Patents

Literature

31results about How to "High degree of corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

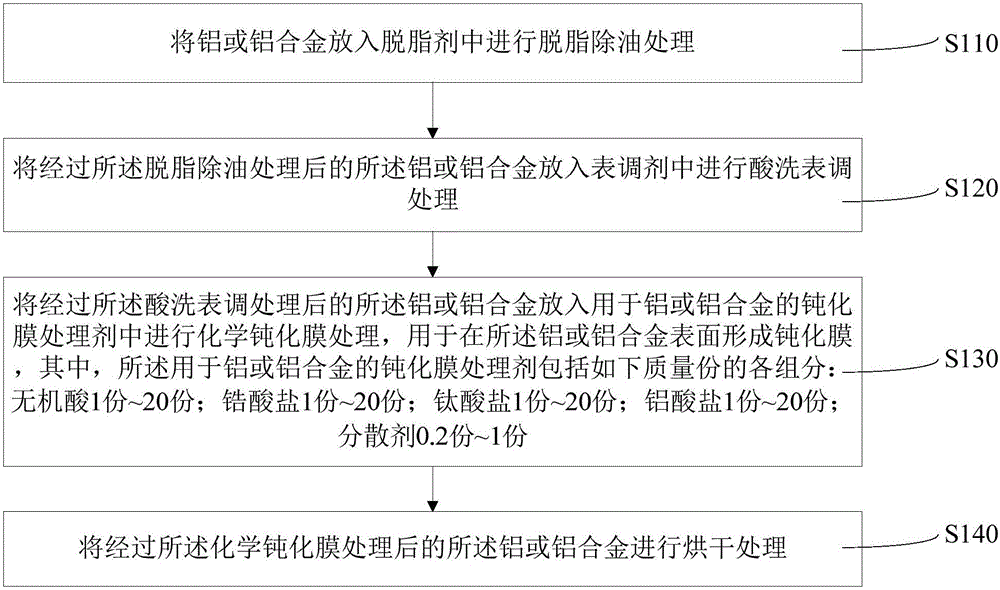

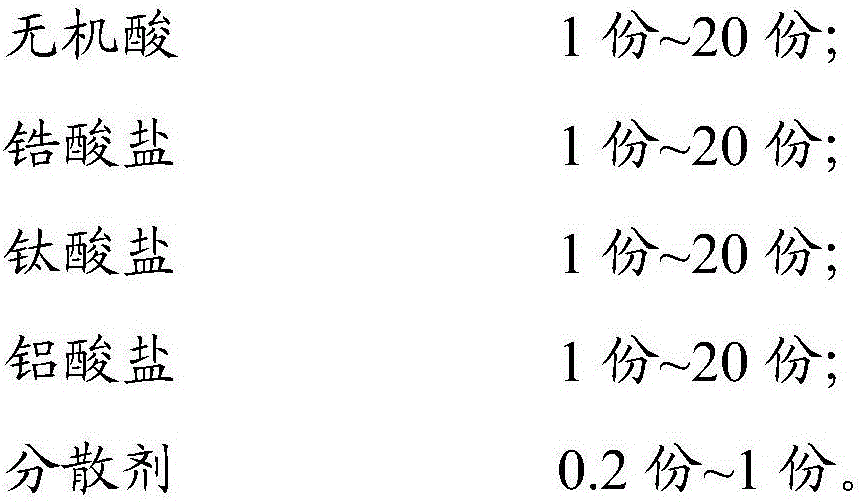

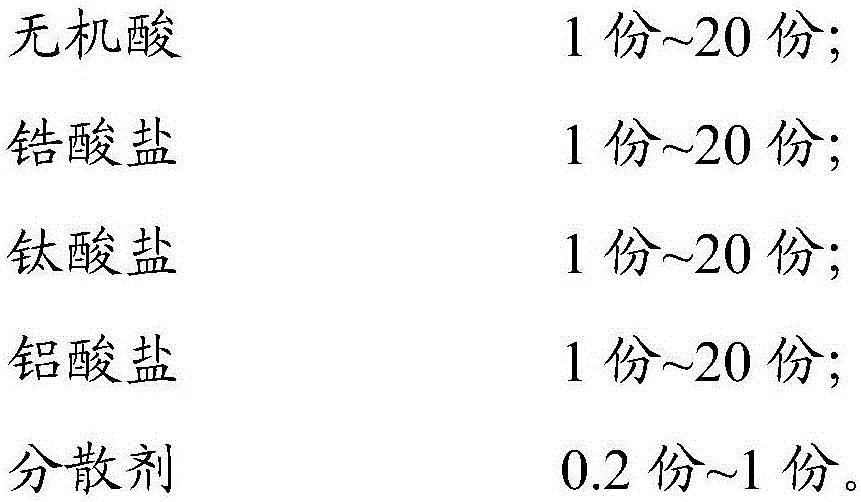

Zr-Ti passive film treating agent for aluminum or aluminum alloy and treating method thereof

InactiveCN105803442AImprove adhesionHigh degree of corrosion resistanceMetallic material coating processesChromium freeAluminate

The invention relates to a passive film treating agent for aluminum or aluminum alloy and a treating method thereof. The passive film treating agent for aluminum or aluminum alloy comprises the following components in parts by mass: 1 to 20 parts of inorganic acid, 1 to 20 parts of zirconate, 1 to 20 parts of titanate, 1 to 20 parts of aluminate and 0.2 to 1 part of a dispersing agent. According to the passive film treating agent for aluminum or aluminum alloy, relative to a traditional phosphorus-containing chromium-free passive film treating agent for aluminum or aluminum alloy which causes environmental pollution, the passive film treating agent for aluminum or aluminum alloy has the advantages that through 1 to 20 parts of inorganic acid, 1 to 20 parts of zirconate, 1 to 20 parts of titanate, 1 to 20 parts of aluminate and 0.2 to 1 part of the dispersing agent, a phosphorus-free chromium-free Zr-Ti passive film can be formed on the surface of aluminum or aluminum alloy, the passive film is good in adhesive force, high in corrosion resistance degree and good in salt spray resistance property and film uniformity, and the obtained passive film can be guaranteed to maintain the same silver white metal appearance as aluminum or aluminum alloy.

Owner:广东东明新材科技有限公司

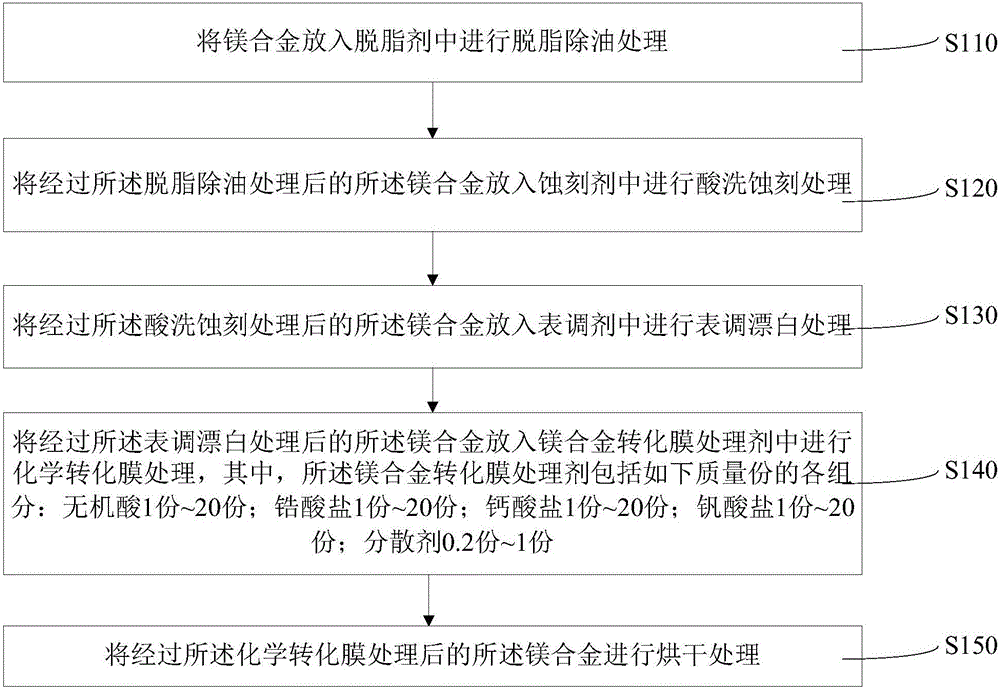

Magnesium alloy Zr-Ga-V conversion film treating agent and magnesium alloy Zr-Ga-V conversion film treating method

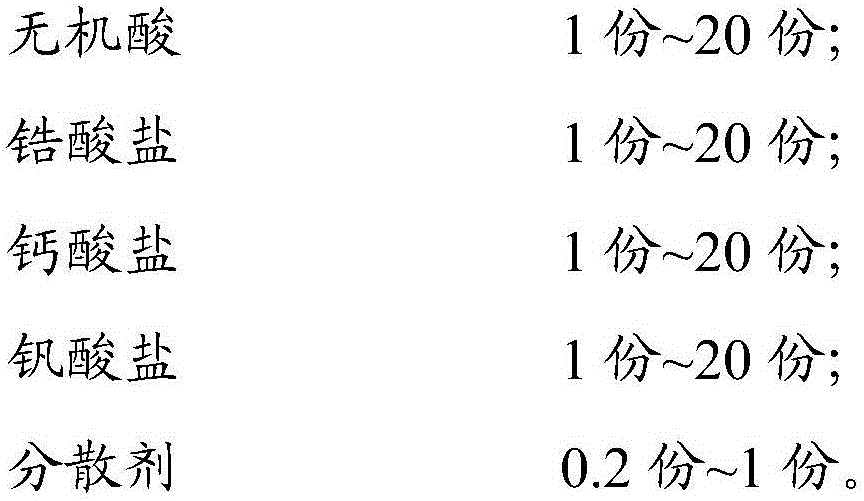

InactiveCN105951076AImprove adhesionHigh degree of corrosion resistanceMetallic material coating processesChromium freeZirconate

The invention relates to a magnesium alloy conversion film treating agent and a magnesium alloy conversion film treating method. The magnesium alloy conversion film treating agent comprises, by mass, 1-20 parts of inorganic acid, 1-20 parts of zirconate, 1-20 parts of calciate, 1-20 parts of vanadate and 0.2-1 part of a dispersing agent. Compared with a traditional phosphorus-containing chromium-free magnesium alloy conversion film treating agent which causes environmental pollution, the magnesium alloy conversion film treating agent adopts 1-20 parts of the inorganic acid, 1-20 parts of the zirconate, 1-20 parts of the calciate, 1-20 parts of the vanadate and 0.2-1 part of the dispersing agent, and thus a phosphorus-free chromium-free Zr-Ga-V conversion film can be formed on the surface of magnesium alloy; and the conversion film has the advantages of being good in adhesive force, high in corrosion resistance degree and good in salt fog resistance and film forming uniformity. The magnesium alloy conversion film treating agent is particularly suitable for a treatment process of a chemical conversion film of die casting magnesium alloy, such as AZ91D magnesium alloy.

Owner:广东东明新材科技有限公司

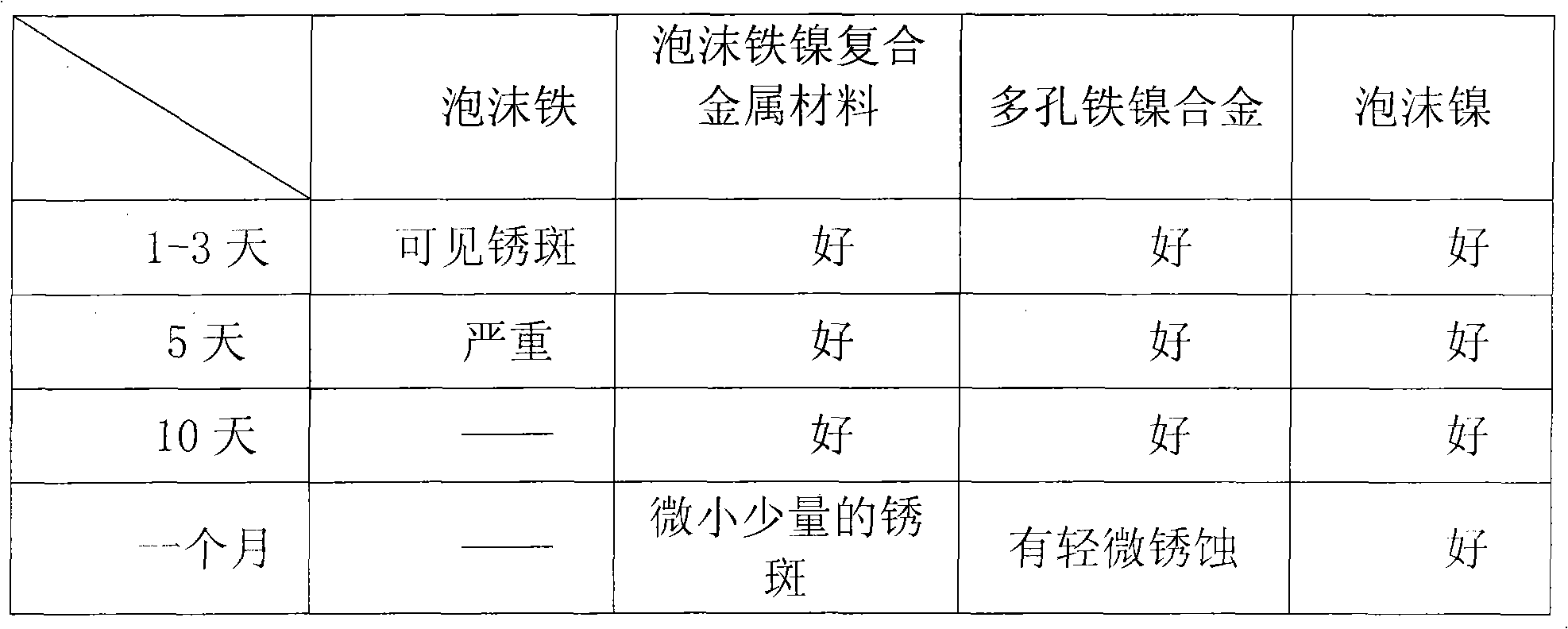

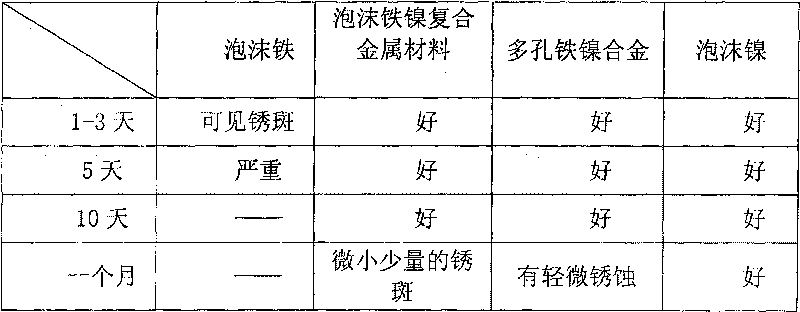

Foam iron-nickel composite metal material and preparation method thereof

ActiveCN101265549AReduce usageReduce manufacturing costVacuum evaporation coatingSputtering coatingPorous substrateFiltration

The invention discloses a foam iron-nickel composite metallic material and a preparation method thereof. The foam iron-nickel composite metallic material has a three-dimensional or two-dimensional network structure; and comprises a base layer composed of iron-nickel alloy and a nickel layer above the alloy base layer as a protective layer, wherein the composite metallic material comprises (wt%) nickel 5-29 and iron in balance. The preparation method comprises electroplating iron-nickel alloy on a conducting porous substrate to obtain the iron-nickel alloy base layer, coating nickel layer above the base layer, and performing high-temperature heat treatment to form the protective layer. The inventive foam iron-nickel composite metallic material has reduced nickel consumption, so as to effectively reduce cost; and can replace porous nickel material to be used in battery substrate, electromagnetic shielding, noise absorption, filtration and other fields.

