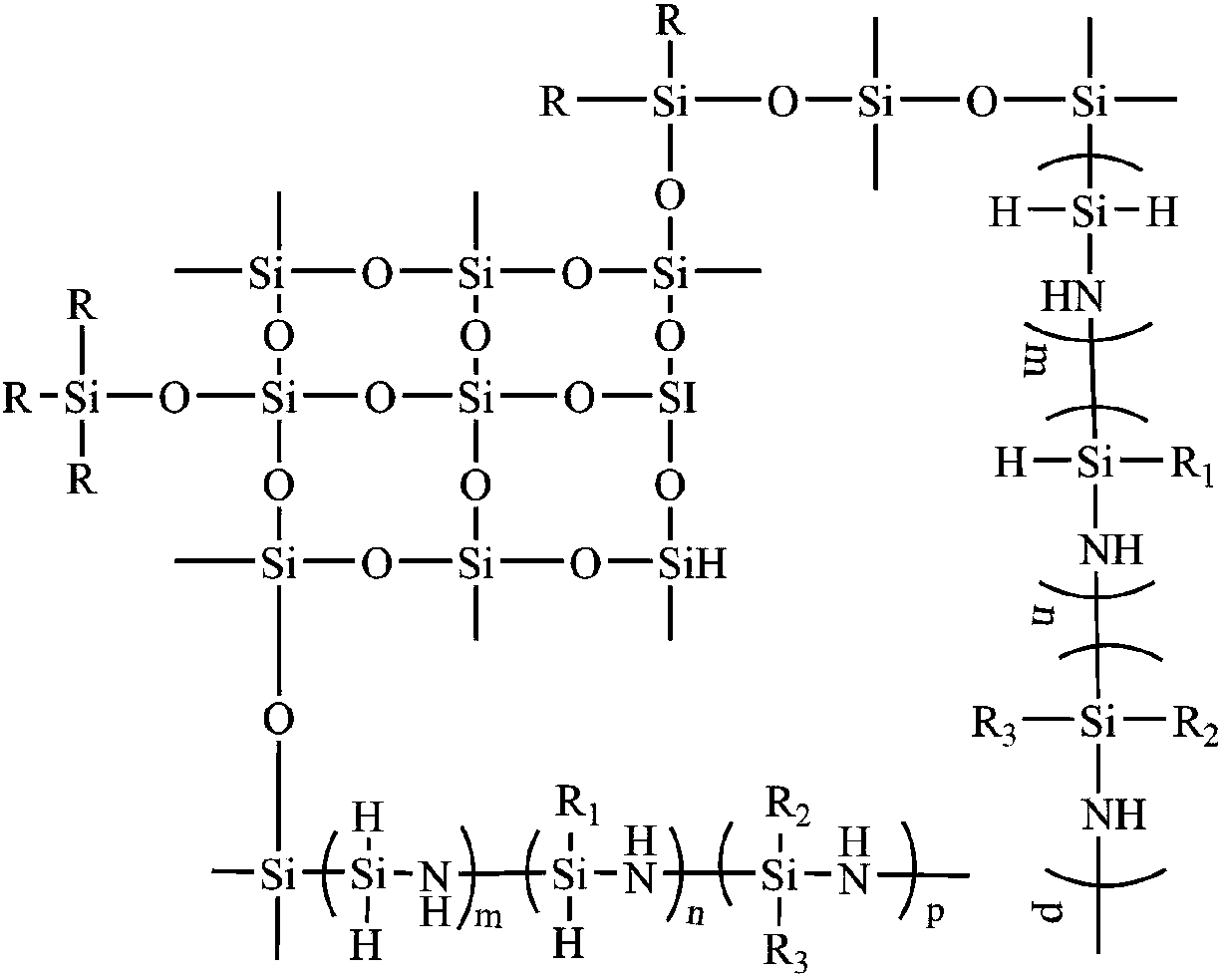

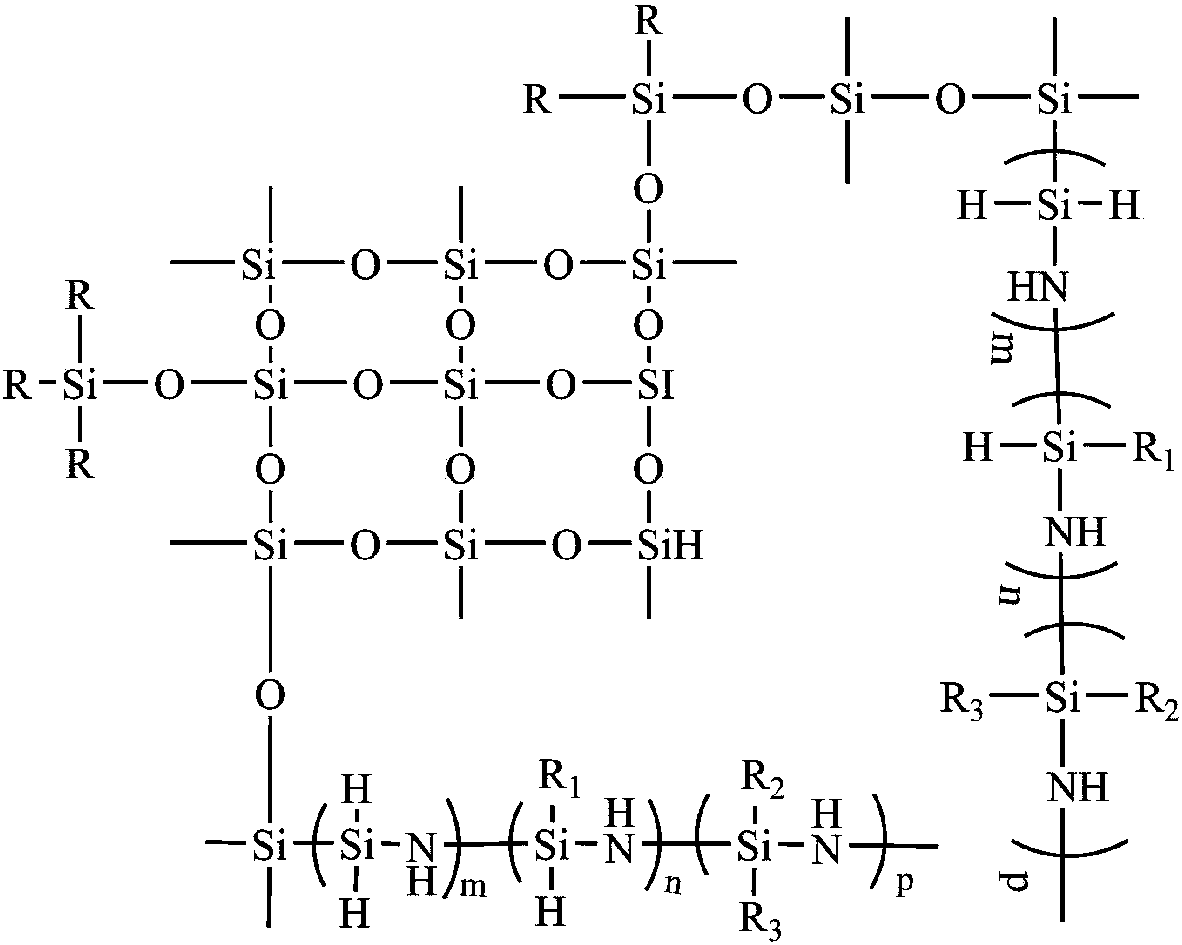

Novel block polyisocyanate and urethane composition containing the same

ActiveCN101896528AExcellent low temperature curingGood weather resistancePolyurea/polyurethane coatingsCarbamatePolyol

Disclosed is a block polyisocyanate obtained by blocking at least a part of isocyanate groups of a polyisocyanate, which is derived from an aliphatic diisocyanate and a polyol and satisfies all of the conditions (1)-(5) shown below, with a pyrazole compound. (1) Average number of isocyanate groups: 3.0-20 (2) Diisocyanate monomer trimer concentration: 10-50% by mass (3) Isocyanate group concentration: 5-22% by mass (4) Polyol content concentration: 5-40% by mass (5) Diisocyanate monomer concentration: 3% by mass or less.

