Bearing Wujin casting segregation control device and control method

The technology of a control device and control method, which is applied in the field of bearing manufacturing, can solve the problems of reducing the bonding force between Wujin and the tile body and the bearing capacity of the bearing, and achieve the effects of stable and reliable measurement, high precision and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

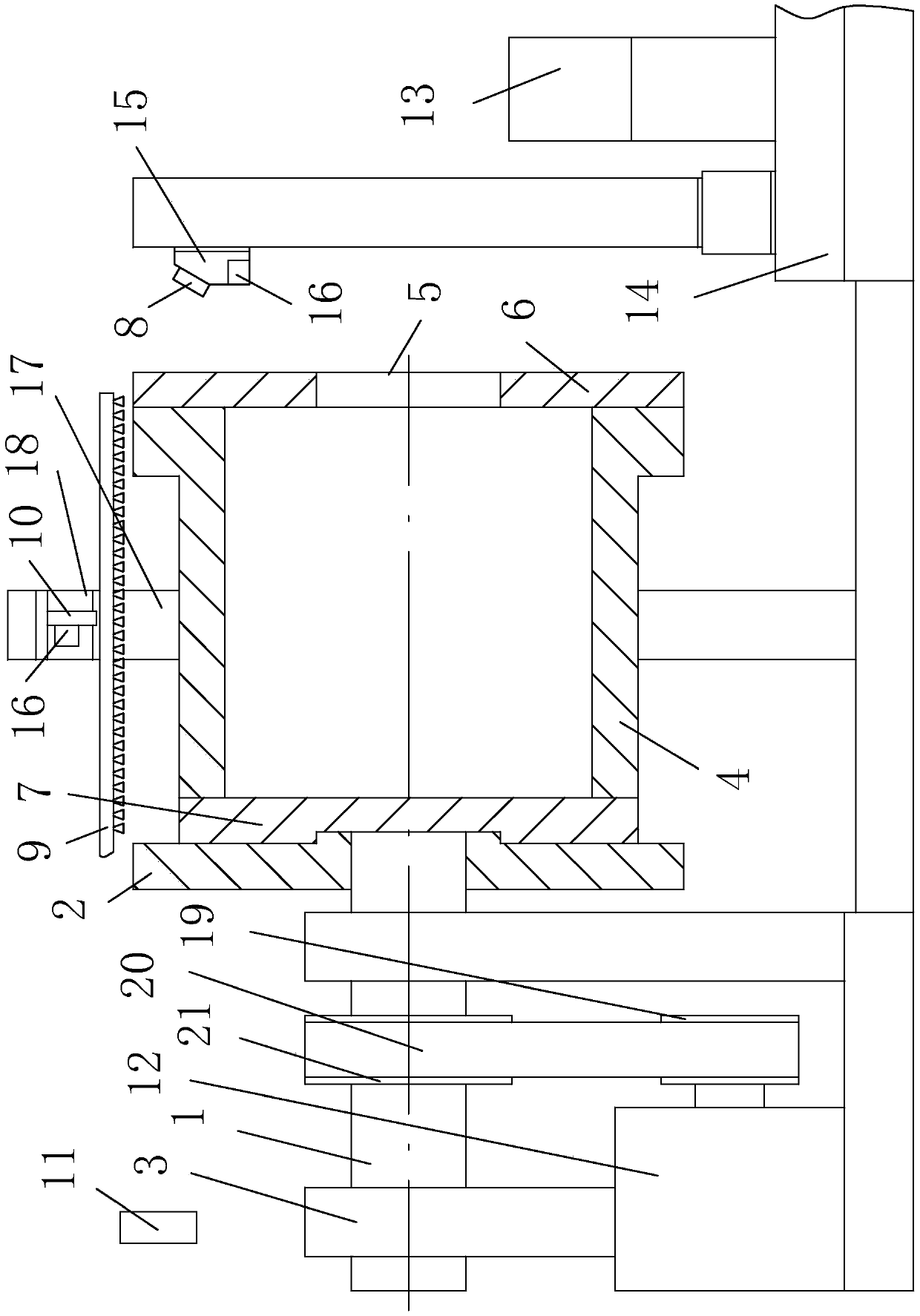

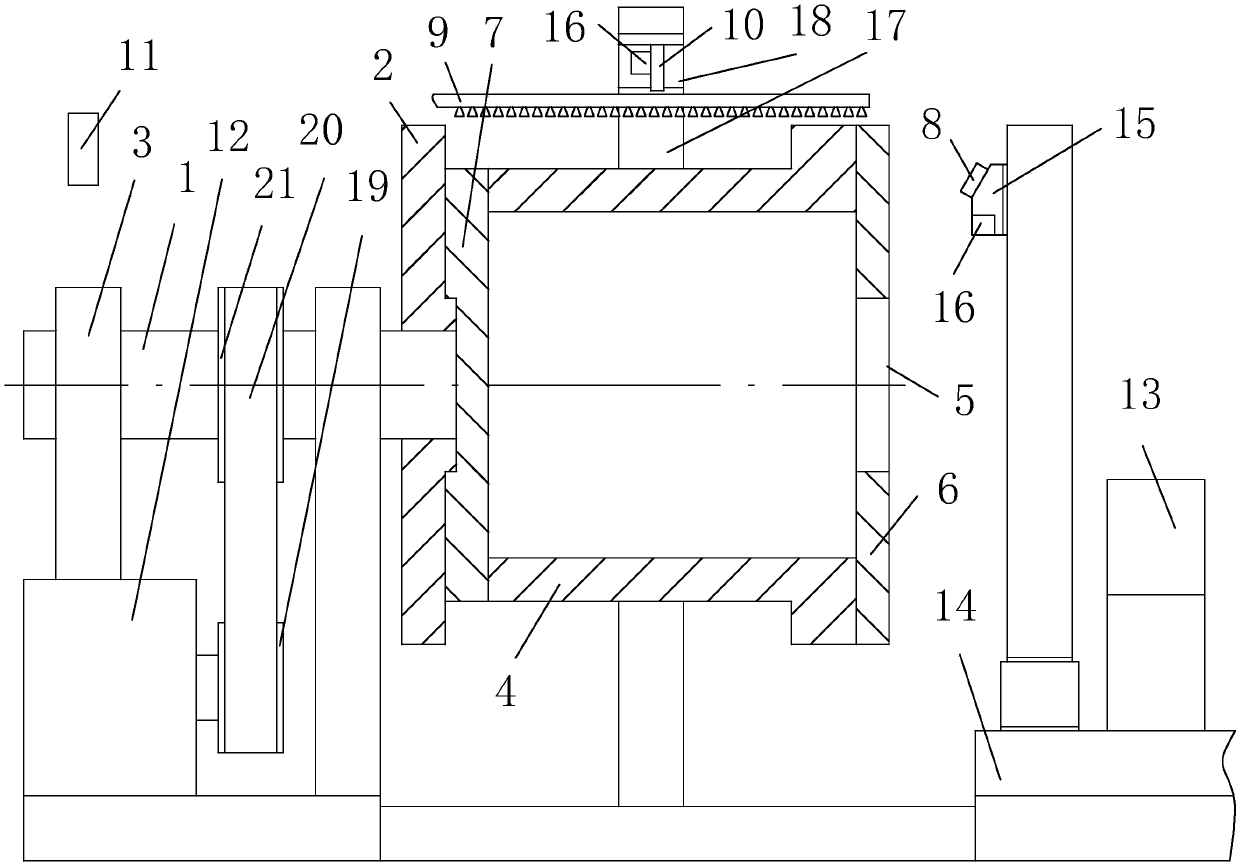

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] as attached figure 1 Shown: a bearing black metal casting segregation control device, including: a centrifugal casting machine 3 provided with a rotating shaft 1 and a chuck 2 keyed to the front end of the rotating shaft 1; The screw-connected front end cover 6, the rear end cover 7 screwed to the rear end of the tile body 4 and the front end of the chuck 2 respectively, is set on the front side of the front end cover 6 and is provided with an adjustment seat of the Wujin temperature sensor 8 opposite to the pouring hole 5 , the cooling water nozzle group 9 arranged on the upper side of the side wall of the tile body 4, the adjusting seat of the tile body temperature sensor 10 opposite to the outside of the side wall of the tile body 4, the ambient temperature sensor 11, and the rotating shaft drive of the servo motor 12 The speed regulating device is a control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com