Patents

Literature

45 results about "White metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The white metals are any of several light-colored alloys used as a base for plated silverware, ornaments or novelties, as well as any of several lead-based or tin-based alloys used for things like bearings, jewellery, miniature figures, fusible plugs, some medals and metal type. The term is also used in the antiques trade for an item suspected of being silver, but not hallmarked.

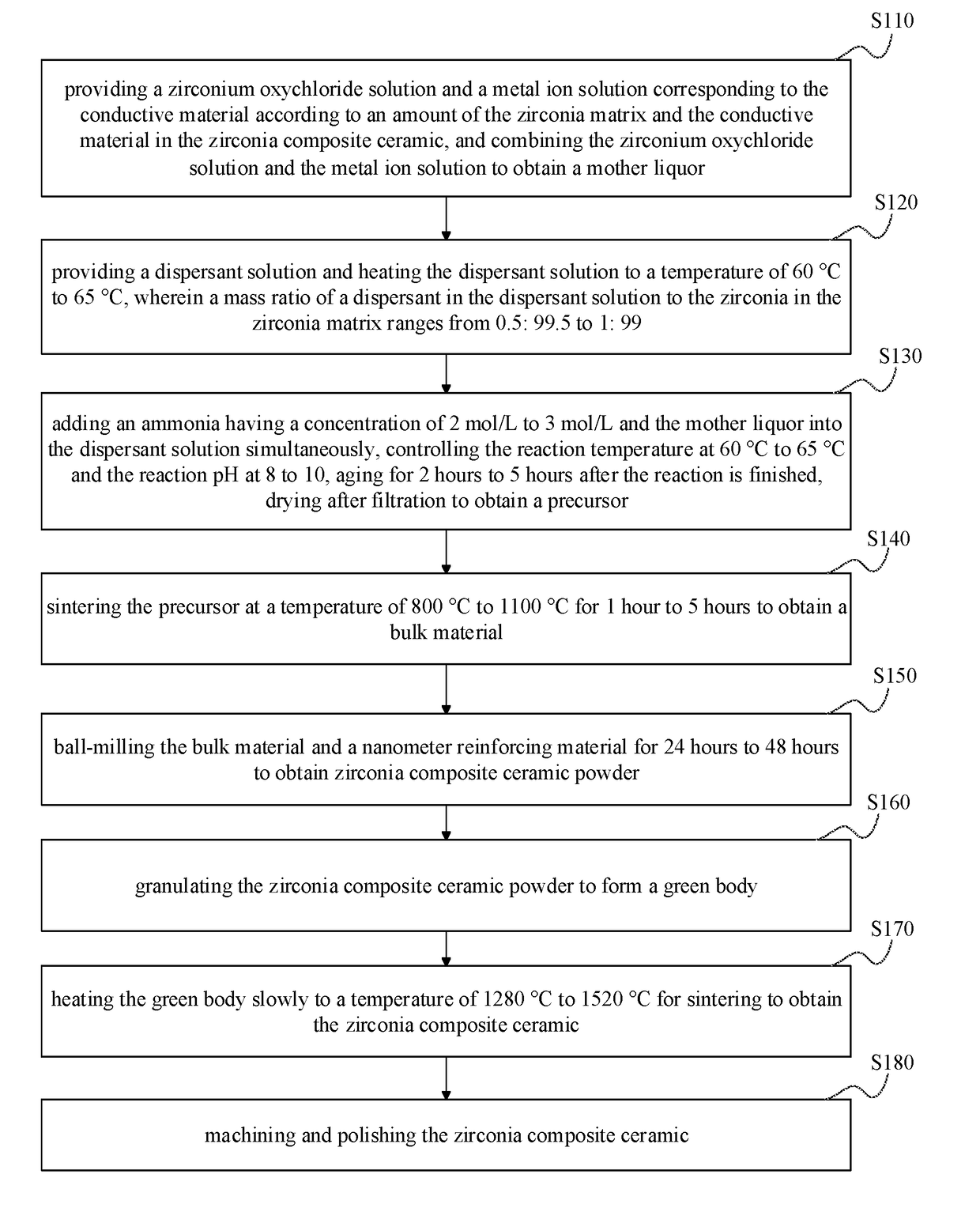

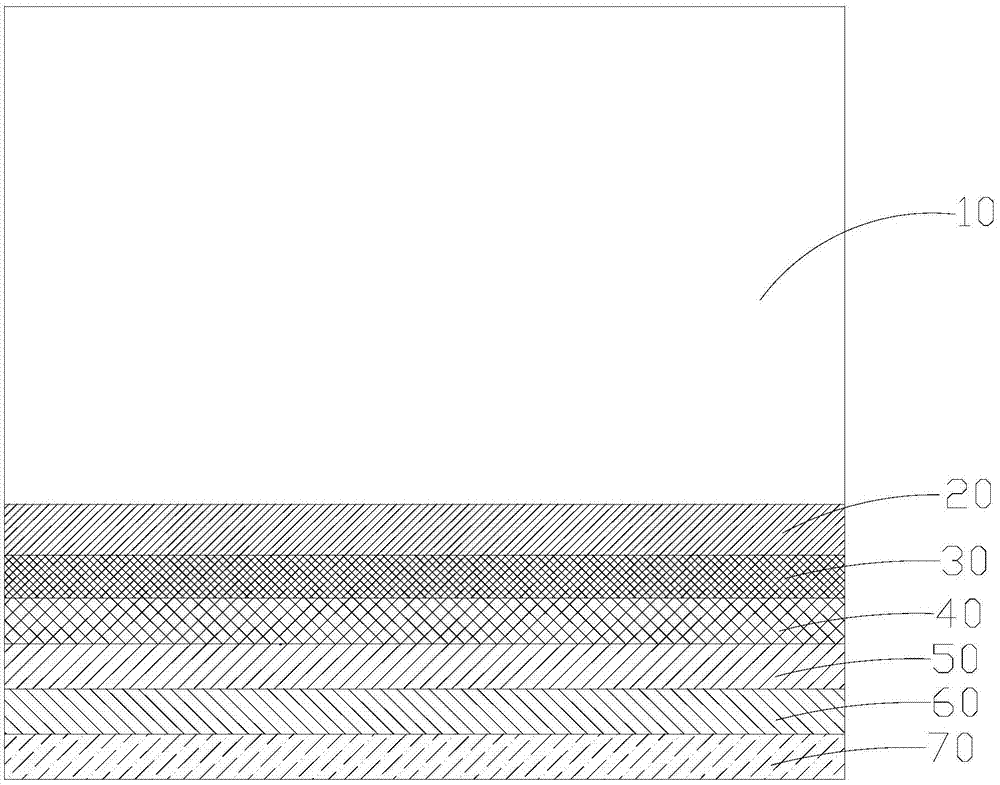

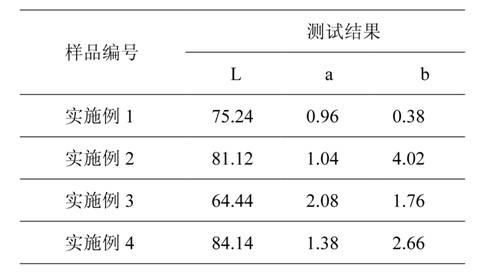

Zirconium oxide composite ceramic and preparation method therefor

InactiveUS20180134624A1Low resistivityImprove antistatic performanceZirconium compoundsOxide conductorsComposite ceramicWhite metal

Provided are a zirconium oxide composite ceramic and a preparation method therefor. The zirconium oxide composite ceramic comprises by mass percentage: 65% to 80% of a zirconium oxide matrix, 10% to 30% of a conductive material, and 2% to 11% of a nano-reinforcing material. The conductive material is selected from at least one of a non-ferrous metal oxide, a white metal oxide, a compound having a perovskite structure and a compound having a spinel structure. The zirconium oxide composite ceramic has excellent antistatic properties and high mechanical properties.

Owner:SHENZHEN SUNTECH ADVANCED CERAMICS

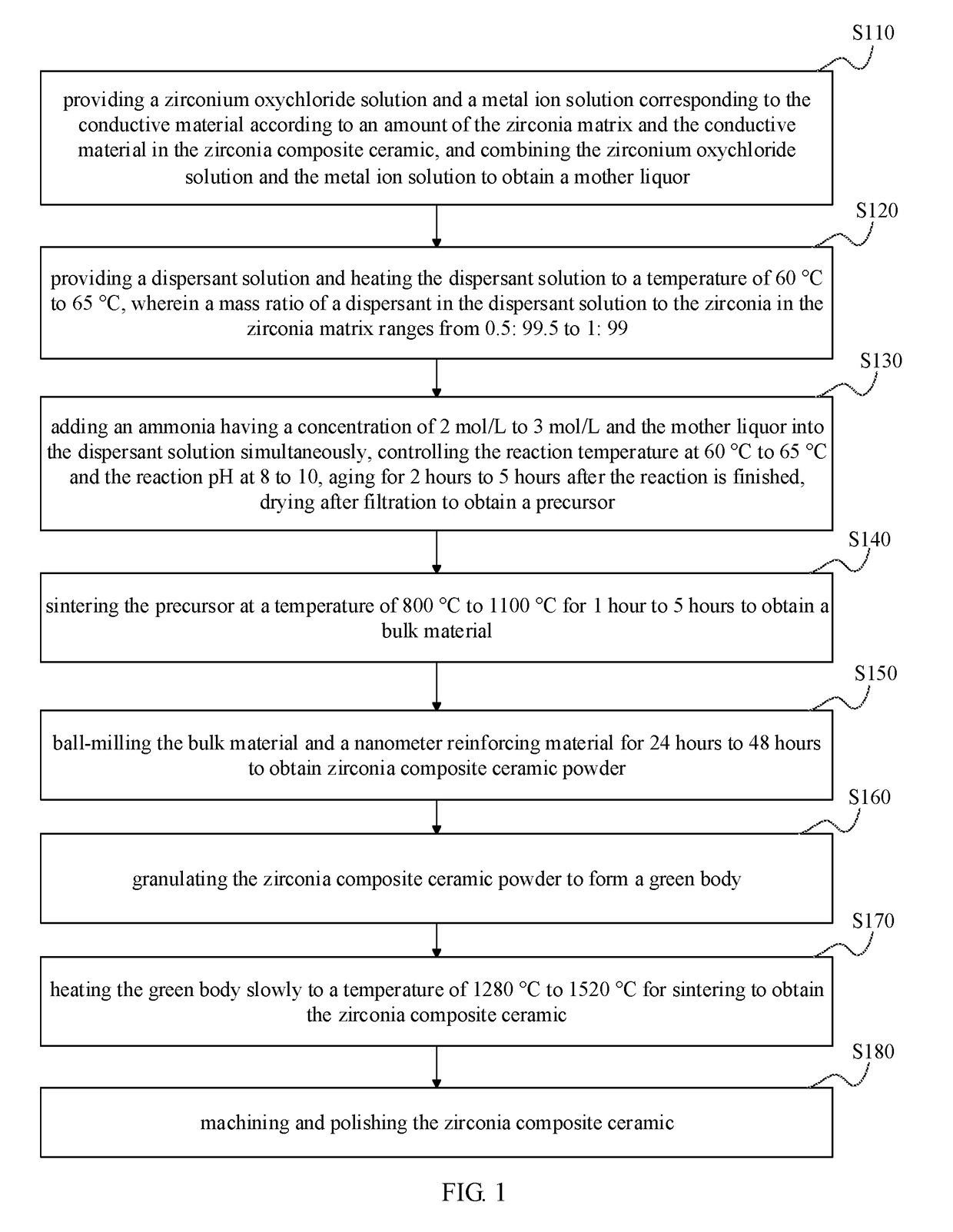

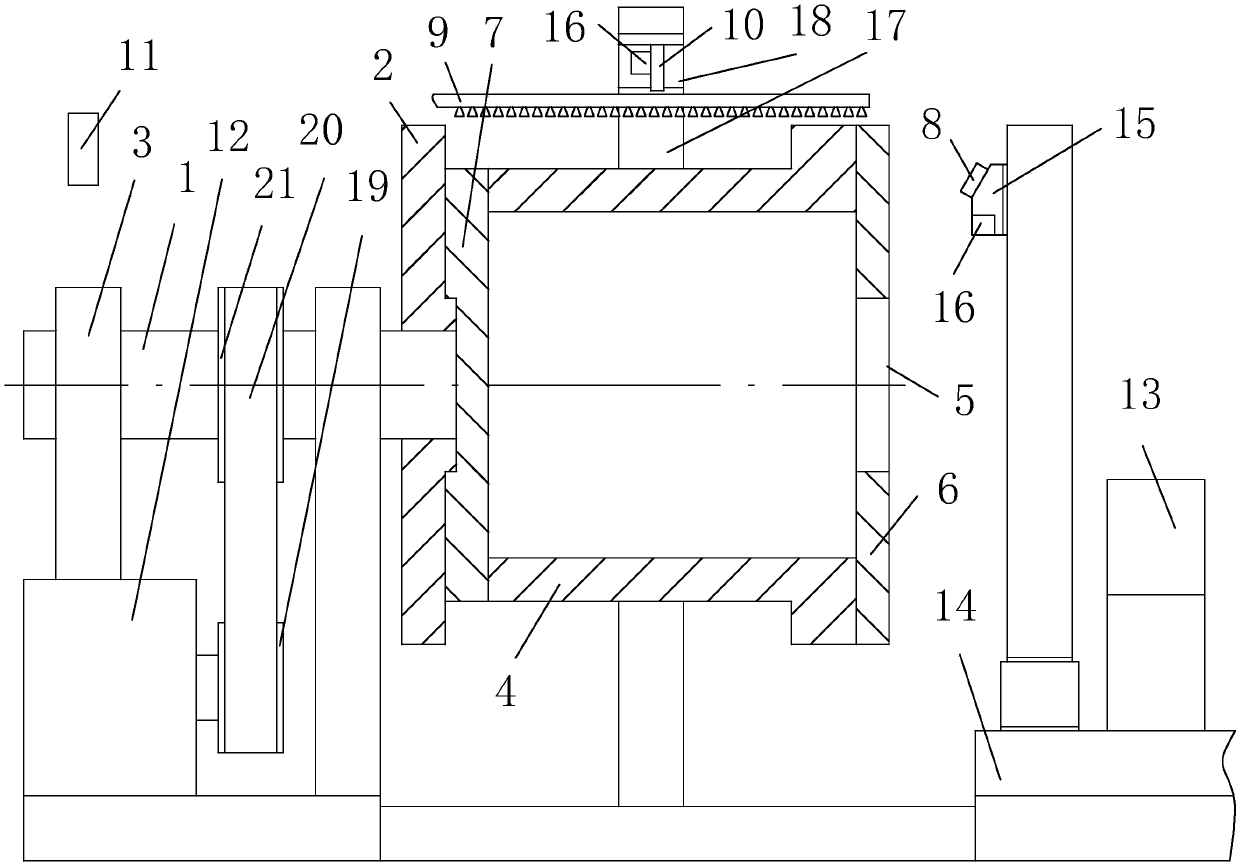

Method for leaching bidery metal by sulfuric acid and inflation agitation leaching trough

The invention relates to a method of lixiviating a white metal with vitriol and a charged churn of lixiviation tank. The method is as follows; the white metal is ground subtly as a lixiviation raw material; in lixiviation phase 1, add certain amount of white metal into a reactor, confect lixiviation solution with a liquid / solid ratio of 5:1 using H2SO4; churn lixiviate under the temperature of 85 - 100 DEG C; in lixiviation phase 2, lead the air to oxidize a lixiviated copper, under the temperature of 80- 85 DEG C, charge a turbine and churn lixiviate; slag and filtrate are generated after a filtration and rinse of pulp, magnetic material is selected and return to lixiviation phase 1; slag and filtrate are generated after the filtration and rinse of pulp, and the pulp is recycled; the lixiviation solution is used as the stock solution for the recycle of Cu and CO. Charge-churn the lixiviation tank comprises a stirrer, a beaker, the lixiviation tank is placed upon an electric cooker, a churn shaft and a blade are made of titanium, two pieces of PTFE baffles are arranged inside the beaker, a charging tube is a glass tube with a nozzle, the nozzle is positioned between the blade and the shaft, a lid is supplied on the beaker.

