A method for manufacturing high-temperature matt purple-gold glazed porcelain fired in a reducing atmosphere

A manufacturing method and technology of purple gold glaze are applied in the manufacture of high-temperature matt purple gold glaze porcelain fired by reduction system, the field of purple gold glaze daily-use porcelain and display porcelain, which can solve the problem that the ancient purple gold glaze does not have the deep and simple unique texture and glossy surface of products. It can improve the appearance effect, have good thermal stability and be beneficial to glazing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

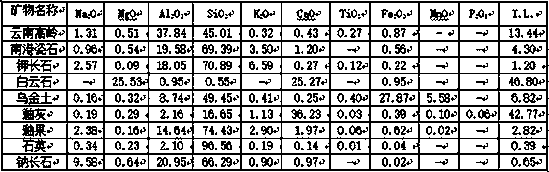

[0015] The weight percentage of high-temperature matt purple gold glaze porcelain body body formula is 45% of Yunnan Gaoling, 46% of Nangang porcelain stone, and 9% of potassium feldspar;

[0016] The weight percentage of the high-temperature matt purple-gold enamel glaze is 7% dolomite, 23% black gold clay, 7% glaze ash, 16% glaze fruit, 17% quartz, 17% potassium feldspar, 12.9% albite feldspar, and 0.1% water glass ;

[0017] Weigh and mix the raw materials according to the requirements of the billet formula. Put the material:ball:water weight ratio of 1:2:0.6 into the ball milling equipment for ball milling for 20 minutes, pass the slurry through a 150-mesh sieve after aging for 48 hours, and then go through defiltration, refining make mud into mud

[0018] Weigh and mix the raw materials according to the requirements of the glaze formula. The weight ratio of material: ball: water is 1:2:0.8, put it into the ball mill and mill it for 28 minutes.

[0019] The green body is...

Embodiment 2

[0023] The weight percentage of high-temperature matt purple gold glaze porcelain body formula is 39% of Yunnan Kaolin, 55% of Nangang porcelain stone, and 6% of potassium feldspar;

[0024] The weight percentage of the high-temperature matt purple-gold enamel glaze is 5% dolomite, 31% black gold clay, 11.8% glaze ash, 12% glaze fruit, 12% quartz, 21% potassium feldspar, 7% albite feldspar, and 0.2% water glass ;

[0025] Weigh and mix the raw materials according to the requirements of the billet formula. Put the material: ball: water weight ratio of 1:2:0.7 into the ball mill equipment and mill for 27 minutes. After the slurry is stale for 48 hours, it passes through a 150-mesh sieve, and then goes through defiltration and refining. mud and other processes to make mud;

[0026] Weigh and mix the raw materials according to the requirements of the glaze formula. Put the material:ball:water weight ratio of 1:2:1.0 into the ball milling equipment and mill for 36 minutes.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com