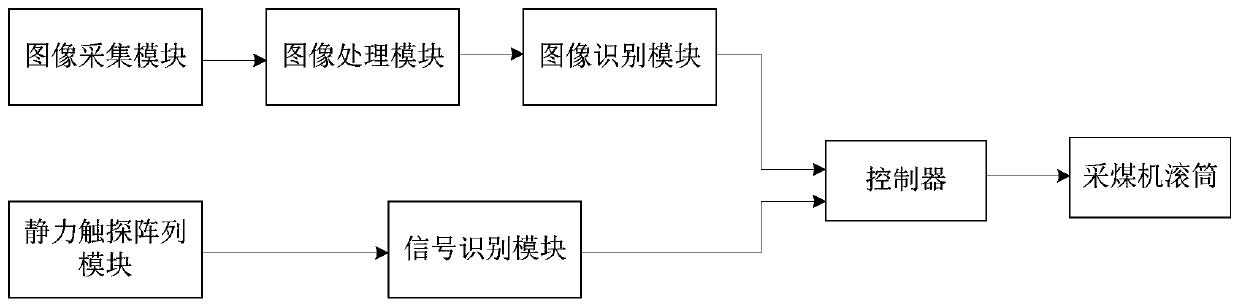

Coal rock identification system and device

A coal-rock identification and subsystem technology, applied in the field of coal-rock identification systems and devices, can solve problems such as the coal mining face is advanced and the mining head cannot be adjusted in time, so as to prolong the service life and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

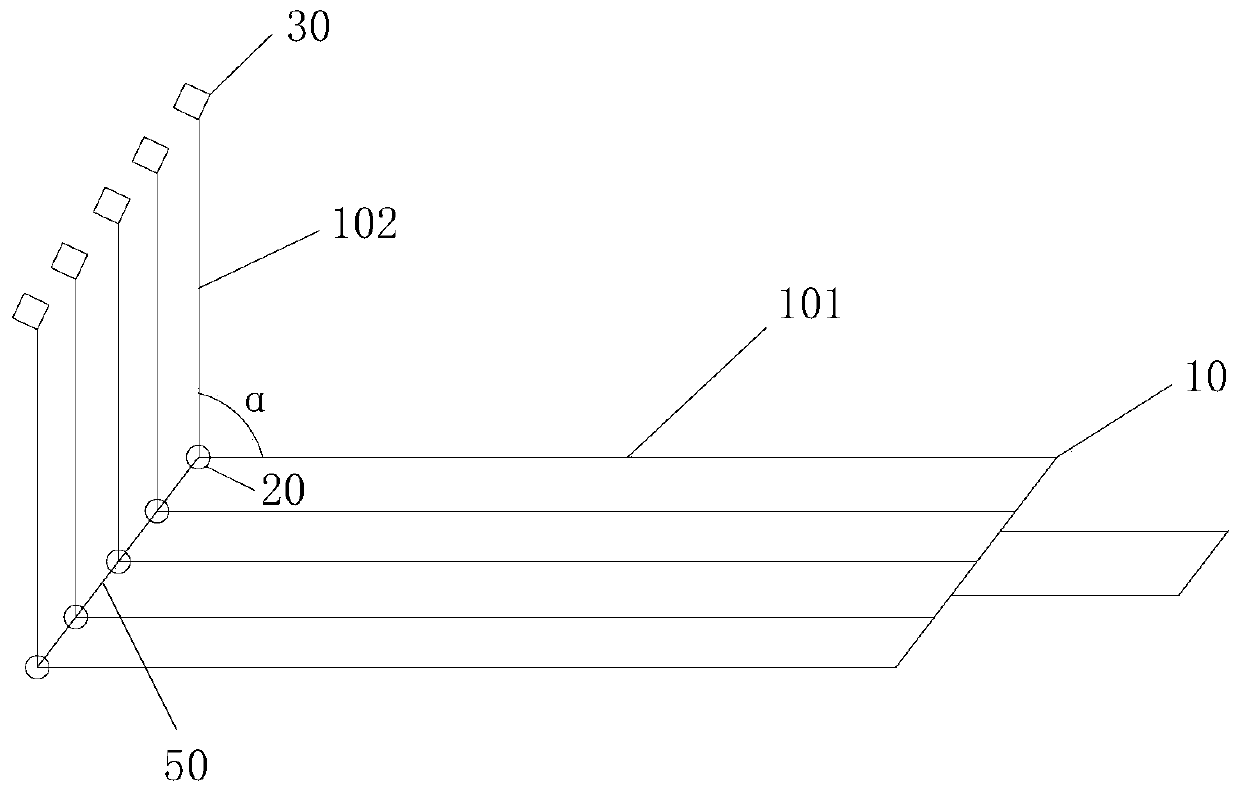

[0052] Such as figure 2 As shown, the support 10 is used to rigidly connect with the coal shearer; the support 10 includes two sides, one side connected to the coal shearer is the first side 101, and one side in contact with the coal wall is the second side 102, The angle between the second side surface 102 and the first side surface 101 is α, 0°≤α<180°, generally set to 60°≤α<150°.