Owner:CHINA ENFI ENGINEERING CORPORATION

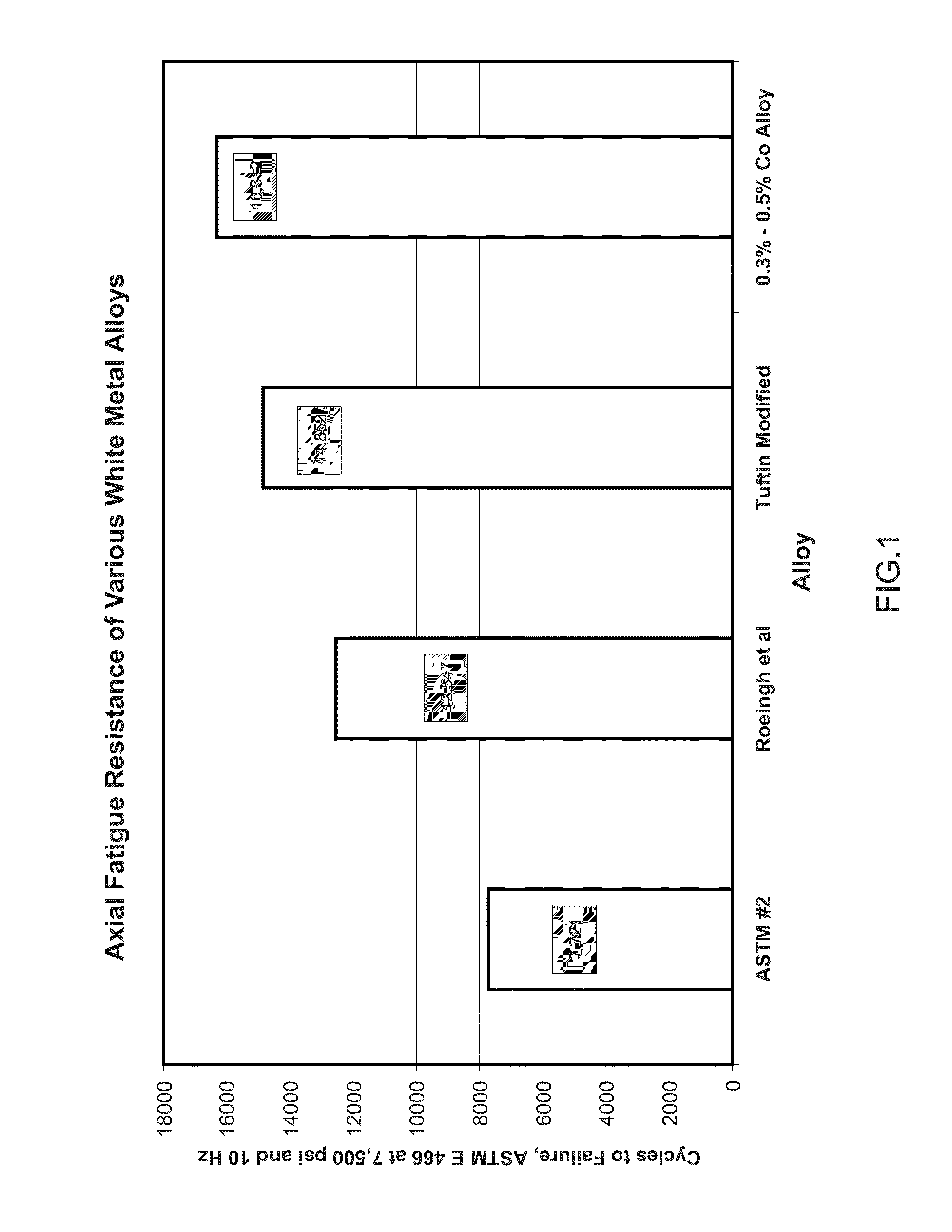

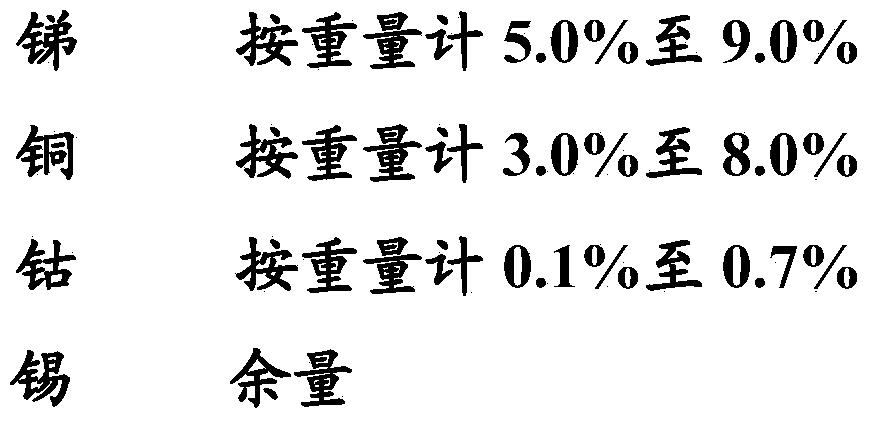

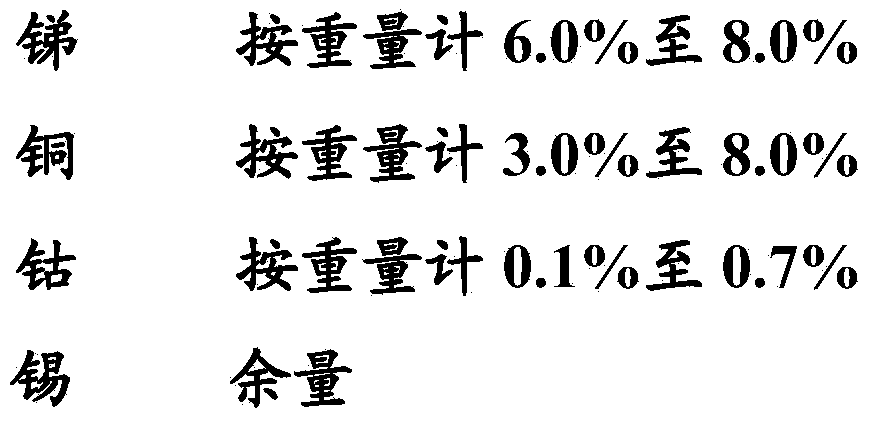

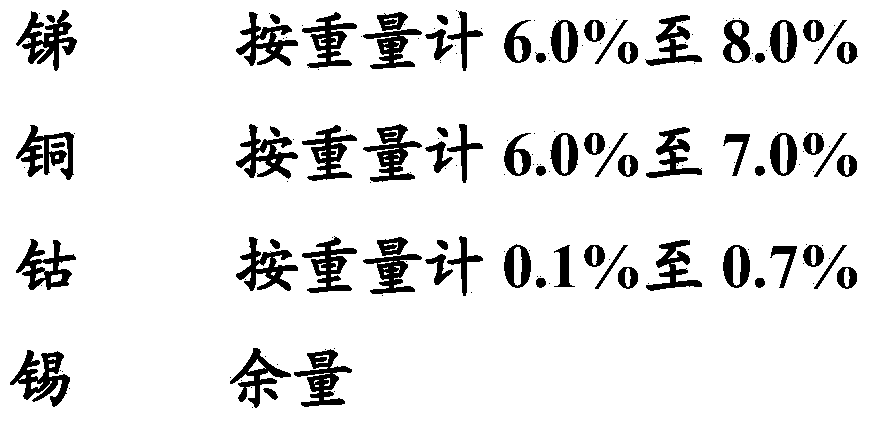

Plain bearing alloy consisting of a tin-based white metal

The invention relates to a plain bearing alloy consisting of a tin-based white metal and containing antimony as the primary alloy element and between 1 and 10 % by weight copper. The aim of the invention is to achieve excellent strength characteristics coupled with a high degree of ecofriendliness without impairing the tribological characteristics. To achieve this, the white metal, which except for inevitable impurities is devoid of cadmium, lead, arsenic and chrome, contains between 4 and 30 % by weight antimony as the primary alloy element, at least one element from an element group containing cobalt, manganese, scandium and germanium, in a total concentration relating to the elements from said group that are used, of between 0.2 and 2.6 % by weight, in addition to at least one element from an element group containing magnesium, nickel, zircon and titanium, in a total concentration relating to the elements from said group that are used, of between 0.05 and 1.7 % by weight, the maximum total proportion of antimony and copper being 35 % by weight for an antimony content that corresponds to three times the copper content.

