Process for optimizing nickel-plated appearance of ultra-wide stainless steel plate

A stainless steel and plate technology, which is applied in the field of nickel-plating appearance optimization process for ultra-wide stainless steel plates, can solve the problems of difficulty in achieving the uniformity and stability of the appearance of the nickel-plated layer, poor density and uniformity of the plating layer, and uneven surface gloss, etc. , to achieve the effect of ensuring uniformity and gloss, reducing porosity, and reducing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

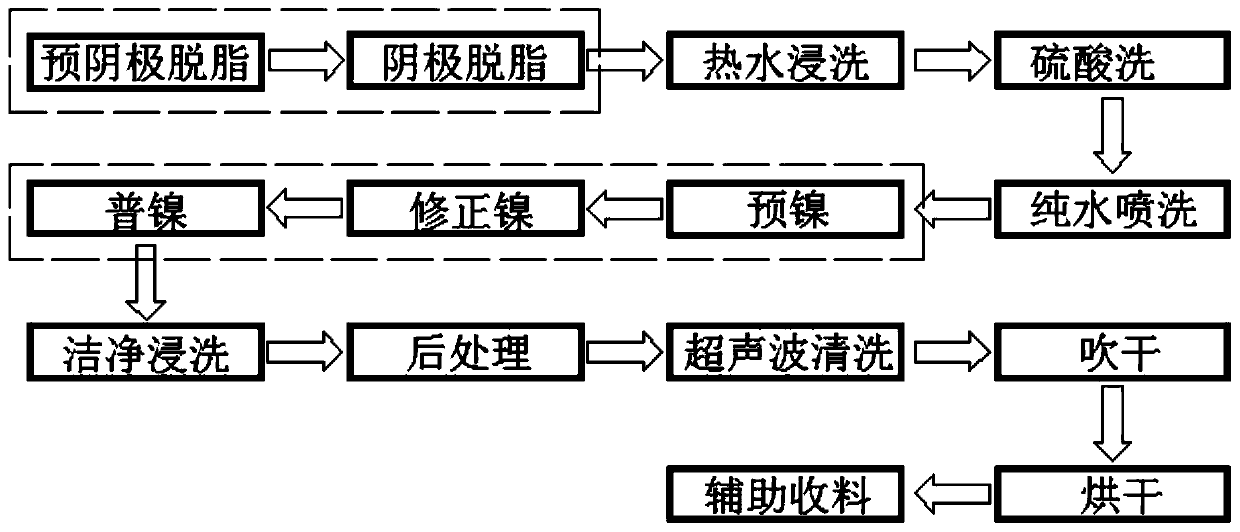

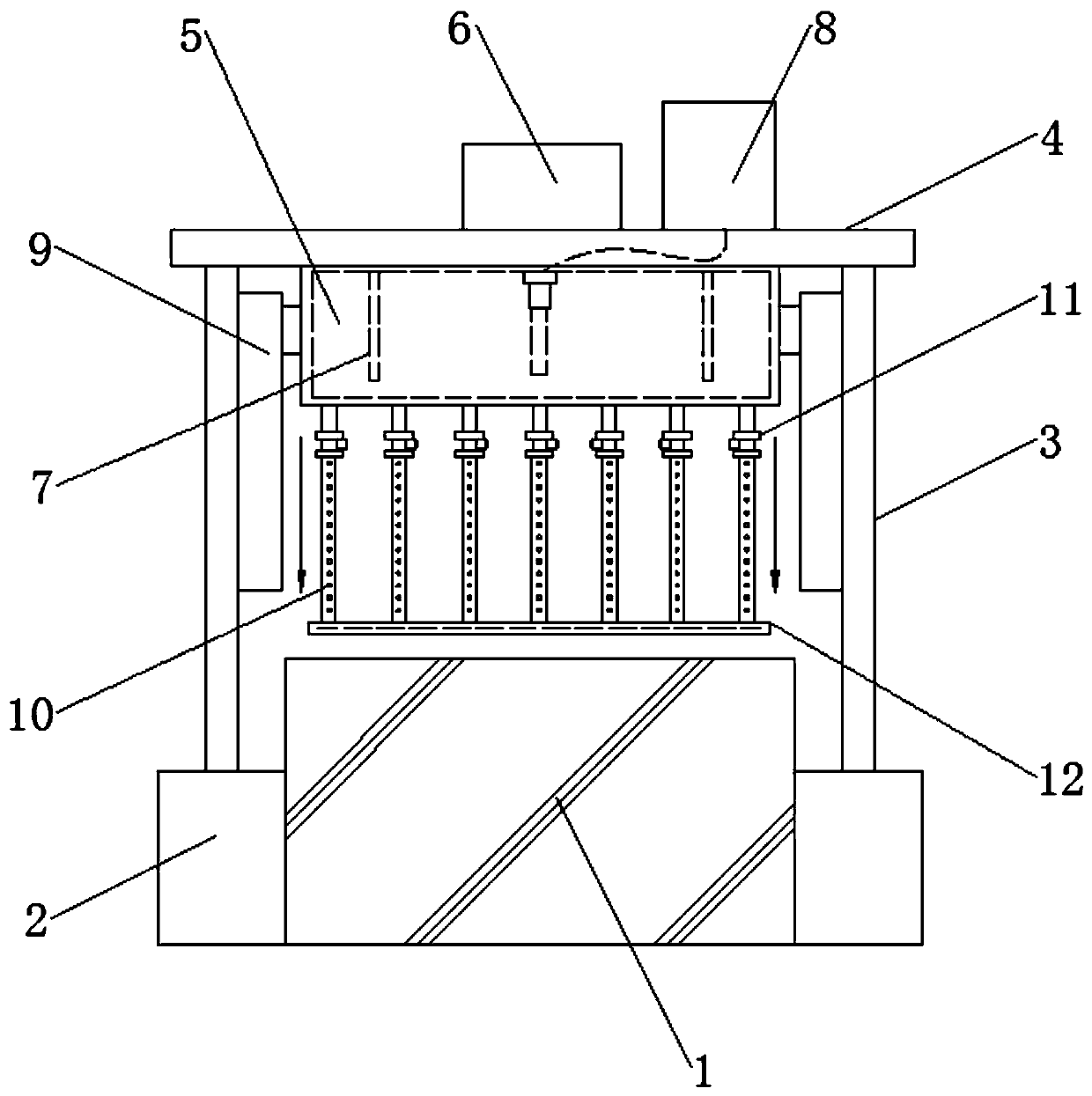

[0052] see figure 1 , the appearance optimization process of nickel plating on ultra-wide stainless steel plates, including the following steps:

[0053] Step 1, degreasing: pre-cathodic degreasing and cathodic degreasing are carried out on the ultra-wide stainless steel plate, and the pre-cathodic degreasing and cathodic degreasing are all performed at a temperature of 50-60 ° C and a current density of 5-10ASD. The weight percentage is 5-10% Metal degreasing agent, improve the degreasing rate of ultra-wide stainless steel plates, remove fatty oil stains and other organic dirt on the surface of ultra-wide stainless steel plates, so as to obtain good electroplating effects and prevent pollution to subsequent processes;

[0054] Step 2, hot water rinsing: use tap water at 50°C to immerse the degreased ultra-wide stainless steel plate;

[0055] Step 3, sulfuric acid washing: Use 10 Baumé sulfuric acid solution to anodically activate the ultra-wide stainless steel plate at room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com