Owner:ASAHI KASEI KK

Super-hard organic silicone hydrophobic glass resin and preparation method thereof

The invention relates to super-hard organic silicone hydrophobic glass resin and a preparation method thereof. Under the catalysis of a Karsted catalyst, active silicon-hydrogen bonds and carbon-carbon double bonds in hydrogen-containing polymethylhydrogensiloxane, vinyl MQ silicone resin, polyhydroxy polysiloxane, and amino silicone oil are crosslinked, and active silicon-hydrogen bonds and hydroxyl or amino in the hydrogen-containing polymethylhydrogensiloxane, the vinyl MQ silicone resin, the polyhydroxy polysiloxane, and the amino silicone oil are crosslinked, so that three-dimensional network-shaped organic silicone resin is formed, and then in the presence of a catalyst, polysilazane reacts with hydroxyl, amino or carbon-carbon double bonds in the organic silicone resin through active -Si-H to be grafted on the molecular chain of the organic silicone resin. The glass resin provided by the invention can be self-catalyzed and cured at a room temperature, and has uniform film formation without cracking or powdering; the film has good water resistance and stain resistance, and the contact angle of water and the film formed after the glass resin coats the surface of a tile can reach 130 degrees; the transparency is good, and the light transmittance is up to 80%; and the hardness of the film is high, the pencil hardness is up to 7H or above, and the film can withstand the hightemperature of 300 DEG C.

Owner:HUNAN QIWEI TECH CO LTD

Electrogalvanized steel plate and steel plate electrogalvanizing process

The present invention is electrogalvanized steel plate and steel plate electrogalvanizing process. The electrogalvanized steel plate has electrogalvanized layer containing tin in 15-8000 ppm. The steel plate electrogalvanizing process includes the steps of defatting the steel plate, pickling treatment and electrogalvanizing, and features the electrogalvanizing solution containing Sn2+ in 1-500 ppm. Adding small amount of Sn2+ into the electrogalvanizing solution can alter the structure of the electrogalvanized layer and electrogalvanized layer containing tin in 15-8000 ppm has greatly raised, 2 times or higher raised, hardness.