Owner:MIBA GLEITLAGER GMBH

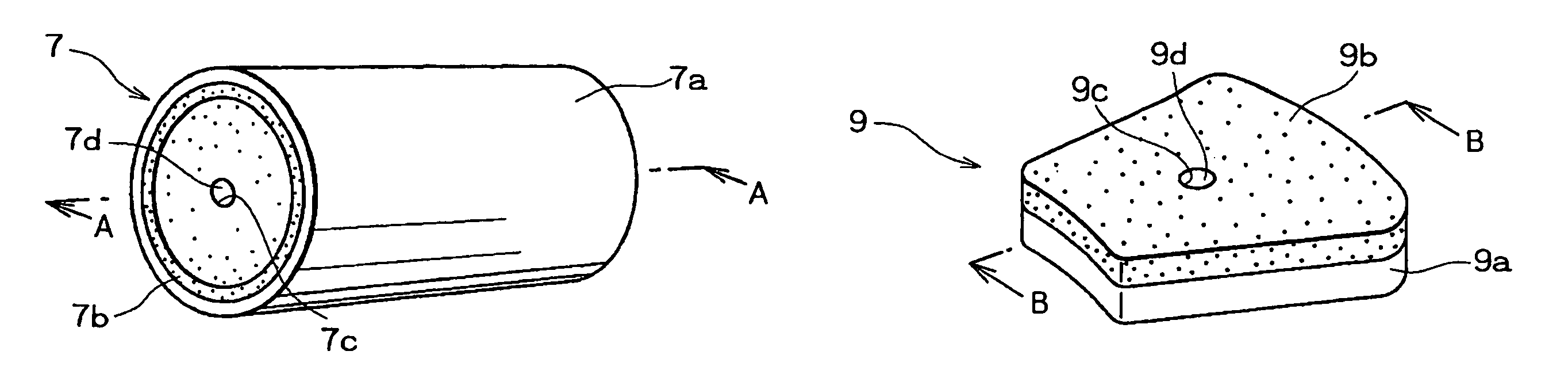

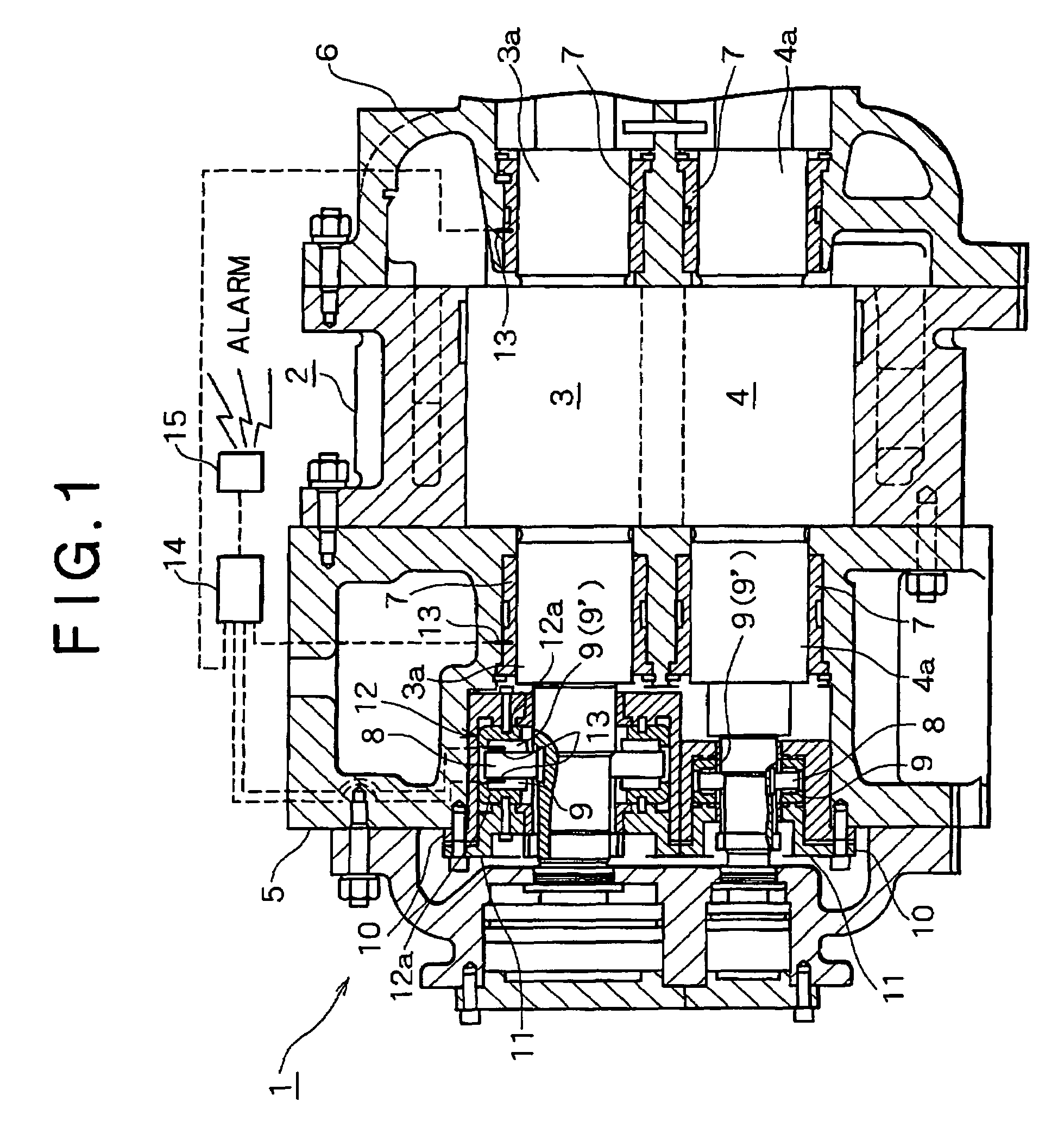

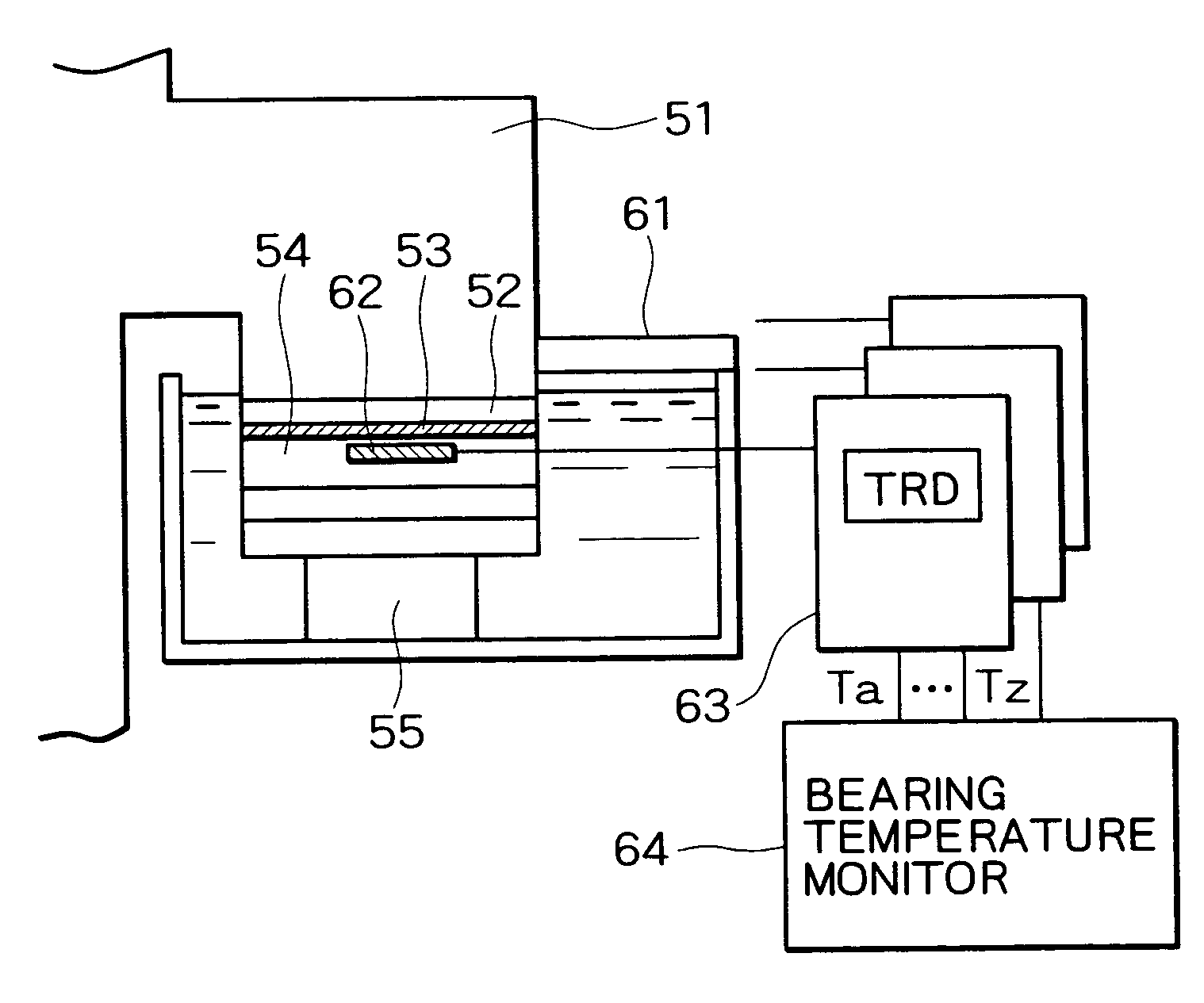

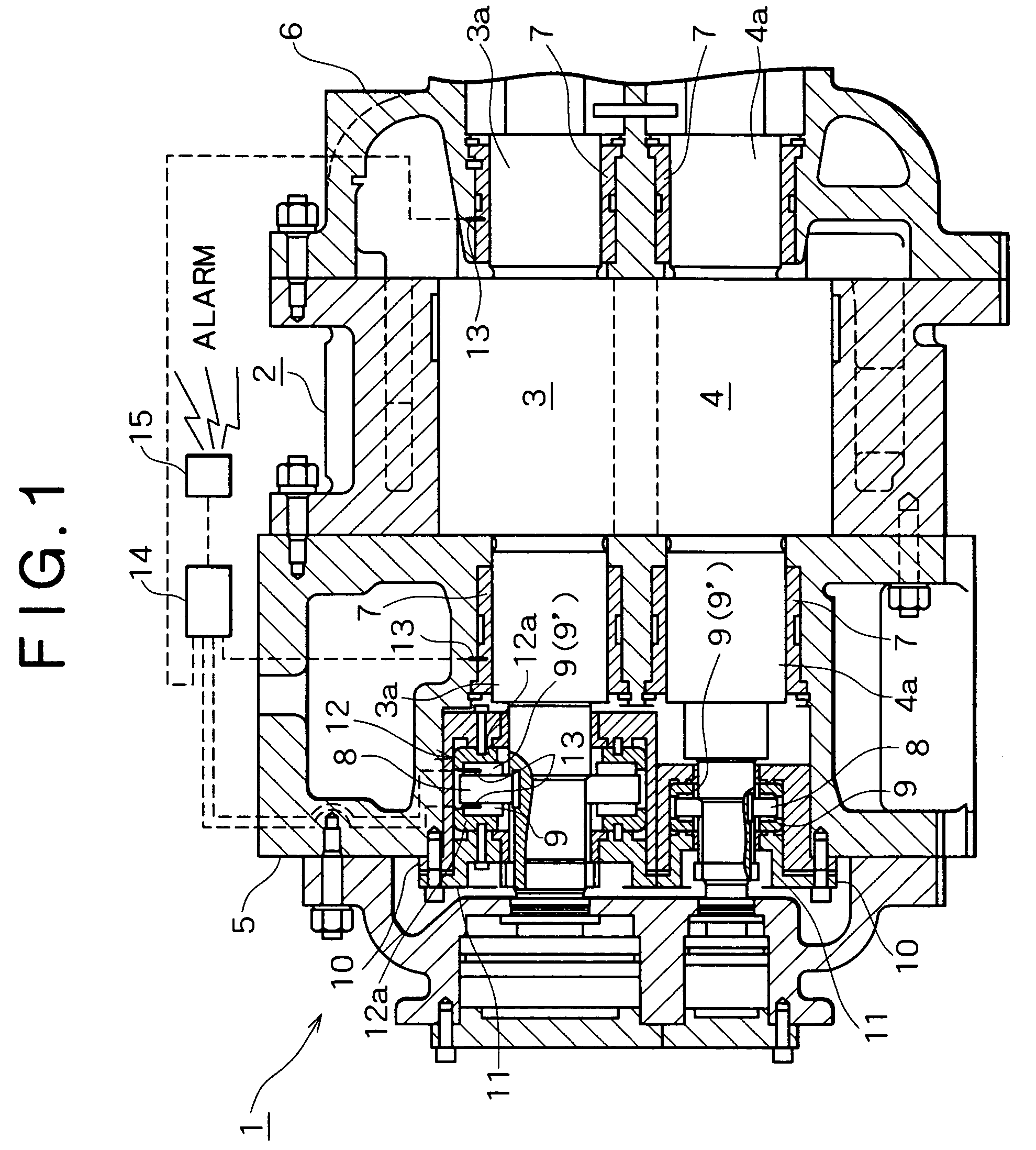

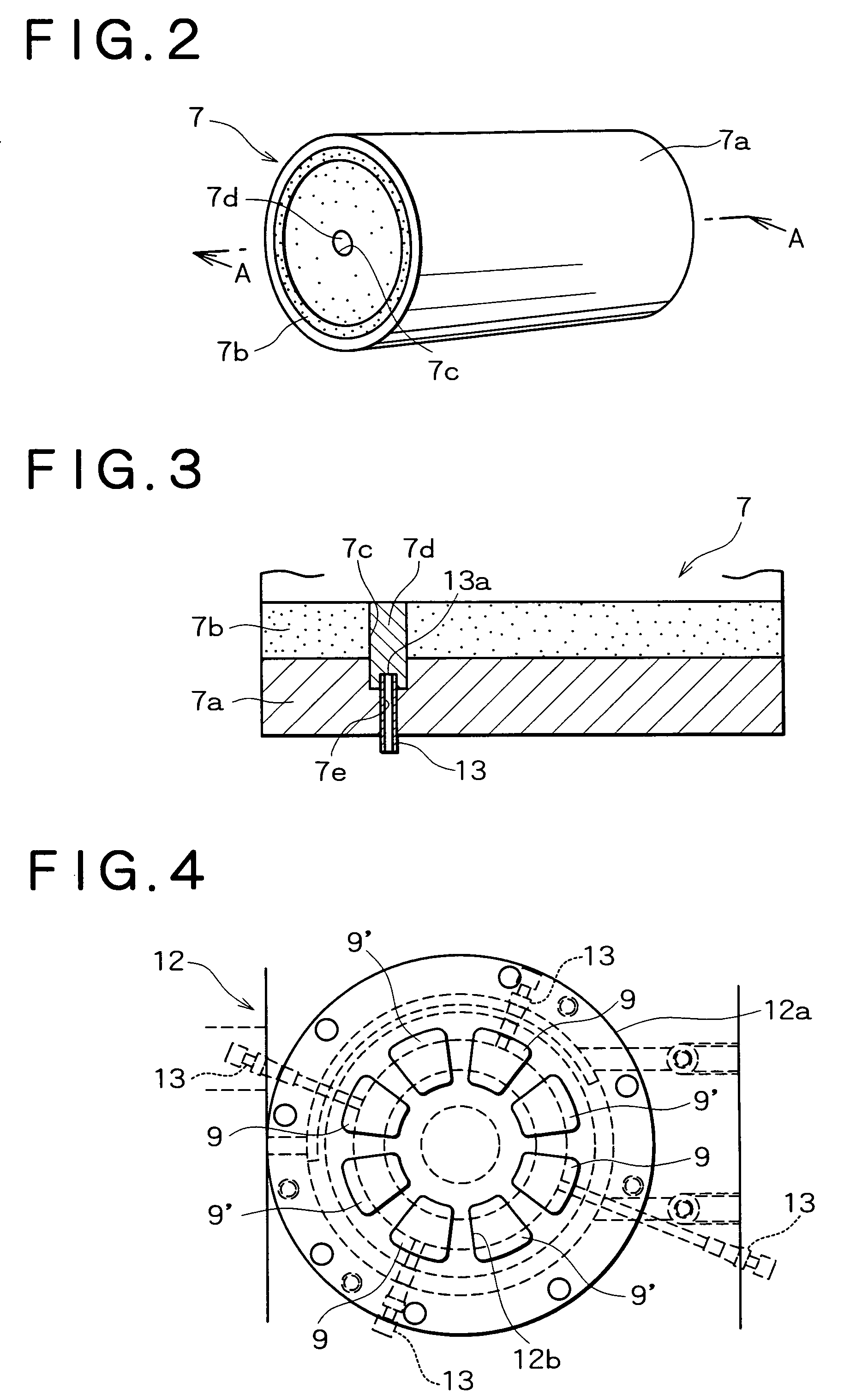

Bearing and screw compressor

ActiveUS7682084B2Accurate temperature detectionAccurate detectionThermometer detailsBearing assemblyWhite metalEngineering

Owner:KOBE STEEL LTD

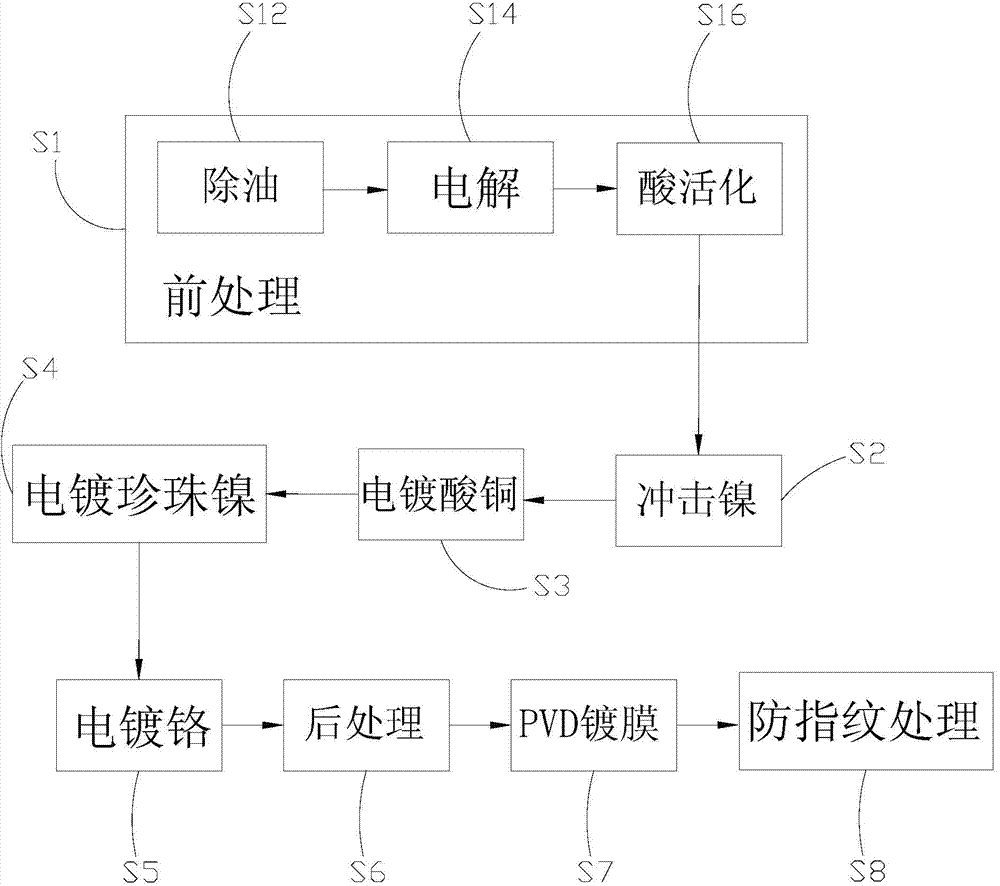

Stainless steel surface treatment method

ActiveCN104726911AImprove corrosion resistanceWith silvery white metal textureSuperimposed coating processCopper coatingSurface layer

The invention is suitable for the technical field of metal surface treatment methods, provides a stainless steel surface treatment method and aims at solving the technical problem of failure in showing stainless steel three-dimensional texture after stainless steel surface treatment in the prior art. The stainless steel surface treatment method comprises the following steps: pretreatment, namely cleaning the surface of a stainless steel substrate; impacting nickel, namely performing impacting electronickelling on the stainless steel substrate to obtain an impact nickel layer; acidic copper electroplating, namely performing acidic copper electroplating treatment on the impact nickel layer and forming a copper coating; pearl nickel electroplating, namely performing pearl nickel electroplating treatment on the surface of the copper coating and obtaining a pearl nickel layer with sand feeling; electrochroming, namely forming a protective chrome layer on the surface layer of the pearl nickel layer; and aftertreatment. The pearl nickel electroplating treatment is adopted to increase the sand feeling of the copper coating and then the surface with the three-dimensional texture can be obtained; and the electrochroming treatment is adopted to form the protective film on the surface of the pearl nickel layer, and therefore, the stainless steel substrate also has silver white metal texture.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Bearing and screw compressor

ActiveUS7140779B2Accurate temperature detectionAccurate detectionBearing assemblyShaftsWhite metalEngineering

In a bearing constituted by a plural-layer slide member, the plural-layer slide member comprises a resin layer of polytetrafluoroethylene as a slide member and a backing strip to which the resin layer is bonded. A fitting hole having a depth exceeding the thickness of the resin layer is formed from the resin layer side. A temperature measuring metallic member formed of a white metal is fitted in the fitting hole. A temperature sensor is positioned within the temperature measuring metallic member. This bearing permits an accurate detection of its temperature. Further, in an oil cooled screw compressor having a bearing lubricating oil supply pipe, a slide surface of the bearing is covered with polyether ether ketone. Even if foaming occurs in the oil, it is possible to prevent the occurrence of a mechanical trouble such as galling.

Owner:KOBE STEEL LTD

Low-temperature glaze with silver white metal luster and preparation method thereof

The invention discloses a low-temperature glaze with silver white metal luster, which comprises ferrisodium pyrophosphate, ferric phosphate and ceramic-based glaze according to the ratio of (2-3):1:(4-7), wherein the ceramic-based glaze comprises the components of soda feldspar, quartz, limestone and kaolin according to the weight ratio of (20-50):(2-5):(0-2):(3-10). The low-temperature glaze has the advantages of fewer raw material kinds, wide resources, low cost, identical manufacturing process with common over glaze, low cost, simple use method, one-time baking, low baking temperature, energy saving and environmental protection. The baked product has beautiful silver white metal luster and is especially applicable to ceramic wall tiles, ceramic mosaic tiles and the like, and the decoration effect is good.

Owner:广东道氏陶瓷材料有限公司

Car trim and preparation method of surface coating of car trim

ActiveCN106011762AHas a silvery-white metallic appearanceImprove corrosion resistanceVacuum evaporation coatingSputtering coatingEngineeringDirect current magnetron sputtering

The invention discloses a car trim and a preparation method of a surface coating of the car trim. The trim comprises a plastic substrate, wherein the plastic substrate is transparent to visible light; the back surface of the substrate is provided with a groove; the groove is internally covered with a nano metal coating and a diamond-like coating from interior to exterior; and an outermost layer is provided with induction type visible light sources which are arrayed according to a certain shape. The invention also provides the preparation method of the surface coating of the car trim. The preparation method of the surface coating of the car trim comprises the following steps of (1), carrying out bombardment on a base material by adopting an Ar ion beam; (2), depositing the nano metal coating by adopting direct-current magnetron sputtering; and (3), depositing a hydrogen-containing diamond-like coating by adopting an ion source. Through the above preparation method of the surface coating, on one hand, a plastic material is enabled to have a silvery white metal appearance, and on the other hand, when the light sources on the back surface of the substrate are lit, a luminous pattern can be seen from a frontal surface; the method is green and environment-friendly; and the zero emission of a pollutant to an environment is achieved.

Owner:NINGBO ZHONGJUN SHANGYUAN AUTO PARTS

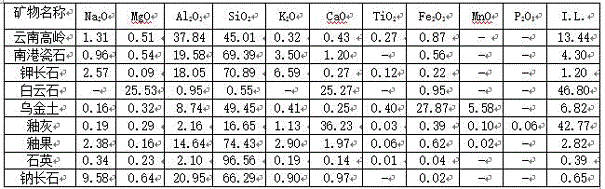

Method used for firing high temperature matte brownish red glazed porcelain in reducing atmosphere

The invention relates to a method used for firing high temperature matte brownish red glazed porcelain in a reducing atmosphere. According to the method, in a green body and a glaze material, a common natural mineral material is mainly adopted at a certain ratio; raw materials such as glaze ash, dolomite, and white metal clay are added into the glaze material; one time firing is carried out at 1280 to 1320 DEG C in the reducing atmosphere so as to obtain the brownish red glazed porcelain. The method is capable of avoiding defects in the prior art that the glossiness of the obtained brownish red glazed porcelain is high, colour generation is nonuniform, and the primitive simplicity unique texture of Ming and Qing official ware brownish red glazed porcelain is impossible to achieve, and the method are capable of satisfying consumption requirements of returning to one's original nature of modern people. The raw materials are natural mineral raw materials, so that production cost is reduced greatly, it is beneficial for inheriting and promoting of excellent porcelain producing technology of our country, conditions are provided for improvement of the colour generation quality and stability of conventional porcelain products, and market prospect is promising.