Owner:先进储能材料国家工程研究中心有限责任公司

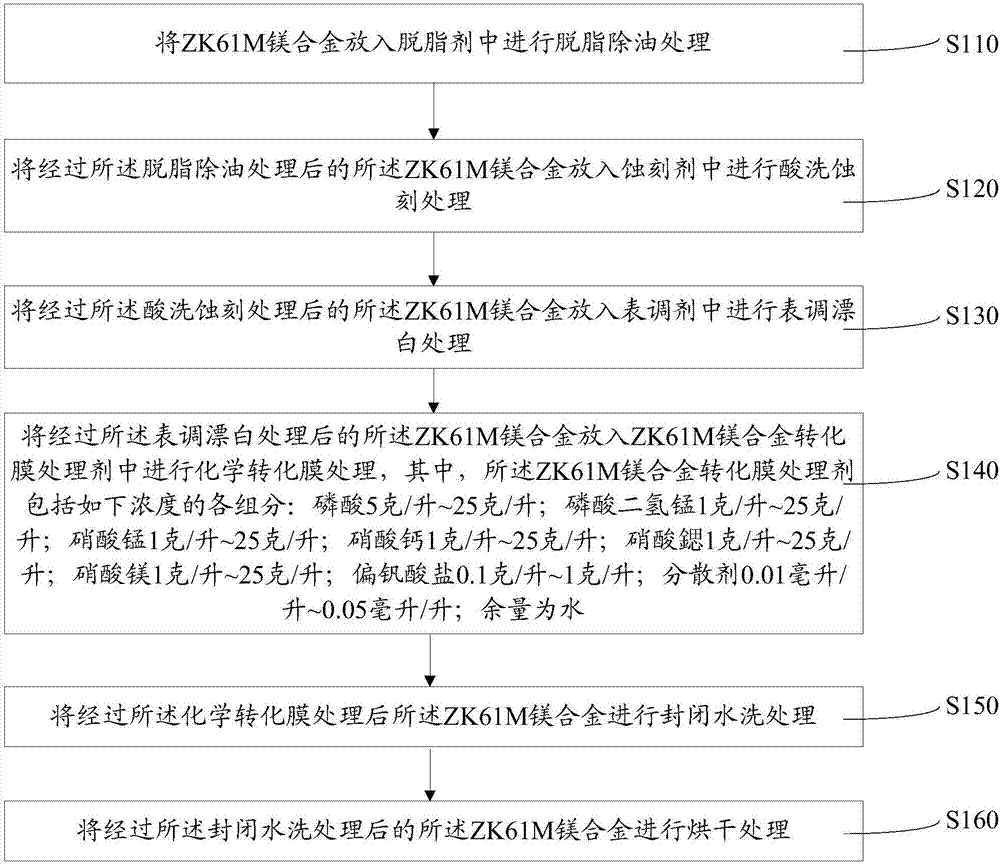

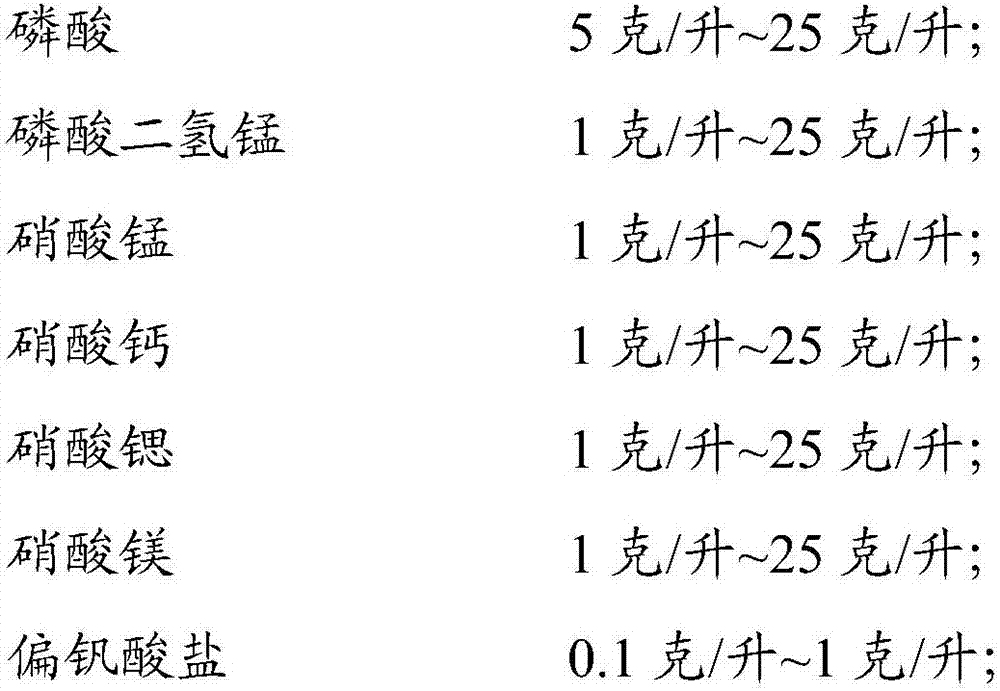

ZK61M magnesium alloy conversion film treatment agent and conversion film treatment method

InactiveCN107130233AImprove adhesionHigh degree of corrosion resistanceMetallic material coating processesNitratePhosphate

The invention relates to a ZK61M magnesium alloy conversion film treatment agent and a ZK61M magnesium alloy conversion film treatment method. The ZK61M magnesium alloy conversion film treatment agent comprises the following components by concentrations: 5-25 g / l of phosphoric acid, 1-25 g / l of manganous dihydrogen phosphate, 1-25 g / l of manganese nitrate, 1-25 g / l of calcium nitrate, 1-25 g / l of strontium nitrate, 1-25 g / l of magnesium nitrate, 0.1-1 g / l of metavanadate, 0.01-0.05 ml / l of dispersing agent, and the balance of water. The ZK61M magnesium alloy conversion film treatment agent performs the chemical conversion film treatment on the surface of a ZK61M magnesium alloy to form a conversion film with good adhesion, high corrosion resisting degree, salt mist resistance and good film forming uniformity.

Owner:广东东明新材科技有限公司

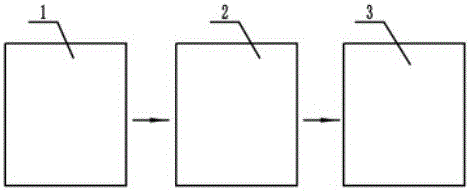

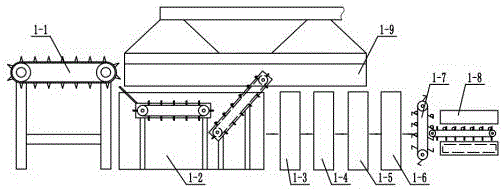

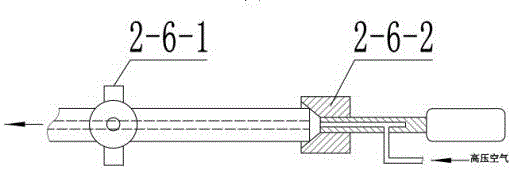

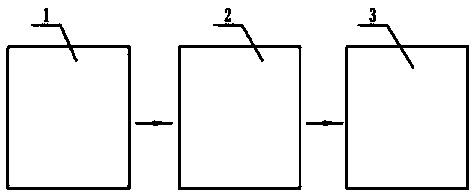

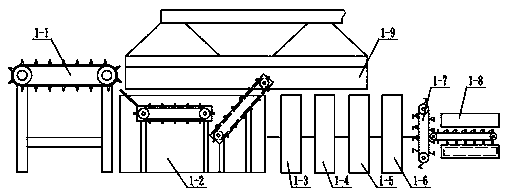

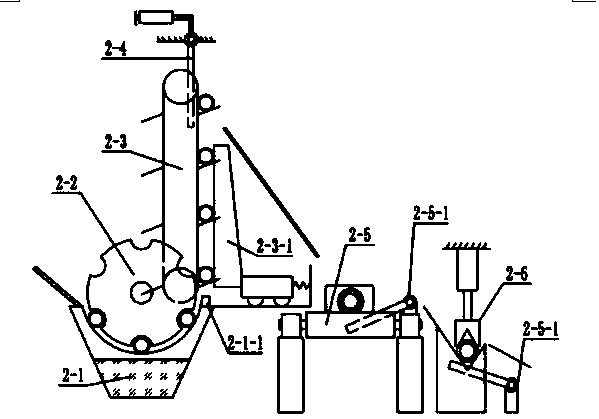

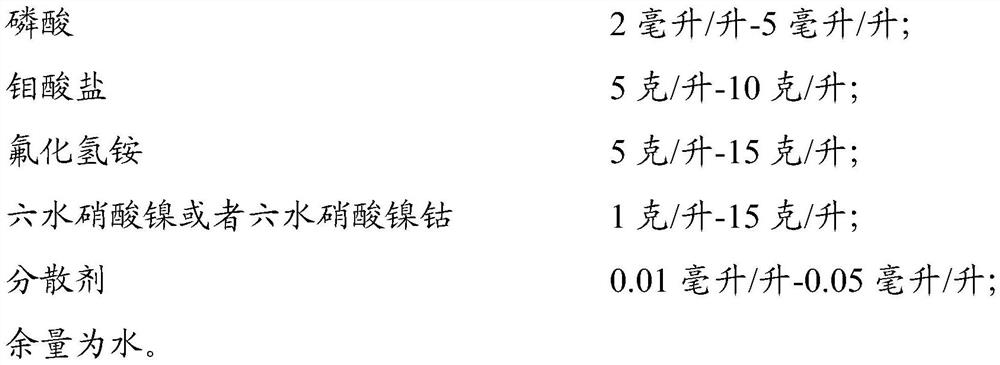

Steel pipe hot-dip galvanizing automatic production line

ActiveCN106591757AGalvanized high efficiencyGalvanized energy savingHot-dipping/immersion processesProduction lineWorking environment

The invention discloses a steel pipe hot-dip galvanizing automatic production line. The steel pipe hot-dip galvanizing automatic production line consists of a steel pipe pretreatment mechanism (1), a steel pipe automatic hot-dip galvanizing mechanism (2) and a galvanizing aftertreatment mechanism (3); the steel pipe pretreatment mechanism (1), the steel pipe automatic hot-dip galvanizing mechanism (2) and the galvanizing aftertreatment mechanism (3) are mounted on the ground in sequence from left to right; the steel pipe pretreatment mechanism (1) is provided with a mist sucking cover (1-9); an elastic car (2-3-1) is arranged on the right side of a pipe fishing mechanism (2-3); and an oven uniform heating fan (3-5-1) is arranged at the top of a primary passivation oven (3-5). The steel pipe hot-dip galvanizing automatic production line treats and galvanizes steel pipes through a single continuous production mode, uses two times of organic and inorganic passivation to largely reduce the environmental protecting energy consumption, improves the working environment cleanness and the product corrosion resisting degree, reduces the user use cost, and achieves the purposes of high efficiency, environmental protection, energy conservation and high quality in steel pipe galvanization.