Owner:BAOSHAN IRON & STEEL CO LTD

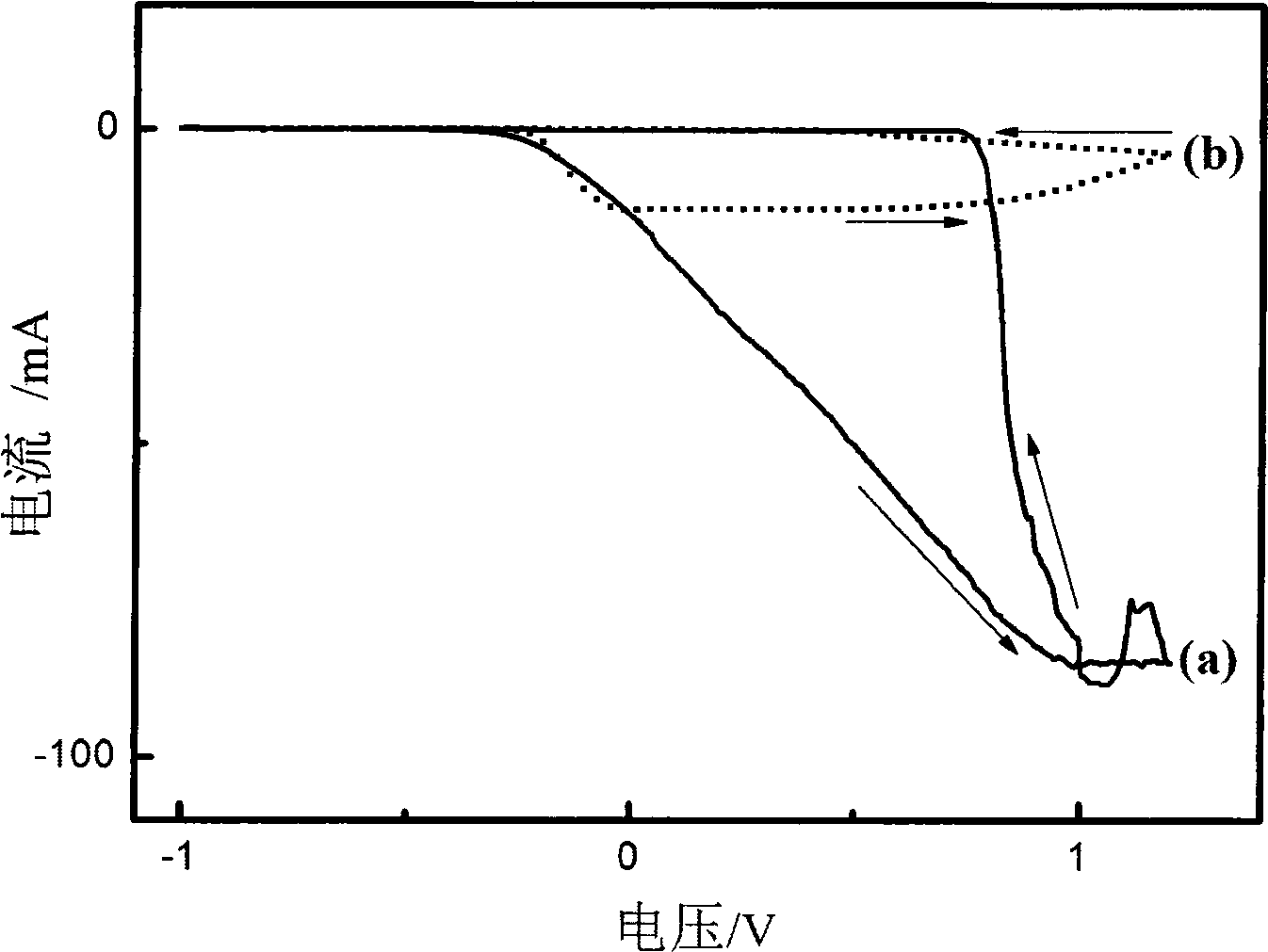

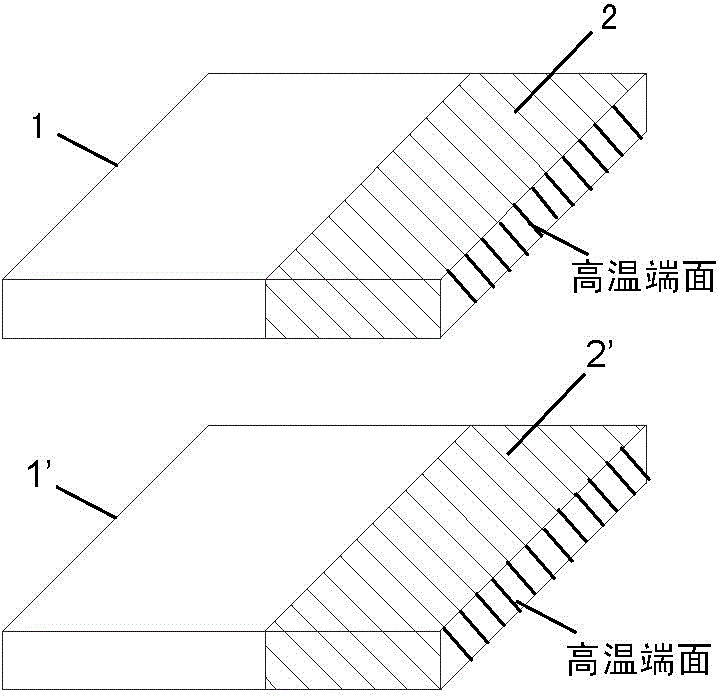

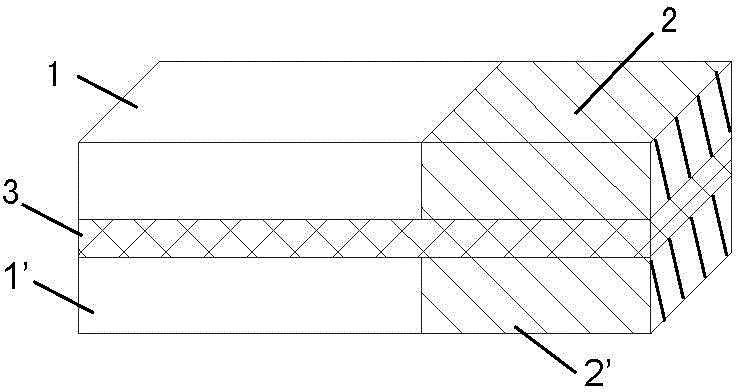

Middle-high temperature thermoelectric module

ActiveCN104934523ABlock sublimationPrevent oxidationThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermal insulationOxidation resistant