Owner:JINGDEZHEN CERAMIC INSTITUTE

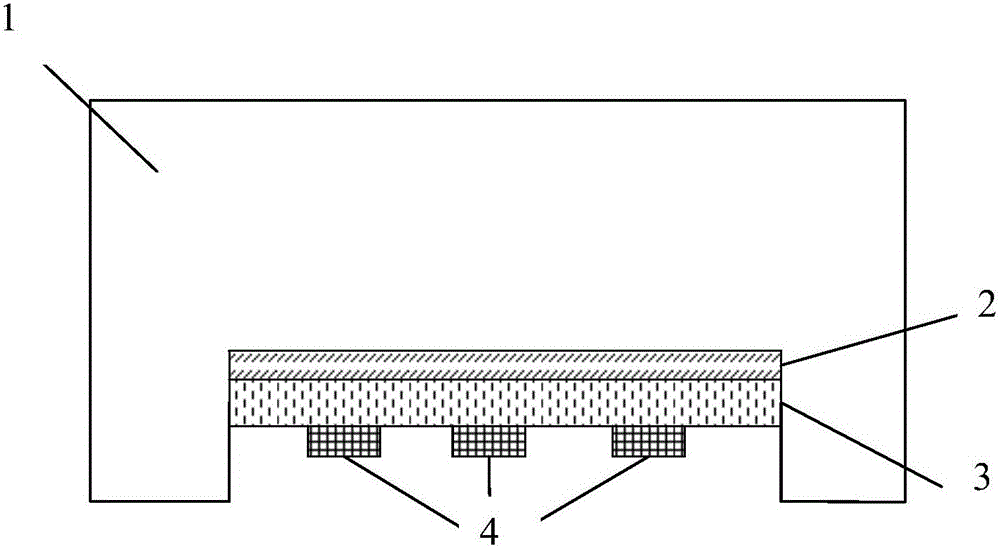

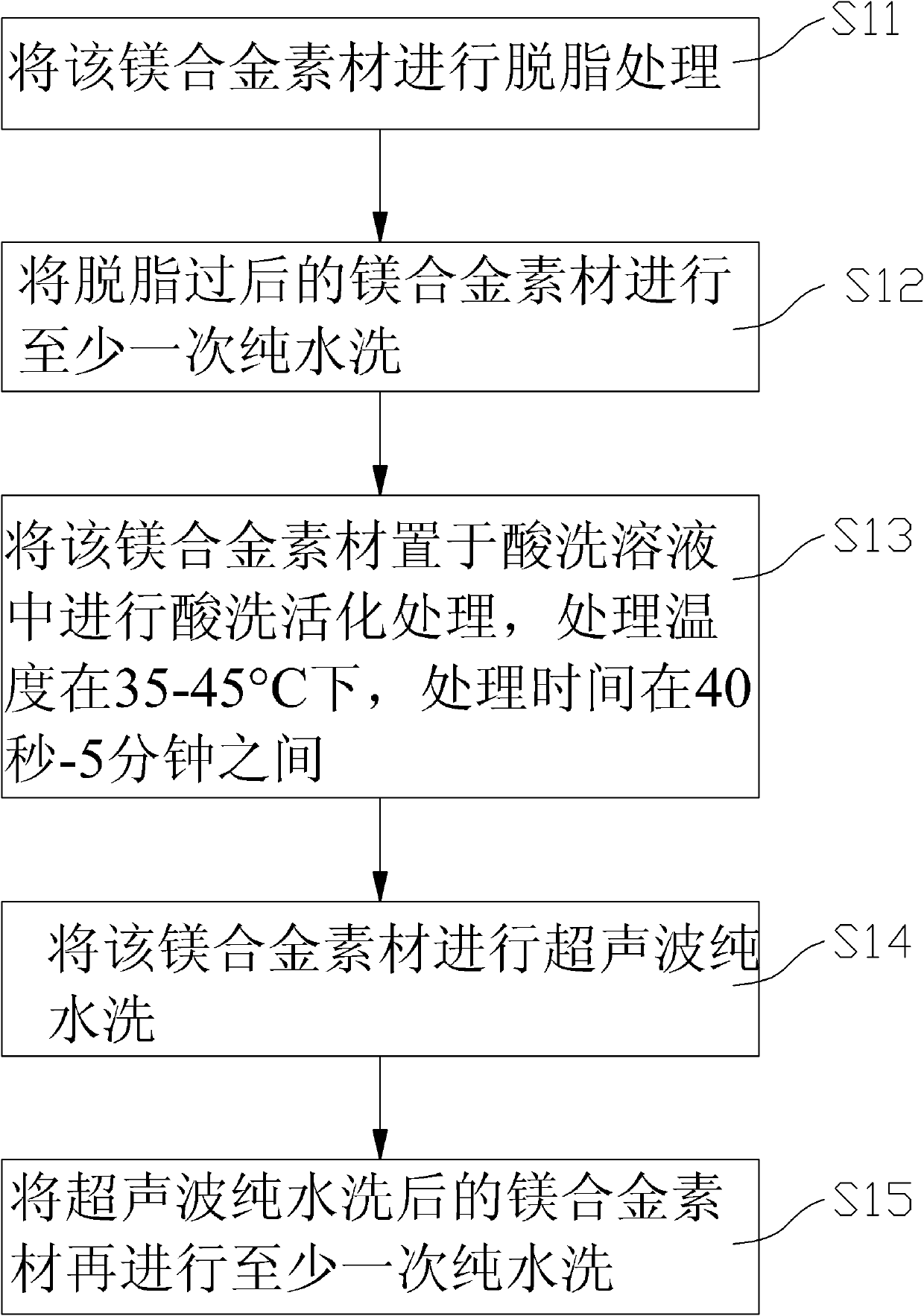

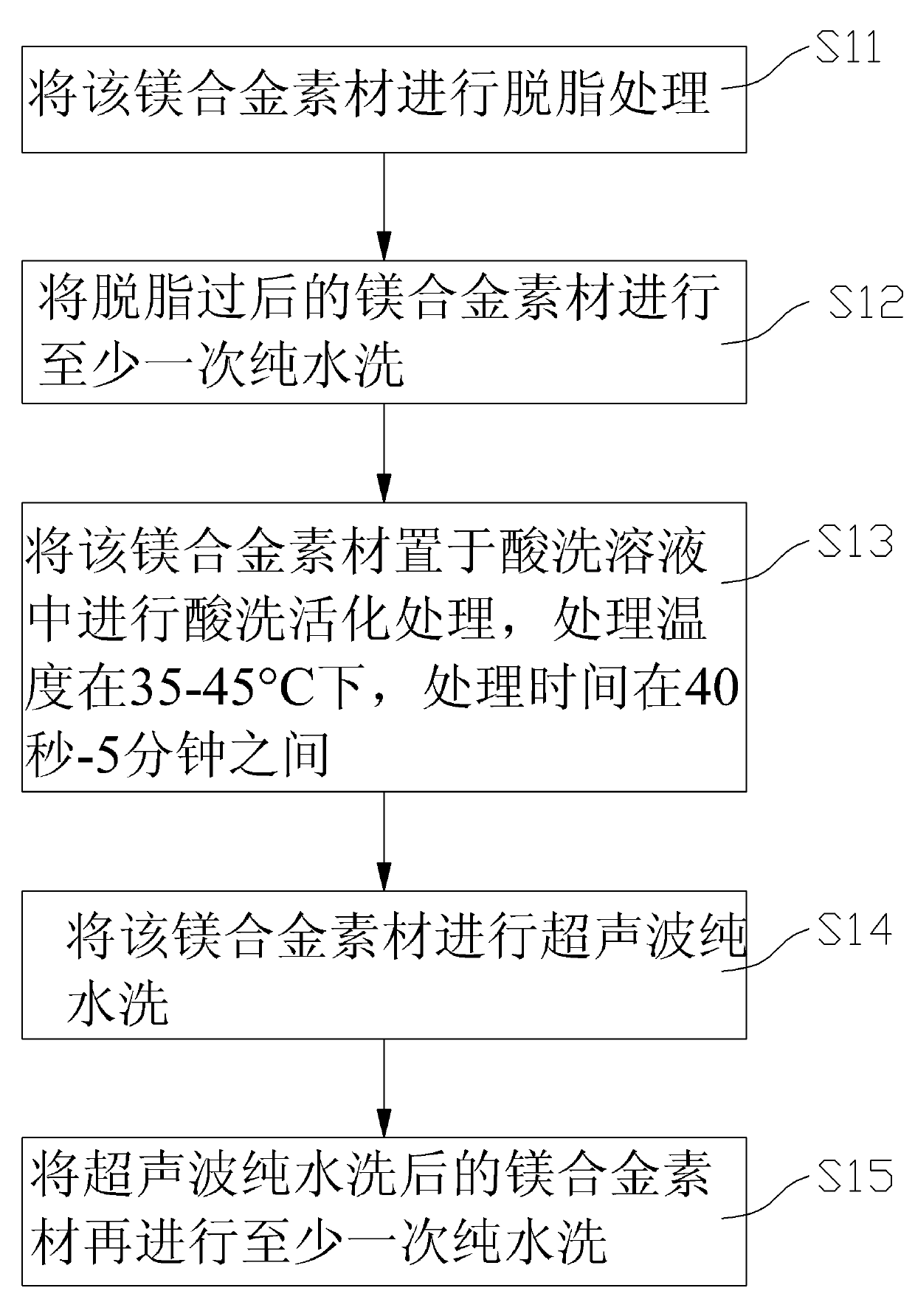

Magnesium alloy pickling activator and pickling method

The invention discloses a magnesium alloy pickling activator for pickling activation treatment of magnesium alloys, which takes water as a solvent and comprises citric acid at a concentration of 5 to 10g / L, lactic acid at a concentration of 10 to 20g / L and inorganic strong acid at a concentration of 2 to 4g / L. The invention also provides a magnesium alloy pickling method. In the magnesium alloy pickling activator and the magnesium alloy pickling method, a mixture of organic acids and an inorganic acid is used, chromium compounds are eliminated, environment pollution is avoided, the reaction in the solution is mild, the cleaning capacity is high, the oxide, release agent and silicon impurities on the surface of the magnesium alloy can be better removed, and the surface of the magnesium alloy has the texture of silvery white metal.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

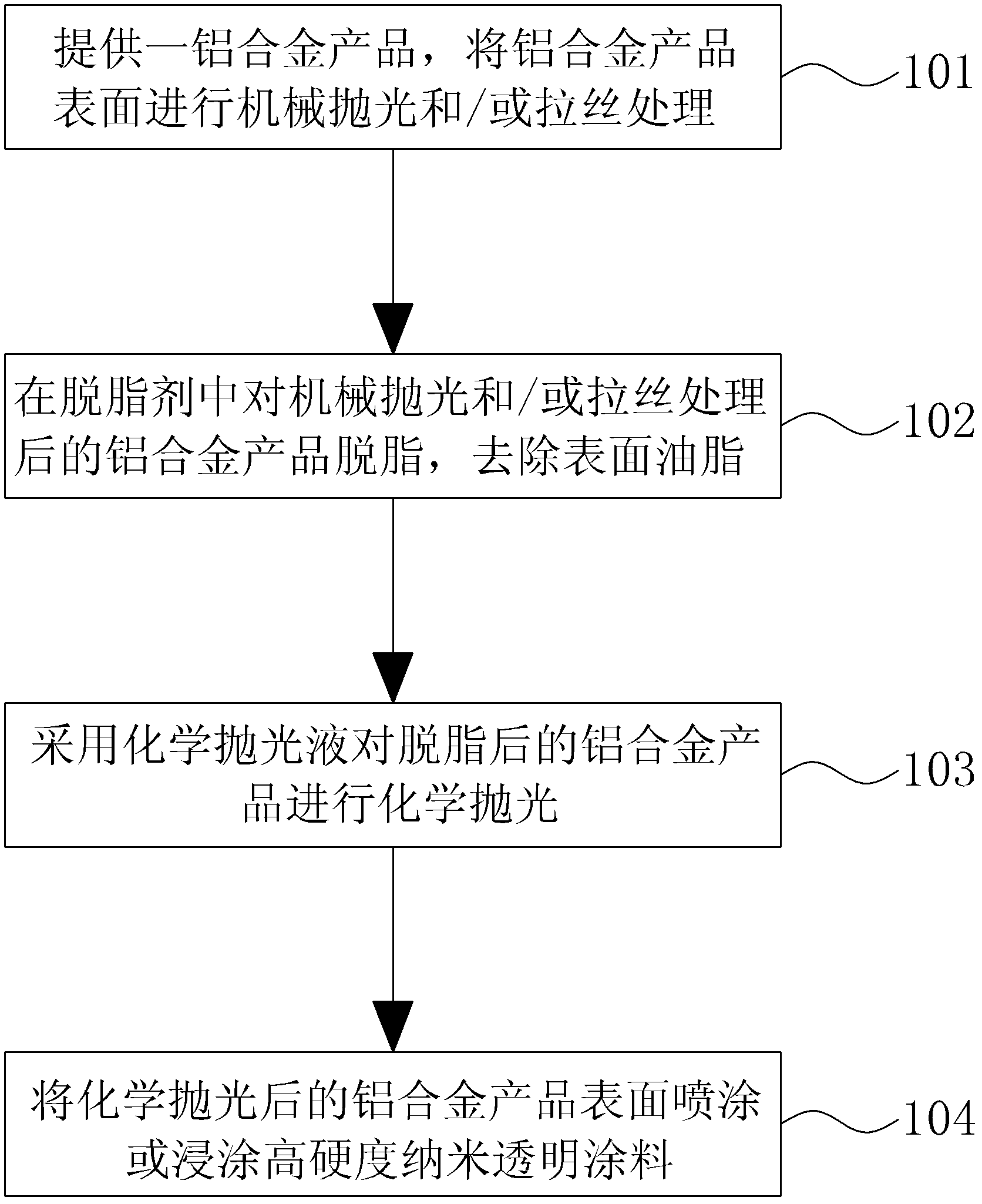

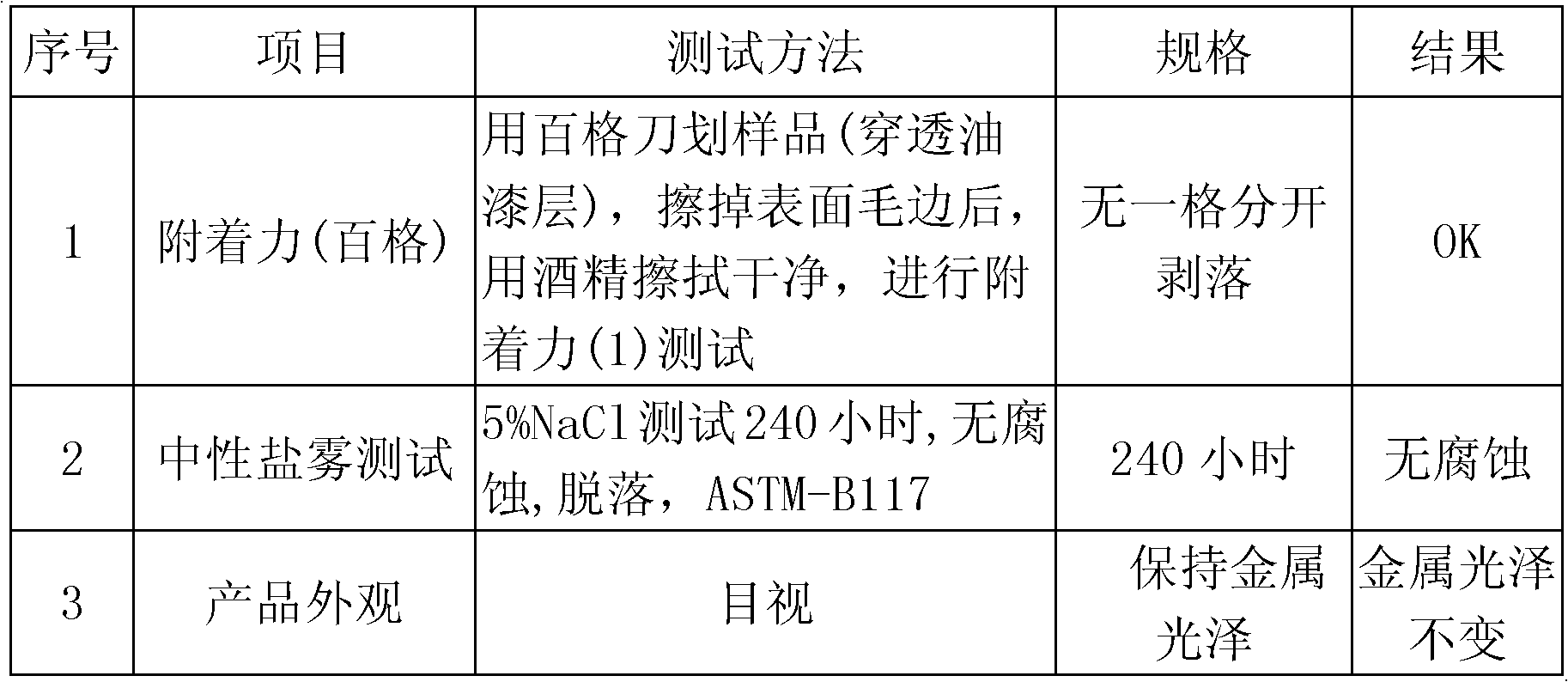

High Si-content aluminum alloy anode imitation processing method and product thereof