Owner:DANYANG TENGHUANG PIPE GALVANIZATION

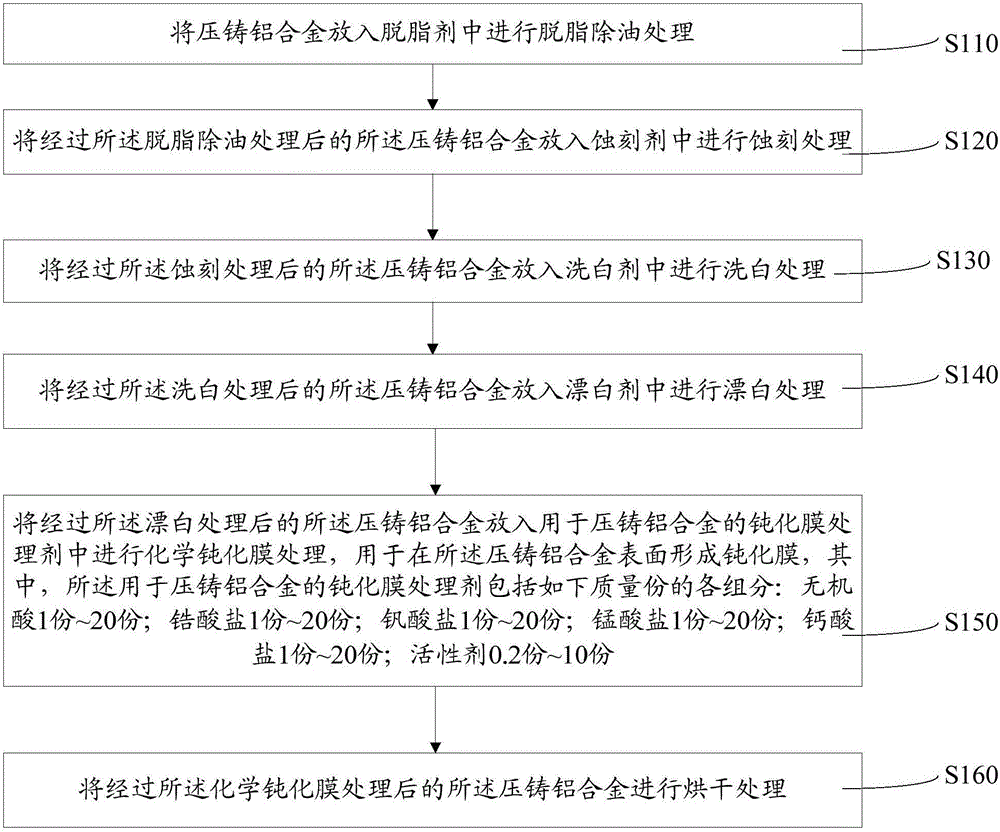

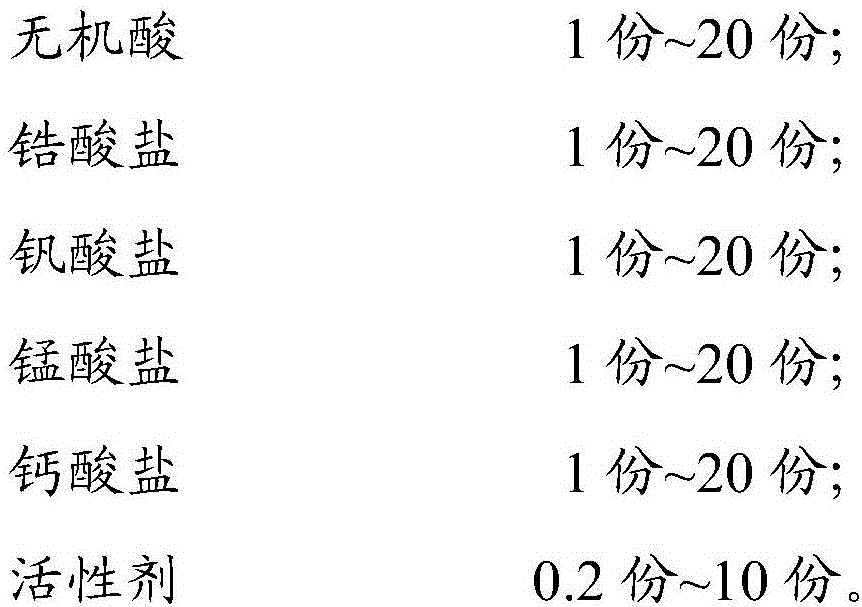

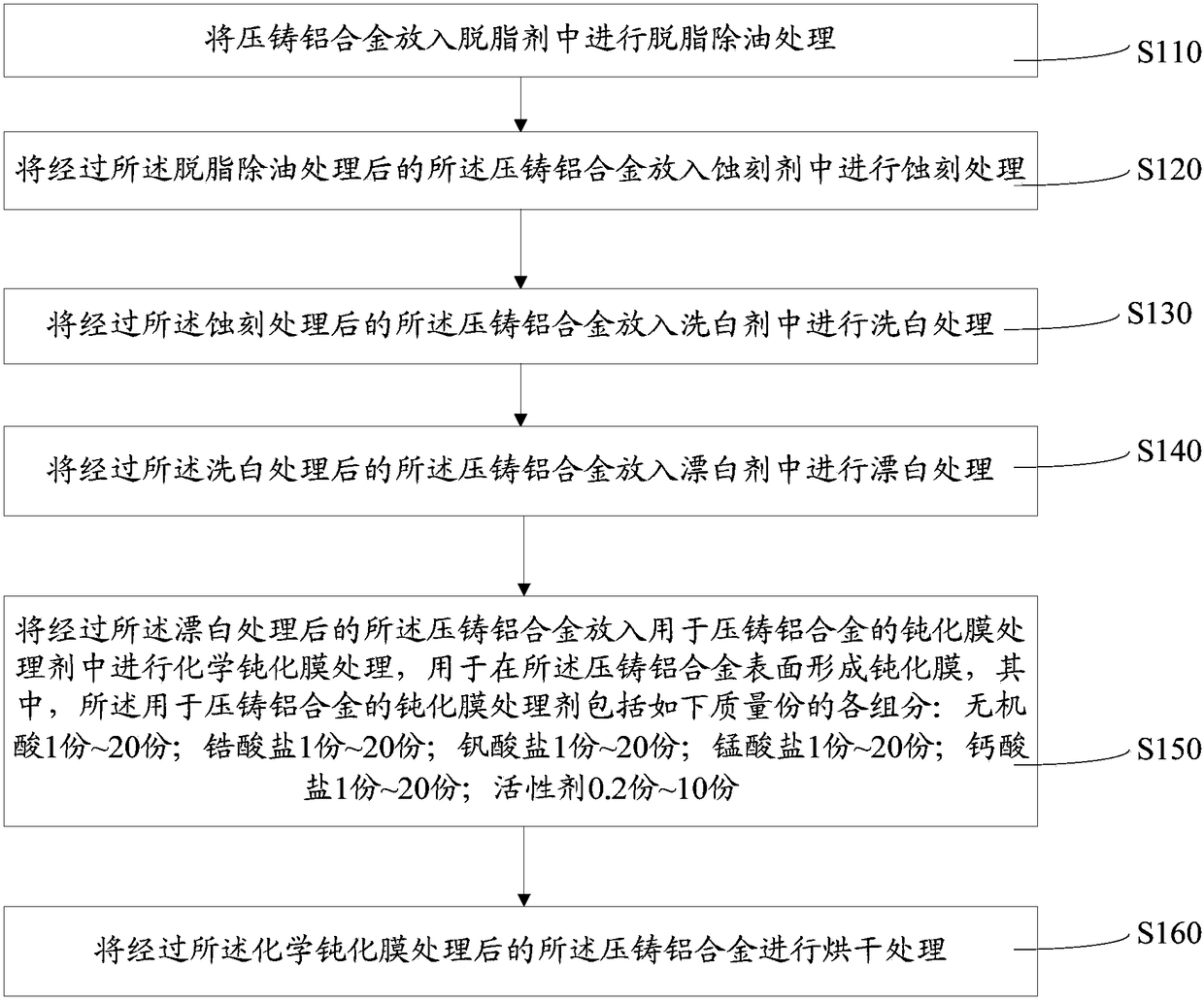

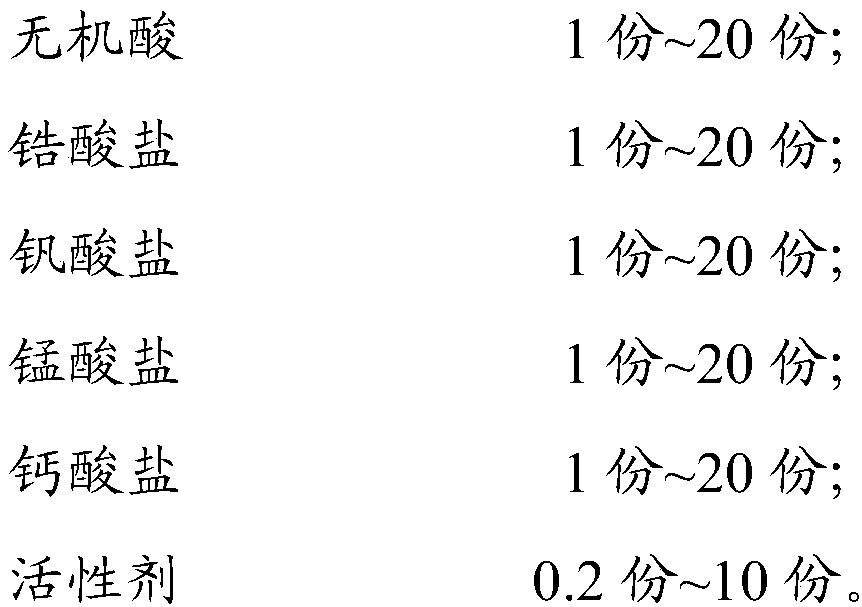

Zirconium-manganese-vanadium passive film treating agent for die cast aluminium alloy and treatment method thereof

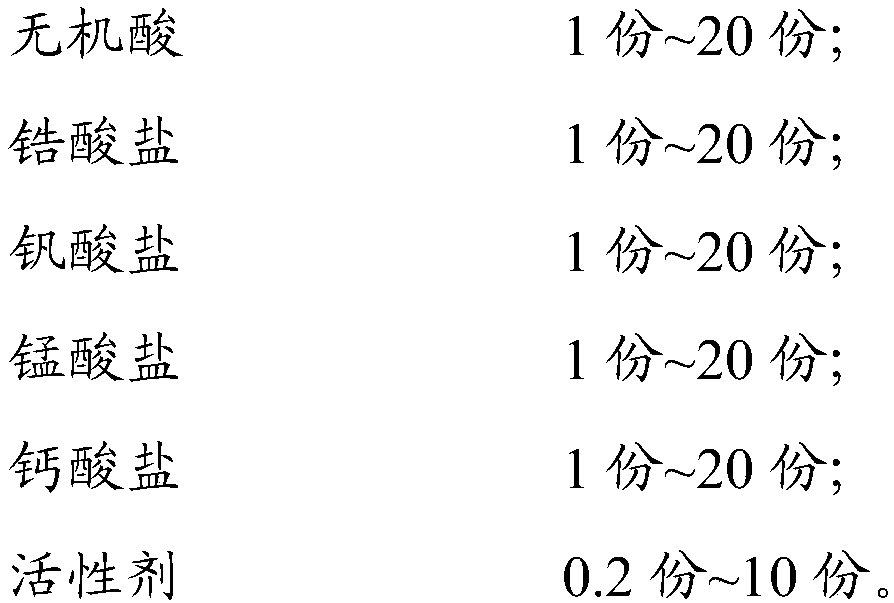

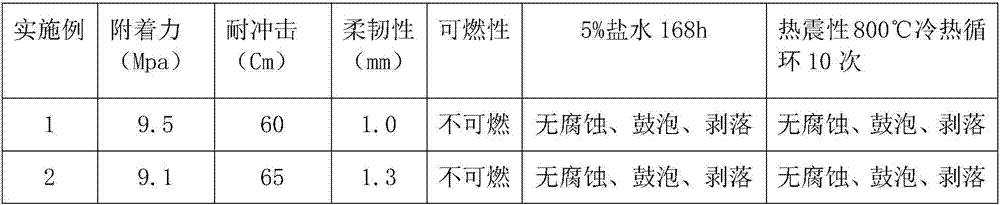

ActiveCN106048580AGood adhesionHigh degree of corrosion resistanceMetallic material coating processesChromium freeZirconate

The invention discloses a passive film treating agent for die cast aluminium alloy and a treatment method thereof. The passive film treating agent for die cast aluminium alloy comprises the following components in parts by mass: 1 to 20 parts of inorganic acid, 1 to 20 parts of zirconate, 1 to 20 parts of vanadate, 1 to 20 parts of manganate, 1 to 20 parts of calciate and 0.2 to 10 parts of an activating agent. Relative to a traditional phosphorus-containing chromium-free passive film treating agent for die cast aluminium alloy, which causes pollution to the environment, the passive film treating agent for die cast aluminium alloy can form a phosphorus-free chromium-free Zr-Mn-V passive film on the surface of die cast aluminium alloy, the passive film has the advantages that the adhesive force is good, the corrosion resistance is high, and the salt mist resistance and film forming uniformity are good, and besides, the obtained passive film can be guaranteed to have a silver white metal appearance the same as the die cast aluminium alloy.

Owner:广东东明新材科技有限公司

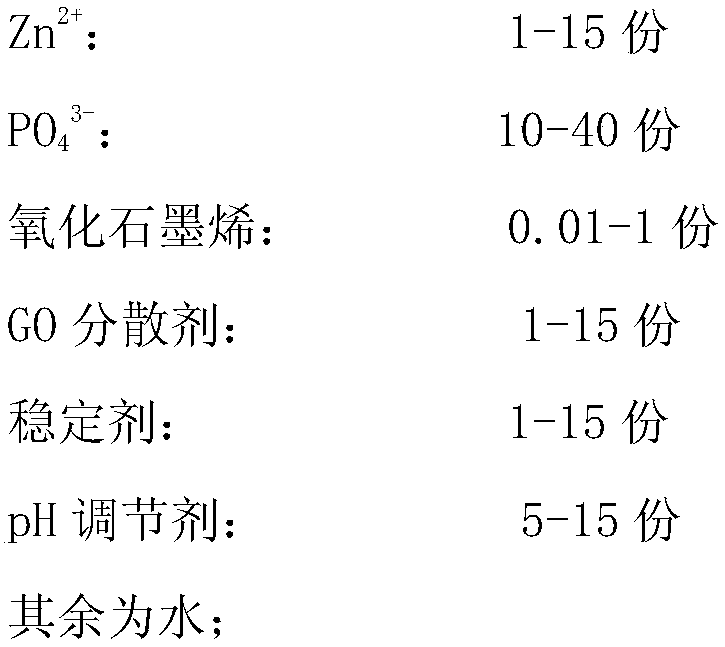

Efficient anticorrosion zinc-type phosphating solution and preparation method thereof

InactiveCN107740168AFast preparationEfficient preparationPhosphatisationElectrochemical corrosionElectrolyte

The invention discloses an efficient anticorrosion zinc-type phosphating solution and a preparation method thereof. The zinc-type phosphating solution comprises the raw material formula components of,by weight, 1-15 parts of Zn<2+>, 10-40 parts of PO4<3->, 0.01-1 part of oxidized graphene, 1-15 parts of a GO dispersing agent, 1-15 parts of a stabilizer, 5-15 parts of a pH modifier and 1000 partsof water. According to the prepared phosphating electrolyte, the safe and non-toxic effects are achieved, a phosphating film can be quickly and efficiently prepared, and especially when a metal workpiece serves as a cathode in the phosphating solution for electrolytic phosphating, the workpiece can have a smooth surface and multiple excellent properties such as scratch resistance and aging resistance. The oxidized graphene can be evenly distributed in a coating of the phosphating film, micro-holes in the surface of a phosphate film are effectively filled with the oxidized graphene, thus an isolation layer is formed, the physical shielding effect is achieved, a way through which a corrosive medium directly makes contact with the metal workpiece is blocked, occurrence of electrochemical corrosion is further inhibited, and the corrosion rate is decreased to a large extent.