[0053] In this embodiment, n brackets 10 are parallel to each other (n brackets 10 may not be parallel to each other, that is, the first side 101 can intersect), and are fixed together by connecting rods 50, that is, in each bracket 10 A connecting rod 50 is installed at the intersection of one side 101 and the second side 102 to fix the n brackets 10, and the image acquisition sensor 20 is installed on the connecting rod 50 at the intersection of the first side 101 and the second side 102, and the acquisition corresponds to The coal rock image is transmitted to the controller for coal rock ide...

Embodiment 2

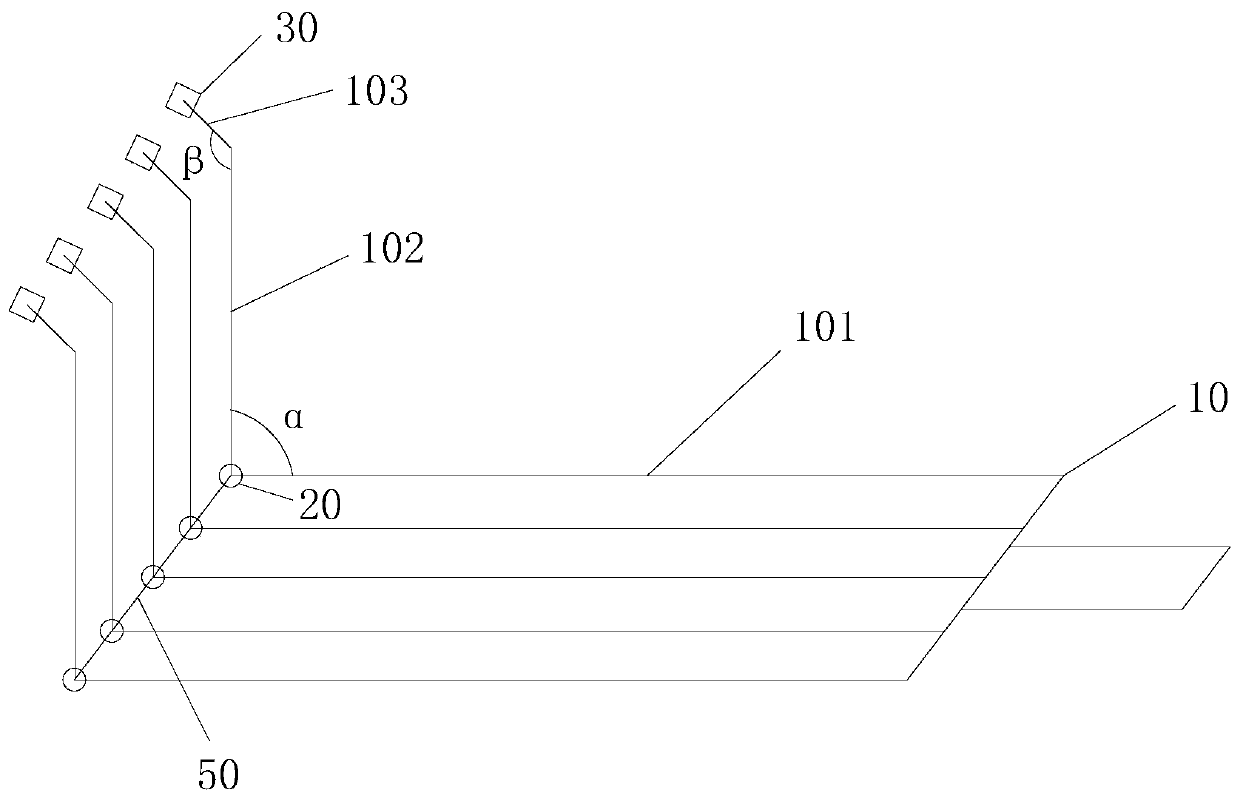

[0057] Such as image 3 As shown, the support 10 is used for rigid connection with the shearer; the support 10 includes three sides, one side connected with the shearer is the first side 101, and one side close to the coal wall (not in contact with the coal wall) is The second side 102, the angle between the second side 102 and the first side 101 is α, 0°≤α<180°; one side in contact with the coal wall is the third side 103, the third side 103 and the second The included angle between the side surfaces 102 is β, α<β<α+90°, and the third side 103 deflects away from the shearer, which facilitates the installation of the static penetrating sensor on the third side 103, The coal and rock in the coal wall can be identified in advance. The advantage of setting the third side 103 is to facilitate the installation of the static penetration sensor 30, and the static penetration sensor 30 can detect and identify the coal and rock in the coal wall in advance when the shearer is moving, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com