ActiveCN103121004AWhite metal textureImprove wear resistancePretreated surfacesSpecial surfacesAnodizingWhite metal

The invention discloses a high Si-content aluminum alloy anode imitation processing method and a product thereof. The method includes the following steps: (1) providing an aluminum alloy product and carrying out mechanical polishing and / or wire drawing for the surface of the aluminum alloy product; (2) in degreasant, degreasing the aluminum alloy product after being processed through the mechanical polishing and / or the wire drawing to degrease oil on the surface of the aluminum alloy product; (3) utilizing chemical polishing liquid to carry out chemical polishing for the aluminum alloy product after being degreased; and (4) placing high-hardness nanometer transparent coating on the surface of the aluminum alloy product which is processed through the chemical polishing in a spaying coating mode or a dip coating mode. The invention further discloses the product generated through the high Si-content aluminum alloy anode imitation processing method. The high Si-content aluminum alloy anode imitation processing method and the product thereof place the high-hardness nanometer transparent coating on the surface of the aluminum alloy product which is processed through the chemical polishing in a spaying coating mode or a dip coating mode, so that the processed aluminum alloy product can maintain white metal texture. In addition, the product generated after being processed is high in wear resistance and corrosion resistance.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Chai kiln porcelain yellowish pea green glaze

The invention relates to Chai kiln porcelain yellowish pea green glaze which is prepared from the following ingredients in parts by weight: 20.18 parts of quartz, 35.28 parts of feldspar, 11.26 parts of calcite, 18.83 parts of slate gray, 5.58 parts of phosphorous bone powder, 3.48 parts of agate, 2.56 parts of hydrotalcite and 2.83 parts of white metal soil, wherein quartz sand serves as the quartz, the feldspar is a combination of one or two of sodaclase and potassium feldspar, the content of ferric oxide in the white metal soil is 30-35%, the content of manganese oxide is 8-10%, the used preparation method of Chai kiln porcelain green glaze comprises the following steps: a. carrying out burdening according to various ingredients and the proportion by weight of the various ingredients; and b. mixing the various ingredients uniformly, adding 20-22 parts of water, ball-milling for 16-20 hours by using a wet method, enabling ball-milled glaze to pass through a 250-mesh screen, then turning the glaze into glaze slip with 60-65 baume degrees, then spraying the glaze slip on a incense ash tire, afterwards, heating the glaze slip at normal temperature to 1,180-1,250 DEG C, then cooling, and drawing for 15 hours or so. The Chai kiln porcelain yellowish pea green glaze has the advantages of fast firing at medium temperature, lower cost, even and clean enamel layer, good glossiness and strong decorative perception.