Owner:SOUTH CHINA UNIV OF TECH

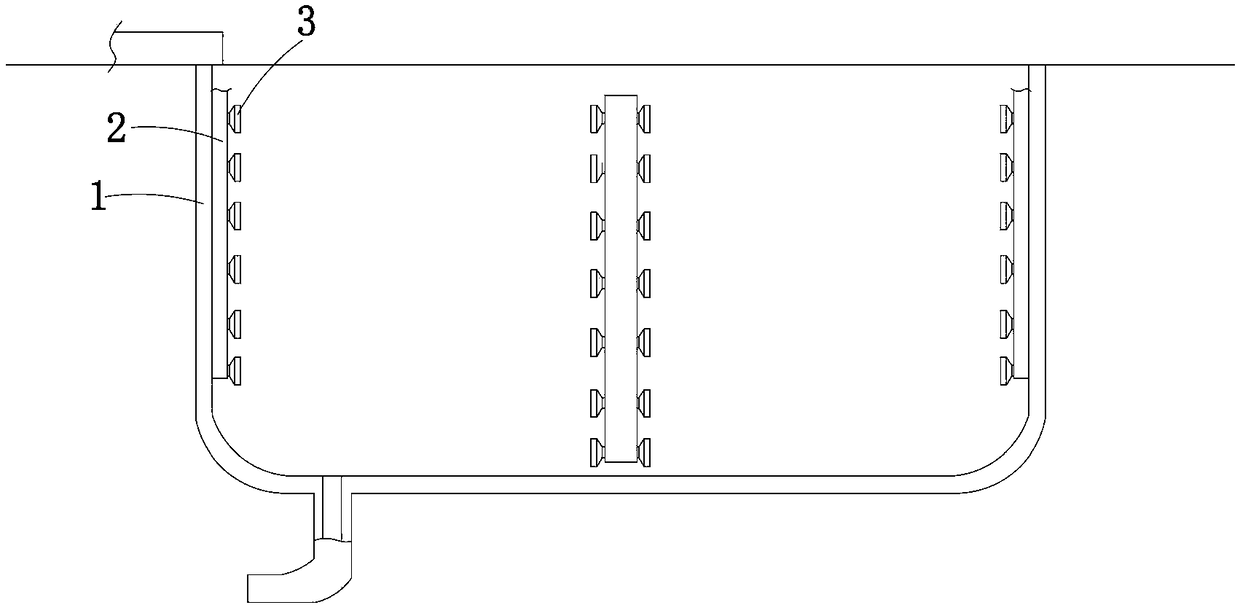

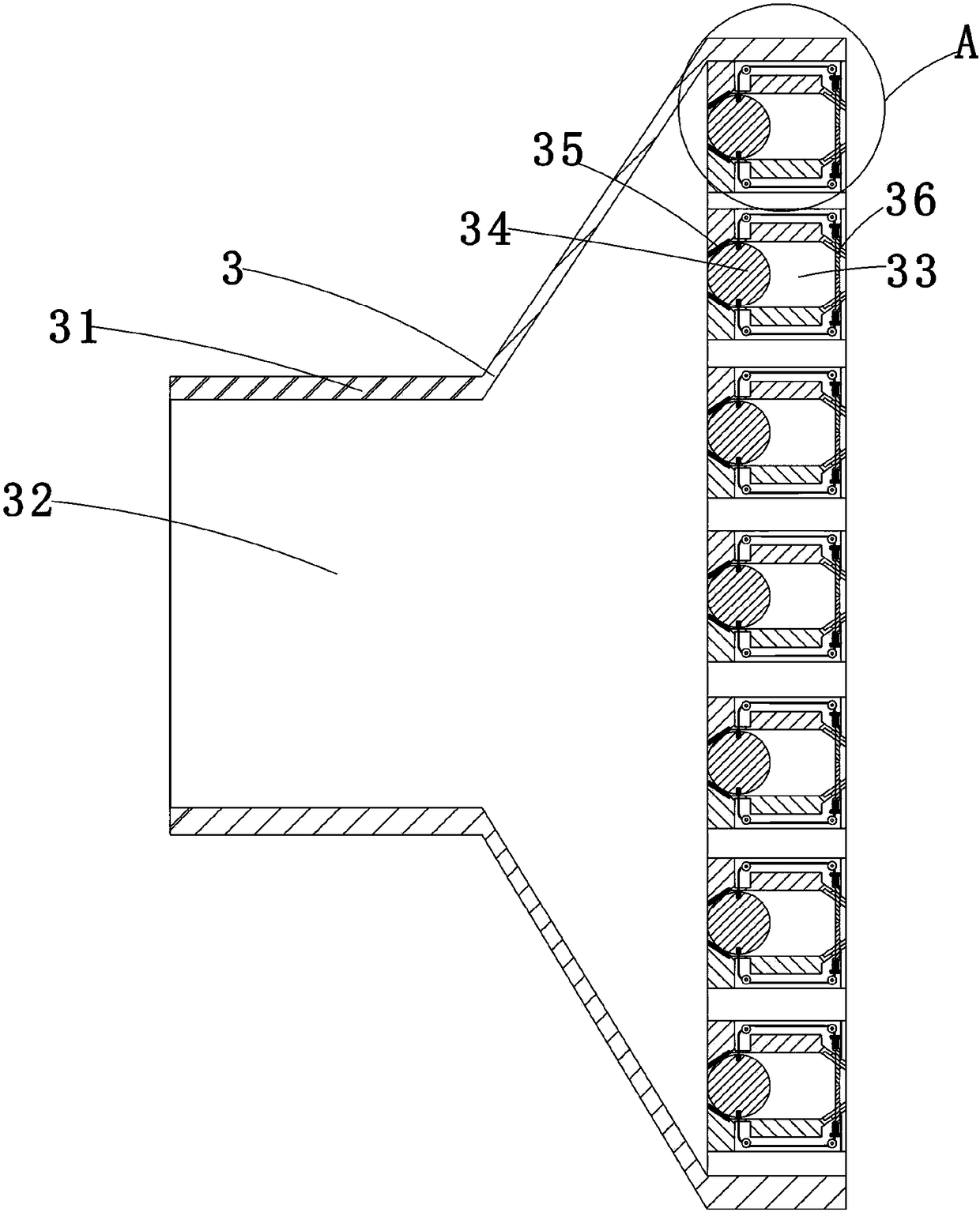

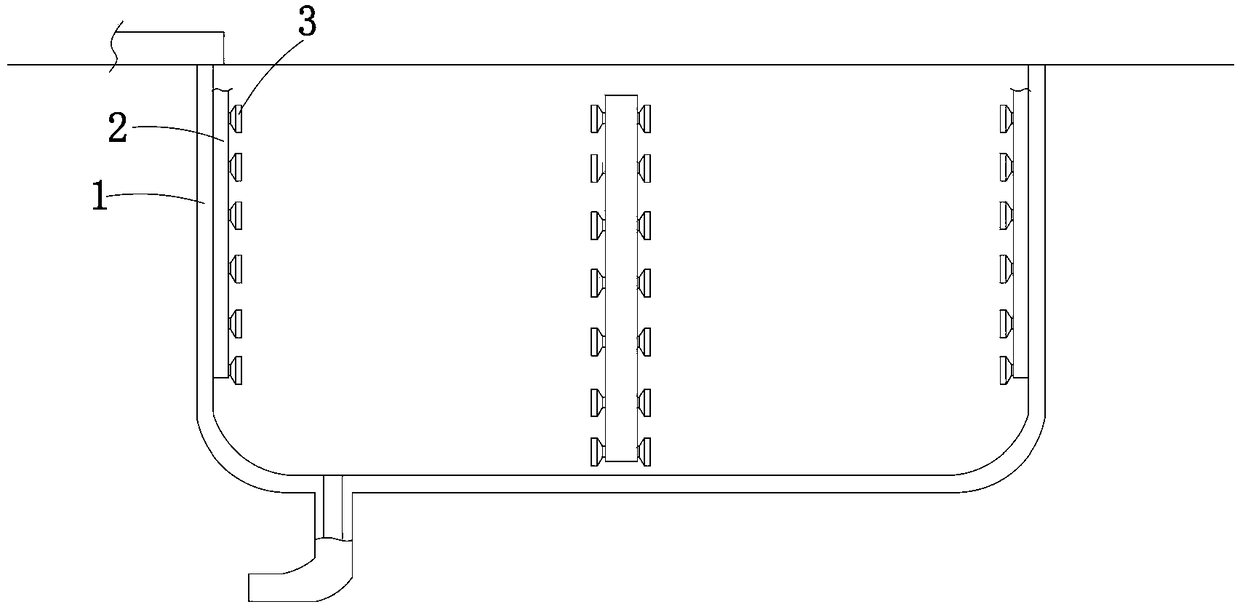

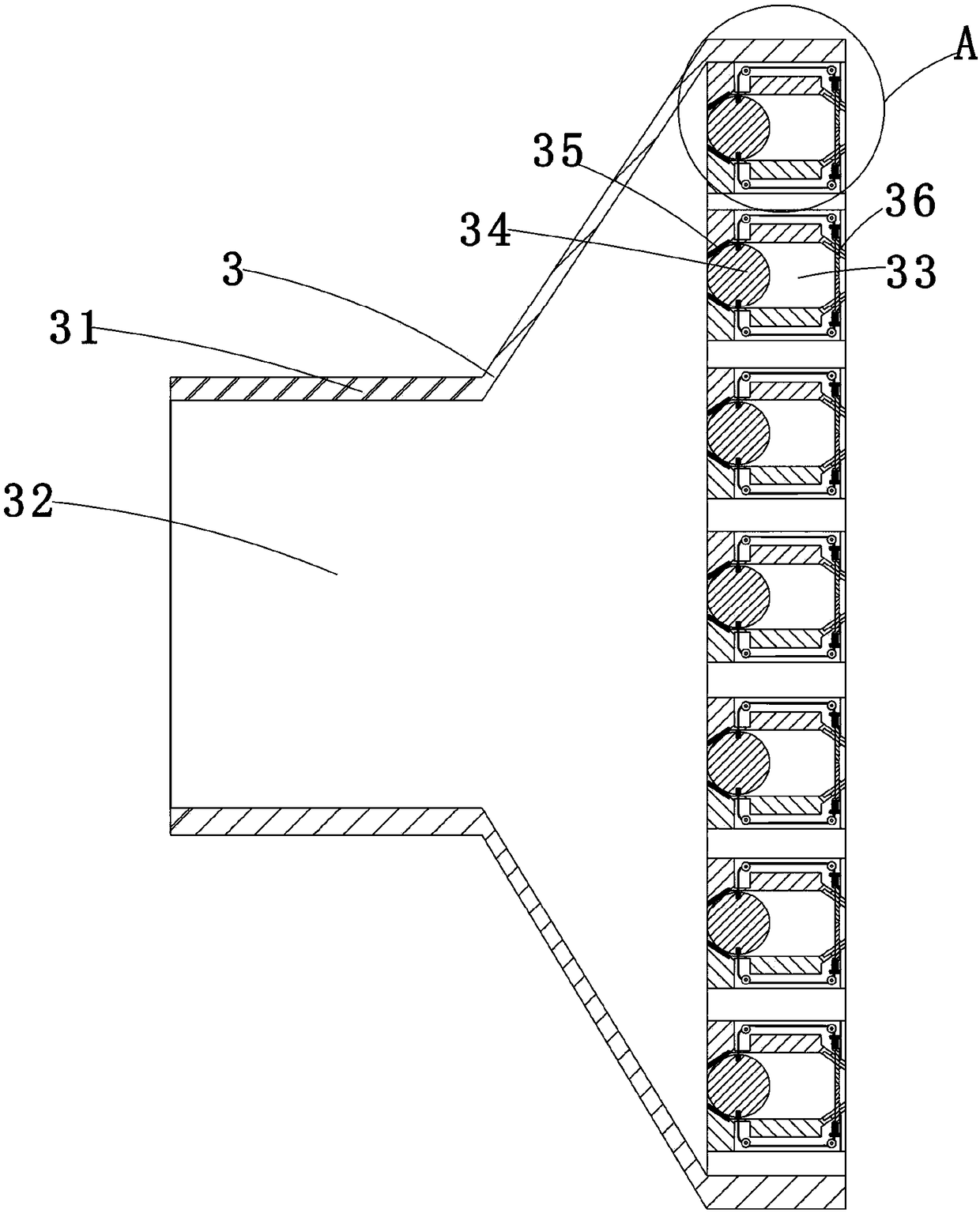

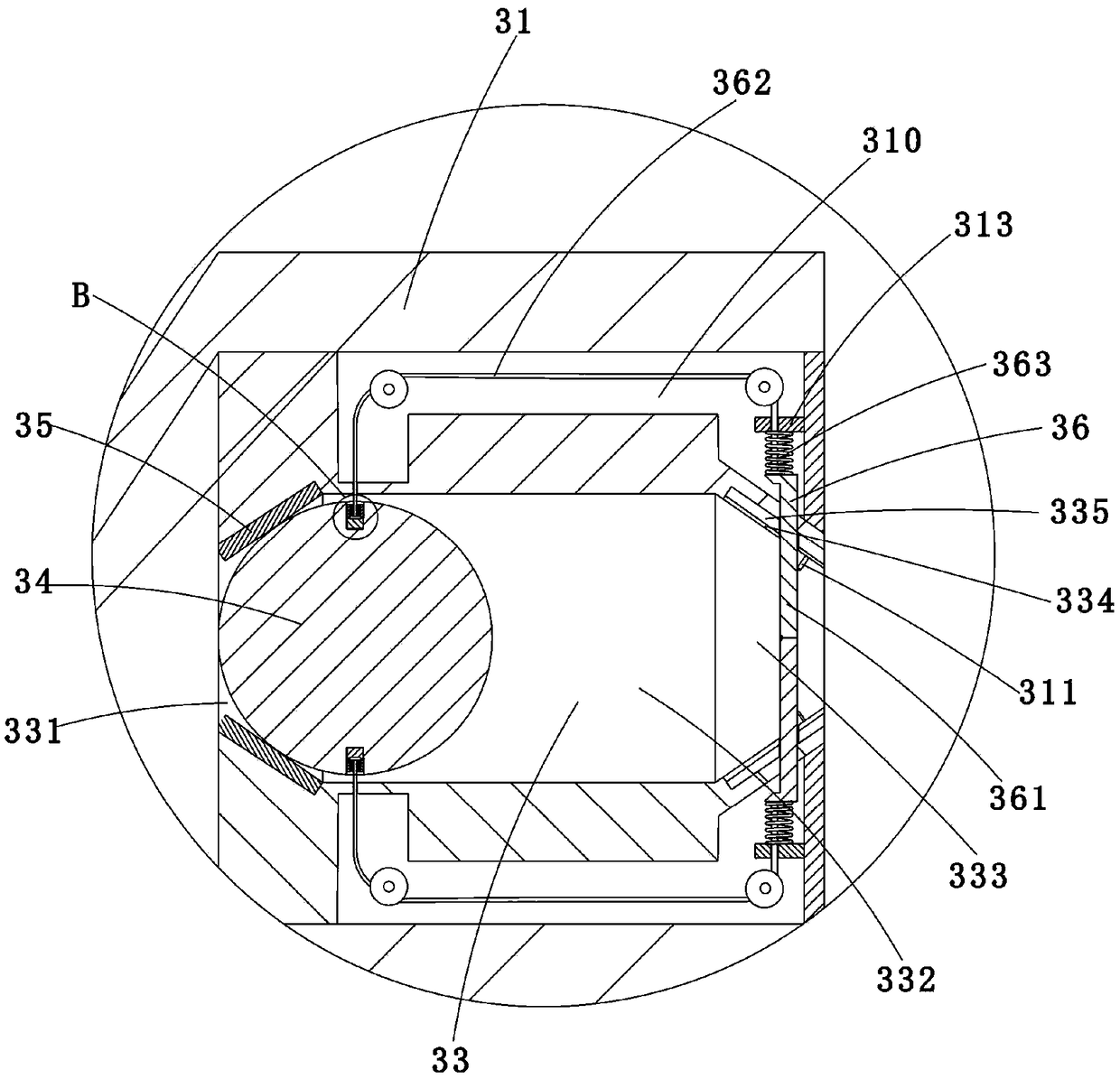

Industrial acidic waste water treatment device

ActiveCN108314199ARealize blockingAvoid blockingWater aerationSustainable biological treatmentSludgeSewage treatment

The invention discloses an industrial acidic waste water treatment device. The industrial acidic waste water treatment device comprises a tank body, oxygen supply pipelines, and aeration parts which are arranged in the tank body; the aeration parts are detachably connected with the oxygen supply pipelines, and each aeration part comprise a pedestal, a main pipe arranged on the pedestal, and a plurality of branched pipes which are connected with the main pipe; a blocking part capable of rolling forward under oxygen supply states and a magnetic part used for driving the blocking part to roll backward under oxygen supply stopped states are arranged in each branched pipe; and each magnetic part is arranged on the internal wall of the corresponding branched pipe. According to the industrial acidic waste water treatment device, the blocking parts and the magnetic parts are arranged in the branched pipes, so that blocking of the branched pipes is realized, the internal parts of the branched pipes are maintained to be clean, blocking of the branched pipes by sludge is avoided, the corrosion resistance is excellent, and the service life is long.