The invention relates to a middle-high temperature thermoelectric module. The middle-high temperature thermoelectric module comprises at least one group of thermoelectric pair, wherein the thermoelectric pair comprises two thermoelectric blocks connected through an insulating supporting plate; an electrode formed on a high temperature end surface of the thermoelectric pair; a diffusion blocking protection layer formed at least on the surface of the thermoelectric pair and / or the surfaces of the two thermoelectric blocks; an anti-oxidation layer formed at least on the surface of the thermoelectric pair and / or the surfaces of the two thermoelectric blocks; and an aerogel thermal insulation layer filling a gap of the at least one group of thermoelectric pair. The thermoelectric module provided by the invention simultaneously has the performance of sublimation prevention, anti-oxidation, heat insulation and the like, and the thermoelectric performance and the efficiency of the thermoelectric module are improved; in addition, the thermoelectric module has a self-protection function when working under conditions relating to corrosive gas, moist, chemical medium corrosion, temperature cold-hot alternation and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

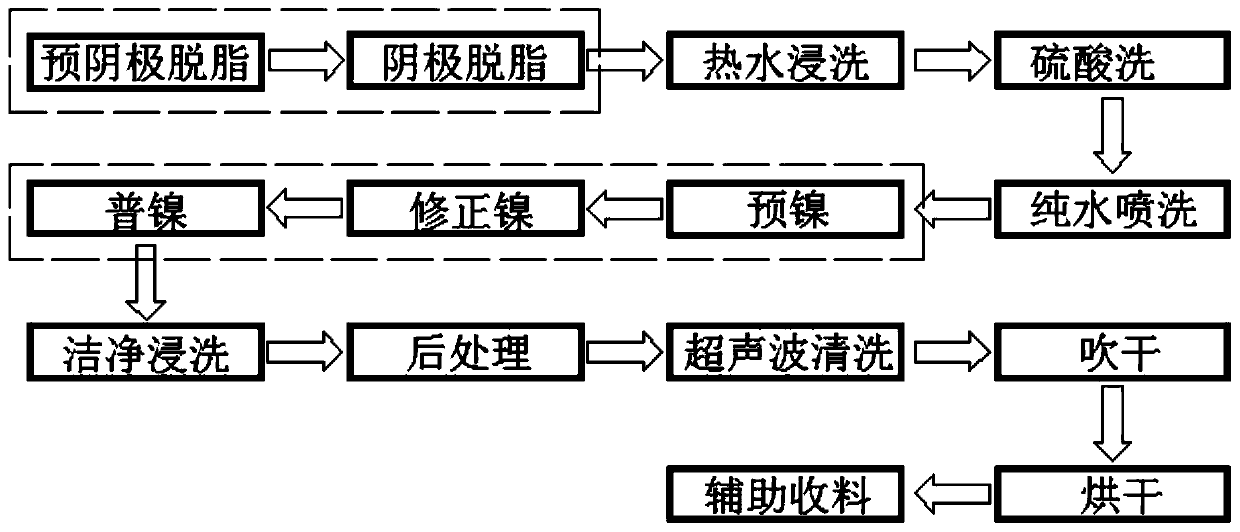

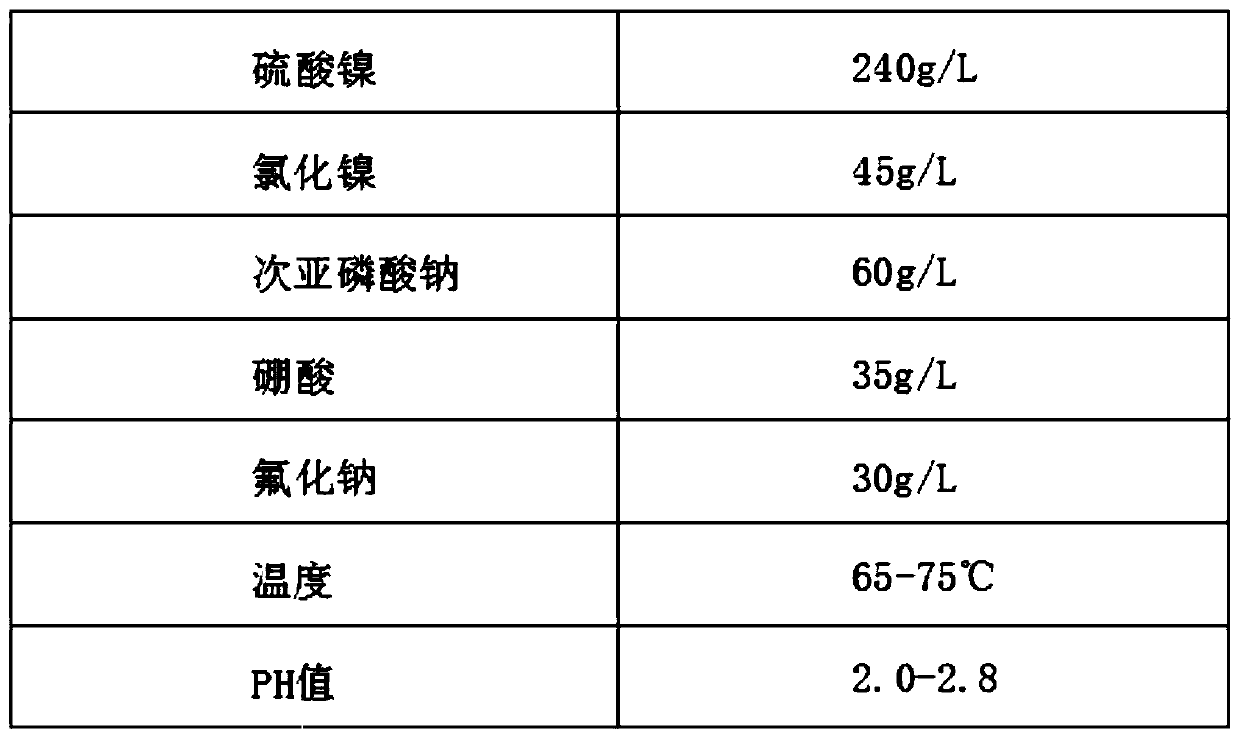

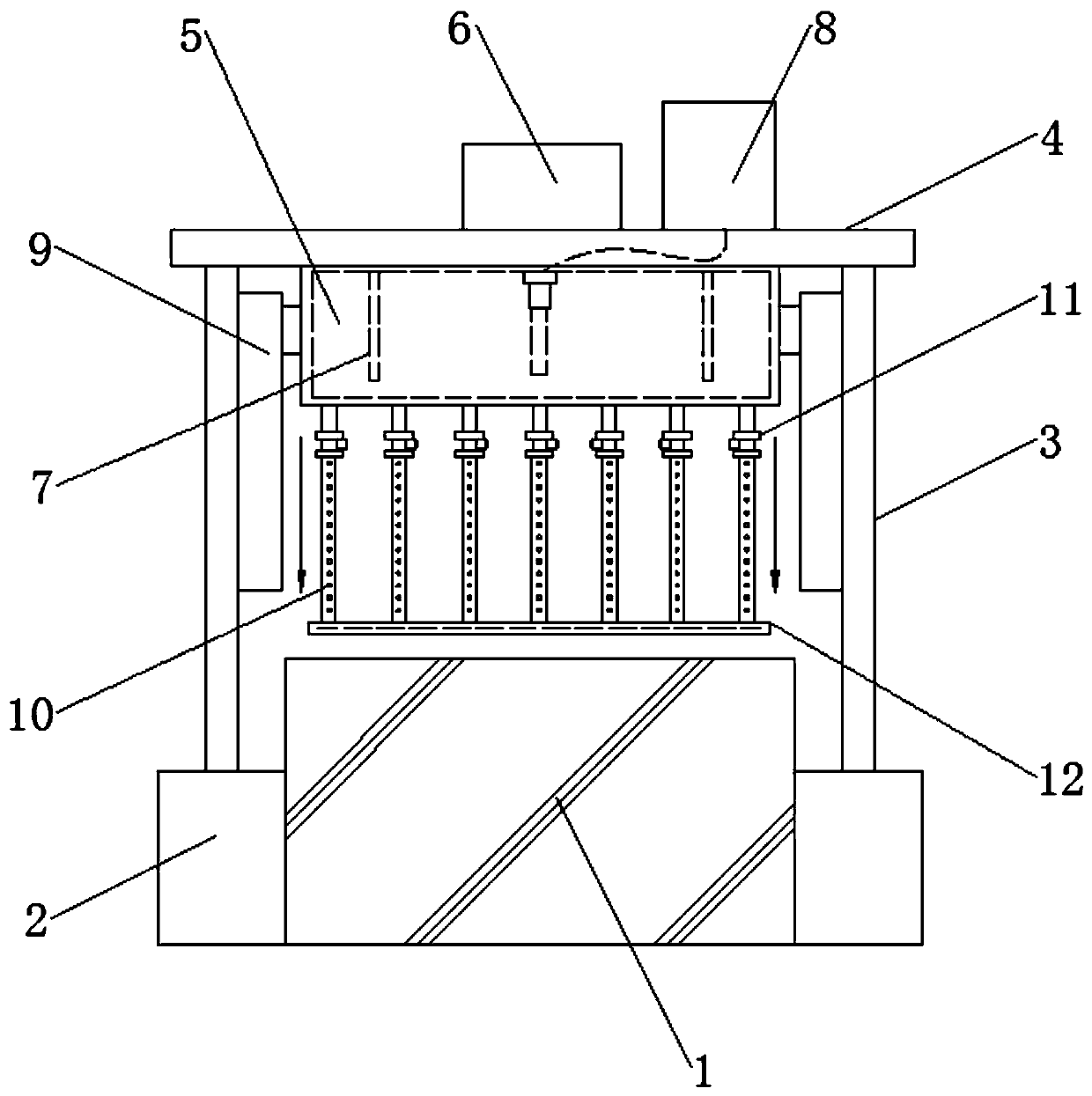

Process for optimizing nickel-plated appearance of ultra-wide stainless steel plate

The invention discloses a process for optimizing the nickel-plated appearance of an ultra-wide stainless steel plate and belongs to the technical field of nickel plating. The process for optimizing the nickel-plated appearance of the ultra-wide stainless steel plate comprises the following steps: step 1, degreasing; step 2, immersion washing with hot water; step 3, washing with sulfuric acid; step4, spray washing with pure water; step 5, nickel pre-plating; step 6, corrective nickel plating; step 7: general nickel plating; step 8, cleaning and immersion washing; step 9, post-treatment; step 10, ultrasonic washing; step 11, blow-drying; step 12, oven-drying; and step 13, auxiliary collecting. By the adoption of the process, the nickel and phosphorus alloying process can be added between the pre-plating operation and the plating operation on a general nickel-plated layer; accordingly, not only can the plated layer deposition speed be improved, but also a lattice of the nickel-plated layer can be remarkably improved, the lattice being compact in structure can be refined, and the plated layer porosity can be reduced; and then, the appearance uniformity and glossiness of the general nickel-plated layer can be guaranteed, the plated layer density, uniformity and bonding strength can be improved, and the corrosion-resistant property can be improved.

Owner:东莞市康圣精密合金材料有限公司

Heavy anti-corrosion clinkery epoxy powder coating

InactiveCN101857763AGood lookingMeet anti-corrosion requirementsAnti-corrosive paintsPowdery paintsEpoxyToughness

The invention relates to a heavy anti-corrosion clinkery epoxy powder coating, which comprises the following components in part by weight: 100 parts of epoxy resin, 20 to 30 parts of curing agent, 2 to 5 parts of flatting agent and 40 to 70 parts of filler. The heavy anti-corrosion clinkery epoxy powder coating is mainly applied in the field of pipeline corrosion prevention and has the advantages of high toughness, high impact resistance, simple preparation process and suitability for mass production.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com