Owner:马聚魁

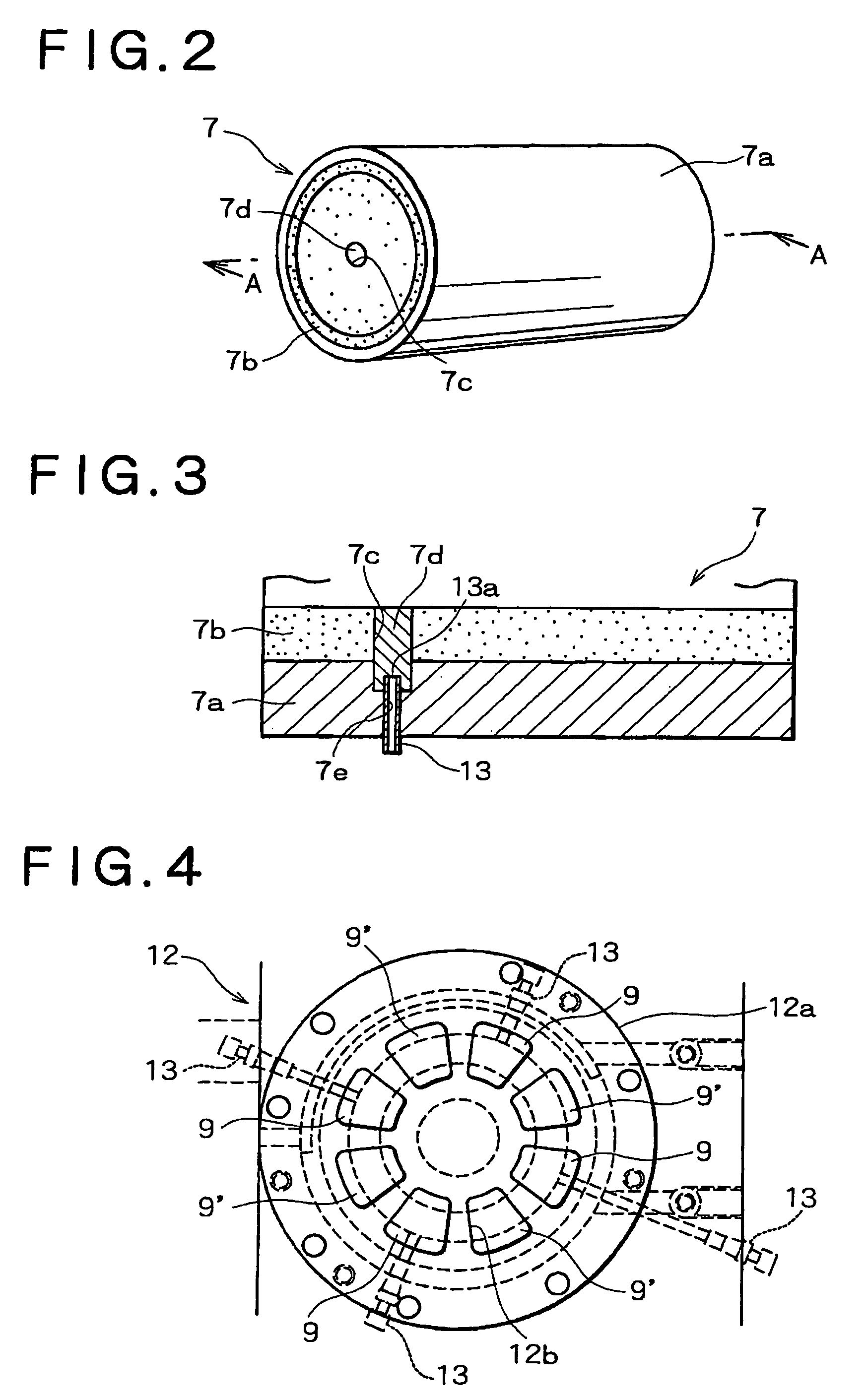

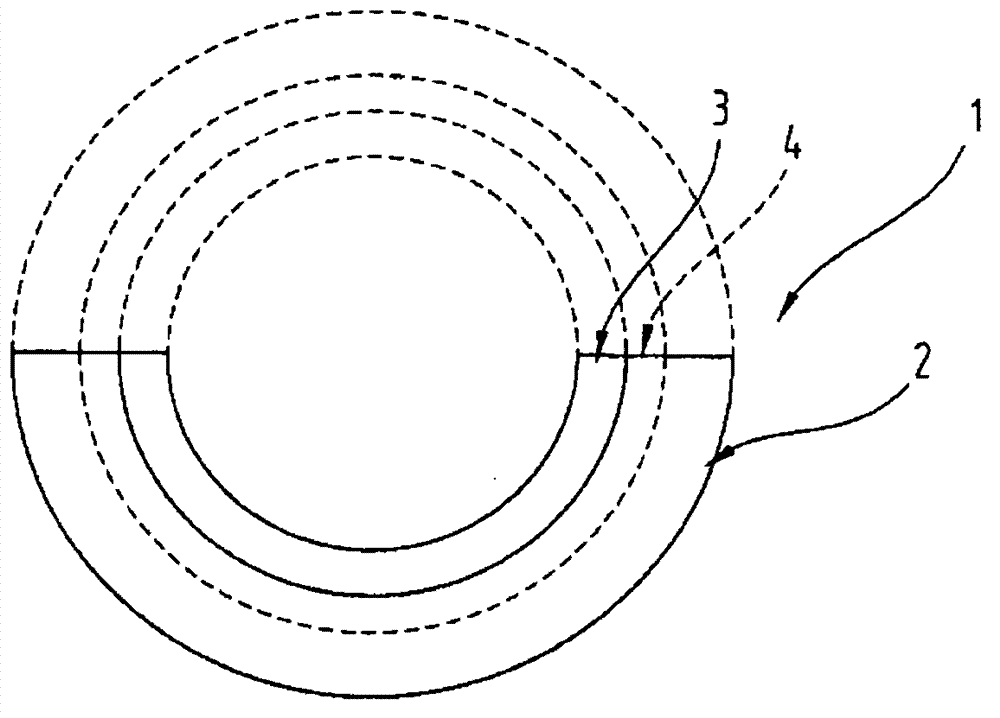

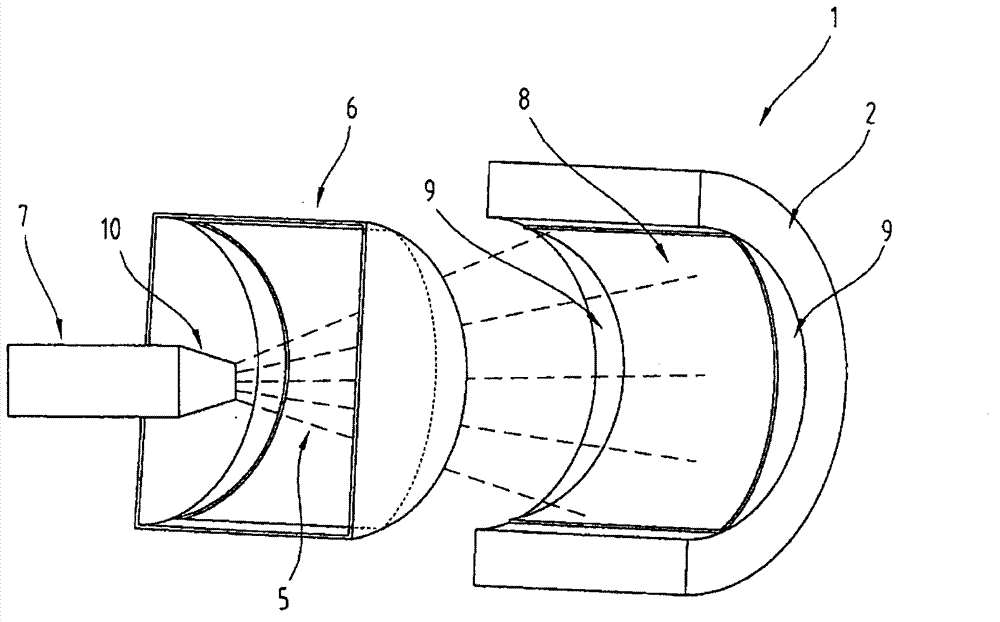

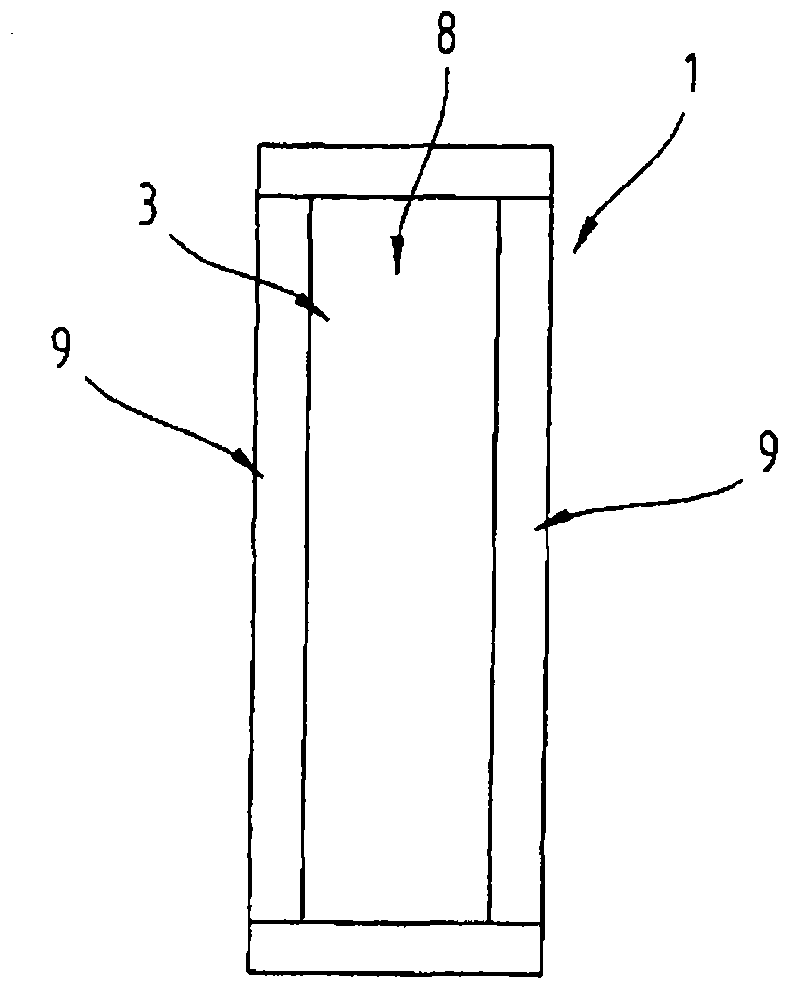

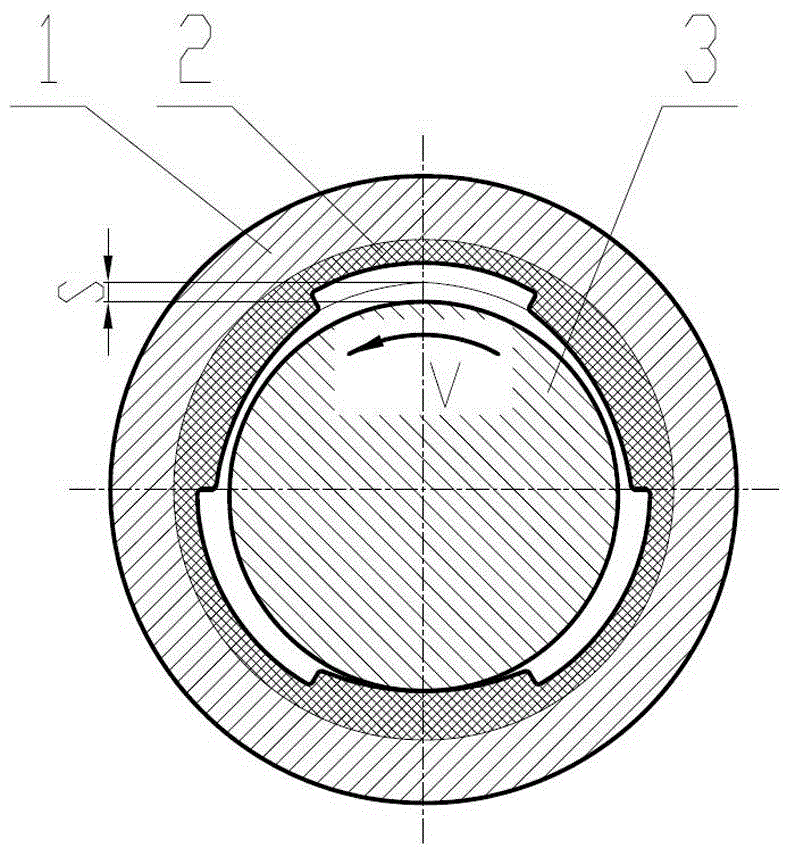

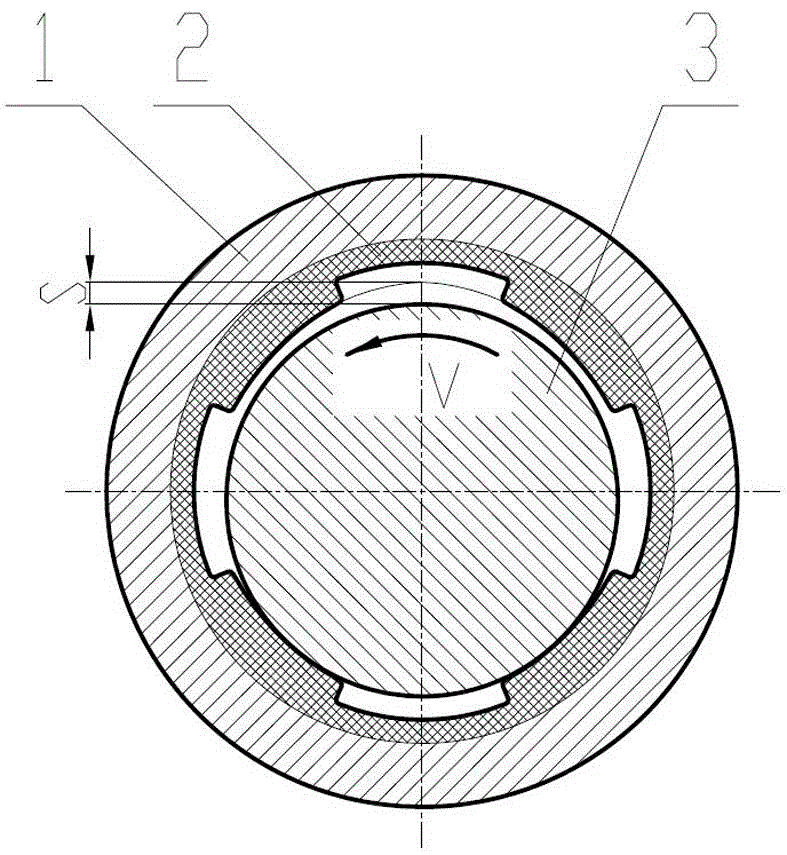

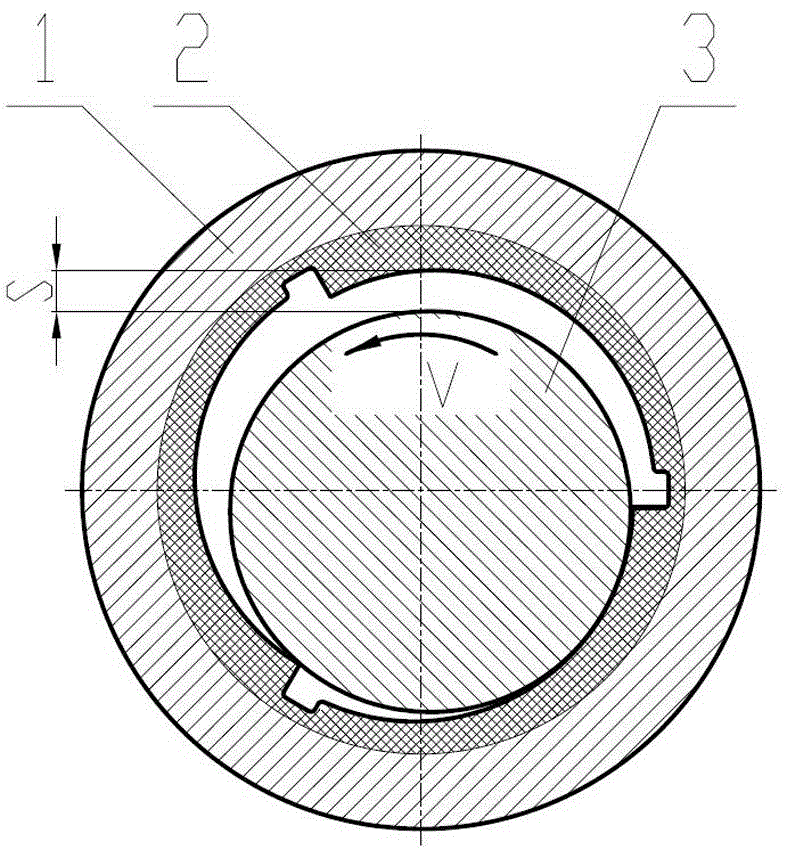

Sliding bearing

InactiveCN103206457AImprove adaptabilityGood embedding effectMolten spray coatingShaftsSlider bearingWhite metal

The invention relates to a sliding bearing (1) comprising a backing layer (2) and a sliding layer (3), wherein the sliding layer (3) in a plane in at least a first region (8) and at least a second region (9) is divided, and wherein the at least one first portion (8) of AISn40Cu and at least one second region (9) consist of a white metal.

Owner:MIBA GLEITLAGER GMBH

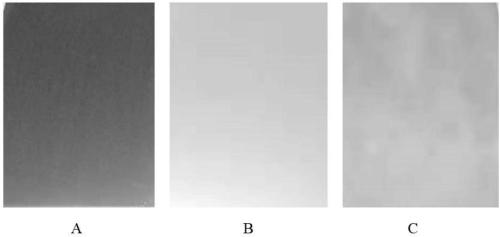

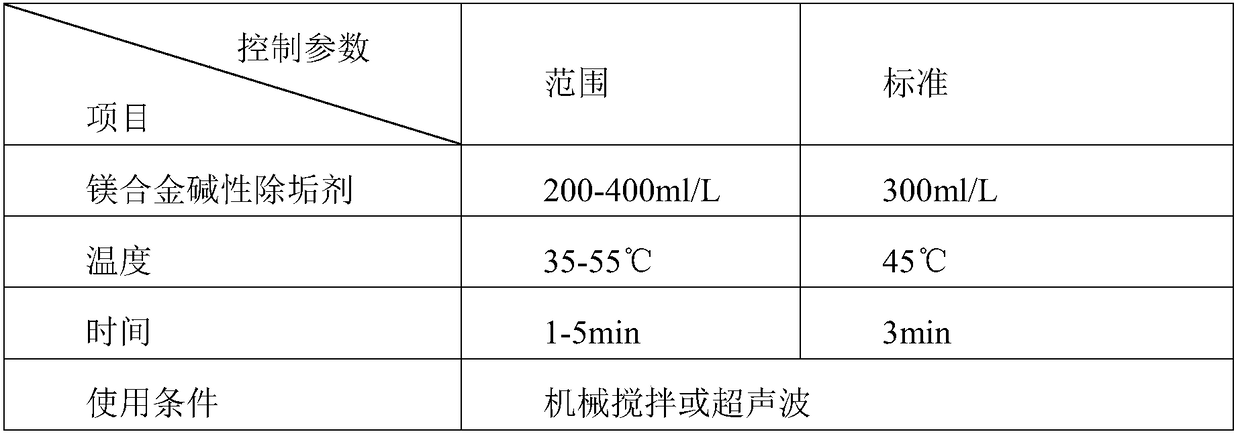

Alkaline scale remover for magnesium alloy

The invention discloses an alkaline scale remover for a magnesium alloy. The alkaline scale remover per kg is prepared from 150-300 g of compound alkali, 10-60 g of a complexing agent, 5-15 g of an activator, 20-60 g of a corrosion inhibitor, 1-5 g of a desorption agent, and the balance water. By adjusting the proportion of the complexing agent, the activator, the corrosion inhibitor and the desorption agent in the alkaline scale remover for the magnesium alloy and by the action of ultrasound, an ash film on the surface of the magnesium alloy can be uniformly desorbed, so that a white metal substrate surface is exposed. The substrate surface is uniform without corrosion spots and residual ash film. The subsequent zinc deposition electroplating is performed on the surface of the substratesurface so that the binding force between the substrate surface and a coating can be improved. The alkaline scale remover for the magnesium alloy does not produce any harmful gases in the descaling process, and is beneficial to protecting the environment and ensuring human health. A copper-nickel-chromium electroplating process can be used for subsequent electroplating production, so that the binding force between an electroplating layer and a matrix is better.

Owner:GUANGZHOU SANFU NEW MATERIALS TECH

Metal ceramic repairing body inner crown and preparation method thereof

InactiveCN106510876AReduce surface stressAvoiding Porcelain ProblemsVacuum evaporation coatingSputtering coatingSurface stressWhite metal

The invention discloses a metal ceramic repairing body inner crown. A TiN metal film coats the surface of a titanium alloy root crown in a sputtering mode, and the TiN metal film is a yellow film, so that silver or grey white metal color of titanium alloy metal is covered, the metal color can be prevented from being exposed in the using process of a titanium alloy ceramic tooth, and the attractiveness of the ceramic tooth can be improved; in addition, the TiN metal film covers the surface of the titanium alloy root crown, so that the titanium alloy root crown is protected, finally, the TiN metal film can reduce the surface stress of the surface of the titanium alloy root crown, and the problem of crackling in the later-stage ceramic preparation process of the titanium alloy root crown can be avoided.

Owner:AI JIA DENTAL LAB

Lobe bearing

ActiveCN104454984AMany supporting surfacesImprove stabilityBearing componentsSliding contact bearingsWhite metalEngineering

The invention discloses a lobe bearing, which comprises a bearing body, white metal pads and white metal pad supporting slide blocks, wherein the white metal pads are poured on the white metal pad supporting slide blocks, and the working face molded line of the bearing is of lobe type or wedge type; the bearing body is of an annular structure, and a plurality of circumferentially distributed radial chutes with bottoms are arranged on the inner wall of the bearing body; each white metal pad supporting slide block poured with the white metal pad is arranged in each corresponding chute and can slide in the chute, and the white metal pad on the slide block faces the center of a circle of the bearing; screw holes and fastening bolts are formed in the back of the slide block, and bolt holes corresponding to the screw holes and the fastening bolts are formed in the bottom of the chute of the bearing body; the fastening bolts penetrate through the bolt holes and are screwed into the screw holes in the back of the slide block, so that the slide block is tightly fixed on the bearing body; an adjusting gasket is arranged at the bottom of the chute. The white metal pad sand the bearing body are of split structures, and are processed by only considering the precision of molded line without considering the dimensional precision of a gap, so that the processing difficulty is reduced; the bearing can be replaced or repaired after partially worn, so that the operating cost is reduced; the bearing has multiple supporting surfaces, so that the stability of rotor operation is improved.

Owner:DONGFANG TURBINE CO LTD

White metal hot spraying mark coating and production method thereof

The invention discloses a white metal hot spraying mark coating and a production method thereof. The invention aims to provide a mark coating adapting to metal hot spraying which can be widely used in coil steel production enterprises and ensure that a cured paint film formed by the coating meets the performance requirements of good heat resistance, friction resistance, excellent attachment and obvious marks. The coating is prepared from the following components in portion by weight: 50 to 60 portions of epoxy modified organic silicon resin, 30 to 40 portions of titanium pigment, 0.5 to 1 portion of dispersant, 0.2 to 0.4 portion of defoaming agent, and 30 to 40 portions of high boiling point organic diluent. The solid content of the coating is over 30 percent. Due to the reasonable proportioning of the components, it is possible, by using the coating, to spray the marks on coil steel materials at a temperature of 400 DEG C and ensure that the cured paint film formed by the coating meets the requirements of good heat resistance, excellent attachment, water resistance and gasoline wiping resistance. The dilutent with high boiling point is adopted, so the coating has no hazard of catching fire and can meet the requirement of safe production.

Owner:天津灯塔涂料工业发展有限公司

Silver-white metal zipper and manufacturing method thereof

InactiveCN105962549AOxidation and corrosion resistanceWith silvery white metallic lusterSlide fastenersMetallic material coating processesPhosphatePhosphoric acid

The invention discloses a silver-white metal zipper, which comprises aluminum alloy teeth and a silver-white oxide layer on the surfaces of the teeth, wherein the oxide layer is either aluminum phosphate or aluminum dihydrogen phosphate. According to the zipper which is manufactured by the silver-white metal zipper manufacturing method disclosed by the invention, the layer of aluminum phosphate or aluminum dihydrogen phosphate covers the surfaces of the teeth, so that the teeth are oxidation-resistant and corrosion-resistant, and the metal zipper has silver-white metallic luster.

Owner:深圳市联星服装辅料有限公司

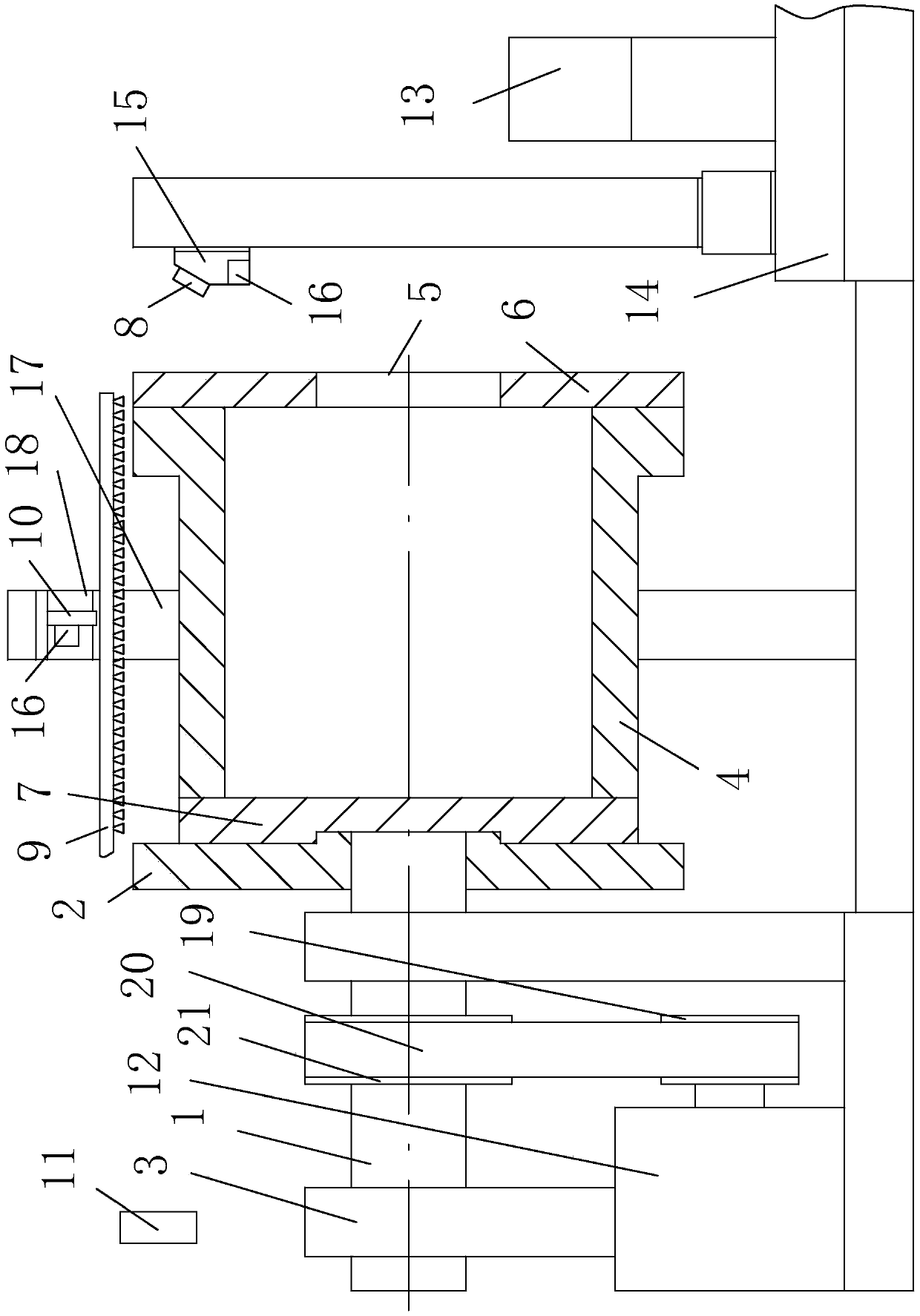

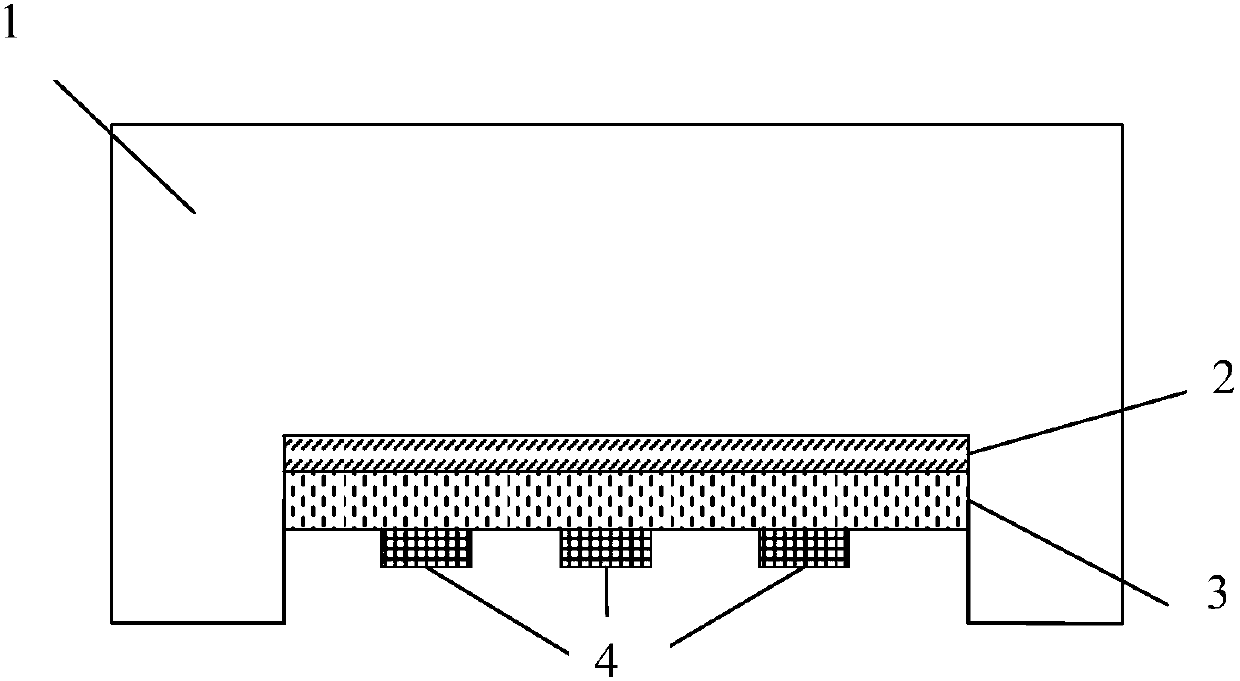

Bearing white metal casting segregation control device and control method

The invention discloses a bearing white metal casting segregation control device. The bearing white metal casting segregation control device comprises a centrifugal casting machine which is provided with a rotating shaft and a chuck connected with the front end of the rotating shaft, a tile body, a front end cover provided with a pouring hole and connected with the front end of the tile body, a back end cover connected with the back end of the tile body and the front end of the chuck, an adjusting base arranged on the front side of the front end cover and provided with a white metal temperature sensor opposite to the pouring hole, a cooling water nozzle set arranged on the upper side of the periphery of the tile body, an adjustment base provided with a tile body temperature sensor oppositeto the outer side of the periphery of the tile body, a rotating shaft driving and speed adjusting device provided with a servo motor, and a controller electrically connected with the white metal temperature sensor, the tile body temperature sensor, an environmental temperature sensor and the servo motor. The bearing white metal casting segregation control device cannot enable CuSn5 and SnSb compounds with high densities in molten white metal to gather and segregate to the outer side of a lining layer in the centrifugal casting process, and improves the bonding force between the white metal and the tile body and the bearing capacity of a bearing.