Owner:HUIZHOU DONGJIANG ENVIRONMENTAL PROTECTION TECH

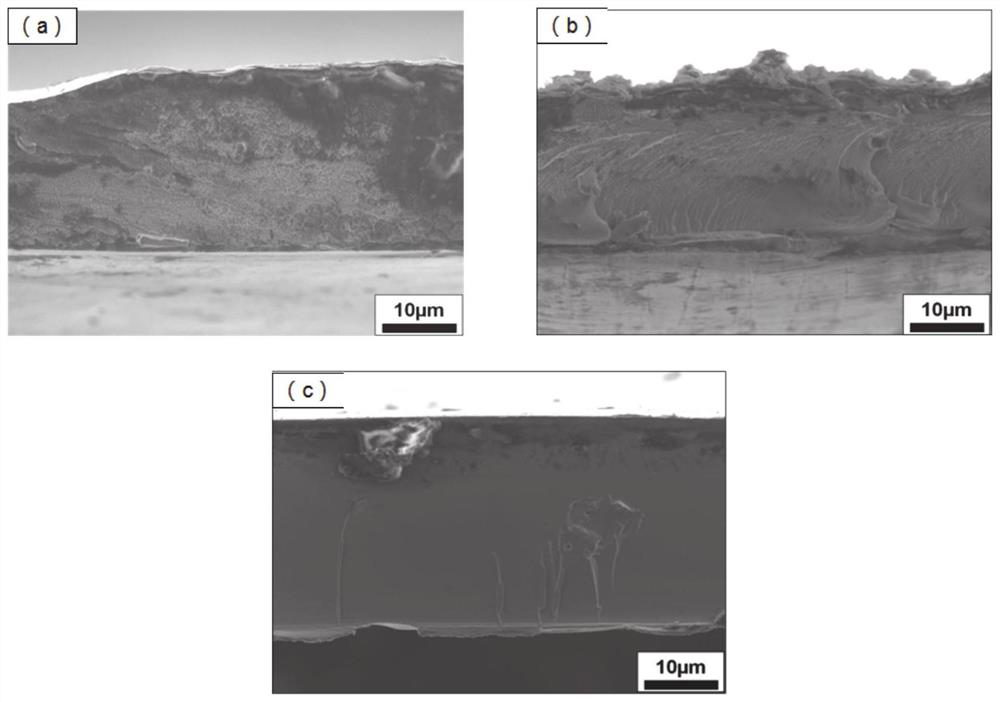

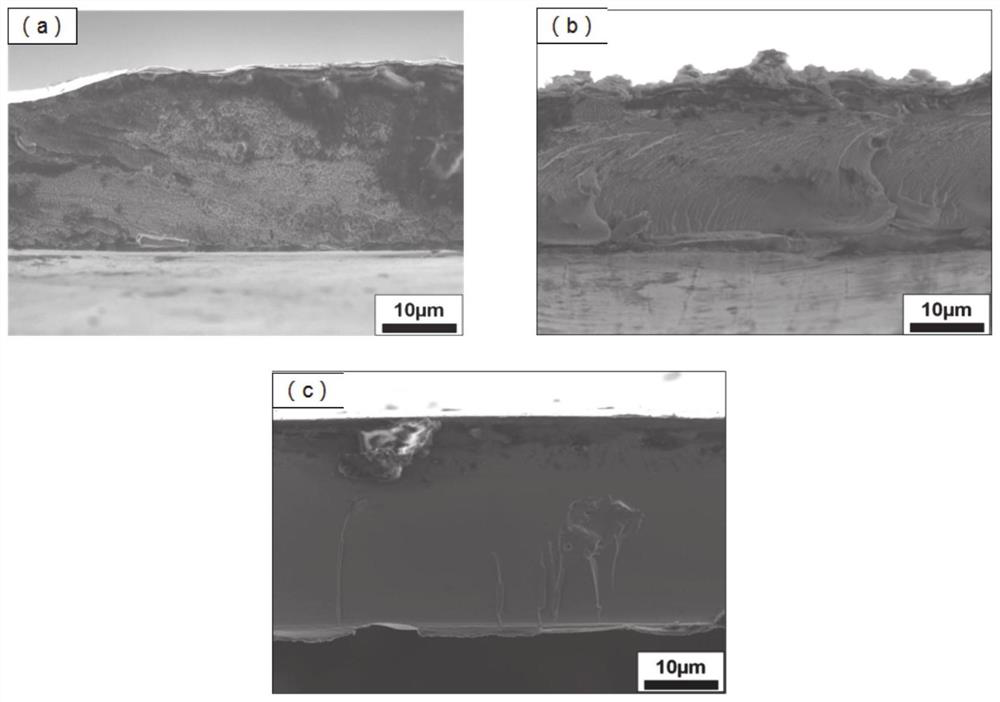

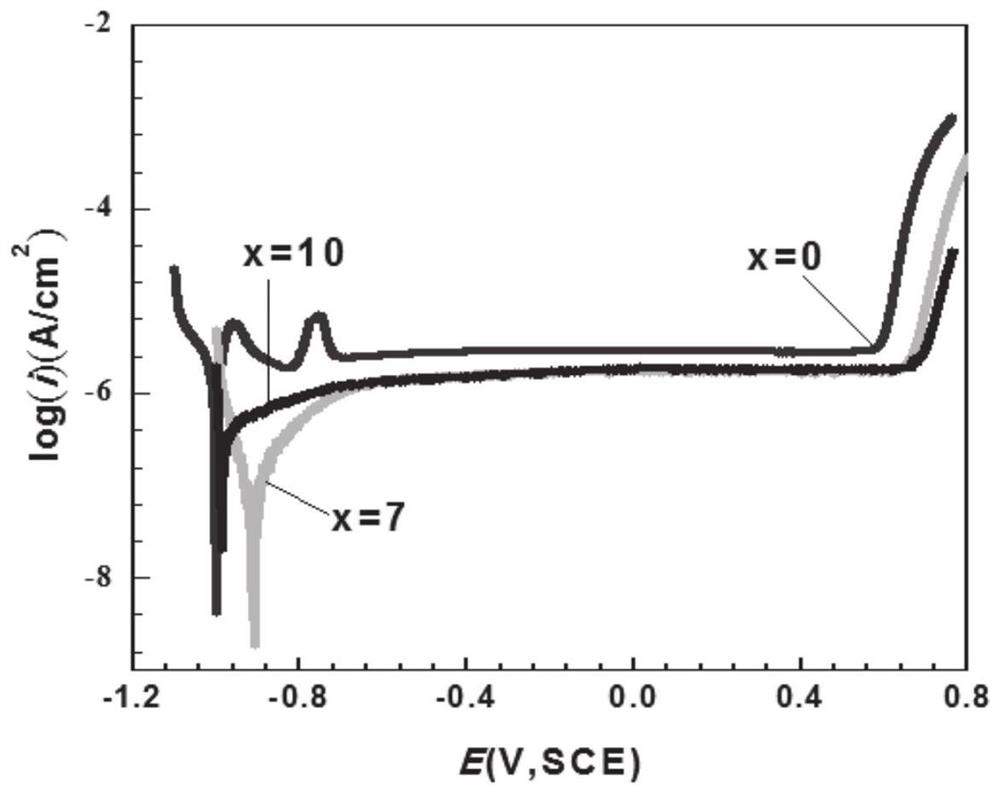

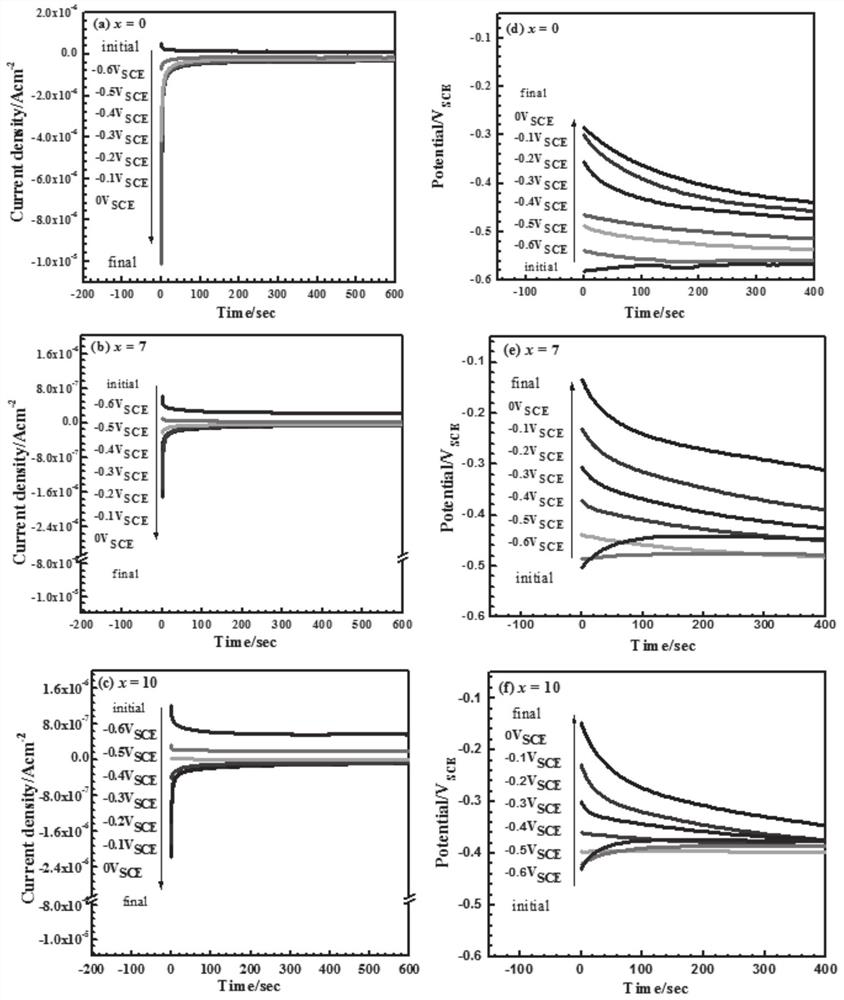

WC-9Ni-0.57Cr hard alloy

A WC-9Ni-0.57Cr hard alloy is developed in order to improve the hardness and the abrasion resistance of a WC-Ni hard alloy. A WC-9Ni-0.57Cr hard alloy and a WC-6Co hard alloy are adopted as raw materials, the prepared hard alloy has good anti-corrosion capacity, the corrosion rate of the WC-9Ni-0.57Cr hard alloy is 0.003 mm / a, the corrosion rate of the WC-6Co hard alloy is 0.009 mm / a, and it is shown that the anti-corrosion capacity of the WC-9Ni-0.57Cr hard alloy is higher. The microcosmic corrosion form shows corrosion of a binding phase. The hardness, the anti-corrosion degree and the bending strength of the prepared WC-9Ni-0.57Cr hard alloy are all greatly improved. A novel production process can be provided for preparing the high-performance WC-Ni hard alloy.

Owner:杨晶

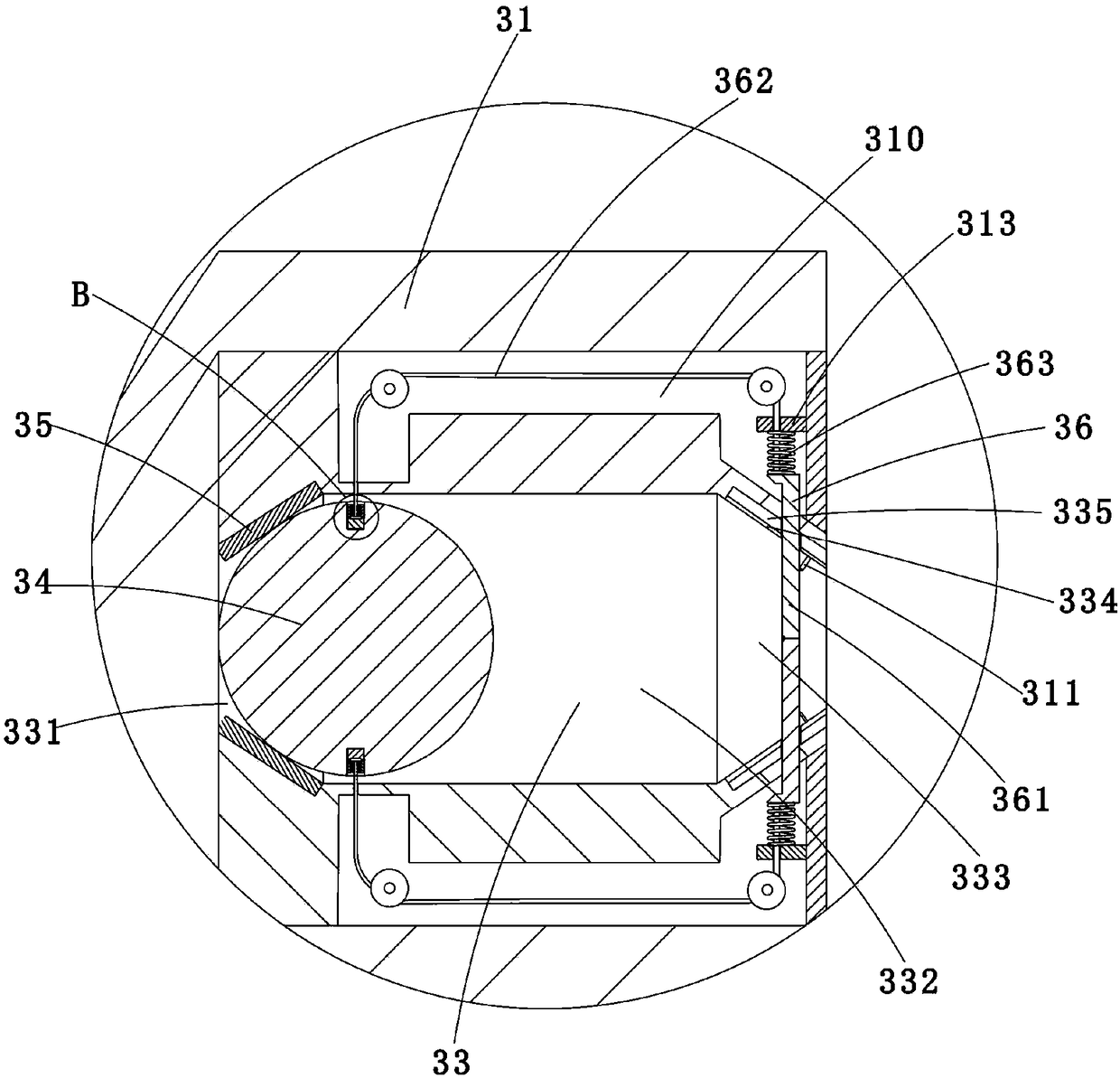

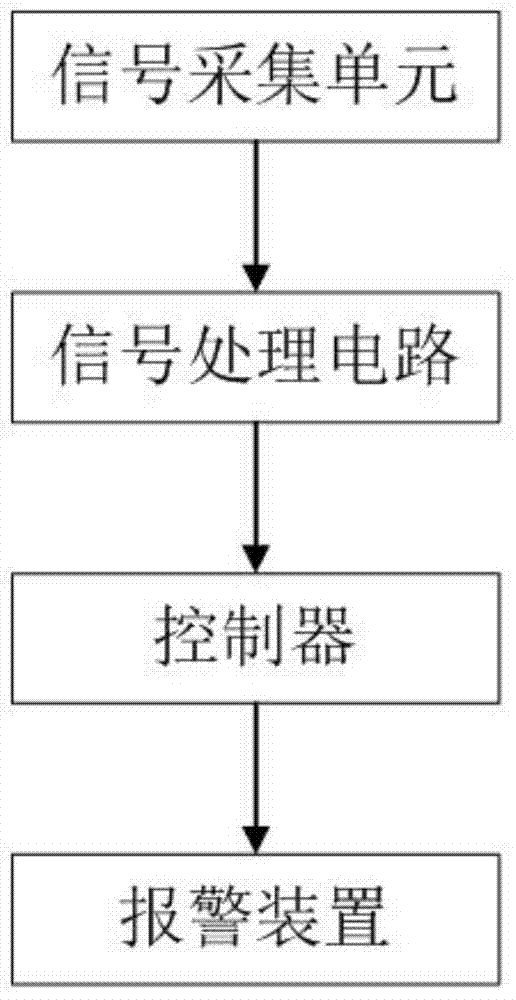

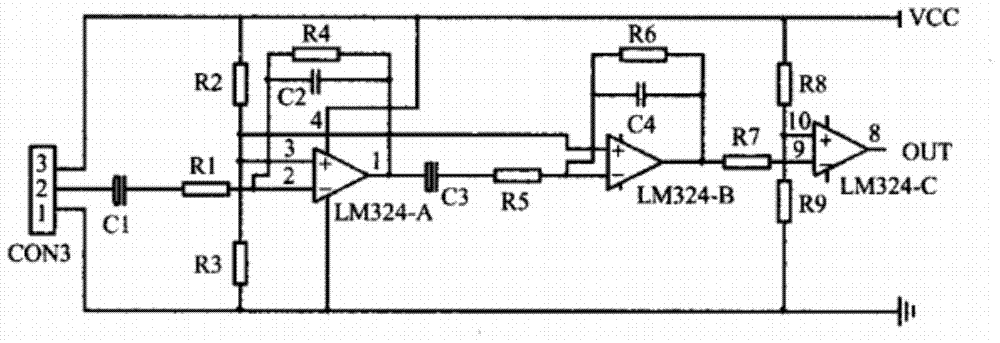

Liquid flow monitoring device

InactiveCN104765384AAccurate measurementHigh control precisionFlow control using electric meansAudio power amplifierSignal processing circuits

The invention relates to the field of sensor detection and discloses a liquid flow monitoring device. The liquid flow monitoring device comprises a signal collection unit, a signal processing circuit, a controller and a warning device. The signal collection unit comprises a turbine and a magnetic resistance sensor which are fixedly arranged in a water pipe. The surface of the turbine is perpendicular to the flowing direction of liquid in the water pipe, and the magnetic resistance sensor used for detecting the rotating speed of the turbine is close to the turbine. The signal processing circuit is a three-terminal differential circuit and comprises three operational amplifiers. The output end of the signal collection unit is connected with the input end of the signal processing circuit. The signal processing circuit outputs a processed signal to the controller. The controller controls the warning device according to the received signal. The liquid flow monitoring device is high in corrosion resistance, accurate in measurement result and high in control accuracy.

Owner:柳州市金旭节能科技有限公司

Process for welding corrugated inner container of boiler

ActiveCN107570838AImprove welding stabilityAvoid crackingArc welding apparatusWelding/cutting media/materialsEngineeringWelding defect

The invention discloses a process for welding a corrugated inner container of a boiler. The process comprises the procedures of rolling, pre-welding treatment, welding treatment operation, and post-welding grinding treatment. The welding treatment operation procedure comprises the following steps: welding from the inner side of a pipe wall; overcoming welding defects from the outer side of the pipe wall by utilization of carbon arc gouging; and welding from the outer side of the pipe wall. Through the two-layer welding operation, not only the high welding stability but also the fusion connection between different welding fluxes and the inner container are achieved, and the different welding fluxes are matched with welding wire so as to achieve the different degrees of stability; especially, an SJ501 welding flux is selected for an inner layer, an SJ101 welding flux is selected for an outer layer, and the two welding fluxes have the different properties of corrosion resistance and structure strength; and accordingly, when the two welding fluxes are utilized in the inner container welding process in a matched manner, the welding stability of a joint of the inner container is high, the cracking possibility is low, and the safety performance high.

Owner:北京奥林匹亚锅炉有限公司

Corrosion resistant plastic

Corrosion resistant plastic is disclosed. The plastic is composed of the following ingredients (by weight): 6-17% of phenolic resin, 5-7% of polyethylene wax, 1-6% of calcium sulfate whiskers, 4-10% of melamine cyanurate, 1-4% of molybdenum trioxide, 1-4% of tributyl citrate, 1-4% of activated clay, 1-4% of calcium carbonate, and the balance ABS resin. The invention has the following beneficial effects: the prepared product has high glossiness, good wear resistance, high hardness and high corrosion resistance, and can be applied in the fields of water conservancy projects, pipeline project andthe like.

Owner:天津市久金管道工程有限公司

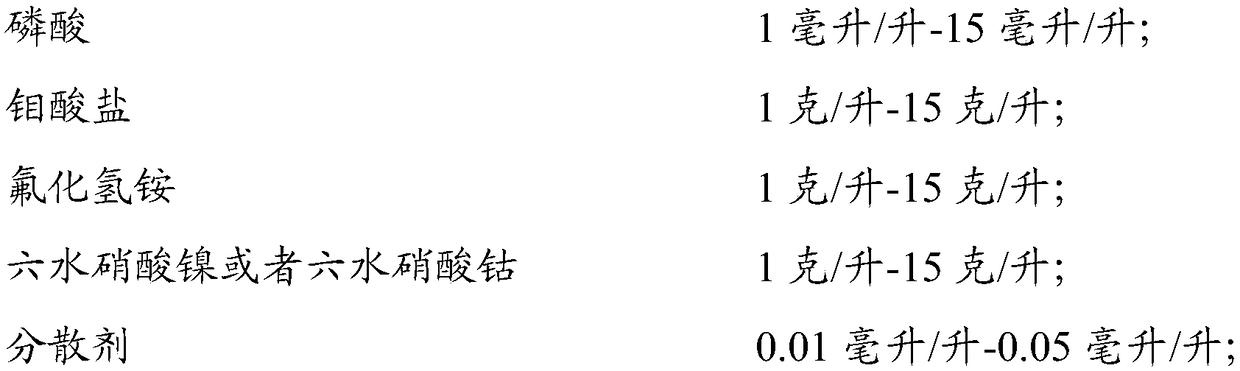

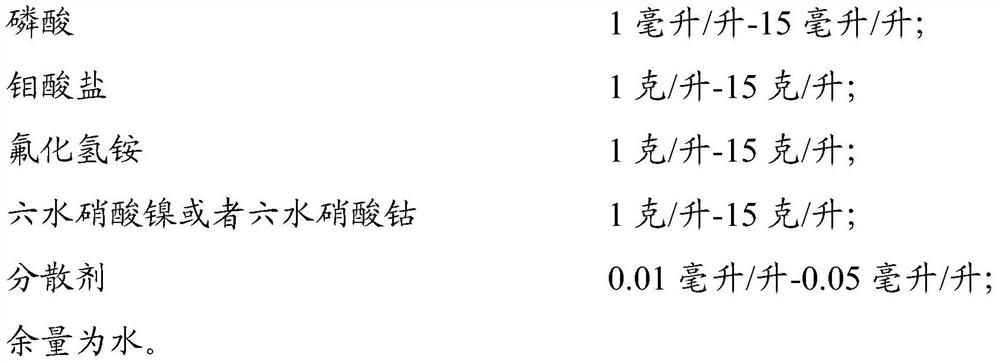

Black chromium-free conversion film treatment agent for ADC12 pressure casting aluminum alloy and surface treatment method for ADC12 pressure casting aluminum alloy

