Method for testing conversion potential of amorphous strip passive film by using constant current method

A technology of constant current and passivation film, applied in measuring devices, material analysis through electromagnetic means, instruments, etc., can solve the problem of when the passivation film will be damaged, so as to improve the service life, expand the application prospect and expand the application field effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for obtaining transition potential by constant current method, comprising the steps of:

[0035] Step 1, weighing pure iron (>99.5wt.%), Fe-B, Fe-Nb according to the corresponding atomic ratio, mixing them and putting them into a resistance furnace for melting.

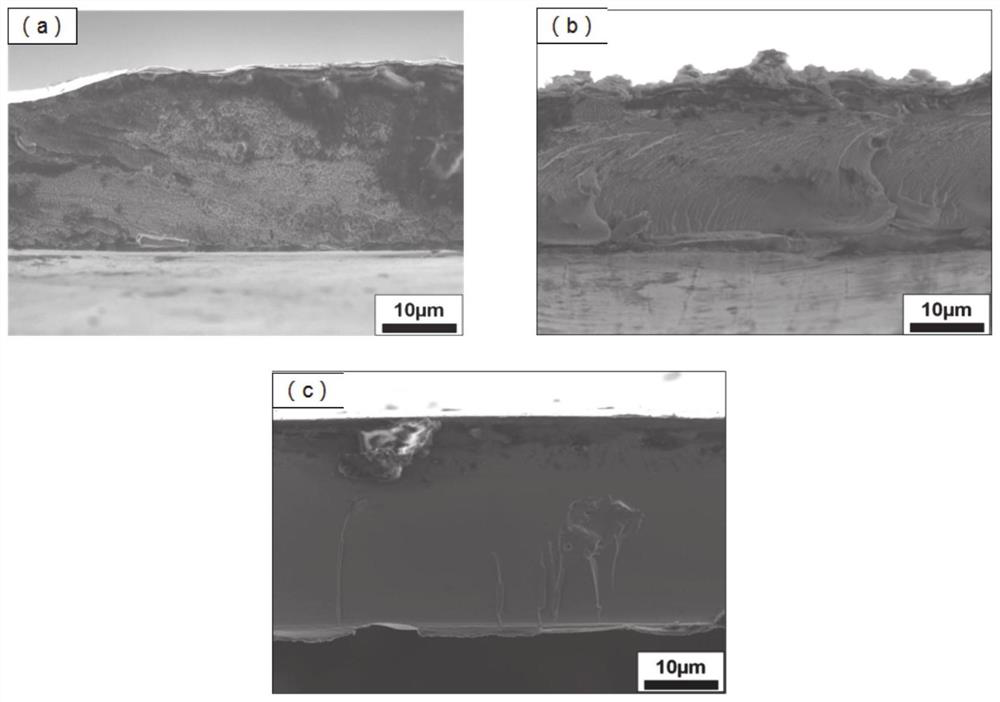

[0036] Step 2, the Fe 87-x B 13 Nb x (x=0, 7 and 10) The three kinds of alloy ingots are respectively placed in the quartz tube and heated and melted in the induction coil. When the rotation speed of the copper roller is 4000r / min, it will have been melted into liquid Fe 87-x B 13 Nb x (x = 0, 7 and 10) alloys are sprayed onto copper rolls to obtain Fe 87-x B 13 Nb x (x = 0, 7 and 10) Three amorphous strips.