Owner:浙江申发轴瓦股份有限公司

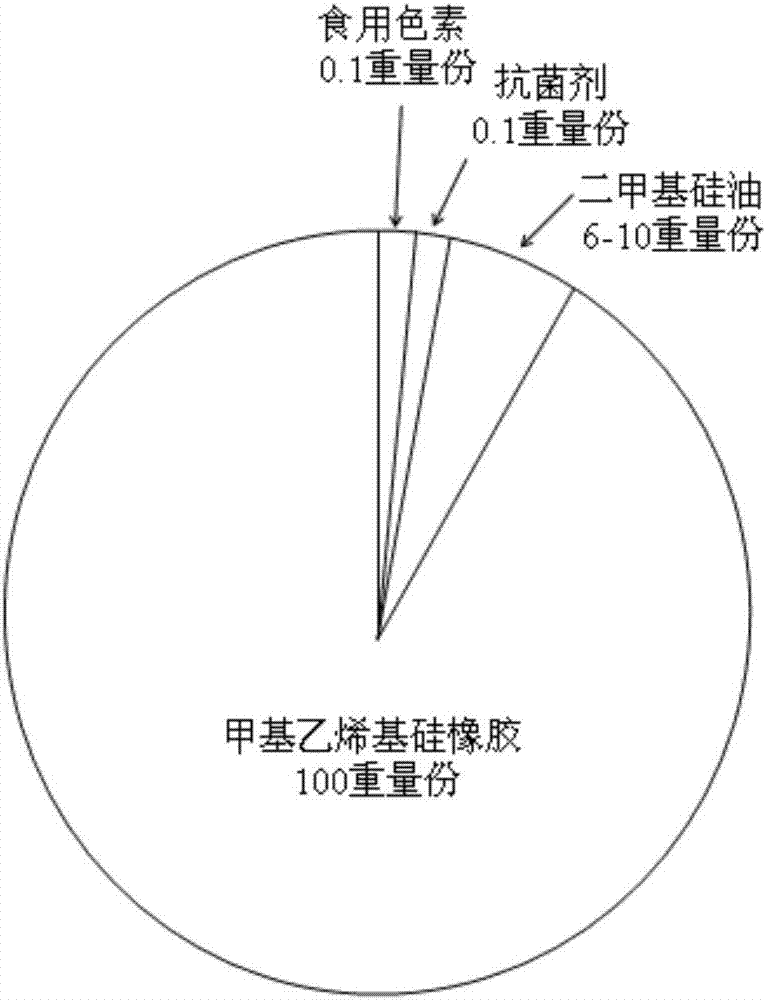

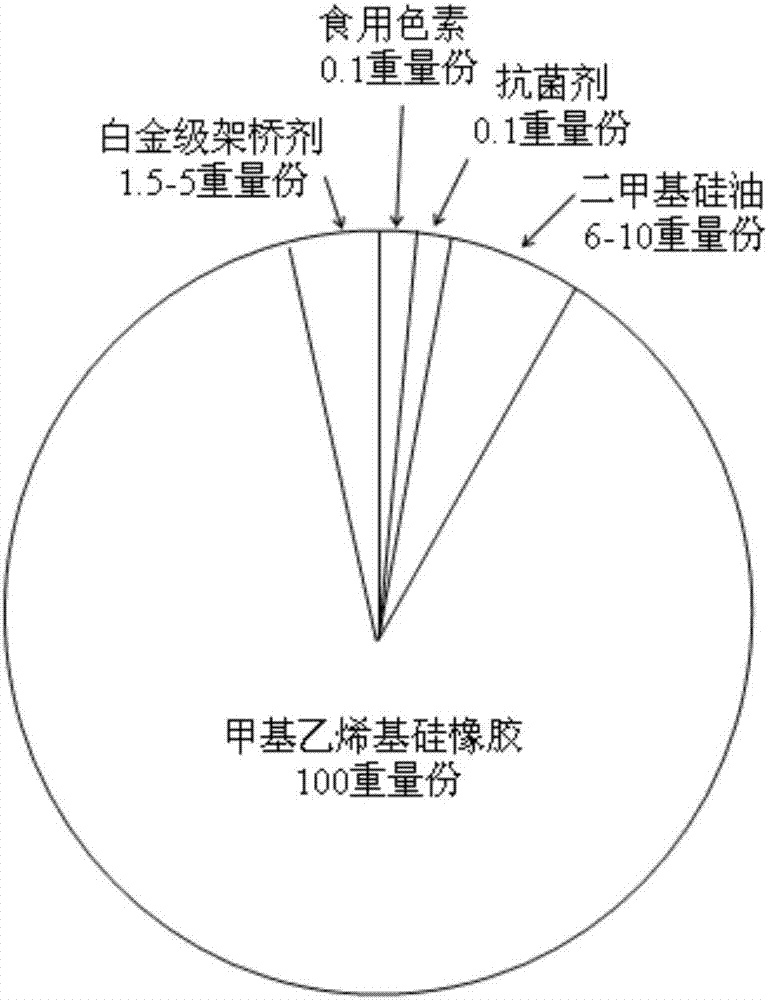

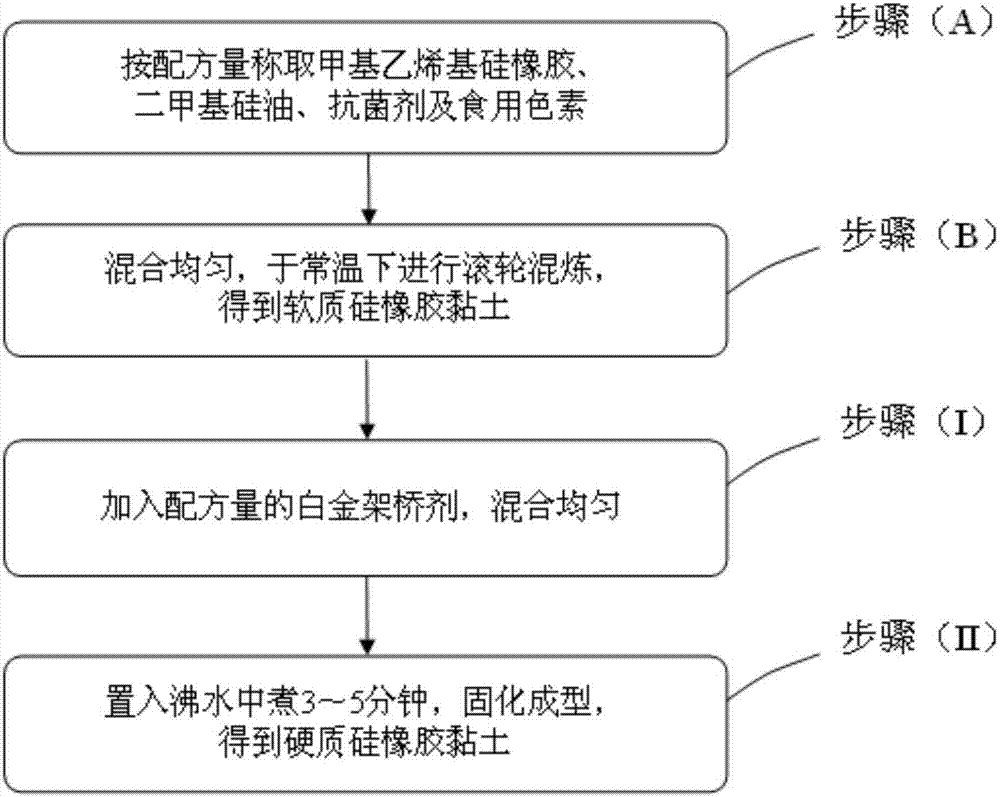

Silicone rubber clay composition and its making method

The present invention discloses a silicone rubber clay composition and its making method. The silicone rubber clay composition comprises methylvinylsilicone rubber, dimethylsilicone oil, food-grade antibacterial agent and food coloring material, and is prepared by mixing at room temperature. Compared to traditional clay, the silicone rubber clay is not easy to dry, is repeatable in plastic molding, has no odor, no shavings, non-sticking, is ideal for beginners or children to practice plastic molding. In addition, the edible white metal bridging agent can be mixed, after the clay molding, the molded clay is boiled in boiling water for 3 to 5 minutes to be hardened and shaped with elasticity.