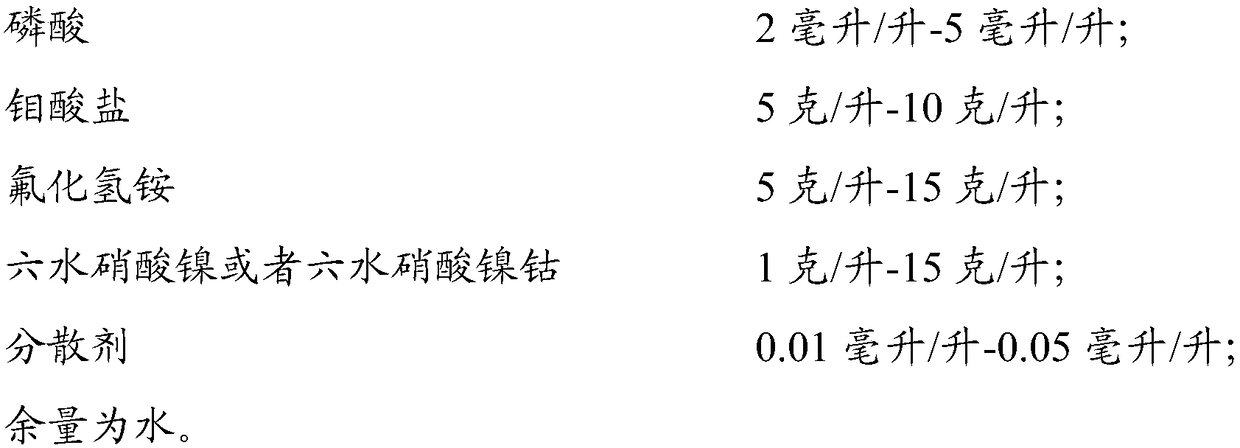

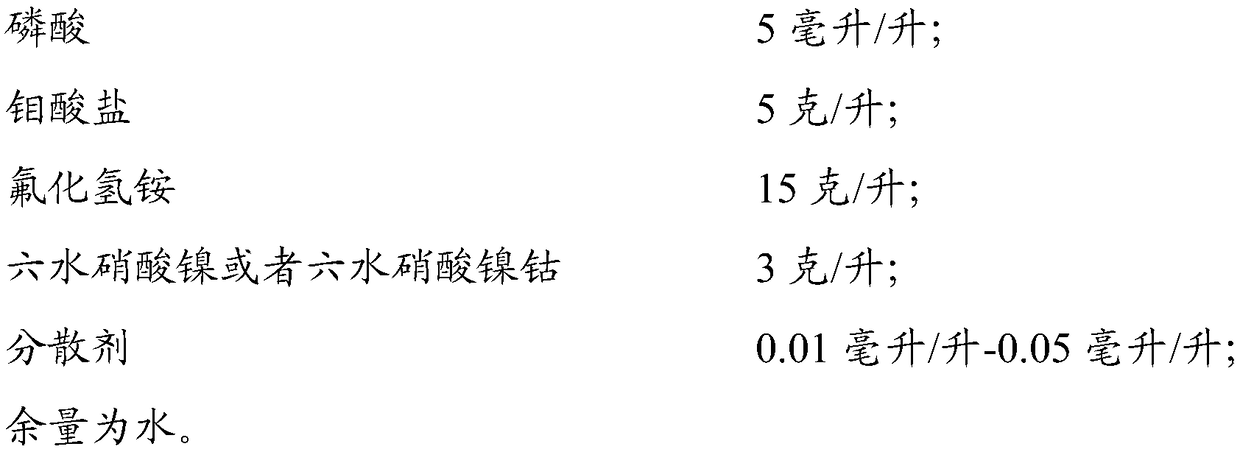

ActiveCN109183016AImprove adhesionHigh degree of corrosion resistanceMetallic material coating processesPhosphoric acidChromium free

The invention relates to a black chromium-free conversion film treatment agent for an ADC12 pressure casting aluminum alloy and a surface treatment method for the ADC12 pressure casting aluminum alloy. The conversion film treatment agent is prepared from the following components with concentrations as follows: 1-15 ml / L phosphoric acid, 1-15 g / L molybdate, 1-15 g / L ammonium hydrogen fluoride, 1-5g / L nickel nitrate hexahydrate, a 0.01-0.05 ml / L dispersant and the balance of water. The black chromium-free conversion film treatment agent for the ADC12 pressure casting aluminum alloy can form a black conversion film on the surface of the ADC12 pressure casting aluminum alloy and the conversion film has the advantages of being good in adhesive force, high in degree of corrosion resistance, good in salt spray resistance property and good in film forming uniformity, and can improve the corrosion resistance and the film adhesive force of the surface of the ADC12 pressure casting aluminum alloy. The black chromium-free conversion film treatment agent is free of chromium and does not pollute the environment, so that the black chromium-free conversion film treatment agent is relatively goodin environment-friendly property.

Owner:广东东明新材科技有限公司

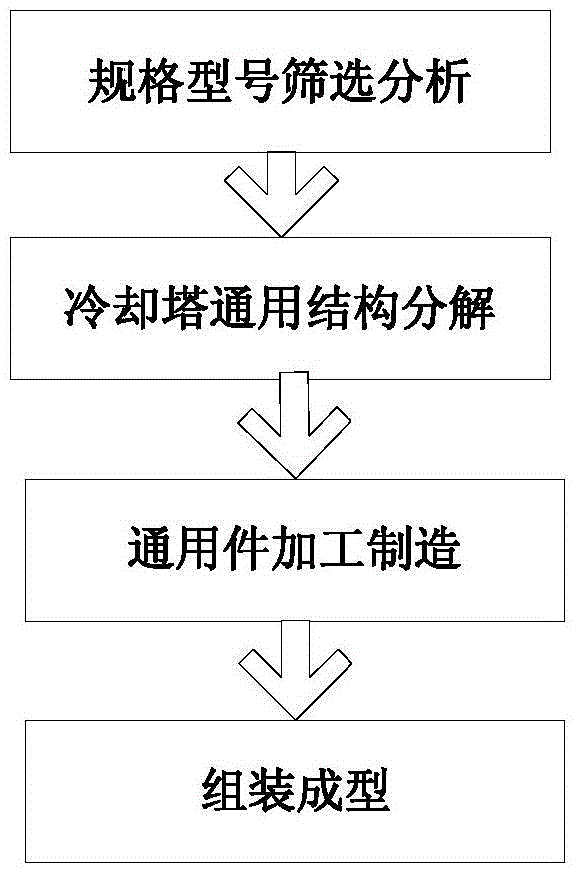

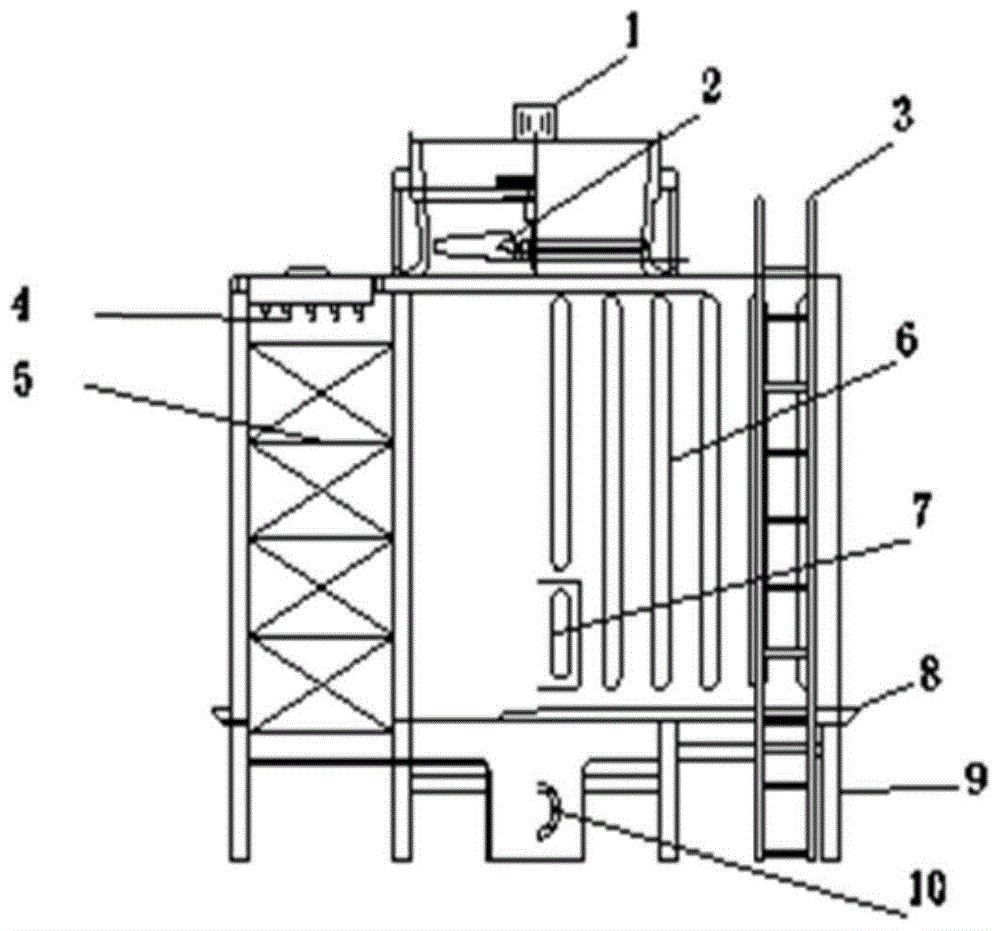

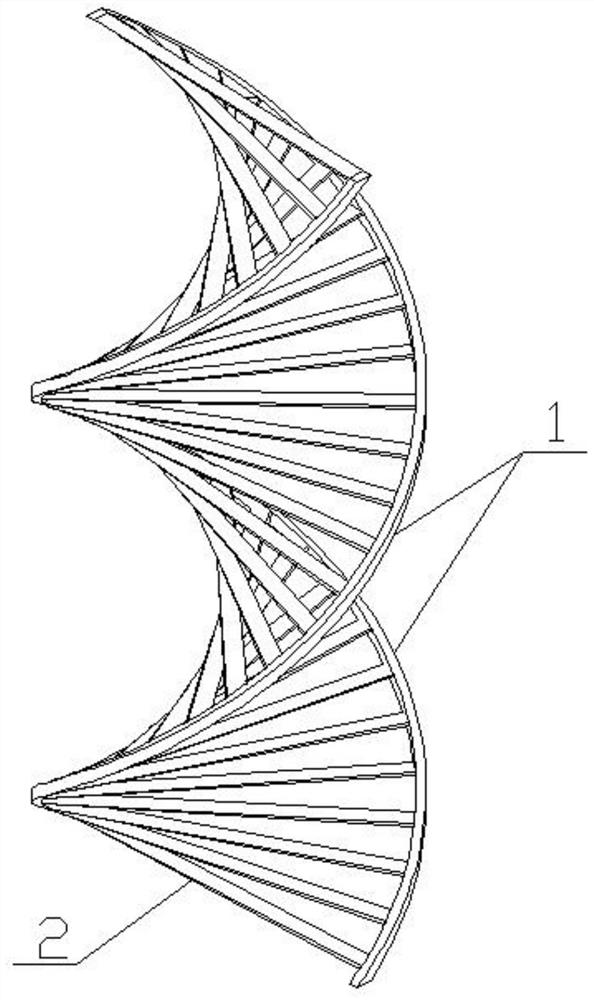

Rapid manufacturing method of auvc cooling tower

The invention discloses an AUVC cooling column quickly producing method which includes the steps of: screening and analyzing specification models, decomposing a general structure of a cooling column, processing and manufacturing general components, and assembling and moulding the AUVC cooling column. In the invention, a crossflow-type glass steel cooling column is finally employed as a general specification model, the processing and manufacturing step is carried out with a shell body of the cooling column as a processing direction of the general components and with a surface plate profile used for the shell body of the cooling column as the general components, wherein the surface plate profile is in the structure of uneven stripes and then is subjected to batched die pressurized extrusion processing and is subjected to surface smoothing treatment and anti-aging UV treatment, and then finally the assembling and moulding step is carried out for producing the AUVC cooling column. The AUVC cooling column quickly producing method is high in production efficiency, is good in thermal product stability, is long in service life, is convenient in maintenance and is low in cost.

Owner:阮帅

Foam iron-nickel composite metal material and preparation method thereof

ActiveCN101265549BImprove corrosion resistanceHigh degree of corrosion resistanceVacuum evaporation coatingSputtering coatingPorous substrateElectrical battery

The invention discloses a foam iron-nickel composite metallic material and a preparation method thereof. The foam iron-nickel composite metallic material has a three-dimensional or two-dimensional network structure; and comprises a base layer composed of iron-nickel alloy and a nickel layer above the alloy base layer as a protective layer, wherein the composite metallic material comprises (wt%) nickel 5-29 and iron in balance. The preparation method comprises electroplating iron-nickel alloy on a conducting porous substrate to obtain the iron-nickel alloy base layer, coating nickel layer abovethe base layer, and performing high-temperature heat treatment to form the protective layer. The inventive foam iron-nickel composite metallic material has reduced nickel consumption, so as to effectively reduce cost; and can replace porous nickel material to be used in battery substrate, electromagnetic shielding, noise absorption, filtration and other fields.

Owner:先进储能材料国家工程研究中心有限责任公司

Zirconium-manganese-vanadium passivation film treatment agent and treatment method for die-casting aluminum alloy

ActiveCN106048580BImprove adhesionHigh degree of corrosion resistanceMetallic material coating processesChromium freeZirconate

The invention discloses a passive film treating agent for die cast aluminium alloy and a treatment method thereof. The passive film treating agent for die cast aluminium alloy comprises the following components in parts by mass: 1 to 20 parts of inorganic acid, 1 to 20 parts of zirconate, 1 to 20 parts of vanadate, 1 to 20 parts of manganate, 1 to 20 parts of calciate and 0.2 to 10 parts of an activating agent. Relative to a traditional phosphorus-containing chromium-free passive film treating agent for die cast aluminium alloy, which causes pollution to the environment, the passive film treating agent for die cast aluminium alloy can form a phosphorus-free chromium-free Zr-Mn-V passive film on the surface of die cast aluminium alloy, the passive film has the advantages that the adhesive force is good, the corrosion resistance is high, and the salt mist resistance and film forming uniformity are good, and besides, the obtained passive film can be guaranteed to have a silver white metal appearance the same as the die cast aluminium alloy.