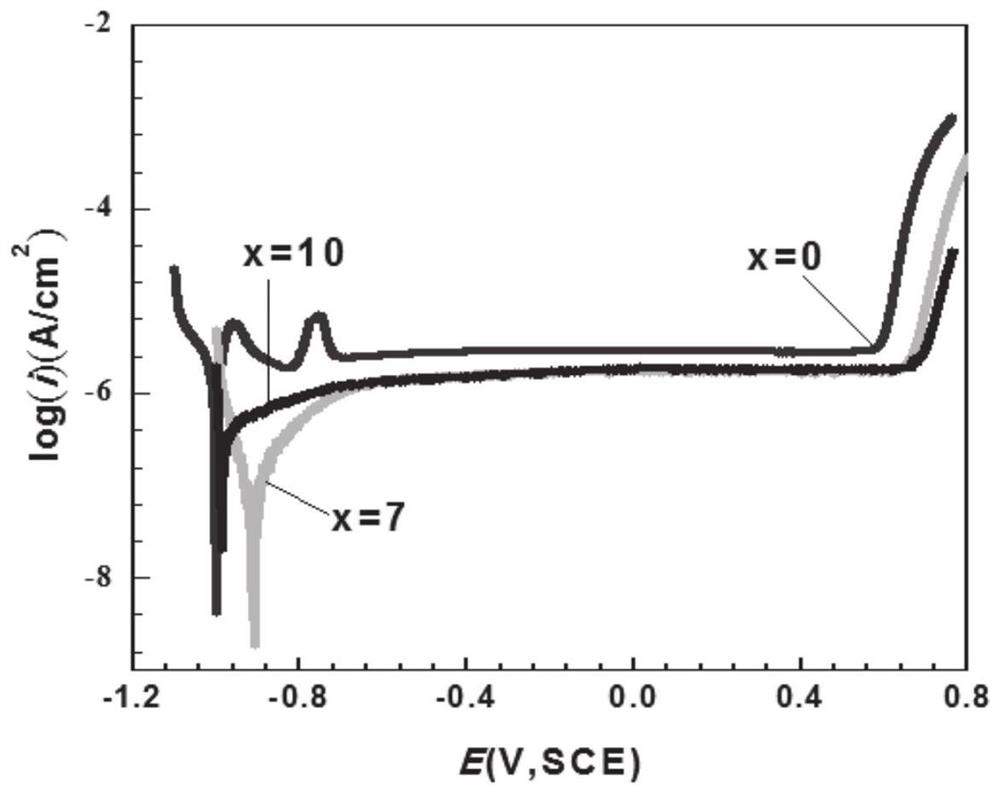

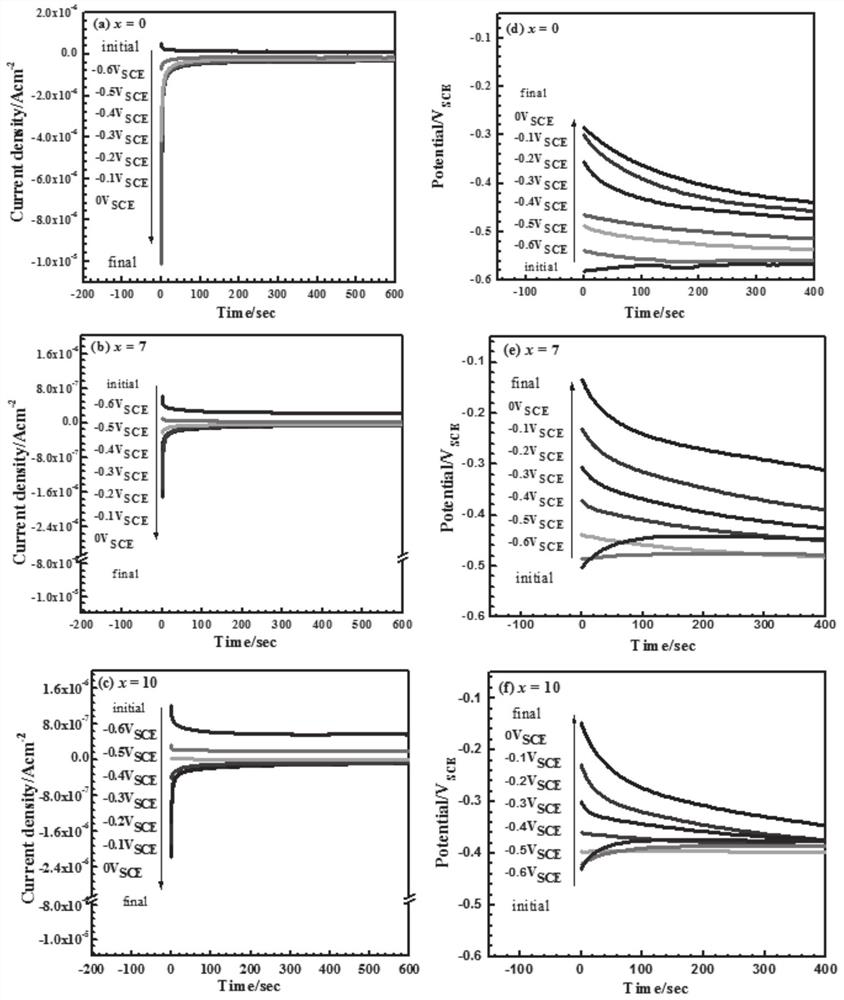

[0037] In step 3, the strip is placed in a three-electrode workstation to test the TAFEL curve to obtain a passivation platform, and a potential value point is selected from the passivation platform.

[0038] Step 4, according to the selected potential value point, according to the const...

Embodiment 2

[0041] A method for obtaining transition potential by constant current method, comprising the steps of:

[0042] Step 1, weigh pure iron (>99.5wt.%) and Fe-B, Fe-Nb according to the corresponding atomic ratio, mix them and put them into a resistance furnace for melting.

[0043] Step 2, the Fe 87-x B 13 Nb x (x=0, 7 and 10) The three kinds of alloy ingots are respectively placed in the quartz tube and heated and melted in the induction coil. When the rotation speed of the copper roller is 3800r / min, it will have been melted into liquid Fe 87-x B 13 Nb x (x = 0, 7 and 10) alloys are sprayed onto copper rolls to obtain Fe 87-x B 13 Nb x (x = 0, 7 and 10) Three amorphous strips.

[0044] In step 3, the strip is placed in a three-electrode workstation to test the TAFEL curve to obtain a passivation platform, and a potential value point is selected from the passivation platform.

[0045] Step 4, according to the selected potential value point, according to the constant curre...

Embodiment 3

[0048] A method for obtaining transition potential by constant current method, comprising the steps of:

[0049] Step 1, weigh pure iron (>99.5wt.%) and Fe-B, Fe-Nb according to the corresponding atomic ratio, mix them and put them into a resistance furnace for melting.

[0050] Step 2, the Fe 87-x B 13 Nb x (x=0, 7 and 10) The three kinds of alloy ingots are respectively placed in the quartz tube and heated and melted in the induction coil. When the rotation speed of the copper roller is 3600r / min, it will be melted into liquid Fe 87-x B 13 Nb x (x = 0, 7 and 10) alloys are sprayed onto copper rolls to obtain Fe 87-x B 13 Nb x (x = 0, 7 and 10) Three amorphous strips.

[0051] In step 3, the strip is placed in a three-electrode workstation to test the TAFEL curve to obtain a passivation platform, and a potential value point is selected from the passivation platform.

[0052] Step 4, according to the selected potential value point, according to the constant current me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com