Owner:MAXMOLD POLYMER

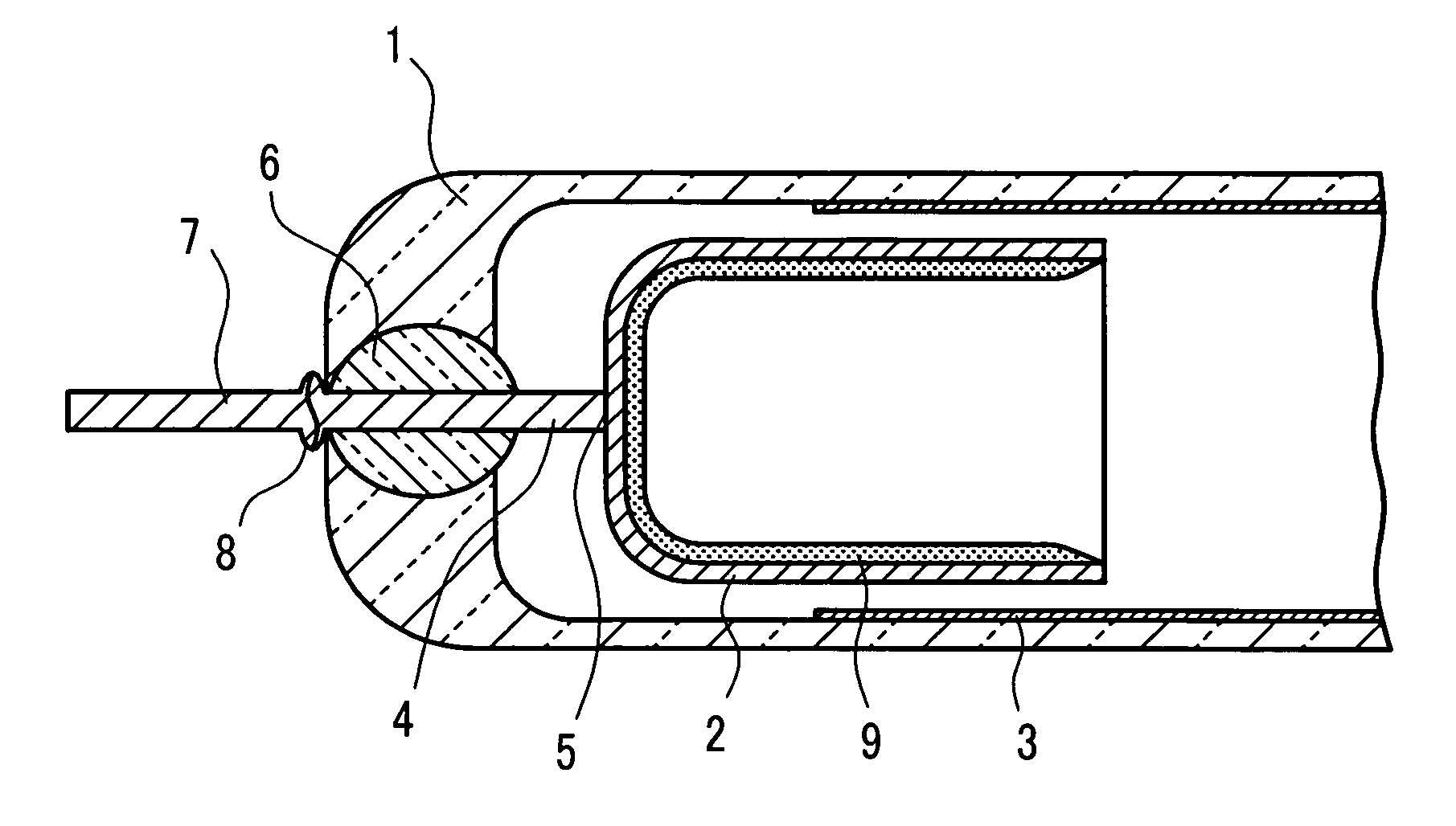

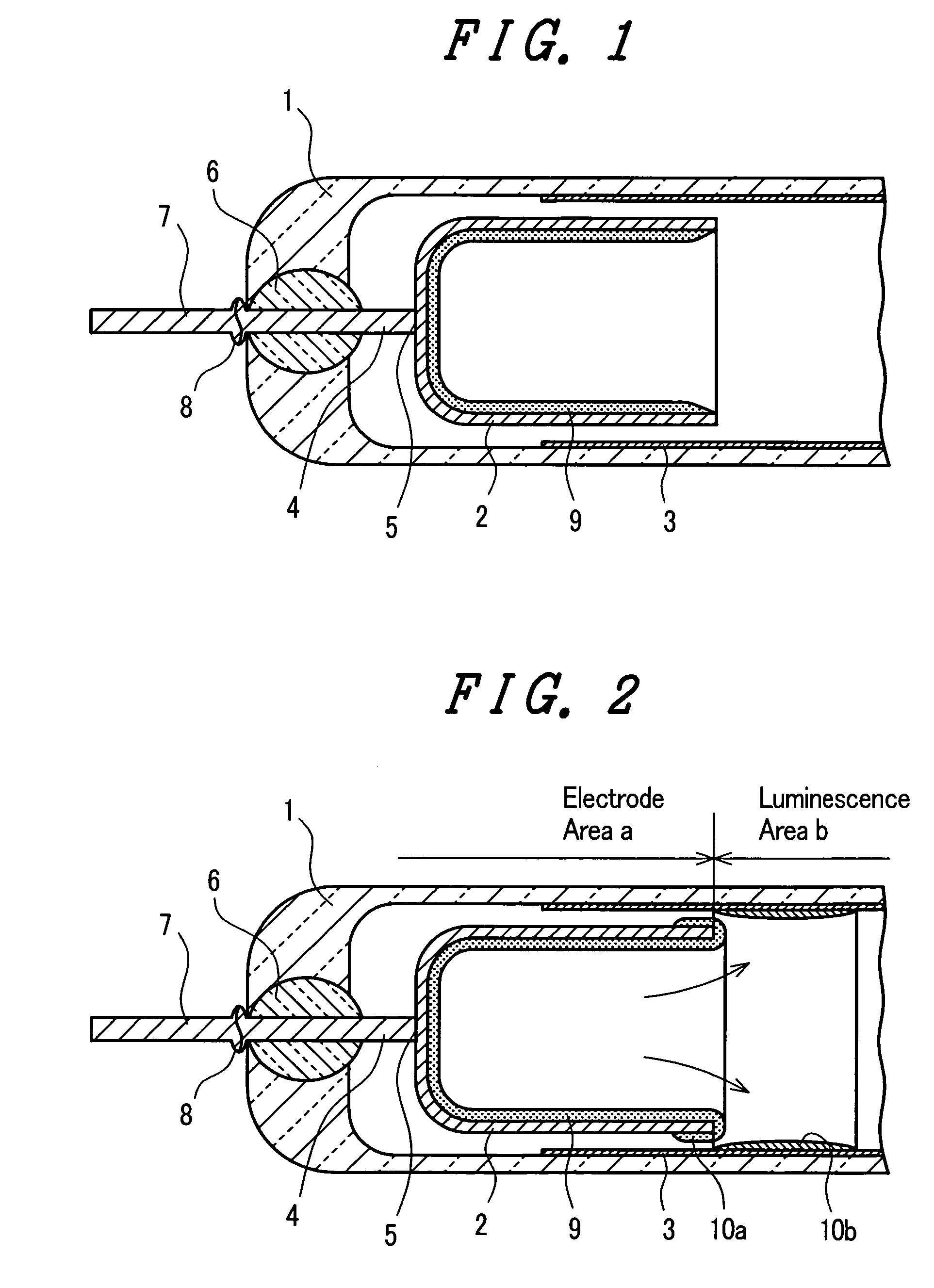

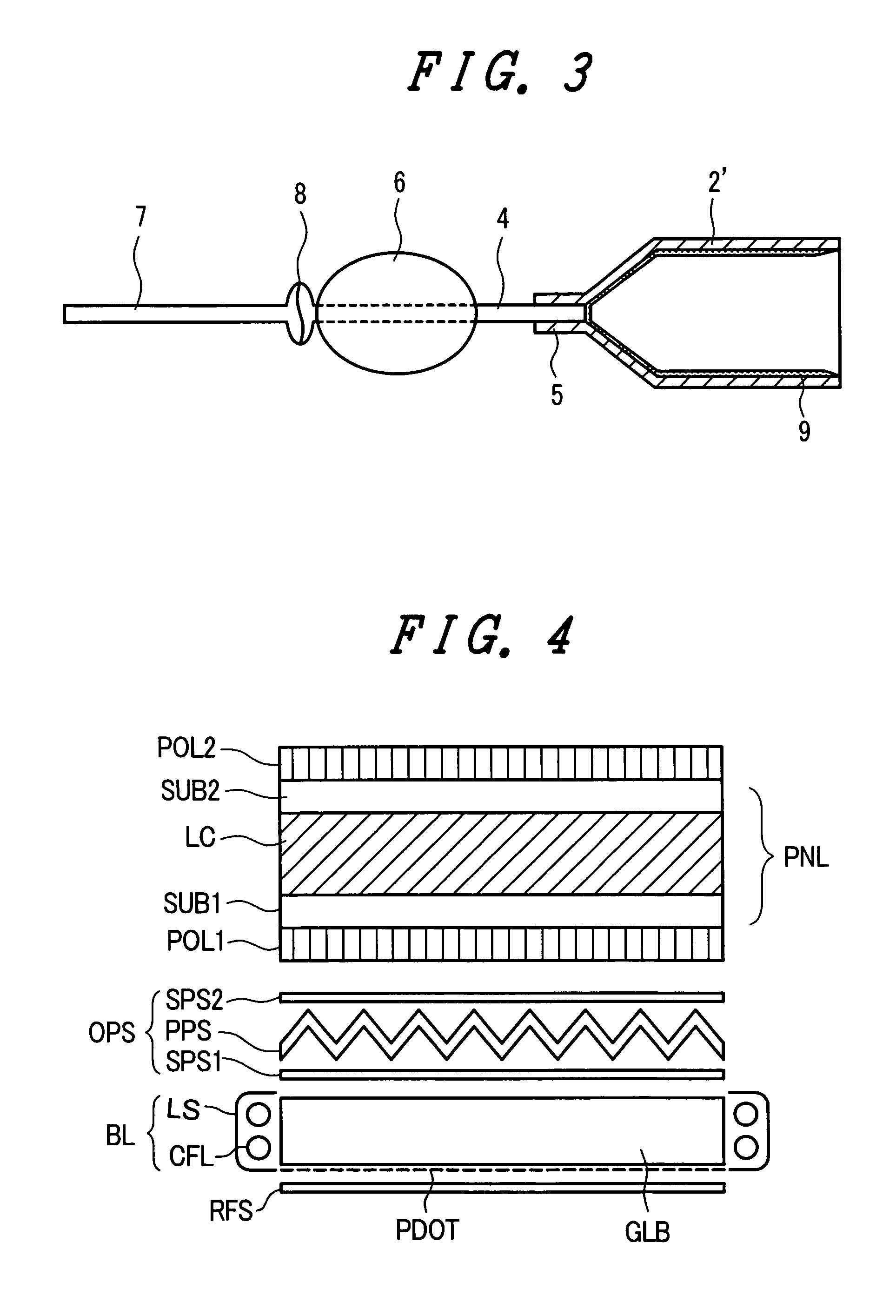

Cold cathode ray fluorescent tube and liquid crystal display device using the cold cathode fluorescent tube

InactiveUS7045945B2Decrease in effective light-emitting areaQuality improvementDischarge tube luminescnet screensLamp incadescent bodiesFluorescenceEvaporation

The present invention decreases invalid light emitting regions, which are generated at both ends of an outer tube and enlarges a valid light emitting region of a phosphor layer, which enlarges the light emitting region of a lighting device. In a cold cathode fluorescent tube, cup-shaped electrodes are provided on the inside of both ends of a glass tube, which has a phosphor layer on the inner surface thereof, wherein each cup-shaped electrode connects to an inner lead, which supplies an electric power. A sputter source is formed on an inner wall surface of the cup-shaped electrode by sintering white metal oxide, whereby the white metal oxide which constitutes a sputter source is sputtered by evaporation, which forms a sputter film on a portion of the opening end of the cup-shaped electrode and inner wall surface of the glass tube.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD

A tin-based babbitt alloy material

The invention discloses a tin-based Babbitt alloy material. The alloy material contains 3.0-15.0wt.% of stibium, 2.0-9.0wt.% of copper, 0.001-0.1wt.% of gallium, 0-0.02wt.% of phosphorus, 0.001-0.1wt.% of indium and / or 0.03-0.1wt.% of nickel and the balance of tin and unavoidable impurities. The alloy material disclosed by the invention has relatively high oxidation resistance, favorable wettability and bonding property and finer and smaller grain tissues; and no matter a tinning-pouring method, a thermal spraying method or a surfacing process is adopted for preparing a bearing bush, the formation probability of slag points and holes can be remarkably reduced, the layering and stripping defects can be reduced, and the bonding property can be improved.

Owner:云南锡业新材料有限公司

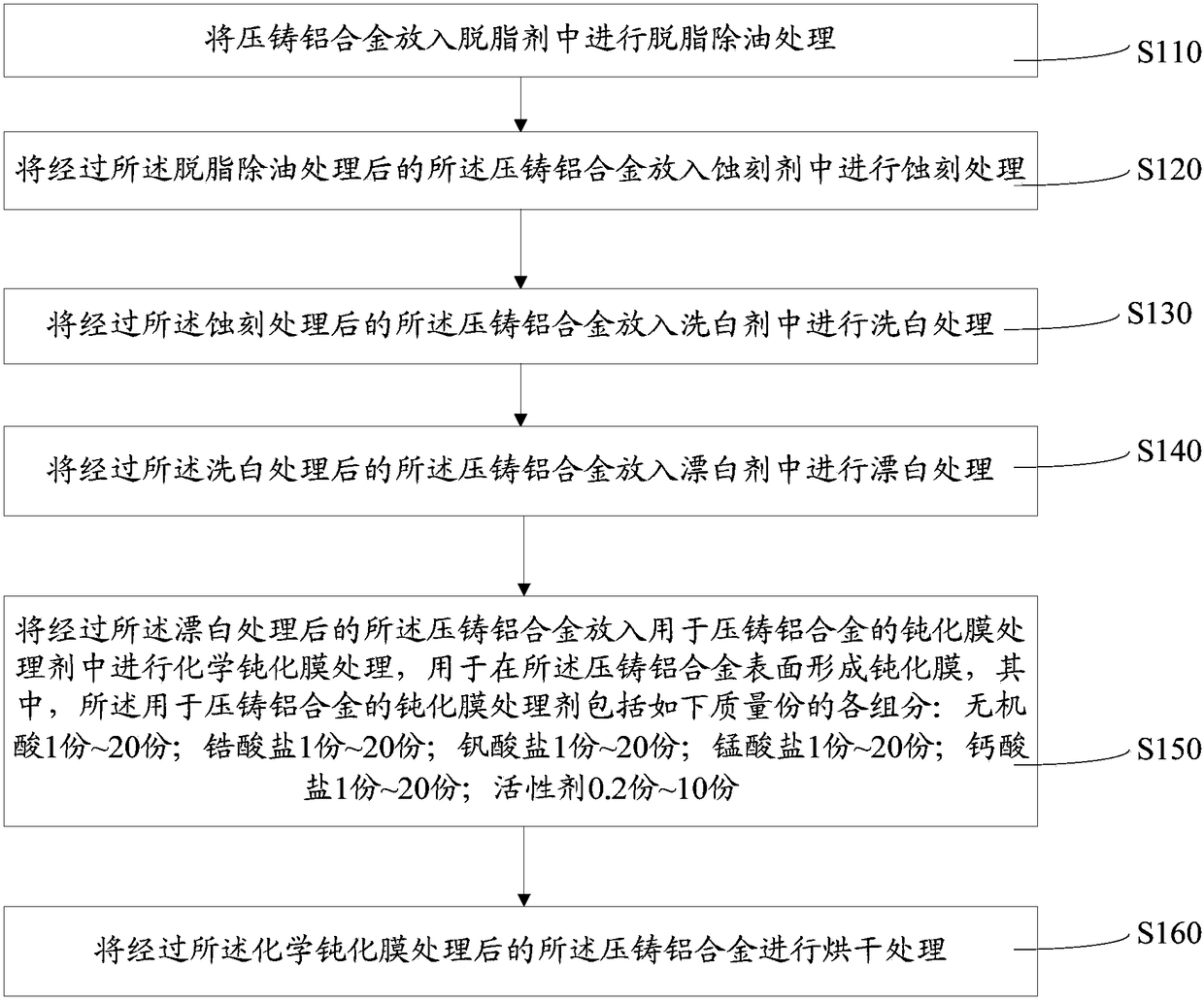

Zirconium-manganese-vanadium passivation film treatment agent and treatment method for die-casting aluminum alloy

ActiveCN106048580BImprove adhesionHigh degree of corrosion resistanceMetallic material coating processesChromium freeZirconate

The invention discloses a passive film treating agent for die cast aluminium alloy and a treatment method thereof. The passive film treating agent for die cast aluminium alloy comprises the following components in parts by mass: 1 to 20 parts of inorganic acid, 1 to 20 parts of zirconate, 1 to 20 parts of vanadate, 1 to 20 parts of manganate, 1 to 20 parts of calciate and 0.2 to 10 parts of an activating agent. Relative to a traditional phosphorus-containing chromium-free passive film treating agent for die cast aluminium alloy, which causes pollution to the environment, the passive film treating agent for die cast aluminium alloy can form a phosphorus-free chromium-free Zr-Mn-V passive film on the surface of die cast aluminium alloy, the passive film has the advantages that the adhesive force is good, the corrosion resistance is high, and the salt mist resistance and film forming uniformity are good, and besides, the obtained passive film can be guaranteed to have a silver white metal appearance the same as the die cast aluminium alloy.

Owner:广东东明新材科技有限公司

Bearing Wujin casting segregation control device and control method

Owner:浙江申发轴瓦股份有限公司

A method for manufacturing high-temperature matt purple-gold glazed porcelain fired in a reducing atmosphere

Owner:JINGDEZHEN CERAMIC UNIV

Processing technology of gold plating for imitation metal sheet

InactiveCN104494274APlay a protective effectPlay durabilityLaminationLamination apparatusColor effectWhite metal

The invention discloses a processing technology of gold plating for imitation metal sheet, which comprises the following steps: using seal heating equipment for fusing an alloy to the metal sheet; folding PET dyeing composite membranes, placing the metal sheet in the folded composite membranes, adding a bonding back glue; using the composite equipment for heating and pressurizing the composite membranes, and bonding the upper PET dyeing composite membrane and the lower PET dyeing composite membrane without slits and then fixing on the metal sheet. According to any white metal sheet after being pressed and sealed through the PET dyeing composite membrane, the finished product can completely reach the verisimilar color effect as gold plating, cost can be greatly saved, and whole processing technology has the advantages of safety, environmental protection and no pollution.

Owner:SHENZHEN CHONGNING IND

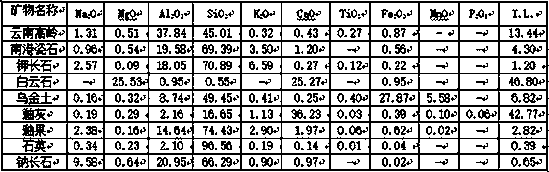

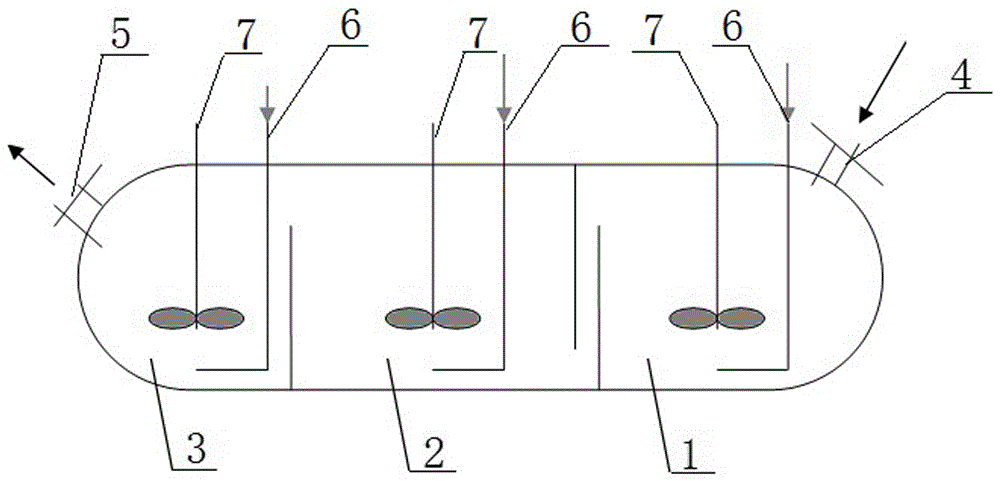

A kind of white metal continuous chlorine gas leaching method

The invention discloses a continuous chlorine leaching method for white alloy. The continuous chlorine leaching method for white alloy comprises the following steps: crushing the white alloy and then sieving to obtain a powder with a size of minus 80 to minus 100 meshes; continuously adding the white alloy powder in a three-compartment leaching kettle, and adding a hydrochloric acid solution with a concentration of 60-80 g / L in the three-compartment leaching kettle; charging chlorine in each compartment of the three-compartment leaching kettle, setting different potentials in the compartments, and adequately carrying out leaching reaction to obtain slurry; continuously discharging the slurry to a leaching intermediate tank, and filtering by a plate-and-frame filter press to obtain leachate and residue; and washing and filtering the residue, and then abandoning the washed residue, and recovering the residue washing solution. The white alloy powder is high in reactivity after being crushed, and capable of increasing a speed of participating in inlet-outlet reaction; chlorine is used as an oxidizing agent in the leaching process, valuable metals such as copper, cobalt and iron in the powder enter the solution in a chloride state by controlling the potentials in the kettle, and the leaching rates of cobalt and copper can achieve more than 99%.

Owner:LANZHOU JINCHUAN NEW MATERIAL SCI & TECH

A kind of automobile decorative part and its surface coating preparation method

ActiveCN106011762BHas a silvery-white metallic appearanceImprove corrosion resistanceVacuum evaporation coatingSputtering coatingPlastic materialsOxide coating

The invention discloses a car trim and a preparation method of a surface coating of the car trim. The trim comprises a plastic substrate, wherein the plastic substrate is transparent to visible light; the back surface of the substrate is provided with a groove; the groove is internally covered with a nano metal coating and a diamond-like coating from interior to exterior; and an outermost layer is provided with induction type visible light sources which are arrayed according to a certain shape. The invention also provides the preparation method of the surface coating of the car trim. The preparation method of the surface coating of the car trim comprises the following steps of (1), carrying out bombardment on a base material by adopting an Ar ion beam; (2), depositing the nano metal coating by adopting direct-current magnetron sputtering; and (3), depositing a hydrogen-containing diamond-like coating by adopting an ion source. Through the above preparation method of the surface coating, on one hand, a plastic material is enabled to have a silvery white metal appearance, and on the other hand, when the light sources on the back surface of the substrate are lit, a luminous pattern can be seen from a frontal surface; the method is green and environment-friendly; and the zero emission of a pollutant to an environment is achieved.

Owner:NINGBO ZHONGJUN SHANGYUAN AUTO PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com