Owner:广东东明新材科技有限公司

A kind of nano-magnesium-aluminum corrosion-resistant coating and preparation method thereof

ActiveCN104673054BLow dielectric lossGood material uniformityAntifouling/underwater paintsPaints with biocidesEpoxyAcrylic resin

The invention discloses a nano magnesium-aluminum anti-corrosion coating. The coating comprises a first component and a second component, wherein the second component is formed by mixing a component A with a component B; the first component comprises components as follows: epoxy resin, hydroxyl acrylic resin and ammonium dihydrogen phosphate; the component A comprises components as follows: nano magnesium oxide, nano aluminum oxide, nano titanium dioxide, nano zirconium dioxide, nano rare earth oxide and deionized water; the component B comprises components as follows: butanol, filler, barium sulfate, diethylenetriamine and dipropylene glycol butyl ether. The invention further discloses a preparation method of the nano magnesium-aluminum anti-corrosion coating. The coating is high in mechanical strength and excellent in wear resistance, hardness, compressive strength and impact resistance, meanwhile, the preparation technology is simple and easy to operate, the cost is lower, the production process is safe and environment-friendly, and no pollutant is produced.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

An automatic production line for hot-dip galvanizing of steel pipes

ActiveCN106591757BGalvanized high efficiencyGalvanized energy savingHot-dipping/immersion processesProduction lineWorking environment

Owner:DANYANG TENGHUANG PIPE GALVANIZATION

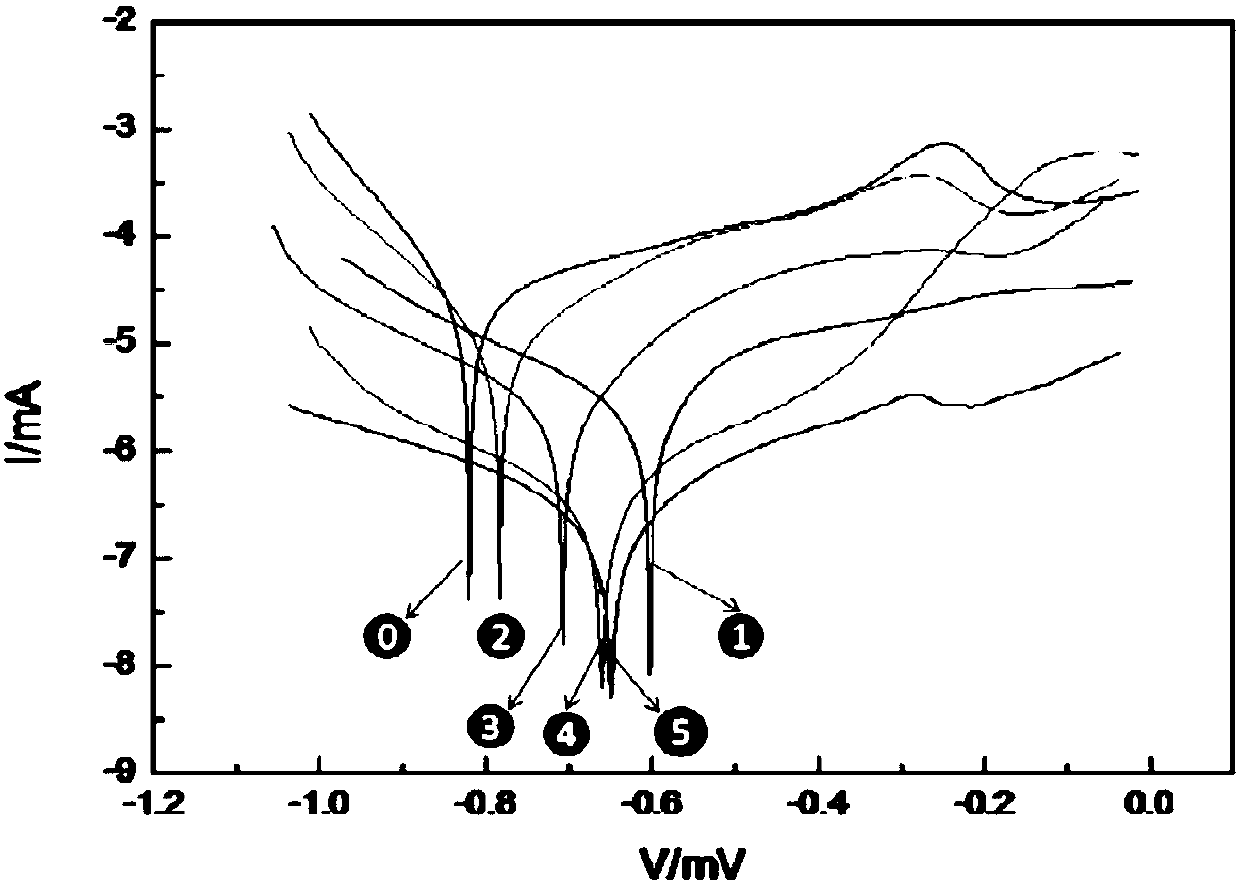

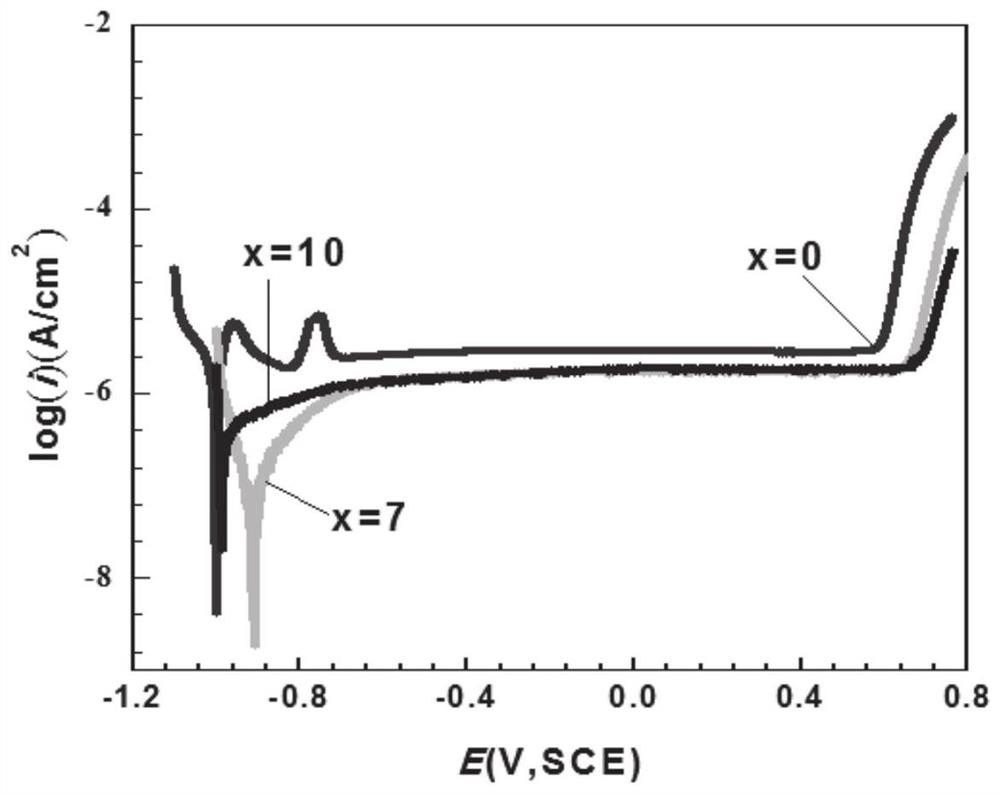

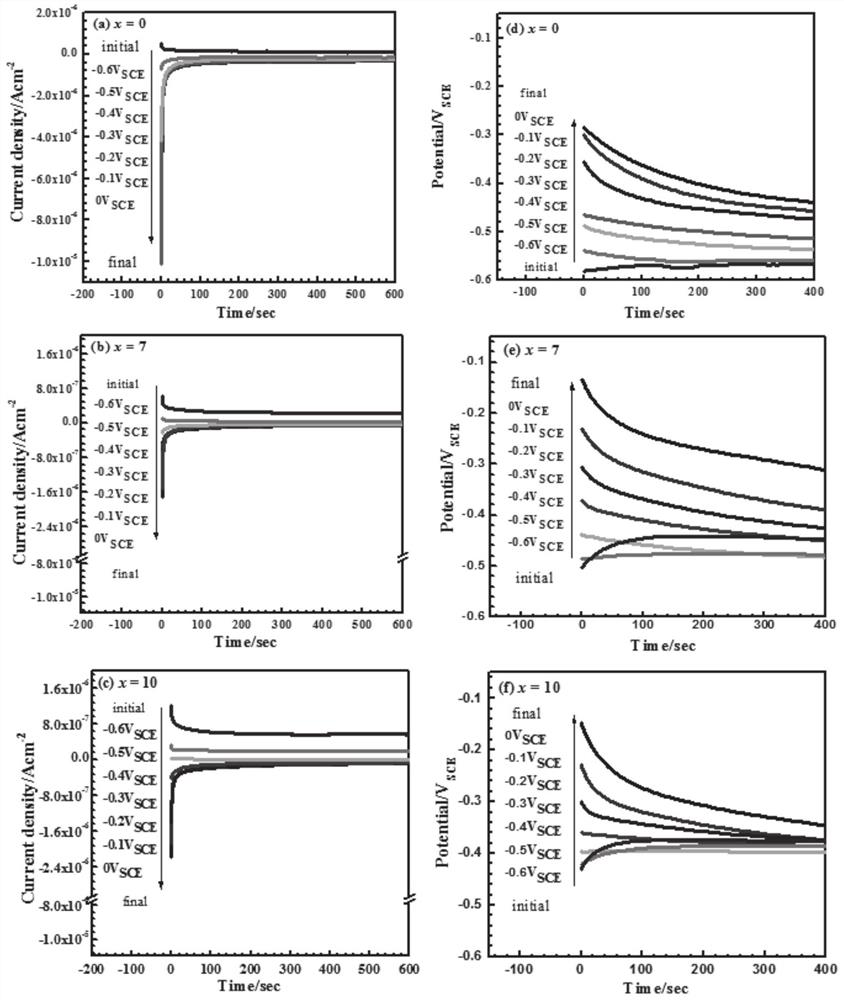

A method for measuring transition potential of amorphous strip passivation film by constant current method

ActiveCN112461910BEasy to useHigh degree of corrosion resistanceMaterial analysis by electric/magnetic meansWorkstationElectrical current

Owner:SHANDONG UNIV

An industrial acid sewage treatment device

ActiveCN108314199BRealize blockingAvoid blockingWater aerationSustainable biological treatmentSludgeSewage treatment

Owner:HUIZHOU DONGJIANG ENVIRONMENTAL PROTECTION TECH

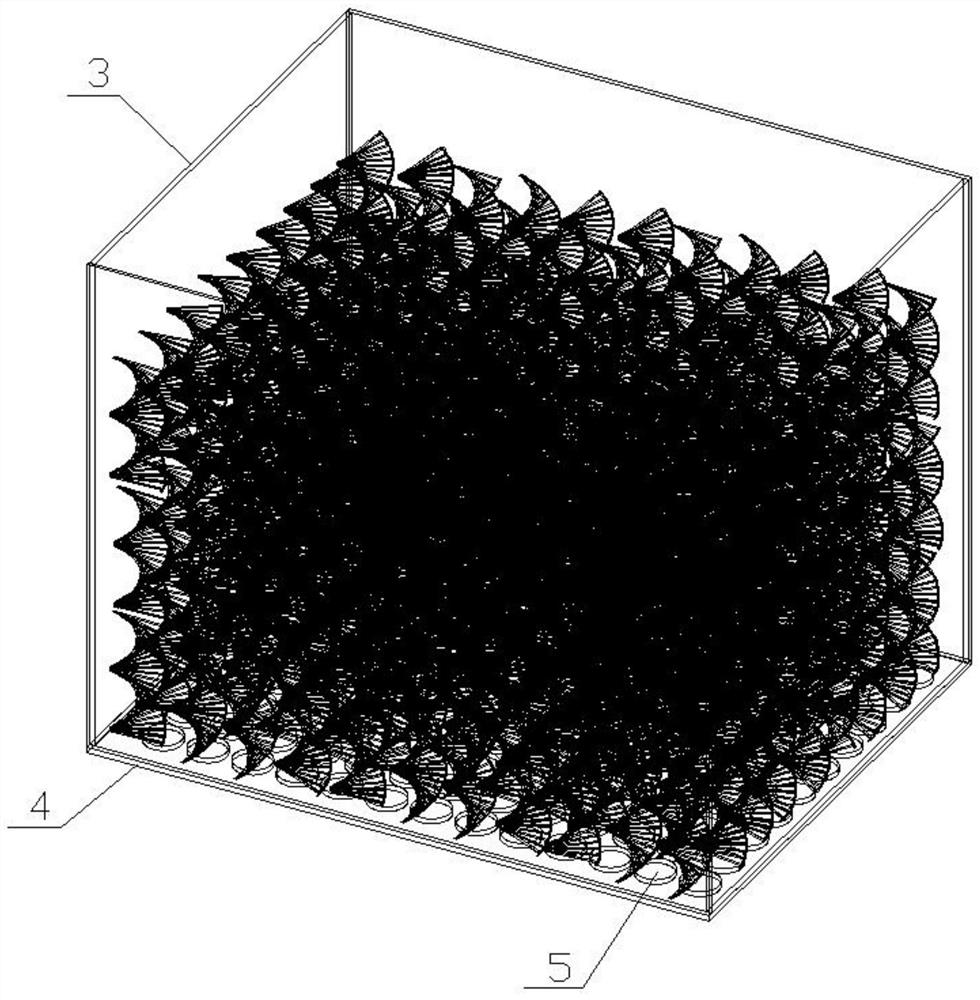

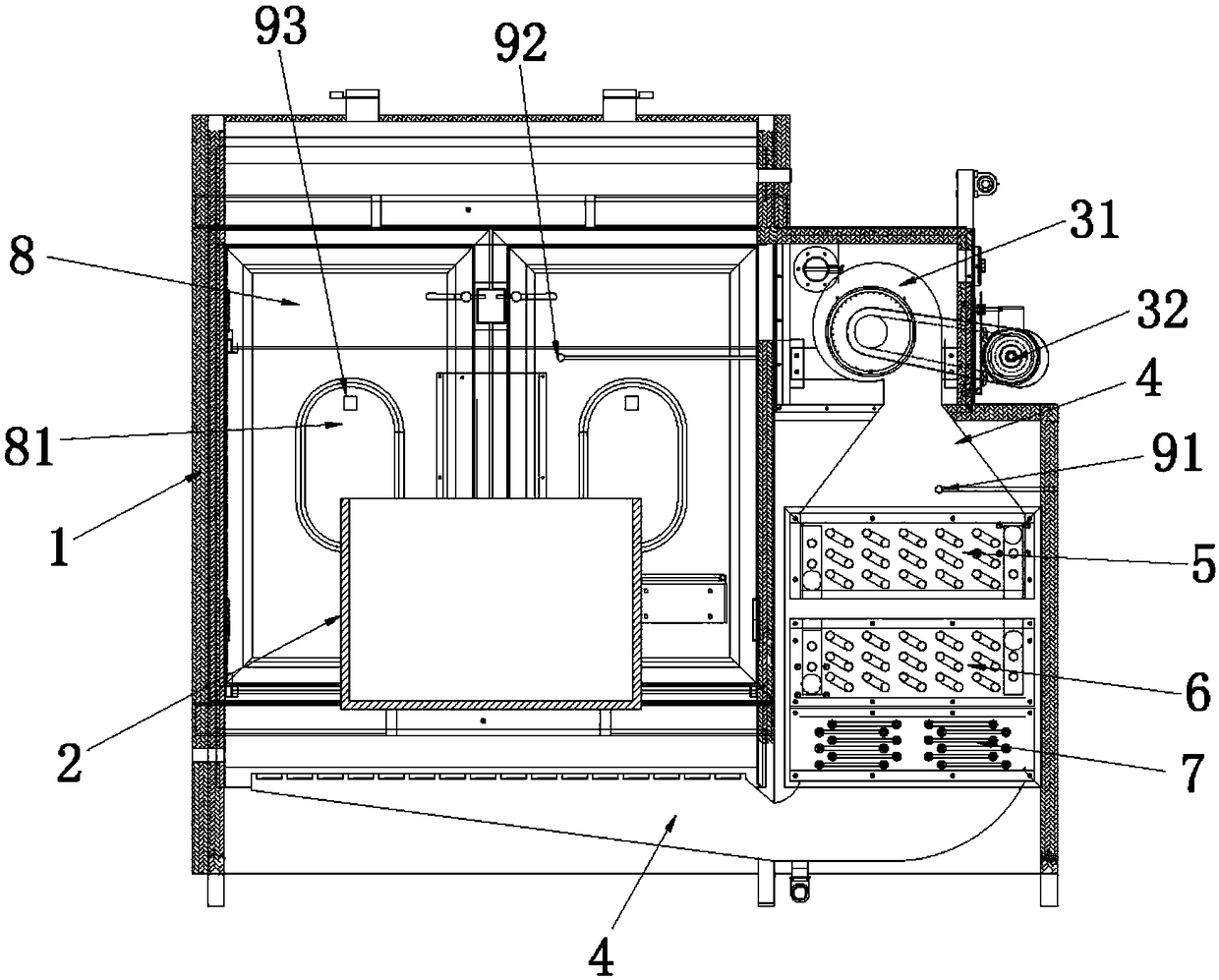

Gas-liquid heat transfer device based on ceramic matrix composite resin filler and preparation method of filler

ActiveCN111744453BHydrophilicIncrease the gas-liquid contact areaChemical/physical/physico-chemical processesResin-Based CompositeUltimate tensile strength

The invention discloses a gas-liquid heat transfer device based on a ceramic-based composite resin filler and a preparation method for the filler; in the filler, a high-efficiency ceramic-based composite resin is formed by adding resin fibers and heat-conducting fibers to the ceramic matrix. Corrosion packing. Compared with ordinary fillers, ceramic matrix composite resin corrosion-resistant fillers have better tensile strength and flexibility, better thermal conductivity, and stronger corrosion resistance.

Owner:安徽国微华芯环境科技有限公司 +1

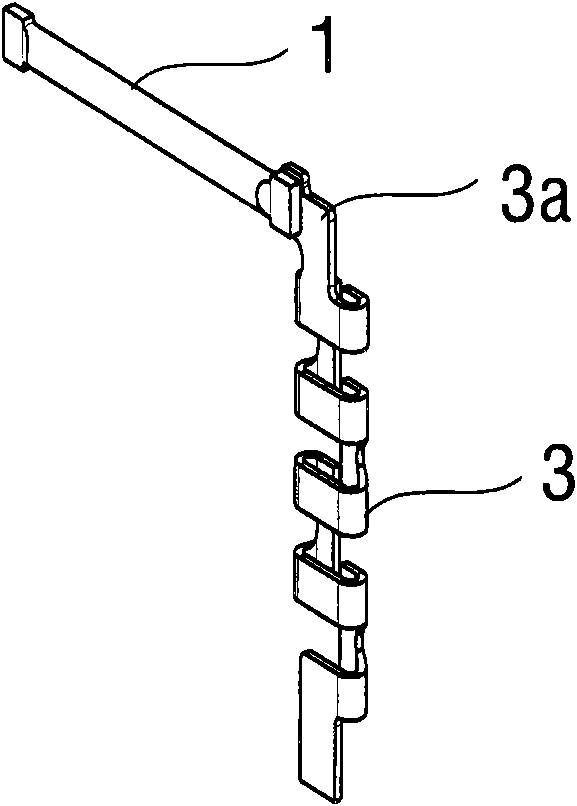

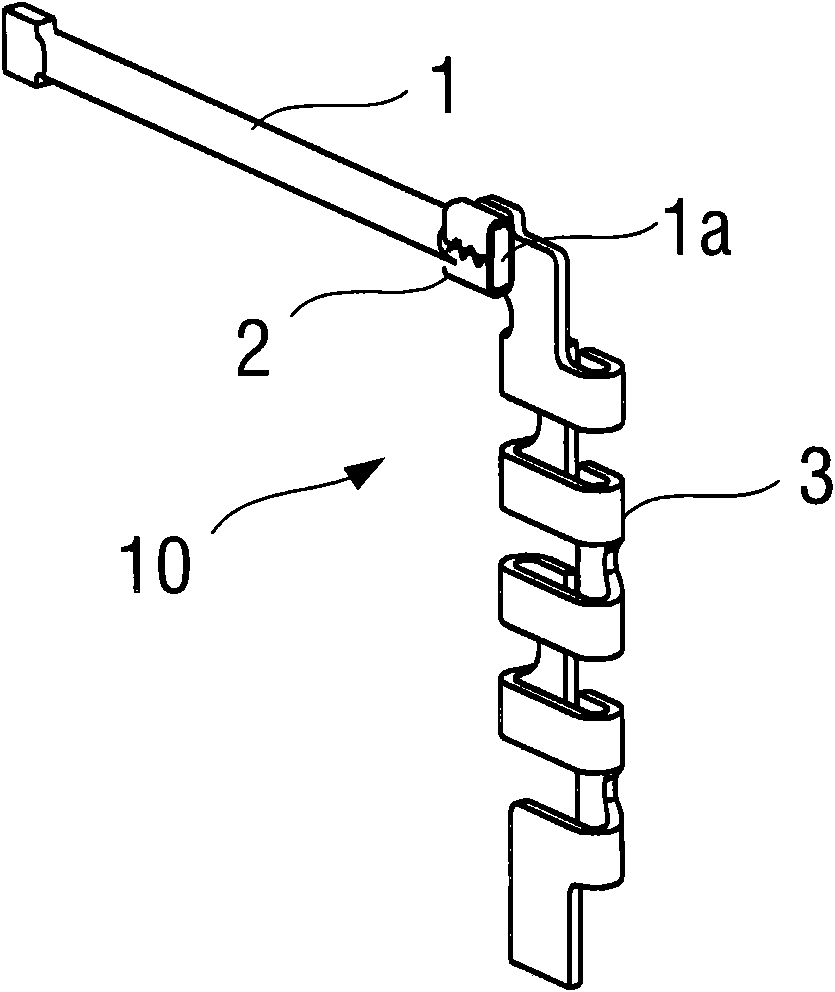

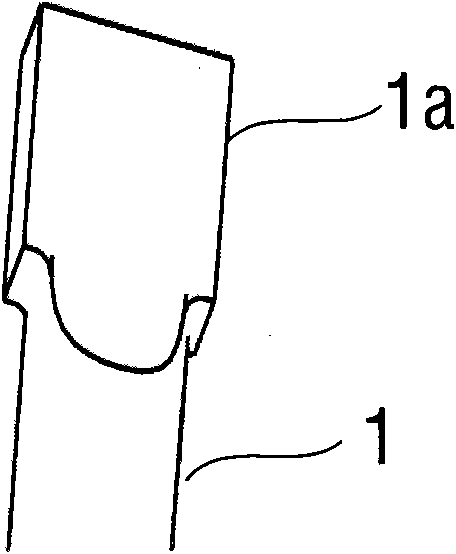

Welding articles, welding methods and circuit breakers

ActiveCN102299027BAdvanced technologyLow priceWelding/cutting media/materialsConductorsEngineeringMedia effect

The present invention provides a welded product which comprises a first element and a second element, and further comprises a third element, wherein the melting point of said third element is between that of the material of said first element and the material of said second element, one end of said first element is fixed into an accommodation space formed by said third element and said third element is welded onto said second element. It is made easy to weld together two parts to be welded by way of the medium effects of the third element, so that the welded product can meet the application requirements regarding mechanical strength and electric strength.

Owner:SHANGHAI SIEMENS CIRCUIT PROTECTION SYST

A boiler corrugated liner welding process

ActiveCN107570838BImprove welding stabilityAvoid crackingArc welding apparatusWelding/cutting media/materialsThermodynamicsEngineering

The invention discloses a process for welding a corrugated inner container of a boiler. The process comprises the procedures of rolling, pre-welding treatment, welding treatment operation, and post-welding grinding treatment. The welding treatment operation procedure comprises the following steps: welding from the inner side of a pipe wall; overcoming welding defects from the outer side of the pipe wall by utilization of carbon arc gouging; and welding from the outer side of the pipe wall. Through the two-layer welding operation, not only the high welding stability but also the fusion connection between different welding fluxes and the inner container are achieved, and the different welding fluxes are matched with welding wire so as to achieve the different degrees of stability; especially, an SJ501 welding flux is selected for an inner layer, an SJ101 welding flux is selected for an outer layer, and the two welding fluxes have the different properties of corrosion resistance and structure strength; and accordingly, when the two welding fluxes are utilized in the inner container welding process in a matched manner, the welding stability of a joint of the inner container is high, the cracking possibility is low, and the safety performance high.

Owner:北京奥林匹亚锅炉有限公司

Semiconductor glass for manufacturing microchannel plate

The invention discloses semiconductor glass for manufacturing a microchannel plate. The semiconductor glass comprises the following components in percentage by mass: 60-75 percent of (P2O5+V2O5), 5-25 percent of (FeO+WO3), not more than 4 percent of Sb2O3 and not less than 15 percent of PbO. The semiconductor glass has the advantages that a chemical composition which is stable in glass state and accords with the manufacture requirement of the microchannel plate can be obtained, therefore, the more ideal semiconductor glass of the microchannel plate is formed; the wetting property and the erosion degree to a mullite refractory crucible can be remarkably reduced, corrosion resistance degree in acid treatment in a process of manufacturing the microchannel plate can be improved; the hardness is improved, and the grinding and polishing quality of subsequent processes is ensured; the stability of a transition metal ion valence state in the semiconductor glass can be ensured; and the requirement of the microchannel plate that a semiconductor glass material bulk resistor must be in a range of 5*10<7>-5*10<9>omega can be met.

Owner:CHANGSHU XINLI MAGNETIC IND

Adc12 die-casting aluminum alloy black chromium-free conversion film treatment agent and surface treatment method of adc12 die-casting aluminum alloy

ActiveCN109183016BImprove adhesionHigh degree of corrosion resistanceMetallic material coating processesO-Phosphoric AcidAdhesive

The invention relates to a black chromium-free conversion film treatment agent for an ADC12 pressure casting aluminum alloy and a surface treatment method for the ADC12 pressure casting aluminum alloy. The conversion film treatment agent is prepared from the following components with concentrations as follows: 1-15 ml / L phosphoric acid, 1-15 g / L molybdate, 1-15 g / L ammonium hydrogen fluoride, 1-5g / L nickel nitrate hexahydrate, a 0.01-0.05 ml / L dispersant and the balance of water. The black chromium-free conversion film treatment agent for the ADC12 pressure casting aluminum alloy can form a black conversion film on the surface of the ADC12 pressure casting aluminum alloy and the conversion film has the advantages of being good in adhesive force, high in degree of corrosion resistance, good in salt spray resistance property and good in film forming uniformity, and can improve the corrosion resistance and the film adhesive force of the surface of the ADC12 pressure casting aluminum alloy. The black chromium-free conversion film treatment agent is free of chromium and does not pollute the environment, so that the black chromium-free conversion film treatment agent is relatively goodin environment-friendly property.

Owner:广东东明新材科技有限公司

Aging treatment device for radiator aluminum profile

PendingCN108384930AImprove physical strengthHigh degree of corrosion resistanceFurnace typesHeat treatment process controlClosed loopEngineering

The invention relates to the technical field of aging treatment devices, in particular to an aging treatment device for a radiator aluminum profile. The aging treatment device comprises a machine boxand a hearth arranged in the machine box; an air supply device is arranged on one side of the machine box; an air outlet of the air supply device communicates with the bottom of the machine box through a heat exchange passage; an air inlet of the air supply device communicates with the upper end of the machine box; and the heat exchange passage is internally and sequentially provided with a firstfluid heat exchange pipe, a second fluid heat exchange pipe and electric heating wires from top to bottom, wherein the first fluid heat exchange pipe is used for containing an external cold source, the second fluid heat exchange pipe is used for containing an external heat source, and the electric heating wires are used for heating. Compared with the prior art, the aging treatment device has the advantages that a structure of a closed-loop circulating air duct is formed, waste heat of gas can be effectively utilized, the utilization efficiency of energy can be improved, the cost can be saved,through the second fluid heat exchange pipe and the electric heating wires arranged inside the heat exchange passage, a heating mode adopting gas in the prior art can be replaced, the structure can besimplified, the applicability performance is good, and the problem of low working efficiency in the prior art can be solved.

Owner:东莞市润华铝业有限公司

Polyimide film for flexible AMOLED

PendingCN114163639AHigh degree of corrosion resistanceIncrease usage intensityTrifluoroacetic anhydrideDiamine

The invention discloses a polyimide film for a flexible AMOLED (Active Matrix / Organic Light Emitting Diode), which comprises the following components: biphenyl tetracarboxylic dianhydride, diaminodiphenyl, diamine, maleic anhydride, phenylacetylene phthalic anhydride, tetrahydrophthalic anhydride, acetenyl aniline, acetic anhydride, trifluoroacetic anhydride, acetyl chloride, triethylamine, pyridine, isoquinoline, silicon dioxide, indium tin oxide and titanium dioxide. The biphenyl tetracarboxylic dianhydride, diaminobiphenyl and diamine are used for enhancing the corrosion resistance of the polyimide film, and the situation that the service life of the polyimide film is shortened due to the fact that the polyimide film is affected by harmful substances in air in long-term use is avoided, so that the use strength of the polyimide film is improved, and the service life of the polyimide film is prolonged. Through maleic anhydride, phenylacetylene phthalic anhydride, tetrahydrophthalic anhydride and acetenyl aniline, in the presence of appropriate functional groups, the molecular chain end of the polymer still can participate in the reaction to grow the chain, and in order to eliminate the activity of the end group, a monofunctional group compound can be added to disappear the functional group of the end group.

Owner:NANJING ZHONGHONG RUNNING ADVANCED MATERIAL TECH CO LTD

Gas-liquid heat transfer device based on ceramic matrix composite resin filler and filler preparation method

ActiveCN111744453AHydrophilicIncrease the gas-liquid contact areaChemical/physical/physico-chemical processesCeramic compositeResin-Based Composite

The invention discloses a gas-liquid heat transfer device based on ceramic matrix composite resin filler and a filler preparation method. In the filler, resin fibers and heat-conducting fibers are added into a ceramic matrix to form the high-efficiency ceramic composite resin corrosion-resistant filler. Compared with common filler, the ceramic composite resin corrosion-resistant filler is better in tensile strength and flexibility, better in heat-conducting property and higher in corrosion resistance.

Owner:安徽国微华芯环境科技有限公司 +1

Method for testing conversion potential of amorphous strip passive film by using constant current method

ActiveCN112461910AExtend the service lifeBroaden the field of applicationMaterial analysis by electric/magnetic meansIron based alloyElectrical current

The invention relates to the technical field of amorphous strip passive film conversion potential, in particular to a method for testing a conversion potential of an amorphous strip passive film by using a constant current method, which comprises the following steps of: placing an amorphous strip in a three-electrode workstation, testing a TAFEL curve to obtain a passivation platform, and selecting a potential value point from the passivation platform; and for the selected potential value point, carrying out testing according to a constant current method to obtain the conversion potential of the amorphous strip. According to the method, the application fields of the iron-based alloy and the amorphous material are expanded, the amorphous material can be applied to more actual production, the greater effect of the amorphous alloy is exerted, and the amorphous alloy has a greater application prospect.

Owner:SHANDONG UNIV

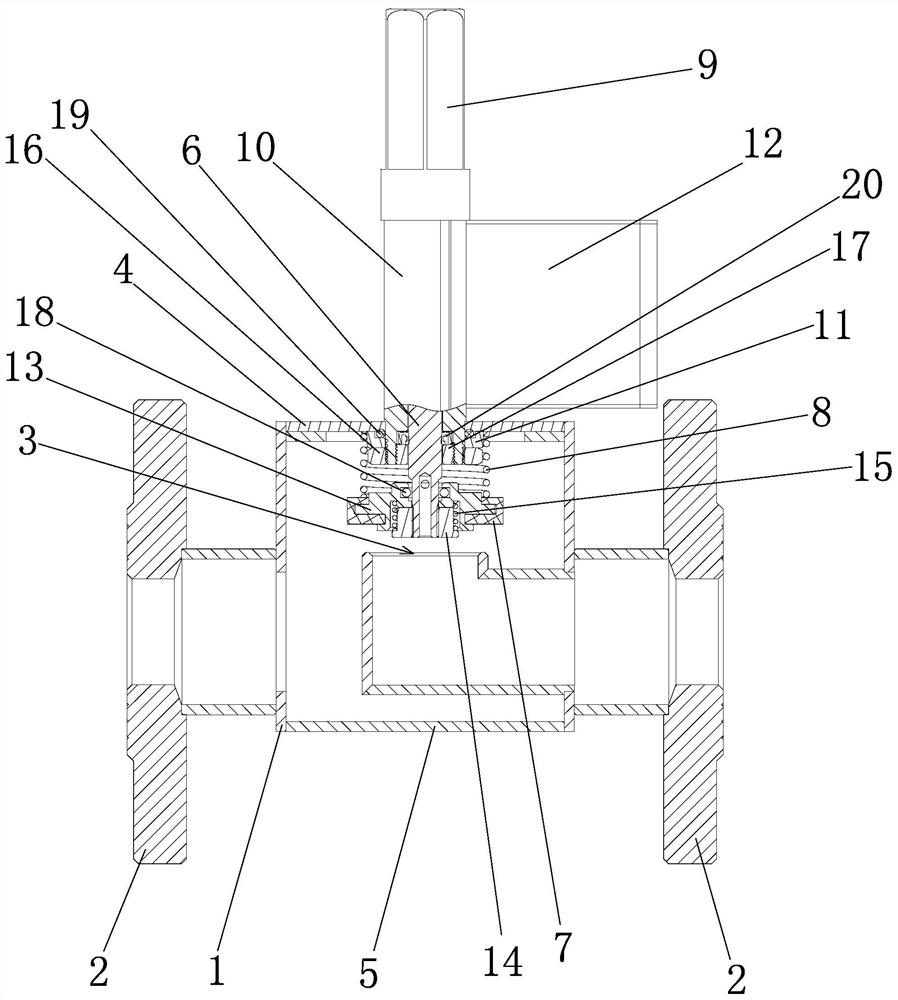

Gas emergency cut-off valve

PendingCN112780817AImprove connection strengthHigh strengthLift valveValve housingsStructural engineeringMechanics

The invention provides a gas emergency cut-off valve, and belongs to the technical field of valves. The gas emergency cut-off valve solves the problems that a valve body of an existing gas emergency cut-off valve is formed by cast steel or cast aluminum, air holes are prone to being generated in the valve body, corrosion resistance is poor, strength is not high, and the service life is short. The gas emergency cut-off valve comprises a valve body, an air inlet and an air outlet are formed in the two ends of the valve body, connecting flanges are arranged at the positions, corresponding to the air inlet and the air outlet, of the valve body, an upper cover plate and a lower cover plate are arranged at the upper end and the lower end of the valve body respectively, a pull rod is arranged in the valve body, the inner end of the pull rod extends into the valve body to be connected with sealing rubber, a large spring is further arranged in the valve body, the connecting flanges and the valve body are made of forged steel or rolled steel plates or seamless steel pipes, the surface of the valve body is treated through electroplating, electrophoresis and plastic spraying processes, and the upper cover plate and the lower cover plate are made of rolled steel plates. The gas emergency cut-off valve has the advantages of high strength, corrosion resistance and prolonged service life.

Owner:TAIZHOU PANSHI METALIC PRODECT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com